Page 1

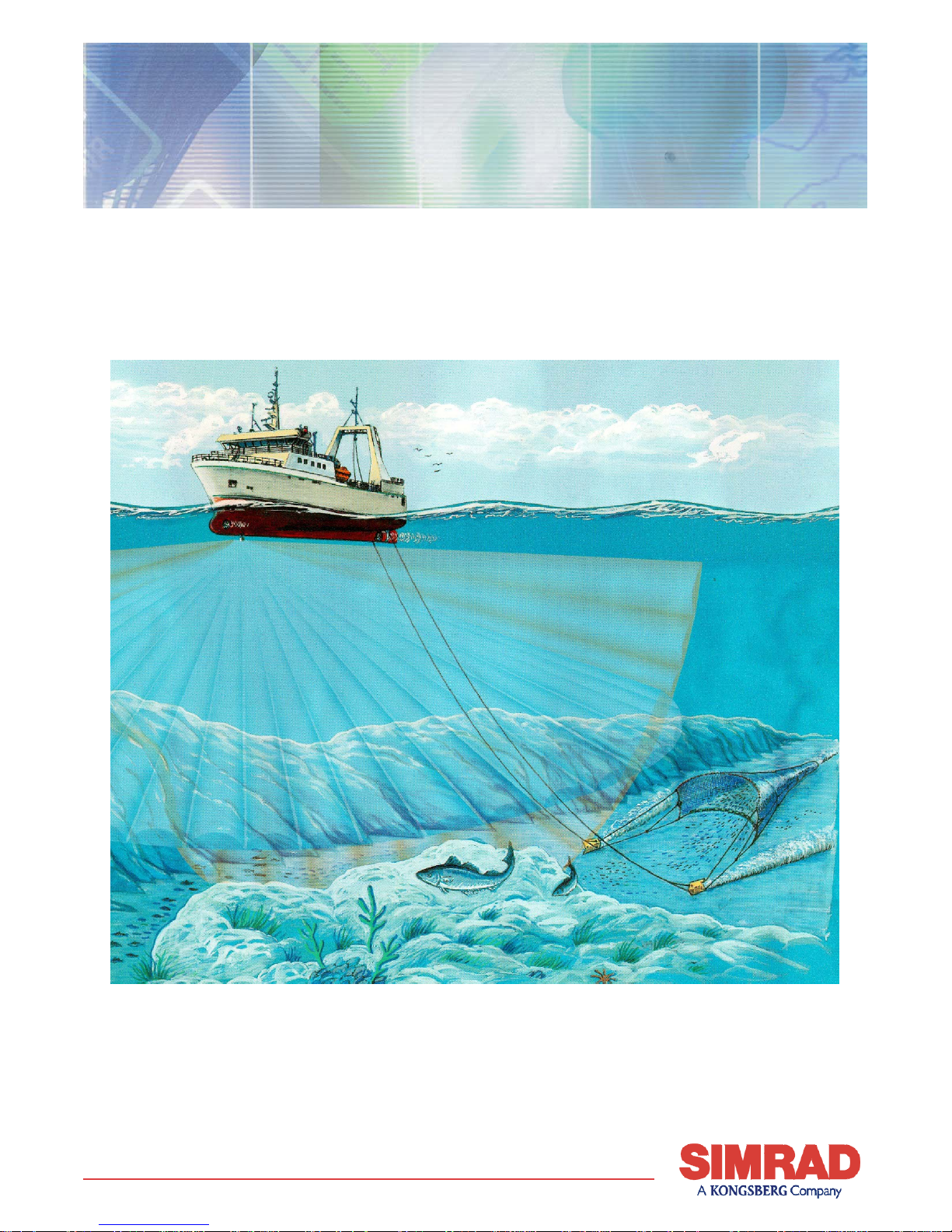

Simrad SP270

Fishery sonar

Installation manual

A L W A Y S A T T H E F O R E F R O N T O F T E C H N O L O G Y

www.simrad.com

Page 2

Page 3

Simrad SP270

Fishery sonar

Installation manual

851--160570 / Rev.B

Page 4

Note

Simrad AS makes every effort to ensure that the information contained within this

document is correct. However, our equipment is continuously being improved and

updated, so we cannot assume liability for any errors which may occur.

Warning

The equipment to which this manual applies must only be used for the purpose for

which it was designed. Improper use or maintenance may cause damage to the

equipment or injury to personnel. The user must be familiar with the contents of the

appropriate manuals before attempting to operate or work on the equipment.

Simrad AS disclaims any responsibility for damage or injury caused by improper

installation, use or maintenance of the equipment.

Copyright

E 2004 Simrad AS

ISBN 82-8066-014-3

The information contained within this document remains the sole property of Simrad

AS. No part of this document may be copied or reproduced in any form or by any

means, and the information contained within is not to be communicated to a third party,

without the prior written consent of Simrad AS.

Support

For support on your Simrad equipment, consult your local dealer, visit

www.simrad.com, or contact us directly at support.fish@simrad.com.

Simrad AS

Strandpromenaden 50

Box 111

N-3191 Horten

Telephone: +47 33 03 40 00

Facsimile: +47 33 04 29 87

M A X I M I Z I N G Y O U R P E R F O R M A N C E A T S E A

Page 5

Installation manual

I

851-160570 /B

Sections

1Introduction

This section gives a brief descriptionoftheSP270sonarandtheinstallation

requirements.

2 Installation procedures

Thissectionprovidesthe necessaryinformation for theinstallationandcabling

of the complete SP 270 sonar system according to Simrad’s requirements.

3 Start-up procedures

This section contains the start-up procedures to be carried out after the

installation of the SP 270 sonar.

4Drawings

This section contains the drawi ngs necessary for the installation.

5 Appendices

This section provides information for installation of optional equipment to the

sonar.

Page 6

Simrad SP270

II

851-160570 / B

Remarks

References

Further i nformation about the SP270 system may be found in the following manual:

• SP270 Operator manual

The reader

This Installation manual is intended for the design and installation engineers at the

shipyard performing the installation. The information is supplied as the basis for the

shipyard’s own installation drawings applicable to the vessel. On completion of the

installation, this manual must be kept on the vessel for reference purposes during

system maintenance.

Note

This manual includes sections that may be revised individually. In the event of a

revision to any part of this manual, this “Cover and Contents” section will be replaced.

Page 7

Installation manual

III

851-160570 / B

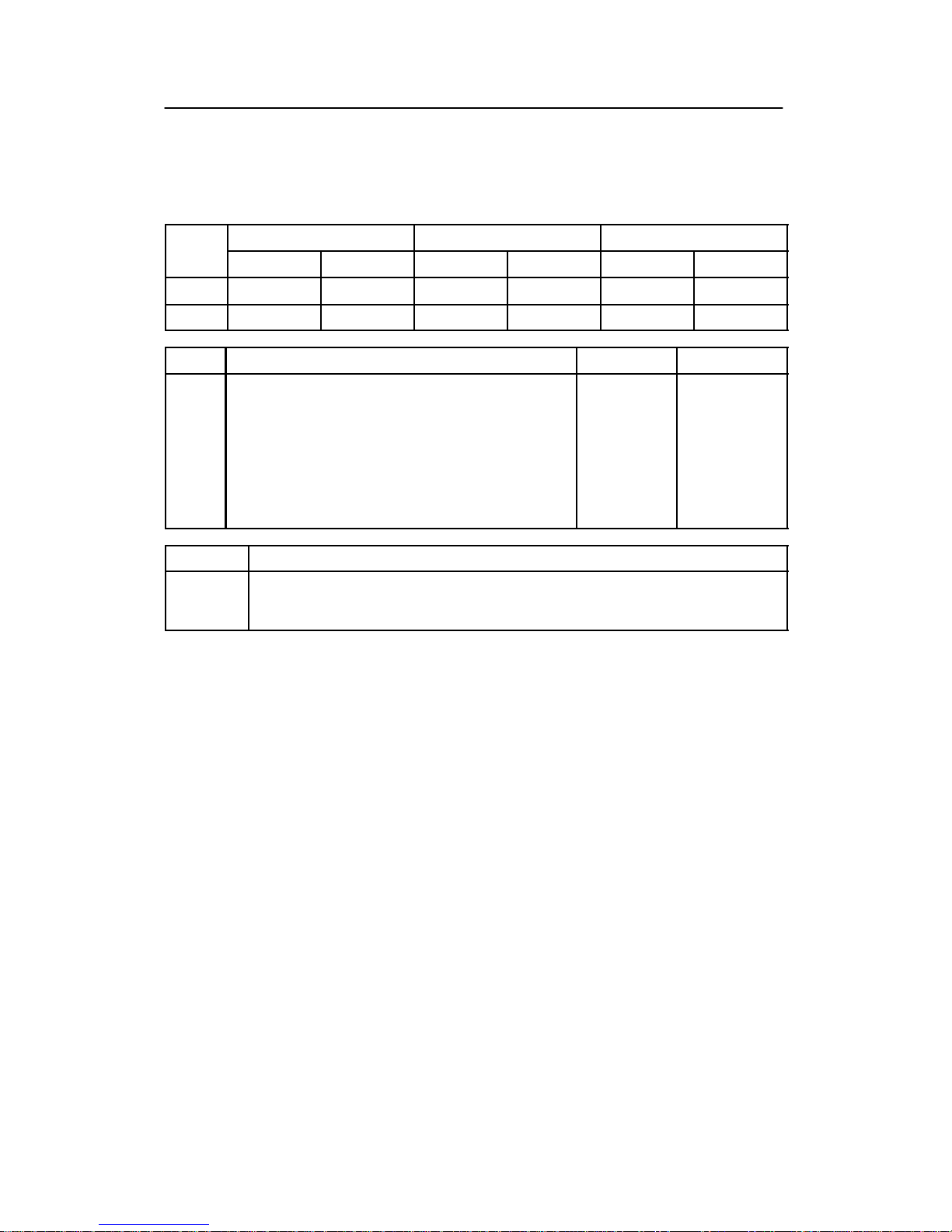

Document revisions

Rev Written by

Checked by Approved by

Date Sign Date Sign Date Sign

A 30.06.99 CL 30.06.99 SØJ 30.06.99 SØJ

B 30.01.04 RBr 30.01.04 EGj 30.01.04 ESB

Sect Title Revision File

0 Cover and contents B 851--160570

1 Introduction B 851--160571

2 Installation procedures B 851--160572

3

4

5

Start--up procedures

Drawings

Appendices

A

A

B

851--160573

851--164095

851--160675

Rev.A First edition.

Rev.B Re--issued. Sections 1 and 2 updated to Rev.B without any significant

changes to the product related information. Section 5 was 851--164096,

now replaced with 851--160675 (Rev.B).

Page 8

Simrad SP270

IV

851-160570 / B

Blank page

Page 9

Installation manual

V

851-160570 / B

High voltage safety warning

Precautionary measures

The voltages used to power this equipment

are potentially lethal. Even 110 volts can kill.

Whenever possible, the following

precautionary measures must be taken before

any work is carried out inside the equipment:

S Switch off all high-voltage power supplies.

S Check the operation of any door interlocks

and any other safety devices.

S Completely discharge all high-voltage

capacitors.

It should be noted that interlocks and safety

devices are normally located only at regular

access points, and high voltages may be

exposed during dismantling.

Never work alone on high-voltage

equipment!

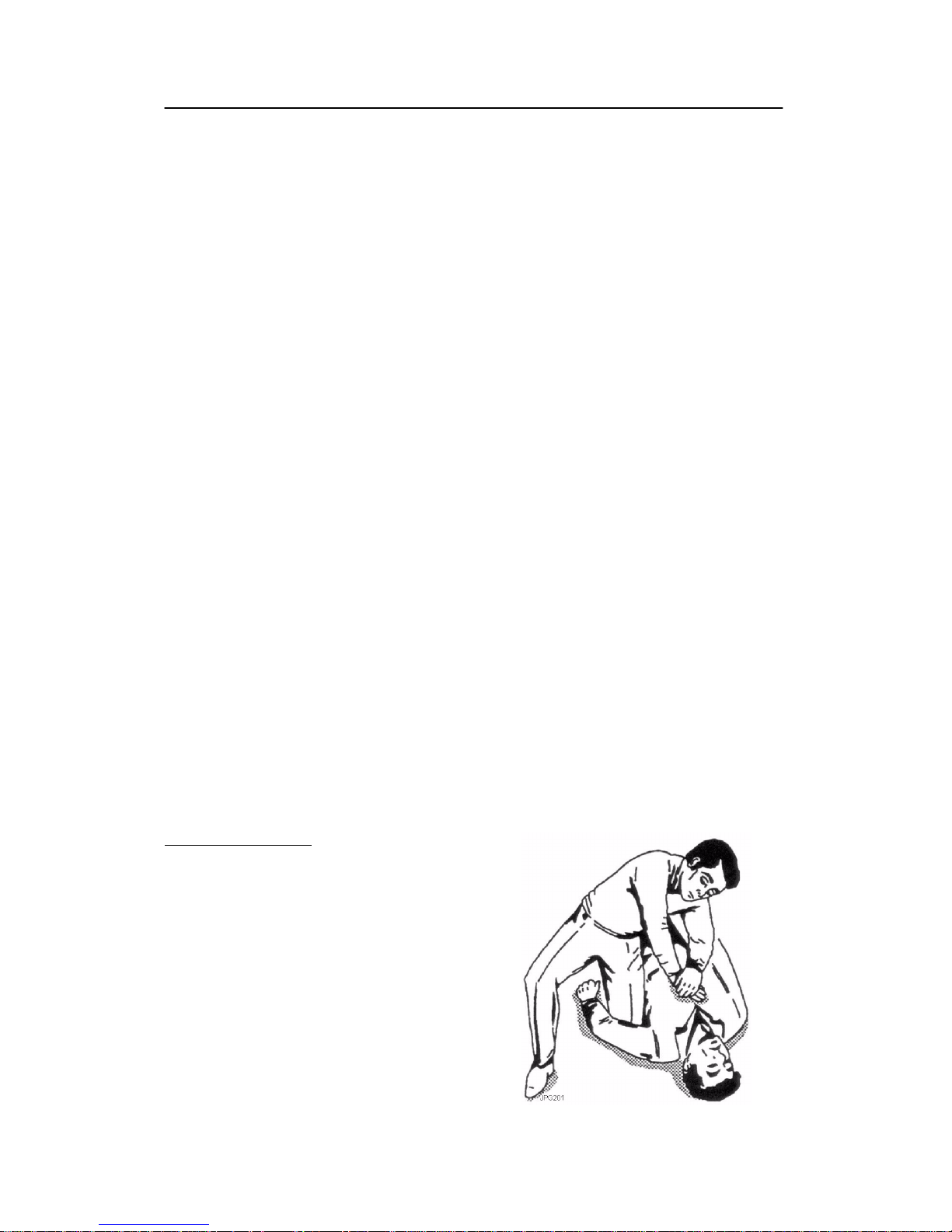

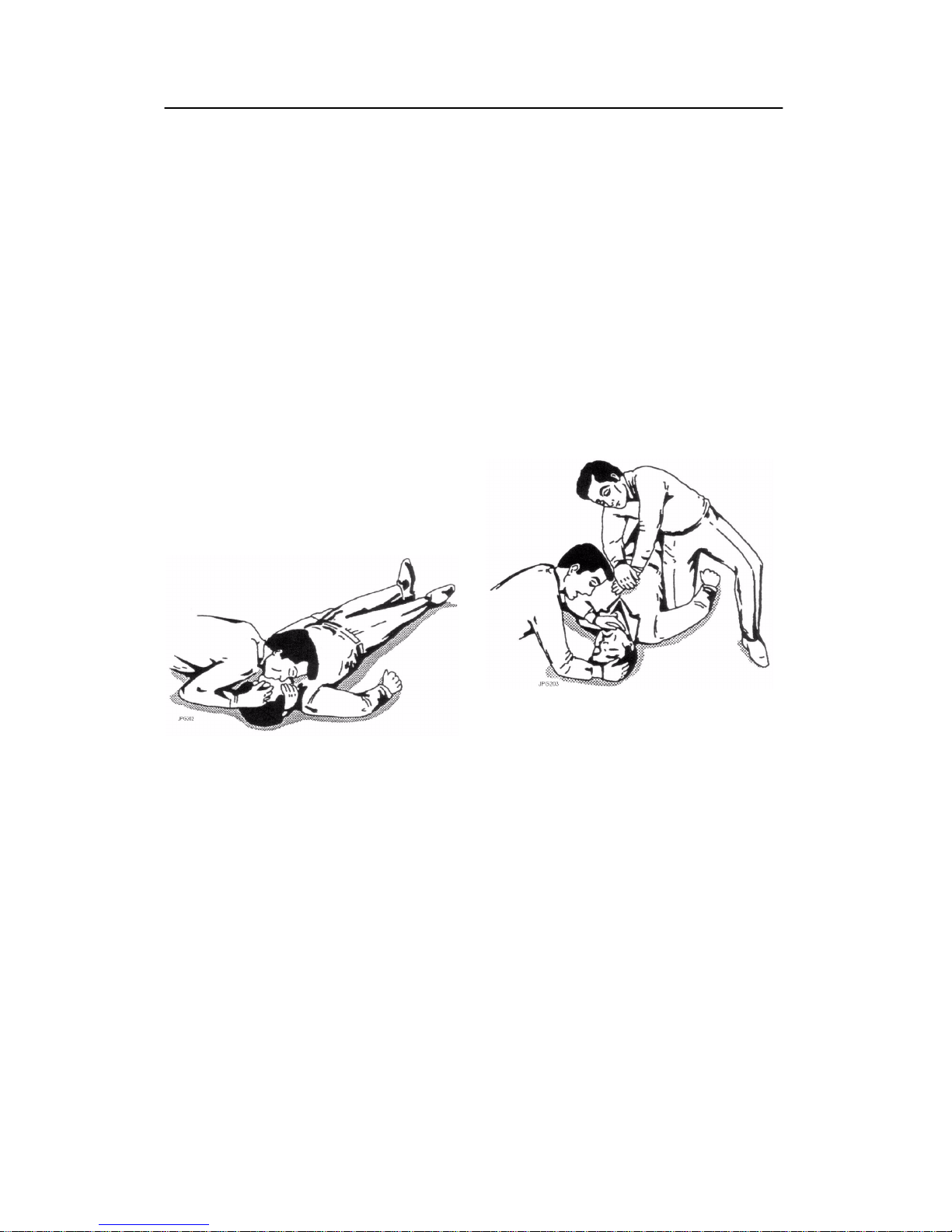

First aid in the event of

electric shock

Normally, even a high voltage electric shock

will not kill instantly. The victim can still be

revived even when his breathing and

heart-beat have ceased.

Could YOU save someone’s life?

In the event of electric shock, the correct

actions, performed quickly may well save the

victim’s life. Make sure you know what to

do!

Immediate action

While shouting for help, remove the source of

power from the victim. Switch off the supply

if possible, or using a dry, non-conductive

material (rubber gloves, broom handle etc.) to

insulate yourself, separate the victim from the

source. If the voltage exceeds 1000 volts,

switch off the supply and be ready to catch

the victim. Take care- do not become a victim

yourself.

Commence first aid on the spot. Continue to

shout for assistance till someone arrives.

1 Lay the victim flat on his back and loosen

any tight clothing (collar, tie, belt etc.).

2 Open his mouth and check for and remove

any false teeth, chewing gum etc.

3 Check if the victim is breathing. If not,

check if his heart is beating. The pulse is

normally easily found in the main arteries

of the neck, either side of the throat, up

under the chin.

If his heart is beating but he is not breathing,

commence artificial respiration. If the

victim’s heart is not beating, commence

external cardiac massage (ECM). Continue to

shout for assistance till someone arrives.

External cardiac massage

1 Kneel beside the victim. Place the heel of

one hand in the centre of his chest, at a

position half way between the notch

between the collar-bones at the top of his

chest, and the dip i n the breast-bone at the

base of his rib cage. Place the other hand

on top of the first.

2 Keeping the arms straight and using your

entire weight, press down rapidly so that

the breast bone is depressed four- five cm,

then release the pressure. Repeat

rhythmically at a rate of one cycle per

second. This will be hard work, but keep

going. His life depends on YOU. Do not

worry about breaking his ribs - these will

heal if he survives.

Page 10

Simrad SP270

VI

851-160570 / B

Artificial respiration

1 Kneel besides the victim’s head. Place one

hand under his neck and lift, allowing his

head to fall back. This will lift his tongue

and open the air passage in his throat.

2 Place the palm of the hand on his forehead

to maintain the ”chin-up” position.

3 Using the index finger and thumb of the

same hand, pinch the victim’s nostrils

closed. Open his mouth.

4 Take a deep breath and cover his mouth

with yours. Blow steadily into his lungs to

expand his chest. Remove your mouth

from his to allow the air t o escape from his

chest. You should be able to see his chest

deflate.

5 Repeat the ”inflation-deflation” cycle at a

rate of about 12 cycles per minute till the

victim begins to breath normally again.

Combining ECM and artificial

respiration

If you are alone, perform one cycle of

artificial respiration for every five cycles of

ECM. This will be hard work, but keep going.

His life depends on you!

If there are other people available to help, one

should perform the ECM while one performs

the artificial respiration for every five cycles

of ECM. It will be much more efficient with

two people.

Once the victim’s heart is beating and he is

breathing, roll him onto his side and support

him in that position. As consciousness returns

he may vomit, and this will allow any liquid

to drain out of his mouth.

Remove the victim to a hospital as soon as

possible, but do not interrupt the artificial

respiration and ECM cycles till his heart beat

and breathing returns.

If started quickly and performed correctly, the

resuscitation methods described will keep a

sufficient volume of oxygenated blood

flowing trough the victims body to allow full

recovery.

Proficiency in the resuscitation methods can

only be achieved trough training. All

personnel concerned should attend courses on

a regular basis. Remember, someone’s life

could depend on you.

Do you know what to do?

Page 11

Introduction

I

851-160571 / B

851-160571

SP270

Introduction

This section gives a brief description of the SP270 sonar

and the installation requirements.

Page 12

Simrad SP270

II

851-160571 / B

Document revisions

Rev Date Written by Checked by Approved by

A 30.06.99 CL SØJ SØJ

B 28.01.04 RBr EGJ ESB

Rev .A Original issue.

Rev .B Document updated for re--issue. General information updated. No specific

changes to product related text or illustrations.

About this document

The information contained in this document is subject to change without prior notice.

Simrad AS shall not be liable for errors contained herein, or for incidental or

consequential damages in connection with the furnishing, performance, or use of this

document.

© 2004 Simrad AS. All rights reserved. No part of this work covered by the copyright

hereon may be reproduced or otherwise copied without prior permission from Simrad

AS.

Simrad AS

Strandpromenaden 50

Box 111

N-3191 Horten

Telephone: +47 33 03 40 00

Facsimile: +47 33 04 29 87

M A X I M I Z I N G Y O U R P E R F O R M A N C E A T S E A

Page 13

Introduction

III

851-160571 / B

Table of contents

Installation document 1...........................................

Overview 1....................................................

General 1................................................

Main units 1..............................................

Options 2......................................................

Installation procedures 4..........................................

Auxiliary equipment 5............................................

Supply conditions 6..............................................

Purpose 6................................................

Equipment responsibility 6..................................

Receipt, unpacking and storage 6..............................

General safety rules 7............................................

Installation requirements 8........................................

Responsibility and approval 8................................

Supply power 8...........................................

Environmental requirements 8................................

Compass deviation 8.......................................

Noise sources 8...........................................

Dry docking 9.............................................

Wiring 9.................................................

Equipment handling 10............................................

Introduction 10.............................................

Transportation 10...........................................

Initial preservation 11.......................................

Inspection and unpacking 13..................................

Storage 15.................................................

After use storage 16.........................................

Re-packing 18.............................................

ESD precautions 18.........................................

Temperature protection 19....................................

Technical specifications 20.........................................

Weights and dimensions 20...................................

Page 14

Simrad SP270

IV

851-160571 / B

Blank page

Page 15

Introduction

1

851-160571 / B

Installation document

This installation manual will act as an installation document for

later updating and service on the sonar, and must therefore be

stored on board the vessel into which the equipment is to be

installed.

To ensure the best possible result of the installation, it is

important that each procedure is carefully followed. Each listed

procedure comprises squares for ticking off while proceeding in

the procedure. In addition to be a sign that the procedure is

followed, this will also be a good guidance for the installer.

Note that the installer becomes fully responsible for the

equipment during the installation, and that the guarantee only is

covered when the installation is made in full accordance with

this installation manual.

Overview

General

The Simrad SP 270 Sonar system is delivered without a dome

system. The Hull Unit uses a Simrad SQ4 installation trunk. The

SP 270 can therefore easily be mounted in an old SQ4 or SR

240 trunk. Note that the trunk is not included in the standard

delivery. This trunk may be made by the shipyard, or be

delivered from Simrad as an option (see chapter 2.3 “Options”).

The optional trunk which is approved by Det norske Veritas

(DnV) also includes a blind cover and a gasket.

The drawings of the trunk and blind cover are included in

section “Drawings”.

Sonar trunk drawing no. 830--113361.....................

Blind cover drawing no. 830--113362......................

Main units

The standard SP 270 Sonar system comprises the following

main units:

Simrad SP 270 Sonar Control Unit SP2--113106...........

Simrad SP 270 Transceiver Unit SP2--113107..............

Simrad SP 270 Hull Unit SP2--113108....................

Note

The Sonar Control Unit can also be delivered without the

internal display. In such case, the electronic drawer is delivered

in a separate box with connection to an external display.

Page 16

Simrad SP270

2

851-160571 / B

Simrad SP 270 Control Unit without display SP2--113281..

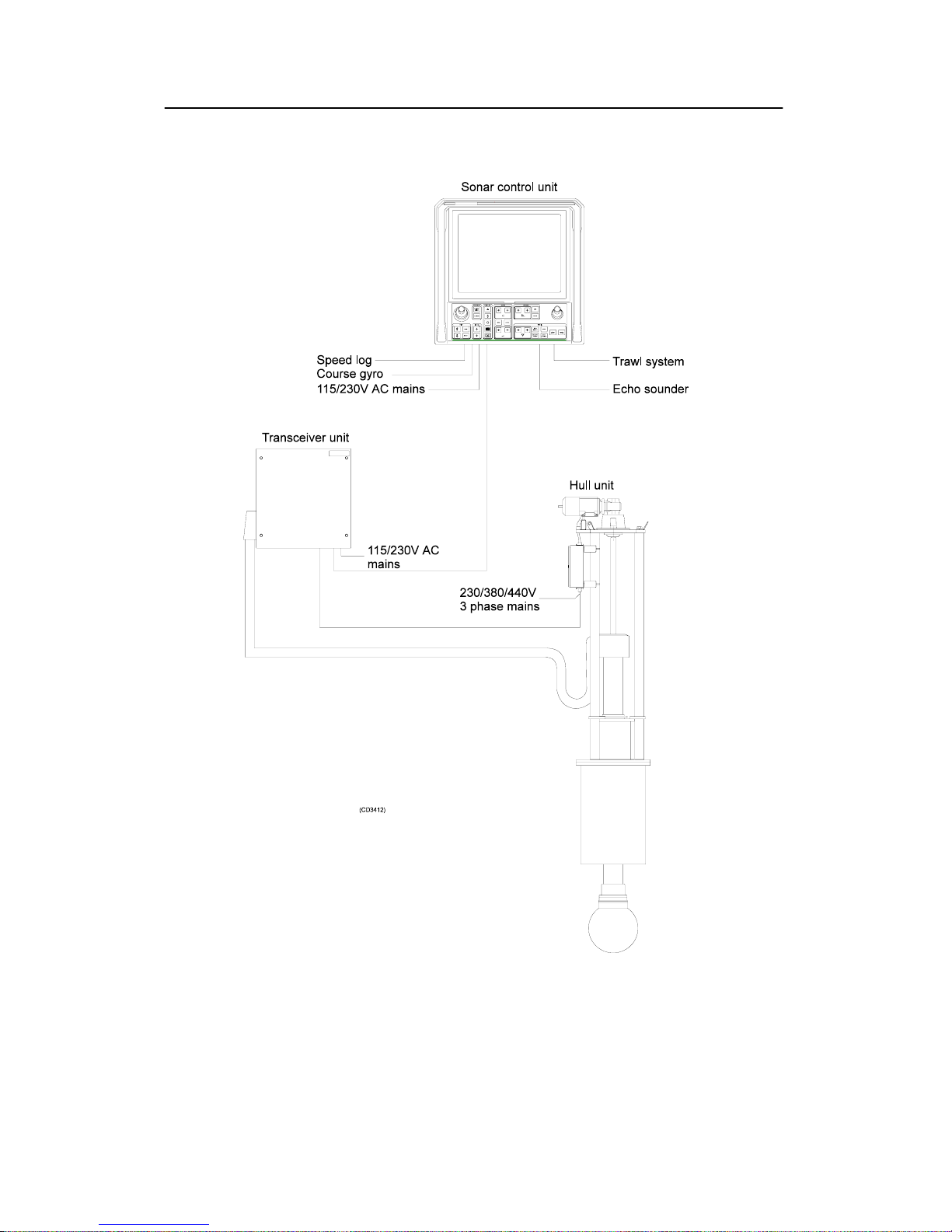

A system diagram of the standard sonar system is shown in

figure 1.

Options

The standard SP 270 sonar is a 27 kHz version with 60° tilt.

This version has five different display modes.

The following options can be delivered to the SP 270 sonar:

• 90° tilt with 180° vertical presentation. This version has nine

different display modes.

-90° tilt KIT-113293...........................

• Triple or multiple frequency, which is specially useful to

suppress interference from other sonars:

- Triple frequency KIT-113291....................

- Multiple frequency KIT-113292..................

• Beam stabilization, where the transducer beam will be

electronically stabilized for roll and pitch.

- Beam stabilization KIT-113200..................

• The installation trunk with blind cover can be ordered as an

optional delivery.

- Installation trunk with blind cover SQ4-042508......

Page 17

Introduction

3

851-160571 / B

Figure 1 SP 270 sonar system

Page 18

Simrad SP270

4

851-160571 / B

Installation procedures

The installation of the standard SP 270 Sonar system includes

the following stages:

• Mounting the Installation Trunk

• Mounting the Hull Unit

• Mounting the Transceiver Unit

• Mounting the Sonar Control Unit

• Cabling

• Start-Up

• Final Test

Refer to the cable plan, the main interconnection diagrams and

the outline dimensions drawings of the units.

The equipment, once unpacked, must be stored inside in a room

with an atmosphere free from corrosive agents. In addition, the

equipment must be covered to protect it from dust and other

forms of contamination.

Page 19

Introduction

5

851-160571 / B

Auxiliary equipment

The SP 270 sonar requires connection of a speed log and a

course gyro. An inaccurate log or gyro input will cause

inaccurate indication of the vessel and target movements.

Speed log

• Pulse log: 100, 200 or 400 pulses/nm.

• Serial line, standard NMEA 0183; RS232, RS422 or Current

loop.

Course gyro

• 3-phase synchro signal, 20-220V L-L, 50/60/400 Hz.

Gear ratio 1:360, 1:180, 1:90, 1:36

• 3-phase stepper signal, 20-220V L-L.

Gear ratio 1:360, 1:180, 1:90, 1:36.

• Serial line, standard NMEA 0183; RS232, RS-422 or Current

loop.

Echo sounder

In order to get a depth indication on the catch control page on

the sonar, one of the following Simrad echo sounders can be

connected:

• EQ50, EQ55, EQ100, ES60, ES380 series, ES500 (RS-232

serial line).

Trawl system

In order to get the trawl information on the sonar display, one of

the following Simrad trawl systems can be connected:

• FS 903 Trawl sonar system (RS-232 serial line)

• FS 3300 Trawl sonar (RS-232 serial line or 20 mA current

loop)

• ITI Integrated trawl instrumentation (RS-232 serial line)

Page 20

Simrad SP270

6

851-160571 / B

Supply conditions

Purpose

The following supply conditions are applicable to standard

Simrad SP270 deliveries and associated optional equipment.

Equipment responsibility

The shipyard performing the installation and/or dealer becomes

fully responsible for the equipment upon receipt unless

otherwise stated in the contract.

The duration of responsibility includes:

• The period of time the equipment is stored locally before

installation.

• During the entire installation process.

• While commissioning the equipment.

• The period of time between commissioning and the final

acceptance of the equipment by the end user (normally the

owner of the vessel which the equipment has been installed).

The Simrad SP270 system guarantee period (as specified in the

contract) begins when the acceptance documents have been

signed unless other arrangements have been made in the

contract.

Receipt, unpacking and storage

Upon accepting shipment of the equipment, the shipyard and/or

the dealer should ensure that the delivery is complete and

inspect each shipping container for evidence of physical

damage. If this inspection reveals any indication of crushing,

dropping, immersion in water or any other form of damage, the

recipient should request that a representative from the company

used to transport the equipment be present during unpacking.

All equipment should be inspected for physical damage, i.e.

broken controls and indicators, dents, scratches etc. during

unpacking.

If any damage to the equipment is discovered, the recipient

should notify both the transportation company and Simrad so

that Simrad can arrange for replacement or repair of the

damaged equipment.

Once unpacked, the equipment must be stored in a controlled

environment with an atmosphere free of corrosive agents,

excessive humidity or temperature extremes. The equipment

must be covered to protect it from dust and other forms of

contamination when stored.

Page 21

Introduction

7

851-160571 / B

General safety rules

The system operates on 115 and/or 230 / 380 / 440 Vac, 50/60

Hz.

Warning This voltage can be lethal.

The following safety precautions must be followed at all times

during installation and maintenance work:

• Always switch off all power before installation or

maintenance. Use the main circuit breaker, and label the

breaker with a warning sign that informs others that

maintenance or installation work is being carried out on the

system.

• Read and understand the first aid instructions for electric

shock.

• For safety reasons during troubleshooting on the equipment

with power ON, two persons should always be present.

• Whenever maintenance is carried out, it is essential that a

first aid kit is available, and that the maintenance personnel

are familiar with the first aid instructions for electrical shock.

• The various parts of the system are heavy. Make sure that the

appropriate tools and certified lifting equipment are

available, and that the personnel are trained in installation

and maintenance work.

Page 22

Simrad SP270

8

851-160571 / B

Installation requirements

Responsibility and approval

The Simrad SP270’s Hull Unit sleeve has been approved by Det

Norske Veritas (DNV) Classification society.

Individual Hull Unit installations must be approved on a

case-by-case basis with regard to the vessel’s national registry

and corresponding maritime authority. The shipowner and

shipyard performing the installation are responsible for

obtaining installation approval.

Supply power

The supply voltage to the equipment is to be kept within ±10%

of the installation’s nominal voltage. Maximum transient

voltage variations on the main switchboard’s bus-bars are not to

exceed -15% to +20% of the nominal voltage (except under

fault conditions).

Simrad strongly recommends that the SP270 sonar be powered

using an Uninterruptible Power Supply (UPS). The UPS should

have the capacity to independently maintain power to the sonar

for a minimum of 10 minutes. This ensures that the system can

be switched off in a controlled manner in the event of a power

failure.

Environmental requirements

Temperature and humidity

All equipment, unless otherwise specified, must be protected

from temperature extremes and excessive humidity.

Compass deviation

Once the installation is complete, the vessel must be swung with

the sonar in both the operative and inoperative modes. The

shipowner and captain are responsible for updating the deviation

table accordingly with regard to the vessel’s national registry

and corresponding maritime authority.

Noise sources

The vessel’s hull, rudder(s) and propeller(s) should be

thoroughly inspected in dry dock prior to installation.

Roughness below the water-line deformities in the shell plating

and protruding obstacles can create underwater noise. These

sources of turbulence must be smoothed or removed as best as

possible. It is especially important that the propeller(s) is not

pitted or damaged.

Page 23

Introduction

9

851-160571 / B

Dry docking

Make sure that ample clearance under the sonar trunk and/or

protection blister is provided when dry docking the vessel.

Avoid locating supporting blocks or structures in the vicinity of

this equipment.

Note The location of the sonar trunk and/or protection blister must be

noted on the vessel’s docking plan for future reference.

Wiring

The cable from the wheelhouse to the sonar room must be

supported and protected along its entire length using conduits

and/or cable trays. Note that the cable must not be installed in

the vicinity of high-power supplies and cables, antenna cables or

other possible sources of interferences.

Page 24

Simrad SP270

10

851-160571 / B

Equipment handling

Introduction

This chapter describes how to transport, pack and unpack, clean,

preserve and store electronic, electro-mechanical and

mechanical units supplied by Simrad AS.

The units may be supplied as spare parts, or as parts of a

delivery.

Transportation

General specifications

Unless otherwise stated in the accompanying documentation,

electronic, electro-mechanical and mechanical units supplied by

Simrad can be transported using all methods approved for

delicate equipment; e.g. by road, rail, air or sea. The units are to

be transported in accordance with general or specific

instructions for the appropriate unit(s), using pallets, transport

cases, or carton boxes as appropriate.

Note Special local restrictions concerning air transportation may be

applied to units containing certain types of batteries. The units

should be checked and the regulations investigated by the

packer/shipper before the unit is dispatched.

Local transportation

All local transportation must be carried out according to the

same specifications as for the initial delivery. In general, all

units must be handled with care. The carton or case containing

the equipment must be kept dry at all times, and must be

sheltered from the weather. It must not be subjected to shocks,

excessive vibration or other rough handling.

The carton or case will normally be marked with text or symbols

indicating which way up it is t o be placed. Follow any

instructions given and ensure the case is always placed with its

“top” uppermost.

The carton or case must not be used for any purpose for which it

was not intended (e.g. step, table, etc.), and in the absence of

other information, no other cartons or cases must be stacked on

top of it.

Page 25

Introduction

11

851-160571 / B

Lifting

A heavy crate will normally be marked with its weight, and the

weights of other cartons or crates will normally be entered on

the packing list.

• Always check the weight of a crate before attempting to lift

it.

• Always use lifting apparatus that is certified for the load.

Heavy units may be equipped with lifting lugs for transportation

by crane within the workshop or installation area. Before a crane

is used, check:

• The applicable weight certificate for the crane.

• The security of the lifting lugs.

Ensure that all available lifting lugs are used. Ensure the unit

remains under control during the operation to avoid damage to

the unit, equipment or personnel.

Heavy units may be transported using a fork-lift t ruck. Special

attention must then be paid to the position of the unit’s centre of

gravity. The units must be properly secured to the truck.

Initial preservation

Introduction

When a system, a unit or a spare part has been delivered to the

customer, it may be subject to long-time storage prior to

installation and use. During this storage period, certain

specifications must be met.

The equipment must be preserved and stored in such a way that

it does not constitute any danger to health, environment or

personal injury.

Specific specifications are presented below.

→ For further information about storage, refer to page 15.

→ For further information about re-packing, refer to page 18.

→ For further information about temperature protection, refer to

page 19.

Original packing crate

1 The equipment must be stored in its original transportation

crate.

2 Ensure that the units are clearly separated in the shelves

and that each unit is easily identifiable.

3 The crate must not be used for any purpose for which it

was not intended (eg. work platform etc.).

Page 26

Simrad SP270

12

851-160571 / B

4 The crates must not be placed on top of each other, unless

specific markings permit this.

5 The crates must not be placed directly on a dirt floor.

6 Do not open the crate for inspection unless special

circumstances permit so.

- “Special circumstances” may be suspected damage to

the crate and its content, or inspections by civil

authorities.

- If any units are damaged, prepare an inspection report

stating the condition of the unit and actions taken.

Describe the damage and collect photographic evidence

if possible. Re-preserve the equipment.

- If the units are not damaged, check the humidity

absorbing material. If required, dry or replace the bags,

then repack the unit(s) according to the packing

instructions.

7 If the crate has been opened, make sure that is it closed

and sealed after the inspection.

- Use the original packing material as far as possible.

→ Refer to the information on page 18.

Ambient temperature and humidity

1 The storage room/area must be dry, with a non condensing

atmosphere. It must be free from corrosive agents.

2 The storage area’s mean temperature must not be lower

than -30°C, and not warmer than +70°C.

- If other limitations apply, the crates will be marked

accordingly.

Note Transducers must not be stored in temperatures below -20°C.

3 The crate must not be exposed to moisture from fluid

leakages.

4 The crate must not be exposed to direct sunlight or

excessive warmth from heaters.

Shock and vibration

1 The crate must not be subjected to excessive shock and

vibration.

ESD precautions

→ Refer to the information on page 18.

Page 27

Introduction

13

851-160571 / B

Batteries

If the unit contains normal batteries, these may have been

disconnected/isolated before the unit was packed. These must

only be reconnected before the installation starts. Units

containing batteries are marked.

Caution Units containing lithium or alkaline batteries must be

handled separately and with care. Such units are

marked accordingly. Do not attempt to recharge such

batteries, open them or dispose of them by

incineration. Refer to the applicable product data

sheets.

Inspection and unpacking

Inspection

An inspection must be carried out immediately after the unit(s)

have arrived at their destination.

• Check all wooden or cardboard boxes, plastic bags and

pallets for physical damage. Look for signs of dropping,

immersion in water or other mishandling.

• If damage is detected externally, you will have to open the

packaging to check the contents.

- Request a representative of the carrier to be present while

the carton is opened, so any transportation damage can be

identified.

• If any units are damaged, prepare an inspection report stating

the condition of the unit and actions taken. Describe the

damage and collect photographic evidence if possible. Send

the inspection report to Simrad as soon as possible.

• If the units are not damaged, check the humidity absorbing

material. If required, dry or replace the bags, then repack the

unit(s) according to the packing instructions.

General unpacking procedure

Normal precautions for the handling, transportation and storage

of fragile electronic equipment must be undertaken.

Note If the unit is not to be prepared for immediate use, you may

consider storing it unopened in its original packing material.

However, it may be useful to open the case to check its contents

for damage and retrieve any accompanying documentation.

• Check the carton before opening it to ensure it shows no

signs of dropping, immersion in water or other mishandling.

- If the carton shows signs of such damage, refer to the

paragraph covering Inspection on receipt.

Page 28

Simrad SP270

14

851-160571 / B

• Place the carton on a stable work bench or on the floor with

the top of the carton uppermost.

• In the absence of other instructions, always open the top of

the carton first. The contents will normally have been

lowered into the carton from above, so this will usually be

the easiest route to follow.

- Care must be used when opening the carton to ensure the

contents are not damaged.

Caution Do not use a knife to open cardboard cartons - the

contents may lie close to the surface, and may be

damaged by the blade.

• If the carton has been closed using staples, remove the staples

from the carton as you open it. This will reduce the

possibilities of scratch injury to yourself and damage to the

contents.

• If a wooden crate has been closed using screws, always

remove them using a screw-driver. Do not attempt to prise

the lid off with a crow-bar or similar.

• Once the carton is open, carefully remove all loose packing

and insulation material. Check for manuals and other

documents that may have been added to the carton during

packing, and put these to one side. Check also for special

tools, door keys etc.

Electronic and electro-mechanical units

Caution BewareofthedangersofElectro-StaticDischarge

(ESD) both to yourself and to the equipment, when

handling electronic units and components. Refer to the

precautions starting on page 18.

Electronic and electro-mechanical units will normally be

wrapped in a clear plastic bag. Lift the unit, in its bag, out of the

carton and place it in a stable position on the floor/work bench.

Inspect the unit for damage before opening the plastic bag.

Note Cables must never be used as carrying handles or lifting points.

Note Do not break the seal to open a circuit board package before the

board is to be used. If the board package is returned to the

manufacturers with the seal broken, the contents will be

assumed to have been used and the customer will be billed

accordingly.

Assuming all is well, open the bag and remove the unit.

Open the unit and check inside. Remove any packing and

desiccant material that may be inside.

Page 29

Introduction

15

851-160571 / B

Mechanical units

Mechanical units may be heavy. Using a suitably certified lifting

apparatus, lift the unit out of the crate and place it in a stable

position on the floor/work bench.

Inspect the unit for damage and remove any packing material

that may be inside the unit.

Transducers

Transducers may be supplied mounted to a hull unit (if any), or

packed separately. Crates are normally identified by the order

number and the serial number.

The transducer face must be protected by a rigid, padded cover

(e.g. a wooden box lined with foam rubber) all the time it is

exposed to the risk of physical damage.

Note Once the units are unpacked, great care must be taken to ensure

that transducers and cabling are not exposed to any mechanical

stress.

Re-packing

If the unit is not to be installed immediately, re-pack it in its

original packing material to prevent damage in the intervening

period.

→ Refer to the information on page 18.

Storage

Pre-installation storage

The equipment should be stored in its original transportation

crate until ready for installation. The crate must not be used for

any purpose for which it was not intended (eg. work platform

etc.).

Once unpacked, the equipment must be kept in a dry, non

condensing atmosphere, free from corrosive agents and isolated

from sources of vibration.

Note Do not break the seal to open a circuit board package before the

board is to be used. If the board package is returned to the

manufacturers with the seal broken, the contents will be

assumed to have been used and the customer will be billed

accordingly.

The unit must be installed in its intended operating position as

soon as possible after unpacking.

Page 30

Simrad SP270

16

851-160571 / B

If the unit contains normal batteries, these may have been

disconnected/isolated before the unit was packed. These must

then be reconnected during the installation procedure. Units

containing batteries are marked.

Caution Units containing lithium or alkaline batteries must be

handled separately and with care. Such units are

marked accordingly. Do not attempt to recharge such

batteries, open them or dispose of them by

incineration. Refer to the applicable product data

sheets.

After use storage

Introduction

If a unit is removed from its operating location and placed into

storage, it must be properly cleaned and prepared before

packing.

Cleaning cabinets

If the unit may have been exposed to salt atmosphere while it

was in use, it must be thoroughly cleaned both internally and

externally to prevent corrosion.

• Wipe the cabinet externally using a damp cloth and a little

detergent. Do not use excessive amounts of water as the unit

may not be water tight. On completion, dry t he unit

thoroughly.

• All surfaces must be inspected for signs of corrosion, eg.

flaking/bubbling paint, stains etc. Damaged or suspect areas

must be cleaned, prepared and preserved using the correct

preservation mediums for the unit. The mediums to be used

will usually be defined in the units’ maintenance manual.

• Open the unit, and using a vacuum cleaner, remove all dust

etc. from the unit. Great care must be taken to ensure the

circuit boards and modules are not damaged in the process.

Mechanical units

If the mechanical unit may have been exposed to a salt

atmosphere while it was in use, it must be thoroughly cleaned

both internally and externally to prevent corrosion.

• If the construction materials and type of unit permits, wash

the unit using a high-pressure hose and copious amounts of

fresh water.

Examples:

- The lower parts of hull units (outside the hull)

- Subsea units

Page 31

Introduction

17

851-160571 / B

• Ensure that all traces of mud and marine growth are removed.

Use a wooden or plastic scraper to remove persistent growth,

barnacles etc. On completion, dry the unit thoroughly.

Caution Do not use a high pressure hose in the vicinity of cables

or transducers. Do not use sharp or metal tools on a

transducer face.

• If the materials or type of unit prevents the use of a

high-pressure hose, wipe the unit using a cloth dampened

with water containing a little detergent.

Example:

- The upper parts of hull units (inside the hull)

- Hydraulic systems

• Do not use excessive amounts of water as some components

on the unit may not be water tight. Wipe off the detergent

with a damp cloth, then dry the unit t horoughly.

• All surfaces must be inspected for signs of corrosion, eg.

flaking/bubbling paint, stains etc. Damaged or suspect areas

must be cleaned, prepared and preserved using the correct

preservation mediums. The mediums to be used will

normally be defined in the unit’s maintenance manual.

Cables

Wipe clean all exposed cables, and check for damage. If a cable

shows signs of wear or ageing, contact Simrad for advice.

Internal batteries

If the unit contains batteries, these may discharge slowly during

storage. If the unit is to be stored for an extended period,

disconnect or remove all internal batteries.

A suitable piece of insulating material can be placed between

the battery and the electrical contacts to prevent electrical

discharge. The battery can then remain in the unit, reducing the

risk of it being misplaced during the storage period.

Caution Units containing lithium or alkaline batteries must be

handled separately and with care. Such units are

marked accordingly. Do not attempt to recharge such

batteries, open them or dispose of them by

incineration. Refer to the applicable product data

sheets.

Page 32

Simrad SP270

18

851-160571 / B

Dehumidifier

Place a suitably sized bag of desiccant material ( silica gel or

similar) into the unit to keep the electronic components as dry as

possible.

Coatings

Spray the unit externally with a corrosion inhibitor (e.g. a light

oil) before packing.

Re-packing

The unit should be stored and transported in its original packing

material and/or crate. In the event that this material is not

available, proceed as follows:

• Small units must be protected from damp by being placed

within a plastic bag at least 0.15 mm thick. An appropriate

quantity of desiccant material should be placed inside this

bag, and the bag sealed. The sealed unit must then be placed

in an appropriate carton or crate, and supported in the

container by appropriate shock-absorbing insulation

(polystyrene foam chips etc.).

• Large units must be placed in a suitable cardboard box or

wooden crate. The unit must be protected against physical

damage by means of shock-absorbing insulation mats. The

box must be clearly marked with its contents, and must be

stored in a dry and dust-free area.

ESD precautions

Electrostatic Discharge (ESD)

Electro-Static Discharge (ESD) is the transfer of an electrostatic

charge between two bodies at different electrostatic potentials,

caused either by direct contact or induction by an electrostatic

field.

The passing of a charge through an electronic device can cause

localised overheating, and it can also “puncture” insulating

layers within the structure of the device. This may deposit a

conductive residue of the vaporised metal on the device, and

thus create a short circuit. This may result in a catastrophic

failure, or degraded performance of the device.

ESD Protection during transport and storage

Sensitive electronic equipment must be transported and stored in

protective packing bags, boxes and cabinets. The equipment

must NOT be transported or stored close to strong electrostatic,

electro-magnetic or radioactive fields.

Page 33

Introduction

19

851-160571 / B

Unpacking and servicing ESD sensitive equipment

If it is necessary to open and touch the electronics inside the

boxes/cabinets, then the following precautions MUST be taken:

• The working area must be covered by an approved

conductive service mat that has a resistance of between 50kΩ

and2MΩ, and is connected directly to a reliable earth point

via its earthing cord.

• The service personnel involved must wear a wrist-band in

direct contact with the skin, connected to the service mat.

• Printed circuit boards and other components should be placed

on the conductive service mat during installation,

maintenance etc.

Caution If, for any reason, it is necessary to move the circuit

board or components from the conductive service mat,

they must be placed in an approved anti-static

transportation container (e.g. static shielding bag)

before transportation.

• During installation and servicing, all electrical equipment

(soldering irons, test equipment etc.) must be earthed.

Temperature protection

If the unit must be protected against extremes of temperature,

the carton/crate must be lined on all walls, base and lid with

5 cm thick polyurethane or polystyrene foam.

These units will be identified as delicate in the applicable

documentation.

The package must then be clearly marked:

Must not be transported or stored in temperatures

below -5 degrees Celsius.

Other units can normally be stored in temperatures between

-30°C and +70°C, though refer to the system’s Technical

Specifications document for details.

Transducers must not be stored in temperatures below -20°C.

Page 34

Simrad SP270

20

851-160571 / B

Technical specifications

Table 1 comprises the specifications required for the installation.

For further details, refer to the Operator Manual.

Sonar Control

Unit

Transceiver Unit Hull Unit

Voltage, nominal 115/230VAC

Single phase*

115/230 VAC

Single phase**

230/380/440 VAC

3--phase***

Voltage deviation 15% of nominal 15% of nominal 230V:15%

380/440V:

340 -- 485V

Voltage transient 20% of nominal

recovery time 3s

20% of nominal

recovery time 3s

20% of nominal

recovery time 3s

Power consumption

100 VA 600 VA 750 VA max.

Frequency 47 -- 63 Hz 47 -- 63 Hz 47 -- 63 Hz

Tem p .: S t ora g e

Operating

-- 4 0 t o + 7 0 °C

0to+40°C

-- 4 0 t o + 7 0 °C

0to+40°C

-- 2 0 t o + 7 0 °C

0to+40°C

Humidity 5--95% relative

non--condensing

5--95% relative

non--condensing

5--96% relative

non--condensing

Refer to the voltage, nominal line in table 1.

* Input voltage is automatically selected.

** Input voltage is selected with two switches.

*** Input voltage is selected on the motor connections

Weights and dimensions

The table below shows the weights for the different units of the

sonar, and a reference for the figures showing the outline

dimensions of the units.

Weight Dimensions

Sonar Control Unit 25 kg Seefigure2

Control Unit without display 10 kg Seefigure3

Transceiver Unit 75 kg Seefigure4

Hull Unit 530 kg Seefigure5

Trunk (optional) 68 kg Seefigure6

Page 35

Introduction

21

851-160571 / B

Figure 2 Outline dimensions of the Sonar Control Unit

Page 36

Simrad SP270

22

851-160571 / B

420

96.5

44

7.5

80

1

5

o

113

340

314.5

(CD4579)

Figure 3 Outline dimensions of the Control Unit without display

Page 37

Introduction

23

851-160571 / B

Figure 4 Outline dimensions of the Transceiver Unit

Page 38

Simrad SP270

24

851-160571 / B

Figure 5 Outline dimensions of the Hull Unit

Page 39

Introduction

25

851-160571 / B

Figure 6 Outline dimensions of the optional trunk

Page 40

Simrad SP270

26

851-160571 / B

Blank page

Page 41

Installation procedures

I

851-160572 / B

851-160572

SP270

Installation procedures

This section provides the necessary information for the

installation and cabling of the complete SP270 sonar

system according to Simrad’s requirements.

Page 42

Simrad SP270

II

851-160572 / B

Document revisions

Rev Date Written by Checked by Approved by

A 30.06.99 CL SØJ SØJ

B 30.01.04 RBr EGJ ESB

Rev .A Original issue.

Rev .B Document re--issued. No changes to product specific text. The same

illustrations are used, but some of them have been slightly modified.

About this document

The information contained in this document is subject to change without prior notice.

Simrad AS shall not be liable for errors contained herein, or for incidental or

consequential damages in connection with the furnishing, performance, or use of this

document.

© 2004 Simrad AS. All rights reserved. No part of this work covered by the copyright

hereon may be reproduced or otherwise copied without prior permission from Simrad

AS.

Simrad AS

Strandpromenaden 50

Box 111

N-3191 Horten

Telephone: +47 33 03 40 00

Facsimile: +47 33 04 29 87

M A X I M I Z I N G Y O U R P E R F O R M A N C E A T S E A

Page 43

Installation procedures

III

851-160572 / B

Table of contents

Installation planning 1............................................

General 1................................................

Location of the hull unit 1...................................

Sonar room requirements 2..................................

Installation of the sonar trunk 5.....................................

Mounting the trunk 5.......................................

Protecting blister 6.........................................

Corrosion protection 6......................................

Trunk installation measurements 6............................

Installation of the hull unit 9.......................................

Mounting the hull unit 9....................................

Air bleeding 9.............................................

Staying 10.................................................

Alignment of the transducer 10................................

Installation checklist 11......................................

Installation of the Transceiver Unit 12................................

Installation of the Sonar Control Unit 16..............................

Location of the Sonar Control Unit 16..........................

Mounting of the Sonar Control Unit 17..........................

Cabling 20......................................................

Cable plan 20..............................................

Sonar Control Unit cabling 22.................................

Transceiver Unit cabling 23...................................

Hull Unit cabling 26.........................................

Connecting auxiliary equipment 27..................................

General 27................................................

Connecting the course gyro 27.................................

Connecting the speed log 37..................................

Connecting other auxiliary equipment 40........................

Remounting the electronic drawer unit 40........................

Page 44

Simrad SP270

IV

851-160572 / B

Blank page

Page 45

Installation procedures

1

851-160572 / B

Installation planning

Note For installation in an already installed trunk system, first read

through chapter “Sonar room requirements”. Then for an

already installed SQ4 or SR 240 trunk system, continue to

procedure “Installation of the Hull Unit“.

General

This chapter provides the necessary information for the ship

designer to plan and carry out the installation of the SP270 hull

system according to Simrad’s requirements. Study this chapter

thoroughly to achieve the recommended knowledge of the

procedures.

Note that individual installation drawings must be designed by

the shipyard, and the construction must be approved by the

classification authorities at the customer’s expense.

Simrad offers free advice for installation planning. The proposal

for the arrangement may be sent to Simrad for comments, or

may be worked out by Simrad. If such assistance is required, the

following drawings should be submitted:

• General arrangement

• Body plan and drawings of bottom tanks and cofferdam

• Sheer drawing

Location of the hull unit

The Hull Unit should preferably be located within 1/10 to 1/3 of

the ship’s length between perpendiculars (LBP), measured from

the fore perpendicular (FP). Refer to figure 1. Larger deviations

from this rule should not be made without consulting Simrad.

The Hull Unit may be located symmetrically on the centre line

of the vessel, or alongside the keel. When determining the exact

location, make sure that the transducer will have free view under

the keel (refer to figure 2 on page 3).

The Hull Unit trunk must be installed such that it will be vertical

under normal operating conditions.

Water inlets and protruding details which create turbulence,

should not be located in front of the transducer. For the same

reason, check that the shell plating in front of the trunk is not

damaged.

Page 46

Simrad SP270

2

851-160572 / B

Welding marks

for docking

Wa terlin e at norm al trim

LBP

(CD1881 WMF/GIF)

1/3 to 1/10

LBP

90°

Figure 1 Location of the hull unit

Sonar room requirements

The sonar room should be dimensioned to house the Hull Unit

and the Transceiver Unit. This because the length of the

flexi-hose protected cabling from the Hull Unit to the

Transceiver Unit is limited to approximately 4 meters.

By installing the units in a well designed sonar room, the risk of

corrosion is reduced, the maintenance is simplified, and the

reliability is increased.

A suggested arrangement of the sonar room is shown in figure 2.

The free space should not be obstructed by girders or pipes etc.,

which might cause problems for the installation and

maintenance work.

Access hatches

The sonar room must be accessible under all conditions, and the

doors or hatches should be so designed that t he installed units

can be removed without being disassembled. A tackle carrier

designed for a load of a minimum of 2 tons should be mounted

above the Hull Unit. The tackle may be used to facilitate the

mounting of the trunk and Hull Unit, and is also intended for use

in future service of the Hull Unit.

Heating

The sonar room should be furnished with a heating element of

1000 W, mounted close to the floor.

Page 47

Installation procedures

3

851-160572 / B

Dia. 508

M

ax. 1200 757

Max. 990

Min. 810

2080

Min. 3000

(+ lifting device)

Heater

Transceiver

unit

Lighting

Load capacity:

Min. 2 tonnes

Air bleeding pipe

Min. Di.=10mm

Air vent pipes

Dia. min.50

Min. 4000

25

All dimensions are in millimeters

Pipes

10mm

Min. 500

520

Min. 150

Transducer cable

Total length: 4 meters

Hatch

Min. 585

Min. 1300

Min. 350

Removable supports

1000 (Recommended)

(CD3411 WMF/GIF)

Figure 2 Example of sonar room

arrangement, seen from the bow

Insulation

The bulkhead must be insulated and plated down to the floor.

The insulation should equal a minimum of 50 mm of rock-wool.

Page 48

Simrad SP270

4

851-160572 / B

Ventilation

The sonar room should preferably be connected to the ship’s

ventilation system. If this is not possible, two 3-inch vent pipes

must be laid from the sonar room to free air on deck. The air

inlet should be close to the floor, while the outlet should be

placed as high as possible. Funnels should be m ounted below

the vent pipes to collect condensed water.

To ensure the best possible ventilation, the outlet pipe should

run at least 4 meters higher than the inlet pipe. To keep rain and

water splash out, the pipes should be fitted with goosenecks or

cowls.

Cable pipes

If the cable between the wheelhouse and the sonar room passes

through hatches or places where it can be damaged, it should be

run through pipes (2” pipes are recommended).

Air vent pipe

An air vent pipe with a minimum of 10 mm internal diameter

must be fitted to the air bleeding cock on the Hull Unit. The

pipe should be laid with continuous rise to free air on deck or

out through the ship s side.

Bilge pump

The sonar room should be connected to the ship’s main bilge

pump system. If this is not possible, a separate bilge pump for

the sonar room must be installed.

Lighting

To simplify the installation and future maintenance, the sonar

room should be equipped with suitable lighting.

Docking

Make sure that there is ample space below the keel for mounting

the hull system, when docking the vessel.

To facilitate future docking, mark the position of the trunk as

indicated in figure 1.

Flooring

When the installation is completed, the sonar room should be

suitably floored.

Page 49

Installation procedures

5

851-160572 / B

Installation of the sonar trunk

Mounting the trunk

The location of the sonar trunk has to be carefully selected, as

described in chapter Location of the hull unit.. Refer also to

figures 4 and 5.

Note the orientation of the centre line of the trunk with regard to

the mounting bolts, shown in figure 3.

Note Remove the gasket on the top flange during the welding.

Parallel to

centre line

(CD1 883 WMF/GIF)

∝±

°

1

∝

Figure 3 Orientation of the sonar trunk

The height from the top of the trunk flange to the underside of

the protection blister must be minimum 920 mm (36 1/4”) as

shown in figures 4 and 5.

The top flange must be parallel to the construction loadline in

the fore-and-aft as well as the athwartships direction.

The installation trunk must be welded to an inserted plate which

should be 1.5 times as thick as the original shell plate. The size

may be determined by the shipyard or the responsible maritime

authorities. The trunk must be stiffened to the inserted plate by

welding knee-plates on the trunk in both fore-and-aft and

athwartships directions.

Page 50

Simrad SP270

6

851-160572 / B

Protecting blister

As illustrated in figures 4 and 5, a steel blister must be fitted for

protection. The blister shown in figure 4 is welded to the shell

plating and then filled with oil to prevent corrosion. This

method provides excellent protection and simplifies

maintenance. The blister shown in figure 5 is of the open type,

to be welded to the shell plating.

Corrosion protection

As soon as the trunk is mounted, and welding and grinding are

finished, the trunk should be painted with a quality protective

paint.

Trunk installation measurements

For future use, the measurements of the distance A, and the

heights B and C shown in figures 4 and 5 have to be carried out

and put into the table below.

mm inches

Distance A

Height B

Height C

Height D

In case of an other installation solution, make a scheme with

dimensions below.

Page 51

Installation procedures

7

851-160572 / B

2.5-3xE

B

D

A

Fore-and-aft view

Thickness of plates

Knee-plates: 3/8" (10 mm)

Blister and deflection

bracket: 1/4" (6 mm)

The circular opening of the

blister should have a

diameter equal to the inside

diameter of the trunk.

Deflection-brackets should

be welded only to the

shell-plating.

3-4 knee-plates, must be

welded to frames or floors

Plug for filling of oil

Bottom view

A:

B:

C:

D:

E:

As short as possible

Max. 35 7/8" (910 mm)

Min. 1 9/16" (40 mm)

Min. 31 7/8" (810 mm)

Min. 22" (560 mm)

Side view

(CD1890)

C

E

Figure 4 Installation of trunk with extension and oil-filled blister

Page 52

Simrad SP270

8

851-160572 / B

(CD1884)

2.5 - 3xE

B

D

A

Fore-and-aft view

Thickness of pl at es

Knee-plates: 3/8" (10 mm)

Blister and deflection

bracket: 1/4" (6 mm)

The circular opening of the

blister should have a

diameter equal to the inside

diameter of the trunk.

Deflection-brackets must

only be welded to the

shell-plating.

3-4 knee-plates, must be

welded to frames or floors

Bottom view

A:

B:

C:

D:

E:

As short as possibl e

Max. 35 7/8" (910 mm)

Min. 1 9/16" (40 mm)

Min. 31 7/8" (810 mm)

Min. 22" (560 mm)

Side view

C

E

Figure 5 Installation of the trunk with open protection blister. No

trunk extension

Page 53

Installation procedures

9

851-160572 / B

Installation of the hull unit

Warning Do not remove the protecting cover from the

transducer until just before the Hull Unit is to be

lowered into the trunk.

Mounting the hull unit

The Hull Unit should normally be oriented with the

hoisting/lowering motor pointing aft (see figure 6). If this

orientation makes the motor control unit on the Hull Unit

difficult to access, the Hull Unit may be oriented in the most

suitable position.

BOW

(CD1 905 WMF/GIF)

Figure 6 Recommended orientation of the hull unit

1 Use a tackle to lower the Hull Unit with the protections

down into the sonar room. Remove the blind cover from

the trunk, and check that the gasket is not damaged. Store

the blind cover in the sonar room for possible future use.

2 Remove the transport -protection from the transducer and

lower the Hull Unit carefully down into the trunk. Tighten

the flange nuts with a torque of approximately 6 kpm.

The transducer cables and connectors must be kept dry and

handled with care to avoid mechanical damage.

Air bleeding

To avoid damage of the transducer by transmitting in air inside

the trunk, a pipe with a minimum inside diameter of 10 mm

must be fitted to the air bleeding cock, and run with continuous

rise to free air above deck or out through the ship s side. Make

sure that the air bleeding cock is opened (see figure 7).

Page 54

Simrad SP270

10

851-160572 / B

Min. 10mm

internal

3/8" pipe

thread

Open position

(CD1889 WMF/GIF)

Figure 7 The air bleeding cock

Staying

The Hull Unit is constructed to be in the lower position with a

maximum speed of 15 knots. To prevent unwanted vibrations,

the Hull Unit has to be stayed off against the bulkhead. Remove

the lifting rings on the top of the gallows on the Hull Unit and

use the holes for fastening of the staying in the fore-and-aft

direction. In case of service on the Hull Unit, it should be

possible to remove the staying.

Alignment of the transducer

Note that the transducer should not be mechanically aligned

even if the Hull Unit is oriented differently from figure 6.

The transducer alignment will be carried out later by turning the

echo picture in the computer.

Page 55

Installation procedures

11

851-160572 / B

Installation checklist

For the following check list, refer to the sonar room

requirements in chapter Sonar room requirements.

YES NO

Are the access hatches satisfactory?

Is the heating satisfactory?

Is the insulation satisfactory?

Is the ventilation satisfactory?

Is the staying of the Hull Unit satisfactory?

Is a bilge pump installed?

Is the lighting satisfactory?

Is the sonar room suitably floored?

Is the air vent pipe satisfactory?

If the answer to any of the questions is NO, make a note in the

installation certificate at the end of section Start-up procedure.

Page 56

Simrad SP270

12

851-160572 / B

Installation of the Transceiver Unit

Note The Transceiver Unit must be mounted as a complete unit, i.e.

the door should not be opened until the unit is securely fastened

to the bulkhead.

Before starting the mounting of the Transceiver Unit, note that

the distance between the Hull Unit and the Transceiver Unit is

limited because of the flexible transducer cables. Also

remember to take into consideration the necessary slack for

lowering of the transducer.

Do not fasten the transducer cables into the Transceiver Unit

before mentioned later in the start-up procedure.

The Transceiver Unit cabinet requires a minimum free bulkhead

space, which is shown in figures 8 and 9.

1 Dismount the two mounting brackets which are fastened

to the shock absorbers on the Transceiver Unit. An Allen

key is located in the plastic bag which is fastened to the

upper shock absorber.

2 Weld the mounting brackets safely to the bulkhead as

shown in figures 8 and 9.

3 Use a tackle carrier to lift the Transceiver Unit in position,

and bolt it to the mounting brackets with the bolts

included in the delivery. These 8 bolts are located in the

plastic bag that was fastened to the upper shock absorber.

Remember to fasten the grounding cable from the

Transceiver Unit to the mounting bracket as shown in

figure 9.

Page 57

Installation procedures

13

851-160572 / B

(CD1988A)

App. 40

150

Min.

150

Min.

Recommended 1100-1200

Min. 300

Min. 75

150

Min.

470

±10

App. 70

Figure 8 Mounting the brackets for the

Transceiver Unit - Forward view

Page 58

Simrad SP270

14

851-160572 / B

A

ngle bars with threaded

holes for shock absorbers.

Bars supplied by Simrad.

680

±2

680

±5

Overhead

Deck

Bulkhead

(CD1988b)

Figure 9 Mounting the brackets for the

Transceiver Unit - Side view

Page 59

Installation procedures

15

851-160572 / B

(CD3110)

Figure 10 Mounting the Transceiver Unit

Page 60

Simrad SP270

16

851-160572 / B

Installation of the Sonar Control Unit

Location of the Sonar Control Unit

The Sonar Control Unit may be mounted on a desk top, in a

panel, or to the bulkhead. The necessary hardware for desk top

and panel mounting of the unit is included in the delivery. It

should be noted that the unit weighs approximately 28 kg, and

this weight must be considered when deciding how to mount it.

In order to secure the best location according to the routines on

board, the location of the Sonar Control Unit should be

thoroughly discussed with the skipper. Make sure that proper

operating and viewing height is provided.

Remember to include the ”Compass Safe Distance” when

planning the location:

• Sonar Control Unit with internal display:

- Steering compass: 1.4 m

- Standard compass: 0.9 m

• Sonar Control Unit without display:

- Steering compass: 1.1 m

- Standard compass: 0.6 m

When mounting the unit, ensure that it is located to allow easy

access to the cable connection panel at the rear of the unit.

Ensure that the installation area is dry, and free from excessive

dust and vibration.

Page 61

Installation procedures

17

851-160572 / B

Mounting of the Sonar Control Unit

Desk top mounting

Refer to figure 11 for minimum space for the desk top mounting

of the cabinet.

1 Dismount the mounting bracket from the Sonar Control

Unit by unscrewing the four bolts on the front. An Allen

key is located in the spare parts box.

2 Bolt the mounting bracket securely to the desk top with

the four 10x30mm bolts which are located in the spare

parts box.

3 Mount the cabinet on the mounting bracket with the four

bolts.

Space for connectors

and cabl es

4 bolt holes, ø10.5,

spaced 200 x 300 mm

600

(CD1879)

540

200

75

30

473

85

Figure 11 Desk top mounting

Page 62

Simrad SP270

18

851-160572 / B

Panel mounting

1 Dismount the mounting bracket from the Sonar Control

Unit by unscrewing the four bolts on the front. An Allen

key is located in the spare parts box.

2 Cut the panel opening to the following size:

a Width: 345 mm

b Height: 380 mm

3 Place the cabinet into the opening to mark the four

fastening holes.

4 Remove the cabinet and drill the four fastening holes in

the panel.

a Metal panel: Drill 5mm holes for threading with M6

tap, or 7mm holes if through-bolts with nuts are

preferred.

b Wooden panel: Drill 9mm holes for the four thread

inserts which are located in the spare parts box. Refer

to figure 12 for information about mounting the thread

inserts.

5 Place the cabinet into the opening and fasten it with the

four bolts.

Figure 12 Mounting the thread inserts

ø9

(CD1861)

Hold on screw with

the allen key, and

loosen the nut

Insert by using spanner

to the nut.

Observe alignment.

Insert to be 90° to panel

+0.3

- 0

Page 63

Installation procedures

19

851-160572 / B

Bulkhead mounting

To obtain the best operation position of the cabinet, the cabinet

should be mounted with a tilt angle of approximately 20 . An

optional mounting bracket can be delivered from Simrad.

1 Dismount the mounting bracket from the Sonar Control

Unit by unscrewing the four bolts on the front. An Allen

key is located in the spare parts box.

2 Bolt the bulkhead mounting bracket securely to the

bulkhead.

3 Mount the cabinet on the mounting bracket with the four

bolts.

Page 64

Simrad SP270

20

851-160572 / B

Cabling

Cable plan

Figure 13 shows the cable plan for the SP 270 sonar. The cable

numbers also refer to the interconnection diagram, drawing no.

824-113282. This drawing is located in section Drawings this

manual. The cable specifications are listed in the table below.

Note that cable no. 4 is delivered with a standard length of 100

meters, and has a preconnected plug in the Sonar Control Unit

(wheelhouse) end. This cable is included in the Sonar Control

Unit package.

Note that the length of the flexible transducer cable 7 is fixed to

approximately 4 meters.

Cable no Cable type Diameter

1 Screened cable, 2 x 0.5 mm2 6mm

2 RCOP5x1mm2 12 mm

3, 5 Mains cable, length 2 m 7mm

4, 6 Data cable 8 x (2 + 1) x 0.5 mm2 14 mm

7 Flexicable, 4 m fixed lenght. Mounted to the

Hull Unit

62 mm

8 RCCP/750 V 4 x 2.5 mm2 17 mm

Page 65

Installation procedures

21

851-160572 / B

MAN

AUTO

TILT

MAIN SW.

ILLUM .

LOWER

HOIST

ON-OFF

DISPLAY GAIN

AUTOMAN

RANGE

TARG ET

TRACK

TRACK

AUTO

POS.

MAN

TRAIN

MAN

SEARCH

AUTO

Sonar contr ol unit

Transceiver unit

Hull unit

Speed log

Course gyro

1 15/230V AC mains

Trawl system

Echo sounder

115/230V AC

mains

(CD3417)

230/380/440V

3 phase mains

12

3

4

5

6

7

8

Figure 13 SP270 cable plan

Page 66

Simrad SP270

22

851-160572 / B

Sonar Control Unit cabling

All the cables to the Sonar Control Unit are to be plug connected

to the electronic drawer unit at the rear of the cabinet (see figure

13). The numbers on the figure refer to the cable numbers on the

cable plan.

Note In order to make service on the Sonar Control Unit, the cables

must have a slack so the electronic drawer unit can have all the

cables connected while it is outside the cabinet. This could be

either by pulling it out from the front, or by reconnecting the

cables with the drawer at floor level.

3

1

2

4

115/230V AC mains

S101

Transceiver

Course gyroSpeed log

GND

N L

(CD3115)

Figure 14 Cable

connections to the Sonar

Control Unit

Note that cable no. 4 (refer to figure 13) is delivered with a

standard length of 100 meters, and has a preconnected plug in

the Sonar Control Unit (wheelhouse) end.

1 Pull cable no.4 from the wheelhouse to the sonar room.

Note that the preconnected plug should be connected to

the Sonar Control Unit in the wheelhouse. Remember to

include the slack for service purpose.

2 The mains power cable (3) may be connected to a normal

mains outlet in the wheelhouse. If the delivered cable does

not fit, put on a suitable connector. Note that the mains

power to the Sonar Control Unit can be 115 VAC or 230

VAC, and that this unit will automatically sense the

voltage.

Page 67

Installation procedures

23

851-160572 / B

The connection of the speed log (1) and the course gyro (2) will

be described in chapter Connecting auxiliary equipment.

Transceiver Unit cabling

The cable numbers on figure 14 and in the following

procedures refer to the numbers on the cable plan and the

interconnection diagram.

1 All cable connections to the Transceiver Unit must have a

slack to allow the Transceiver Unit to move up to 10 cm

because of the flexible shock mounting.

2 Start the termination with cable no.6. This because this

cable is connected to the lowest row of the terminals on

E201. Use the surplus of cable no.4, or a similar type of

cable. Use the cable gland on the left hand side (refer to

figure 15) and terminate the main screen of the cable as

shown in figure 16. For termination of each cable pair

with screen, refer to the interconnection diagram. Use a

part of the enclosed cable sleeve on the screen of each

cable pair.

(CD3416)

6 4 5

L N

GND

Figure 15 The cable

connections in the bottom of

the Transceiver Unit

3 Continue with cable no. 4 through the cable gland on the

right hand side (see figure 15) and make the termination of

the main screen according to figure 16. Make the

connections to terminal E201 according to the

interconnection diagram.

Page 68

Simrad SP270

24

851-160572 / B

Cable

main

screen

(CD3117 / GIF)

Figure 16 Termination of

the cable main screen

Note that the mains power connection to the Transceiver Unit

can be 115 VAC or 230 VAC. Use the following procedure for

the connection of the mains power:

1 Pull out the mains input connector P201 on the power

supply in the Transceiver Unit. For location of the

connector, refer to figure 17.

2 Set the mains voltage selector switch S201 on the Power

Supply and S203 on the HV Power Unit to correspond to

the correct mains voltage (115V or 230V), and replace the

switch lock to secure the switch in the correct position.

3 Set the service switch S202 on the Power Supply to OFF

(middle) position.

4 The mains power cable (3) may be connected to a normal

mains outlet in the sonar room. If the delivered cable

connector does not fit, put on a suitable connector.

5Donotmount the flexible transducer cables to the

Transceiver Unit.

Page 69

Installation procedures

25

851-160572 / B

ANALOG

POWER

SUPPLY

SWITCHED

POWER

SUPPLY

SERVICE

OFF

NORMAL

ON/OFF

RELAY

24V

STAND

BY

CAUTION

DO NOT PULL OUT THIS UNIT

BEFORE THE METER SHOWS

ZERO ( 0 ) VOLTAGE

FOR CONTINUED PRO T ECTION

AGAINST RISK OF FIRE

REPLACE ONLY WITH SAME

TYPE AND RATING OF FUSE.

+8V

AREF

-8V

+5VA

-5VA

+5V

+12V

-12V

+24V

GND

L204

F203

L203

S202

L202

L201

+24V

REF

F201

8A

F204

8A

F202

8A

F205

8A

SLOW

BLOW

SLOW

BLOW

HIGH

MIDDLE

LOW

f (SW)

MAINS INPUT

115/23 0V AC

S203

230V AC

S201