SURGICAL TABLE

OPERATORS MANUAL

1/07

3501B EZ SLIDE

Page 1

TABLE OF CONTENTS

Title Page

EQUIPMENT LABELS AND SPECIFICATIONS................................................................................... 2

3501B E-Z Slide General Purpose Surgical Table Specifications ........................................................ 3

SPECIAL USER ATTENTION ............................................................................................................... 4

SECTION I INTRODUCTION............................................................................................................... 10

1-1. General ................................................................................................................................ 10

1-2. Power Requirements ........................................................................................................... 10

1-3. Pendant Control Unit ........................................................................................................... 11

1-4. Floor Lock/Brake System .....................................................................................................11

SECTION II OPERATION .................................................................................................................... 12

2-1. Electrical Power ................................................................................................................... 12

2-2. AC 120V Operation .............................................................................................................. 12

2-3. Battery Operation ................................................................................................................. 13

2-4. Automatic Shut-Off .............................................................................................................. 13

2-5. Charging the Battery ............................................................................................................ 14

2-6. Positioning Functions ........................................................................................................... 15

a. Floor Lock/Brake system ................................................................................................. 15

b. Trendelenburg .................................................................................................................16

c. Lateral Tilt ........................................................................................................................ 16

d. Back Section ................................................................................................................... 17

e. Elevation .......................................................................................................................... 17

f. Top Slide ......................................................................................................................... 18

g. Leg Section ..................................................................................................................... 18

h. Flex Positioning ............................................................................................................... 19

i. Kidney Lift ........................................................................................................................ 19

j. Return To Level ...............................................................................................................20

2-7. Emergency Back-up controls ............................................................................................... 21

2-8. Emergency Brake Release .................................................................................................. 22

2-9. Head Section ....................................................................................................................... 22

2-10. Leg and Back Section Removal ........................................................................................... 23

SECTION III MAINTENANCE .............................................................................................................. 26

3-1. Preventive Maintenance ......................................................................................................26

3-2. Cleaning Recommendations ................................................................................................ 26

3-3. Service ................................................................................................................................. 27

1/07

Although current at the time of publication, SKYTRON’s policy of continuous development makes this

manual subject to change without notice.

Page 2

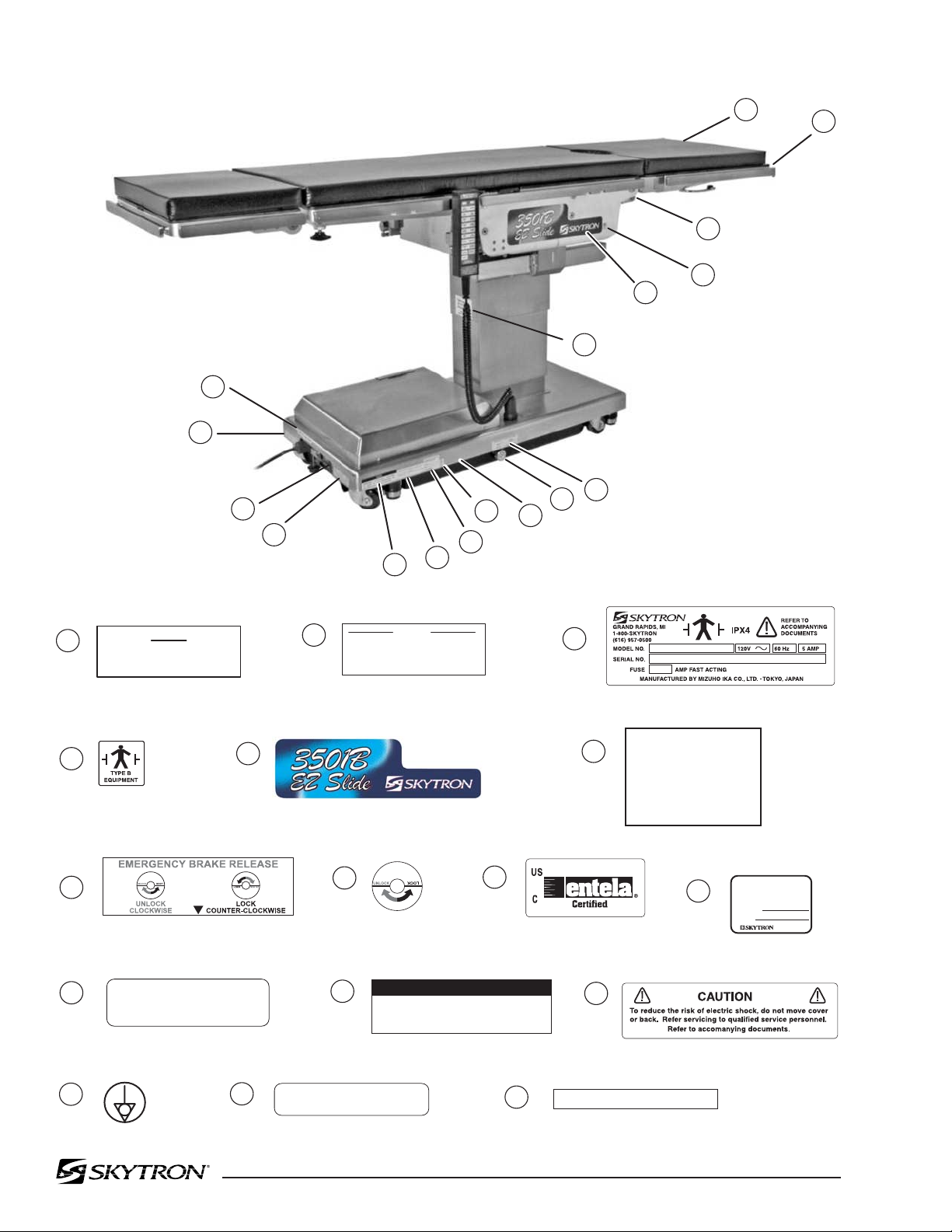

3501B EZ SLIDE EQUIPMENT LABELS

15

16

14

13

12

11

10

1

2

3

4

5

6

7

4

8

9

D6-032-47

1

USE HEAD SECTION AS FOOT EXTENSION

ONLY - WHEN REVERSING PATIENT ON TABLE

REFER TO OPERATOR MANUAL.

WARNING

D6-017-05

4

5

D6-065-26

7

D6-011-32

DANGER - E

XPLOS

ION

H

AZARD.

DO

11

T

HE

PRESENCE OF

DANGER - RISQUE

EMPLOYER EN

INFLAMMABLES

FLA

D'E

PRE

MMAB

LE

XPL

OSION. NE

SENCE

D'A

NOT USE IN

ANAE

STHETICS

NESTHESIQUES

PAS

D6-032-46

2

DO NOT SIT ON END OF LEG SECTION(S) AS LOADS

IN EXCESS OF 140 LBS, MAY CAUSE INSTABILITY

THAT COULD CAUSE THE TABLE TO BE TIPPED OVER.

WARNING

D3-035-60 right D3-035-61 left

D6-067-33

8

D6-031-43

12

POSSIBL

IF USED IN THE PRESENCE OF

FLAMMABLE ANESTHETICS.

E E

XPLOSION

DANGER

9

HAZARD

3

L1-010-00

6

13

D6-035-38

Table Capacity:

Lift

7

00 lbs.

Articulate 6

See Operators

Manual for Limitations.

10

D6-065-22

00 lbs.

D6-011-34

THIS PRODUCT COMPLIES WITH RADIATION PERFORMANCE STANDARD 21 CFR

AT THE TIME OF MANUFACTURE

Manufactured:

Model No.

14

D6-034-21

D6-065-21

Grounding reliability can only be achieved when

15

the equipment is connected to an equivalent

receptacle marked "Hospital Only" or "Hospital Grade"

16

D6-067-27

TWIST TO LOCK OR RELEASE PLUG

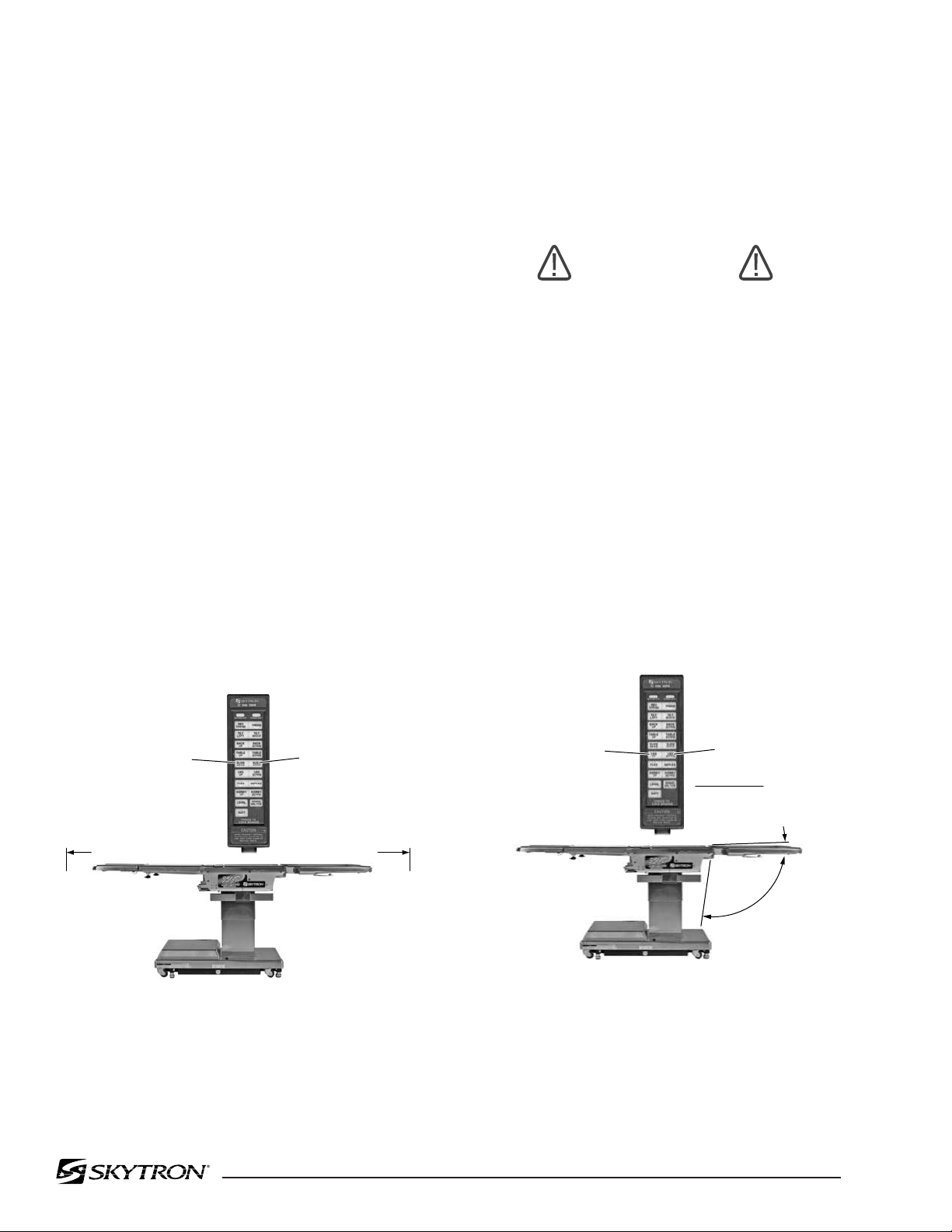

3501B EZ Slide General Purpose Surgical Table Specifications

14-1/2"

Page 3

60˚

90˚

12-1/2"

18-1/4" 25" 23"

14-1/2"

TOP VIEW

83"

5-1/2"

3"

6"

19-3/4"

21-3/4"

45" MAX

26" MIN

8-1/2"

40-1/2"

SIDE VIEW

ENTELA CERTIFIED

TO UL2601-1

CAN/CSA601.1, IEC 60601-2-46

Electrical Specifications

Power requirements

Current Leakage

Power Cord

120 VAC, 60Hz, 450 Watts

Less than 100 micro amps

15 feet w/hospital grade connector (removable)

19"

END VIEW

Page 4

SPECIAL USER ATTENTION

Prior to use, all personnel that may operate this

table must be instructed in the correct operational procedures. This table is designed for

use by trained and qualified personnel for human medical purposes only.

Initial use should not begin until after the users

have been instructed by the manufacturer's

representative.

A routine instructional program must be implemented by the facility for proper usage instructions for all personnel that may operate this

table.

The maximum lifting capacity of the 3501B

EZ Slide table is 700 pounds and the maximum

articulation weight capacity is 600 pounds.

When lifting or articulating large patients, pay

close attention to the patient position as well as

the positioning guidelines and limitations listed

in the operation instructions.

In general, common sense will dictate when there

is a potential hazard.

The following precautions should be reviewed

by all personnel prior to operating the table.

WARNING

Indicates a possibility of personal injury.

CAUTION

Indicates a possibility of damage to

equipment.

NOTE

Indicates important facts or helpful hints.

The extreme positioning capabilities of the 3501B

E-Z Slide Table requires special attention for possible interference points when using multiple function positioning. As with the operation of any

surgical table, a certain amount of care should be

exercised to position the patient safely. Although

the thick pads and sheets substantially protect the

patient, pinch points, located at the joints of the top

section should always be considered. BE SURE

THAT THE ARMS, HANDS AND FINGERS OF

THE PATIENT AND THOSE OF THE OPERATING ROOM PERSONNEL ARE CLEAR OF ALL

MOVING PARTS BEFORE MOVING THE TABLE.

Proper restraints should always be used for patient

safety.

Certain accessories such as the Uro-Drain Tray,

Armboards and X-Ray top can be damaged when

changing the position of the table top sections.

Always look first to see if a desired movement is

going to interfere with any accessories in use.

The operator has the ultimate responsibility of

preventing damage to the table and surrounding

equipment or possible injury to the patient or staff.

Do not use worn or damaged accessories, they

represent an injury hazard.

Remove possible obstacles before lowering or

tilting the operating table

Do not place objects on the base of the table, a

danger of damage exists during positioning.

Use caution when articulating the table top, pinch

hazards exist.

The operator must ensure proper positioning is

maintained to prevent compromising respiration,

nerve pathways or circulation.

SPECIAL USER ATTENTION

Page 5

NOTE

Activating any function button will activate the brake system. Using the TABLE

UP function to set the brakes provides

a visual assurance that the brakes are

locked without altering the table position, except when emergency brake is

released.

WARNING

Prior to operating the table, observe

all table caution labels and review the

SPECIAL USER ATTENTION section

in the front of this manual.

WARNING

NOTE

Battery Operation must be turned OFF

at the pendant control. It cannot be

turned OFF using the main power

switch.

NOTE

Turning the Main Power Switch ON will

change the table operation to 120 VAC

power.

NOTE

When the red light starts to blink (indicating low power in battery) the table

will operate for approximately 5 continuous minutes, typically long enough

to use the table for the rest of the day.

Possible explosion hazard exists if table

is used in the presence of FLAMMABLE

ANESTHETICS.

NOTE

An equalization terminal is located under the main power panel. This is provided as an alternate pathway to reduce the risk of static shock hazards.

Always follow recommended grounding procedures to ensure patient and

staff safety.

NOTE

The table will operate correctly on battery power with the power cord connected to a wall outlet or disconnected.

NOTE

The charging system operates ONLY

when the table is in AC120V operation

mode.

NOTE

The table can be operated on 120VAC

power while the battery is being recharged.

NOTE

If the table is stored for a period greater

than 6 months, the batteries should be

removed and stored in a dry, clean condition at a storage temperature of 68° F

(20° C). Batteries should be recharged

every 6 months of product storage.

Page 6

SPECIAL USER ATTENTION

WARNING

•DO NOT unlock brakes when a patient

is on the table. An uneven patient

weight load may cause instability.

•If circumstances demand table brakes

to be unlocked, the patient must be

centered and evenly distributed on the

table top (i.e. supine or prone position)

with the table lowered to its lowest

height position. The maximum patient

weight should not exceed 500 pounds.

Table top slide must be centered (indicated by a red LED light on the pendant

control) prior to unlocking brakes.

Patient's head must be on the head

section. Head section must be attached

in its normal orientation to the table's

back section.

•Prior to unlocking brakes, check for

obstructions on the floor that might

prevent the table from moving smoothly

to new location. Relock the brakes immediately once the final position is

reached and before commencing surgery. Table brakes should remain locked

at all times if patient weight exceeds

500 pounds.

WARNING

To maximize patient safety, utilize

proper restraint methods during extreme

lateral tilt positioning.

NOTE

If the table top is slid toward the foot

end, the back section will not go below

horizontal. An audible alarm will sound.

NOTE

To prevent damage to the kidney lift, a

safety interlock prevents the back section from going more than 45° above

horizontal if the kidney lift is not all the

way down. An audible alarm will sound.

NOTE

If the leg section is positioned more

than 45° below horizontal, the top will

not slide toward the head end. An

audible alarm will sound.

NOTE

With an evenly distributed patient weight

load, all table positioning functions will

operate smoothly and quietly with a

patient weight of up to 600 pounds

(700 pounds lift).

WARNING

To maximize patient safety, utilize

proper restraint methods during extreme

Trendelenburg positioning.

NOTE

If the back section is positioned below

horizontal, the top will not slide toward

the foot end. An audible alarm will

sound.

CAUTION

The Leg section may hit the table base

or the floor if both the leg and elevation

systems are placed in their full down

position.

SPECIAL USER ATTENTION

Page 7

NOTE

If the top is slid toward the head end the

leg section will only go down 45°. An

audible alarm will sound.

NOTE

When FLEX button is activated and if

the top is slid toward the foot end, the

back section will not go below horizontal. An audible alarm will sound.

NOTE

Return to Level will lower the kidney lift.

NOTE

To prevent damage to the kidney lift, a

safety interlock prevents the kidney lift

from going up if the back section is 45°

above horizontal. An audible alarm will

sound .

NOTE

Elevation and brake system functions

are not affected by the return to level

function.

CAUTION

The safety interlock system is not operational when the emergency backup control switches are used.

CAUTION

The EMERGENCY BRAKE LOCK

switch does not activate the brake system timer. The switch must be held

until the brakes are completely locked,

approximately 10 seconds.

NOTE

The emergency back-up control

switches will function when the table is

operating on 120VAC power, battery

power, or turned off.

WARNING

•DO NOT unlock brakes when a patient

is on the table. An uneven patient

weight load may cause instability.

•If circumstances demand table brakes

to be unlocked, the patient must be

centered and evenly distributed on the

table top (i.e. supine or prone position)

with the table lowered to its lowest

height position. The maximum patient

weight should not exceed 500 pounds.

Table top slide must be centered (indicated by a green LED light on the

pendant control) prior to unlocking

brakes. Patient's head must be on the

head section. Head section must be

attached in its normal orientation to the

table's back section.

•Prior to unlocking brakes, check for

obstructions on the floor that might

prevent the table from moving smoothly

to new location. Relock the brakes immediately once the final position is

reached and before commencing surgery. Table brakes should remain locked

at all times if patient weight exceeds

500 pounds.

Page 8

SPECIAL USER ATTENTION

NOTE

The Emergency Brake Release Valve

must be closed and tightened (clockwise) before activating any function.

•If the Emergency Brake Release Valve

has been operated, the UNLOCK button

on the pendant control will have to be

pressed before brakes will lock again.

WARNING

Consult manufacturer's instructions

when using high frequency surgical

equipment, cardiac defibrillator and cardiac defibrillator monitors.

WARNING

Certain accessories may limit weight

capacities. Check with your SKYTRON

representative.

CAUTION

Consult SKYTRON prior to using accessories produced by other manufacturers.

NOTE

Always follow current AORN Journal

Guidelines to ensure proper cleaning

and disinfection procedure.

WARNING

When an antistatic pathway is required,

the table has to be used on an antistatic

floor.

WARNING

The antistatic properties of the table

are dependent on the use of the original

pad set which was furnished with the

table or an alternate approved replacement.

WARNING

Always follow OSHA blood-borne pathogens standards for protective clothing,

including gloves, masks and eye protection when cleaning the surgical table.

CAUTION

Thoroughly read and follow the

manufacturer's directions for all cleaning fluids. DO NOT use cleaners containing phenolics.

CAUTION

When using spray cleaners DO NOT

spray fluids directly into electrical receptacles or micro switches.

CAUTION

Before replacing pads on the table, make

sure the pads and all mating surfaces

are completely dry. Moisture trapped

between the pads and mating surfaces

may cause distortion of table tops.

Page 9

WARNING

SKYTRON assumes no liability for table

performance, table damage or injury to

patient or staff when accessories not

sold or serviced by SKYTRON are

used on SKYTRON surgical tables.

Page 10

SECTION I INTRODUCTION

SIDE

RAIL

HEAD SECTION

LOCKING KNOB

HEAD

SECTION

SERVICE

ACCESS COVER

POWER

CORD

REMOVABLE

BACK SECTION

PENDANT

CONTROL

SEAT

SECTION

REMOVABLE

LEG SECTION

LEG SECTION

RELEASE LEVER

FLOOR/LOCK

BRAKE (4)

MAIN POWER

SWITCH

Figure 1-1. 3501B EZ Slide

1-1. General

SKYTRON’s 3501B EZ Slide Surgical Table is an

electro-hydraulically operated, general purpose surgical table. See figure 1-1.

The electro-hydraulic positioning functions operated by the hand-held, push button, pendant control unit are: Trendelenburg, lateral tilt, back section, elevation, leg section, top slide, flex/reflex,

kidney lift, return to level and the floor lock/brake

system.

Manual controls are provided for head section

positioning, emergency brake release and leg section removal.

EMERGENCY

BRAKE RELEASE

main power ON/OFF switch is located on the

electrical panel on the front edge of the table base.

See figure 1-2.

The battery charging indicator and an optional foot

control connector are also located on the electrical

panel.

1-2. Power Requirements

The 3501B EZ Slide Surgical Table requires a

120VAC, 60 Hz electrical power supply. The table

is equipped with a removable 15 foot long power

cord with a three prong, hospital grade plug. The

POWER

CORD

MAIN POWER

SWITCH

BATTERY

INDICATOR

Figure 1-2. Electrical Panel

OPTIONAL

FOOT CONTROL

CONNECTOR

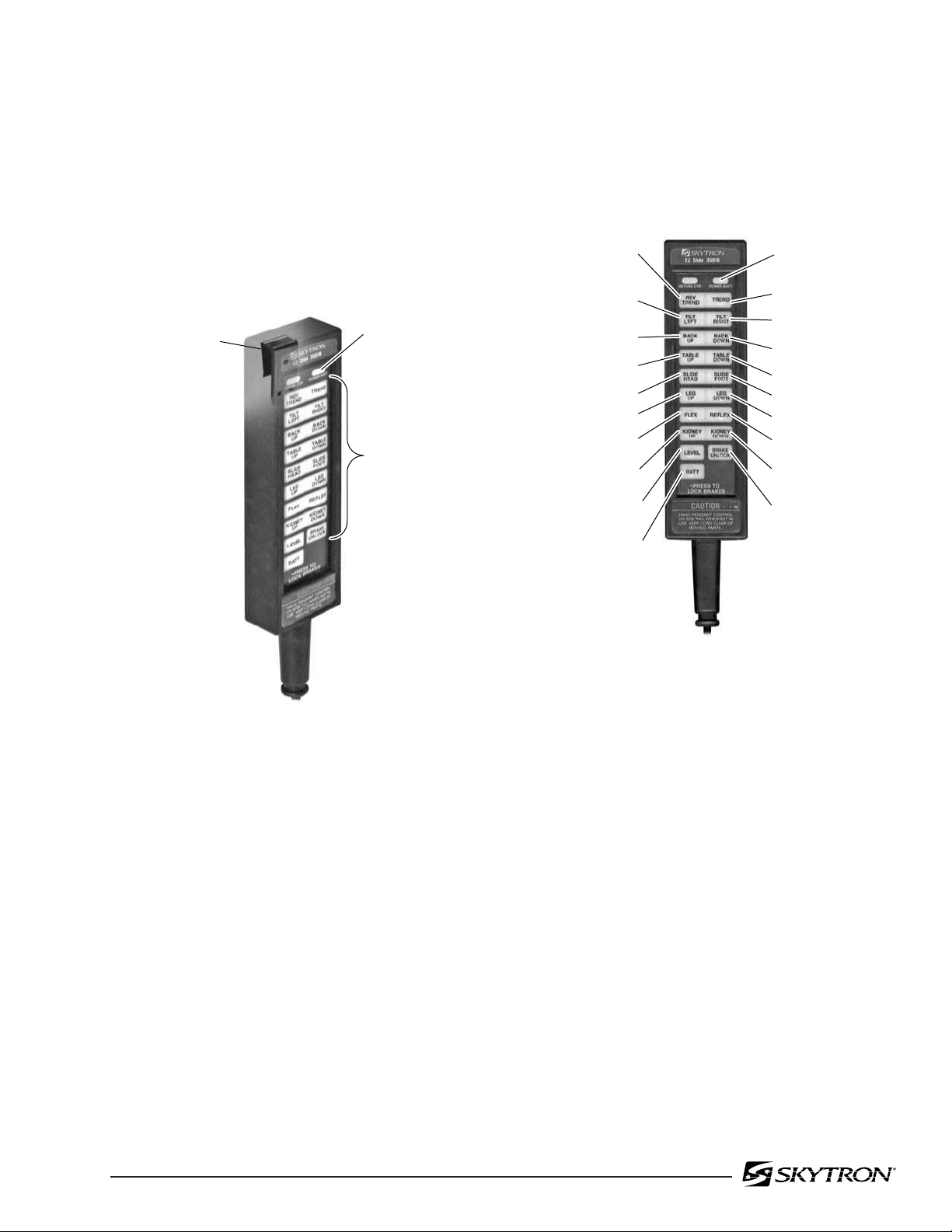

1-3. Pendant Control Unit

AC120V POWER ON

INDICATOR LIGHT

(GREEN)

TABLE UP

(BRAKE LOCK)

LATERAL

TILT LEFT

BACK UP

LEG UP

SLIDE HEAD

FLEX

KIDNEY

LIFT UP

RETURN

TO LEVEL

BATTERY

LATERAL

TILT RIGHT

BACK DOWN

TABLE DOWN

LEG DOWN

SLIDE FOOT

REFLEX

KIDNEY

LIFT DOWN

BRAKE

UNLOCK

REVERSE

TRENDELENBURG

TRENDELENBURG

Page 11

The hand-held pendant control unit (figure 1-3)

has a non-slip rubber cover which assures a positive grip during use. A spring clip hanger is located

on the back of the control for storage. When the

Pendant Control is not in use, it should be stored on

a convenient side or end rail.

POWER

SIDE RAIL

CLIP

INDICATOR

FUNCTION

BUTTONS

The function push buttons are identified with abbreviated descriptions for all functions. See figure

1-4. When illuminated the Trendelenburg and

table up buttons are red, the remaining buttons are

all green.

Figure 1-3. Pendant Control Unit

Figure 1-4. Function Buttons

1-4. Floor Lock/Brake System

The floor lock/brake system consists of four selfleveling, hydraulic brake cylinders which raise and

support the table base off from the casters. Press

the TABLE UP button on the pendant control to set

the table’s brakes. An electronic timer will activate

the brake system until the brakes are completely

set, approximately 8-10 seconds.

NOTE

Activating any function button will activate the brake system. Using the TABLE

UP function to set the brakes provides

a visual assurance that the brakes are

locked without altering the table position, except when emergency brake is

released.

Page 12

SECTION II OPERATION

2-1. Electrical Power

The 3501B table will operate on either 120 VAC or

battery power.

WARNING

Prior to operating the table, observe

all table caution labels and review the

SPECIAL USER ATTENTION section

in the front of this manual.

WARNING

POWER

CORD

MAIN POWER

SWITCH

TWIST TO

LOCK

OPTIONAL

FOOT CONTROL

BATTERY

INDICATOR

GROUNDING TERMINAL

CONNECTOR

EQUALIZATION

Possible explosion hazard exists if table

is used in the presence of FLAMMABLE

ANESTHETICS.

NOTE

An equalization terminal is located under the main power panel. This is provided as an alternate pathway to reduce the risk of static shock hazards.

Always follow recommended grounding procedures to ensure patient and

staff safety.

2-2. AC 120V Operation

Use the following procedures to operate the table

on 120 VAC power.

Figure 2-1. Electrical Panel

The pendant control buttons and the green AC

120V, POWER indicator light located in the upper

right corner of the pendant control will illuminate.

See figure 2-2.

AC120V POWER ON

INDICATOR LIGHT

(GREEN)

a. Make sure the Power cord is securely at-

tached to the table. To install the power cord, align

the cord connector with the base connector, insert

the cord and twist clockwise to lock the cord into the

connector. See figure 2-1. Plug the cord into a

properly grounded, Hospital Grade, 120 VAC outlet. Make sure the power cord is routed to the outlet

to prevent it from being in the way of operating

personnel.

b. Activate the POWER SWITCH located on the

electrical panel. The switch will illuminate.

Figure 2-2. Pendant Control

c. The table is now ready for 120VAC operation.

Page 13

2-3. Battery Operation

a. Make sure the Main Power Switch indicator

light, on the electrical panel, is OFF. See figure 2-

2. If the indicator light is ON, turn AC120V operation OFF with the main power switch.

NOTE

The table will operate correctly on battery power with the power cord connected to a wall outlet or disconnected.

b. Press the BATT button on the hand-held

pendant control. The pendant control buttons, the

red BATTERY indicator light, located in the upper

right corner of the pendant control and the Battery

Indicator on the electrical panel will illuminate.

2-4. Automatic Shut-Off

a. To prevent unnecessary discharge of the

battery, a timer is built into the battery circuit. This

timer will automatically shut the battery power OFF

after 1½ hours of table inactivity.

b. To turn the table ON again, press the BATT

button on the pendant control, the pendant control

buttons and the red indicator light will illuminate.

NOTE

Turning the Main Power Switch ON will

change the table operation to 120 VAC

power.

c. The table is now ready for BATTERY opera-

tion.

d. To extend the battery charge life, turn the

BATTERY power OFF with the pendant control

when the table is not going to be used.

NOTE

Battery Operation must be turned OFF

at the pendant control. It cannot be

turned OFF using the main power

switch.

Page 14

2-5. Charging the Battery

Batteries should be charged:

• When the table is placed into initial

service

• As indicated by Battery Indicator

• Every week under normal service

conditions

a. Battery Indicator The Battery Indicator

consists of ten lighted bars, 3 red, 4 yellow and 3

green. See figure 2-3. Each bar represents a

percentage of the battery charge condition. When

all ten bars are illuminated, the batteries are fully

charged. The following list shows the battery

charge level as indicated by the lighted bars;

3 green 100% -Fully charged

2 green 89%

1 green 78%

4 yellow 67%

3 yellow 56%

2 yellow 45% -Needs Charging (BATT

indicator on pendant will flash)

1 yellow 34% -Needs Charging

3 red 23% -Needs Charging

(poor performance)

2 red 12% -Needs Charging

(intermittent performance)

1 red 1% -Needs Charging

(inoperable)

b. If the battery needs to be charged when

operating the table on battery power, the red indicator light on the pendant control will begin to blink.

NOTE

When the red light starts to blink (indicating low power in battery) the table

will operate for approximately 5 continuous minutes, typically long enough

to use the table for the rest of the day.

NOTE

The charging system operates ONLY

when the table is in AC120V operation

mode.

c. To recharge the battery, make sure the power

cord is connected, plugged into a 120VAC wall

outlet and the main POWER SWITCH - ON.

NOTE

The table can be operated on 120VAC

power while the battery is being recharged.

During charging, the bars will light in sequence to

the respective charge level, turn off and light in

sequence again.

BATTERY

INDICATOR

Figure 2-3. Battery Indicator

d. A full battery charge will last approximately 2

weeks under normal operating conditions. However, it is recommended to charge the batteries at

the end of each week to establish a normal routine

protocol. Lead acid batteries last longer if they are

not permitted to fully discharge. The table features

(2) 12 volt, sealed, lead acid batteries which require no manual maintenance. Lead acid gel batteries, under a proper charging program, feature

an approximate normal life of 4 years.

NOTE

If the table is stored for a period greater

than 6 months, the batteries should be

removed and stored in a dry, clean condition at a storage temperature of 68° F

(20° C). Batteries should be recharged

every 6 months of product storage.

2-6. Positioning Functions

Page 15

The hand-held pendant control (figure 2-4) activates the following table functions:

TRENDELENBURG

REVERSE

LATERAL

TILT LEFT

BACK UP

TABLE UP

(BRAKE LOCK)

SLIDE HEAD

LEG UP

FLEX

KIDNEY

LIFT UP

RETURN

TO LEVEL

BATTERY

AC120V POWER ON

INDICATOR LIGHT

(GREEN)

TRENDELENBURG

LATERAL

TILT RIGHT

BACK DOWN

TABLE DOWN

SLIDE FOOT

LEG DOWN

REFLEX

KIDNEY

LIFT DOWN

BRAKE

UNLOCK

Figure 2-4. Pendant Control Function Buttons

a. Floor Lock/Brake System. To activate the

brakes without affecting table positioning, press

the TABLE UP button. See figure 2-5. The

elevation cylinder will not function until the brakes

are completely extended.

Press the BRAKE UNLOCK button on the pendant

control to release the four self-leveling brake feet in

order to move the table. See figure 2-5. The brake

delay circuit automatically retracts the brake system. It takes approximately 7-8 seconds to totally

release the system.

WARNING

•DO NOT unlock brakes when a patient

is on the table. An uneven patient

weight load may cause instability.

•If circumstances demand table brakes

to be unlocked, the patient must be

centered and evenly distributed on the

table top (i.e. supine or prone position)

with the table lowered to its lowest

height position. The maximum patient

weight should not exceed 500 pounds.

Table top slide must be centered (indicated by a red LED light on the pendant

control) prior to unlocking brakes.

Patient's head must be on the head

section. Head section must be attached

in its normal orientation to the table's

back section.

•Prior to unlocking brakes, check for

obstructions on the floor that might

prevent the table from moving smoothly

to new location. Relock the brakes immediately once the final position is

reached and before commencing surgery. Brake should remain locked at all

times if patient weight exceeds 500

pounds.

TABLE UP

(BRAKE LOCK)

BRAKE

UNLOCK

Figure 2-5. Brake System Activation

NOTE

With an evenly distributed patient weight

load, all table positioning functions will

operate smoothly and quietly with a

patient weight of up to 600 pounds

(700 pounds lift).

Page 16

b. Trendelenburg. To place the table in a

Trendelenburg (head down) position, press the

TREND button (figure 2-6). Trendelenburg positioning of up to 25° may be obtained. To place the

table in a reverse Trendelenburg (head up) position, press the REV TREND button. Reverse

Trendelenburg positioning of up to 20° may be

obtained.

WARNING

To maximize patient safety, utilize

proper restraint methods during extreme

Trendelenburg positioning.

TRENDELENBURG

REVERSE

TRENDELENBURG

c. Lateral Tilt. To achieve lateral tilt right (as

viewed from the head end of the table), press the

TILT RIGHT button (figure 2-7). Tilt of up to 20° may

be obtained. To achieve lateral tilt left, press the TILT

LEFT button. Tilt of up to 20° may be obtained.

WARNING

To maximize patient safety, utilize

proper restraint methods during extreme

lateral tilt positioning.

LATERAL

TILT LEFT

LATERAL

TILT RIGHT

20˚

25˚

Figure 2-6. Trendelenburg Positioning

20˚ 20˚

Figure 2-7. Lateral Tilt Positioning

Page 17

45"

TABLE

UP

TABLE

DOWN

26"

d. Back Section. To raise the back section,

press the BACK UP button (figure 2-8). The back

section will raise up to 90° above horizontal. To

lower the back section, press the BACK DOWN

button. The back section will go down to 40° below

horizontal.

NOTE

If the table top is slid toward the foot

end, the back section will not go below

horizontal. An audible alarm will sound.

NOTE

To prevent damage to the kidney lift, a

safety interlock prevents the back section from going more than 45° above

horizontal if the kidney lift is not all the

way down. An audible alarm will sound.

e. Elevation. To raise table top, press the

TABLE UP button (figure 2-9). The table will lift a

patient weight of 700 pounds up to a maximum

height of 45". To lower the table top, press the

TABLE DOWN button. The table top will go down

to a minimum height of 26" (minus pad).

BACK UP

90˚

40˚

BACK DOWN

Figure 2-8. Back Section Positioning

Figure 2-9. Elevation Function

Page 18

f. Top Slide. To move the table top toward the

head end, press the SLIDE HEAD button. From

center position, the top will slide up to 7-1/2". See

figure 2-10.

NOTE

If the leg section is positioned more

than 45° below horizontal, the top will

not slide toward the head end. An

audible alarm will sound.

To move the table top toward the foot end, press

the SLIDE FOOT button. From center position, the

top will slide up to 13-1/2". Slide function will stop

and SLIDE/CTR Indicator will illuminate when table

is centered.

NOTE

g. Leg Section. To lower the leg section, press

the LEG DOWN button (figure 2-11). The leg

section will go down to 98° below horizontal. To

raise the leg section, press the LEG UP button.

The leg section will go up to level.

CAUTION

The Leg section may hit the table base

or the floor if both the leg and elevation

systems are placed in their full down

position.

NOTE

If the top is slid toward the head end, the

leg section will only go down 45°. An

audible alarm will sound.

If the back section is positioned below

horizontal, the top will not slide toward

the foot end. An audible alarm will

sound.

SLIDE HEAD

7-1/2"

SLIDE FOOT

13-1/2"

LEG UP

LEG DOWN

2˚

98˚

Figure 2-10. Top Slide

Figure 2-11. Leg Section Positioning

h. Flex Positioning. To place the table top in

a flex position from horizontal, press the FLEX

button (figure 2-12). To return the table top to a

horizontal position or into a reflex position, press

the REFLEX button.

Page 19

NOTE

When FLEX button is activated and if

the top is slid toward the foot end, the

back section will not go below horizontal. An audible alarm will sound.

FLEX

REFLEX

KIDNEY UP

5-1/2"

KIDNEY DOWN

Figure 2-13. Kidney Lift Positioning

j. Return To Level. To return the table top to a

level position, press the LEVEL button (figure 2-14).

NOTE

Figure 2-12. Flex/Reflex Positioning

i. Kidney Lift. To raise the built-in kidney lift,

press the KIDNEY UP button (figure 2-13). Up to

5-1/2" of lift can be achieved. Press the KIDNEY

DOWN button to lower the kidney lift.

NOTE

Return to Level will lower the kidney lift.

NOTE

To prevent damage to the kidney lift, a

safety interlock prevents the kidney lift

from going up if the back section is 45°

above horizontal. An audible alarm will

sound .

Elevation and brake system functions

are not affected by the return to level

function.

RETURN

TO LEVEL

Figure 2-14. Return To Level

Page 20

2-7. Emergency Back-up Controls

a. The emergency back-up control switches are

located under the access door on the service

access cover in the table base. See figure 2-15.

REV

TREND

TILT

BACKUPTABLEUPLEGUPBRAKE

RIGHT

LOCK

FUNCTION CONTROL

ACCESS DOOR

Figure 2-15. Emergency Controls Location

b. In the event of either a power failure or a

problem with the hand-held pendant control, the

table can be operated using the emergency backup switches. Simply push the desired emergency

switch in the appropriate direction to operate the

table functions. See figure 2-16.

CAUTION

TREND TILT

LEFT

BACK

DOWN

TABLE

DOWN

LEG

DOWN

KIDNEY

DOWN

Figure 2-16. Emergency Back-Up Controls

CAUTION

The EMERGENCY BRAKE LOCK

switch does not activate the brake system timer. The switch must be held

until the brakes are completely locked,

approximately 10 seconds.

NOTE

The emergency back-up control

switches will function when the table is

operating on 120VAC power, battery

power, or turned off.

The safety interlock system is not operational when the emergency backup control switches are used.

c. Switches are provided for Trendelenburg,

lateral tilt, back section, elevation, leg section,

kidney down and brake lock. These switches are

spring-loaded so they return to the neutral or

center position when released.

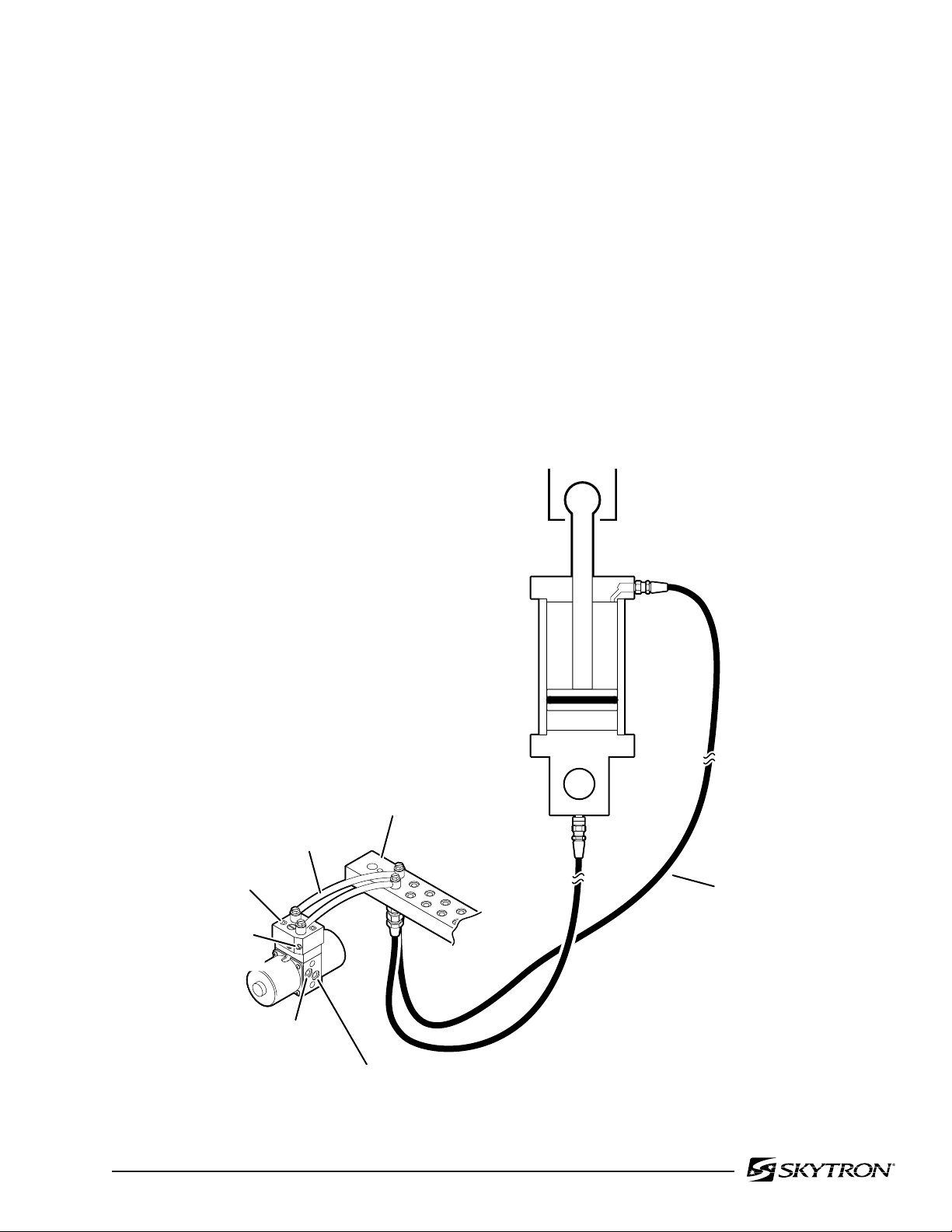

2-8. Emergency Brake Release.

SERVICE ACCESS

COVER

POWER

CORD

EMERGENCY

BRAKE RELEASE

BRAKE (4)

In case of a power failure or an electrical problem

within the table, the emergency brake release

system can be used to move the table. The control

knob for this function is located on the side of the

table base and is identified by an EMERGENCY

BRAKE RELEASE label. Turn the knob counterclockwise to release the brakes. See figure 2-17.

WARNING

•DO NOT unlock brakes when a patient

is on the table. An uneven patient

weight load may cause instability.

Page 21

•If circumstances demand table brakes

to be unlocked, the patient must be

centered and evenly distributed on the

table top (i.e. supine or prone position)

with the table lowered to its lowest

height position. The maximum patient

weight should not exceed 500 pounds.

Table top slide must be centered (indicated by a green LED light on the

pendant control) prior to unlocking

brakes. Patient's head must be on the

head section. Head section must be

attached in its normal orientation to the

table's back section.

•Prior to unlocking brakes, check for

obstructions on the floor that might

prevent the table from moving smoothly

to new location. Relock the brakes immediately once the final position is

reached and before commencing surgery. Table brakes should remain locked

at all times if patient weight exceeds

500 pounds.

Figure 2-17. Emergency Brake Release

NOTE

The Emergency Brake Release Valve

must be closed and tightened (clockwise) before activating any function.

•If the Emergency Brake Release Valve

has been operated, the UNLOCK button

on the pendant control will have to be

pressed before brakes will lock again.

Page 22

2-9. Head Section

a. A quick release positioning bar located under

and to the front of the head section (figure 2-18) is

used to raise or lower the head section. Pull the

release bar toward the head end to allow the

section to pivot up or down. Positioning from 60°

above horizontal to 90° below horizontal in 15°

increments is available. Release the bar to lock the

head section in position.

HEAD SECTION

RELEASE BAR

Figure 2-18. Head Section Adjustment

2-10. Leg Section Removal.

NOTE

The leg section with the x-ray top + pad

attached weighs 31 lbs. It is recommended that the x-ray top and pad be

removed before detaching the leg section.

a. To remove the leg section, position the table

top height to elbow height, and simultaneously

depress both release levers and pull the leg section

out. See figure 2-20. Press the LEG-DOWN

button on the pendant control to position the leg

section attachment pins down and out of the way.

FOOT/LEG SECTION

b. By loosening two locking knobs beneath the

back section, an additional 2" of longitudinal adjustment can be achieved. If desired, the head

section may be removed by loosening the locking

knobs and pulling it straight out of the back section.

3501B EZ Slide Table has the capability of attaching the head section to the leg section

for use as a

foot extension ONLY. Do Not reverse the patient

on the table without first consulting with SKYTRON.

Two locking knobs are located on the inside of the

leg section for securing the head section. See

figure 2-19.

HEAD

SECTION

LOCKING

KNOB

FOOT/LEG

SECTION

LOCKING

KNOB

(RECESSED)

LOCKING

LEVERS

Figure 2-20. Leg Section Release Levers

b. To Install Leg Section, press and hold the

LEG-UP button until the leg section attachment

pins completely stop before reinstalling the leg

section to the table. Pull out on the leg section after

installation to make sure the release levers are

completely locked.

Figure 2-19. Repositioning Head Section

(for use as a Foot Extension)

WARNING

Consult manufacturer's instructions

when using high frequency surgical

equipment, cardiac defibrillator and cardiac defibrillator monitors.

WARNING

When an antistatic pathway is required,

the table has to be used on an antistatic

floor.

Page 23

2-11. Positioning

The use of certain optional accessories available

from SKYTRON further extend the positioning

capabilities of the 3501B E-Z Slide Table. Refer to

the following "Positioning Guidelines" or contact

your SKYTRON representative for further details.

WARNING

Certain accessories may limit weight

capacities. Check with your SKYTRON

representative.

CAUTION

WARNING

The antistatic properties of the table

are dependent on the use of the original

pad set which was furnished with the

table or an alternate approved replacement.

Consult SKYTRON prior to using accessories produced by other manufacturers.

Page 24

SECTION III MAINTENANCE

3-1. Preventive Maintenance

The following preventive maintenance checks and

services are recommended to ensure the serviceability and proper operation of your SKYTRON

Surgical Table, and should only be performed by

qualified SKYTRON trained personnel.

a. During normal cleaning, a general visual

examination should be made checking for leaks,

loose bolts or parts, and cracked, chipped, or

missing paint. Any necessary repairs should be

made.

b. Semi-annually the following checks and ser-

vices should be performed:

1. Check all hydraulic fittings, mini-valves and

slave cylinders for proper operation and

any signs of leaks.

2. Check the hydraulic speed controls and

adjust if necessary.

3. Pressure check (with a gauge) the pressure relief valve.

4. Check all mechanical adjustments and adjust as necessary.

3-2. Cleaning Recommendations

NOTE

Always follow current AORN Journal

Guidelines to ensure proper cleaning

and disinfection procedure.

The following procedures should be followed when

cleaning the surgical table between cases.

Place table top in level position prior to starting

cleaning procedure.

WARNING

Always follow OSHA blood-borne pathogens standards for protective clothing,

including gloves, masks and eye protection when cleaning the surgical table.

Remove major contaminants from the table with

disposable materials following appropriate biohazard waste disposal procedures.

5. Check hydraulic fluid level.

6. Lubricate the slider assembly.

7. Check function of foot leg release levers,

lubricate as necessary.

Remove all table pads and place them on a flat

surface for cleaning.

CAUTION

Thoroughly read and follow the

manufacturer's directions for all cleaning fluids. DO NOT use cleaners containing phenolics.

Apply cleaning fluid liberally to top and sides of

each pad and wipe with a clean lint-free cloth.

Using a clean, damp, lint-free cloth, wipe the pads

to remove the cleaning fluid.

Using a clean, dry, lint-free cloth, wipe the pads to

remove all moisture.

3-3. Service

Page 25

Repeat the steps to clean the bottom of the each

pad.

CAUTION

When using spray cleaners DO NOT

spray fluids directly into electrical receptacles or micro switches.

Repeat cleaning procedure for all table surfaces

including the top, sides, elevation column, base

and all accessories.

CAUTION

Before replacing pads on the table, make

sure the pads and all mating surfaces

are completely dry. Moisture trapped

between the pads and mating surfaces

may cause distortion of table tops.

Table maintenance can be performed by trained

maintenance personnel using SKYTRON authorized replacement parts and service techniques.

Service instructions and parts are available from

SKYTRON.

Preventive Maintenance contracts are available

through your local SKYTRON representative.

To obtain service instructions, replacement parts,

factory service or preventive maintenance contracts, contact the SKYTRON representative listed

below.

WARNING

SKYTRON assumes no liability for table

performance, table damage or injury to

patient or staff when accessories not

sold or serviced by SKYTRON are

used on SKYTRON surgical tables.

When the cleaning procedure is complete, replace

all pads and accessories as applicable.

Remove pendant control from table side rail and

apply cleaning solution to the pendant control and

cord.

Use a clean cloth dampened with water to remove

cleaning solution.

Use another clean damp cloth to remove any

remaining residue.

Or contact:

SKYTRON

5000 36th Street S.E.

Grand Rapids, MI 49512

1-800-SKYTRON (1-800-759-8766)

Fax. 1-616-957-5053

Install pendant control on side rail for storage when

cleaning procedure is complete.

5000 36th Street S.E., Grand Rapids, MI 49512

1-800-SKYTRON or 1-616-957-0500 • FAX 1-616-957-5053

SURGICAL TABLE

PARTS CATALOG

1/07

3501B EZ SLIDE

INTRODUCTION

This manual contains the exploded views and replacement parts lists for the service-

able components of the SKYTRON Model 3501B EZ SLIDE Surgical Table.

Each serviceable part in these exploded views is identified by a reference number.

Use this number to locate necessary part information in the parts list adjacent to the exploded view.

Always use the complete SKYTRON part number and description when ordering

replacement parts.

Always use the complete table serial number (S.N.) when ordering replacement

parts.

Special Tools and Maintenance Items listed on page 40.

Page 1

Abbreviations

As Required ........................................... A/R

Optional ................................................... opt

Serial Number ....................................... S.N.

Not Shown............................................... NS

1/07

Although current at the time of publication, SKYTRON's policy of continuous development makes this

manual subject to change without notice.

Page 2

3501B EZ SLIDE EQUIPMENT LABELS

Page 3

15

16

14

13

12

11

10

1

2

3

4

5

6

7

4

8

9

D6-032-47

1

USE HEAD SECTION AS FOOT EXTENSION

ONLY - WHEN REVERSING PATIENT ON TABLE

REFER TO OPERATOR MANUAL.

WARNING

D6-017-05

4

5

D6-065-26

7

D6-011-32

DANGER - E

XPLOS

ION

H

AZARD.

DO

11

T

HE

PRESENCE OF

DANGER - RISQUE

EMPLOYER EN

INFLAMMABLES

FLA

D'E

PRE

MMAB

LE

ANAE

XPL

OSION. NE

SENCE

D'A

NOT USE IN

STHETICS

PAS

NESTHESIQUES

D6-032-46

2

DO NOT SIT ON END OF LEG SECTION(S) AS LOADS

IN EXCESS OF 140 LBS, MAY CAUSE INSTABILITY

THAT COULD CAUSE THE TABLE TO BE TIPPED OVER.

WARNING

D3-035-60 right D3-035-61 left

D6-067-33

8

D6-031-43

12

POSSIBL

IF USED IN THE PRESENCE OF

FLAMMABLE ANESTHETICS.

E E

XPLOSION

DANGER

9

HAZARD

3

L1-010-00

6

13

D6-035-38

Table Capacity:

Lift

7

00 lbs.

Articulate 6

See Operators

Manual for Limitations.

10

D6-065-22

00 lbs.

D6-011-34

THIS PRODUCT COMPLIES WITH RADIATION PERFORMANCE STANDARD 21 CFR

AT THE TIME OF MANUFACTURE

Manufactured:

Model No.

14

D6-034-21

D6-065-21

Grounding reliability can only be achieved when

15

the equipment is connected to an equivalent

receptacle marked "Hospital Only" or "Hospital Grade"

16

D6-067-27

TWIST TO LOCK OR RELEASE PLUG

Page 4

1. Head Section Assembly...................................... Page 8. 2. Back Section Assembly ...................................... Page 10.

3. Leg Section Assembly ...................................... Page 12. 4. Side Frame Assemblies ......................................Page 14.

Page 5

5. Back & Leg Section Cylinder Assemblies ......... Page 16. 6. Kidney Lift Assembly ........................................... Page 18.

7. Slide Assembly ................................................. Page 20. 8. Lateral Tilt Assembly........................................... Page 22.

Page 6

9. Trendelenburg Assembly .................................. Page 24. 10. Elevation Assembly ...........................................Page 28.

11. Hydraulic Components ................................... Page 30. 12. Electro Mini-Valve Assembly............................. Page 34.

Page 7

13. Pump & Electrical Components ...................... Page 36. 14. Base & Electrical Components ......................... Page 38.

Page 8

1. HEAD SECTION ASSEMBLY

3

1

2

4

31

30

17

27

29

18

26

28

24

25

23

22

17

21

7

9

8

10

11

5

6

12

13

14

16

15

19

3501B.0711.01

18

20

17

Page 9

1. HEAD SECTION ASSEMBLY

Item Part No. Description Qty.

1-010-55-P PAD SET, regular.........................................................................................................opt.

1-010-55-S PAD SET, soft ..............................................................................................................opt.

D3-067-00 COMPLETE HEAD SECTION .......................................................................................1

1 D3-010-19 SCREW, phillips head ...................................................................................................4

2 D3-067-01 TOP, head section ......................................................................................................... 1

3 D3-010-18-H VELCRO, hook ............................................................................................................A/R

4 5-010-01-8 BUSHING, x-ray top ...................................................................................................... 2

5 D4-010-14 O-RING, P-12 ................................................................................................................2

6 D3-067-02 SHAFT, extension, head section (roll pin) .....................................................................2

7 D6-050-33 PIN, roll, M5 x 20 ...........................................................................................................2

8 D3-032-80 GEAR, trunnion, right .................................................................................................... 1

D3-032-81 GEAR, trunnion, left ......................................................................................................1

9 D6-010-41-1 SCREW, set, M8 x 15 (plated).......................................................................................2

10 D6-010-38-1 BOLT, allen, M6 x 15 (plated) ........................................................................................ 2

11 D6-010-40-1 WASHER, lock, M6 (plated) ..........................................................................................2

12 D3-067-03 FRAME, head section ................................................................................................... 1

13 D3-034-22 BUSHING, head section ................................................................................................2

14 D6-010-53-1 BOLT, allen, M8 x 20 (plated) ........................................................................................ 2

15 D3-032-34 STUD, side rail mount, M8 x 45 .....................................................................................2

16 D3-067-04 RAIL, side, head section ...............................................................................................2

17 D3-032-35 STUD, side rail mount, M8 x 40 .....................................................................................4

18 D3-010-01 COLLAR, side rail .......................................................................................................... 6

19 D6-010-38 BOLT, allen, M6 x 15......................................................................................................4

20 D6-010-40 WASHER, lock, M6........................................................................................................4

21 D3-067-05 PLUNGER, release, right ..............................................................................................1

D3-067-06 PLUNGER, release, left.................................................................................................1

22 D6-010-13 NUT, hex, M8 .................................................................................................................6

23 D6-010-09 WASHER, lock, M8........................................................................................................6

24 D3-032-33 RAIL, accessory ............................................................................................................ 1

25 D3-067-07 SPRING, release ...........................................................................................................2

26 D3-032-40 BLOCK, bearing ............................................................................................................ 2

27 D6-010-11 SCREW, set, M5 x 8 (plated) ......................................................................................... 2

28 D6-010-13-1 NUT, hex, M8 (plated) .................................................................................................... 2

29 D3-010-24 RELEASE BAR, head section .......................................................................................1

30 D6-010-09 WASHER, lock, M8........................................................................................................2

31 D6-010-08 NUT, acorn, M8 ............................................................................................................. 2

Page 10

2. BACK SECTION ASSEMBLY

1

2

3

21

22

20

19

18

16

15

17

9

12

10

14

11

4

5

6

7

8

13

3501B.0711.02

Page 11

2. BACK SECTION ASSEMBLY

Item Part No. Description Qty.

1-010-55-P PAD SET, regular .........................................................................................................opt.

1-010-55-S PAD SET, soft ..............................................................................................................opt.

1 D3-035-37 TOP, seat section ...........................................................................................................1

2 D3-010-18-H VELCRO, hook ............................................................................................................A/R

3 D3-035-01 TOP, seat section, small ................................................................................................1

4 D3-010-19 SCREW, phillips ..........................................................................................................A/R

5 D3-035-45 TOP, back section .......................................................................................................... 1

6 D6-032-28 BOLT, allen ....................................................................................................................2

7 D3-035-34 CAP, back section .......................................................................................................... 1

8 D6-010-50 SCREW, set M6 x 15 .....................................................................................................4

9 D3-032-21 BUSHING, back section ................................................................................................2

10 D3-035-41 GEAR, spur, back section .............................................................................................2

11 D6-032-30 PIN, spur gear ............................................................................................................... 4

12 D3-035-46 FRAME, back section, right ...........................................................................................1

D3-035-47 FRAME, back section, left .............................................................................................1

13 D3-032-36 CAP, back section, axis ................................................................................................. 2

14 D3-035-48 SIDE RAIL, back section, right ......................................................................................1

D3-035-49 SIDE RAIL, back section, left ........................................................................................ 1

15 D3-010-41 PIN, rail stop .................................................................................................................. 2

16 D3-010-43 RAIL STOP, large ..........................................................................................................2

17 D3-032-34 STUD, side rail mount, M8 x 45 .....................................................................................6

18 D3-010-01 COLLAR, side rail .......................................................................................................... 6

19 D6-010-09-1 WASHER, lock, M8 (plated) ..........................................................................................6

20 D6-010-13-1 NUT, M8 (plated) ........................................................................................................... 6

21 D6-060-38 SCREW, set, M5 x 10 ....................................................................................................2

22 D3-010-17 KNOB, retaining .............................................................................................................2

Page 12

3. LEG SECTION ASSEMBLY

1

2

3

4

17

19

18

16

15

14

23

21

20

13

5

6

12

10

11

10

7

8

9

25

26

24

22

3501B.0711.03

Page 13

3. LEG SECTION ASSEMBLY

Item Part No. Description Qty.

1-010-55-P PAD SET, regular .........................................................................................................opt.

1-010-55-S PAD SET, soft ..............................................................................................................opt.

1 D3-035-50 TOP, foot / leg section....................................................................................................1

2 D3-010-18-H VELCRO, hook ............................................................................................................A/R

3 D3-010-19 SCREW, phillips ...........................................................................................................10

4 D6-031-01 KNOB, locking ............................................................................................................... 2

5 D3-035-51 FRAME, foot / leg section, right ..................................................................................... 1

D3-035-52 FRAME, foot / leg section, left .......................................................................................1

6 D3-010-43 STOP, rail, large .............................................................................................................2

7 D3-010-41 PIN, rail stop ..................................................................................................................2

8 D3-035-53 RAIL, side, foot / leg section, right .................................................................................1

D3-035-54 RAIL, side, foot / leg section, left ...................................................................................1

9 D3-032-35 STUD, side rail mount, M8 x 40 .....................................................................................2

10 D3-032-34 STUD, side rail mount, M8 x 45 .....................................................................................4

11 D3-010-01 COLLAR, side rail .......................................................................................................... 6

12 D6-010-09-1 WASHER, lock, M8 (plated) ..........................................................................................6

13 D6-010-13-1 NUT, M8 (plated) ........................................................................................................... 6

14 D3-032-51 SPRING, back section, right ..........................................................................................1

D3-032-51-1 SPRING, back section, left ............................................................................................1

15 D6-010-65-1 BOLT, allen, M5 x 35 (plated) ........................................................................................ 2

16 D6-032-37 PIN, roll, M4 x 30 ...........................................................................................................2

17 D6-010-87 SCREW, set, M6 x 20 ....................................................................................................2

18 D3-034-31 LEVER, axis, foot / leg section, right .............................................................................1

D3-034-32 LEVER, axis, foot / leg section, left ...............................................................................1

19 D3-030-05 AXIS, foot / leg section ..................................................................................................2

20 D3-035-55 LEVER, release, right .................................................................................................... 1

D3-035-56 LEVER, release, left ......................................................................................................1

21 D6-067-01 SCREW, phillips, button head, M3 x 8 ...........................................................................2

22 D6-010-79 SCREW, phillips, button head, M3 x 5 ...........................................................................2

23 D3-035-57 HINGE ........................................................................................................................... 2

24 D3-034-46 STOP, rubber .................................................................................................................2

25 D6-010-76 NUT, hex, M5 .................................................................................................................2

26 D6-010-83 BOLT, allen, M5 x 30 ...................................................................................................... 2

Page 14

4. SIDE FRAME ASSEMBLIES

6

5

7

8

4

2

1

3

9

11

15

17

18

10

14

12

13

16

19

22

32

31

20

30

21

29

23

24

26

25

27

28

3501B.0711.04

Page 15

4. SIDE FRAME ASSEMBLIES

Item Part No. Description Qty.

1 D6-060-07 BOLT, allen, M4 x 8 ........................................................................................................ 2

2 D6-035-19 WASHER, flat, M4 .........................................................................................................2

3 D5-036-07 MICRO-SWITCH ........................................................................................................... 1

4 D5-036-08 BRACKET, micro-switch mounting ................................................................................1

5 D3-035-08 FRAME, side, left...........................................................................................................1

6 D6-066-18 SCREW, countersunk phillips, M4 x 15 .........................................................................4

7 D5-032-17 MICRO-SWITCH ........................................................................................................... 2

8 D3-035-20 BRACKET, micro-switch mounting, left ..........................................................................1

D3-035-21 BRACKET, micro-switch mounting, right .......................................................................1

9 D3-035-58 COVER, micro-switch .................................................................................................... 1

10 D6-035-04 SCREW, phillips, M4 x 6 ................................................................................................2

11 D3-035-20 BRACKET, slide bar, left ................................................................................................ 1

12 D6-010-53 BOLT, allen, M8 x 20 ...................................................................................................... 8

13 D3-035-22 ACTUATOR, slide, micro-switch .................................................................................... 1

14 D6-010-28-1 BOLT, allen, M5 x 6........................................................................................................3

15 D3-035-19 BAR, slide ...................................................................................................................... 2

16 D6-010-33 BOLT, allen, M8 x 25 ...................................................................................................... 8

17 D3-035-13 COVER, hose, left .........................................................................................................1

D3-035-14 COVER, hose, right .......................................................................................................1

18 D6-043-10 SCREW, phillips, M4 x 8 ................................................................................................6

19 D3-035-59 BRACKET, slide bar, right ..............................................................................................1

20 D6-010-13-1 NUT, M8 (plated) ........................................................................................................... 6

21 D6-010-09-1 WASHER, lock, M8 (plated) ..........................................................................................6

22 D3-035-07 FRAME, side, right ........................................................................................................ 1

23 D3-035-60 NAMEPLATE, decal, 3501B, right ................................................................................. 1

D3-035-61 NAMEPLATE, decal, 3501B, left ................................................................................... 1

24 D3-010-43 STOP, rail (large) ...........................................................................................................2

25 D3-010-41 PIN, rail stop .................................................................................................................. 2

26 D3-032-34 STUD, side rail mount, M8 x 45 .....................................................................................6

27 D3-035-04 SIDE RAIL, seat section, right .......................................................................................1

D3-035-05 SIDE RAIL, seat section, left .........................................................................................1

28 D3-010-01 COLLAR, side rail .......................................................................................................... 6

29 D3-035-30 AXIS, eccentric cam ......................................................................................................2

30 D6-035-05 SCREW, set, M6 x 8 ......................................................................................................2

31 D3-035-29 ROLLER, support .......................................................................................................... 2

32 D3-035-28 SPACER, nylon .............................................................................................................. 2

Page 16

5. BACK & LEG SECTION CYLINDER ASSEMBLIES

1

30

29

2

25

26

27

31

33

30

32

34

35

12

7

6

28

8

9

11

10

8

3

4

5

8

36

37

38

30

13

29

14

41

40

15

39

18

16

19

20

21

17

20

22

30

29

31

23

32

30

20

24

34

42

43

44

38

3501B.0711.05

Page 17

5. BACK & LEG SECTION CYLINDER ASSEMBLIES

Item Part No. Description Qty.

D4-035-06-1 CYLINDER ASSEMBLY, leg section, left .......................................................................1

D4-035-06-2 CYLINDER ASSEMBLY, leg section, right .....................................................................1

1 ----- •RAM .............................................................................................................................1

2 D4-036-67 •PENTASEAL, PS-22A ..................................................................................................1

3 D6-010-55 •NUT, M8 .......................................................................................................................4

4 ----- •HEAD CAP ................................................................................................................... 1

5 D4-035-07 •STUD ........................................................................................................................... 4

6 ----- •PISTON ........................................................................................................................1

7 D4-010-02 •O-RING, P-14 ...............................................................................................................1

8 D4-010-54 •O-RING, P-34 ...............................................................................................................3

9 D6-010-42 •WASHER, lock, M10 ....................................................................................................1

10 D6-010-43 •NUT, M10 ..................................................................................................................... 1

11 ----- •CYLINDER ...................................................................................................................1

12 ----- •TAIL CAP ...................................................................................................................... 1

D4-035-04-1 CYLINDER ASSEMBLY, back section, left .................................................................... 1

D4-035-04-2 CYLINDER ASSEMBLY, back section, right ..................................................................1

13 ----- •RAM ............................................................................................................................. 1

14 D4-036-67 •PENTASEAL, PS-22A ..................................................................................................1

15 D6-010-55 •NUT, M8 ....................................................................................................................... 4

16 ----- •HEAD CAP ................................................................................................................... 1

17 D4-035-05 •STUD ........................................................................................................................... 4

18 D4-010-02 •O-RING, P-14 ............................................................................................................... 1

19 ----- •PISTON ........................................................................................................................ 1

20 D4-010-54 •O-RING, P34 ................................................................................................................3

21 D6-010-42 •WASHER, lock, M10 .................................................................................................... 1

22 D6-010-43 •NUT, M10 ..................................................................................................................... 1

23 ----- •CYLINDER ...................................................................................................................1

24 ----- •TAIL CAP ...................................................................................................................... 1

25 D6-036-08 CIRCLIP ........................................................................................................................2

26 D6-036-07 CLEVIS .......................................................................................................................... 2

27 D6-036-06 PIN, clevis......................................................................................................................2

28 D6-010-34 SCREW, set, M6 x 6 ......................................................................................................2

29 D4-010-29 FITTING, hydraulic, 90° elbow .................................................................................... A/R

30 ----- HOSE, flexible (specify function) ................................................................................. A/R

31 D6-010-53 BOLT, allen, M8 x 20 ...................................................................................................... 4

32 D4-036-05 PLATE, cylinder mounting, left ...................................................................................... 1

D4-036-06 PLATE, cylinder mounting, right ....................................................................................1

33 D6-010-87 SCREW, set, M6 x 20 ....................................................................................................2

34 D4-031-06 FITTING, flexible hose.................................................................................................A/R

35 D4-010-01 O-RING, P8 ...................................................................................................................1

36 D4-035-15-2 BLOCK, plumbing, left ................................................................................................... 1

D4-035-15-1 BLOCK, plumbing, right .................................................................................................1

37 D6-032-09 BOLT, allen, M5 x 50 ...................................................................................................... 2