Page 1

Page 2

Page 3

i ¸ i_

,_i!__ii,i,_!i

$I

GE

?"i¸iiii_iiiii_i_i_ii_,_,i_'_!_!,,!!ii!i_!iii_!i!i¸ii!ii!ii'ili_iiil,¸¸¸_

Page 4

Solid-state Electronic Sewing Machine

Congratulations,.

'cou are aeou[ to sew on _ne mos_ aavancee sewtng macnme _nthe wollo..

ATHENA 2000.

It makes sowm _ _o simele _c fooIDroof -- arc so much f[JR[ -- joe W e@

_stounaea

The crov--g acmevemem of years of Singer research ATHENA _ 2000

sewing machine teatures--esE "_or_an_ [ecnnoJoc ca creaKmrougr]s:

® Exclusive Sotidostate Electronic Sewi,ng System ATHENA 2000 is the

sewm_ macn_n_ w_m the electronic 'brair_ ' a storehouse of sewm

Knowledge [ au_omanca y programs your macmne _'_sew o-_e of twer [y

ve different shtches--mc doing two t3 Des of buttonno_es

Exclusive Light Touch Fingertip Controls. They re the buttons on the front

of the macnme. You SImD_V tOUCh me one unaer me Da_e<n you want

the red indicate- ign_ c_mes on-- _nd ATHENA 20C2 _s read _o sew.

Am, s[ncn S ins[at - _V_laOle. at the to Jch of e Sing e euz_on.

Exclusive Individual Preference Panet. Your ver own centre ean_

31lows yoL lo modify _ne orr-_grammed stilcn e]rnens )ns [_ 3ur heart's

conten'(, re suit sEocta fabr :_ and satisfy persone_ preference2

And tha_ _s onw me begmmng! There are so many more ne'-- features. Such as

_ne Exclusive Pattern Receet Button-that lets you sew one or]it )t a oatten

for sueerc eecorat ve _o__sbes. And Exclusive L_ght Touch F/ngeR_ 3uick

Reverse Button--for an _nstan_ reverse stra ght stitch A-]a over a cozen more

Singer Excluswes _lus all 3] the other Singer advances of the Eas_ decade

Such as the fabuJous Exclusive built-i- Flio& Sew* _ _nel for both nat ana _n

me-rouna sewing. 3oft-touch Fabric Feed. _nat ore[acts even tne most ee_

ca_e fabrics. Variah}e-seeeo Solid-state Control System, that enables you to

rnamta q the same pressure on [ne eoeeo controller as ou sew [nrougn vary-

ng fabric m_cKnesses And mar, man_, more advances from Stager.

We suggest you take a Tew moments to read [-_ougn [n_s new oeerator s

guide, as ¢ou sit at _our machine You will qulc_/ • discover now s mole i_ Is to

co any sewing ooerat_on ,ou aeswe on ATHENA 200L

We/corr?e to [Re fUrL re worlQ or se_ _o

Today!

¸.%¸¸

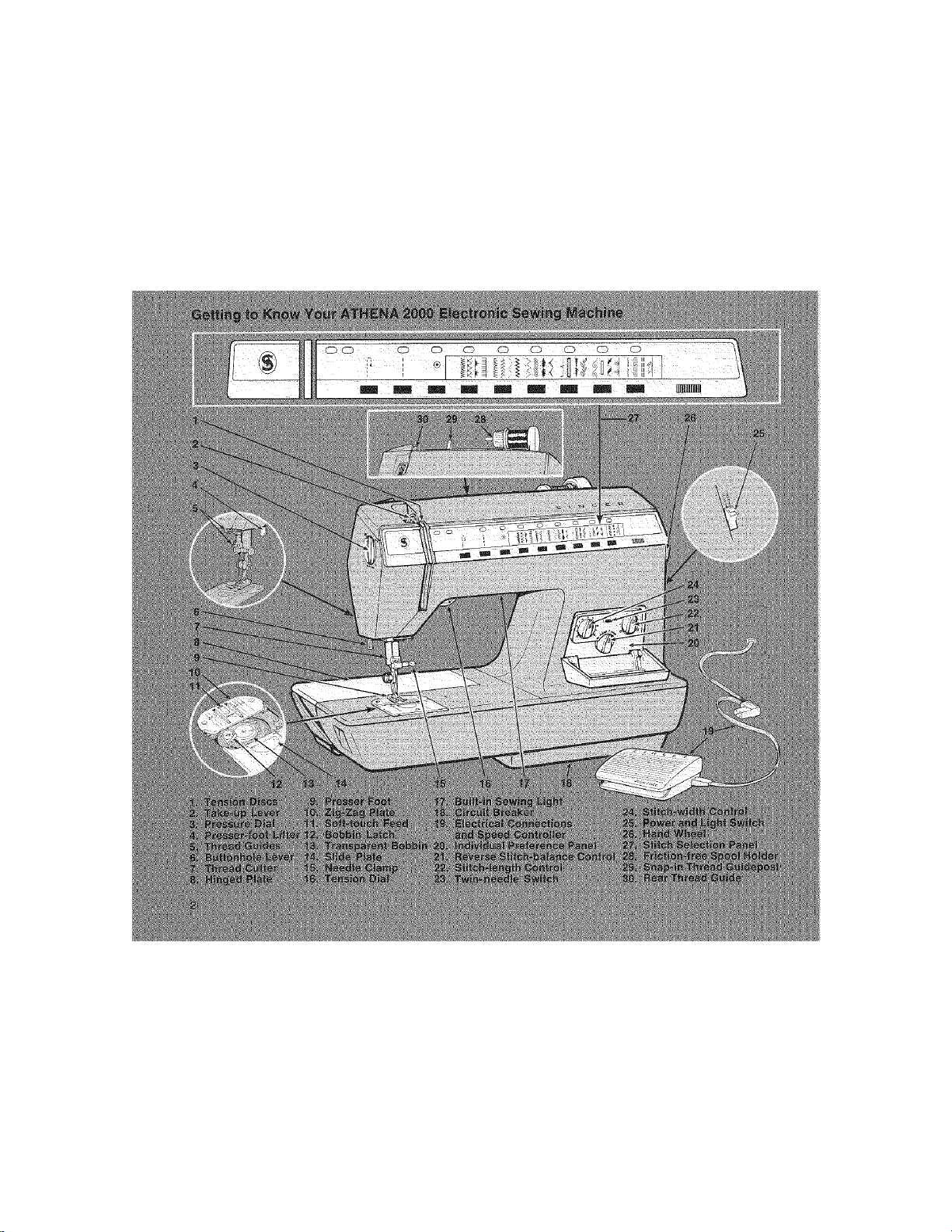

Page 5

CONTENTS

Getting to Know Your ATHENA 2000 Electronic Sewing Machine ........................ 2

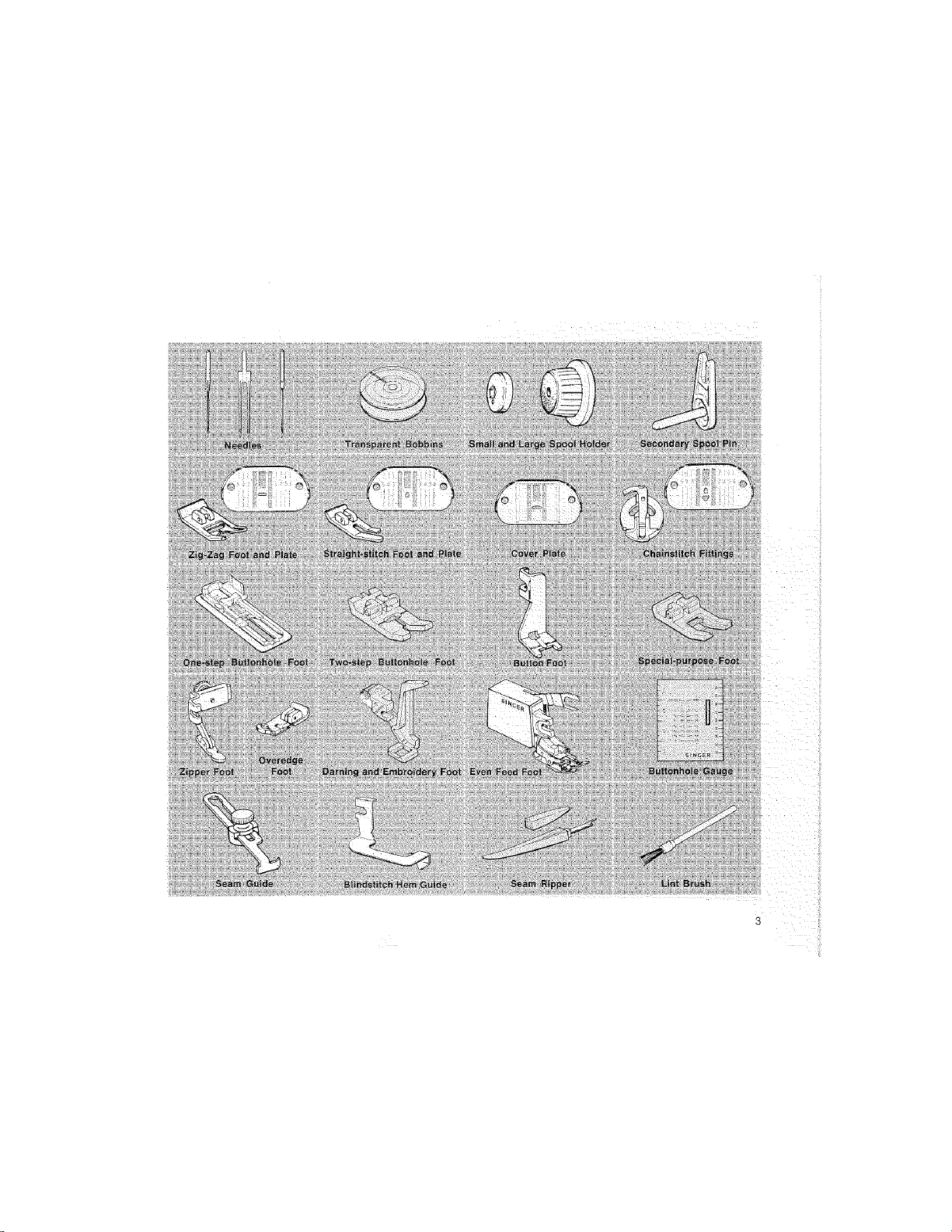

Accessories ........................................................................ 3

Changing Presser Feet .............................................................. 4

Snap-on Presser Feet • The Button Foot, Even Feed Foot

Changing Plates ................................................................... 5

Chainstitch Plate and Insert ........................... : .............................. 5

Speed Control ..................................................................... 6

Needles ........................................................................... 6

Changing the Needle

Threading the Machine ............................................................. 7

Threading the Needle

The Bobbin .................. ; ................................................. 8

Winding the Bobbin - Removing the Bobbin ,, Replacing a Wound Bobbin •

Raising the Bobbin Thread • Removing Thread from Bobbin

Threading for Twin-Needle Stitching ................................................... 10

Regulating Pressure ................................................................ 11

Adjusting Thread Tension ............................................................ 11

Lifting the Presser Foot ............................................................... 11

Electronic Sewing ..... .... ..... _. .................. , _: : ...... ................... 12

Selecting a Stitch * Straight-Stitching • Straight-Stitch Plate and Foot •

Pattern Repeat Button, Starting to Sew, Sewing in Reverse *

Removing Work from Machine • Chainstitching

Individual Preferences., ,: ............ ......... , .................................... 14

Stitch Width ,, Stitch Length ,, Reverse Stitch-balance

One-step Buttonholing ..... . ....... , ....... , ...................................... !5

Balancing the Density • Stitching a Series of Buttonholes

Two-step Buttonholing .......................... : .................................. 16

Corded Buttonholes ............................................................... 17

inserting Cord in One-step Buttonhole Foot • inserting Cord in Two-step Buttonhole Foot

Free*Arm Sewing ................................................................... t8

Circuit Breaker ................................................................ 18

Cleaning the Machine ............................................................... 19

Changing the Light Bulb ............................................ : .... :. : ......... 19

Performance Checklist ............................................................... 20

Page 6

Page 7

Page 8

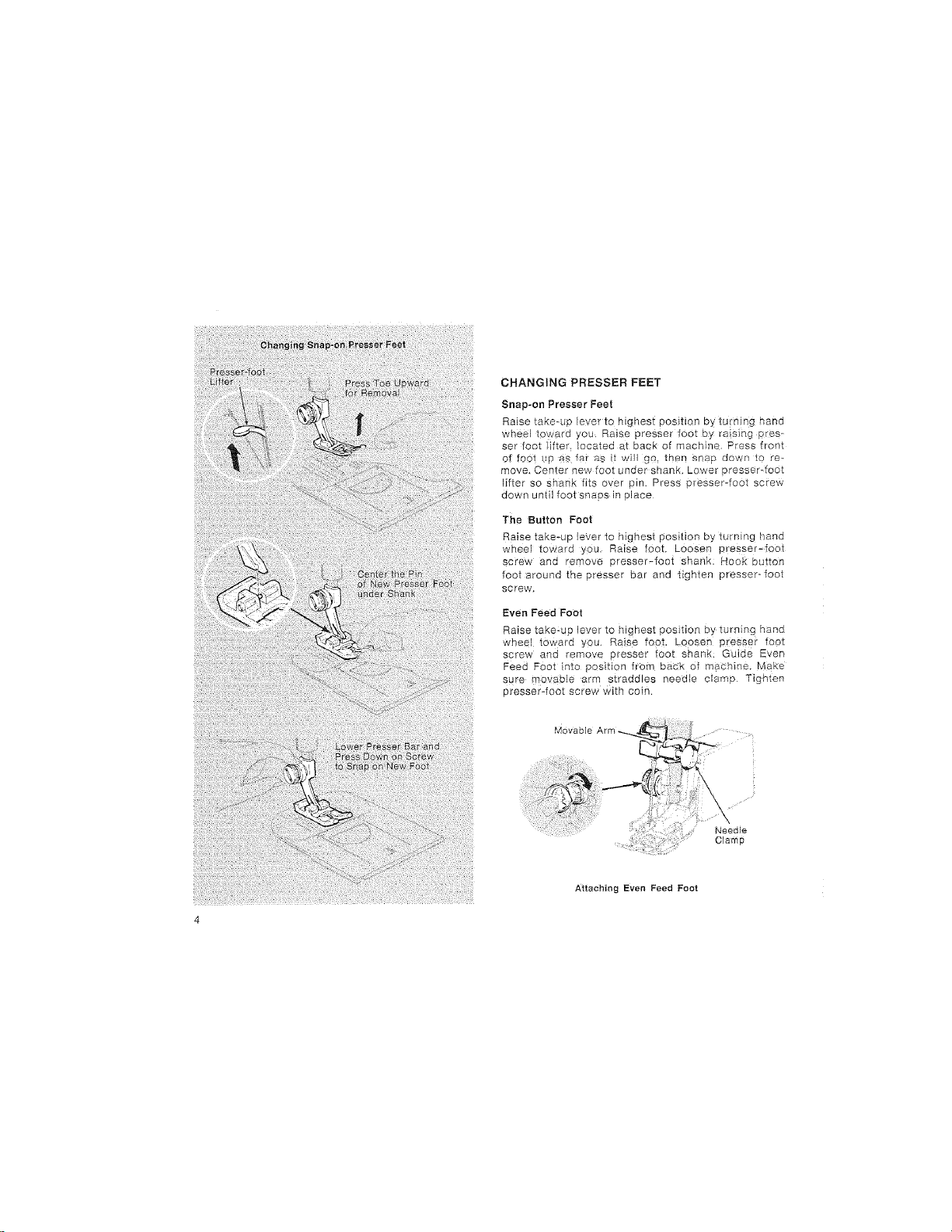

CHANGING PRESSER FEET

Snap-on Presser Feet

Raise take-up fever to highest position by turning hand

wheel toward you, Raise presser foot by ra!sing pros _

ser foot lifter, }ocated at back of machine. Press front

of foot _Jt_as far as it will go_ then snap down to re-

move. Center new foot under shank Lower presser-foot

lifter so shank fits ever pin. Press presser_foot screw

down untii foot snaps in place

The Button Foot

Raise take-up lever to highest position by turnin 9 hand

wheel toward you. Raise foot. Loosen presser-foot

screw and remove presser-foot shank: Hook button

foot around the presser bar and tighten presser-foot

screw.

Even Feed FoOt

Raise take,up lever to highest position by turning hand

wheel toward you, Raise foot. Loosen presser foot

screw and remove presser foot shank Guide Even

Feed Foot into position from back of machine. Make

sure movable arm straddles needle clamp Tighten

presser-foot screw with coin.

Me

NeedJe

Clamp

Attaching Even Feed Foot

Page 9

Darning and Embroidery Foot

Raise needle to highest position by turning hand wheel

toward you. Raise foot. Loosen presser foot screw and

remove presser foot shank: Guide Darning and Embreid_

ery Foot into position from back of machine. Make sure

lifting finger is above needle ctamp. Tighten presser foot

screw with coin.

/

_er

CHANGING PLATES

Note: Remove bobbin if it contains thread in order to

prevent thread being caught when plate is replaced.

Raise take-up lever to its highest position by turning

the hand wheel toward you. Raise presser fQot, Pull

slide plate toward you, As shown in top diagram at

_ight, press down on front edge of plate you have been

sewing with, and lift up and out.

Position new plate over pins. Ptate is d_awn into posi-

tion by magnets. Replace bobbin. Close slide plate.

Attaching Darning and Embroidery Foot

CHAINSTITCH PLATE AND iNSERT

Raise take-up lever to its highest position and raise

presser foot, Open slide plate, Move bobbin latch to

left and remove bobbin and plate you have been sew-

ing with. Place bobbin*case insert in bobbin case as

shown, with finger of insert positioned under the feed.

Position chainstitch plate over holding pins, making

certain that the post of the bobbin-case insert finger

enters the hole in the plate. Close slide plate.

Page 10

SPEED CONTROL

Note: Before plugging in machine, be sure voltage and

number of cycles shown by machine socket conform

to your electrical power supply:

Push machine plug into machine socket. Connect pow-

erline plug to electrical outlet, To turn on machine and

sewing light, and to set speed range, press power and

light switch on.

,, SLOW (switch pressed halfway} allows for maximum

control.

FAST switcP oressea au me way aRROWSfor ful!

sceeo

CAUTION: We recommeno , ou turn oft the sower ano

ignt swltcn before changing needles, ores._er feet or

elates and wnen leaving macnme unattended. This

eliminates the oossibilil/ of starting me macnme oy

accidentally press/ng rne s_eeo oemrouer

tf at any nine _ou acclaen[a _ sw_tch your machine off

make sure /ou re-select tne oesirea StltCr

To run machine Dress soeec controller The harder

you press, the faster maomne v. sew To sioe me

machine from sewing remove 3ressure from seeea

controller

NEEDLES

For best results use SINGER* needles in :/our macmne.

For general-purpose sewing m a wide range of fabrics

use Style 2020 neede inslzes9througn 18.

Knits woven stre[cr fabrics Dcqded vir,ts ana elas-

tic reouire the Style 2045 ba point wei_ow band neeaie

for best resorts

The twin needle Style 2025 is used exclusive, for aec-

orati e stitching in light- and medium-weignt fabrics.

For sewing leathers, real one sJmula[ea the Style 2032

needle, avauae_e for ourcnase at your Singer Sewing

Center is recommenaeo

Changing the Needle

Raise needle [o n gRes[ Delta Dy 1urnmg Tile Dane wneol

toware • or. Loosen neeo/e-clame screw _ne remove

needle insert new neeo e n clapt •wmcn w, only ac-

Coot neeele wner nsertea :orrec_, _v_rnflat si_e ol

nee(lie re DaOK Push neeele JO as far as w go

Tgmen screw

Page 11

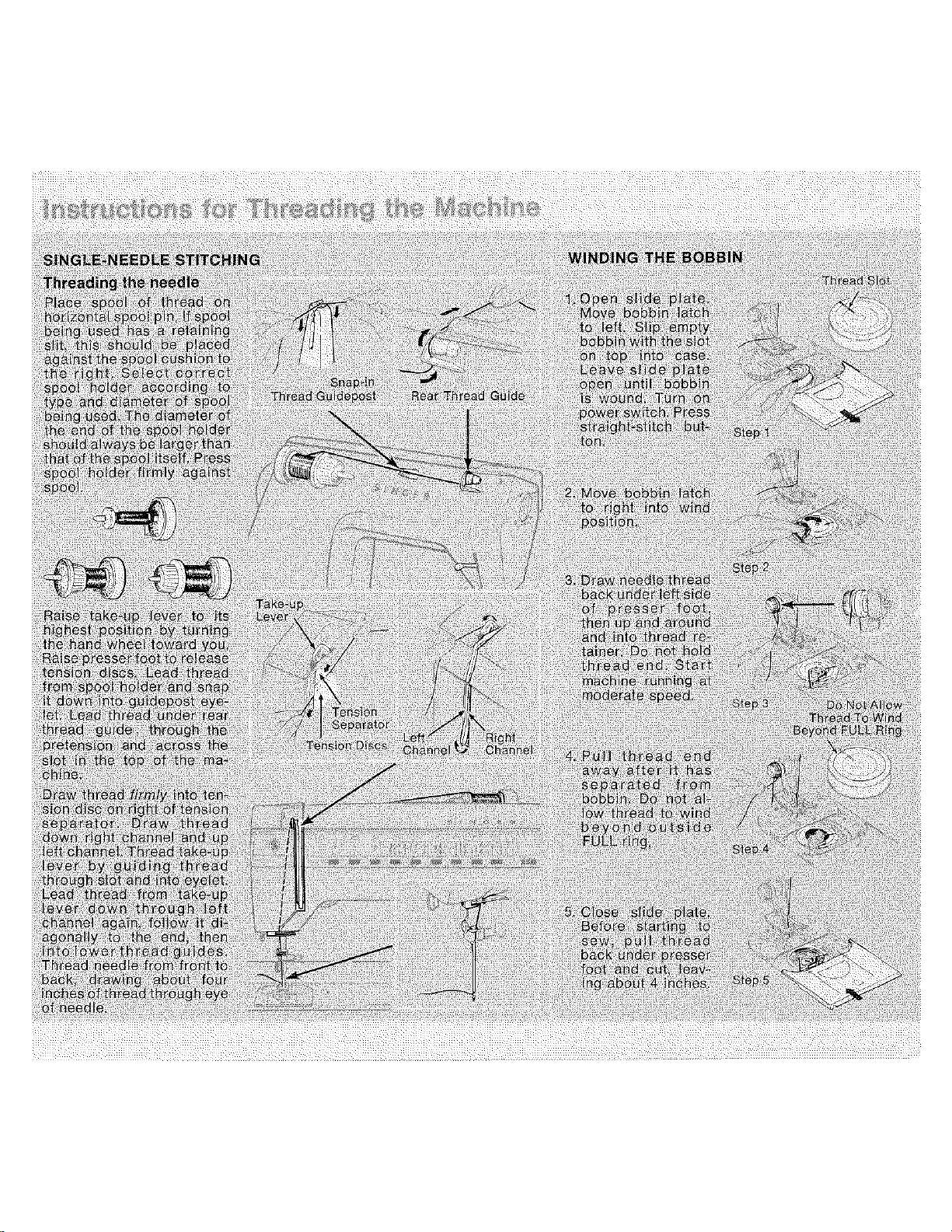

THREADING THE MACHINE

Threading _he Needle

Ptace spool of thread on horizontal spool pin. If spool

befng used has a retaining slit, this should be placed

against the spoo! cushion to the right. Select correct

spool holder according to type and diameter of spool

being used. The diameter of the end of the spool holder

shouJd always be larger than that of the spool itself

Press spool hoider firmly against spool

Raise take-up lever to its highest position by turning

the hand wheel toward you: Raise presser foot to re-

lease tension discs. Lead thread from spool holder and

snap it down into guidepost eyeieL Lead thread under

rear thread guide, through the pretension and across

the slot in the top of the machine.

Note: Dotted lines in illustrations represent path of

thread where concealed by machine,

Draw thread firmly into tension disc on right of tension

separator. D_aw thread dewn right channel and up left

ehannet. Thread takewup lever by guiding thread

through slot and into eyetet Lead thread from take-up

lever down through left channel again; _eilow it diagon-

ally to the end then into lower thread guides. Thread

needle from _ront to baek_ drawing about four inches

of thread through eye of needle:

Page 12

THE BOBBIN

Winding the Bobbin

1: Opee slide plate; Move bobbin latch to left. Slip

empty bobbin with the slot on top into case. Leave

slide plate open until bobbin is wound. Turn on

power switch. Press straight-stitch button,

2 Move bobbin latch to right into wind position.

3. Draw needle thread back, under left side of presser

foot, then up and around and into thread retainer

Do not hold thread end. Start machine running at

moderate speed.

4,

Pull thread end away after it has separated from

bobbin, Do not allow thread to wind beyond outside

FULL ring,

5.

Close slide plate. Before starting to sew, puli thread

back under presser foot and cut, leaving about four

inches.

Removing the Bobbin

Raise take-up lever Open slide plate; move bobbin

latch to left. Remove bobbin by inserting finger under

rim.

Removing Bobbin

Page 13

Replacing a Wound Bobbin

Raise take-up lever. Open stide plate move latch to eft

Draw four inches of thread from bobbin and mace DODDIR

in case. Pull thread into slo_ of bobbin case at Point 1

araw it under flat senng and beyond Point 2. Leave four

inches of free thread. Leave suae Dlate open

Raising the Bobbin Thread

] MOle neea e tnreaa ilgntl'_ with left qand and turn

nanc Nheel slo_ , toward you so needle en[ers

elate.

2. Continue um neeule rises. Tigmen no_o on neee_e

tnreaa anc erlrg ue _ooe of bobbin thread.

3. Oeen IOODwith fingers and pUll needle ane DODDIn

threads under presser foot elag3nally ;o me eft

Close slide dlate

Replacing a Wound Bobbin

Insert Bobbin

Pull Thread into

Slot at Point 1

Flat Spring,,

Removing Thread from Bobbin

You can leave the bobbin in place while removing

thread. With slide plate closed, pull thread end toward

you thrdugh plate with a steady motion. Do not pull

thread across feed as this may damage feed.

Draw Thread

Under Fiat Spring

Beyond Point 2

Page 14

THREADING FOR TWiN-NEEDLE STITCHING

The twin needle simultaneously produces two parallel,

closely spaced lines of straight or zig_zag stitching.

Effective for decoration, twin-needle stitching is not

recommended for seams. Soft fabrics should be sewn

with a firm fabric backing or paper backing which can

be removed after stitching.

Thread machine with first thread in usua manner maKing

cer[am I( passes De!.ween tension separator aria r gn[=

qana tension d_sc Wind bobbin wnn enougn tnreaa to

cometete STircnng Since a Dobbin cannot De filled

after a twinmeedle _s_nser[eo t _swise to Keeo an extra

wouna DODQIB at hand for reolacemem Unthread ana

remove neeale. Attach secondary spoo Din ana nsen

me twin peedle. Pass first threaa mrougn right eye of

_eeaie Place second SPOOl of (nreaa on seconaar,

spoo_ p_n ana tnreaa as eetore except oypass snaD-in

tnreaa gu_depes[ ana Dass thread between [enslon sep-

arator and left-hand tension d sc ana mrougn left eye of

qeea e

10

CAUTION: Always move tee [w/n-neeoJe switch, to-

ca[ea on the molvJoL al greferenoe DaneJ to the right

( _ symDoI before doing [w n-neeale sewing, umess

rne switch has been activated neeole oreaKage will

resum WheF you nave con, 31eteG [win-needle sewing

return the switch to the left _ symoo_ oosition

Page 15

REGULATING PRESSURE

The pressure dial regulates the pressure that the

presser foot exebts on the fabric; Correct p_essure is

important to insure that tabric feeds smoothly and

evenly, The NORM (normal) setting is an all-purpose

setting that can be used for sewing a wide variety of

fabrics; Lower the presser foot before setting pressure.

To inorease Pressure turn the dla! from NQRMtoward

MAX imaximum) To decrease pressure, turn the dial

from NORM toward _ . For darning, set on

ADJUSTING THREAD TENSION

The _enslon ala controls neeole-mreao [ensJor only

Bobbln-th!'eae tens[or1 no5 Deem se_ at _P_e factory, To

Nerease neee e-tnrea(] _er'_lor _Llrn _neclJa/io a n/grief

qulTber, Tc aecrease ter1slon. _urn Irle Ll_al GO a owe

number. Be ¢}ef_aln fie[ [o accioer17,a]ly [ouch Da_,[efR

_elecnon DUrrOfTS wlset_ 8ojustlng rer1sio_r twowever

_ou Uo So De eFralFl to re-sclec t, Gesifeo oar_€/n

Col'_ect tensior sim Doriar1_ because toe mucr1 Dr TOO

]:_le v weaKen /ou_ seams or mar Trle aooearance of

eecoratlve wc _k. To obtain the correct fension settmq

slake a "_es_ or a SamPle of }/ou_ fabric _ 1:he fob _"

OUcKers oecrease _ens_on • [ne s:_cnes ]o_, oose

increase tension

LIFTING THE PRESSER FOOT

T_e presserZfoot liftes allows you to raise and lower

the p_esser foot. Extra-h!gh lift position permits easy

placement of bulky fabrics. Make sure the lifter is al_

the way down before starting to sew

1!

Page 16

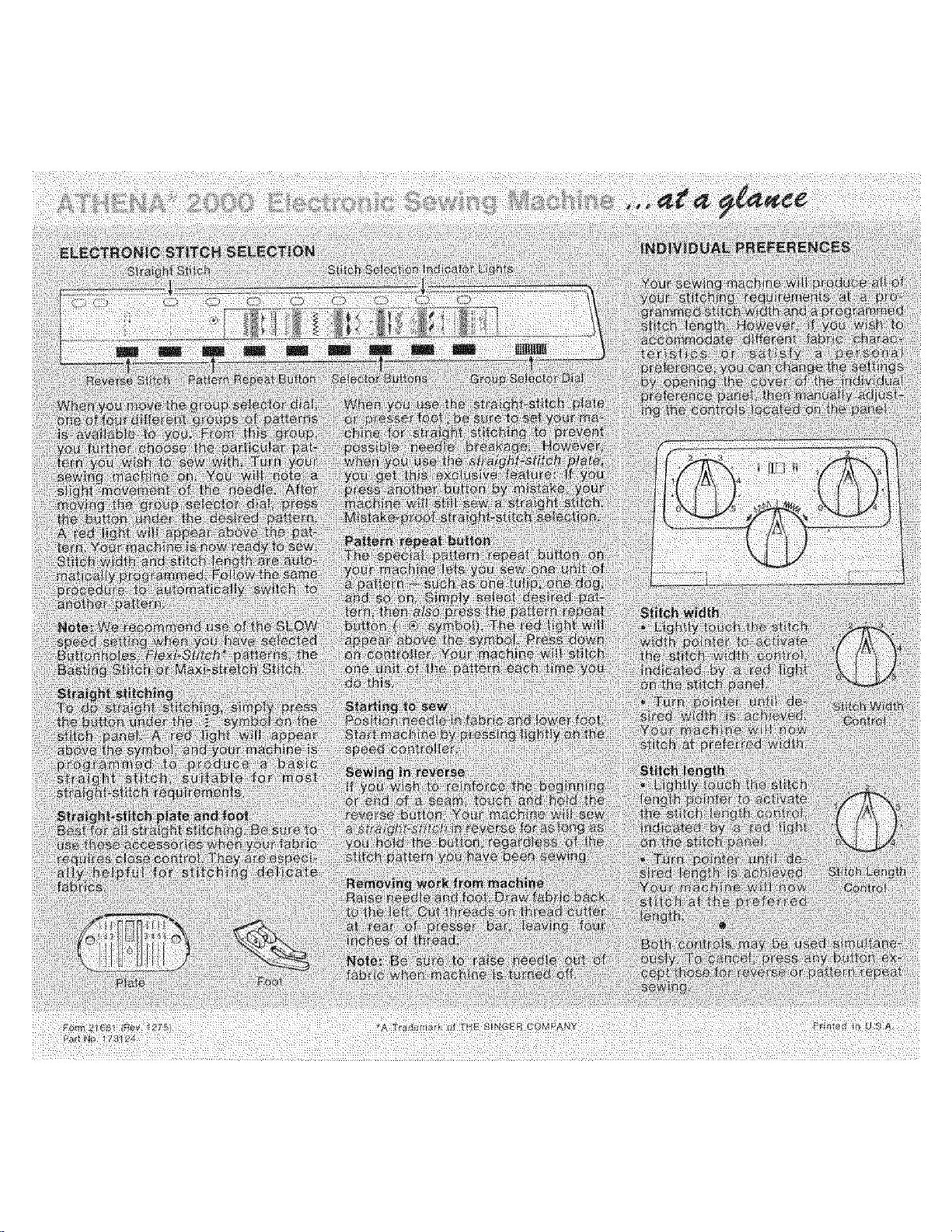

ELECTRONIC SEWING

Stitch Length Light

ii___ iiC_StitchWidth Light -- Straightl: Stitch Stitch Selection_._lndicator_ Lights _

CD 0 CZ) 0 _.._D C_ tiED LC_

t 1 t

Reverse Stitch Pa_ternRepeat Button Selector Buttons Group Selector Dial

Selecting a Stitch

When you rotate the group selector dial, one of four different groups of patterns is avaiiabIe to you. From this group,

you further choose the particular pattern you wish to sew

Turn your sewing machine on. You will note a slight movement of the needle each time the power switch is activated.

When you rotate the group selector dial as far to the

right as it will go, the following patterns a_e available to Next, as you rotat_ the group selector dial to the le_, a

you. and wilt appear ye!!ow on your panel: second group of patterns is made available:

in the third position, these patterns are avai!aMe

And, in its /eftmost position, the group selector dial

makes these patterns available:

After rotating the group selector dial, press the button under the d_sired pattern. Ared light will appear above the

pattern selected. Your machine is now ready to sew the desired pattern. Stitch width and stdeh length are automat-

ically programmed, but can be changed to suit individual preferences or fabric requirements, as described on page

14. Follow the same procedure to automatically switch to another pattern.

Note: We recommend use of the SLOW speed setting when you have selected Buttonholes, Basting Stitch, Flexi-

Stitch* patterns, or Maxi_Stretch Stitch_

fBasting Stitch

12 t_Flexr_StLtch Patterns

fttMaxilStretch Stitch

Page 17

Straight Stitching

To do s_ralgm Stl[cnlng.simply press tne DUttOn uric

IRe SVmDO on toe sTitCh aan@l 5 tea go1 w an-

pear above tne symDoI aria • our machine s _ro

]rammea ro )roauce a oasis _tragnt stitch, suitable

for most straight-stitch reouwernents

Straight-Stitch Plate and Foot

Best for all stratum stacmng. Be sure to use _nese ac

cessorles wnen, our fabric re8 4_res close control They

_reesoec_a , nelEful for stt[cmng dehcate fabrics

When,ouusetne straight-stitch piateor oresserfoot

De sur_ _o set .,our macmne for stralgn_ srl[cmng to

prevent eOSSlDle neeale ereaKage However when you

use me s[ra gnr-srl_cn olaze you get ires exclusive

featulg: f you Dress another burton D_ mistake, you

n3acnlne w st sew a _tralgnt Silica Mistake-proof

stral _ht-stitch selectior

Starting to Sew

Position needle in fabric and lower foot: Start machine

by pressing lightly on the speed controller.

Sewing in Reverse

i_ you wish to _einforce the beginning or end of a

seam; touch and h0td the reverse button. Yeu¢ ma _

chine will sew a straight-stitch in reverse foras long as

you hold the button, regardless of the stitch pattern you

have been sewing.

Removing Work from Machine

Raise needle and foot. Draw fabric back to the left. Cut

threads on thread cutter at rear of presser bar, leav:

ing four inches of thread.

Note: Be sure to raise needle out of fabric when ma-

chine is turned off.

Pattern Repeat Button

The special pattern repeat button on your machine lets

you sew one unit of a pattern such as one tdlip, one

dog, and so on. Simply select desired pattern (such as

the tulip shown here), then a/so press the pattern re-

peat button ( ® symbol). The red light will appear

above the symbol. Press down on controller: Your ma

chine will stitch one unit of the pattern each time You

follow this procedure. You can also use the pattern

repeat button to stitch a series of identical buttonholes,

as descbbed on page 151

Red

Light

CDZ -"_O

m

:I+

One

, \

Pattern Pattern

Selector Repeat

Button Button

Single Unit Sewing

Tulip

Chainstitching

Place bobbin-case insert and chainstitoh plate in

machine. Thread machine in regular manner_ except

pass thread through triangular eyelet in take-up lever,

Set your machine for programmed straight stitching

only - do not press any Other button and do not adjust

stitch width or stitch length.

13

Page 18

iNDIVIDUAL PREFERENCES

Your sewing macmne _ oroauce all of your stitching

"eoJirements at a programmed stitch w]a[n and a

programmed s[_cr _engtn, tlowever f you w_sn To ac-

commouate differenl fabric characteHs[_cs o[ satisf.

apersona 3reference ,oucancnar#e_neset_mgsey

opening [ne cover of the individual 9reference Dane

[nen manua _ adjusting tne DOtard,S _o:atea _n [ne

Dane

Stitch Width

Select des eo _at_ern, as instructed Lghtly tOUCh the

st_[cn w_otn oomter to ac[wate me st_tcr_ w_atn control

nmcatea eya red Hgm on_nesutcn oanel. Turn comter

until desired width is obtained. Your machine _,v, now

s,rltcn at TR6 are[erred width

Stitch Length

Select desired Ea_tern, ugn[_y toucn me sn_cn _er _tn

pointer to activate tne stitch leng[n contro na_catea

oy a red _ _n[ on [ne sutcn ganei, Turn aointer unto ]e_

sired length _sobtained Your macmne w now stitch

at tne preferred lengtn.

Note: Bo[n Sn_Ch width and stttcn leng_n controls maj

De used s_mu[[aneous_, To cance Dress _n3 OUttOr

exceot _nose for reverse or pattern repeat sewing.

Reverse Stitch-balance

To change the appearance of a FlexJ-StJtch cat,err or

eu_';onnoles ac_,JsTere reverse shtch-balance contro

Before ,ou move tne aointer from its neutra oos_ on

make a _es: samote t_ aa. astment is reau_reu sn_cr

SlOWly and move _ne reverse S'(l[Cl3=balanee Doimer in

el[net o_rectlor as you sew um desired pattern ap-

pearance is obtained. Return ooln_er _o neu_ra_ posit/on

after sewing F/exi-Stitoh oaEems and buttonholes.

CAUTION: Always move me _wm_neeale swlmn o-

Dated on the individual oreterence oanel to the right

iJ

14

_ symeol) before doing twin-needle sewm 9. unless

the switch has been actJvate_ neea]e oreaKage wm re-

sut[. When , ou nave corroteted twin-needle sewing

return [ne swt_cn to the left _ symboh oostt_on

Note: f.wnen adjusting a comro you accidenta y

[oucn anotner comro_ re-select aestrea oat[ern tner

readjust aes_reo c)mro_ Close individJal 3reference

pane_ cover wnen you nave at[ained desired shtch ap_

pearance

iii

Page 19

ONE-STEP BUTTONHOLING

Your machine offers you two types of oar-tacK outton-

qoles aDO tWO ourtorlnollrlg methods. :or f_at OUItOnS

UO to I _/8 nones across use me one-sieD melDed For

Best results, we recommena removing unaerolate from

foot when sewing light-weigt [ana knit fabrics. SUChas

thin muslin and ny on trlco_

Determine _nIon buttonhole Best suits your garment.

Make a test ou[tonnole on sample of fabric w_tn mer-

facing '" being usea. Mark start line of aut[onnole on

garment. Attach zlg-zag ulate ana fool with unaer-

elate. L.engm of Buttonhole s set by button-carrier

clamp on foot. Put BUttOn on carrier aria slide clamp

back. Put QOWI?buttontTole lever maKing sure it is Bet-

ween tabs or foot. Draw needle and Dobbin threads

Between foot aria underplate to DOCK of machine.

Place garment between foot and unaerelate. Align BUt-

tonho{e start line on fabric w_tn rec gu_aeline on foot.

Lower foot Pull foot toward you, assuring engagement

of ou_tonnole lever. Press aane_ butter under but-

tonhole s_,mboL Dress aown on controller Machine

w_ stoa wnen out[onnole is completed. Remove work

from machine secureana c Dmreaa enas.

Balancing the Density

Makeatest outtonno_e on asamoleof -eL fabric As

yoL 9roceeooe nme eft side )f the buttonno_ wnlcr

s stitched hrsl you may aa_ue_ lne aensRj of tne out-

tonqole By turnmg tne sflrcr eng.*n oolntel Turning

rne sr_te_ _engm coiner toward a mcner numoer opens

the stitching onrne eft side of the buttonhole Turning

tne counter towars a ower qumoe cEoses rne strtcn-

ng, As ou _roceee uo me ngm sloe 3f the outtonnole

you may aa us1 ins aensit_ of the outton hole ay turn_ng

the -everse srn ;n-oalance oo_nte_ Turning tne reverse

stitch-balance 9olnter to me "lgnt cJoses the stlton -g

on me ngnr sloe of tne au[tonno4e Turning oc qTer _o

the left ooens tne st toning.

Stitching a Series of Buttonholes

Once yOL nave aa Jstec outl.onnole oensitj or Lf th_

programmeo cens_y su_ts your purpose, you rna_ sr_tcr

aaaltiQna aen[ica Buttonholes Close Dalvloual

oreference oanel cover. Push oat_ern reoea_ ou'_ton

Press down on controller.Your macn_ne ^ sutcn one

aentlca Buttonnole when you follow this 3roceaure

Note: Press oarterF eoeat DU[IOtq Dr?l X " yOU acci-

Dents j Dress au_tonnole DUUIOr reaD,us1 na_vlaual

oreference :omro_s.

15

Page 20

TWO-STEP BUTTONHOLING

Two-step Buttonhole Foot

For buttons larger than 11/8 nches across or for but-

tons of unusual sha_e or tnlcKness use tne _wo_ste[

method of stdchmg Du[tonno_es

CAUTION: Do not pull down buttonhole lever,

Always maKe a teat outtonnole on a sample of your

fabric wlm qterfacing, f being used Determine length

of button ano mark start aria ena re of buttonhole on

garment. Attach z_g-zag plate and two-step puttonnole

foot. Draw qeedle and bobblr threads under foot [o back

of machine. Place garment under foot so that buttonno_e

start line is a gneu with re(] guideline on foot. Lower

foot Select reou_rea buttonhole 13y pusnlng OUt[On on

stitch selection oanei. See directions for one-step eu[-

[onnonng to balance density of your ouzronnole Start

machine and let It complete step I of buttonhole cycle

Stop macmne ust before gu_aenne on buttonhole foot

reacnes end of bUtTOnhole ena Hne on garmem Press

ou[[c nno e lever away from. 3u. Start machine and let

comolete step 2 of buttonhole cycle Stop sewing Nnen

SD[cnmg reaches s_artlng bar tack. For additiona DUr-

[onnoles. Dress me narrern reDear button and follow the

same procedure.

For sewing on buttons, see instructions in Sewing

Applications book.

16

Page 21

CORDED BUTTONHOLES

Corded or raised buttonholes are made by stitching

over a fil_er cord. Embroidery or crochet threads make

good filler cords, but double strands of sewing thread

or a sew_off chain of needle and bobbin fhread may

aJso be used

Inserting Cord in One-step Buttonhole Foot

• Raise foot, Hold fi}]er cord in both hands and insert it

between foo_ and underplate, from left side (the side

opposite underplate tab). Inse_t one end of the filler

cord in the right notch in front of foot: Lead cord

back under foot and loop it up and over the cord spur

from right to left.

• B_ing cord forward between foot and undcrplate

and secure end in left notch:

Inserting Cord in Two-step Buttonhole Foot

With foot up, pass a loop of fillep cord around the

spur at the back of the foot. Draw ends or cord under

the foot and pull taut to secure in spur notches.

, Hold cord ends as illustrated, during stitching.

Procedure

Insert cord in buttonhole foot as shown and sew

buttonhole in the usual way.

• When stitching is completed, retease cord fsom foot

and remove work by drawing it to the bask of the

machine.

Draw the loop of [iller cord into the buttonhole stitch-

ing by holding fabric at the starting end of the but-

tonhole with one hand and pulling ends of filler cord

firmly with the of her,

= Trim ends of filler cord.

17

Page 22

FREE-ARM SEWING

When sewing tubdlar and hard-to-reach ger_nant areas

fabric handling is simplified when you eonvert your

machine to freearm _ewing. To de _his, simply press

down on the co_ner of the hinged plate To return to

flat-surface sawing, _aise hinged plate until it snaps

into fiat-surface position

CIRCUIT BREAKER

The e_ectron_c system of your macnne _sDro_ecteo Dy a

c_rcuit breaker, if the sewing Hgnt goes on and the nee-

dle bar moves ue and down. OUt you cannot select a par-

tern you must 9usr the red c_rcu_t breaker outton to

reactivate me macnlne if your macmne s a ocrtaole

mode carefu . ft or tilt it to gain access re tne DUttOn.

_ush 3urron - f_our macr ne_ssecuredtoa :aolne]

reaon under front of cabinet and locale the seecJal no_e

Wnl:n gives ,'ou access to the eutton. Push button. Cer-

•,aln caDEnet models ma, not nave an _ccess hole

SUCh instances re_ease tne machine Item tne Cabinet

tilt macmne and 3USF DUttOP Re-secure machine [o

cabinet Re-selec_ desired aattern

Note: tf button continues to disengage contact /our

Singer rearesentat_ve or Aeeroved Dealer.

18

Circuit Breaker

Circuit Breaker

Page 23

CLEANING THE MACHINE

CAUTION: Before cleaning your machine, disconnect

power-line plug from electrical supply,

With a soft cloth or lint brush clean at points indicated

by arrews.

Your machine requires no oiling under I_otmal con-

ditions: Your SINGER representative, or Approved

Dealer, will examine the permanently lubricated parts

whenever your sewing machine requires servicing

NOTE: There are no user-serviceable parts inside the

AU_ena 2000 Dectronic Sewing Machine. Therefore any

unauthorized tampering inside the machine will void the

guarantee:

CHANGING THE LIGHT BULB

This machine is designed io use a 15-watt maximum

light bulb, Using thumb and forefinger, puU down on tab

located under light lens to lower the light bracket. Do

not attempt to unscrew bulb.

CAUTION: Before changing Light bulb. disconnect

power-fine plug from electrical outlet

Unlocking Bulb

Locking Bulb

Changing the Light Bulb

19

Page 24

PERFORMANCE CHECKLIST

20 Form 21680 (Rev 576/

Part NO 173122

Page 25

Here, there, everywhere...S | _ 0 _ R

-L [r8demaH oTTHE S_NGER COMPAN _r_]t_rJ p USA

Loading...

Loading...