Page 1

SL 30/35 HULL SONAR OPERATORS MANUA L

974-25007001

Issue 2.0 September 2003

Page 2

Page 3

SL 30/35 Hull Sonar Operators Manual 974-25007001/2.0

List of Contents Page 1

Kongsberg Simrad Mesotech Ltd

Products Warranty Policy

Effective January 1, 2003

Kongsberg Simrad Mesotech Ltd. Warrants each new product (equipment) to be

free of defect s caused by faulty materials or poor workmanship for a period of t welve

(12) months for underwater equipment and twenty-four (24) months for surface

equipment from date of installation by an authorized Kongsberg Group Company,

Simrad Distributor, Dealer or Agency. The warranty does not apply to defects

caused by, force majeure events or misuse, including water damage t o the surface

equipment, improper maintenance and installation, including excessive wear and

tear for which Kongsberg Simr ad Mesotech Ltd. I s not r esponsible.

Underwater Equipment:

Warranty for Underwater Equipment that is hull mounted, such as those

•

mentioned below, will be assessed on a

not be covered by the warranty:

case-by-case

basis but shall generally

Hull Units, Sonar Dome Assemblies and Echo Sounder Transducer s

•

Transducer Units, Speed, Temperature and Depth Sensors

•

Note:

dry- docking and diving, are not covered by this warranty.

Additional expenses connected with replacement of transducers, such as

Warranty on Parts or Equipment Replacement:

It is at the sole discretion of Kongsberg Simrad Mesotech Ltd. t o either repair or

•

replace any unit/part that fails within the lim its of the Warranty Policy.

The Warranty Policy is only valid on new equipment

•

Replacement of parts, components, and/or PCB Boards during a warranty repair

•

does not extend the original warranty period.

Consumable Materials:

Consumable materials, such as lamps, fuses, o-rings, gaskets and batteries,

•

shall not be replaced free of charge.

Kongsberg Simrad Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 4

974-25007001/2.0 SL 30/35 Hull Sonar Operators Manual

Page 2 List of Contents

Warranty Service:

Warranty service is available worldwide through authorized Kongsberg Group

•

Companies, Simrad Distributors, Dealers or Agencies. When requesting

warranty service, you must supply the following information:

1. Proof of purchase.

2. Equipment part number and serial number.

3. Fault description and all relevant vessel inf or mation.

Labour cost for the repair or replacement of any products/equipment and/or

•

module/parts is the responsibility of t he servicing agent or dealer.

All customs duties, brokerage char ges and local taxes, overtime, expenses for

•

meals, tools, launch services, ferries, lodgings, normal adjustment s and routine

maintenance are not covered by this warranty policy.

DISCLAIMER

Maximum liability shall not, in any case, exceed the contract price of the pr oduct s

•

claimed to be defective.

Consequent ial damages including, but not limited to, any loss of pr ofit, property

•

damage or personal injury, are not covered by the warranty policy.

This equipment is not certified or approved for navig ation and/or safe-navig ation

•

practices, and is not to be used for navigation purposes under any

circumstances.

Kongsberg Simrad Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 5

SL 30/35 Hull Sonar Operators Manual 974-25007001/2.0

List of Contents Page 3

LIST OF CONTENTS

Part 1

Part 2

Part 3

Part 4

Part 5

Part 6

Part 7

Part 8

Part 9

...........................................................................................

................................................................................................

.........................................................

............................................................................

Control Panel Operation and Display Modes

Menu and Software Description

..................................................................................................

.....................................................................

.....................................................................

SL 35 Installation, Start-Up and Test

SL 30 Installation, Start-Up and Test

System Familiarization

System Description

Selecting Settings

..........................................................................................................

....................................................................................

Attachments and Drawings

Maintenance

Kongsberg Simrad Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 6

974-25007001/2.0 SL 30/35 Hull Sonar Operators Manual

Page 4 List of Contents

Kongsberg Simrad Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 7

SL 30/35 Hull Sonar Operators Manual 974-25007001/2.0

List of Contents Page 5

MODIFICATION RECORD

SL 30/35 HULL SONAR OPERA TORS MANUAL

974-25007001

Issue: 2.0

September 2003

Issue

No. Date Initial Comments

1.0 05.02 L.F. First Release

2.0 09-03 L.F. Second Release

To assist us in making improvements t o t he product and this document,

Kongsberg Simrad Mesotech welcomes comments and constructive

criticisms. Please send all such comments, in writing or by e-mail, to:

Kongsberg Simrad Mesotech Ltd.

Documentation Department

1598 Kebet Way

Port Coquitlam, BC V3C 5M5

CANADA

E-mail: vancouver.sales@kongsberg-simrad.com

Kongsberg Simrad Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 8

974-25007001/2.0 SL 30/35 Hull Sonar Operators Manual

Page 6 List of Contents

Kongsberg Simrad Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 9

SL 30/35 Hull Sonar Operators Manual 974-25007001/2.

0

System Familia riza tio n Page 1.1

PART 1

SYSTEM FAMILIARIZATION

1. SYSTEM FAMILIARIZATION..........................................................................1.3

1.1 OVERVIEW.................................................................................................1.3

1.1.1 Equipment Configuration......................................................................1.3

1.1.2 System Diagram...................................................................................1.4

1.1.3 Display..................................................................................................1.5

1.1.4 Processor Unit......................................................................................1.5

1.1.5 Control Panel and Interface Unit...........................................................1.5

1.1.6 Sonar Room Unit..................................................................................1.6

1.2 SL 30/35 TECHNICAL SPECIFICATIONS...................................................1.7

Kongsberg Simrad Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 10

974-25007001/2.0 SL 30/35 Hull Sonar Operators Manual

Page 1.2 System Familia riza tio n

Kongsberg Simrad Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 11

SL 30/35 Hull Sonar Operators Manual 974-25007001/2.

0

3

System Fa milia riza tio n Page 1.

1. SYSTEM FAMILIARIZATION

1.1 OVERVIEW

The SIMRAD SL 30/35 Hull Sonar Series is a short range, mechanical scanning

sonar designed for small and medium sized purse seiners and trawl fishing vessels.

The system provides real time images from the sonar dome to the bridge, thus

maximizing the best possible presentation on a high-resolution colour monitor,

providing the operator with 6 different display modes and 4 customized user modes,

giving a flexible choice for a large r ange of user applications.

The SL 303/35 Sonar allows the operator to monitor the complete operation, by

displaying individual fish school target locations in the Horizontal Plane. In addition

to the Horizontal plane, the SL 30/35 Sonar provides a Vertical Fan mode, specially

made for trawling, where a complete overview of the Hor izontal and Vertical Planes

are presented.

The sonar beam can be horizontally trained 360° and 180° in the Vertical Plane.

The automatic search features and full -90° tilt capability ensure maximum cont rol

during the tow and/or pursing. T he active motion com pensation f or pitch and r oll and

the audio speaker are optional.

The SL 30/35 Sonar is a modular system. It is operated with ease through a direct

access Control Panel with an integrated mouse.

1.1.1 Equipment Configuration

A complete SL 30/35 Hull Sonar consists of:

• Simrad LCD or VGA Display Monitor. (Optional)

• SL 30/35 Processor Unit.

• SL 30/35 Control Panel and Interface Module.

• SL 30 or 35 Transceiver Assembly.

• SL 30 or 35 Sonar Dome Assembly, Frequency, 90kHz or 160kHz.

• SL 35 Lower and Raise unit, travel, 250 millimeters or 400 millimeters.

• SL 35 Shaft Length: 2.4m, or 3.0m,.

• SL 30/35 Motion Sensor Option.

• SL 30/35 Built-in Internal Audio Speaker, (Optional External Audio Speaker).

• SL 35 Standard Installation Materials

Important notice:

Windows, Windows NT, W indows 2000 and Windows XP are either registered

trademarks or tradem arks of Microsoft Corporat ion in the United States and /or

other countries.

Kongsberg Simrad Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 12

974-25007001/2.0 SL 30/35 Hull Sonar Operators Manual

Page 1.4 System Familia riza tio n

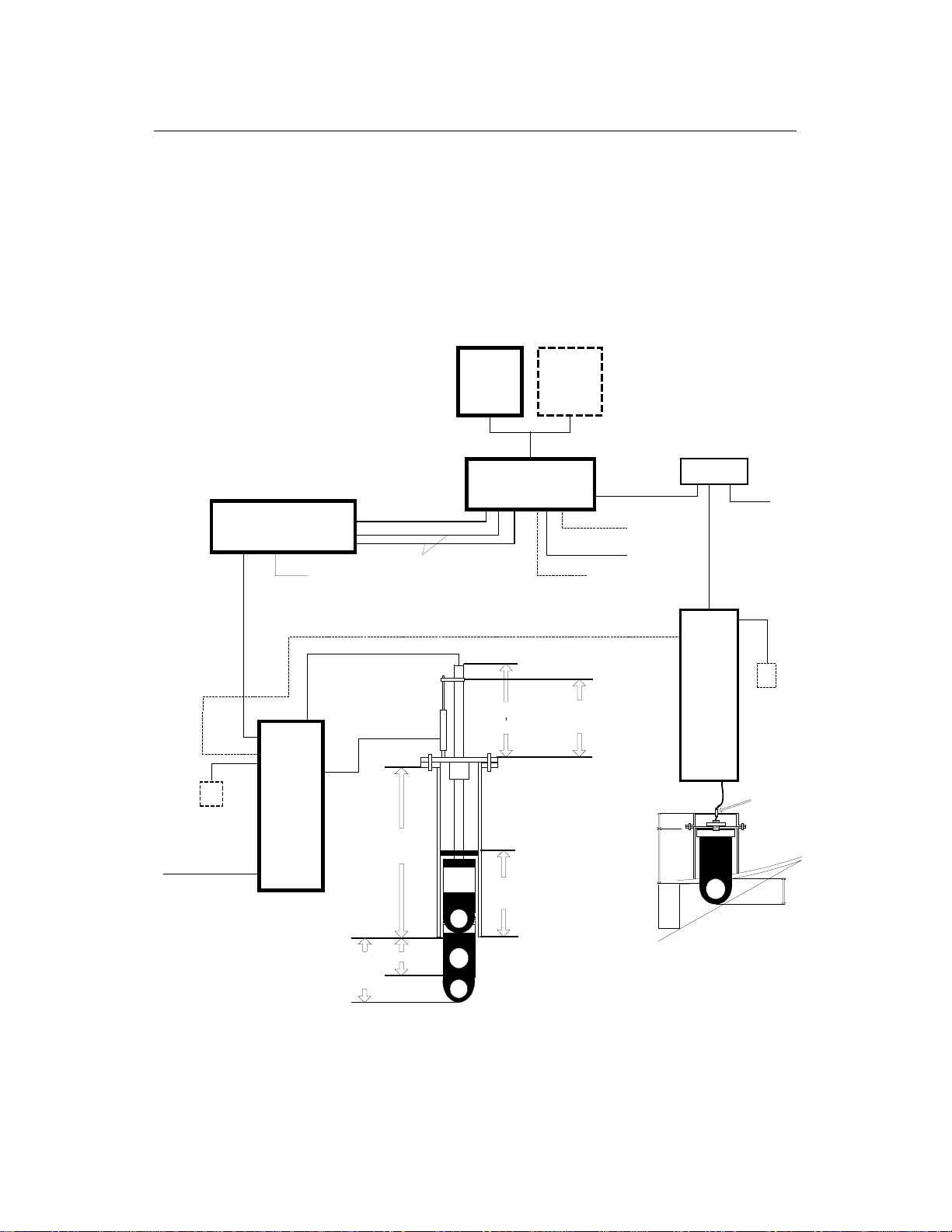

1.1.2 System Diagram

SL 35 Hull Mounted Sonar & SL 30 Catch Sonar

Interconnection System Diagram

(15m / 30m / 50m)

Special Order 100m

(10m)

Optional

Motion Sensor

(2.5m)

Simrad Operating Panel

User Interface

(2.5m)

Power Input

110/220 VAC +/- 10%

RX / TX

Unit

Com 1, RS232 Cable

(2m)

PS 2 KBD/Mouse Cables

(2m) each

( 4.5m / 5.1m )

(1.0m) Input Power

24 VDC

Tank length

(Min. 660 mm)

LCD

Monitor

Processing Unit

Optional

Synchronisation Cable for

Catch Sonar(10m)

1.0m for a 250mm Hoist Unit

1.4m for a 400mm Hoist Unit

Optional

LCD

Monitor

Speaker

Option

Com 2, RS232

(2.5m)

Cable (2m)

External Nav. Unit

Power input

110/220 VAC +/- 10%

254mm

206mm

Interfa ce U n it

Optional

SL 30

(3.5m)

Power input

110/220 VAC +/- 10%

(15m / 30m / 50m)

Special Order 100m

(10m)

RX / TX

Unit

(5m)

Cable Gland

Ship H u ll

Optional

Motion

Sensor

Input Power

24 VDC =/- 10%

250mm

400mm

Travel

Travel

Kongsberg Simrad Mesotech Ltd.

Port Coquitlam, BC - Canada

450 mm

Sonar Dome

90kHz or 160kHz

Keel

Catch Sonar Dome

90kHz or 160kHz

140mm

Page 13

SL 30/35 Hull Sonar Operators Manual 974-25007001/2.

0

5

System Fa milia riza tio n Page 1.

1.1.3 Display

The display monitor for the SL 30/35 Sonar can be either a VGA “CRT” or LCD

Simrad ruggedized monitor, but any commercially available monitor may be used. In

order to have the full benefit of high resolution, you should use a Simrad LCD

Monitor.

1.1.4 Processor Unit

The SL 30/35 Sonar Processing Unit is a rug gedized computer, which can interface

with other auxiliary equipment (Control Panel, Interface Unit, GPS, Echo Sounder

and Trawl Systems, etc.). The processor unit runs on the Microsoft Windows XP

Operating System. The SL 30/35 Sonar System software provides a mechanism f or

the sonar operation. It is operated through the Main Control Panel to enable the

sonar selection, tilt, range, gain and cursors; moving the mouse pointer over the

toolbar will allow the operator to perform certain operations with a simple mouse

click. A flush mounted Control Panel is provided to simplify the operation of the

system.

The rear panel of the processing unit cont ains the connector s f or AC and DC power,

Monitor port, two RS232 Serial Ports, Keyboard, Mouse, Printer, Network LAN and

USB port. The Network LAN port can be used to connect a remote work station, or t o

download data from the processing unit.

Note: A security key (or “dongle”) must be attached to the parallel por t to enable

full operation of the system.

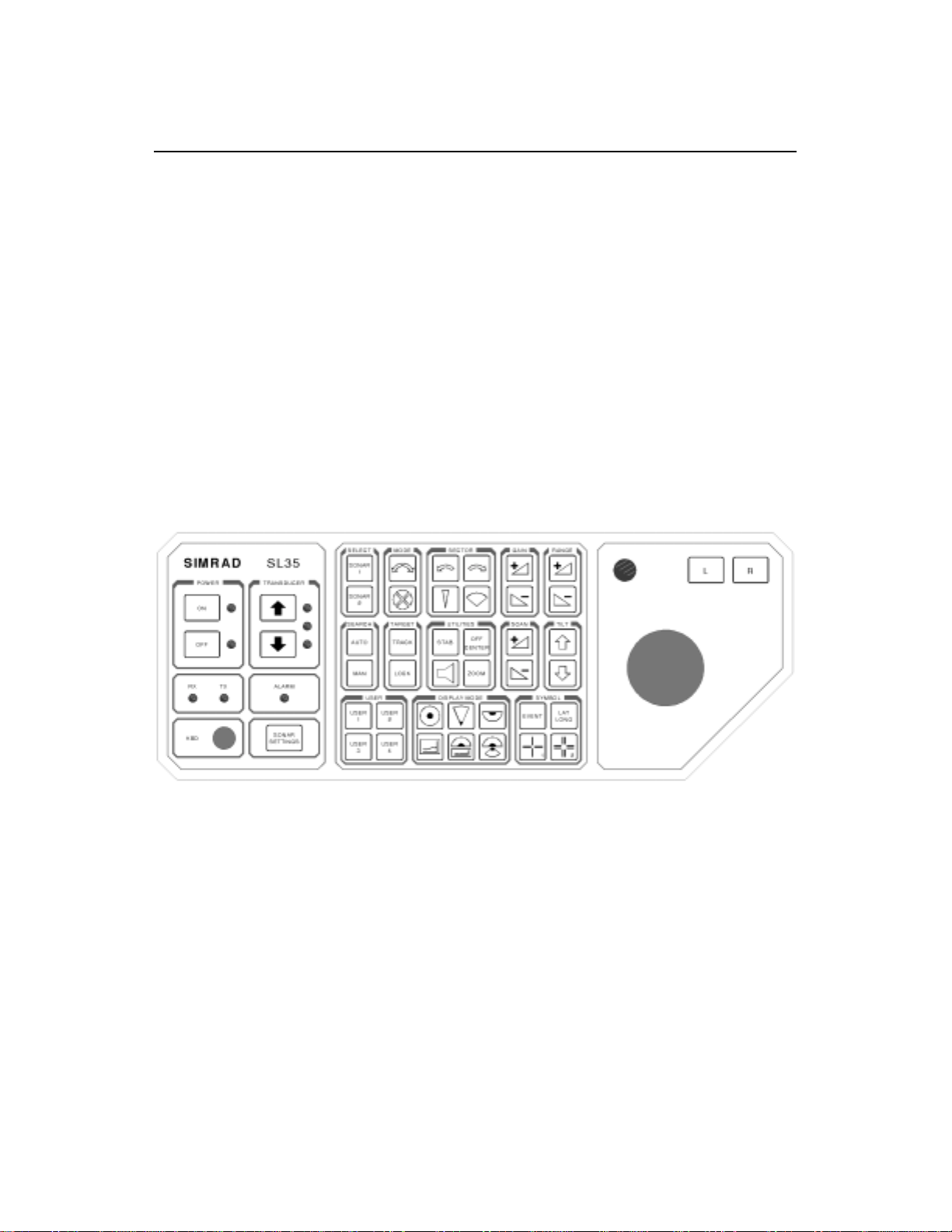

1.1.5 Control Panel and Interface Unit

The SL 30/35 Control Panel contains all necessary control functions for operating

the sonar. As some of the functions are used more frequently than others, the

control buttons are arranged in f unction groups, as Sector T rain, Tilt, Scan Speed,

Range, Display Mode, User Setting and Utilities. The Power ON and OFF butt ons,

the Lower and Raise buttons are also provided for on the SL 35 Hoist Cont r ol.

Note: All sonar operations may also be controlled f rom the int egrated roller ball, or

from an optional remote standard m ouse.

The SL 30/35 Interface Unit is incorporated into the Control Panel assembly,

providing the interface telemetry communication between the Processing Unit and

the Transceiver Unit in the sonar room.

Note that only one signal cable is used for communication between the Interface

Unit and the Transceiver Unit.

Kongsberg Simrad Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 14

974-25007001/2.0 SL 30/35 Hull Sonar Operators Manual

Page 1.6 System Familia riza tio n

1.1.6 Sonar Room Unit

The Transceiver Unit and Lower/Raise Unit are located in the sonar room, mounted

to the tank flange.

The Hull Unit sonar dome is lowered 250 millimeters or 400 millimeters below the

ship’s hull. In case of a power failure the dome assembly will automatically retract

back up into the sonar tank.

Note: The sonar dome can be manually raised by means of a hand pump.

The optional motion sensor for the electronic stabilization of the sonar beams is also

located in the sonar room. A 10 meters int er c onnect ion cable is supplied.

WARNING!!

If the sonar dome hits a larg e object or the bottom, the dome shaft

may be bent, or in the worst case it can be broken off. A broken

sonar dome may cause water leakage at the top of the shaft. To

prevent large leakages in such a case, DO NOT raise the sonar

dome shaft to the upper position. It is t heref or e of gr eat im portance t o

have a good pump and warning system in the sonar room.

DISCLAIMER

This equipment is not certified or approved for navigation and/or safe-

navigation practices and is not to be used for navigation purposes

under any circumstances.

Kongsberg Simrad Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 15

SL 30/35 Hull Sonar Operators Manual 974-25007001/2.

0

7

System Fa milia riza tio n Page 1.

1.2 SL 30/35 TECHNICAL SPECIFICATIONS

• Processing Unit

Operating System: MS Windows XP Professional

40GB Hard Drive

2 SVGA Monitors output

Sound Card

Network LAN Port

4 USB Ports and 2 RS232 Serial Ports

Built-in Audio Speaker

Power input: 115/240VAC, 50/60Hz, +/- 10%, (<5A)

• Data Input/output

NMEA 183 format (RS232)

• Range

Operating Range: 5 meters to 1250 meters

Detection Range: 750m for 90kHz; 450m for the 160kHz Dome

• Tilt

Upward: From 0° to +10°

Downward: From 0° to –90°

• Stabilization

Pitch and Roll: +/- 30°

• Operating Panel

Flush Mounted

Integrated Inter face Unit

Power input: 115/240VAC, 50/60Hz, +/- 10%, (<5A)

Hull Unit

Hoist Unit: Hydraulic Ram

Travel: 250mm or 400mm Stroke

Raising Time: 10 Seconds

Maximum Raising Ship Speed: 15 Knots

• Transceiver Unit

Frequency: 90kHz or 160kHz

Transmit O/P Power: 1.2 kW

Power input: 24/32VDC, +/- 10%, for Hoist Unit Only (<10A)

Sonar Dome Size: 8 inches

• Sonar Dome Unit

Transducer Beam: Cone 8° X 8°, Side Lobe: - 25dB

Installation Trunk: Not DnV approved Trunk. (In process)

• Options:

LCD Monitor

Motion Sensor

External Audio Speaker

UPS Input Power Supply

Kongsberg Simrad Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 16

974-25007001/2.0 SL 30/35 Hull Sonar Operators Manual

Page 1.8 System Familia riza tio n

Kongsberg Simrad Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 17

SL 30/35 Hull Sonar Operators Manual 974-25007001/2.

0

System Description Page 2.1

PART 2

SYSTEM DESCRIPTION

2. SYSTEM DESCRIPTION ................................................................................2.3

2.1 INTRODUCTION .........................................................................................2.3

2.1.1 Basic Principles ....................................................................................2.3

2.1.2 Determining Target Position .................................................................2.3

2.1.3 Forming an Image.................................................................................2.3

2.1.4 Wheelhouse Units Description ..............................................................2.4

2.1.4.1 Display Monitor..............................................................................2.4

2.1.4.2 Processor Unit...............................................................................2.4

2.1.4.3 Control Panel.................................................................................2.5

2.1.4.4 Interface Unit.................................................................................2.5

2.1.4.5 Interconnect Cables.......................................................................2.5

2.1.5 Sonar Room Units Description..............................................................2.5

2.1.5.1 Transceiver Unit.............................................................................2.6

2.1.5.2 Lower and Raise Unit.....................................................................2.6

2.1.5.3 Hull Sonar Dome Unit....................................................................2.6

2.1.5.4 Tank Flange Assembly..................................................................2.6

2.1.5.5 Interconnect Cables.......................................................................2.7

2.1.6 Options.................................................................................................2.7

2.1.6.1 Motion Sensor................................................................................2.7

2.1.6.2 Audio Warning Speaker................................................................. 2.7

2.1.7 Remarks...............................................................................................2.7

2.1.8 Warning................................................................................................2.8

2.1.9 Copyright..............................................................................................2.8

Kongsberg Simrad Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 18

974-25007001/2.0 SL 30/35 Hull Sonar Operators Manual

Page 2.2 System Description

Kongsberg Simrad Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 19

SL 30/35 Hull Sonar Operators Manual 974-25007001/2.

0

3

System Description Page 2.

2. SYSTEM DESCRIPTION

2.1 INTRODUCTION

This section explains the theory of operation of the SL 30/35 Mechanical Scanning

Sonar System.

2.1.1 Basic Principles

• Sound waves travel very efficiently through water.

• A sound pulse can be projected thr ough water in a controlled direction with the

sonar transducer.

• An object in the path of the projected sound pulse will reflect some sound pulse

back toward the sonar transducer.

• The speed of the sound pulse projected through the water can be predicted for

given conditions.

2.1.2 Determining Target Position

The SL 30/35 scanning sonar processor measures the time from the start of the

sound pulse projected through water, to the r eception of the sound pulse ref lected

back to the sonar transducer. The measured time is then convert ed to distance by

using the speed of sound through water.

Since the sound pulse is projected in a known direction, the bearing of the reflected

object is also known. This makes it possible t o locate the object with respect t o the

sonar transducer; the information will be used to plot the position of the reflected

target on a video graphic display monitor.

2.1.3 Forming an Image

The sound pulse projected will be attenuated as it travels through the water from t he

transducer to the target and back. Much of this att enuation is a predictable function

of the total time or the dist ance the sound pulse traveled through water. Increasing

the receiving gain with time can compensate for this decrease in the signal level.

This is done automatically in the sonar with a Time Varying Gain circuit.

Kongsberg Simrad Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 20

974-25007001/2.0 SL 30/35 Hull Sonar Operators Manual

Page 2.4 System Description

After the TVG correction, the absolute levels of the received signals will be

determined by the acoustic response of the ref lect ing target.

The sonar processor system repeatedly measures the TVG corrected target levels

by digitizing a sequence of samples after each sound pulse transmission. Each

sample is then plotted on the video display at the appropriate position according to

its range and bearing. The level of the target strength sample determines the color

used to plot each sample.

The process can be repeated with the transducer pointed in different directions,

forming an image of a large area of the bot t om and displaying it on the video screen.

2.1.4 Wheelhouse Units Description

The following paragraphs will describe the key features of the W heelhouse Units of

the SL 30/35 Hull Sonar.

2.1.4.1 Display Monitor

The display monitor required for the SL 30/35 can be either a VGA “CRT” type or

any commercial LCD monitor. In order t o have the full benefit of high resolution, we

recommend that you select the Simrad rug gedized LCD colour monitor. T he Simrad

colour monitors are available in two sizes, 18” and 20”. The monitor can be desk,

ceiling, or flush mounted into the bridge console.

The Simrad LCD monitor will run on 110/240VAC, 50/60Hz or on 24VDC, +/- 10%.

All mounting hardware is included.

2.1.4.2 Processor Unit

The processor unit is a ruggedized HP “Hewlett Packard” Compaq Processing Unit

designed for use in a marine environment. T he processor unit runs on the Microsoft

Windows XP Prof essional O per ating System.

In the event that you have a problem with the HP computer we recommend that you

contact your Simrad dealer or Agent to assist you in solving the pr oblem.

Hewlett Packard Customer Center can help you solve hardware issues related to HP

products and, if necessary, initiate the appropriate service procedur es. I n the U.S. A.,

telephone support is available 24 hours a day, seven days a week. Elsewhere, in the

world, it is available during normal off ice hour s.

Kongsberg Simrad Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 21

SL 30/35 Hull Sonar Operators Manual 974-25007001/2.

0

5

System Description Page 2.

The HP Customer Care Centers are list ed in the HP Warranty and Support Guide

included with the computer.

Note: If the Hewlett Packard Customer Center can not help you, all warranty and

service requirements are also supplied by the Simrad Dealer s, or Simrad Agents.

2.1.4.3 Control Panel

The SL 30/35 Control Panel contains all of the most frequently used control buttons

required to operate the sonar. The sonar can also be operat ed using the int egrated

roller ball and the on-screen menus and toolbars. Note that the integrat ed roller ball

with its left and right buttons eliminate the need for an external mouse.

All buttons are back-lit f or night operation. An automatic dimmer is incorporated in

the panel, eliminating the need to r aise or lower the intensity of the back illumination.

An external PC keyboard connector is also provided for use during software

maintenance or upgrading.

The SL 30/35 Control Panel is designed for durability and water resistance. The unit

can easily cleaned with a soft cloth dampened with soap and water only.

Details of operation are described in Part 3.

2.1.4.4 Interface Unit

The Interface Unit is incor porated into the Control Panel Assembly. It consists of an

internal 24VDC Power Supply, the RS 232 Interface, the Control Panel keyboard

interface and the Sonar Telem etry Translation Module (TTM) assembly PCB.

2.1.4.5 Interconnect Cables

The interconnection cables are pre-made to specific length. The RS232 and t he PS2

mouse/keyboard cables are 2 meters in leng th. The transceiver cable to t he Control

Panel is available in 4 lengths: 15 meters, 30 meter s, 50 m eter s and special order at

100 meters. The power input cable is 2.5 meters in length.

2.1.5 Sonar Room Units Description

The following paragraphs will explain the key f eatures of the Sonar Room Hull Unit

of the SL 30/35 Sonar.

Kongsberg Simrad Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 22

974-25007001/2.0 SL 30/35 Hull Sonar Operators Manual

Page 2.6 System Description

2.1.5.1 Transceiver Unit

The Transceiver Unit is mounted on the tank flange in a standard installation, but

can also be bulkhead mounted if required. The maximum Sonar Dome cable length

permissible is 5.1 meters depending on the shaft length used during the inst allat ion.

The Transceiver Unit contains the receiver and transmitter PCB assembly and the

lower and raise PCB assembly. A safety power ON/OFF switch is also provided so

power can be shut off when working on the lower and raise assembly. The

transceiver assembly is splash proof to protect t he elect ronics circuits from water.

Note: The safety power ON/ O FF switch is not required for the SL 30 Sonar.

2.1.5.2 Lower and Raise Unit

The SL 35 Lower and Raise Unit is a self-contained hydraulic assembly. Installation

is simple and only requires the fitting of 2 clevis pins and connection of the power

cable from the Transceiver Unit.

.

The travel length is available in two sizes, 250 millimeters and 400 millimeters

depending on the installation requirement.

2.1.5.3 Hull Sonar Dome Unit

The Hull Sonar Dome unit is available in two frequencies, 90kHz and 160 kHz. The

cable length is available in 4.5 meters for a 2.4 or 3 meter shaft and 5.1 meters with

a 3.6 meters optional shaft. Special attention must be paid to matching cable and

shaft lengths when ordering the system.

Note: The SL 30 Catch Sonar Dome comes with a standard 5 meter cable length.

2.1.5.4 Tank Flange Assembly

The SL 35 Tank Flange Assembly main body is cast in ASTM A536, 60-40-18

Ductile Iron. Special mounting pads and a guide are incorporated into the flange.

The shaft bearing is made of SEA 660 Bearing Bronze. Special attent ion was given

during the design to the seal and shaft packing in order to prevent water leakage

into the sonar room. A zinc anode is also installed on the tank flange, to reduce

electrolysis.

Note: The Tank Flange Assembly is not required for the SL 30 Dome; all flanges are

serial-numbered.

Kongsberg Simrad Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 23

SL 30/35 Hull Sonar Operators Manual 974-25007001/2.

0

7

System Description Page 2.

2.1.5.5 Interconnect Cables

The only interconnection cable supplied with the transceiver is the 2.5 meters power

input cable. All other cables are supplied with the other units.

2.1.6 Options

The following paragraph explains the key features of the Optional Units of the SL

30/35 Hull Sonar.

2.1.6.1 Motion Sensor

The Motion Sensor unit will compensate +/- 30 degrees for the pitch and r oll of the

fishing vessel. A 10 meter interconnect ion cable and mounting hardware is supplied

when you purchase the Sensor.

2.1.6.2 Audio Warning Speaker

The Audio Warning Speaker is built into the Processor Unit. If you require an

external audio speaker, You may purchase it locally. The audio speak er connects to

the rear of the Processing Unit

2.1.7 Remarks

Further information about the SL 30/35 system may be found in the following

manual.

This Operator and Installation Manual is intended for the design and installation

engineers at the shipyard. On completion of the installation, this manual must be

kept on the vessel for ref er ence pur poses dur ing system maintenance.

Kongsberg Simrad Mesotech Ltd. mak es every effort to ensure t hat the informat ion

contained within this manual is correct. However, our products are continuously

being improved and updated, so we cannot assume liability for any errors that m ay

occur.

Note: All specifications are subject to change wit hout notice.

Kongsberg Simrad Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 24

974-25007001/2.0 SL 30/35 Hull Sonar Operators Manual

Page 2.8 System Description

2.1.8 Warning

The product to which this manual applies must only be used for the purpose for

which is it was designed. Improper use or maintenance may cause damage to the

product or injury to personnel. The user must be familiar with the contents of the

appropriate manual before att em pt ing to operate or work on the product.

Kongsberg Simrad Mesotech Ltd. disclaims any responsibility for damage or injury

cause by improper installation, use or maintenance of t he pr oduct.

2.1.9 Copyright

The information contained within this document remains the sole property of

Kongsberg Simrad Mesotech Ltd. No part of this document may be copied or

reproduced in any form or by any means, and the information contained within is not

to be communicated to a third party, without the pr ior written consent of Kongsberg

Simrad Mesotech Ltd.

DISCLAIMER

This equipment is not certified or approved for navigation and/or safe-navigation

practices and is not to be used for navigation purposes under any circum st ances.

Kongsberg Simrad Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 25

SL 30/35 Hull Sonar Operators Manual 974-25007001/2.

0

Control Panel Page 3.1

PART 3

SL 30/35 CONTROL PANEL

3. SL 30/35 CONTROL PANEL OPERATION.....................................................3.3

3.1 INTRODUCTION .........................................................................................3.3

3.2 CONTROL PANEL.......................................................................................3.3

3.3 MAIN POWER SWITCH.............................................................................. 3.4

3.3.1 Power ON/OFF Buttons........................................................................3.4

3.3.2 Sonar Dome Transducer Buttons..........................................................3.5

3.3.3 Sonar Settings Button...........................................................................3.5

3.3.4 Roller Ball and Mouse Buttons.............................................................. 3.6

3.3.5 Sonar Selection Buttons........................................................................3.6

3.3.6 Range Buttons......................................................................................3.7

3.3.7 Gain Buttons.........................................................................................3.7

3.3.8 Scan Buttons ........................................................................................3.8

3.3.9 Tilt Buttons............................................................................................3.9

3.3.10 Sector Control Buttons ......................................................................3.9

3.3.10.1 Move Sector Left Button ..............................................................3.10

3.3.10.2 Move Sector Right Button............................................................3.10

3.3.10.3 Narrow Sector Button...................................................................3.10

3.3.10.4 Widen Sector Button....................................................................3.10

3.3.11 Sector Aiming Mode Buttons...........................................................3.11

3.3.12 Utilities Buttons................................................................................3.12

3.3.12.1 Off Center Button.........................................................................3.12

3.3.12.2 Zoom Button................................................................................3.12

3.3.12.3 Stabilize Button............................................................................3.13

3.3.12.4 Speaker Button............................................................................3.13

3.3.13 Target Track and Lock Buttons.......................................................3.13

3.3.14 Auto and Manual Search Buttons....................................................3.14

3.3.15 Symbol Buttons...............................................................................3.15

3.3.15.1 Latitude / Longitude Button..........................................................3.15

3.3.15.2 Event Mark Button.......................................................................3.15

3.3.15.3 Cursor Buttons.............................................................................3.16

3.3.16 User Buttons ...................................................................................3.17

3.3.17 Display Mode Buttons......................................................................3.17

3.3.17.1 Horizontal Display Mode Button...................................................3.18

3.3.17.2 Bow Up Display Mode Button.......................................................3.18

3.3.17.3 Vertical Fan Mode Button.............................................................3.18

Kongsberg Simrad Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 26

974-25007001/2.0 SL 30/35 Hull Sonar Operators Manual

Page 3.2 Control Panel

3.3.17.4 Sounder Mode Button..................................................................3.19

3.3.17.5 Horizontal Mode with History Mode button...................................3.19

3.3.17.6 Horizontal Mode with Real Time Vertical Strata Mode Button......3.19

3.3.18 RX and TX Indicator LED................................................................3.20

3.3.19 Alarm Indicator LED........................................................................3.20

3.3.20 Keyboard (KBD) External Plug-in....................................................3.20

3.3.21 Panel Light Dimmer Sensor.............................................................3.21

3.3.22 Menu Description ............................................................................3.21

Kongsberg Simrad Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 27

SL 30/35 Hull Sonar Operators Manual 974-25007001/2.

0

3

Control Panel Page 3.

3. SL 30/35 CONTROL PANEL OPERATION

3.1 INTRODUCTION

The SL 30/35 Sonar uses a Control Panel for the most frequently needed

adjustments and a software menu system f or less frequently needed controls. This

chapter describes how to use the Control Panel to operate the sonar .

3.2 CONTROL PANEL

A thorough understanding of the system functions and controls is necessary to

optimize the overall performance. Sonar condit ions vary, sometimes drastically, and

it is not possible to identify proper sett ings that will provide the best sonar image at

all times.

Careful study of the information in this manual is highly recommended, preferably

while exploring the sonar’s various functions. System operation is a dynamic activity

requiring regular adjustment and fine-tuning to achieve the best possible results

under varying environmental conditions.

The Control Panel Buttons are described in the following paragraphs.

Kongsberg Simrad Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 28

974-25007001/2.0 SL 30/35 Hull Sonar Operators Manual

Page 3.4 Control Panel

3.3 MAIN POWER SWITCH

The Main Power Switch controls power to the Interface Unit, t he Sonar Transceiver

Unit, the hull Transducer Dome Assembly and the hoisting and lowering unit of the

hull transducer dome.

Note: When the SL 30/35 System is supplied with a HP/PC Processing Unit, power

must be turned on separately.

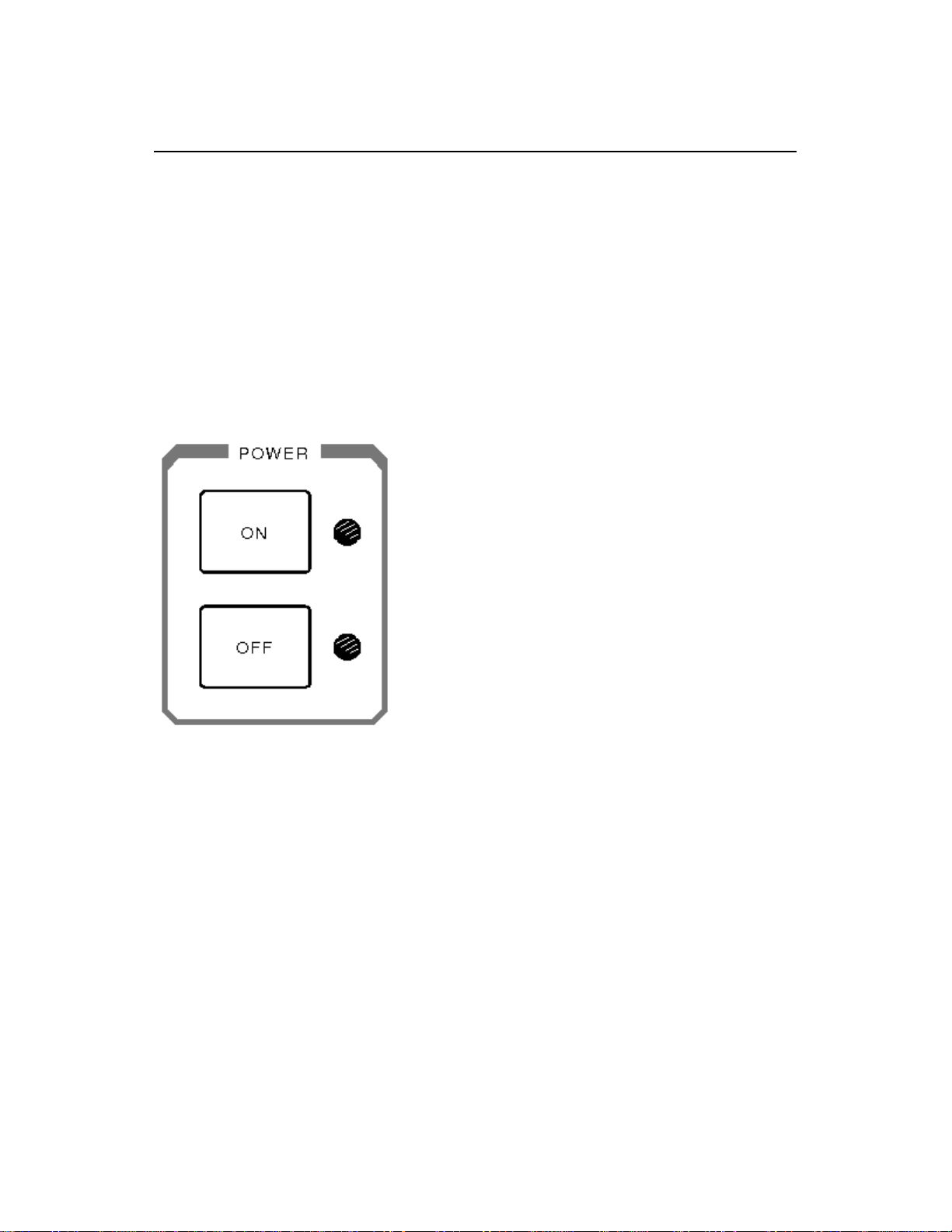

3.3.1 Power ON/OFF Buttons

Press the Power ON button for approximately two seconds to power up the sonar.

The adjacent green LED will light up and remain illuminated indicating that power

has been supplied to the sonar and the system is ready for operat ion.

Press the Power OFF button to remove the power to the sonar. The adjacent red

LED will light up and remain illuminated indicating that power has been rem o ved.

Note: The Hull sonar dome transducer unit will automatically retract into the tank if

Power is turned OFF, or if a loss of Power is detected. The green LED adjacent to

the UP Transducer Arrow button will light, indicating that the hull sonar dome

transducer is retracted into t he t ank and will remain illuminated.

Kongsberg Simrad Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 29

SL 30/35 Hull Sonar Operators Manual 974-25007001/2.

0

5

Control Panel Page 3.

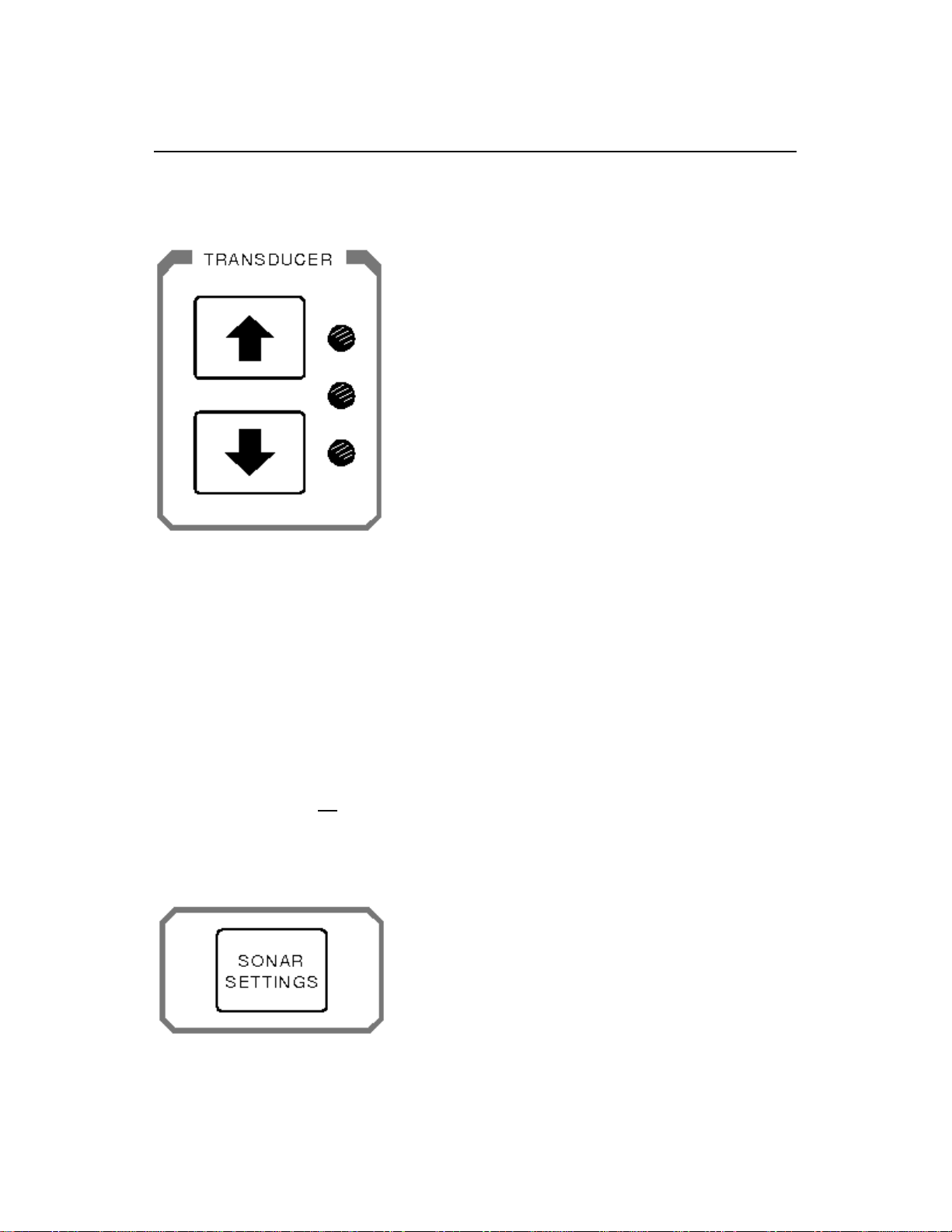

3.3.2 Sonar Dome Transducer Buttons

Press the UP Transducer Arrow button to raise the sonar dome to its upper position.

The middle yellow LED will blink while the sonar dome is being raised. The upper

green LED will light and remain illuminated when the sonar dome has reached the

full up position and is housed safely inside the hull of t he vessel.

Press the DOWN Transducer Arrow button to lower the sonar dome into its down

position. The middle yellow LED will blink while the sonar dome is lowering. The

lower green LED will light and remain illuminated when the sonar dome has reached

the full down position.

When the Power is tur ned off or if a power failure is detect ed, the sonar dome will

automatically retract safely inside the hull of the vessel and the upper gr een LED will

remain illuminated. If no Transducer LED’s are illuminated while the power has been

turned OFF, this indicates that the sonar dome has not been retr acted safely into the

hull of the vessel.

3.3.3 Sonar Settings Button

Press the Sonar Settings Button to display or hide the Header Menu at the top of the

display. Use the roller ball to move the cursor over one of the Header Menu and click

Kongsberg Simrad Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 30

974-25007001/2.0 SL 30/35 Hull Sonar Operators Manual

Page 3.6 Control Panel

the “L” button (left m ouse button). The Header Menu allows quick access to several

features that do not have a dedicated icon or but t on on the Control Panel.

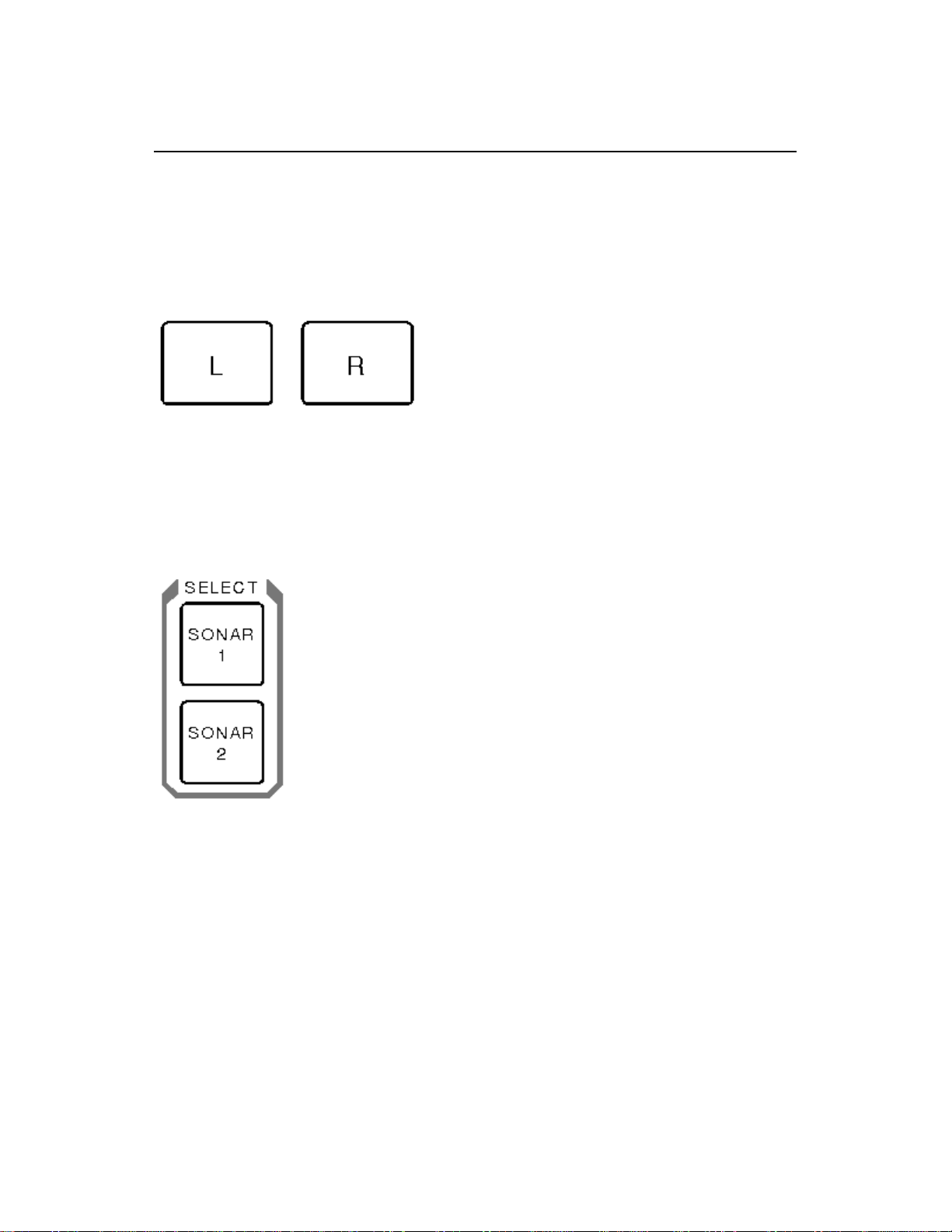

3.3.4 Roller Ball and Mouse Buttons

The Roller Ball (Trackball), “L” (left m ouse button) and the “R” (r ight mouse button)

allow you to move the mouse cursor and control the system by means of the menu

system and Tool Bar system on the display.

3.3.5 Sonar Selection Buttons

You do not need to use the Sonar Selection buttons if you only have one sonar hull

unit. These buttons are provided to allow you to select the active sonar when two

sonar hull units have been installed; for example: one SL 35, 90 kHz sonar and one

SL 35, 160 kHz sonar.

Press the Sonar 1 button or the Sonar 2 button to select the sonar you want to

control.

Note: If you only have a single sonar installed on the vessel, sonar 1 will be

automatically selected. If a second sonar is installed on the vessel, sonar 1 will be

automatically selected during the power-up.

Kongsberg Simrad Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 31

SL 30/35 Hull Sonar Operators Manual 974-25007001/2.

0

7

Control Panel Page 3.

3.3.6 Range Buttons

The Range Buttons control the Hor izontal and the Vertical range of the sonar. Use

the roller ball and move the mouse cursor over the sonar display you want to contr ol

and click on the “L” Left but t on.

Press the Range “+” or “-“ buttons to increase or decrease the operating range of

the sonar.

Note: You also can control the sonar r ange by using the roller ball and moving the

mouse cursor over the display window control panel. Click on the Up or Down arrow

pointer to increase or decrease the range.

See Part 4 for Pop-Up Control Panel descr iption and operation.

3.3.7 Gain Buttons

The Gain Buttons can control the gain settings of the selected sonar.

• Use the roller ball and m ove the mouse cursor over the sonar display you want

to control then click the “L” Left button.

Kongsberg Simrad Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 32

974-25007001/2.0 SL 30/35 Hull Sonar Operators Manual

Page 3.8 Control Panel

• Press the Gain “+” or “-“ buttons to increase or decrease the operating gain of

the sonar.

• You also can control the sonar g ain by using the roller ball to move t he mouse

cursor over the display window control panel to adjust the gain slider level.

See Part 4 for Pop-Up Control Panel descr iption and operation.

3.3.8 Scan Buttons

The Scan Buttons control the Horizontal and the Vertical scanning speed of the

selected sonar.

• Use the roller ball to move the mouse cursor over the sonar display you want to

control then click the “L” Lef t but ton.

• Press the Scan “+” or “-“ buttons to increase or decrease the operating

scanning speed of the sonar.

• You also can control the sonar scanning speed by using the roller ball to move

the mouse cursor over the display window control panel scan speed. Click on

the Up or Down arrow pointer to increase or decrease the scanning speed.

See Part 4 for Pop-Up Control Panel descr iption and operation.

Kongsberg Simrad Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 33

SL 30/35 Hull Sonar Operators Manual 974-25007001/2.

0

9

Control Panel Page 3.

3.3.9 Tilt Buttons

The Tilt Up and Tilt Down arrow buttons contr ol the tilt ang le of the transducer for a

selected sonar.

• Positive tilt from 0 degrees to +10 degrees (upward)

• Negative tilt from 0 degr ees to -90 degrees (downward)

• You also can control the sonar transducer tilt angle by using the roller ball to

move the mouse cursor over the display window control panel tilt angle and click

on the Up or Down arrow pointer to increase or decrease the tilt

See Part 4 for Pop-Up Control Panel descr iption and operation.

3.3.10 Sector Control Buttons

The Sector Control buttons are used to control the direction (Train Heading) and

width of the sector to be scanned by the sonar.

Kongsberg Simrad Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 34

974-25007001/2.0 SL 30/35 Hull Sonar Operators Manual

Page 3.10 Control Panel

3.3.10.1 Move Sector Left Button

Press the Move Sector Left button to re-center the scanning sector (T rain Heading)

more to the left.

3.3.10.2 Move Sector Right Button

Press the Move Sector Right button to re-center the scanning sect or (T rain heading)

more to the right.

3.3.10.3 Narrow Sector Button

Press the Narrow Sector button to reduce the width of the scanned sector. The

minimum sector width is 8 degrees.

3.3.10.4 Widen Sector Button

Press the Widen Sect or but ton to increase the width of the scanned sector.

• The maximum width setting will provide a full 360 degrees horizontal display.

• You also can control the sonar sector width opening by using the roller ball to

Kongsberg Simrad Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 35

SL 30/35 Hull Sonar Operators Manual 974-25007001/2.

0

Control Panel Page 3.11

move the mouse cursor over the display window control panel sector width and

click on the Up or Down arrow pointer to increase or decrease the sector width.

See Part 4 for Pop-Up Control Panel descr iption and operation.

3.3.11 Sector Aiming Mode Buttons

Press the Mode double arrow button to reverse the scan train direction (same as

Scan Reverse mode).

Press the Mode four-quadrant button to change the sector train heading by 90

degrees. Press the four-quadrant button a second time to change the sector train

heading by another 90 degrees.

For example: If your center of sector train heading is at 0 degrees, it will change to

90 degrees, next to 180 degrees and then to 270 deg rees. The next time you pr ess

the quadrant button it will return to 180 degrees and next t o 90 degrees and back t o

0 degrees.

Note: This feature allows quick adjustm ent of the sector heading.

Kongsberg Simrad Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 36

974-25007001/2.0 SL 30/35 Hull Sonar Operators Manual

Page 3.12 Control Panel

3.3.12 Utilities Buttons

3.3.12.1 Off Center Button

Press the Off Cent er but ton to move the Own vessel’s center of origin.

• Press the Off Center button, a red marker will be displayed on the screen

• Move the mouse red marker cursor t o the position that you want to extend the

view and left click the mouse button; the r ange will be doubled in that direction

• Press the Off Center button a second time to return the Own vessel center of

origin back to its original position.

3.3.12.2 Zoom Button

Press the Zoom Button to magnif y an area of the display around the mouse cursor.

Press again to change the magnificat ion. The Zoom button will select X1, X2, and

X4 magnification.

Kongsberg Simrad Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 37

SL 30/35 Hull Sonar Operators Manual 974-25007001/2.

0

3

Control Panel Page 3.1

3.3.12.3 Stabilize Button

Press the Stabilize (STAB) Button to turn ON automatic transducer pitch and roll

stabilization. Press the STAB button a second tim e t o t ur n st abilization O FF.

3.3.12.4 Speaker Button

Press the Speaker Mute button to activate or deactivate the audio monitor of fish

and/or bottom detection. T his option is used as an audio alert t o inform the oper ator

that detection has been made.

3.3.13 Target Track and Lock Buttons

Press the Target Tr ack button to activate the tracking of the selected target. To track

a target, place the mouse cursor over the desired location and press the Target

Track button. A circ le will appear on the display and its position will be automatically

tracked by the system using the strongest fish echo centered in the “window”

represented by two lines on the audio line. The window’s size may be selected in the

track Window menu.

Kongsberg Simrad Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 38

974-25007001/2.0 SL 30/35 Hull Sonar Operators Manual

Page 3.14 Control Panel

The vector originating from the target’s center indicates target course and speed.

The length of the vector increases relative to the target’s speed. One knot is

represented by a small mark on the vector. A course line can also be displayed

showing the target’s track.

When the Aut o Search is activated during the Target Track mode, t he tilt angle will

automatically follow the strongest f ish echo. The upper and lower tilt angle limit s can

be used to prevent tracking surf ace or bottom echoes The target tracking symbols

and data are displayed in a different colour.

Note: The Target Track and Lock option are not available at this time on the SL

35 Sonar and will be available in the near future.

3.3.14 Auto and Manual Search Buttons

Press the Auto Search button to activate the selected tilt angle upper and lower

limits, with the tilt step size that was pre-set by the system operator.

• In Auto Search, the transducer will automatically change tilt angle after each

complete scan search is performed. Af ter each scan search the transducer will

tilt up or down within the pre-set limits.

• Press the Manual Search button to allow the transducer to be tilted by pressing

the Tilt up or Tilt down buttons.

• The search limits can be changed by using the roller ball and moving the mouse

cursor on the Sonar Icon located on the Tool Bar and clicking on the “L” left

button.

See Part 4 for the Tool Bar Icon and Sonar setting description and operation.

Kongsberg Simrad Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 39

SL 30/35 Hull Sonar Operators Manual 974-25007001/2.

0

5

Control Panel Page 3.1

3.3.15 Symbol Buttons

The Symbol Buttons are used to place special symbols on the display.

3.3.15.1 Latitude / Longitude Button

This button allows you to mark the latitude and longitude of a target on the display.

Use the roller ball to move the mouse cursor over a specific location on the sonar

image then press the LAT/LO NG but ton to display a Lat/Long marker with a window

indicating the latitude and longitude of the selected target. Pr ess t he LAT/LONG

button a second time to remove the marker and window.

3.3.15.2 Event Mark Button

You can place up to four Event marker symbols anywhere on the display screen as

follows:

• Use the roller ball to move the mouse cursor to the desired location on the sonar

image.

• Press the Event button to automatically display an event marker 1. If you move

the cursor and press the Event button a second time, you can display a second

Event marker 2.

Kongsberg Simrad Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 40

974-25007001/2.0 SL 30/35 Hull Sonar Operators Manual

Page 3.16 Control Panel

• To delete an existing event marker, use the roller ball to move the m ouse cursor

over it and press the Event button again.

3.3.15.3 Cursor Buttons

Two special reference cursors are available to be placed anywhere on the sonar

image. The positions of t hese cursor s and the rang e and bear ing between t hem are

shown in a Cursor Gauge window.

To place Cursor 1 on the display:

• Use the roller ball to move the mouse cursor to t he desir ed location on the image

• Press the Cursor 1 button to automatically display the Cursor Gauge Window

and the Cursor 1 marker.

Use the same procedure with the Cursor 2 button to place t he Cur sor 2 marker.

To move Cursor 1 to a new position:

• Use the roller ball to move the mouse cursor over the Curs or 1 m arker

• Press and hold down the Left “L” button and drag t he cur s or t o a new position

Use the same procedure with the Cursor 2 button to m ove the Curs or 2 m ar ker.

To delete a cursor:

• Move the mouse cursor over the W iper icon locat ed on the Tool Bar and

click the Left “L” but t on

• Then move the Wiper over the cursor t o be deleted and click the Left “L” mouse

button

To hide the Cursor Gauge Window:

• Move the mouse cursor over the X in the upper right hand corner and click the

Left “L” button

Kongsberg Simrad Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 41

SL 30/35 Hull Sonar Operators Manual 974-25007001/2.

0

7

Control Panel Page 3.1

3.3.16 User Buttons

The User Buttons selection can be perfor med using the menu or the main contr ol

panel, which contains four operator selectable set-ups.

Frequently used tasks specific to a par ticular phase of the fishing operation can be

pre-set in the User 1, 2, 3 or 4.

For example “User 1” may be used for the search phase, “User 2” f or the evaluation

phase, “User 3” for the catch phase and “ User 4” for the Dual operation.

3.3.17 Display Mode Buttons

The Display Mode Buttons are used to set the format of the sonar display.

Kongsberg Simrad Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 42

974-25007001/2.0 SL 30/35 Hull Sonar Operators Manual

Page 3.18 Control Panel

3.3.17.1 Horizontal Display Mode Button

Press the Horizontal Display Mode button to provide a 360 degree plane of coverage

for general search.

See Part 5 for Setting Select ion.

3.3.17.2 Bow Up Display Mode Button

Press the Bow Up Display Mode button to provide a sector up plane coverage of 180

degrees, with the center of origin at the bottom of the scr een. You can change the

scanned sector width by using the Sector Width button.

See Part 5 for Setting Select ion.

3.3.17.3 Vertical Fan Mode Button

Press the Vertical Fan Display Mode button to provide a vertical section of the

underwater bottom conditions on the entire screen. T he maximum coverage is 180

degrees. You can change the scanned sector width and heading by using the Sector

Width and Heading but tons.

See Part 5 for Setting Select ion.

Kongsberg Simrad Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 43

SL 30/35 Hull Sonar Operators Manual 974-25007001/2.

0

9

Control Panel Page 3.1

3.3.17.4 Sounder Mode Button

Press the Sounder Display Mode button to provide a fixed echo beam displaying f ish

echoes below and/or around the vessel.

See Part 5 for Setting Select ion.

3.3.17.5 Horizontal Mode wi t h Hi st ory Mode button

Press the Horizontal with History Display Mode button to provide a 180 degrees

Horizontal Sector main display with the history displayed in a second window. This

enables the operator to observe the history of fish movement and distribution

equivalent to approximately four full 360 degrees scans. It is also useful for detecting

bottom fish and reefs.

Note: The History Window cannot be adjust ed.

See Part 5 for Setting Select ion.

3.3.17.6 Horizontal Mode wi t h Real Time Vertical Strata Mode Button

Press the Horizontal / Vertical Fan Strata Display Mode button to provide a 180

degree Horizontal Sector main display, with the Real Time Vertical Fan displayed in

a second window. This enables the operator to observe the history of fish

movement and distribution in real time. T he Vertical Fan Strata Mode also provides

in real time the range, depth and heading of the fish echoes.

Note: The Vertical Fan Strata Window cannot be adjusted.

Kongsberg Simrad Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 44

974-25007001/2.0 SL 30/35 Hull Sonar Operators Manual

Page 3.20 Control Panel

See Part 5 for Setting Select ion.

3.3.18 RX and TX Indicator LED

Receiver “RX” and Transmitter “TX” LEDs are provided to indicate that

communication is functioning between the Processing Unit and the Transceiver Unit.

If the LEDs do not blink, a com m unication problem has occurred.

3.3.19 Alarm Indicator LED

The Alarm LED provides a visual indication that the processor unit has f ailed or a

communication error has occured.

3.3.20 Keyboard (KBD) External Plug-in

An external Keyboard (KBD) is provided for software maint enance support.

Kongsberg Simrad Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 45

SL 30/35 Hull Sonar Operators Manual 974-25007001/2.

0

Control Panel Page 3.21

3.3.21 Panel Light Dimmer Sensor

A Panel Light Dimmer Sensor is provided to automatically increase or decrease

brightness of the lig ht and to turn it off completely in daylight.

3.3.22 Menu Description

The SL 30/35 Menu Description and Operation is described in Part 4 of this manual.

DISCLAIMER

This equipment is not certified or approved for navigation and/or safe-navigation

practices and is not to be used for navigation purposes under any circum st ances.

Kongsberg Simrad Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 46

974-25007001/2.0 SL 30/35 Hull Sonar Operators Manual

Page 3.22 Control Panel

Kongsberg Simrad Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 47

SL 30/35 Hull Sonar Operators Manual 974-25007001/2.

0

Menu and Software Description Page 4.1

PART 4

MENU AND SOFTWARE DESCRIPTION

4. MENU AND SOFTWARE DESCRIPTION.......................................................4.5

4.1 INTRODUCTIONS.......................................................................................4.5

4.2 ASSUMPTIONS...........................................................................................4.5

4.3 SCOPE OF THIS MANUAL..........................................................................4.5

4.4 SOFTWARE INSTALLATION......................................................................4.6

4.5 HARDWARE SECURITY KEY.....................................................................4.6

4.6 MAIN CONTROL PANEL.............................................................................4.7

4.7 THE TOOLBARS.........................................................................................4.8

4.8 SONAR TOOLBAR......................................................................................4.8

4.9 MARKER TOOLBAR..................................................................................4.10

4.10THE STATUS BAR....................................................................................4.10

4.11REFERENCE CURSORS ..........................................................................4.11

4.12KEY SETTINGS PANEL............................................................................4.11

4.13HO W TO CONNECT AND SETUP A HEAD (FIRST TIME OPERATION). 4.12

4.14HOW TO USE THE SONAR (SOME RULES OF THUMB)........................4.12

4.15HOW TO RESET TO THE FACTORY DEFAULT SETTINGS...................4.13

4.16HOW TO USE THE BASIC SONAR CONTROLS......................................4.13

4.17HOW TO SELECT UNITS OF MEASURE (FEET, YARDS, METERS)......4.14

4.18HOW TO SET OR ESTIMATE THE VELOCITY OF SOUND.....................4.14

4.19HOW TO INTERPRET THE SONAR IMAGE.............................................4.15

4.19.1 The Color Palette............................................................................4.15

4.19.2 Bright Spots.....................................................................................4.15

4.19.3 Dark Spots ......................................................................................4.15

4.19.4 Shadows .........................................................................................4.16

4.19.5 Noise and Interference....................................................................4.16

4.19.6 Masking Effects...............................................................................4.16

4.19.7 Range Scale and Target Size..........................................................4.17

4.19.8 Mirroring Effects..............................................................................4.17

4.20HOW TO GET THE HIGHEST RESOLUTION IMAGE..............................4.17

4.21HOW TO GET THE FASTEST UPDATE RATE......................................... 4.17

4.22HOW TO USE THE MULTIPLE USER FEATURE.....................................4.18

4.22.1 To create a new user name and configuration:................................ 4.18

4.22.2 To select a different user configuration: ..........................................4.18

4.23HOW TO RECORD AND PLAYBACK SONAR DATA ...............................4.18

4.23.1 To record sonar data:......................................................................4.18

Kongsberg Simrad Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 48

974-25007001/2.0 SL 30/35 Hull Sonar Operators Manual

Page 4.2 Menu and Software Description

4.23.2 To playback sonar data:..................................................................4.19

4.24HOW TO CUSTOMIZE THE HEAD SETTINGS DISPLAY ........................4.19

4.25HOW TO CREATE A CUSTOM GAUGE WINDOW ..................................4.20

4.26HOW TO SHOW A CLOSED OR HIDDEN GAUGE WINDOW .................4.20

4.27ABOUT NETWORKING.............................................................................4.20

4.28STAND ALONE MODE..............................................................................4.21

4.28.1 Server Mode....................................................................................4.21

4.28.2 Passive Client Mode........................................................................4.21

4.28.3 Active Client Mode...........................................................................4.21

4.29HO W TO SETUP A NETW ORK CONNECTION (WINDOWS NT/2000) ...4.22

4.30HOW TO SETUP THIS SONAR AS THE SERVER...................................4.23

4.31HOW TO SETUP THIS SONAR AS A PASSIVE CLIENT..........................4.23

4.32HOW TO SETUP THIS SONAR AS THE ACTIVE CLIENT.......................4.24

4.33HOW TO SETUP THIS SONAR FOR STAND-ALONE OPERATION........4.24

4.34HOW TO EXPORT DATA TO A FILE........................................................4.24

4.35HOW TO EXPORT DATA TO A SERIAL PORT........................................4.25

4.36HOW TO SETUP FOR AND DISPLAY GPS DATA...................................4.26

4.36.1 To setup the system to accept position data from a GPS receiver: .4.26

4.36.2 To setup the system to display position data fr om a GPS receiver:. 4. 26

4.37HOW TO SETUP FOR AND DISPLAY COMPASS DATA.........................4.26

4.38HOW TO SETUP FOR AND DISPLAY OTHER NMEA DATA...................4.27

4.39HOW TO SETUP USER DEFINED SENSORS.........................................4.28

4.40THE FILE MENU........................................................................................4.29

4.41THE VIEW MENU......................................................................................4.29

4.42CONTROL PANEL MENU.........................................................................4.30

4.43DISPLAY MENU........................................................................................4.31

4.44MESSAGE LOG MENU.............................................................................4.31

4.45THE CONFIGURATION MENU.................................................................4.32

4.46USERS MENU...........................................................................................4.33

4.47THE OPERATIONS MENU........................................................................4.33

4.48PLAYBACK DATA MENU..........................................................................4.34

4.49THE TARGETS MENU ..............................................................................4.35

4.50NETWORK MENU.....................................................................................4.36

4.51THE WINDOW MENU...............................................................................4.38

4.52THE HELP MENU......................................................................................4.39

4.53POPUP MENUS ........................................................................................4.39

4.54HEAD SETTINGS GAUGE WINDOW .......................................................4.40

4.55ABOUT DIALOG BOX ...............................................................................4.41

4.56ADD USERS AND GROUPS (WINDOW S NT/2000 OR XP).....................4.42

4.57CLIENT LIST DIALOG BOX.......................................................................4.42

4.58CONFIRM EXIT DIALOG BOX.................................................................. 4.43

4.59DISPLAY SETTINGS DIALOG BOX..........................................................4.44

4.59.1 Display Settings: Colors ..................................................................4.44

4.59.1.1 Palette Styles...............................................................................4.46

4.59.1.2 Primary Overlay Colors buttons...................................................4.46

4.59.1.3 The Palette Threshold..................................................................4.46

Kongsberg Simrad Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 49

SL 30/35 Hull Sonar Operators Manual 974-25007001/2.

0

3

Menu and Software Description Page 4.

4.59.2 Display Settings: Controls ...............................................................4.46

4.59.2.1 Sector View..................................................................................4.47

4.59.2.2 Display Gain................................................................................4.47

4.59.2.3 Rx Gain Type...............................................................................4.47

4.59.2.4 Scan marker................................................................................4.47

4.59.2.5 Grid control.................................................................................. 4.47

4.59.2.6 Timer ...........................................................................................4.47

4.59.2.7 Scroll Speed ................................................................................4.48

4.59.3 Distributed COM Configuration Properties Applications................... 4.48

4.59.4 Distributed COM Configuration Properties Default Properties .........4.48

4.59.5 Export Data File Selection Dialog Box.............................................4.48

4.59.5.1 Export Dialog Box........................................................................4.48

4.59.5.2 Export: Export Selection ..............................................................4.49

4.59.5.3 Automatic File..............................................................................4.49

4.59.5.4 Export: Ports Configuration..........................................................4.50

4.59.6 Head Settings Dialog Box................................................................4.51

4.59.6.1 Head Settings: Scan....................................................................4.52

4.59.6.2 Head Settings: Transmit ..............................................................4.53

4.59.6.3 Head Settings: Info ......................................................................4.55

4.59.6.4 Head Settings: TVG.....................................................................4.57

4.59.7 Machine Name Dialog Box..............................................................4.59

4.59.8 Parameters Dialog Box....................................................................4.59

4.59.8.1 Parameters: Magnetic Variation...................................................4.60

4.59.8.2 Parameters: Sound Velocity......................................................... 4.60

4.59.8.3 Parameters: Units of Measure .....................................................4.61

4.59.9 SL35 Properties Identity (Windows NT/2000)..................................4.62

4.59.9.1 SL35 Properties Location (Windows NT/2000)............................4.63

4.59.9.2 SL35 Properties Security (Windows NT/2000).............................4.64

4.59.10 Playback Data Dialog Box...............................................................4.65

4.59.10.1 Read Event Log File Dialog Box...............................................4.66

4.59.10.2 Record Data Dialog Box...........................................................4.66

4.59.10.3 Record Dialog Box ...................................................................4.67

4.59.11 User Configuration Dialog Box........................................................4.68

4.59.11.1 File Types Used by the SL35 System.......................................4.68

4.59.12 Factory Reset Settings....................................................................4.69

4.59.13 Gauge Windows: Customize...........................................................4.69

4.59.14 Magnifier Window............................................................................4.71

4.59.15 Cursors Gauge Window..................................................................4.71

4.59.16 Pointer Gauge Window ...................................................................4.72

4.59.17 Target Position Gauge Window.......................................................4.72

4.59.18 Overload Counter............................................................................4.72

4.59.19 Playback Progress Display..............................................................4.73

4.59.20 Scope Graph Display.......................................................................4.74

4.59.21 Security Key Warning......................................................................4.74

4.59.22 Sensors Configuration Dialog Box...................................................4.75

4.59.22.1 Sensors Sensor Selection........................................................4.75

Kongsberg Simrad Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 50

974-25007001/2.0 SL 30/35 Hull Sonar Operators Manual

Page 4.4 Menu and Software Description

4.59.22.2 Sensors Ports Configuration.....................................................4.77

4.59.22.3 User Defined Sensors..............................................................4.77

4.59.22.4 Sensors Data Display Box........................................................4.79

4.59.23 System Configuration Dialog Box....................................................4.79

4.59.24 System Message Log Dialog Box....................................................4.81

4.60AUDIO SET-UP WINDOW ........................................................................4.81

4.61POST PROCESSING SET-UP WINDOW ................................................. 4.82

4.62AUDIO AND POST PROCESSING SET-UP PROCEDURE ......................4.82

Kongsberg Simrad Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 51

SL 30/35 Hull Sonar Operators Manual 974-25007001/2.

0

5

Menu and Software Description Page 4.

4. MENU AND SOFTWARE DESCRIPTION

4.1 INTRODUCTIONS

The SL 30/35 Sonar System uses a PC as the processing and display unit for one or

two sonars. The system operates with digital sonar heads. With the use of this

system, a real-time image can be displayed on the screen and can also be r ecorded

for later viewing.

In addition to the sonar data, the system can be connected to receive information

from an external sensor, such as DGPS.

4.2 ASSUMPTIONS

This manual was written with the assumption that you are already reasonably

familiar with Windows operating system. If not, you should spend a couple of hours

with the “Introduction to Microsoft Windows’”.

4.3 SCOPE OF THIS MANUAL

The Installation section describes the software set-up of the SL 30/35 Sonar

System.

The Display section describes the major components found in the sonar display

windows.

The How to section describes how to perf orm many of t he most important f unctions

of the system, in step-by-step detail.

The Menu System section describes each of the menus and t heir com m ands.

The Dialog Boxes section illustrates and descr ibes all of the dialog boxes used by

the system.

The Reference section includes descriptions of file formats.

Kongsberg Simrad Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 52

974-25007001/2.0 SL 30/35 Hull Sonar Operators Manual

Page 4.6 Menu and Software Description

4.4 SOFTWARE INSTALLATION

The software CD-ROM installation and set-up procedure are described in Part 8

“Attachments and Drawings”

4.5 HARDWARE SECURITY KEY

The SL 30/35 uses a software protection system that requires a hardware security

key or “dongle” to be connected to the processing unit printer port to enable full

operation of the system. If you are using an HP/ PC processing unit, simply plug t he

security key “dongle” into the printer port and then connect the printer into the

security key “dongle”.

Important Note

The SL30/35 HP/PC Processing Unit is a dedicated unit and is not to be used for

any other application, except for which it was intended.

Kongsberg Simrad Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 53

SL 30/35 Hull Sonar Operators Manual 974-25007001/2.

0

7

Menu and Software Description Page 4.

4.6 MAIN CONTROL PANEL

Head numbers indicate, as well as select, the active sonar head in multiple head

configuration. All other heads are still r unning in the back g round, but t he act ive head

will have the top most display window and the focus of the control buttons and

sliders of the control panel.

Kongsberg Simrad Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 54

974-25007001/2.0 SL 30/35 Hull Sonar Operators Manual

Page 4.8 Menu and Software Description

The main control panel allows you to set the Gain, Range, Sect or Heading, Sector

Width, and Scan Speed for each sonar head in the system. A colour coded

graphical symbol shows the sector size and heading for the selected head.

Scroll Speed controls the speed with which the sonar image is scrolled across the

window. Adjusting the setting of this control has no ef fect in Polar or Sector display

mode.

Tilt Angle control is used to adjust the tilt angle of the transducer.

The main control panel can be Docked, Undocked, Hidden or put into Autohide

mode through the View | Control Panel menu.

4.7 THE TOOLBARS

A Toolbar allows you to perform certain operat ions with a single m ouse click instead

of the two or more clicks that are normally required for m enu com mands.

The SL35 includes two separate toolbars:

• Sonar Toolbar containing frequently used controls for the sonar

• Marker Toolbar containing markers f or use with the sonar

Notice that as you move the mouse pointer over any of the toolbar buttons, a simple

help message will pop up beside the button describing its function, and a more

complete description of the tool will be displayed in the Stat us Bar .

The toolbars can be hidden by un-checking the appropriate toolbar item in the View

Menu. This will allow you to use more of the screen for the sonar image.

4.8 SONAR TOOLBAR

Button Action Menu Equivalent

Full Screen View | Full Screen

Kongsberg Simrad Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 55

SL 30/35 Hull Sonar Operators Manual 974-25007001/2.

0

9

Menu and Software Description Page 4.

High Resolution View | Display | High Resolution

Save Image File | Save Image

Clear Display View | Display | Clear Display

Pause Head Operations | Pause Head

Run Heads Operations | Run Sonar Heads

Stop Heads Operations | Stop Sonar Heads

Playback Data Operations | Playback Data | Begin Playback

Max. Playback Speed Operations | Playback Data | Max Speed

Pause Operations | Playback Data | Pause Playback

Start/End Record Data Operations | Start/End Record

Scan Reverse Operations | Scan Reverse

Control Head Operations | Control Head

Display Settings View | Display | Display Settings