ELITE SERIES SURGICAL TABLES

MAINTENANCE MANUAL

MODEL ELITE 6600

INCLUDING BATTERY MODELS

Table of Contents

SECTION I HYDRAULIC SYSTEM ....................................................................................................... 1

1-1. General ......................................................................................................................................... 1

1-2. Component Operation................................................................................................................... 2

a. Motor/Pump Operation ............................................................................................................. 2

b. Pressure Relief Valve .............................................................................................................. 2

c. Mini-Valves............................................................................................................................... 3

d. Mini-valve in Neutral Position ................................................................................................... 3

e. Mini-Valve Right Port Activated................................................................................................ 4

f. Mini-Valve Left Port Activated .................................................................................................. 4

g. Hydraulic Cylinders (Slave Cylinders) ..................................................................................... 5

h. Elevation Cylinder Return Circuit ............................................................................................. 7

i. Brake System ........................................................................................................................... 7

j. Emergency Brake Release ...................................................................................................... 8

k. Flex/Reflex System ................................................................................................................... 8

1-3. Hydraulic Adjustments.................................................................................................................. 9

a. Fluid Level ................................................................................................................................ 9

b. Bleeding The Hydraulic System ............................................................................................... 9

c. Pressure Relief Valve .............................................................................................................. 9

d. Speed Controls......................................................................................................................... 9

SECTION II MECHANICAL TABLE ADJUSTMENTS.......................................................................... 11

2-1. Back Section Gear Mesh Adjustment.......................................................................................... 11

2-2. Hydraulic Cylinder Adjustment .................................................................................................... 11

a. Back Section ........................................................................................................................... 11

b. Leg Section ............................................................................................................................. 11

2-3. Head Section Adjustment ............................................................................................................ 12

2-4. Torque Specifications .................................................................................................................. 12

SECTION III HYDRAULIC TROUBLESHOOTING .............................................................................. 13

3-1. Precautions.................................................................................................................................. 13

3-2. Troubleshooting Notes................................................................................................................. 13

3-3. ELEVATION DIAGNOSIS CHART ............................................................................................. 14

3-4. TRENDELENBURG DIAGNOSIS CHART ................................................................................ 15

3-5. LATERAL - TILT DIAGNOSIS CHART ....................................................................................... 16

3-6. FLEX SYSTEM DIAGNOSIS CHART ........................................................................................ 17

3-7. BACK SECTION DIAGNOSIS CHART ...................................................................................... 18

3-8. LEG SECTION DIAGNOSIS CHART ......................................................................................... 19

3-9. KIDNEY LIFT DIAGNOSIS CHART ........................................................................................... 20

3-10. BRAKE CIRCUIT DIAGNOSIS CHART ..................................................................................... 21

3-11. Flexible Hose Identification and Placement ................................................................................. 22

9/03

Although current at time of publication, SKYTRON's policy of continuous development makes this manual

subject to change without notice.

Table of Contents (continued)

SECTION IV ELECTRICAL SYSTEM ................................................................................................... 24

4-1. General ........................................................................................................................................ 24

4-2. Components ................................................................................................................................ 24

4-3. Battery Model Components ......................................................................................................... 24

SECTION V 6600 ELECTRICAL SYSTEM TROUBLESHOOTING .................................................... 26

5-1. Troubleshooting Notes................................................................................................................. 26

5-2. Main Switch ................................................................................................................................. 26

5-3. Pendant Control........................................................................................................................... 27

5-4. Auxilliary Switches ....................................................................................................................... 28

5-5. Relay Box .................................................................................................................................... 28

5-6. Solenoids ..................................................................................................................................... 30

5-7. Motor/Pump Assembly ................................................................................................................ 32

5-8. Return-to-Level Micro-Switches. ................................................................................................. 34

5-9. Troubleshooting ........................................................................................................................... 34

SECTION VI -6600B- BATTERY MODEL, ELECTRICAL TROUBLESHOOTING .............................. 40

6-1. General ........................................................................................................................................ 40

6-2. Troubleshooting Notes................................................................................................................. 40

6-3. Main Switch ................................................................................................................................. 40

6-4. Batteries....................................................................................................................................... 41

6-5. Battery Charging Box/AC 120V Transformer .............................................................................. 41

6-6. Switch-Over Relay ...................................................................................................................... 43

6-7. Pendant Control........................................................................................................................... 43

6-8. Auxiliary Switches ....................................................................................................................... 45

6-9. Relay Box .................................................................................................................................... 45

6-10. Main Wire Harness Continuity Tests ........................................................................................... 47

6-11. Solenoids..................................................................................................................................... 48

6-12. Motor/Pump Assembly ................................................................................................................ 49

SECTION VII ELECTRICAL SYSTEM ADJUSTMENTS ..................................................................... 51

8-1. Relay Box Adjustments ............................................................................................................... 51

WARNING

Indicates a possibility of personal injury.

CAUTION

Indicates a possibility of damage to

equipment.

Indicates important facts or helpful hints.

NOTE

BASIC RECOMMENDED TOOLS:

1/8". 1/4" STRAIGHT BLADE SCREWDRIVERS

#2 PHILLIPS SCREWDRIVER

HYDRAULIC PRESSURE GAUGE SKYTRON P.N. 6-050-02

METRIC ALLEN® WRENCHES 1.5mm-8mm

ADJUSTABLE CRESCENT WRENCH

DIGITAL VOLTMETER, TRUE RMS

METRIC OPEN END WRENCHES 7mm-18mm

LEVEL (CARPENTERS)

BASIC RECOMMENDED MAINTENANCE PROCEDURES

The basic items notes below should be inspected at a minimal interval period of 6 months (dependant on

usage). For optimal usage, safety and longevity of the product, have it serviced only by an authorized

Skytron representative with authentic Skytron replacement parts.

• Check Power Cord (if applicable)

• Check Pendant Control (if applicable)

• Check Oil Level in Reservoir

• Check For Hydraulic Leaks

• Check Pressure Relief Valve Setting

• Check All Table Functions

• Check Side Rails

• Check Velcro

• Check Lateral Tilt Housing Bolts

• Lubricate Elevation Slider Assembly with SKYTRON Slider Grease P/N D6-010-89

• Tighten X-Ray Top Stand-Offs, Use Loc-tite

• Lubricate Castors

•Check brake pads for wear and inspect brake cylinders for proper operation.

Only facility-authorized SKYTRON trained, maintenance personnel should troubleshoot the

SKYTRON 6600 Surgical Table. Trouble shooting by unauthorized personnel could result in

personal injury or equipment damage.

How to contact us:

Skytron

5000 36th St. SE, Grand Rapids, MI 49512

PH: 1-800-759-8766 (SKY-TRON)

FAX: 616-957-5053

TYPE B

EQUIPMENT

EQUIPMENT LABELS AND SPECIFICATIONS

INDICATES DANGEROUS VOLTAGE, 120 V, 60 Hz

CLASS I DEFIBRILLATION PROOF, TYPE B EQUIPMENT- IPX4 RATED.

INTERNALLY POWERED EQUIPMENT

PROTECTIVE GROUNDING.

IN ORDER TO ENSURE PROPER GROUNDING RELIABILITY,

THIS TABLE MUST BE CONNECTED TO A PROPERLY GROUNDED

HOSPITAL GRADE OUTLET.

N

IPX4

V

A

HZ

CONNECTION FOR NEUTRAL CONDUCTOR SUPPLIED

UNIT TO BE USED ONLY IN SPECIFIED ENVIRONMENTAL CONDITIONS

TEMPERATURE: 15˚ - 30˚ C (60˚ -85˚ F)

HUMIDITY: 30% - 60% RELATIVE HUMIDITY, NON CONDENSING

AC VOLTAGE

ENCLOSURE CLASS

VOLTAGE RATING OF THE UNIT

AMPERAGE RATING OF THE UNIT

FREQUENCY OF THE UNIT

ATTENTION, CONSULT MANUAL FOR FURTHER INSTRUCTIONS.

INDICATES SPECIAL USER ATTENTION.

POWERED BY AC VOLTAGE

POWERED BY BATTERY

BATTERY TYPE:

FUSE:

BATTERY MODELS

SEALED

LEAD ACID 12V, VALVE REGULATED

16AH, 10HR (530W/10MIN)

15 AMP FAST ACTING INTERNAL FUSE

15A

6600 Series General Purpose Surgical Table Specifications

15"

10" 19-1/2" 21-1/2" 24"

60˚

90˚

9"

6"

14-1/2"

TOP VIEW

76"

36-1/2"

3"

19-3/4"

21-3/4"

45" MAX

26" MIN

5-3/4"

19"

SIDE VIEW

Electrical Specifications

Power requirements

Current Leakage

Power Cord

15 feet w/hospital grade connector(removeable)

ENTELA CERTIFIED

TO UL2601-1

CAN/CSA601.1, IEC 60601-2-46

END VIEW

120 VAC, 60Hz, 450 Watts

Less than 100 micro amps

SECTION I HYDRAULIC SYSTEM

1-1. General

Electro-Hydraulic System

The hydraulic system (with the exception of the

hydraulic cylinders and hoses) is contained within

the base of the table. The hydraulic valves and

pump are electrically controlled by the use of a handheld push button pendant control. The power requirements for the table are 120 VAC, 5 amp, 60 Hz.

The table contains the following components. Refer

to the block diagram (figure 1-1) for relationship.

a. Oil Reservoir - Main oil supply. Approximately

two quarts.

b. Motor/Pump Assembly - A positive displacement gear type pump provides the necessary oil

pressure and volume.

c. Pressure Relief Valve - Provides an alternate oil

path when the hydraulic cylinders reach the end of

their stroke.

d. Electro/Hydraulic Mini-Valve Assemblies -These

direct the fluid to the appropriate hydraulic cylinders.

Figure 1-1. Hydraulic Block Diagram

Page 1

e. Hydraulic Lines, Fittings, Connections - They

provide a path for the hydraulic oil.

f. Hydraulic Cylinders - They convert the hydraulic

fluid pressure and volume into mechanical motion.

1-2. Component Operation

The main component of the valve is an adjustable

spring loaded plunger that is pushed off from its

seat by the oil pressure. The oil then flows back into

the reservoir. See figure 1-4. Turning the adjustment nut clockwise increases the amount of oil

pressure required to open the valve, and turning it

counterclockwise decreases the amount of oil pressure. (See adjustment section for specification.)

a. Motor/Pump Operation

The motor/pump assembly is a gear type pump that

provides the oil pressure and volume for the entire

hydraulic system. The pump has an inlet side and

an outlet side. The inlet side is connected to the

reservoir which provides the oil supply. The reservoir has a very fine mesh screen strainer which

prevents foreign material from entering the oil system.

The output line of the pump is connected to the main

oil galley which is internal and common to all the

hydraulic mini-valves and pressure relief valve.

Also, common to the hydraulic mini-valves and

pressure relief valve is an oil galley that internally

connects to the oil reservoir to provide a return path

for the hydraulic oil. See figure 1-2.

PRESSURE RELIEF

ADJUSTMENT NUT

PRESSURE

GAUGE

SPRING LOADED

PLUNGER

Figure 1-3. Pressure Relief Valve Not

Functioning

Figure 1-2.

b. Pressure Relief Valve

This device provides an alternate oil path when the

hydraulic cylinders reach the end of their stroke

and the pump continues to run. If this path were not

provided, the pump motor would stall because the

oil cannot be compressed. The pressure relief

valve is directly connected to the mini-valve bodies

and shares both the common internal main pressure oil galley, and the return oil galley, that internally connect to the reservoir. See figure 1-3.

Page 2

PRESSURE RELIEF

ADJUSTMENT NUT

PRESSURE

GAUGE

SPRING LOADED

PLUNGER

Figure 1-4. Pressure Relief Valve Functioning

c. Mini-Valves

The operation of the mini-valves is identical for all

table functions except the elevation and brake

circuits. These two hydraulic circuits use a 3-way

(single check valve) type mini-valve. All other functions use a 4-way (dual check valve) type minivalve.

Also, by using this control method, it doesn’t matter

what size cylinder and piston is used because the

speed can be controlled by restricting the return oil.

If the pump puts out more volume to a certain slave

cylinder than the speed control is allowing to go

back to the reservoir, the pressure relief valve

provides an alternate path for the pump oil.

Either type mini-valve is controlled by two pushing

type, electrically operated solenoids. The solenoids push the spool valve (located in the lower

portion of the valve) one way or the other. This

motion opens the main supply galley (which has

pump pressure) allowing the oil to flow through the

various parts of the mini-valve to the function. The

spool valve also opens an oil return circuit which

allows the oil to return to the oil reservoir.

The main components of the mini-valve and their

functions are listed below:

1. Spool Valve - Opens the main oil galley

(pump pressure) to either mini-valve outlet depending on which direction the spool valve is

pushed. Also it provides a return path for the oil

returning back into the reservoir.

2. Pilot Plunger - There are two plungers in a

four-way mini-valve (one in a 3-way mini-valve),

one under each check valve. The purpose of the

pilot plungers is to mechanically open the return

check valve allowing the oil to return back into the

reservoir.

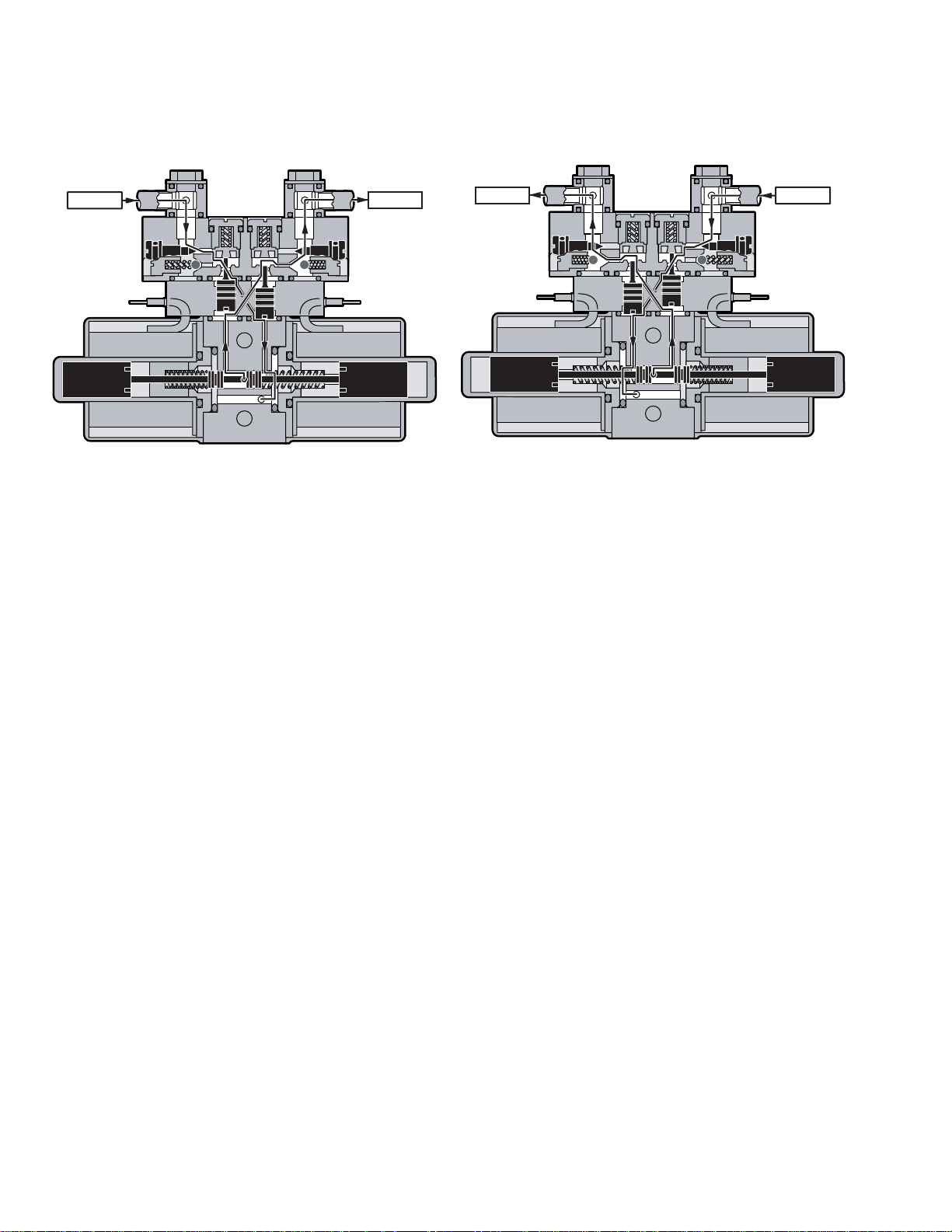

d. Mini-Valve in Neutral Position

(No fluid flow) See figure 1-5.

1. Spool Valve Centered - This closes off both

oil pressure and oil return galleys.

2. Pilot Plungers Both Closed -The pilot plungers control the opening of the check valves. If they

are closed, the check valves must be closed.

3. Check Valves - Both check valves are

closed trapping the oil in the cylinder and oil lines.

4. Speed Adjustment - When the mini-valve is

in the neutral position, the speed adjustment does

not affect anything because there is not any oil

flow.

3. Check Valve - Two are provided in each

four-way mini-valve to seal the oil in the cylinders

and oil lines and prevent any movement of the

table. One check valve is provided in a 3-way minivalve.

4. Speed Adjustments - There are two speed

adjustments in each mini-valve. They are needle

valve type controls which restrict the volume of oil

returning back into the reservoir, thereby controlling the speed of the table surface movement. A 3way mini-valve has only one speed adjustment.

The speed controls are always located in the return

oil circuit. This prevents uncontrolled movement of

the piston in the slave cylinder due to one side of

the piston being loaded with hydraulic pressure

and the other side having no load.

Figure 1-5. Mini-Valve in Neutral Position

Page 3

e. Mini-Valve Right Port Activated

(See figure 1-6)

Slave Cylinder Piston Moves to Left

Right Mini-Valve Port is Supply Line

Left Mini-Valve Port is Return Line

f. Mini-Valve Left Port Activated

(See figure 1-7.)

Slave Cylinder Piston Moves to Right

Left Mini-Valve Port is Supply Line

Right Mini-Valve Port is Return Line

INLET OUTLET

Figure 1-6. Mini-Valve Right Port Activated

1. Spool Valve - Pushed to the left by electric

solenoid. This opens the internal oil pressure galley allowing the fluid to go through the check valve

and on to the cylinder. Also, the spool valve opens

the oil return line providing an oil path through the

internal oil galley back to the reservoir.

2. Pilot Plunger Valve - Left pilot plunger valve

is pushed up by the incoming oil pressure mechanically opening the check valve located above it in

the return circuit. This action allows the oil from the

left side of the slave cylinder to go back into the

reservoir. The right pilot plunger valve is not

affected in this operation mode.

OUTLET

INLET

Figure 1-7. Mini-Valve Left Port Activated

1. Spool Valve-Pushed to the right by electric

solenoid. This opens the internal oil pressure galley

allowing the fluid to go through the check valve and

on to the cylinder. Also, the spool valve opens the

oil return line providing an oil path through the

internal oil galley back to the reservoir.

2. Pilot Plunger Valve - Right pilot plunger valve

is pushed up by the incoming oil pressure mechanically opening the check valve located above it in

the return circuit. This action allows the oil from the

right side of the slave cylinder to go back into the

reservoir. The left pilot plunger valve is not affected

in this operation mode.

3. Check Valves - Both check valves are

opened in this operation mode. The right check

valve is pushed open by the oil pressure created by

the pump. The oil then continues to go through the

lines and pushes the slave cylinder piston to the

left. At the same time, the left check valve is held

open mechanically by the pilot plunger providing a

return path for the oil through the mini-valve back to

the reservoir.

4. Speed Adjustment - The right speed control

(output side) does not have any effect in this

operation mode because the oil is routed around

the speed adjustment through a by-pass valve and

then to the output port. The left speed adjustment

controls the speed of the table function by restricting the amount of oil going back into the reservoir.

Page 4

3. Check Valves - Both check valves are

opened in this operation mode. The left valve is

pushed open by the oil pressure created by the

pump. The oil then continues to go through the

lines and pushes the slave cylinder piston to the

right. At the same time, the right check valve is held

open mechanically by the pilot plunger providing a

return path for the oil through the mini-valve back to

the reservoir.

4. Speed Adjustment - The left speed control

(output side) does not have any effect in this operation mode because the oil is routed around the

speed adjustment through a by-pass valve and

then to the output port. The right speed adjustment

controls the speed of the table function by restricting the amount of oil going back to the reservoir.

g. Hydraulic Cylinders (Slave Cylinders)

RAM

HYDRAULIC LINE

PISTON

O-RING

O-RING

There are several different types of hydraulic cylinders used in the table that activate the control

functions. With the exception of the elevation and

brake cylinders, all operate basically the same

way. The control functions are listed below. See

figure 1-8.

Back Section--2, double action cylinders

Leg Section--2, double action cylinders

Trendelenburg--1, double action cylinder

Lateral Tilt--1, double action cylinder

Elevation--1, single action cylinder

Kidney Lift--1, double action cylinder

Brakes--4, single action cylinders

TRENDELENBURG

CYLINDER

BACK SECTION

CYLINDER

Figure 1-9. Back Section Cylinder

2. Trendelenburg Cylinder Assembly - This

cylinder / piston arrangement has rack teeth cut

into the top of each piston. These teeth mesh with

a pinon gear that is connected directly to the table

side frames. The pinion gear shaft and table side

frames are supported by bearings at either side.

When hydraulic fluid is pumped into one side of the

cylinder, the pistons are pushed in one direction,

moving the pinion gear and table side frames with

them. Oil pressure can be applied to either side of

the piston, making the table tilt end for end. See

figure 1-10.

KIDNEY LIFT

CYLINDER

ELEVATION

CYLINDER

LEG SECTION

CYLINDER

LA TERAL TIL T

CYLINDER

Figure 1-8. Cylinder Placement

1. Back Section and Leg Section Cylinders The double action cylinders are closed at one end

and have a movable piston with hydraulic fluid on

both sides. Connected to this piston is a ram or

shaft that exits out of the other end of the cylinder.

Through the use of either a gear, or clevis and pin

arrangement, this ram is connected to a movable

table surface.

The movable surface can be moved one way or

the other by pumping hydraulic fluid into the cylinder on either side of the piston. Obviously, if oil is

pumped into one side of the cylinder, a return path

must be provided for the oil on the other side. See

figure 1-9.

T ABLE TOP

PINION GEAR

PISTONS

SIDE VIEW

Figure 1-10. Trendelenburg Cylinder Assy.

In order to remove any looseness or play in the

table top, the trendelenburg pistons are made in two

pieces as shown in figure 1-11. This arrangement

eliminates any gear lash between the piston teeth

and the table pinion gear due to oil pressure always

being present on both sides of the pistons.

OIL PRESSURE

SPLIT PISTONS

REMOVE GEAR LASH

OIL PRESSURE

TOP VIEW

Figure 1-11. Trendelenburg Cylinder Pistons

Page 5

3. Lateral Tilt Assembly - The lateral tilt assembly consists of two cylinders, pistons and connecting rods. The connecting rods attach to the lateral

tilt lever which connects to the table side frames.

When hydraulic fluid is pumped into one cylinder,

the piston and connecting rod pushes the lateral tilt

lever which tilts the table top to one side. To tilt the

table top in the opposite direction, fluid is pumped

into the opposite cylinder. See figure 1-12.

T ABLE TOP

LA TERAL TIL T

LEVER

5. Kidney Lift - The kidney lift cylinder assembly is a unique type of double action cylinder where

the piston remains stationary and the outer housing

or cylinder has the relative motion. The cylinder

housing has rack teeth cut into the top which

meshes with a pinion gear. This gear meshes with

other gears to supply the up or down drive for the

kidney lift bars, depending on which direction the oil

is pumped into the cylinder. See figure 1-14. A

cross shaft transmits the rotary motion of the

cylinder pinion gear to a gear set on the other side

of the table. This enables the kidney lift bars to

move up and down together without binding.

PINION

GEARS

KIDNEY

LIFT BAR

PISTON PISTON

CONNECTING

RODS

Figure 1-12. Lateral Tilt Cylinder Assembly

4. Elevation Cylinder - This single action cylinder does not have hydraulic fluid on both sides of

the piston. It depends on the weight of the table top

assembly to lower it.

The cylinder is set in the center of the elevation

main column. The two stage cylinder is elevated by

the driven force of the oil pressure. When lowering,

the oil that is accumulated in the cylinder is returned

to the oil reservoir through the mini-valve due to the

table top weight.

A slider support assembly is used to support the

weight of the upper table section. A stainless steel

shroud covers the flexible hydraulic hoses and

slider. See figure 1-13.

ELEVATION

CYLINDER

EXTERIOR

SHROUD

SLIDER

SUPPORT

ASSEMBLY

PRIMARY

PISTON

OIL FLOW

PISTON

CYLINDER

HOUSING

Figure 1-14. Kidney Lift Cylinder Assembly

6. Brake Cylinders - The brake cylinders are

single action type similar to the elevation cylinder.

The movable piston's ram is connected to a brake

pad. See figure 1-15. Oil pumped into the top of the

cylinder pushes the piston down raising the table

base off its casters. An internal return spring on the

bottom of the piston, pushes the piston up to return

the oil through the mini-valve to the reservoir.

OIL LINE

PISTON

RETURN

SPRING

SECONDARY

PISTON

BRAKE

PAD

RAM

Figure 1-13. Elevation Cylinder Assembly Figure 1-15. Single Action Brake Cylinder

Page 6

h. Elevation Cylinder Return Circuit

A three-way (single check valve type) mini-valve

controls both the elevation and return circuits. The

elevation circuit operation within the mini-valve is

identical to the operation of the four-way valves

previously described (inlet pressure opens the

check valve allowing the oil to enter the cylinder). In

the return position, inlet pressure pushes the pilot

plunger up and opens the return check valve. See

figure 1-16. The open check valve allows a path for

the oil in the elevation cylinder to return to the

reservoir. When the pilot plunger valve is opened,

the continuing pump pressure opens the pressure

relief valve which provides a return oil path to the

reservoir.

The mini-valve used in the elevation circuit contains only one check valve (all four-way minivalves use two check valves). The check valve is

used to trap the oil in the elevation cylinder thereby

supporting the table top. When the top is being

lowered the check valve is mechanically held open

by the pilot plunger through pump pressure.

3. Manually controlled emergency brake re-

lease.

4. Plumbing terminal, flexible hoses, copper

lines and "O" rings.

5. Portions of the electrical system.

BRAKE SYSTEM

EMERGENCY

BRAKE RELEASE

PLUMBING

TERMINAL

RELIEF

VALVE

INLET

TO RESERVOIR

THROUGH

PRESSURE

RELIEF V AL VE

RETURN TO

RESERVOIR

Figure 1-16. Elevation Return Circuit

i. Brake System

The brake system consists of the following components: (figure 1-17)

1. Single action slave cylinders (4 each).

2. 3-way (single check valve type) mini-valve.

BRAKE

RESERVOIR

PUMP/MOTOR

ASSEMBLY

Figure 1-17. Brake System Block Diagram

Each corner of the cast-iron table base has a

hydraulic brake cylinder. These single action cylinders are hydraulically connected in parallel to the

mini-valve and all four are activated together. It is

normal for one corner of the table to raise before the

others due to the weight distribution of the table.

An electronic timer in the relay box is activated

when any function on the pendant control is

pushed momentarily. The pump/motor and brake

system mini-valve are activated and the brake

cylinders are completely set. The electronic timer

runs for approx. 8-10 seconds.

The brakes are released by pushing the BRAKE

UNLOCK button momentarily. An electronic timer

in the relay box activates the brake function hydraulic mini-valve and pump/motor.

Page 7

When activated, the return hydraulic circuit operates similar to the elevation cylinder return circuit.

Return springs inside the single action brake cylinders retract the brake pads and provide the pressure to return the hydraulic oil back to the reservoir.

The electronic timer operates the return circuit for

approximately 8-10 seconds.

j. Emergency Brake Release

The emergency brake release is simply a manually

operated bypass valve connected in parallel to the

brake cylinders and the oil reservoir. See figure 1-

18. When the valve is opened (turned counterclockwise) a return circuit for the brake hydraulic

fluid is opened. The return springs force the pistons

up pushing the hydraulic oil back into the reservoir

and retracting the brake pads.

k. Flex/Reflex System

The Flex/Reflex system incorporates an additional

mini-valve which connects the trendelenburg and

back section hydraulic systems in a series. When

FLEX is activated by the pendant control, the Flex/

Reflex mini-valve opens the oil pressure path to the

Reverse Trendelenburg piston. The return oil path

from the Trendelenburg piston is routed through the

back section cylinder to the mini-valve return port.

See figure 1-19

EMERGENCY BRAKE

RELEASE LEVER

Figure 1-18.

NOTE

•The emergency brake release valve

must be tightened securely when not in

use.

•If the emergency brake release valve

has been operated, the UNLOCK button on the pendant control may have to

be pressed before brakes will lock

again.

TREND

REV TREND

BACK

DOWN

FLEX/REFLEX

MINI-VALVE

BACK UP

PLUMBING

TERMINAL

Figure 1-19. Flex/Reflex System

If the emergency brake release valve is open or

loose, the brakes will release slowly- depending on

how loose the valve is, this could take anywhere

from a few minutes to several hours.

Page 8

1-3. Hydraulic Adjustments

To adjust:

a. Fluid Level.

The fluid level should be approximately 1/2" below

the filler hole or gasket surface. If additional fluid is

needed, remove the filler vent cap with a phillips

screwdriver and add fluid through this opening

using a funnel. See figure 1-20.

NOTE

The elevation cylinder should be completely down, the brakes released and

all the other control functions in their

neutral position when checking oil level.

FILLER VENT

FILLER

CAP

RESERVOIR

OPENING

Figure 1-20.

The type of oil that should be used is Mobil DTE #25

or equivalent. This is a very high quality hydraulic

oil. The table requires approximately two quarts of

oil to operate properly. Excercise caution when

determining equivalance to avoid damage to the

hydraulic system.

1. Remove the blind cap and attach a hydraulic

pressure gauge to the main oil galley using a 6mm

plumbing bolt. See figure 1-21.

PRESSURE

RELIEF VALVE

BACK VIEW OF

RELIEF VALVE

PRESSURE

GAUGE

ATTACH

HERE

Figure 1-21.

2. Raise the table top until the piston reaches

the end of its stroke and stalls. Observe reading

on pressure gauge and turn the adjustment nut

(clockwise to increase oil pressure, counterclockwise to decrease) until desired reading is

obtained. Pressure should be 8MPA (80KG/CM

2

1138 PSI). An erratic reading and/or inability to

adjust to the recommended setting may indicate

the need for replacement of the pressure relief

valve.

d. Speed Controls

-

b. Bleeding The Hydraulic System

To purge the air from the hydraulic system, operate

each function back and forth at least two or three

times.

NOTE

Whenever a hydraulic line or component is replaced, bleed the air out of the

lines using the pump pressure before

making the final connection. Then operate the function until it stalls in both

directions.

c. Pressure Relief Valve

The pressure relief valve is adjusted by turning the

adjustment nut until the desired pressure is reached.

The speed controls restrict the volume of oil returning back to the reservoir thereby controlling the

speed of each control function.

All four-way mini-valves, have two speed controls

located in the ends of each valve body. All threeway mini-valves have only one speed control.

One speed control adjusts one direction of a

particular function and the opposite speed control

adjusts the other direction. They are adjustable by

using a small straight blade screwdriver and

turning the adjustment screw clockwise to decrease the speed and counterclockwise to

increase the speed. See figure 1-22.

Page 9

TABLE DOWN

REV TREND

TILT LEFT

TREND

FLEX

BACK DOWN

FOOT UP

TILT RIGHT

REFLEX

KIDNEY DOWN

BACK UP

FOOT DOWN

KIDNEY UP

BRAKE

A pressure gauge should be used to set the speed

of the back section, trendelenburg and flex control

functions.

To adjust:

1. Attach the pressure gauge onto the main oil

galley as shown in figure 1-21.

2. The gauge should read the following values

when operating the various control functions in

either direction. Turn the speed controls until

desired values are obtained.

Figure 1-22.

Any control function should move in either direction at the same rate. If the rate of a certain function

is too slow, open the speed control slightly and

recheck. Use the second hand on a watch and time

a particular function. Match that time in the opposite

direction by opening or closing the speed control.

Approximate operating times are as follows:

Lateral Tilt 7 seconds

Back Up 25 seconds

Back Down 15 seconds

Kidney Lift 7 seconds

Back Section Up 65KG/CM

2

-925PSI

Dn 65KG/CM2 -925PSI

Trendelenburg Up 65KG/CM2 -925PSI

Dn 65KG/CM2 -925PSI

Flex 70KG/CM2 -995PSI

Reflex 70KG/CM2 -995PSI

NOTE

When adjusting Flex/Reflex speed controls, set Reflex last.

Elevation - There is not a speed adjustment for

raising the table. The speed control will only affect

the rate of descent and it should equal the rate of

elevation.

Page 10

SECTION II MECHANICAL TABLE ADJUSTMENTS

2-1. Back Section Gear Mesh Adjustment

The gear mesh is adjusted by the use of an eccentric cam. This cam moves the gear teeth closer

together to eliminate gear lash. This adjustment

arrangement compensates for any wear between

the gears that might occur.

To adjust:

Loosen the cam locking allen set screw. Use an

allen wrench to rotate the eccentric cam. See

figure 2-1. Tighten the locking set screw when

adjustment is complete.

ECCENTRIC

CAM

SET SCREW

ALLEN

WRENCH

Figure 2-1. Eccentric Cam Adjustment

To adjust:

Remove the seat section top for access to the cam

locking set screws and loosen the set screws.

Use an allen wrench to turn the cylinder eccentric

cams as required to shift either cylinder fore or aft

as needed so no twisting or flexing of the back

section is observed when it is stalled in the full up

position. See figure 2-2. Tighten the set screws

and replace the seat section top when the adjustment is completed.

BACK SECTION

SEAT SECTION TOP

SET

SCREW

BACK SECTION CYLINDER

ECCENTRIC CAM

2-2. Hydraulic Cylinder Adjustment

The hydraulic cylinder rams that control both the

back and foot / leg sections must move together so

that these sections are not twisted when operated.

This is accomplished by the use of eccentric cams

that move the cylinder bodies fore and aft to adjust

their effective stroke.

NOTE

Adjust gear mesh before adjusting eccentric cams for the back section.

a. Back Section

Position the back section all the way up until it

stalls. Both sides of the back section should stop

moving at the same time and should not show any

signs of twisting.

Any twisting or flexing of the back section as it

approaches the stalled position indicates that one

of the cylinders is not reaching its fully extended

position at the same time as the other. This

condition would require an adjustment.

Figure 2-2. Back Section Adjustment

b. Leg Section

Position the leg section all the way up. Both sides

of the leg section should stop moving at the same

time and should not show any signs of twisting.

Any twisting or flexing of the leg section as it

approaches the stalled position indicates that one

of the cylinders is not reaching its fully extended

position at the same time as the other and an

adjustment is required.

Page 11

To adjust:

NOTE

The leg section cylinder eccentric cam

is located under the nameplate on the

side casting. To make an adjustment,

the nameplate will have to be removed

and a new nameplate will have to be

installed when the adjustment is com-

pleted.

To adjust:

Loosen the cam locking set screws located inside

the table side frames. See figure 2-3. Use an allen

wrench to turn the cylinder eccentric cams as

required to shift either cylinder fore or aft as needed

so no twisting or flexing of the leg section is observed when it is stalled in the above horizontal

position. Tighten set screws when proper adjustment is achieved.

Place the head section in level position and remove

the top. See figure 2-4. Loosen but do not remove

the allen bolts securing the bearing block to the

frame. Loosen the allen bolt in the top of the frame

and turn the set screw as required to achieve

proper adjustment. One or both of the blocks may

require adjustment to achieve proper alignment.

Tighten all allen bolts when adjustment is complete.

Test the head section throughout its range of travel.

Re-adjust as needed. Replace top section when

proper adjustment is achieved.

ADJUSTMENT

SET SCREW

ALLEN

BOLT

ALLEN

BOLTS

Figure 2-4. Head Section Adjustment

6600 NAMEPLATE

LEG SECTION CYLINDER

ECCENTRIC ARM

Figure 2-3. Leg Section Adjustment

2-3. Head Section Adjustment

LEG SECTION

2-4. Torque Specifications

If the bolts for the Trendelenburg end caps or the

lateral tilt housing are removed, refer to figure 2-5

for the proper torque specifications when installing

the bolts.

ALLEN BOLT

M6 x 20

TORQUE TO 156 IN-LBS

TRENDELENBURG

TAIL CAP

ALLEN BOLT

M10 x 30

TORQUE TO 58 FT-LBS

LA TERAL TIL T

HOUSING

The head section can be adjusted to eliminate any

flexing throughout it's range of travel.

Page 12

Figure 2-5. Torque Specifications

NOTE

Trendelenburg Head Cap Bolts Torque

to 120in-lbs

SECTION III HYDRAULIC TROUBLESHOOTING

3-1. Precautions

Before attempting to troubleshoot any hydraulic

problem on the table, please read through the precautions and notes below.

CAUTION

When disconnecting any of the hydraulic lines, fittings, joints, hoses, etc., for

the following control functions, be sure

these table surfaces are in their down

position or completely supported.

Elevation

Back Section

Leg Section

Kidney Lift

When working on the trendelenburg or

lateral tilt hydraulic circuits, be sure to

support the table top. When working on

the brake system make sure the brakes

are completely retracted.

5. Is the problem no movement of a table

surface or does the table surface lose position?

Once the problem has been determined, concen-

trate on that particular hydraulic circuit or control

function.

Listed below are the hydraulic components that

are common with all hydraulic circuits. If there is a

problem with any of them, it could affect all control

functions.

1. Motor/Pump Assembly

2. Reservoir

3. Pressure Relief Valve

4. Certain Oil Lines and Galleys

If there was a problem in the following components,

only one control function would normally be affected.

1. Mini-Valve

2. Slave Cylinder

3. Oil Lines

WARNING

Failure to follow these precautions may

result in an uncontrolled oil spray and

damage to the table or personal injury.

3-2. Troubleshooting Notes

When troubleshooting a table malfunction, first

determine the following:

1. Does the problem affect all control func-

tions?

2. Does the problem affect only one control

function?

3. If the problem affects one control function is

it in both directions?

4. Is the problem intermittent?

NOTE

Whenever a hydraulic line or component is replaced, bleed the air out of the

lines using the pump pressure before

making the final connection. After all

connections are tight, cycle the control

function back and forth two or three

times to purge the remaining air from the

system.

CAUTION

When installing new "O" rings use hydraulic oil to thoroughly lubricate the "O"

rings and cylinder. Keep everything

clean.

Each complete oil circuit is shown on the following

pages. When troubleshooting a particular function,

refer to the appropriate oil circuit diagram and the

list of possible problems.

Page 13

Problem

Table will not elevate properly

3-3. ELEVATION DIAGNOSIS CHART

Reason

Pressure Relief Valve Not Set Properly

Low on Oil

Spool Valve Not Centered

Defective Pump

Defective Mini-Valve

Defective Solenoid or Wiring

Defective Relay Box or Pendant Control

Leaking Cylinder Hose

Uneven Weight Distribution

Table will not descend properly

Table loses elevation

Incorrect Speed Adjustment

Bad Check Valve

Spool Valve Not Centered

Galled Slider Assembly

Defective Solenoid or Wiring

Defective Relay Box or Pendant Control

Uneven Weight Distribution

Bad Check Valve

Leaking Mini-Valve

Loose Fittings, Joints, Hoses

Leaking "O" Ring Inside Cylinder

PRIMARY

PISTON

O-RING

Page 14

CHECK

VALVE

SPEED

CONTROL

COPPER

LINE

MINI-VALVE

PLUMBING

TERMINAL

INTERNAL OIL

FROM PUMP

INTERNAL OIL RETURN

TO RESERVOIR

Figure 3-1. Elevation Circuit

SECONDARY

PISTON

O-RING

FLEXIBLE

HOSE

3-4. TRENDELENBURG DIAGNOSIS CHART

Problem

Trendelenburg function moves improperly

Trendelenburg function chatters or loses position

PINION

GEAR

O-RING

FRONT PIVOT

BLOCK

Reason

Incorrect Speed Adjustment

Spool Valve Not Centered

Bad Check Valves

Low on Oil

Pinched Hose

Defective Mini-Valve

Pressure Relief Valve Not Set Properly

Bad Solenoid or Wiring

Defective Relay Box or Pendant Control

Defective or Dirty Check Valve

Oil Leakage in Circuit

Air Inside Cylinder

Pinched Hose

Low on Oil

REAR PIVOT

BLOCK

O-RING

TAIL CYLINDER CAP

PISTON

ASSEMBLY

HEAD

CYLINDER

CAP

COPPER

LINES

CHECK VALVE

SPEED

CONTROL

MINI-VALVE

HEAD DOWN

CIRCUIT

PLUMBING

TERMINAL

O-RING

FLEXIBLE

HOSES

HEAD UP

CIRCUIT

INTERNAL OIL

FROM PUMP

INTERNAL OIL RETURN

TO RESERVOIR

Figure 3-2. Trendelenburg Circuit

Page 15

3-5. LATERAL TILT DIAGNOSIS CHART

Problem

Lateral tilt function moves improperly

Lateral tilt function chatters or loses position

Reason

Incorrect Speed Adjustment

Spool Valve Not Centered

Bad Check Valves

Low on Oil

Pinched Hose

Defective Mini-Valve

Pressure Relief Valve Not Set Properly

Bad Solenoid

Defective Relay Box or Pendant Control

Defective or Dirty Check Valves

Oil Leakage in Circuit

Air Inside Cylinder

Pinched Hose

Low on Oil

Page 16

Figure 3-3. Lateral Tilt Circuit

3-6. FLEX SYSTEM DIAGNOSIS CHART

Problem

Back Section or Trendelenburg function moves

improperly

NOTE

If Flex System does not function properly, check the back section and

Trendelenburg functions before adjusting the flex system.

Back Section or Trendelenburg function chatters

or loses position

Reason

Incorrect Speed Adjustment (Trendelenburg, Back

section or Flex - check with gauge)

Spool Valve Not Centered

Bad Check Valves

Low on Oil

Pinched Hose

Defective Mini-Valve

Pressure Relief Valve Not Set Properly

Bad Solenoid

Defective Relay Box or Pendant Control

Kidney Bridge Raised

Defective or Dirty Check Valves

Oil Leakage in Circuit

Air Inside Cylinder

Pinched Hose

Low on Oil

Figure 3-4. Flex System Circuit

Page 17

3-7. BACK SECTION DIAGNOSIS CHART

Problem

Back Section function moves improperly

Back Section function chatters or loses position

Reason

Incorrect Speed Adjustment

Spool Valve Not Centered

Bad Check Valves

Low on Oil

Pinched Hose

Defective Mini-Valve

Pressure Relief Valve Not Set Properly

Bad Solenoid

Defective Relay Box or Pendant Control

Kidney Bridge Raised

Defective or Dirty Check Valves

Oil Leakage in Circuit

Air Inside Cylinder

Pinched Hose

Low on Oil

Page 18

Figure 3-5. Back Section Circuit

3-8. LEG SECTION DIAGNOSIS CHART

Problem

Leg function moves improperly

Leg function chatters or loses position

Reason

Incorrect Speed Adjustment

Spool Valve Not Centered

Bad Check Valves

Low on Oil

Pinched Hose

Defective Mini-Valve

Pressure Relief Valve Not Set Properly

Bad Solenoid

Defective Relay Box or Pendant Control

Defective or Dirty Check Valves

Oil Leakage in Circuit

Air Inside Cylinder

Pinched Hose

Low on Oil

Figure 3-6. Leg Section Circuit

Page 19

3-9. KIDNEY LIFT DIAGNOSIS CHART

Problem

Kidney Lift moves improperly

Kidney Lift chatters or loses position

Reason

Incorrect Speed Adjustment

Spool Valve Not Centered

Bad Check Valve

Low on Oil

Pinched Hose

Defective Mini-Valve

Pressure Relief Valve Not Set Properly

Bad Solenoid

Defective Relay Box or Pendant Control

Defective or Dirty Check Valve

OiI Leakage in Circuit

Air Inside Cylinder

Pinched Hose

Low on Oil

Lift Rods Binding

KIDNEY LIFT

CYLINDER ASSEMBLY

Page 20

CHECK

VALVE

SPEED

CONTROL

MINI-VALVE

INTERNAL OIL

FROM PUMP

DOWN CIRCUIT

UP CIRCUIT

FLEXIBLE

HOSES

PLUMBING

TERMINAL

COPPER

LINES

INTERNAL OIL RETURN

TO RESERVOIR

Figure 3-7. Kidney Lift Circuit

3-10. BRAKE CIRCUIT DIAGNOSIS CHART

Problem

Brakes will not set properly

NOTE

If brakes have been released with the

Emergency Brake Release Valve,

brakes will not reset until BRAKE UNLOCK Circuit has been activated.

Brakes Will Not Stay Locked

Brakes will not retract properly

Reason

Emergency Brake Release Valve Open or Defective

Spool Valve Not Centered

Bad Check Valve

Low on Oil

Pressure Relief Valve Not Set Properly

Pinched Hose

Defective Mini-Valve

Defective Relay Box or Pendant Control

Emergency Brake Release Valve Open or Defective

Defective or Dirty Check Valve

Oil Leakage in Circuit

Leaking "O" Ring Inside Cylinder

Incorrect Speed Adjustment

Bad Check Valve

Spool Valve Not Centered

Defective Mini-Valve

Pinched Hose

Defective Solenoid or Wiring

Defective Relay Box or Pendant Control

Defective Brake Cylinder

BRAKE

CYLINDER

CHECK V AL VE

SPEED

CONTROL

MINI-VALVE

INTERNAL OIL

FROM PUMP

PLUMBING

TERMINAL

FLEXIBLE

HOSES

INTERNAL OIL RETURN

TO RESERVOIR

BRAKE

CYLINDER

BRAKE

CYLINDER

FLEXIBLE

HOSES

FLEXIBLE

HOSE

RETURN TO

RESERVOIR

EMERGENCY

BRAKE RELEASE

COPPER LINE

RELEASE LEVER

Figure 3-8. Brake System Circuit

Page 21

3-11. Flexible Hose Identification and Placement

The following figures will show the correct placement of the flexible hydraulic hoses used in the

table and their respective number codes.

KIDNEY CYLINDER

INNER END CAP

KIDNEY CYLINDER

OUTER END CAP

LEG CYLINDER, PISTON

(LEFT)

LEG CYLINDER, PISTON

(RIGHT)

Figure 3-9 shows the hose connections to the

plumbing terminal.

246810

1357911

NUMBER FUNCTION

1 ELEVATION

2 REV TREND

3 TREND

4 TILT LEFT

5 TILT RIGHT

6 BACK DOWN

7 BACK UP

8 LEG UP

9 LEG DOWN

10 KIDNEY DOWN

11 KIDNEY UP

Figure 3-9. Main Plumbing Terminal

TOP VIEW

FRONT

PIVOT BLOCK

LEG CYLINDER, RAM (LEFT)

LEG CYLINDER, RAM (RIGHT)

Figure 3-11. Leg Section/Kidney lift Hoses

Figure 3-12 shows the placement and number

code for the long flexible hoses which connect from

the plumbing terminal to the front and rear pivot

blocks.

NOTE

The number codes will be on a label or

stamped into the elevation clamp ring

and the plumbing terminal.

(3) TREND.

(4) LAT. TILT LEFT

Figure 3-10 shows the placement of the short

flexible hoses which connect to the back section

cylinders.

BACK CYLINDER, RAM (RIGHT)

BACK CYLINDER, RAM (LEFT)

TOP VIEW

FRONT

PIVOT

BLOCK

BACK CYLINDER, PISTON (RIGHT)

BACK CYLINDER, PISTON (LEFT)

Figure 3-10. Back Section Hoses

Figure 3-11 shows the placement of the short

flexible hoses which connect to the leg section

cylinders and the kidney lift cylinder.

TOP VIEW

REAR PIVOT

FRONT

PIVOT BLOCK

(5) LAT. TILT RIGHT

(2) REV. TREND

BLOCK

Figure 3-12. Pivot Block Hoses

Figure 3-13 shows the placement and number

code for the long flexible hoses that connect from

the elevation clamp ring to the plumbing terminal.

(6) BACK SECTION,

DOWN

FRONT

PIVOT BLOCK

(7) BACK

SECTION, UP

(10) KIDNEY, UP

(11) KIDNEY, DOWN

(8) LEG, UP

TOP VIEW

(9) LEG, DOWN

Figure 3-13. Elevation Clamp Ring Hoses

Page 22

Page 23

SECTION IV ELECTRICAL SYSTEM

4-1. General

The complete electrical system (with the exception of the hand-held pendant control and the return

circuit micro-switches) is contained within the base

of the table. The pump motor and the hydraulic

valves are controlled electrically with the pendant

control.

The electrically operated functions are as follows:

- ELEVATION - Up and Down

- TRENDELENBURG - Head up and down

- LATERAL TILT - Right and left

- BACK SECTION - Up and Down

- LEG SECTION - Up and Down

- FLEX / REFLEX

- KIDNEY LIFT - Up and down

- RETURN TO LEVEL

4-2. Components

Refer to figure 4-1 for the relationship of the electrical components.

a. Wires, Connectors, Switches, Fuse - These

provide the path for the various electrical circuits.

b. Relay Box - Contains the step down transformer, full wave rectifier, micro-processor and

relay switches. The relay switches are activated

by the pendant control signal to the micro-processor and in turn energize the solenoids.

c. Hand-Held Pendant Control - Contains

circuit board mounted switches and a micro-processor which activate the relay box. Operates on

5 VDC.

d. Solenoids - These electrically open and

close the hydraulic ports of the mini-valve to direct

the fluid to the correct cylinders. They operate on

120 VAC.

e. Motor/Pump Assembly - 120 VAC, 60 HZ,

200 Watt capacitor induction motor.

- BRAKE UNLOCK - Brake release

The power requirements are 120 VAC, 60 Hz. The

main power on-off switch is an enclosed DPST

circuit breaker type and the power cord is a threewire, fifteen foot long, UL listed cord with a threeprong hospital grade plug.

4-3. Battery Model Components

The functions of the battery model tables are the

same as the standard 120 VAC models. The

electrical components and operation however, vary

greatly between the two models. To simplify the

troubleshooting procedures, the battery model

tables are covered separately in Section VI for the

model 6600B.

Page 24

SOLENOID

COIL 120 VAC

MINI-VALVES

PENDANT

CONTROL

CN21

THROUGH

CN37

BUZZER

RELAY BOX

CN12

CN3

CN4

CAPACITOR

CN1

CN2A

CN2B

CN15

CN7

CN8

CN35

PUMP

TO

RETURN

CIRCUIT

CN10

CN37

CN36

AUXILIARY

SWITCHES

POWER

CORD

ICN1

MAIN

POWER

SWITCH

CN38

FOOT

CONTROL

CONNECTOR

Figure 4-1. 6600 Electrical Circuit Block Diagram

Page 25

SECTION V 6600 ELECTRICAL SYSTEM TROUBLESHOOTING

-1. Troubleshooting Notes

The basic operation of each component will be

defined along with a drawing and explanation on

how to check it out.

NOTE

This section does not cover the battery table components. They are

covered separately in Section 6.

Certain defective components could cause the

entire table to stop functioning or only one control

function to stop. It would depend on what part of the

component failed. Other defective components

would only cause one control function to stop.

The following defective components could cause

all control functions to be affected:

a. Motor/Pump Assembly (starting capacitor)

b. Main Switch Circuit and Wiring

1. Plug the power cord into the 120VAC power

supply (wall receptacle) and turn ON the main

switch.

2. Disconnect connector CN4 from the relay

box. See figure 5-1. Leave all other connectors

connected.

WARNING

Line voltage (120 VAC) will be measured in this test. Do not touch uninsulated connector pins or meter test leads.

CN3

CN1 CN7

RELAY BOX

CN8

CN2A

The following defective components could cause

all control functions to be affected or only one

control function:

a. Relay Box

b. Pendant Control

The component listed below would only affect one

control function:

Solenoid

When troubleshooting an electrical circuit, start at

the problem and work back to the power source.

5-2. Main Switch

The main power supply, 120 VAC, 60 HZ, comes in

through the power cord and through the Power

Switch. The Power Switch opens both lines when

in the "OFF" position. The Power Switch is also a

10 Amp circuit breaker that is used to protect the

complete electrical system.

CN10

CN2B

CN4

Figure 5-1. Main Power Test

3. Use an AC voltmeter capable of measuring

120 VAC and measure the voltage between pins 1

and 2 (black and white wires) located in connector

CN4. See figure 5-2. You should receive line

voltage 120 VAC.

ACV

5

3

2

4

1

a. Main Switch Test

The following test will determine if line voltage is

applied to connector CN4, which in turn would

power the table.

Page 26

PIN NO. COLOR

1 White

2 Black

3 Red

4 Blue

5 Yellow

Figure 5-2. Connector CN4

b. Test Results

OHM

BLACK 1

WHITE 6

BROWN 4

BLUE 5

3 BLACK

2 RED

Test Leads

Base Conn.

Pin

1

2

3

4

3

4

2

7

5

6

7

5

6

1

Pend. Conn.

Pin

Base Conn.

Pin

Pend. Conn.

Pin

1 YELLOW

7 GREEN

RED 3

4 GREEN

5 BLUE

2 BROWN

WHITE 6

7 YELLOW

If you do not receive the correct voltage measurement, the problem would have to be in the wires,

main switch or power cord. If the correct voltage is

obtained, everything is good up to this point and the

problem would have to be in another area.

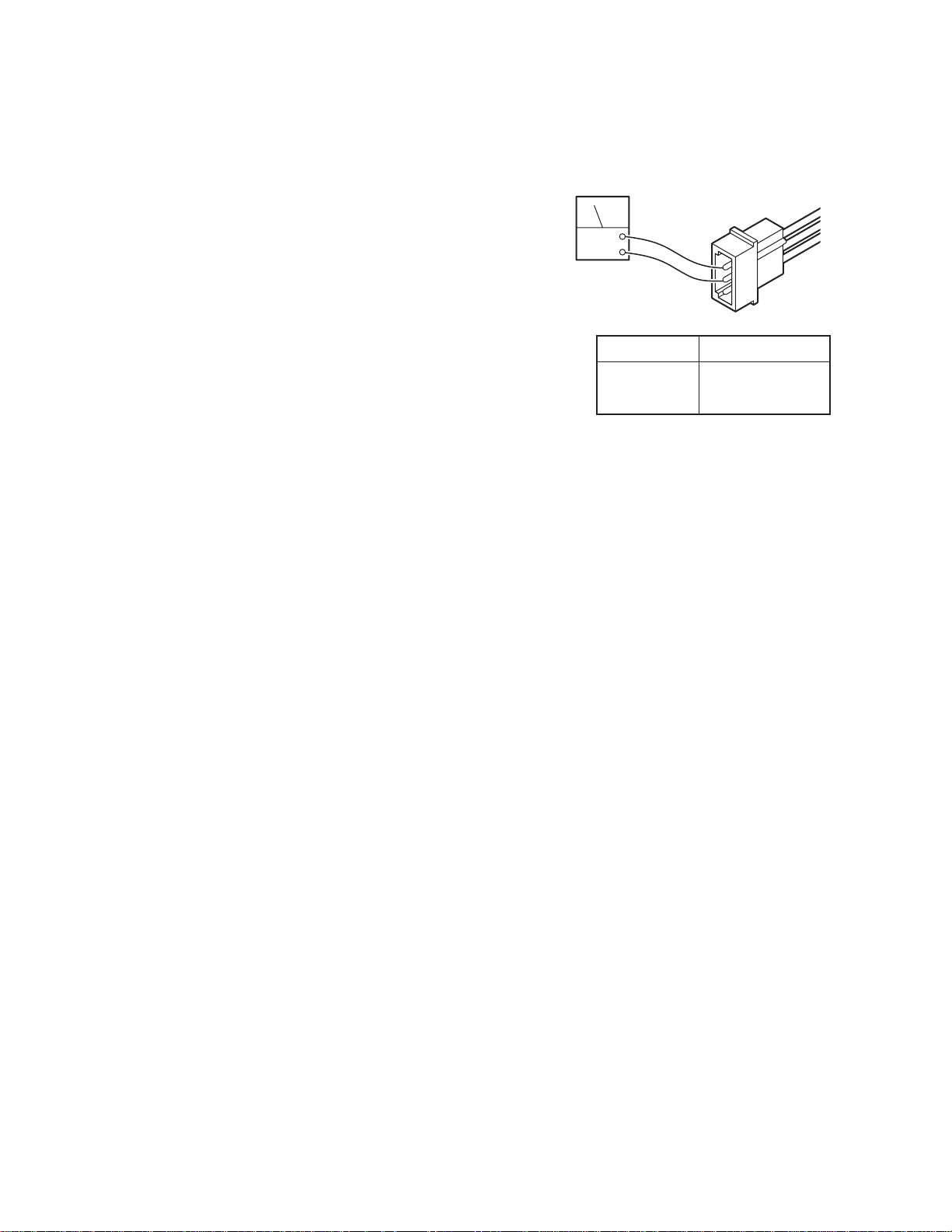

5-3. Pendant Control

The Pendant Control is part of the solid state, multiplex, logic control system. The pendant control

contains illuminated, circuit board mounted switches

and a micro processor. The encoded output from the

pendant control is serial bit stream logic.

The output signal is transmitted to the micro processors in the relay box where the logic is decoded

and the appropriate relays for the selected function

are activated.

Figure 5-3. Pendant Control Test

Pendant Control troubleshooting should begin by

switching the operating mode of the table. For

example; if a function fails when operating the table

in the AC120V mode, use the auxiliary switches to

operate the function. If the function now operates,

the problem is probably in the pendant control,

connectors or wiring from the pendant control to

the relay box.

a. Pendant Control Test

There are some serviceable components within

the Pendant Control. The cord is detachable and

can be tested for continuity between the pins on the

connectors. Use the following procedure to test the

pendant control cord.

Disconnect the cord from the table connector and

from the pendant control connector and using an

ohmmeter, test the continuity between the corresponding pins in the connectors. See figure 5-3.

b. Test Results

c. Table Connector CN37 Test

If correct readings are received, test the wiring

from the table connector to connector CN7 at the

Relay Box. Disconnect connector CN7 from the

Relay Box and using an ohmmeter, test the continuity between the corresponding pins in connectors CN7 and the table connector. See figure 5-4.

OHM

1

1

2

34

5

6

7

TABLE CONNECTOR

CN37

1 BLACK

2 BROWN

3 RED

4 GREEN

CN36

CN37 - CN7

5 BLUE

6 WHITE

7 NOT USED

2

3

4

5

6

7

CN7

Figure 5-4. Table Connector Continuity Test

If you do not receive the correct readings, the

wiring or connector pins may be faulty.

d. Test Results

If the correct readings are not obtained, test the

wiring from the table connector CN37 to connector

CN36 (located under the elevation column shroud)

and from connector CN7 to CN36. Disconnect

connector CN36 and using an ohmmeter, test the

continuity between the corresponding pins in connectors CN36 to CN7 and CN36 to CN37. See

figure 5-4.

Page 27

If the correct readings are obtained, this part of the

circuit is okay and the problem may be the Pendant

Control circuit board or the Relay Box. Contact

SKYTRON if all tests performed indicate that the

problem is located in the Pendant Control.

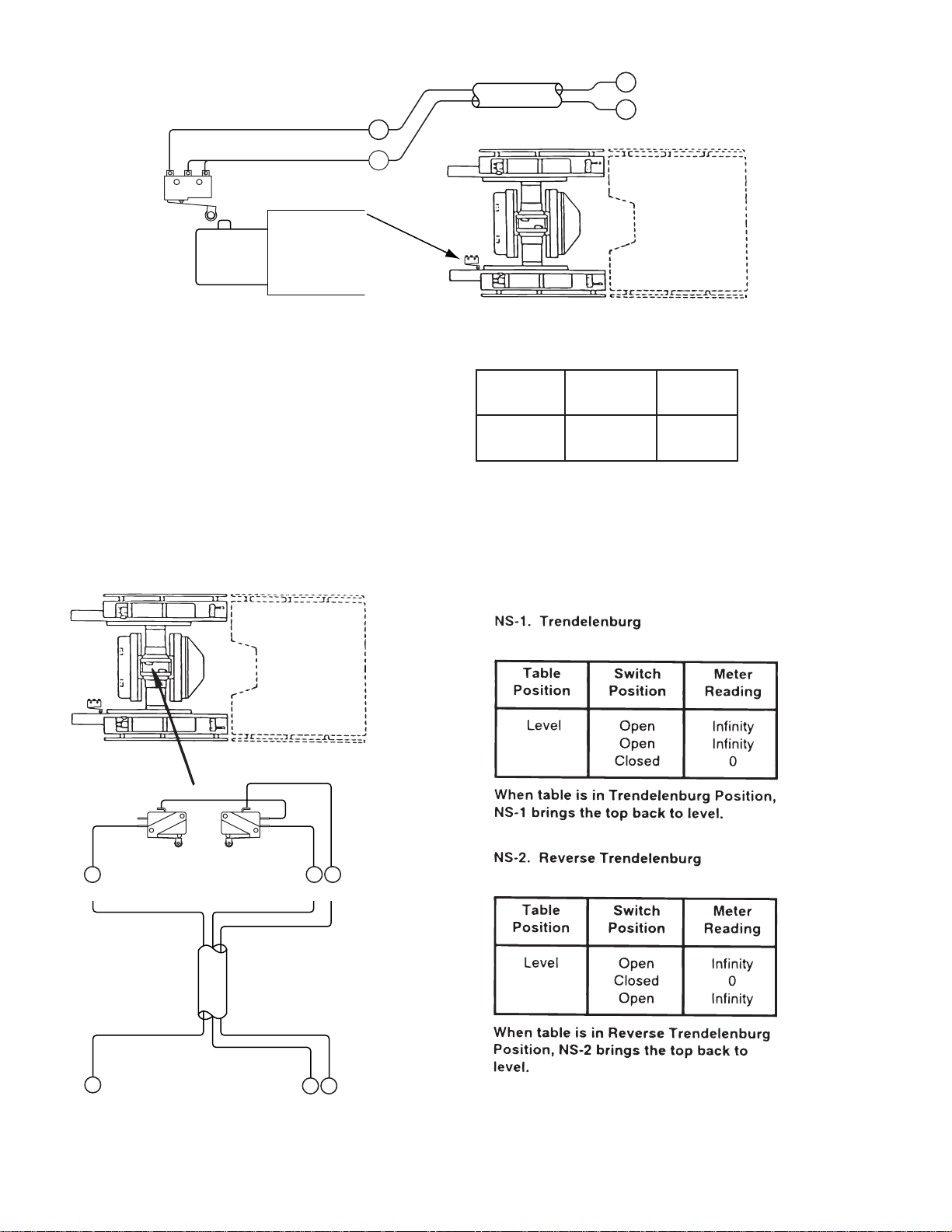

5-4. Auxiliary Switches

OHM

Figure 5-6. Auxiliary Switch Test

The following tests will determine if the auxiliary

switches are functioning properly.

a. Switch Test

Disconnect connector CN3 at the Relay Box and

using an ohmmeter check for continuity at the

connector pins (pin 1A common) while activating

the appropriate switch. See figure 5-5. Meter

should read 0 ohms.

b. Test Results

If proper meter readings are not received, test the

individual switches as necessary. Using an ohmmeter, test the operation of an individual switch with the

(+) test lead at the center terminal of the switch and

the (-) test lead at the terminal opposite the direction

of the switch actuation. Refer to figure 5-6. Meter

should read 0 ohms. If the switches check out, the

problem would have to be in the wires, the switch

circuit board or connector CN3.

CN3

TABLE UP

1

TABLE DOWN

2

TREND

3

REV TREND

4

TILT RIGHT

5

TILT LEFT

6

BACK UP

7

BACK DOWN

8

9

10

KIDNEY DOWN

11

BRAKE LOCK

12

LEG UP

13

LEG DOWN

14

PUMP MOTOR

15

+24V

16

SW1

SW2

SW3

SW4

SW5

SW6

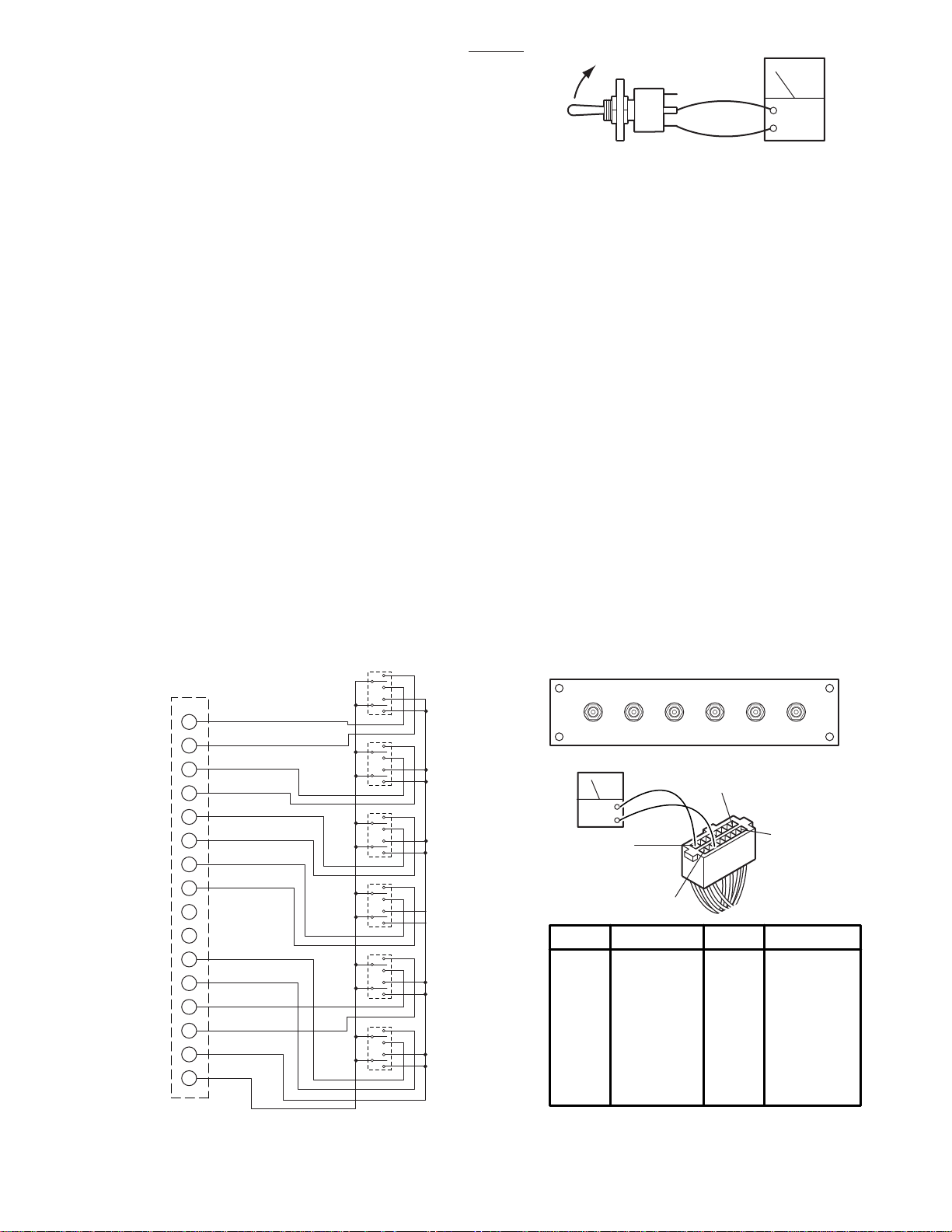

5-5. Relay Box

The power supply is directly connected to the relay

contacts. When these contacts are closed, 120

volts is supplied to the solenoids which are mounted

on the hydraulic mini-valves. One relay is used to

supply power to the pump/motor and is always

activated no matter what control function is selected. The brake locking circuit relay is also

activated when any control function other than

BRAKE UNLOCK is initially selected.

Also, inside the relay box is a step-down transformer

and full-wave rectifier which decreases the voltage to

5-6 volts. This low voltage potential controls the

relays by the use of the hand-held pendant control

buttons. Basically the relays enable a 5-6 volt potential to control the 120 volt circuit.

The following tests will determine if the relay box is

functioning correctly.

B8/B2 B8/A3 B8/A4 B8/A1 B8/A7 B8/B6

REV

TILT

TREND

TREND TILT

B8/A2 B8/B3 B8/B4 B8/B1 B8/B7 B8/A6

OHM

1 (A1)

PIN NO

1 (A1)

2 (B1)

3 (A2)

4 (B2)

5 (A3)

6 (B3)

7 (A4)

8 (B4)

Purple/White (-A) White/Yellow (-A)

BACKUPTABLEUPLEGUPBRAKE

RIGHT

BACK

DOWN

TABLE

DOWN

LEFT

15 (A8)

2 (B1)

COLOR

Red

White/Red

Brown

Yellow

Orange

White/Orange

White/Brown

Blue/White

LOCK

LEG

KIDNEY

DOWN

DOWN

16 (B8)

CN8

PIN NO COLOR

9 (A5)

10 (B5)

11 (A6)

12 (B6)

13 (A7)

14 (B7)

15 (A8)

16 (B8)

--

--

White/Purple

Purple

Gray

White/Gray

Red/White

Pink

Page 28

Figure 5-5. Auxiliary Switch Connector CN3

a. Checking Relay Box Connector CN4

1. Connect the power cord to the table. Plug the

power cord into the 120 VAC power supply (wall

receptacle) and turn the main switch ON. Leave all

connectors connected.

WARNING

Line voltage (120 VAC) will be measured in this test. Do not touch uninsulated connector pins or meter test leads.

2. Use an AC voltmeter capable of measuring

120 volts and measure the voltage between pins 1

(white) and 2 (black) of connector CN4 for input

voltage. See figure 5-7. Meter should read line

voltage 120 VAC.

3. Activate any table function with the Pendant

Control and using an AC voltmeter, test the voltage

at pins 3 and 4 of CN4 for output to the pump. Meter

should read 120 VAC.

NOTE

•The Brake Lock function is activated

by pressing any function button (except

BRAKE UNLOCK). A timer in the Relay Box allows continuous output for

about 7 seconds. If the brakes are

already locked, no output is provided.

•The BRAKE UNLOCK button activates

another timer in the relay box which

allows continuous output for the brake

release function for approximately 7

seconds. If the brakes are released

(using the BRAKE UNLOCK button) no

output is provided.

1. The power cord should be plugged into the

wall receptacle and Power Switch turned ON.

2. Disconnect the motor connector. All other

connectors should be connected. Test connectors

CN1, CN2A and CN2B from the back while attached to the relay box.

4

ACV

5

PIN NO.

1

2

3

4

5

COLOR

WHITE

BLACK

RED

BLUE

YELLOW

Figure 5-7. Connector CN4

b. Test Results:

If you do not receive the correct meter readings, the

relay box or wiring is defective. If the correct

readings are obtained, this part of the relay box is

okay. Proceed to the next step.

c. Checking Output to Solenoids

This test checks the high voltage (120V) that is

used to energize the solenoids.

3. Activate each of the Pendant Control buttons

measure the voltage for the corresponding connector pins with an AC voltmeter. See figure 5-8.

Meter should read 120VAC.

ACV

1

CN1, CN2A OR CN2B

16

Back Up

Leg Up

CN2B

CN2A

1 - 2

3 - 4

5 - 6

7 - 8

13 - 14

15 - 16

1 - 2

CN1

FUNCTION PINS FUNCTION PINS

Table Up 1 - 2

Table Down 3 - 4

Trend 5 - 6

Rev Trend 7 - 8

Tilt Right

Tilt

Left

Reflex

Flex

9 - 10 9 - 10

11 - 12 11 - 12

13 - 14

15 - 16

Back Down

Slide Foot

Slide Head

Kidney Up

Kidney Down

Leg Down

Brake Set

Brake Unlock 3 - 4

WARNING

120 VAC will be measured in this test.

Do not touch uninsulated connector

pins or meter test leads.

Figure 5-8. Solenoid Output Connectors

Page 29

d. Test Results:

If you do not receive the correct meter readings, the

relay box or wiring is defective and should be

replaced.

NOTE

Before deciding the relay box is defective, check the wires and pins in the

connector blocks to make sure they are

not loose or making a bad connection

with their mate.

e. Checking Output to Pendant Control

The output to the Pendant Control can not be tested

without specialized equipment. If all tests have

been conducted and it appears that the Relay Box

is faulty, contact SKYTRON.

5-6. Solenoids

The solenoids are energized by 120 volt potential

that is controlled by the relays located inside the

relay box.

The solenoid windings are protected from excessive heat with an internal thermal fuse that will open

after approximately seven (7) minutes of continuous operation. The solenoid must be replaced if the

internal thermal fuse has been blown. The solenoids are mounted directly on either side of the

hydraulic mini-valves and push the spool valve in

one direction or the other depending upon which

solenoid is activated.

a. Solenoid Test

NOTE

Each solenoid is controlled with 120V

source coming from the relay box. This

source can easily be checked by measuring the voltage at the 2 pin connector

in question.

WARNING

Line voltage will be measured in this

test. Do not touch uninsulated connector pins or meter test leads.

b. Step #1

1. Plug the table cord into the wall receptacle

and turn main switch ON.

2. Disconnect the 2 pin connector from the

solenoid in question. See figure 5-9.

3. Use a voltmeter capable of measuring 120

VAC and measure the voltage across the 2 pin

connector. Polarity of meter leads is not important.

NOTE

The appropriate pendant control button must be pushed during this test.

The motor will run when this test is

performed, and the brake locking solenoid will be activated by any function

other than UNLOCK.

The following tests check the voltage applied to the

solenoids and the resistance of the solenoid coil.

NOTE

If a solenoid does not function when the

pendant control button is pushed, the

problem could be the pendant control,

the relay box, or the solenoid.

Page 30

c. Test Results:

If you do not receive the correct voltage, the problem could be in the wires leading to the connectors.

The problem could also be in the relay box or the

Pendant Control (refer to appropriate section for

troubleshooting).

If the correct voltage is obtained, everything is good

up to that point and the problem is more than likely

the solenoid.

d. Test #2

ACVOHM

BLUE

WHITE/BLUE

BLUE

WHITE/BLUE

BLUE

CN1

RED

BLUE

WHITE/BLUE

BLUE

WHITE/BLUE

BLUE

WHITE/BLUE

BLUE

WHITE/BLUE

BLUE

WHITE/BLUE

BLUE

WHITE/

BLUE

BLUE

BLACK/

WHITE

BLUE

WHITE/BLACK

BLUE

WHITE/BLUE

BLUE

WHITE/BLUE

BLUE

WHITE/BLUE

BLUE

WHITE/BLUE

BLUE

WHITE/BLUE

BLUE

WHITE/BLUE

BLUE

WHITE/BLUE

BLUE

WHITE/BLUE

BLUE

BROWN

BLUE

ORANGE

BLUE

BROWN/WHITE

BLUE

WHITE/BROWN

BLUE

WHITE/GREY

BLUE

PURPLE

BLUE

WHITE/PURPLE

BLUE

GREY

BLUE

BLUE/WHITE

BLUE

RED/WHITE

BLUE

WHITE/ORANGE

BLUE

YELLOW

BLUE

WHITE/RED

ELEV.

UP

DN.

UP

DN.

UP

DN.

UN

LOCK

LOCK

DN.

UP

HD

DN.

HD

UP.

RT.

LT.

REFX

FLEX

TREND FLEX KIDNEY BRAKE

LAT.

TILT

BACK

SECT.

LEG

SECT.

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

CN2A

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

CN2B

4

3

2

1

e. Test Results:

The solenoid can be checked out using an ohmmeter R x 1 scale.

1. Measure the resistance between the two

pin connector in question as shown in figure 5-9.

Connector must be disconnected. Polarity of

meter leads is not important.

2. The meter should read approximately 58

ohms at room temperature.

3. Measure the resistance between either pin

and ground.

4. Meter should read infinity.

If the solenoid does not check out with the meter, it

is more than likely defective and must be replaced.

NOTE

Whenever there are several components of the same type, a defective unit

can also be detected by substituting a

known good unit or wire connector. In

some cases this may be faster than

using a multi-meter.

Figure 5-9. Solenoid Test

Page 31

5-7. Motor/Pump Assembly

The electric motor is a capacitor start type with a

rating of 120 VAC, 200 watts. The field windings

are protected with a thermal protector that will open

the winding circuit if the motor is run continuously

for approximately 10 minutes. This protector will

take about 10 minutes to automatically reset. The

oil pump unit is attached to the bottom of the motor

and is a gear type displacement pump with a

pumping capacity of .4 liter per min. The Motor/

Pump Assembly is mounted on an insulated motor

plate in the base of the table. The starting capacitor

is mounted along side the motor/pump assembly.

a. Motor/Pump Test

The following tests will check the voltage applied to

the motor and the resistance of the motor field

windings.

WARNING

3. Use a voltmeter capable of measuring 120

VAC and measure the following connector pins in

connector CN15. See figure 5-11.

ACV

3

2

1

PIN NO

1 - 2

1 - 3

2 - 3

AC VOLTS

120

120

0

Figure 5-11. Connector CN15

c. Test Results:

Line voltage will be measured in this

test. Do not touch uninsulated connector pins or meter test leads.

b. Step #1

1. Plug the power cord into 120 VAC power

supply (wall receptacle). Turn main switch ON.

2. Disconnect the 3 pin connector CN15 at the

motor. Leave all other connectors connected. See

figure 5-10.

CAPACITOR

CN15

PUMP

If you do not receive the correct meter readings, the