Page 1

Manual

Simrad IS80

Heading Repeater HR80

English

www.simrad-yachting.com A brand by Navico - Leader in Marine Electronics

Page 2

Page 3

Manual

Simrad IS80

Heading Repeater HR80

English

Document no: 20223194

Revision: B

Date: December 2008

The original language for this document is English. In the

event of any discrepancy between translated versions

and the English version of this document, the English

document will be the official version.

To the best of our knowledge, the content in this

publication was correct at the time of printing.

As we are continuously improving our products we

retain the right to make changes to the product and

the documentation at any time. Updated manuals are

available from our website www.simrad-yachting.com,

and are free to download.

© Copyright 2008 by Navico Holding AS.

Page 4

2 | HR80 Heading Repeater

About this manual

3 s

SELECT

3 s

MODE

SETUP SELECT

+

3 s

A. 1 A.2

SELECT

1 s

0FFS

This manual is a reference guide for installing and

operating the Simrad HR80 Instrument.

The manual does not include installation procedures for

sensors that can be connected to the system.

In this manual, names of modes and keys are written in

boldface (e.g. User setup, Mode/Setup ke y).

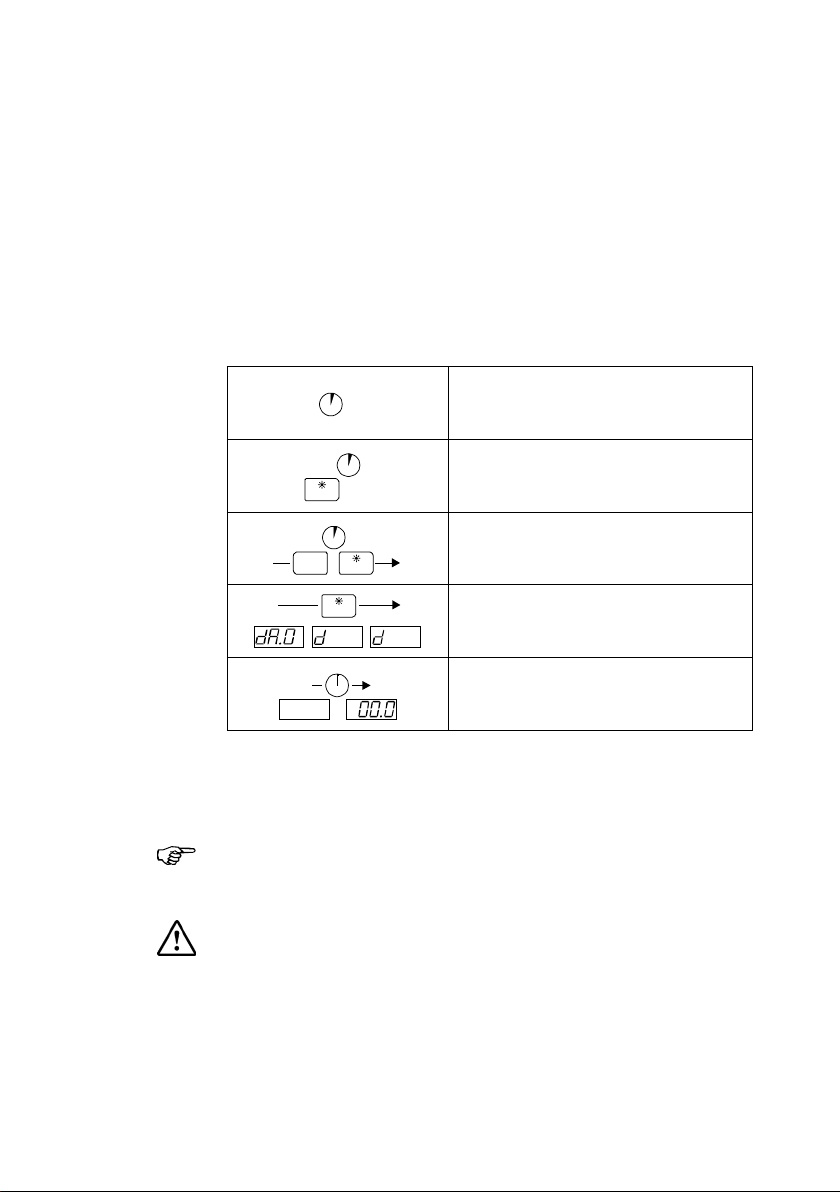

In the illustrations throughout the manual the following

symbols are used:

Time indication (1, 3, 5 or 10

seconds)

Single key press with time

indication

Combined key press with time

indication

Repeated key presses on single

key

Automatic change in LCD readings

with time indication (no key

presses required)

Important text that requires special attention from the

reader is emphasized as follows:

Used to draw the reader’s attention to a comment or

some important information.

When necessary, used to warn personnel they

should proceed carefully to prevent risk of injury

and/or damage to equipment.

Page 5

HR80 Heading Repeater | 3

Contents

1 Introduction ............................................... 5

General information ......................................5

Instrument layout .........................................5

2 Installation ................................................. 7

Location of the unit .......................................7

Panel mounting .............................................7

Cable connection and interface .......................8

Securing the cables .......................................9

Interconnecting instruments ...........................9

Installation setup ........................................ 10

3 Operation ................................................. 11

Turning the HR80 on .................................... 11

Using the keys ............................................ 12

Selecting bargraph resolution ....................... 12

Commanded heading display ........................ 13

Backlighting ............................................... 14

Error Alarm ................................................ 14

Maintenance ............................................... 15

Operation ow chart .................................... 16

4 Changing the default settings ................... 17

General ..................................................... 17

Heading alignment ...................................... 17

Heading reference ....................................... 18

Beep on/off ................................................ 18

Page 6

Heading Command ...................................... 19

Light bank selection ....................................20

5 Spare parts ............................................... 21

Spares and auxiliaries .................................. 21

SimNet cables and accessories ..................... 21

6 Specications ........................................... 23

Technical specications ................................ 23

Dimensional drawing ................................... 24

4 | HR80 Heading Repeater

Page 7

1 Introduction

General information

The HR80 Instrument presents you with heading

information on a combined analog and digital display.

Adjustable backlight for night operation is provided

as well as adjustable intensity on the LED displays for

operation in sunshine.

Instrument layout

The HR80 display includes an LED bargraph, compass

card and LED display. Modes of operation and signal

input are indicated by monitor diodes.

The instrument is

operated by 2 keys.

These are used to switch

between display modes,

to set parameter values

and to adjust background

illumination.

Introduction | 5

Page 8

Blank page

6 | Introduction

Page 9

2 Installation

Location of the unit

The HR80 should be mounted with special regard to the

unit’s environmental protection, temperature range and

cable length. Refer to the Specifications section.

Avoid mounting the unit where it is easily exposed to

sunlight, as this may unintendedly overheat the unit.

Panel mounting

The mounting surface must be at and even to within

0.5 mm.

Drill 4 mounting holes and make a panel cut-out 1

according to the drilling template included in the

package

Use the supplied self tapping screws to secure the 2

unit to the panel

Apply the front corners3

Do not over-tighten the screws!

Installation | 7

Page 10

8 | Installation

Cable connection and interface

1

Signal input, network and power supply are wired to the

enclosed terminal block that is to be plugged in on the

rear side.

The instrument is delivered with a 0.3 m SimNet cable

with a standard SimNet plug in both ends. One plug

must be cut off and the wires connected to terminals 3

through 6 according to the color codes shown below.

TERMINAL

NO

1 GND

2 VCC + Supply 12-24V DC -

3 SimNet - H NMEA2000 channel Yel low

4 SimNet - C NMEA2000 channel Black

5 SimNet - L NMEA2000 channel Blue

6 SimNet - S NMEA2000 channel Red

7 RS485 A NMEA0183 (Rx+) -

8 RS485 GND No connection -

9 RS485 B NMEA0183 (Rx-) -

Any voltages other than those specied in the

product specication, may cause damage to the

instrument (Refer to Specications section).

Data on the NMEA0183 port will be converted to SimNet/

NMEA2000 format and distributed to other instruments

that are interconnected on the SimNet network.

SIGNAL TYPE COLOR

- Supply

-

Page 11

Installation | 9

Securing the cables

SimNet

Supply

(Red disk)

Power

SimNet

T-joiner

SimNet

T-joiner

SimNet

T-joiner

Use the eclosed tie wrap to secure the cables to the

instrument.

Interconnecting instruments

Interconnect a series of instruments by using a SimNet

power cable with termination and T-joiners as illustrated

below.

If the instruments are connected to other SimNet

compatible products, refer to the manual for those

products

Use only 12V as SimNet supply!

Page 12

Installation setup

5 1

A. 1 A.2

SELECT

MODE

SETUP

SELECT

+

1 s

3 s

5 1

0 183

- MODE 1

- MODE 2

- INPUT

SIGNAL

- RESET

MAIN

MODES

INSTALLATION

SETUP

MODE

SETUP

SELECT

10 s

+

MODE

SETUP

SELECT

+

5 s

- MODE 1

- MODE 2

- INPUT

SIGNAL

- RESET

MAIN

MODES

INSTALLATION

SETUP

MODE

SETUP

SELECT

10 s

+

MODE

SETUP

SELECT

+

5 s

SimNet, NMEA0183 and Demo mode are selectable

inputs on the HR80. After installation, the system must

be configured to read the preferred input signal before

the instrument is ready for use.

The Installation

setup is accessed

as shown in the

illustration.

As an example the illustration below shows the LED

reading when the input type is changed from SimNet to

Demo.

10 | Installation

Refer also to the Operation flow chart in the Operation

section.

The compas card position will change accordingly as

shown in the table.

SIGNAL INPUT LCD COMPASS CARD

SimNet

NMEA183

Demo

Local SimNet reset

Under the SimNet input, select the L.res window and

press both keys to save the local reset of SimNet.

Page 13

3 Operation

1 s

Turning the HR80 on

HR80 has no power key, and will be running as long as

power is connected.

When power is applied to the system the display will

indicate the active mode as shown in the table.

MODE

Mode 1

Mode 2

LED

Initial After 1 second

4-digit heading

readout

Compass

card

Analog

heading

readout

Bargraph

step

1°

0.1°

After approximately 3 seconds the instrument is

operative.

Default: Hd 1

Before the instruments is ready to operate the default

settings should be checked and changed if other values

are preferred. Refer to Changing the default settings

section.

If no heading data is available, no value will be displayed

in the LED.

In certain applications the display may show the

following:

This is an alignment prompt. Refer to Heading Alignment

in chapter 4 for further instructions.

Operation | 11

Page 14

12 | Operation

Using the keys

MODE

SETUP

SELECT

MODE

SETUP

SELECT

1 DEG

1/10 DEG

MODE

SETUP

225.2

225.2

1 s 1 s

The instrument is operated by the 2 keys on the front.

They are used to switch between display modes, to set

values and to adjust the illumination as illustrated in the

table below.

Key presses or key combinations not indicated in the

table have no effect.

Refer also to Operation flow chart in this chapter.

KEY

+

KEY

PRESS

Short Go to next main display Go to next Setup mode

3 sec. Switch to User Setup Switch to main display

Short Increase light level

3 sec.

Short

10 sec.

5 sec Return to main display

DISPLAY MODE SETUP MODES

Enter Installation

Setup

MODE/ACTION

Select parameter/

Adjust parameter

None /

Change to next digit

Save setting and return to

Setup parameter

Time out from User Setup is 10 sec. Time out from

Installation Setup is 5 min.

Selecting bargraph resolution

The HR80 can display heading with 1° (Mode 1) or 0.1°

(Mode 2) resolution on the bargraph.

The instrument

will scroll through

these displays

by pressing the

Mode/Setup key.

Active mode is indicated by a lit diode in the display.

Page 15

Operation | 13

The bargraph operates as a turn indicator with a

C230

PORT STBD

PORT STBD

resolution according to the active display mode.

MODE BARGRAPH

3 lit diodes runs in a pattern from lef t or right in

Hd 1

Hd 2

steps per 1° heading change. The pattern runs

from left to right when the heading is increasing

and opposite when the heading is decreasing.

3 lit diodes runs in a pattern from lef t or right in

steps per 0.1° heading change. The pat tern runs

from left to right when the heading is increasing

and opposite when the heading is decreasing.

The buzzer beeps once per 1° change in actual heading.

Commanded heading display

If the HR80 reads a heading command from the

autopilot, the instrument will automatically switch to

show commanded heading.

The bargraph will show the difference between actual

and commanded heading, lighting the diodes from centre

to right or left. When the actual heading is higher than

the commanded heading, the bargraph is lit to the left

with one diode per 2° difference. Similarly the bargraph

is lit to the right when the actual heading is lower than

the commanded heading.

Initial

display

LED

Reading

heading command

After

1 second

Compass

card

Actual

heading

Page 16

14 | Operation

The buzzer beeps once per 1° change in actual heading.

SELECT

The HR80 will automatically return to last active mode

when the heading differs less than 3° from commanded

heading for more than 10 seconds.

You may exit this mode and return to the previous Hd 1

or Hd 2 mode at any time using the Mode/Setup key.

Backlighting

The backlighting is adjusted by pressing the Light key

when the instrument is in normal operation.

Current light setting will be indicated with the right LED

digit.

The light setting affects the diodes, the digital display

and the backlight as shown in the table:

LIGHT LEVEL DIODES AND DISPLAY BACKLIGHT

0 Low Off

1-7 Steps Steps

8 Medium Off

9 High Off

Level 8 and 9 are for bright daylight.

The instrument will return to normal operation 1 second

after the last key press.

Range: 0 - 9 Default value: 2

If several instruments are connected via SimNet, the

instruments can be grouped in different light banks.

Changing the backlight settings on one of the

instruments will affect all instruments in the group. Refer

to Light bank selection in chapter 4.

Error Alarm

In the event the error indicator is lit, the

instrument is not operable and service/repair is

required.

Page 17

Operation | 15

Maintenance

The HR80 instruments are “repair by replacement” units,

and the operator is therefore required to perform only a

very limited amount of preventive maintenance.

If the unit requires any form of cleaning, use fresh

water and a mild soap solution (not a detergent). It

is important to avoid using chemical cleaners and

hydrocarbons such as diesel, petrol etc.

If a weather cover is available this should be put on

when the unit is not in use.

Page 18

Heading mode 1

(1° bargraph resolution)

Heading mode 2

(0.1° bargraph resolution)

Commanded heading

Input Type

- SimNet

- NMEA0183

- Demo

Reset

- Local SimNet

reset

Heading reference

- True

- Magnetic

Beep

- On

- Off

Heading Command

- On

- Off

Light Bank Selection

- Simrad

- Gr 1

- Gr 2

- Gr 3

- Gr 4

- Gr 5

- Gr 6

- None

USER SETUPMAIN MODES

INSTALLATION

SETUP

MODE

SETUP

3 s

MODE

SETUP

SELECT

+

5 s

10 s

5 min

MODE

SETUP

SELECT

10 s

+

Operation ow chart

16 | Operation

Page 19

4 Changing the default settings

- MODE 1

- MODE 2

MODE

SETUP

MODE

SETUP

3 s

MAIN

MODES

USER

SETUP

- HEADING

REFERENCE

- BEEP

- HEADING

COMMAND

- LIGHT

BANK

1 s

General

The factory default

settings may all be

changed in the User

setup, accessed

as shown in the

illustration.

Detailed illustrations

for the different

settings are shown on

the following pages.

Refer also to the

Operation flow chart in

chapter 3.

Heading alignment

In applications where a Simrad GI51 Gyro Interface is

used to interface the instrument to a gyrocompass the

following may be displayed on the LED:

Follow the instructions in the GI51 manual to align the

gyrocompass. When the alignment is completed the

instrument will return to the main mode (Hd1 or Hd2)

and display the correct heading.

Changing the default settings | 17

Page 20

18 | Changing the default settings

Heading reference

ERROR

TRUE

MAG

A. 1

SELECT

MODE

SETUP

SELECT

+

1 s

3 s

- MODE 1

- MODE 2

MODE

SETUP

3 s

MAIN

MODES

USER

SETUP

- HEADING

REFERENCE

- BEEP

- HEADING

COMMAND

- LIGHT

BANK

SELECT

MODE

SETUP

SELECT

+

1 s

3 s

A. 1

- MODE 1

- MODE 2

MODE

SETUP

3 s

MAIN

MODES

USER

SETUP

- HEADING

REFERENCE

- BEEP

- HEADING

COMMAND

- LIGHT

BANK

True and Magnetic inputs are selectable as heading

reference for the HR80.

The active reference is indicated by a lit diode on the

instrument.

Default reference: True

Beep on/off

The HR80 has a buzzer, and when turned ON the

instrument will give a short beep when reading a heading

change of 1°.

Default value: On

Page 21

Changing the default settings | 19

Heading Command

SELECT

MODE

SETUP

SELECT

+

1 s

3 s

A. 1

- MODE 1

- MODE 2

MODE

SETUP

3 s

MAIN

MODES

USER

SETUP

- HEADING

REFERENCE

- BEEP

- HEADING

COMMAND

- LIGHT

BANK

The heading command function can be switched on and

off as shown:

Default value: On

Page 22

Light bank selection

SELECT

MODE

SETUP

SELECT

+

1 s

3 s

- MODE 1

- MODE 2

MODE

SETUP

3 s

MAIN

MODES

USER

SETUP

- HEADING

REFERENCE

- BEEP

- HEADING

COMMAND

- LIGHT

BANK

The light bank function is used to globally control light

settings for group of units that are connected via the

SimNet network.

By assigning several units to the same group, the light

adjustment on one unit will be effective on the rest of

the members in the same group.

LIGHT BANK LCD POINTER BEEPS

Simrad

Group 1

Group 2

Group 3

Group 4

Group 5

Group 6

None

Default value: Simrad

1

1

1

1

1

1

1

1

20 | Changing the default settings

Page 23

5 Spare parts

Spares and auxiliaries

Part no. Description

27107523 HR80 instrument head

Mounting kit including:

- 4 screws

- 6 corners

- 1 terminal block

22098495 NMEA0183 Interface cable 2.5 m (8’)

SimNet cables and accessories

Part. no. Description

24005829 0.3 m (1’) SimNet cable (SDC:0.3M)

24005837 2 m (6.6’) SimNet cable (SDC:02M)

24005845 5 m (16.6’) SimNet cable (SDC:05M)

24005852 10 m (33’) SimNet cable (SDC:10M)

24005860 SimNet T-joiner (SDJ) (3p)

2400 6298 SimNet Multijoiner (7p)

24006306 SimNet Bulkhead T-connector

24005878 SimNet cable gland

24005886 SimNet protection plug

2400589 4 SimNet termination plug

24005902 2 m (6.6’) SimNet power w/termination

24005910 2 m (6.6’) SimNet power w/o termination

24005936 AT10 Universal NMEA0183 conver ter

2400594 4 AT15 Active T-connector, IS15

24005928 SimNet cable protection cap

Spare par ts | 21

Page 24

Part. no. Description

24005729

SimNet cable to Micro–C male

Cable that connects a SimNet product to a

NMEA2000 network

240 06199

24006363 SimNet cable, 5.5 m (18’), with 1 plug

SimNet cable to Micro-C female cable that

connects a NMEA2000 product to SimNet

22 | Spare par ts

Page 25

6 Specications

Technical specications

Power supply ....................................12/24V DC (+30%, -10%)

Power consumption .......................................................< 5W

SimNet network load ...................................................... 1 NL

Input signals:

NMEA2000/SimNet ....................................... 1 can channel

NMEA0183: .......................... 1 optoisolated RS485 channel

Input mode selection: ..........................NMEA2000/SimNet,

NME A0183,

Demo mode

NMEA0183 to SimNet converter: ................When NMEA0183

is selected

Weight: ....................................................... 0.55 kg (1.21 lb)

Material: .......................................................ASA/PC Luran S

Color: .......................................................................... Black

Display:

Dial: ................................................................... 0 - 359°

Mar king: ....................................................................10°

Illumination:.................................... Adjustable in 10 steps

Digital display: ................................. Four 7-segment LEDs

Environmental protection:

Front ....................................................................... IP66

Back: ...................................................................... IP20

Safe distance to compass:

Steering compass .................................... 0.40 m (1.32 ft.)

Stand-by/Emergency distance ................... 0.20 m (0.66 ft.)

Temperature:

Operating: ............................. -15 to +70°C (+5 to +158°F)

Storage: ...............................-40 to +80°C (-40 to +176°F)

Climate

Max 95% RH: ................................... Max 30 days per year

Max 85% RH: ........................................... Remaining days

Max 75% RH: ......................................... Average per year

Specications | 23

Page 26

Dimensional drawing

172 mm [6.78"]

172 mm [6.78"]

136 mm [5.35"]

152 mm [5.98"]

136 mm [5.35"]

153 mm [6.02"]

21 mm [0.83"]

47 mm [1.86"]

10 mm [0.37"]

24 | Specications

Page 27

HR80 Manual EN, Doc.no.20223194

Loading...

Loading...