Service and Maintenance Manual

Model

3606

8990300

OCTOBER 1999

ANSI

Foreword

SKY TRAK Model 3606

Service Manual

This manual is designed to provide the service technician with complete information on the maintenance and

repair of the Sky Trak International SKY TRAK Model

3606 rough-terrain material handler.

Particular effort has been made to produce a manual to

serve as a reference handbook for the experienced

service technician, but also provide essential step-bystep procedures for the professional development of

the less experienced person. Remember that even the

best manual in the world is no substitute for an appropriate education, skill development that comes through

experience alone, safety, wise and judicious discernment, and, ultimately, proper performance of service

procedures.

There are many variations in service environments and

skill levels of repair technicians, as well as procedures,

techniques, tools, and service parts. A ser vice manual

cannot possibly anticipate all such variations and

provide advice or cautions for each one. Accordingly,

any departure from the instructions in this manual must

take into consideration both personal safety as well as

vehicle integrity.

This service manual provides general directions for

accomplishing service and repair procedures with

tested, effective techniques. Following the procedures

in this manual will help assure safety and equipment

reliability. Appropriate service methods and proper

repair procedures are essential for the safety of the

individual doing the work, for the safety of the operator ,

and for the safe, reliable operation of the vehicle. All

references to the right side, left side, front, and rear are

given from the perspective of the operator's position,

facing forward (see figure below).

Section Contents

The

allows the user to quickly locate

any desired section. Each section begins with its own

table of contents, and, where applicable, an informative

introduction and exploded-view illustration appears, to

show the location of major section components.

Provision for supplementary information is made by

Trak International in the form of Service Bulletins,

Service Campaigns, Service Training Schools, the

OmniQuip web site, other literature, and through

updates to the manual itself. Comments and suggestions for improvement are welcomed and encouraged.

All information, illustrations and specifications contained in this manual are based on the latest product

information available at the time of publication

approval. Trak reserves the right to make changes and

improvements to its products, and to discontinue the

manufacture of any product, at its discretion at any time

without public notice or obligation. When additional

information is desired to satisfy a situation not covered

sufficiently, consult the nearest Sky Trak International

distributor, or the Sky Trak International Service

Department at 1-414-268-8959.

LEFT

All references to direction are as viewed from the operator’s position, facing forward.

Model 3606 • Origin 10/99

FRONT

TOP

RIGHT

FRONT REAR

BOTTOM

MS2240

REAR

© 1999 Sky Trak International

i

Section Cont ents

Section Subject Page

Section 1 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.2 OWNERS/OPERATORS MANUAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.3 SAFETY INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.4 ACCIDENT PREVENTION TAGS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.5 SAFETY INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1.6 SAFETY DECALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Section 2 General Information, Specifications, and Maintenance . . . . . . . . . . . 2-1

2.1 REPLACEMENT PARTS AND WARRANTY INFORMATION. . . . . . . . . . 2-3

2.2 SERIAL NUMBER LOCATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.3 TORQUE VALUES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.4 SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2.5 FLUIDS, LUBRICANTS AND CAPACITIES . . . . . . . . . . . . . . . . . . . . . . . 2-9

2.6 CLEANING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

2.7 REPLACEMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

2.8 HOSES AND TUBES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

2.9 BEARINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

2.10 PRESSURE TESTING AND ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . 2-15

2.11 AFTER SERVICE STARTUP AND CHECKS . . . . . . . . . . . . . . . . . . . . . . 2-15

2.12 MAINTENANCE INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

2.13 EMERGENCY OPERATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-41

Section 3 Boom . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

INTRODUCTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.1 SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3.2 BOOM ASSEMBLY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3.3 QUICK-ATTACH ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-23

3.4 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-25

Section 4 Cab, Covers and Mirrors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

INTRODUCTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.1 SERIAL NUMBER DECAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

4.2 CAB REPLACEMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

4.3 CAB COVERS AND GUARDS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-21

Section 5 Axles, Wheels and Tires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

INTRODUCTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5.1 GENERAL INFORMATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

5.2 AXLE ASSEMBLIES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

5.3 WHEELS AND TIRES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

ii

Model 3606 • Origin 10/99

Section 6 Transfer Case and Drive Shafts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

INTRODUCTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

6.1 GENERAL INSTRUCTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

6.2 SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

6.3 TRANSFER CASE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

6.4 DRIVE SHAFTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

6.5 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

Section 7 Transmission: Clark-Hurth T 12000 . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

INTRODUCTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

7.1 TRANSMISSION SERIAL NUMBER . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

7.2 TRANSMISSION SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

7.3 TOWING A DISABLED VEHICLE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

7.4 TRANSMISSION MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

7.5 TRANSMISSION REPLACEMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

7.6 TRANSMISSION TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . 7-11

Section 8A Engine: Perkins 1004 Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8A1

INTRODUCTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8A-2

8A.1 SAFETY INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8A4

8A.2 PERKINS ENGINE SERIAL NUMBER. . . . . . . . . . . . . . . . . . . . . . . . . . . 8A6

8A.3 PERKINS SPECIFICA TIONSAND MAINTENANCE INFORMATION. . . . 8A6

8A.4 PERKINS ENGINE STANDARD PRACTICES . . . . . . . . . . . . . . . . . . . . . 8A6

8A.5 PERKINS ENGINE COOLING SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . 8A6

8A.6 PERKINS ENGINEELECTRICAL SYSTEM . . . . . . . . . . . . . . . . . . . . . . . 8A10

8A.7 PERKINS ENGINE FUEL SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8A10

8A.8 PERKINS ENGINE EXHAUST SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . 8A15

8A.9 PERKINS ENGINE REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8A16

8A.10 PERKINS ENGINE STORAGE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8A22

8A.11 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8A24

Section 8B Engine: Cummins 4BT3.9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8B-1

INTRODUCTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8B-2

8B.1 SAFETY INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8B-4

8B.2 CUMMINS ENGINE SERIAL NUMBER . . . . . . . . . . . . . . . . . . . . . . . . . . 8B-6

8B.3 CUMMINS SPECIFICATIONS AND MAINTENANCE INFORMATION. . . 8B-6

8B.4 CUMMINS ENGINE STANDARD PRACTICES . . . . . . . . . . . . . . . . . . . . 8B-6

8B.5 CUMMINS ENGINE COOLING SYSTEM. . . . . . . . . . . . . . . . . . . . . . . . . 8B-6

8B.6 CUMMINS ENGINE ELECTRICAL SYSTEM. . . . . . . . . . . . . . . . . . . . . . 8B-10

8B.7 CUMMINS ENGINE FUEL SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8B-10

8B.8 CUMMINS ENGINE EXHAUST SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . 8B-15

8B.9 CUMMINS ENGINE REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . 8B-16

8B.10 CUMMINS ENGINE STORAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8B-22

8B.11 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8B-23

Model 3606 • Origin 10/99

iii

Section 9 Hydraulic System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

INTRODUCTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

9.1 SAFETY INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-4

9.2 SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-4

9.3 HYDRAULIC PRESSURE DIAGNOSIS . . . . . . . . . . . . . . . . . . . . . . . . . . 9-4

9.4 HYDRAULIC FLUID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-8

9.5 HOSES, TUBE LINES, FITTINGS, ETC. . . . . . . . . . . . . . . . . . . . . . . . . . 9-9

9.6 HYDRAULIC RESERVOIR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-10

9.7 HYDRAULIC SYSTEM PUMP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-12

9.8 HYDRAULIC CIRCUITS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-19

9.9 VALVES AND MANIFOLDS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-64

9.10 CYLINDERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-86

9.11 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-117

Section 10 Electrical System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

INTRODUCTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-3

10.1 SERVICE WARNINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-7

10.2 SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-8

10.3 EFFECTIVE GROUND CONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . 10-8

10.4 WIRING HARNESSES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-9

10.5 FUSES AND RELAYS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-36

10.6 ENGINE START CIRCUIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-37

10.7 CHARGING CIRCUIT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-42

10.8 ELECTRICAL SYSTEM COMPONENTS. . . . . . . . . . . . . . . . . . . . . . . . . 10-49

10.9 ELECTRICAL SYSTEM TROUBLESHOOTING. . . . . . . . . . . . . . . . . . . . 10-84

iv

Model 3606 • Origin 10/99

Section 1

Safety

Contents

PAR. TITLE PAGE

1.1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.2 OWNERS/OPERATORS MANUAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.3 SAFETY INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.3.1 Safety Alert Symbol. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.3.2 Signal Words. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.4 ACCIDENT PREVENTION TAGS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.5 SAFETY INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1.5.1 Personal Hazards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1.5.2 Equipment Hazards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1.5.3 General Hazards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1.5.4 Operational Hazards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1.6 SAFETY DECALS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Model 3606 • Origin 10/99

1-1

Section 1

1.1 INTRODUCTION

Sky Trak International (hereafter, Sky Trak) products

meet all applicable industry safety standards. Sky Trak

actively promotes safe practices in the use and maintenance of its products through training programs, instructional manuals, and the pro-active efforts of all

employees involv ed in engineering, design, manufacture,

marketing and service.

Many factors contribute to unsafe conditions: carelessness,

fatigue, overload, inattentiveness, unfamiliarity, even

drugs and alcohol, among others. Although equipment

damage can usually be repaired in a brief period of time,

death and irreparable injury are permanent. For optimal

safety, encourage everyone to think, and to act, safely.

Read, understand and follow the information in this manual, and obey all locally-approved safety practices, procedures, rules, codes, regulations and laws. Prior to

performing any maintenance on the vehicle, consider all

factors, circumstances and conditions which can have an

effect upon the safety of personnel and equipment, and

take appropriate action to ensure the safety of all

involved.

These instructions cannot cover all details or variations in

the equipment, procedures, or processes described, nor

provide directions for meeting every possible contingency

during operation, maintenance, or testing. When additional

information is desired to satisfy a situation not covered

sufficiently, consult the local Sky Trak distributor or the

Sky Trak Service Department at 1-800-439-8959.

1.2 OWNERS/OPERATORS MANUAL

The vehicle must be driven and operated a s a consequence

of, or when performing, service, maintenance and test procedures. The service technician must, therefore, thoroughly read, understand, and follow the

Owners/Operators Manual

.

An owners/operators manual is supplied with each vehicle

and must be kept in the holder or storage compartment

located to the left and below the operators seat (for vehicles without the closed cab option, see Fig. 1–1; for vehicles with the closed cab option, see Fig. 1–2).

In the event that the owners/operators manual is missing,

consult the local Sky Trak distributor or the Sky Trak Service Department before proceeding.

Sky Trak 3606

WITHOUT CLOSED CAB

Seat Base (ref.)

Owners/Operators

Manual Holder

FRONT

Figure 1–1. The Owners/Operators Manual holder is

located beneath the seat (

FRONT

Seat Base

(ref.)

Owners/Operators

Manual Holder

Figure 1–2. The Owners/Operators Manual holder is

located at the left side of the seat base (

without

closed cab option).

WITH CLOSED CAB

closed cab option

MS2630

MS2620

1.3 SAFETY INFORMATION

The following information provides general safety instructions, inclu ding signal words, hazard stat ement defin itions,

notification of hazards, methods to help avoid hazards,

and the consequences of failing to follow the safety

information. For safe maintenance of the vehicle, read,

understand and follow all DANGER, WARNING, and

CAUTION information.

The information in this manual does not replace any

other safety rules or proper judgment. Governmental

authorities and employers also have their own sets of

rules, codes, regulations and laws. Before starting work

at a site, check with the supervisor or safety coordinator

and ask about the safety policy. Learn the safety requirements in effect before operating, maintaining, servicing

or testing the vehicle. Safety depends on following safety

requirements.

).

1-2

Model 3606 • Origin 10/99

Safety

DANGER

DANGER

1.3.1 Safety Alert Symbol

The exclamation mark within a triangle is the Safety Alert

Symbol.

The Safety Alert Symbol means ATTENTION! BECOME

ALERT! YOUR SAFETY IS INVOLVED! The symbol is

used to attract attention to safety hazards found on

vehicle safety decals and throughout this manual.

The message that follows the symbol contains important

information about Safety. To avoid possible death or

injury, carefully read and follow all safety messages. Fully

understand the potential ca use s of death or inju ry.

Also, know where to obtain medical assistance, how to

use a first-aid kit and fire extinguisher/fire suppression

system. Keep emergency telephone numbers (fire and

police departments, ambulance, rescue squad or paramedics, etc.) nearby. If working alone, routinely check

with another person to help assure personal safety.

1.3.2 Signal Words

Three types of hazard statements are used in this manual. Each signal word indicates the existence and degree

of relative risk of the hazard described within the statement that follows the signal word. The three types of hazard statements use the following signal words:

DANGER

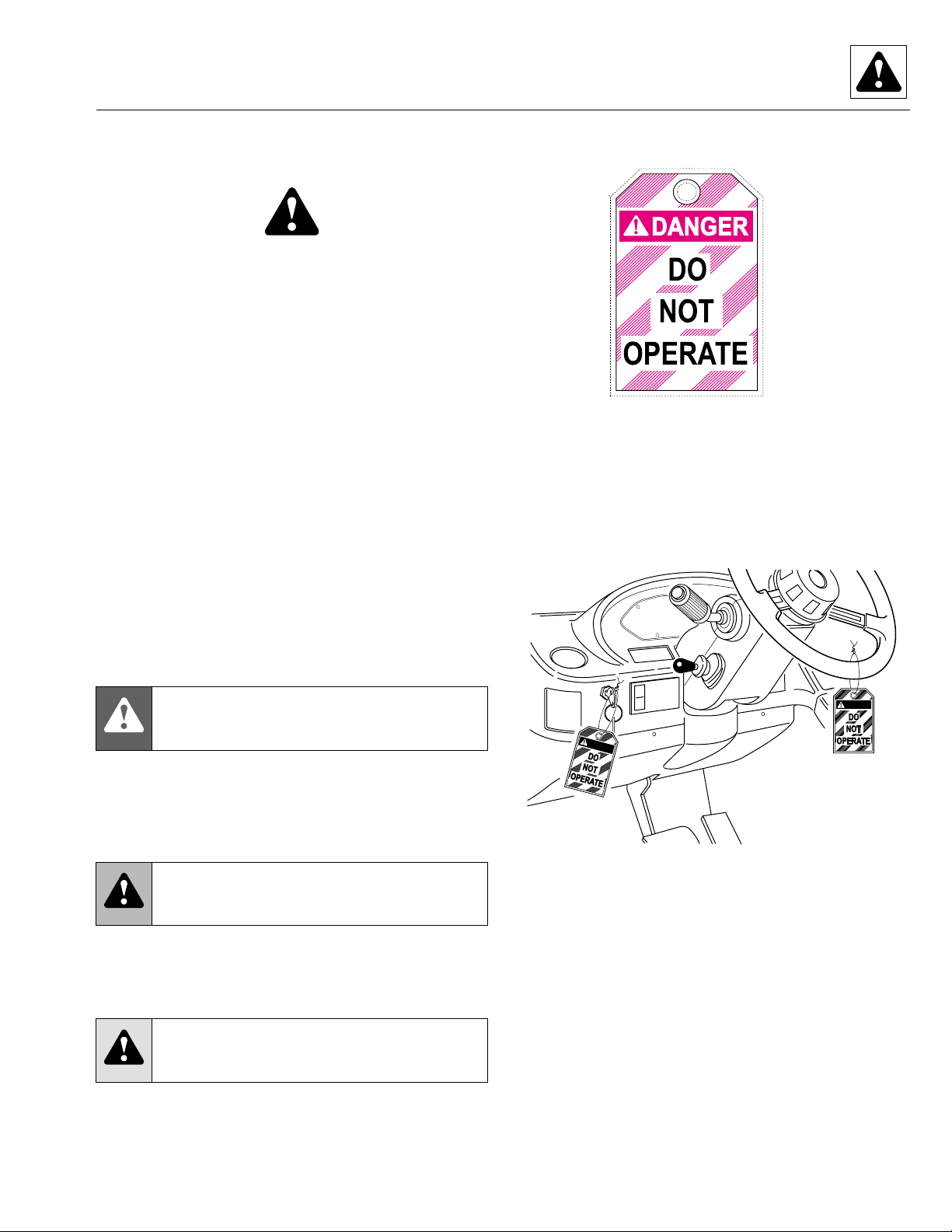

1.4 ACCIDENT PREVENTION TAGS

OS2180

Figure 1–3. Accident Prevention Tag.

Before beginning any maintenance or service, place an

Accident Prevention Tag on both the ignition switch and

the steering wheel (Fig. 1–4), stating that the vehicle

should not be operated. Copies of Accident Prevention

Tags are provided on pages 1-9 and 1-10.

DANGER:

The signal word

DANGER

denotes an extremely hazardous situation exists on or near the vehicle which would

result in a high probability of death or irreparable injury if

proper precautions are not taken.

WARNING

WARNING:

The signal word

WARNING

denotes a hazard exists on or

near the vehicle which can result in injury or death if the

proper precautions are not taken.

CAUTION

CAUTION:

The signal word

practices or directs attention to unsafe practices on or

near the vehicle which could result in personal injury if

CAUTION

denotes a reminder of safety

the proper precautions are not taken.

OS1520

Figure 1–4. Place Accident Prevention Tags on both

the ignition switch and the steering wheel.

Model 3606 • Origin 10/99

1-3

Section 1

1.5 SAFETY INSTRUCTIONS

Following are general safety statements to consider

before

vehicle. Additional statements related to specific tasks

and procedures are located throughout this manual and

are listed prior to any work instructions to provide safety

information before the hazard occurs.

For all safety messages, carefully read, understand and

follow the instructions

1.5.1 Personal Hazards

HAIR and CLOTHING:

jewelry. Tie up or restrain hair. Wear the correct safety

equipment for the job (including but not limited to: hard

hat; safety shoes; safety glasses, goggles, or face shield;

heavy gloves; hearing protection; reflective clothing; wetweather gear; respirator or filter mask).

EYE PROTECTION: Always wear appropriate eye protection when chiseling, grinding, sanding, welding, painting, repairing hydraulic systems, or checking, testing or

charging the battery.

BREA T HING PROTECTION: Wear respiratory protection

when grinding or painting.

HEARING PRO TECTION: Alw ays wear he aring protection

in a high-noise area.

FOOT PROTECTION: Wear protective footwear with

reinforced toe caps and slip-resistant soles.

LIFTING:

least one assistant or a suitable sling and hoist.

1.5.2 Equipment Hazards

OWNERS/OPERATORS MANUAL: Before operating the

vehicle, carefully read, understand and follow the Owners/

Operators manual.

performing maintenance procedures on the

NEVER

before

lift a heavy object without the help of at

proceeding.

DO NOT

wear loose clothing or

DO NOT

equipment. Always support equipment with propercapacity blocks or approved stands. Hoist or jack failure

can allow the equipment to tip or to fall.

COMPRESSED AIR: Before and during the use of compressed air, wear eye protection and advise other personnel in the work area that compressed air is about to

be used.

HAND TOOLS: Always use the proper tool for the job;

keep tools clean and in good working order, and use

special service tools only as recommended.

use a hoist, jack, or jack stands only to support

1.5.3 General Hazards

SOLVENTS: Only use approved solvents, and solvents

that are known to be safe for use.

HOUSEKEEPING: Keep the work area and operator’s

cab clean and remove all hazards (debris, oil, tools, etc.).

FIRST AID: Immediately clean, dress, and report all injuries resulting in bleeding or opened skin (cuts, abrasions,

burns, etc.), no matter how minor. Know where the First

Aid Kit is, and how to use it.

CLEANLINESS: Wear eye protection, and clean all components with a high-pressure or steam cleaner before

attempting service.

When removing hydraulic components, plug hose ends

and connections to prevent excess leakage and contamination. Place a suitable catch basin beneath the vehicle

to capture fluid run-off.

1.5.4 Operational Hazards

OPERATIONAL CONSIDERATIONS: Before operating

the vehicle, carefully read, understand and follow the

owners/operators manual.

ENGINE: Stop the engine before performing any service.

OPERATIONAL PROTECTION: Before operating the

vehicle or returning it for operational use, check that the

cab and all roll-over protection systems and falling-object

protection system s (R OPS /FOP S) are inta ct, un da ma ged

and secure. Replace any component as required.

LIFTING OF EQUIPMENT: Before using any lifting

equipment (chains, slings, brackets, hooks, etc.), verify

that it is of the proper capacity, in good working condition,

properly attached.

and

NEVER

suspended load or under raised equipment. The load or

equipment could fall or tip.

1-4

stand or otherwise become positioned under a

DANGEROUS START: Place a warning sign on vehicles

that are dangerous to start. Disconnect battery leads if

leaving the vehicle unattended. Place Accident Prevention

Tags on the steering wheel and ignition key switch before

attempting to perform any service or maintenance.

VENTILATION: Avoid prolonged engine operation in

enclosed areas with inadequate ventilation.

RADIATOR CAP: Always wear steam-resistant, heatprotective gloves when opening the radiator cap. Cover

cap with a clean, thick cloth and turn slowly to the first

stop to relieve pressure.

Model 3606 • Origin 10/99

Safety

SOFT SURFACES AND SLOPES :

vehicle parked on soft surfaces or slopes (inclined ground

or hills). Vehicle must be on hard, level surface with

wheels blocked when necessary before performing any

service. Obtain assistance, block all wheels, and add

supports if necessary before beginning any work.

SUPPORT S AND ST RAPS : I nst a ll s afe, stable supports,

slings or straps beneath or around a component or structural member before beginning any work.

FLUID PRESSURE: Before loosening any hydrau lic or

diesel component, hoses or tubes, turn engine OFF. Wear

heavy, protective gloves and eye protection.

check for leaks using any part of your body; use a piece

of cardboard or wood instead. If injured, see a doctor

immediately. Diesel fuel leaking under pressure can

explode. Hydraulic fluid and diesel fuel leaking under

pressure can penetrate the skin, cause infection, gangrene, and other serious personal injury. Relieve all pressure before disconnecting any component, part, line or

hose. Slowly loosen parts and allow release of residual

pressure before removing any part or component. Before

starting engine or applyi ng pressure, use components,

parts, hoses and pipes that are in good condition, connected and tightened to the proper torque. Capture fluid

in an appropriate container and dispose of in accordance

with prevailing environmental regulations.

NEVER

work on a

NEVER

1.6 SAFETY DECALS

Locations of vehicle safety and other decals are shown

on the following pages. As part of routine maintenance,

check that ALL safety and informational decals on the

vehicle are present and readable. Keep the safety decals

clean. If a replacement decal is needed, refer to the

owners/operators manual and parts catalog for the latest

parts numbers and ordering information. Or, contact

OmniQuip Parts Worldwide directly at:

1-888-872-5123

PRESSURE TESTING: When conducting any test, only

use test equipment that is correctly calibrated and in

good condition. Use the correct equipment in the proper

manner, and make changes or repairs as indicated by the

test procedures to achieve the desired results.

LEAVING VEHICLE: Lower the attachment to the ground

before leaving the vehicle.

TIRE PRESSURE: Always keep tires inflated to the

proper pressure to help prevent dangerous travel and

load-handling situations.

DO NOT

over-inflate tires.

Model 3606 • Origin 10/99

1-5

Section 1

Safety Decal List –

1. No Riders WARNING

2. Vehicle Rollaway WARNING

3. Electrocution DAN GER

4. Load Chart Booklet

5. Tipover DANGER – Operating

6. Tipover DANGER – Tire Pressure

DANGER

CONTACTING

ELECTRIC

POWER LINES

can result in

electrocution.

2

NEVER operate

vehicle within

10 feet (3m) of

electric power

lines.

3

Earlier

6

Models

DANGER

LOW TIRE

PRESSURE

can result

in tipover.

MAINTAIN

proper tire

pressure at

all times.

5

7. Safety Instructions

8. Moving Parts WARNING

9. Explosive Gases WARNING

10. Carrying Personnel WARNING

11. Boom Extend Stripes

12. Boom Angle Indicator

9

4

SAFETY INSTRUCTIONS

1

Note:

1. Read operators manual

before operating.

2. Fasten seat belt.

Many of these hazard related decals are available free of charge by calling

3. Allow no riders.

4. Use an approved work

platform to lift or lower

personnel.

7

OS1511

OmniQuip Parts Worldwide at 1-888-872-5123.

10

11

8

12

OS1256

1-6

Model 3606 • Origin 10/99

Safety

Safety Decal List –

1. No Riders WARNING

2. Vehicle Rollaway WARNING

3. Electrocution DANGER

4. Load Chart Booklet

5. Tipover DANGER – Operating

6. Tipover DANGER – Tire Pressure

CONTACTING

ELECTRIC

POWER LINES

can result in

electrocution.

6

2

DANGER

3

NEVER operate

vehicle within

10 feet (3m) of

electric power

lines.

DANGER

LOW TIRE PRESSURE

can result in tipover.

MAINTAIN

proper tire

pressure at

all times.

Later

VEHICLE

TIPOVER

can result

in death or

serious injury.

Models

DANGER

DO NOT

travel

with the

boom

raised.

SAFETY INSTRUCTIONS

1. Read operators manual

before operating.

2. Fasten seat belt.

DO NOT raise

boom while

on a slope

unless load

is level.

3. Allow no riders.

4. Use an approved work

platform to lift or lower

personnel.

7. Safety Instructions

8. Moving Parts WARNING

9. Explosive Gases WARNING

10. Carrying Personnel WARNING

11. Boom Extend Stripes

12. Boom Angle Indicator

5

9

7

WARNING

VEHICLE

ROLLAWAY

can cause

death or

serious

injury.

WARNING

Allow no riders.

ALWAYS

engage

parking

brake

before

dismounting.

4

1

OS1241

Note:

Many of these hazard related decals are available free of charge by calling

OmniQuip Parts Worldwide at 1-888-872-5123.

10

11

8

12

OS1255

Model 3606 • Origin 10/99

1-7

Section 1

Copies of Accident Prevention Tags are provided on pages 1-9 and 1-10.

1-8

Model 3606 • Origin 10/99

Safety

OS2180

Model 3606 • Origin 10/99

1-9

Section 1

1-10

OS2180

Model 3606 • Origin 10/99

Section 2

General Information, Specifications, and Maintenance

Contents

PAR. TITLE PAGE

2.1 REPLACEMENT PARTS AND WARRANTY INFORMATION. . . . . . . . . . 2-3

2.2 SERIAL NUMBER LOCATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.3 TORQUE VALUES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.3.1 Fastener Rating. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.3.2 Straight Thread O-ring Fitting (non-adjustable). . . . . . . . . . . . . 2-3

2.3.3 Straight Thread O-ring Fitting (adjustable) . . . . . . . . . . . . . . . . 2-3

2.3.4 Metric Conversion Factors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.4 SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2.4.1 Vehicle Dimensions (Fig. 2-1) . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2.4.2 Performance Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2.4.3 Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

2.4.4 Miscellaneous Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

2.5 FLUIDS, LUBRICANTS AND CAPACITIES . . . . . . . . . . . . . . . . . . . . . . . 2-9

2.5.1 Axles (Differential Housings) and Transfer Case. . . . . . . . . . . . 2-9

2.5.2 Wheel Ends. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

2.5.3 Lubrication Points (grease fittings) . . . . . . . . . . . . . . . . . . . . . . 2-9

2.5.4 Hydraulic System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

2.5.5 Engine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

2.5.6 Transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

2.5.7 Drive Shaft Splines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

2.5.8 General Anti-corrosion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

2.5.9 Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

2.5.10 Paint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

2.5.11 Thread Locking Compound. . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

2.6 CLEANING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

2.7 REPLACEMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

2.8 HOSES AND TUBES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

2.8.1 Hose and Tube Inspection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

2.8.2 Hose and Tube Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

2.9 BEARINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

2.9.1 Bearing Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

2.9.2 Bearing Cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

2.9.3 Bearing Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

2.10 PRESSURE TESTING AND ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . 2-15

2.11 AFTER SERVICE STARTUP AND CHECKS . . . . . . . . . . . . . . . . . . . . . . 2-15

2.11.1 After Service Startup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

2.11.2 After Electrical/Electronic Component Service . . . . . . . . . . . . . 2-15

2.11.3 After Hydraulic Component Service . . . . . . . . . . . . . . . . . . . . . 2-15

Model 3606 • Origin 10/99

2-1

Section 2

2.11.4 After Brake System Service . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

2.11.5 After Fuel System Service. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

2.11.6 After Transmission Service or Replacement . . . . . . . . . . . . . . . 2-16

2.11.7 After Tire and Wheel Service . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

2.11.8 After Engine Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

2.11.9 After Boom Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

2.11.10 After Axle Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

2.12 MAINTENANCE INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

2.12.1 Maintenance Schedule and Checklist. . . . . . . . . . . . . . . . . . . . 2-17

2.12.2 Boom Wear Pad Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

2.12.3 Air Cleaner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

2.12.4 Optional Closed Cab Air Filters. . . . . . . . . . . . . . . . . . . . . . . . . 2-21

2.12.5 Engine Cooling System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-22

2.12.6 Engine Oil and Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

2.12.7 Engine Fuel System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-25

2.12.8 Engine Fan Belt. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-28

2.12.9 Hydraulic System Oil And Filter. . . . . . . . . . . . . . . . . . . . . . . . . 2-29

2.12.10 Transmission Oil And Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-31

2.12.11 Axle Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-32

2.12.13 Transfer Case Oil. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-34

2.12.14 Wheels and Tires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-34

2.12.15 BATTERY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-35

2.12.16 Fuse and Relay Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . 2-37

2.12.17 Boom Chains. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-39

2.12.18 Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-40

2.12.19 Transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-40

2.13 EMERGENCY OPERATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-41

2.13.1 Towing a Disabled Vehicle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-41

2-2

Model 3606 • Origin 10/99

General Information, Specifications, and Maintenance

2.1 REPLACEMENT PARTS AND

WARRANTY INFORMATION

The replacement of any part with any other than a Sky

Trak authorized replacement part can adversely affect

the safety, performance, or durability of the vehicle, and

may void the warranty. Sky Trak International assumes

no liability whatsoever for unauthorized replacement

parts.

A warranty registration form must be filled out by the Sky

Trak distributor, signed by the purchaser, and returned to

Sky Trak when the vehi cle is sold and/or put into use.

Registration activates the warranty period and helps to

assure that warranty claims are promptly processed. To

guarantee full warranty service, verify that the distributor

has returned the business reply card of the warranty registration form to Sky Trak.

2.2 SERIAL NUMBER LOCATIONS

When ordering replacement parts or making service

inquiries about the vehicle, various serial numbers are

required to help assure the provision of

correct parts and information. Before ordering parts or

initiating service inquiries, make note of the pertinent

serial numbers.

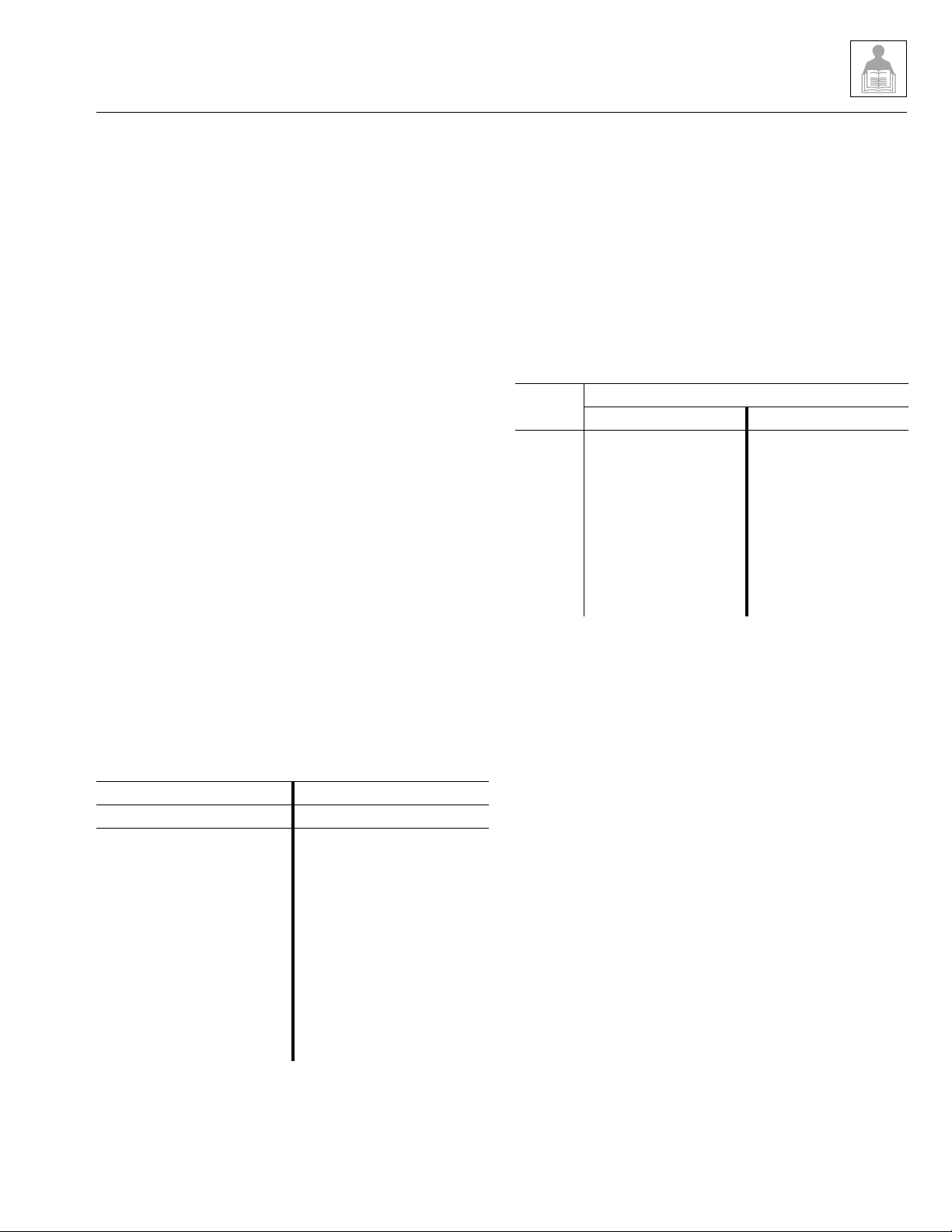

2.3.2 Straight Thread O-ring Fitting

(non-adjustable)

When the vehicle leaves the factory, it is equipped only

with straight thread O-ring fittings. Customer-added

accessories may differ; therefore, consult the manufacturer's product literature for information.

1. V erify that both threads and sealing surfaces are free

of burrs, nicks, scratches, and any foreign material.

2. Lubricate the new O-ring with a light coating of

hydraulic oil.

3. Tighten fitting to the proper torque according to the

following chart:

SAE

Size

4 22-26 30-35

6 46-54 62-73

8 95-105 129-142

10 125-135 170-183

12 165-175 224-237

16 245-255 332-346

20 270-290 366-393

24 365-385 495-522

lb/ft Nm

Torque

2.3 TORQUE VALUES

2.3.1 Fastener Rating

All fasteners (nuts, bolts, washers, etc.) are equal to SAE

Grade 5 (PC8.8) and are plated, u nless otherwis e specified.

Unless otherwise specified, the following values apply for

Grade 5 (PC8.8) nuts and bolts:

Size Torque Size Torque

Inch lb/ft Nm mm Nm lb/ft

1/4 9 12 6.0 10 7

5/16 18 24 8.0 25 18

3/8 31 42 10.0 50 37

7/16 50 68 -- -- --

1/2 75 102 12.0 80 59

9/16 110 150 14.0 130 95

5/8 150 203 16.0 200 146

3/4 250 340 20.0 360 263

7/8 380 515 22.0 510 372

1.0 585 793 24.0 650 475

2.3.3 Straight Thread O-ring Fitting

(adjustable)

When the vehicle leaves the factory, it is equipped only

with straight thread O-ring fittings. Customer-added

accessories may differ; therefore, consult the manufacturer's product literature for information.

1. Verify that both mating parts are free of burrs, nicks,

scratches, and any foreign material.

2. Lubricate the new O-ring with a light coat of hydraulic

oil.

3. Back off the locknut as far as possible.

4. Screw the fitting into the port by hand until the

backup washer contacts the face of the port and is

pushed all the way towards the locknut.

5. To position the fitting, unscrew by the required

amount, but not more than one full turn.

Model 3606 • Origin 10/99

2-3

Section 2

6. Hold the fitting in the desired position and tighten to

the proper torque according to the following chart:

Adjustable Straight-thread O-ring Fitting Torque Chart

SAE

Size

lb/ft Nm

Torque

4 14.5-17.5 20-24

6 37-43 50-58

8 75-85 102-115

10 115-125 156-170

12 155-165 210-224

16 225-235 305-319

20 260-280 353-380

24 340-360 461-488

2.3.4 Metric Conversion Factors

A. Approximate American to Metric Conversions

When this is known Multiply by - - -To Find

TORQUE (moment of force)

Pound/feet (lb/ft) 1.356 Newton meters (Nm)

Pound/inches (lb/in) 0.113 Newton meters (Nm)

POWER

Horsepower (hp) 745.7 Watts

SPEED (velocity)

Miles per hour

(mph)

FUEL CONSUMPTION

Miles per gallon,

US (mpg)

[Miles per gallon values are commonly converted to

liters/100 kilometers; mpg (Imperial x l/100 km = 282;

US mpg x l/100 m = 235)]

LENGTH (distance)

Inches (in) 25.4 Millimeters (mm)

Inches (in) 2.5 Centimeters (cm)

Feet (ft) 30.5 Centimeters (cm)

Feet (ft) 0.305 Meters (m)

Yards (yd) 0.9 Meters (m)

Miles (mi) 1.6 Kilometers (km)

AREA

Square inches (in

Square feet (ft

Square yards (yd

Square miles (mi

1.609 Kilometers per hour

(km/hr; kph)

0.425 Kilometers per liter (km/l)

2

) 6.5 Square centimeters (cm2)

2

) 0.09 Square meters (m2)

2

) 0.8 Square meters (m2)

2

) 2.6 Square kilometers (km2)

Acres 0.4 Hectares (ha)

MASS (weight)

Ounces (oz) 28 Grams (g)

Pounds (lb) 0.4536 Kilograms (kg)

Short tons (2000 lb) 0.9 Metric ton (t)

VOLUME

Teaspoons (tsp) 5 Milliliters (ml)

Tablespoons (Tbsp) 15 Milliliters (ml)

Cubic inches (in

3

) 16 Milliliters (ml)

Fluid ounces (fl oz) 30 Milliliters (ml)

Cups (c) 0.24 Liters (l)

Pints (pt) 0.47 Liters (l)

Quarts (qt) 0.95 Liters (l)

Gallons (gal) 3.8 Liters (l)

Cubic feet (ft

Cubic yards (yd

3

) 0.03 Cubic meters (m3)

3

) 0.76 Cubic meters (m3)

AIR PRESSURE

Pounds per square

6.895 Kilopascals (kPa)

inch (psi)

HYDRAULIC PRESSURE

Pounds per square

0.069 Bars

inch (psi)

TEMPERATURE (exact)

C), subtract 32, then

To determi ne degree s Celsius (

multiply by 0.56; (°

F - 32) x 0.56 = °C.

°

B. Approximate Metric to American Conversions

When this is known Multiply by - - -To Find

TORQUE (moment of force)

Newton meters (Nm) 0,738 Pounds/feet (lb/ft)

Newton meters (Nm) 8,85 Pounds/inches (lb/in)

POWER

Watts 0,0013 Horsepower (hp)

SPEED (velocity)

Kilometers per hour

0,621 Miles per hour (mph)

(km/hr; kph)

FUEL CO NSUMPTION

Kilometers per liter

2,352 Miles per gallon, US (mpg)

(km/l)

[Miles per gallon values are commonly converted to liters/

100 kilometers; mpg (Imperial x l/100 km = 282;

US mpg z l/100 km = 235)]

2-4

Model 3606 • Origin 10/99

General Information, Specifications, and Maintenance

LENGTH (distance)

Millimeters (mm)

Centimeters (cm)

Meters (m)

Meters (m)

Kilometers (km)

AREA

Square centimeters

2

(cm

)

Square meters (m

Square kilometers

2

)

(km

Hectares (10000 m

MASS (weight)

Grams (g) 0,035 Ounces (oz)

Kilograms (kg) 2,2 Pounds (lb)

Metric ton (1000 kg)

(t)

VOLUME

0,0394 In che s (in)

0,394 Inches (in)

3,281 Feet (ft)

1,1 Yards (yd)

0,621 Miles (mi)

0,4 Square inches (in

2

) 1,1 Square yards (yd2)

0,6 Square miles (mi

2

)2,5 Acres

1,1 Short tons

2

)

2

)

Milliliters (ml) 0,03 Fluid ounces (fl oz)

3

Milliliters (ml) 0,06 Cubic inches (in

)

Liters (l) 2,1 P ints (pt )

Liters (l) 1,06 Quarts (qt)

Liters (l) 0,26 Gallons (gal)

Cubic meters (m

Cubic meters (m

3

)35 Cubic feet (ft3)

3

) 1,3 Cubic yards (yd3)

AIR PRESSURE

Kilopascals (kPa) 0,145 Pounds per square inch

(psi)

HYDRAULIC PRESSURE

Bars 14,5 Pounds per square inch

(psi)

TEMPERATURE (exact)

To deter mine degree s Fahrenheit (

Celsius (

°C) by 1.8, then add 32; (°C x 1.8) + 32 = °F.

°F), multiply degrees

Model 3606 • Origin 10/99

2-5

Section 2

V

2.4 SPECIFICATIONS

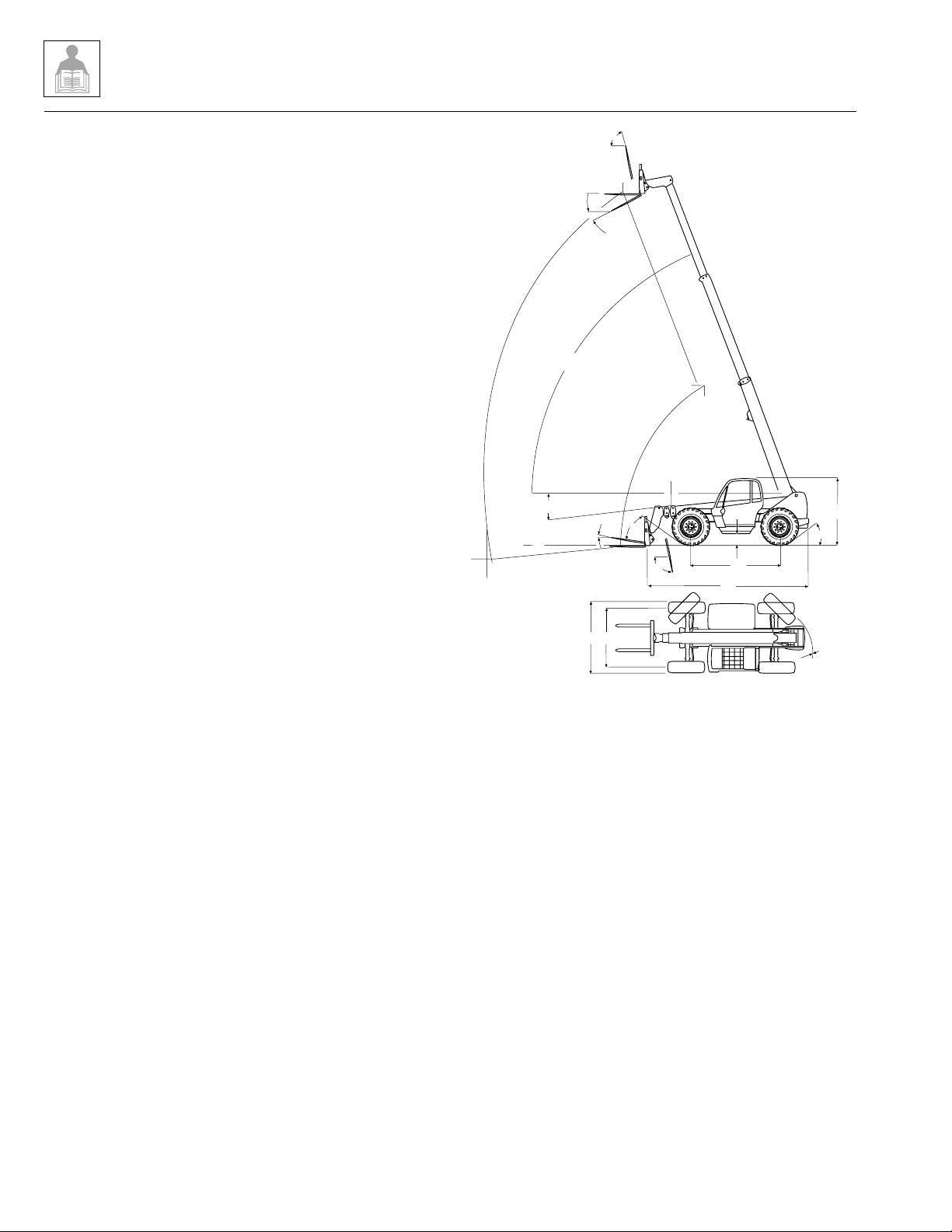

2.4.1 Vehicle Dimensions

(Fig. 2-1)

With Standard 12-ply 13.00-24 Tir es

Ref. Description

A. Length

(without attachment) 221.0" (5613 mm)

B. Wi dth 98.0" (2489 mm)

C. Height (boom lowered) 91.75" (2330 mm)

D. Wheelbase 122.0" (3099 mm)

E. Tread 84.0" (2 134 mm)

F. Ground Clearance 17.0" (432 mm)

G. Turning radius, curb to curb 138.0" (3505,2 mm)

H. Turning radius, clearance 180.5" (4584,7 mm)

I. Maximum lift height,

boom extended 36' 2" (11023,6 mm)

J. Maximum lift height,

boom retracted 18' 6" (5638,8 mm)

K. Maximum below grade depth,

boom extended 2' 5" (736,6 mm)

L. Maximum reach,

from front of front tires 24' 8" (7518,4 mm)

M. Maximum reach at maximum lift angle,

boom extended 67.2" (1707 mm)

N. Maximum reach at maximum lift angle,

boom retracted -26.2" (-665,48 mm)

O. Maximum reach at minimum lift angle,

boom extended 24' 2" (7366 mm)

P. Maximum boom lift angle 68

Q. Minimum boom lift angle -3.8

°

°

R. Angle of approach N/A

S. Angle of departure 33

°

Fork tilt angle:

T. At minimum boom angle up 8.1

°

U. At minimum boom angle down -10 8.3°

V. At maximum boom angle up 80.8°

W. At maximum boom angle down -21.8

°

M

I

W

P

J

N

0.0

Q

0.0

K

O

L

Figure 2–1. Vehicle dimensions with standard tires.

T

R

U

B

E

F

D

A

2.4.2 Performance Specifications

Performance criteria is based on full throttle engine

speed unless otherwise specified or not applicable:

A. Travel Speed (standard tires, no load)

4-SPEED 3-SPEED

First gear 4.3 mph 4.2 mph

(6,9 km/hr) (6,8 km/hr)

Second gear 9.1 mph 9.2 mph

(14,6 km/hr) (14,8 km/hr)

Third gear 15.3 mph 17.7 mph

(24,6 km/hr) (28,5 km/hr)

Fourth gear 20.8 mph N/A

(33,5 km/hr)

C

S

G

MS2110

Frame tilt angle

(not shown)

:

Right 10.0

Left 10.0°

2-6

B. Braking Distance (standard tires, no l oad)

°

4-SPEED 3-SPEED

From road speed

to stop 29.0 ft (8,8 m) 21.4 ft (6,5 m)

Model 3606

•

Origin 10/99

General Information, Specifications, and Maintenance

C. Cylinder Times (with no load, at full throttle)

Function Approximate Times, in seconds

Boom extend 12.00

Boom retract 7.00

Boom lift retracted 12.75

Boom lower retracted 10.75

Fork tilt up 4.20

Fork tilt down 3.75

Frame tilt left to right

with boom down 8.50

and emergency

Fr ame tilt le ft to right with boom abo v e 40

°

brake engaged 24.0 to 30.0

Frame tilt right to left

with boom down 13.50

and emergency

Frame tilt right to left with boom above 40

°

brake engaged 24.0 to 30.0

D. Draw Bar Pull

Per SAE drawbar test, 200 ft (61 m) track

4-SPEED 3-SPEED

Peak drawbar

in 1st gear

at converter stall

(no load) 15,000 lb 13,250 lb

(6.810,0 kg), slip (6.015,5 kg), no slip

Peak drawbar

in 1st gear

at converter stall

(rated load) 16,750 lb 13,250 lb

(7.604,5 kg), no slip (6.015,5 kg), no slip

E. Engine Performance

Low idle setting for all engines = 1050 +/- 50 RPM

Engine Model

Perkins

Turbo

Perkins

Natural/

EPA

Cummins

Turbo

1004.4T 243 CID 2600 +/-

1004.42 258 CID 2600 +/-

4BT3.9 239 CID 2700 +/-

Displace-

ment

High Idle

100

100

100

Horse-

power

108 HP @

2400 rpm

86 HP

@ 2400

rpm

110 HP @

2500 rpm

Peak

Torqu e

277 lb/ft

@ 1600

rpm

221 lb/ft

@ 1600

rpm

293 lb/ft

@ 1500

rpm

Note: Engine manufacturer’s maximum “high idle” setting

is lockwired and sealed. DO NOT disturb this setting.

F. Fuel Consumption

Average, depending on load/duty:

2 gal/hr (1,67 Imp gal/hr, or 7,57 l/hr)

G. Steering Wheel

Maximum number of turns, lock to lock

3.80 turns

Minimum number of turns, lock to lock

3.20 turns

H. Breakout Force

Utility bucket (calculated at -24

lip angle, max moment)

°

15,100 lb (6.855,4 kg).

2.4.3 Weights

A. Basic Vehicle

Curb Weight 20,195 lbs (9.160 kg)

Operating Load 6,600 lbs (3.000 kg)

B. Working Weight

Machine working weight is figured with 48" carriage, two

48" pallet forks, 25%-full fuel tank, and standard bias ply

tires (no hydrofill):

Front Axle Rear Axle TOTAL

Open Cab 8,390 lb 12,540 lb 20,930 lb

(3,8 kg) (5,6 kg) (950 kg)

Closed Cab N/A N/A N/A

C. Attachments

Std 48" carriage with shaft ....................... 456 lb (205 kg)

Std 60" carriage with shaft .................... 526 lb (236,7 kg)

Std 72" carriage with shaft .................... 677 lb (304,6 kg)

48" side tilt carriage

with shaft and cylinder.............................. 640 lb (288 kg)

60" side tilt carriage

with shaft and cylinder.............................. 700 lb (315 kg)

72" side tilt carriage

with shaft & cylinder.............................. 770 lb (346,5 kg)

52" swing carriage

with shaft & cylinders ............................ 950 lb (427,5 kg)

72" swing carriage

with shaft and cylinder...................... 1,135 lb (510,75 kg)

3

Bucket, 1.125 yd

Broom, 8 foot (2,44 m) .......................... 1,100 lb (495 kg)

Pallet forks, 2.25 x 4 x 48 (5,7 x 10 x 122 cm),

quantity: 2 ............................................. 312 lb (140,4 kg)

(0,855 m3)................... 760 lb (342 kg)

Model 3606 • Origin 10/99

2-7

Section 2

Block forks, 2 x 2 x 48 (5 x 5 x 122 cm)

quantity: 6................................................. 480 lb (216 kg)

Lumber forks, 1.75 x 7 x 60 (4 x 17,8 152,4 cm)

quantity: 2.............................................. 466 lb (209,7 kg)

Auger drive unit..................................... 285 lb (128,2 kg)

Auger mounting frame................................ 180 lb (81 kg)

Auger (various sizes available)............................... Varies

Auger extension (various sizes available).............. Varies

2.4.4 Miscellaneous Specifications

A. Wheels and Tires

Wheel lug nut torque............................370 lb/ft (500 Nm)

Air Pressure

13.00-24, 12-ply (minimum) tires ........... 65 psi (448 kPa)

Tire Footprint Area

(area is established under max tip load)

13.00-24, 12-ply tires @ 65 psi (448 kPa),

Vehicle with no load: ............................ 140 in

13.00-24, 12-ply tires @ 65 psi (448 kPa),

Vehicle with rated load: ...................165 in

Maximum Ground Pressure

Vehicle with no load,

13.00-24 12-ply tires @ 65 psi (448 kPa):

............................................................ 75 psi (516,6 kPa)

Vehicle with 6,600 lb (2.994 kg) load,

13.00-24 12-ply tires @ 65 psi (448 kPa):

............................................................ 85 psi (585,4 kPa)

Note: Maximum ground pressure at tip = (machine

weight + load) / (foot print area x 2)

B. Valve Relief Settings

Main system relief .............3,500 +/- 100 psi (241,5 Bars)

Port relief boom hoist ........3,700 +/- 100 psi (255,3 Bars)

Port relief boom extend..........3,175 +/- 75 psi (219 Bars)

Port relief boom retract......3,750 +/- 100 psi (258,8 Bars)

Port relief fork tilt

(both sides) .......................3,700 +/- 100 psi (255,3 Bars)

Pressure-reducing/rel ieving valve,

stabilizer cylinder........................100 +/- 25 psi (6,9 Bars)

Power steering relief..........2,500 +/- 100 psi (172,5 Bars)

Park brake relief......................... 550 +/- 50 psi (38 Bars)

2

(910 cm2)

2

(1072,5 cm2)

C. Tamper Proofing

A tamper-proof means is in place on the following adjustable components prior to machine shipment. This can

either be tamper-proof paint, or a steel tamper-proof cap.

DO NOT attempt to defeat, by-pass or alter any tamperproof device.

• Hoist cylinder counterbalance valves (1)

• Main valve port relief valves (5)

• Extend cylinder counterbalance valves (2)

• Steering relief valve (1)

• Fork cylinder counterbalance valves (2)

• Pilot relief valve (1)

• Main system relief valve (1)

• Park brake relief (1)

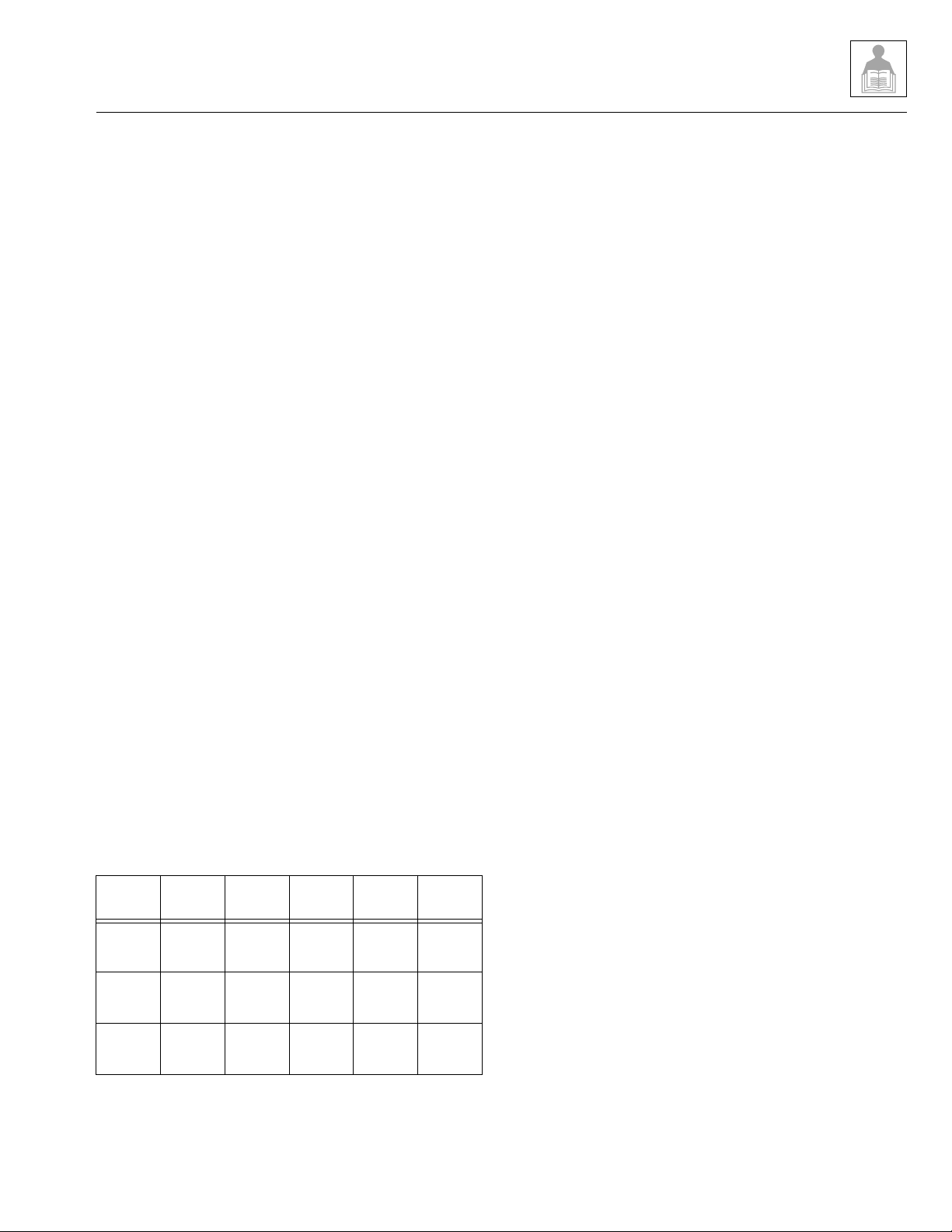

D. Fork Ratings

All approved forks for this vehicle are marked with a

maximum load capacity rating. This rating is stamped on

the left edge of the fork, just below the fork pivot shaft

(Fig. 2–2). The rating is listed in U.S. pounds and based

upon a 24" (610 mm) load center.

This rating specifies the maximum load capacity that the

individual fork can safely carry at a maximum load center

of 24" (610 mm).

Since forks are always used in multiples, the total rating

of any combination of forks is the sum of their rated

capacity.

Other than block forks, use all forks in matched pairs.

Use block forks in matched sets.

Stamped

Fork Rating

24 in.

Load

Center

Figure 2–2. The stamped fork rating specifies the

maximum load capacity that the individual fork can

safely carry at a maximum load center of 24" (610 mm).

(610mm)

4000 x 24

4000 x 24

OS0390

2-8

Model 3606 • Origin 10/99

General Information, Specifications, and Maintenance

2.5 FLUIDS, LUBRICANTS AND

CAPACITIES

2.5.1 Axles (Differential Housings) and

Transfer Case

A. Axle and Transfer Case Lubricants

In general, use gear oil that meets the requirements of

U.S. ordinance specification MIL-L-2105C with an API

classification of GL-5. The oil should be a multi-grade

80W90 with EP properties.

Products known to meet these requirements include:

• AMOCO GEAR LUBE 80W90

• ARCO HD 90W GEAR LUBE

• BP TRANS GEAR 80W90

• CATERPILLAR 80W90 EP GL-5

• CHEVRON ULTRA GEAR LUBE 80W90

• CITGO PREMIUM GEAR LUBE 80W90

• CONOCO UGL 80W90

• EXXON GEAR OIL GX80W90

• FRANKLIN GEAREX AGMA 5 EP GEAR OIL

• KENDALL NS-MP 80W90

• MOBIL MOBILUBE HD 80W90

• MP GEAR LUBE GL-5 80W90

• PENNZOIL 409L 80W90

• QUAKER STATE HIGH PERFORMANCE 80W90

• QUAKER STATE SYNTHETIC 80W90

• SHELL SPIRAX HD 80W90

• STUART M2C-105A 80W90

• SUNOCO DURO GEAR GL-5, SYNTHETIC

• SUNOCO MULTI-PURPOSE GL-5

• TEXACO DIFFERENTIAL GEAR LUBE 80W90

• TEXACO MULTIGEAR EP 80W90

• UNICAL 76 MP GEAR LUBE-LS

•VALVOLINE

HIGH PERFORMANCE GEAR LUBE 80W90

Note: Use of a premium grade 80W140 gear oil is recommended for operation where the ambient (outside air)

temperature is consistently above 80°F (27°C).

B. Axle and Transfer Case Capacities

Axles (differential housings) ......... ....... ...... ...... 18 qt (17 l)

Transfer case.................................................1.5 qt (1,4 l)

2.5.2 Wheel Ends

A. Wheel-end Lubricants

In general, use gear oil with an API classification of GL-5

that meets the requirements of U.S. ordinance specification MIL-L-2105 and MIL-L-2105D, respectively. The oil

should be a 90W, a multi-grade 80W -90, or 80W -140 with

EP properties (80W-90 EP). Products known to meet

these requirements include:

• BP TRANS GEAR 80W90

• CHEVRON ULTRA GEAR LUBE 80W90

• CITGO PREMIUM GEAR LUBE 80W90

• MOBIL MOBILUBE HD 80W90

DO NOT add additional friction modifier to factory-filled

wheel ends. All wheel ends are factory-filled by the manufacturer with oil. If a wheel end is drained for service, it

should be refilled with the gear oils listed above.

Note: DO NOT use synthetic oil without the express written consent of the manufacturer.

B. Wheel-end Capacity

Wheel end capacity.............. 1.4 qt (44.8 oz, or 1,324 ml)

2.5.3 Lubrication Points (grease fittings)

Lubricants

When lubricating any component via the grease fittings,

use multi-purpose lithium-based grease with EP additives

that meets NLGI Grade-2 specifications. Products known

to meet these requirements include:

• AMOCO AMOLITH EP2

•ARCO LITHOLINE EP2

• BENZ MOLY-SERVICE EP2

• CHEVRON DUROLITH EP2

• CITGO H EP2

• GULF GULFCROWN EP2

• MOBILE MOBILUX EP2

• SHELL ALVANIA EP2

• SUN PRESTIGE 742EP

• TEXACO MULTIFAX EP2

Note: Refer to section

and Checklist

locations.

for lubrication intervals and grease fitting

2.12.2 Maintenance Schedule

Model 3606 • Origin 10/99

2-9

Section 2

2.5.4 Hydraulic System

A. Hydraulic Fluids

The hydraulic system is factory filled with ISO Grade 46

anti-wear hydraulic oil. When filling the hydraulic system,

use an anti-wear hydraulic oil meeting ISO Grade 46 with

-40°F (-40°C) pour point/ASTM viscosity SUS 215 at

100°F (38°C), or a 10W motor oil that meets the requirements of U.S. ordinance specification MIL-L-2104C.

Products known to meet these requirements include:

• AMOCO RYKON 46

• ARCO DURO AW S-215

• BENZ PETRAULIC 46-7C

• CASTROL AGRICASTROL HDD

• CASTROL/DEUSOL CRD

• CHEVRON AW HYDRAULIC OIL 46

• CITGO PACEMAKER XD-46

• ESSO ESSOLUBE D-3HP

• ESSO ESSOLUBE XD-3

• GULF HARMONY 46 AW

• ISO-46 HYDRAULIC OIL

• MOBIL DTE-25

• SAE 10W MOTOR OIL

• SHELL RIMULA CT

• SHELL RIMULA TX

• SHELL RIMULA X

• SHELL TULLUS 46

• SUN SUNVIS 821 WR

• TEXACO RANDO HD 46

Note: For -30°F to +70°F (-34°C to 21°C), 5W20 motor

oil with -50°F (-45°C) pour point can be substituted. However, above 70°F (21°C), hydraulic system oil must be

changed to ISO-46 hydraulic oil or SAE 10W motor oil.

B. Hydraulic System Capacity

System capacity ................................... 59.5 gal (225,2 l)

Reservoir capacity ................................ 32.2 gal (121,9 l)

2.5.5 Engine

A. Engine Fluids and Lubricants

1. Engine oil:

Diesel Engine Oil, SAE 10W-30, or 15W40

In general, use a premium-quality 10W-30 diesel engine

(motor) oil. Add itives ar e not necessary. For most cli mates,

use 15W40 motor oil that meets API, CD or CE (severe

duty diesel engine) specifications. In cold climates where

ambient (outside air) temperatures are consistently below

32°F (0°C), 10W30 motor oil can be used; however, continuous use of low viscosity oil may cause premature

engine wear.

2. Cooling system (engine coolant):

In general, use a 50/50-mix of premium-quality ethylene

glycol (commonly referred to as “anti-freez e/anti-b oilo v er”)

and water. Additives are not necessary.

3. Fuel:

In general, use No. 2 diesel fuel. From November 15 to

March 15 when operating in cooler climates where ambient (outside air) temperatures are consistently at or

below 32°F (0°C), use a 50/50 mix of #1 and #2 diesel

fuels. Use good quality diesel fuel and change the fuel

filter regularly. Additives are not necessary.

B. Engine Capacities

1. Engine oil capacity:

TOTAL CAPACITY FILTER

WITH FILTER CHANGE CAPACITY

Cummins Turbo......... 11.6 qt (11,0 l)............1.3 qt (1,2 l)

Perkins Turbo ............ 9.0 qt (8,5 l)............... 1.5 qt (1,5 l)

Perkins Natural.......... 9.0 qt (8,5 l)............... 1.5 qt (1,5 l)

2. Cooling system capacity (w/o heater):

Cummins Turbo......... 5.0 gal (18,9 l)

Perkins Turbo ............ 5.0 gal (18,9 l)

Perkins Natural.......... 5.0 gal (18,9 l)

Coolant system overflow bottle capacity:

CAPACITY CAPACITY

W/O HEATER W/ HEATER

Overflow bottle.......... 3.0 qt (2,8 l)............... 3.0 qt (2,8 l)

3. Fuel tank capacity:

Total capacity ............ 35.1 gal (132,8 l)

Usable capacity......... 33.6 gal (127,2 l)

2-10

Model 3606 • Origin 10/99

General Information, Specifications, and Maintenance

2.5.6 Transmission

A. Transmission Fluid

Vehicle transmissions are factory filled with 10W motor

oil. Any suitable 10W motor oil, which meets the requirements of U.S. ordinance specification MIL-L-2104C, can

be used. Products known to meet these requirements

include:

• ARCO TRACTOR FLUID or equivalent

• CASTROL AGRICASTROL HDD

• CASTROL/DEUSOL CRD

• ESSO ESSOLUBE D-3HP

• ESSO ESSOLUBE XD-3

• SAE 10W MOTOR OIL

• SHELL RIMULA CT

• SHELL RIMULA TX

• SHELL RIMULA X

In general, use any approved 10W or 5W20 motor oil

(depending on ambient temperatures; see information

below), Dexron* or Dexron II D*, or an anti-wear hydraulic

oil meeting ISO Grade 46 specifications with a -40°F

(-40°C) pour point/ASTM viscosity SUS 215 at 100°F

.

(38°C)

For -30°F to +120°F (-34°C to 49°C), Dexron* II transmis-

sion fluid with a -50°F pour point may be substituted.

5W20 motor oil may be substitute d for use with tempera-

ture conditions of -30

Products known to m eet the se r e qui reme nts include:

• AMOCO RYKON 46

• ARCO DURO AW S-215

• BENZ PETRAULIC 46-7C

• CHEVRON AW HYDRAULIC OIL 46

• CITGO PACEMAKER XD-46 or equivalent

• GULF HARMONY 46

• ISO-46 HYDRAULIC OIL

• MOBIL DTE-25

• SHELL TULLUS 46

• SUN SUNVIS 821 WR

• TEXACO RANDO HD 46

If anti-wear h ydr aulic oil as specifi ed above is not av ailab le ,

a suitable tractor fluid may be substituted which meets

the requirements of any of the following specifications:

• ARCO TRACTOR FLUID or equivalent

• DETROIT DIESEL C-3

• FORD TRACTOR M2C134B

• JOHN DEERE J20A

•TEXACO TDH OIL

• WHITE FARM Q1826

F to 70°F (-34°C to 21°C) only.

°

RECOMMENDED LUBRICANTS FOR CLARK-HURTH

T12000 POWER SHIFTED TRANSMISSION

150

140

130

120

110

100

3

-10

-20

-30

-40

-50

-60

Farenheit

90

80

70

60

50

40

30

20

10

0

60

50

40

30

20

10

0

-10

-20

-30

-40

-50

Celsius

Te mpe rature Range "3"

If using Dexron*,

Use ONLY Dexron*

or Dexron II D*

See NOTE Below

Chart 2-1. Transmission fluid temperature range.

PREFERRED OIL VISCOSITY: Select the highest vis-

cosity compatible with prevailing ambient temperatures

and the oil application information listed under

2.5.6 A. Transmission Fluid

.

Section

The Clark Hurth T12000 modulated shift transmission

used in this vehicle should use ONLY C-3 or Temperature Range 3 transmission fluids, Dexron* or Dexron II

D*.

Note: Dexron II D* is not compatible with graphitic clutch

plate friction material UNLESS IT MEETS THE

APPROVED C-3 SPECIFICATIONS.

*Dexron and Dexron II D are registered trademarks of General

Motors Corporation.

B. Transmission Capacity

Capacity w/ filter change ................. 3.4 gal (12,9 l)

Filter .................................................... 1.5 qt (1,4 l)

Model 3606 • Origin 10/99

2-11

Section 2

2.5.7 Drive Shaft Splines

IMPORTANT: DO NOT disassemble any of the drive

shafts (see

Section 6 Transfer Case

of this manual for

information covering drive shafts and U-joints). To help

ensure optimum performance, the drive shaft assemblies

are specially balanced as a unit at the factory. When servicing any flange yoke, slip yoke or drive shaft tube, order

a complete assembly. Refer to the parts manual for

ordering information.

Respective of the above statement, should it become

necessary to coat the transmission input drive shaft

splines, use molybdenum disulfide grease. Molybdenum

disulfide grease specifically formulated for this purpose is

marketed by several manufacturers under various

names, including:

Aldrich Chemical Co., Inc.

Product name:

Aldrich MOLYBDENUM (IV) SULFIDE,

Catalog Number 23,484-2

Pac kage Size: 5 g (0.175 oz)

100 g (3.5 oz)

500 g (17.5 oz)

Contact:

Aldrich Chemical Co., Inc.

P.O. B ox 3 3 5

Milwaukee, Wisconsin 53201 USA

Telephone: (414) 273-3850

DOW CORNING INC.

Product name:

MOLYKOTE

®

77 Paste

Contact:

Dow Corning Corporate Center

P.O. B ox 9 9 4

Midland, MI 48686-0994

Telephone: (517) 496-4400

2.5.8 General Anti-corrosion

A. Anti-corrosion Compound

For general anti-corrosion protection, use a wax film rust

inhibitor that provides a protective film two ten-thousandths

of an inch (0.0002", or 0,00005 mm) thick. One such rust

inhibitor that is specifically formulated for this purpose is

LPS 3

. It is marketed by:

LPS Laboratories, Inc.

4647 Hugh Howell Rd.

Tucker GA 30085-5052

Phone: 1-800-241-8334

Fax: (770) 493-9206

Note: Anti-corrosion protection is especially important in

frame and stabilizer cylinder pin support bores for protection from fretting corrosion wear.

B. Anti-corrosion Need Areas

Coat all unplated pins and all bores f o r cylinder pins, attachment pivot pins, chain sheave pins, the quick-attach lock

pin, and all quick-attach lock pin bores. On the boom,

coat the fork shaft and unpainted boom slide pathways.

2.5.9 Electrical

A. Basic Ratings

Battery Type................ 12Vdc, Negative (-) ground/earth,

Maintenance Free

Battery Rating..........................1,000 cold cranking amps

@ 0°F (-18°C)

Number of Batteries ............................................. One (1)

Alternator Rating.................................................65 amps

B. Fuse Ratings, amps

• Main (S/N 8249 and Before) ..................................... 40

(S/N 8250 and After) ........................................ 30

• Cold Start (Optional) ................................................. 15

• Logic Panel .............................................................. 7.5

• Display Panel ........................................................... 7.5

• Fuel Shutoff ............................................................. 7.5

• Neutral Sense .......................................................... 7.5

• Neutral Relay/Starter ............................................... 7.5

• Hourmeter ................................................................ 7.5

• Horn ......................................................................... 7.5

• Stabil-TRAK ............................................................. 7.5

• Stabilizer Lock Relay ................................................ 7.5

• Steering Solenoids ................................................... 7.5

• Park Brake Sense Relay .......................................... 7.5

• Transmission Solenoids ........................................... 7.5

• Transmission Relay (without Closed Cab Option)..... 7.5

• Transmission Relay (with Closed Cab Option)........... 15

• Switch Lamps (Optional) .......................................... 7.5

• Closed Cab Option - Front Wiper Motor .................. 7.5

• Closed Cab Option - Skylight Wiper Motor .............. 7.5

• Closed Cab Option - Rear Wiper Motor ................... 7.5

• Closed Cab Option - Blower Motor ........................... 25

• Closed Cab Option - Power WIndow Motor .............. 30

• Closed Cab Option - Power Accessories Relay ........ 40

• Closed Cab Option - Power Window Motor Relay .... 40

• Light Package Option - Circuit A ............................... 20

• Light Package Option - Circuit B ............................... 20

2-12

Model 3606 • Origin 10/99

General Information, Specifications, and Maintenance

2.5.10 Paint

Unless otherwise specified, paint components as indicated in the following sections.

A. Orange Paint

Durable, premium Sky Trak orange paint is available in

both a convenient 16-ounce (480 ml) spray can for touchups, and in a production-sized one gallon (3,8 l) container

for extensive repainting. Consult the current

Model 3606 PARTS MANUAL

for the applicable part

number and ordering information. Use orange paint on all

vehicle components except as specified in paragraphs

2.5.10

A, B, C

and D.

B. Black Paint

Durable, premium black paint is available in both a convenient 16-ounce (480 ml) spray can for touch-ups, and in a

production-sized one gallon (3,8 l) container for extensive

repainting. Consult the current

PARTS MANUAL

for the applicable part number and

Sky Trak Model 3606

ordering information.

• Boom Angle Indicator Pointer

• Wheels (some models )

• Brake Pedal

•Radiator

• Seat Adapter Plate

• Radiator Shroud

• Transmission Oi l Cool er

•Axles

• Drive Shafts

• Drop Box

•Forks

• Mirrors and Mirror Brackets

• Air Cleaner

• Steering Column

Sky Trak

C. White Paint

Durable, premium white paint is available in both a convenient 16-ounce (480 ml) spray can for touch-ups, and

in a production-sized one gallon (3,8 l) container for

extensive repainting. Consult the current

3606 PARTS MANUAL

for the applicable part number

Sky Trak Model

and ordering information.

• Boom Extend Cylinder

• Extend Cylinder Mount Bracket (some models)

D. Gray Paint

The following parts must be painted dark gray (Ref.: Sky

Trak Color Chip 8528102):

• Wheels

• Engine mount/Hyd. tank

• Counterweight

•Cab Mount

Durable, premium gray paint is available in both a convenient 16-ounce (480 ml) spray can for touch-ups, and in a

production-sized one gallon (3,8 l) container for extensive

repainting. Consult the current

PARTS MANUAL

for the applicable part number and

Sky Trak Model 3606

ordering information.

• Wheels (some models)

• Fuel Tank Cradle

• Hydraulic Fluid Reservoir

• Battery Cover Panel

2.5.11 Thread Locking Compound

For general thread-locking purposes, Loctite® products,

manufactured by Loctite Corporation, are recommended.

Contact:

Loctite Corporation

1001 Trout Brook Crossing

Rocky Hill, CT 06067 USA

Phone: 1-800-LOCTITE (1-800-562-8483)

FAX: (860) 571-2460

Internet: http://www.loctite.com

®

Loctite

is a registered trademark of Loctite Corporation.

Model 3606 • Origin 10/99

2-13

Section 2

2.6 CLEANING

Dirt and abrasive dust reduce the efficient working life of

parts and systems, and lead to the costly replacement of

components. To help increase the service life of parts,

clean the exterior of all parts before be gi nn ing any repairs.

Use cleaning fluids and solvents suitable for cleaning

parts that do not create safety hazards. Certain types of

cleaning fluids can cause skin irritation and damage to

components (such as rubber, electrical parts, etc.).

Servicing the hydraulic system in particular requires

cleanliness.

Follow these precautions before attempting to service

any hydraulic component:

1. Flush hose and tube assemblies with a solvent

compatible with hose materials. Blow excess solvent

away with shop air.

2. Cap hydraulic fittings, hoses and tube assemblies,

and protect threads until time of installation. Clean up

any hydraulic fluid spillage immediately.

3. Flush hydraulic reservoir , fuel tank, and gear housing

with a suitable solvent to remove paint, metal chips,

etc.

4. Protect hydraulic system components from airborne

contaminants. Plug all cylinder, valve, reservoir, tank

and pump openings until time of installation.

5. Use clean, filtered oil whe n filling th e system. Maint ain

the hydraulic system at a minimum cleanliness level

of ISO code 18/15-particle ration count.

2. Hoses must remain in good condition. Obvious signs

of external hose wear or hydraulic fluid leaking or

weeping indicates the need to replace the hose

assembly. If in doubt, replace the hose.

3. Replace if any of the foll owing conditions exis t:

• Ballooning (replace hose immediately!)

• Kinking, crushing, stretching or deforming

• Concealed corrosion of wire reinforcement

• Chafed outer cover

2.8.2 Hose and Tube Installation

1. When installing a new hose, loosely connect each

end and verify that the hose takes up the designed

position before tightening the connection completely.

Tighten clamps sufficiently to hold the hose without

crushing it, and to prevent movement and chafing.

2. If a hose is replaced on a moving part, move the part

through its entire range of motion to verify that the

hose will not incur damage. Adjust as necessary.

3. When installing any hose, verify that it does not

become kinked or twisted.

4. NEVER allow freely-moving or unsupported hoses to

contact each other or a related work surface. Such

contact causes chafing and reduces hose life.

2.9 BEARINGS