Page 1

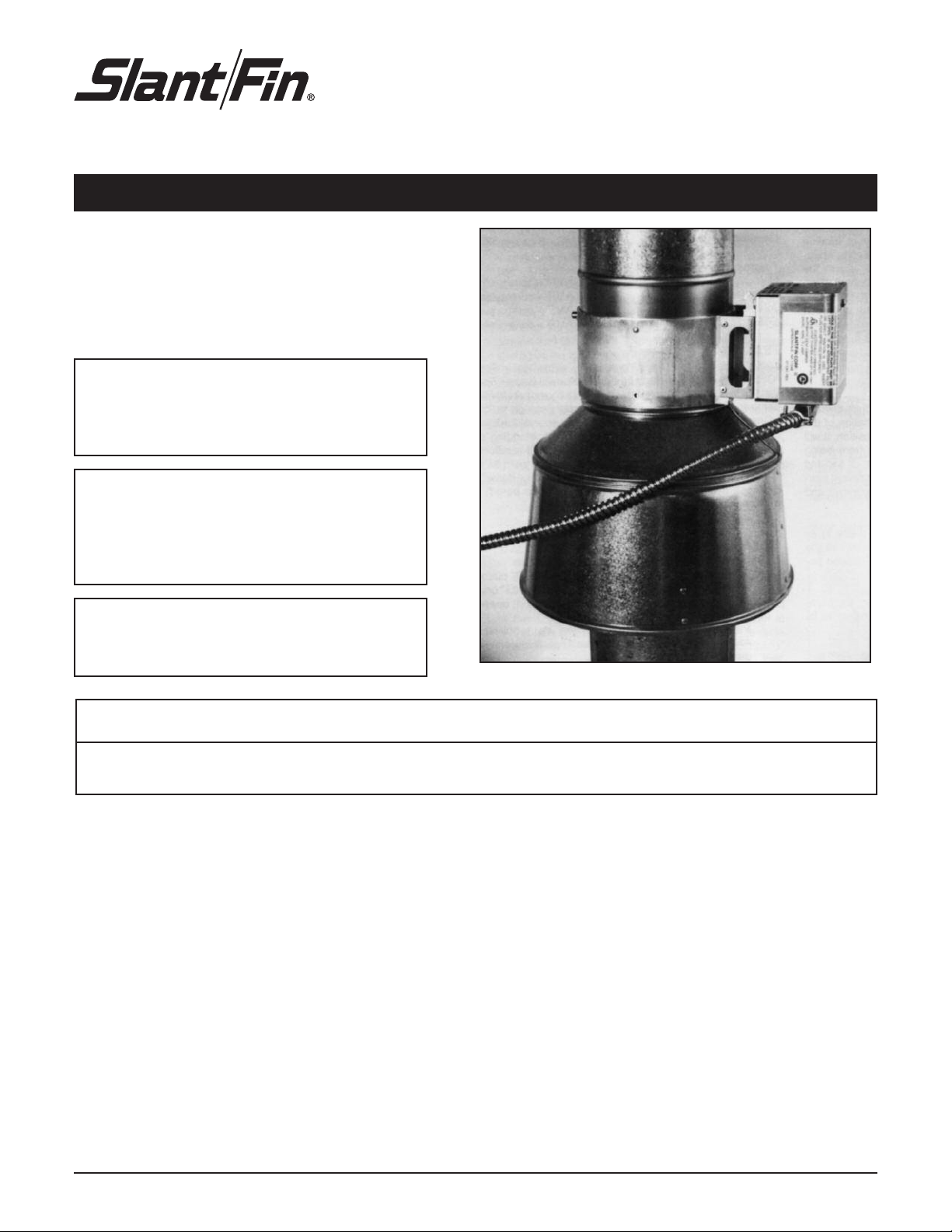

AUTOMATIC VENT DAMPER

INSTALLATION INSTRUCTIONS AND TROUBLESHOOTING GUIDE

For Galaxy, Sentinel

and Sentry Series Boilers

READ AND SAVE THESE INSTRUCTIONS

FOR REFERENCE.

The installation must conform to the requirements of

the authority having jurisdiction or, in the absence of

such requirements, to the National Fuel Gas Code,

ANSI Z223.1-latest edition.

In addition, where required by the authority having

jurisdiction, the installation must conform to American

Society of Mechanical Engineers Safety Code for

Controls and Safety Devices for Automatically Fired

Boilers, No. CSD-1.

THIS MANUAL MUST BE LEFT WITH OWNER AND

SHOULD BE HUNG ON OR ADJACENT TO THE

BOILER FOR REFERENCE.

WARNING

By failing to follow the WARNING instructions listed below, a hazardous condition

such as explosion, carbon monoxide poisoning, fire or all of these could result.

• This device is design certified by C.S.A. for use only on

specific Slant/Fin Corporation gas boiler models. These

boilers must also be equipped with a plate or rating plate

which states that the boiler must* (may*) be used with a

Slant/Fin Corp. automatic vent damper device and indicates

the proper vent damper model or part number (See Table 1).

* Boilers under 300,000 Btu/hr. input MUST use a vent damper.

Note: GG-75 HES (Constant circulation), MAY use a vent

damper.

Boilers with 300,000 Btu/hr. input or greater equipped with IID

(intermittent pilot ignition) MAY use a vent damper.

Boilers with 300,000 Btu/hr. input equipped with continuous

pilot and VR8300A gas valve MAY use a vent damper.

• This device must be installed and inspected annually by a qualified installer in accordance with the Slant/Fin vent damper

installation instructions, Slant/Fin boiler installation instructions

and the vent damper manufacturer's installation instructions

included with this damper. If improperly installed, a hazardous

condition such as explosion or carbon monoxide poisoning could

result. If installed improperly, all vent damper and boiler warranties shall be voided.

The vent damper shipped with your boiler may be a different model than illustrated above.

• Use of this device on boilers other than those indicated above is

not permitted.

• CAUTION: When servicing controls all wires must be labeled

prior to disconnection. Wiring errors can cause improper and

dangerous operation.

• This device must be installed on the outlet end of the draft hood

of the boiler as close to the draft hood as practicable, and without modification of the draft hood (see figures 3 through 7).

• The inlet size of the vent damper must be the same nominal

trade size as the outlet of the draft hood. See Table 1 for the

boiler models and their corresponding vent damper models.

• The device must be located in a venting system or section of a

venting system so that it serves only the single appliance for

which it is installed.

• Clearances of not less than 6 inches (152 mm) must be maintained from combustible materials, with provisions for access.

• If the boiler will not fire, DO NOT jump any of the safety controls

(the vent damper circuit is part of the safety control circuit).

Check page 12 of this manual for troubleshooting guide.

Part No. 41-1676. Printed in U.S.A. 112 Publication No. VD-40, Rev. V

Page 2

INTRODUCTION

This product is an automatic, motorized stack damper that has been

developed to increase the efficiency of heating systems by reducing

standby losses from the heating apparatus and the conditioned air

space. The damper closes the chimney vent when the burner is off

and fully opens it when combustion is required. The concept is similar

to the opening and closing of a fireplace flue, except that the operation

is completely automatic. An interlock has been added which prevents

burner operation unless the damper is in an open position. A closed

damper substantially reduces standby losses on boilers.

DESCRIPTION

The unit must be installed after the appliance draft diverter and as

close to it as practicable, without modification of the draft hood. When

the damper is in the closed position, it will prevent residual heat in the

heating appliance from being drawn up the chimney vent by its natural

draft. If located within a heated area, a closed damper will also prevent conditioned air from being pulled through the draft diverter and

up the chimney by the same stack effect.

When combustion is required, the damper will rotate to its open position BEFORE an integral end switch activates the burner circuit. If the

damper does not rotate to its open position, the burner circuit will not

be activated.

When the heating requirement has been satisfied, the burner will go

off immediately, and the damper will rotate to its fully closed position.

Potential fuel savings can vary based on the following factors:

1. Geographical location of dwelling

2. The size of heating plant relative to heat loss

of dwelling

3. Location of heating plant within dwelling

4. Diameter of venting system

5. Total height of chimney above heating plant

6. Outdoor temperatures over a given period of time

7. Sustained wind velocities over a given period of time

8. Settings of operating and limit controls on heating plant

9. Source of domestic hot water, temperature of water, and

amount used

10. Room thermostat settings

11. Infiltration factors of dwelling

12. Number of heating zones

13. Day/night thermostats

14. Presence of other vents and exfiltration factors

15. Chimney vent friction

GENERAL INFORMATION

VENT

SIZE

10"

ELECTRICAL

Minimum Wiring

Requirements 24VAC,18 gauge, 90°C

Thermostat Anticipation

Flair0.1 AMP + control circuit

Honeywell Inc. 0.2 AMP + control circuit

Johnson 0.2 AMP + control circuit

Field Controls (Effikal) 0.1 AMP + control circuit

FEATURES

100,000 trouble-free operations in life cycle test • Burner "OFF" before

start of damper close • Normal burner operations with damper disabled open • No burner operation with damper disabled closed •

External damper position indicator • Direct drive, no-linkage and

switch for burner off/on cycle • Low voltage (24V) circuitry compatible

with standing pilot and intermittent ignition devices • CSA

retrofit certification ANSI Z21.66 - latest edition • "Free-wheeling" permits free rotation of vane during installation without motor damage •

Both operator motor and operator control (P.C. board) are replaceable

INSTALLATION INSTRUCTIONS

I. Before you start to install

1. Read this installation manual, vent damper manufacturer’s

instructions, the "WARNING" label attached to the top of the

boiler, the "WARNING" on the wiring diagram and the “DANGER” label on the vent damper carton.

APPROX SHIP WT.

(WITH HARNESS) IN LBS.

4"

5"

6"

7"

8"

9"

3.5

3.5

4.5

4

5

6

7

2. Perform pre-installation inspection as required by ANSI specification Z21.66. See manufacturer’s vent damper instructions.

3. Turn off all electrical power, gas supply and wait for system to

cool (for previous installed boilers).

4. Select a proper, convenient location

(see figures 3, 4, 6 and 7).

5. Carefully unpack the unit. DO NOT FORCE IT OPEN OR

CLOSED! Forcing the damper may damage the gear train and

void the warranty.

WARNING—DANGER

Once you have begun vent damper installation procedure, DO NOT

restore electric power and gas supply until installation and inspection

have been completed (in order to prevent the main burners from operating). DO NOT operate the boiler until the vent damper harness

"RECEPTACLE B" is plugged into "MALE PLUG" (as described in the

installation instructions), and the vent damper installation and checkout procedures have been completed. Failure to observe this warning

may create a hazardous condition that could cause an explosion or

carbon monoxide poisoning.

II. Now, proceed as follows for Boilers with input under 300,000

Btu/hr.:

1. Remove the front cover of the boiler (Galaxy models only)

exposing the wiring compartment. With all electrical power to

boiler off, locate “MALE PLUG”. Refer to the wiring diagram

attached to boiler. A copy of the wiring diagram may also be

found in the boiler installation manual. To find the correct wiring

diagram in installation manual, match the number found in the

lower right hand corner of the boiler wiring diagram with the

identical number on one of the diagrams in the manual.

2. This device must be installed on top of the draft hood or diverter in position as shown in figures 3, 4, 5, 6 and 7. The vent

damper must be installed so that the damper position indicator

is in a visible location after installation for position indicator

description. The arrow imprint on the damper should point in

direction of vent gas flow (towards chimney). Flue pipe (other

than flue collector on boiler) insertion depth for the male end

should not exceed one inch into the vent damper. Be sure the

vent damper is well seated and fasten with 3 sheet metal

screws. Screws should be no longer than 1/2 inch.

3. Be sure that undersized vent pipe does not block move-

ment of damper vane

4. NOTE:

Galaxy 300,000 Btu/hr. Standing Pilot boilers, and Intermittent

Pilot (IID) boilers 300,000 Btu/hr and larger may

have a vent

damper (see page 1). They are factory wired with “MALE

PLUG” and “RECEPTACLE A”. To install the vent damper, cut

the RED wire connected between number 3 and 4 of

“RECEPTACLE A” (the only wire connected to this receptacle)

and then disconnect “RECEPTACLE A” from “MALE PLUG”.

Remove “RECEPTACLE A” from job site and discard. Boilers

that must have a vent damper (boilers with input under

300,000 Btu/hr.) are factory wired with “MALE PLUG” only.

5. a) Galaxy boilers: Attach the flexible metallic conduit vent

damper harness to the right hand side of the jacket by

passing the free end (“RECEPTACLE B”) of the harness

through the 7/8" diameter hole in the top of the jacket, and

using the BX connector at the free end of the metallic conduit, fasten to jacket. Connect “RECEPTACLE B” into

“MALE PLUG” (see correct wiring diagram). Attach the

other side of the vent damper harness to vent damper operator (if not attached) and connect Molex connector to operator receptacle. For more information, see Galaxy installation manual, GG-40.

b) Sentry and Sentinel boilers: All Slant/Fin Sentry and

Sentinel boilers are supplied with vent damper. “MALE

PLUG” and “RECEPTACLE B” are in control box. For vent

damper installation instruction see Sentry installation

manual, S-40 or Sentinel installation manual SE-40.

6. All Slant/Fin Corp. Galaxy steam boilers equipped with inter-

mittent pilot ignition and continuous (standing) pilot systems

are factory wired except for the wires to the low water cut-off

and pressure cut-off. Wire these controls with wire provided

with boiler (see boiler wiring diagram on boiler). Then follow

previous instructions shown in 4 and 5 above.

7. Follow instruction for electrical wiring in boiler installation manual (Galaxy, GG-40; Sentry, S-40 or Sentinel SE-40) or restore

electrical power and turn on gas supply (for previously installed

boilers). See wiring diagram attached to the boiler or in boiler

installation manual.

Page 3

III. After Installation

1. Operate system through two complete cycles to check for

opening and closing in proper sequence, and proper burner

operation. Damper must be in open position when boiler

main burners are operating.

2. Perform installation checks as required by ANSI specification

Z21.66. See manufacturer’s vent damper instructions.

3. Replace the front cover of the boiler. (Galaxy models only.)

4. Check the troubleshooting section if problems arise with the

installation.

For more information, see Slant/Fin boiler installation manual GG40 for Galaxy, S-40 for Sentry, SE-40 for Sentinel, and the vent

damper manufacturer's booklet shipped with the vent damper.

VENT DAMPER SUITABILITY

Check the rating plate attached to the boiler for proper vent damper

part number to use on the boiler.

Damper circuit is designed to be controlled by low

voltage controls. DO NOT use line voltage operating con-

trols to interrupt supply voltage to the L8148E and L8124E

aquastats or system transformer on steam system.

Label all wires prior to disconnection when servicing control.

iring errors can cause improper and dangerous operation.

W

WARNING - IMPORTANT

AUTION

C

“Verify proper operation after servicing”

VENT DAMPER MODEL NUMBER

In Table 1, the proper Slant/Fin Corp. vent damper model numbers are shown adjacent to the specific Slant/Fin Corp. boilers

with which these vent dampers may be used.

WARNING

THIS DEVICE CANNOT BE USED WITH BOILERS WITH 300,000 BTU/HR. INPUT OR GREATER EQUIPPED WITH CONTINU-

OUS PILOT (see note). OTHER VENT DAMPERS OR DEVICES WITH SIMILAR PURPOSE ARE NOT PERMITTED.

NOTE: BOILERS WITH 300,000 BTU/HR. EQUIPPED WITH HONEYWELL VR 8300A GAS VALVE MAY USE A VENT DAMPER.

Table 1.

Vent Size Use Slant/Fin Vent

For Slant/Fin Boiler Model No.† Inches Damper Part No.

S-34, S-60, SE-70 4 41-2704#

GG-75H, GXH-105, GXHA-100, GXHA-120, S-90, SE-105, SE-140 5 41-2705#

GG-100H, GG-125H, GG-150H, GG-175H, GXH-125, GXHA-160, S-120, SX-150, SE-175 6 41-2706#

GG-200H, GG-225H, GXH-150, GXH-170, GXH-190, GXH-210, GXH-230,

GXHA-200, GXH-250, GXH-275, S-150, SX-180, SX-210, SE-210, SE-245 7 41-2707#

GX-225, GX-250,GG-250H, GG-275H, GG-300, GG-325, GXH-300 8 41-2708#

GG-350, GG-350H, GG-375, GXH-300H 9 41-2709

GG-375H, GG-399H 10 41-2710#

† May have suffix “E”, “D”, “P”, “PZ”, etc.

# May be any 3 digits.

DIMENSIONS

Figure 3. Vertical Installation

Figure 1.

Figure 2.

Table 2.

Vent

Size 4" 5" 6" 7" 8" 9" 10"

A9

* May be plugged with plug provided, ONLY if boiler is equipped with an inter-

mittent ignition pilot. Note on Honeywell vent dampers there is only the 7/8

dia. hole and no knockout. For more information on specific vent dampers

see manufacturer’s manual included.

5

⁄8" 105⁄8" 115⁄8" 125⁄8" 135⁄8" 145⁄8" 155⁄8"

Figure 4. Horizontal or Sloping Installation

Page 4

NOTE: READ MANUFACTURER'S INSTRUCTION MANUAL INCLUDED IN VENT DAMPER CARTON.

Figure 5.

SYMPTOM POSSIBLE CAUSE REMEDY

Heating required and burner

will not operate. Damper open.

Burner operates normally.

Burner shuts down normally,

but damper will not close.

Burner will not operate.

Damper closed and will not

open.

Burner will not operate.

Damper operates normally.

Burner operates before

damper is open.

Damper vane stops in other

than fully open or fully closed

position.

Intermittent burner operation.

(Damper operates normally.)

Burner operates with damper

closed.

Figure 6.

igure 7.

F

TROUBLESHOOTING GUIDE

(listed in order of probability)

Thermostat is set wrong. Reset room thermostat to call for heat.

No electrical power. Turn on switch, replace fuse, reset circuit breaker, or

repair wiring.

Improper wiring. Recheck and correct any wiring errors.

Defective burner components. Check, repair or replace burner components, gas valve,

pilot, IID, IID sensor, etc.

Damaged or defective damper operator. Replace damper operator.

Damper is blocked open. Check for free damper movement, and remove blockage.

Improper wiring. Recheck and correct any wiring errors.

Damaged or defective damper operator. Replace damper operator.

No call for heat. Reset thermostat (heat or hot water) to call for heating.

Damper is blocked closed. Check for free damper movement and remove blockage.

Improper wiring. Recheck and correct any wiring errors in line and low volt-

age circuits.

Broken return spring (if equipped). Replace drive assembly.

Improper wiring. Recheck and correct any wiring errors.

Defective burner components. Check, repair or replace burner components.

Improper wiring. Recheck and correct any wiring errors.

Damper is blocked. Check for maximum 90° damper movement. If less than

90°, remove blockage.

Missing roll pin damper stop. Replace stainless steel roll pin.

Broken coupling. Inspect and replace drive assembly.

Broken return spring (if equipped). Replace drive assembly.

Broken spring stop (if equipped). Replace drive assembly.

Burner access door open. Re-install door and fasten with wing nuts.

Bent or broken coupling. Replace drive assembly.

Bad ground. Recheck and correct any wiring errors.

Damaged or defective switch. Replace damper operator.

Improper wiring. Recheck and correct any wiring errors.

INSTALLATION AND SERVICE SHOULD BE PERFORMED BY A QUALIFIED INSTALLING OR SERVICE AGENCY.

SLANT/FIN CORPORATION, Greenvale, N.Y. 11548 • Phone: (516) 484-2600

FAX: (516) 484-5921 • Canada: Slant/Fin LTD/LTEE, Mississauga, Ontario

www.slantfin.com

Loading...

Loading...