Page 1

TINV

T^K

mending machine

Fast and easy

IMPORTANT SAFEGUARDS

• Before connecting machine, be sure voltage on transformer conforms to your electrical

supply.

-*1

1

• Disconnect machine plug when changing needles, cleaning machine or removing bobbin.

• Disconnect transformer when machine is unattended.

• Because of the up-and-down movement of needle, work carefully and watch sewing area

when operating machine.

• Do not pull fabric while stitching, as this may bend needle causing it to break.

SAVE THESE INSTRUCTIONS

Copyngnt « 1962 THE SINGER COMPANY

All flignu RftMrved Througfioul tn* World

* A Tra<i«fn«r)i ol THE SMCER COMPANY

Mod«4 M100A

SINGER

Page 2

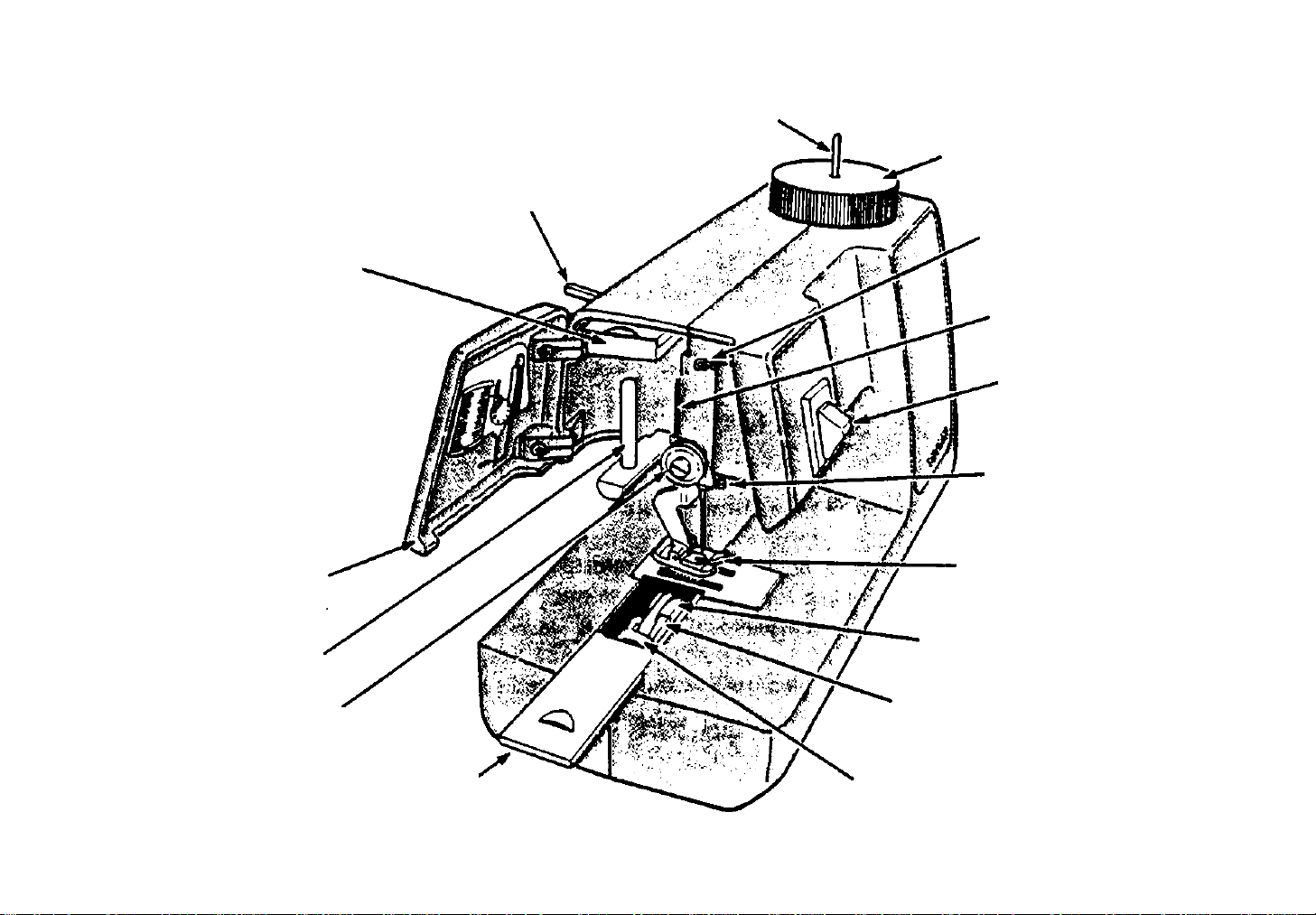

PRINCIPAL PARTS

ACCESSORY TRAY

BOBBIN WINDER PIN

HAND WHEEL

FOOT LEVER

THREAD GUIDE

Containing;

Needle Threader

Needles

Bobbin

Bobbin

Winder Pin

HINGED DOOR

SPOOL PIN

THREAD DISCS

THREAD GUIDE

POST

ON-OFF

SWITCH

NEEDLE CLAMP

SCREW

FOOT

BOBBIN

BOBBIN CASE

BOBBIN CASE CARRIER

SLIDE COVER

-1-

Page 3

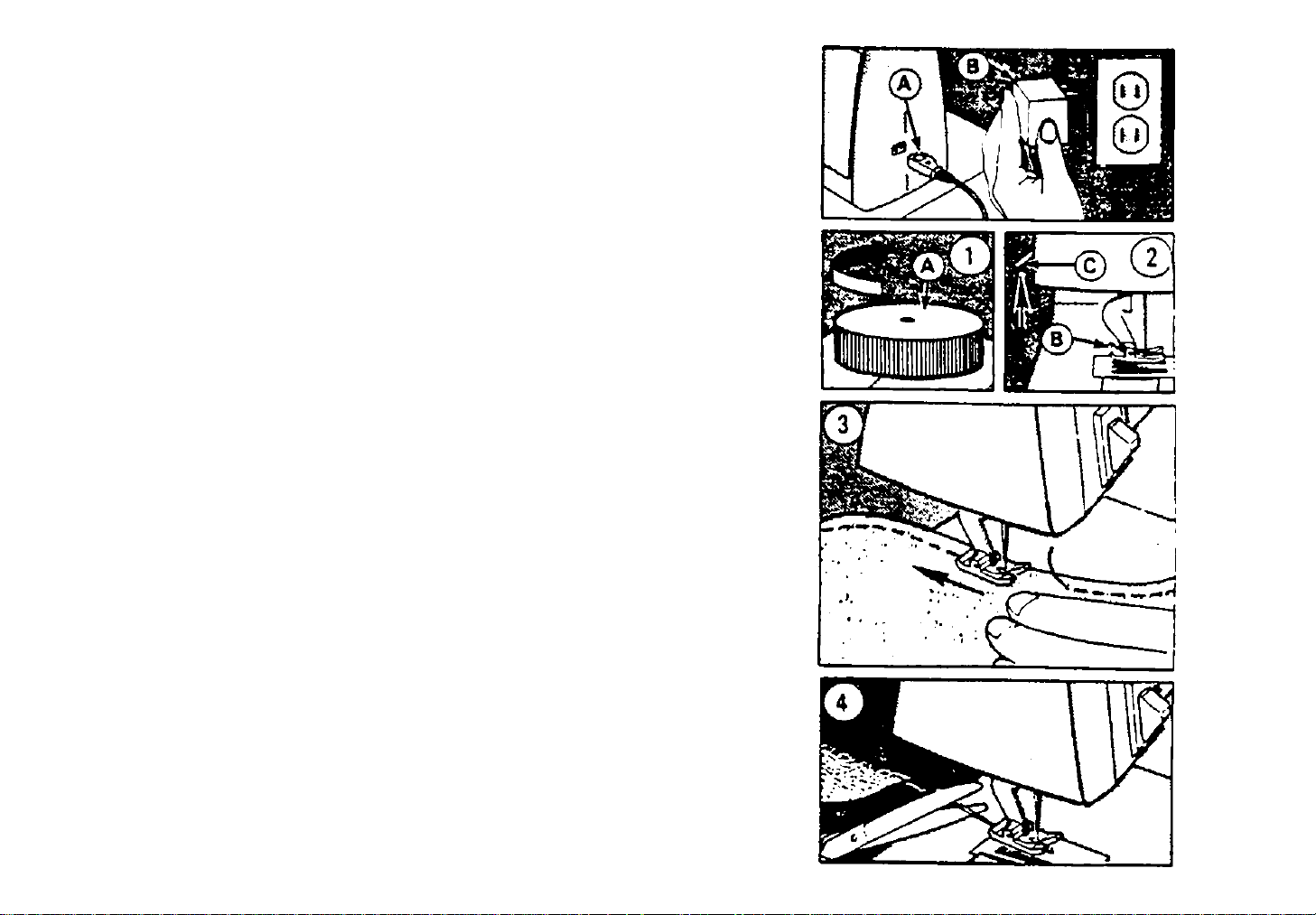

TO CONNECT YOUR MACHINE

Be sure power switch is < OFF ». INSERT machine plug (A) into the

machine socket. CONNECT the transformer (B) to your electrical

outlet.

Check that machine is threaded correctly (see pages 6 and 7).

< This machine is not intended for garment construction.»

TO BEGIN MENDING

1. TURN hand wheel (A) clockwise, raising needle to highest

position.

2. LIFT foot (B) with foot lever (C).

3. POSITION area to be mended under foot.

• TURN hand wheel clockwise, lowering needle into existing

stitches in fabric.

• Lower foot.

• GUlOB fabric toward back of machine.

• TURN machine “ON" and machine will begin operating

Immediately.

• Continue running machine until new stitches overlap

existing stitches.

• When mend is completed, TURN power "OFF".

4. RAISE needle to highest position: LIFT foot.

• MOVE fabric toward back of machine.

• CUT threads 4" (10cm) from edge of fabric.

Your mend Is now completed!

-2-

Page 4

TO WIND THE BOBBIN

1. REMOVE bobbin winder pin (A) from accessory tray behind

door.

• PUSH it down firmly in center of hand wheel.

2. MOVE slide cover to the left.

• LIFT foot with foot lever.

• TURN hand wheel clockwise, moving carrier to the far left.

3. LIFT OUT bobbin case from carrier.

4. RE.MOVE'bobbin (B) from case (C).

5. PLACE spobi of thread, with slit on bottom, on spool pin (D)

behind door so thread unwinds from back of spool.

• LEAD thread from spool through back of thread guide (E).

• BRING thread from guide into center hole of slotted end of

bobbin.

• SLIDE slotted end of bobbin over winder pin and PUSH

DOWN into place.

• CUT excess thread from top of bobbin.

• TURN machine "ON" and slowly GUIDE thread up and

down as bobbin winder turns.

• TURN machine "OFF" before thread winds beyond rims

of bobbin.

• CUT thread 3" (7.5cm) from bobbin.

• REMOVE bobbin from winder pin and REMOVE winder pin

from hand wheel.

• PULL center thread from slotted end of bobbin and trim.

• PLACE bobbin into case as follows:

-3-

Page 5

TO REPLACE THE BOBBIN

Be sure to follow these steps carefully. If bobbin is incorrectly

placed, machine will not stitch properly.

1. With slotted end (A) to the right, PLACE filled bobbin into

case (8).

• LEAVE 3" (7.5cm) of thread outside case.

2. HOLD finger over case opening to keep bobbin m place, and

PULL thread completely into slot (C).

• SNAP thread back between the two metal guides (D).

• PULL 3" (7.5cm) of thread from case.

3. MOVE slide cover to the left.

• TURN hand wheel clockwise, moving carrier to the far left.

• With metal guides facing up, RETURN case to carrier (E).

• CLOSE cover, leaving about 3" (7.5cm) of thread on

outside.

-4-

Page 6

TO CHANGE YOUR NEEDLE

When the needle is broken or dull, replace it as follows:

• OPEN door for better visibility.

• UNTHREAD needle.

• TURN hand wheel clockwise until needle clamp screw (A) is

easy to see.

• LOWER foot.

• HOLD needle with fingers and LOOSEN clamp screw one turn

with screwariver.

• LOWER needle and REMOVE.

• To replace needle: LOWER needle, with flat side to the back

of the machine, into hole under foot, then up into clamp as far

as it will go.

• TIGHTEN needle clamp screw.

For best results, change your needle periodically, using Singer

#3347-14 needles, which may be ordered on the enclosed form.

-5-

Page 7

TO THREAD YOUR MACHINE

When it’s lime to change thread:

• TURN hand wheel clockwise until needle is in its highest

position.

• LOWER foot.

• PLACE thread spool, with slit down, on spool pin behind door.

Thread will unwind from back of spool.

• DRAW thread from spool around back of thread guide post

(A).

• HOLD spool in place; PULL thread between discs from back

to front (8).

• BRING thread up through guide (C) from back to front

• Then BRING thread down through needle from front to back,

pulling 3" (7.5cm)'of thread through needle.

To use needle threader (D). first insert wire loop from back of

needle's eye. Place thread through wire loop. Draw needle

threader, with thread, back through eye.

-6-

Page 8

TO RAISE THE LOWER THREAD

All machines making a lockstitch sew with both an upper and

lower thread. Thè thread coming through the needle's eye is the

upper thread. The thread coming from the bobbin is the lower

thread. Before mending, the lower thread must be brought up to

meet the upper thread. To do this:

1. RAISE foot.

• HOLD upper thread lightly with left hand.

• Slowly TURN hand wheel. 1 revolution clockwise, moving

needle down and up again.

• Gently PULL thread in left hand, drawing up a loop (A) of

lower thread.

2. UNDO loop with your fingers until you find the end of the

lower thread.

3. PULL 6" (15cm) of upper-and lower threads under foot and

toward back of machine.

-7-

Loading...

Loading...