Page 1

OWNER’S MANUAL

Submersible Solids

Handling Pumps

NOTICE D’UTILISATION

Pompes submersibles

pour les matières solides

MANUAL DEL USUARIO

Bombas submergibles para el

manejo de líquidos con sólidos

Installation/Operation/Parts

For further operating, installation,

or maintenance assistance:

Call 1-800-468-7867

English . . . . . . . . . . . . . . . Pages 2-6

Installation/Fonctionnement/Pièces

Pour plus de renseignements

concernant l’utilisation,

l’installation ou l’entretien,

Composer le

1 (800) 468-7867

Français . . . . . . . . . . . . Pages 7-11

Instalación/Operación/Piezas

Para mayor información sobre el

funcionamiento, instalación o

mantenimiento de la bomba:

Llame al 1-800-468-7867

Español . . . . . . . . . . .Paginas 12-16

©2005 1000000854 (Rev. 12/10/08)

664 0997 SIM NF

Model 2961

293 Wright St., Delavan, WI 53115

Phone:

1-800-468-7867

1-800-546-7867

Fax:

1-800-390-5351

Page 2

Warranty 2

RETAIN ORIGINAL RECEIPT FOR YOUR RECORDS.

LIMITED WARRANTY

SIMER warrants to the original consumer purchaser (“Purchaser” or “You”) of its products that they are free from defects in

material and workmanship for a period of twelve (12) months from the date of the original consumer purchase.

If, within twelve (12) months from the original consumer purchase, any such product shall prove to be defective, it shall be

repaired or replaced at SIMER’s option, subject to the terms and conditions set forth below. The original purchase receipt

and product warranty information label are required to determine warranty eligibility. Eligibility is based on purchase date of

original product – not the date of replacement under warranty. The warranty is limited to repair or replacement of product

only – Purchaser pays all removal, installation, labor, shipping, and incidental charges.

For parts or troubleshooting assistance, DO NOT return product to your retail store. Contact SIMER Customer Service at

1-800-468-7867 / 1-800-546-7867.

Claims made under this warranty shall be made by returning the product (except sewage pumps, see below) to the retail

outlet where it was purchased immediately after the discovery of any alleged defect. SIMER will subsequently take

corrective action as promptly as reasonably possible. No requests for service will be accepted if received more than

30 days after the warranty expires.

SEWAGE PUMPS

DO NOT return a sewage pump (that has been installed) to your retail store. Contact SIMER Customer Service. Sewage

pumps that have seen service and been removed carry a contamination hazard with them.

If your sewage pump has failed:

• Wear rubber gloves when handling the pump;

• For warranty purposes, return the pump’s cord tag and original receipt of purchase to the retail store;

• Dispose of the pump according to local disposal ordinances.

Exceptions to the Twelve (12) Month Limited Warranty

Product Warranty Period

BW85P, CM10, CMK, M40, M40P 90 days

2300, 2310, 2330, 2520ULST, 2943, 2955, 2956, 2957, 2960, 5023SS, A5500 2 Years

4” Submersible Well Pumps, 2945, 2958, 2975PC, 2985, 3075SS, 3983, 3984 3 Years

Pre-Charge Water System Tank, 3985, 3986 5 Years

3963, 3988, 3995, 3997 Lifetime

General Terms and Conditions

You must pay all labor and shipping charges necessary to replace product covered by this warranty. This warranty does not

apply to the following: (1) acts of God; (2) products which, in SIMER’s sole judgement, have been subject to negligence,

abuse, accident, misapplication, tampering, or alteration; (3) failures due to improper installation, operation, maintenance or

storage; (4) atypical or unapproved application, use or service; (5) failures caused by corrosion, rust or other foreign

materials in the system, or operation at pressures in excess of recommended maximums.

This warranty sets forth SIMER’s sole obligation and purchaser’s exclusive remedy for defective products.

SIMER SHALL NOT BE LIABLE FOR ANY CONSEQUENTIAL, INCIDENTAL, OR CONTINGENT DAMAGES

WHATSOEVER.

THE FOREGOING WARRANTIES ARE EXCLUSIVE AND IN LIEU OF ALL OTHER EXPRESS AND IMPLIED

WARRANTIES, INCLUDING BUT NOT LIMITED TO THE IMPLIED WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE. THE FOREGOING WARRANTIES SHALL NOT EXTEND BEYOND THE

DURATION PROVIDED HEREIN.

Some states do not allow the exclusion or limitation of incidental or consequential damages or limitations on how long an

implied warranty lasts, so the above limitations or exclusions may not apply to You. This warranty gives You specific legal

rights and You may also have other rights which vary from state to state.

SIMER • 293 Wright Street • Delavan, WI U.S.A. 53115

Phone: 1-800-468-7867 / 1-800-546-7867 • Fax: 1-800-390-5351

E-Mail: info@simerpumps.com • Web Site: http://www.simerpumps.com

Page 3

Safety / Performance / Installation 3

READ AND FOLLOW

SAFETY INSTRUCTIONS!

This is the safety alert symbol. When you see this

symbol on your pump or in this manual, look for

one of the following signal words and be alert to the

potential for personal injury:

warns about hazards that will cause serious

personal injury, death or major property damage if

ignored.

warns about hazards that can cause serious

personal injury, death or major property damage if

ignored.

warns about hazards that will or can cause

minor personal injury or property damage if ignored.

The label NOTICE indicates special instructions which

are important but not related to hazards.

Carefully read and follow all safety instructions in this

manual and on pump.

Keep safety labels in good condition.

Replace missing or damaged safety labels.

1. Read this manual carefully. Failure to follow these

Instructions could cause serious bodily injury and/or

property damage.

2. Check your local codes before installing. You must

comply with their rules.

3. Vent sewage or septic tank according to local codes.

4. Do not install pump in any location classified as

hazardous by National Electrical Code, ANSI/NFPA

70-1990.

Hazardous voltage, Can shock, burn or cause

death. During operation, the pump is in water. To avoid

fatal shocks, proceed as follows if pump needs servicing:

Risk of electrical shock. Can burn or kill.

Do not lift pump by power cord. See “Cord Lift Warning”

on Page 5.

5A. Disconnect power to outlet box before unplugging

pump.

5B. Take extreme care when changing fuses. Do not

stand in water or put your finger in fuse socket.

5C. Do not modify cord and plug. When using cord and

plug, plug into a grounded outlet only. When wiring

to a system control, connect pump ground lead to

system ground.

6. Do not run pump dry. Dry running can overheat

pump, (causing burns to anyone handling it) and will

void warranty.

7. Pump normally runs hot. To avoid burns when servicing pump, allow it to cool for 20 minutes after

shut-down before handling it.

8. In normal service, motor should not need oiling.

Motor has been filled at the factory with a special oil.

NOTICE: This unit is not designed for applications involving salt water or brine! Use with salt water or brine will

void warranty.

INSTALLATION

NOTICE: Install pump on a hard, level surface (cement,

asphalt, etc.). Never place pump directly on earth, clay

or gravel surfaces.

Piping – Effluent Applications

(3/4" or Less Solids)

Piping must be 1-1/2" minimum to carry volume of

pump discharge. Check local codes to determine if a

check valve is required in your system. In cold climates,

check valves are not used to prevent effluent from freezing in piping.

If using as a sump pump, a check valve is recommended.

Piping – Sewage Applications

(2" or Less Solids)

In any case, piping must not be smaller than pump discharge.

When installed in a sewage system, pipe must be capable

of handling semi-solids of at least 2" (5.1 cm) diameter.

The rate of flow in the discharge pipe must keep any

solids present in suspension in the fluid. To meet minimum flow requirements (2 feet (.6 m) per second in discharge line), size pipe as follows:

A Pipe Size Of: Will Handle a Flow Rate Of:

1-1/2" (3.8 cm) 12 GPM (45 LPM)

2" (5.1 cm) 21 GPM (80 LPM)

2-1/2" (6.3 cm) 30 GPM (114 LPM)

3" (7.6 cm) 48 GPM (182 LPM)

For parts or assistance, call Simer Customer Service at 1-800-468-7867 / 1-800-546-7867

PERFORMANCE

GPH (LPH) AT DISCHARGE FT. OF HEAD

Model 5 (1.5m) 10 (3m) 15 (4.6m) 18 (5.5m)

2961 3900(14,763) 2550(9,653) 960(3,634) 0

Page 4

Electrical / Operation / Service 4

Use a 2" (5.1 cm) swing check valve in pump discharge

to prevent backflow of liquid into sump basin. Check

valve should be a free flow valve that will easily pass

solids.

NOTICE: For best performance of check valve when

handling solids, do not install it with the discharge pipe

angled more than 45° above the horizontal. Do not

install check valve in a vertical position as solids may

settle in valve and prevent the check valve from opening

on startup.

Drill a 3/16" (4.7mm) hole in discharge pipe about 1"-2"

(2.5 - 5.1cm) above pump discharge connection (but

below check valve) to prevent airlocking the pump.

ELECTRICAL

Hazardous voltage. Can shock, burn, or

cause death. When installing, operating, or servicing this

pump, follow safety instructions listed below.

1. DO NOT splice the electrical power cord.

2. DO NOT allow electrical cord plug to be submerged.

3. DO NOT use extension cords. They are a fire hazard

and can reduce voltage sufficiently to prevent pumping and/or damage motor.

4. DO NOT handle or service pump while it is connected

to power supply.

5. DO NOT remove grounding prong from plug or

modify plug.To protect against electrical shock, the

power cord is a three-wire conductor and includes a

3-prong grounded plug. Plug pump into a 3-wire,

grounded, grounding-type receptacle. Connect pump

according to electrical codes that apply.

For automatic operation, plug or wire pump into an

automatic float switch or pump controller. Pump will run

continuously when plugged directly into an electrical

outlet. Connect or wire pump to an individual branch

circuit with no other outlets or equipment in the circuit.

Size fuses or circuit breakers according to Fuse Size

Chart at right.

Risk of electrical shock and fire. Can cause

severe personal injury, property damage or death. Be

sure that power supply information (Voltage/

Hertz/Phase) on pump motor nameplate matches incoming power supply exactly. Install pump according to all

electrical codes that apply.

FUSE SIZE CHART

Individual Dual Element

Branch Circuit Time Delay

Model H.P. Voltage Required (Amps) Fuse Amps

2961 4/10 115 15 10

OPERATION AND INSTALLATION

NOTICE: Do not allow pump to run in a dry sump. It

will void the warranty and may damage the pump.

An automatic overload protector in the motor will pro-

tect motor from burning out due to overheating/overloading. When motor cools down, overload protector

will automatically reset and start motor.

If overload trips frequently, check for cause. It could be a

stuck impeller, wrong/low voltage, or electrical failure in

motor. If an electrical failure in the motor is suspected,

have it serviced by a competent repairman.

Pump is permanently lubricated. No oiling or greasing is

required.

GENERAL

Hazardous voltage. Can shock, burn, or

cause death. Before removing pump from basin for ser-

vice, always disconnect electrical power to pump and

control switch.

Risk of electrical shock. Can burn or kill.

Do not lift pump by the power cord.

Submerge pump in a disinfectant solution (chlorox or

chlorine) for at least one hour before disassembling

pump.

The pump motor contains a special lubricating oil which

should be kept clean and free of water at all times.

For parts or assistance, call Simer Customer Service at 1-800-468-7867 / 1-800-546-7867

Page 5

Troubleshooting 5

For parts or assistance, call Simer Customer Service at 1-800-468-7867 / 1-800-546-7867

A. Pump fails to operate:

B. Pump fails to empty sump:

C. Pump will not shut off:

Risk of sudden starts. Can result in an electri-

cal shock and pinching of hands or fingers. If the power is on

to the pump when the thermal overload resets, the pump may

start without warning. Disconnect the power before servicing

the pump.

1. Check to be sure that power cord is securely plugged into outlet. Disconnect power to

outlet before handling pump or motor.

2. Check to be sure you have electrical power.

3. Check that liquid fluid level is high enough to activate switch or controller.

4. Check to be sure that 3/16" (4.7 mm) vent hole in discharge pipe is not plugged.

5. Check for blockage in pump inlet, impeller, check valve or discharge pipe.

6. Thermal overload may have tripped. Test start pump; if it starts and then stops immediately, disconnect from power source for 30 minutes to allow motor to cool, then

reconnect to power source. Check for cause of overheating/overloading.

1. Be sure all valves in discharge valve are fully open.

2. Clean out discharge pipe and check valve.

3. Check for blockage in pump inlet or impeller.

4. Pump not sized properly. A higher capacity pump may be required.

1. Check switch or controller automatic floats for proper operation and location.

See installation instructions for switch/controller.

2. If pump is completely inoperative or continues to malfunction, consult your local

serviceman.

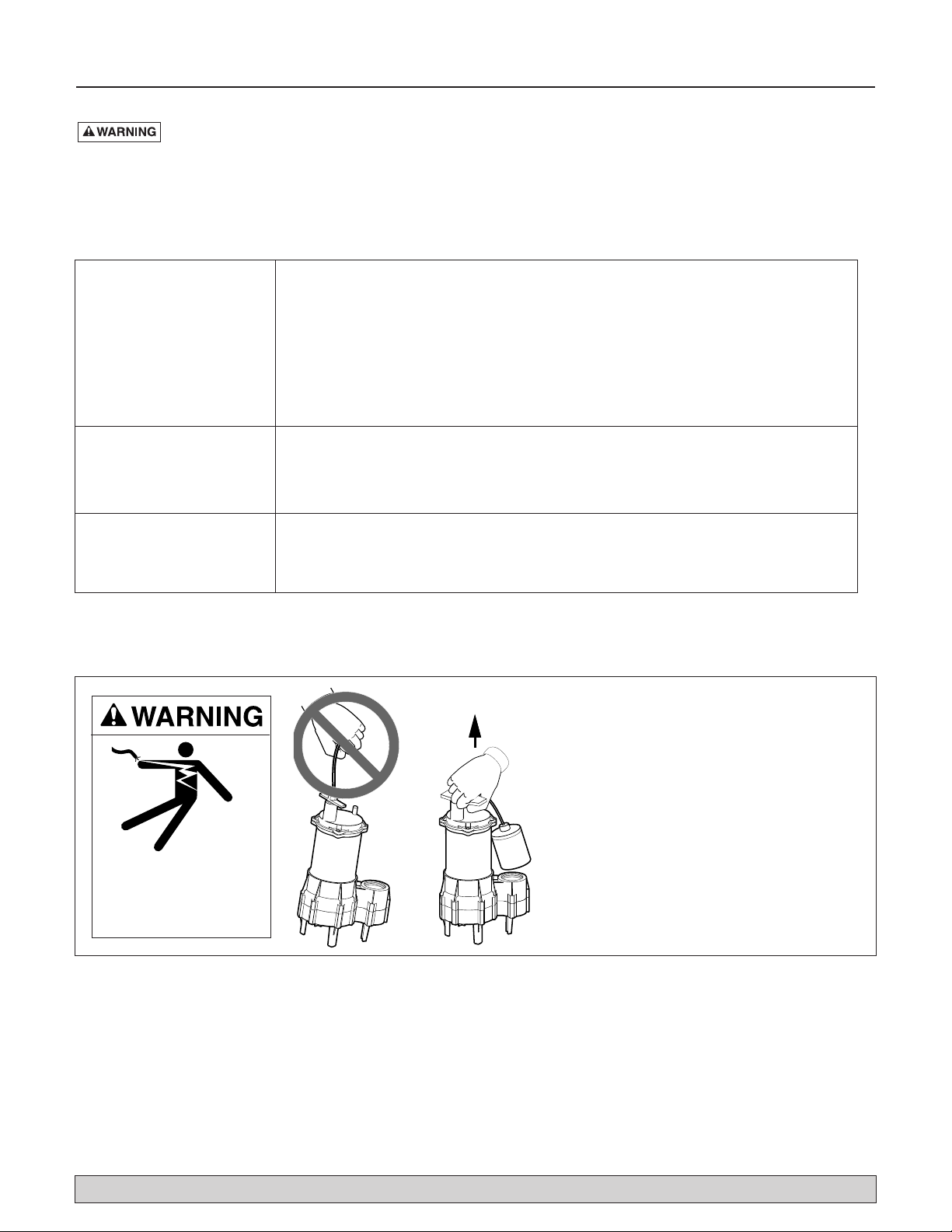

1. Attempting to lift or support pump by

power cord can damage cord and

cord connections.

2. Cord may pull apart, exposing bare

wires with possibility of fire or electrical shock.

3. Lifting or supporting pump by power

cord will void warranty.

4. Use lifting ring or handle on top of

pump for all lifting/lowering of pump.

Disconnect power to pump before

doing any work on pump or attempting to remove pump from sump.

1476 0195

Risk of electrical shock.

Can burn or kill.

Do not lift pump by

power cord.

CORD LIFT WARNING

Page 6

Repair Parts 6

For parts or assistance, call Simer Customer Service at 1-800-468-7867 / 1-800-546-7867

Key Part 2961

No. Description Qty. 115 Volt

1 Power Cord Assembly 1 PS117-54-TSE

2 Upper Volute 1 PW1-10P

3 Impeller 1 PW5-15P

4 Lower Volute 1 PW1-11P

5 Automatic Float Switch 1 PS117-144P

4

3

2

1

5

664 0997 SIM

REPAIR PARTS LIST

IF THE MOTOR FAILS, REPLACE THE PUMP.

Page 7

Garantie 7

CONSERVER L’ORIGINAL DU REÇU POUR TOUTE RÉFÉRENCE ULTÉRIEURE.

GARANTIE LIMITÉE

SIMER garantit à l’acheteur/au consommateur d’origine (l’Acheteur) que ses produits sont exempts de tout vice de matériau et de

fabrication. Cette garantie est valable pendant douze (12) mois à partir de la date d’achat d’origine.

Si, dans les douze (12) mois suivant la date d’achat d’origine, un produit se révèle défectueux, il sera réparé ou remplacé, à la

discrétion de SIMER, conformément aux modalités et conditions exposées ci-dessous. Le reçu de l’achat d’origine et l’étiquette

d’information sur la garantie sont requis pour déterminer la recevabilité de la réclamation au titre de la garantie. La recevabilité de

la réclamation se base sur la date de l’achat d’origine du produit, et non sur la date d’un éventuel remplacement sous garantie.

La garantie est limitée à la réparation ou au remplacement du produit uniquement. L’Acheteur assume les frais de retrait,

d’installation, de transport et tous les frais accessoires.

Pour obtenir des pièces ou de l’aide technique, NE PAS retourner le produit au détaillant. Contacter le service à la clientèle de

SIMER au 1-800-468-7867 / 1-800-546-7867.

Les réclamations au titre de cette garantie doivent être effectuées en retournant le produit (à l’exception des pompes d’eaux

d’égout, voir ci-dessous) au détaillant où il a été acheté, et ce, immédiatement après la découverte de la défaillance supposée.

SIMER prendra les mesures correctives nécessaires dans un délai rapide et raisonnable. Aucune demande de réparation ne sera

acceptée plus de 30 jours après l’expiration de la garantie.

POMPES D’EAUX D’ÉGOUT

NE PAS RETOURNER une pompe d’eaux d’égout (qui a été installée) au détaillant. Communiquer avec le service à la clientèle de

SIMER. Les pompes d’eaux d’égout qui ont été utilisées, puis retirées présentent un risque de contamination.

En cas de défaillance de la pompe d’eaux d’égout :

• Porter des gants en caoutchouc pour manipuler la pompe.

• À des fins de garantie, retourner l’étiquette figurant sur le cordon de la pompe et l’original du reçu au détaillant.

• Mettre la pompe au rebut conformément à la réglementation locale.

Exceptions à la garantie limitée de douze (12) mois

Produit Période de garantie

BW85P, CM10, CMK, M40, M40P 90 jours

2300, 2310, 2330, 2520ULST, 2943, 2955, 2956, 2957, 2960, 5023SS, A5500 2 ans

Pompe pour puits submersibles de 4 pouces, 2945, 2958, 2975PC, 2985, 3075SS, 3983, 3984 3 ans

Réservoir préchargé de système d’eau, 3985, 3986 5 ans

3963, 3988, 3995, 3997 À vie

Modalités et conditions générales

L’Acheteur doit payer tous les frais de main d’œuvre et de transport nécessaires au remplacement du produit garanti couvert par

cette garantie. Cette garantie ne s’applique pas à ce qui suit : (1) Les catastrophes naturelles; (2) Les produits qui, selon SIMER,

ont fait l’objet d’une négligence, d’une utilisation abusive, d’un accident, d’une mauvaise application ou d’une altération; (3) Les

défaillances dues à une installation, une utilisation, un entretien ou un entreposage inappropriés; (4) Une application, une

utilisation ou une réparation atypique ou non approuvée; (5) Les défaillances causées par la corrosion, la rouille ou d’autres

matériaux étrangers au système, ou par une utilisation à une pression supérieure au maximum recommandé.

Cette garantie établit la responsabilité unique de SIMER et le recours exclusif de l’Acheteur en cas de produit défectueux.

SIMER NE POURRA ÊTRE TENUE RESPONSABLE DE TOUT DOMMAGE INDIRECT OU CONSÉCUTIF QUEL QU’IL SOIT.

LES PRÉSENTES GARANTIES SONT EXCLUSIVES ET REMPLACENT TOUTE AUTRE GARANTIE EXPRESSE OU

IMPLICITE, Y COMPRIS, MAIS SANS S’Y LIMITER, CELLE DE QUALITÉ MARCHANDE OU D’APTITUDE DU PRODUIT À UN

EMPLOI PARTICULIER. LES PRÉSENTES GARANTIES NE PEUVENT SE PROLONGER AU-DELÀ DE LA PÉRIODE DE

GARANTIE INDIQUÉE ICI.

Certains États ne permettent pas l’exclusion ou la limitation des dommages indirects ou consécutifs, ni les limitations relatives

à la durée des garanties implicites. Par conséquent, il se peut que les limitations ou les exclusions ci-dessus ne s’appliquent pas.

Cette garantie procure des droits juridiques précis à l’Acheteur. Cependant, il est possible de bénéficier d’autres droits, qui varient

selon l’État.

SIMER • 293 Wright Street • Delavan, WI U.S.A. 53115

Téléphone : 1 800 468-7867 / 1 800 546-7867 • Télécopieur : 1 800 390-5351

Courriel : info@simerpumps.com • Site Web : http://www.simerpumps.com

Page 8

Sécurité / Rendement / Installation 8

LIRE TOUTES CES INSTRUCTIONS

ET LES SUIVRE!

Ce symbole indique qu'il faut être prudent. Lorsque ce sym-

bole apparaît sur la pompe ou dans cette Notice, rechercher une

des mises en garde qui suivent, car elles indiquent un potentiel

possible de blessures corporelles :

avertit d'un danger qui causera des blessures

corporelles, la mort ou des dommages matériels importants si on

l'ignore.

avertit d'un danger qui risque de causer des

blessures corporelles, la mort ou des dommages matériels importants si on l'ignore.

avertit d'un danger qui causera ou qui risquera de

causer des blessures corporelles, la mort ou des dommages

matériels importants si on l'ignore.

Le mot NOTA indique des instructions spéciales et importantes

n'ayant aucun rapport avec les dangers.

Lire attentivement toutes les consignes de sécurité

contenues dans cette Notice ou collées sur la pompe.

Garder les autocollants de sécurité en bon état; les remplacer s'ils

manquent ou s'ils ont été endommagés.

1. Lire attentivement ces règles d’utilisation et instructions. Le nonrespect de ces prescriptions peut entraîner des blessures graves

ou des dommages matériels.

2. Vérifier les codes locaux avant l’installation. Leurs règles

doivent être suivies.

3. Ventiler les eaux usées ou le réservoir septique conformément

aux règles du code local.

4. Ne pas installer la pompe à un endroit classé dangereux par le

Code National de l’électricité, ANSI/NFPA 70-1990.

Tension dangereuse. Risques d’électrocution,

de brûlures ou d’accident mortel. Pendant son

fonctionnement, la pompe est immergée. Pour éviter les chocs

électriques mortels, suivre la procédure suivante si la pompe

nécessite intervention :

Risques de secousses électriques. Risques de

brûlures, voire de mort. Ne pas lever la pompe

par le cordon d’alimentation. Se reporter à «Avertissement - Ne pas

lever la pompe par le cordon» sur la Page 10.

5A. Couper l’alimentation au niveau de la prise de courant avant

de débrancher la pompe.

5B. Exercer la plus grande prudence lors du remplacement des

fusibles.

Éviter de se placer dans l’eau ou de placer le doigt dans le

support du fusible.

5C. Ne modifier le cordon d’alimentation. Lors de l’utilisation du

cordon et du connecteur, ne les enficher que dans une prise

de courant reliée à la terre. Lorsque la connexion se fait vers

le boîtier de commande du système, relier le fil de masse de la

pompe à la prise de terre du système.

6. Ne pas faire fonctionner la pompe à vide. Faire fonctionner

la pompe sans eau risque de la faire surchauffer (et de causer

ainsi des brûlures) et annule la garantie.

7. La pompe chauffe lorsqu’elle fonctionne. Pour éviter les

brûlures lors des interventions sur la pompe, la laisser refroidir

après la mise à l’arrêt pendant 20 minutes avant de la

manipuler.

8. Lors d’une utilisation normale, le moteur ne devrait pas avoir

besoin d’huile ; il a été lubrifié en usine avec une huile

spéciale.

REMARQUE : Cette pompe n’est pas conçue pour pomper de

l’eau salée ni de la saumure! La garantie sera annulée si cette

pompe est utilisée pour pomper de l’eau salée ou de la saumure.

INSTALLATION

REMARQUE : Installer la pompe sur une surface plane et dure

(ciment, asphalte, béton etc.).

Ne jamais poser la pompe à même la terre, sur de l’argile ou du

gravier.

Tuyauterie – applications effluentes

(matières solides de 1,8 cm (3/4 po) ou moins)

Les tuyauteries doivent être d’au moins 3,8 cm (1-1/2 po) de

diamètre pour évacuer le matériau que refoule la pompe. Vérifier

les réglementations locales pour déterminer si votre système

requiert un clapet de non-retour. Dans les régions aux basses

températures, les clapets de non-retour ne sont pas utilisés pour

empêcher l’effluent de geler dans la tuyauterie.

Il est recommandé d’utiliser un clapet de non-retour dans un puisard.

Tuyauterie – réseau d’égouts

(matières solides de 5,1 cm (2 po) ou moins)

Les tuyauteries ne peuvent en aucun cas être de diamètre inférieur

au matériau que refoule la pompe. Lorsqu’elle est installée dans un

réseau d’égouts, il faut que la tuyauterie puisse évacuer des semisolides d’au moins 5,1 cm (2 po) de diamètre.

L’écoulement dans le tuyau d’évacuation doit permettre à tous

solides de demeurer en suspension dans le liquide. Pour assurer

l’écoulement minimum imposé (0,6 m (2 pi) par seconde dans la

canalisation de refoulement), utiliser des tuyauteries des dimensions suivantes :

Un tuyau de diamètre : Assure un écoulement de :

3,8 cm (1-1/2”) 45 LPM (12 GPM)

5,1 cm (2”) 80 LPM (21 GPM)

6,3 cm (2-1/2”) 114 LPM (30 GPM)

7,6 cm (3”) 182 LPM (48 GPM)

Pour obtenir des pièces ou de l’aide, appeler le Service à la clientèle Simer en composant le 1 800 468-7867/1 800 546-7867

RENDEMENT

LPH / Hauteur de refoulment en mètres

Modèle 1,5 3 4,5 5,5

2961 14 763 9 653 3 634 0

Page 9

Électricité / Fonctionnement / Entretien 9

Utiliser un clapet de non-retour de 5,1 cm (2 po) dans le tuyau

d’évacuation pour éviter que le liquide ne refoule dans le bassin

du puisard. Le clapet de non-retour devrait constituer une valve à

écoulement libre laissant passer les solides.

REMARQUE : Pour obtenir les meilleurs rendements possible du

clapet de non retour lorsque l’on pompe des matières solides, ne

pas l’installer sur un tuyau de refoulement dont l’angle d’inclinaison est supérieur à 45 ° par rapport à l’horizontale. Ne pas

installer le clapet de non retour en position verticale, étant donné

que les matières solides risquent de se déposer sur l’obturateur et

empêcher le clapet de non retour de s’ouvrir lors du démarrage de

la pompe.

Forer un trou de 4,7 mm (3/16èmes de pouce) dans le tuyau d’évacuation à une distance de 2,5 à 5,1 cm (1 à 2 po) de la connexion

de refoulement de la pompe (mais en dessous du clapet de nonretour) pour éviter les poches d’air et le blocage de la pompe.

ÉLECTRICITÉ

Tension dangereuse. Risque d’électrocution, de

brûlures ou d’accident mortel. Lors de l’installa-

tion, du fonctionnement de la pompe ou lors d’une intervention

sur la pompe, suivre scrupuleusement les instructions ci-dessous :

1. NE PAS épisser le cordon d’alimentation.

2. NE PAS immerger le connecteur du cordon d’alimentation.

3. NE PAS utiliser de rallonges. Elles constituent un danger

d’incendie et peuvent réduire la tension de manière suffisante

pour empêcher le pompage ou endommager la pompe.

4. NE PAS manipuler la pompe ou intervenir sur la pompe lorsqu’elle est branchée.

5. NE PAS retirer la broche de mise à la masse du connecteur ou

modifier celui-ci. Pour assurer la protection contre l’électrocution, le cordon d’alimentation est un conducteur à trois fils et

comporte un connecteur à trois broches avec prise de terre.

Brancher la pompe dans une prise à 3 fils, raccordée à la

masse. Connecter la pompe en accord avec les codes électriques en vigueur.

Pour le fonctionnement automatique, brancher le connecteur de la

pompe ou brancher ses fils directement à un interrupteur automatique à flotteur ou à un boîtier de commande en pompe. La

pompe fonctionnera de façon permanente lorsqu’elle sera reliée à

une prise de courant. Brancher le connecteur ou directement les

fils de la pompe sur circuit de dérivation individuel spécifique,

libre de tout autre équipement ou prise de courant. Déterminer le

calibre des fusibles ou des disjoncteurs conformément au tableau

de calibre des fusibles à droite.

Risque d’incendie ou d’explosion pouvant

causer de graves blessures, des dommages matériels, voire la

mort. Le moteur n’est pas anti-étincelant. Ne pas le faire fonction-

ner dans des atmosphères explosives. S’assurer que les informations relatives à l’alimentation (tension/ fréquence en Hertz/phase)

sur la plaquette d’identification de la pompe correspondent exactement à l’alimentation disponible. Installer la pompe en accord

avec les codes électriques en vigueur.

TABLEAU DE CALIBRE DES FUSIBLES

Circuit de

dérivation Ampérage

individuel de fusibles

requis temporisés

Modèle CV Tension (en ampères) bicomposants

2961 4/10 115 15 10

FONCTIONNEMENT ET

INSTALLATION

REMARQUE : Ne pas faire fonctionner la pompe dans un puisard

sec. La garantie sera annulée et la pompe pourra être endommagée.

Une protection automatique contre les surcharges empêche le mo-

teur de brûler suite à une surchauffe/surcharge. Lorsque le moteur se

sera refroidi, le dispositif de protection contre les surcharges (le disjoncteur) se réinitialisera automatiquement et relancera le moteur.

Si le moteur disjoncte fréquemment, en rechercher la cause. Il peut

s’agir d’un démarreur coincé, d’une tension incorrecte ou trop faible, ou d’une panne électrique à l’intérieur du moteur. Dans ce

dernier cas, il faut avoir recours à l’intervention d’un spécialiste.

La pompe a été lubrifiée en usine. Aucun huilage ou graissage

n’est nécessaire.

GÉNÉRALITÉS

Tension dangereuse. Risque d’électrocution, de

brûlures ou d’accident mortel. Avant de retirer la pompe du bassin

pour une intervention, déconnecter

l’alimentation de la pompe et du boîtier de commande.

Risques de secousses électriques. Risques de

brûlures, voire de mort.

Ne pas lever la pompe par le cordon d’alimentation.

Immerger la pompe dans une solution désinfectante (chlorox ou

solution chlorée) pendant une heure minimum avant de la démonter.

Le moteur de la pompe contient une huile spéciale qui doit être gar-

dée propre en permanence et ne pas entrer en contact avec de l’eau.

Pour obtenir des pièces ou de l’aide, appeler le Service à la clientèle Simer en composant le 1 800 468-7867/1 800 546-7867

Page 10

Localisation des pannes 10

Pour obtenir des pièces ou de l’aide, appeler le Service à la clientèle Simer en composant le 1 800 468-7867/1 800 546-7867

A. La pompe ne

fonctionne pas

:

B. La pompe ne vide pas le

puisard :

C. La pompe ne s’arrête pas

de fonctionner :

Possibilités de démarrages soudains, ce qui

risque de causer des secousses électriques. On risque aussi de se

pincer les doigts ou les mains. Si la pompe est alimentée en

courant lorsque le dispositif de protection thermique contre les

surcharges se réenclenche, la pompe peut démarrer inopinément.

Avant d’intervenir sur la pompe, toujours couper le courant qui

l’alimente.

1. Vérifier si le cordon est bien enfoncé dans la prise de courant. Déconnecter

l’alimentation de la prise de courant avant de manipuler la pompe ou le moteur.

2. Vérifier si la tension est bien présente.

3. Vérifier si le niveau du liquide est suffisamment haut pour activer le contact ou la

commande.

4. Vérifier si le trou de ventilation de 4,7 mm (3/16èmes de pouce) du tuyau

d’évacuation n’est pas bouché.

5. Vérifier un blocage de la crépine d’entrée, du rotor, du clapet de non-retour ou du

tuyau d’évacuation.

6. Le disjoncteur de surcharge thermique a peut-être fonctionné. Vérifier le démarrage

de la pompe : si la pompe démarre et s’arrête aussitôt, la déconnecter de la source

d’alimentation pendant 30 minutes pour permettre au moteur de refroidir, puis

rebrancher l’alimentation. Rechercher la cause de la surchauffe/de la surcharge.

1. Vérifier si toutes les valves de la valve de refoulement sont com plètement ouvertes.

2. Nettoyer le tuyau d’évacuation et vérifier la valve.

3. Vérifier si la crépine d’entrée ou le rotor ne sont pas bloqués.

4. La capacité de la pompe ne convient pas. Il est peut-être nécessaire d’installer une

pompe de plus grande capacité.

1. Vérifier le fonctionnement et l’emplacement des contacts ou de la commande

automatique du flotteur. Consulter les instructions d’installation pour le contact/la

commande.

2. Si la pompe est com plètement hors fonctionnement ou continue à mal fonctionner,

consulter le réparateur local.

1. Les connexions et le cordon électrique de la

pompe seront endommagés si on essaye de

lever ou de supporter la pompe par son

cordon.

2. Le cordon peut se débrancher et des fils nus

peuvent être exposés, ce qui peut présenter

le risque d’un incendie ou de subir des secousses électriques.

3. La garantie sera annulée si on lève ou supporte la pompe par son cordon électrique.

4. Pour lever ou abaisser la pompe, toujours

utiliser son anneau ou sa poignée de levage

qui se trouve dessus. Avant d’intervenir sur

la pompe ou avant de la sortir du puisard,

couper le courant qui l’alimente.

1476 0195

Risque de secousses électriques, de brûlures, ou de

mort. Ne pas lever la pompe

par son cordon électrique.

AVERTISSEMENT

AVERTISSEMENT CONCERNANT LE LEVAGE PAR LE CORDON ÉLECTRIQUE

Page 11

Liste des pièces de rechange 11

Pour obtenir des pièces ou de l’aide, appeler le Service à la clientèle Simer en composant le 1 800 468-7867/1 800 546-7867

Réf. Désignation

2961

No. des pièces Qté 115 Volts

1 Cordon d’alimentation 1 PS117-54-TSE

2 Volute supérieure 1 PW1-10P

3 Rotor 1 PW5-15P

4 Volute inférieure 1 PW1-11P

5 Contact-flotteur autom. 1 PS117-144P

4

3

2

1

5

664 0997 SIM

LISTE DES PIÈCES DE RECHANGE

SI LE MOTEUR TOMBE EN PANNE,

REMPLACER LA POMPE.

Page 12

Garantía 12

GUARDE EL RECIBO ORIGINAL PARA CULAQUIER REFERENCIA POSTERIOR.

GARANTÍA LIMITADA

SIMER le garantiza al comprador consumidor original (el “Comprador” o “Usted”) de sus productos, que éstos estarán libres de

defectos en materiales y en mano de obra por un período de doce (12) meses, a partir de la fecha de la compra original del

consumidor.

Si dentro de los doce (12) meses a partir de la fecha de la compra inicial del consumidor, se comprueba que cualquiera de esos

productos es defectuoso, éste será reparado o reemplazado, a la discreción de SIMER, sujeto a los términos y a las condiciones

indicadas a continuación. Se necesitará su recibo de compra original y la etiqueta de información sobre la garantía del producto,

para determinar la admisibilidad de la garantía. La admisibilidad se basa en la fecha de compra del producto original - no en la

fecha de reemplazo bajo la garantía. La garantía está limitada a la reparación o el reemplazo del producto solamente - El comprador

pagará todos los costos de remoción, instalación, mano de obra y envío necesarios, así como todo costo adicional asociado.

Si necesita piezas o resolución de problemas, NO regrese el producto a la tienda minorista. Llame el Servicio a la Clientela de

SIMER al 1-800-468-7867 / 1-800-546-7867.

Las reclamaciones bajo esta garantía se deberán realizar mediante la devolución del producto (excepto en el caso de las bombas

cloacales, ver a continuación) a la tienda minorista en donde se haya adquirido, inmediatamente después de haber descubierto

un supuesto defecto. SIMER entonces tomará la medida correctiva tan pronto como sea razonablemente posible. No se

aceptarán solicitudes de servicio, si se reciben más de 30 días después del vencimiento de esta garantía.

BOMBAS CLOACALES

NO devuelva una bomba cloacal (que se haya instalado) a su tienda minorista. Comuníquese con el Departamento de Atención

al Cliente de SIMER. Las bombas cloacales que hayan estado en servicio y se hayan removido pueden representar un peligro de

contaminación.

Si su bomba cloacal ha fallado:

• Use guantes de caucho cuando manipule la bomba;

• Para los fines de la garantía, devuelva la etiqueta del cordón de la bomba y el recibo de compra original a la tienda minorista;

• Descarte la bomba cumpliendo con todas las normas locales que correspondan para su eliminación.

Excepciones para la Garantía Limitada de Doce (12) Meses

Producto Período de garantía

BW85P, CM10, CMK, M40, M40P 90 días

2300, 2310, 2330, 2520ULST, 2943, 2955, 2956, 2957, 2960, 5023SS, A5500 2 años

Bombas de pozo sumergibles de 4”, 2945, 2958, 2975PC, 2985, 3075SS, 3983, 3984 3 años

Tanque precargado del sistema de agua, 3985, 3986 5 años

3963, 3988, 3995, 3997 De por vida

Términos y condiciones generales

Usted deberá pagar por todos los gastos de mano de obra y de envío necesarios para reemplazar el producto cubierto por esta

garantía. Esta garantía no se aplicará en las siguientes situaciones: (1) caso de fuerza mayor (2) productos que, a sólo juicio de

SIMER hayan sido sometidos a negligencia, abuso, accidente, mala aplicación, manejo indebido o alteraciones; (3) fallas debido a

instalación, operación, mantenimiento o almacenamiento inadecuados; (4) aplicaciones, usos o servicios que no sean normales o

aprobados; (5) fallas provocadas por corrosión, herrumbre u otros materiales extraños en el sistema, o una operación a presiones

que excedan los máximos recomendados.

Esta garantía establece la única obligación de SIMER y el recurso exclusivo del Comprador con respecto a los productos

defectuosos.

SIMER NO SE HARÁ RESPONSABLE DE NINGÚN DAÑO CONSECUENTE, INCIDENTAL O CONTINGENTE.

LAS GARANTÍAS QUE ANTECEDEN SON EXCLUSIVAS Y REEMPLAZAN TODA OTRA GARANTÍA EXPLÍCITA O IMPLÍCITA,

INCLUYENDO PERO SIN LIMITARSE A LAS GARANTÍAS IMPLÍCITAS DE COMERCIABILIDAD E IDONEIDAD PARA UN FIN

ESPECÍFICO. LAS GARANTÍAS QUE ANTECEDEN NO SE EXTENDERÁN MÁS ALLÁ DE LA DURACIÓN PROVISTA EN LA

PRESENTE.

Algunos Estados no permiten la exclusión o limitación de daños incidentales o consecuentes o de limitaciones de tiempo sobre

garantías implícitas, de modo que es posible que las limitaciones o exclusiones que preceden no correspondan en su caso. Esta

garantía le otorga derechos legales específicos y es posible que Usted también tenga otros derechos que pueden variar de un

Estado al otro.

SIMER • 293 Wright Street • Delavan, WI U.S.A. 53115

Teléfono: 1-800-468-7867 / 1-800-546-7867 • Fax: 1-800-390-5351

E-Mail: info@simerpumps.com • Sitio Web: http://www.simerpumps.com

Page 13

Instructions de seguridad / Rendimiento / Instalación 13

LEA Y SIGA LAS INSTRUCCIONES

DE SEGURIDAD!

Este es el símbolo de alerta de seguridad. Cuando usted vea

este símbolo en su bomba o en este manual, busque alguna de las

siguientes palabras de advertencia y esté alerta a la posibilidad de

una herida personal:

advierte acerca de los peligros que ocasionarán

lesiones personales serias, la muerte o un daño severo a la

propiedad si se ignoran dichos peligros.

advierte acerca de los peligros que

pueden ocasionar lesiones personales serias, la muerte o un daño

severo a la propiedad si se ignoran dichos peligros.

advierte acerca de los peligros que

ocasionarán o podrán ocasionar lesiones personales menores o

daños a la propiedad si se ignoran dichos peligros.

La etiqueta AVISO indica instrucciones especiales que son

importantes pero no relacionados a los peligros.

Lea y siga cuidadosamente todas las instrucciones de seguridad en

este manual y en la bomba.

Mantenga las etiquetas de seguridad en buenas condiciones.

Reemplace las etiquetas de seguridad faltantes o dañadas.

1. Lea cuidadosamente estas reglas e instrucciones. Su omisión

podría provocar graves lesiones y/o daños materiales.

2. Verifique los códigos del lugar de la instalación antes de

realizarla. Debe usted respetar estas normas.

3. Instale un sistema de ventilación en el tanque de aguas cloacales o en el tanque séptico de acuerdo con los códigos

locales.

4. No instale la bomba en ningún lugar que el Código Nacional

de Electricidad, ANSI/NFPA 70-1990, clasifique como peligroso.

Voltaje peligroso, puede ser causa de

descargas eléctricas, quemaduras o muerte.

Riesgo de choque eléctrico. Puede pro-

ducir quemaduras o la muerte. No levante la bomba por el

cordón. Ver “Advertencia de no levantar la bomba por el cordón”

en la Pagina 15.

Durante el funcionamiento la bomba está sumergida en agua; para

evitar descargas fatales proceda del siguiente modo si es necesario

prestar servicio a la bomba:

5A. Corte la corriente eléctrica en la caja de conexiones antes de

desconectar el enchufe de la bomba.

5B. Proceda con sumo cuidado al cambiar los fusibles. No trabaje

con los pies en el agua ni introduzca sus dedos en el zócalo

del fusible.

5C. No modifique el cable y el enchufe. Si usa cable con enchufe

utilice sólo una toma con conexión a masa. Si conecta a un

sistema de control, ponga a tierra el cable conector de tierra

de la bomba.

6. No haga funcionar la bomba en seco. El funcionamiento en

seco sobrecalienta la bomba (puede causar quemaduras a

quien la manipule). El sobrecalentamiento invalida la garantía.

7. Las bombas funcionan normalmente en caliente. Para evitar

quemaduras al prestar servicios a la bomba déjela enfriar 20

minutos después de desconectarla y antes de manipularla.

8. En servicio normal, no es necesario aceitar el motor. El motor

ha sido lubricado en fábrica con aceite especial. Al hacer una

reparación, reemplace este aceite por aceite nuevo.

AVISO: Esta unidad no ha sido diseñada para uso con agua salada

o salubre. El uso con agua salada o salubre anulará la garantía.

INSTALACIÓN

AVISO: Instale la bomba sobre una superficie dura y nivelada (de

cemento, asfalto, etc.) Jamás instale la bomba directamente sobre

superficies de tierra, arcilla o grava.

TuberÍa – efluentes (Sólidos de 3/4 de pulgada

o menos)

La tubería debe medir un mínimo de 1 - 1/2 pulgadas para transportar el volumen de descarga de la bomba. Compruebe los códigos locales para determinar si su sistema requiere una válvula de

retención. En climas fríos, las válvulas de retención no se utilizan

para evitar la congelación del efluente en la tubería.

Si utiliza una bomba de sumidero, se recomienda el uso de una

válvula de retención.

Tubería – residuos cloacales (Sólidos de

2 pulgadas o menos)

En todos los casos el diámetro de la tubería debe ser inferior al de

la descarga de la bomba. Cuando se instale en un sistema cloacal,

la tubería debe ser capaz de conducir semisólidos de por lo menos

2 pulg. (5,1 cm) de diámetro.

La velocidad del flujo en la tubería de descarga debe poder mantener los sólidos en suspensión en el líquido. Para mantener el

caudal mínimo necesario (velocidad de 2 pies o 0,6 m por segundo en el caño de descarga) el tamaño del tubo debe ajustarse a los

valores de la siguiente tabla:

Un tubo de un diámetro de: Admite un caudal de:

3,8 cm (1-1/2") 45 LPM (12 GPM)

5,1 cm (2") 80 LPM (21 GPM)

6,3 cm (2-1/2") 114 LPM (30 GPM)

7,6 cm (3") 182 LPM (48 GPM)

ADVERTENCIA

ADVERTENCIA

PRECAUCIÓN

ADVERTENCIA

Si necesita repuestos o asistencia llame al Servicio al Cliente de Simer, 1-800-468-7867/1-800-546-7867

RENDIMENTO

(LPH - Litros Por Hora) Por Total de Metros (M)

Modelo 1,5 3 4,5 5,5

2961 14 763 9 653 3 634 0

Page 14

Éléctrica / Operación / Servico 14

Use una válvula de retención de charnela de 2 pulgadas en la

descarga de la bomba para impedir el retorno del líquido al sumidero. La válvula de retención debe ser de flujo libre para permitir

que los sólidos pasen con facilidad.

AVISO: Para obtener el mejor desempeño de la válvula de retención cuando se manejen partículas sólidas, no la instale con la

tubería de descarga a un ángulo mayor que 45 grados por encima

de la horizontal. No instale la válvula de retención en posición

vertical ya que las partículas sólidas podrán depositarse en la

misma e impedir que la válvula de retención se abra cuando se

active la bomba.

Perfore un agujero de 3/16 pulgadas (4,7 mm) en el tubo de

descarga a una distancia de 1 a 2 pulgadas (2,5 a 5,1 cm) por

encima de la conexión de descarga de la bomba (pero por debajo

de la válvula de retención) para impedir el bloqueo por aire de

la bomba.

INSTALACIÓN ELÉCTRICA

Voltaje peligroso, puede ser causa de

descargas eléctricas, quemaduras o muerte. Al instalar, operar o

prestar servicios a esta bomba, respete las instrucciones de seguridad enumeradas a continuación:

1. NO utilice cable con empalmes para la alimentación eléctrica.

2. NO permita que el enchufe del cordón eléctrico quede

sumergido.

3. NO use cables de prolongación. Presentan riesgo de incendio

y pueden reducir el voltaje lo suficiente como para impedir el

bombeo, dañar el motor o ambas cosas.

4. NO manipule o preste servicios a la bomba mientras esté

conectada a la corriente eléctrica.

5. NO saque la clavija (ficha) de puesta a tierra ni modifique el

enchufe. Para protección contra la descarga eléctrica el cable

de alimentación está constituido por un conductor de tres

alambres y termina en un enchufe de tres pernos con puesta a

tierra. Enchufe la bomba en un receptáculo de toma de tres

alambres del tipo de puesta a tierra, con la tierra conectada.

Conecte la bomba respetando los códigos de electricidad que

corresponda.

Para el funcionamiento automático, enchufe o conecte la bomba a

un interruptor automático de flotante o a un controlador la bomba.

Si la bomba se conecta directamente a una toma eléctrica, funcionará en forma continua. La bomba debe conectarse a su propio

un ramal individual y no deben colocarse otras tomas o equipo en

ese circuito. Determine el calibre de fusible o de disyuntor interruptor basándose en la tabla de calibres de fusible que se encuentra a la derecha.

Peligro de incendio y de explosión.

Puede causar lesiones graves, daños materiales o muerte. El motor

no es a prueba de inflamación. No se debe usar en atmósferas

explosivas. Asegúrese de que la información sobre la corriente

eléctrica (voltaje, frecuencia y número de fases) inscrita en la

chapa del motor de la bomba corresponde exactamente a la de la

corriente eléctrica utilizada. Instale la bomba en conformidad con

todos los códigos de electricidad que corresponda.

TABLA DE CALIBRES DE FUSIBLE

Amperios con

Requiere fusibles de

un ramal dos telementos

individual y retardo

Modelo HP Voltaje (amperios) de tiempo

2961 4/10 115 15 10

OPERACIÓN E INSTALACIÓN

AVISO: No permita que la bomba funcione en un sumidero seco.

Si lo hace, invalidará la garantía y podrá dañar la bomba.

El uso de un protector automático de sobrecarga en el motor lo

protegerá contra el sobrecalentamiento o la sobrecarga e impedirá

que éste se queme. Cuando el motor se enfría el protector de

sobrecarga se reconecta automáticamente y permite el arranque

del motor.

Si el protector de sobrecarga funciona con excesiva frecuencia,

investigue los motivos. La sobrecarga podría deberse a un rodete

trabado, al uso de voltaje erróneo o reducido o a una falla eléctrica en el motor. Si se sospecha que el motor tiene una falla eléctrica, hágalo revisar por personal de servicio competente.

La bomba está lubricada permanentemente y no requiere ser

aceitada o engrasada.

GENERALIDADES

Voltaje peligroso, puede ser causa de

descargas eléctricas, quemaduras o muerte. Antes de retirar la

bomba del sumidero para prestarle servicio, desconecte la corriente eléctrica a la bomba y al interruptor de control.

Riesgo de choque eléctrico. Puede

producir quemaduras o la muerte. No levante la bomba por

el cordón.

Sumerja la bomba en una solución desinfectante de agua clorada

(Clorox, agua lavandina, agua de Javel, etc.) por lo menos durante

una hora antes de desarmar la bomba. El motor de la bomba

contiene un aceite lubricante especial que debe mantenerse limpio

y libre de agua.

ADVERTENCIA

ADVERTENCIA

ADVERTENCIA

ADVERTENCIA

Si necesita repuestos o asistencia llame al Servicio al Cliente de Simer, 1-800-468-7867/1-800-546-7867

Page 15

Guía para la resolución de problemas 15

Si necesita repuestos o asistencia llame al Servicio al Cliente de Simer, 1-800-468-7867/1-800-546-7867

A. La bomba no funciona:

B. La bomba no vacía el

sumidero:

C. La bomba no se apaga:

Riesgo de arranques repentinos. Puede

provocar choques eléctricos o apretar los dedos o las manos.

Si la bomba está conectada cuando el dispositivo de sobrecarga

térmica se reposiciona, ésta podrá activarse sin advertencia

previa. Desconecte la corriente antes de realizar trabajos de

mantenimiento o servicio en la bomba.

ADVERTENCIA

1. Verifique que el cable de alimentación esté enchufado correctamente en el receptáculo.

Antes de manipular la bomba o el motor, desconecte la energía eléctrica.

2. Asegúrese de que haya corriente eléctrica.

3. Verifique que el nivel de líquido sea lo suficientemente elevado para activar el

interruptor o el control.

4. Verifique que el agujero de 3/16 pulgadas (4,17 mm) en el caño de descarga no esté

tapado.

5. Verifique que la entrada de la bomba, el rodete, la válvula de retención o el caño de

descarga no estén bloqueados.

6. Es posible que el protector térmico de sobrecarga haya accionado. Haga arrancar la

bomba; si arranca y se detiene de inmediato desconecte la bomba de la corriente

eléctrica por 30 minutos para permitir que el motor se enfríe; luego vuelva a conectarla

a la corriente eléctrica. Investigue la causa del sobrecalentamiento o sobrecarga.

1. Asegúrese de que todas las válvulas en la tubería de descarga estén totalmente abiertas.

2. Limpie el caño de descarga y verifique la válvula.

3. Verifique que la entrada de la bomba o el rodete no estén bloqueados.

4. Quizás la bomba no tenga el tamaño correcto y es posible que se requiera una bomba

de mayor capacidad.

1. Verifique que los flotantes del interruptor o el control automático funcionen

correctamente y tengan la ubicación adecuada. Consulte las instrucciones de instalación

del interruptor o control automático.

2. Si la bomba no funciona en absoluto o continúa funcionando con fallas, consulte al

personal de servicio de su localidad.

1. Se puede dañar el cordón y sus conexiones si se trata de levantar o de sostener

la bomba por medio del cordón eléctrico.

2. El cordón se puede abrir, dejando los hilos

expuestos y creando la posibilidad de

incendio o de choque eléctrico.

3. Si la bomba se levanta o se sostiene por

medio del cordón eléctrico, la garantía

quedará anulada.

4. Use el aro o mango que se encuentra en

la parte superior de la bomba para levantar o bajar la bomba. Desconecte la corriente eléctrica a la bomba antes de realizar

trabajos en la misma o de tratar de sacar

la bomba del sumidero.

1476 0195

Riesgo de choque eléctrico. Puede quemar o

matar. No levante la

bomba por medio del

cordón eléctrico.

ADVERTENCIA

ADVERTENCIA SOBRE EL LEVANTAMIENTO POR MEDIO DEL CORDÓN

Page 16

Liste de piezas de repuesto 16

Si necesita repuestos o asistencia llame al Servicio al Cliente de Simer, 1-800-468-7867/1-800-546-7867

Descripción

2961

Réf. de piezas Cantidad 115 Voltios

1 Cable de alimentación 1 PS117-54-TSE

2 Voluta superior 1 PW1-10P

3 Rodete 1 PW5-15P

4 Voluta inferior 1 PW1-11P

5 Interruptor automático

de flotador 1 PS117-144P

4

3

2

1

5

664 0997 SIM

LISTA DE PIEZAS DE REPUESTO

SI EL MOTOR FALLA, REEMPLACE LA BOMBA.

Loading...

Loading...