SINGER 9100 User Manual

£ njoy Carefree Sewing!

CongratulationsYou are about to discover the wonderful pleas-

uie of sewing with your new SINGER sewing

machine. We know you are eager to get started

on a sewing project --but we urge you to be

come familiar with this book before you begin.

It is designed to help you get the benefit of all

the capabilities of this machine. Especially, we

recommend that you keep the following points

in mind.

DO

choose the correct needle and thread for

your fabric— if either is the wrong size or type,

you may encounter broken or knotted thread or

faulty stitching. The Fabric. Thread and Needle

Table on page 5 will help you make a perfect

choice.

DO N’T

needle is damaged—or improperly inserted in

the machine— it can cause skipped stitches.

See page 6 for instructions.

DO

threading the machine

Copyright

All Rights Reserved Throughout the World.

sew with a bent or blunt needle. If the

follow the instructions on pages 6 to 8 tor

C C)

197S THE SINGER COMPANY

DO N’T

when you thread the bobbin case. Page 8 tells

you how to do this correctly.

DO

regulating stitch length (page 13). presser-fool

pressure (page 14), and thread tension (page

15) Take advantage of the capability of your

sewing machine!

DO N’T

late in the lower thread area— they can cause

lamming or excessive noise. Clean and lubricate

machine regularly, as instructed on page 39

DO

Service is always available. If your sewing ma

chine should require maintenance or repair, be

sure to call your Singer Sewing Centre or Au

thorized Singer Dealer. You will find the number

listed under "Singer Company" in your tele

phone book.

Above all, do enjoy sewing!

forget to hold the bobbin properly

become familiar with the instructions for

allow lint or thread ends to accumu

remember that expert, dependable SINGER

CONTENTS

1. Getting to Know Your Machine

Principal Parts and What They Do

2. Getting Ready to Sew

Preliminary Steps................................................. 4

Fabric, Thread, Needle and Stitch Length

Table..................................................................... 5

Needles and Thread............................................. 6

Needle Threading..................................................6

Threading Bobbin Case

3. Straight Stitching

Preparation.......................................................... 11

Starting to Sew....................................................12

Adjusting Selectors for Your Fabric

Sewing a Seam

................................................

..................................................

............................

...........................................

........................................

............

........

Page

2

2.3

11

13

17

4. Zig-Zag Stitching................................................ 20

Adjusting Selectors

4

8

Adjusting Needle-Thread Tension

Adjusting Stitch Length.......................................23

5. Sewing The Professional Way

Construction Details........................................... 24

Keeping up Appearances................................... 33

6. Caring for Your Machine......................................39

Cleaning and Lubricating

Adjusting Motor Belt Tension...............................42

Replacing the Slide Plate.................................... 42

Your Personal Measurement Chart

Index

............................................

....................

.........................

....................................

..........................

Page

20

22

24

39

44

1 .G et ti ng t o K no w Yo ur M ac hi ne

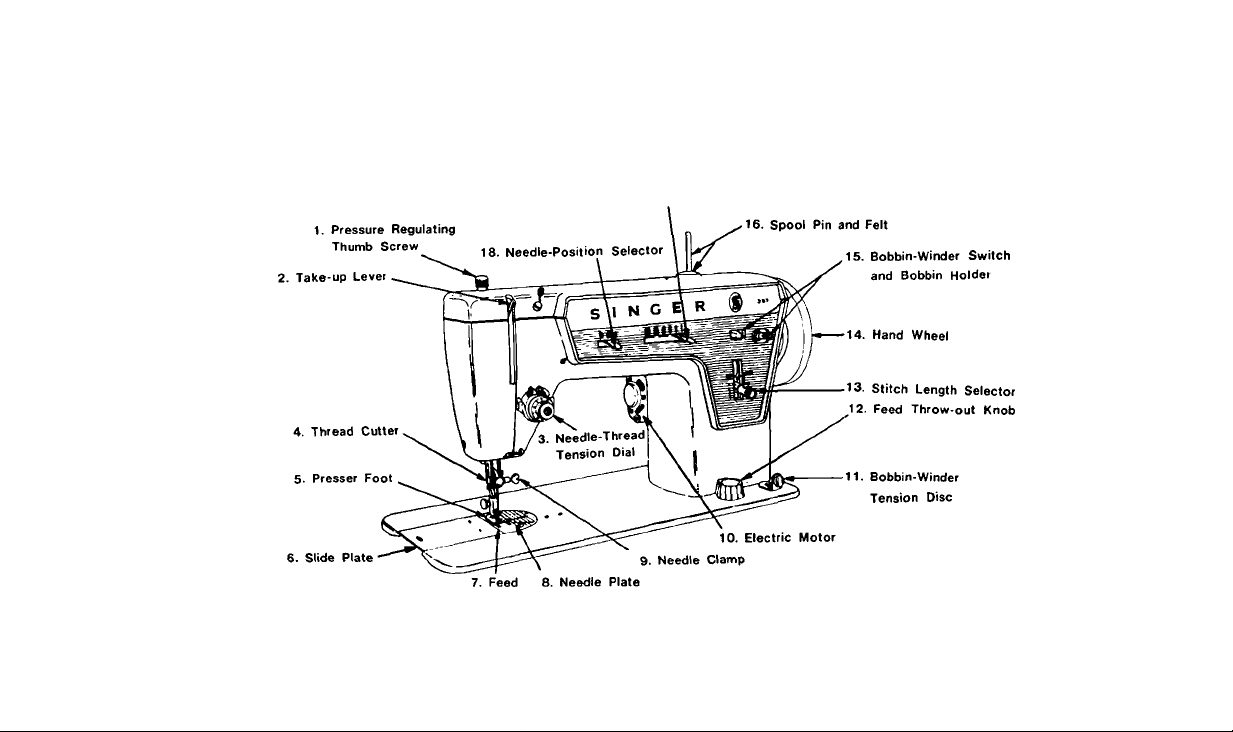

principal parts and

what they do

1. Pressure Regulating Thumb Screw regu

lates presser foot pressure on the fabric.

2. Take-up Lever controls flow of needle

thread

3. Needle-ThreadTensionOial letsyou select

the right tension for your fabric, stitch, and

thread. The numbers eliminate guesswork

in duplicating settings.

To increase tension, turn dial to higher

number

To decrease tension, turn dial to lower

number.

4. Thread Cutter located on presser bar

5. Presser Foot holds fabric against teed.

Presser foot lifter at rear of machine (not

shown) raises and lowers the presser foot.

6. Slide Plate opens easily, provides access

to bobbin case latch tor removal and re

placement of the bobbin.

7. Feed moves fabric under the presser foot.

8. Needle Plate provides working surface

around the needle. Guidelines on plate

help you keep seams straight.

9. Needle Clamp holds needle.

— 2—

10. Electric Motor supplies power to machine

through a belt to the hand wheel. Motor is

activated by a speed controller.

11. Bobbin-Winder Tension Discs regul.ite

thread tension for winding bobbins

1 2. Feed Throw-out Knob lowers feed below

needle plate for free-motion darning and

embroidery.

13. Stitch Length Selector .illows you to

choose from a variety ot stitch lengths, in

cluding fine adjustments for close zig z.ig

stitching.Raising the lever permits reverse

stitching.

14. Hand Wheel controls movement of take-up

lever and needle. Always turn it toward you.

1 5. Bobbin-Winder Switch and Bobbin Holder

let you fill the bobbin with thread quickly

and easily.

1 6. Spool Pin and Felt. Pin holds thread spools

of various sizes. Felt helps thread unwind

smoothly.

I 7. stitch Width Selector controls the widthof

zig-zag stitching and positions the needle

for straight stitching.

18. Needle-Position Selector places needle

in either left, centre or right stitching

position. Use centre position for straight

stitching.

PRINCIPAL PARTS OF MACHINE 287N

17. Stitch Width Selector

— 3—

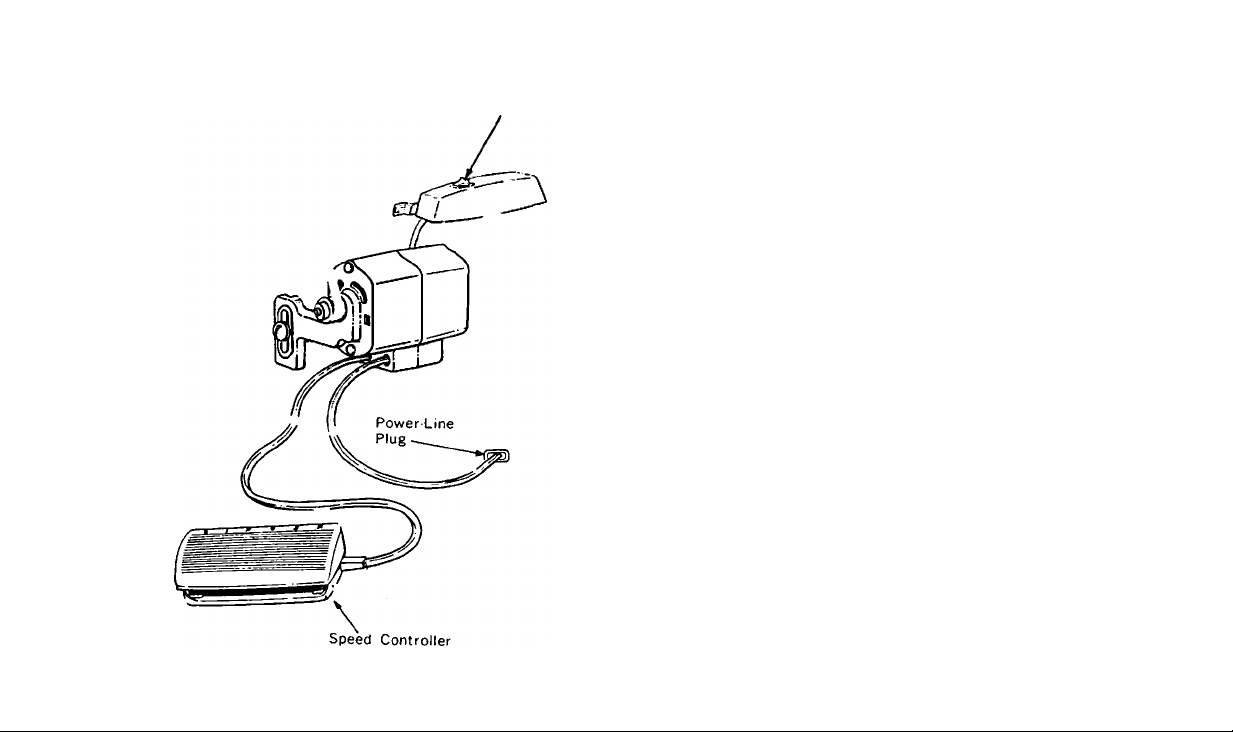

Electrical Connections

power and Light Switch

2. Ge tt in g R ea dy t o Se w

preliminary steps

CONNECTING MACHINE

Before plugging in your machine, be sure that

the electrical information on the motor bracket

conforms to your electrical power suppy.

To connect the machine, insert the power line

plug into your electrical outlet.

OPERATING MACHINE AND

CONTROLLER

To turn on both machine and sewing light,

press the switch located at top of light.

CAUTION: recommend that you turn off

the power and fight switch before changing

needles and presser feet, removing needle plate,

and when leaving the machine unattended. This

eliminates the possibility of starting the ma

chine by accidentally pushing the speed con

troller.

To run the machine, press the speed con

troller. The harder you press, the faster the

machine will sew.

To stop the machine from sewing, remove

pressure from speed controller.

— 4—

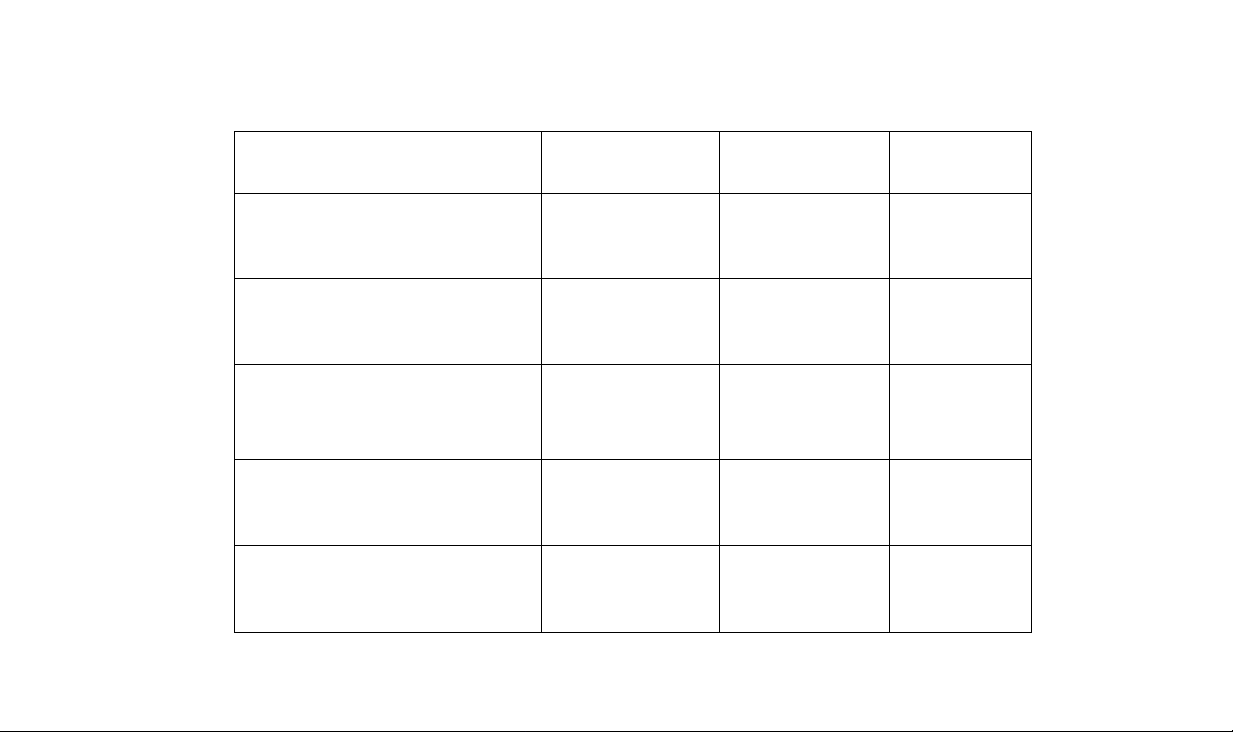

fabric, thread, needle and stitch length table

FABRICS

DELICATE ^ tulle, chiffon, fine lace. silk,

organdy, fine tricot

LIGHTWEIGHT^ batiste, organdy, jersey,

volile, taffeta, silk crepe, plastic film

MEDIUM WEIGHT^gingam. percale.pique,

linen, chintz, faille, satin, fine cordu

roy. suitings

MEDIUM HEAVY-gabardine, tweed, sail

cloth, denim. coatings, drapery fabrics

HEAVY—overcoatings.dungaree, upholstery ‘

fabrics, canvas.

THREAD SIZES

Fine mercerized cotton

Fine synthetic thread

50 mercerized cotton

"A" Silk

Synthetic thread

Polyester core/cotton

50 mercerized cotton

60 cotton

"A"Silk

Synthetic thread

Polyester core/cotton

Heavy-duty

mercerized cotton

40 to 60 cotton

Synthetic thread

Heavy-duty

mercerized cotton

24 to 40 cotton

Synthetic thread

-5 —

cat 2020(1 5 x1)

NEEDLE SIZES

9

9— 11

11~ 14 12 to 15

16

18

STITCH LENGTH

(8 to 10 for plastic)

SETTING

15 to 20

12 to 15

10 to 12

6 to 10

NEEDLES AND THREAD

This machine uses needles Catalogue 2020 (15x 1),

available in sizes 9. 11, 14. 16 and 18.

For perfect stitching, select correct needle and thread

to correspond with fabric according to the table on page

5. Be sure to use like threads for both needle and

bobbin.

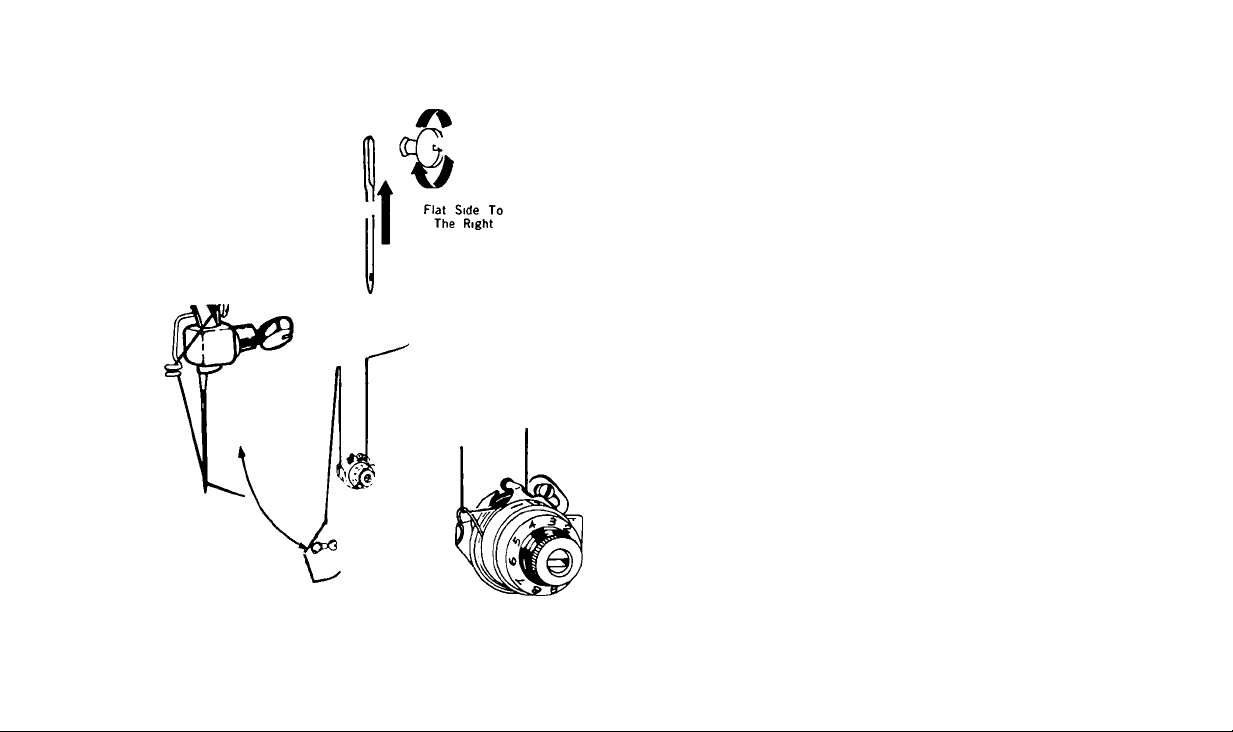

CHANGING THE NEEDLE

Raise needle bar to its highest point by turning the

hand wheel toward you. Loosen the needle clamp screw

and insert needle into clamp as far as it will go. with

the flat side of the needle to the right. Then tighten

needle clamp screw.

NEEDLE THREADING

1. Turn hand wheel toward you to raise take-up lever

to Its highest position.

2. Raise the presser foot.

3. Lead thread through all the threading points shown

at right and thread needle from left to right.

4 Draw about 4 inches of thread through eye of

needle

—6 —

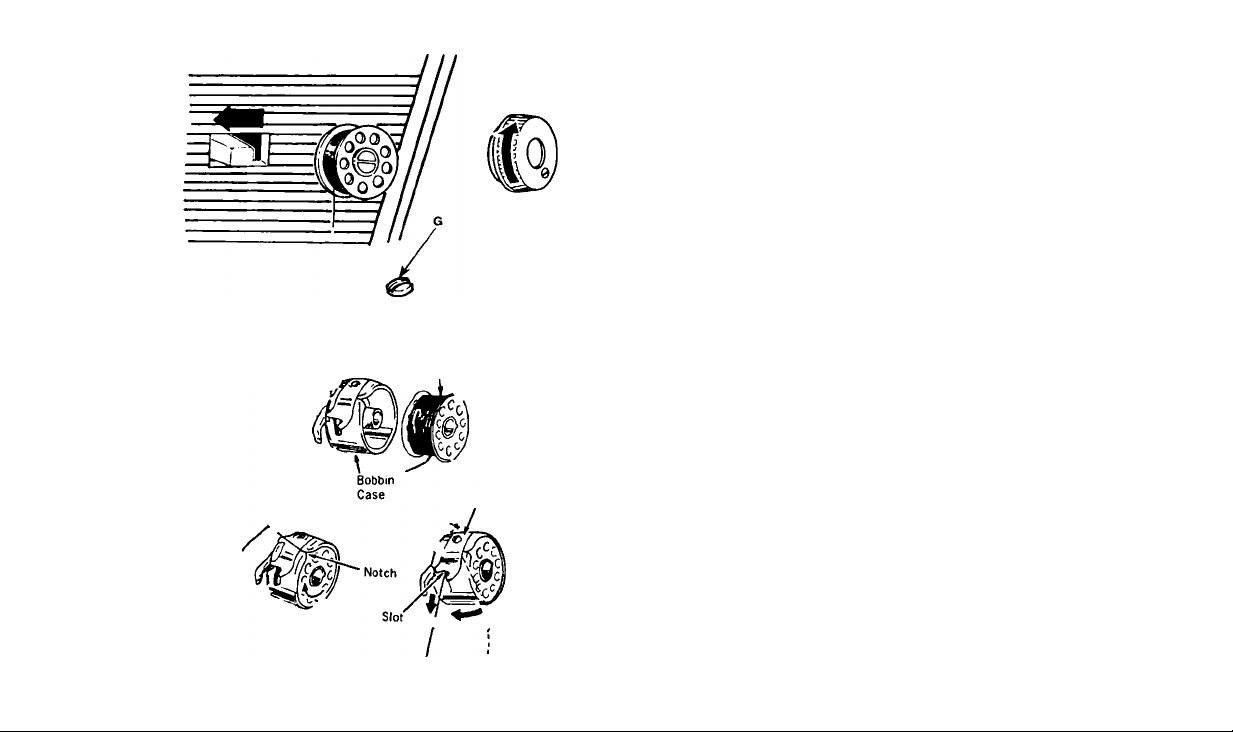

REMOVING THE BOBBIN

1. Raise presser foot and turn hand wheel toward you

until needle is at its highest point.

2. Drawslide plate to the left.

3. Reach down with left hand, open bobbin case latch

and lift out bobbin case.

4. Release latch and remove bobbin from bobbin case.

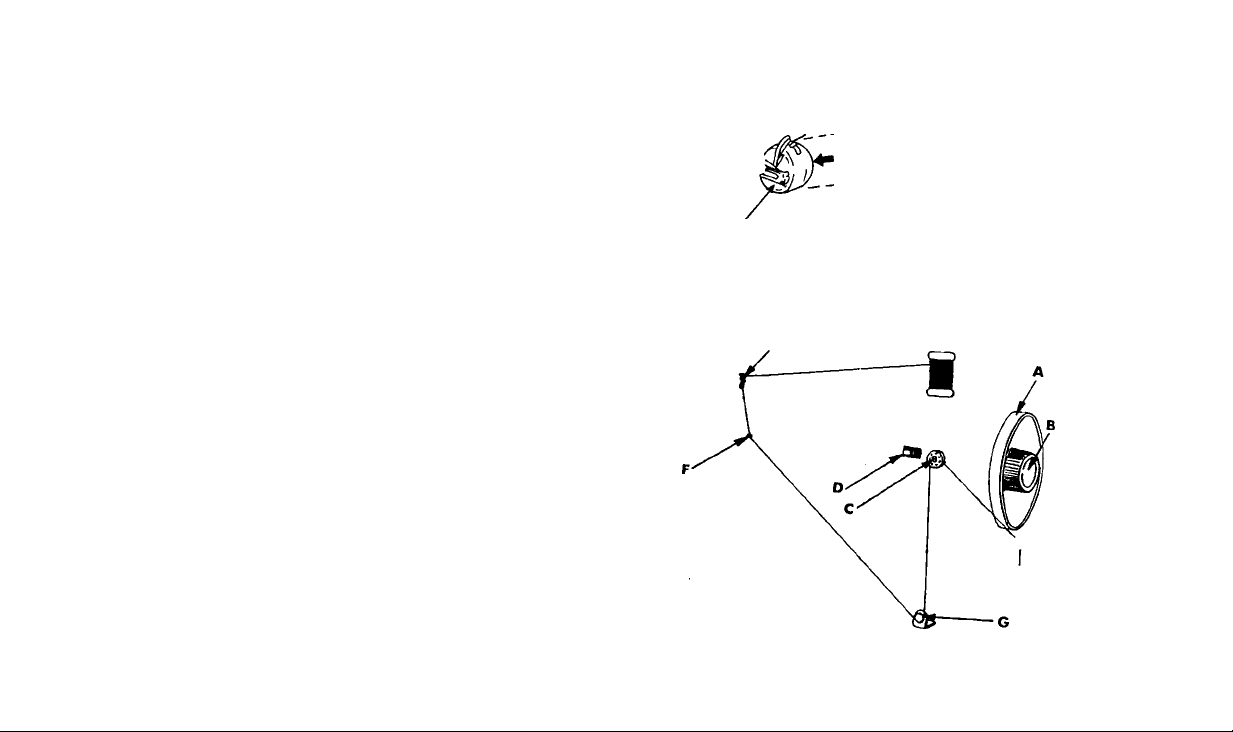

WINDING THE BOBBIN

1. To stop motion of needle, hold hand wheel A and

loosen clamp stop motion screw B. by turning it

toward you.

2. Place bobbin on bobbin winder spindle C and move

bobbin winder switch D to the right.

3. Place spool of thread on spool pin, and carry the

thread through the thread guides E and F, and

between bobbin winder tension discs G as shown

at right.

4. Draw thread up and through the hole of bobbin.

5. Hold thread end until a few coils are wound and

break off the thread end.

Latch

— 7—

WHEN BOBBIN IS FULL

Move bobbin winder switch to the left, remove

bobbin and retighten stop motion screw.

If bobbin does not wind evenly, loosen screw G which

holds tension bracket in position.

• Move bracket away from you if bobbin winds high

to the front.

• Move bracket toward you if bobbin winds high to the

back.

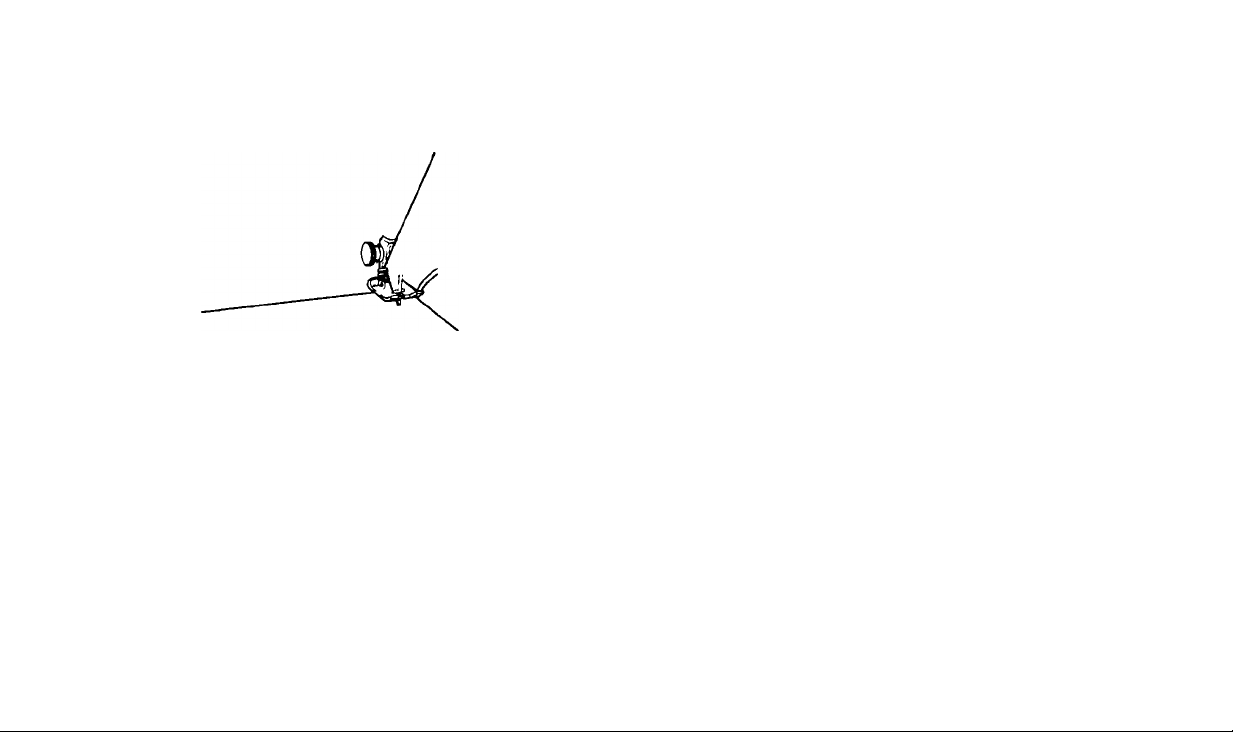

THREADING BOBBIN CASE

Tension

Spring

1. Hold bobbin so that thread unwinds in the direction

as shown at left and place bobbin in the bobbin

case.

2. Pull thread into notch, draw it under tensionspring

and Into slot. Allow about 4 inches (10cm) of thread

to hang freely from bobbin case.

— 8 —

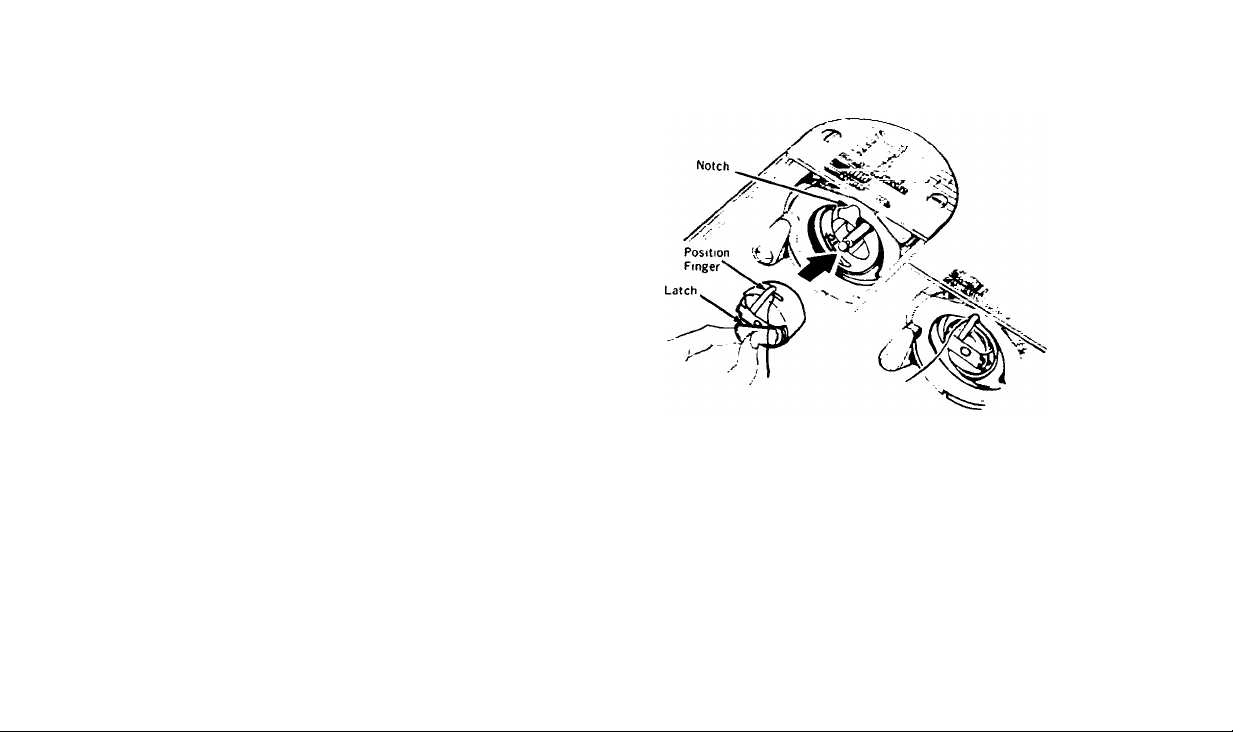

REPLACING BOBBIN CASE

1. Raise needle to its highest position.

2. Hold bobbin case by latch and place it on the

stud of the shuttle allowing position finger

to enter notch at top of shuttle body.

3. Release latch and press bobbin case in until

it clicks into place. Then close slide plate.

Replacing Bobbin Case

-9 —

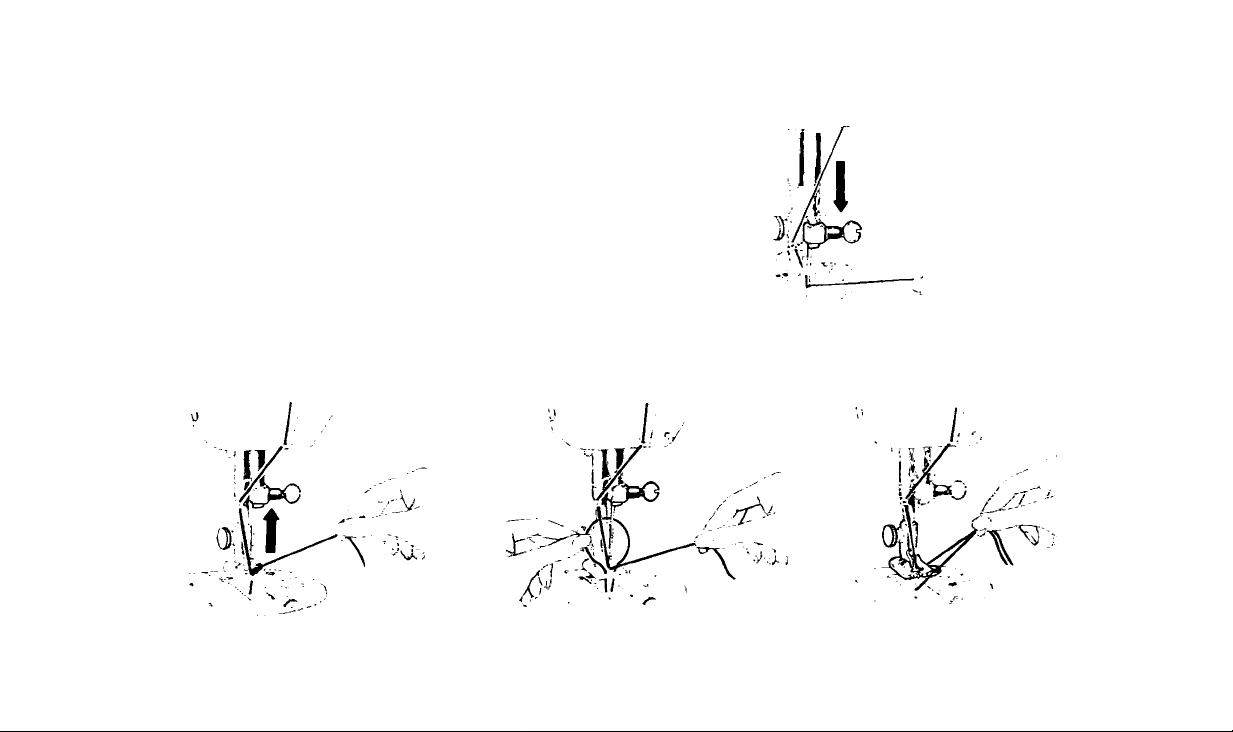

RAISING THE BOBBIN THREAD

Now that you have wound the bobbin and

threaded the needle, you will need to raise the

bobbin thread through the hole in the needle

plate.

1. Hold needle thread lightly with left hand and

turn hand wheel slowly toward you so that

needle enters needle plate.

2. Continue turning hand wheel and holding

needle thread until needle rises and brings

up bobbin thread in a loop.

3. Undo the loop with your fingers.

Place both needle and bobbin threads under

the presser foot, and draw them diagonally

to the back of the machine.

Step 2

Step 3

Step 1

\

Step 4

10—

3. st ra ig ht St it ch in g

preparation

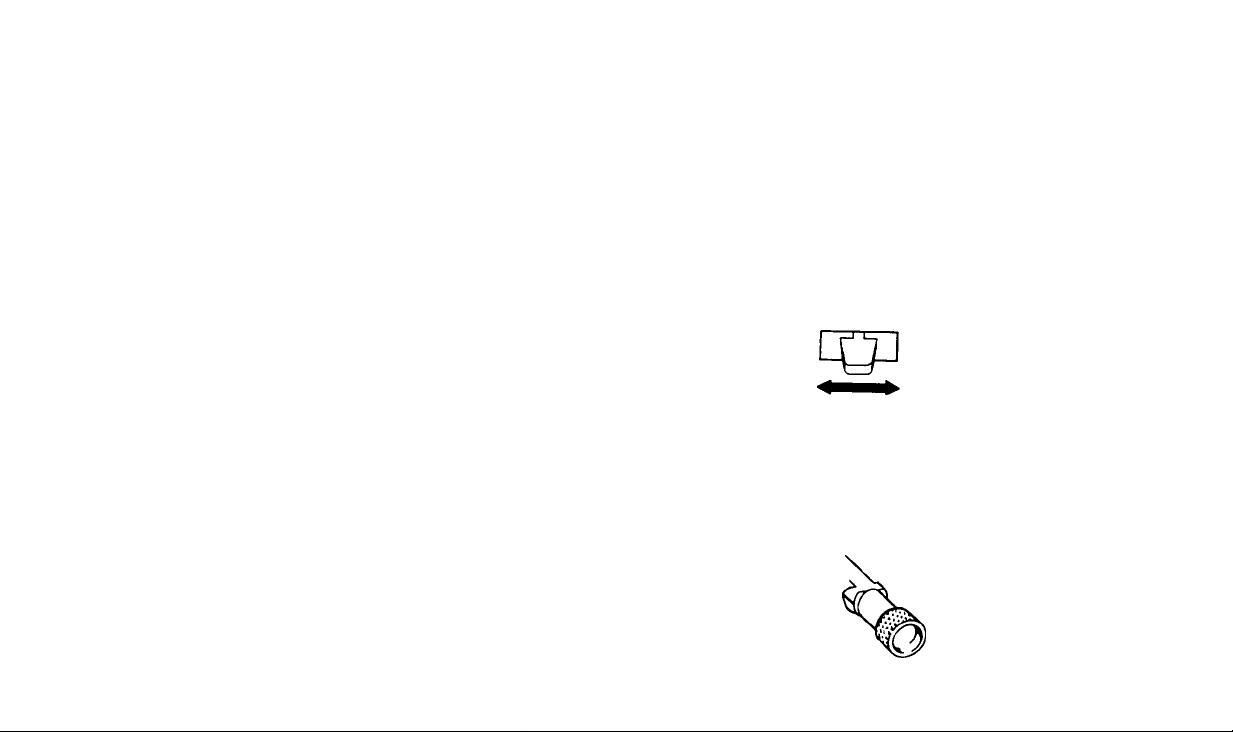

Before moving the stitch width selector, make

sure the needle is above the needle plate.

Stitch Width Selector

Set for Straight Stitching

SETTING THE MACHINE

1. Press down on stitch width selector lever

and slide lever to right until groove in lever

is directly under the straight-stitch symbol \

(setting 0).

For your convenience, the position numbers

0.1 .2 .3.4.5 will be used throughout this

book when the instructions require stitch

width settings.

2 For ordinary stitching, centre needle position

is preferred. To meet special requirements.

a line of stitching may be placed to right

or left of centre

3 Set stitch length selector for desired stitch

length. (See page 13 for instructions.)

— 11—

Needle Position Selector

, Centre

Left

I I p Right

Stitch Length Selector

Starting to Sew

starting to seiv

1. Position the needle in the fabric where de

sired for stitching start.

I

2. Lower the presser foot and start the machine.

To sew perfectly on a wide variety of fabrics

adjust stitch length, pressure and thread ten

sion as instructed on following pages.

— 12—

adjusting selectors

for your fabric

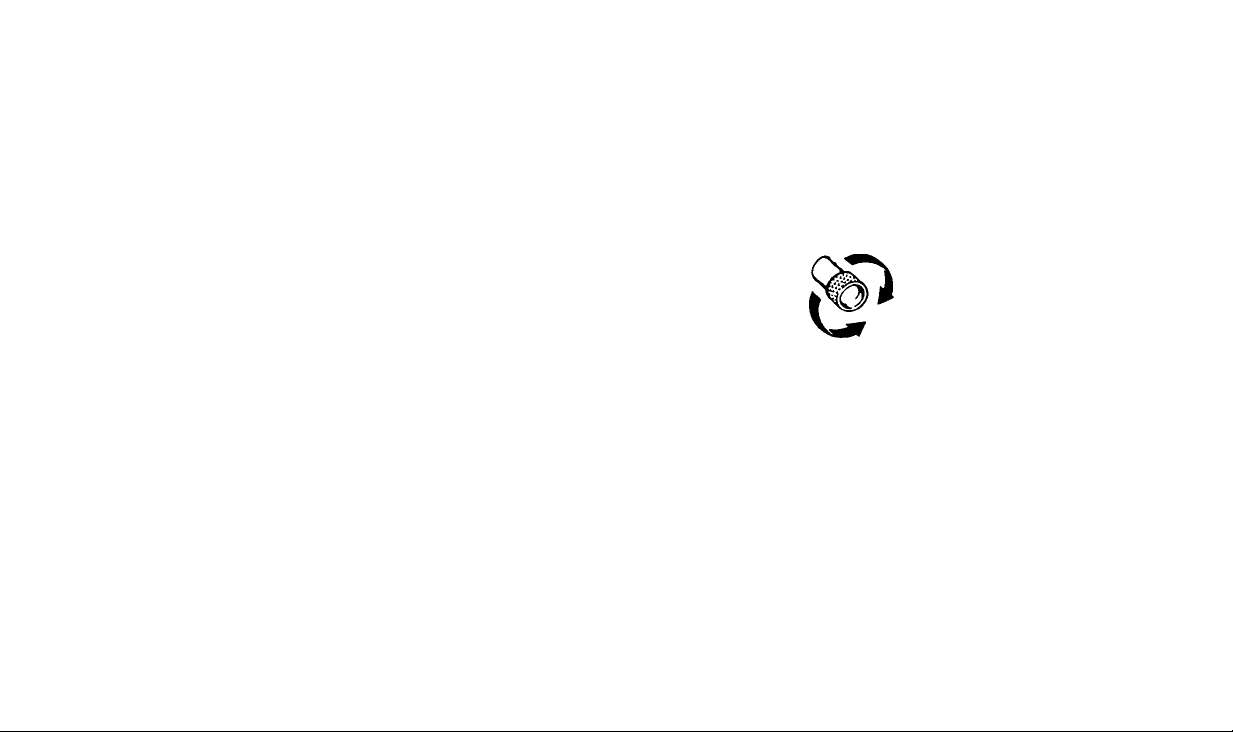

SETTING STITCH LENGTH

The stitch length selector regulates the length

of both straight and zig zag stitches. The num

bers at the right of the lever represent the

number of stitches per inch: the higher the

number, the shorter the stitch. The numbers

at the left of the lever represent stitch length

in millimetres : the higher the number, the

longer the sf/fc/t.Generally. shorter stitches

are best for lightweight fabric: longer ones for

heavy fabric.

Setting Selector

1. Loosen thumb nut by turning to left.

2. Position lever tor desired stitch length.

3. Tighten thumb nut by turning to right.

For reverse stitching, simply raise the selector

lever as far as it will go. Do not loosen thumb

nut to reverse.

Setting Stitch Length

To Reverse

Stitching

Tighten

I

— 13—

Loading...

Loading...