Page 1

14SH744/14CG744

(2.3.4 THREAD OVERLOOK MACHINE)

(2.3.4 MAQUINA SOBREORILLADORA)

(SURJETEUSE2.3.4FILS)

14SH754/14CG754/14ET754/14SH764

(2.3.4 THREAD OVERLOOK MACHINE WITH DIFFERENTIAL FEED)

(2.3.4 MAQUINA SOBREORILLADORA CON TRANSPORTE DIFERENCIAL)

(SURJETEUSE2.3.4FILS ENTRAINEMENT DIFFERNTIEL)

Manual de Instrucciones

Operator's Guide

Manuel D'instructions

SINGER

Page 2

14SH744/14CG744

(2.3.4 THREAD OVERLOOK MACHINE)

14SH754/14CG754/14ET754/14SH764

(2.3.4 THREAD OVERLOOK MACHINE WITH DIFFERENTIAL FEED)

Operator's Guide

Page 3

14SH744/14CG744

14SH754/14CG754/14ET754/14SH764

For European Territories:

This Singer Sewing Machine was tested according to European norms and meets the requirements

regarding electrical safety radio interference and electromagnetic immunity.

The conformity is documented with the ^ ^ mark.

C€

* Before servicing the appliance , unplug the machine.

* If the light Is damaged, It must be replace by authorized dealer.

i) Singer is a registered trademark of The Singer Company Limited or its affiliates.

Copyright©2005 The Singer Company Limited

Page 4

IMPORTANT SAFETY INSTRUCTIONS

When using this machine, basic safety precautions should always be followed including the following.

Read all instructions before using the machine

A DANGER

The machine should never be left unattended when plugged in. Always unplug the machine from the

electric outlet immediately after using and before cleaning.

- To reduce the risk of electric shock:

A WARNING -To reduce the risk of burns, fire, electric shock or iniury lo persons:

• Be sure that the electrical voltage of the electric outlet (wall receptacle) is the same as the rated voltage of

the motor.

. Use this machine only for its intended use as described in this Operator’s Guide. Use only attachments

recommended by the manufacturer as contained in the Operator's Guide

• To disconnect, turn all controls to the off (“0") position, then remove plug from outlet.

. Disconnect the power line plug from the socket outlet or switcti tlie machine oft when making any adjustments

in the needle area, such as threading needle and loopers, changing needle, changing throat plate or

changing presser foot, etc.

. Always unplug the machine from the electrical outlet when removing covers, lubricating, or when making

any other user servicing adjustments mentioned in the Operator's Guide

• Do not attempt to adjust the motor belt. Contact your nearest Service Center should any adjustment be

required.

• Do not unplug by pulling on cord. To unplug, grasp the plug, not the cord.

- Handle the foot controller with care and avoid dropping it on the floor. Be sure not to place anything on top

of it.

. Always use the proper throat plate The wrong plate can cause the needle to break

• Do not use bent needles.

. When sewing, keep fingers away from all moving parts. Special care is required around the sewing

machine needle.

• Do not pull or push fabric while stitching. It may deflect the needle causing it to break.

. Use only the handle to lift and move the machine.

. Never operate the machine if it has a damaged cord or plug, if it is not working properly, if it has been

dropped or damaged, or dropped into the water. Return the machine to the nearest authorized dealer or

Service Center for examination, repair, electrical, or mechanical adjustment.

- Never operate the machine with any air openings blocked. Keep ventilation openings of the machine and

foot controller free from the accumulation of lint, dust and loose cloth.

. Never drop or insert any object into any opening.

Page 5

+ Do not use outdoors.

* Do not operate where aerosol (spray) products are being used or where oxygen is being administered.

» Do not allow to be used as a toy. Close attention is necessary when the machine is used by or near

children.

* Do not expose the machine or machine plastic case to sunlight directly. Also, do not keep it in a very warm

or damp place.

» Do not touch the machine, toot controller and power line cord with wet hand, wet cloth or with anything wet.

♦ Do not connect power line cord to one of the many cords connected to one power outlet with adapters.

• Use machine on flat and stable table.

V Be sure to close the cylinder cover and looper cover before operating the machine.

• Keep presser foot and needles away from children’s reach.

« Do not dismantle or modify the machine yourself.

♦ Be sure to turn off the power switch and disconnect the power line plug before caring for your machine as

instructed in the operator's guide.

SAVE THESE INSTRUCTIONS

Servicing should be performed by an authorized service representative.

This product is not intended for industrial use.

FOR EUROPEAN AND SIMILAR TERRITORIES:

Machines for Great Britain and some other countries having similar wiring standards are shipped from the

factory without a plug for connection to the mains. The wires in this mains lead are colored In accordance with

the following code.

Blue: neutral (N) Brown: live (L)

As the colors of the wires in the mains lead of this appliance may not correspond with the colored markings

identifying the terminals in your plug, proceed as follows:

The wire which Is colored blue must be connected to the terminal which is marked with the letter N or colored

black. The wire which is colored brown must be connected to the terminal which is marked with letter L or

colored red. If a 13 Amp. (BS 1363) plug is used, a 3 Amp. fuse must be fitted, or if any other type of plug is

used, a 5 Amp. fuse must be fitted either in the plug or adaptor or at the distribution board.

Neither cord is to be connected to the earth terminal of a Ihree-pin plug.

Page 6

CONTENTS

Page

1. Selection of Stitches..............................................5

2. Handy Reference Chan..........................................6

3. Accessories

4. Needle Information

............................................................

................................................

7

7

5. Principal Parts........................................................8

6. How to Open Looper Cover

..................................

9

7. Principal Parts Behind Looper Cover ..................9

8. Preparation Prior to Sewing

.................................

9

9. Preparation for Threading................................................................ 10

•Setting up the thread guide holder

10. How to Remove and Insert Needles

•To remove needle(s)

.............................................

.....................

...................

10

11

11

•To insert needle(s)................................................11

11. Threading the Machine..........................................12

•Threading diagram

•Understanding the color code

•To thread the machine correctly

1) Threading the upper looper (Orange)

2) Threading the lower looper (Yellow)

3) Threading the right needle (Green)

................................................

.............................

.........................

...........

.............

................

12

12

12

14

4) Threading the left needle (Blue).....................I8

•Important threading information

12. How to Change Threads / Tie on Method

.........................

............

19

20

13. How to Adjust the Stitch Length .........................21

14. How to Adjust the Seam Width

...........................

21

•Width adjustment by changing needle position .. .21

•Width adjustment with adjustment knob

15. How to Adjust the Presser Foot Pressure

16. Differential Feed

..............................................

............

..........

1 - - 23

22

• Gathered overedge...............................................23

• Stretch overedge

17. How to Disengage Movable Upper Knife

..................................................

...........

24

25

18. Converting the upper looper into spreader..., 26

19. Free Arm Sewing (Tubular Work)

.......................

27

20. Standard Overedge and Rolled Hem Stitching .. 28

• To sew standard overedge

..................................

•To sow rolled hem.................................................28

21. Chaining Off and Test Sewing .............................29

22. Suggested Tension Setting

1) 2-thread wrapped edge overlook

...............................................

2) 2-thread standard rolled hem stitching

3) 3-Thread Overlook......................................................32

4) 3-Thread Flatlock

5) 3-Thread Wrapped Edge Overirick..........................34

....

..................................................33

6) 4-Thread Ultra Stretch Mock Sateiy Slilch...............35

23. How to Sew a Rolled Hem

1) 2-thread wrapped edge overlook

...............................................

2- thread standard rolled hem stitching.............37

2) 3-thread standard rolled hem stitching

3- thread upper looper thread wrapped

rolled hem stitching

24 Stitch Variations and Sewing Techniques.........................40

• Hov/ to sew a flatlock decorative seam

•Hov/ to sew an overlock blind hem..................................42

• How to sew pin tucks........................................................42

12

15

2I

•Turning square corners.....................................................43

•Pin placement.....................................................................44

•Securing the thread chain............................................... 44

•How to reinforce a seam....................................................45

•Braiding by chaining off....................................................45

25. Machine Maintenance.........................................................46

•Cleaning the machine

• Oiling the machine...........................................................

•How to replace the stationary knife

26. Troubleshooting Chart.......................................................48

27. Relationship between Cloth. Thread and Needle. . 49

28. Specification

.......................................................................

...............................................

........................................................

.................................

28

Page

..............................

..................

............................

..................

..........................

30

30

31

36

37

38

38

40

46

46

47

50

Page 7

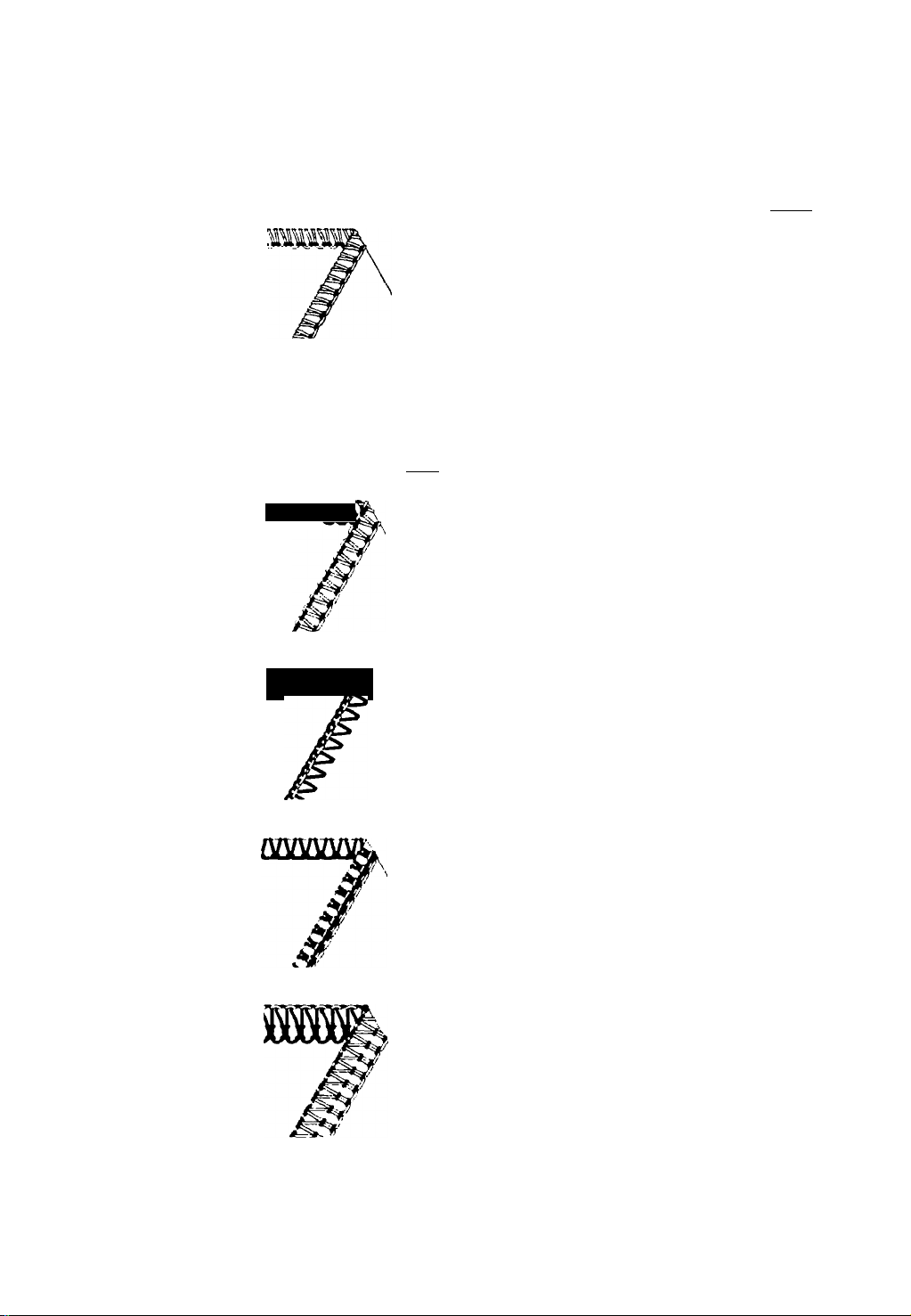

1. SELECTION OF STITCHES

This machine is capable of producing various types of stitches according to the combination ot needle positions,

threading methods, tension adjustment,

Stitch Type

Reference

Pages

1. Two-thread

wrapped edge

overtook

2. Two-thread

standard rolled

hem stitching

3. Three-thread

Overlock

4. Three-thread

Flatlock

4?

miimm

(502)

(503)

(504)

1-needle 2-thread stitch is used for

light weight or knits fabrics. Also.a

3.5mm and 5.7mm wrapped overlock

seam width can be obtained by

changing the needle position.*

1-needle 2-thread stitch is used for

overedge seaming.blindstitch

hemming on edge finishing operations.

Also.a 3.5mm and 5.7mm standard

rolled hem seam width can be obtained

by changing the needle position.*

1-needle 3-thread stitch is used for

overedging and seaming on common

fabrics. Also, a 3 5mm and 5.7mm

overlook seam width can oe obtained by

changing the needle position "

1-needle 3-thread stitch is used for butted

or lapped seams and ornamental stiiching

with decorative thread. Also, a 3.5mm and

5.7mm flatlock width can be obtained by

changing the needle position.'

30

31

32

33

(505)

5. Three-thread

Wrapped Edge

Overlook

1-needle 3-thread stitch is used for sewing

narrow rolled hems or ornamental edges.

Also, a 3.5mm and 5.7mm wrapped

34

overlook seam width can be obtained by

changing the needle position *

6. Four-thread

Stretch Mock

Safety Stitch

(514)

* Depending on the needle positions used, this machine can sew 3-thread standard width 3.5mm overedge and

a 5.7mm wide overedge seams.

2-needle 4-thread stitch which is ideal lor

medium to heavy weight stretchy fabrics

such as double knits and swim wear.

35

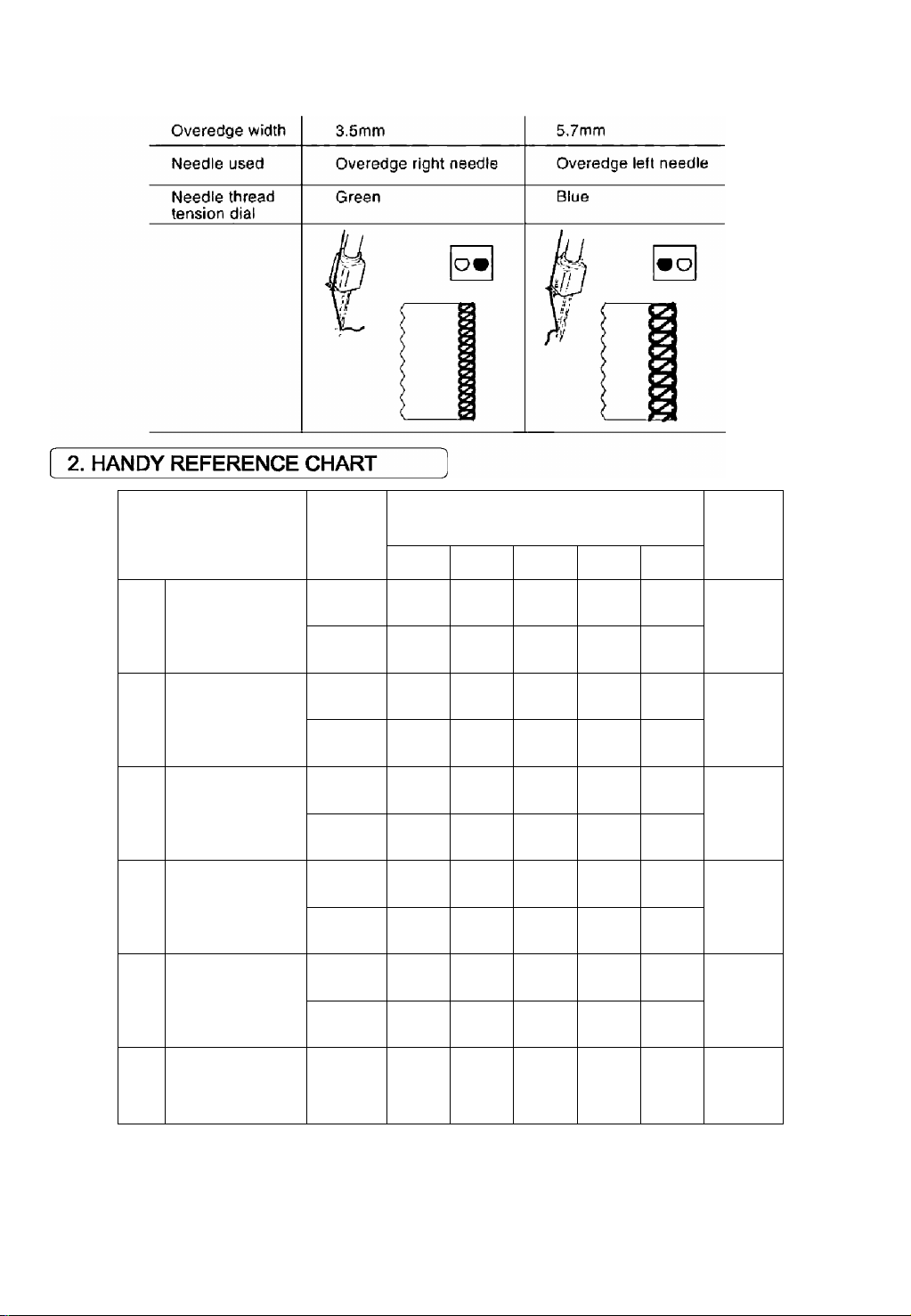

Page 8

Also, for overedging heavyweight fabrics, the seam width can be increased still more by turning the overedge

seam width adjustment knob. (See page 21)

Tension Dial: Numbers shown are average

settings on medium weight fabric with

standard #80 polyester spun thread

Blue Green Orange Yellow

4.0 2.0

3.5 1.0

0.5 6.0

0.5

3.0

3.0 3.0 3.0

0.5 5.0

0.5 5.0 7.0

3.0

5.0 0 8.5

3.0 3.0

1.0

5.0

7.0

7.0

spreader

Spreader

Spreader

Spreader

Spreader

Upper

looper

Upper

looper

Upper

looper

Upper

looper

Upper

looper

Upper

looper

Page

30

31

32

33

34

Stitch Type

Two-Thread

Wrapped Edge

Overiock

1

Two-Thread

Standard Rolled

2

Hem Stitching

Three-Thread

Overlock

3

Three-Thread

Flatlock

4

Three-Thread

Wrapped Edge

5

Overlock

Needle

Positions

3.5mm

5.7mm

(602)

3.5mm

5.7mm

(503)

3.5mm

5.7mm

(504)

3.5mm

S

5.7mm

(505)

3.5mm

S

5.7mm

Four-Thread Ultra-

Stretch Mock

6

Safety Stitch

3.0 3.0 3.0 3.0

(514)

Upper

looper

35

The thread tension becomes tighter as the dials are turned to higher numbers. The tension sellings shown on

this page as well as throughout the operator's manual are suggested guides. Adjust thread tensions to suit the

fabric and size of thread used. For host results make tension adjustments in small increments of no greater

than half a number at a time.

Page 9

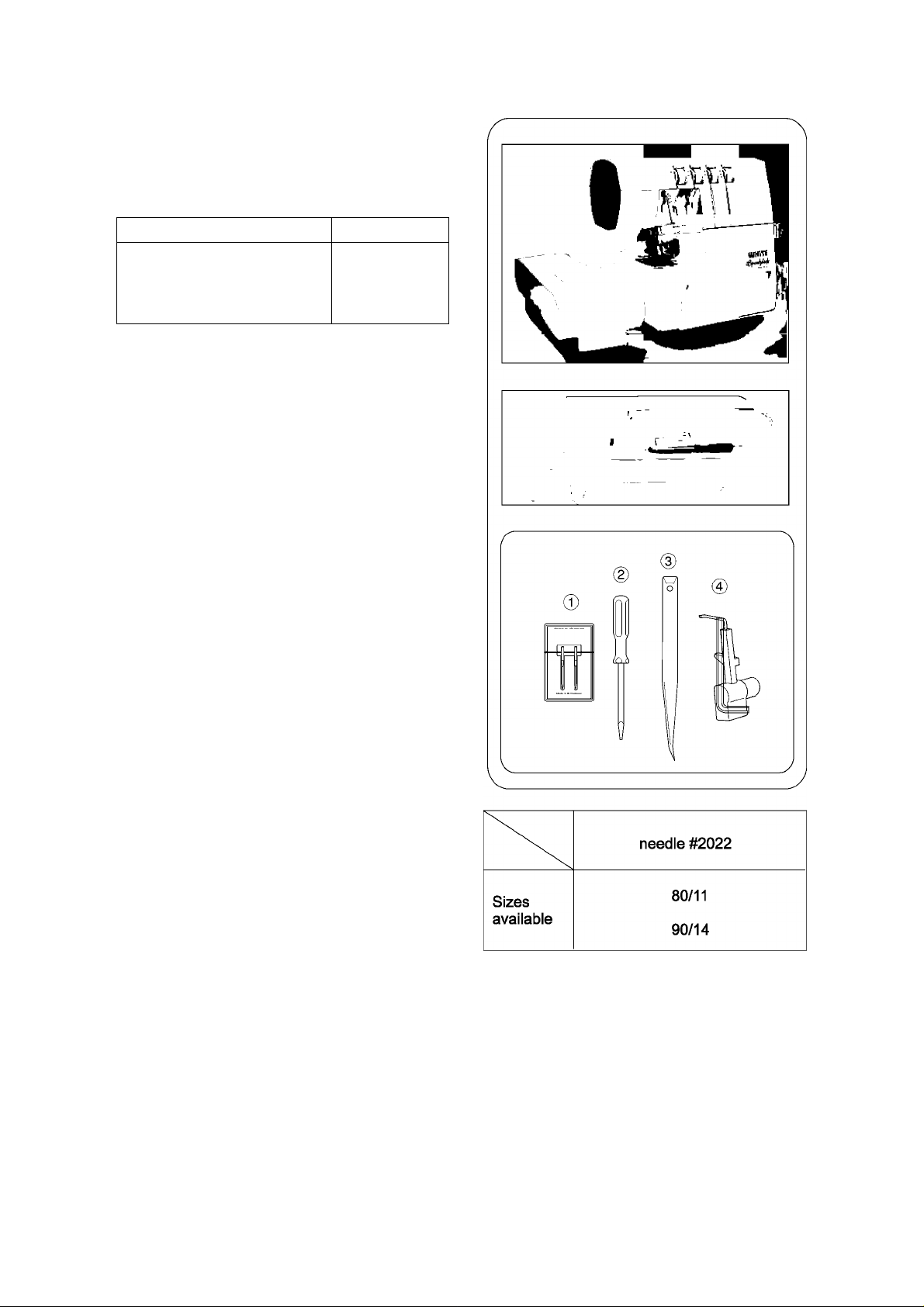

3. ACCESSORIES

Accessories are contained in the accessory case in

the cloth plate.

744 / 754 / 764

1 Needle set

2 Screw driver (small size)

3 Tweezers

4 Spreader

1

1

1

1

4. NEEDLE INFORMATION

• Needle #2022 size 90/14 Is furnished with the

machine.

• In an emergency, standard needle #2020 may

be used.

However, unless the suggested tension setting is

readjusted, skipping of the stitches may occur.

•

Page 10

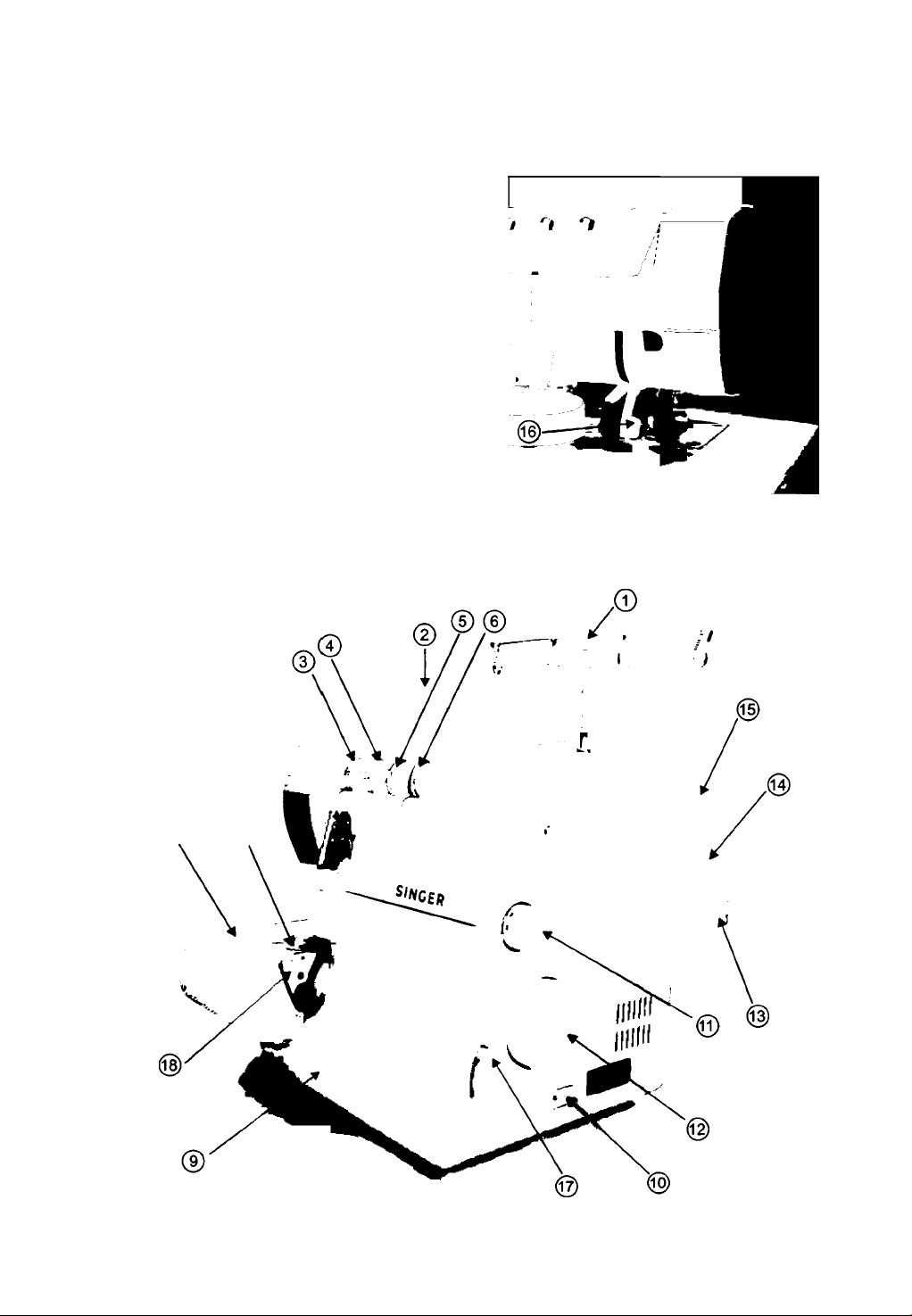

5. PRINCIPAL PARTS

1 Thread guides and holder

2 Handle

3 Left needle thread tension dial (blue)

4 Right needle thread tension dial (green)

5 Upper looper thread tension dial (orange)

6 Lower looper thread tension dial (yellow)

7 Throat plate

8 Cloth plate

9 Looper cover

10 Power & light switch

11 Stitch length dial

12 Handwheel

13 Spool stand

14 Spool holder

15 Spool pin

16 Presser bar lifter

17 Differential feed adjusting lever knob

18 Seam width finger support plate

Page 11

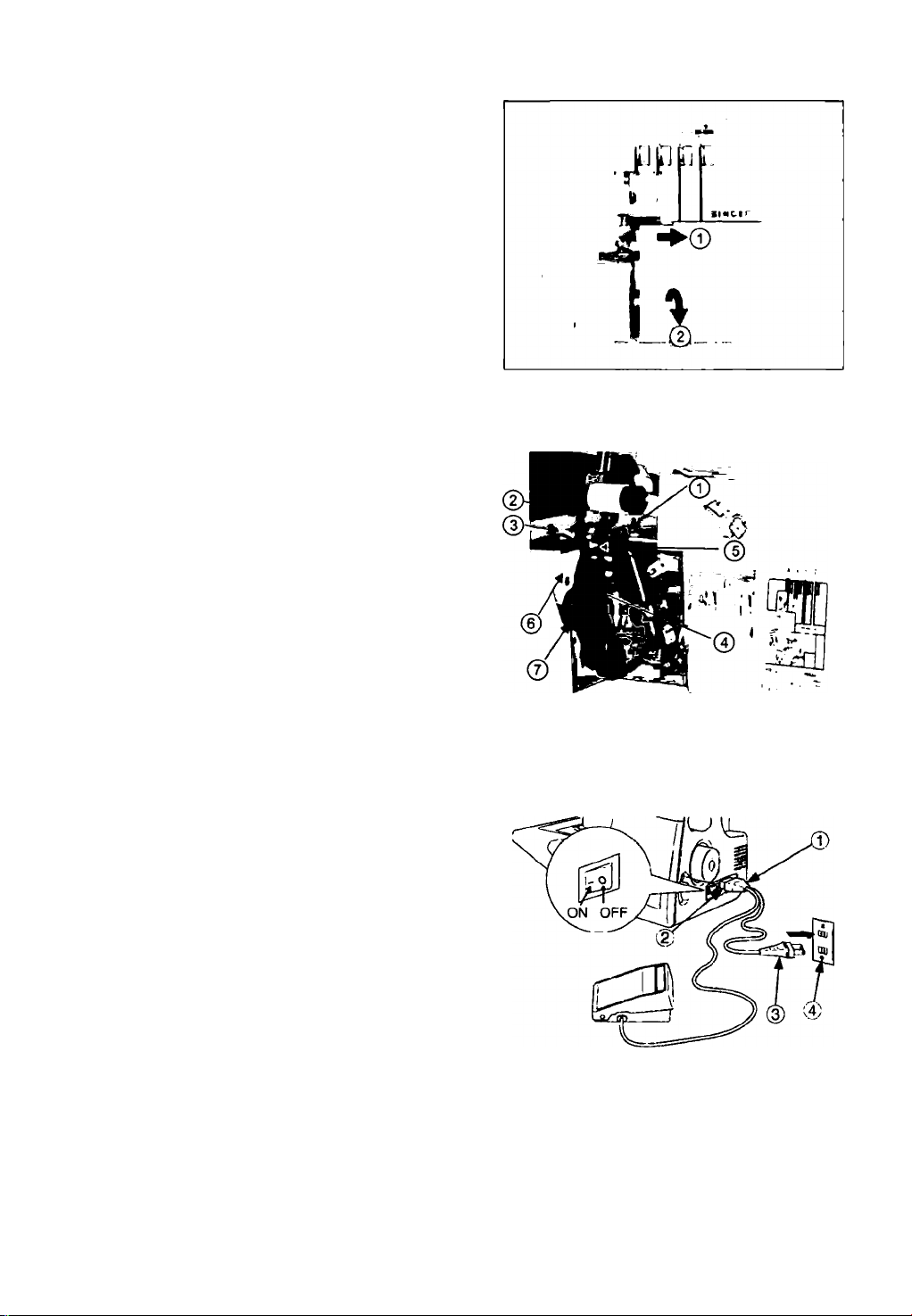

6. HOW TO OPEN LOOPER COVER

Caution ;

A

• Push the cover to the right as far as it will go 1 .

• Pull cover down toward you 2 .

A

Be sure to turn off power switch.

Caution:

Be sure looper cover is closed when sewing.

7. PRINCIPAL PARTS BEHIND

LOOPER COVER

1 Upper looper

2 Movable upper knife

3 Presser foot

4 Stationary lower knife

5 Lower looper

6 Seam width finger knob

7 Seam width adjustment knob

8. PREPARATION PRIOR TO SEWING

• Connect the controller / electric plug 1 to the

machine receptacle 2.

• Plug power line 3 into electric outlet 4 .

^ ■ I« W k n

• Power Switch: Push mark side to turn “ON".

Push “O" mark side to turn “OFF".

• To run the machine and control the speed, press

the controller.

• The harder you press, the faster the machine will

•

sew.

• To stop the machine from sewing, remove your foot

from the controller.

WARNING:

Use only foot controller provided with this

machine. (YC-482 for U.S.A. & CANADA only)

Be sure to make reference to "Warning" on

following page.

Page 12

POLARIZED PLUG INFORMATION (FOR U.S.A. & CANADA ONLY)

This appliance has a polarized plug (one blade wider than the other). To reduce the risk of

electric shock, this plug is intended to fit in a polarized outlet only one way. If the plug

does not fit fully in the outlet, reverse the plug. If it still does not tit, contact a qualified

electrician to install the proper outlet. Do not modify the plug in any way.

Warning;

A

* Be sure that the electrical voltage of the electric outlet (wall receptacle) is the same as the rated

voltage of the motor.

* Handle the foot controller with care and avoid dropping it on the floor. Be sure not to place

anything on top of it when not in use.

* Disconnect the power line plug from the electric outlet when changing needles, presser feet or

throat plates, or when leaving the machine unattended. This eliminates the possibility of starting

the machine by accidentally pressing the controller.

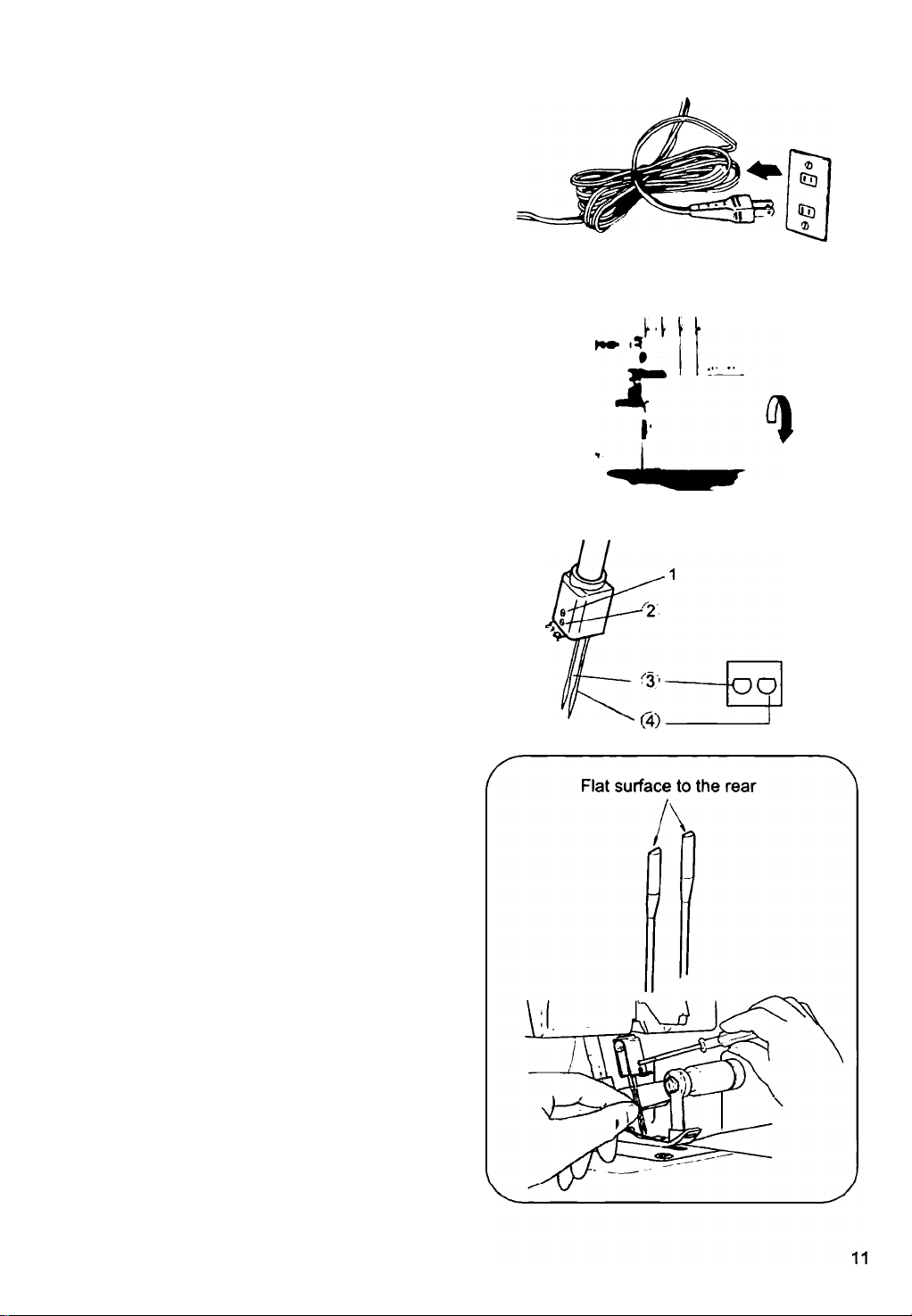

9. PREPARATION FOR THREADING

Setting Up the Thread Guide Holder

This machine is shipped with the thread guide bolder

in the lowered position.

Fully extend the thread guide holder.

The two joints on the telescope will click into place

when they are correctly positioned.

Center the thread guides above the spool pins.

Place thread over the cone adapters on the spool

pins.

Note: If the machine is threaded, straighten the

threads to prevent tangling.

i

SlftfOfill

O

10

Page 13

10. HOW TO REMOVE AND INSERT

NEEDLES

To Remove Needle(s)

Caution ;

l\ Be sure to disconnect the machine from the

A

electric outlet before removing needle(s).

Turn the hand wheel toward you until the needle is

at its highest position.

Loosen, but do not remove the needle set screw

with the small screwdriver.

1 Left needle set screw

2 Right needle set screw

3 Left needle

4 Right needle

Remove the needle(s).

To Insert Needle(s)

Caution :

|\ Be sure to disconnect the machine from the

A

• Hold the needle with the flat surface to the back.

• Insert the needle into the needle clamp as far as it

• Securely tighten the needle set screw.

electric outlet before replacing needle(s).

will go.

Note: » This machine uses #2022 needles. Refer

to page 7 lor additional needle information.

* Remove the cloth plate if you find it difficult

to remove and replace the needle.

Page 14

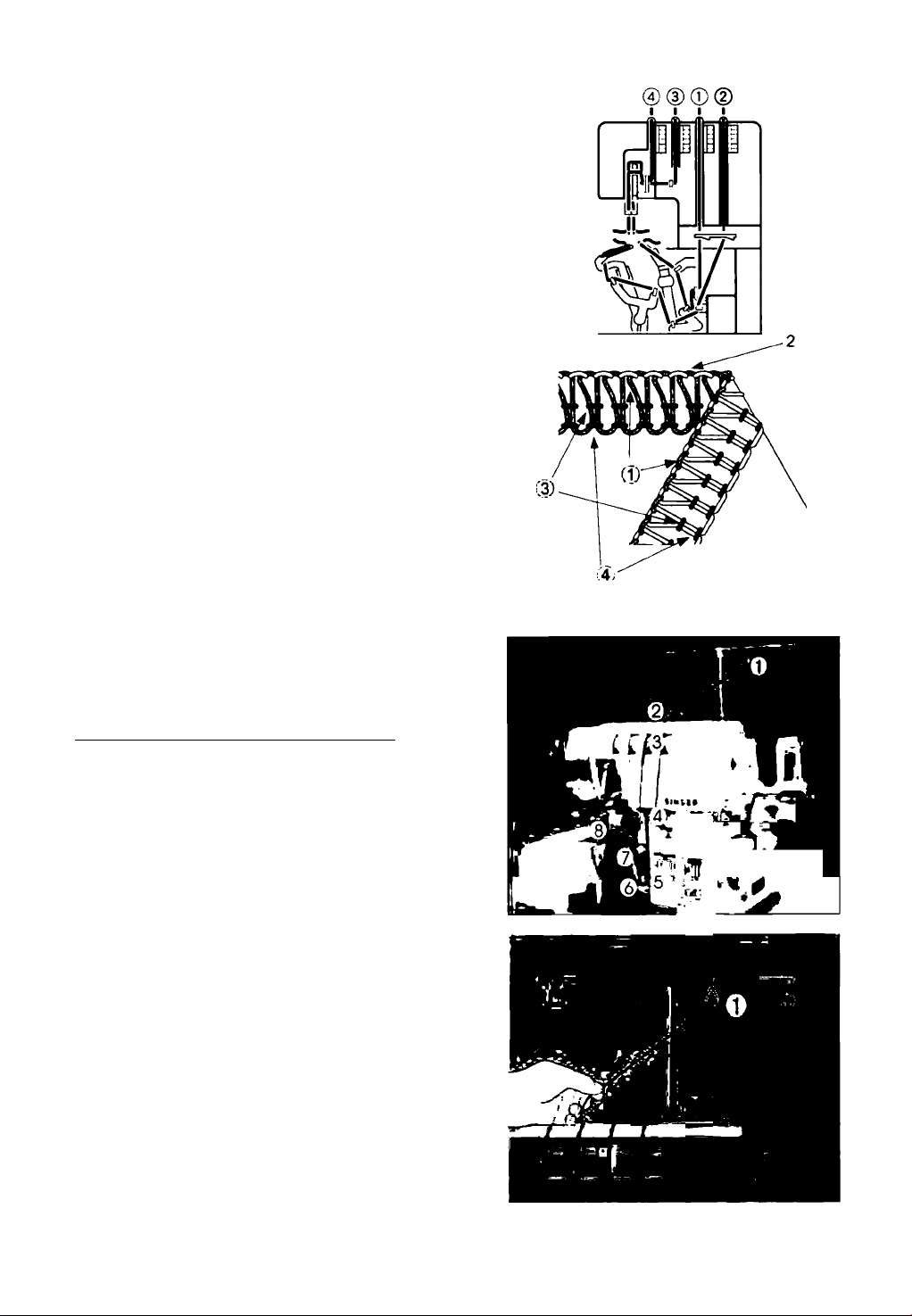

11. THREADING THE MACHINE

Threading Diagram

• A color coded threading diagram is located inside

the looper cover for quick reference.

• Thread the machine in the order 1 to 4 as shown.

Understanding the Color Code

1 Upper looper thread

2 Lower looper thread

3 Right needle thread

4 Left needle thread............................ Blue

................

................

.................

Orange

Yellow

Green

To Thread The Machine Correctly

Caution :

A

Be sure to turn off power switch.

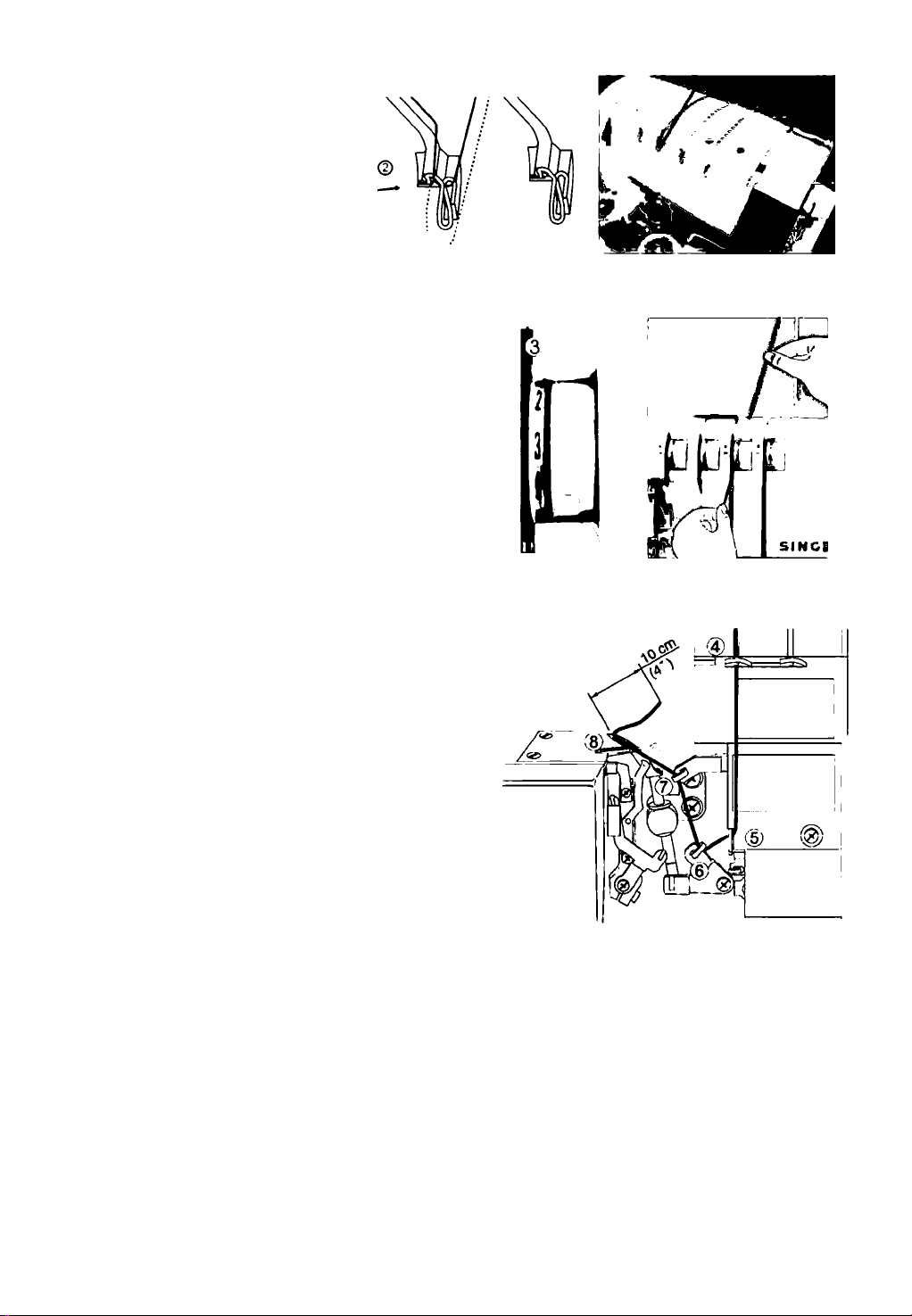

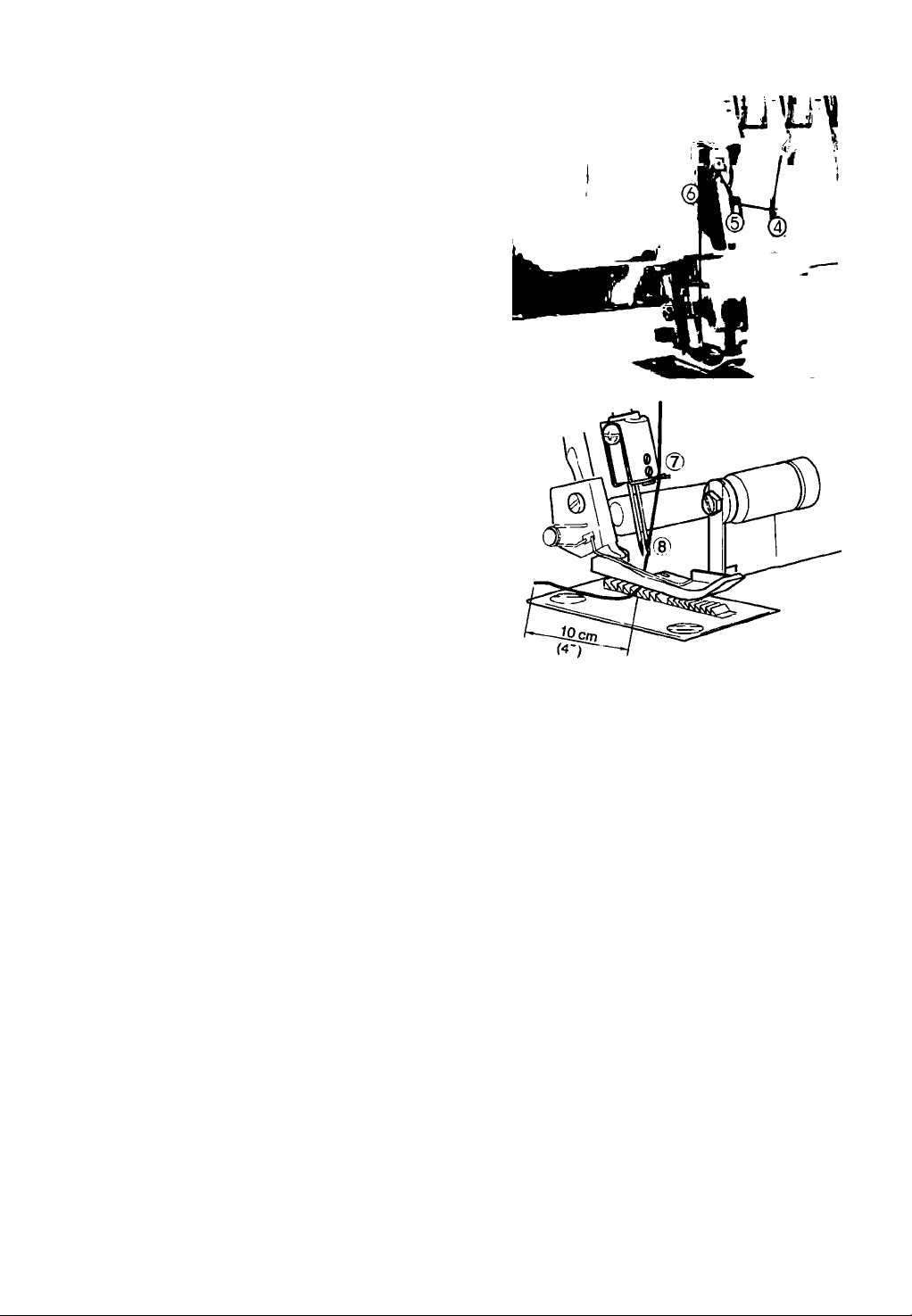

1) Threading the Upper Looper (Orange^______

• Thread the upper looper as indicated 1 ~ 8 .

12

Pass thread from back to the front through the

thread guide 1

Page 15

• Thread the top cover thread

guide by pulling the thread

downward until it slips

under thread guide 2 .

While holding thread with finger, pass it between

the tension discs and pull thread down to make

certain it is properly located in between the

tension discs 3 ,

r

Thread the looper area of the machine following the

orange color coded thread guides ( 4 ~ 7 ).

Thread the hole in the upper looper from front to

back 8 .

Note: Use of tweezers provided in the accessory

set to aid in threading the looper.

Pull about 10cm (4 inches) of thread through the

looper and place to the back of the throat plate.

13

Page 16

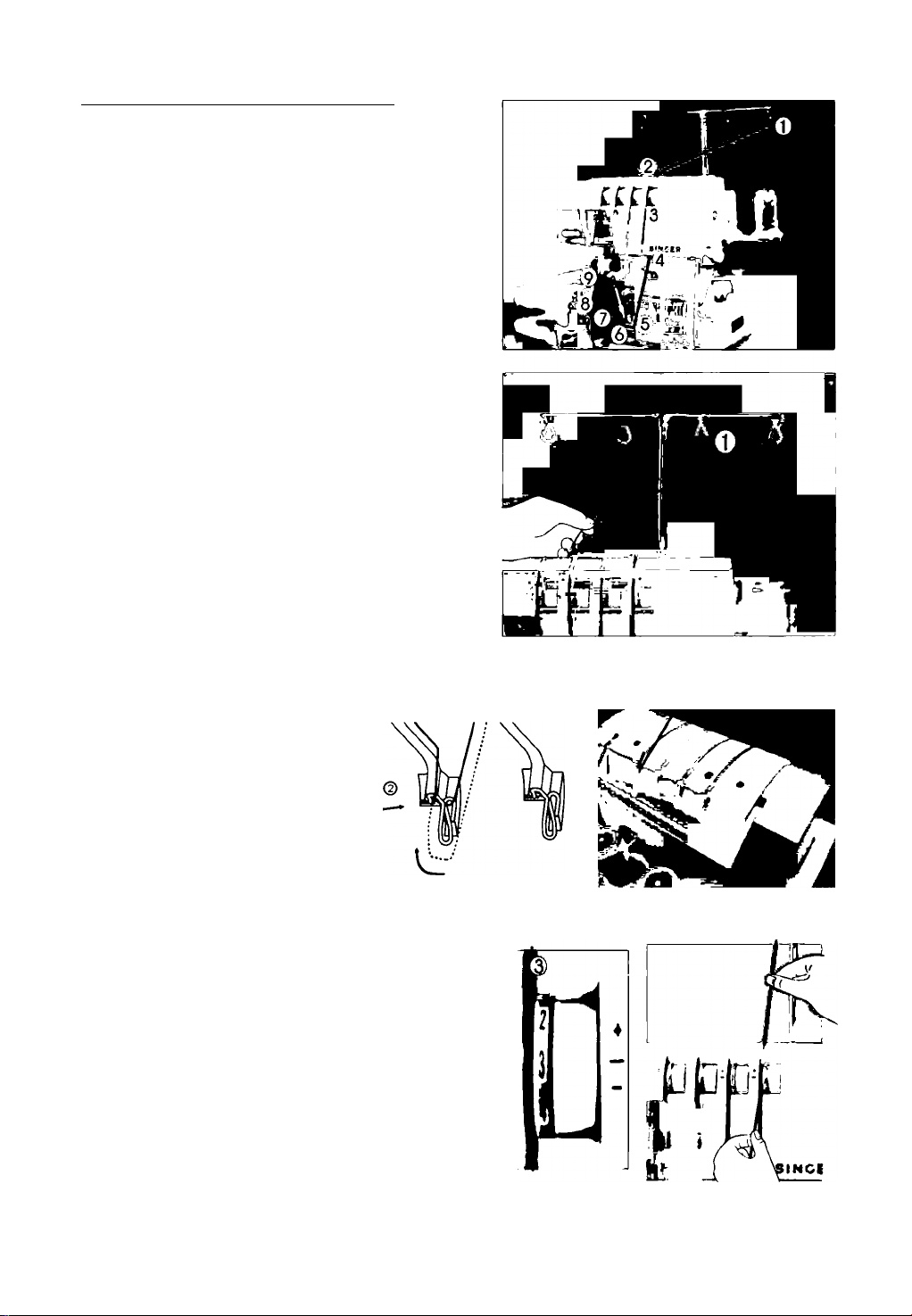

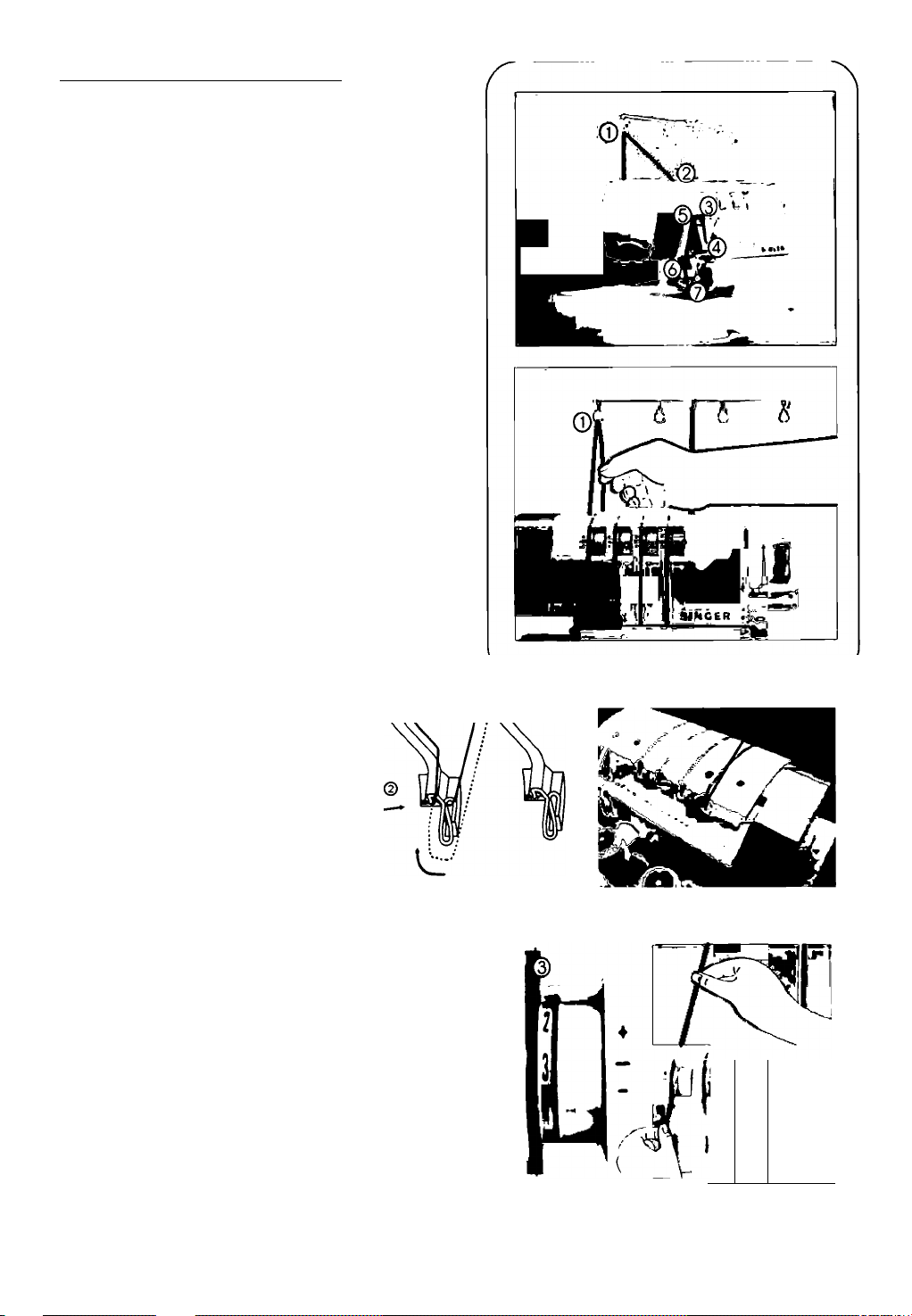

2) Threading the Lower Looper (Yellow)

• Thread the lower looper as indicated 1 ~ 9 .

Pass thread Irom back to the front through the

thread guide 1 .

Thread the top cover thread

guide by pulling the thread

downward until it slips under

thread guide 2 .

While holding thread with finger, pass it between

the tension discs and pull thread down to make

certain it is properly located in between the

tension discs 3 .

14

Page 17

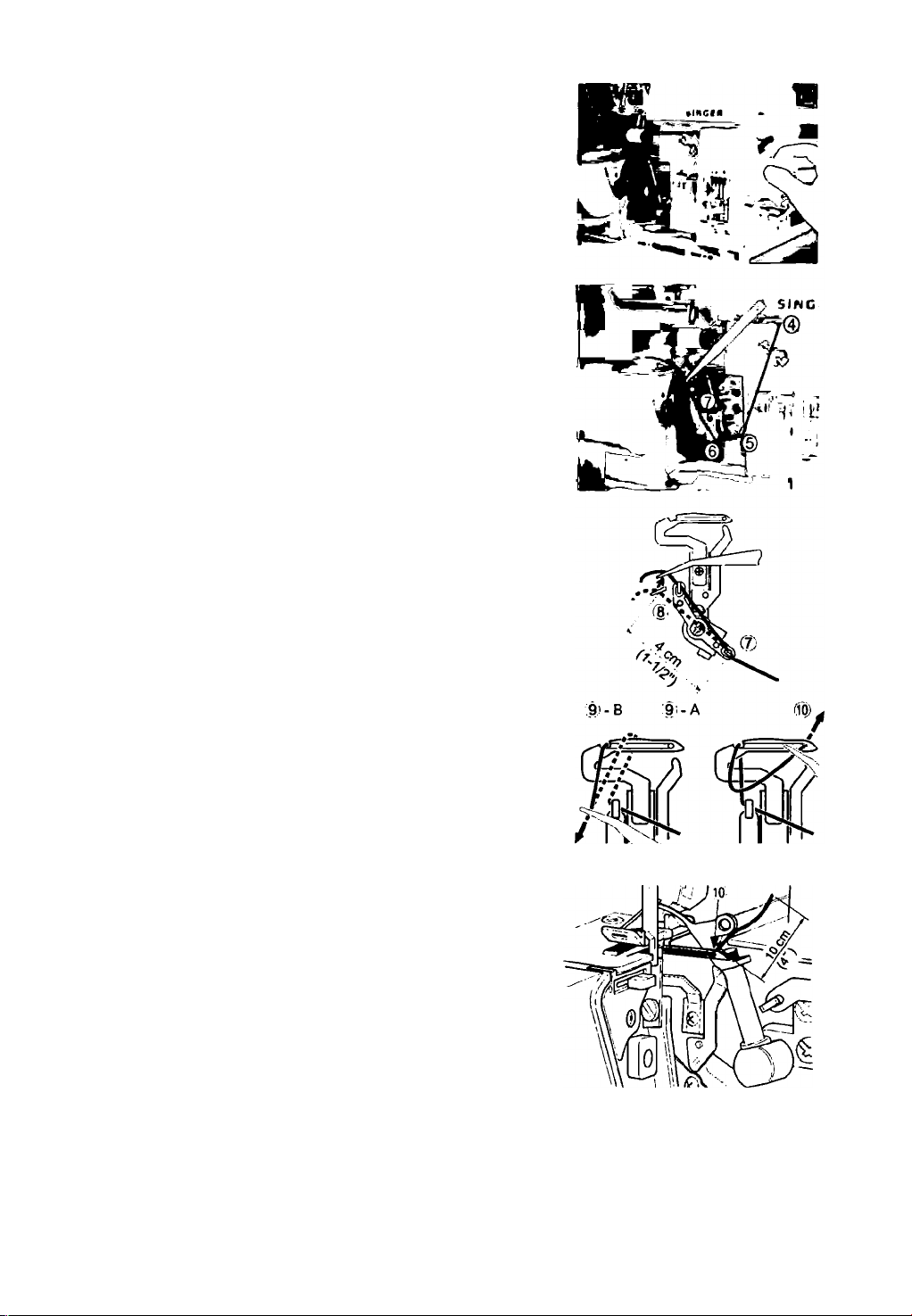

• Turn the hand wheel toward you until the lower

looper is at the far right.

Thread the looper area of the machine following

the yellow color coded thread guides 4 ~ 7 .

Note: Use the tweezers provided in the accessory

set to aid in threading the looper.

Grasp the thread with the tweezers 4 cm (1-1/2

inches) from thread guide 7.

Place the thread with the point of the tweezers

slightly under and to the left of threading guide 8.

Pull the thread up and into thread guide 8.

• Pass the thread behind and over the top end of

left looper 9-A.

♦ Then pull it downward gently so that it will slip

into the slot in the looper 9-B.

Pick up the thread and pass it through the hole in

the end of the looper 10 .

Note : Use the tweezers provided in the

accessory set to aid in threading the

looper.

The thread should be positioned in the groove of

the lower looper.

Pull about 10cm (4 inches) of thread through the

looper and place it over the top of the upper

looper and to the back of the throat plate.

15

Page 18

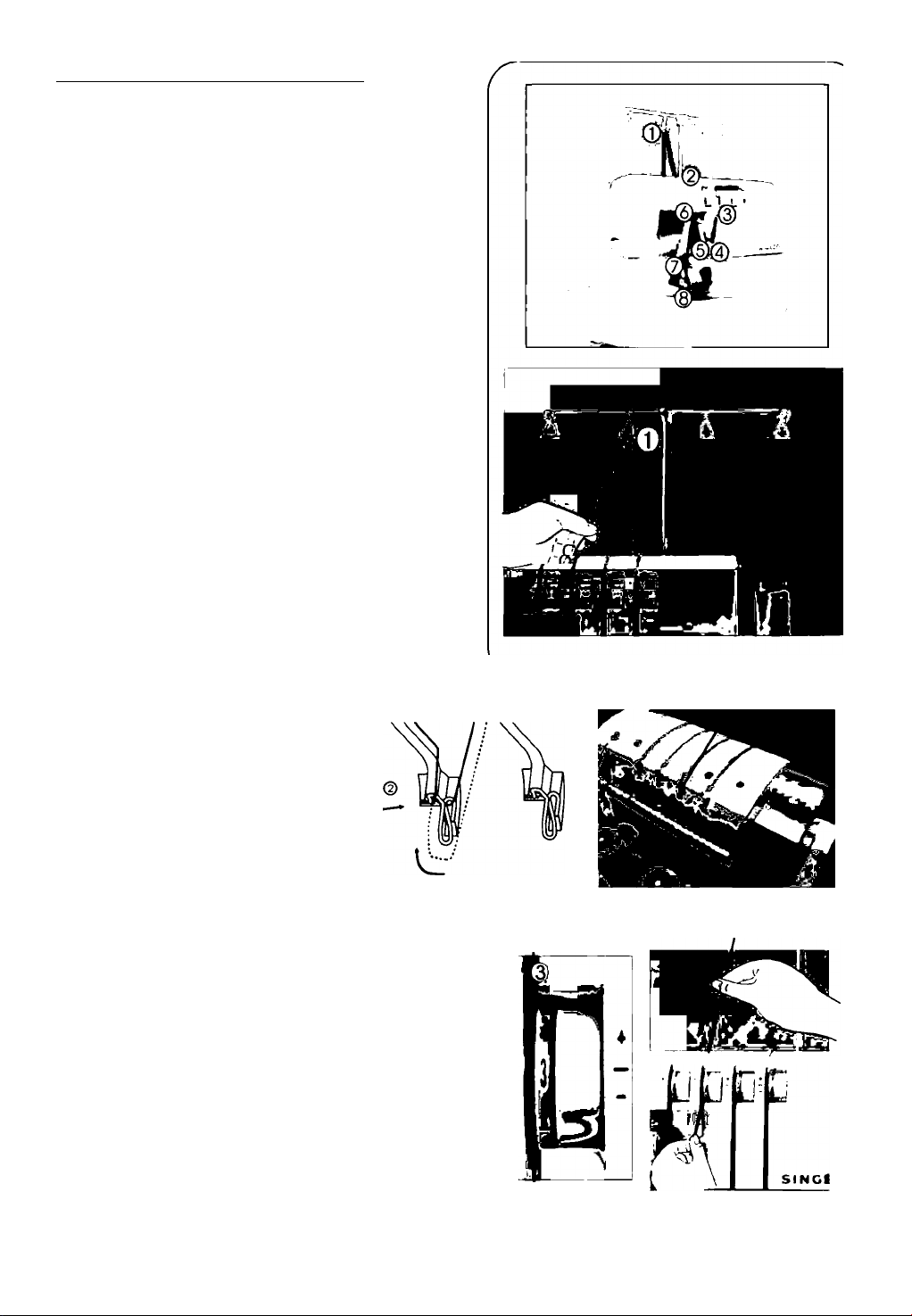

3) Threading the Right Needle (Green^

• Thread the right needle as indicated 1 ~ 8.

Pass thread from back to the front through the

thread guide 1 .

Thread the top cover

thread guide by pulling the

thread downward until it

slips under thread guide

2.

While holding thread with finger, pass it between

the tension discs and pull thread down to make

certain it is properly located in between the

tension discs 3.

16

Page 19

Continue to thread points 4 ~ 7 .

Note; Be sure to pass the thread through upper

thread path of the thread guide 6.

• Thread the eye of the right needle 8 .

Note; Use of tweezers in the accessory set will

make needle eye threading easy.

• Draw about 10cm (4 inches) of thread through

needle eye to hang free.

• Place the thread to the back, under the presser

foot.

17

Page 20

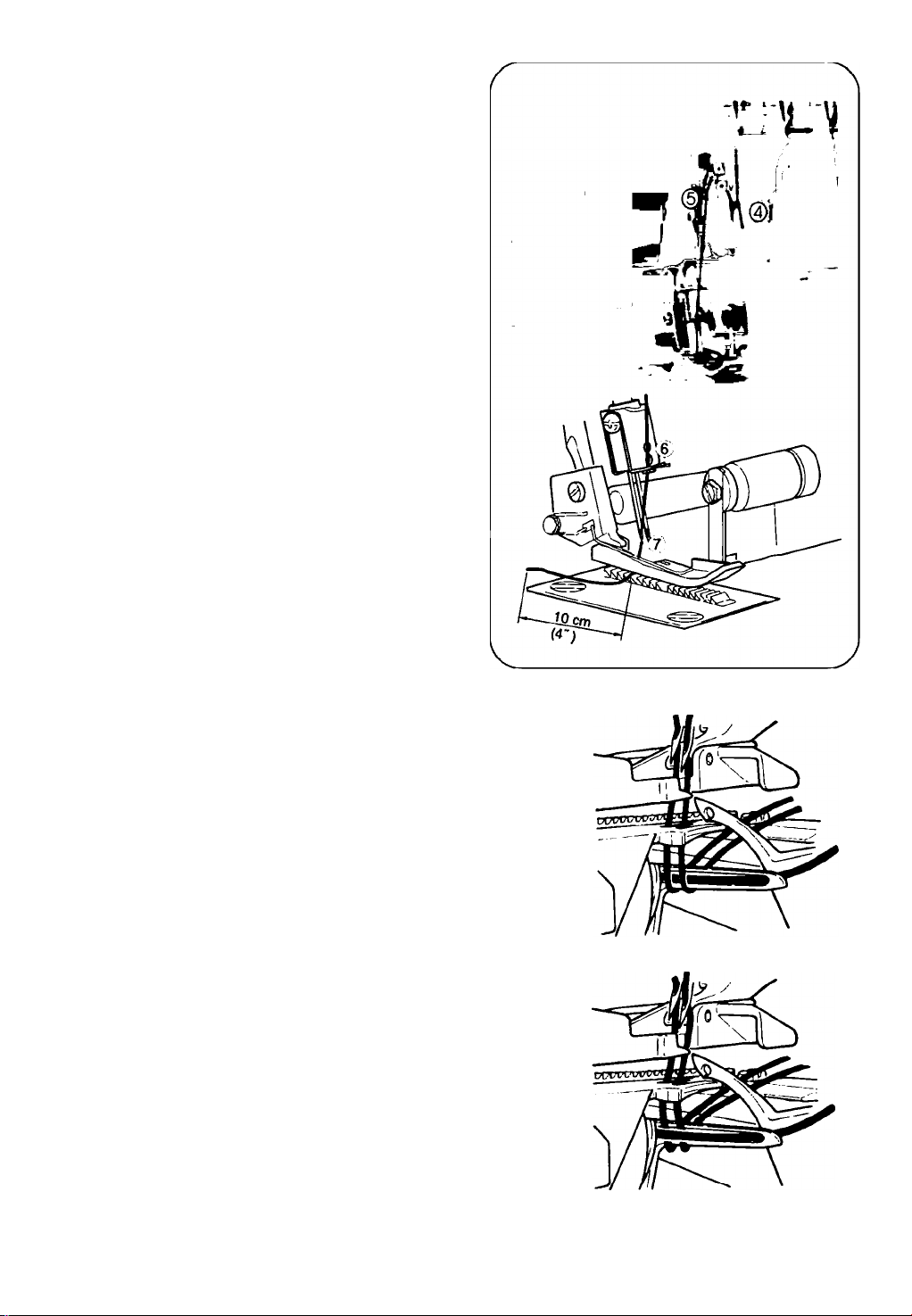

4) Threading the Left Needle (Blue^

Thread the left needle as indicated 1 - 7.

• Pass thread from back to the front through the

thread guide 1 .

Thread the top cover thread

guide by pulling the thread

downward until it slips

under thread guide 2 .

r

V

While holding thread with finger, pass if between

the tension discs and pull thread down to make

certain It is properly located in between the

tension discs 3.

f j-

L'

Tii

U

T

L

SINCI

18

Page 21

Continue to thread points 4 ~ 6 .

Note: Be sure to pass the thread through lower

thread path of the thread guide 5.

• Thread the eye of the left needle 7 .

Note: Use of tweezers in the accessory set will

make needle eye threading easy.

• Draw about 10cm (4 inches) of thread through

needle eye to hang free.

• Place the thread to the back, under the presser

foot.

Important Threading Information

• Always thread the needle(s) last to prevent

misthreading the lower looper.

• If the lower looper should come unthreaded;

1) Unthread the needle(s)

2) Thread the lower looper

3) Thread the needle(s)

* •

Correct

View

Wrong

View

19

Page 22

12. HOW TO CHANGE THREADS /

TIE ON METHOD

To change thread type or color, clip thread near the

spool.

Place new thread on stand.

Tie new thread and old thread ends together.

Clip thread tails to 2 ~ 3cm (1 inch) length.

If clipped too short, threads may come untied.

Firmly pull both thread to test knot security.

Note tension dial settings.

Turn the tension dials down until the dial stops.

• Pull the threads through the machine one at a time.

• If threads do not pull easily, check for tangles on

thread guides or looping under thread stand.

• When pulling thread through the needle, STOP when

the knot is in front of the needle.

•

• Cut the thread, and insert it through the needle.

• Return tension dials to previous settings.

20

Page 23

13. HOW то ADJUST THE STITCH

LENGTH

The stitch length dial should be set on the 3 mm

(1/8 inch) setting for most sewing conditions.

Adjust the stitch length to 4mm (5/32 inch) when

sewing heavy weight fabrics.

Adjust the stitch length to 2mm (5/64 inch) when

sewing light weight fabrics to obtain excellent seams

without puckering.

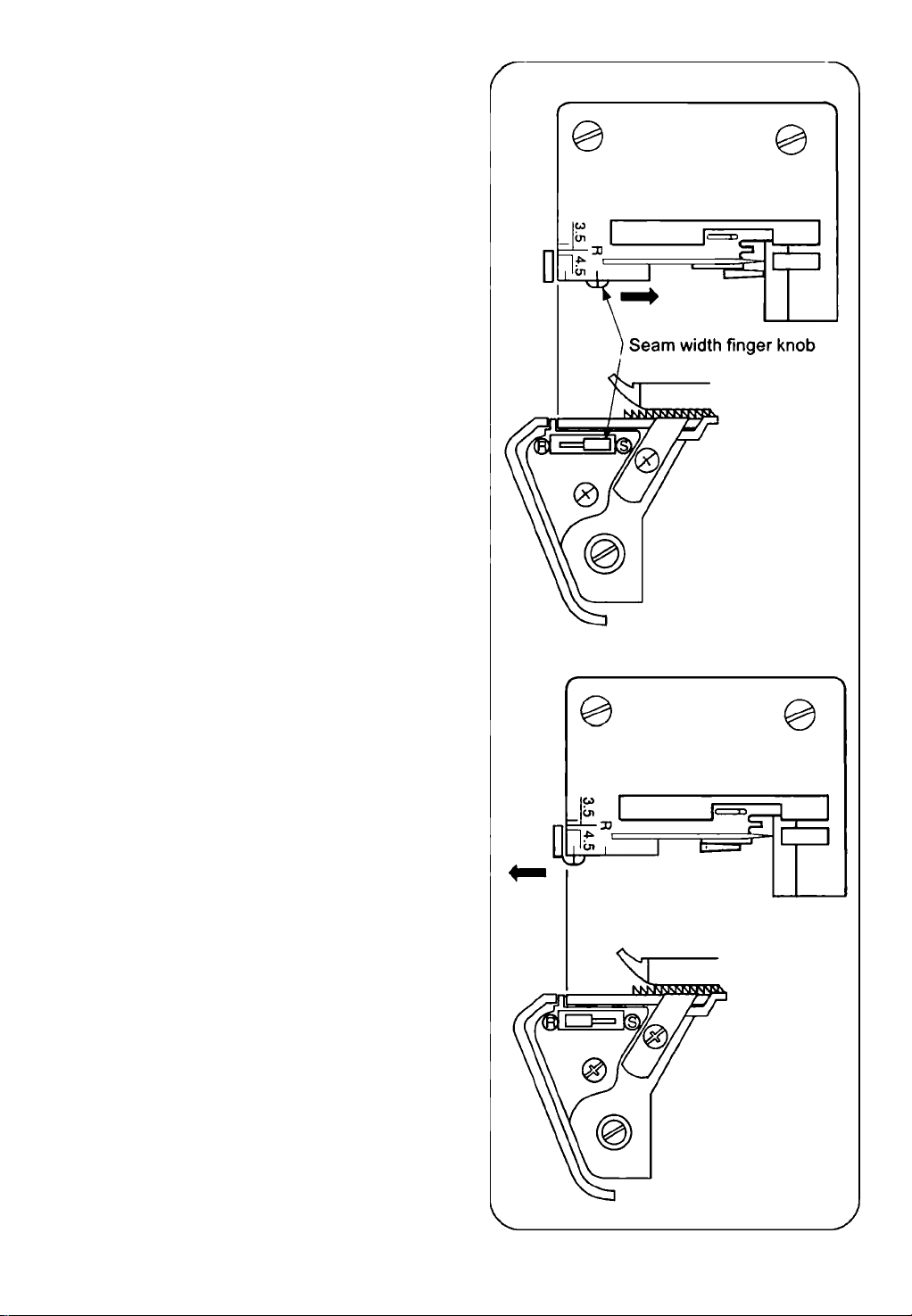

14. HOW TO ADJUST THE SEAM

WIDTH

• Overedge seam width can be achieved by

repositioning the needle position and also with the

width adjustment knob.

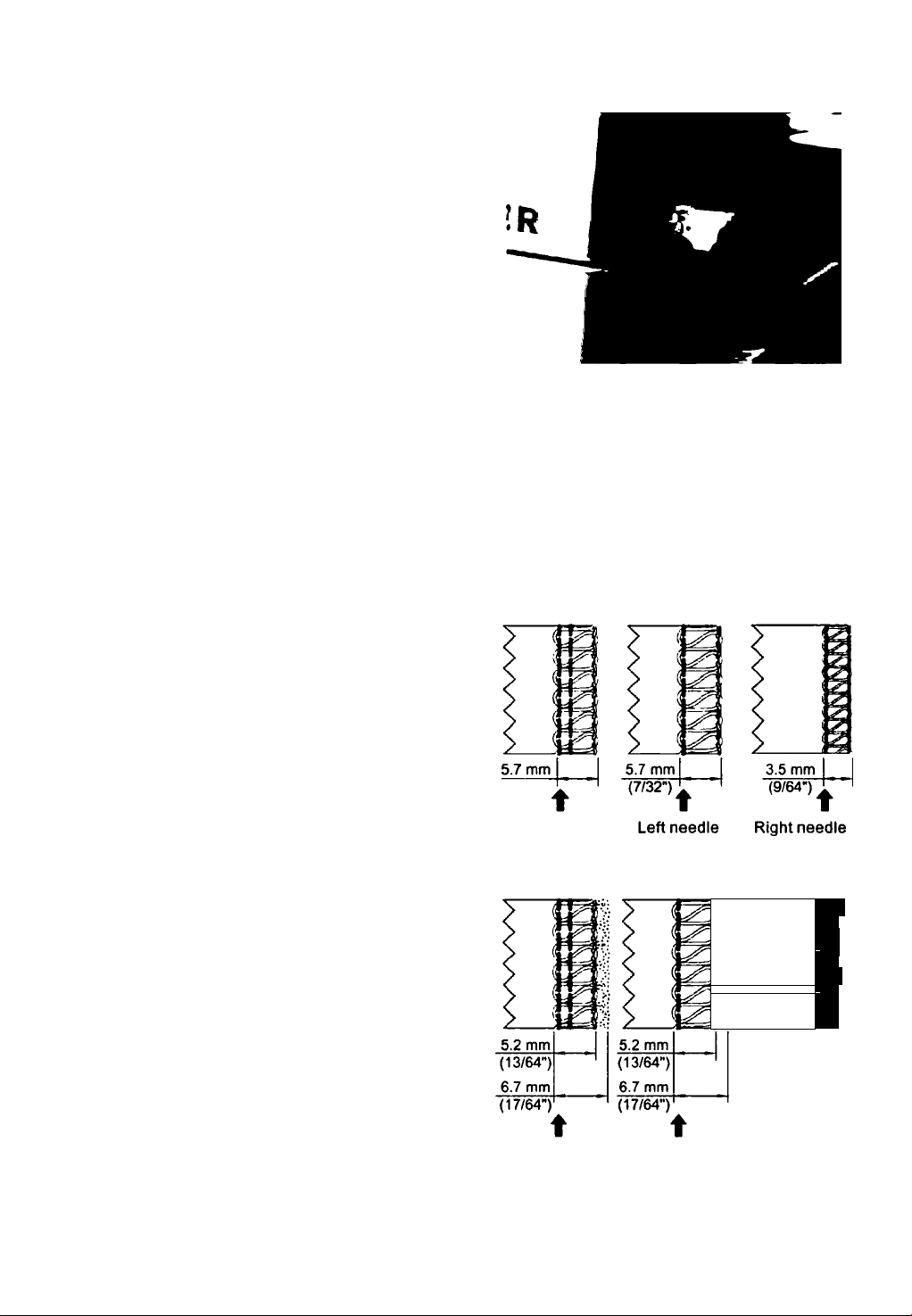

Width Adjustment by Changing Needle Position

Overedge seam width can be adjusted by changing

the needie position.

a) When only left needle is used.....................5.7 mm

(7/32 inch)

b) When only right needle is used

..................

3.5 mm

(9/64 inch)

Width Adjustment with Adjustment Knob

• Use of width adjustment knob will permit further

adjustment within the width range shown below,

a) When only left needle is used

b) When only right needle is used... 3.0 ~ 4.5 mm

..........

5.2 ~ 6.7 mm

(13/64 ~ 17/64 inch)

(1/8-11/64 inch)

(7/32")

Left/Right

needle

N 1

Й S !

0 \ %

/ 1

1 < ;

¿ / •

> !

3.0 mm

(1/8")

4.5 mm

(11/64")

t

Ri»

*Sf

Left/Right

needle

Left needle

Right needle

J

21

Page 24

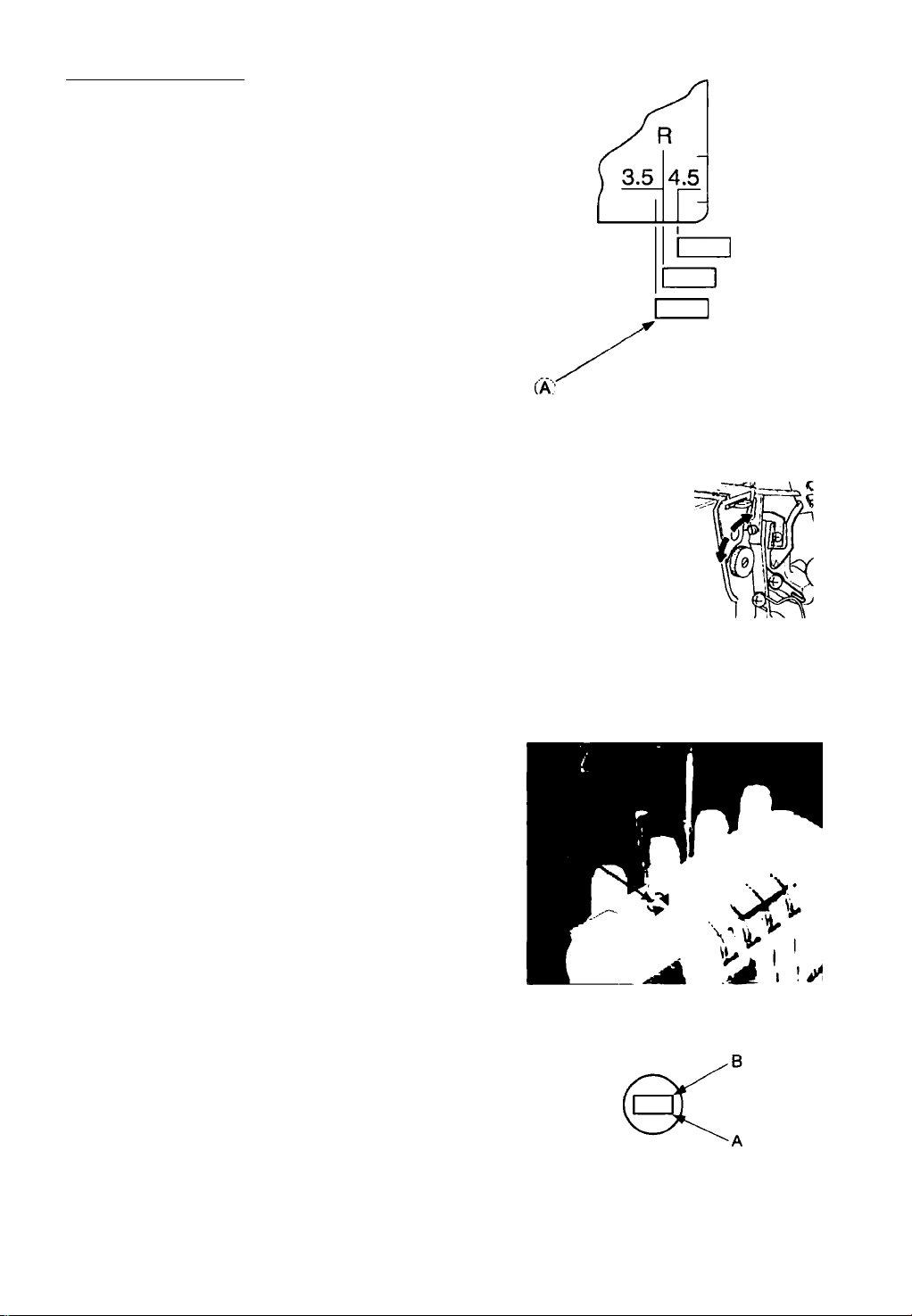

Width adjustment knob

Caulion:

Before making adjustments, be sure to turn off

A

power switch

Opening the looper cover will make adjustment

easier.

Push the upper knife to the right and while maintain

the knife in this position.tum the knob away to adjusts

the desired seam width,using te graduations on the

throat plate as a guideline.

Caution:

A

Always close looper cover before operating

machine.

Push«

4.5

3.5/Rolled hem

(When shipped

from (octoty.)

3.0mm

ÎD

15. HOW TO ADJUST THE PRESSER

FOOT PRESSURE

The presser foot pressure of this machine is

preadjusted at the factory to suit the sewing of

medium weight fabrics.

Most of the materials do not require adjustment of

presser foot pressure however, there are some

instances where adjustment is necessary when

sewing lightweight and heavyweight fabrics.

In such case, insert screwdriver through access hole

(A) in top cover and into slot (B) in pressure

regulating screw and turn regulating screw as

required.

Note: Turn regulating screw counterclockwise until

It stops against the top cover. Then turn

screw clockwise 6 turns which will be the

standard presser bar pressure.

For lightweight fabric ... Decrease the pressure

For heavyweight fabric ... Increase the pressure

s

22

Page 25

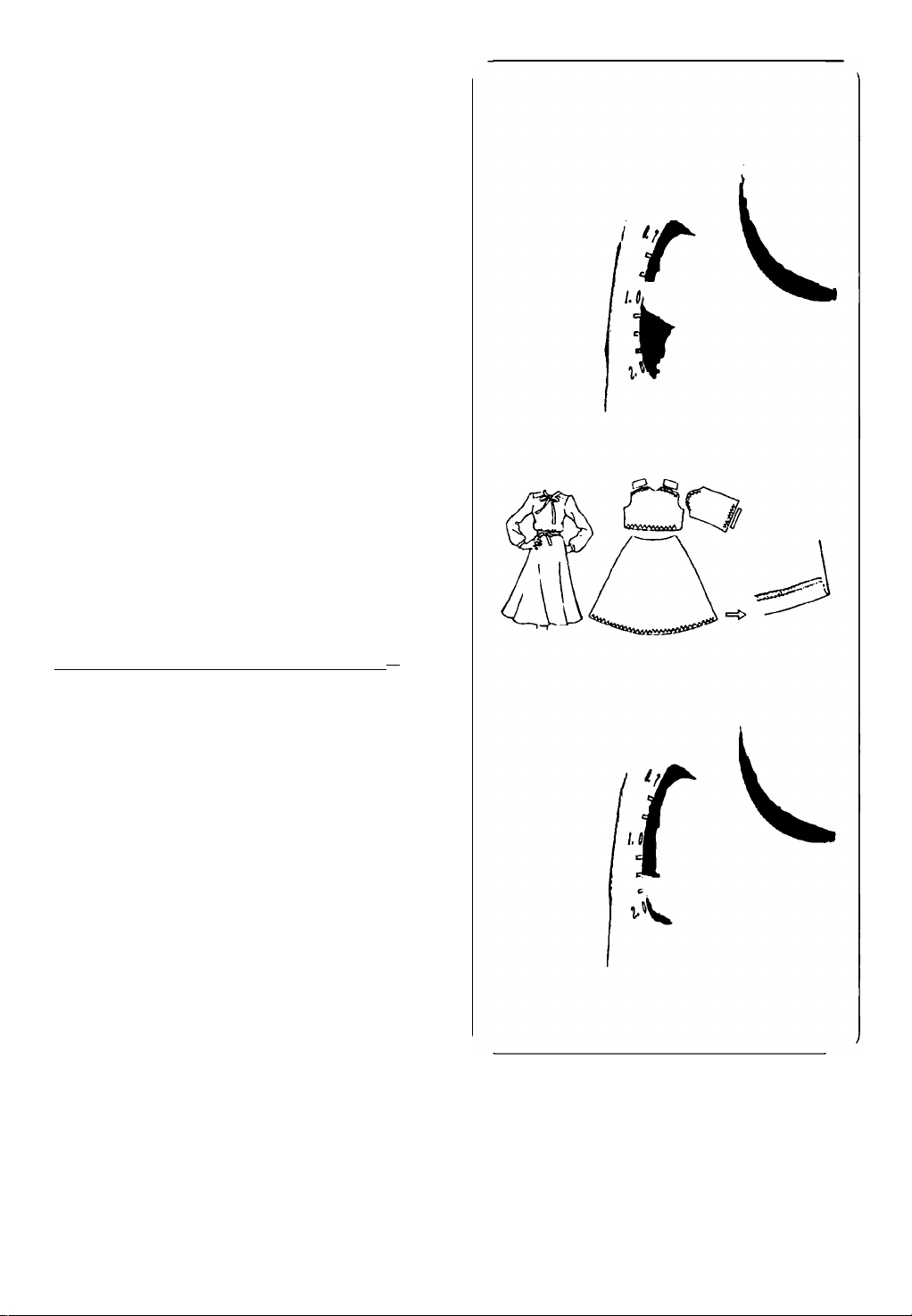

16. DIFFERENTIAL FEED

• Differential feed is a system which “stretches" or

"gathers" the fabric, when amount of feed of front

feed dog in relation to the rear feed dog is changed.

• The differential feed ratio ranges from 1 ; 0.7 ~

1 : 2.0. Adjustment is made by means of the

differential feed adjusting lever pictured below.

• Use of differential feed is very effective in overedging

stretch fabrics and fabrics cut on the bias.

• Graduation “1.0" is differential feed adjusting lever

setting for ratio 1:1.

Gathered Overedge

Gathered overedge is most suited for shirring

sleeves, yokes, front and back bodices, skirt hems,

etc. in stretch fabrics such as knits and jersey before

assembling into garment.

To set the differential feed adjusting lever

• Set differential feed adjusting lever knob below

graduation “1.0". Setting of adjusting lever knob

depends on material being sewn as well as the

amount of gather therefore set knob to suit the fabric

and test sew before sewing your garment.

• When feed regulating dial is set at "3" or over, the

amount of feed of the main feed dog will change to

"3“ automatically when adjusting lever knob is set

to 2.0.

Note: For normal overedge stitching, set differential

feed adjusting lever knob to graduation "1.0".

* •

23

Page 26

Stretch Overedge

stretch overedge is ideal for sewing decorative

collars, sleeves, skirt hems, etc. on loosely knit and

woven fabrics.

To set the differential feed adjusting lever

• Set differential feed adjusting lever knob above

graduation "1.0".

To sew a seam, apply gentle tension to the fabric

by holding the seam lightly in front and back of the

presser foot.

Note: * If amount of “stretch" is not correctly set in

relation to the fabric being sewn, the fabric

is apt to shift away from the needle

resulting in improperly sewn overedge

seam. In such case, reset differential feed

adjusting lever closer to the center mark.

* Be sure to reset the differential feed

adjusting lever to graduation "1.0" for

normal overedge stitching.

24

Page 27

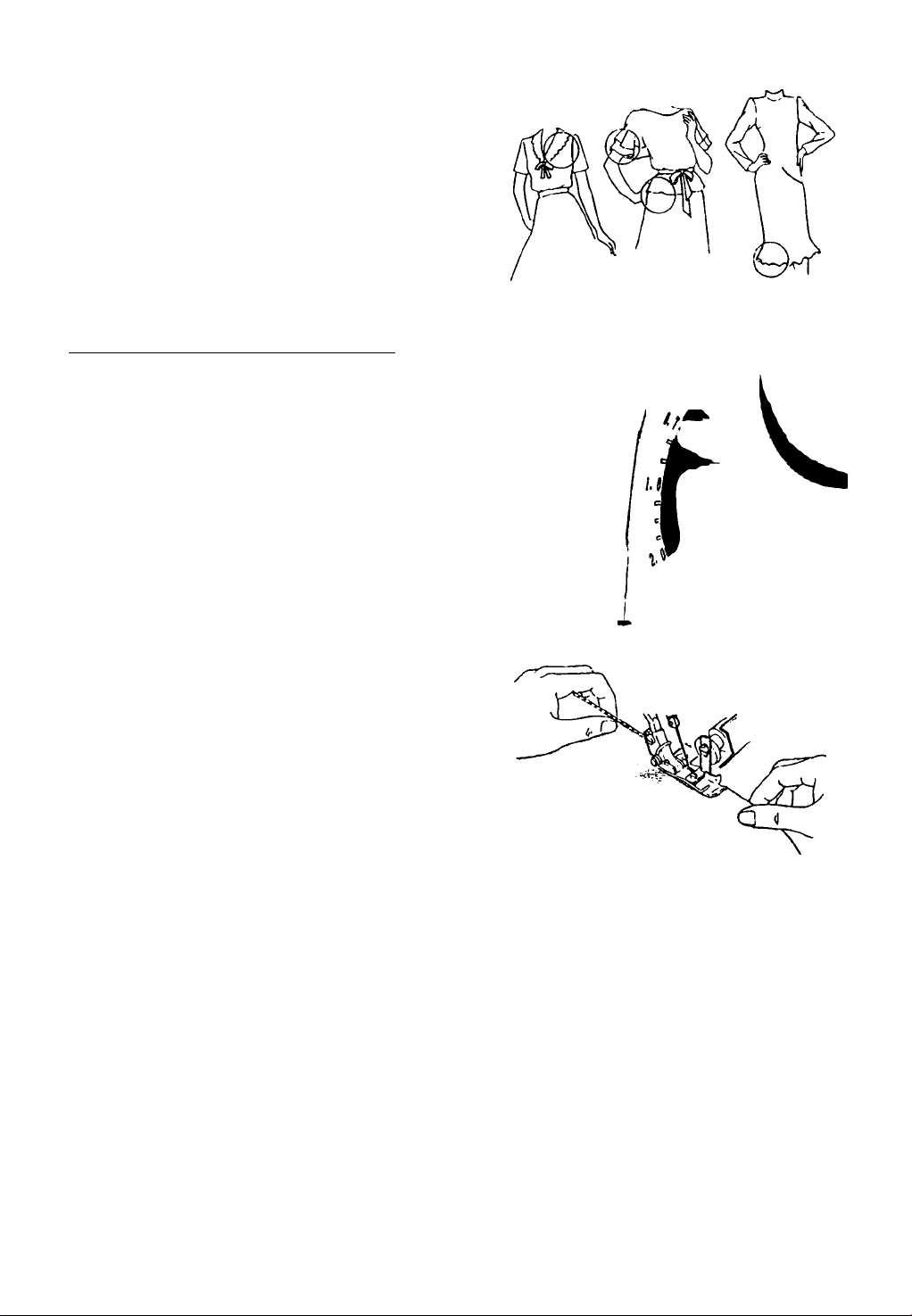

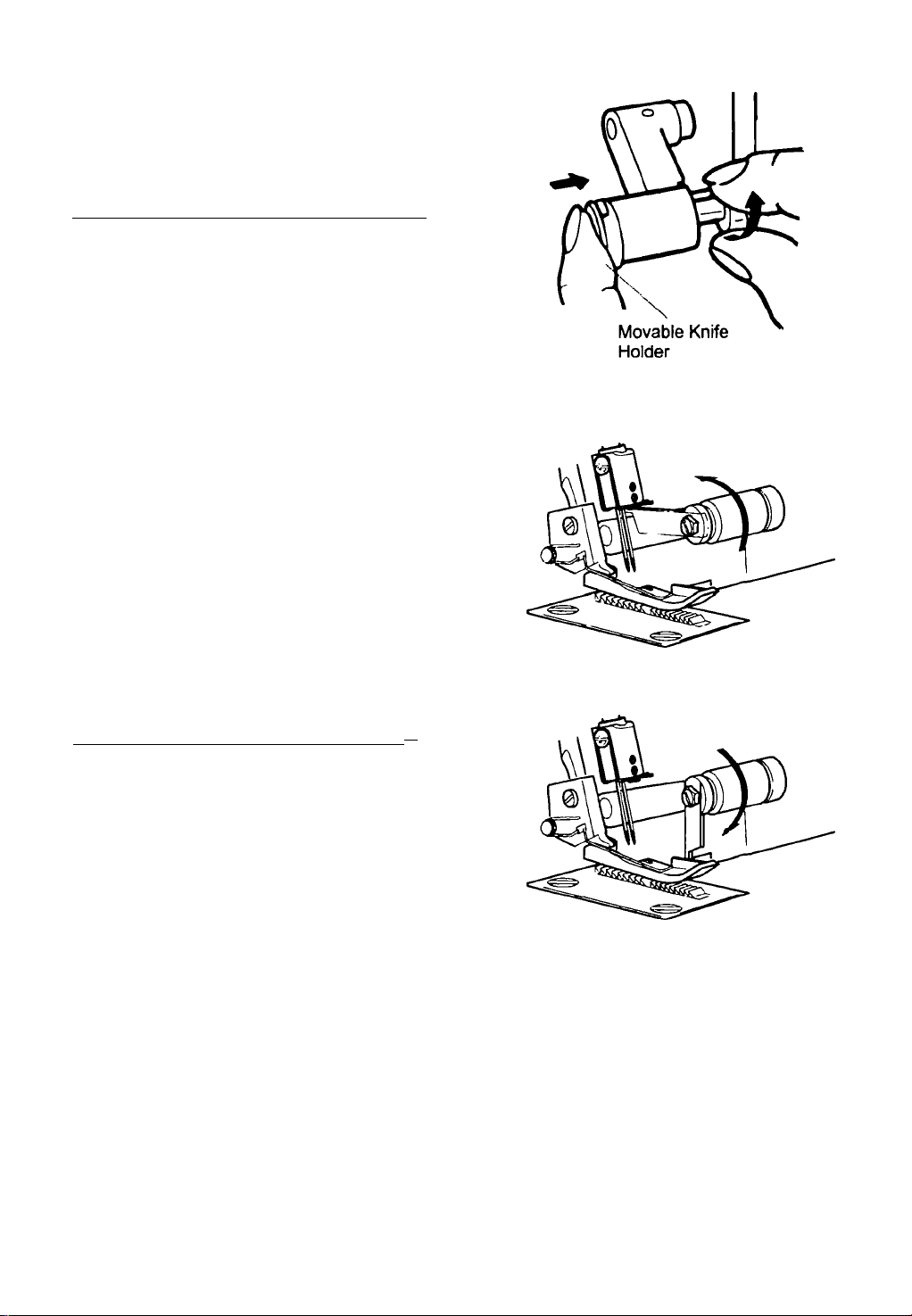

17. HOWTO DISENGAGE MOVABLE

UPPER KNIFE

Caution :

A

To place movable knife in nonworkina position

Be sure to turn off power switch.

• Turn handwheel over toward you and raise upper

knife to its highest position.

Open looper cover (page 9 ).

Push the movable knife holder to the right as far as

it will go.

Turn the knob away from you until the knife clicks

into a horizontal position.

Note: If the knife stops in the up position:

* Turn the hand wheel toward you until the

knife clears the top of the machine.

* Continue to rotate the knife to the horizontal

position.

To place movable knife in working position

• Open looper cover and push the movable knife

holder to the right as far as it will go.

• Turn the knob up and toward you until the knife

clicks into the working position.

Caution :

A

Always close looper cover before operating

machine.

* •

25

Page 28

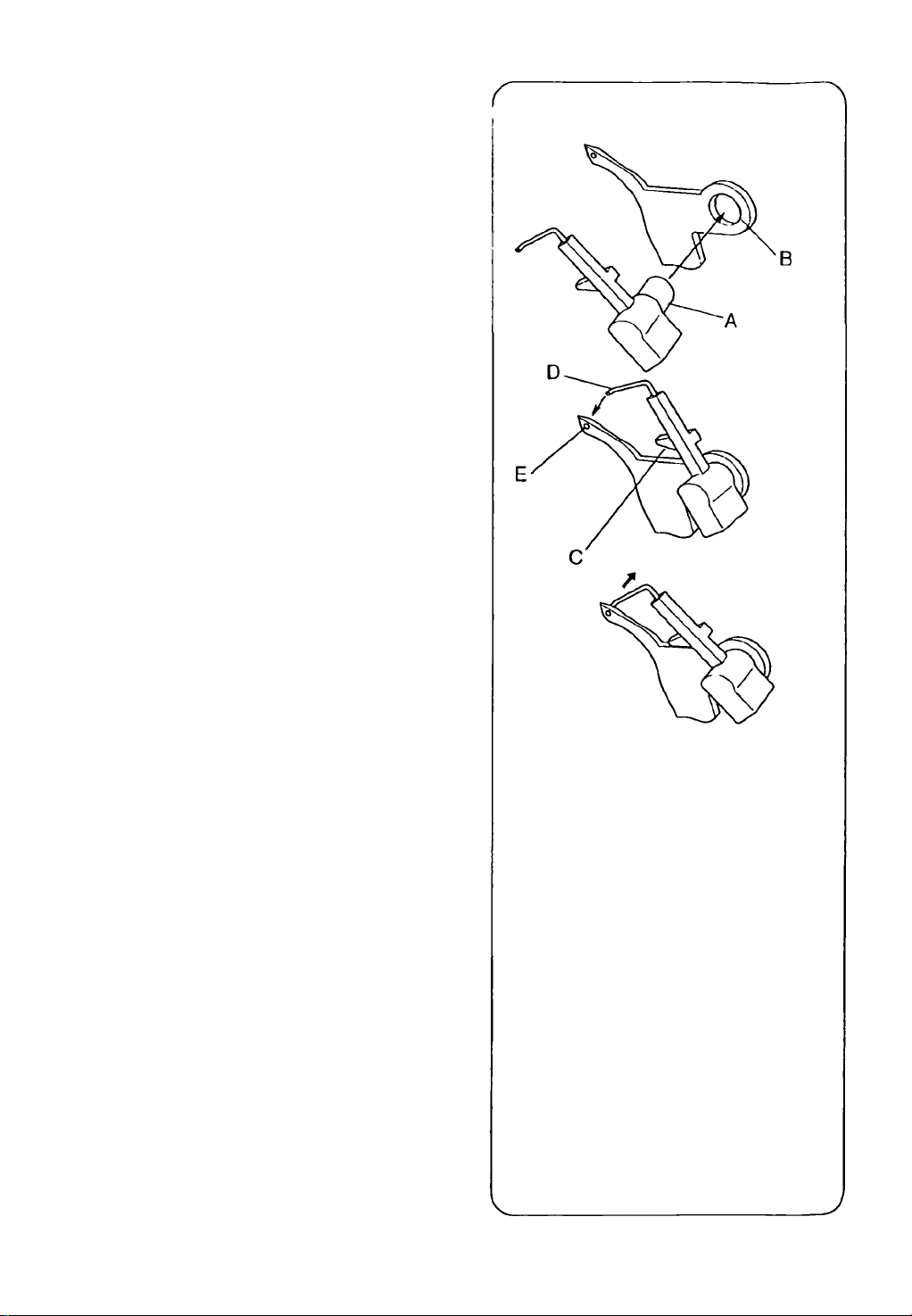

18. CONVERTING THE UPPER

LOOPER INTO SPREADER

Warning:

A

Switch off the machine before installing or removing the spreader.

Installing the spreader

Insert the pin (A) of the spreader in the

hole (B) of the upper looper.

Put the positioning rib (C) in contact

with the upper surface of the looper.

Insert the point (D) in the hole (E)

of the upper looper.

Removing the spreader

• Remove the point (D) of the hole (E)

of the upper looper and take the

spreader off the looper.

Note: Put the spreader back to the

accessory storage.

26

Page 29

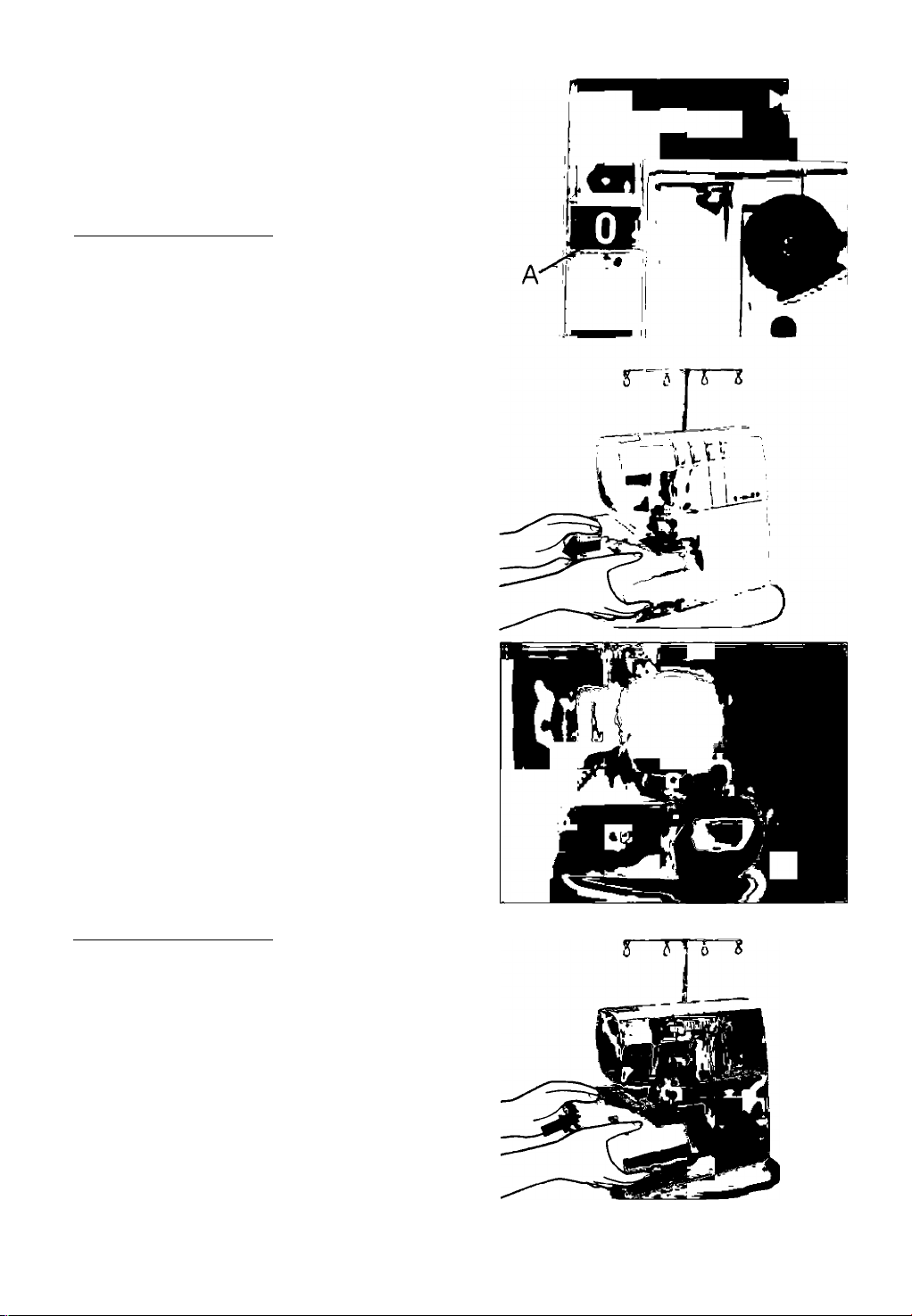

19. FREE ARM SEWING

(TUBULAR WORK)

This machine become a free arm machine simply

by removing the cloth plate.

To remove the cloth plate

Slide cloth plate to the left and remove from machine

while pressing button (A) located on the underside.

This is especially suited for sewing hard to reach

garment areas such as armholes and overcasting

trouser cuffs.

Place garment over the free arm and sew.

To replace the cloth plate

Align projection on cloth plate with groove in cylinder

cover and slide to the right until tab on cloth plate

(front) snaps into slot in cylinder cover.

27

Page 30

20. STANDARD OVEREDGE AND

ROLLED HEM STITCHING

To Sew Standard Overedge

Set seam width finger knob to S to move seam

width finger to projected position.

Note: Be sure to push seam width finger knob as

far as it will go in the direction of setting S .

To Sew Rolled Hem

Set seam width finger knob to R to retract the

seam width finger.

Note: Be sure to push seam width finger knob as

far as it will go in the direction of setting R .

28

Page 31

21. CHAINING OFF AND TEST

SEWING

• When the machine is completely threaded, bring all

of the threads over the throat plate and slightly to

the left under the presser foot.

• Hold the threads and apply a slight tension.

• Turn the hand wheel toward you 2 or 3 complete

turns to start the thread chain.

• Lower presser foot.

• Continue holding the chain and press on the foot

controller until the chain is 5 ~ 7.5cm (2-3 inches)

in length.

Place fabric under the front of the presser foot and

sew a test sample.

Note; Do not pull on the fabric while sewing as this

may deflect the needle, causing it to break.

29

Page 32

NEEDLE POSITION

SEAM WIDTH FINGER KNOB

STITCH LENGTH

SPREADER

to o\

2-4

USE

Needle thread

Topside

Fabric

Light weigt

Medium weight

Heavy weight

Fabric

Light weigt

Tension Dial

Green

Blue

2.5

3.5

4.0

Tension Dial

Blue Green Orange Yellow

2.5

Medium weight 4.0

Heavy weight

Needle thread

5.0 Spreader2.0

r looper

thread

Underside (502)

Orange

Yellow

Spreader

Spreader

Spreader

Spreader

Spreader

1.0

1.0

1.0

2.0

2.0

30

Topside

Needle thread

Topside

Lower looper

thread

Underside

r looper

thread

Underside

Page 33

2) 2-Thread standard rolled hem stitching

NEEDLE POSITION

Note; * These are suggested tension settings only.

+ Tension settings are effected by;

1) Type and thickness of fabric

2) Needle size

3) Size, type and fiber content of thread

* See page26 to converting the upper looper

into spreader.

Correct Balance

• Set Each Tension Dial to Settings Shown at Right

and Test Sew on a Sample of Your Fabric

_____________________________

SEAM WIDTH FINGER KNOB

STITCH LENGTH

SPREADER

Lower looper

thread

Topside

Fabric

Light weigt

Medium weight

Heavy weight 1.0

Fabric

Light weigt

Medium weight

Heavy weight 1.0

Tension Dial

Green

Blue

0

0.5

Tension Dial

Blue Green Orange Yellow

0

0.5

2-4

USE

(503)

Orange Yellow

Spreader

Spreader

Spreader

Spreader

Spreader

Spreader

5.0

5.0

5.0

5.0

6.0

6.5

How to Balance

• When the lower looper thread is botton side of the

fabric.

- Turn the lower looper thread tension dial(yellow)

toward a higher number.

- Or, turn the needle thread tension dial (blue or

green) toward a lower number.

• When the needle thread tension is too loose;

- Turn the needle thread tension dial (blue on green)

toward a lower number.

- Or, turn the lower looper thread tension dial (yellow)

toward a lower number.

Lower looper

thread

Topside

Lower looper

thread

Topside

Needia thread

Underside

31

Page 34

3) 3-thread Overlook

Note; * These are suggested tension settings only.

T Tension settings are effected by.

1) Type and thickness of fabric

2) Needle size

3) Size, type and fiber content of thread

Correct Balance

Set Each Tension Dial to Settings Shown at Right

and Test Sew on a Sample of Your Fabric

NEEDLE POSITION

SEAM WIDTH FINGER KNOB S

STITCH LENGTH 2-4

Upper looper thread

___________

•O

/

Needle thread

Topside

Fabric

Light weight 2.5

Medium weight

Heavy weight

Blue Green Orange Yellow

3.0

3.5

Underside

Tension Dial

3.0 3.0

3.0 3.0

3.0

(504)

3.0

How to Balance

When the upper looper thread lies on the underside

of the fabric;

- Turn the upper looper thread tension dial

(orange) to a higher number.

- Or, turn the lower looper thread tension dial

(yellow) to a lower number.

When the lower looper thread appears on the top

of fabric;

- Turn the lower looper thread tension dial (yellow)

toward a higher number.

- Or, turn the upper looper thread tension dial

(orange) to a lower number.

When the needle Ihread is too loose, turn the

needle tension dial (blue or green) to a higher

number.

Fabric

Light weight

Medium weight

Heavy weight

Upper looper thread

Needle thread

Topside

Upper loop>er thread

Needle thread

Topside

Upper looper Ihread

Needle thread

Topside

Tension Dial

Blue Green Orange Yellow

2.5 3.0 3.0

3.0 3.0 3.0

3.0 3.0

3.5

Lower looper

thi^d

Underside

er looper

th(oad

Underside

Lower looper

Ihread

Underside

32

Page 35

4) 3-thread Flatlock

Note; * These are suggested tension settings only

» Tension settings are effected by;

1) Type and thickness of fabric

2) Needle size

3) Size, type and fiber content of thread

Correct Balance

Set Each Tension Dial to Settings Shown at Right

and Test Sew on a Sample of Your Fabric

NEEDLE POSITION •O

SEAM WIDTH FINGER KNOB S

STITCH LENGTH 2-4

Needle thread

Topside

Fabric

Light weight 0.5

Medium weight

Heavy weight

Tension Dial

Blue Green Orange Yellow

0.5 5.0 7.0

0.5

Needle wread

Underside

5.0

5.0

O*

(505)

7.0

7.0

How to Balance

• When the lower looper thread tension is too loose;

- Turn the lower looper thread tension dial (yellow)

toward a higher number.

- Or, turn the needle thread tension dial (blue or

green) toward a lower number.

When the upper looper thread tension is too loose;

- Turn the upper looper thread tension dial

(orange) toward a higher number.

- Or. turn the needle thread tension dial (blue or

green) toward a lower number.

When the needle thread tension is too loose;

- Turn the needle thread tension dial (blue or

green) toward a higher number.

- Or, turn the upper looper thread tension dial

(orange) toward a lower number.

Blue

Tension Dial

Green

Fabric

Light weight 0.5 5.0

Medium weight

Heavy weight

0.5 5.0 7.0

0.5

Needle thread

Upper looper

thread

Topside

Needle thread

Upper looper

thread

Topside

Needle thread

Upper looper

thread

Topside

Orange Yellow

5.0

Needle thread

Lowdr looper

thread

Underside

'Needle thread

Lower looper

thread

Underside

Needle thread

Lower looper

thread

Underside

7.0

7.0

33

Page 36

5) 3-thread Wrapped Edge Overlock

Note: * These are suggested tension settings onl/.

■r Tension settings are effected by;

1) Type and thickness of fabric

2) Needle size

3} Size, type and fiber content of thread.

Correct Balance

Set Each Tension Dial to Settings Shown at Right

and Test Sew on a Sample of Your Fabric

NEEDLE POSITION

SEAM WIDTH FINGER KNOB

STITCH LENGTH

Needle thread

Upper looper

thread

Topside

Fabric

Light weight 4.0 0 8.0

Medium weight

Heavy weight

Tension Dial

Green

Blue

5.0 0 8.5

5.0 0 8.5

»O

2-4

Underside

Orange

Yellow

How to Balance

When the upper looper thread tension is too loose;

- Turn the upper looper thread tension dial

(orange) toward a higher number

When the lower looper thread tension is too loose;

- Turn the lower looper thread tension dial (yellow)

toward a higher number.

- Or, turn the upper looper thread tension dial

(orange) toward a lower number.

When the needle thread tension is too loose;

- Turn the needle thread tension dial (blue or

green) toward a higher number.

- Or, turn the upper looper thread tension dial

(orange) toward a lower number.

Fabric

Light weight

Medium weight

Heavy weight

Needle thread

Upper looper i

thread

Topside

Needle thread

Upper looper

thread

Topside

Needle thread

Upper looper

thread

Topside

Tension Dial

Blue Green Orange Yellow

2.5 1.0

3.0 1.0 7.0

3.5 1.0 7.0

PPPPPP

PPIWP

/

7.0

pwer looper

sad

Underside

iwer looper

tht^d

Needle thread

Underside

.ower looper

'ead

thread

Underside

34

Page 37

6) 4-thread Ultra Stretch Mock Safely Stitch

Note; * These are suggested tension settings only.

* Tension settings are effected by:

1) Type and thickness of fabric

2) Needle size

3) Size, type and fiber content of thread

Correct Balance

Set Each Tension Dial to Settings Shown at Right

and Test Sew on a Sample of Your Fabric

How to Balance

When the upper looper thread lies on the underside

of the fabric;

- Turn the upper looper thread tension dial

(orange) to a higher number.

- Or, turn lower looper thread tension dial (yellow)

to a lower number.

When the lower looper thread appears on the top

of the fabric;

- Turn lower looper thread tension dial (yellow)

toward a higher number

- Or, turn the upper looper thread tension dial

(orange) toward a lower number.

When the left needle thread tension is too loose;

- Turn the left needle thread tension dial (blue)

toward a higher number.

When the right needle thread tension is too loose;

- Turn the right needle thread tension dial (green)

toward a higher number.

NEEDLE POSITION

SEAM WIDTH FINGER KNOB

STITCH LENGTH 2-4

Upper looper thread

Right

needle Left

thread

Topside

Fabric

Light weight

Medium weight

Heavy weight

Upper looper thread

Right /

needle

thread

Topside

Right /

needle

thread

Topside

Right /

needle "

thread Left

Topside

Right

needle . _

Topside

thread

Blue Green

2.5 2.5

3.0 3.0 3.0 3.0

3.5 3.5 3,0

Left

needle

thread

Upper looper thread

Left

needle

thread

Upper looper thread

needle

thread

Upper looper thread

ne^le

Underside

Tension Dial

Orange Yellow

3.0 3.0

Underside

Underside

Lower

looper

thread

(514)

3.0

Lower

looper

thread

Underside

Lower

looper

thread

Underside

Lower

looper

thread

Lower

looper

thread

35

Page 38

23. HOW TO SEW A ROLLED HEM

This machine can sew four types of rolled hems.

Rolled hemming is done by rolling and overedging

the fabric edge.

Light weight fabrics such as lawn, voil, organdy,

crepe, etc. perform the best.

Rolled hemming is not suited for heavy or stiff

fabrics.

Machine Set Up

• Remove the left needle.

• Move seam width finger knob to setting R . (See

page 28)

• Align left face of seam width finger support plate

with R mark on throat plate by turning seam width

finger knob, as required.

• Set stitch length dial to “F ' 2" and a fine seam will

be sewn.

• Needle: Singer Needle it2022 size 80/11 or 90/14

• Thread: A variety of thread combinations can be

used for rolled hemming.

36

Page 39

NEEDLE POSITION

SEAM WIDTH FINGER KNOB

STITCH LENGTH

SPREADER

F~2

USE

r looper

ttnead

(502)

Upper looper

thread

Polyester

Wooly nylon

Lower

thread

Upper looper

thread

Wooly nylon

Tension Dial

Green

Blue

Blue Green Orange Yellow

Orange

3.0 2.0

3.0 2.0

Tension Dial

2 . 0 4 . 0

Yellow

37

Page 40

NEEDLE POSITION

SEAM WIDTH FINGER KNOB

STITCH LENGTH F~2

Upper looper thread

Upper looper

thread

Polyester

Wooly nylon

Upper looper

thread

Topside

Upper looper

thread

Tension Dial

Green

Blue

3 . 0

3 . 0 3 . 5 3 . 5

Needle thread

Tension Dial

Blue Green Orange Yellow

Polyester 2.0

Wooly nylon

2.0

Orange

5 . 0 3 . 0

Underside

5.0

2.0

Yellow

7.0

5.0

38

Page 41

Additional Information About Rolled Hemming

• Hold the thread chain when you begin sewing to

keep it from curling into the seam.

Place a slight tension on the material in the sewing

direction and a finer seam finish can be obtained.

The minimum overedge stitch width that can be

obtained for rolled hemming is approximately 1.

5mm (1/16 inch) since the cutting width cannot be

set below 3.5mm (9/64 inch).

To Secure the Rolled Hem Thread Chain

• Apply a small drop of liquid seam sealant to the

end of the seam. Allow to dry, then cut the chain

close to the stitches.

Note: Test the liquid seam sealant for color

fastness before use.

39

Page 42

24. STITCH VARIATIONS AND

SEWING TECHNIQUES

How to Sew a Flatlock Decorative Seam

A flatlock stitch is achieved by adjusting the tension

of the 3-thread overlock stitch, sewing the seam and

pulling the fabric apart to flatten the seam.

The flatlock stitch can be used as a construction

and decorative stitch or for ornamentation only.

Machine Set Up_________________________________

• Remove the left or right needle.

• Begin with the machine threaded and tension

balanced for the 3-thread overlock stitch

(page 29 ).

• Loosen the needle thread tension (green or blue)

generously.

• Loosen the upper looper thread tension (orange)

slightly.

• Tighten the lower looper thread tension (yellow)

generously.

(2) Flatlockina a Seam

• Place the fabric wrong sides together to sew a

decorative stitch on the right side of the garment.

_

/J—«.

0 0 0 0

Remove

(f

-- -- - --

L

Remove

• Sew the seam, trimming the excess fabric.

The needle thread (green or blue) will form a V

on the underside of the fabric.

The lower looper thread will pull into a straight

line at the fabric edge.

40

Needle thread

Upper looper thread

Topside

Needle thread

Lower looper thread

Underside

Page 43

Pull on opposite sides of the seam to pull th«

stitches flat.

(3) Decorative Flatlocking

Place the movable upper knife in the nonworking

position (page 25). The fabric is not trimmed or

this stitch.

Fold fabric wrong sides together.

Position the fabric so the seam is sewn with par

of the stitch extending off the fabric.

Pull on opposite sides of the stitch to flatten.

(4) Additional Information About Flatlocking

• The tensions must be correctly adjusted for the

fabric to pull flat.

• The upper looper thread is the prominent thread

in the flatlock stitch. Place a decorative thread

in the upper looper and inconspicuous threads

in the lower looper and needle.

• For a ladder stitch, sew seam with right sides

together The needle thread will be the prominent

thread that creates the ladder (A).

41

Page 44

How to Sew an Overlook Blind Hem

• The excess fabric is trimmed and the hem is sewn

and the raw edges are overlooked in one operation.

• The overlook blind hem is best suited for sewing

knit wear. It provides a durable finish that is almost

invisible.

• Remove the left needle and adjust machine for a

narrow 3-thread overlook stitch.

Note; The three-thread flatlock stitch can also be

used.

• Set the stitch length dial at 4.

0 0

• Fold the hem to the wrong side of the fabric, then

back to the right side with 6mm (1/4") beyond the

fold.

• Stitch on the extended hem edge, allowing the

machine needle to barely catch the edge of the fold.

How to Sew Pin Tucks

• Sew decorative pin tucks on the fabric before cutting

out the garment.

• Remove the left needle and adjust machine for a

narrow 3-thread overlook stitch.

Note; The rolled hem stitch can also be used for

this technique.

Remove

• Place the movable upper knife in the nonworking

position (page 25).

• Mark the fabric with the desired number of pin tucks

using a water soluble fabric marker.

42

Page 45

• Fold the fabric with the wrong sides together and ^

sew.

Press the pin tucks in the same direction.

Turning Square Corners

(1) Outside Corner

• Cut out approximately 2 cm (51/64 inch) from the

corner, in line with the overedge seam edge.

• Sew one stitch beyond point (A) and stop.

• Raise needle and presser foot.

• Pull the fabric to the rear of the machine just

enough to release the thread caught on the finger

of the throat plate.

Note: Presser foot has been removed to show

detail.

• Turn the fabric and lower the presser foot so that

the knife is positioned in line with the cut edge.

Cutting line"^

2 cm

12 cm

• Pull slack threads up, then start to sew.

(2) Inside Corner

Cut fabric at seam edge.

/'I

Cuttingi line I

V

Cut Slit

43

Page 46

• Place the movable upper knife in nonworking ^

position (page 25).

• Stitch on cut edge of fabric.

• Stop sewing before you reach the corner and fold

the fabric to the left to straighten the corner.

Continue to sew slowly holding the fabric edge in

a straight line moving the fold as you sew.

[ Pin Placement

Insert pins to the left of the presser foot. The pins

will be easy to remove and are away from the cutting

action of the knives.

Caution:

A

Sewing over pins will damage and/or destroy

the cutting edge of the knives.

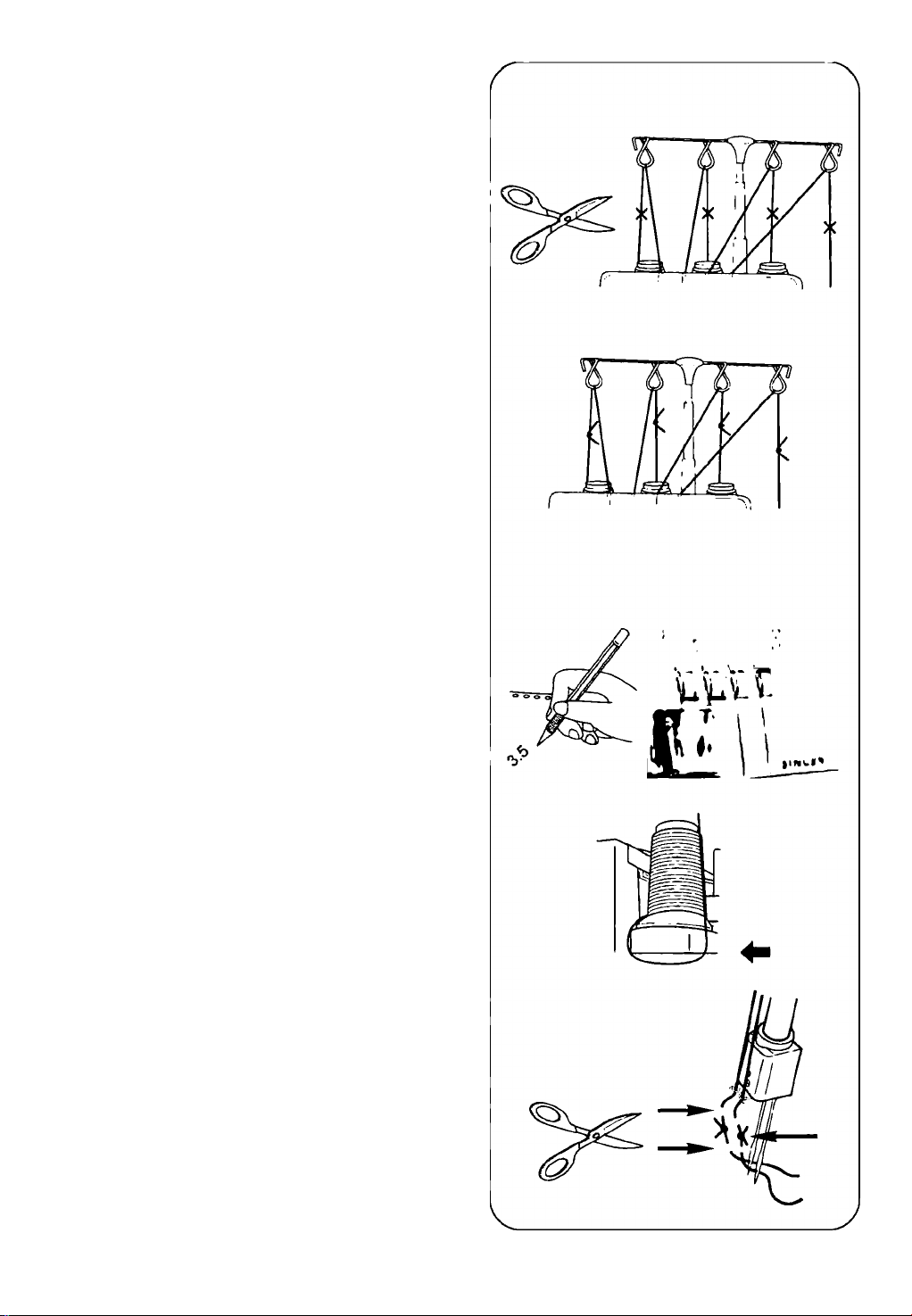

[ Securing the Thread Chain

• Thread a large eye, hand sewing needle (such as a

tapestry needle) with the thread chain.

• Insert the needle into the end of the seam to secure

thread.

Note; To secure a rolled hem thread chain, see

page 39-

44

Page 47

How to Reinforce a Seam

• Inserting twill tape while overedge sewing will

stabilize the seam.

• Insert the tape through the hole in the front of the

foot.

• Position the tape under the foot to the back of the

machine and sew the garment seam.

• The tape is attached as the seam is sewn.

Braiding by Chaining Off

• Place the movable upper knife in nonworking

position

• Insert tiller cord such as yarn or twill tape through

the hole in the tront ot the foot.

• Position the filler cord under the toot and chain ott

the desired length.

• Chained oft braids can be used individually or woven

into 3 or 4 ply braids.

•

Page 48

25. MACHINE MAINTENANCE

An overlook requires more maintenance than a

conventional machine mainly due to two reasons.

1 ) A lot of lint is produced due to the cutting action

of the knives.

2) An overlock runs at a very high speed and needs

to be oiled frequently to lubricate the internal

working parts.

Cleaning the Machine

Danger;

Before cleaning your machine, disconnect

A

power line plug from the wall receptacle.

• Clean the lint from the looper and knife area often

with a dry lint brush.

Note: Lint brush is an optional part.

Oiling the Machine

Danger:

A

Before lubricating your machine, disconnect

power line plug from the wall receptacle.

The oiling points shown in the diagram, should be

oiled periodically.

Note: Use sewing machine oil. Do not use any

other oil or damage could result.

46

Page 49

I How to Replace the Stationary Knife

Danger:

A

Before replacing the stationary knife,

disconnect power line plug from the wall

receptacle.

• The stationary knife should be changed when it

becomes dull.

• The stationary knife can be replaced according to

the directions provided, however if there are any

difficulties experienced, consult your Singer

representative to make the adjustments.

• Be sure that the power line plug is disconnected

from the electric source.

• Open the looper cover and set the movable upper

knife 1 in the nonworking position (page 25).

• Loosen the stationary knife set screw 2 and remove

the stationary knife 3 .

A

o

• Place a new stationary knife in the groove of the

stationary knife holder.

• Tighten stationary knife set screw 2 .

• Return the movable upper knife 1 to its working

position.

47

Page 50

26. TROUBLE SHOOTING CHART

Problem Solution

Fabric does not feed

well

Needle breaks

Thread breaks

Stitches skip

- Lengthen stitch length.

- Increase presser foot pressure for heavy weight fabric.

- Decrease presser foot pressure for light weight fabric.

- Insert needle correctly.

- Do not pull fabric while sewing.

- Tighten needle set screw.

- Use a larger needle on heavy fabrics.

- Check threading

- Check for tangled or caught thread

- Insert needle correctly

- Insert new needle, current needle may be bent or have a

blunt point.

- Use a high quality thread. 49

- Loosen thread tension.

- Insert new needle, current needle may be bent or have a

blunt point.

- Tighten needle set screw.

- Insert needle correctly.

- Change type or size of needle.

- Check threading.

- Increase presser foot pressure.

- Use a high quality thread.

Page

21

22

22

11

29

11

7

12-19

20

11

7

30-38

7

11

11

7

12-19

22

49

Irregular stitches

Fabric puckers

Irregular trimming

Fabric jams

Machine does not

operate

- Balance thread tension.

- Check for tangled or caught thread.

- Check threading.

- Loosen thread tension.

- Check for tangled or caught thread

- Use high quality light weight thread.

- Shorten stitch length.

- Decrease presser foot pressure for light weight fabrics.

- Check alignment of knives.

- Replace one or both knives.

- Close looper cover before sewing.

- Check for tangled or caught thread.

- Compress thick layers of fabric with conventional

machine before sewing with overlook.

- Connect machine to power source.

30-38

20

12-19

30-38

20

49

21

22

47

47

9

20

9

48

Page 51

27. RELATIONSHIP BETWEEN CLOTH, THREAD AND NEEDLE

Type of Fabric Type of Thread

Light Weight

Lawn, Organdy,

Voil, Crepe, etc.

Medium Weight

Muslin. Sheersucker,

Satin. Gabardine,

Broadcloth, etc.

Heavy Weight

Oxford, Denim,

Tweed, Corduroy,

Serge

Cotton: #100

Silk: #100

Spun: #80 - #90

Tetron: #80-#100

Cotton: #60-#80

Silk: #50

Spun: #60 - #80

Tetron: #60-#80

Cotton: #40 - #60

Silk: #40 - #60

Spun: #60 - #80

Tetron: #50-#80

Needle

Singer Cat. No. 2022

#11

#11. #14

#14

Knit

Tricot

Jersey

Wool (woven, knit)

Singer needle, Cat. No. 2022 is furnished with the machine however.

It is recommended that you select your needle in accordance with the material you are sewing.

Spun: #80 - #90

Tetron; #60-#80

Spun: #60 - #80

Tetron: #60 - #80

Cotton: #60 - #80

Spun: #60 - #80

Tetron; #50-#60

Woolly nylon

Woolly tetron

#11

#11, #14

#11, #14

49

Page 52

28. SPECIFICATION

Item

Sewing speed

Stitch length (feed amount)

Differential feed ratio

Overedge stitch width

Needle bar stroke

Presser foot rise

Needle

Model

Number of threads

Machine dimensions (mm)

Width

Depth

Height

Weight (Kg)

Specification

1,300 spm maximum

1 - 4mm (standard: rolled hemming F - 2, ordinary overedge 3.0)

1:0.7 ~ 1:2 (with differential feed machine)

Rolled hemming 1.5mm, ordinary overedge 3.0 - 6.7mm

(standard 3.5mm)

27mm

4.5mm

Rolled hemming: Cat. No. 2022 #11

Ordinary overedge: Cat. No. 2022 #11, #14

14SH744/14CG744 14SH754/14CG754/14ET754/14SH764

2,3,4 2,3,4

338 338

280 280

265 265

6.0 6.0

50

Page 53

NOTES

51

Page 54

14SH744/14CG744

(SURJETEUSE 2.3.4 FILS)

14SH754/14CG754/14ET754/14SH764

(SURJETEUSE 2.3.4 FILS ENTRAINEMENT DIFFERNTIEL)

Manual de Instrucciones

Page 55

14SH744/14CG744

14SH754/14CG754/14ET754/14SH764

Introducción

Le agradecemos su compra de esta máquina de coser. Esta máquina destinada para uso doméstico le proporcionará

un excelente rendimiento al coser material desde ligero a pesado (de lino a tela vaquera). Le rogamos consulte

este folleto para un uso adecuado y un servicio óptimo. Para conseguir lo máximo de su máquina de coser, lea todo

este manual del operador antes de manejar la máquina. Después familiarícese por si mismo con la máquina

siguiendo el manual del operador, página a página.

Para asegurarse que siempre dispone de las más modernas capacidades de costura, el fabricante se reserva el

derecho a cambiar el aspecto, el diseño o los accesorios de esta máquina de coser, cuando lo considere necesario,

sin notificación ni obligación por su parte.

IMPORTANTES INSTRUCCIONES DE SEGURIDAD

A

Si el cable de alimentación eléctrica está dañado, deberá sustituirse por el fabricante o su servicio técnico

autorizado o una persona de cualificación similar con el fin de evitar un peligro.

La máquina no está destinada para ser utilizada por niños o personas de avanzada edad, sin supervisión.

Deberá vigilarse a los niños para asegurarse de que no utilizan este aparato como un juguete.

Desconectar o desenchufar la máquina cuando no se utilice.

Antes de proceder a reparar la máquina debe desenchufarla.

Si se funde la lámpara debe ser cambiada por un distribuidor autorizado.

s>Singer es una marca registrada de The Singer Company Limited o sus afiliados.

Copyright © 2005 The Singer Company Limited

Page 56

Al utilizar esta máquina, deberán seguirse unas precauciones de seguridad básicas, incluyendo lo siguiente:

. Lea todas las instrucciones antes de utilizar la máquina.

¿h PELIGRO! -Para reducir el riesgo de descargas eléctricas:

* La máquina nunca deberá dejarse sin vigilancia cuando esté enchutada. Desenchufar siempre de la toma

eléctrica inmediatamente después de utilizarla y antes de limpiarla.

IMPORTANTES INSTRUCCIONES DE SEGURIDAD

i\ ADVERTENCIA!

A

eléctricas o lesiones a personas.

Asegurarse de que la tensión eléctrica de la toma de corriente (receptáculo de pared) es la misma que la

tensión nominal del motor.

Utilizar esta máquina solamente para su uso previsto, tal como se describe en esta Guia del Operador. Utilizar

solamente las conexiones recomendadas como el fabricante, tal como se contiene en la Guía del Operador.

Para desconectar, girar todos los mandos a la posición de apagado ("0") y a continuación, desenchufar de la

toma de corriente.

Desconectar el cable de alimentación desde la toma de corriente o desconecte la máquina al efectuar cualquier

ajuste en la zona de la aguja, tales como enhebrado de aguja y ojo-guía, cambio de aguja, cambio de placa

de aguja o cambio del prénsatelas, etc.

Desenchufar siempre la máquina desde la toma de corriente cuando retire las tapas, al lubricar o cuando

efectúe cualesquiera otros ajustes de revisión mencionados en la Guía del Operador.

No intente ajustar la correa del motor. Póngase en contacto con el Centro de Servicio más cercano si necesita

hacer algún ajuste.

No desenchufe la máquina tirando del cable. Para desenchufar, agarre el enchufe y no el cable.

Maneje el controlador del pedal con cuidado y evite que se caiga al suelo. Asegurarse no colocar nada encima

del mismo

Utilice siempre la placa de aguja adecuada. Una placa gastada puede hacer que la aguja se rompa.

-Para reducir el riesgo de quemaduras, incendio, descargas

No utilizar agujas dobladas.

Al coser, mantenga sus dedos alejados de las piezas en movimiento. Se precisa un cuidado especial sobre la

aguja de la máquina de coser.

No empuje ni tire de la tela mientras realiza puntadas. Puede doblar la aguja haciendo que se rompa.

Utilizar solamente el asa manual para levantar y mover la máquina.

Nunca haga funcionar la máquina si tiene un cable o enchufe dañados, si no funciona adecuadamente, si se

ha caído o dañado o si ha caído dentro del agua. Devuelva la máquina al concesionario autorizado más

cercano o Centro de Sen/lcio Técnico para examen, reparación, ajuste eiéctrico o mecánico.

Nunca haga funcionar la máquina con las salida de aire bloqueadas. Mantenga las aberturas de ventilación

de la máquina y el controlador del pedal, libres de acumulación de hilachas, polvo y ropa suelta

Nunca deje caer ni introduzca objetos en cualquier abertura.

Page 57

No la utilice al aire líbre

No la utilice cuando se estén empleando productos en aerosoles (spray) o cuando se está administrando

oxigeno.

No permita que se utilice como un juguete. Es necesario prestar la máxima atención cuando la máquina se

utilice por o cerca de niños.

No exponga la máquina o su maleta portátil de plástico a la luz directa del sol. Asimismo, no la deje en un lugar

muy caliente o húmedo.

No toque la máquina, el controlador del pedal y el cable de alimentación con manos húmedas, ropas húmedas

o cualquier otra cosa húmeda.

No conecte el cable de alimentación a uno de los muchos cables conectados a una toma de corriente con

adaptadores.

Utilizar la máquina sobre una mesa plana y estable.

Mantener el prénsatelas y las agujas fuera del alcance de los niños.

No desmonte ni modifique la máquina por usted mismo.

Asegúrese de poner en la posición 'off' el interruptor de encendido y desconectar el cable de alimentación

antes de prestar servicio a su máquina, tal como se recomienda en la guia del operador,

GUARDE ESTAS INSTRUCCIONES

El servicio debe realizarse por un servicio técnico autorizado

Este producto no es para uso Industrial

PARA TERRITORIOS EUROPEOS Y SIMILARES

Las máquinas para Gran Bretaña y algunos otros países, que tengan normas de cableado similares, se envían

desde fábrica sin enchufe para conexión a la red principal Los cables en estas redes se colorean de acuerdo con

el siguiente código:

Azul: neutro (N) Marrón: cable con corriente (L)

Puesto que los colores de los cables de conducción do corriente de este equipo puede que no so correspondan

con las marcas coloreadas que identifican los termínales en su enchute, proceda como sigue:

El cable con color azul debe conectarse al terminal que está marcado con la letra N o colorado en negro.. El cable

de color marrón debe conectarse al terminal que está marcado con la letra L o de color rojo. Si se utiliza un enchufe

de 13 Amp. (BS 1363), debe instalarse un fusible o si se utiliza cualquier otro tipo de enchufe, deberá instalarse un

fusible de 3 Amp. en el enchufe o en el adaptador o en el cuadro de distribución.

Ningún cable ha de conectarse a cada terminal de tierra de un enchufe de tres patillas.

Page 58

INDICE

Página

1. Selección de puntadas

2. Tabla de referenciarápida

3. Accesorios...................................................................7

4. Información de agujas................................................7

5. Componentes principales

6. Cómo abrir la tapa del ojo-guia

7. Componentes principales más allá de la tapa

de ojo-gula...................................................................9

8. Preparación antes de coser.......................................9

9. Preparación para el enhebrado...............................10

• Cómo ajustar el soporte del guiahilos

10. Cómo retirar e insertar agujas

• Para retirar agujas................................................. 11

• Para insertar agujas...............................................11

11 .Cómo enhebrar la máquina

• Diagrama de enhebrado

• Entendimiento del código de colores..................12

• Cómo enhebrar correctamente la máquina... 12

1) Enhebrado del ojo-guia superior (naranja).. 12

2) Enhebrado del ojo-guia inferior (amarillo).. 14

3) Enhebrado de la aguja derecha (verde)... 16

4) Enhebrado de la aguja izquierda (azul). 18

• Información importante sobre el enhebrado

12. Como cambiar los hilos/método para atadura... 20

13. Cómo ajustar la longitud de la puntada

14. Cómo ajustar el ancho de lacoslura

• Ajuste del ancho cambiando la posición de aguja... 21

• Ajuste del ancho con el mando de ajuste

15. Como ajustar la presión del prénsatelas...............22

16. Transporte diferencial .............................................23

• Sobreorillado fruncido...........................................23

• Sobreorillado cxtensible

17. Cómo desacoplar la cuchilla superior móvil

IB.Convirtiendo la ancora superior

a un separador..........................................................26

19.Costura de brazo libre (Trabajo tubular)................27

20.Sobreoriilado estándar y puntada de dobladillo

enrollado....................................................................28

• Cómo coser un sobreorillado estándar...............28

• Cómo coser un dobladillo enrollado....................28

21.Cadeneta y costura de prueba

.............................................

..........................................

..........................................

.................................

................

....

..........................

....................................

........................................

......

................

.....................

...........

......................................

........

................................

5

10

11

12

12

19

21

21

24

25

29

22. Mótodo sugerido de montaje de tensión

6

8

9

21

1) Esta puntada de envoltura de ruedo

usa 2 hilos...............................................................30

2) La norma para la puntada del ruedo

enrollado es 2 hilos

3) Sobreorillado de 3hllos

4) Costura plana de 3 hilos

5) Sobreorillado envuelto de 3 hilos

6) Falsa puntada de seguridad ultra elástica de

4 hilos......................................................................35

23. Cómo coser un dobladillo enrollado

1 )Esta puntada de envoltura de ruedo

usa 2 hilos................................................................37

La norma para un ruedo enrollado de 2 hilos

2)Puntada de dobladillo enrollado estándar

de 3 hilos..................................................................38

Puntada de dobladillo enrollado envuelto

de hilo en ojo-guiá superior a 3 hilos

24. Variaciones de puntadas y técnicas para coser... 40

• Cómo coser una costura decorativa plana... 40

• Cómo coser un dobladillo ciego

• Cómo coser pequeños pliegues........................42

• Cómo girar esquinas cuadradas

• Colocación de allileres

• Fijación de la cadena de hilo

• Cómo reforzar una costura

• Trenzado de cadeneta.........................................45

25. Mantenimiento de la máquina

• Limpieza de la máquina

• Aceitado de la máquina

• Cómo sustituir la cuchilla fija

26 Diagrama de localización de averias..................... 48

27. Relación entre tipos de telas, hilos y agujas... 49

28. Especificaciones..................................................... 50

...............................................

.........................................

.......................................

........................

.......................

.......................

.......................................

.............................

................................

...............................

......................................

......................................

...........................

Página

...............

.....................

......

...................

30

31

32

33

34

36

37

38

42

43

44

44

45

46

46

46

47

Page 59

1. SELECCION DE PUNTADAS

Esta máquina es capaz de obtener varios tipos de puntadas de acuerdo con la combinación de las posiciones de

la aguja, métodos de enhebrado y ajuste de la tensión.

Type de point page de reference

Una aguja de dos hilos puntada es

1 .Dos hilos cubrídor

de orilla del

pespunte.

(502)

2.Dos hilos lo

normal para el

dobladillo del

ruedo.

(503)

3. Sobreorillado

de tres hilos

(504)

usada en trabajos con telas livianas

o en tejIdos.Tambíen a 3.5mm y 5.7mm

a lo ancho de la puntada la orilla del

pespunte puede ser cambiada cambiando

la posldon de la aguja.*

Una aguja de dos hilos puntada es usada

para costura de fileteadora, puntada

invisible a la orilla temnlnada. También

a 3.5mm y 5.7mm para hacer la costura

normal para el dobladillo del ruedo, esto

lo puede obtener cambiando la posición

de la aguja. '

Se utiliza una puntada de 3 hilos, con una

aguja, para sobreorillado y costura en

telas normales. También puede obtenerse

una costura de sobreonllado de 3,5 mm y

5,7 mm de ancho cambiando la posición

de la aguja *

30

31

32

4. Costura plana

de tres hilos

Se utiliza una puntada de tres hilos, con

una aguja, para costuras de bordes

33

encarados o cargadas y puntos

decorativos. También puede obtenerse una

costura plana de 3.5 mm y de 5.7 mm

cambiando la posición de la aguja.'

Se utiliza una puntada de 3 hilos, con 1

aguja, para coser dobladillos enrollados

estrechos u orillas decorativas. También

34

5. Sobreorillado

borde envuelto

tres hilos

(505)

mu»

puede obtenerse una costura envuelta con

sobreorillado de 3,5 mrn y 5,7 mm de

ancho cambiarKio la posición de la aguja.*

6. Puntada de

seguridad

falso elástico

cuatro hilos

(514)

Dependiendo de las posiciones de la aguja utilizadas, esta máquina puede coser con .sobreorillado estándar

de 3 hilos con un ancho de 3.5 mm y costuras de sobreorillado de 5.7 mm de ancho.

Puntada de 4 hilos, con 2 agujas, que es

ideal para telas extensibles medias a

pesadas, tales como tejidos de punto

doble y trajes de baño.

35

Page 60

2.TABLA DE REFERENCIA MANUAL

Tipo de puntada

Dos hilos cubridc

de orilla del

1

pespunte.

Dos hilos lo norma

para el dobladillo

2

del ruedo.

Sobreorillado de

tres hilos

3

Costura plana de

tres hilos

4

Sobreorillado

5

envuelto de

tres hilos

Falsa puntada de

seguridad-ultra

6

elastica de cuatr

hilos (514^

Posiciones

de aguja

3.5mm

r ^

5.7mm

(502)

3.5mm

-

5.7mm

(503)

3.5mm

5.7mm

(504)

3.5mm

5.7mm

(505)

3.5mm

5.7mm

3

ko]

Dial de tensTon;log*^numeros mostrados son

ajustes medios en telas de peso medio con hi

de viscosilla con el 80%de poliesteí^estanda

2.0

1.0

7.0

7.0

Separador/

Ojo-guía superio

Separador

Separador

Separador

Separador

Ojo-guía

superior

Ojo-guía

superior

Ojo-guia

superior

Ojo-guía

superior

Ojo-guía

superior

Ojo-guía

superior

Ojo-guía

superior

Azul Verde Naranja Amarillo

4.0

3.5

0.5 6.0

0.5 5.0

3.0

3.0 3.0 3.0

0.5

0.5 5.0 7.0

3.0

3.0 3.0

5.0

1.0

5.0 0 8.5

3.0

3.0 3.0 3.0

Lo

'•Patina

30

31

32

33

34

35

La tension del hilo se hace mayor a medida que los diales se giren a números más altos. Los ajustes de tensión