Page 1

Installation manual

Simrad SU90

Fish nding sonar

www.simrad.com

TECHNOLOGY FOR SUSTAINABLE FISHERIES

Page 2

Page 3

SimradSU90

Installationmanual

Thismanualprovidesyouwiththebasicinformation

requiredtoinstalltheSimradSU90Sonar.Forinformation

aboutthepracticaluseoftheproduct,refertotheSimrad

SU90OperatormanualortheSimradSU90Reference

manual.

AlluserdocumentationisincludedontheUSBmemory

devicethatisprovidedwiththeSimradSU90.Themanuals

canalsobedownloadedfromhttp://www.simrad.com/su90

WARNING:TheSimradSU90sonarmustneverbe

poweredupwhentheshipisindrydock.Thetransducer

willbedamagedifittransmitsinopenair.Toprevent

inadvertentuseofthesonar,pulloutthemainsplugon

theProcessorUnitwheneverthevesselisindrydock.

.

381293/A

2013-09-13

©

KongsbergMaritimeAS

Page 4

Revisionstatus

Documentno:381293/V ersion:A/ISBN-13:978-82-8066-158-6

Rev.A2013–09–13

Firstversion

Copyright

©2013KongsbergMaritimeAS

TheinformationcontainedinthisdocumentremainsthesolepropertyofKongsbergMaritimeAS.Nopart

ofthisdocumentmaybecopiedorreproducedinanyformorbyanymeans,andtheinformationcontained

withinitisnottobecommunicatedtoathirdparty,withoutthepriorwrittenconsentofKongsberg

MaritimeAS.Thedocument,oranypartofit,maynotbetranslatedtoanyotherlanguagewithoutthe

writtenapprovalfromKongsbergMaritimeAS.

Disclaimer

KongsbergMaritimeASendeavourstoensurethatallinformationinthisdocumentiscorrectandfairly

stated,butdoesnotacceptliabilityforanyerrorsoromissions.

Warning

Theequipmenttowhichthismanualappliesmustonlybeusedforthepurposeforwhichitwas

designed.Improperuseormaintenancemaycausedamagetotheequipmentand/orinjury

topersonnel.Allusersmustbefamiliarwiththecontentsoftheappropriatemanualsbefore

attemptingtoinstall,operate,maintainorinanyotherwayworkontheequipment.

KongsbergMaritimeASdisclaimsanyresponsibilityfordamageorinjurycausedbyimproper

installation,useormaintenanceoftheequipment.

Supportinformation

Ifyourequiremaintenanceorrepair,contactyourlocaldealer.Youcanalsocontactususingthefollowing

address:simrad.support@simrad.com.Ifyouneedinformationaboutourotherproducts,visithttp:

//www.simrad.com.Onthiswebsiteyouwillalsondalistofourdealersanddistributors.

SeealsoSupportinformationonpage33.

KongsbergMaritimeAS

www.kongsberg.com

Page 5

Installationmanual

Tableofcontents

ABOUTTHISMANUAL.....................................................13

SIMRADSU90.................................................................15

Systemdescription.................................................................................................16

Systemdiagram......................................................................................................18

Systemunits...........................................................................................................19

Colourdisplay............................................................................................19

ProcessorUnit............................................................................................19

OperatingPanel..........................................................................................19

OperatingPanelpowersupply.....................................................................20

Audioamplierwithloudspeakers...............................................................20

TransceiverUnit.........................................................................................20

HullUnit....................................................................................................20

Transducer.................................................................................................21

Scopeofsupply......................................................................................................21

Mainunitsincludedwiththestandarddelivery.............................................21

Additionalitems.........................................................................................22

Additionalrequireditems.......................................................................................22

Colourdisplay............................................................................................22

UninterruptedPowerSupply(UPS)..............................................................23

Installationtrunk.........................................................................................23

Speedlog...................................................................................................24

Coursegyro................................................................................................24

Optionalitems........................................................................................................25

Hullunit.....................................................................................................25

Installationtrunk.........................................................................................25

Extendedrange...........................................................................................26

Scienticinterface......................................................................................26

Otherperipheralequipment.........................................................................26

Audiooutput..............................................................................................28

Externalmotionreferenceunit(MRU).........................................................30

SecondaryOperatingPanel..........................................................................30

Generalsupplyconditions......................................................................................31

Equipmentresponsibility.............................................................................31

Receipt,unpackingandstorage....................................................................31

Generalinstallationrequirements...........................................................................32

Supplypower.............................................................................................32

UninterruptedPowerSupply(UPS)..............................................................32

Wiring........................................................................................................32

Compassdeviation......................................................................................33

381293/A

3

Page 6

SimradSU90

Noisesources.............................................................................................33

Drydocking...............................................................................................33

Approvalbyclassicationsociety................................................................33

Supportinformation...............................................................................................33

INSTALLATIONPROCEDURE...........................................35

PREPARATIONS..............................................................37

Installationdrawings..............................................................................................38

Necessarytoolsandequipment..............................................................................38

Workerskills...........................................................................................................39

Determingthelocationofthehullunit..................................................................40

Foreandaftlocation...................................................................................40

Athwartshipslocation..................................................................................41

Importantconsiderationsrelatedtonoise......................................................41

Sonarroomrequirements.......................................................................................42

Watertightintegrity.....................................................................................42

Sizeandaccess...........................................................................................43

Heating......................................................................................................43

Insulation...................................................................................................43

Ventilation..................................................................................................43

Cableprotection.........................................................................................44

Electricalinstallationsandlights..................................................................44

Bilgepumpanddecking..............................................................................44

Liftingdevice.............................................................................................44

Communication..........................................................................................44

Sonarroomarrangementexample..........................................................................45

Sonarroomarrangementexample1–Topview............................................45

Sonarroomarrangementexample2–Sideview...........................................46

Hullunitorientationexample.......................................................................47

Acousticnoise........................................................................................................47

Contributingnoisefactors...........................................................................48

Selfnoise...................................................................................................49

Ambientnoise............................................................................................51

Fishinggearnoise.......................................................................................51

Electricalnoise...........................................................................................52

Reverberation.............................................................................................52

Somemeanstoreducethenoise...................................................................52

INSTALLINGTHESONARTRUNK.....................................55

Aboutthesonartrunkinstallation..........................................................................56

Mountingthesonartrunk.......................................................................................57

Mountingthetrunkextension.................................................................................58

Protectingthesonartrunk.......................................................................................59

4

381293/A

Page 7

Installationmanual

Sonartrunkinstallationprinciples..........................................................................59

Installationofatrunkwithopenblister.........................................................60

Installationofatrunkwithoillledblister...................................................61

Sonartrunkinstallationmeasurementsandchecklist............................................62

INSTALLINGTHEHULLUNIT..........................................63

Aboutthehullunitinstallation...............................................................................64

Hullunitfamiliarizationandmainpartsidentication..........................................65

MotorControlUnitfamiliarizationandmainpartsidentication.........................66

Hullunitmodelsoverview.....................................................................................67

Unpackingthehullunitfromitstransportbox......................................................68

Mountingthehullunit............................................................................................70

Bleedingaircock....................................................................................................72

Mountingthemechanicalsupport..........................................................................72

Transduceralignment.............................................................................................73

Visualinspectionofthetransducer........................................................................73

Loweringandhoistingthetransducermanuallyusingthehandcrank.............74

Hullunitinstallationchecklist...............................................................................76

INSTALLINGTHETRANSCEIVERUNIT............................77

INSTALLINGTHEBRIDGEUNITS....................................81

Preparationsforinstallation....................................................................................82

Basicrequirements......................................................................................82

Locationofthecolourdisplay......................................................................82

LocationoftheProcessorUnit.....................................................................83

LocationoftheOperatingPanel...................................................................83

LocationoftheOperatingPanelPowerSupply.............................................84

Locationoftheamplierandloudspeakers...................................................84

Maximumdistancesbetweentheunits...................................................................85

Installationofthecolourdisplay............................................................................85

InstallationoftheProcessorUnit...........................................................................86

InstallationoftheOperatingPanel.........................................................................88

InstallationoftheOperatingPanelPowerSupply.................................................89

Installationoftheamplierandloudspeakers........................................................89

CABLELAYOUTANDINTERCONNECTIONS......................90

Readthisrst!........................................................................................................91

Cableplan...............................................................................................................93

Bridgecables..............................................................................................93

Sonarroomcables......................................................................................94

Listofcables..........................................................................................................95

Cableprocedures..................................................................................................100

ConnectingACmainstotheUninterruptedPowerSupply...........................101

381293/A

5

Page 8

SimradSU90

ConnectingthevideocablefromtheProcessorUnittothecolour

display.....................................................................................................102

ConnectingtheUSBcablefromtheOperatingPaneltotheProcessor

Unit.........................................................................................................103

ConnectingthedualinterfacecablefromtheOperatingPaneltothe

ProcessorUnit..........................................................................................104

ConnectingtheOperatingPanelPowerSupplytotheProcessorUnit...........105

ConnectingACmainsandgroundtotheProcessorUnit..............................106

ConnectingACmainstothecolourdisplay................................................107

ConnectinggroundtotheOperatingPanel..................................................108

ConnectingtheProcessorUnittotheTransceiverUnit................................109

ConnectingACmainstotheTransceiverUnit.............................................111

ConnectingACmainstotheMotorControlUnit........................................112

ConnectingtheTransceiverUnittotheMotorControlUnit.........................113

ConnectingACmainstotheHeatExchanger..............................................114

ConnectingtheEthernetcableforscienticoutput......................................115

Connectingtheaudiocablesforexternalpoweredspeakers.........................116

Connectingthetransducercable.................................................................117

Connectingtheinterfacecablestotheperipheralequipment........................117

MoxaCP114EL-ISerialadaptersetup.................................................................117

Seriallinesupport.....................................................................................118

JumperandDIPswitchsettings.................................................................118

Softwaresetup(WindowsXP)...................................................................118

Softwaresetup(Windows7)......................................................................120

Adaptercable...........................................................................................121

Referencestodetailedcabledrawingsandspecications....................................123

INTERFACINGPERIPHERALEQUIPMENT......................124

Overviewofinterfacesandsupportedtelegramformats......................................125

Telegramsreceivedfromexternaldevices...................................................125

Telegramssenttoexternaldevices.............................................................127

Monitoringandchangingtheinterfacesettings...................................................128

Defaultinterfacesettings...........................................................................128

Changingtheinterfacesettings..................................................................129

MonitoringthetrafconaserialorEthernetline........................................132

Synchronisationwithotheracousticsystems.......................................................135

Settingupthesynchronisationfunction......................................................135

Aboutsynchronisation..............................................................................137

Synchronisationusingaserialline.............................................................138

SU90setupasSlave.................................................................................138

SU90setupasMaster...............................................................................138

Synchronisationsequences........................................................................139

Synchronisationofthesonarclockwithanexternalclock..................................140

OpeningtheInstallationmenu...................................................................141

6

381293/A

Page 9

Installationmanual

Changingthenecessaryparametertoallowforclocksynchronization...........141

Connectingthespeedlogandcoursegyro...........................................................141

Connectingthespeedlog...........................................................................142

Connectingthecoursegyro.......................................................................143

Connectinganexternalmotionreferenceunit(MRU).........................................144

Physicalinstallationofthemotionreferenceunit........................................144

Installationofthemotionreferenceunitcable.............................................144

OpeningtheInstallationmenu...................................................................145

Conguringandtestingtheinterfacetothemotionreferenceunit................145

EnteringthestabilisationoffsetangleintotheSU90....................................146

ConnectingasecondaryOperatingPanel.............................................................147

PartsandtoolsrequiredtoinstallasecondaryOperatingPanel....................147

PhysicalinstallationoftheOperatingPanel................................................148

InstallationoftheOperatingPanelcables...................................................148

OpeningtheInstallationmenu...................................................................149

ConguringandtestingtheinterfacetothesecondaryOperating

Panel........................................................................................................150

CableplanforasecondaryOperatingPanel................................................151

ListofcablesrequiredforthesecondaryOperatingPanel............................152

Establishingemergencyhoistfunctionality..........................................................154

Designingtheemergencyhoistinterface.....................................................154

Circuitboardinterfacedescription.............................................................155

Testingtheinterfacestoperipheraldevices..........................................................156

OpeningtheInstallationmenu...................................................................156

Conguringandtestingtheinterfacetothespeedlog..................................157

Conguringandtestingtheinterfacetothecoursegyro...............................158

Conguringandtestingtheinterfacetothepositioningsystem(GPS)...........159

Conguringandtestingtheinterfacetoatrawlsystem................................160

Conguringandtestingtheinterfacetoacatchmonitoringsystem...............161

Conguringandtestingtheinterfacetoaradiobuoysystem........................161

Conguringandtestingtheinterfacetoaseacurrentmeter..........................162

SETTINGTOWORK.......................................................163

StartinguptheHullUnit......................................................................................164

Hullunitfamiliarizationandmainpartsidentication.................................165

MotorControlUnitfamiliarizationandmainpartsidentication..................166

Functionalcheck.......................................................................................166

Apply3-phaseACpower..........................................................................167

Checkthehoistingmotor's3–phaseACconnections...................................168

Check3–phaseconnectionforcorrectrotation............................................169

ChecktheK301contactoroperation...........................................................170

Verifycorrecthoistandlowerfunctionality................................................171

Startingupthebridgeunits..................................................................................173

381293/A

7

Page 10

SimradSU90

StartingupoftheProcessorUnitforthersttime.......................................173

Settingupthesonartoretrievesimulatedsonarechoes................................174

OpeningtheInstallationmenu...................................................................174

CheckingtheOperatingPanel..............................................................................175

OperatingPanelfunctionaltests.................................................................175

CheckingtheOperatingPanelbacklight.....................................................180

Poweringoffthesonar..............................................................................181

StartinguptheTransceiverUnit...........................................................................181

Checkingthehoist/lowerfunctionality................................................................183

ConnectingtheTransceiverUnittotheProcessorUnit................................183

Selectingwhichhullunittypetobeused....................................................184

Checkingthehoist/lowerfunctionalityfromthebridge................................185

Checkingthehoist/lowerfunctionalityfromthesonarroom........................187

Measuringtheself-noise......................................................................................188

StartinguptheSU90system................................................................................190

PreparationsbeforetheSU90systemisstarted...........................................190

StartinguptheSU90system,bridgeactions...............................................191

StartinguptheSU90system,sonarroomactions........................................192

Alignmentofthesonarpicture.............................................................................193

Adjustingthestabilisationsensoroffset...............................................................194

Estimatingtheoffsetangle........................................................................194

EnteringthestabilisationoffsetangleintotheSU90....................................195

Deningownshipparameters..............................................................................195

Specifyingshipdimensions.......................................................................195

Specifyinginstrumentpositionoffsets........................................................196

OpeningtheInstallationmenu...................................................................196

FINALTESTSANDMEASUREMENTS..............................198

Sourcelevel(SL)measurements..........................................................................199

Preparationsandtesthydrophonedata........................................................199

Testsetup.................................................................................................200

Sonarparameters......................................................................................200

Testprocedure..........................................................................................201

Finalizingtheprocedure............................................................................202

Sourceleveltestresults.............................................................................202

Receivingvoltageresponse(VR)measurements.................................................203

Preparations.............................................................................................203

Sonarparameters......................................................................................203

Testprocedure..........................................................................................204

Finalizingtheprocedure............................................................................205

Receivingvoltageresponsetestresults.......................................................205

Noise/speedcurvemeasurements.........................................................................206

Preparations.............................................................................................206

8

381293/A

Page 11

Installationmanual

Testprocedure..........................................................................................206

Problemswithownoise..........................................................................207

Noise/speedtestresults.............................................................................207

ProcessorUnitbackupandrestore.......................................................................210

AboutSU90backupandrestore.................................................................210

Creatingabackupimageofallthesonarsoftware.......................................211

Restoringthesonarsoftwarefromabackupimage......................................212

ReactivatingtheWindowslicense..............................................................213

CreatingabootableUSBmemorystick......................................................218

TECHNICALSPECIFICATIONS.......................................219

Performancespecications...................................................................................220

Weightsandoutlinedimensions...........................................................................221

Powerspecications.............................................................................................223

Environmentalspecications...............................................................................223

Minimumdisplayrequirements............................................................................224

TELEGRAMFORMATS....................................................226

TelegramsreceivedandsentbytheSU90............................................................227

Coursegyrotelegrams...............................................................................227

Speedlogtelegrams..................................................................................227

GPStelegrams..........................................................................................228

ITIandtrawlsystemtelegram....................................................................228

Echosoundertelegrams.............................................................................229

Windsensortelegrams..............................................................................230

Seacurrenttelegrams................................................................................230

Catchmonitoringsystemtelegrams............................................................230

Buoytelegrams.........................................................................................230

Targetoutputtelegrams.............................................................................230

AbouttheNMEAtelegramformat.......................................................................231

NationalMarineElectronicsAssociation(NMEA)......................................231

NMEAtelegramprinciples........................................................................232

StandardNMEA0183communicationparameters......................................232

NMEAsentencestructure..........................................................................232

SpecicationofNMEAtelegrams.......................................................................233

DBSDepthbelowsurface.........................................................................234

DBTDepthbelowtransducer.....................................................................234

DPTDepth...............................................................................................234

GGAGlobalpositioningsystemxdata.....................................................235

GLLGeographicalpositionlatitude/longitude............................................235

HDGHeading,deviationandvariation.......................................................236

HDMHeading,magnetic...........................................................................237

HDTHeading,true...................................................................................237

MWDWinddirectionandspeed................................................................237

381293/A

9

Page 12

SimradSU90

MWVWindspeedandangle.....................................................................238

RMCRecommendedminimumspecicGNSSdata....................................238

VBWDualgroundandwaterspeed...........................................................238

VHWWaterspeedandheading.................................................................239

VTGCourseoverground&groundspeed..................................................240

VWRRelative(apparent)windspeedandangle..........................................240

ZDATimeanddate..................................................................................240

Proprietarytelegramsandformats.......................................................................241

DBSDepthoftrawlbelowsurface.............................................................242

FS3300Binarydepth................................................................................242

GLLTrawlposition..................................................................................242

HFBTrawlheadropetofootropeandbottom..............................................243

MDSMeasureddatashoal.........................................................................243

MTWWatertemperatureatthetrawl.........................................................244

PSIMP-DPISensordata...........................................................................244

PSIMP-FPISensordata............................................................................246

TDSTrawldoorspread.............................................................................246

TFITrawllling.......................................................................................247

TPCTrawlpositionincartesiancoordinates...............................................247

TPPTrackedtargetpositionormarker.......................................................247

TPTTrawlpositiontruevessel..................................................................248

TS2Trawlspread2...................................................................................248

TTSTrawltoshoaldistance......................................................................248

Proprietarythirdpartytelegramsandformats......................................................250

FurunoCIFSeacurrent.............................................................................250

KaijoVDVCDVectorcurrentdirection......................................................253

RyokoseiRBYBuoyinput........................................................................253

SerpeBSCBuoyinput..............................................................................254

DRAWINGFILE.............................................................255

Cabinetoutlinedrawings......................................................................................256

TransceiverUnitdimensions......................................................................257

ProcessorUnitdimensions........................................................................260

OperatingPaneldimensions......................................................................261

HullUnitdrawings...............................................................................................262

SU92Hullunitdimensionsdrawing...........................................................263

SU93Hullunitdimensionsdrawing...........................................................265

SU92/SU93Mountingtrunkproductiondrawing........................................267

SU92/SU93Extensiontrunkproductiondrawing........................................269

SU92/SU93Blindcoverdrawing...............................................................271

AGENERALSAFETYRULES...............................................272

BEQUIPMENTHANDLING................................................273

Transportation.......................................................................................................274

10

381293/A

Page 13

Installationmanual

Lifting...................................................................................................................274

Storagepriortoinstallationoruse.......................................................................275

Inspection.............................................................................................................276

Unpacking............................................................................................................276

Generalunpackingprocedure....................................................................276

Unpackingelectronicandelectromechanicalunits......................................277

Unpackingmechanicalunits......................................................................277

Unpackingtransducers..............................................................................277

Storageafterunpacking........................................................................................278

Storageafteruse...................................................................................................278

Cleaningcabinets......................................................................................278

Mechanicalunits.......................................................................................279

Cables......................................................................................................279

Internalbatteries.......................................................................................279

Dehumidier............................................................................................280

Coatings...................................................................................................280

Re-packaging........................................................................................................280

Temperatureprotection.........................................................................................280

Circuitboardhandlingandpackaging..................................................................281

Electro-StaticDischarge(ESD)............................................................................282

Disposal................................................................................................................282

CSU90CABLEDETAILS...................................................284

Cablingprinciples.................................................................................................285

Cablestoperipheraldevices.................................................................................285

Positioningsysteminterface......................................................................286

Echosoundersysteminterface...................................................................286

Trawlsonarinterface.................................................................................286

Catchmonitoringsysteminterface.............................................................287

Currentmeterinterface..............................................................................287

Radiobuoysconnectioninterface...............................................................287

Cabledrawings.....................................................................................................288

GenericRS-232Serialline(Threewires)...................................................289

RS-232usedasexternaltriggerinputoroutput...........................................290

GenericRS-422Serialline(Fivewires).....................................................291

MoxaCP114EL-ISeriallineadapter..........................................................292

Mini-jacktophonoaudiocable..................................................................294

Vesselground...........................................................................................295

ACmainswithIEC60320socketandinlineplug.......................................296

3–phaseACmainstoMotorControlUnit...................................................297

ACmainswithIEC320/C7inlineplug......................................................298

OperatingPanelpowersupply...................................................................299

RJ45Ethernet,straight..............................................................................300

381293/A

11

Page 14

SimradSU90

UniversalSerialBus(USB).......................................................................302

DVI–IDisplaycable.................................................................................303

Commercialpoweredspeakersystem.........................................................304

OperatingPanel“Dual”cable....................................................................306

DBASICCABLEREQUIREMENTS......................................307

Cabletrays............................................................................................................308

RadioFrequencyinterference..............................................................................308

Physicalprotection...............................................................................................309

Grounding.............................................................................................................309

Cableconnections.................................................................................................310

Cableterminations................................................................................................310

Cableidentication...............................................................................................310

EINSTALLATIONREMARKS.............................................311

12

381293/A

Page 15

Aboutthismanual

Aboutthismanual

Purpose

Thepurposeofthismanualistoprovidetheinformationandbasicdrawingsrequiredfor

installationoftheSimradSU90.

Formoredetailedinformationaboutthepracticaluseoftheproduct,refertotheSimrad

SU90OperatormanualortheSimradSU90Referencemanual.

Targetaudience

Themanualisintendedfortechnicalpersonnel;qualiedmaintenanceengineersand

technicians.Itisassumedthatthepersonnelisconversantwiththegeneralprinciplesof

maritimeelectronicequipment,inparticularsonar,echosounderandcatchmonitoring

systems.Thepersonnelmustalsobefamiliarwithcomputerhardware,signalprocessing,

interfacetechnologyandtraditionaltroubleshootingonelectronicandmechanical

products.

®

WeassumethatyouarefamiliarwiththeWindows

system,andconversantwithnetworkaddressingandcommunicationprinciples.

Installationinstructions

Theinstructionsprovidedinthismanualmustbefollowedcarefullytoensureoptimal

performance.Asaguide,installationproceduresarepresentedintheordertheyareto

beperformed.

Theequipmentdescribedinthismanualincludesthecompletesystemwithrelevant

cabinets,butnotsystemunitsprovidedlocallybythecustomer,installationshipyardor

localrepresentative.Themanualalsodenestheequipmentresponsibility,andprovides

applicableinstructionsforunpackingandstorage.

Note

®

XP

and/orWindows

®

7operating

Theinstallationinstructionsgiveninthisdocumentmustbeadheredto.Failuretodoso

mayrendertheguaranteevoid.

KongsbergMaritimeASwillacceptnoresponsibilityforanydamageorinjurytothe

system,vesselorpersonnelcausedbyequipmentthathasbeenincorrectlyinstalledor

maintained,orbydrawings,instructionsorproceduresthathavenotbeenprepared

byus.

381293/A

13

Page 16

SimradSU90

Installationdrawings

Detailedvesselspecicmechanicaldrawingsfortheinstallationmustbeprovidedbythe

customer,oranyshipyardcontractedtoperformtheinstallation.

KongsbergMaritimeASmay,onspecialorder,provideassistancetothesedrawings.

Drawingsmustbeapprovedbytheappropriatevesselcerticationauthoritypriorto

installationofthesystem.

Applicablegenericoutlinedimensionandproductionsdrawingsareprovidedinthe

Drawinglechapter.DrawingsmayalsobedownloadedinPDFand/orDWGformats

fromhttp://www.simrad.com

.

Registeredtrademarks

Windows

®

,Windows

®

®

XP

,andWindows

®

7areeitherregisteredtrademarks,or

trademarksofMicrosoftCorporationintheUnitedStatesand/orothercountries.

Simrad

®

,SIMRAD

®

andtheSimrad

®

logoareeitherregisteredtrademarks,or

trademarksofKongsbergMaritimeASinNorwayandothercountries.

Recordofchanges

A2013–09–13:Firstversion

14

381293/A

Page 17

SimradSU90

StudythischaptertofamiliarizeyourselfwiththeSimradSU90.

Topics

•Systemdescriptiononpage16

•Systemdiagramonpage18

•Systemunitsonpage19

SimradSU90

•Scopeofsupplyonpage21

•Additionalrequireditemsonpage22

•Optionalitemsonpage25

•Generalsupplyconditionsonpage31

•Generalinstallationrequirementsonpage32

•Supportinformationonpage33

381293/A

15

Page 18

SimradSU90

Systemdescription

TheSimradSU90

isalongrange

omnidirectionallow

frequencysonar.

Itisdesignedformedium

andlargesizedshing

vessels,preferablyfor

purseseiners,butitis

alsowellsuitablefor

trawlers.

TheSimradSU90

allowsyoutochoose

anoperationalfrequency

between20to30kHz

(in1kHzsteps).The

cylindricalmulti-element

transducerallows

theomnidirectional

sonarbeamtobetilted

electronicallyfrom

+10to–60degrees.

Thisallowsyouto

automaticallytrack

schoolsofsh,and

toobservethewhole

watervolumearound

thevessel.Astabilising

systemisincludedfor

electronicpitchandroll

compensation.

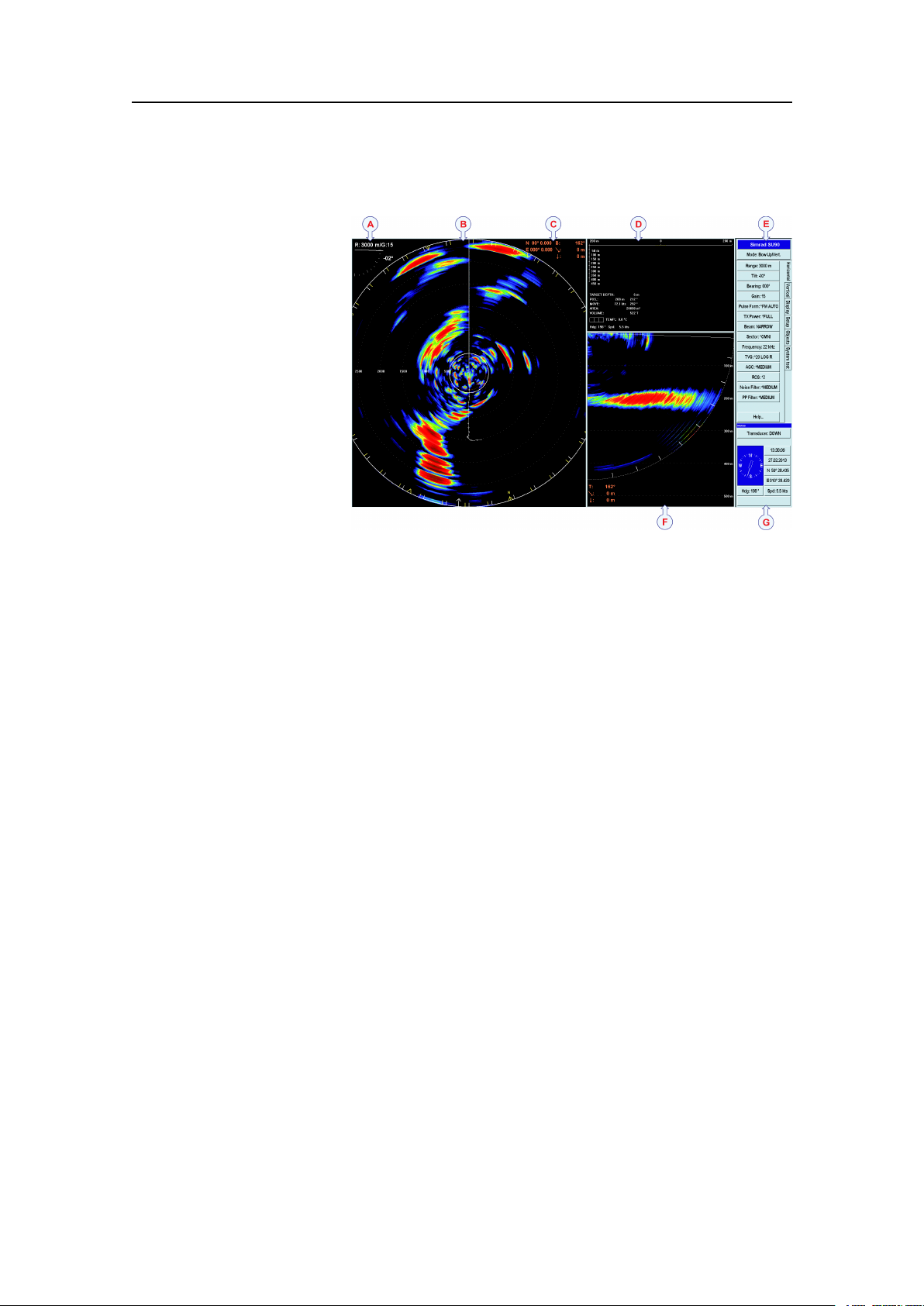

ThisSU90screencaptureshowsyouatypicalcatch

situation.Thepresentationprovidesyouwithalotof

information.

ACurrentrange,transducertiltandgain

BSonarpresentation

CCursor’sposition,bearing(relativetothevessel),

rangeanddepth

DPurseseineandtargetinformation(depthand

estimatedschoolsize),includinginformationfrom

catchmonitoringdepthsensors

EMenusystem

FVerticalview

GNavigationinformationandhullunitposition

TheSimradSU90hasbeendesignedwithnocompromises.ComparedtotheSX90,the

numberofchannelsisincreasedby50%givingthesonaranevenbetterperformance

inselectivityandrange.Thenarrowopeningangle(4,9°at30kHz)andtheincreased

sourcelevel(3dB)makestheSU90averypowerfulandhighresolutionlowfrequency

sonar.ThenarrowbeammakestheSU90evenmoreidealforsearchingshcloseto

thebottomorclosetothesurfaceatlongranges.Italsoprovidesafarbettervertical

viewwithless“bottomclimbing”thatisseenonsonarswithawiderbeam.

Greatemphasishasbeenplacedongivingthebestpossiblesonarpresentationsona

highresolutioncolourdisplay.

TheSU90ProcessorUnitiscontrolledbyMicrosoft’sWindows

whichresultinaexiblechoiceofpresentationmodesforalargerangeofuser

applications.Thesignalprocessingandbeamformingisperformedinafastdigital

16

®

operatingsystem,

381293/A

Page 19

SimradSU90

signalprocessingsystemusingthefulldynamicrangeofthesignals.Inadditiontothe

traditionalsinglefrequencytransceiversystem,theSimradSU90containsanadvanced

frequencymodulatedltersystem(FM).

381293/A

17

Page 20

SimradSU90

SIMRAD

PWR

MENU

SIMRAD

SIMRADSU90

(CD015050-001)

B

C

D

E

G

H

F

A

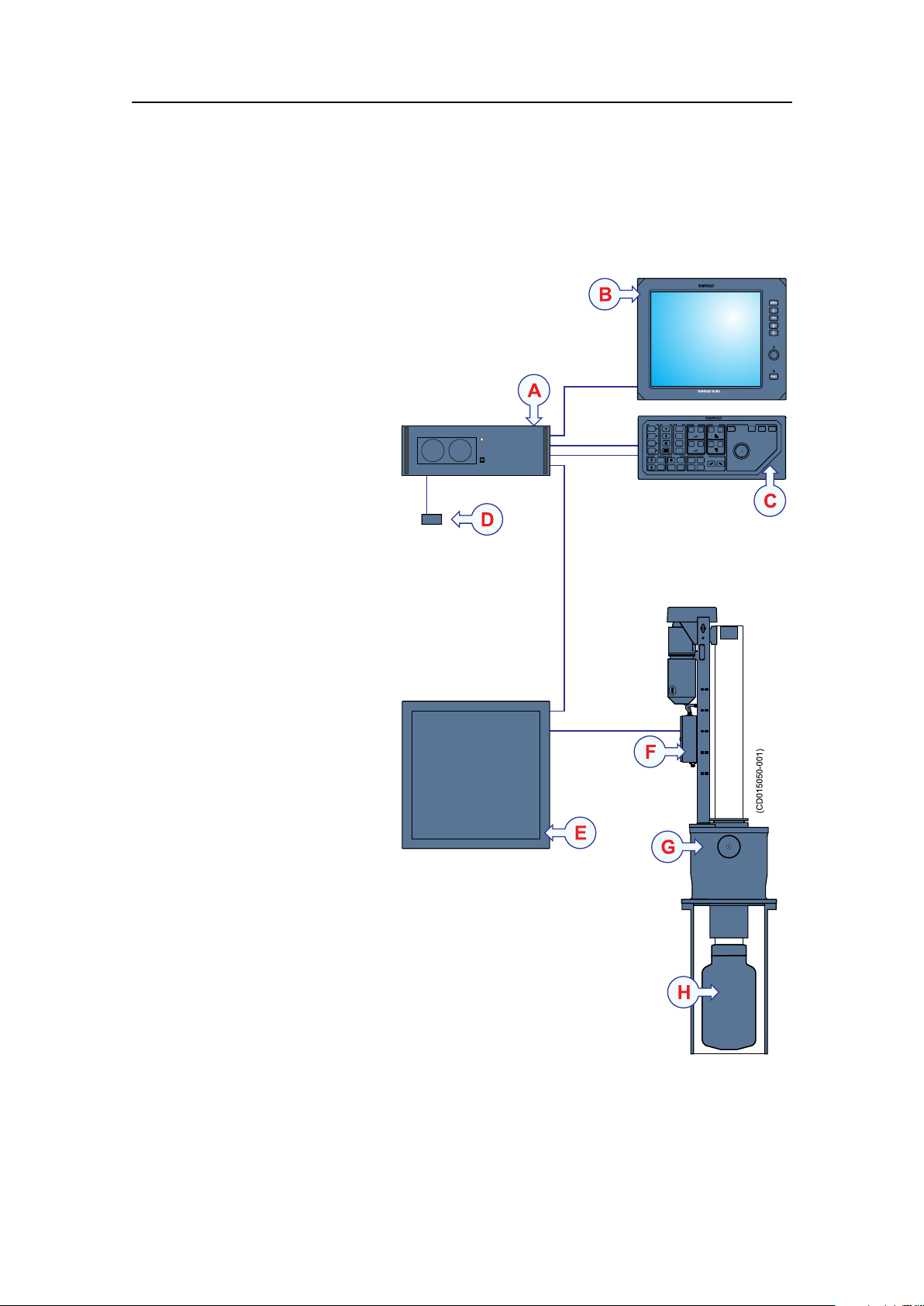

Systemdiagram

AstandardSU90systemdiagramisprovided.Interfacecapabilities,uninterruptedpower

suppliesandpowercablesarenotshown.

AProcessorUnit

BColourdisplay

COperatingPanel

DOperatingPanelPower

Supply

ETransceiverUnit

FMotorControlUnit

GHullUnit

HTransducer

Thecolourdisplayisnot

includedinthestandard

deliveryfromSimrad.Thisis

acommercialitemthatcanbe

purchasedlocally.

18

381293/A

Page 21

Systemunits

TheSimradSU90comprisesthefollowingunits.

Topics

•Colourdisplayonpage19

•ProcessorUnitonpage19

•OperatingPanelonpage19

•OperatingPanelpowersupplyonpage20

•Audioamplierwithloudspeakersonpage20

•TransceiverUnitonpage20

•HullUnitonpage20

•Transduceronpage21

SimradSU90

Colourdisplay

AnycommercialcolourdisplaycanbeusedwiththeSimradSU90system.Thechosen

displaymustbedesignedformaritimeuse,anditmustmeettheminimumperformance

specications.

NotethatthecolourdisplayisnotastandardpartoftheSU90delivery.

ProcessorUnit

TheProcessorUnitisamarinecomputerbasedon

®

theMicrosoftWindows

designedforruggeduse.

Thecomputerisbasedonacommercialdesign,but

thesoftwareandhardwarehasbeenspeciedand

assembledspecicallyforSimradtosuittheSU90requirements.

ThecomputerholdsmultipleUSBportsforusewithfuturesoftwareupgrades.These

USBportswillalsoallowyoutoexportscreencapturesfromthesonar.

®

XP

operatingsystem.Itis

OperatingPanel

TheOperatingPanelcontainsallnecessarycontrol

functionsfornormaloperationoftheSU90.

Thecontrolsarearrangedinlogicalfunctiongroups,

thisgivesaclearandeasyoperation.

ThemajorityoftheSU90functionscanbeaccessed

usingthetrackballontheOperatingPanelandthemenusystemonthedisplay.You

canalsouseastandardcomputermouse.

381293/A

19

Page 22

SimradSU90

OperatingPanelpowersupply

Asmallcommercialpowersupplyisimplementedtoprovidestand-bypowertothe

OperatingPanel.ThepowersupplyisconnectedtotheProcessorUnit.

Audioamplierwithloudspeakers

AnamplierwithoneortwoloudspeakersmaybeconnectedtotheProcessorUnitto

providetheaudiooutput.

Theseoptionalitemsarenotprovidedwiththestandardsonardelivery.

IfstandardcommercialPCloudspeakersareused,thesearenormallypoweredbya

separatepowersupply.

TransceiverUnit

TheSU90TransceiverUnitislocatedinthesonar

room,closetotheHullUnit.

Thetransceiverperformsthetransmissionand

receptioncontrolofthe384transmittersand384

receiverchannels.12identicaltransceiverboards

areused.TheTransceiverUnitalsoholdstwopower

supplies,anEthernetswitch,andalargecapacitorbank.

TwoEthernetcablesareusedforcommunicationwith

theProcessorUnitonthebridge,whileathirdEthernet

cableisusedtocontrolthehullunit.

Thetransducercablesfromthehullunitareplugged

intothesidewalloftheTransceiverUnitcabinetusingaspecialplug.

TheTransceiverUnitismountedonthebulkheadusingpowerfulshockabsorbers.The

connectorsforpowerandinterfacearelocatedatthebottomofthecabinet.

HullUnit

ThestandardSU92HullUnitisdesignedtolowerthetransducer1.2metersbelowthe

ship’shull.Maximumvesselspeedisthen25knots.

TheoptionalSU93HullUnitwilllowerthetransducerto1,6metersbelowthehull.With

theSU93HullUnit,themaximumvesselspeedis20knots.

Whenthesonarisswitchedon,presstheDownbuttonontheOperatingPaneltolower

thetransducerintothewater.Beforethesonarisswitchedoff,presstheUpbuttonon

theOperatingPaneltoretractthetransducerintotheinstallationtrunkforprotection.

Ifyouforgetthis,thetransducerishoistedautomaticallybeforethesonarisswitched

off.Itisalsohoistedautomaticallyifaseriousmalfunctionoccurstothecommunication

betweenthebridgeandthehullunit.

Thetransducercanalsobeloweredtoanyselectedmiddleposition.Incaseofvoltage

failure,thetransducercanberaisedorloweredmanuallybymeansofahandcrank.

20

381293/A

Page 23

SimradSU90

ThesensorfortheelectronicstabilisationofthesonarbeamsishousedintheMotor

ControlUnit,whichismountedontheHullUnit.

Caution

Ifthetransducerhitslargerobjectsorbottom,thetransducershaftmaybe

bent,or-inworstcase-itcanbebrokenoff.Abrokentransducershaftwill

causewaterleakagethroughthetopoftheshaft.

Insuchcases,donotraisethetransducershafttoitsupperposition.

Topreventseriousdamage,youmusthaveawaterpumpandawarning

systeminthesonarroom.

Transducer

ThecylindricalTransducerallowsthesonarbeamtogivefull360degreescoverageof

thewatervolumefrom+10anddownto-60degrees.

Scopeofsupply

PleaseobservethestandardandoptionalpartsprovidedwiththeSimradSU90delivery.

Topics

•Mainunitsincludedwiththestandarddeliveryonpage21

•Additionalitemsonpage22

Relatedtopics

•Additionalrequireditemsonpage22

•Optionalitemsonpage25

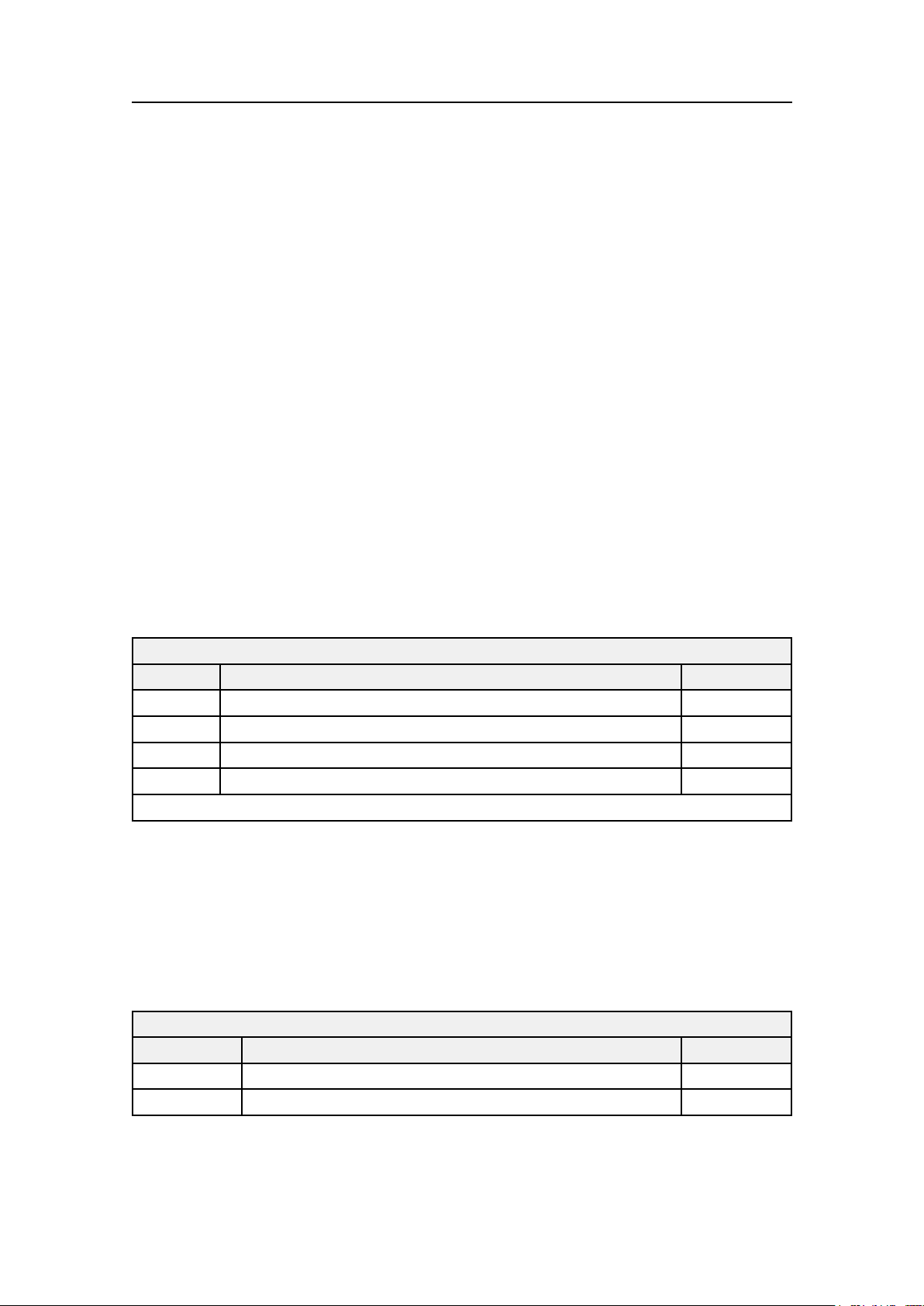

Mainunitsincludedwiththestandarddelivery

Partnumber

SH8-203593

382924

381908

373017

Note

ThestandarddeliveryincludesanSU92hullunitwith4.6mtransducercable.Other

hullunitsandcablelengthsareoptional.

Part/unitnameanddescription

OperatingPanel

ProcessorUnit

TransceiverUnit

SU92HullUnit(with4.6mtransducercable)

Relatedtopics

•Additionalrequireditemsonpage22

•Optionalitemsonpage25

381293/A

21

Page 24

SimradSU90

Additionalitems

Requireditems

SeveraladditionalitemsarerequiredfortheSU90operation.Theseitemsarenormally

notsuppliedbySimrad.Theitemsare:

•Colourdisplayonpage22

•UninterruptedPowerSupply(UPS)onpage23

•Installationtrunkonpage23

•Speedlogonpage24

•Coursegyroonpage24

Optionalitems

Severaloptionalitemsmaybeused:

•Installationtrunkonpage25

•Extendedrangeonpage26

•Scienticinterfaceonpage26

•Otherperipheralequipmentonpage26

•Audiooutputonpage28

•Externalmotionreferenceunit(MRU)onpage30

•SecondaryOperatingPanelonpage30

Additionalrequireditems

Thefollowingadditionalitemsarerequiredforafullyoperationalsystem,butthey

arenotincludedinthestandarddelivery:

Topics

•Colourdisplayonpage22

•UninterruptedPowerSupply(UPS)onpage23

•Installationtrunkonpage23

•Speedlogonpage24

•Coursegyroonpage24

Colourdisplay

TheSimradSU90requiresaVGAorDVIcolourdisplaywitharesolutionofatleast

1280x1024pixels.

TheSU90ProcessorUnitofferstwovideooutputs.Asecondarydisplaymaythen

bemountedatanotherlocationonthevessel.Thetwodisplaywillalwaysshowthe

presentation.

same

22

381293/A

Page 25

SimradSU90

IfyoualsowishtocontroltheSU90fromthissecondarydisplaylocation,youcanadd

anextraOperatingPanel.

Relatedtopics

•SecondaryOperatingPanelonpage30

UninterruptedPowerSupply(UPS)

InordertoensurecontinuousoperationoftheSimradSU90independentofvarying

qualityofthevessel'smainssupply,theuseofuninterruptedpowersupplies(UPS)is

required.

Twouninterruptedpowersupplyunitsareused:

•Oneisusedtopowerthebridgeunits.

•OneisusedtopowertheTransceiverUnit.

Important

Uninterruptedpowersupply(UPS)unitsarenotincludedinthestandardSU90delivery.

Severalcommercialtypesareavailable.TochoosethebestUPSfortheSU90

installation,considerenvironmentalconditions,spaceavailable,theavailabilityand

durationofthebatteries,andthepowerrequirementsoftheSU90units.

TheminimumspecicationsfortheUninterruptedPowerSupply(UPS)are:

•Inputvoltage:Musttvesselsupplyvoltage

•Outputvoltage:230Vac,50Hz

•Outputpower:

–Bridgeunits:1000W

–Sonarroomunits:1500W

•Outputrequirement:TheACoutputvoltagemustbeasinewave

Relatedtopics

•Powerspecicationsonpage223

Installationtrunk

Theinstallationtrunkrequiredforthehullunitinstallationisnotincludedinthestandard

delivery.

Theinstallationtrunkmaybefabricatedbytheshipyard,orsuppliedbySimradasan

option.Themechanicaldrawingsofthetrunkandblindcoverareincludedinthis

manual.TheSimradSU90sonarisdeliveredwithoutadomesystem.

TheoptionaltrunkofferedbyKongsbergMaritimeisapprovedbyDetNorskeV eritas

(DNV),andincludesablindcoverandagasket.

Relatedtopics

•Installationtrunkonpage25

381293/A

23

Page 26

SimradSU90

Speedlog

Inordertooperatecorrectly,theSimradSU90requiresinputfromaspeedlog.Inmost

casesasuitablesensorisalreadyinstalledonthevessel.Adifferentialglobalpositioning

system((D)GPS)canalsobeused.

Speedloginterfaceparameters:

•Serialline:StandardNMEA0183telegramformat

Relatedtopics

•Connectingthespeedlogonpage142

•Conguringandtestingtheinterfacetothespeedlogonpage157

Coursegyro

Inordertooperatecorrectly,theSimradSU90requiresinputfromacoursegyro.Inmost

casesasuitablesensorisalreadyinstalledonthevessel.

Coursegyrointerfaceparameters:

•Serialline:StandardNMEA0183telegramformat

Ifthecoursegyroinstalleddoesnotoutputthecorrectserialinterfaceformat,anoptional

gyrointerfaceboxisavailable.Itwillconvertthefollowingsynchroandstepping

gyrosignals:

•3-phasesynchrosignal,20to150VL-L,50/60/400Hz,gearration1:360or1:180

•3-phasesteppersignal,20to150VL-L,gearration1:360or1:180

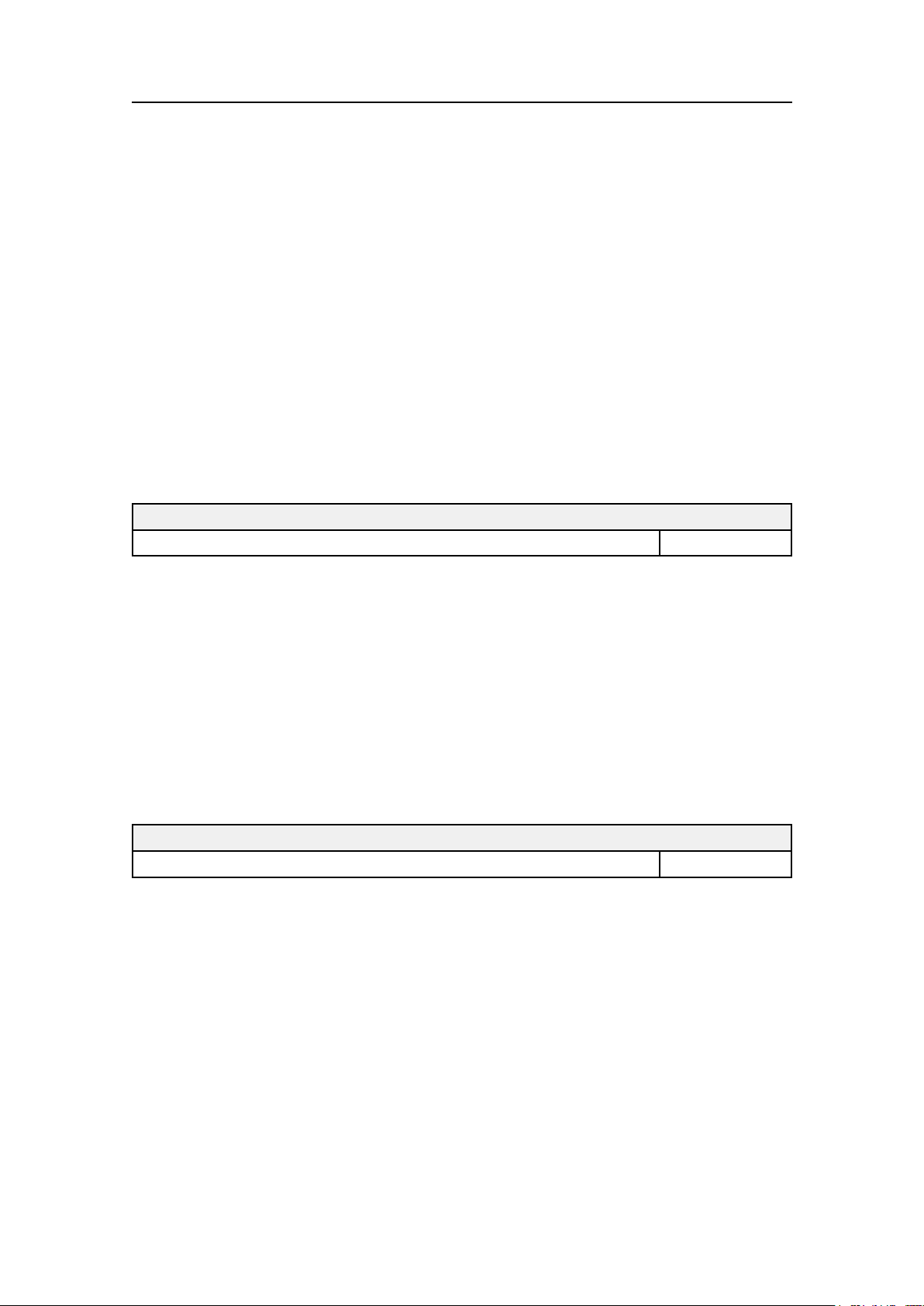

Orderinginformation

LR40Gyrointerface

298-078535

Relatedtopics

•Connectingthecoursegyroonpage143

•Conguringandtestingtheinterfacetothecoursegyroonpage158

24

381293/A

Page 27

Optionalitems

Thefollowingoptionalequipmentandfunctionalitymaybeorderedatanadditional

chargetoaugmentthestandardSimradSU90systemdelivery,orpurchasedlocally

bytheinstallationshipyardorenduser.

Topics

•Installationtrunkonpage25

•Extendedrangeonpage26

•Scienticinterfaceonpage26

•Otherperipheralequipmentonpage26

•Audiooutputonpage28

•Externalmotionreferenceunit(MRU)onpage30

•SecondaryOperatingPanelonpage30

SimradSU90

Hullunit

ThestandardSU92HullUnitcanbelowered1.2metersataspeedof21knots.The

mountingangehas24boltswithpitchcentrediameter(PCD)680mm.Otherhull

unitsareavailableaslistedbelow.

HullunitsavailablefromKongsbergMaritime

HullUnitSpecicationsOrderno.

SU92*1.2m,21knots,24bolts,PCD680mm,4.6mtransducercable

SU92

SU93

SU93

(*=SU92with4.6mtransducercableisthestandardhullunit)

1.2m,21knots,24bolts,PCD680mm,7mtransducercable

1.6m,16knots,20bolts,PCD620mm,4.6mtransducercable

1.6m,16knots,20bolts,PCD620mm,7mtransducercable

373017

386420

373018

386422

Installationtrunk

Theinstallationtrunkmaybefabricatedbytheinstallationshipyard,orsuppliedby

KongsbergMaritime.Thesameinstallationintrunkisusedforallhullunits.

IfyouarereplacinganSX90orSP90sonarwithanewSU90,youcanuseyourexisting

trunk.However,duetothelargertransducerontheSU90sonar,atrunkextensionmust

beused.

OptionalinstallationtrunksavailablefromKongsbergMaritime

Trunktype

SU92/SU9324bolts,PCD680mm

Extension24bolts,PCD680mm

SpecicationsOrderno.

Relatedtopics

•Mountingthetrunkextensiononpage58

381293/A

376655

374676

25

Page 28

SimradSU90

•SU92Hullunitdimensionsdrawingonpage263

•SU93Hullunitdimensionsdrawingonpage265

•SU92/SU93Mountingtrunkproductiondrawingonpage267

•SU92/SU93Extensiontrunkproductiondrawingonpage269

•SU92/SU93Blindcoverdrawingonpage271

Extendedrange

Duetointernationalregulations,sonarswithoperationalrangeexceeding5000meters

canonlybeexportedonlicense.

ForthisreasonthestandardrangeontheSU90hasbeenlimitedto4500meters.

However,ifanexportlicenceisobtained,themaximumrangecanbeextendedto

8000meters.

Orderinginformation

Extended8000mrange

314506

Scienticinterface

TheScienticOutputisdesignedforresearchpurposes.Whenactivated,thefollowing

dataareavailableonanEthernet(LAN)output:

•Beamdata

•Targetdata

•Ownshipdata

•Geardata

ThescienticoutputoptionmayalsoincludesoftwareforaScienticDataLogger.

Orderinginformation

Scienticinterface

KIT-203477

Otherperipheralequipment

TheSimradSU90providesseveralseriallines.Twooftheseareusedtointerfacetothe

speedlogandcoursegyro.Theremainingseriallinescanbeusedtocommunicate

withotherperipheralequipment.

26

381293/A

Page 29

Thisequipmentmayforexampleinclude:

•DifferentialGlobalPositioningSystem((D)GPS)

•Motionreferenceunit(MRU)

•Echosounder

•Catchmonitoringsystem

•Trawlsonar

•Currentmetersystem

•Radiobuoysystem

Alltheseperipheralsmaybeconnectedusingtheseriallines.Mostofthemwill

communicatebymeansofthestandardNMEA0183format.

Notethatperipheralequipmentandsensorsmustbepurchasedlocallybytheinstallation

shipyardorenduser.

SimradSU90

DifferentialGlobalPositioningSystem((D)GPS)

A(D)GPSmaybeinterfacedwiththeSimradSU90sonartoestablishthevessel’s

positionandprovidecursorandmarkerlatitudeandlongitude.

Inadditiontonavigationaldata,the(D)GPSmayalsobeusedfortheinputofspeedlog

information.Most(D)GPSareequippedtopresentcourseinformation,butthisdatais

generallytooinconsistenttoprovideastablesonarpresentation.

Relatedtopics

•Positioningsysteminterfaceonpage286

Motionreferenceunit(MRU)

TheSU90offersabuilt-inmotionsensortoprovidestabilisationofthesonarbeams.

Youmayincreasetheefciencyandaccuracyifyouinstallaseparatemotionreference

unit(MRU).TheSU90providesaninterfacetotheMRU3sensormanufacturedby

KongsbergMaritime.Relevantinstallationproceduresareincludedinthismanual.

Relatedtopics

•Externalmotionreferenceunit(MRU)onpage30

•Connectinganexternalmotionreferenceunit(MRU)onpage144

Catchmonitoringsystem

Toprovidetrawlandpurseseinedepthinformationonthesonar’sdisplay,thefollowing

Simradcatchmonitoringsystemsmaybeconnected:

•SimradPISeriesCatchmonitoringsystems

•SimradITIIntegratedTrawlInstrumentationsystem

Relatedtopics

•Catchmonitoringsysteminterfaceonpage287

381293/A

27

Page 30

SimradSU90

Trawlsonar

Toprovidetrawlinformationonthesonar’sdisplay,oneofthefollowingSimradtrawl

systemsmaybeconnected:

•SimradFS903Trawlsonar

•SimradFS3300Trawlsonar

•SimradFS20/25Trawlsonar

•SimradFS70Trawlsonar

Relatedtopics

•Trawlsonarinterfaceonpage286

Currentmetersystem

Acurrentmetersystemmaybeconnectedtothesonartodisplaythedirectionandspeed

oftheseacurrentsonvariousdepths.Thefollowingcurrentsystemcanbeconnected:

•KaijoDCG-200

Relatedtopics

•Currentmeterinterfaceonpage287

Radiobuoysystem

AGPSbasedradiobuoysystemmaybeconnectedtothesonartoshowthepositionand

buoydataonthedisplay.Thefollowingbuoysystemscanbeconnected:

•SERPE

•Ariane

•Ryokusei

Relatedtopics

•Radiobuoysconnectioninterfaceonpage287

Audiooutput

Topics

•Abouttheaudiooutputonpage29

•PoweredspeakersystemforPCuseonpage29

•Stereosystemwithamplierandtwoormoreloudspeakersonpage29

Relatedtopics

•Mini-jacktophonoaudiocableonpage294

•Commercialpoweredspeakersystemonpage304

28

381293/A

Page 31

SimradSU90

SIMRAD

PWR

MENU

SIMRAD

SIMRAD

(CD015043-021)

Abouttheaudiooutput

Theaudiooutputmustthereforebeconnectedtoapoweredaudiosystem.Thesystem

mustincludeavolumecontrol,astheaudiooutputlevelfromthesonarisxed.The

audiooutputlevelcannotbecontrolledbytheAudiooffbuttonontheOperatingPanel,

asthisbuttonwillsilencetheaudiooutputcompletely.

Donotconnectaloudspeakerdirectlytotheaudiooutput.Thismaydamagetheaudio

outputcircuitry.

Werecommendthatoneofthefollowingaudiosystemsisused:

•CommercialpoweredspeakersystemforPCuse

•Commercialstereosystemwithamplierandtwo(ormore)loudspeakersand/or

headphones

PoweredspeakersystemforPCuse

AcommercialpoweredspeakersystemforPCusecanbeobtainedfromalmostanykind

ofshopforelectricappliances,homestereoorcomputers.

Thenumberofspeakers,sizeandpoweroutputcanbeselectedtosuitthecrew

preferences.Thelocationofthespeakersmustbedecidedtoallowforeasyadjustment

oftheaudiolevel.

Stereosystemwithamplierandtwoormoreloudspeakers

Ifastereosystemisalreadyinstalledonthebridge,theaudiooutputfromtheSU90

canbeconnectedtoanauxiliaryinput.

381293/A

29

Page 32

SimradSU90

SIMRAD

PWR

MENU

SIMRAD

SIMRADSX90

(CD015043-022)

Theadvantageofthissetupisthatmoststereosystemsareprovidedwitharemote

control,andthisallowsforeasyadjustmentoftheaudiolevel.

Externalmotionreferenceunit(MRU)

Bydefault,theSU90usesabuilt-inmotionreferencedetectormountedonthehullunit.

Forimprovedaccuracy,andexternalmotionreferenceunit(MRU)maybeused.

ThemotionreferenceinterfacefunctionalityontheSU90hasbeendesignedtomatch

theMRUsmanufacturedbyKongsbergSeatex.Descriptionsofallavailabletypesare

providedonhttp://www.km.kongsberg.com/seatex

.TheMRUinterfaceintheSU90

willhoweverallowyouuseanytypeofsensorprovidedthatitoutputstheEM3000

datagramformat.

Relatedtopics

•Otherperipheralequipmentonpage26

•Connectinganexternalmotionreferenceunit(MRU)onpage144

SecondaryOperatingPanel

AsecondaryOperatingPanelmaybeconnected

totheSU90ProcessorUnit.Thismaybeusefulin

conjunctionwithasecondarydisplayifyouwishto

controltheSU90fromtwodifferentlocationsonyour

vessel.

Thesecondaryoperatingpanelwillallowyoutodoallsonaroperationsexceptpower

on/off.

Orderinginformation

SecondaryOperatingPanel(kitwithallparts)

Relatedtopics

•ConnectingasecondaryOperatingPanelonpage147

30

372980

381293/A

Page 33

Generalsupplyconditions

ThefollowinggeneralsupplyconditionsapplytothisSimradSU90delivery.

Topics

•Equipmentresponsibilityonpage31

•Receipt,unpackingandstorageonpage31

Equipmentresponsibility

Theshipyardperformingtheinstallationand/orequipmentdealerbecomesfully

responsiblefortheequipmentuponreceiptunlessotherwisestatedinthecontract.

Thedurationofresponsibilityincludes:

•Theperiodoftimetheequipmentisstoredlocallybeforeinstallation.

•Duringtheentireinstallationprocess.

SimradSU90

•Whilecommissioningtheequipment.

•Theperiodoftimebetweencommissioningandthenalacceptanceoftheequipment

bytheenduser(normallytheownerofthevesselwhichtheequipmenthasbeen

installed).

Unlessotherarrangementshavebeenmadeinthecontract,theSimradSU90guarantee

period(asspeciedinthecontract)beginswhentheacceptancedocumentshavebeen

signed

Receipt,unpackingandstorage

Uponacceptingshipmentoftheequipment,theshipyardand/orthedealershouldensure

thatthedeliveryiscompleteandinspecteachshippingcontainerforevidenceofphysical

damage.Ifthisinspectionrevealsanyindicationofcrushing,dropping,immersionin

wateroranyotherformofdamage,therecipientshouldrequestthatarepresentative

fromthecompanyusedtotransporttheequipmentbepresentduringunpacking.

Allequipmentmustbeinspectedforphysicaldamage,i.e.brokencontrolsandindicators,

dents,scratchesetc.duringunpacking.Ifanydamagetotheequipmentisdiscovered,the

recipientshouldnotifyboththetransportationcompanyandKongsbergMaritimesothat

KongsbergMaritimecanarrangeforreplacementorrepairofthedamagedequipment.

Onceunpacked,theequipmentmustbestoredinacontrolledenvironmentwithan

atmospherefreeofcorrosiveagents,excessivehumidityortemperatureextremes.The

equipmentmustbecoveredtoprotectitfromdustandotherformsofcontamination

whenstored.

Formoreinformation,seetheinformationrelatedtoequipmenthandling.

Relatedtopics

•Equipmenthandlingonpage273

381293/A

31

Page 34

SimradSU90

Generalinstallationrequirements

ThefollowinggeneralinstallationrequirementsareapplicabletothisSU90delivery.

Topics

•Supplypoweronpage32

•UninterruptedPowerSupply(UPS)onpage32

•Wiringonpage32

•Compassdeviationonpage33

•Noisesourcesonpage33

•Drydockingonpage33

•Approvalbyclassicationsocietyonpage33

Supplypower

Thesupplyvoltagetotheequipmentistobekeptwithin±10%oftheinstallation’s

nominalvoltage.Maximumtransientvoltagevariationsonthemainswitchboard’s

bus-barsarenottoexceed-15%to+20%ofthenominalvoltage(exceptunderfault

conditions).

UninterruptedPowerSupply(UPS)

TheSimradSU90system(exceptthehullunit)mustbepoweredusinganUninterrupted

PowerSupply(UPS)withsinewaveoutput.

TheUninterruptedPowerSupplymusthavethecapacitytoindependentlymaintain

powertothesystemforaminimumof10minutes.ThisensuresthattheSU90canbe

switchedoffinacontrolledmannerintheeventofapowerfailure.

Wiring

Allcablesrunningbetweensystemcabinetslocatedindifferentroomsand/orondifferent

decksmustbesupportedandprotectedalongtheirentirelengthsusingconduitsand/or

cabletrays.Notethatthecablesmustnotbeinstalledinthevicinityofhigh-power

suppliesandcables,antennacablesorotherpossiblesourcesofinterference.

Formoredetailedinformationaboutcablesandwiring,refertothebasiccable

requirements.

Relatedtopics

•Basiccablerequirementsonpage307

32

381293/A

Page 35

SimradSU90

Compassdeviation

Oncetheinstallationiscomplete,thevesselmustbeswungwiththesysteminboth

theoperativeandinoperativemodes.Theshipownerandcaptainareresponsiblefor

updatingthedeviationtableaccordinglywithregardtothevessel’snationalregistryand

correspondingmaritimeauthority.

Noisesources

Thevessel’shull,rudder(s)andpropeller(s)shouldbethoroughlyinspectedindrydock

priortoinstallation.

Roughnessbelowthewater-linedeformitiesintheshellplatingandprotrudingobstacles

cancreateunderwaternoise.Thesesourcesofturbulencemustbesmoothedorremoved

asbestaspossible.Itisespeciallyimportantthatthepropeller(s)isnotpittedordamaged.

Relatedtopics

•Acousticnoiseonpage47

Drydocking

Makesurethatampleclearanceunderthesonartrunkand/orprotectionblisteris

providedwhendrydockingthevessel.

Avoidlocatingsupportingblocksorstructuresinthevicinityofthisequipment.

Note

Thelocationofthesonartrunkmustbenotedonthevessel’ sdockingplanforfuture

reference.

Priortodrydocking,powerdownallhydroacousticsystems,andlabeleachsystem

accordinglytopreventaccidentalpoweron.

Removecircuitbreakersifnecessary.

Approvalbyclassicationsociety

TheSimradSU90sonartrunkinstallationmustbeapprovedbyDetNorskeVeritas

(DNV)oranotherclassicationsociety.

Theshipownerandshipyardperformingtheinstallationareresponsibleforobtaining

theinstallationapproval.

Supportinformation

IfyouneedtechnicalsupportforyourSimradSU90youmustcontactyourlocal

dealer,oroneofoursupportdepartments.Alistofallourdealersisprovidedon

http://www.simrad.com.

381293/A

33

Page 36

SimradSU90

Norway(Mainofce)

•Companyname:KongsbergMaritimeAS/Simrad

•Address:Strandpromenaden50,3190Horten,Norway

•Telephone:+4733034000

•Telefax:+4733042987

•E-mailaddress:simrad.support@simrad.com

•Website:http://www.simrad.no

Spain

•Companyname:SimradSpain

•Address:PoligonoPartidaTorres38,03570Villajoyosa,Spain

•Telephone:+34966810149

•Telefax:+34966852304

•E-mailaddress:simrad.spain@simrad.com

•Website:http://www.simrad.es

USA

•Companyname:KongsbergUnderwaterTechnologyInc/SimradFisheries

•Address:1921033rdAveW,Lynnwood,WA98036,USA

•Telephone:+14257121136

•Telefax:+14257121193

•E-mailaddress:simrad.usa@simrad.com

•Website:http://www.simrad.com

Malaysia

•Companyname:KongsbergMaritimeMalaysiaSdn.Bhd

•Address:Unit27-5SignatureOfces,TheBoulevard,MidV alleyCity,Lingkaran

SyedPutra,59200KualaLumpur,Malaysia

•Telephone:+6564117488

•Telefax:+60322013359

•E-mailaddress:simrad.asia@simrad.com

•Website:http://www.simrad.com

34

381293/A

Page 37

Installationprocedure

Installationprocedure

TheSimradSU90isacomplexandadvancedproductforprofessionaluse.

Anoverallinstallationprocedureisprovidedbelow.Theproceduredoesnotdescribe

anydetailedtasks,butreferstotherelevantproceduresinthismanual.

Note

Inordertoobtainmaximumsafetyandperformance,itisveryimportantthatthe

installationproceduresinthismanualarecompliedto,andthatthetasksarecarried

outinthesuccessiontheyaredescribed.Thevesselownermustmakesurethatthe

installationshipyardholdstheapplicablecompetencetoperformtheinstallation,and

thattheapplicablemaritimeauthoritiesareavailabletoverifyandcertifytheinstallation.

ObservethebasicrequirementsinGeneralsafetyrulesonpage272!

1Basedonthevesseldrawingsandbestpractice,determinewherethehullunitshall

belocated.Necessaryconsiderationsmustbetakentoavoidacousticandelectric

disturbances.Makesurethatthesonarroommeetsthespecicationsprovided.

→Preparationsonpage37

2Performthephysicalinstallationofthesonartrunk.Theinstallationshipyardmust

provideallnecessaryinstallationdrawingsinordertocarryoutthisoperation,andif

required,thesedrawingsmustbeapprovedbytheapplicablemaritimeauthorities.

Thetrunkpenetratesthehull,anditisthereforeacrucialpartofthehullunit

assembly.

→Installingthesonartrunkonpage55

3Installthehullunit.Duetoitsphysicalsizeandweight,andthefactthatthetrunk

penetratesthevesselhull,itisveryimportantthatthehullunitisinstalledand

securedproperly.

→Installingthehullunitonpage63

4InstalltheTransceiverUnit.

→InstallingtheTransceiverUnitonpage77

5Installthebridgeunits.

→Installingthebridgeunitsonpage81

381293/A

35

Page 38

SimradSU90

6Performthesystemcabling.Observetheproceduresandcableplans,thedetailed

cabledrawingsandthegeneralrequirementsforthecabling.

→Cablelayoutandinterconnectionsonpage90

→SU90cabledetailsonpage284

→Basiccablerequirementsonpage307

7Performthe“settingtowork”procedures.

Note

InordertosetuptheSU90inasafeandcorrectmanner,theseproceduresmustbe

compliedto!

→Settingtoworkonpage163

8Connecttheperipheralunits.Observethesetupandtestprocedures,thedetailed

cabledrawingsandthegeneralrequirementsforthecabling.

→Interfacingperipheralequipmentonpage124

→SU90cabledetailsonpage284

→Basiccablerequirementsonpage307

9Checkthesourcelevelandreceivingvoltageresponse,andmakethenoise/speed

measurements.

→Finaltestsandmeasurementsonpage198

10Createabackupofallthesoftwareandinstallationsetupparametersonthe

ProcessorUnit.

→ProcessorUnitbackupandrestoreonpage210

11FillinandsigntheInstallationRemarksform,andsendittoSimrad'ssupport

departmentasspeciedontheform.

→Installationremarksonpage311

36

381293/A

Page 39

Preparations

Preparations

Note

Ifyouareinstallingthehullunitonapreviouslyttedinstallationtrunk,rstreadthe

informationaboutsonarroomrequirements.ThenproceedtotheHullUnitinstallation

description.

ThischapterprovidestheinformationnecessarytoplantheinstallationoftheSimrad

SU90accordingtoKongsbergMaritime’srequirements.

Correctinstallationofthehullunitandtransducerisvitaltothesystemperformance.

Severalvariablesmustbetakenintoconsideration,themostimportantofwhichisthe

vessel’sconstruction.Thisguidecanbeusedtoselectthebestlocationforthehull

unitandtransducer.

Topics

•Installationdrawingsonpage38

•Necessarytoolsandequipmentonpage38

•Workerskillsonpage39

•Determingthelocationofthehullunitonpage40

•Sonarroomrequirementsonpage42

•Sonarroomarrangementexampleonpage45

•Acousticnoiseonpage47

381293/A

37

Page 40

SimradSU90

Installationdrawings

Allinstallationdrawingsmustbesuppliedbytheshipyardperformingtheinstallation.

Note

Theinstallationshipyardmustprovideallnecessaryinstallationdrawings,andif

required,thesemustbeapprovedbytheapplicableauthorities.

Note

Theinstallationmustbeapprovedbythevessel’ snationalregistryandcorresponding

maritimeauthorityand/orclassicationsociety.Theshipownerandshipyardperforming

theinstallationareresponsibleforobtainingandpayingforinstallationapproval.

KongsbergMaritimeoffersfreeadviceforinstallationplanning.Proposedarrangements

maybesentforcommentaryorsuggestionssuppliedbyKongsbergMaritime.The

followingdrawingsshouldbesubmittedshouldassistanceberequested:

•Generalarrangement

•Bodyplananddrawingsofrelevantbottomtanksandcofferdams

•Linesplan

Relatedtopics

•Drawingleonpage255

Necessarytoolsandequipment

TheinstallationoftheSimradSU90musttakeplaceindrydock,andtheworkmust

bedonebyaqualiedshipyard.

InordertodotheSU90installation,allnecessarytoolsandequipmentformechanical

hullwork,cabinetinstallationandelectricalwiringmustbeavailable.Itisnotpractical

toprovideadetailedlistofallnecessarytoolsandequipment.However,youmustmake

surethatthefollowingspecializedtoolsareavailable.

•Allnecessarytoolsanditemsrequiredforwelding

•Acranecapableofliftingtheentirehullunit

38

381293/A

Page 41

Preparations

Workerskills

TheinstallationoftheSimradSU90isademandingtask,anditisveryimportantthatthe