Singer 312U141 Service Manual

SERVICE

MANUAL

SINGER

Copyright'^ 1977THE

AllRights Reserved Throughout the World

SINGER

COMPANY

H N D E X=

Specifications 2

Partsofthe

machine

head

2

I. Preparation

1). Placeof installation of machine 3

2). Howto mount the machinehead

3). How to mount the motor 3

4). Howto connect the motor to the treadle 3

5). How to mount the bobbin winder assembly 3

6). Howto mount andadjustthekneelifterand

For

Installation OfMachine.

•'

accessories

II. Lubrication Before Starting To Sew.

1).Oiltypeand oil

2). Adjustmentfor lubrication 7

3). Precautionbefore startingto sew 7

III. Preparation

1). Selection of thread 8

2), Howto insert the needles 8

3). Methodof threadingthe upper thread 8

4). How to windthe lower thread on the bobbin 9

5).

How

6).

IV.

2),After

V.

4). Proper

to adjustthe

How

to placethe bobbininto the hook 10

HowToOperate.

1). Start

sewing

sewing

Stitch

1).

Adjustment

2).

Adjustment

Adjustmentoffeed

3).

5),Proper

6).

Relative

Positionsoffeed

7).

8). Relative positionoffeed dog and needles

reservoirs

For

Operation.

bobbin

Adjustment.

of stitch

of thread

timing

timing

positions

length

tension

dog

between

of the hookand take up

of thehookandthe

regulator

winder

assembly

height

and

thehook and

pressure

needle

lever

opener

foot

presser

3

4

6

9

H

11

12

12

15

16

18

18

18

VI.

Qeaning

1).

Cleaning

2).

Lubrication

And

Lubrication.

20

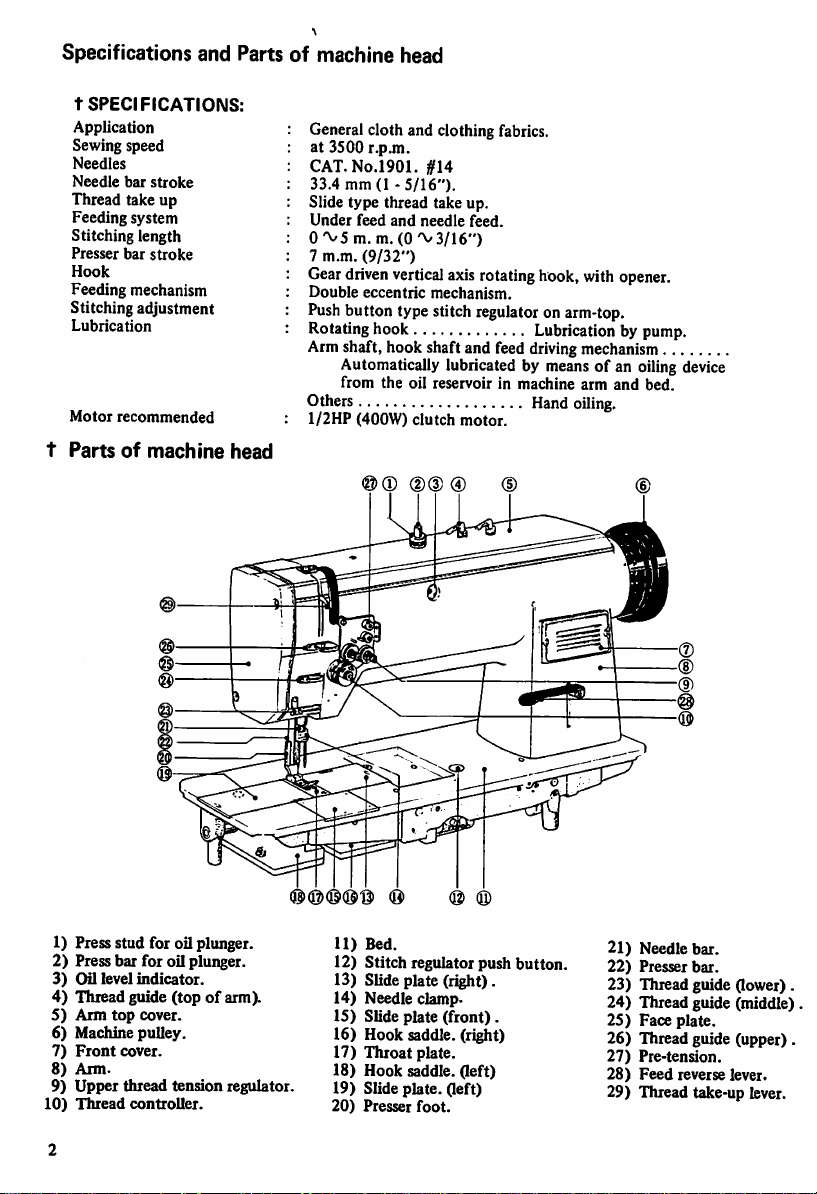

Specifications

t

SPECIFICATIONS:

Application

Sewing speed

Needles

Needle

bar

Thread take up

Feeding

system

Stitching length

Presser

bar

Hook

Feeding mechanism

Stitching adjustment

Lubrication

Motor

t

Partsofmachine

stroke

recommended

stroke

and

Partsofmachine

head

head

Generalcloth and clothing fabrics,

at 3500

r.pjn.

CAT.No.1901.

33.4 mm (1 -

Slide type thread take up.

Under

feed

O'VS

m. m.

7

m.m.

(9/32")

Gear

driven

Double

eccentric

Push

button type stitch regulator on arm-top.

Rotating hook

Armshaft, hook shaft and feed drivingmechanism

Automatically lubricated by meansof an oilingdevice

from

Others Hand

1/2HP

(400W)

@(D

#14

5/16").

and

needle

(0'\/3/16")

vertical

mechanism.

the

oil reservoir in

clutch

(D®

feed.

axisrotatinghook, with opener.

Lubricationbypump.

machine

arm

and

bed.

oiling.

motor.

@ ®

1) Press stud for oil plunger.

2) Press bar for oil plunger.

3)

Oil level

4)

Thread guide

5)

Arm

6) Machine

7)

Front

8)

Arm.

9)

Upper

10)

Thread

indicator.

top

cover.

pulley.

cover.

thread

controller.

(topofarm).

tension

regulator.

(SxS)®®®

11)

® (8)

Bed.

12) Stitch regulator push

13) Slide plate (right).

14) Needle

15) Slide plate

16) Hook saddle, (right)

17)

Throat

18) Hook saddle, (left)

19) Slide plate, (left)

20)

Presser

clamp>

(front).

plate.

foot.

(0)

button.

21) Needle

22)

Presser

bar.

bar.

23) Thread guide (lower) .

24)

Thread guide (middle)

25)

Face

plate.

26) Thread guide (upper) .

27)

Pre-tension.

28)

Feed

reverse lever.

29) Thread take-up lever.

.

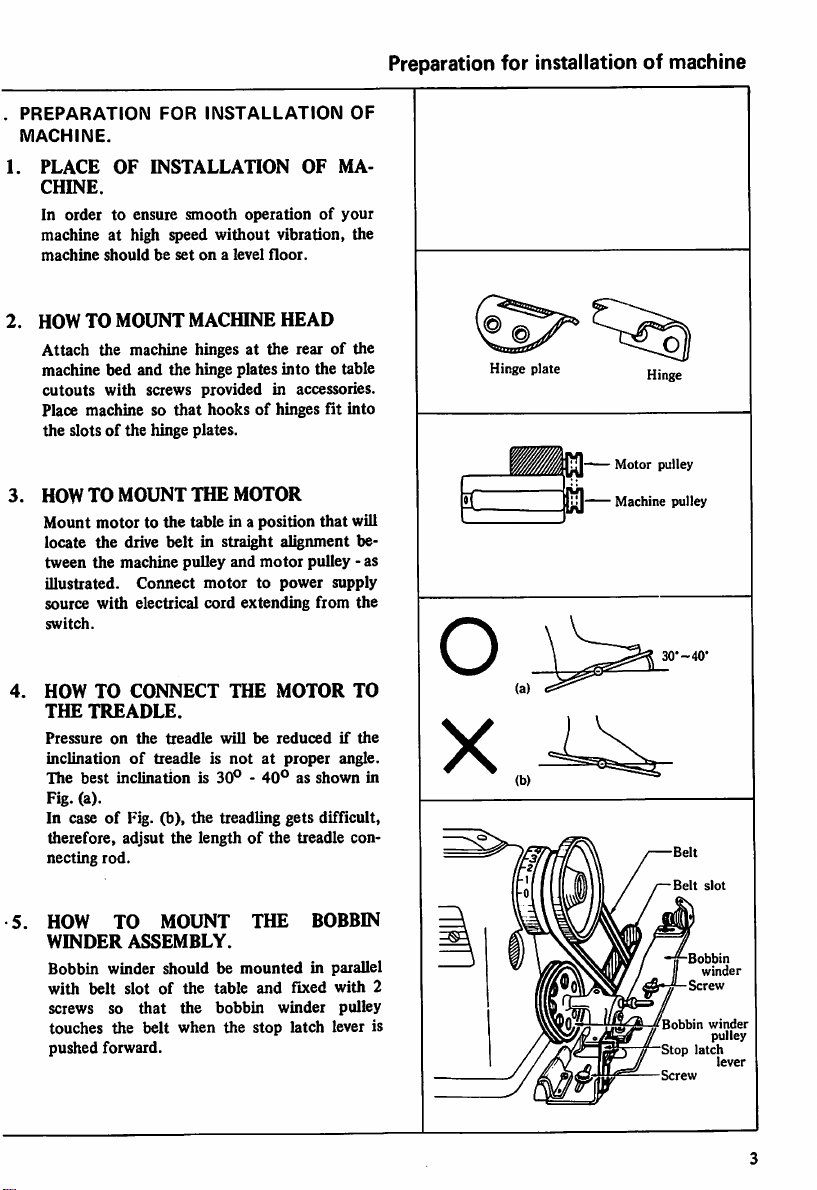

PREPARATION

MACHINE.

1.

PLACE

CHINE.

In

order

OF

to ensure

machine at high speed

machine

shouldbesetona

FOR

INSTALLATION

INSTALLATION

smooth

operationofyour

without

level

OF

vibration, the

floor.

Preparation for installation of machine

OF

MA

HOWTOMOUNT

Attach

the machine hinges at the rearofthe

MACHINE

HEAD

machine bed and the hinge plates into the table

cutouts with screws provided in accessories.

Place machine so

the

slotsofthe

HOWTO MOUNT

Mount

motortothe

locate

the

tween the machine pulley and

illustrated.

source

with

switch.

HOW

TO

THE

TREADLE.

Pressure

inclinationoftreadle is

The

on

best

that

hooksofhinges fit

hinge plates.

THE

MOTOR

drive

belt

in straight alignment be

Connect

electrical

CONNECT

the

motortopower

cord

extending

THE

treadle

willbereducedifthe

notatproper

inclinationis30°-40°asshown

table in a position

motor

MOTOR

that

pulley - as

supply

from

angle.

into

will

Fig. (a).

In caseofFig. (b),

the

treadling

gets

difficult,

therefore, adjsut the lengthofthe treadle con

necting

rod.

the

TO

Hinge

plate

—

Motor

pulley

jjfj

Machine

•C

in

pulley

30*-40*

Belt

slot

HOW

WINDER

Bobbin

with

screws so

TO

winder

belt

MOUNT

ASSEMBLY.

shouldbemounted

slotofthe

that

the

table

bobbin

THE

and

fixed

winder

BOBBIN

in parallel

with

pulley

touches the belt when the stop latch lever is

pushed

forward.

Bobbin

2

f^-ZBobbin

winder

Stop

Screw

latch

winder

pulley

lever

/

Preparation

.

HOW

KNEE

.

KNEE

The

presser

promote

for

installationofmachine

TO

MOUNT

LIFTER

LIFTER

knee

bar.

AND

MECHANISM.

lifter

mechanism

Mountitproperlyonthe

operating efficiency.

AND

ADJUST

ACCESSORIES.

lifts

and

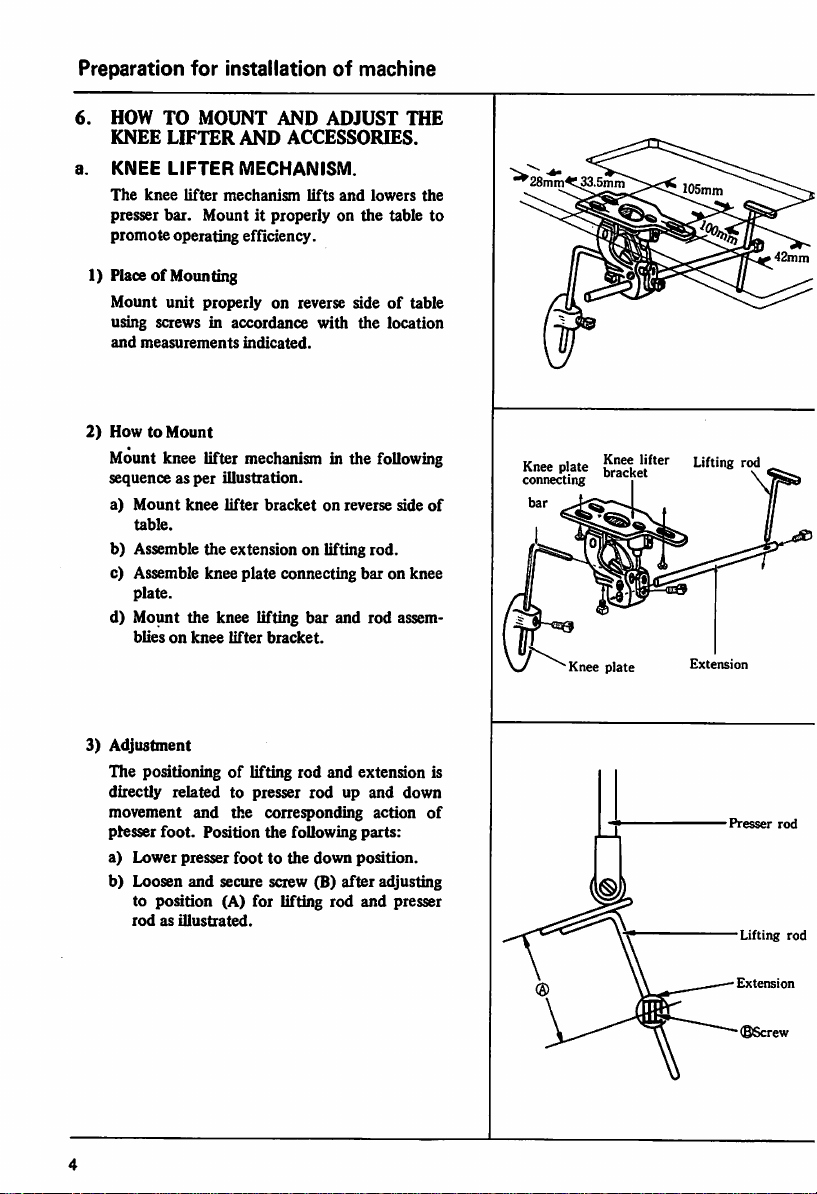

1) PlaceofMounting

Mount

unit

using screws in accordance

and

measurements

2)

HowtoMount

properly on reverse sideoftable

with

the

indicated.

Mount knee lifter mechanism in the following

sequence as

a)

Mount

table.

per

knee

illustration.

lifter

bracketonreverse

b) Assemble the extension on lifting rod.

bar

bar

and

c) Assemble knee plate connecting

plate.

d) Mount the knee lifting

bliesonknee

lifter

bracket.

lowers

table to

location

on knee

rod

THE

the

side

assem

•^28mm^33.5nim

Knee

plate

connecting

of

Efki"'"

105mm

Knee plate Extension

3)

Adjustment

The positioningoflifting rod and extension is

directly related to presser rod up and down

movement

pfesser

a)

b) Loosen

rodasillustrated.

foot.

Lower

poation

to

and

the

Position

presser

foottothe

and

secure screw (B)

(A) for lifting rod

corresponding

the

following

down

after

action

parts:

position.

adjusting

and

presser

of

Presser

Lifting

Extension

(BScrew

rod

rod

c)

Loosen

screw

4)

Placing die

adjust

tighten

the

lifting

screw

Stopper

(C)ofknee

rod

after

Pin

lifter

for

proper

adjustment.

a) Loosen set screw (D)ofstopper

b) Move knee plate to the right so

foot

lifts to its highest

c)

Tighten

set

screw (D).

NOTE

After

this adjustment, stopper pin should

contact

part

(A)ofknee

5)

PositionofKnee

Adjust

knee

plate

postureofoperator

cal

comfortable

b.

OIL

Position oil

as

not

secure oil

c.

VIBRATION-PREVENTING

PAN

to interfere

pan

position

pan

to table using nails.

The vibration-preventing

stabilize the machine

smooth

operation.

comersofthe

as

follows.

1) Make

mm

tableasshowninthe

spot

facingof20

depthatthe

Be suretogive

Plate

in accordance

on reverse sideoftable

portion

lifter

to provide for

then

tighten

with

knee lifter operation,

rubber

and

Fit

thereby to provide

these

rubbersatAe

mm radius

four

cornersofthe

smooth

facingtoface A.

bracket.

with

RUBBER

2) Nail the vibration-preventing rubbers down

at

the

four

cornersofthe

tableasshown

Fig.

bracket

and

inclination;

pin.

that

presser

(12.7

mm).

the

physi

the

most

screw (E).

cut-out

is used to

four

illustration

and

table.

Preparation

13

in

Knee

Vibration

preventing

plate

5.5%

for

installationofmachine

Lifting

Knee

lifter

bracket

Nail

rubber

®

Extension

Screw

rod

Stepper

Screw

Screw

13%

pin

Lubrication

11.

LUBRICATION

SEW.

1.

OIL

TYPE

a.

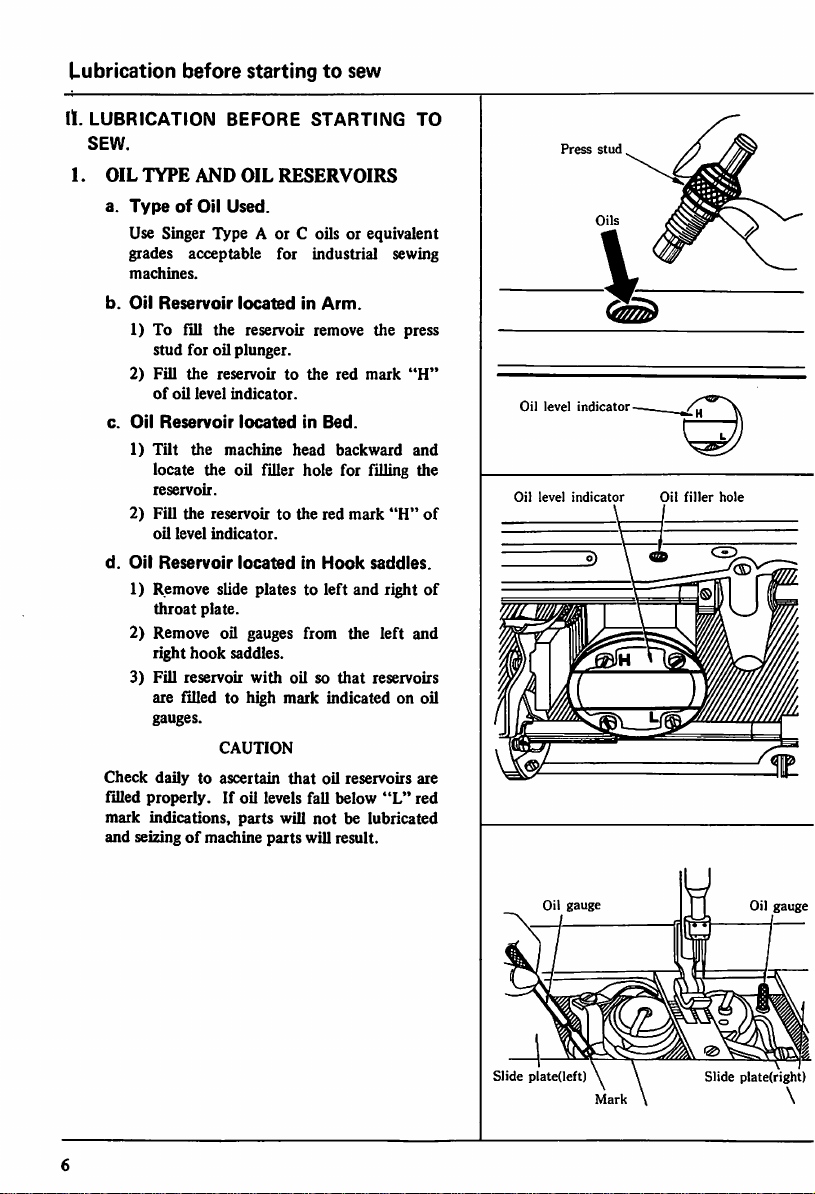

TypeofOil

Use Singer

grades

machines.

b.

Oil

Reservoir

1) To fill the reservoir remove the press

stud

2)

Fill

of

c.

Oil

Reservoir

1)

Tilt

locate the oil filler hole for filling the

reservoir.

2)

Fill

oil

d.

Oil

Reservoir

1) Remove slide plates to left and right

throat

2) Remove oil gauges from the left and

right

3)

Fill

are filled to high mark indicated on oil

gauges.

Check

dailytoascertain

filled

properly.Ifoil levels fall

mark

indications,

and seizingofmachine

before

AND

Type

acceptable

for

oil plunger.

the

reservoirtothe

oil

level

the

machine

the

reservoirtothe

level

indicator.

plate.

hook

reservoir

CAUTION

startingtosew

BEFORE

OIL

Used.

locatedinArm.

indicator.

locatedinBed.

locatedInHook

saddles.

parts

STARTING

RESERVOIRS

A or C oils or equivalent

for

industrial sewing

red

mark

head

backward

red

mark

with

oilsothat

that

oil reservoirs are

below

will

notbelubricated

parts

will result.

TO

"H"

and

"H"

saddles.

reservoirs

"L"

red

Press

stud

Oil

level

indicator

Oil

level

indicator

Oil

filler

hole

of

of

Slide

Oil

gauge

plate(left)

Mark

Slide

Oil

gauge

plate(right)

\

Loading...

Loading...