Page 1

82387 No. 66

Singer Sewing Machine

No. 66

Oscillating Hook, For Family Use

INSTRUCTION MANUAL

Table of Contents | Next Page

Page 2

82387 No. 66

Table of Contents

Main Parts

Parts of the Machine Stand

Instructions for Operating the Machine

To Ensure Perfect Action of the Machine

To Take Out the Bobbin

To Wind the Bobbin

To Replace the Bobbin

To Set the Needle

To Thread the Needle

To Prepare for Sewing

To Commence Sewing

To Remove the Work

Tensions

To Regulate Tensions

To Turn a Corner

To Regulate the Length of Stitch

To Regulate the Pressure on the Material

To Sew Flannel or Bias Seams

A Stitch to Ravel Easily

To Oil the Machine

Hints

The Belt

Machine WOrking Heavily

To Avoid Breaking Needles

Breaking of Needle Thread

Breaking of Bobbin Thread

Skipping of Stitches

Attachments with the Machine

Instructions for Using the Attachments

Foot Hemmer

-- Hemming

-- Hemming and

Sewing on Lace

-- Felling

Adjustable Hemmer

-- Hemming

-- Wide Hemming

Binder -- Binding

Bias Gauge

-- To Bind with Dress Braid

Ruffling

Ruffler -- Ruffling Between Bands

To Ruffle and Sew On

-- Five Stitch Ruffling or Paiting

Ruffler with Shirring Plate -- Shirring

Quilter

Tucker

Under Braider

Embroidary and Darning

Relative Sizes of Needles and Thread

Previous Page | Next Page

Page 3

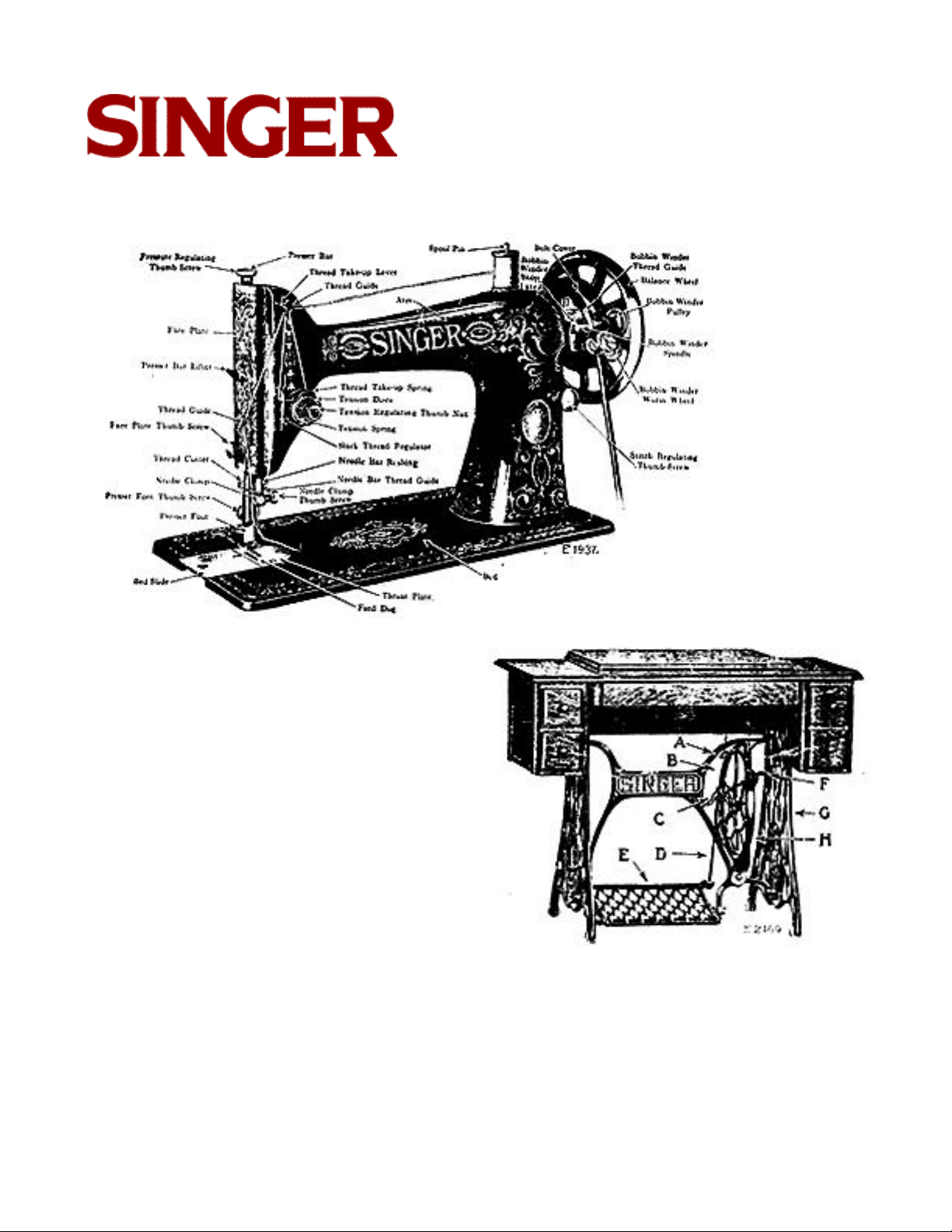

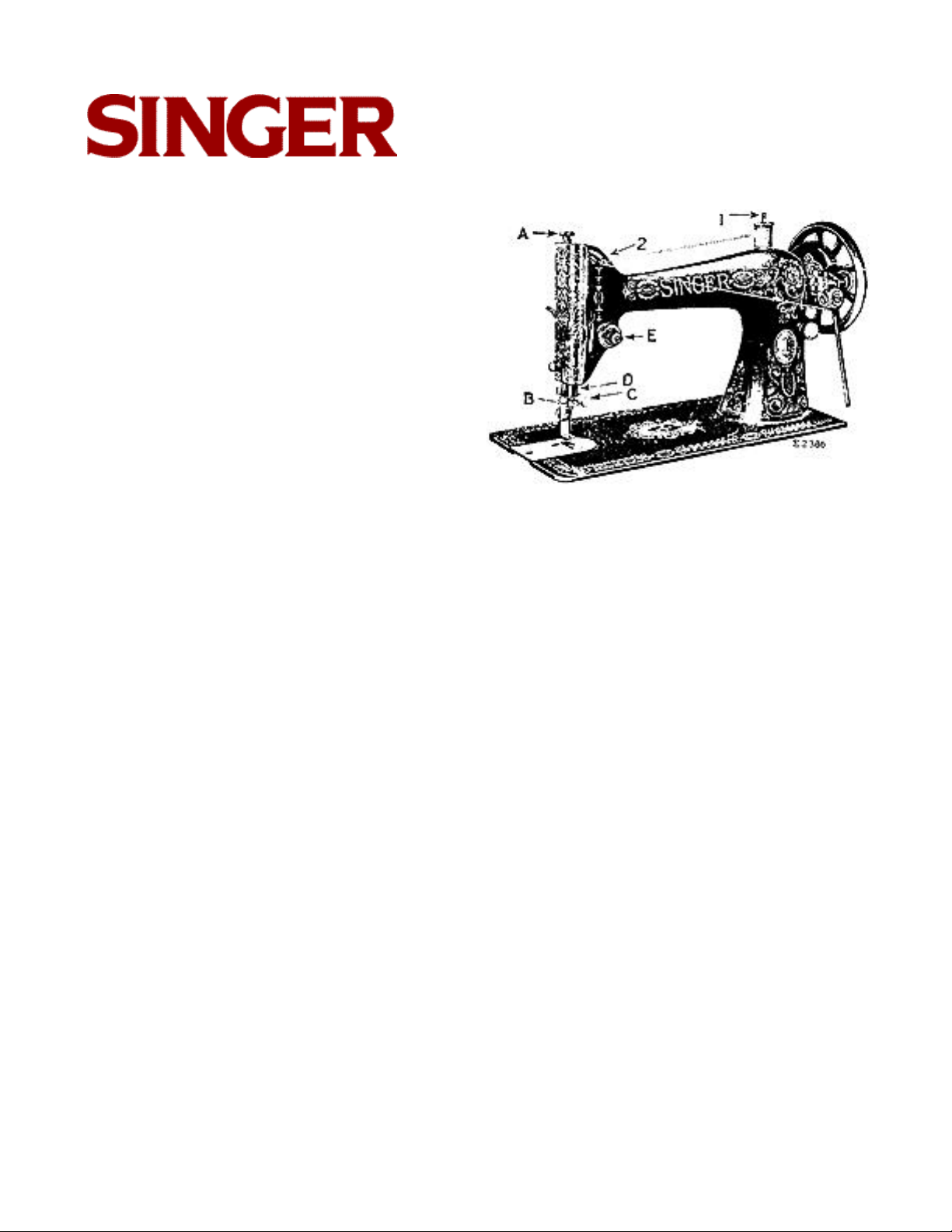

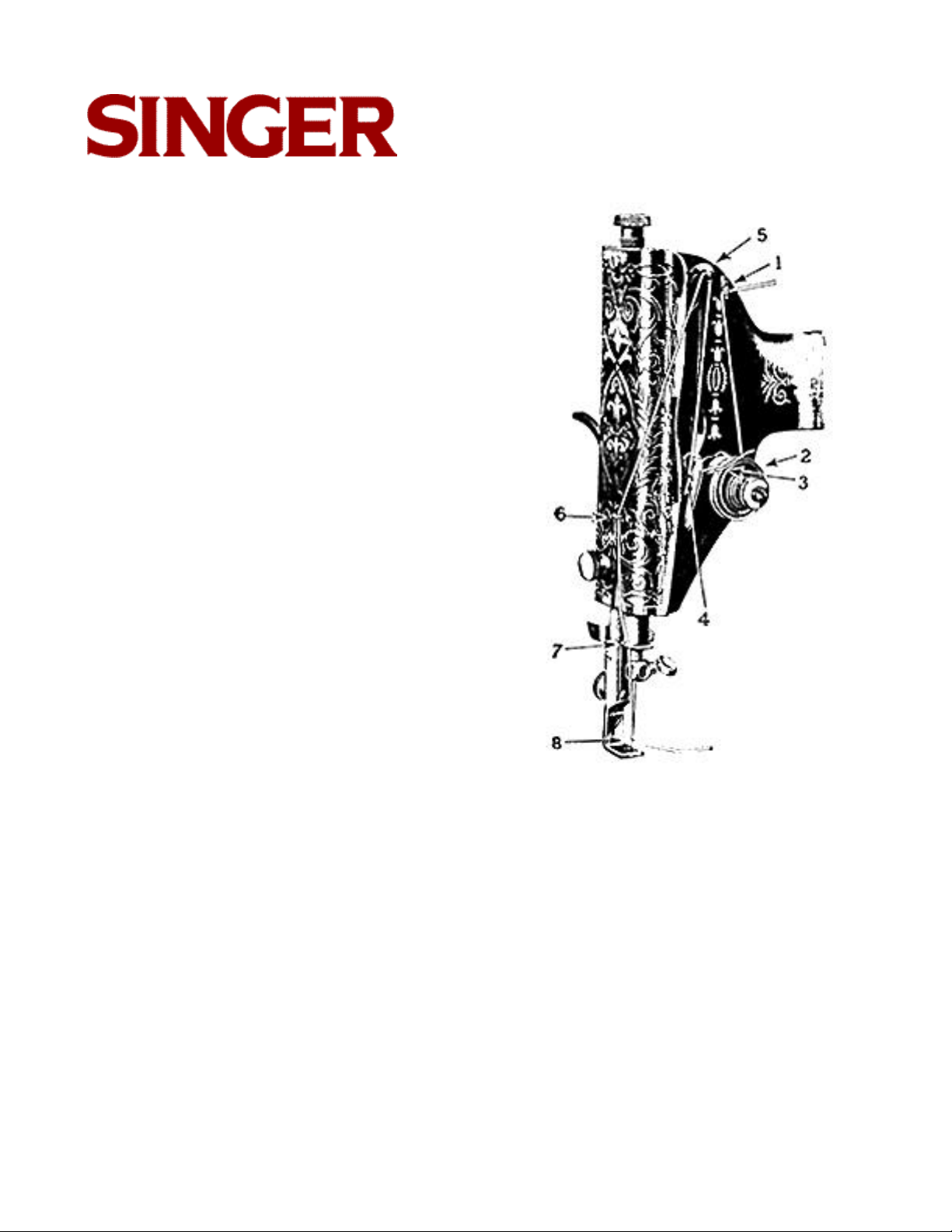

Main Parts

82387 No. 66

Parts of the Machine Stand

A. BELT GUIDE

B. BAND WHEEL

C. BAND WHEEL CRANK

D. PITMAN

E. TREADLE

F. BELT SHIFTER

G. LEG

H. DRESS GUARD

Table of Contents Previous Page | Next Page

3

Page 4

82387 No. 66

INSTRUCTIONS FOR

OPERATING THE MACHINE

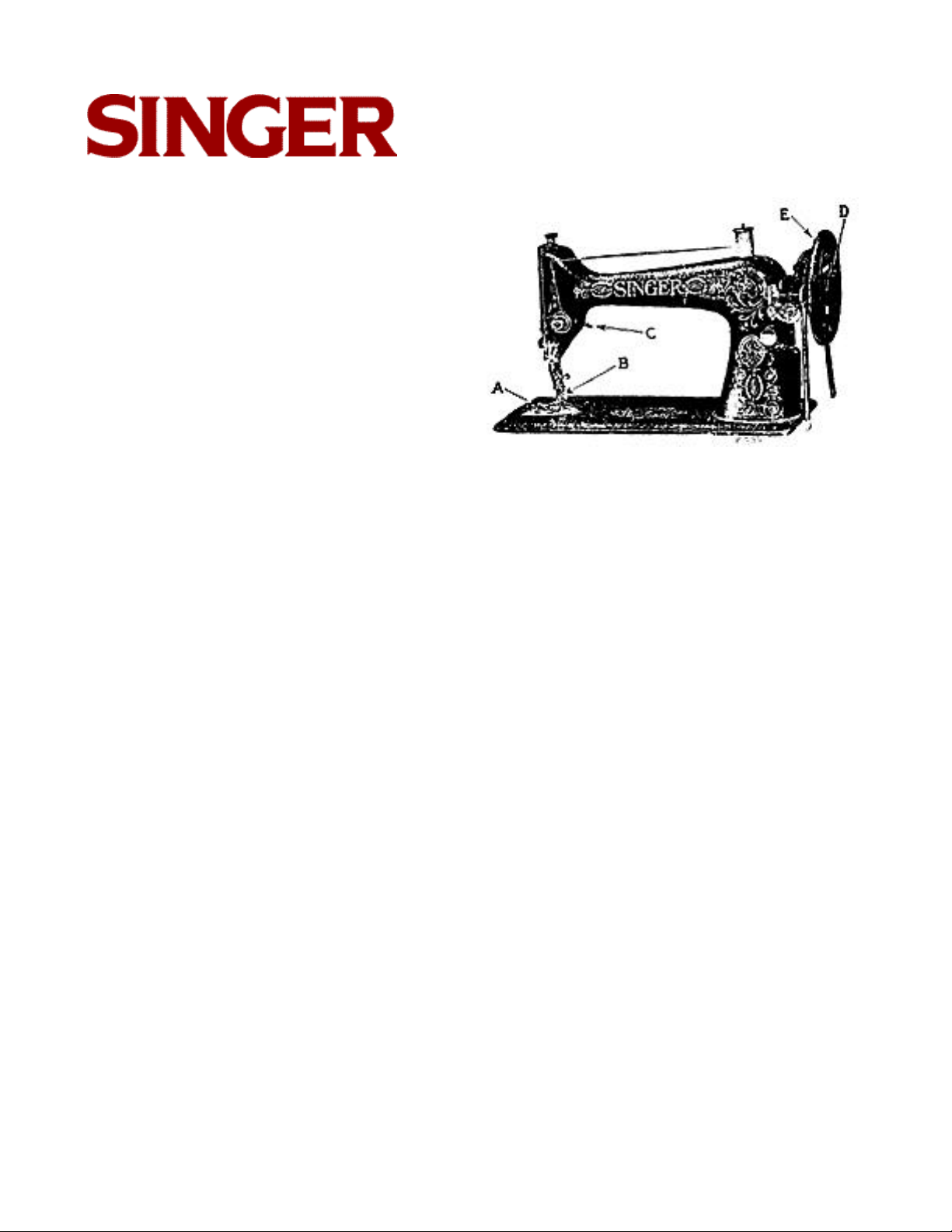

Raise the presser foot (B. Fig. 3) by means of

the presser bar lifter (C, Fig. 3) to prevent

injury to the foot (B. Fig. 3) and feed (A, Fig.

.3).

It is necessary to understand the stop motion

(D, Fig. 3) by which the balance wheel (E,

Fig. 3) can be released when required, thus

enabling the operator to become proficient in

the use of the treadle and permitting the

winding of bobbins without running the stitching mechanism. It also allows the operator to

wind bobbins without removing partially sewn

work and without unthreading the machine.

To release the balance wheel (E, Fig. 3) turn

the stop motion screw (D, Fig. 3, page 3)

over toward you. It may be necessary to hold

the balance wheel while loosening the stop

motion screw.

After releasing the balance wheel place your

feet upon the treadle and with the right hand,

turn the balance wheel over toward you. This

will start the band wheel, treadle and pitman,

the sewing mechanism having been disconnected.

FIG.3. FRONT VIEW OF THE MACHINE

Continue the motion thus begun by an alternate pressure of heel and toe, until a regular

and easy movement is acquired, and the balance wheel kept in continuous rotation by use

of the feet alone.

When you are thoroughly familiar with the

treadle movement, and can restart the

machine without turning the balance wheel in

the wrong direction, tighten the stop motion

screw to connect the balance wheel with the

stitching mechanism.

Place a piece of cloth under the presser foot,

let the foot down upon it, and operate the

machine in this way without being threaded,

until you have become accustomed to guiding

the material.

Table of Contents Previous Page | Next Page

4

Page 5

82387 No. 66

To Ensure Perfect Action of the Machine

The balance wheel must always turn over

toward the operator.

Do not run the machine with the presser foot

resting on the feed without cloth under the

presser foot.

Do not run the machine when both bobbin

case and needle are threaded unless there is

material under the presser foot.

Do not try to help the machine by pulling the

fabric lest you bend the needle. The machine

feeds the work without assistance.

The slide over the bobbin case should be

kept closed when the machine is in operation.

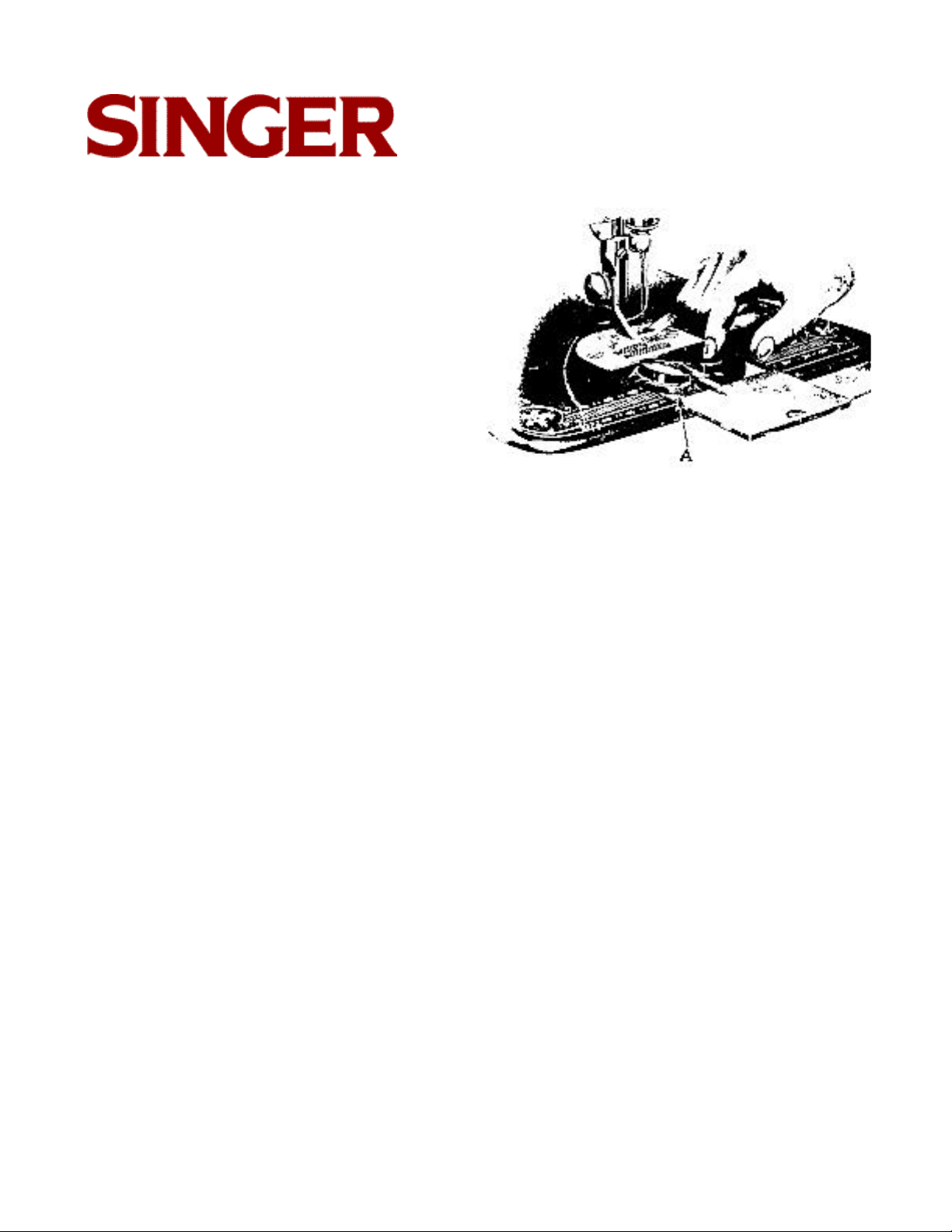

FIG. 4. REMOVING THE BOBBIN

To Take Out the Bobbin

Draw to the left the slide in the bed of the

machine and press the forefinger of the right

hand upon the bobbin ejected as shown

above; this will raise the bobbin so that it can

be easily taken out.

Table of Contents Previous Page | Next Page

5

Page 6

82387 No. 66

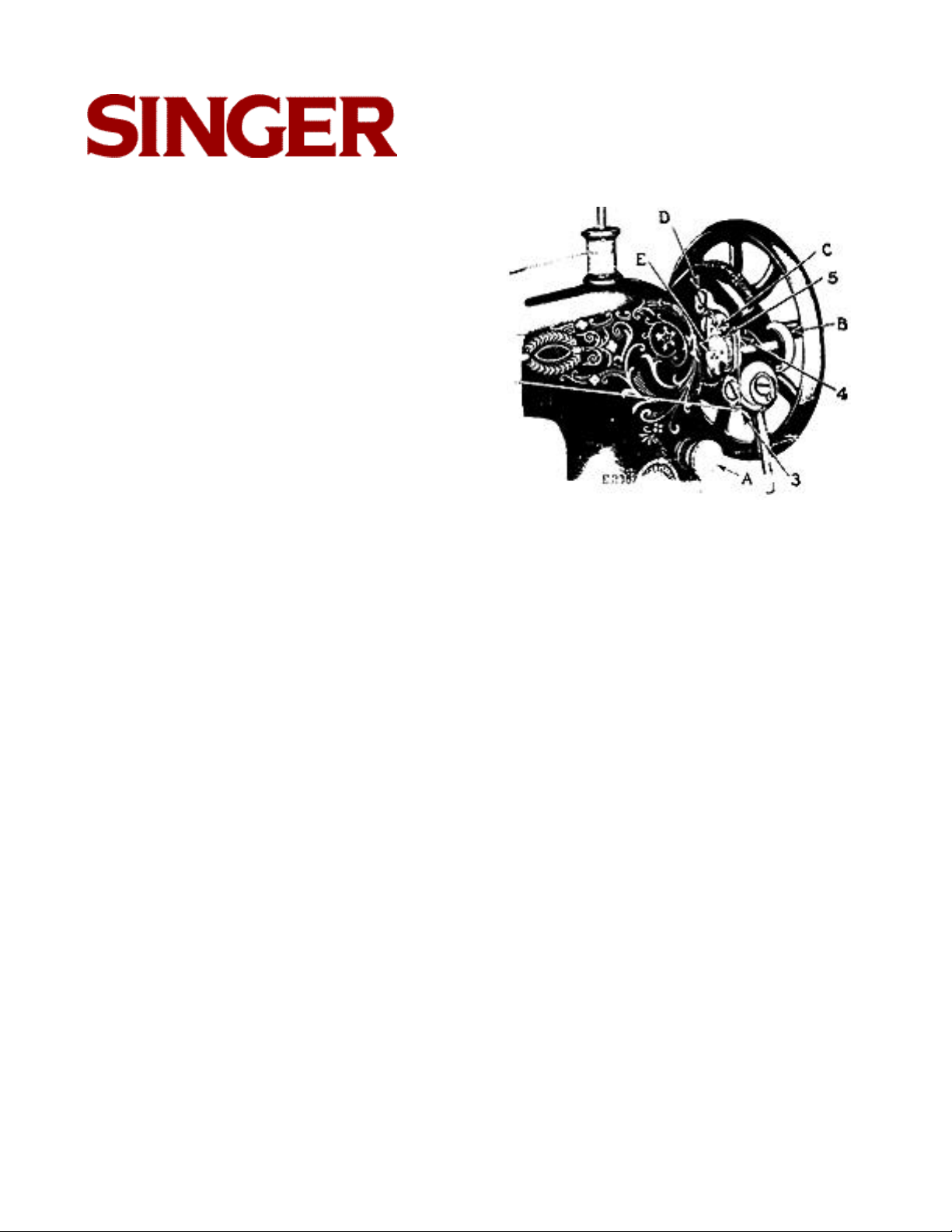

To Wind the Bobbin

Release the balance wheel (E, Fig. 3, page

3) by turning the stop motion screw (D, Fig.

3, page 3) over toward you.

Place the bobbin on the bobbin winder spindle (E, Fig. 6, page 7) and push it up closely

against the shoulder, having the small pin in

the spindle enter the hole in the side of the

bobbin. Put the spool of thread on the spool

pin (1, Fig. 5). Pass the end of the thread into

the thread guide (2, Fig. 5) then up into the

lower eyelet (3, Fig. 6) of the bobbin winder

thread guide, into the notch (4, Fig. 6) and

pass the thread through the hole in the left

side of the bobbin (5, Fig. 6) from the inside.

Press the bobbin winder pulley (B, FIG. 6)

down on the balance wheel hub and the latch

(C, Fig. 6) will drop down and hold it. Then

operate the treadle the same as for sewing.

FIG. 5. MACHINE THREADED

FOR WINDING THE BOBBIN

Table of Contents Previous Page | Next Page

6

Page 7

82387 No. 66

To Wind the Bobbin continued...

The end of the thread must be held by the

hand unti1 a few coils are wound and should

then be broken off. Figs. 5 and 6 show the

bobbin winder properly threaded and in position for winding. When sufficient thread has

been wound upon the bobbin it is automatically released from the stop latch (C, Fig. 6).

If the pressure of the rubber ring (B, Fig. 6)

against the hub of the balance wheel is insufficient for winding the bobbin, loosen the

adjusting screw (D, Fig. 6) and press the bobbin winder lightly until the rubber ring is in

contact with the hub of the balance wheel;

then tighten the screw.

FIG. 6. WINDING THE BOBBIN

Table of Contents Previous Page | Next Page

7

Page 8

82387 No. 66

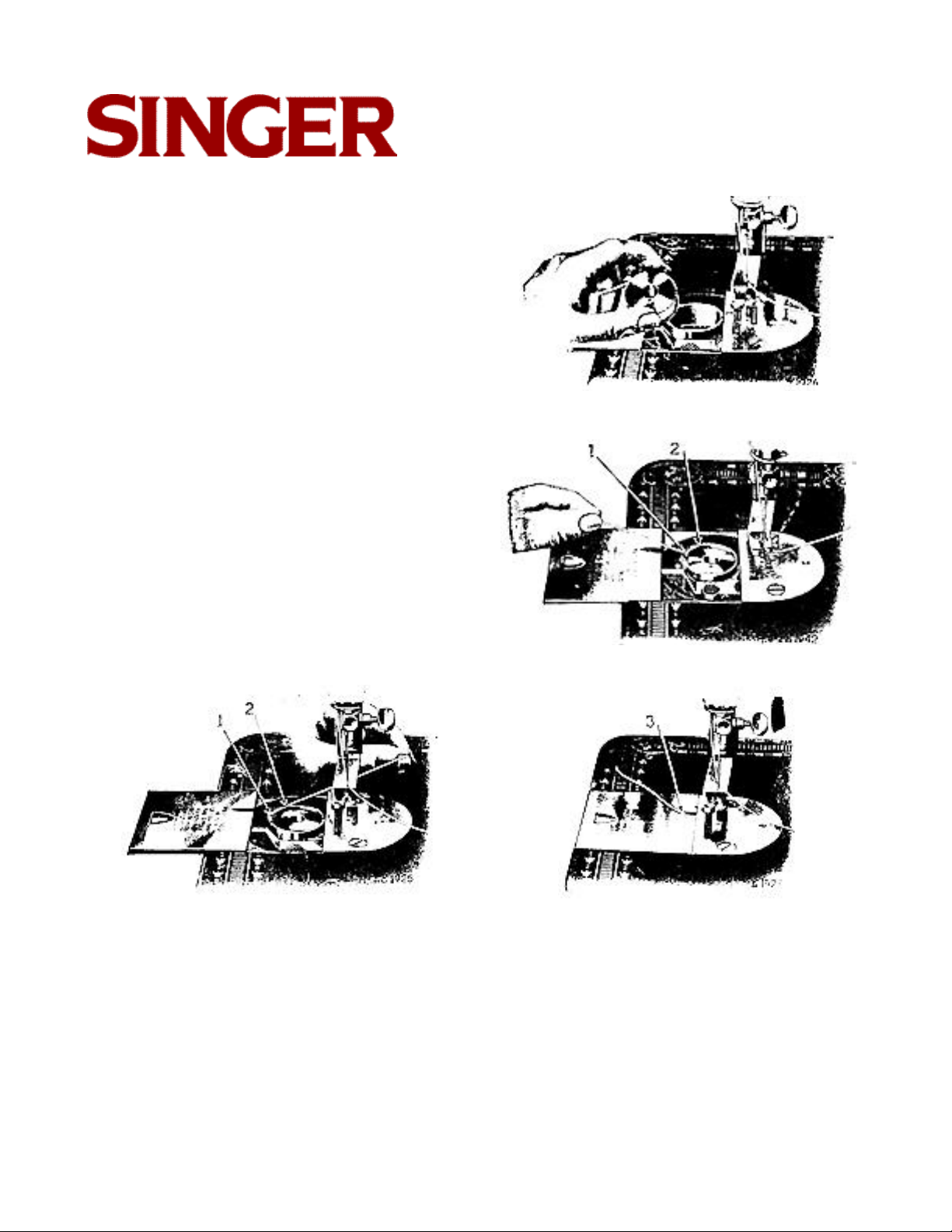

To Replace the Bobbin

Hold the bobbin between the thumb and forefinger of the left hand, the thread leading on

top from the right toward the left, as shown in

Fig. 7.

Place the bobbin into the bobbin case and

draw the thread into the slot (1, Fig. 8) in the

bobbin case, as shown below.

Draw the thread backward between the bobbin case and the tension spring until it reaches the notch (2, Fig. 9) then pull the thread

toward the right as shown in Fig. 9.

When closing the slide see that the thread is

in the slot (3, Fig. 10) in the right edge of the

slide, as shown below.

FIG. 7.REPLACING THE BOBBIN

FIG. 8. THREADING the BOBBIN CASE

FIG. 9. BOBBIN CASE THREADED

FIG. 10. UNDER THREADING COMPLETED

Table of Contents Previous Page | Next Page

8

Page 9

82387 No. 66

To Set the Needle

Turn the balance wheel over toward you until

the needle bar moves up to its highest point

in the sleeve (D, Fig. 5), loosen the thumb

screw (C, Fig. 5) in the needle clamp (B. Fig.

5) and put the needle up into the clamp as far

as it will go, with its flat side toward the right,

then tighten the thumb screw.

To Thread the Needle

SEE FIG. 11

Turn the balance wheel over toward you until

the thread take-up lever (5) is raised to its

highest point. Place the spool of thread on

the spool pin at the top of the machine; lead

the thread into the thread guide (1) at the left,

down, under and from right to left between

the tension discs (2), into the small wire

spring (3), under the thread regulator (4) at

the left (not through the eye in the thread regulator), up and from right to left through the

hole in the end of the thread take-up lever

(5), down into the eyelet (6), into the lower

wire guide (7), then from left to right through

the eye of the needle (8).

FIG. 11. THREADING THE NEEDLE

Draw about two inches of thread through the

eye of the needle with which to commence

sewing.

Instructions for threading the machine for

darning and for embroidery are given on

pages 34 and 35.

Table of Contents Previous Page | Next Page

9

Page 10

82387 No. 66

To Prepare for Sewing

With the left hand hold the end of the needle

thread, leaving it slack from the hand to the

needle.

Turn the balance wheel over toward you until

the needle moves down and up again to its

highest point, thus catching the bobbin

thread; draw up the needle thread and the

bobbin thread will come up with it through the

hole in the throat plate (see Fig. 12). Lay both

threads back under the presser foot.

To Commence Sewing

Place the material beneath the presser foot,

lower the presser foot and commence to sew,

turning the balance wheel over toward you.

FIG. 12. DRAWING UP THE BOBBIN THREAD

To Remove the Work

Let the thread take-up lever rest at its highest

point, raise the presser foot and draw the fabric back and to the left, pass the threads over

the thread cutter (A, Fig. 12) and pull down

lightly to sever them. Leave the ends of the

threads under the presser foot.

Table of Contents Previous Page | Next Page

10

Page 11

82387 No. 66

Tensions

For ordinary stitching the needle and bobbin

threads should be locked in the centre of the

thickness of the material, thus:

FIG. 13. PERFECT STITCH

If the tension on the needle thread is too

tight, or if that on the bobbin thread is too

loose, the needle thread will lie straight along

the upper surface of the material, thus:

FIG. 14. TIGHT NEEDLE THREAD TENSION

If the tension on the bobbin thread is too tight

or if hat on the needle thread is too loose, the

bobbin thread will lie straight along the under

side of the material, thus:

To Regulate the Tensions

The tension on the needle thread should only

be regulated when the presser foot is down.

Having lowered the presser foot, turn the

small thumb nut (E, shown in Fig. 16, above,

and Fig. 5, page 6) at the front of the tension

discs over to the right to increase the tension.

To decrease the tension, turn the thumb nut

over to the left.

FIG 16. NEEDLE THREAD TENSION

The tension on the bobbin thread is regulated

by the larger screw (Fig. 4) which is nearest

the back in the bobbin case tension spring.

To increase the tension, turn the screw over

toward you. To decrease the tension, turn the

screw over from you.

FIG. 15. LOOSE NEEDLE THREAD TENSION

been once properly adjusted it is seldom necessary to change it, as a correct stitch can

usually be obtained by varying the tension on

the needle thread.

Table of Contents Previous Page | Next Page

11

When the tension on the bobbin thread has

Page 12

To Turn a Corner

82387 No. 66

Stop the machine with the needle at its lowest point. Raise the presser foot and turn the

work as desired, using the needle as a pivot.

To Regulate the Length of Stitch

The length of stitch is regulated by the large

thumb screw (A, Fig. 6) at the front of the

machine near the bobbin winder.

To lengthen the stitch turn this screw over to

the right. To shorten the stitch turn this screw

over to the left.

To Regulate the Pressure on the Material

For ordinary family sewing it is seldom necessary to change the pressure on the material.

If sewing fine silk or flimsy material, lighten

the pressure by turning the thumb screw (A,

Fig. 5) on the top of the machine over to the

left.

To increase the pressure turn this screw over

to the right. The pressure should be only

heavy enough to prevent the material from

rising with the needle and to enable the feed

to move the work along evenly; a heavier

pressure will make the machine run hard.

To Sew Flannel or Bias Seams

Use a short stitch and as light a tension as

possible on the needle thread so as to leave

the thread loose enough in the seam to allow

the goods to stretch if necessary.

A Stitch to Ravel Easily

can be made if desired, by having the tension

on the needle thread so light that the bobbin

thread will not draw into the goods but lie

straight, as shown in Fig. 15.

Table of Contents Previous Page | Next Page

12

Page 13

82387 No. 66

To Oil the Machine

To ensure easy running the machine and

stand requires oiling and if used continuously

it should be oiled each day. With moderate

use an occasional oiling is sufficient. Oil

should be applied at each of the places

shown by arrows in Figs. 17, 18 and 19. One

drop of oil at each point is sufficient. Oil holes

are provided in the machine for bearings

which cannot be directly reached.

To oil the mechanism under the slide, draw

the slide (see Fig. 17) to the left and after

removing the lint and dust which may have

accumulated put a few drops of oil on the

small piece of felt at the right of the bobbin

ejector. The slide should then be closed.

FIG. 17. FRONT VIEW, SHOWING OILING POINTS

Take out the thumb screw (A, Fig. 17) near

the lower end of the face plate, raise the

plate and slip it off over the head of the screw

near the upper end of the plate; put one drop

of oil into each of the oil holes and joints.

Table of Contents Previous Page | Next Page

13

Page 14

82387 No. 66

To Oil the Machine continued...

At the back of the machine is a round plate or

cover, fastened by a thumb screw; loosen the

screw, turn the plate upward and fasten by

tightening the screw; turn the balance wheel

slowly and oil the moving parts inside then

turn the cover down and fasten it as before.

To reach the parts underneath the bed the

belt must be thrown off the band wheel on

the machine stand. For this purpose the belt

shifter (F. Fig. 1, page 1) is placed at the front

of the band wheel. By pressing the belt shifter

lever to the left and working the treadle

meanwhile, the belt is released and the

machine can then be turned back on its

hinges. The places to be oiled are indicated

in Fig. 18, page 17, by arrows pointing to the

oil holes and bearings.

FIG. 18. OILING POINTS IN BASE OF MACHINE

To oil the stand, put a drop of oil on each of

the places shown by arrows in the above

illustration (Fig. 19).

FIG. 19. POINTS IN STAND

Table of Contents Previous Page | Next Page

14

Page 15

82387 No. 66

HINTS

The Belt.

See that the belt is not too tight; it should

always be tight enough not to slip. If too

loose remove the hook at one end, shorten

the belt and rejoin.

Machine Working Heavily.

If the machine runs hard after standing idle

for some time use a little kerosene in the oiling places, run the machine rapidly, then wipe

clean and oil.

To Avoid Breaking Needles.

See that the presser foot or attachments are

securely fastened by the thumb screw. Do not

sew heavy seams or very thick goods with

too fine a needle. A large needle and thread

to correspond should be used on heavy work

(see page 36).

See that the needle is not bent and avoid

pulling the material when stitching.

Breaking of Needle Thread.

If the needle thread breaks it may

be caused by:

Improper threading.

Tension being too tight.

The thread being too coarse

for size of needle.

The needle being bent, having a

blunt point, or being

set incorrectly.

Breaking of Bobbin Thread.

If the bobbin thread breaks it may

be caused by:

Improper threading of bobbin case.

Tension being too tight.

Skipping of Stitches.

The needle may not be accurately set into the

needle bar or the needle may be blunt or

bent. The needle may be too small for the

thread in use.

Singer Needles are the best for every kind of sewing

machine. They are the only satisfactory needles on the

market and are sold in the Singer Green Needle

Packet with the famous red letter "S" upon it. Singer

Needles can be obtained from any Singer Shop or

Singer Salesman.

Table of Contents Previous Page | Next Page

15

Page 16

82387 No. 66

ATTACHMENTS WITH THE MACHINE

Table of Contents Previous Page | Next Page

16

Page 17

82387 No. 66

INSTRUCTIONS FOR USING

THE ATTACHMENTS

FOOT HEMMER - Hemming

Raise the needle to its highest point. Remove

the presser foot and attach the toot hemmer

in its place (see Fig. 21). Clip off the right

hand corner of the cloth, so that it will take

the roll easily, turn up the edge about a quarter of an inch, insert it in the mouth of the

hemmer and draw or push it along with the

stiletto until under the needle. Then let down

the presser bar and after taking two or three

stitches, draw gently on the ends of the

threads to help the work along till the feed

catches it. In order to produce a smooth even

hem the mouth of the hemmer must be kept

just full.

Fig 21.

Fig. 21 shows also what is known as a bag

seam or fell, made by passing two pieces of

fabric through the hemmer together and hemming them down.

Table of Contents Previous Page | Next Page

17

Page 18

82387 No. 66

FOOT HEMMER

Hemming and Sewing on Lace

Start the hem as previously explained, and

when it is well started raise the needle to its

highest point.

Raise the hemmer to relieve its pressure on

tile hem, pass the end of the lace through the

slot in the side of the hemmer, under the

back of tile hemmer and over the hem, as

shown in Fig. 22.

Take care that the hem is not displaced in the

hemmer and that the needle goes down

through the lace and hem together. Then let

down tile presser bar and guide the lace over

the front of the hemmer, keeping it well into

the slot.

FIG. 22

Table of Contents Previous Page | Next Page

18

Page 19

82387 No. 66

FOOT HEMMER

Felling

The two pieces of cloth to he felled should be

laid one over the other, right sides together,

the edge of the under piece being a little farther to tile right than the upper piece. Stitch

them together using the hemmer as a presser

foot, the front end of the hemmer forming a

guide for tile edges of both pieces, the upper

piece being guided by the inside and the

under piece by the outside of the projecting

front of the foot hemmer (see Fig. 23). Then

open the work out flat, wrong side up, the

edges straight, and taking the edges near the

beginning of the seam in the right hand, and

the ends of the threads in the left hand, draw

the edges into the hemmer which will ill turn

them as in hemming. Guide the second row

of stitching by following the first row with the

inside of the projecting front of the foot hemmer (see Fig. 24).

FIG. 23

FIG. 24

Table of Contents Previous Page | Next Page

19

Page 20

82387 No. 66

ADJUSTABLE HEMMER

Hemming

Remove the presser foot and attach the

adjustable hemmer in its place as shown in

Fig. 25. This hemmer will turn hems from

3/16 inch to 1 inch wide. The adjustment is

made by loosening the thumb screw on the

hemmer and moving the slide to the right or

left until the hem turned is of the desired

width. Enter the edge of the cloth into the

hemmer under the scale and draw it back

and forth until the hem is formed, stopping

with the end under the needle. Lower the

presser bar and commence to sew, being

careful to guide cloth as to keep hemmer full.

Felling can also be done with the adjustable

hemmer

FIG. 25

ADJUSTABLE HEMMER

Wide Hemming

To make a hem more than one inch wide take

out the thumb screw in the hemmer and

FIG. 26

remove the slide and pointer; fold and crease

down a hem of the desired width; pass the

fold under the extension at the right of the

hemmer, and the edge into the folder as

shown in Fig. 26 and proceed to stitch the

hem.

Table of Contents Previous Page | Next Page

20

Page 21

82387 No. 66

BINDER

Binding

Remove the presser foot and attach the

binder in its place. Pass the binding through

the scroll of the hinder and draw it back

under the needle. Place the edge of the

goods to he bound between the scrolls of the

hinder and draw it under the needle. Lower

the presser bar and sew as usual. To make

French folds proceed as directed for binding

except that the fold is stitched on to the face

of the material instead of on the edge (see

Fig. 27). After loosening the binder set screw

and adjusting the binder the line of stitching

can be brought nearer the centre, this being

more effective when making French folds.

FIG. 28

BIAS GAUGE

The bias gauge may be used by placing it on

the point of a pair of scissors, as below, and

different widths of material may be cut by

adjusting the slide (S. Fig. 28,). Bias binding

for binder No. 36595 should be cut fifteen-sixteenths of an inch wide if muslin or similar

fabrics are used, and to do this the slide (S)

should be placed half way between the lines

marked "F" and "B." The edge of the goods

should be passed through the attachment

and against the slide while cutting. When

binding with fine, soft or flimsy materials, cut

the bias binding a suitable fraction wider.

BINDER

Bind with Dress Braid

FIG. 27

The braid being stitched on the edge it should

fit the binder without turning in the edges, as

is the case with bias binding.

Table of Contents Previous Page | Next Page

21

Page 22

82387 No. 66

RUFFLER

Ruffling

Remove the presser foot and attach the ruffler in its place, connecting the arm with the

needle clamp, as shown in Fig. 29.

The ruffler can be adjusted to make a gather

or plait either at every stitch or once in every

five stitches as the operator may choose.

To make a ruffle with a gather or plait at

every stitch see that the adjusting lever (A,

Fig. 29) of the ruffling is at its lowest point.

Place the material to be ruffled between the

lower or separator blade and the ruffling

blade, draw the material slightly back of the

needle, lower the presser bar and proceed to

sew.

FIG. 29

To make a finer gather shorten the stroke of

the ruffling blade by turning the regulating

thumb screw (B. Fig. 29) over to the left, also

shorten the stitch. To make a fuller gather or

plait lengthen the stroke of the arm by turning

the regulating thumb screw (B. Fig. 29) over

to the right, also lengthen the stitch. By varying these adjustments many pleasing varieties of work can be accomplished.

Table of Contents Previous Page | Next Page

22

Page 23

82387 No. 66

RUFFLER

Ruffling Between Bands

Place the lower piece of material below the

separator blade, the piece of material to be

ruffled under the ruffling blade and over the

separator blade and the upper piece of material over the ruffling blade, as shown in Fig.

30.

TO RUFFLE AND SEW ON

Place the band below the separator blade the

piece to be ruffled between the separator

blade and the ruffling blade, and proceed.

The ruffler should never be operated without

cloth between the blades.

FIG. 30

RUFFLER

Five Stitch Ruffling or Plaiting

To make a five stitch ruffle or plait, raise the

adjusting lever (A, Fig. 31) to its highest

point. The ruffling blade will then move for-

FIG. 31

ward and back once every fifth stitch.

Table of Contents Previous Page | Next Page

23

Page 24

82387 No. 66

RUFFLER WITH SHIRRING PLATE

Shirring

To attach the shirring plate (see Fig. 20) draw

to the left the slide that covers the bobbin

case, insert the downwardly projecting hooks

on the shirring plate under the edge of the

throat plate, push as far as possible to the

right and press the pin into the hole at the

right of the throat plate, then close the slide

covering the bobbin case.

FIG. 32

The lower or separator blade of the ruffler is

fastened by a screw. Loosen the screw, take

off the separator blade and attach the ruffler

to the presser bar as instructed.

Place the cloth between the ruffling blade and

the shirring plate, lower the ruffler on the

goods and operate as in ruffling.

Table of Contents Previous Page | Next Page

24

Page 25

82387 No. 66

QUILTER

Remove the presser foot and attach the quilter foot in its place. The quilter guide can be

used on either the right or left side of the needle and the distance of the guide from the

needle determines the width of space

between the rows of stitching. Slide the wire

of the guide into the holder prepared for it on

the foot and set it to the width desired.

Let the quilter guide follow the edge of the

goods, a straight crease, or a chalk line, as

the case may be, for the first row of stitching.

All succeeding rows are made straight and at

a uniform distance by keeping the last row

steadily under the guide.

FIG. 33

Table of Contents Previous Page | Next Page

25

Page 26

82387 No. 66

TUCKER

Remove the presser foot and attach the tucker in its place. The width of the tuck is determined by the scale of figures nearest the

needle, which shows in eighths and sixteenths of an inch the distance of the edge of

the fold from the line of stitching.

The crease or mark for the second and following tucks is determined by the scale nearest the operator and this is set by the line in

front of the needle hole in the presser foot.

For blind tucks without spaces set both

scales at the same figure; to make spaces

between the tucks move the front scale farther to the left until the desired space is

obtained.

Having adjusted the scales for tuck and

space as desired, fold the material and

crease by hand; pass the folded edge

between the spring and spur near you, then

between the two blades of the second scale,

and back under the presser foot; draw to the

right against the guide, lower the presser bar;

see that the lever for the needle clamp to

strike is in its backward position so as to form

a crease for the next tuck, then proceed with

the first tuck.

FIG. 34

For the second tuck fold carefully at the

crease made by the spur and place the edge

of the first tuck underneath and against the

spur at the left. The spur will serve as a guide

and will also make a distinct crease for the

next tuck. Always place the last tuck against

the spur to ensure perfect work.

When making the last tuck the lever upon

which the needle clamp strikes while tucking

should he raised to its highest point; while the

lever is in this position no crease for a succeeding tuck is made upon the goods.

Table of Contents Previous Page | Next Page

26

Page 27

82387 No. 66

UNDER BRAIDER

Remove the presser foot and attach the quilter foot in its place. Attach the under braider

(see Fig. 20) as directed for the shirring plate

(see page 30). The design to be braided must

be stamped or traced on the wrong side of

the goods. Pass the end of the braid back

through the guides in the under braider and

under the quilter foot as shown above. Lower

the quilter foot and proceed to sew.

FIG. 35

Table of Contents Previous Page | Next Page

27

Page 28

82387 No. 66

EMBROIDERY AND DARNING

While embroidery anti darning can be done

on the machine when threaded for regular

sewing, the use of feed cover plate (B. Fig.

36) No. 32622 is recommended, as movable

contact with the feed in some cases might

interfere with the handling of the work.

Do not change the adjustment of the feed

dog in any way as it is essential that its position should remain as originally fixed.

When the feed cover plate (B. Fig. 36) is

used it is necessary to lead the needle thread

through the eye in the thread regulator (A,

Fig. 36) at the left of the tension discs, and

not under the thread regulator. With this

exception the threading is the same as for

regular sewing (see Fig. 11).

into position, and close the slide (see Fig.

36).

Feed cover plates are not included in the reg-

ular sets of attachments; they are on sale at

all Singer shops at the price of ten cents

each.

Remove the presser foot and let down the

presser bar lifter to restore the tension on the

needle thread, which is released and inoperative when the lifter is raised.

To attach the feed cover plate draw to the left

the slide that covers the bobbin case and

insert the downwardly projecting hooks on the

cover plate under the edge of the throat plate

and push to the right. After bringing the hole

at the right of the cover plate in line with the

hole in the throat plate, press the cover

Table of Contents Previous Page | Next Page

28

Page 29

82387 No. 66

RELATIVE SIZES OF NEEDLES AND THREAD

(Class and Variety of Needles Used, 15 x 1)

SIZES

OF

NEEDLES

9

11

14

16

18

19

21

CLASSES

OF

WORK

Very thin Muslins, Cambrics,Linens,

etc.

Very fine Calicoes, Linens,Shirtings.

fine Silk Goods, etc.

Shirtings, Sheetings, Calicoes,

Muslins, Silk and general domestic

goods and all classes of general work.

All kinds of heavy Calicoes, light

Woolen Goods, heavy Silk, Seaming,

Stitching,. etc.

Tickings. Woolen Goods, Trousers,

Boys' Clothing,Corsets, Cloaks,

Mantles, etc.

Heavy Woolens, Tickings, Bags, Heavy

Coats, Trousers, etc. Heavy Clothing

generally.

SIZES of COTTON,

SILK OR

LINEN THREAD

100 to 150 Cotton 00 & 000 Silk

Twist

80 to 100 COTTON 0 Silk Twist

60 to 80 Cotton

A & B Silk Twist

40 to 60 Cotton C Silk Twist

30 to 40 Cotton D Silk Twist

24 to 30 Cotton E Silk Twist

60 to 80 Linen

40 to 60 Linen or very Coarse

Cotton

Bags, Coarse Cloths and Heavy

Goods.

Table of Contents Previous Page

29

When sending orders for needles

always specify size required.

Loading...

Loading...