Page 1

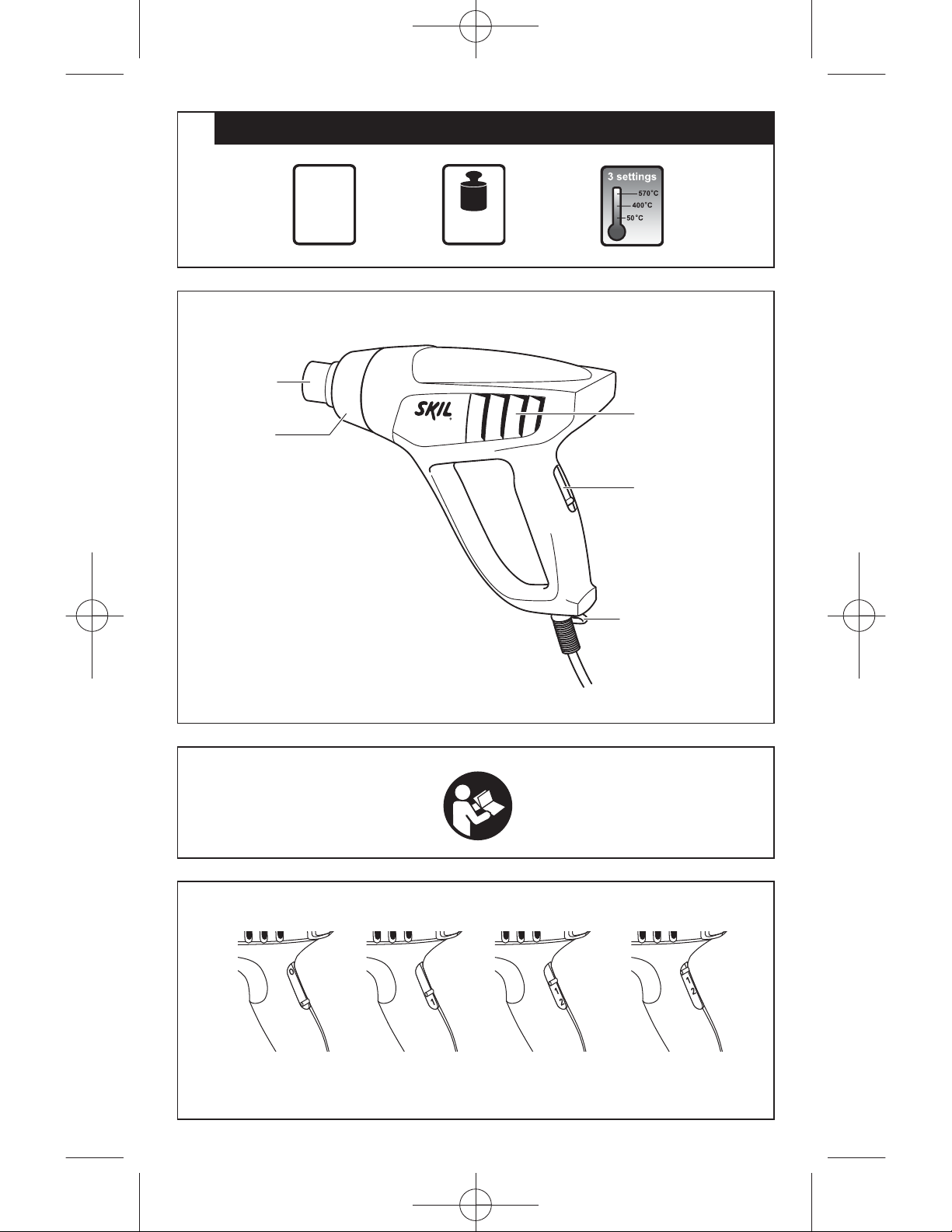

HEAT GUN

8006 (F0158006 . . )

4825 BD Breda - The Netherlands

www.skil-ap.com

12/0906 grebnenjinoK - VB eporuE LIKS

4

18

1619PA0398

Page 2

1

2

8003

C

B

1800

Watt

0,8 kg

EPTA 01/2003

E

A

3

4

50°

250 ltr/min

400°

250 ltr/min

D

3

570°

500 ltr/min

2

Page 3

5 6

G

7

8

J

9

11 12

G

F

H

10

F

G

J

13

H

14

H

15

3

Page 4

3008nugtaeH

INTRODUCTION

This tool is intended for the removal of paint, the forming

and welding of plastic, and the warming of heat-shrinkable

tubing; the tool is also suitable for soldering and tinning,

loosening adhesive joints and defrosting water pipes

Read and save this instruction manual (pay special

attention to the safety instructions at the back)

TECHNICAL SPECIFICATIONS

SAFETY

BEFORE USE:

Check the functioning of the tool before each use and, in case

of a defect, have it repaired immediately by aqualified person;

never open the tool yourself

Inspect tool cord and plug before each use and, if

damaged, have them replaced by a qualified person

Use completely unrolled and safety extension cords

Inspect the extension cord periodically and replace it, if damaged

Only use the original SKIL accessories supplied with the tool

Use the tool and its accessories in accordance with this

instruction manual and in the manner intended for the tool;

use of the tool for operations, different from those normally

expected to be performed by the tool, could result in a

hazardous situation

This appliance is not intended for use by persons (including

children) with reduced physical. Sensory or mental capabilities,

or lack of experience and knowledge, unless they have been

given supervision or instruction concerning use of the appliance

by a person responsible for their safety.

Children should be supervised to ensure that they do

not play with the appliance.

Always check that the supply voltage is the same as the

voltage indicated on the nameplate of the tool

Be sure tool is switched off when plugging in

DURING USE:

Handle the tool with care; prevent fire and burns

- do not touch the air outlet/nozzle and the heated

object; they become extremely hot

- do no hold the air outlet/nozzle too close to the object

to be worked on

- do not direct the hot air stream towards the same

surface for too long

- never look down the air outlet/nozzle

- wear protective gloves and use safety glasses

- never direct the hot air stream towards persons or

animals

- never use the tool for drying hair

- do not leave the tool unattended0

- never use the tool in the proximity of inflammable

gases or combustible materials (risk of explosion)

- when working with plastic, paint, varnish and similar

materials, inflammable and poisonous gases may be

produced; inform yourself beforehand about the

materials to be worked on

- take into account, that heat may be transferred to

combustible materials out of eyesight

- to be on the safe side, have a bucket of water or a fire

extinguisher handy, in case any material catches fire

Prevent electrical shock

- never poke anything down the air outlet/nozzle

- avoid body contact with earthed surfaces (e.g. pipes,

radiators, ranges, refrigerators)

- ensure the tool does not get wet

- do not use the tool in damp locations

- when used outdours, connect the tool via a fault

current (FI) circuit breaker with a triggering current of

30 mA maximum, and only use an extension cord

which is intended for outdour use and equipped with

a splashproof coupling-socket

Handle the cord with care

- always keep away the cord from the hot air stream

and the air outlet/nozzle

- keep the cord away from heat, oil and sharp edges

- do not carry the tool by the cord, and do not yank the

cord to disconnect it from the socket

- do not suspend the tool by the cord

Never use the tool in conjunction with chemical solvents

Make sure work area is adequately ventilated

Keep work area clean and well lit

Keep children away from work area

Stay alert; watch what you are doing, use common

sense and do not operate the tool when you are tired

Take a secure stance; do not overreach, especially on

ladders and stages

Ensure that the tool is switched off, before putting it aside

In case of electrical or mechanical malfunction,

immediately switch off the tool and disconnect the plug

AFTER USE:

Switch off the tool and disconnect the plug

Suspend the tool on hanging ring D or set it down on

its rear in an upright position; when doing so, make sure

no combustible materials or inflammable gases are in

the proximity

Allow the tool to cool down for at least 30 minutes before

storage

Store the tool in a dry and locked-up place, out of reach

of children

USE

On/off switch with 3 temperature settings

! check if switch A is in position "0" before

plugging in

- switch on the tool by pushing switch A in desired

position:

1 = 50°C, air stream 250 litres/minute

2 = 400°C, air stream 250 litres/minute

3 = 570°C, air stream 500 litres/minute

- when using it for the first time, some smoke may emit

from the tool; this is normal and will soon cease

- switch off the tool by pushing switch A in position "0"

General use

- determine the right temperature by testing out on an

inconspicuous part of the workpiece; start with a low

temperature setting

- the temperature falls as the distance between the air

outlet/nozzle and the workpiece increases

- the temperature required depends on the material to

be worked on

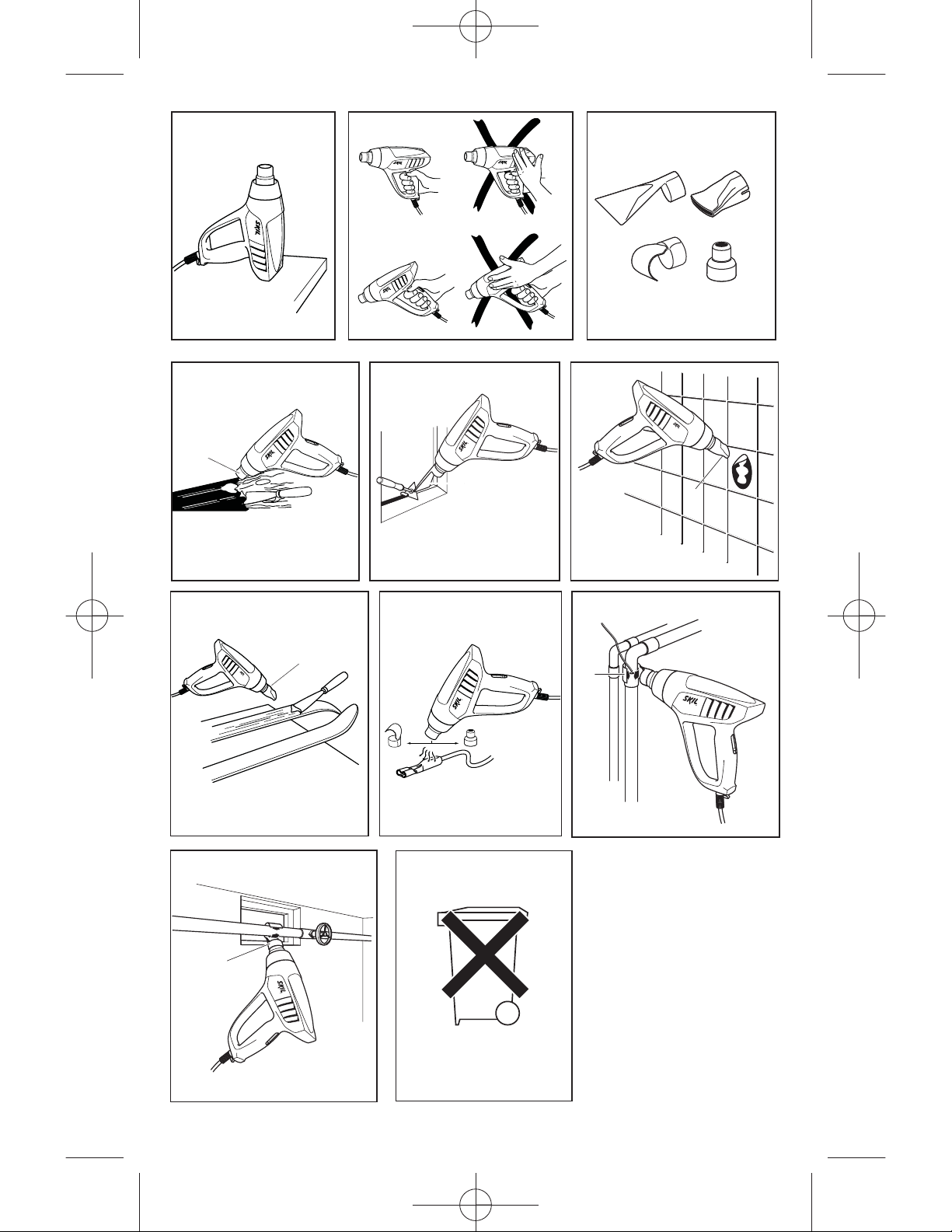

Stationary use

- set the tool down on its rear in an upright position

- make sure the surface is clean and dustfree; polluted

air damages the motor

- make sure the air stream is directed away from you

- secure the cord to prevent pulling down the tool

4

Page 5

- do not touch the air outlet

- made sure nothing drops into the air outlet

- carefully hold the tool with one hand while switching it

off with the other hand, and then allow it to cool down

-

WARNING: Switch off the tool before the tool with itʼs accessories

is put on itʼs stand position. Because the tool with accessories may

overturn and fire hazard will happen.

Use at hard-to-reach places

- remove ring B thus releasing the metal air outlet

over a greater distance

! pay attention to increased risk of fire and burns

Holding and guiding the tool

- hold the tool with one hand

- keep ventilation slots E uncovered

Standard accessories

- glass protection nozzle F (for deflecting air stream)

- flat nozzle G (for broadening air stream)

- reflector nozzle H (for reflecting air stream)

- reduction nozzle J (for concentrating air stream)

All application examples (except removing paint next

to glass) can be performed without accessories;

however, using the appropriate accessory simplifies the

work and significantly improves the quality of the results

Mounting/removing accessories

- simply fit the accessory onto air outlet C

- remove an accessory by pulling it off to the front after

it has cooled down

! mount an accessory only when the air outlet is

cold, when the switch is in position "0" and when

the plug is disconnected

Constant heat control (overload protection)

Protects heating element from damage when tool is

overloaded without having to stop it and/or let it cool

down for a period of time

- when the temperature gets too high, the heating

element switches itself off, while the motor continues

to run and produces cold air

- when the temperature has fallen down sufficiently

(taking only a few seconds), the heating element will

be switched on automatically

2

5

2

6

2

APPLICATION ADVICE

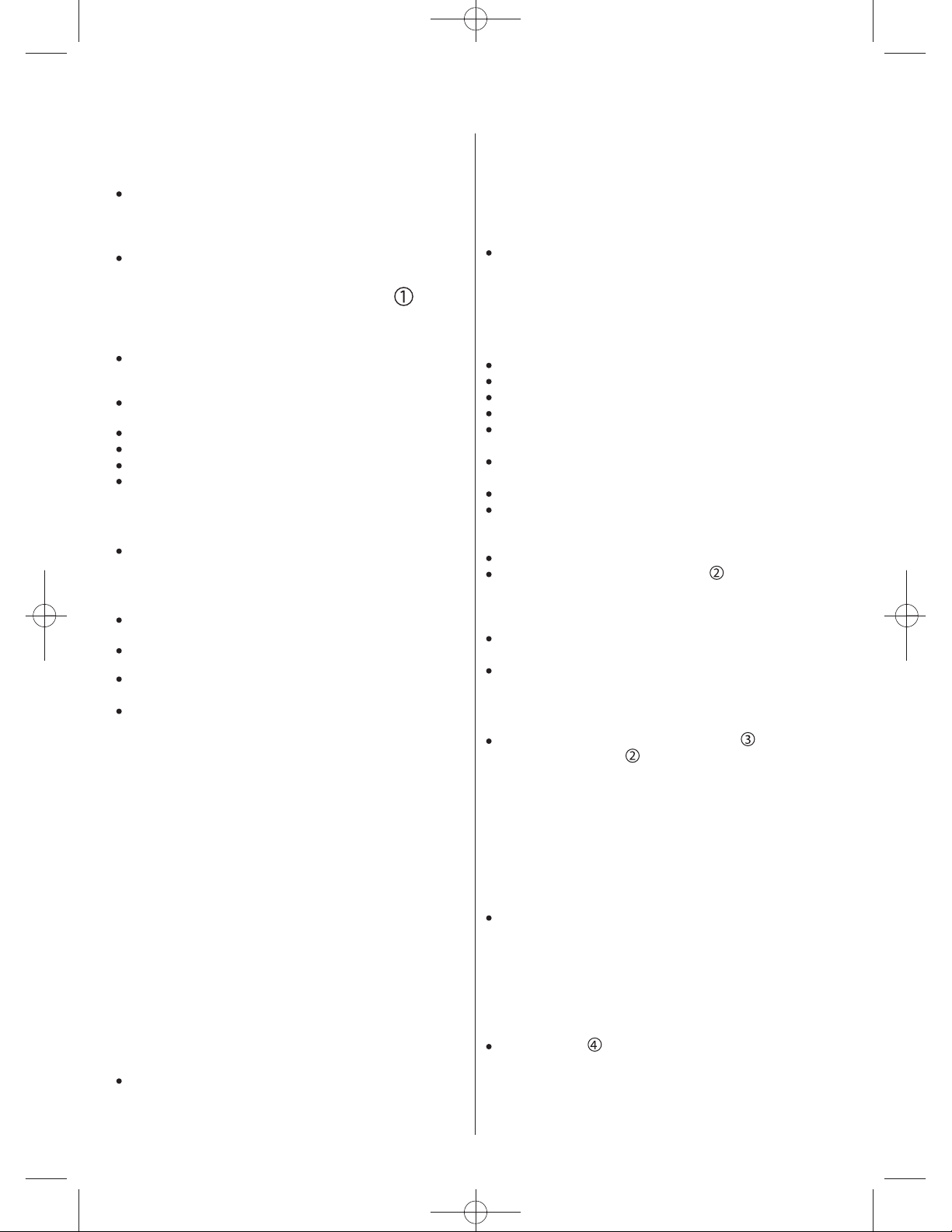

Removing paint/lacquer

- use a clean, sharp scraper

- scrape firmly, when the paint softens

- experiment to establish the length of time necessary

to apply the heat for optimal results

- scrape the softened paint immediately, or it will

harden again

- keep a 30° to 40° angle between the tool and the

workpiece

- remove paint and debris immediately from the scraper

to prevent them from ignition

- scrape with the grain of the wood, wherever possible

- do not direct the hot air stream towards the same

surface for too long

- dispose of all paint debris safely

- thoroughly clean the work area after completing the job

! be careful when removing layers of paint in old

buildings; in the past the building may have been

painted with paint containing lead, which is highly

poisonous

! exposure to even low levels of lead can cause

serious brain and nervous system damage; young

and unborn children are particularly vulnerable

7

! have lead-based paint removed by a professional

without using a heatgun

OTHER APPLICATION EXAMPLE:

removing (synthetic) wall covering

Removing paint/lacquer next to glass

8

- always use glass protection nozzle F when working

next to glass

- remove the paint with a hand scraper

! do not use the tool for removing paint on metal-

framed windows; metal is heat-conducting which

might lead to breaking of the glass

Removing stickers (use flat nozzle G)

9

- many adhesives become softer when heated, allowing

adhesive bonds to be separated and superfluous

adhesive to be removed

! heat sticker on the upper side

! always take care not to overheat the underlying

surface

OTHER APPLICATION EXAMPLES:

removing linoleum and vinyl carpeting

removing carpet tiles made of synthetic fibres

removing veneers/applying veneer strips

softening/melting tar, tin, bitumen, wax

(use flat nozzle G)

waxing (skis, furniture) (use flat nozzle G)

10

removing resin

loosening rusty/too tightly fastened metal screws, nuts

and bolts

removing candle wax (do not overheat the

underlying surface)

repairing broken candles/restoring bent candles to

their original shape

Shrink fitting

11

- use reflector nozzle H or reduction nozzle J

- select a shrink-fit tube with a diameter matching that

of the workpiece

- heat the shrink-fit tube evenly

OTHER APPLICATION EXAMPLE:

shrink-wrapping

Soldering water pipes

12

This tool is most suitable for working with soft solders

(melting point below 400°)

- use reflector nozzle H

- thoroughly clean both joining sections before soldering

- pre-heat both sections and apply soldering wire

(do not use lead-based soldering wire)

OTHER APPLICATION EXAMPLES:

de-soldering of integrated circuits and other electronic

components (use reduction nozzle J)

releasing old soldered joints (use reduction nozzle J)

Thawing out frozen water pipes

13

- use reflector nozzle H

- heat the frozen area evenly

! do no thaw out water pipes made of PVC

! water pipes are often difficult to distinguish from

gas pipes; heating gas pipes is extremely

dangerous – risk of explosion

OTHER APPLICATION EXAMPLES:

thawing out frozen car locks (use reduction nozzle J)

defrosting freezers (do not damage the plastic

housing)

thawing out ice-covered steps and pavements

5

Page 6

SKIL8003pages 16-03-2004 13:46 Pagina 6

● Shaping plastic tubes

- use reflector nozzle H

- fill the tube with sand and seal it at both ends, to avoid

kinking of the tube

- heat the tube evenly by moving it from side to side

OTHER APPLICATION EXAMPLES:

★ shaping all plastics with a low melting-point

(polyethylene, PVC etc.)

★ shaping all plastics with a high melting-point (acrylic

glass, Plexiglas etc.)

★ shaping and bending carpet tiles made of synthetic

fibres

★ shaping and bending of wood (model-building)

● Welding plastics

- the weld seam must be clean and grease-free

- keep welding rod close to weld seam and apply heat,

until the welding rod gets tacky

- remove heat, when weld seam is filled up

OTHER APPLICATION EXAMPLES:

★ repairing of surfboards, skis and other synthetic sports

goods (use flat nozzle G)

★ welding PVC-materials

★ smoothening blisters after sticking PVC-labels

★ connecting garden hoses (use reflector nozzle H)

● Drying

! only dry with a low or medium temperature setting

(position 1 or 2) and with an increased distance

between the tool and the workpiece

★ drying of paint, varnish, gypsum, mortar and plaster

★ drying wet timber prior to filling

★ drying thickly applied filler or adhesive quickly

★ drying building joints before spraying insulation or

sealant

★ drying joints and cracks in boatbuilding

● Cleaning/disinfecting

★ disinfecting rabbit hutches, dove cotes, etc. (remove

your pet first)

★ combatting ant colonies

★ combatting woodworms and boring beetles (hold the

tool at an adequate distance from the wood)

★ eliminating weeds

● Igniting

★ igniting charcoal (barbecues)

★ setting fire to wood (open fires)

GUARANTEE / ENVIRONMENT

● Always keep tool and cord clean (especially the

ventilation slots E 2)

! disconnect the plug before cleaning

● Never use easy inflammable liquids for cleaning the heat

gun in general and the air outlet/nozzle in particular)

● This SKIL product is guaranteed in accordance with

statutory/country-specific regulations; damage due to

normal wear and tear, overload or improper handling will

be excluded from the guarantee

● In case of a complaint, send the tool undismantled

together with proof of purchase to your dealer or the

nearest SKIL service station

● Dispose of the tool by sorting tool, accessories and

packaging for environment-friendly recycling (the plastic

components are labeled for categorized recycling)

SAFETY INSTRUCTIONS

When using electric tools, the following basic safety precautions should

always be followed to reduce the risk of fire, electric shock and personal

injury. Read all these instructions before attempting to operate this

product. Save these instructions.

1 Check voltage indicated on nameplate

2 Keep work area clean

Cluttered areas and benches invite injuries.

3 Consider work area environment

Do not expose power tools to rain.

Do not use power tools in damp or wet locations.

Keep work area well lit.

Do not use power tools in presence of flammable liquids or gasses.

4 Guard against electric shock

Avoid body contact with earthed surfaces (e.g. pipes, radiators, ranges,

refrigerators).

5 Keep children away

Do not let visitors contact tool or cord; they should be kept away from

work area.

6 Store idle tools

When not in use, tools should be stored in a dry and locked-up place,

out of reach of children.

7 Do not force the tool

It will do the job better and safer at the rate for which it was intended.

8 Use the right tool

Do not force small tools or attachments to do the job of a heavy-duty tool.

Do not use tools for purposes not intended (e.g. do not use a circular

saw for cutting tree limbs or logs).

9 Dress properly

Do not wear loose clothing or jewelry; they can be caught in moving parts.

Rubber gloves and non-skid footwear are recommended when working

outdoors. Wear protective hair covering to contain long hair.

10 Use safety glasses

Also use face or dust mask, if cutting operation is dusty.

11 Connect dust extraction equipment

If devices are provided for the connection of dust extraction and

collection facilities, ensure these are connected and properly used.

12 Do not abuse the cord

Never carry the tool by the cord, never yank the cord to disconnect it from

the socket, and keep the cord away from heat, oil and sharp edges.

13 Secure work

Use clamps or a vise to hold the work; it is safer than using your hand

and it frees both hands to operate the tool.

14 Do not overreach

Keep proper footing and balance at all times.

15 Maintain tools with care

Keep tools sharp and clean for better and safer performance. Follow

instructions for maintenance and changing accessories. Inspect tool

cords and plugs periodically and, if damaged, have them repaired by a

qualified person. Inspect extension cords periodically and replace them,

if damaged. Keep handles dry, clean and free from oil and grease.

16 Disconnect tools

Disconnect tool when not in use, before servicing, or when changing

accessories such as blades, bits and cutters.

17 Remove tool keys

Form the habit of checking to see that keys and adjusting wrenches are

removed from the tool before turning it on.

18 Avoid unintentional starting

Do not carry a plugged-in tool with a finger on the switch. Be sure the

switch is off when plugging in.

19 Outdoor use extension cords

When tool is used outdoors, use only extension cords intended for use

outdoors and so marked.

20 Stay alert

Watch what you are doing, use common sense and do not operate tool

when you are tired.

21 Check damaged parts

Before you use the tool, always carefully check the guarding and other

parts to determine that they will operate properly and perform their

intended functions. Check for alignment of moving parts, binding of

moving parts and breakage of parts. Check for proper mounting of all

parts and any other conditions that may affect their operation. A guard,

switch or other part that is damaged or defective should be properly

repaired or replaced by a qualified person. Do not use tool, if switch

does not turn it on and off.

22 Warning! Use the tool and its accessories in accordance with these

safety instructions and in the manner intended for the particular tool,

taking into account the working conditions and the work to be performed.

Use of the tool for operations, different from those normally expected to

be performed by the particular tool, could result in a hazardous situation.

23 Have the tool repaired by a qualified person

This electric tool is in accordance with the relevant safety rules. Repairs

should only be carried out by qualified persons using original spare

parts, otherwise this may result in considerable danger for the user.

6

Page 7

SKIL8003 Asia.qxd 2004.3.6 2:06 Page 7

7

Page 8

SKIL8003 Asia.qxd 2004.3.6 2:06 Page 8

8

Page 9

SKIL8003 Asia.qxd 2004.3.6 2:06 Page 9

9

Page 10

SKIL8003pages 16-03-2004 13:46 Pagina 23

✎

23

Page 11

SKIL8003pages 16-03-2004 13:46 Pagina 24

Loading...

Loading...