SkyTrak 6042 Service Manual

SECTION CONTENTS

Model 6042 Legacy Origin 7/02

i

ã 2002 OmniQuip Textron Inc.

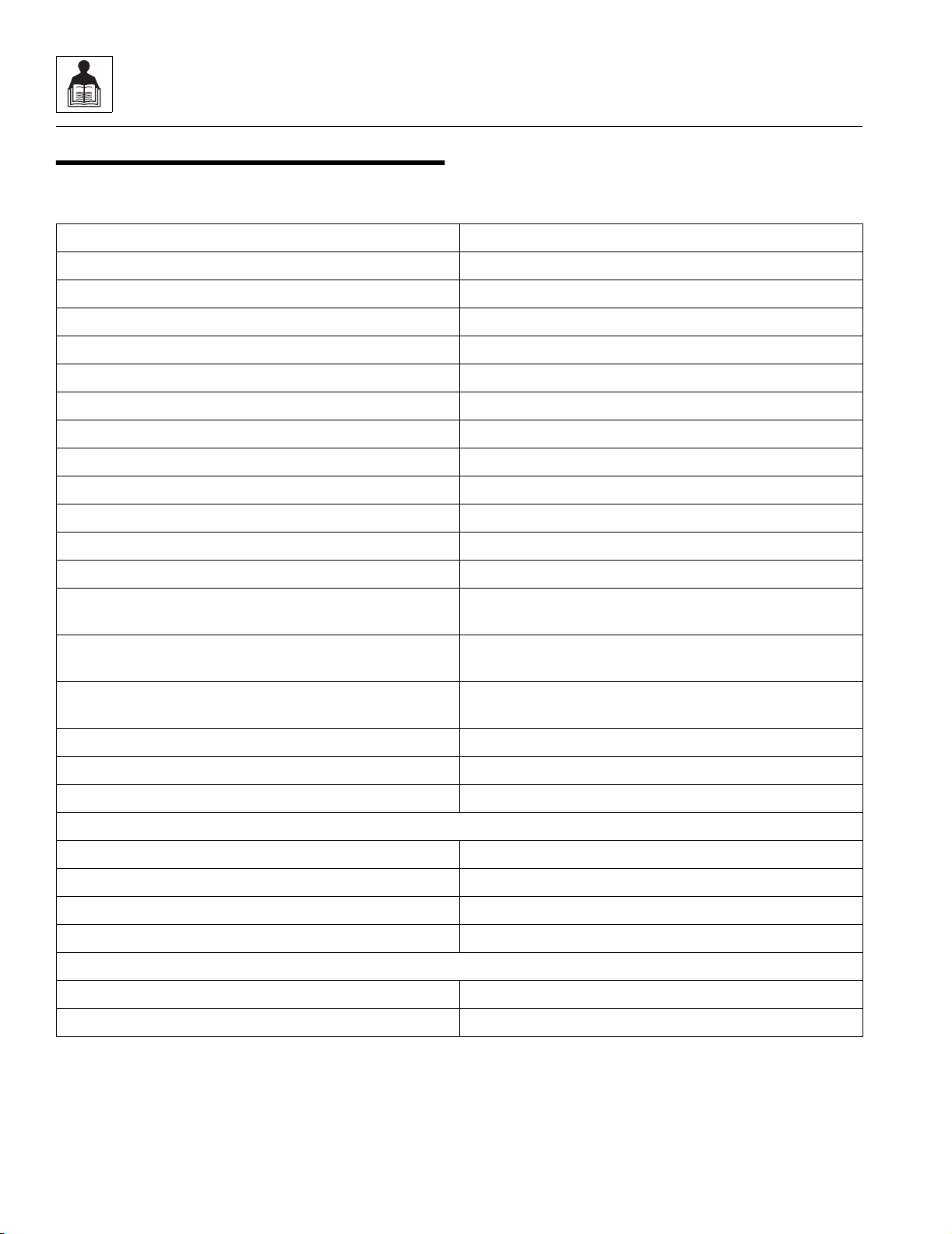

Section Subject Page

Section 1

Safety Practices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.1

1.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.2

1.2 Owners/Operators Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.2

1.3 Training Mechanics as Operators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.3

1.4 Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.3

1.5 Accident Prevention Tag Usage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.4

1.6 Safety Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.5

1.7 Emergency Exit Rear Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.6

1.8 Hazard/Emergency Information Decals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.7

Section 2

General Information and Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.1

2.1 6042 Component Terminology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.3

2.2 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.4

2.3 Torques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.6

2.4 Metric Conversion Factors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.12

2.5 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.14

2.6 Fluids, Lubricants and Capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.23

2.7 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.27

2.8 Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.28

2.9 Hoses and Tubes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.28

2.10 Bearings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.28

2.11 Pressure Testing and Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.29

2.12 After Service Startup and Checks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.29

Section 3

Boom . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.1

3.1 Boom System Component Terminology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.2

3.2 Boom System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.3

3.3 Boom Assembly Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.3

3.4 Boom Chains. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.46

3.5 Boom Wear Pads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.65

3.6 Quick Attach Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.68

3.7 Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.71

Section 4

Cab and Covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.1

4.1 Operator’s Cab and Covers Component Terminology. . . . . . . . . . . . . . . . . . . . . . . . . . 4.2

4.2 Operator’s Cab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.3

4.3 Open Cab Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.4

4.4 Enclosed Cab (Optional) Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.20

4.5 Cab Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.26

4.6 Cab Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.29

4.7 Access Panels and Covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.32

Section Subject Page

ii

Model 6042 Legacy Origin 7/02

Section 5

Axles, Drive Shafts, Wheels and Tires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.1

5.1 Axle, Drive Shaft and Wheel Component Terminology . . . . . . . . . . . . . . . . . . . . . . . . . 5.2

5.2 General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.3

5.3 Axle Assemblies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.3

5.4 Drive Shafts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.15

5.5 Wheels and Tires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.21

Section 6

Transmission: ZF 4 WG-98 TC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.1

6.1 Transmission Assembly Component Terminology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.2

6.2 Transmission Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.3

6.3 Transmission Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.3

6.4 Transmission Serial Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.3

6.5 Transmission Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.4

6.6 Transmission Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.4

6.7 Transmission Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.6

6.8 Towing a Disabled Vehicle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.13

6.9 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6.14

Section 7

Engine: Cummins 4BT3.9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.1

7.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.2

7.2 Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.4

7.3 Engine Serial Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.6

7.4 Specifications and Maintenance Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.6

7.5 Standard Practices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.6

7.6 Engine Cooling System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.7

7.7 Engine Electrical System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.14

7.8 Fuel System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7.15

7.9 Engine Exhaust System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.23

7.10 Air Cleaner Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.24

7.11 Engine Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.25

7.12 Engine Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7.37

7.13 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7.38

Section 8

Hydraulic System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8.1

8.1 Hydraulic Component Terminology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8.3

8.2 Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8.4

8.3 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8.5

8.4 Hydraulic Fluid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8.5

8.5 Hoses, Tube Lines, Fittings, Etc. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8.6

8.6 Hydraulic Pressure Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8.7

8.7 Hydraulic System Testing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8.10

8.8 Hydraulic Circuits and Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8.13

8.9 Four-Wheel Steer Indexing Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8.58

8.10 Hydraulic Reservoir . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8.60

8.11 Hydraulic System Pump. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8.61

8.12 Valves and Manifolds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8.68

8.13 Hydraulic Cylinders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8.98

Section Subject Page

iii

Model 6042 Legacy Origin 7/02

Section 9

Electrical System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9.1

9.1 Electrical Component Terminology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9.4

9.2 Service Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9.6

9.3 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9.6

9.4 Effective Ground Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9.7

9.5 Wiring Harnesses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9.7

9.6 Fuses and Relays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9.9

9.7 Electrical System Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9.11

9.8 Transmission Gear Selection Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9.60

9.9 Dash Panel Warning Indicator Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9.68

9.10 Engine Start Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9.80

9.11 Charging Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9.82

9.12 Electrical System Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9.89

9.13 Window Wiper/Washer (Option) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9.95

9.14 Cab Heater and Fan (Option) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9.102

9.15 Switches and Solenoids . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9.104

Section 10

Stabil-TRAK™ System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10.1

10.1 Stabil-TRAK™ System Component Terminology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10.2

10.2 Stabil-TRAK™ Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10.3

10.3 Stabil-TRAK™ Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10.4

10.4 Stabil-TRAK™ Electrical Circuit Operation and Troubleshooting . . . . . . . . . . . . . . . . . 10.8

10.5 Stabil-TRAK™ Hydraulic Circuit Operation and Troubleshooting . . . . . . . . . . . . . . . . . 10.12

10.6 Stabil-TRAK™ System Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10.27

Section 11

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11.1

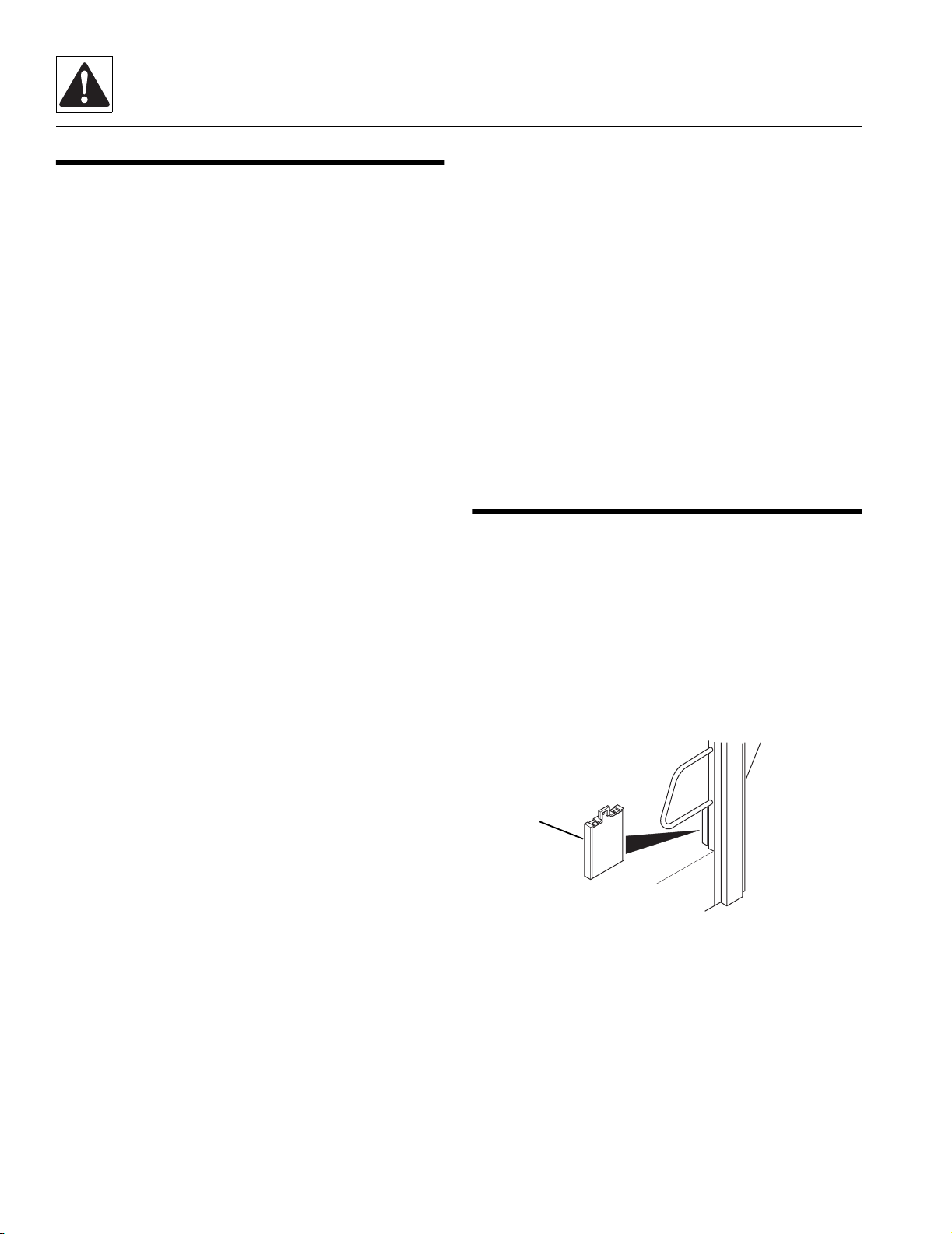

Accident Prevention Tags

Section Subject Page

iv

Model 6042 Legacy Origin 7/02

This Page Intentionally Left Blank

1.1

Model 6042 Legacy Origin 7/02

Section 1

Safety Practices

Contents

PARAGRAPH TITLE PAGE

1.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.2

1.2 Owners/Operators Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.2

1.3 Training Mechanics as Operators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.3

1.4 Safety Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.3

1.4.1 Safety Alert Symbol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.3

1.4.2 Hazard Statements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.4

1.5 Accident Prevention Tag Usage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.4

1.6 Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.5

1.6.1 Personal Hazards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.5

1.6.2 Equipment Hazards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.5

1.6.3 General Hazards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.6

1.6.4 Operational Hazards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.6

1.7 Emergency Exit Rear Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.6

1.8 Hazard/Emergency Information Decals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.7

Safety Practices

1.2

Model 6042 Legacy Origin 7/02

1.1 INTRODUCTION

OmniQuip Textron Inc. (hereafter, OmniQuip) products

meet all applicable industry safety standards. OmniQuip

actively promotes safe practices in the use and mainte-

nance of its products through training programs, instruc-

tional manuals and the pro-active efforts of all employees

involved in engineering, design, manufacture, marketing

and service.

This manual is designed to provide service technicians

with complete information on the maintenance and repair

of the Sky Trak Model 6042 Legacy Telescopic Material

Handler.

Particular effort has been made to produce a manual to

serve as a reference handbook for the experienced

service technician, but also provide essential step-by-

step procedures for the professional development of the

less experienced person. Remember, even the best

manual in the world is no substitute for an appropriate

education, skill development that comes through

experience alone, safety, wise and judicious

discernment, and ultimately, proper performance of

service procedures.

This service manual provides general directions for

accomplishing service and repair procedures with tested,

effective techniques. Following the procedures in this

manual will help assure safety and equipment reliability.

Read, understand and follow the information in this

manual, and obey all locally approved safety practices,

procedures, rules, codes, regulations and laws. Prior to

performing any maintenance on the vehicle, consider all

factors, circumstances and conditions which can have an

effect upon the safety of personnel and equipment, and

take appropriate action to ensure the safety of all

involved.

These instructions cannot cover all details or variations in

the equipment, procedures or processes described, nor

provide directions for meeting every possible contingency

during operation, maintenance or testing. When additional

information is desired to satisfy a situation not covered

sufficiently, consult the local OmniQuip Authorized

Service Center (ASC) or the OmniQuip Service

Department at 1-800-439-8959 (Domestic) or

1-262-268-8957 (Internationally).

Many factors contribute to unsafe conditions:

carelessness, fatigue, overload, inattentiveness,

unfamiliarity, even drugs and alcohol, among others.

Although equipment damage can usually be repaired in a

brief period of time, death and irreparable injury are

permanent. For optimal safety, encourage everyone to

think, and to act, safely.

Appropriate service methods and proper repair

procedures are essential for the safety of the individual

doing the work, for the safety of the operator, and for the

safe, reliable operation of the vehicle.

Provisions for supplementary information are made by

OmniQuip in the form of Service Bulletins, Service

Campaigns, Service Training Schools, the OmniQuip

website, other literature, and through updates to the manual

itself. Comments and suggestions for improvement are

welcome and encouraged.

All information, illustrations and specifications contained

in this manual are based on the latest product information

available at the time of publication approval. OmniQuip

reserves the right to make changes and improvements to

its products, and to discontinue the manufacture of any

product, at its discretion at any time without public notice

or obligation.

1.2 OWNERS/OPERATORS MANUAL

The vehicle must be driven and operated as a

consequence of, or when performing, service,

maintenance and test procedures. The service technician

must, therefore, thoroughly read, understand and follow

the Sky Trak Model 6042 Legacy Telescopic Material

Handler Owners/Operators Manual.

An owners/operators manual is supplied with each

vehicle and must be kept in the owners/operators manual

holder (Fig. 1-1, 1) located on the cab post to the left and

below the operator’s seat.

Figure 1-1 The Owners/Operators Manual Holder

In the event that the owners/operators manual is missing,

consult the local OmniQuip Authorized Service Center

(ASC) or the OmniQuip Service Department before

proceeding.

MH0770

1

1.3

Model 6042 Legacy Origin 7/02

Safety Practices

1.3 TRAINING MECHANICS AS

OPERATORS

Because it is necessary to move the vehicle to service or

maintain the vehicle, it is necessary that all mechanics

are OSHA trained and certified as operators. A mechanic

trained in the proper operation of the vehicle can better

determine whether all functions are operating correctly.

At the time of original purchase, the purchaser of this

vehicle was instructed by the seller on its proper use.

When this vehicle is to be serviced or maintained by

someone other than the purchaser, make certain that the

mechanic is trained, in accordance with the OSHA

regulations listed in the NOTICE below, and reads and

understands the SKY TRAK Model 6042 Legacy

Telescopic Material Handler Owners/Operators Manual

before

operating or maintaining the vehicle.

NOTICE: Under OSHA rules, it is the responsibility of the

employer to provide operator training. Successful

completion and certification of Safety Training for Rough

Terrain Forklifts is required. Operator Training Kits are

available by calling the Ken Cook Company at

(414) 466-6060. An order form for these kits is available

through our website, http://www.omniquip.com.

In addition, make sure that the mechanic has completed

a walk-around inspection of the vehicle, is familiar with all

decals and/or decal plates on the vehicle, and has

demonstrated the correct use of all controls.

1.4 SAFETY INFORMATION

The following information provides general safety

instructions, including examples of hazard statements

with signal words, notification of hazards, methods to

help avoid hazards and the consequences of failing to

follow the safety information. To avoid possible death or

injury, carefully read and follow all safety messages. Fully

understand the potential causes of death or injury.

In the event of an accident, know where to obtain medical

assistance and how to use a first-aid kit and fire

extinguisher/fire suppression system. Keep emergency

telephone numbers (fire department, ambulance, rescue

squad/paramedics, police department, etc.) nearby. If

working alone, check with another person routinely to

help ensure personal safety.

The information in this manual does not replace any other

safety rules or proper judgment. Governmental

authorities and employers also have their own sets of

rules, codes, regulations and laws. Before starting work

at a site, check with the supervisor or safety coordinator

and ask about the safety policy. Learn the safety

requirements in effect before operating, maintaining,

servicing or testing the vehicle. Safety depends on

following safety requirements.

1.4.1 Safety Alert Symbol

The exclamation mark within a triangle is the Safety Alert

Symbol.

This symbol means “Attention! Become Alert! Your

Safety Is Involved!” The symbol is used to attract

attention to safety hazards found on the vehicle safety

decals and throughout this manual.

OP0330

Safety Practices

1.4

Model 6042 Legacy Origin 7/02

1.4.2 Hazard Statements

Signal words and messages are used in conjunction with

the safety alert symbol to create hazard statements.

These hazard statements convey important information

about safety.

Four types of hazard statements are used in this manual.

Each statement indicates the existence and degree of

relative risk of the hazard described within the statement

that follows the signal word.

Explanations of the types of hazard statements are as

follows:

The signal word “DANGER” indicates an imminently

hazardous situation which, if not avoided, will result in

death or serious injury.

The signal word “WARNING” indicates a potentially

hazardous situation which, if not avoided, could result in

death or serious injury.

The signal word “CAUTION” indicates a potentially

hazardous situation which, if not avoided, could result in

minor or moderate injury.

The signal word “CAUTION,” used without the safety

alert symbol, indicates a potentially hazardous situation

which, if not avoided, could result in property damage.

For safe maintenance of the vehicle, read, understand

and follow all DANGER, WARNING and CAUTION

information.

1.5 ACCIDENT PREVENTION TAG

USAGE

Figure 1-2 Accident Prevention Tag

Before beginning any maintenance or service, place an

Accident Prevention Tag (Fig. 1-2) on both the ignition

key switch and the steering wheel (Fig. 1- 3), stating that

the vehicle should not be operated. Actual Accident

Prevention Tags, which can be punched out and used,

are included as the last page in this manual. Retain these

Accident Prevention Tags for reuse at a later date.

Figure 1-3 Place Accident Prevention Tags on Both the

Ignition Key Switch and the Steering Wheel

DANGER:

WARNING:

CAUTION:

CAUTION:

MC0690

DANGER

DANGER

OH1720

1.5

Model 6042 Legacy Origin 7/02

Safety Practices

1.6 SAFETY INSTRUCTIONS

Following are general safety statements to consider

before

performing maintenance procedures on a vehicle.

Additional statements related to specific tasks and

procedures are located throughout this manual and are

listed prior to any work instructions to provide safety

information before the hazard occurs.

For all safety messages, carefully read, understand and

follow the instructions before

proceeding.

1.6.1 Personal Hazards

HAIR and CLOTHING: DO NOT wear loose clothing or

jewelry. Tie up or restrain hair. Wear the correct safety

equipment for the job (including but not limited to: hard

hat; safety shoes; safety glasses, goggles, or face shield;

heavy gloves; hearing protection; reflective clothing; wet-

weather gear; respirator or filter mask).

EYE PROTECTION: Always wear appropriate eye

protection when chiseling, grinding, sanding, welding,

painting, repairing hydraulic systems, or checking, testing

or charging the battery.

BREATHING PROTECTION: Wear respiratory

protection when grinding or painting.

HEARING PROTECTION: Always wear hearing

protection in a high-noise area.

FOOT PROTECTION: Wear protective footwear with

reinforced toe caps and slip-resistant soles.

LIFTING: NEVER lift a heavy object without the help of at

least one assistant or a suitable sling and hoist.

1.6.2 Equipment Hazards

OWNERS/OPERATORS MANUAL: Before operating the

vehicle, carefully read, understand and follow the owners/

operators manual.

OPERATIONAL PROTECTION: Before operating the

vehicle or returning it for operational use, check that the

Operator’s Protective Structure is intact, undamaged,

unmodified and secure.

LIFTING OF EQUIPMENT: Before using any lifting

equipment (chains, slings, brackets, hooks, etc.), verify

that it is of the proper capacity, in good working condition

and properly attached.

NEVER stand or otherwise become positioned under a

suspended load or under raised equipment. The load or

equipment could fall or tip.

DO NOT use a hoist or jack to support raised equipment.

A hoist or jack failure can allow the equipment to fall or tip.

Always support equipment with proper capacity blocks or

stands that are properly rated for the load.

COMPRESSED AIR: Before and during the use of

compressed air, wear eye protection and advise other

personnel in the work area that compressed air is about

to be used.

HAND TOOLS: Always use the proper tool for the job;

keep tools clean and in good working order, and use

special service tools only as recommended.

Safety Practices

1.6

Model 6042 Legacy Origin 7/02

1.6.3 General Hazards

SOLVENTS: Only use approved solvents, and solvents

that are known to be safe for use.

HOUSEKEEPING: Keep the work area and operator’s

cab clean and remove all hazards (debris, oil, tools, etc.).

FIRST AID: Immediately clean, dress and report all

injuries (cuts, abrasions, burns, etc.), no matter how

minor. Know the location of a first-aid kit, and know how

to use it.

CLEANLINESS: Wear eye protection, and clean all

components with a high-pressure or steam cleaner

before attempting service.

When removing hydraulic components, plug hose ends

and connections to prevent excess leakage and

contamination. Place a suitable catch basin beneath the

vehicle to capture fluid run-off.

1.6.4 Operational Hazards

OPERATIONAL CONSIDERATIONS: Before operating

the vehicle, carefully read, understand and follow the

owners/operators manual.

ENGINE: Stop the engine before performing any service.

DANGEROUS START: Place Accident Prevention Tags

on both the ignition key switch and the steering wheel

before attempting to perform any service or maintenance.

Disconnect battery leads. Place a warning sign on a

vehicle that is dangerous to start, if leaving the vehicle

unattended.

VENTILATION: Avoid prolonged engine operation in

enclosed areas without adequate ventilation.

RADIATOR CAP: Always wear steam-resistant, heat-

protective gloves when opening the radiator cap. Cover

cap with a clean, thick cloth and turn slowly to the first

stop to relieve pressure.

SOFT SURFACES AND SLOPES: NEVER work on a

vehicle that is parked on a soft surface or slope (inclined

ground or hill). The vehicle must be on a hard, level

surface with the wheels blocked when performing any

service. Obtain assistance, block all wheels, and add

supports if necessary before beginning any work.

SUPPORTS AND STRAPS: Install safe, stable supports,

slings or straps beneath or around a component or

structural member before beginning any work.

FLUID PRESSURE: Before loosening any hydraulic or

diesel fuel component, hose or tube, turn engine OFF.

Wear heavy, protective gloves and eye protection.

NEVER check for leaks using any part of your body; use

a piece of cardboard or wood instead. If injured, seek

medical attention immediately. Diesel fuel leaking under

pressure can explode. Hydraulic fluid and diesel fuel

leaking under pressure can penetrate the skin, causing

infection, gangrene and other serious personal injury.

Relieve all pressure before disconnecting any

component, part, line or hose. Slowly loosen parts and

allow release of residual pressure before removing any

part or component. Before starting engine or applying

pressure, use components, parts, hoses and pipes that

are in good condition, connected properly and tightened

to the proper torque. Capture fluid in an appropriate

container and dispose of it in accordance with prevailing

environmental regulations.

PRESSURE TESTING: When conducting any test, only

use test equipment that is correctly calibrated and in good

condition. Use the correct equipment in the proper

manner, and make changes or repairs as indicated by the

test procedures to achieve the desired results.

LEAVING VEHICLE: Lower the attachment to the ground

before leaving the vehicle.

TIRE PRESSURE: Always keep tires inflated to the

proper pressure to help prevent dangerous travel and

load-handling situations. DO NOT over-inflate tires.

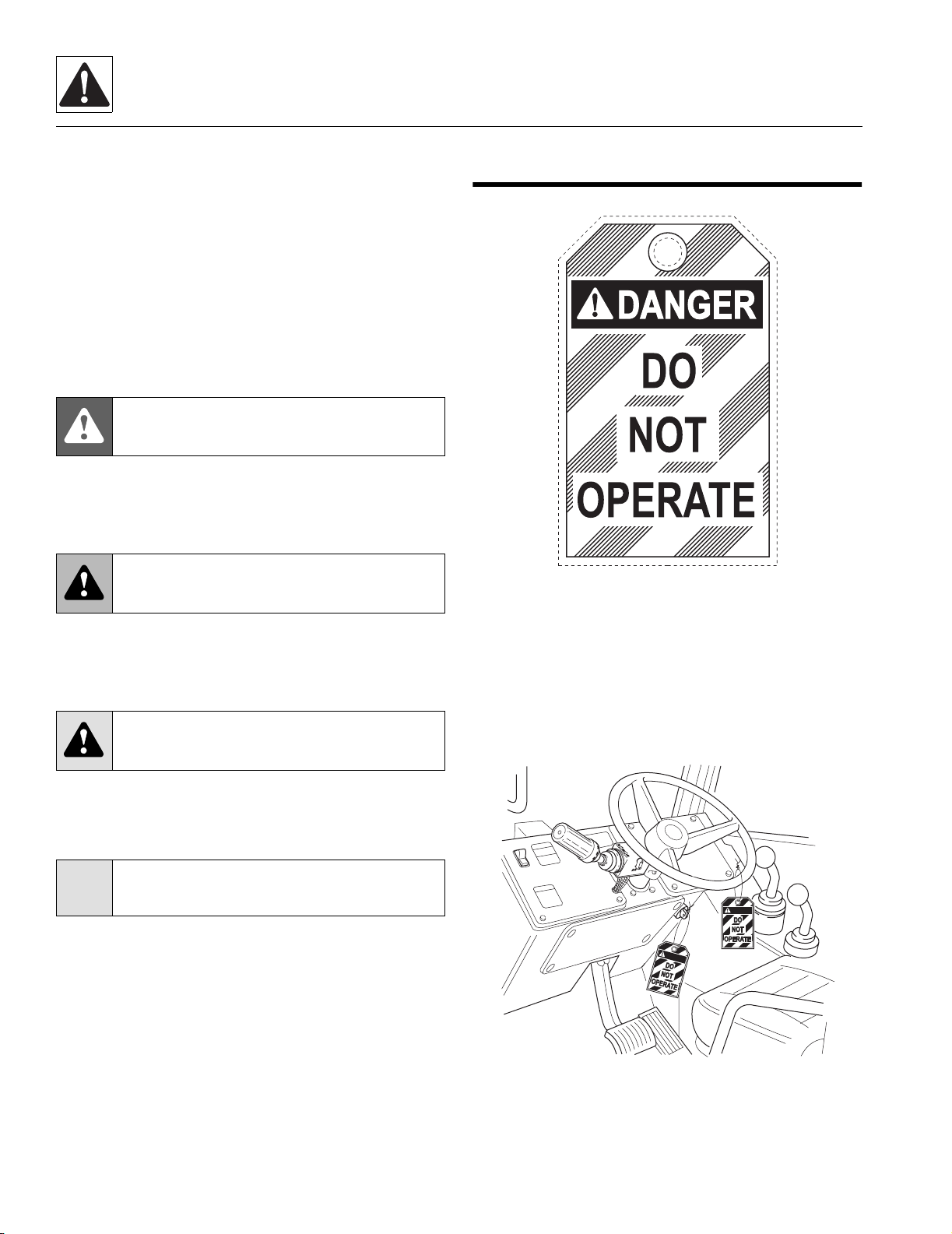

1.7 EMERGENCY EXIT REAR WINDOW

The rear window in the enclosed cab can be used as an

emergency exit by removing the latch pins (Fig. 1-4, 1)

located on the two window latches (2). Once the latch

pins have been removed, the window (3) can be swung

open.

Figure 1-4 Emergency Exit Rear Window Latch Pins

4

1

0

9

7

9

1

2.

3.

1.

OH1730

1

3

2

~

1.7

Model 6042 Legacy Origin 7/02

Safety Practices

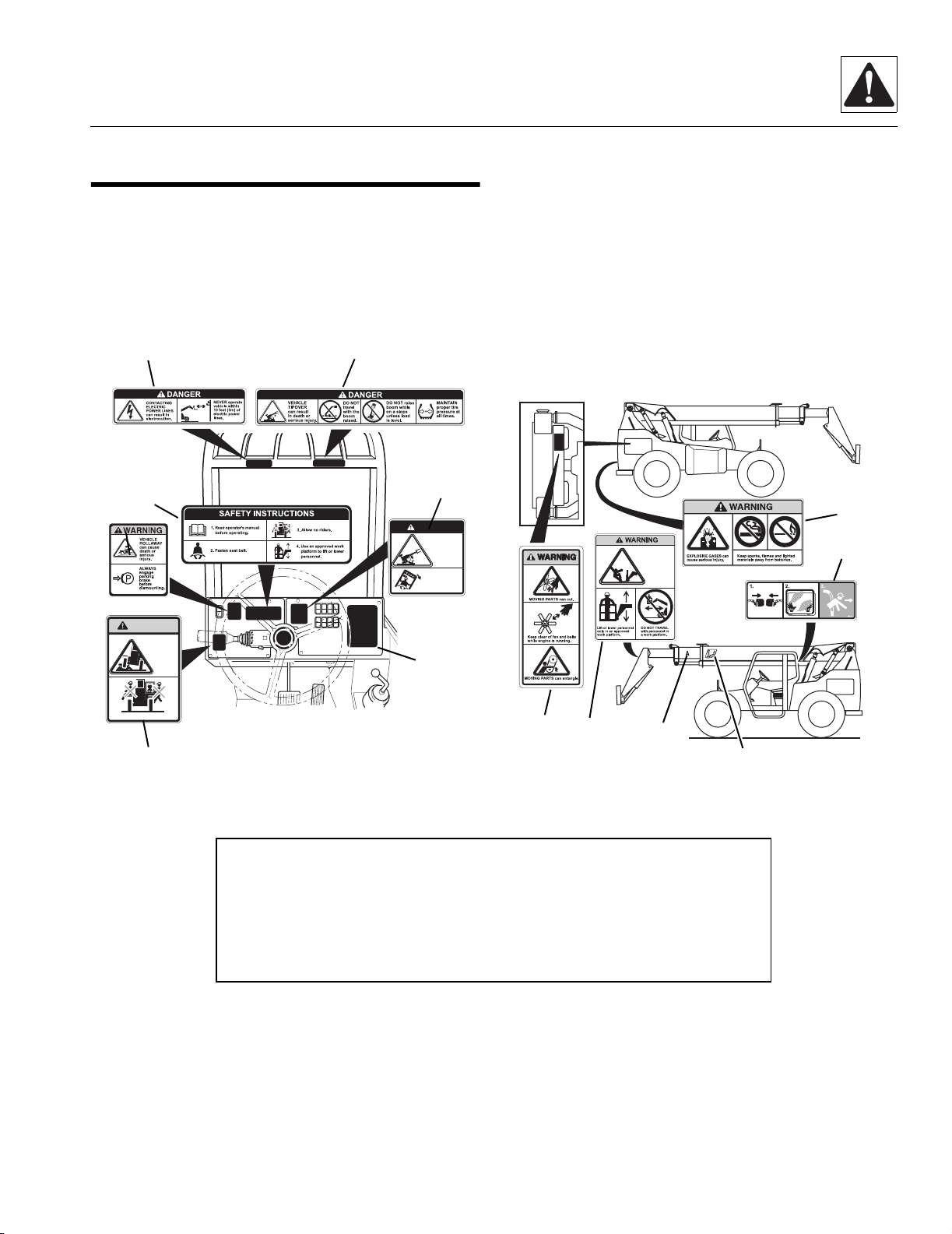

1.8 HAZARD/EMERGENCY

INFORMATION DECALS

Locations of vehicle hazard and other emergency

information decals are shown below. As part of routine

maintenance, check that ALL hazard and emergency

information decals on the vehicle are present and

readable. Keep all decals clean.

If a replacement decal is needed, refer to the owners/

operators manual and parts catalog for the latest parts

numbers and ordering information, or, contact OmniQuip

Textron Parts Worldwide directly at:

Domestic: 1-888-872-5123

or

International: 1-262-268-8958

Note: Many of these hazard related decals are available free of charge by

calling OmniQuip Textron Parts Worldwide at 1-888-872-5123 (Domestic) or

1-262-268-8958 (International).

WARNING

Allow no riders

AVOID

CRUSHING,

falling off

vehicle can

cause death

or serious

injury

DO NOT JUMP.

Brace yourself.

Stay in cab.

Keep seat belt on.

if vehicle tips.

Jumping can

result in death

or serious

injury.

DANGER

AVOID CRUSHING

FALLING OFF ATTACHMENT,

can result in death or

serious injury.

OH17422

OA14402

5

3

6

7

4

1

2

10

11

12

13

9

8

1. No Riders WARNING

2. Vehicle Rollaway WARNING

3. Safety Instructions

4. Electrocution DANGER

5. Tipover DANGER - Operating

6. Do Not Jump DANGER

7. Load Chart Booklet

8. Moving Parts WARNING

9. Carrying Personnel WARNING

10. Boom Extend Letters

11. Boom Angle Indicator

12. Explosive Gases WARNING

13. Emergency Exit (Enclosed Cab Only)

Safety Practices

1.8

Model 6042 Legacy Origin 7/02

This Page Intentionally Left Blank

2.1

Model 6042 Legacy Origin 7/02

Section 2

General Information and Specifications

Contents

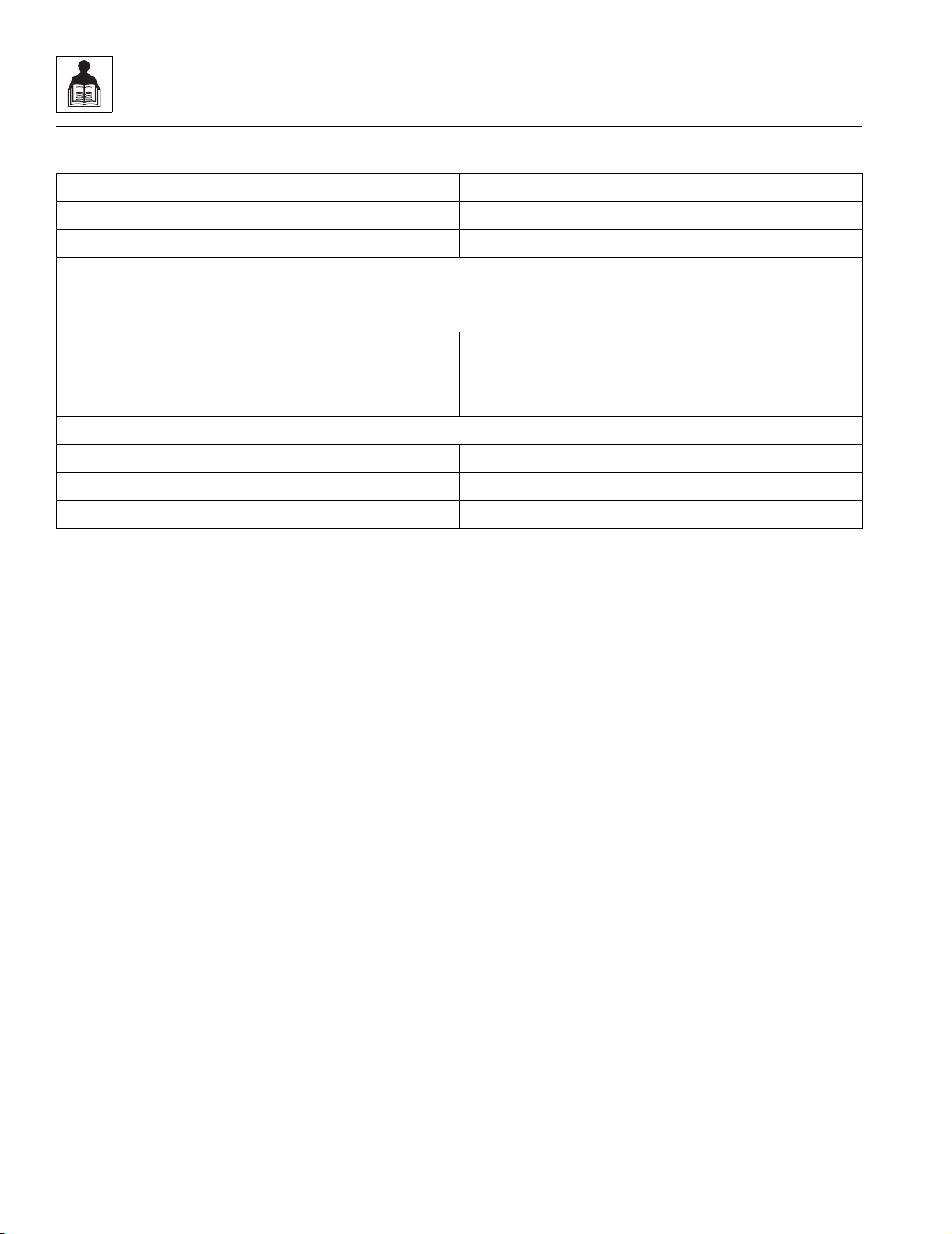

PARAGRAPH TITLE PAGE

2.1 6042 Component Terminology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.3

2.2 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.4

2.2.1 Service Methods. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.4

2.2.2 The Owners/Operators Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.4

2.2.3 Replacement Parts and Warranty Information . . . . . . . . . . . . . . . . . . . . . . . . . 2.4

2.2.4 Disclaimer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.5

2.3 Torques. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.6

2.3.1 Fasteners . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.6

2.3.2 Bolts and Nuts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.6

2.3.3 SAE 37° Flare Hydraulic Fittings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.6

2.3.4 SAE Flat Face O-Ring Seal Hydraulic Fittings . . . . . . . . . . . . . . . . . . . . . . . . . 2.9

2.4 Metric Conversion Factors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.12

2.4.1 Approximate American to Metric Conversions . . . . . . . . . . . . . . . . . . . . . . . . . 2.12

2.4.2 Approximate Metric to American Conversions . . . . . . . . . . . . . . . . . . . . . . . . . 2.13

2.5 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.14

2.5.1 Vehicle Dimensions (With Standard 12-ply 13.00-24 Tires) . . . . . . . . . . . . . . . 2.14

2.5.2 Vehicle Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.16

2.5.3 Attachment Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.17

2.5.4 Performance Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.17

2.5.5 Hydraulic Cylinder Performance Specifications . . . . . . . . . . . . . . . . . . . . . . . . 2.18

2.5.6 Electrical System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.19

2.5.7 Engine Performance Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.20

2.5.8 Fluid and Lubricant Capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.21

2.5.9 Hydraulic System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.22

2.5.10 Tires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.22

2.5.11 Miscellaneous Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.22

2.5.12 Tamper Proofing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.23

2.5.13 Fork Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.23

General Information and Specifications

2.2

Model 6042 Legacy Origin 7/02

2.6 Fluids, Lubricants and Capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.23

2.6.1 Axles (Differential Housings) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.23

2.6.2 Axle Wheel Ends . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.24

2.6.3 Transmission. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.24

2.6.4 Lubrication Points (Grease Fittings) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.24

2.6.5 Hydraulic System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.25

2.6.6 Engine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.25

2.6.7 Drive Shaft Splines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.26

2.6.8 General Anti-Corrosion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.26

2.6.9 Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.26

2.6.10 Paint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.27

2.6.11 Thread Locking Compound . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.27

2.7 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.27

2.8 Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.28

2.9 Hoses and Tubes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.28

2.9.1 Hose and Tube Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.28

2.9.2 Hose and Tube Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.28

2.10 Bearings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.28

2.10.1 Bearing Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.28

2.10.2 Bearing Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.28

2.10.3 Bearing Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.29

2.11 Pressure Testing and Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.29

2.12 After Service Startup and Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.29

2.12.1 After Service Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.29

2.12.2 After Electrical/Electronic Component Service . . . . . . . . . . . . . . . . . . . . . . . . . 2.29

2.12.3 After Hydraulic Component Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.30

2.12.4 After Brake System Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.30

2.12.5 After Fuel System Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.30

2.12.6 After Transmission Service or Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . 2.30

2.12.7 After Tire and Wheel Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.31

2.12.8 After Engine Service. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.31

2.12.9 After Boom Service. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.31

2.12.10 After Axle Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.31

2.3

Model 6042 Legacy Origin 7/02

General Information and Specifications

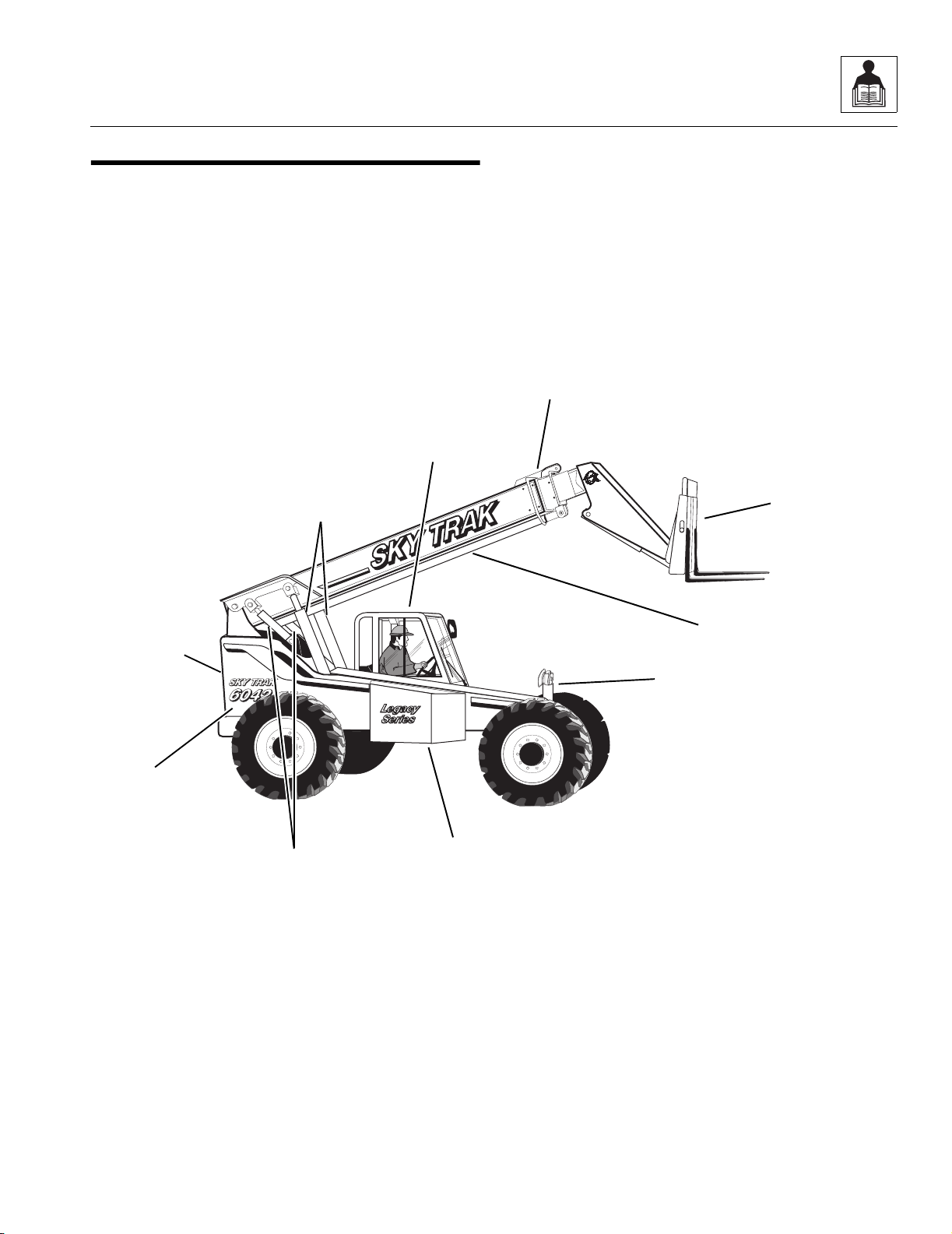

2.1 6042 COMPONENT TERMINOLOGY

To understand the safety, operation and maintenance

information presented in this manual, it is necessary that

the operator/mechanic be familiar with the names and

locations of the major assemblies on this vehicle. The

following illustration identifies the components that are

referred to throughout this manual.

MA10,0650

Operator’s

Protective

Structure

Boom

Assembly

Hydraulic

Oil Tank

Carriage

Assembly

Rear Door

(Not Visible)

Engine

Compartment

Frame Sway

Cylinder

Slave

Cylinders (2)

Lift/Lower

Cylinders (2)

Extend/Retract

Cylinder

~

General Information and Specifications

2.4

Model 6042 Legacy Origin 7/02

2.2 INTRODUCTION

2.2.1 Service Methods

Appropriate service methods and proper repair

procedures are essential for safe, reliable operation of

this vehicle and the safety of the individual doing the

work. This Service Manual provides general direction for

accomplishing service and repair work with tested, effective

techniques. Following them will assure reliability.

There are many variations in procedures, techniques,

tools and parts for servicing vehicles, as well as work

skills. This manual cannot possibly anticipate all such

variations and provide advice or cautions for each one.

Accordingly, anyone who intends to depart from the

instructions in this manual must first consider personal

safety and then vehicle integrity.

IMPORTANT: OmniQuip recommends the use of

environmentally sound waste storage and disposal

practices. NEVER drain fluids on the ground or into a

sewer or catch basin. Use suitable collection containers,

then store and/or dispose of waste products in an

approved and safe manner. Check and obey all Federal,

State and/or Local regulations regarding waste storage,

disposal and recycling.

2.2.2 The Owners/Operators Manual

The Owners/Operators Manual provides information you

need to properly operate and maintain this vehicle.

IMPORTANT: Before you operate this vehicle, read the

manual completely and carefully, so that you will understand

the safety instructions and the operation of the controls

and safety equipment. You must comply with all Danger,

Warning and Caution notices. They are for your benefit.

All references to the right side, left side, front and rear are

given from the operator’s seat looking in a forward direction.

2.2.3 Replacement Parts and Warranty

Information

For reference when ordering replacement parts or making

service inquiries about the vehicle, the vehicle serial

number is required to help assure the provision of correct

parts and information. Before ordering parts or initiating

service inquiries, make note of the serial number.

2.5

Model 6042 Legacy Origin 7/02

General Information and Specifications

The vehicle serial number plate (Fig. 2-1, 1) is located at

the front of the vehicle on the frame sway cylinder upright.

Figure 2-1 Vehicle Serial Number Plate Location

IMPORTANT: The replacement of any part on this

vehicle with any other than a OmniQuip authorized

replacement part can adversely affect the performance,

durability, or safety of the vehicle, and will void the

warranty. OmniQuip disclaims liability for any claims or

damages, whether regarding property damage, personal

injury or death arising out of the use of unauthorized

replacement parts.

A warranty registration form must be filled out by the

OmniQuip Authorized Service Center (ASC), signed by

the purchaser and returned to OmniQuip when the

vehicle is sold and/or put into use.

Registration activates the warranty period and helps to

assure that warranty claims are promptly processed. To

guarantee full warranty service, verify that the distributor

has returned the business reply card of the warranty

registration form to OmniQuip.

2.2.4 Disclaimer

OmniQuip reserves the right to make changes to and to

add improvements upon its product at any time, without

public notice or obligation. OmniQuip also reserves the

right to discontinue manufacturing any product at its

discretion at any time.

OH0280

1

General Information and Specifications

2.6

Model 6042 Legacy Origin 7/02

2.3 TORQUES

2.3.1 Fasteners

All fasteners (nuts, bolts, washers, etc.) are equal to SAE

Grade 5 (PC8.8) and are plated, unless otherwise specified.

2.3.2 Bolts and Nuts

Unless otherwise specified, the following values apply for

Grade 5 (PC8.8) nuts and bolts:

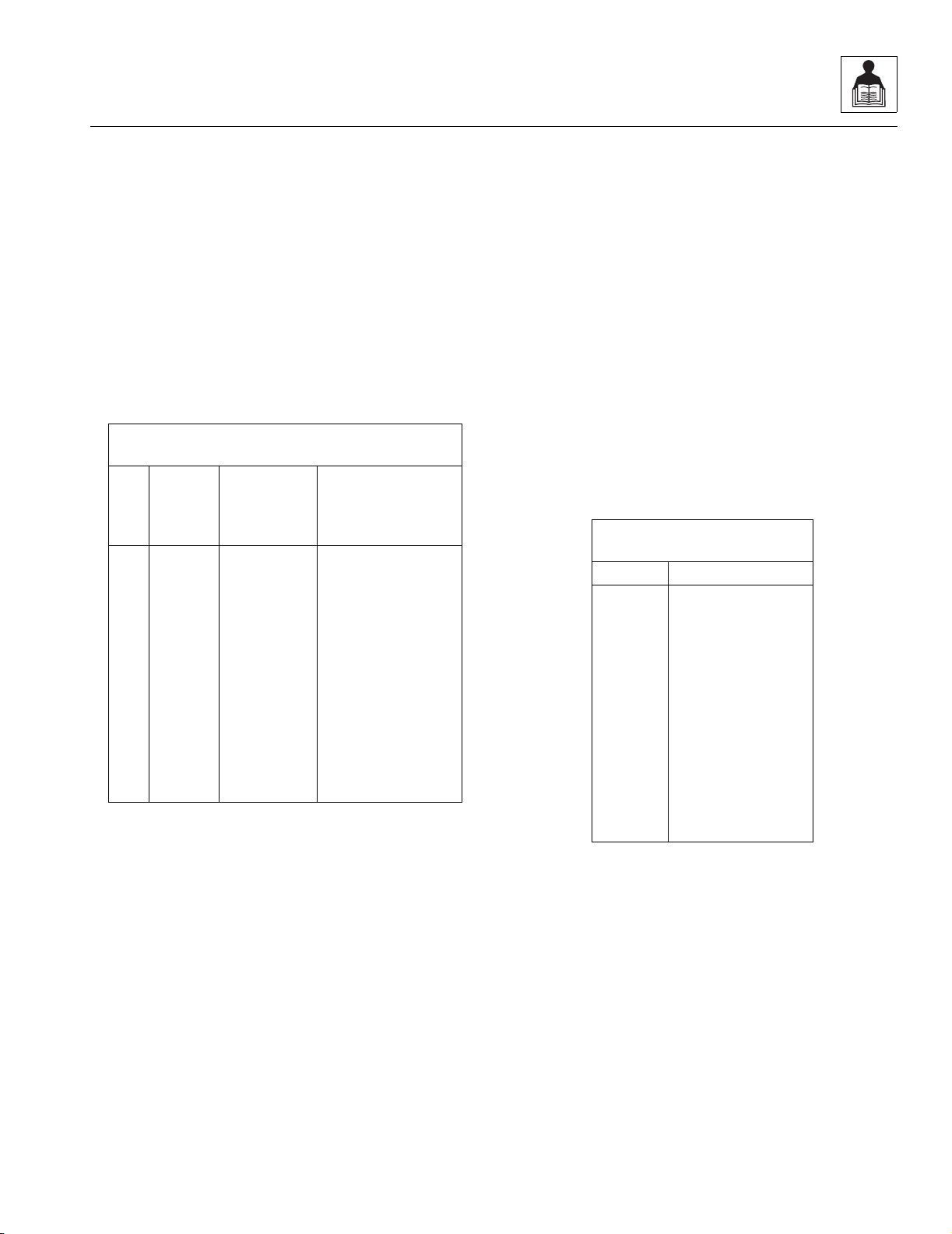

2.3.3 SAE 37° Flare Hydraulic Fittings

a. Assembly Procedure

Follow these steps when tightening hose ends, tube ends

and fitting swivel ends onto fitting male end connections

(Refer to Fig. 2-2).

Improper assembly of this type of joint will result in

leaking joints. Over tightening can result in cracking of the

female swivel seat or deformation of the male fitting

tapered seat. Under tightening will result in the joint

loosening during normal usage. Foreign material on

either seal surfaces will cause damage to one or both

mating parts when the joint is tightened, resulting in a

leaking joint.

1. Inspect both the male and female sealing cone

surfaces for burrs, scratches, dents, other damage,

or foreign material. If any damage is found on the

seat the part is to be rejected as unusable. Clean off

any foreign material from the sealing surfaces before

assembly.

2. Align the mating parts and check to see that the flare

seats properly on the nose of the fitting.

3. Finger tighten the nut onto the fitting. If necessary a

wrench may be used to snug the nut against the

fitting (30 lb-in maximum torque). This is considered

the “finger tight” (Fig. 2-2, 1) condition.

Figure 2-2 F.F.F.T. Tightening Method

Size Torque Size Torque

Inchlb-ftNmmmNmlb-ft

1/4 9 12 6,0 10 7

5/16 17 24 8,0 25 18

3/8 31 42 10,0 50 37

7/16 50 68 -- -- --

1/2 75 102 12,0 80 59

9/16 110 150 14,0 130 95

5/8 150 203 16,0 200 146

3/4 250 340 20,0 360 263

7/8 380 515 22,0 510 372

1.0 585 793 24.0 650 475

MA10,0810

1

2

3

4

~

~

~

2.7

Model 6042 Legacy Origin 7/02

General Information and Specifications

4. Using a permanent type ink marker, make a mark

(Fig. 2-2, 2) on one of the flats on the nut and

continue it onto the static fitting or port.

5. Complete the joint by wrench tightening (Fig. 2-2, 3)

the nut

the number of flats (4) specified in the table

for the size and type of fitting. This assembly

procedure is referred to as Flats From Finger

Tight (FFFT).

6. A less desirable tightening method is nut torque.

First follow 1 & 2 above. Apply clean petroleum

based oil to the male thread. Finger tighten the nut

onto the fitting. Torque the nut to the value listed in

the table.

b. Straight O-Ring Boss Fittings To

O-Ring Boss Ports

Improper assembly of this joint will result in leaking joints.

Under tightening of the fitting will result in the fitting

loosening during normal operation and the joint leaking.

Damaging the o-ring during assembly will result in

immediate joint leakage.

1. Inspect components to ensure that male and female

port threads and sealing surfaces are free of burrs,

nicks, or scratches, or any foreign material. If any

damage is found the bad part must not be used.

Clean any foreign material from the mating parts

before assembly.

2. Lubricate the o-ring with a clean petroleum based

lubricant.

3. Screw the fitting into the port.

4. Torque the fitting to the value listed in table.

Hose Ends, Tube Ends and Fitting Swivel Ends

To Fitting Male Ends

SAE

Size

Tube

Conn.

(FFFT)

Swivel Nut

or

Hose Conn.

(FFFT)

Torque lb-ft (Nm)

w/Oiled

Threads

4 2 2 16 ± 3 (22 ± 4)

5 2 2 19 ± 4 (26 ± 5)

6 1-1/2 1-1/4 25 ± 5 (34 ± 7)

8 1-1/2 1 49 ± 10 (66 ± 14)

10 1-1/4 1 74 ± 11 (100 ± 15)

12 1-1/4 1 103 ± 15 (140 ± 20)

14 1 1 121 ± 18 (164 ± 24)

16 1 1 135 ± 35 (183 ± 47)

20 1 1 166 ± 33 (225 ± 45)

24 1 1 210 ± 40 (285 ± 54)

32 1 1 314 ± 54 (426 ± 73)

O-Ring Boss Fittings To

O-Ring Boss Ports

SAE Size Torque lb-ft (Nm)

4 14 ± 1 (19 ± 1)

5 18 ± 1 (24 ± 1)

6 23 ± 1 (31 ± 1)

8 41 ± 1 (56 ± 1)

10 45 ± 3 (61 ± 4)

12 72 ± 3 (98 ± 4)

14 95 ± 4 (129 ± 5)

16 118 ± 5 (160 ± 7)

20 154 ± 7 (209 ± 10)

24 162 ± 8 (220 ± 11)

32 229 ± 11 (311 ± 15)

General Information and Specifications

2.8

Model 6042 Legacy Origin 7/02

c. Adjustable (Angle) O-Ring Boss Fittings To

O-Ring Boss Ports

Improper assembly of this joint will result in a leaking joint.

Failure to position the locknut properly will result in

damage to the o-ring. Under tightening of the fitting will

result in the fitting loosening during normal operation and

the joint leaking. Damaging the o-ring during assembly

will result in immediate joint leakage.

1. Inspect components to ensure that male and female

port threads and sealing surfaces are free of burrs,

nicks, or scratches, or any foreign material. If any

damage is found the bad part must not be used.

Clean any foreign material from the mating parts

before assembly.

Figure 2- 3 Adjustable Fitting to Port

2. Back off the locknut as far as possible (Fig. 2-3, 1).

Make sure the back-up washer is not loose. If the

back-up washer is loose the fitting must be replaced.

3. Lubricate the o-ring (Fig. 2-3, 2) and male thread

with a clean petroleum based lubricant.

4. Screw the fitting into the port as far as possible by

hand (Fig. 2-3, B & C).

5. To align the tube end (Fig. 2-3, 3) of the fitting to

accept the mating tube or hose, unscrew the fitting

as required but not more than one turn.

6. Using two wrenches, hold the fitting in the desired

position and tighten the locknut (Fig. 2-3, 4) to the

appropriate torque value listed in the table in Section

2.3.3, b. “Straight O-Ring Boss Fittings To

O-Ring Boss Ports.”

d. Pipe Fittings to Pipe Ports

Improper assembly of this joint will result in a leaking joint

and possible damage to the port.

1. Inspect the port and fitting to insure that there are no

burrs, nicks, or foreign material. If any thread

damage is found the part must not be used. Clean

off any foreign material.

2. Apply sealant/lubricant to male pipe thread. If Teflon

tape is used it should be wrapped 1.5 to 2 turns in a

clockwise direction when viewed from the pipe

thread end. With any sealant the first 1 to 2 threads

should be left uncovered to avoid system

contamination.

3. Screw the connector into the port finger tight.

4. Wrench tighten the fitting to the appropriate Turns

From Finger Tight (TFFT) from Table 4. Make sure

that angle fittings are aligned with the mating tube or

hose within the listed number of turns. Never back

off (loosen) pipe thread connectors to achieve

alignment.

C

D

B

A

MF0620

2

1

3

4

Pipe Fittings To Pipe Ports

Pipe Thread Size Turns From Finger Tight

(T.F.F.T

1/8" 2 - 3

1/4" 2 - 3

3/8" 2 - 3

1/2" 2 - 3

3/4" 2 - 3

1" 1-1/2 - 2-1/2

1-1/4" 1-1/2 - 2-1/2

1-1/2" 1-1/2 - 2-1/2

2" 1-1/2 - 2-1/2

2.9

Model 6042 Legacy Origin 7/02

General Information and Specifications

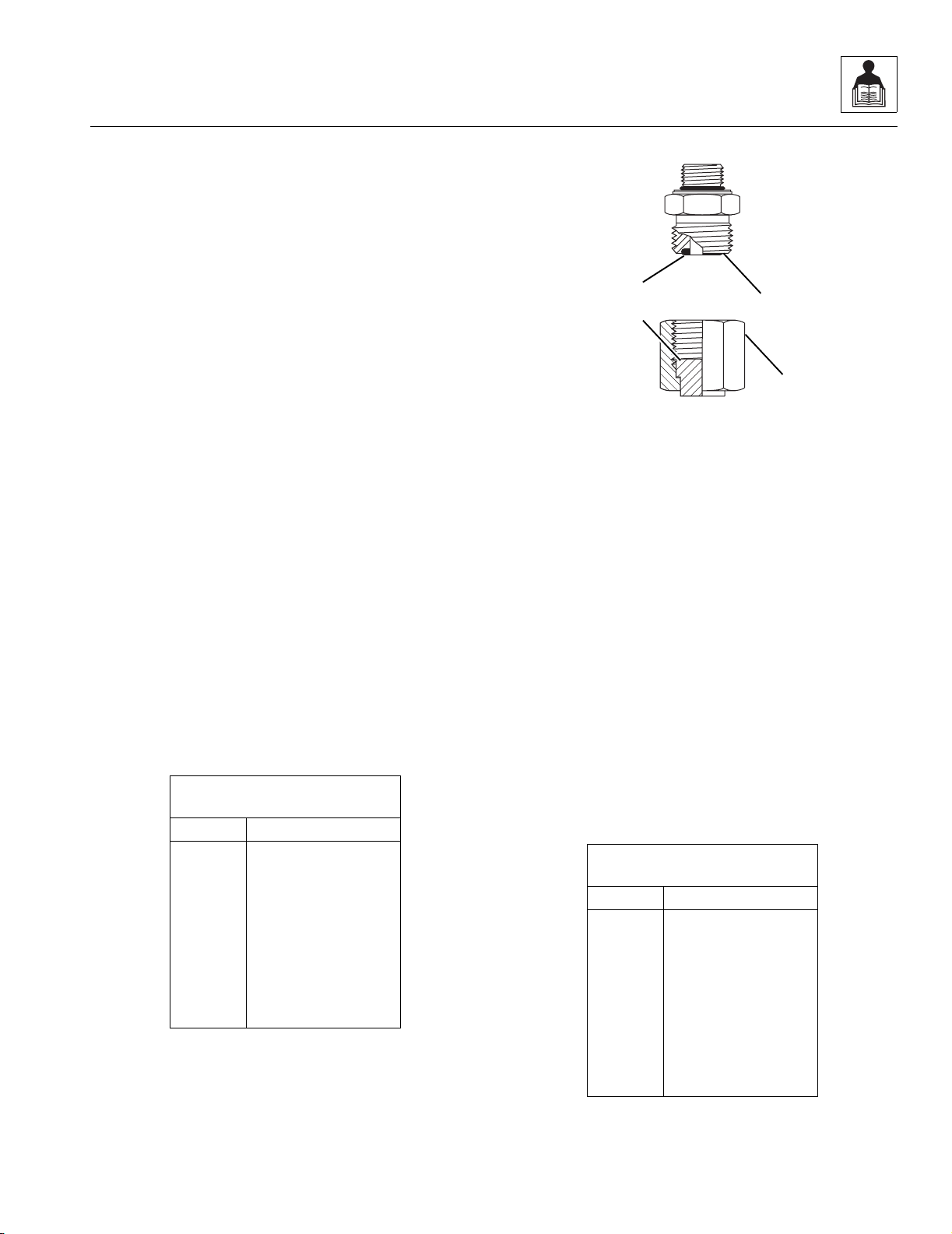

2.3.4 SAE Flat Face O-Ring Seal

Hydraulic Fittings

a. Assembly Procedure

Improper assembly of this type of joint will result in

leaking joints. Under tightening will result in the joint

loosening during normal usage. Foreign material on

either seal surfaces will cause damage to one or both

mating parts when the joint is tightened resulting in a

leaking joint. The absences of the fitting o-ring will cause

the joint to leak.

1. Inspect both the male (Fig. 2-4, 1) and female (2)

sealing surfaces for burrs, scratches, dents, other

damage, or foreign material. If any damage is found

on either surface, the part is to be rejected as

unusable. Clean off any foreign material from the

sealing surfaces before assembly.

2. Inspect the male fitting for the presence of the seal

o-ring (Fig. 2-4, 3). Inspect the o-ring for any sign of

damage. If the o-ring is missing or damaged replace

it.

3. Apply clean petroleum based oil to the male thread.

4. Place the flat surface of the female connector

(Fig. 2-4, 1) in full contact with the o-ring (3) in the

male connector.

5. Finger tighten the nut (Fig. 2-4, 4) onto the fitting.

6. Complete the joint by tightening the nut

to the torque

specified in the table. For hoses and swivel fittings

use a second wrench to keep the female connector

from moving during tightening.

Figure 2-4 Flat Face O-Ring Seal Connections

b. Straight O-Ring Boss Fittings To

O-Ring Boss Ports

Improper assembly of this joint will result in leaking joints.

Under tightening of the fitting will result in the fitting

loosening during normal operation and the joint leaking.

Damaging the o-ring during assembly will result in

immediate joint leakage.

1. Inspect components to ensure that male and female

port threads and sealing surfaces are free of burrs,

nicks, or scratches, or any foreign material. If any

damage is found the bad part must not be used.

Clean any foreign material from the mating parts

before assembly.

2. Lubricate the o-ring and male thread with a clean

petroleum based lubricant.

3. Screw the fitting into the port.

4. Torque the fitting to the values found in table.

O-Ring Boss Fittings To

O-Ring Boss Ports

SAE Size Torque lb-ft (Nm)

4 19 ± 5 (26 ± 7)

6 35 ± 5 (47 ± 7)

8 52 ± 7 (70 ± 10)

10 83 ± 17 (112 ± 23)

12 120 ± 20 (163 ± 27)

16 165± 35 (224 ± 47)

20 215 ± 65 (292 ± 88)

24 252 ± 77 (342 ± 104)

O-Ring Boss Fittings To

O-Ring Boss Ports

SAE Size Torque lb-ft (Nm)

4 15 ± 1 (20 ± 1)

6 25 ± 1 (34 ± 1)

8 55 ± 5 (75 ± 7)

10 76 ± 5 (103 ± 7)

12 130 ± 5 (176 ± 7)

16 210± 10 (285 ± 14)

20 245 ± 35 (332 ± 47)

24 315 ± 45 (427 ± 61)

MA10,0800

1

2

3

4

General Information and Specifications

2.10

Model 6042 Legacy Origin 7/02

c. Adjustable (Angle) O-Ring Boss Fittings To

O-Ring Boss Ports

Improper assembly of this joint will result in a leaking joint.

Failure to position the locknut properly will result in

damage to the o-ring. Under tightening of the fitting will

result in the fitting loosening during normal operation and

the joint leaking. Damaging the o-ring during assembly

will result in immediate joint leakage.

1. Inspect components to ensure that male and female

port threads and sealing surfaces are free of burrs,

nicks, or scratches, or any foreign material. If any

damage is found the bad part must not be used.

Clean any foreign material from the mating parts

before assembly.

Figure 2- 5 Adjustable Fitting to Port

2. Back off the locknut as far as possible (Fig. 2-5, 1).

Make sure the back-up washer is not loose. If the

back-up washer is loose the fitting must be rejected.

3. Lubricate the o-ring (Fig. 2-5, 2) and male thread

with clean petroleum based lubricant.

4. Screw the fitting into the port as far as possible by

hand (Fig. 2-5, B & C).

5. To align the tube end (Fig. 2-5, 3) of the fitting to

accept the mating tube or hose, unscrew the fitting

as required but not more than one turn.

6. Using two wrenches, hold the fitting in the desired

position and tighten the locknut (Fig. 2-5, 4) to the

appropriate torque value listed in the table in Section

2.3.4, b. “Straight O-Ring Boss Fittings To

O-Ring Boss Ports.”

d. Pipe Fittings to Pipe Ports

Improper assembly of this joint will result in a leaking joint

and possible damage to the port.

1. Inspect the port and fitting to insure that there are no

burrs, nicks, or foreign material. If any thread

damage is found the part must not be used. Clean

off any foreign material.

2. Apply sealant/lubricant to male pipe thread. If Teflon

tape is used it should be wrapped 1.5 to 2 turns in a

clockwise direction when viewed from the pipe

thread end. With any sealant the first 1 to 2 threads

should be left uncovered to avoid system

contamination.

3. Screw the connector into the port finger tight.

4. Wrench tighten the fitting to the appropriate Turns

From Finger Tight (TFFT) from Table 4. Make sure

that angle fittings are aligned with the mating tube or

hose within the listed number of turns. Never back

off (loosen) pipe thread connectors to achieve

alignment.

A

B

C

D

MA10,0820

2

1

3

4

Pipe Fittings To Pipe Ports

Pipe Thread Size Turns From Finger Tight

(T.F.F.T

1/8" 2 - 3

1/4" 2 - 3

3/8" 2 - 3

1/2" 2 - 3

3/4" 2 - 3

1" 1-1/2 - 2-1/2

1-1/4" 1-1/2 - 2-1/2

1-1/2" 1-1/2 - 2-1/2

2" 1-1/2 - 2-1/2

2.11

Model 6042 Legacy Origin 7/02

General Information and Specifications

This Page Intentionally Left Blank

General Information and Specifications

2.12

Model 6042 Legacy Origin 7/02

2.4 METRIC CONVERSION FACTORS

2.4.1 Approximate American to

Metric Conversions

When this is known Multiply by To find

TORQUE

(moment of force)

Pound/feet (lb-ft) 1.356 Newton meters (Nm)

Pound/inches (lb-in) 0.113 Newton meters (Nm)

POWER

Horsepower (hp) 745.7 Watts

SPEED (velocity)

Miles per hour (mph) 1.609 Kilometers per hour

(km/hr; kph)

LENGTH (distance)

Inches (in) 25.4 Millimeters (mm)

Inches (in) 2.5 Centimeters (cm)

Feet (ft) 30.5 Centimeters (cm)

Feet (ft) 0.305 Meters (m)

Yards (yd) 0.9 Meters (m)

Miles (mi) 1.6 Kilometers (km)

AREA

Square inches (in

2

) 6.5 Square centimeters (cm

2

)

Square feet (ft

2

) 0.09 Square meters (m

2

)

Square yards (yd

2

) 0.8 Square meters (m

2

)

Square miles (mi

2

) 2.6 Square kilometers (km

2

)

Acres 0.4 Hectares (ha)

MASS (weight)

Ounces (oz) 28.3 Grams (g)

Pounds (lb) 0.4536 Kilograms (kg)

Short tons (2000 lb) 0.9 Metric ton (t)

When this is known Multiply by To find

VOLUME

Teaspoons (tsp) 5 Milliliters (ml)

Tablespoons (Tbsp) 15 Milliliters (ml)

Cubic inches (in

3

) 16 Milliliters (ml)

Fluid ounces (fl oz) 30 Milliliters (ml)

Cups (c) 0.24 Liters

Pints (pt) 0.47 Liters

Quarts (qt) 0.95 Liters

Gallons (gal) 3.8 Liters

Cubic feet (ft

3

) 0.03 Cubic meters (m

3

)

Cubic yards (yd

3

) 0.76 Cubic meters (m

3

)

AIR PRESSURE

Pounds per

square inch (psi) 6.895 Kilopascals (kPa)

HYDRAULIC PRESSURE

Pounds per

square inch (psi) 0.069 Bar

TEMPERATURE (exact)

To determine degrees Celsius (° C), subtract 32, then

multiply by 0.56; (° F -32) x 0.56 = ° C.

2.13

Model 6042 Legacy Origin 7/02

General Information and Specifications

2.4.2 Approximate Metric to

American Conversions

When this is known Multiply by To find

TORQUE

(moment of force)

Newton meters (Nm) 0,738 Pounds/feet (lb-ft)

Newton meters (Nm) 8,85 Pounds/inches (lb-in)

POWER

Watts 0,0013 Horsepower (hp)

SPEED (velocity)

Kilometers per

hour (km/hr; kph) 0,621 Miles per hour (mph)

LENGTH (distance)

Millimeters (mm) 0,0394 Inches (in)

Centimeters (cm) 0,394 Inches (in)

Meters (m) 3,281 Feet (ft)

Meters (m) 1,1 Yards (yd)

Kilometers (km) 0,621 Miles (mi)

When this is known Multiply by To find

AREA

Square centimeters

(cm

2

) 0,4 Square inches (in

2

)

Square meters (m

2

) 1,1 Square yards (yd

2

)

Square kilometers

(km

2

) 0,6 Square miles (mi

2

)

Hectares (10000 m

2

)2,5 Acres

MASS (weight)

Grams (g) 0,035 Ounces (oz)

Kilograms (kg) 2,2 Pounds (lb)

Metric ton

(1000 kg) (t) 1,1 Short tons

VOLUME

Milliliters (ml) 0,03 Fluid ounces (fl oz)

Milliliters (ml) 0,06 Cubic inches (in

3

)

Liters 2,1 Pints (pt)

Liters 1,06 Quarts (qt)

Liters 0,26 Gallons (gal)

Cubic meters (m

3

) 35 Cubic feet (ft

3

)

Cubic meters (m

3

) 1,3 Cubic yards (yd

3

)

AIR PRESSURE

Kilopascals (kPa) 0,145 Pounds per square

inch (psi)

HYDRAULIC PRESSURE

Bar 14,5 Pounds per square

inch (psi)

TEMPERATURE (exact)

To determine degrees Fahrenheit (° F), multiply degrees

Celsius (° C) by 1.8, then add 32; (° C x 1.8) + 32 = ° F.

General Information and Specifications

2.14

Model 6042 Legacy Origin 7/02

2.5 SPECIFICATIONS

2.5.1 Vehicle Dimensions (With Standard 12-ply 13.00-24 Tires)

Description (Fig. 2- 6)

(A) Length (without Attachment) 220" (5588 mm)

(B) Width 98" (2489 mm)

(C) Height (Boom Lowered) 102" (2591 mm)

(D) Wheelbase 113" (2870 mm)

(E) Tread 84" (2134 mm)

(F) Ground Clearance 16" (406 mm)

(G) Turning Radius, Curb to Curb 165" (4191 mm)

(H) Turning Radius, Clearance 168" (4267 mm)

(I) Maximum Lift Height, Boom Extended 41' 11" (12,8 m)

(J) Maximum Lift Height, Boom Retracted 21' 7" (6,6 m)

(K) Maximum Below Grade Depth, Boom Extended 3' 1" (940 mm)

(L) Maximum Reach, from Front of Front Tires 27' 11" (8,5 m)

(M) Maximum Reach at Maximum Lift Angle,

Boom Extended

6' 4" (1930 mm)

(N) Maximum Reach at Maximum Lift Angle,

Boom Retracted

-20" (-508 mm)

(O) Maximum Reach at Minimum Lift Angle,

Boom Extended

21' 9" (6,6 m)

(P) Maximum Boom Lift Angle 68.4°

(Q) Minimum Boom Lift Angle -8°

(R) Angle of Departure 27°

Fork Tilt Angle:

(S) At Minimum Boom Angle - UP 11°

(T) At Minimum Boom Angle - DOWN -101°

(U) At Maximum Boom Angle - UP 87°

(V) At Maximum Boom Angle - DOWN -25°

Frame Tilt Angle (Not Shown):

Right 10.0°

Left 10.0°

2.15

Model 6042 Legacy Origin 7/02

General Information and Specifications

Figure 2-6 Vehicle Dimensions with Standard Tires

S

U

N

J

M

I

0.0

O

L

K

V

F

R

C

Q

D

A

T

24.0"

P

G

H

BE

MA10,0670

General Information and Specifications

2.16

Model 6042 Legacy Origin 7/02

2.5.2 Vehicle Weights

Curb Weight w/48" Carriage (Open Cab) 23,520 lb (10.668 kg)

Curb Weight w/48" Carriage (Enclosed Cab) 23,720 lb (10.759 kg)

Operating Load 6,000 lb (2721 kg)

Working Weight (Machine working weight is figured with 72" carriage, two 48" pallet forks, 25%-full fuel tank, and

standard bias ply tires [no hydrofill]):

Open Cab:

Front Axle 9,030 lb (4.096 kg)

Rear Axle 14,710 lb (6.672 kg)

Total (Open Cab) 23,740 lb (10.768 kg)

Closed Cab:

Front Axle 9,130 lb (4.141 kg)

Rear Axle 14,810 lb (6.718 kg)

Total (Closed Cab) 23,940 lb (10.859 kg)

Loading...

Loading...