Page 1

OWNER’S MANUAL

Automatic

Booster Pump

NOTICE D’UTILISATION

Pompe de surpression

à fonctionnement

automatique

MANUAL DEL USUARIO

Bomba automática

de refuerzo

Installation/Operation/Parts

For further operating, installation,

or maintenance assistance:

Call 1-800-468-7867

English . . . . . . . . . . . . . . Pages 2-8

Installation/Fonctionnement/Pièces

Pour plus de renseignements

concernant l’utilisation,

l’installation ou l’entretien,

Composer le

1 (800) 468-7867

Français . . . . . . . . . . Pages 10-16

Instalación/Operación/Piezas

Para mayor información sobre el

funcionamiento, instalación o

mantenimiento de la bomba:

Llame al 1-800-468-7867

Español . . . . . . . . . .Paginas 18-24

©2002 PRINTED IN U.S.A. SIM591 (10/14/02)

Mod. 3075SS

293 Wright St., Delavan, WI 53115

Phone: 1-800-468-7867

1-800-546-7867

Fax: 1-800-390-5351

Web Site: http://www.simerpump.com

®

®

4219 0702 SIM NF

Page 2

Safety 2

For parts or assistance, call Simer Customer Service at 1-800-468-7867 / 1-800-546-7867

READ AND FOLLOW

SAFETY INSTRUCTIONS!

This is the safety alert symbol. When you see this

symbol on your pump or in this manual, look for

one of the following signal words and be alert to the

potential for personal injury.

warns about hazards that will cause serious

personal injury, death or major property damage if

ignored.

warns about hazards that can cause serious

personal injury, death or major property damage if

ignored.

warns about hazards that will or can cause

minor personal injury or property damage if ignored.

The label NOTICE indicates special instructions which

are important but not related to hazards.

Carefully read and follow all safety instructions in this

manual and on pump.

Keep safety labels in good condition.

Replace missing or damaged safety labels.

Make workshops childproof; use padlocks and master

switches; remove starter keys.

GENERAL SAFETY

1. To avoid risk of serious bodily injury and property

damage, read the safety instructions carefully before

installing this pump.

2. Follow local and/or national plumbing, building and

electrical codes when installing the pump. Use rigid

pipe when installing this pump.

3. Hazardous Pressure. The pump body

may explode if used to boost pressure above 100 psi

(689 kPa). Do not use this pump with inlet pressure

greater than 50 psi (345 kPa). If not already in the

plumbing system, install a pressure relief valve in the

pump discharge line capable of passing the full pump

flow at 100 psi (689 kPa). If local code requires

installation of a pressure relief valve capable of handling the full pump flow at a pressure less than 100

psi (689 kPa), follow the code requirements.

4. A low pressure safety cutoff switch is recommended

to shut off power to the pump in case of low discharge pressure due to interruption of the incoming

water supply, broken pipe, etc.

5. Never run the pump dry. To do so can damage inter-

nal parts, overheat pump (which can cause burns to

people handling or servicing pump), and will void

warranty.

6. Risk of fire or explosion. To avoid risk

of fire and explosion, Pump Water Only with this

pump. Do not pump flammable liquids or chemicals.

Do not use the pump near gas pilot lights or where

chemical or gas fumes are present. Use of an electric

pump with liquids other than water or in an atmosphere containing chemical or gas fumes may ignite

those liquids or gases and cause injury or death due

to an explosion and/or fire.

7. Burn Hazard. If water is trapped in the

pump during operation it may turn to steam.

Trapped steam can lead to an explosion and burns.

Never run the pump with the outlet closed or

obstructed.

8. Do not touch an operating motor.

Modern motors can operate at high temperatures. To

avoid burns when servicing the pump, allow it to

cool for 20 minutes after shut-down before handling.

ELECTRICAL SAFETY

The pump is supplied with a 3-conductor ground-

ing type cord. Connect only to a properly grounded, GFCI protected outlet. Do not lift the pump by the

electrical cord.

Hazardous voltage. Can shock, burn or

cause death. Ground the pump before connecting to a

power supply. Disconnect the power before working on

the pump, motor or tank.

The pump and controller are non-submersible.

Keep the motor dry at all times. Do not wash the

motor. Do not immerse. Protect the motor from wet

weather.

If using an extension cord, use only an approved

indoor/outdoor, 3-wire, grounding type cord. Do

not allow any part of the cord or the receptacle ends to

sit in water or in damp locations.

Unplug the pump before servicing. To avoid

fatal shock, proceed as follows if the pump needs

servicing.

A. Disconnect the power to the pump outlet box before

unplugging the pump. After the plug is pulled, let the

pump cool for 20 minutes before attempting to work

on it.

B. Take extreme care when changing fuses. To reduce

the chance of fatal electrical shock, DO NOT stand

in water or put your finger in the fuse socket.

C. Ground the electrical outlet box.

D. Plug the pump and the controller into a Ground

Fault Circuit Interrupter (GFCI) protected grounded

outlet only.

Page 3

For parts or assistance, call Simer Customer Service at 1-800-468-7867 / 1-800-546-7867

Ta b le of Contents 3

Thank you for purchasing a top quality, factory tested pump.

Page

General Safety .....................................................................................................2

Warranty..............................................................................................................3

General Information.............................................................................................4

Installation .......................................................................................................4, 5

Electrical Connection...........................................................................................6

Automatic Pressure Controller..............................................................................6

Operation ............................................................................................................6

When Does Pump Stop Operating? .................................................................6, 7

Service ................................................................................................................7

Troubleshooting ...................................................................................................7

Repair Parts .........................................................................................................8

SIMER warrants to the original consumer purchaser (“Purchaser”) of its products

that they are free from defects in material or workmanship.

If within twelve (12) months from the date of the original consumer purchase

any such product shall prove to be defective, it shall be repaired or replaced at

SIMER’s option, subject to the terms and conditions set forth below. Your original receipt of purchase is required to determine warranty eligibility.

Exceptions to the Twelve (12) Month Warranty

Three (3) Year Warranty:

If within three (3) years from original consumer purchase any 3075SS shall

prove to be defective, it shall be repaired or replaced at SIMER’s option, subject

to the terms and conditions set forth below.

General Terms and Conditions

Purchaser must pay all labor and shipping charges necessary to replace product

covered by this warranty. This warranty shall not apply to acts of God, nor shall

it apply to products which, in the sole judgement of SIMER, have been subject

to negligence, abuse, accident, misapplication, tampering, alteration; nor due

to improper installation, operation, maintenance or storage; nor to other than

normal application, use or service, including but not limited to, operational failures caused by corrosion, rust or other foreign materials in the system, or operation at pressures in excess of recommended maximums.

Requests for service under this warranty shall be made by returning the defective product to the Retail outlet or to SIMER as soon as possible after the discovery of any alleged defect. SIMER will subsequently take corrective action as

promptly as reasonably possible. No requests for service under this warranty

will be accepted if received more than 30 days after the term of the warranty.

This warranty sets forth SIMER’s sole obligation and purchaser’s exclusive remedy for defective products.

SIMER SHALL NOT BE LIABLE FOR ANY CONSEQUENTIAL, INCIDENTAL, OR

CONTINGENT DAMAGES WHATSOEVER.

THE FOREGOING WARRANTIES ARE EXCLUSIVE AND IN LIEU OF ALL

OTHER EXPRESS WARRANTIES. IMPLIED WARRANTIES, INCLUDING BUT

NOT LIMITED TO THE IMPLIED WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE, SHALL NOT EXTEND BEYOND THE

DURATION OF THE APPLICABLE EXPRESS WARRANTIES PROVIDED HEREIN.

Some states do not allow the exclusion or limitation of incidental or consequential damages or limitations on how long an implied warranty lasts, so the

above limitations or exclusions may not apply to you. This warranty gives you

specific legal rights and you may also have other rights which vary from state

to state.

Simer Limited Warranty

SIMER • 293 Wright St. • Delavan, WI U.S.A. 53115

Phone: 1-800-468-7867 / 1-800-546-7867 • Fax: 1-800-390-5351

Page 4

General Information / Installation 4

For parts or assistance, call Simer Customer Service at 1-800-468-7867 / 1-800-546-7867

Use the 3075SS to boost city water pressure. Plumbing

connections are described in this manual.

GENERAL INFORMATION

• Pump only clean water with your 3075SS. To avoid

clogging the pump and damaging the shaft seal, do

not pump water containing solids, foreign material,

sand, silt, or abrasives.

• If you are boosting the pressure from a well pump, be

sure that the system check valves are tight. If the system pressure drops when the well pump is not running, the 3075SS may start and cycle. Excessive or

rapid cycling may damage the motor and will void

the warranty.

• Do not use pipe joint compound on pump ports; use

only teflon tape to seal the threads. Pipe joint compound will damage the controller materials.

NOTE: The priming plug has an O-ring already

installed and does not require sealing.

•Tighten all the piping joints to the pump hand tight

plus 1-1/2 turns (not more).

Overtightening may break the pump and will void the

warranty.

• Pipe and fittings to the pump should be at least nominal 1” diameter. Pipe or fittings less than 1” in diameter will reduce performance and may damage the

pump through cavitation.

• Make sure that there are no air leaks or air pockets in

the suction pipe. An air leak in the suction pipe may

draw air in, although no water leaks out. Air leaks and

air pockets will prevent the pump from priming properly, and can substantially reduce its performance.

• The pump mount should be level, solid, as near as

possible to the water source, and protected against

excess moisture and flooding.

• Use the shortest possible run for piping and the

smallest possible number of fittings. Long pipe runs

and numerous fittings increase friction and reduce the

flow of water.

• Support the weight of the piping and pump.

• Do not allow the pump, pressure controller, or any

system components to freeze. Freezing will damage

the pump and void the warranty.

• Periodically inspect the pump, pressure controller,

and system components.

NOTE: Local code may require a pressure relief valve or

pressure regulator.

Risk of leaks and flooding. Do not use this

pump with inlet pressure greater than 50 psi (345 kPa).

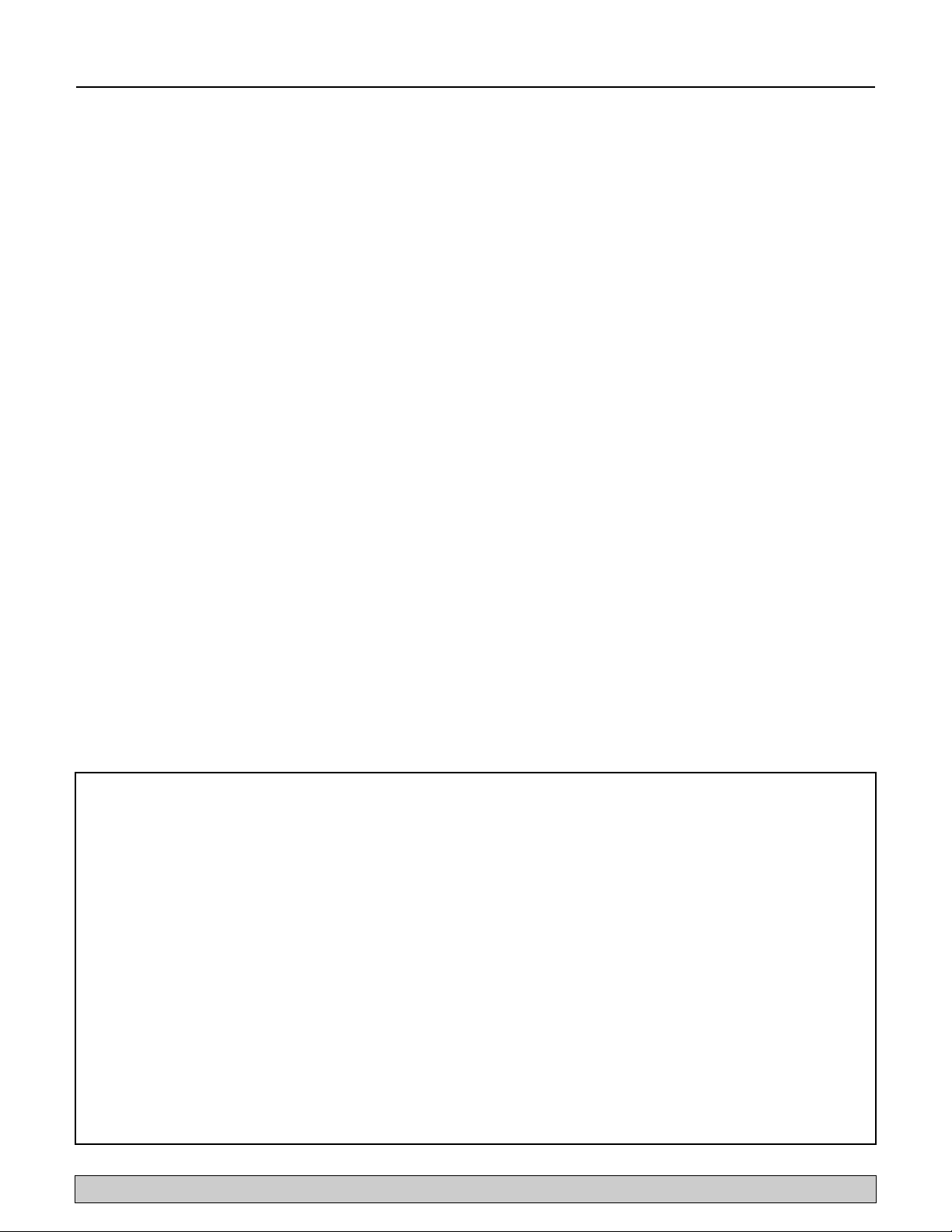

Pressure hazard and risk of explosion. This

pump can develop high pressure when operated with the

discharge shut off or obstructed. For safe operation, we

recommend the following:

If not already in the plumbing system, install a pressure

relief valve in the pump discharge line capable of pass-

ing the full pump flow at 100 psi (689 kPa) (See Figure

2). If local code requires installation of a pressure relief

valve capable of handling the full pump flow at a pressure less than 100 psi (689 kPa), follow the code requirements. Run the relief valve discharge to a floor drain or

other drain that will give adequate runoff.

INSTALLATION

Risk of flooding. Be sure that all plumbing

and fittings are rated to withstand the system pressure

which you expect the pump to generate.

1. Decide what’s the best place to install the pump.

Think about these things:

• it must be near the main water supply line

• the pump must be accessible

• the power cord must reach a power outlet

• the controller’s LED lights must be visible

• ease of plumbing

• space saving

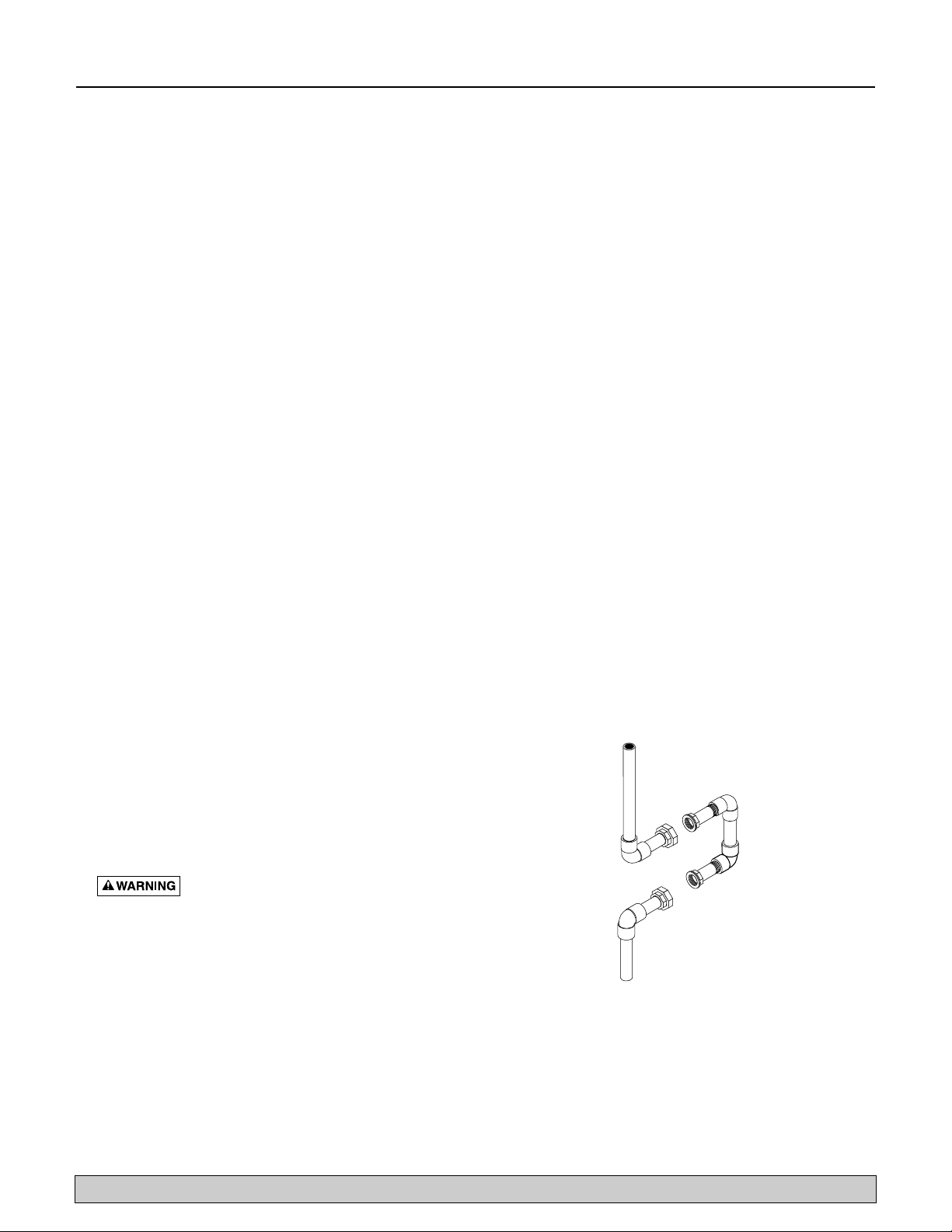

Figure 2:Typical household booster installation.

Purchase plumbing fittings separately. Consult code for

relief valve/pressure regulator requirements.

Figure 1 – Do Not Run the Pump With Inlet Shut Off

Grounded, GFCI

protected 115V outlet

To Household

(Pump Discharge)

Unions

Check Valve

Water Supply In

(Pump Suction)

®

4253 0902 SIM

Page 5

Installation 5

For parts or assistance, call Simer Customer Service at 1-800-468-7867 / 1-800-546-7867

NOTE: Installation of a low pressure safety cutoff

switch on the pump discharge is recommended (and

may be required by your local code) to shut off the

power in case of low discharge pressure (caused by

broken pipe, etc.).

2. Mount the pump on a solid base in the location you

have decided on.

3. Choose a time that will allow you to shut off the

water to the household while you install the 3075SS.

4. Shutoff the main water supply valve to the household.

5. Open any faucet to relieve water pressure in the

plumbing. Once the water pressure is relieved, close

the faucet.

6. READ STEP 6 COMPLETELY BEFORE STARTING TO

WORK ON IT. You must remove a length of pipe

from the main water supply line to allow installation

of elbows for the 3075SS. The locations of the cuts

must take into consideration the size of the elbows

being used, the length of the threads in threaded

joints or the overlap in glued or soldered joints, etc.

Position the elbows in line with the pump suction

and discharge threads. There may be slight water

leakage while cutting the pipe. Remove any burrs or

shavings caused by the cutting tool.

NOTE: Galvanized pipe may not need to be cut. If

there is a union close to the pump location, disassemble the union and remove (unscrew) pipe back

past the pump location. Have new lengths of pipe cut

and threaded to allow for the pump installation.

NOTE: Both female suction and male discharge ports

have 1” NPT threads. Depending on your type of

connection and the size of your home’s piping, you

may need to install adapters on the ports.

7. Once the short piece of pipe is removed, the piping

above the cut can be drained to prevent water mess.

Place a pail under the opening going to the household. Open the highest faucet in the system to let in

air so the water can fall out of the pipes into the pail.

Once it’s drained, close the faucet.

8. Install the elbows in the main water supply line. Point

them toward the pump.

Risk of burst hose and flooding. Do not

install with flexible hoses. Use only rigid piping that

meets code.

9. Install piping from elbows to pump including a union

in each line and a check valve in the pump suction

line. The arrow on the check valve must point to the

pump suction (see Figure 2). If not already in the

plumbing system, install a pressure relief valve in the

pump discharge line capable of passing the full pump

flow at 100 psi (689 kPa). If local code requires

installation of a pressure relief valve capable of handling the full pump flow at a pressure less than 100

psi (689 kPa), follow the code requirements. A low

pressure safety cutoff switch should also be installed

in the discharge line, and may be required by your

local codes.

10.With all pipe and fittings installed and sealed, turn on

the main water supply slowly to pressurize the system

and check for leaks. If any leaks appear, turn the

main valve off, open a faucet to relieve the pressure,

and repair the leak. Repeat this step until there are no

leaks in the system.

11. Open a faucet to release the air from the pipes and

allow water to flow. When a steady stream of water

flows out of the faucet, the pump is full of water and

fully primed. Close the faucet.

12.Turn the controller knob to the desired pressure for

the pump to turn on. The 3075SS comes factory preset at 30 psi (207 kPa), and we recommend starting

there and adjusting it later according to your experience with the system.

13.Before continuing with the installation, see the sections

of this manual titled “Electrical Connections”,

“Automatic Pressure Controller”, “Normal Operation”,

and “When Does The Pump Stop Operating” for

detailed information on how the system functions.

14.At this point, you can plug in the pump for the first

time. When you plug in the power cord, the pump

will start and run for 15 seconds regardless of the

controller setting. If the inlet pressure is above the set

point, the pump will stop after 15 seconds.

15.When the pump is running and after it shuts off automatically, the system is at the boosted pressures.

Inspect the pipe and fittings again for water leaks. If

any leaks appear, unplug the pump, turn the water

main valve off, open a faucet to relieve the pressure

and repair the leak. Repeat this step until there are no

leaks in the system.

Figure 3:Typical bypass piping needed to allow removal of

pump for repair without shutting down household water

system.

To

Household

Water

Supply In

4254 0902

Page 6

Installation / Operation 6

For parts or assistance, call Simer Customer Service at 1-800-468-7867 / 1-800-546-7867

ELECTRICAL CONNECTION

Hazardous voltage. Risk of dangerous or

fatal electric shock. Plug the pump into a 115 Volt, 60

Cycle, Ground Fault Circuit Interrupter (GFCI) protected grounded outlet only. The pump is equipped with a

3-wire grounded cord and plug. Do not modify or

remove the plug. Make sure the outlet meets the

National Electric Code or the Canadian Electrical Code,

as applicable. To avoid dangerous electrical shock hazard, keep the cord dry at all times. See Figure 2.

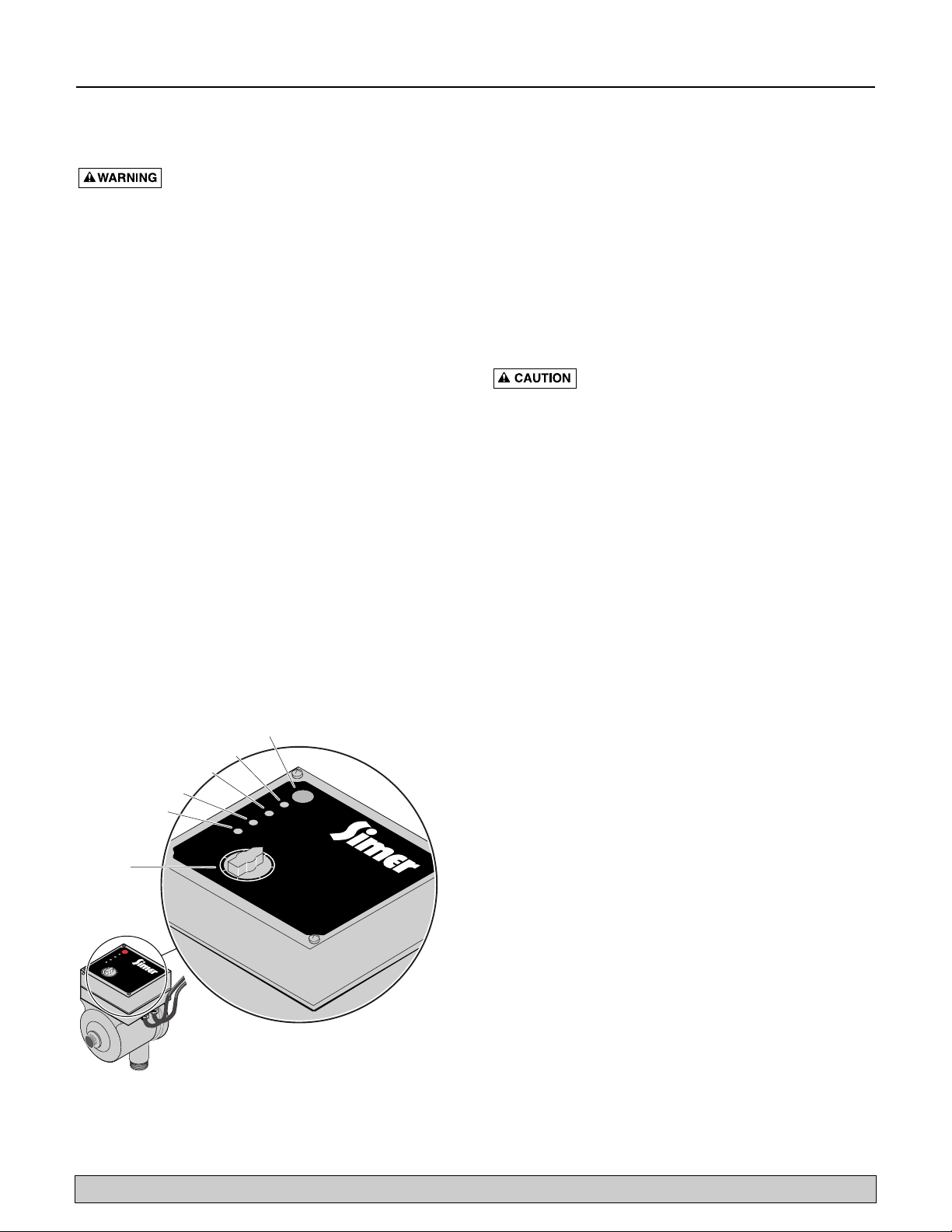

AUTOMATIC PRESSURE CONTROLLER

The Automatic Pressure Controller mounts on the pump.

It protects against:

• Run-dry operation;

• Overheating;

• Frequent starts caused by small water losses in the system;

• Pressure drop.

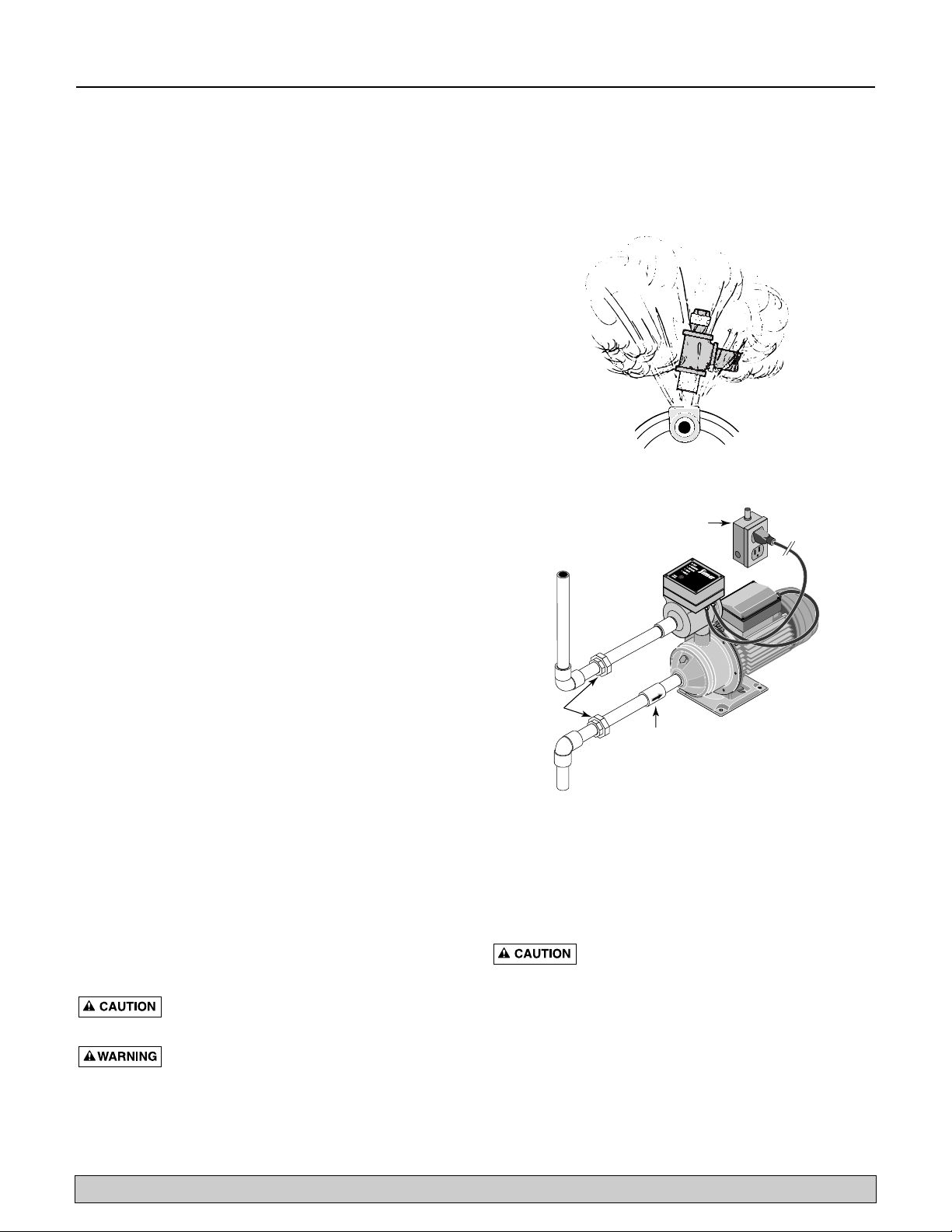

The Automatic Pressure Controller features the following

LEDs and controls:

“POWER ON” LED: indicates that the unit is electrically

connected and that voltage is present. The pump is ready

to operate.

“PUMP ON” LED: indicates that the pump is running

and actually pumping water.

“WATER FAILURE” LED: indicates that no water is

detected coming into the pump.

“TEMPERATURE FAILURE” LED: indicates that the temperature inside the pump has reached 158° F (70° C).

“Starting Pressure” dial: allows you to set the system

pressure at 15 to 45 psi (103 to 310 kPa). The pump will

start automatically when the system pressure drops

below the pressure point which you have set on the

“Starting Pressure” dial.

“Reset” button: resets any safeties which have tripped

and allows the pump to restart.

NOTE: The unit will not respond if the ‘RESET’ button is

held down. It must be pressed and released to activate

the reset function.

NORMAL OPERATION OF THE 3075SS

Burn Hazard. NEVER run the pump dry.

Running the pump without water may cause pump to

overheat and cause burns to persons handling the pump.

It may also damage the impeller and may damage the

seal, causing leaking or flooding, and will void the warranty. Fill the pump with water before starting it.

Make sure that the 3075SS has been properly installed,

primed (see page 4), and that the suction pipe is unobstructed and open.

Turn the ‘STARTING PRESSURE’ dial to the minimum

desired system pressure.

Plug in the pump. The ‘POWER ON’ and ‘PUMP ON’

lights will come on indicating, respectively, that voltage

is present and that the pump is ready to operate.

The pump will start and will continue to operate until 15

seconds after the system pressure has risen past the setpoint on the “STARTING PRESSURE” dial and flow has

stopped.

WHEN DOES THE PUMP

STOP OPERATING?

Pressure Set-Point/No Flow: The pump will stop operat-

ing and the ‘PUMP ON’ LED will go off 15 seconds after:

• The system pressure is above the point set by the

STARTING PRESSURE dial, and

• The flow has stopped.

This is normal operation.

Restart: A water flow in the system greater than

1 GPM or a drop in pressure below the STARTING

PRESSURE set-point will cause the pump to restart and

the ‘PUMP ON’ LED to light up. The pump will continue to operate until 15 seconds after:

• It reaches the set pressure, and

• The flow stops.

NOTE: The 15-second delay in shutting off the pump

prevents rapid cycling when water faucets are being

turned on and off quickly (for example, when brushing

teeth, etc.).

Figure 4 - Control Panel

Water Failure LED

Temp. Failure LED

Pump-on LED

Power-on LED

STARTING

PRESSURE

20

Starting

Pressure

Dial

W

A

TE

T

E

M

P

. FA

P

ILU

U

M

P

O

P

N

O

W

E

R

O

S

25

T

N

P

A

R

R

E

T

30

S

IN

S

G

U

20

R

E

35

1

5

PS

40

I

45

1-800-365-6832

www.flotecwater.com

RESET

R

F

A

ILU

R

E

R

E

®

15

PSI

25

45

Reset

PUMP ON

POWER ON

40

TEMP. FAILURE

30

35

www.simerpump.com

RESET

WATER FAILURE

1-800-468-7867

®

3963 0401 SIM

Page 7

Operation / Service / Troubleshooting 7

For parts or assistance, call Simer Customer Service at 1-800-468-7867 / 1-800-546-7867

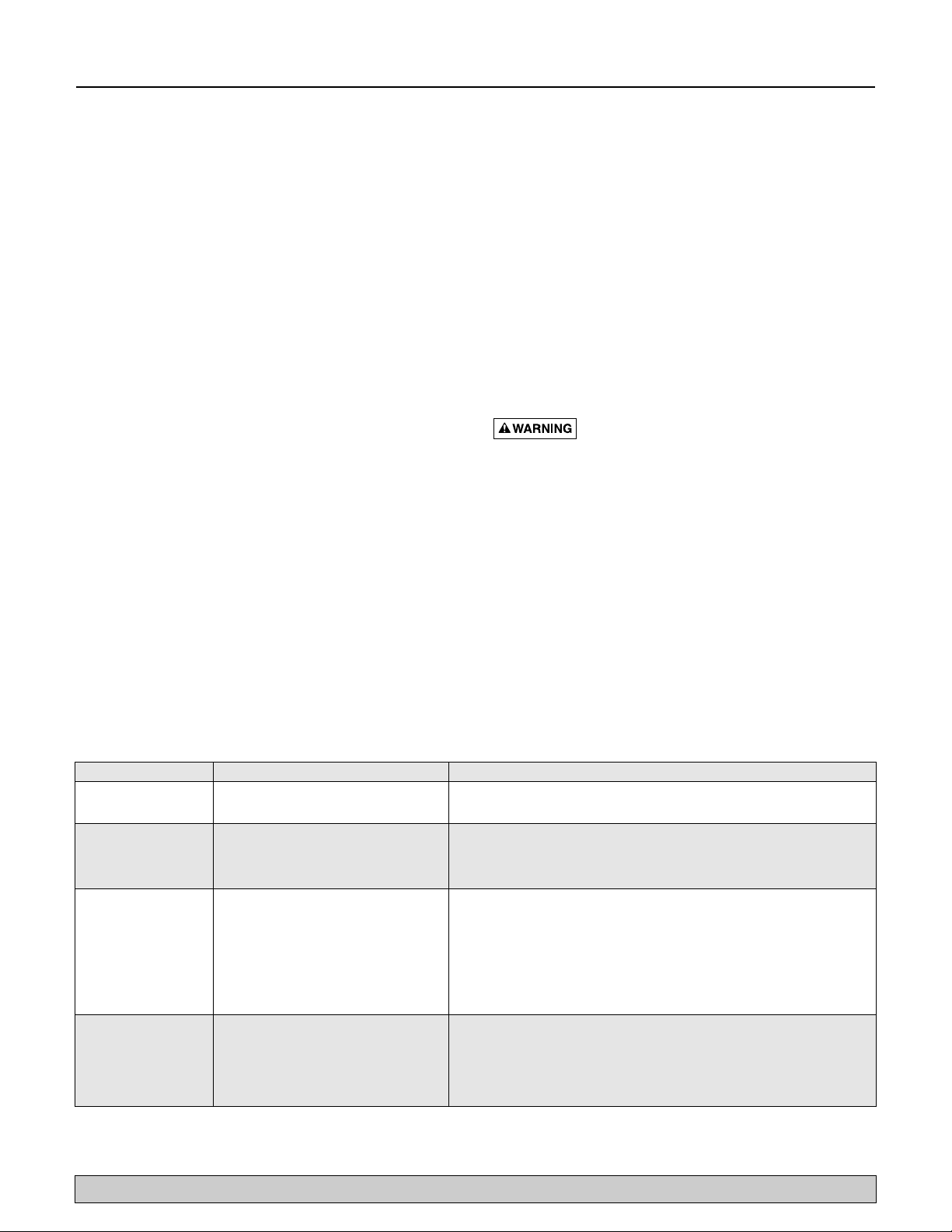

TROUBLESHOOTING

SYMPTOM POSSIBLE CAUSE(S) CORRECTIVE ACTION

Motor will not run Fuse is blown or circuit breaker tripped DISCONNECT POWER; Replace fuse or reset circuit breaker.

Power cord not plugged in Plug into 115 Volt grounded outlet.

Motor runs hot and Voltage is too low Check voltage being supplied to pump.

overload kicks off or

Impeller not moving freely Check that impeller moves freely and is not clogged.

motor does not run

and only hums

Motor runs but no Improper priming Re-prime according to instructions.

water is delivered*

Clogged water filter Stop pump, shut off water, and change filter cartridge. Filter should be

installed on discharge side of pump.

Discharge valve closed Open valve.

Pipe size too small Re-pipe using pipe of the same size as suction and discharge ports on pump.

Impeller is plugged Clean impeller.

Pipes are frozen Thaw pipes.

*Pump does not Corroded pipes Replace with plastic or new steel pipe.

deliver water to full

Piping is too small in size Re-pipe using pipe the same size as suction and discharge ports on pump.

capacity

Pump not being supplied with Enlarge inlet pipe; check well pump system.

enough water

Low voltage Make sure outlet is at 115 Volts.

* (Note: Unplug

pump; then open

faucets and see if

water is flowing

through system).

Pressure Drop/No Flow: Normally, when the pump

starts, it will very quickly generate pressure and sense

flow. If there is no flow and the pressure does not rise, it

senses a “no water” condition. It can also sense this during operation if the water supply to the pump fails. To

protect the pump from running dry:

• 15 seconds after it detects “no water”, the pump will

stop operating,

• The ‘PUMP ON’ LED will go out, and

• The ‘WATER FAILURE’ LED will begin flashing.

Restart: Make sure that the suction line is not obstruct-

ed, and that it is connected to a water source.

• Press and release the ‘RESET’ button.

• The ‘PUMP ON’ LED should light up, and

• The ‘WATER FAILURE’ LED should stop flashing.

If flow is adequate, the pump will operate until it

reaches the set-point pressure and the flow stops.

High Temperature: When the water temperature inside

the pump reaches 158°F (70°C),

• The pump will stop operating,

• The ‘PUMP ON’ LED will go out, and

• The ‘TEMPERATURE FAILURE’ LED will begin flashing.

Restart: Wait 20 minutes to let the water temperature

drop below 104°F (40°C):

• Make sure that the pump is supplied with water and

that the flow is unobstructed.

• Press and release the ‘RESET’ button.

• The ‘PUMP ON’ LED should light up, and

• The ‘TEMPERATURE FAILURE’ LED should stop

flashing.

• If not, let it cool some more and retry

NOTE: If the pump continues to run hot, shut it off

and call Simer Customer Service at 1-800-468-7867.

LUBRICATION

The motor is lubricated at the factory for the life of

the bearings. The pump seal is water cooled and self

lubricating.

PUMP SERVICE

Hazardous voltage. Can shock, burn, or

cause death. Unplug the pump and controller before servicing them. Do not handle the pump or controller or

attempt to work on the pump with wet hands or while

standing on a wet or damp floor.

The motor has an auto-reset thermal overload protector.

If the motor overheats, the overload will cut off the

power to prevent damage and will reset after the motor

cools. If the overload trips repeatedly, check the pump

for the cause (low voltage, a clogged impeller, etc.).

Page 8

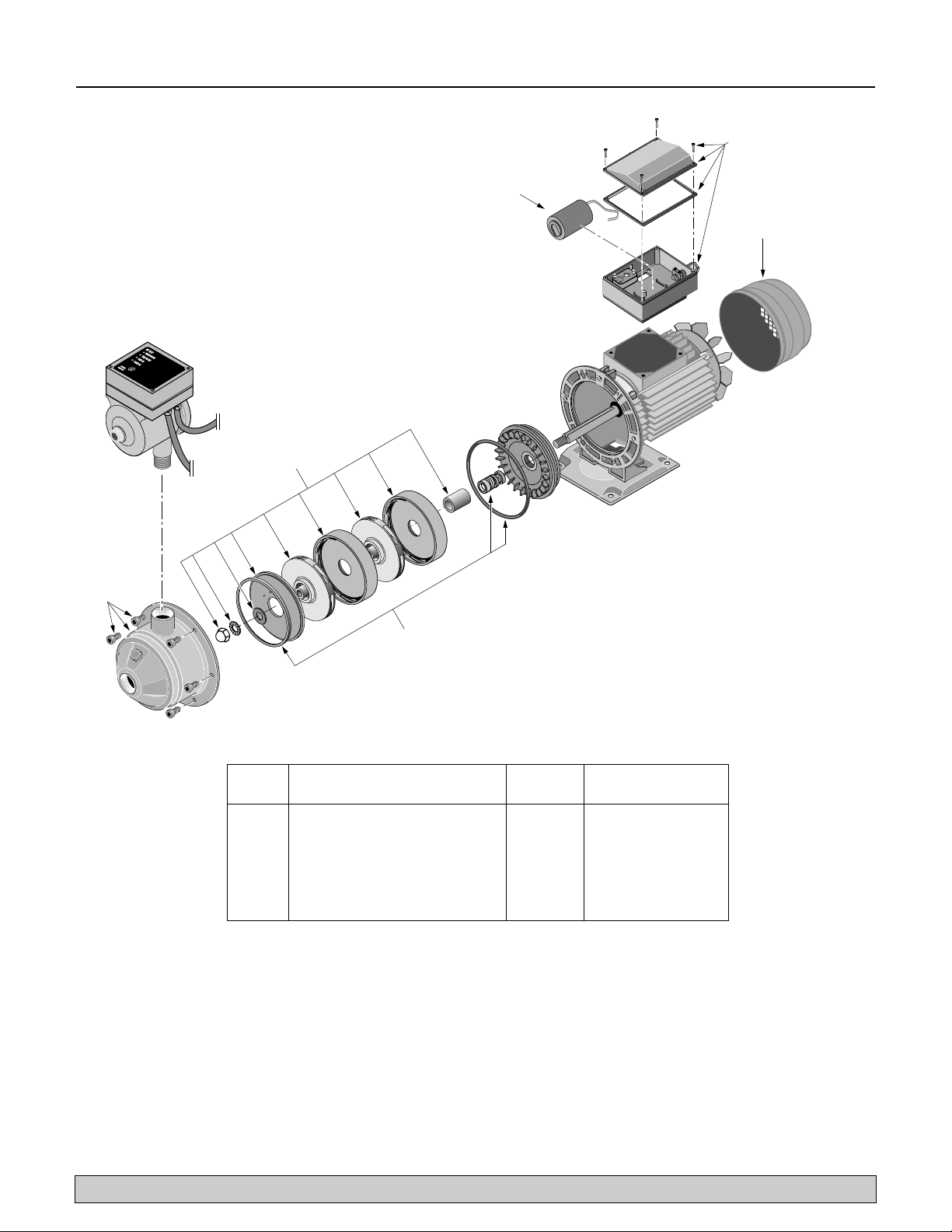

Repair Parts 8

For parts or assistance, call Simer Customer Service at 1-800-468-7867 / 1-800-546-7867

Key Part No. 3075SS

No. Description Used 1/2 HP

1 Pump Body Kit (includes Bolts) 1 FPP1801

2 Internal Parts Kit 1 FPP1870

3 Capacitor 1 171P5750

4Wiring Box/Cover/Gasket Kit 1 FPP1802

5 Fan Guard 1 721S1090

6 Shaft Seal and O-Ring Kit 1 FPP1850

Ace-In-The-Hole Series Model 3075SS

4

3

5

2

1

4220 0702

6

Page 9

9

For parts or assistance, call Simer Customer Service at 1-800-468-7867 / 1-800-546-7867

Page 10

Sécurité 10

Pour obtenir des pièces ou de l’aide, appeler le Service à la clientèle Simer en composant le 1 800 468-7867/1 800 546-7867

LIRE TOUTES CES CONSIGNES DE

SÉCURITÉ ET LES RESPECTER!

Ce symbole indique qu’il faut être prudent. Lorsque ce

symbole apparaît sur la pompe ou dans cette Notice,

rechercher une des mises en garde qui suivent, car elles

indiquent un potentiel possible de blessures corporelles.

avertit d’un danger qui causera des blessures

corporelles, la mort ou des dommages matériels importants si

on l’ignore.

avertit d’un danger qui risque de causer des

blessures corporelles, la mort ou des dommages matériels

importants si on l’ignore.

avertit d’un danger qui causera ou qui ris-

quera de causer des blessures corporelles, la mort ou des dommages matériels importants si on l’ignore.

Le mot NOTA indique des instructions spéciales et importantes

n’ayant aucun rapport avec les dangers.

Lire attentivement toutes les consignes de sécurité contenues

dans cette Notice et collées sur la pompe.

Garder les autocollants de sécurité en bon état; les remplacer

s’ils manquent ou s’ils ont été endommagés.

Rendre les ateliers à l’épreuve des enfants; poser des cadenas

et des interrupteurs principaux; enlever la clé des démarreurs.

CONSIGNES DE SÉCURITÉ GÉNÉRALES

1. Pour éviter tout risque de blessures corporelles graves et

de dommages matériels importants, lire attentivement ces

consignes de sécurité avant de procéder à l’installation de

la pompe.

2. Pour installer cette pompe, respecter les codes de la

plomberie, du bâtiment et de l’électricité de la municipalité

et du gouvernement fédéral. Pour installer cette pompe,

n’utiliser que des tuyaux rigides.

3. Pression dangereuse. Le corps de la

pompe risque d’exploser si la pompe est utilisée pour augmenter la pression à plus de 689 kPa (100 lb/po

2

). Sur la

tuyauterie de refoulement, poser une soupape de sûreté qui

permettra d’évacuer tout le débit de la pompe à une pression de 689 kPa (100 lb/po

2

). Si cet énoncé est contraire

aux codes, respecter ce qui est stipulé par les codes. Ne

pas utiliser cette pompe si la pression d’arrivée de l’eau est

supérieure à 345 kPa (50 lb/po

2

).

4. Il est recommandé d’utiliser un disjoncteur de sécurité

basse pression pour couper le courant alimentant la pompe

au cas où la pression de refoulement chuterait suite à une

interruption de l’arrivée de l’eau d’alimentation, à un tuyau

brisé, etc.

5. Ne jamais faire fonctionner la pompe à sec, sinon ses

pièces internes risquent d’être endommagées, la pompe

risque de surchauffer (et les personnes qui manipuleront ou

interviendront sur la pompe risqueront d’être brûlées). De

plus, cette pratique annule la garantie.

6. Risque d’incendie ou d’explosion. Pour

empêcher tout risque d’incendie ou d’explosion, ne pom-

per que de l’eau avec cette pompe. Ne pas pomper de liq-

uides inflammables ni de produits chimiques. Ne pas utiliser cette pompe près de veilleuses fonctionnant au gaz, ni

en présence de vapeurs de produits chimiques, d’essence

ou de tout autre produit inflammable. L’utilisation d’une

électropompe pour pomper des liquides autres que de l’eau

ou dans une atmosphère contenant des vapeurs de produits

chimiques, d’essence ou de tout autre produit inflammable

risque d’enflammer ces liquides ou ces vapeurs et de

causer des blessures, voire la mort, suite à une explosion

et/ou à un incendie.

7. Risque de brûlures. Si de l’eau reste

emprisonnée dans la pompe pendant qu’elle fonctionne,

cette eau risque de se transformer en vapeur. La vapeur

emprisonnée dans la pompe risque de provoquer une

explosion et des brûlures. Ne jamais faire fonctionner la

pompe si son refoulement est fermé ou obstrué.

8. Ne pas toucher un moteur pendant qu’il

fonctionne. Les moteurs modernes sont conçus pour fonctionner par des températures élevées. Pour ne pas se brûler

pendant qu’on intervient sur la pompe, toujours la laisser

refroidir pendant au moins 20 minutes après l’avoir arrêtée

et avant de la manipuler.

CONSIGNES DE SÉCURITÉ

CONCERNANT L’ÉLECTRICITÉ

Cette pompe est livrée avec un cordon électrique à 3

conducteurs, dont un de mise à la terre. Ne brancher ce

cordon électrique que dans une prise de courant adéquatement mise à terre et protégée par un disjoncteur de fuite à la

terre. Ne pas lever cette pompe par son cordon électrique.

Tension dangereuse. Risque de secousses

électriques, de brûlures, voire de mort. Mettre cette pompe à

la terre avant de la brancher sur le courant électrique. Couper

le courant avant d’intervenir sur la pompe, le moteur ou le

réservoir.

Cette pompe et son servorégulateur ne sont pas sub-

mersibles. Toujours garder le moteur sec. Ne pas le

laver. Ne pas l’immerger. Le protéger contre la pluie.

Si on doit utiliser un cordon prolongateur, n’utiliser

qu’un cordon prolongateur à 3 conducteurs dont un de

mise à la terre et approuvé pour l’utilisation intérieure et

extérieure. Ne permettre à aucune partie du cordon prolongateur ni à sa fiche et à sa prise de reposer dans l’eau ou dans

un endroit humide.

Avant d’intervenir sur la pompe, la débrancher de la

prise de courant. Pour éviter de subir des secousses élec-

triques mortelles si on doit intervenir sur la pompe, procéder

comme il est indiqué ci-dessous.

A. Couper le courant alimentant la prise de courant avant

d’intervenir sur la pompe. Après avoir débranché la fiche

du cordon électrique de la prise de courant, attendre au

moins 20 minutes avant d’intervenir sur la pompe afin de la

laisser refroidir.

B. Il faut être extrêmement prudent lorsqu’on remplace un

fusible. Pour réduire les possibilités de secousses électriques mortelles, NE PAS se tenir dans l’eau et ne pas mettre de doigt dans la douille du fusible.

C. Mettre à la terre la boîte de sortie de la prise de courant.

D. Ne brancher la pompe et son servorégulateur que dans

une prise de courant adéquatement mise à la terre protégée par un interrupteur de fuite à la terre.

ATTENTION

ATTENTION

Page 11

Pour obtenir des pièces ou de l’aide, appeler le Service à la clientèle Simer en composant le 1 800 468-7867/1 800 546-7867

Ta b le des matières 11

Merci d’avoir acheté une pompe de qualité supérieure, mise à l’essai à l’usine.

Pages

Consignes de sécurité générales.........................................................................10

Garantie.............................................................................................................11

Renseignements généraux..................................................................................12

Installation ...................................................................................................12, 13

Branchements électriques ..................................................................................14

Servorégulateur..................................................................................................14

Fonctionnement.................................................................................................14

Quand la pompe cesse-t-elle de fonctionner?..............................................14, 15

Entretien.............................................................................................................15

Dépannage ........................................................................................................15

Pièces de rechange ............................................................................................16

SIMER garantit à l’acheteur-utilisateur initial (“Acheteur”) que ses produits sont

exempts de tout défaut de fabrication et de matériaux.

Tout produit reconnu défectueux dans les douze (12) mois qui suivent la date

d’achat d’origine sera remplacé ou réparé à la discrétion de SIMER, selon les conditions stipulées ci-dessous. La preuve datée de l’achat servira à déterminer si le

produit est sous garantie.

Exceptions à la garantie de douze (12) mois

Garantie de trois (3) ans :

Si, dans les trois (3) ans à compter de la date d’achat par l’acheteur-utilisateur

initial, n’importe quel modèle 3075SS s’avérait défectueux, il sera réparé ou

remplacé, au choix de SIMER, conformément aux conditions générales stipulées

ci-dessous.

Conditions générales

L’Acheteur s’engage à payer tous les frais de main-d’oeuvre et d’expédition nécessaires au remplacement du produit couvert par la garantie. Cette garantie ne couvre pas les cas de force majeure et ne s’applique pas aux produits qui, du seul avis

de SIMER, ont fait l’objet de négligence, d’utilisation abusive ou incorrecte, d’accident, de modification ou d’altération; ni aux produits qui n’ont pas été installés,

utilisés, entreposés ou entretenus correctement; ni à ceux qui n’ont pas été utilisés

ou entretenus normalement, y compris, mais sans s’y limiter, aux produits ayant

subi des pannes de fonctionnement causées par la corrosion, la rouille ou tout

autre corps étranger qui se serait introduit dans le système ou aux produits ayant

fonctionné à des pressions dépassant la pression maximum recommandée.

Les demandes de service en vertu de la présente garantie seront faites en retournant le produit défectueux au détaillant ou à SIMER dès la découverte du défaut

allégué. SIMER prendra alors les mesures correctives aussi rapidement qu’il est

raisonnablement possible. Aucune demande de service en vertu de la présente

garantie ne sera acceptée si elle est reçue plus de 30 jours après l’expiration de

ladite garantie.

La présente garantie énonce la totalité des obligations de SIMER et le seul recours

possible de l’Acheteur dans le cas de produits défectueux.

SIMER NE PEUT ÊTRE TENUE RESPONSABLE D’AUCUN DOMMAGE INDIRECT,

ACCIDENTEL OU FORTUIT QUEL QU’IL SOIT.

LES PRÉSENTES GARANTIES SONT EXCLUSIVES ET TIENNENT LIEU DE TOUTE

AUTRE GARANTIE EXPRESSE. LES GARANTIES IMPLICITES, Y COMPRIS, MAIS

SANS S’Y LIMITER, LES GARANTIES IMPLICITES AYANT TRAIT À LA

COMMERCIABILITÉ ET À L’ADAPTATION À UN USAGE PARTICULIER, NE

DÉPASSERONT PAS LA DURÉE DES GARANTIES EXPRESSE APPLICABLES

STIPULÉES DANS LES PRÉSENTES.

Certaines provinces n’autorisent pas d’exclure ou de limiter des dommages fortuits ou indirects ou de limiter la durée d’une garantie implicite; il se peut donc que

les limitations ou exclusions ci-dessus ne s’appliquent pas à votre cas. La présente

garantie vous donne des droits juridiques spécifiques et vous pouvez en avoir

d’autres qui varient d’une province à l’autre.

Garantie limitée Simer

SIMER • 293 Wright St. • Delavan, WI 53115

Tél. 1 800 468-7867/1 800 546-7867 • Téléc. 1 800 390-5351

Page 12

Renseignements généraux et Installation 12

Pour obtenir des pièces ou de l’aide, appeler le Service à la clientèle Simer en composant le 1 800 468-7867/1 800 546-7867

Utiliser cette pompe PressureMate®pour augmenter la pression

de l’eau fournit par la municipalité. Les branchements de la

tuyauterie sont décrits dans cette Notice.

RENSEIGNEMENTS GÉNÉRAUX

• Ne pomper que de l’eau propre avec cette pompe

PressureMate

®

. Pour ne pas boucher la pompe et pour ne pas

endommager le joint de son arbre, ne pas pomper d’eau

contenant des matières solides, des corps étrangers, du sable,

du limon ou des substances abrasives.

• Si on doit augmenter la pression de l’eau pompée d’un puits,

s’assurer que les clapets de non-retour du système sont bien

serrés. Si la pression du système chute pendant que la pompe

du puits ne fonctionne pas, la pompe PressureMate

®

peut

démarrer et s’arrêter continuellement. Des démarrages et des

arrêts rapides ou excessifs de la pompe PressureMate risquent

d’endommager son moteur, ce qui annulera la garantie.

• Ne pas utiliser de pâte pour raccords filetés sur les orifices

filetés de la pompe. N’utiliser que du ruban d’étanchéité au

téflon pour rendre étanches ces filets. Les pâtes d’étanchéité

pour raccords filetés endommageront les matériaux du servorégulateur.

NOTA : Le bouchon d’amorçage est déjà doté d’un joint

torique; il n’est donc pas nécessaire de le rendre étanche.

• Serrer à la main tous les raccords et tous les tuyaux branchés

sur la pompe, puis les serrer de 1 1/2 tour de plus au

maximum.

• Un serrage excessif de ces raccords et de ces tuyaux risque

de briser la pompe, ce qui annulera la garantie.

• Le diamètre nominal minimum des tuyaux et des raccords

branchés sur la pompe doit être d’au moins 1 pouce. Des

tuyaux et des raccords ayant un diamètre inférieur à 1 pouce

diminueront le débit, ce qui risque d’endommager la pompe

suite à une cavitation.

• S’assurer qu’il n’y a pas de prises d’air ni de poches d’air

dans le tuyau d’aspiration. Toute prise d’air dans le tuyau

d’aspiration aspirera de l’air, sans toutefois que l’eau coule

par cette prise d’air. Toute prise d’air et toute poche d’air

empêcheront la pompe de s’amorcer adéquatement, ce qui

risquera de diminuer considérablement son débit.

• Le socle sur lequel la pompe sera posée doit être de niveau,

bien solide et aussi près que possible de la source d’eau. Il

doit également être protégé contre toute humidité et inondation excessives.

• Utiliser la plus courte longueur de tuyau possible et le moins

possible de raccords. De grandes longueurs de tuyau et de

nombreux raccords augmentent le frottement, ce qui diminue

le débit de la pompe.

• Supporter le poids de la tuyauterie et de la pompe.

• Ne pas permettre à la pompe, à son servorégulateur ni aux

composants de système de geler. Le gel endommagera la

pompe et la garantie sera annulée.

• Périodiquement, inspecter la pompe, le servorégulateur et les

composants du système.

NOTA : Les codes de la municipalité exigent peut-être l’utilisation d’une soupape de sûreté ou d’un régulateur de pression.

Risque de fuite et d’inondation. Ne pas

utiliser cette pompe si la pression d’arrivée de l’eau est

supérieure à 345 kPa (50 lb/po

2

).

Pression dangereuse et risque d’explosion.

Cette pompe peut développer des pressions extrêmement

élevées pendant qu’elle fonctionne si son refoulement est fermé

ou obstrué. Pour utiliser cette pompe en toute sécurité, nous

recommandons de respecter ce qui suit :

Sur la tuyauterie de refoulement, poser une soupape de sûreté

qui permettra d’évacuer tout le débit de la pompe à une pres-

sion de 689 kPa (100 lb/po

2

). Amener le tuyau de refoulement

branché sur la soupape de sûreté jusqu’à un renvoi à l’égout

de plancher ou jusqu’à tout autre renvoi à l’égout qui assurera

une évacuation adéquate.

INSTALLATION

Risque d’inondation. S’assurer que tous les

tuyaux et que tous les raccords utilisés sont certifiés pour supporter les pressions que la pompe du système peut produire.

1. Décider du meilleur emplacement pour installer la pompe.

Dans cette optique, il faudra considérer ce qui suit :

• La pompe doit être posée le plus près possible de la

conduite principale d’arrivée d’eau

• On doit pouvoir accéder facilement à la pompe

• Une prise de courant doit être assez proche pour que le

cordon puisse y être branché

• Les témoins électroluminescents du servorégulateur

doivent être visibles.

• On doit pouvoir facilement brancher la tuyauterie sur la

pompe

• La pompe doit prendre le moins de place possible

Figure 2 : Installation type d’une pompe de surpression

dans une habitation. Les raccords des tuyaux doivent

être achetés séparément. Consulter les codes pour

savoir quelle soupape de sûreté/quel régulateur de

pression doivent être utilisés.

Figure 1 – Ne pas faire fonctionner la pompe si l’arrivée

est fermée

Prise de courant de 115 volts,

mise à la terre et protégée par

un interrupteur de fuite à la terre

Vers l’habitation

(refoulement de la pompe)

Soupape

de sûreté

Raccordsunions

Alimentation en eau

(aspiration de la pompe)

Clapet de non-retour

ATTENTION

Grounded, GFCI

protected 115V outlet

To Household

(Pump Discharge)

Unions

Water Supply In

(Pump Suction)

Check Valve

®

4253 0902 SIM

ATTENTION

Page 13

Installation 13

Pour obtenir des pièces ou de l’aide, appeler le Service à la clientèle Simer en composant le 1 800 468-7867/1 800 546-7867

NOTA : Il est recommandé (et cette recommandation peut

être exigée par les codes de la municipalité) de poser un

disjoncteur de sécurité au cas où la pression côté refoulement de la pompe chuterait suite à un tuyau cassé, etc.,

afin que le courant alimentant la pompe soit coupé.

2. Monter la pompe sur un socle solide, à l’endroit que l’on a

choisi.

3. Choisir un moment dans la journée qui permettra de

couper l’arrivée d’eau alimentant l’habitation pendant que

l’on procédera à l’installation de la pompe PressureMate

®

.

4. Fermer le robinet de la conduite d’arrivée d’eau principale

de l’habitation.

5. Ouvrir n’importe quel robinet de façon à dissiper la pression d’eau dans les tuyaux. Dès que la pression de l’eau

dans les tuyaux sera dissipée, fermer le robinet.

6. AVANT DE POURSUIVRE, LIRE ATTENTIVEMENT TOUTE

L’OPÉRATION 6. Pour permettre le branchement de la

pompe PressureMate

®

à l’aide de coudes, il faudra couper

une certaine longueur de la conduite d’arrivée d’eau principale. Pour choisir l’emplacement des coupes à effectuer, il

faudra prendre en considération la dimension des coudes

qu’on utilisera, la longueur du filetage des raccords ou l’emboîtement des raccords lisses à coller ou à souder, etc.

Positionner les coudes en ligne avec les orifices d’aspiration

et de refoulement de la pompe. Un peu d’eau coulera peutêtre pendant que l’on coupera le tuyau. Enlever toutes les

bavures ou tous les copeaux laissés par l’outil de coupe.

NOTA : Il ne sera peut-être pas nécessaire de couper les

tuyaux galvanisés. Si un raccord union se trouve à proximité de l’emplacement où la pompe sera installée, le démonter, puis enlever (en le dévissant) le tuyau jusqu’au-delà de

l’emplacement où la pompe sera posée. Couper de nouvelles longueurs de tuyau et les fileter de façon à permettre

l’installation de la pompe.

NOTA : Les orifices d’aspiration femelle et de refoulement

mâle de la pompe ont 1 pouce NPT de diamètre et ils sont

filetés. En fonction du type des raccordements et du

diamètre des tuyaux de l’habitation, il faudra peut-être

poser des adaptateurs dans ces orifices.

7. Après avoir déposé la petite longueur de tuyau, on pourra

vider la tuyauterie au-dessus de la coupe de façon à ne pas

causer de dégâts d’eau. Mettre un seau sous le tuyau coupé

alimentant l’habitation. Ouvrir le robin et se trouvant le

plus haut et laisser l’air s’introduire dans les tuyaux pour

que l’eau coule dans le seau. Lorsque les tuyaux seront

vides, fermer le robinet.

8. Installer les coudes sur la conduite d’arrivée d’eau principale, en les orientant vers la pompe.

Des tuyaux souples risquent d’éclater et

de causer une inondation. Il ne faut donc pas utiliser de

tuyaux souples pour procéder à cette installation. N’utiliser

que des tuyaux rigides conformes aux codes.

9. Brancher les tuyaux sur les coudes, jusqu’à la pompe, en

utilisant un raccord-union sur chaque conduite et un clapet

de non-retour sur la conduite d’aspiration de la pompe. La

flèche frappée sur le clapet de non-retour doit être orientée

vers l’aspiration de la pompe (se reporter à la Figure 2.)

Sur la conduite de refoulement, poser une soupape de

sûreté qui permettra d’évacuer tout le débit de la pompe à

une pression de 689 kPa (100 lb/po

2

). Si cette stipulation

est contraire aux codes, respecter les codes. Un disjoncteur de sécurité doit également installé sur la conduite de

refoulement au cas où la pression de refoulement de la

pompe chuterait. Les codes de la municipalité peuvent

aussi exiger l’utilisation d’un tel disjoncteur de sécurité.

10. Une fois les tuyaux et les raccords installés et rendus

étanches, ouvrir le robinet de la conduite d’arrivée d’eau

principale de façon à mettre sous pression le système et

pouvoir vérifier son étanchéité. Si on remarque des fuites,

fermer le robinet de la conduite d’arrivée d’eau principale,

ouvrir un robinet de l’habitation pour dissiper la pression

dans les tuyaux, puis réparer la fuite. Répéter cette opération jusqu’à ce que le système soit complètement étanche

(qu’il ne fuit plus).

11. Ouvrir un robinet pour chasser l’air des tuyaux et permettre

à l’eau de couler. Dès que l’eau coulera normalement du

robinet, la pompe sera pleine d’eau et complètement amorcée. Fermer le robinet.

12. Tourner la manette rotative du servorégulateur sur la pression à laquelle on désire que la pompe se mette en marche.

La pompe PressureMate

®

est livrée réglée à 207 kPa (30

lb/po

2

). Au début, il est recommandé de faire fonctionner la

pompe sur ce réglage, puis de le modifier par la suite, au

fur et à mesure que l’on acquerra de l’expérience avec le

fonctionnement du système.

13. Avant de poursuivre l’installation, et pour de plus amples

détails concernant les fonctions du système, se reporter aux

rubriques de cette notice intitulées « Branchements

électriques », « Servorégulateur », « Fonctionnement normal de

la pompe » et « Quand la pompe cesse-t-elle de fonctionner? ».

14. À ce point, on peut brancher pour la première fois le cordon électrique de la pompe dans la prise de courant.

Après avoir branché le cordon électrique de la pompe dans

la prise de courant, la pompe démarrera et fonctionnera

pendant 15 secondes, quelle que soit la pression réglée

avec la manette rotative du servorégulateur. Si la pression

d’arrivée est supérieure à la pression réglée, la pompe s’arrêtera après 15 secondes.

15. Pendant que la pompe fonctionne et après qu’elle s’arrête

automatiquement, le système fonctionne à la pression

réglée. Inspecter de nouveau les tuyaux et les raccords pour

s’assurer qu’il n’y a pas de fuites. En cas de fuites,

débrancher le cordon électrique de la pompe de la prise de

courant; fermer le robinet de la conduite d’arrivée d’eau

principale, puis ouvrir un robinet de l’habitation pour dissiper la pression dans les tuyaux. Réparer la fuite. Répéter

cette opération jusqu’à ce que le système soit complètement étanche (qu’il ne fuit plus).

Figure 3 : Branchement type de la tuyauterie de dérivation pour permettre la dépose de la pompe au cas où

elle devrait être réparée, sans avoir à fermer toute l’alimentation d’eau de l’habitation.

Vers

l’habitation

Arrivée

d’eau

To

Household

Water

Supply In

4254 0902

Page 14

Installation et fonctionnement 14

Pour obtenir des pièces ou de l’aide, appeler le Service à la clientèle Simer en composant le 1 800 468-7867/1 800 546-7867

BRANCHEMENTS ÉLECTRIQUES

Tension dangereuse. Ne brancher cette

pompe que dans une prise de courant adéquatement mise à la

terre, protégée par un interrupteur de fuite à la terre et alimentée en courant alternatif de 115 volts, 60 Hz. Cette

pompe est livrée avec un cordon électrique à 3 conducteurs

dont un de mise à terre et une fiche à 3 broches. Ne pas mod-

ifier ni enlever la fiche. S’assurer que la prise de courant correspond, selon le cas, au National Electric Code ou au Code

canadien de l’électricité. Pour ne pas subir de secousses électriques dangereuses, toujours garder le cordon électrique sec.

Se reporter à la Figure 2.

SERVORÉGULATEUR

Le servorégulateur est monté sur la pompe. Il protège la pompe

contre :

• Un fonctionnement à sec;

•Toute surchauffe;

• Des démarrages fréquents causés par de petites pertes d’eau

dans le système;

• Les chutes de pression.

Le servorégulateur se caractérise par les témoins électrolumi-

nescents et les commandes suivants :

Témoin électroluminescent « POWER ON » (Sous tension) : Il

indique que l’appareil est électriquement branché et qu’il est alimenté en courant électrique. La pompe est prête à fonctionner.

Témoin électroluminescent « PUMP ON » (Pompe en marche):

Il indique que la pompe fonctionne et qu’elle pompe de l’eau.

Témoin électroluminescent « WATER FAILURE » (Manque

d’eau) : Il indique que la pompe n’est pas alimentée en eau.

Témoin électroluminescent « TEMPERATURE FAILURE » (Panne

de température) : Il indique que la température à l’intérieur de

la pompe a atteint 70° C (158° F).

Manette rotative de réglage de la pression « STARTING PRESSURE » (Pression de démarrage) : Elle permet de régler la pres-

sion du système entre 103 et 310 kPa (entre 15 et 45 lb/po

2

).

La pompe démarrera automatiquement dès que la pression du

système chutera sous la pression réglée avec la manette rotative

«STARTING PRESSURE » (Pression de démarrage).

Touche « RESET » (Réenclenchement) : Elle permet de réenclencher les caractéristiques sécurité qui se sont déclenchées et

à la pompe de redémarrer.

NOTA : Le servorégulateur ne répondra pas si la touche

« RESET » (Réenclenchement) est tenue appuyée. Il faut appuyer sur cette touche puis la relâcher pour actionner la fonction

de réenclenchement.

FONCTIONNEMENT NORMAL DE LA

POMPE PRESSUREMATE

®

Risque de brûlures. Ne JAMAIS faire fonc-

tionner la pompe à sec, sinon elle risque de surchauffer et les

personnes qui la manipuleront risqueront de se brûler.

L’impulseur et le joint de l’arbre de la pompe peuvent également

être endommagés si la pompe fonctionne à sec, ce qui pourrait

causer des fuites ou une inondation. De plus, la garantie sera

annulée. Avant de démarrer la pompe, la remplir d’eau.

S’assurer que la pompe PressureMate

®

a été adéquatement

installée, amorcée (se reporter à la page 11), que le tuyau

d’aspiration n’est pas obstrué et qu’il est ouvert.

Tourner la manette rotative « STARTING PRESSURE » (Pression

de démarrage) à la pression minimum désirée du système.

Brancher le cordon électrique de la pompe dans la prise de

courant. Les témoins électroluminescents « POWER ON »

(Sous tension) et « PUMP ON » (Pompe en marche) s’allumeront indiquant, respectivement, que le courant électrique

alimente la pompe et que la pompe est prête à fonctionner.

La pompe démarrera et fonctionnera pendant 15 secondes

après que la pression dans le système aura dépassé la pression

réglée avec la manette rotative « STARTING PRESSURE »

(Pression de démarrage) et après que le ou les robinets de

l’habitation auront été fermés.

QUAND LA POMPE CESSE-T-ELLE DE

FONCTIONNER?

Réglage de la pression/Plus de débit : La pompe cesse de fonc-

tionner et le témoin électroluminescent « PUMP ON » (Pompe

en marche) s’éteint 15 secondes après :

• Dès que la pression dans le système est supérieure à la pres-

sion réglée avec la manette rotative « STARTING PRESSURE »

(Pression de démarrage) et

• Que le ou les robinets de l’habitation auront été fermés.

Ce fonctionnement est normal.

Redémarrage : Dès que le débit est supérieur à 1 gal/min ou

dès que la pression chute sous le réglage de la pression

« STARTING PRESSURE » (Pression de démarrage), la pompe

redémarre et le témoin électroluminescent « PUMP ON »

(Pompe en marche) s’allume. La pompe continuera de fonctionner pendant 15 secondes après :

• Que la pression aura atteint la pression réglée, et

• Que le ou les robinets de l’habitation auront été fermés.

NOTA : Ce délai de 15 secondes avant que la pompe s’arrête

empêche des fonctionnements et des arrêts rapides dés qu’on

ouvre et ferme rapidement un robinet (par exemple, pendant

qu’on se brosse les dents).

Figure 4 – Panneau des commandes du servorégulateur

Réenclenchement

Témoin Manque d’eau

Témoin Panne de température

Témoin Pompe en marche

Témoin Sous tension

Manette rotative

de réglage de la

pression

Reset

Water Failure LED

Temp. Failure LED

Pump-on LED

Power-on LED

Starting

Pressure

Dial

RESET

W

AT

E

R

FA

TE

M

ILU

P. F

R

E

A

P

ILU

U

M

R

P

E

O

P

N

O

W

E

R

O

S

25

TA

N

P

R

R

E

T

30

S

IN

S

G

U

20

R

E

35

15

PSI

40

45

1-800-365-6832

www.flotecwater.com

RESET

WATER FAILURE

TEMP. FAILURE

PUMP ON

STARTING

PRESSURE

®

POWER ON

25

20

15

PSI

30

35

40

45

1-800-468-7867

www.simerpump.com

®

3963 0401 SIM

ATTENTION

Page 15

Fonctionnement, entretien et dépannage 15

Pour obtenir des pièces ou de l’aide, appeler le Service à la clientèle Simer en composant le 1 800 468-7867/1 800 546-7867

Chute de pression/Plus de débit : Normalement, dès que la

pompe démarre, la pression de l’eau augmente très rapidement

et le servorégulateur détecte qu’il y a débit. S’il n’y a pas de

débit d’eau pas et si la pression dans le système n’augmente

pas, le servorégulateur a détecté « qu’il y a manque d’eau ». Il

peut également détecter cette situation pendant que la pompe

fonctionne si l’eau cesse de parvenir à la pompe. Pour protéger

la pompe contre un fonctionnement à sec :

• 15 secondes après que le servorégulateur aura détecté « qu’il

n’y a pas d’eau », la pompe cessera de fonctionner.

• Le témoin électroluminescent « PUMP ON » (Pompe en

marche) s’éteindra et

• Le témoin électroluminescent « WATER FAILURE » (Manque

d’eau) clignotera.

Redémarrage : S’assurer que la conduite d’aspiration n’est pas

obstruée et qu’elle est bien branchée sur une source d’eau.

• Appuyer sur la touche « RESET » (Réenclenchement) et la

tenir appuyée.

• Le témoin électroluminescent « PUMP ON » (Pompe en

marche) doit s’allumer, et

• Le témoin électroluminescent « WATER FAILURE »

(Manque d’eau) doit cesser de clignoter.

Si le débit est adéquat, la pompe continuera de fonctionner pen-

dant 15 secondes après qu’elle aura atteint la pression réglée et

que le ou les robinets de l’habitation auront été fermés.

Température élevée : Dès de la température de l’eau à l’intérieur de la pompe atteint 70° C (158° F),

• La pompe cesse de fonctionner,

• Le témoin électroluminescent « PUMP ON » (Pompe en

marche) s’éteint, et

• Le témoin électroluminescent « PANNE DE TEMPÉRATURE »

clignote.

Redémarrage : Attendre 20 minutes pour laisser la température de l’eau chuter sous 40° C (104° F) :

• S’assurer que la pompe est alimentée en eau et que le débit

n’est pas obstrué.

• Appuyer sur la touche « RESET » (Réenclenchement) puis

la relâcher.

• Le témoin électroluminescent « PUMP ON » (Pompe en

marche) doit s’allumer, et

• Le témoin électroluminescent « WATER FAILURE »

(Manque d’eau) doit cesser de clignoter.

• Sinon, laisser refroidir la pompe plus longtemps, puis réessayer.

NOTA : Si la pompe continue de chauffer pendant qu’elle

fonctionne, l’arrêter et appeler le Service à la clientèle

Simer en composant le 1 800 468-7867.

LUBRIFICATION

Le moteur a été lubrifié à l’usine pour la durée des paliers. Le

joint de l’arbre de la pompe est lubrifé et refroidi par l’eau.

ENTRETIEN DE LA POMPE

Tension dangereuse. Risque de secousses élec-

triques, de brûlures, voire de mort. Avant d’intervenir sur la pompe

et le servorégulateur, débrancher le cordon électrique de la prise

de courant. Ne pas manipuler la pompe ni le servorégulateur et ne

pas essayer d’intervenir sur la pompe si on a les mains humides ou

si l’on se tient sur un plancher mouillé ou humide.

Le moteur est doté d’un limiteur de surcharge à réenclenchement automatique. Si le moteur surchauffe, le limiteur de surcharge interrompra le courant électrique alimentant la pompe

pour empêcher qu’elle soit endommagée; le limiteur de surcharge se réenclenchera automatiquement dès que le moteur

aura refroidi. Si le limiteur de surcharge se déclenche de façon

répétitive, vérifier la pompe et déterminer la cause de cet incident (basse tension, impulseur bouché, etc.).

DÉPANNAGE

SYMPTÔMES CAUSES POSSIBLES MESURES CORRECTIVES

Le moteur ne Le fusible est sauté ou le disjoncteur COUPER LE COURANT; Remplacer le fusible ou réenclencher le disjoncteur.

démarre pas est disjoncté

Le cordon électrique n’est pas branché Brancher le cordon électrique dans une prise de courant mise à la terre,

dans une prise de courant alimentée en courant alternatif de 115 volts.

Le moteur chauffe et le La tension est trop basse Vérifier la tension alimentant la pompe.

limiteur de surcharge se

L’impulseur ne tourne pas librement Vérifier l’impulseur pour s’assurer qu’il tourne librement et qu’il n’est pas bouché.

déclenche ou bien le

moteur ne fonctionne

pas et ne fait que

« murmurer »

Le moteur fonctionne La pompe n’est pas adéquatement amorcée Réamorcer la pompe conformément aux instructions.

mais la pompe ne

Le filtre à eau est bouché Arrêter la pompe. Fermer l’arrivée d’eau et remplacer la cartouche filtrante.

débite pas d’eau*

Le filtre doit être posé sur le côte refoulement de la pompe.

Le robinet de refoulement est fermé Ouvrir le robinet.

Le diamètre des tuyaux est trop petit Remplacer les tuyaux par des tuyaux du même diamètre que les orifices

d’aspiration et de refoulement de la pompe.

L’impulseur est bouché Nettoyer l’impulseur.

Les tuyaux sont gelés Les dégeler.

*La pompe ne débite Les tuyaux rigides sont corrodés Les remplacer par des tuyaux rigides en plastique ou des tuyaux en acier neufs.

pas à son débit maximal

Le diamètre des tuyaux est trop petit Remplacer les tuyaux par des tuyaux du même diamètre que les orifices

d’aspiration et de refoulement de la pompe.

La pompe n’est pas suffisamment Utiliser un tuyau d’arrivée d’eau de diamètre plus gros; vérifier le système

alimentée en eau de pompage du puits.

Basse tension S’assurer que la prise de courant est alimentée en courant alternatif de 115 volts.

* (Nota : Débrancher le

cordon électrique de la

pompe de la prise de

courant, puis ouvrir un

robinet pour confirmer

que l’eau circule dans le

système).

Page 16

Pièces de rechange 16

Pour obtenir des pièces ou de l’aide, appeler le Service à la clientèle Simer en composant le 1 800 468-7867/1 800 546-7867

Désignation 3075SS

Réf. des pièces Qté 1/2 ch

1 Corps de la pompe (comprend les boulons) 1 FPP1801

2Trousse des pièces internes 1 FPP1870

3 Condensateur 1 171P5750

4Trousse de boîte de câblage/Couvercle/Joints 1 FPP1802

5 Carter du ventilateur 1 721S1090

6Trousse de joints d’arbre et de joints toriques 1 FPP1850

Série Ace-In-The-Hole, modèle 3075SS

4

3

5

2

1

4220 0702

6

Page 17

17

Pour obtenir des pièces ou de l’aide, appeler le Service à la clientèle Simer en composant le 1 800 468-7867/1 800 546-7867

Page 18

Seguridad 18

Si necesita repuestos o asistencia llame al Servicio al Cliente de Simer, 1-800-468-7867/1-800-546-7867

¡ES IMPORTANTE LEER Y SEGUIR LAS

INSTRUCCIONES DE SEGURIDAD!

Este es el símbolo de alerta de seguridad. Cuando vea

este símbolo en su bomba o en este manual, busque una

de las siguientes palabras de señal y esté alerta a la posibilidad

de lesiones personales.

Advierte sobre peligros que provocarán

lesiones personales graves, muerte o daños materiales considerables si se les ignora.

Advierte sobre peligros que pueden provocar

lesiones personales graves, muerte o daños materiales considerables si se les ignora.

Advierte sobre peligros que provocarán o

pueden provocar lesiones personales o daños materiales

menores si se les ignora.

La etiqueta de ATENCIÓN (NOTICE), indica instrucciones

especiales que son importantes pero que no están asociadas a

peligros.

Lea y observe cuidadosamente todas las instrucciones de

seguridad que aparecen en este manual y en el equipo.

Mantenga las etiquetas de seguridad en buen estado.

Cambie toda etiqueta de seguridad que falte o esté dañada.

Asegúrese de que los talleres sean “a prueba de niños”, use

candados e interruptores maestros; retire las llaves de

arranque/encendido.

INSTRUCCIONES GENERALES

DE SEGURIDAD

1. Para evitar el riesgo de lesiones corporales graves y daños

materiales, lea con atención las instrucciones de seguridad

antes de instalar esta bomba.

2. Observe los códigos de plomería, construcción y electrici-

dad tanto locales como nacionales cuando instale la

bomba. Use tubos rígidos cuando instale esta bomba.

3. Presión peligrosa. El cuerpo de la bomba

puede explotar si ésta se usa para reforzar presión por

encima de los 100 psi (689 kPa). Instale una válvula de

desahogo de presión en la línea de descarga, capaz de

pasar el caudal total de la bomba a 100 psi (689 kPa). Si

esta disposición está en conflicto con el código, siga las

instrucciones del código. No use esta bomba con una presión de admisión superior a 50 psi (345 kPa).

4. Se recomienda instalar un interruptor de cierre de seguri-

dad por baja presión, para apagar la bomba en caso de una

presión de descarga baja debido a la interrupción del suministro de agua entrante, a una tubería rota, etc.

5. Nunca deje marchar la bomba en seco. Esto podría dañar

las piezas internas de la bomba, recalentarla (lo que provocaría quemaduras a las personas que estuviesen trabajando

con la bomba o reparándola), y anulará la garantía.

6. Riesgo de incendio o de explosión. Para

evitar el riesgo de incendio y explosión, bombee agua sola-

mente con esta bomba. No bombee líquidos ni sustancias

químicas inflamables. No use la bomba cerca de luces

piloto de gas o en áreas en presencia de vapores químicos

o de gases. El uso de una bomba eléctrica con líquidos que

no sean agua o en una atmósfera que contenga vapores

químicos o gases, podrá inflamar esos líquidos o gases,

provocando lesiones o muerte debido a una explosión y/o

un incendio.

7. Peligro de quemaduras. Si el agua queda

atrapada en la bomba durante el funcionamiento, ésta se

puede convertir en vapor. El vapor atrapado puede conducir a una explosión y a quemaduras. Nunca deje marchar la bomba con la llave de salida cerrada u obstruida.

8. No toque un motor en funcionamien-

to. Los motores modernos están diseñados para funcionar a

altas temperaturas. Para evitar quemaduras durante las

reparaciones y el mantenimiento de la bomba, deje que se

enfríe durante 20 minutos después de apagarla y antes de

intentar manipularla.

INSTRUCCIONES DE SEGURIDAD

ASOCIADAS CON LA ELECTRICIDAD

La bomba viene provista de un cordón de 3 conductores

con conexión a tierra. Conéctela solamente a un tomacorriente debidamente puesto a tierra y protegido por un

“GFCI” (disyuntor diferencial). No levante la bomba por

medio del cordón eléctrico.

Tensión peligrosa. Puede provocar choque

eléctrico, quemaduras o muerte. Conecte la bomba a tierra

antes de conectarla a una fuente de suministro de energía.

Desconecte la corriente antes de trabajar con la bomba, con el

motor o con el tanque.

La bomba y el controlador no son sumergibles.

Mantenga el motor seco en todo momento. No lave el

motor. No lo sumerja. Proteja el motor en situaciones de

clima lluvioso.

Si usa un cordón de alargue, use solamente un cordón

trifilar, aprobado para uso en el interior y al aire libre,

con conexión a tierra. No permita que ninguna parte del

cordón o los extremos del receptáculo queden apoyados en el

agua o en lugares húmedos.

Desenchufe la bomba antes de repararla o de realizar

trabajos de mantenimiento. Para evitar choques fatales,

proceda de la siguiente manera si es necesario reparar o

realizar trabajos de mantenimiento en la bomba.

A. Desconecte la corriente a la caja de salida de la bomba

antes de desenchufarla. Después de haberla desenchufado,

deje que la bomba se enfríe durante 20 minutos antes de

tratar de trabajar en la misma.

B. Proceda con extrema cautela cuando cambie los fusibles.

Para reducir la posibilidad de choques eléctricos fatales,

NO se pare sobre el agua ni ponga sus dedos en el portafusibles.

C. Conecte a tierra la caja eléctrica de salida.

D. Enchufe la bomba y el controlador en un tomacorriente

conectado a tierra y protegido por un Disyuntor

Diferencial (“GFCI” según sus siglas en inglés).

PELIGRO

PRECAUCIÓN

PRECAUCIÓN

Page 19

Si necesita repuestos o asistencia llame al Servicio al Cliente de Simer, 1-800-468-7867/1-800-546-7867

Índice 19

Gracias por comprar una bomba de alta calidad, probada en la fábrica.

Página

Información General sobre la Seguridad............................................................18

Garantía.............................................................................................................19

Información general...........................................................................................20

Instalación ...................................................................................................20, 21

Conexión eléctrica.............................................................................................22

Controlador automático de presión....................................................................22

Operación..........................................................................................................22

¿Cuándo deja de funcionar la bomba?.........................................................22, 23

Servicio..............................................................................................................23

Localización de fallas ........................................................................................23

Repuestos para la reparación .............................................................................24

SIMER garantiza al comprador consumidor original (“Comprador”) de sus productos que se encuentran libres de defectos en material o mano de obra.

Si dentro de los doce (12) meses a partir de la fecha de la compra original por el consumidor, ese producto resulta defectuoso, éste será reparado o reemplazado a

opción de SIMER, sujeto a los términos y condiciones mencionados a continuación.

Su recibo de compra se usará para determinar la elegibilidad de la garantía.

Excepciones a la Garantía de doce (12) meses

Garantía de tres (3) años

Si dentro de los tres (3) años de la compra por parte del comprador inicial, se

comprueba que un producto 3075SS es defectuoso, éste será reparado o reemplazado a opción de SIMER, sujeto a los términos y condiciones indicados a

continuación.

Términos y Condiciones Generales

El comprador deberá pagar por toda la mano de obra y cargos de envío necesarios para reemplazar el producto cubierto por esta garantía. Esta garantía no corresponde en caso de actos fortuitos ni corresponde a productos que, a solo juicio

de SIMER, hayan sido objeto de negligencia, abuso, accidente, mala aplicación,

alteraciones forzosas o de otro tipo; ni debido a instalación, operación, mantenimiento o almacenamiento indebidos; ni debido a toda operación, uso o servicio

que no sea normal, incluyendo, pero sin limitarse a, fallas de operación ocasionadas por corrosión, herrumbre u otros materiales foráneos en el sistema, o por la

operación a presiones en exceso a los máximos que se recomiendan.

Las solicitudes de servicio bajo esta garantía se deberán realizar por medio de la

devolución del producto defectuoso a la tienda minorista o a SIMER a la brevedad

posible después de haber descubierto el supuesto defecto. SIMER entonces tomará

una acción correctiva tan pronto como sea razonablemente posible. No se aceptarán solicitudes de servicio bajo esta garantía si se reciben después de más de 30

días de terminado el período de la garantía.

Esta garantía establece la única obligación de SIMER y el recurso exclusivo del

comprador en relación a productos defectuosos.

SIMER NO SE HARÁ RESPONSABLE DE NINGÚN DAÑO CONSECUENTE, INCIDENTAL O CONTINGENTE.

LAS GARANTÍAS QUE ANTECEDEN SON EXCLUSIVAS Y EN LUGAR DE TODA

OTRA GARANTÍA EXPLÍCITA O IMPLÍCITA, INCLUYENDO PERO SIN LIMITARSE

A LAS GARANTÍAS IMPLÍCITAS DE COMERCIABILIDAD E IDONEIDAD PARA

UN FIN ESPECÍFICO, Y NO SE EXTENDERÁN MÁS ALLÁ DE LA DURACIÓN DE

LAS GARANTÍAS EXPLÍCITAS CORRESPONDIENTES SUMINISTRADAS EN LA

PRESENTE.

Algunos estados no permiten la exclusión o limitación de daños incidentales o

consecuentes o de limitaciones de tiempo sobre garantías implícitas, de modo que

es posible que las limitaciones o exclusiones que preceden no correspondan en

su caso. Esta garantía le otorga derechos legales específicos y es posible que Ud.

también tenga otros derechos que pueden variar de un estado al otro.

Garantía limitada de Simer

SIMER. • 293 Wright St. • Delavan, WI, E.U.A. 53115

Teléfono: 1-800-468-7867/1-800-546-7867 • Fax: 1-800-390-5351

Page 20

Información general / Instalación 20

Si necesita repuestos o asistencia llame al Servicio al Cliente de Simer, 1-800-468-7867/1-800-546-7867

Use PressureMate®para reforzar la presión del agua de servicio

municipal. Las conexiones de plomería se describen en este

manual.

INFORMACIÓN GENERAL

• Bombee solamente agua limpia con su PressureMate. Para

evitar obstruir la bomba y dañar el sello del eje, no bombee

agua que contenga partículas sólidas, materiales extraños,

arena, limo o sustancias abrasivas.

• Si está reforzando la presión de una bomba de pozo, verifique que las válvulas checadoras del sistema estén bien

ajustadas. Si cae la presión del sistema cuando la bomba de

pozo no está marchando, la PressureMate puede encenderse

y comenzar el ciclo. Un ciclo excesivo o rápido puede dañar

el motor y anulará la garantía.

• No use compuestos para juntas de tuberías en los orificios de

la bomba; use solamente cinta de teflón para sellar las

roscas. El compuesto para juntas de tuberías dañará los

materiales del controlador.

NOTA: El tapón de cebadura ya tiene un aro tórico instalado

y no es necesario sellarlo.

• Ajuste a mano todas las juntas de las tuberías a la bomba

más 1-1/2 vueltas (no más).

Si ajusta demasiado, puede romper la bomba y se anulará la

garantía.

• Las tuberías y los accesorios a la bomba deben ser por lo

menos de 1 pulgada de diámetro nominal. Las tuberías o los

accesorios menores de 1 pulgada de diámetro reducirán el

rendimiento y pueden dañar la bomba debido a la cavitación.

•Verifique que no hayan fugas de aire ni bolsas de aire en la

tubería de aspiración. Una fuga de aire en la tubería de

aspiración puede hacer penetrar aire, aunque no se observen

fugas de agua. Las fugas de aire y las bolsas de aire evitarán

que la bomba se cebe debidamente, y puede reducir su