Page 1

2

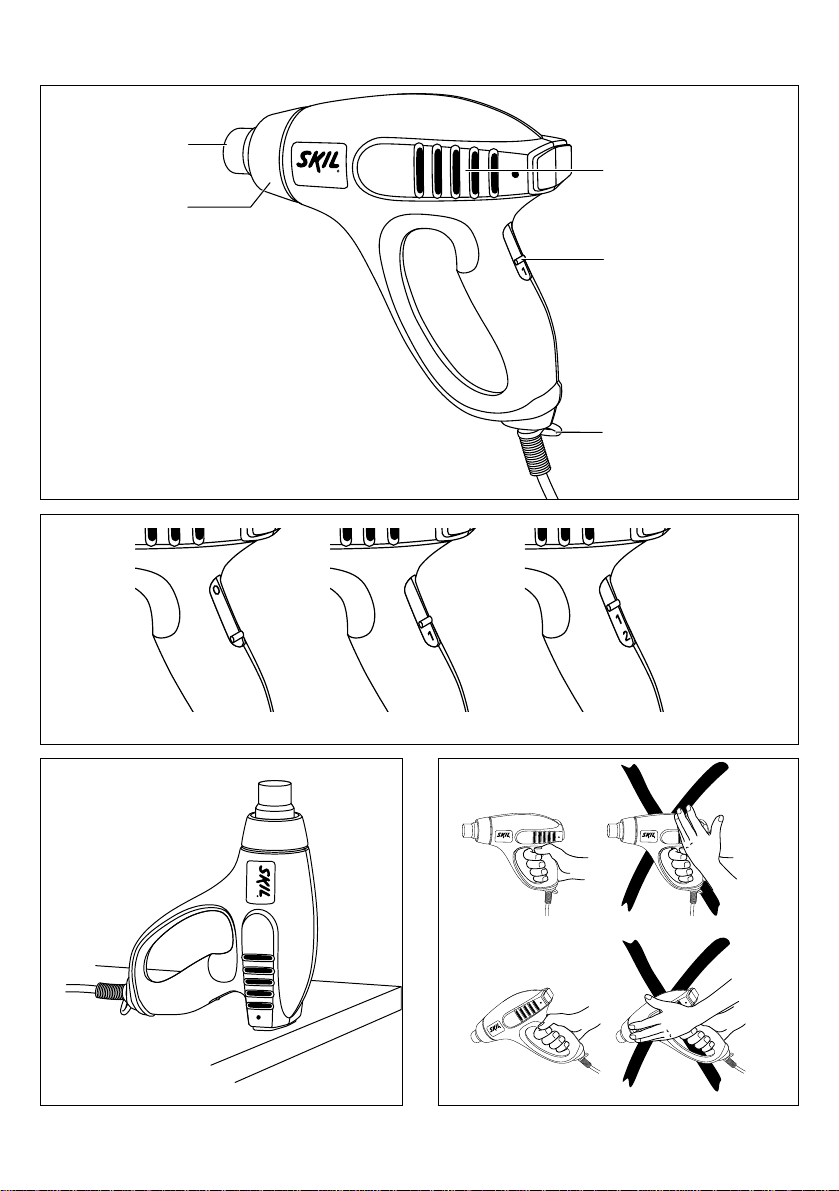

300°

550°

2

3

C

B

A

E

D

1

1

6

0

0

W

a

t

t

4

Page 2

3

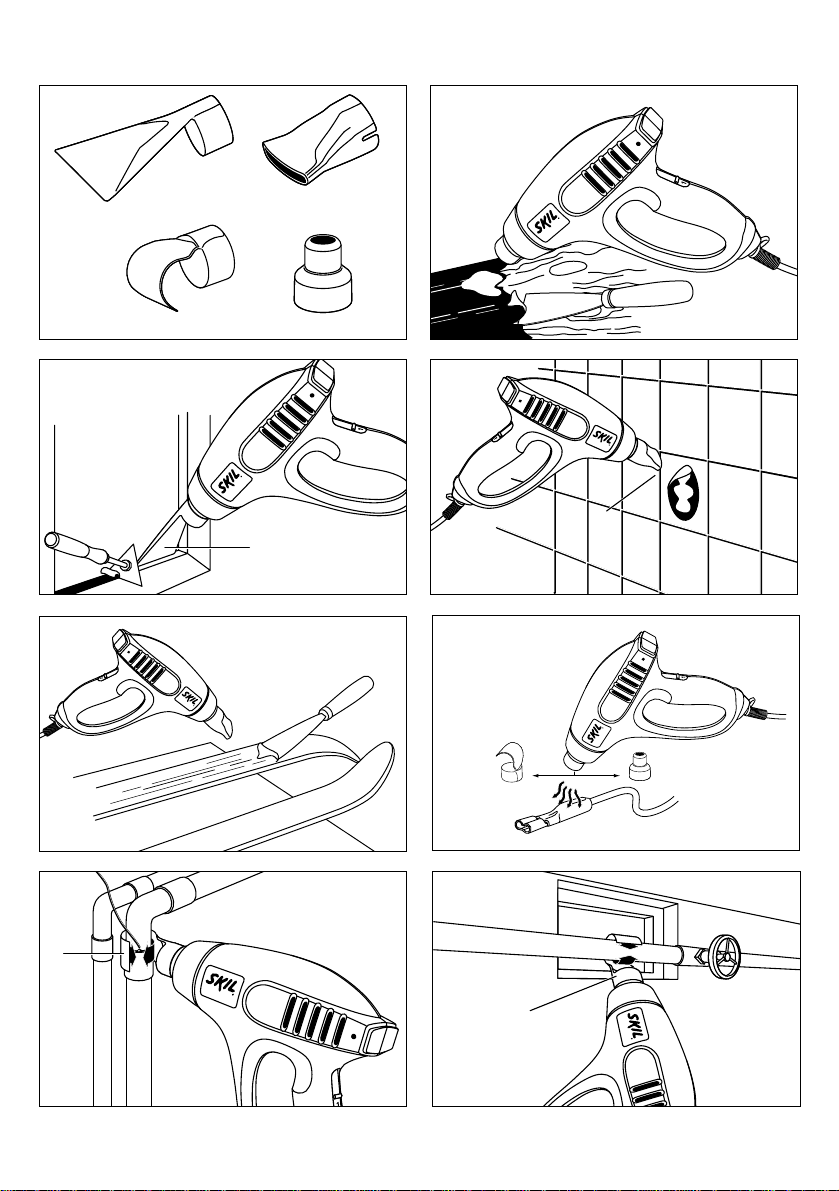

F

H

J

G

5 6

F

7

G

8

1600

W

a

t

t

9

H

0

H

!

@

Page 3

INTRODUCTION

• This tool is intended for the removal of paint, the forming

and welding of plastic, and the warming

of heat-shrinkable tubing; the tool is also suitable for

soldering and tinning, loosening adhesive

joints and defrosting water pipes

• Read this instruction manual carefully, before you use

the tool, and pay special attention to the

safety instructions; save this instruction manual and

other documentation supplied with this tool

for future reference

TECHNICAL SPECIFICATIONS

8000

Input 1600W

Temperature 300°/550°

Air flow 250/500 l/min.

Weight 0.7 kg

SAFETY

BEFORE USE:

• Check the functioning of the tool before each use and, in

case of a defect, have it repaired immediately by a

qualified person; never open the tool yourself

• Inspect tool cord and plug before each use and, if

damaged, have them replaced by a qualified person

• Use completely unrolled and safe extension cords with a

capacity of 16 Amps (U.K. 13 Amps)

• Inspect the extension cord periodically and replace it, if

damaged

• Only use the original SKIL accessories supplied with the

tool (only 8000 in plastic case)

• Use the tool and its accessories in accordance with this

instruction manual and in the manner intended for the

tool; use of the tool for operations, different from those

normally expected to be performed by the tool, could

result in a hazardous situation

• This tool should not be used by people under the age of

16 years

• Always check that the supply voltage is the same as the

voltage indicated on the nameplate of the tool

• Be sure tool is switched off when plugging in

DURING USE:

• Handle the tool with care; prevent fire and burns

- do not touch the air outlet/nozzle and the heated

object; they become extremely hot

- do no hold the air outlet/nozzle too close to the object

to be worked on

- do not direct the hot air stream towards the same

surface for too long

- never look down the air outlet/nozzle

- wear protective gloves and use safety glasses

- never direct the hot air stream towards persons or

animals

- never use the tool for drying hair

- do not leave the tool unattended

- never use the tool in the proximity of inflammable

gases or combustible materials

- when working with plastic, paint, varnish and similar

materials, inflammable and poisonous gases may be

produced; inform yourself beforehand about the

materials to be worked on

- take into account, that heat may be transferred to

combustible materials out of eyesight

- to be on the safe side, have a bucket of water or a fire

extinguisher handy, in case any material catches fire

• Prevent electrical shock

- never poke anything down the air outlet/nozzle

- avoid body contact with earthed surfaces (e.g. pipes,

radiators, ranges, refrigerators)

- ensure the tool does not get wet

- do not use the tool in damp locations

- when used outdours, connect the tool via a fault

current (FI) circuit breaker with a triggering current of

30 mA maximum, and only use an extension cord

which is intended for outdour use and equipped with

a splashproof coupling-socket

• Handle the cord with care

- always keep away the cord from the hot air stream

and the air outlet/nozzle

- keep the cord away from heat, oil and sharp edges

- do not carry the tool by the cord, and do not yank the

cord to disconnect it from the socket

- do not suspend the tool by the cord

• Never use the tool in conjunction with chemical solvents

• Make sure work area is adequately ventilated

• Keep work area clean and well lit

• Keep children away from work area

• Stay alert; watch what you are doing, use common

sense and do not operate the tool when you are tired

• Take a secure stance; do not overreach, especially on

ladders and stages

• Ensure that the tool is switched off, before putting it

aside

• In case of electrical or mechanical malfunction,

immediately switch off the tool and disconnect the plug

AFTER USE:

• Switch off the tool and disconnect the plug

• Suspend the tool on hanging ring D 1 or set it down on

its rear in an upright position; when doing so, make sure

no combustible materials or inflammable gases are in

the proximity

• Allow the tool to cool down for at least 30 minutes before

storage

• Store the tool in a dry and locked-up place, out of reach

of children

WHEN CONNECTING NEW 3-PIN PLUG (U.K. ONLY):

• Do not connect the blue (= neutral) or brown (= live) wire

in the cord of this tool to the earth terminal of the plug

• If for any reason the old plug is cut off the cord of this

tool, it must be disposed of safely and not left

unattended

4

GB

Page 4

USE

• On/off switch with two temperature settings 2

! check if switch A 1 is in position "0" before

plugging in

- switch on the tool by pushing switch A in desired

position:

1 = 300°C, air stream 250 litres/minute

2 = 550°C, air stream 500 litres/minute

- when using it for the first time, some smoke may emit

from the tool; this is normal and will soon cease

- switch off the tool by pushing switch A in position "0"

• General use

- determine the right temperature by testing out on an

inconspicuous part of the workpiece; start with a low

temperature setting

- the temperature falls as the distance between the air

outlet/nozzle and the workpiece increases

- the temperature required depends on the material to

be worked on

• Stationary use 3

- set the tool down on its rear in an upright position

- make sure the surface is clean and dustfree; polluted

air damages the motor

- make sure the air stream is directed away from you

- secure the cord to prevent pulling down the tool

- do not touch the air outlet/nozzle

- make sure nothing drops into the air outlet/nozzle

- carefully hold the tool with one hand while switching it

off with the other hand, and then allow it to cool down

• Use at hard-to-reach places

- remove ring B 1, thus releasing the metal air outlet

over a greater distance

! pay attention to increased risk of fire and burns

• Holding and guiding the tool 4

- hold the tool with one hand

- keep ventilation slots E 1 uncovered

• Standard accessories (only 8000 in plastic case) 5

- glass protection nozzle F (for deflecting air stream)

- flat nozzle G (for broadening air stream)

- reflector nozzle H (for reflecting air stream)

- reduction nozzle J (for concentrating air stream)

All application examples (except removing paint next

to glass) can be performed without accessories;

however, using the appropriate accessory simplifies the

work and significantly improves the quality of the results

• Mounting/removing accessories (only 8000 in plastic

case)

- simply fit the accessory onto air outlet C 1

- remove an accessory by pulling it off to the front after

it has cooled down

! mount an accessory only when the air outlet is

cold, when the switch is in position "0" and when

the plug is disconnected

• Overload protection

Protects heating element from damage when tool is

overloaded without having to stop it and/or let it cool

down for a period of time

- when the temperature gets too high, the heating

element switches itself off, while the motor continues

to run and produces cold air

- when the temperature has fallen down sufficiently

(taking only a few seconds), the heating element will

be switched on automatically

APPLICATION ADVICE

• Removing paint/lacquer 6

- use a clean, sharp scraper

- scrape firmly, when the paint softens

- experiment to establish the length of time necessary

to apply the heat for optimal results

- scrape the softened paint immediately, or it will

harden again

- keep a 30° to 40° angle between the tool and the

workpiece

- remove paint and debris immediately from the scraper

to prevent them from ignition

- scrape with the grain of the wood, wherever possible

- do not direct the hot air stream towards the same

surface for too long

- dispose of all paint debris safely

- thoroughly clean the work area after completing the

job

! be careful when removing layers of paint in old

buildings; in the past the building may have been

painted with paint containing lead, which is highly

poisonous

! exposure to even low levels of lead can cause

serious brain and nervous system damage; young

and unborn children are particularly vulnerable

! have lead-based paint removed by a professional

without using a heatgun

OTHER APPLICATION EXAMPLE:

- removing (synthetic) wall covering

• Removing paint/lacquer next to glass 7

- always use glass protection nozzle F when working

next to glass

- remove the paint with a hand scraper

! do not use the tool for removing paint on metal-

framed windows; metal is heat-conducting which

might lead to breaking of the glass

• Removing stickers (use flat nozzle G) 8

- many adhesives become softer when heated,

allowing adhesive bonds to be separated and

superfluous adhesive to be removed

! heat sticker on the upper side

! always take care not to overheat the underlying

surface

OTHER APPLICATION EXAMPLES:

- removing linoleum and vinyl carpeting

- removing carpet tiles made of synthetic fibres

- removing veneers/applying veneer strips

- softening/melting tar, tin, bitumen, wax (use flat

nozzle G)

- waxing (skis, furniture) (use flat nozzle G) 9

- removing resin

5

Page 5

- loosening rusty/too tightly fastened metal screws,

nuts and bolts

- removing candle wax (do not overheat the

underlying surface)

- repairing broken candles/restoring bent candles to

their original shape

• Shrink fitting 0

- use reflector nozzle H or reduction nozzle J

- select a shrink-fit tube with a diameter matching that

of the workpiece

- heat the shrink-fit tube evenly

OTHER APPLICATION EXAMPLE:

- shrink-wrapping

• Soldering water pipes !

This tool is most suitable for working with soft solders

(melting point below 400°)

- use reflector nozzle H

- thoroughly clean both joining sections before

soldering

- pre-heat both sections and apply soldering wire

OTHER APPLICATION EXAMPLES:

- de-soldering of integrated circuits and other electronic

components (use reduction nozzle J)

- releasing old soldered joints (use reduction nozzle J)

• Thawing out frozen water pipes @

- use reflector nozzle H

- heat the frozen area evenly

! do no thaw out water pipes made of PVC

! water pipes are often difficult to distinguish from

gas pipes; heating gas pipes is extremely

dangerous – risk of explosion

OTHER APPLICATION EXAMPLES:

- thawing out frozen car locks (use reduction nozzle J)

- defrosting freezers (do not damage the plastic

housing)

- thawing out ice-covered steps and pavements

• Shaping plastic tubes

- use reflector nozzle H

- fill the tube with sand and seal it at both ends, to

avoid kinking of the tube

- heat the tube evenly by moving it from side to side

OTHER APPLICATION EXAMPLES:

- shaping all plastics with a low melting-point

(polyethylene, PVC etc.)

- shaping all plastics with a high melting-point (acrylic

glass, Plexiglas etc.)

- shaping and bending carpet tiles made of synthetic

fibres

- shaping and bending of wood (model-building)

• Welding plastics

- the weld seam must be clean and grease-free

- keep welding rod close to weld seam and apply heat,

until the welding rod gets tacky

- remove heat, when weld seam is filled up

OTHER APPLICATION EXAMPLES:

- repairing of surfboards, skis and other synthetic

sports goods (use flat nozzle G)

- welding PVC-materials

- smoothening blisters after sticking PVC-labels

- connecting garden hoses (use reflector nozzle H)

• Drying

! only dry with a low temperature setting (position 1)

and with an increased distance between the tool

and the workpiece

- drying of paint, varnish, gypsum, mortar and plaster

- drying wet timber prior to filling

- drying thickly applied filler or adhesive quickly

- drying building joints before spraying insulation or

sealant

- drying joints and cracks in boatbuilding

• Cleaning/disinfecting

- disinfecting rabbit hutches, dove cotes, etc.

(remove your pet first)

- combatting ant colonies

- combatting woodworms and boring beetles (hold the

tool at an adequate distance from the wood)

- eliminating weeds

• Igniting

- igniting charcoal (barbecues)

- setting fire to wood (open fires)

MAINTENANCE/REPAIR

• Keep tool and cord clean (some household cleaning

products and solvents can damage plastic parts; these

products include among others benzine,

trichloroethelene, chloride, amonium)

• Disconnect the plug before cleaning

• Keep ventilation slots E 1 clean

• Never use easy inflammable liquids for cleaning the heat

gun in general and the air outlet/nozzle in particular

• Excessive sparking mostly indicates worn-out carbon

brushes

• In case of an electrical or mechanical defect, hand in

tool at one of the officially registered SKIL Service

Stations for repair (addresses are listed on the service

diagram supplied with the tool)

ENVIRONMENTAL PROTECTION

• Ensure to dispose of the tool according to the countryspecific regulations (inform yourself at your local

authorities)

• Sort tool, accessoires and packaging for environmentfriendly recycling

• Be aware of the fact that the plastic components are

labelled for categorized recycling

6

Page 6

CE DECLARATION OF CONFORMITY

We declare under our sole responsibility that this product is in

conformity with the following standards or standardized documents:

EN 55 014, EN 60 335, EN 61000-3,

in accordance with the regulations 73/23/EEC, 89/336/EEC,

98/37/EEC.

99 SKIL Europe B.V. J. P. Houben

INFORMATION ON NOISE/VIBRATION

Measured in accordance with EN 50 144 the sound pressure level of

this tool is < 70 dB(A) and the vibration < 2.5 m/s2(hand-arm

method).

66

GB

CE DÉCLARATION DE CONFORMITÉ

Nous déclarons sous notre propre responsabilité que ce produit est

en conformité avec les normes ou documents normalisés suivants:

EN 55 014, EN 60 335, EN 61000-3,

conforme aux réglementations 73/23/EEC, 89/336/EEC, 98/37/EEC.

99 SKIL Europe B.V. J. P. Houben

BRUIT/VIBRATION

Mesuré selon EN 50 144 le niveau de la pression sonore de cet outil

est < 70 dB(A) et la vibration < 2,5 m/s2(méthode main-bras).

F

CE KONFORMITÄTSERKLÄRUNG

Wir erklären in alleiniger Verantwortung, daß dieses Produkt mit den

folgenden Normen oder normativen Dokumenten übereinstimmt:

EN 55 014, EN 60 335, EN 61000-3,

gemäß den Bestimmungen der Richtlinien 73/23/EWG,

89/336/EWG, 98/37/EWG.

99 SKIL Europe B.V. J. P. Houben

GERÄUSCH- /VIBRATIONSINFORMATION

Gemessen gemäß EN 50 144 beträgt der Schalldruckpegel dieses

Gerätes < 70 dB(A) und die Vibration < 2,5 m/s2(Hand-Arm

Methode).

D

CE CONFORMITEITSVERKLARING

Wij verklaren, dat dit product voldoet aan de volgende normen

of normatieve documenten: EN 55 014, EN 60 335, EN 61000-3,

overeenkomstig de bepalingen van de richtlijnen 73/23/EEG,

89/336/EEG, 98/37/EEG.

99 SKIL Europe B.V. J. P. Houben

INFORMATIE OVER GELUID/VIBRATIE

Gemeten volgens EN 50 144 bedraagt het geluidsdrukniveau van

deze machine < 70 dB(A) en de vibratie < 2,5 m/s2(hand-arm

methode).

NL

CE KONFORMITETSFÖRKLARING

Vi intygar och ansvarar för, att denna produkt överensstämmer med

följande norm och dokument: EN 55 014, EN 60 335, EN 61000-3,

enl. bestämmelser och riktlinjema 73/23/EWG, 89/336/EWG,

98/37/EWG.

99 SKIL Europe B.V. J. P. Houben

LJUD- /VIBRATIONSDATA

Ljudtrycksnivån som uppmätts enligt EN 50 144 är på denna

maskin < 70 dB(A) och vibration < 2,5 m/s2(hand-arm metod).

CE KONFORMITETSERKLÆRING

Vi erklærer under almindeligt ansvar, at dette produkt er i

overensstemmelse med følgende normer eller normative

dokumenter: EN 55 014, EN 60 335, EN 61000-3,

i henhold til bestemmelserne i direktiverne 73/23/EØF, 89/336/EØF,

98/37/EØF.

99 SKIL Europe B.V. J. P. Houben

STØJ- /VIBRATIONSINFORMATION

Måles efter EN 50 144 er lydtrykniveau af dette værktøj

< 70 dB(A) og vibrationsniveauet < 2,5 m/s2(hånd-arm metoden).

DK

CE SAMSVARSERKLÆRING

Vi erklærer at det er under vårt ansvar at dette produkt er i samsvar

med følgende standarder eller standard- dokumenter:

EN 55 014, EN 60 335, EN 61000-3,

i samsvar med reguleringer 73/23/EWG, 89/336/EWG, 98/37/EWG.

99 SKIL Europe B.V. J. P. Houben

STØY- /VIBRASJONSINFORMASJON

Målt ifølge EN 50 144 er lydtrykknivået av dette verktøyet

< 70 dB(A) og vibrasjonsnivået < 2,5 m/s2(hånd-arm metode).

N

CE TODISTUS STANDARDINMUKAISUUDESTA

Todistamme täten ja vastaamme yksin siitä, että tämä tuote en

allalueteltujen standardien ja standardoimisasiakirjojen vaatimusten

mukainen EN 55 014, EN 60 335, EN 61000-3,

seuraavien sääntöjen mukaisesti 73/23/EWG, 89/336/EWG,

98/37/EWG.

99 SKIL Europe B.V. J. P. Houben

MELU- /TÄRINÄTIETO

Mitattuna EN 50 144 mukaan työkalun melutaso on < 70 dB(A) ja

tärinän voimakkuus < 2,5 m/s2(käsi-käsivarsi metodi).

FIN

S

Loading...

Loading...