INSTALLATION INSTRUCTIONS FOR SLOAN SERIES 900 HYDRAULIC

FLUSHING SYSTEM — EXPOSED CLOSET, URINAL AND SERVICE SINK

Exposed Closet Flushometer

1½” (38 mm) Top Spud

MODEL 910/911

MODEL 913

MODEL 915

MODEL 916

Exposed Closet Flushometer

1½” (38 mm) Back Spud

MODEL 920

MODEL 921

MODEL 922

Exposed Urinal Flushometer

Model 910/911

Model 986

Model 920

1 ” (32 mm) Top Spud

MODEL 980

Exposed Urinal Flushometer

¾” (19 mm) Top Spud

MODEL 986

Exposed Service Sink Flushometer

1½” (38 mm) Top Spud

MODEL 917

Code No. 0816300

Rev. 4 (05/13)

LIMITED WARRANTY

Unless otherwise noted, Sloan Valve Company warrants this product, manufactured and sold for commercial or industrial uses, to be free from defects in material and

workmanship for a period of three (3) years (one (1) year for special finishes, SF faucets, PWT electronics and 30 days for PWT software) from date of first purchase. During

this period, Sloan Valve Company will, at its option, repair, replace, or refund the purchase price of any product which fails to conform with this warranty under normal use and

service. This shall be the sole and exclusive remedy under this warranty. Products must be returned to Sloan Valve Company, at customer’s cost. No claims will be allowed for

labor, transportation or other costs. This warranty extends only to persons or organizations who purchase Sloan Valve Company’s products directly from Sloan Valve Comapny

for purpose of resale. This warranty does not cover the life of the batteries.

THERE ARE NO WARRANTIES WHICH EXTEND BEYOND THE DESCRIPTION ON THE FACE HEREOF. IN NO EVENT IS SLOAN VALVE COMPANY RESPONSIBLE FOR ANY

CONSEQUENTIAL DAMAGES OF ANY MEASURE WHATSOEVER.

PRIOR TO INSTALLATION

Prior to installing the flushometer, install the items listed below as illustrated in

the Rough-in Diagrams on Page 2.

• Installclosetorurinalfixture.

• Install1-1/2”(38mm)drainline(NOTsuppliedbySloan).

• Boreahole(seerough-inforsize)inwallforwatersupplyline,andinstall

water supply line.

• Bore1-1/2”(38mm)holesinwallforboththeHydraulicPushButton

Actuator and the Valve Actuator.

• ForModelHY-72-APushButtonActuator,installanelectricalboxatboth

Push Button Actuator and Valve Actuator. Run conduit between the two

electrical boxes.

IMPORTANT:

• INSTALLALLPLUMBINGINACCORDANCEWITHAPPLICABLECODES

AND REGULATIONS.

• WATERSUPPLYLINESMUSTBESIZEDTOPROVIDEANADEQUATE

VOLUME OF WATER FOR EACH FIXTURE.

• FLUSHALLWATERLINESPRIORTOMAKINGCONNECTIONS.

Sloan’s flushometers are designed to operate with 10 to 100 psi (69 to 689

kPa) of water pressure.

DETERMINED BY THE TYPE OF FIXTURE SELECTED.

for minimum pressure requirements.

THE MINIMUM PRESSURE REQUIRED TO THE VALVE IS

Consult fixture manufacturer

Most Low Consumption water closets (1.6 gpf/6.0 Lpf) require a minimum

flowing pressure of 25 psi (172 kPa).

IMPORTANT: With the exception of Control Stop Inlet, DO NOT use pipe thread

sealant or plumbing grease on valve components or couplings!

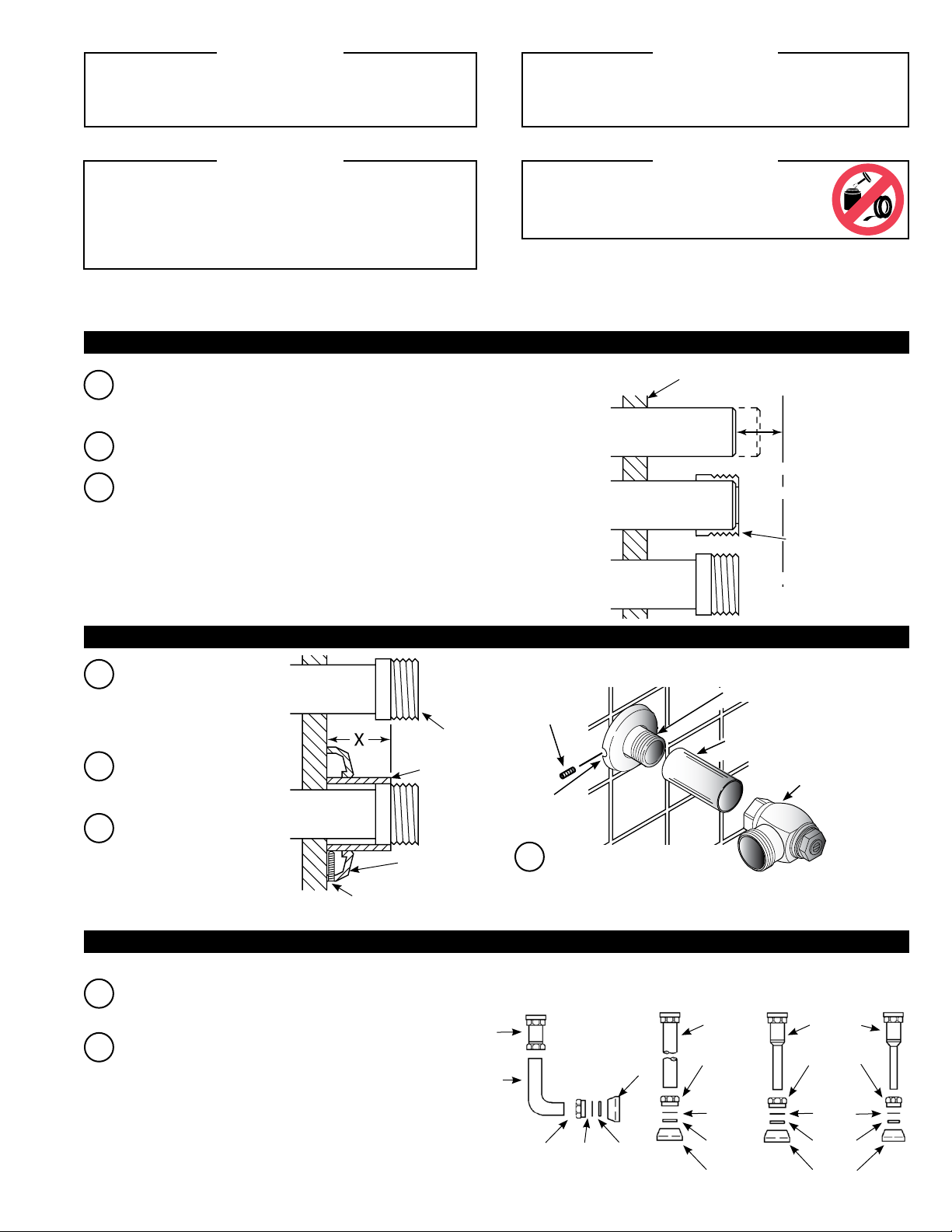

SUPPLY AND ACTUATOR ROUGH-IN

2-9/16” (65 mm) ‡

SEE VALVE

ROUGH-IN

TOP OF FIXTURE

4-3/4” (121 mm)

WATER

SUPPLY

LINE

1-1/2” (38 mm) ‡

VALVE ACTUATOR

LOCATION

1-1/2” (38 mm)

DIAMETER HOLE

‡ Dimension must be

held to 1/8” (3 mm).

4” x 4”

(102 mm x 102 mm)

BOX OPTIONAL -

FURNISHED BY OTHERS

CENTERLINE OF FIXTURE

TOOLS REQUIRED FOR INSTALLATION

• Straightblade(flathead)screwdriver

• 5/64”hexwrench

• ParkerTubeCutter(PTC)

• SloanA-50Super-Wrench™,SloanA-109PlierWrenchorsmooth

jawed spud wrench

VALVE ROUGH-INS (NOTE: SPECIFY ACTUATOR VARIATION NEEDED FOR YOUR APPLICATION)

MODEL 910/911

1-1/2” (38 mm)

OPENING

IN WALL

1-1/2”

(38 mm)

11-1/2”

(292 mm)

2-1/4” (57 mm)

MIN.

2-9/16”

(65 mm)

FIN. WALL

CENTERLINE

OF FIXTURE

FIN.

FLOOR

4-3/4”

(121 mm)

PUSH BUTTON

(LOCATION

OPTIONAL)

1” I.P.S.

(25 mm DN)

WATER SUPPLY

MODELS 913/915/916

1-1/2” (38 mm)

OPENING

IN WALL

1-1/2”

(38 mm)

(913): 16” (406 mm)

(915): 24” (610 mm)

(916): 27” (686 mm)

MODELS 920/921/922 MODEL 980

1-1/2” (38 mm)

OPENING

IN WALL

1-1/2”

(38 mm)

11-1/2”

(292 mm)

2-1/4” (57 mm)

MIN.

2-9/16”

(65 mm)

CENTERLINE

OF FIXTURE

4-3/4”

(121 mm)

PUSH BUTTON

(LOCATION

OPTIONAL)

1” I.P.S.

(25 mm DN)

WATER SUPPLY

1-1/2” (38 mm)

OPENING

IN WALL

1-1/2”

(38 mm)

11-1/2”

(292 mm)

2-1/4” (57 mm)

MIN.

2-9/16”

(65 mm)

FIN. WALL

2-1/4” (57 mm)

MIN.

2-9/16”

(65 mm)

CENTERLINE

OF FIXTURE

FIN.

FLOOR

CENTERLINE

OF FIXTURE

4-3/4”

(121 mm)

4-3/4”

(121 mm)

PUSH BUTTON

(LOCATION

OPTIONAL)

1” I.P.S.

(25 mm DN)

WATER SUPPLY

PUSH BUTTON

(LOCATION

OPTIONAL)

1” I.P.S.

(25 mm DN)

WATER SUPPLY

6-1/2” (165 mm)

7-1/2” (191 mm) IF

2” (51 mm) SPUD

MODEL 986

1-1/2” (38 mm)

OPENING

IN WALL

1-1/2”

(38 mm)

11-1/2”

(292 mm)

FIN.

WALL

2-1/4” (57 mm)

MIN.

2-9/16”

(65 mm)

FIN.

WALL

CENTERLINE

OF FIXTURE

FIN.

FLOOR

FIN.

FLOOR

PUSH BUTTON

(LOCATION

4-3/4”

(121 mm)

OPTIONAL)

3/4” I.P.S.

(20 mm DN)

WATER SUPPLY

NOTE: Water Closet Valves with

“-2.4” Model Designation deliver 2.4

gpf (9.0 Lpf).

2

MODEL 917

1-1/2” (38 mm)

OPENING

IN WALL

1-1/2”

(38 mm)

24”

(610 mm)

FIN. WALL

2-1/4” (57 mm)

MIN.

2-9/16”

(65 mm)

FIN.

WALL

FIN.

FLOOR

CENTERLINE

OF FIXTURE

FLOOR

(121 mm)

FIN.

4-3/4”

PUSH BUTTON

(LOCATION

OPTIONAL)

1” I.P.S.

(25 mm DN)

WATER SUPPLY

!!! IMPORTANT !!! !!! IMPORTANT !!!

NEVER OPEN THE CONTROL STOP TO WHERE THE FLOW FROM

THE VALVE EXCEEDS THE FLOW CAPABILITY OF THE FIXTURE. IN

THE EVENT OF A VALVE FAILURE, THE FIXTURE MUST BE ABLE TO

ACCOMMODATE A CONTINUOUS FLOW FROM THE VALVE.

THIS PRODUCT CONTAINS MECHANICAL AND THAT ARE SUBJECT

TONORMALWEAR.THESECOMPONENTSSHOULDBECHECKEDON

A REGULAR BASIS AND REPLACED AS NEEDED TO MAINTAIN THE

VALVE’S PERFORMANCE.

!!! IMPORTANT !!!!!! IMPORTANT !!!

PROTECT THE CHROME OR SPECIAL FINISH OF SLOAN’S

FLUSHOMETERS. DO NOT USE TOOTHED TOOLS TO INSTALL OR

SERVICE VALVES. USE A SLOAN A-50 SUPER WRENCH™, SLOAN

WITH THE EXCEPTION OF THE CONTROL STOP INLET,

DO NOT USE PIPE THREAD SEALANT OR PLUMBING

GREASE ON VALVE COMPONENTS OR COUPLINGS.

A-109 PLIER WRENCH OR SMOOTH JAWED SPUD WRENCH TO

SECURE COUPLINGS. SEE “CARE AND CLEANING” SECTION FOR

MORE DETAILS.

When further assistance is required, please consult your local Sloan

Representative, or Sloan Technical Support at:

1-888-SLOAN-14 (1-888-756-2614)

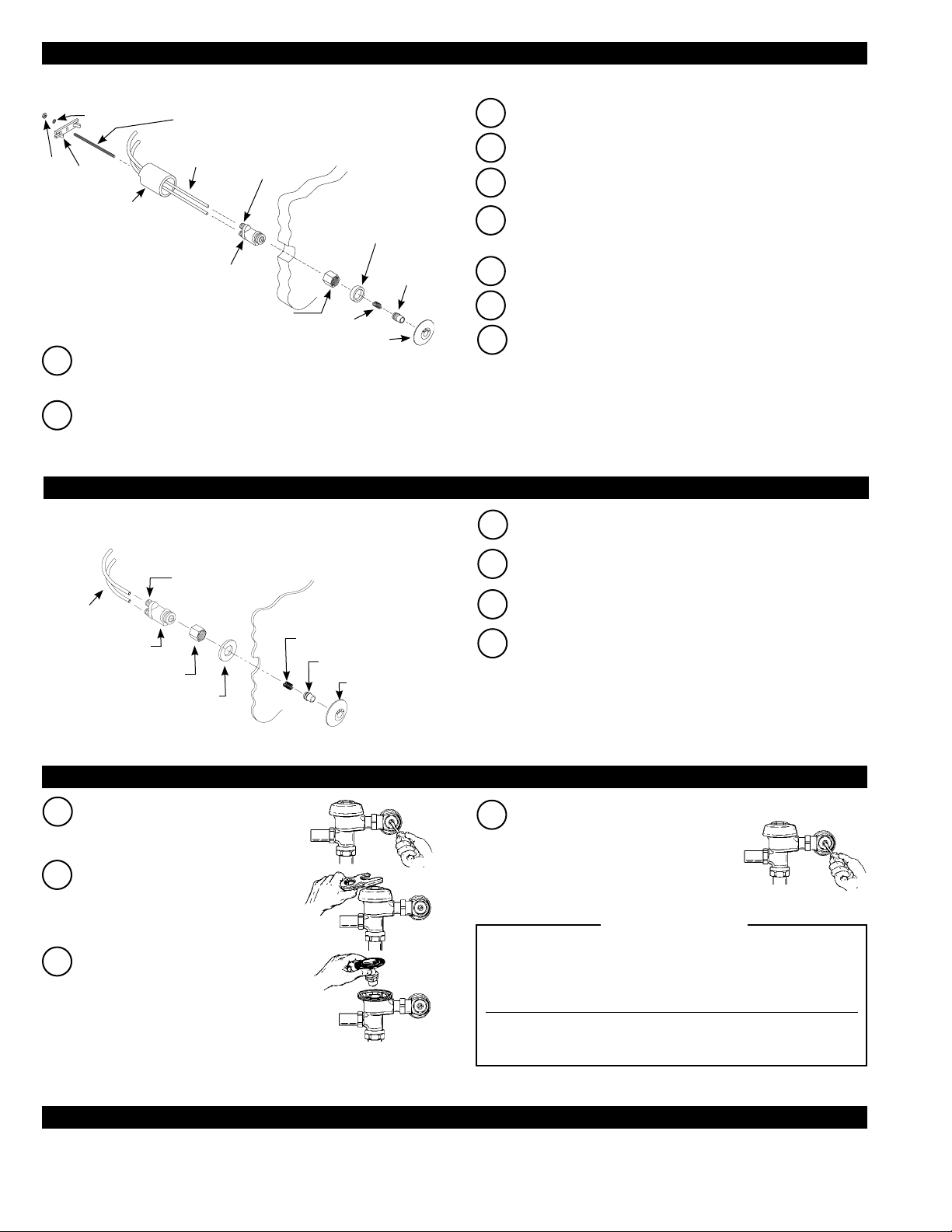

1 - INSTALL OPTIONAL SWEAT SOLDER ADAPTER (ONLY IF YOUR SUPPLY PIPE DOES NOT HAVE A MALE THREAD)

A

Measure from finished wall to C/L of Fixture Spud. Cut pipe 1¼” (32

mm) shorter than this measurement. Chamfer O.D. and I.D. of water

supply pipe.

B

Slide Threaded Adapter fully onto pipe.

C

Sweat solder the Adapter to pipe.

2 - INSTALL COVER TUBE, WALL FLANGE, AND CONTROL STOP TO SUPPLY PIPE

A

Measure from finished wall

to first thread of adapter

or threaded supply pipe

(dimension “X”). Cut cover tube

to this length.

B

Slide cover tube over pipe.

Slide wall flange over cover

tube until against wall.

C

Install the Sloan Bak-Chek

control stop to the water supply

line with the outlet positioned

as required.

®

WATER

SUPPLY PIPE

SET SCREW

SWEAT SOLDER

ADAPTER

COVER TUBE

WALL

FLANGE

SET SCREW

SUPPLY

FLANGE ‡

D

Tighten Set Screw with a 1/16”

hex wrench. DO NOT install vandal

resistant stop cap at this time.

FINISHED WALL

WATER SUPPLY PIPE

1-1/4”

(32 mm)

SWEAT

SOLDER

ADAPTER

C/L OF

FIXTURE

SPUD

IRON PIPE NIPPLE OR

COPPER PIPE WITH SWEAT

SOLDER ADAPTER

COVER TUBE ‡

BAK-CHEK

CONTROL STOP

‡ Cover Tube

®

and Supply

Flange with

Set Screw is

supplied with

Royal valves;

available in

“YBYC” Sweat

Kit for Regal

valves.

3-INSTALLVACUUMBREAKERFLUSHCONNECTION

A

Slide the spud coupling, nylon slip gasket, rubber gasket and

spud flange over the vacuum breaker tube.

B

Insert tube into fixture spud. Hand tighten spud coupling

onto fixture spud.

VACUUM

BREAKER

ELBOW

FLUSH

CONNECTION

3

920, 921 & 922

SPUD

COUPLING

MODELS

NYLON

SLIP

GASKET

910, 913, 915,

SPUD

FLANGE

RUBBER

GASKET

MODELS

916 & 917

VACUUM

BREAKER

TUBE

SPUD

COUPLING

NYLON

SLIP

GASKET

RUBBER

GASKET

SPUD

FLANGE

MODEL

980

MODEL

986

VACUUM

BREAKER

TUBE

SPUD

COUPLING

NYLON

SLIP

GASKET

RUBBER

GASKET

SPUD

FLANGE

4 - INSTALL VALVE ACTUATOR

OBSERVE“L”AND“O”MARKINGSONTUBING.

TUBING MUST BE CONNECTED TO CORRESPONDING

“L”AND“O”MARKINGSONVALVEACTUATOR.

Insert actuator cartridge into ushometer valve body.

A

!!! IMPORTANT !!!

COVER PLATE

VACUUM

BREAKER TUBE

WITH REPAIR KIT

BAK-CHEK®

CONTROL STOP

Install valve actuator housing onto ushometer valve body. Tighten

B

housing nut with a wrench.

C

Cut off excess tubing with plastic tube cutter (PTC) so that there will

PLASTIC

TUBES

FLANGE

HOUSING

NUT

be about 3” to 4” (76 to 102 mm) of slack when connected to valve

actuator. If “L” and “O” marketings on the tubing will be cut off, then

remark tubing appropriately to retain identication.

D

Slide plastic tubing into its corresponding valve actuator tting. Pull

tubing to make sure connection is secure. (Tubing can be removed by

CHROME

SLEEVE

QUICK

CONNECT

FITTINGS (2)

VALVE

ACTUATOR

HOUSING

pressing on blue connection button to release.)

5 - INSTALL FLUSHOMETER

Align flushometer Body on top of vacuum

A

breaker flush connection. Measure distance

from valve actuator Housing to finished wall. Cut

chrome sleeve adding an additional 1” (25 mm)

to the previously measured distance.

IMPORTANT: DO NOT CUT THREADED END OF

CHROME SLEEVE. ONLY CUT NON-THREADED END.

B

Remove flushometer body from top of

vacuum breaker flush connection.

C

Slide chrome sleeve (threaded end first) over

MEASURE DISTANCE

AND ADD 1” (25 mm)

plastic tubing. Thread onto valve actuator until chrome sleeve is tight

against valve actuator housing.

D

Slide flange and cover plate over plastic tubing and onto chrome

sleeve.

Run plastic tubing through wall hole to push button actuator location.

E

(If installing HY-72-A push button actuator, run plastic tubing through

electrical box and conduit and out through the electrical box at push

button actuator location.

MAXIMUM ADJUSTMENT OF

THE SLOAN ADJUSTABLE

TAILPIECE IS 1/2” (13 MM)

IN OR OUT FROM THE

STANDARD 4-3/4” (121 MM)

(C/L OF FLUSHOMETER TO

C/L OF CONTROL STOP). IF

ROUGH-IN MEASUREMENT

EXCEEDS 5-1/4” (133 MM),

CONSULT FACTORY FOR

LONGER TAILPIECE.

2-9/16”

(65 mm)

4-1/4”

(108 mm)

MIN.

5-1/4”

(133 mm)

MAX.

1-1/2” (38 mm)

— DIMENSION

MUST BE HELD

TO 1/8” (3 mm)

IMPORTANT: USE A SLOAN A-50 SUPER WRENCH™, SLOAN A-109

PLIER WRENCH OR SMOOTH JAWED SPUD WRENCH TO SECURE ALL

COUPLINGS. THIS WILL ELIMINATE DAMAGE TO CHROME OR SPECIAL

FINISH THAT NORMALLY OCCURS WHEN SLIP-JOINT PLIERS, PIPE

WRENCHES OR OTHER “TOOTHED” TOOLS ARE USED.

Insert adjustable tailpiece into control stop.

F

Lubricate o-ring seal with water. Hand

tighten tailpiece coupling.

Align flushometer body on top of vacuum

G

breaker flush connection. Hand tighten

vacuum breaker coupling.

Align flushometer body. Using a wrench, securely tighten couplings in

H

order given:

(3) spud coupling. Then tighten valve actuator housing nut securely.

With flushometer

I

(1) tailpiece coupling, (2) vacuum breaker coupling and

ACTUATOR

ASSEMBLY

body aligned on top

of vacuum breaker

flush connection,

assemble cover plate

to plaster ring with

hex head screws.

Slide flange against

cover plate.

FLUSHOMETER

BODY

VACUUM

BREAKER

COUPLING)

2

VACUUM

BREAKER

FLUSH

CONNECTION

C/L

FIXTURE

6A - INSTALL PUSH BUTTON ACTUATOR (HY-72-A SIDE WALL (SW VARIATION) PUSH BUTTON ACTUATOR)

A

Mount Wall Flange onto Cover Plate using (2) Flathead Screws,

Lockwashers and Nuts provided. Tighten Fasteners securely.

Insert extension Stem into extension Adapter and thread extension

B

Adapter onto Push Button Actuator.

Insert threaded end of Push Button Actuator Assembly through Cover

C

Plate Assembly. Fasten to Plate with Nut. Tighten securely.

Place Brass Insert into black Push Button. Concave side of Brass Insert

D

must face outward of Push Button.

Insert black Push Button into Button Flange. Place Spring against

E

Brass Insert of Push Button. Install Push Button Assembly onto Cover

Plate. Secure with Setscrew located on Button Flange.

Attach plastic tubing. See: Steps to attach plastic tubing on next page.

F

Mount Cover Plate Assembly onto electrical box cover using the four (4)

G

Screws provided.

UNIVERSAL

(2) GANG

ELEC. BOX

1-5/8” D x

4-1/2” H x

6-13/16”

W (NOT

SUPPLIED

BY SLOAN)

PLASTIC

TUBING

4

(2) GANG ELEC. BOX DEVICE COVER 3/4” RAISED

x 4-3/4” H x 7-1/16” W (NOT SUPPLIED BY SLOAN)

ACTUATOR

WALL

NUTS (2)

LOCKWASHERS (2)

COVER PLATE

EXTENSION STEM

EXTENSION ADAPTER

WALL FLANGE

FLATHEAD SCREWS (2)

PUSH BUTTON

FLUSHOMETER

VALVE BODY

HY-83-A

ACTUATOR

CARTRIDGE

TAILPIECE

COUPLING

1

CONTROL

ADJUSTABLE

TAILPIECE

VACUUM

BREAKER

REPAIR KIT

4-3/4”

(121 mm)

COVER PLATE SCREWS (4)

NUT

STOP

O-RING

G-44

FRICTION

RING

SPUD

COUPLING

3

C/L

SUPPLY

SPRING

BRASS INSERT

BUTTON

FLANGE

SETSCREW

6B - INSTALL PUSH BUTTON ACTUATOR (HY-33-A FIXTURE WALL (FW VARIATION) PUSH BUTTON ACTUATOR

– WALL INSTALLATION)

NOTE: The HY-33-A Fixture Wall may be installed directly onto fixture wall where access behind wall is available. If rear access is not available,

HY-33-A may be installed onto a Sloan Easy Access Wall Box Assembly. Parts for both installations are included with the HY-33-A Push Button.

NUT

RETAINING

BAR

SPACER SLEEVE — USE ONLY IF

WALL THICKNESS IS LESS THAN

QUICK

CONNECT

FITTINGS (2)

A

B

C

LOCKWASHER

THREADED

ROD

2” (51 mm)

PUSH BUTTON

ACTUATOR

If not already completed, bore a 1½” (38 mm) diameter hole in wall

for the push button sctuator. Refer to the rough-in drawings on pages

1 and 2.

Screw Threaded Rod into back of Push Button Actuator.

Insert threaded end of Push Button Actuator into Wall Flange and

install Nut. Tighten Nut securely.

WALL

WALL

FLANGE

PLASTIC TUBING

SPRING

NUT

PUSH BUTTON

BRASS

INSERT

BUTTON

FLANGE

SETSCREW

D

Place Brass Insert into black Push Button. Concave side of Brass Insert

must face outward of Push Button.

E

Insert black Push Button into Button Flange. Place Spring against

Brass Insert of Push Button. Install Push Button Assembly onto Wall

Flange. Secure with Setscrew located on Button Flange.

F

If spacer sleeve is required, from behind wall, run plastic tubing through

sleeve (notched end of sleeve toward rear) and through wall. Spacer

sleeve is only required if wall thickness is less than 2” (51 mm).

Attach Plastic Tubing. See: Steps to Attach Plastic Tubing below.

G

H

Insert Push Button Assembly into the 1-1/2” (38 mm) wall hole.

I

From behind wall, slide spacer sleeve (if required) over threaded

rod and rest it against rear of wall. Slide retaining bar onto threaded

rod and into slots of sleeve (if required), or against wall if Sleeve is

not required. Install lockwasher and nut onto threaded rod. Tighten

securely. Carefully cut excess threaded rod, making certain to not

damage plastic tubing.

6C - INSTALL PUSH BUTTON ACTUATOR (HY-33-A FIXTURE WALL (FW VARIATION) PUSH BUTTON ACTUATOR – WALL

BOX INSTALLATION)

NOTE: Sloan WB-1-A easy access wall box is designed for use with HY-33-A and HY-108-A Actuators.

LOCKWASHERS (2)

NUTS (2)

QUICK

CONNECT

FITTINGS (2)

PUSH

BUTTON

ACTUATOR

WALL BOX COVER PLATE

PLASTIC TUBING

FLATHEAD SCREWS (2)

WALL

FLANGE

NUT

PUSH

BUTTON

SPRING

BRASS

INSERT

SETSCREW

BUTTON

FLANGE

A

Insert threaded end of push button actuator through wall flange and

install nut. Tighten nut securely.

B

Mount wall flange and push button actuator to wall box cover plate

using flathead screws, lockwashers and nuts provided. Tighten

fasteners securely.

C

Place Brass Insert into black push button. Concave side of Brass Insert

must face outward of Push Button.

D

Insert black push button into button flange. Place spring against brass

Insert of push button. Install push button assembly onto wall flange.

secure with setscrew located on Button flange.

E

Attach plastic tubing. See: Steps to Attach Plastic Tubing (lower left

side of this page).

6D - INSTALL PUSH BUTTON ACTUATOR (HY-49-A METAL PARTITION (MP VARIATION) PUSH BUTTON ACTUATOR)

METAL

PARTITION

CLIP

NUTS (2)

PLASTIC

TUBING

QUICK

CONNECT

FITTINGS (2)

Using cover plate as a template, drill two 3/16” (5 mm) cover plate

A

mounting holes and cut opening for push button actuator into the metal

partition. Install clip nuts with threaded side toward back.

COVER PLATE MOUNTING HOLE

PUSH BUTTON ACTUATOR

COVER PLATE

WALL

FLANGE

NUT

PUSH BUTTON

FLATHEAD SCREWS (2)

SPRING

BRASS INSERT

BUTTON

FLANGE

SETSCREW

B

Insert threaded end of push button actuator through cover plate and

wall flange and install nut. Tighten nut securely.

C

Attach plastic tubing. See: Steps to attach plastic tubing (lower right

side of page).

Insert flathead Screws through wall flange and cover plate mounting

D

holes. Mount wall flange and cover plate to metal partition using

flathead screws provided. Tighten fasteners securely.

Place brass Insert into black push button. Concave side of brass insert

E

must face outward of push button.

Insert black push button into button flange. Place spring against brass

F

Insert of push button. Install Push Button assembly onto wall flange.

Secure with Setscrew located on Button flange.

STEPS TO ATTACH PLASTIC TUBING

1. The push button actuator is connected to the flushometer body by two plastic

tubes, marked “L” and “O”. Match markings on the tubes to markings on the

actuator.

2. Cut off excess plastic tubing with plastic tube cutter (PTC) leaving 3” to 4”

(76 to 102 mm) of slack when push button actuator is installed. If the “L” and

“O” markings will be cut off, remark the tubing to not lose identification.

3. Slide plastic tubing into its corresponding valve actuator fitting. Pull tubing to

make sure connection is secure. (Tubing can be removed by pressing on blue

connection button to release.)

5

6E - INSTALL PUSH BUTTON ACTUATOR (HY-100-A METAL BUTTON (MBFW VARIATION) ACTUATOR – FIXTURE WALL)

Note: Behind wall access required to install HY-100-A (MBFW)

C

LOCKWASHER

THREADED ROD

Thread Actuator Assembly Nut onto end of Push Button Actuator.

PLASTIC

NUT

RETAINING

BAR

SPACER SLEEVE —

USE ONLY IF WALL

THICKNESS IS LESS

THAN 2” (51 mm)

If not already completed, bore a 1-1/2” (38 mm) diameter hole in

A

wall for the Push Button Actuator. Refer to the Rough-in drawings on

Pages 1 and 2.

B

Screw Threaded Rod into back of Push Button Actuator.

TUBING

BUTTON

ACTUATOR

PUSH

QUICK

CONNECT

FITTINGS (2)

ACTUATOR

ASSEMBLY

NUT

WALL

SPRING

BUTTON FLANGE

SPACER

RING

METAL

BUTTON

D

Slide Spring over Metal Push Button until it snaps into place.

Insert Metal Push Button into Button Flange.

E

Place Spacer Ring over threads of Button Flange and thread

Button Flange Assembly into Actuator Assembly Nut.

F

From behind wall, run Plastic Tubing through optional Spacer Sleeve

(notched end of sleeve toward rear) and wall. Spacer Sleeve only

required if wall thickness is less than 2” (51 mm).

Attach Plastic Tubing. See: Steps to Attach Plastic Tubing (Page 5).

G

Insert Push Button Assembly into the 1-1/2” (38 mm) wall hole.

H

From behind wall, slide Spacer Sleeve (if required) over Threaded Rod

I

and rest it against rear of wall. Slide Retaining Bar onto Threaded

Rod and into slots of Sleeve (if required), or against wall if Sleeve is

not required. Install Lockwasher and Nut onto Threaded Rod. Tighten

securely. Carefully cut excess Threaded Rod, making certain to not

damage Plastic Tubing.

6F - INSTALL PUSH BUTTON ACTUATOR (HY-108-A METAL BUTTON (MBPM VARIATION) ACTUATOR – PANEL MOUNT)

Note: Use HY-108-A (MBPM) on punched stainless steel plates and

PLASTIC

TUBING

PUSH BUTTON

ACTUATOR

security fixtures with front access.

QUICK CONNECT

FITTINGS (2)

ACTUATOR

ASSEMBLY NUT

WASHER

PANEL

SPRING

METAL BUTTON

BUTTON FLANGE

Attach plastic tubing to push button actuator. See: Steps to Attach

A

plastic tubing (Page 5).

B

Thread actuator assembly nut onto threaded end of push button

actuator.

Slide Spring over Metal Push Button until it snaps into place.

C

Insert Metal Push Button into Button Flange.

D

From front of panel, insert Button Flange Assembly into hole of panel.

Behind panel, place Washer over threads of Button Flange. Thread

Button Flange onto Actuator. Tighten Flange securely.

7 - FLUSH OUT SUPPLY LINE AND ADJUST CONTROL STOP

A

Shut off control stop by turning handle

CLOCKWISE. Then remove flushometer

cover.

Lift out the inside parts assembly as a

B

complete unit. Reinstall flushometer cover

and tighten with wrench. Open control

stop. Turn on water supply to flush line of

any debris or sediment.

Shut off control stop and remove flushometer

C

cover. Reinstall Inside Parts assembly and

flushometer cover. Tighten cover with

wrench. Open control stop and activate

flushometer.

Adjust control stop to meet flow rate required

D

for proper cleansing of fixture. Open control

stop COUNTERCLOCKWISE ONE FULL turn

from closed position. Activate flushometer.

Adjust control stop after each flush until the

rate of flow delivered properly cleanses the

fixture.

SLOAN FLUSHOMETERS ARE ENGINEERED FOR QUIET OPERATION.

EXCESSIVE WATER FLOW CREATES NOISE, WHILE TOO LITTLE WATER

FLOW MAY NOT SATISFY THE NEEDS OF THE FIXTURE. PROPER

ADJUSTMENT IS MADE WHEN TEH PLUMBING FIXTURE IS CLEANSED

AFTER EACH FLUSH WITHOUT SPLASHING WATER OUT FROM THE LIP

AND A QUIET FLUSHING CYCLE IS ACHIEVED.

NEVER OPEN CONTROL STOP TO WHERE THE FLOW FROM THE VALVE

EXCEEDS THE FLOW FROM THE VALVE EXCEEDS THE FLOW CAPABILITY OF

THE FIXTURE. IN THE EVENT OF A VALVE FAILURE, THE FIXTURE MUST BE

ABLE TO ACCOMMODATE A CONTINUOUS FLOW FROM THE VALVE.

!!! IMPORTANT !!!

CARE AND CLEANING OF CHROME AND SPECIAL FINISHES

DO NOT USE abrasive or chemical cleaners (including chlorine bleach) to clean flushometers that may dull the luster and attack the chrome or special decorative

finishes. Use ONLY mild soap and water, then wipe dry with clean cloth or towel.

While cleaning the bathroom tile, protect the Flushometer from any splattering of cleaner. Acids and cleaning fluids will discolor or remove chrome plating.

6

8 - INSTALL VANDAL RESISTANT CONTROL STOP CAP

ROYAL FLUSHOMETERS

IMPORTANT: DO NOT INSTALL CAP ONTO SLEEVE UNLESS THE SLEEVE HAS BEEN

THREADED ONTO THE BONNET. IF THE SLEEVE AND CAP ARE ASSEMBLED OFF

THE CONTROL STOP, THE SLEEVE WILL NOT COME APART FROM THE CAP.

A

Thread the plastic sleeve

onto the stop bonnet until it

is snug. Hand tighten only; do

not use pliers or a wrench.

CONTROL STOP

BONNET

B

Place the metal control stop cap over the plastic sleeve. Use the palm

of your hand to push or “pop” the cap over the fingers of the Sleeve.

The cap should spin freely on the sleeve.

BAK-CHEK®

CONTROL STOP

PLASTIC SLEEVE

CONTROL

STOP CAP

TROUBLESHOOTING

1. PUSHBUTTONLEAKS.

The actuator cartridge has an accumulation of lime or its seals are damaged or worn.

Replace with a new HY-32-A cartridge.

2. THEFLUSHOMETERDOESNOT FLUSHANDASMALLAMOUNTOFLEAKEAGEIS

VISIBLE BELOW THE VALVE.

A. Foreign material lodged in the cartridge. Remove the cartridge and inspect for foreign

material. Clean under running water.

B. The actuator cartridge has an accumulation of lime or its seals are damaged or worn.

Replace with a new HY-32-A cartridge.

C. Plastic tubing is installed incorrectly. Install plastic tubing correctly (Steps 4 and 6).

ACTUATOR CARTRIDGE REMOVAL

PLASTIC PUSH BUTTON ACTUATOR REMOVAL:

(1) Loosen the setscrew in the button flange and remove the button, flange, and spring from

the actuator body.

(2) Unscrew the cartridge from the actuator body.

NOTE: An automatic check valve in the actuator body allows removal of the

cartridge without turning off the water.

METAL PUSH BUTTON ACTUATOR REMOVAL:

(1) Remove the button or actuator assembly from the wall or fixture.

(2) Disassemble the flange or button assembly from the actuator body.

(3) Unscrew the cartridge from the actuator body.

NOTE: The metal Push Button is designed to be vandal-proof and must be removed

from the wall or fixture for service.

3. THE FLUSHOMETER DOES NOT FLUSH OR FLUSHES ONLY ONCE AND WILL NOT

FLUSH A SECOND TIME WHEN THE BUTTON IS PUSHED.

A. The plunger is lodged in the actuator cartridge or the plunger bypass hole is clogged.

Remove actuator housing and cartridge from the ushometer. Clean under running

water. If cartridge parts are worn, deteriorated or limed up and problem persists after

cleaning, replace with a new HY-83-A cartridge.

B. Plastic tubing is installed incorrectly. Install plastic tubing correctly (Steps 4 and 6).

REMOVAL OF THE ACTUATOR FROM THE FLUSHOMETER:

Turn off water at the control stop. Unscrew the actuator housing coupling nut from the

flushometer. Remove the actuator housing from the flushometer. The tubing connections

can be left intact. Carefully remove the actuator cartridge from the flushometer body to

prevent the actuator from abrupt separation due to expansion of an internal spring. If the

actuator cartridge is lodged in the flushometer body cavity, gently grip the exposed portion of

the cartridge with a channel-lock pliers and rotate back and forth to loosen the o-ring seal.

Carefully separate the actuator housing to reveal the spring and plunger.

4. FLUSHOMETER DOES NOT FUNCTION (NO FLUSH).

A. Control stop or main valve is closed. Open control stop or main valve.

B. Relief valve is worn. Replace performance kit (Royal) or inside parts kit (Regal XL).

5. VOLUME OF WATER IS NOT SUFFICIENT TO SIPHON FIXTURE.

A. Control stop is not open wide enough. Adjust control stop for desired delivery of water

volume.

B. Urinal flushometer parts installed in a closet flushometer. Replace inside urinal

ushometer parts with proper closet flushometer parts.

C. Incorrect dual filtered diaphragm assembly (Royal) or inside parts kit (Regal XL) is

installed in flushometer; for instance, urinal assembly inside a closet flushometer, or low

consumption assembly inside a higher consumption fixture. Determine the flush volume

required by the fixture and replace Royal performance kit or inside parts kit. Use valve

label and markings on fixture for reference.

D. Water supply volume or pressure is inadequate. If no gauges are available to properly

measure supply pressure or volume of water at the ushometer, then remove the relief

valve from the dual ltered xed bypass diaphragm assembly (Royal) or inside parts kit

(Regal XL), reassemble the flushometer and completely open the control stop. If the

fixture siphons, more water volume is required.

For Royal — Install a higher flushing volume Royal performance kit.

For Regal XL — If a 3.5 gpf inside parts kit is installed in the flushometer, then first

flip the refill head (under the diaphragm) to obtain a 4.5 gpf volume. If this volume is still

inadequate, remove the flow ring from the guide to obtain a 6.5 gpf Kit. If additional flow

is still required, try a low pressure guide kit A-175-A (0301104).

Control Stop Cap Removal (Royal)

Use a large flat screwdriver as a lever to remove the

cap from the control stop. Insert the screwdriver blade

between the bottom edge of the cap and the flat

surface of the control stop body as shown. Push the

screwdriver handle straight back toward the wall to

gently lift the cap. If necessary, work the screwdriver

around the diameter of the cap until you can grasp

the cap and lift it completely off the sleeve. The sleeve should

remain attached to the bonnet of the control stop.

REGAL XL FLUSHOMETERS

Install control stop plug onto the

A

control stop. Wrench tighten

control stop plug to eliminate

vandalism.

IMPORTANT — LAWS AND REGULATIONS REQUIRING PROHIBIT THE USE OF

HIGHER FLUSHING VOLUMES THAN LISTED ON FIXTURE OR FLUSHOMETER.

If the fixture does not siphon or if a Low Consumption flush is required, steps must

be taken to increase the water supply pressure and/or volume. Contact the fixture

manufacturer for minimum water supply requirements of the fixture.

6. FLUSHOMETER CLOSES OFF IMMEDIATELY.

A. Ruptured or damaged diaphragm. Replace Royal performance kit (Royal) or inside parts

kit (Regal XL).

B. For Regal XL— An enlarged bypass orifice from corrosion or damage. Replace Inside

parts kit.

7. LENGTH OF FLUSH IS TOO SHORT (SHORT FLUSH).

A. For Regal XL — The diaphragm Assembly and Guide Assembly are not hand tight.

Screw the two assemblies hand tight.

B. For Regal XL — An enlarged bypass orifice from corrosion or damage. Replace inside

parts kit.

C. Dual ltered xed bypass diaphragm assembly (Royal) or inside parts kit (Regal XL) is

damaged. Replace Royal performance kit or inside parts kit.

D. Incorrect dual filtered diaphragm assembly (Royal) or inside parts kit (Regal XL) is

installed in flushometer; for instance, urinal assembly inside a closet flushometer, or low

consumption assembly inside a higher consumption fixture. Determine the flush volume

required by the fixture and replace Royal performance kit or inside parts kit. Use valve

label and markings on fixture for reference.

5. LENGTH OF FLUSH IS TOO LONG (LONG FLUSH) OR CONTINUOUS.

A. For Royal — Metering bypass hole in diaphragm is clogged. Remove the dual filtered

diaphragm assembly. Remove the primary and secondary lter rings from the diaphragm

and wash under running water. Replace Royal performance kit if cleaning does not

correct the problem.

B. For Regal XL — Relief Valve (A-19-A) is not seating properly or bypass orifice

is clogged. Disassemble the working parts and wash thoroughly. NOTE:SIZEOF

THE ORIFICE IN THE BYPASS IS OF UTMOST IMPORTANCE FOR THE PROPER

METERING OF WATER INTO THE UPPER CHAMBER OF THE FLUSHOMETER.

DONOTENLARGEORDAMAGETHISORIFICE.REPLACEINSIDEPARTSKITIF

CLEANING DOES NOT CORRECT PROBLEM.

C. Supply line water pressure has dropped and is not sufficient to close the valve. Close

control stop until pressure is restored.

D. Dual filtered xed bypass diaphragm assembly (Royal) or inside parts kit (Regal XL) is

damaged. Replace Royal performance kit or inside parts kit.

E. Incorrect dual filtered xed bypass diaphragm assembly (Royal) or inside parts kit

(Regal XL) is installed in flushometer; for instance, urinal assembly inside a closet

flushometer, or low consumption assembly inside a higher consumption fixture.

Determine the flush volume required by the fixture and replace Royal performance kit or

inside parts kit. Use valve label and markings on fixture for reference.

F. White closet relief valve has been used in a urinal flushometer. Replace closet relief

valve (A-19-AC) with black urinal relief valve (A-19-AU).

G. Inside cover is cracked or damaged. Replace the inside cover (A-71).

H. Conditions in the piping system may contribute to the noise. A degree of high pressure

in the piping may be relieved by adjustments to control stop. Other noises created by

loose pipes, lack of air chambers, inadequate pipe sizes, etc., are problems that must be

discussed with the building engineer.

6. CHATTERING NOISE IS HEARD DURING FLUSH.

A. Inside cover is damaged. Replace inside cover (A-71).

B. For Regal XL — A-156-A segment diaphragm has been installed upside-down.

Reposition the segment diaphragm properly (see markings on the diaphragm).

When further assistance is required, please contact your

local Sloan Representative or Sloan Technical Support at:

7

1-888-SLOAN-14 (1-888-756-2614)

BAK-CHEK®

CONTROL STOP

CONTROL

STOP PLUG

PARTS LIST

7

3A

3B

11B

10

2C

1

9

11A

8

2B

2A

4D

4A

6A

5

6A

4C

6C

4B

6B

Item Part Description

No. No.

1 † Valve Assembly

2A HY-65 Valve Actuator Housing

2B A-6 Housing Nut

2C HY-83 Actuator Cartridge Assembly

3A H-700-A Bak-Chek

3B H-790-A Bak-Chek

4A V-600-AA 1-1/2” (38 mm) Vacuum Breaker Assembly

4B V-600-AA 1-1/4” (32 mm) Vacuum Breaker Assembly

4C V-600-AA 3/4” (19 mm) Vacuum Breaker Assembly

4D V-600-A Vacuum Breaker

5 F-109 1-1/2” (38 mm) Elbow Flush Connection

6A F-5-A 1-1/2” (38 mm) Spud Coupling Assembly (Royal Valves)

F-56-A 1-1/2” (38 mm) Spud Coupling Assembly (Regal XL Valves)

®

Control Stop (Royal Valves)

®

Control Stop (Regal XL Valves)

Item Part Description

No. No.

6B F-5-A 1-1/4” (32 mm) Spud Coupling Assembly (Royal Valves)

F-57-A 1-1/4” (32 mm) Spud Coupling Assembly (Regal XL Valves)

6C F-5-A 3/4” (19 mm) Spud Coupling Assembly (Royal Valves)

F-58-A 3/4” (19 mm) Spud Coupling Assembly (Regal XL Valves)

7 H-633-AA 1” (25 mm) Sweat Solder Kit & Cast Wall Flange w/Set Screw

H-636-AA 3/4” (19 mm) Sweat Solder Kit & Cast Wall Flange w/Set Screw

8 HY-64 Chrome Sleeve

9 F-7 Tube Flange

10 HY-112-A Plate with Screws

11A H-1010-A Free Spinning Vandal Resistant Stop Cap (Royal Valves)

11B H-528 Vandal Resistant Hole Plug (Regal Valves)

†

Part number varies with valve model variation; consult factory.

NOTE: The information contained in this document is subject to change without notice.

SLOAN HEADQUARTERS • 10500 SEYMOUR AVENUE • FRANKLIN PARK, IL 60131

Phone:1-800-982-5839or1-847-671-4300•Fax:1-800-447-8329or1-847-671-4380•www.sloanvalve.com

© 2013 SLOAN VALVE COMPANY Code No: 0816300 – Rev. 4 (05/13)

Loading...

Loading...