Slant-Fin S-150, SX-210, SX-150 User Manual

GAS-FIRED CAST-IRON BOILERS FOR NATURAL AND L.P. PROPANE GASES

®

“S” AND “SX” MODELS

HOT WATER MODELS S-34 THROUGH S-150

SENTRY

and SX-150 THROUGH SX-210

INSTALLATION AND OPERATING INSTRUCTIONS

CONTENTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . PAGE

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2,3

Installation Requirements:

Boiler Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Boiler Foundation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Chimney Requirements . . . . . . . . . . . . . . . . . . . . . . . . 4

Minimum Clearance . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Draft Hood . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Vent Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

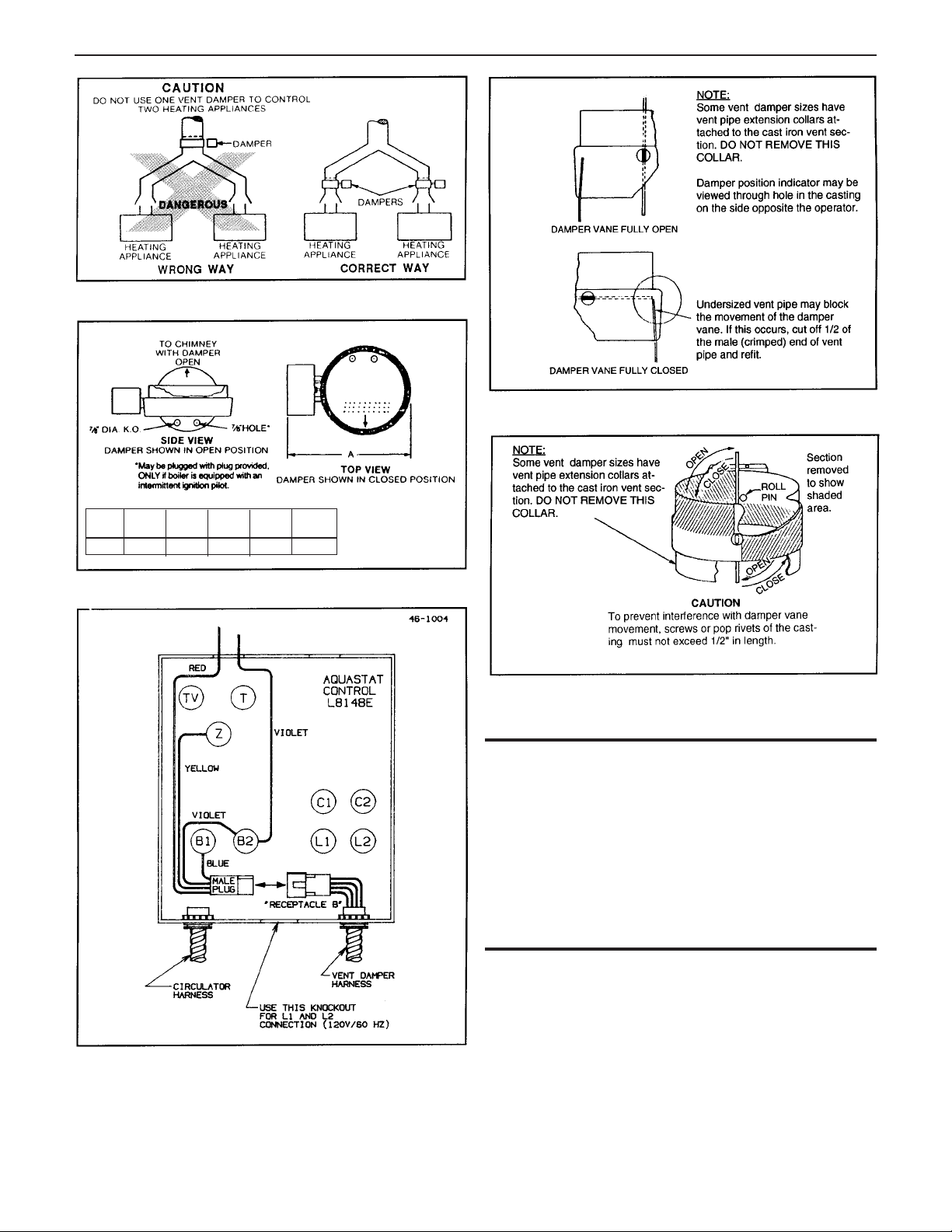

Vent Damper Installation . . . . . . . . . . . . . . . . . . . . 5,6,7

Gas Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Electrical Controls and Wiring . . . . . . . . . . . . . . . . . . . 8

Boiler Room Air Supply and Ventilation . . . . . . . . . . . . 8

Water Piping at Boiler . . . . . . . . . . . . . . . . . . . . . . . . . 8

Operating Instructions:

Filling and Venting Water Systems. . . . . . . . . . . . . . . . 8

Initial Start, Safety and Lighting Instructions . . . . . 9,10

Burner Adjustment, Checking Gas Input . . . . . . . 10,11

Care and Maintenance

General Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . 11

Water Level Check. . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Annual Inspection and Cleaning . . . . . . . . . . . . . . . . 12

Safety Check for Control Systems . . . . . . . . . . . . . . . 12

Protection from Freezing/Water Treatment. . . . . . . . . 12

Keeping Area Clear . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Sequence of Operations . . . . . . . . . . . . . . . . . . . . . . . . . 13

Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14,15

Pump or Valve Zoning of Water Boilers . . . . . . . . . . . . . 16

Troubleshooting Guide . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Piping a Heating-Cooling System . . . . . . . . . . . . . . . . . . 18

Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Appendix A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

READ ALL OF THE FOLLOWING WARNINGS AND

STATEMENTS BEFORE READING THE

INSTALLATION INSTRUCTIONS

LIQUEFIED PETROLEUM (L.P.)

PROPANE GAS-FIRED BOILERS

Installation location ONLY as permitted in paragraph entitled "LIQUEFIED PETROLEUM (L.P.) PROPANE GASFIRED BOILER LOCATION" on page 4 of this instruction

book.

The above warning does not apply to

fired boilers.

The installation must conform to the requirements of the

authority having jurisdiction or, in the absence of such

requirements, to the National Fuel Gas Code, ANSI

Z223.1-latest edition. The installation must also conform

to the additional requirements in this Slant/Fin Instruction

Book.

In addition, where required by the authority having jurisdiction, the installation must conform to American Society of

Mechanical Engineers Safety Code for Controls and Safety

Devices for Automatically Fired Boilers, No. CSD-1. If there

is any conflict in the above requirements, then the more

stringent requirement will apply.

This manual must be left with owner and should be hung

on or adjacent to the boiler for reference.

This boiler, gas piping and accessories must be installed,

connected, serviced and repaired by a trained, experienced service technician, familiar with all precautions

required for gas-fired equipment and licensed otherwise

qualified, in compliance with the authority having jurisdiction.

IMPORTANT

WARNING

NATURAL gas-

WARNING

Heating Contractor

Address

Phone Number

Printed in U.S.A. 605 PUBLICATION S-40

Part No. 46-0528 Rev. N

Boiler Model Number

Boiler Serial Number

Installation Date

2

Sentry

Sentry

3

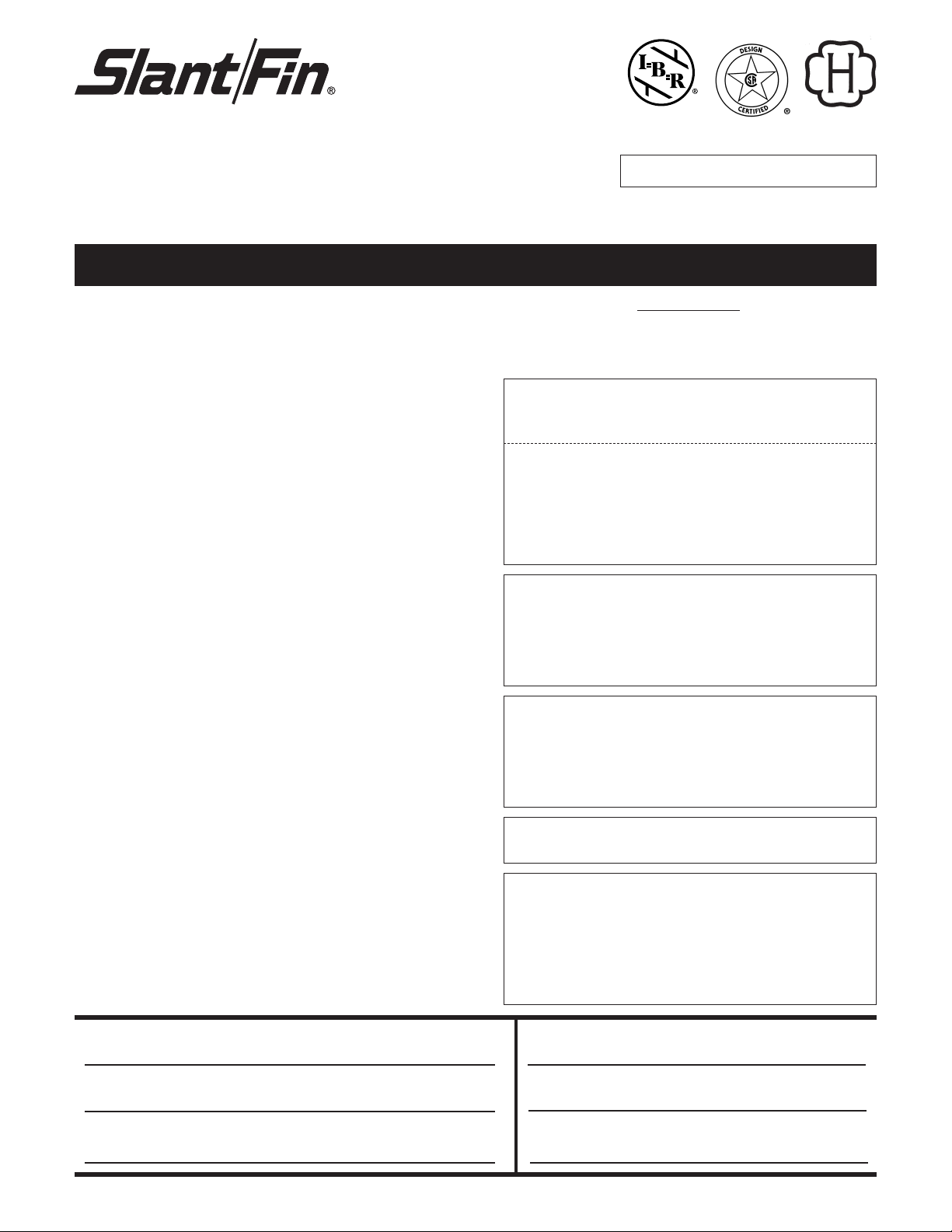

Boiler

Model

No. of

Sect.

S-34 2 8

S-60 3 11

S-90 4 14

S-120 5 17

S-150 6 20

SX-150 6 20

SX-180 7 23

SX-210 8 26

Boiler

Model

S-34

S-60 thru S-150 and

SX-150 thru SX-210

Dimensions

(inches)

A B C D E FG

1

⁄8"145⁄8" 4 33" — — 61⁄4" 190

1

⁄8"175⁄8" 4 37" 41⁄2"26"6

1

⁄8"205⁄8" 5 37" 51⁄2"251⁄2"61⁄4" 310

1

⁄8"235⁄8" 6 37" 71⁄2"25"6

1

⁄8"265⁄8" 7 37" 81⁄2"241⁄2"81⁄4" 425

1

⁄8"265⁄8"6511⁄2"101⁄2"107⁄8"61⁄4" 425

1

⁄8"295⁄8"7523⁄4" 12" 107⁄8"81⁄4" 485

1

⁄8"325⁄8"7523⁄4"131⁄2"107⁄8"81⁄4" 545

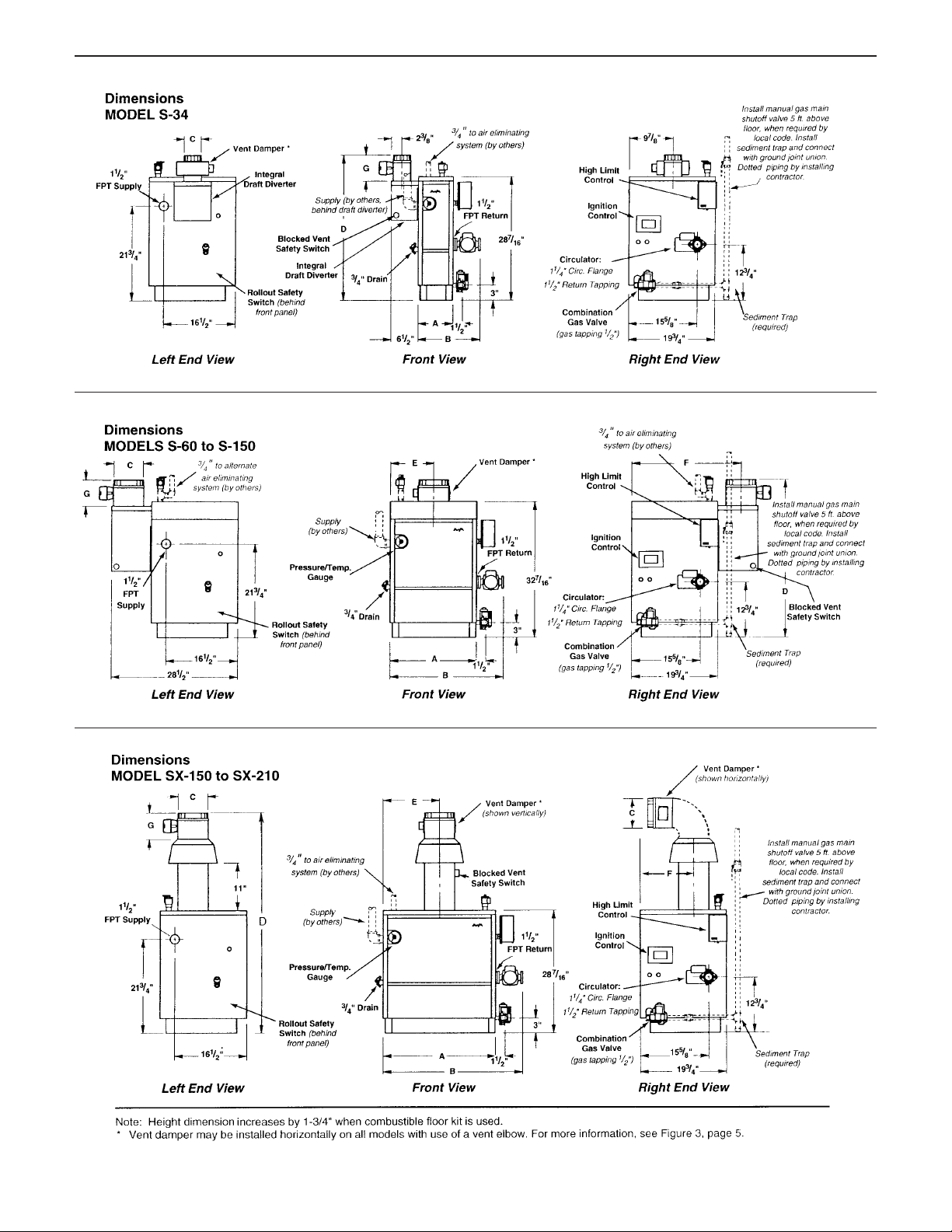

Orifice Sizes for High Altitudes

Includes 4% Reduction for Each 1000 Feet

Gas

Type

Orifice

Size for

Sea

Level

2000 3000 4000 5000 6000

(max)

Elevation - Feet

Approx.

Total Wt.

Full of

Water (lb.)

1

⁄4" 250

1

⁄4" 365

7000 8000 9000 10000

CHIMNEY RECOMMENDATIONS

HEIGHT:15 ft. (minimum) from draft

hood skirt to top of chimney.

INSIDE DIAMETER: Same as dimension C (or larger).

NOTE: Larger chimney may be

required if two or more boilers or a boiler and another appliance are vented to

a single chimney.

Slant/Fin supplies vent dampers by

several manufacturers. Some are

smaller than the indicated “G maximum”.

Natural 47 48 48 49 49 49 50 50 51 51

Propane 56 56 56 57 57 57 58 59 59 60

Natural 50 51 51 51 51 52 52 52 53 53

Propane 57 58 59 59 60 60 61 62 63 63

Orifice indicated for sea level above are factory installed in boiler unless otherwise specified by the local authority.

See III page 10 f

Base Assembly

Sentry Boiler

or burner input adjustment.

INSTALLATION REQUIREMENTS

The installation must conform to the requirements of the authority

having jurisdiction or, in the absence of such requirements, to the

National Fuel Gas Code, ANSI Z223.1-latest edition.

This installation must also conform to the additional requirements

in this Slant/Fin Instruction Book.

Burners

NATURAL GAS-FIRED BOILER LOCATION

Pilot

Burner

Access

Door

Gas Valve

Provide a level, solid foundation for the boiler. Location should be

as near as possible to chimney or outside wall so that the flue pipe

from boiler is short and direct.

The location should also be such that the gas ignition system components are protected from water (dripping, spraying, rain, etc.)

during appliance operation and service (circulator replacement,

condensate trap, control replacement, etc.).

BOILER FOUNDATION

A. Provide a solid, level foundation, capable of supporting the

weight of the boiler filled with water, and extending at least 2"

past the jacket on all sides. See dimensions of boiler, page 2.

B. For installation on non-combustible floors only. The

Combustible Floor Kit part number printed on the boiler rating

plate is the only one to be used when installing on combustible

floors. The boiler must not be installed on carpeting.

C. If boiler is to be located over buried conduit containing electric

wires or telephone cables, consult local codes or the National

Board of Fire Underwriters for specific requirements.

4

Sentry

W

ARNING

LIQUEFIED PETROLEUM (L.P.) PROPANE

GAS-FIRED BOILER LOCATION

REQUIRES SPECIAL ATTENTION

Liquefied Petroleum (L.P.) propane gas is

heavier than air.

Therefore, propane boilers, piping, valves should not be

i

nstalled in locations where propane leaking from defective

equipment and piping will “pool” in a basement or other space

below the leak.

A

spark or flame from the boiler or other source may ignite

the accumulated propane gas causing an explosion or fire.

Provide a level, solid foundation for the boiler.Location should

be as near the chimney as possible so that the flue pipe from

boiler to chimney is short and direct.

T

he UNIFORM MECHANICAL CODE may be in effect in

your geographic area

The following precautions are cited by the 1994 UNIFORM

MECHANICAL CODE, section 304.6:

“LPG Appliances. Liquefied petroleum gas-burning

appliances shall not be installed in a pit, basement or similar location where heavier-than-air-gas might collect.

Appliances so fueled shall not be installed in an abovegrade under-floor space or basement unless such location is provided with an approved means for removal of

unburned gas.”

Consult Chapter 5 of the 1994 UNIFORM MECHANICAL

CODE for design criteria of the “approved” means for removal

of unburned gas.

CHIMNEY REQUIREMENTS

A. Sentry boilers may be vented into a masonry vitreous tile-

lined chimney or type “B” venting system NOT EXPOSED to

the OUTDOORS below the roof line.

Venting and sizing of venting system must be in accordance

with Part 7, Part 10 and Appendix G of the National Fuel

Gas Code ANSI Z223.1, NFPA 54, -latest edition which will

be referred to as the National Fuel Gas Code. Local codes

apply.

If a masonry chimney is exposed to the outdoors on one or

more sides below the roof line (exterior chimney), ONE of

the following options apply:

1. Chimney must be re-lined with a metallic liner. When this

is done, the chimney will be considered NOT exposed to

the outdoors and the requirements of the National Fuel

Gas Code for NON-exposed chimneys and/or local codes

will apply.

2. If an exposed tile-lined chimney is to be used WITHOUT

a metallic liner, the boiler must first meet the requirements of the following tables and paragraphs of the

National Fuel Gas Code:

I. For Single Sentry Boiler - Paragraph 10.1.9 and

table 10.11.

II. For multiple appliances - Paragraph 10.2.18 and table

10.12 (or 10.13 if applicable).

In addition, all requirements of Part 7, Part 10 and

Appendix G of the National Fuel Gas Code and/or local

codes apply.

B. If an existing boiler is removed from a common venting

system, the common venting system may be too large

for proper venting of the remaining appliances connected to

the common vent. Follow the test procedure shown in

Appendix “A” on page 19 of this manual to insure proper

operation of venting system and appliances.

C. Inspect for proper and tight construction. Any restrictions or

obstructions must be removed. An existing chimney may

require cleaning.

D. Chimney or vent must extend at least 3 feet above any

ridge within 10 feet of the chimney.

MINIMUM CLEARANCES FROM COMBUSTIBLE

C

ONSTRUCTIONS

SENTRY SERIES

MINIMUM CLEARANCE FOR COMBUSTIBLE CONSTRUCT

ION. MINIMUM ALCOVE AND CLOSET CLEARANCE.

S-34 through SX-150 through

S-150

SX-210

Front 6" 6"

Rear 6" 6"

Left Side 6" 6"

Right Side 12" 12"

Top (above boiler) 12" 28"

Flue Connector 6" 6"

A. Minimum boiler clearances shall be as follows:

B. Provide accessibility clearance of 24” on sides requiring

servicing and 18” on sides used for passage.

C. All minimum clearances shown above must be met. This

may result in increased values of some minimum clearances

in order to maintain the minimum clearances of others.

D. Clearance from hot water pipes shall be 1 inch**.

** At points where hot water pipes emerge from a floor wall or ceiling, the

clearance at the opening through the finished floor, wall or ceiling boards

may not be less than 1/2 inch. Each such opening shall be covered with

a plate of non-comb

ustib

le mater

ial.

SAFETY—

KEEP THE BOILER AREA CLEAR AND FREE FROM

COMBUSTIBLE MATERIALS, GASOLINE AND OTHER

FLAMMABLE VAPORS AND LIQUIDS.

DRAFT HOOD—

The draft hood supplied with SX-150 through SX-210 models is

part of the listed boiler assembly. DO NOT alter the hood. See

dimensions, page 2.

Attach the hood to the boiler flue outlet. Connect flue pipe full

size of hood outlet. Vent damper must be installed on the outlet

side of the hood. See Vent Piping, below.

VENT PIPING—

A. Vent piping installation must be in accordance with ANSI

Z223.1-latest edition, National Fuel Gas Code, Part 7,

Venting of Equipment. Other local codes may also apply and

must be followed.

B. Boiler vent pipe must be the full diameter of the boiler outlet.

See dimensions, page 2.

C. If more than one appliance vents into a common breeching,

the area of the breeching must be equal to the area of the

largest vent plus 50% of the area of the additional vent

areas. Vent connectors serving appliances vented by natural draft shall not be connected into any portion of mechanical draft systems operating under positive pressure.

Horizontal breeching or vent pipe should be as high as possible, consistent with codes, so that vertical vents from appliances will have a high rise above draft diverter openings. All

horizontal runs must slope upwards not less than 1/4 inch

per foot of run. Horizontal portions of the venting system

Sentry

5

must be supported to prevent sagging by securing each joint

with metal screws and by providing hanger spaced no

greater than 5 feet apart.

D. Vent or breeching into chimney should not be inserted past

the inside wall of the chimney liner.

E. All venting means should be inspected frequently. See Care

and Maintenance and separate User's Information Manual.

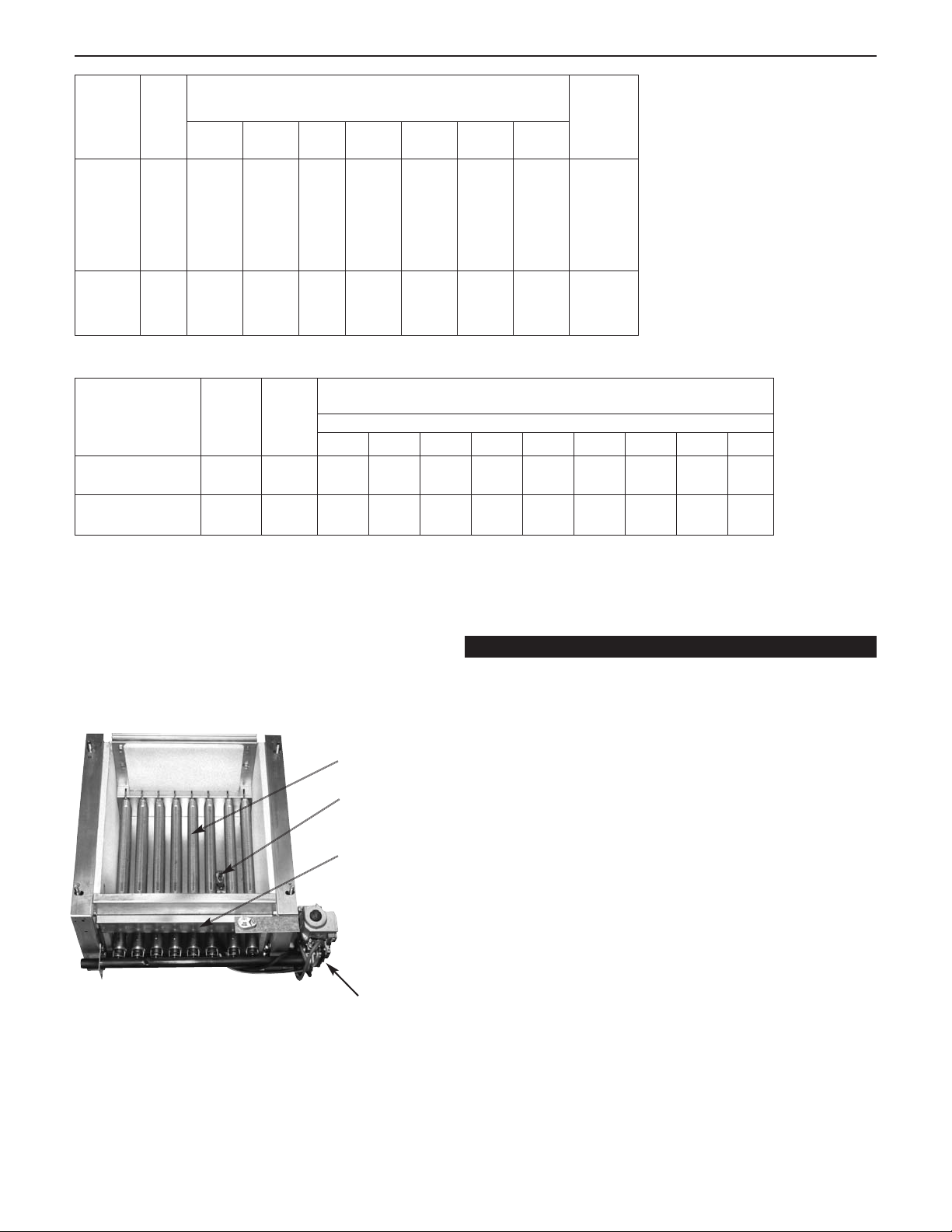

V

ENT DAMPER INSTALLATION

The vent damper referred to in the following instructions is

the Slant/Fin Corporation vent damper.

This device is design certified by A.G.A. for use ONLY on specific Slant/Fin Corp. gas boiler models. These boilers must also

be equipped with a plate which states that the boiler may be

used with a Slant/Fin Corp. automatic vent damper device and

indicates the proper vent damper model number. This device

cannot be used with millivolt ignition system.

A. INSTALLATION INSTRUCTIONS BEFORE YOU START TO

INSTALL

1. Read this installation manual, the "DANGER" plate

attached to the top of the boiler, the "WARNING" on the

wiring diagrams, vent damper carton and operator cover.

2. Perform pre-installation inspection as required by ANSI

specification Z21.66. (See Vent Damper Instructions.)

3. Select a proper, convenient location for vent damper.Vent

damper may be installed vertical or horizontal on all models (see figures 1, 2 and 3).

4. Carefully unpack the unit. DO NOT FORCE IT OPEN OR

CLOSED. Forcing the damper may damage the gear

train and void the warranty.

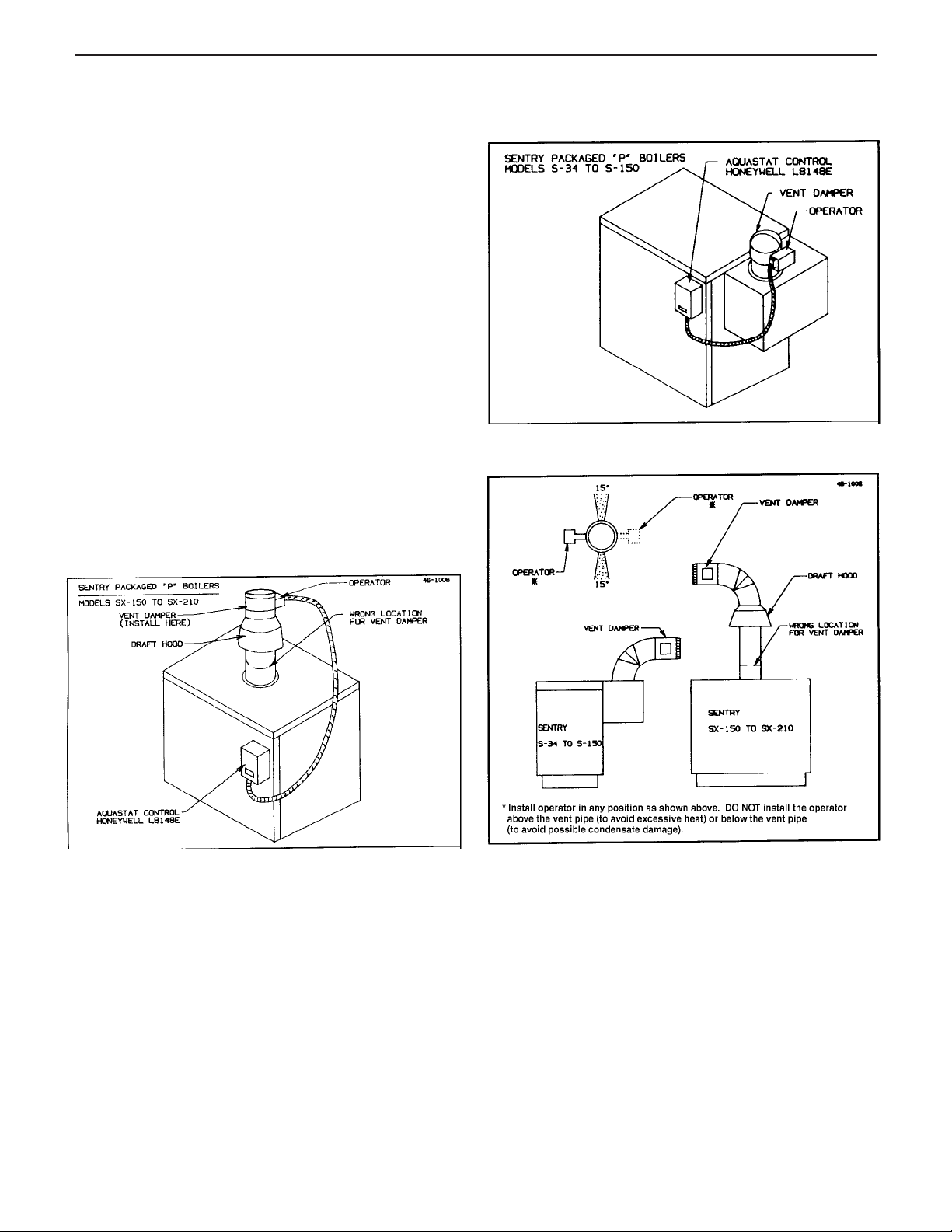

Figure 2. Vertical Installation of Vent Damper on Sentry “S”

Boilers

Figure 1. Vertical Installation of Vent Damper on

Sentr

y “SX” Boilers

Figure 3.

Horizontal or Sloping Installation of Vent Damper

6

Figure 4.

TABLE

Vent

ize 4" 5" 6" 7" 8"

S

5

A9

⁄16"105⁄16"115⁄16"125⁄16"135⁄16"

Sentry

Figure 8. Damper Vane

Figure 5. Vent Damper Dimensions

Figure 9.

WARNING—DANGER

Once you have begun vent damper installation procedure, DO

NOT restore electric power and gas supply until installation

and inspection ha

ve been completed (in order to prevent the

main burners from operating). DO NOT operate the boiler until

the vent damper harness "RECEPTACLE B" is plugged into

"MALE PLUG" (as described in the installation instructions),

and the vent damper installation and checkout procedures

have been completed. Failure to observe this warning may

create a hazardous condition that could cause an explosion or

carbon monoxide poisoning.

Figure 6. Connecting “RECEPTACLE B” to “MALE PLUG” inside

L8148E Aquastat Box for Sentry Packaged “S” and

“SX” boilers.

Loading...

Loading...