UNCRATING INSTRUCTIONS

8/05

MODEL 3002

IMAGING TABLE

3002 IMAGING TABLE UNCRATING INSTRUCTIONS

NOTE

Always contact your SKYTRON representative prior to uncrating and use to

ensure proper performance and safety.

IMPORTANT

Assistance by a second individual or

employment of lifting devices is recommended. Always practice OSHA recommended safety procedures when

lifting to avoid personal injury and damage

to the product.

RECOMMENDED TOOLS FOR UNCRATING:

Claw hammer, nail puller, crow-bar, razor knife,

adjustable wrench, pliers, torque wrench (at least

40 ft. lbs.) - 3/8" drive, 10mm Allen socket - 3/8"

drive, 8mm Allen socket - 3/8" drive, 19mm open

end wrench. An electrical power outlet must also

be available.

2. Remove the strap securing the box to the top of

the service access cover and remove the brace.

See figure 2. The box contains: power cord, pendant control, joystick control, hydraulic tank vented

cap parts package, and the top retaining bolts.

BRACE

STRAP

Uncrating Procedure

1. Cut and remove the plastic straps and remove

the nails around the base of the crate. See figure

1. Remove the complete box top by lifting it

straight up over the table.

NAILS

STRAPS

Figure 2.

3. Use an adjustable wrench to remove the nuts

securing the cross tie(s). It may be necessary to

hold the threaded rod with a pair of pliers, or use

grips when removing the nuts. Remove cross ties.

See figure 3.

4. Remove the nails securing the positioning

blocks and remove the outer blocks and the front

center block.

REMOVE CROSS TIES

Figure 1.

NOTE

At this time, inspect the table thoroughly

for shipping damage. Notify the trucking company immediately if damage

has occurred.

REMOVE NAILS

Figure 3.

SHIPPING CAP

(PARTS PACKAGE)

WARNING LABEL VENTED CAP

5. Rock the table to one side and remove the lower

SHIPPING PLATE

SECURING BOLTS

SHIPPING

PLATE

blocks. See figure 4.

Figure 6.

10. Remove the 4 philips head screws securing the

Service Access Cover and carefully remove the

cover.

REMOVE LOWER BLOCKS

Figure 4.

6. Slide the end of the table off from the crate base

(figure 5) and position it so that just the edge of the

table remains on the crate base.

The Parts package (refer to Step 2) contains a

vented cap (black) for the hydraulic tank and 2

spare Service Access Cover Screws.

11. Remove the clear shipping cap from the hydraulic tank (lift & pull) and replace it with the black

vented cap (snaps on) supplied. See figure 7.

7. Lift upward on the end of the table and slide the

crate base out from under the table and lower the

table gently.

8. Remove hardware securing Shipping Plate. Discard Shipping Plate and hardware. See Figure 6.

9. Check the crate thoroughly for table parts and

accessories before discarding. Pad set may be

attached to the crate top.

Figure 5.

Figure 7.

12. Cycle all control functions back and forth 2 or 3

times to purge any air from the system.

13. Check hydraulic fluid level. To do this, the table

elevation should be completely down and all other

controls in thir neutral position.

14. Check hydraulic connections for oil leaks.

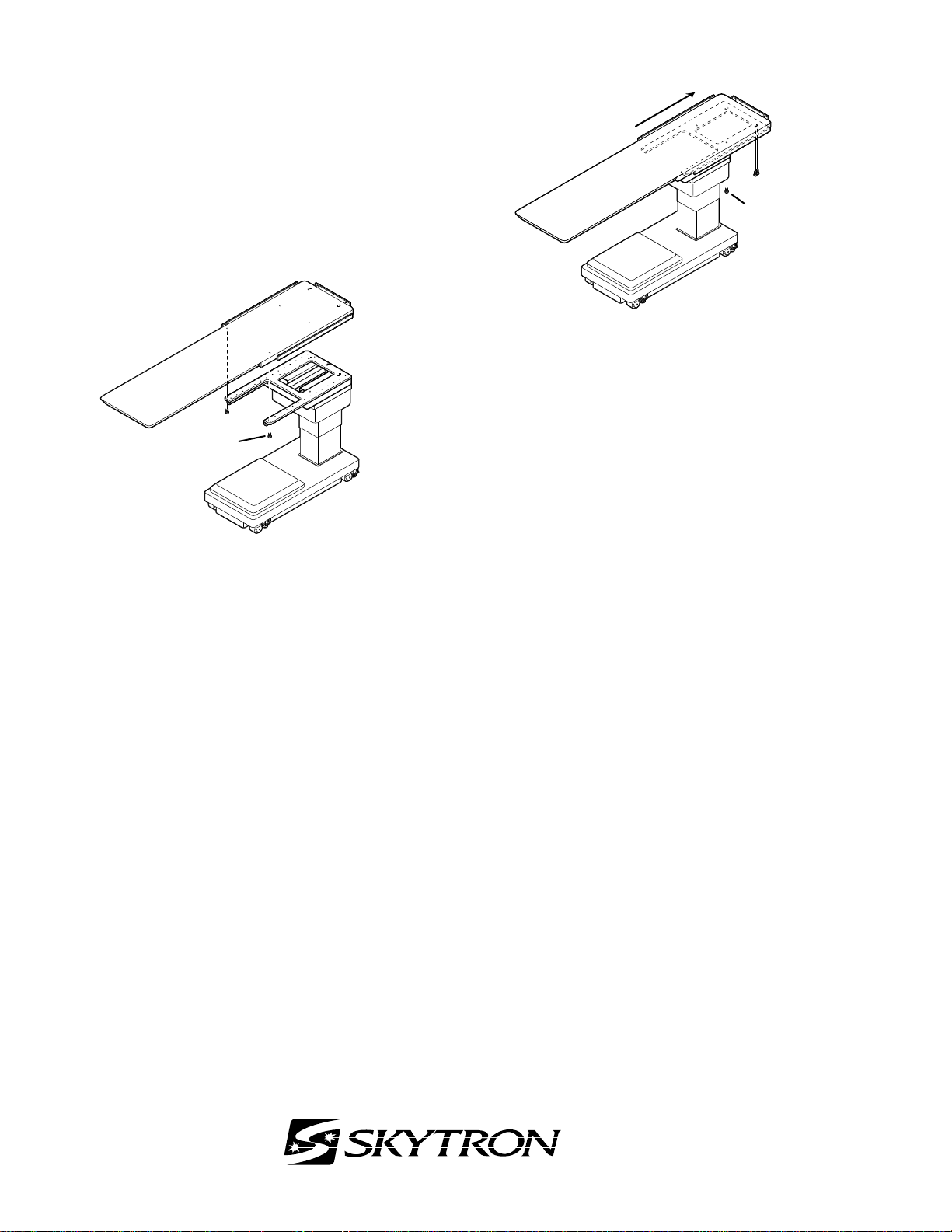

Top Installation Procedure

6)

The carbon fiber top is shipped in a separate crate

along with the table.

SLIDE

1. Remove the Table Top from the crate, align the

top with the base, and install (2) of the M12X30

bolts provided. See figure 8.

BOLT

M12X30 (2)

Figure 8.

3. Plug power cord into 120 VAC outlet, turn Main

Power Switch ON, and use the hand control to slide

the table top as shown in figure 9. Install the (6)

remaining M12X30 bolts.

BOLT

M12X30 (

Figure 9.

4. Torque all of the bolts to 40 ft. lbs. DO NOT

overtighten. Doing so will damage the top.

NOTE

The bolts supplied with the table are

custom made. Do not use bolts other

than the ones supplied with the table to

ensure proper operation.

Always consult with your SKYTRON representative prior to placing the unit into use.

IMPORTANT

Cycle all functions to be sure the table

operates correctly before delivering to

the surgery area.

1skytron/tables/uncrating instructions/3002

5000 36th Street S.E., Grand Rapids, MI 49512

1-800-SKYTRON or 1-616-957-0500 • FAX 1-616-957-5053

Loading...

Loading...