Page 1

SEWING MACHINE

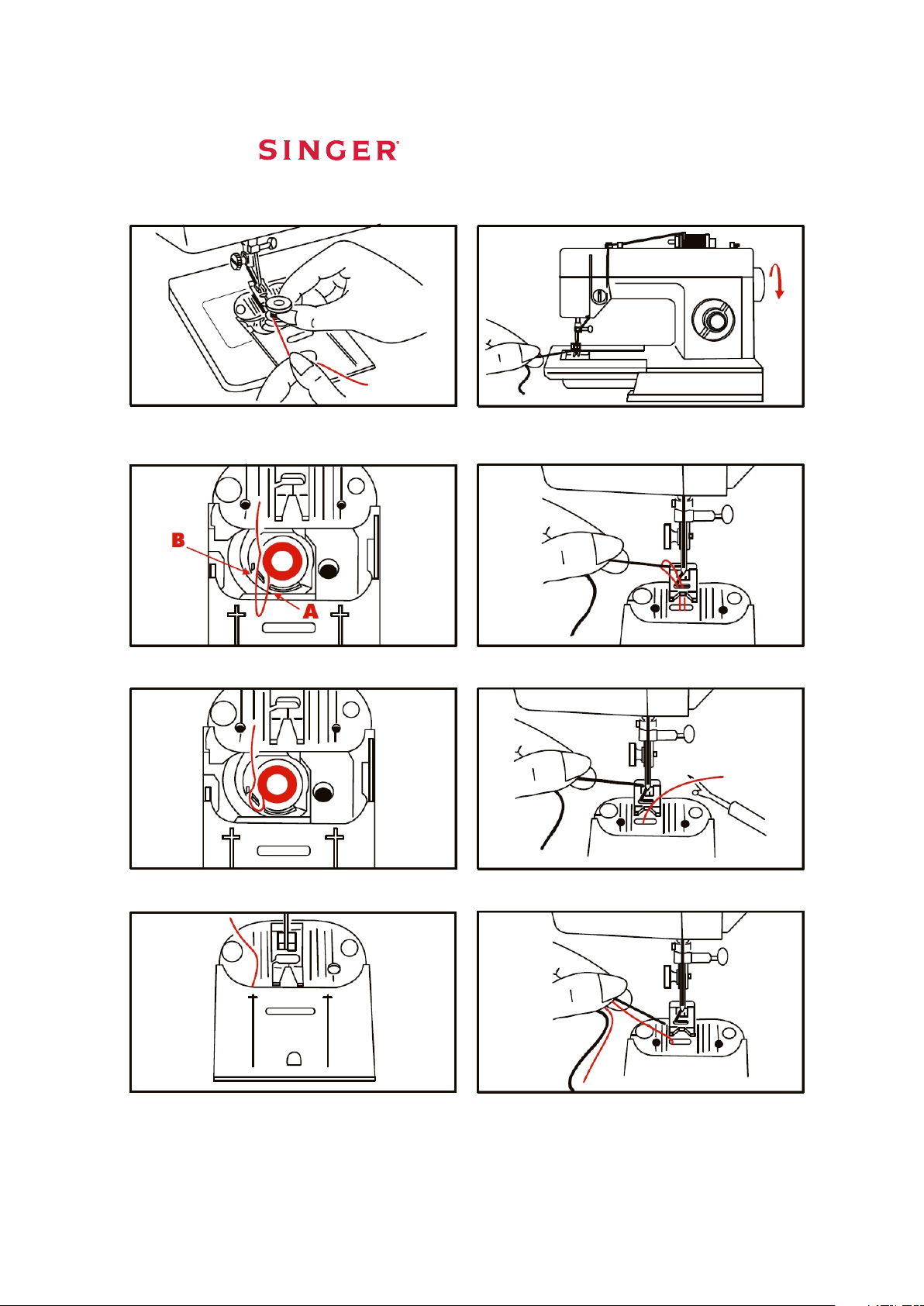

BOBBIN CASE THREADING INSTRUCTIONS

(Consult Instruction Book for bobbin winding instructions)

1. Slide bobbin cover plate toward you. Insert wound bobbin

into bobbin case with thread spooling off to the left.

2. Guide thread to left through notch A and then pull straight

back toward needle so that it passes through notch B.

5. Hold top (needle) thread and turn handwheel toward you

until needle goes to its lowest and then its highest point.

Raise the presser foot using the presser bar lifter.

6. Gently pull top thread until lower (bobbin) thread comes

up in the form of a loop.

3. Leave several inches of thread laying across top of bobbin

toward the back of the machine.

4. Slide bobbin cover plate back intro position. thread tail

should be visible, sticking out at top of cover.

P/N: 357626-002REV.1

7. Use the flat side of a seam ripper or a pin to open up

bobbin thread loop until end is visible.

8. Pull both thread tails straight back under presser foot.

Page 2

SEWING MACHINE

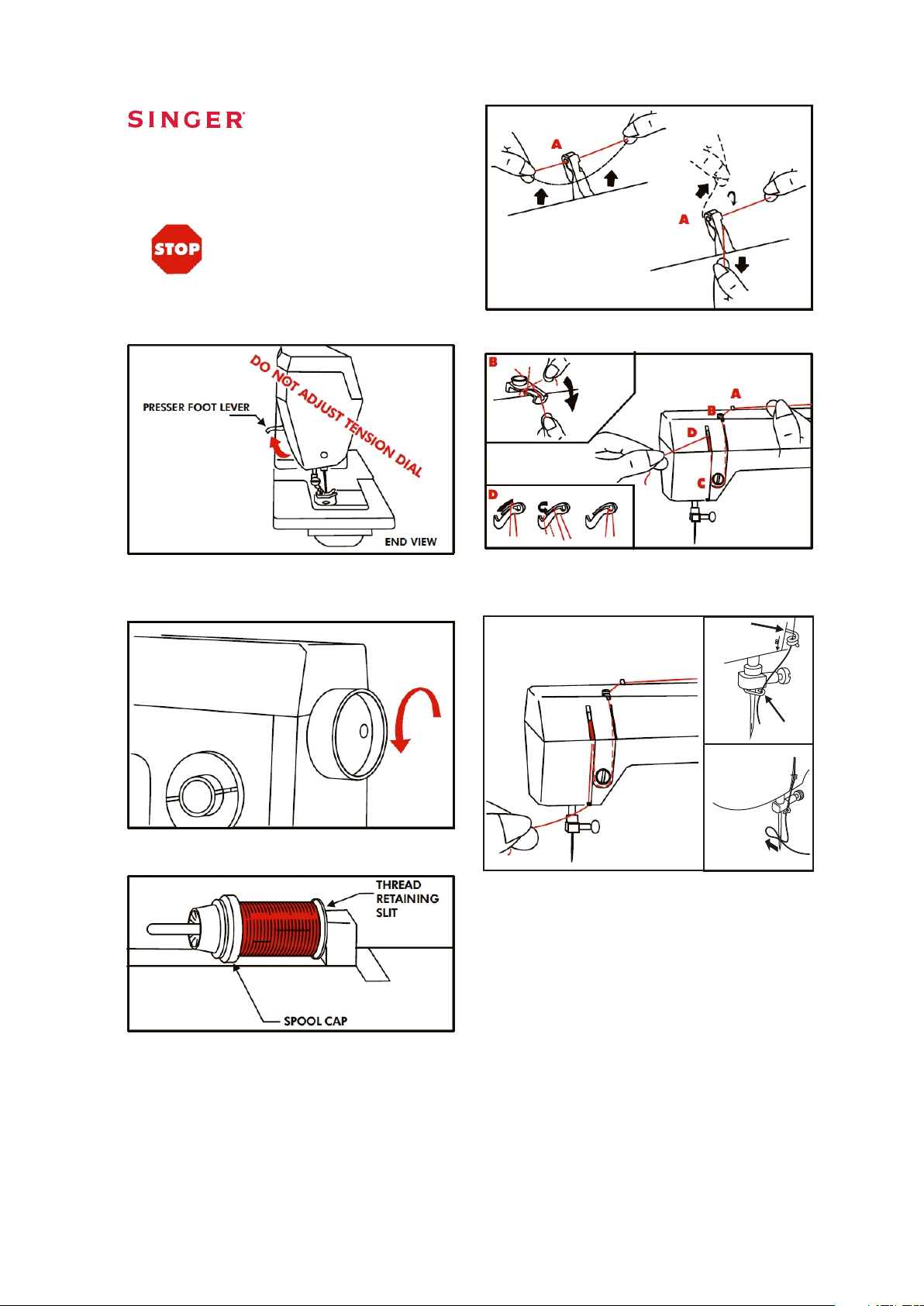

IMPORTANT THREADING

INSTRUCTIONS

This machine features a special

Easy Threading System. Even if you

have sewn before, take the time to

learn how to properly thread the

machine, and you will avoid

serious sewing problems in the

future.

1. Raise presser foot lever. This separates the tension discs in

the machine that you will be feeding the thread through in

step 5.

4. Using two hands, snap thread into thread guide post A,

as illustrated.

5. Holding thread secure at A, pass the thread under guide B

and through the slot, guide thread down threading channel

to tension system C. Pull thread firmly up to top of channel

D, and then back down again.

A

2. Turn handwheel toward you to raise needle to highest

position.

3. Remove spool cap. Place spool of thread on spool pin,

with Thread Retaining Slit to right. Slide spool cap onto

spool pin until it touches spool to prevent thread from

tangling. For large spools of thread, larger end of spool

cap should touch spool. For small spools, smaller end

should touch spool.

Before threading needle, test for proper threading as

6.

follows: Pull a few inches of thread through theading

channel. Lower presser foot to engage tension discs,

pull a few more inches through. There should be a

noticeable difference between the thread tension when the

presser foot is down and when it is up. If the thread pulls

through easily when the presser foot is down, the machine

is not properly threaded and sewing problems will result.

R e - t hr e a d t h e m a ch i n e a n d t es t a ga i n .

To pass the thread through the spiral thread guide,

start from the left, making a circular clockwise

movement with your hand twice. The thread will

slide inside the center of the spiral (illustration A).

Pass the thread through the last thread guide from

right to left and turn hand wheel toward you until

needle is in its highest position. Lower presser foot.

Thread eye of the needle.(illustration B).

B

IMPORTANT NOTE: If thread balls up in the bobbin case or knots up on the underside of the fabric,

th e m a c hi n e may not be pro p er l y thre a d ed . D O N OT adj u s t the thr e ad

tension until you have checked for proper threading using the test described in step 6.

Loading...

Loading...