Page 1

MOD. 2825ss

OWNER’S MANUAL

Portable Utility/Sprinkler Pump

NOTICE D’UTILISATION

Pompe portable tout

usage et pour l’arrosage

MANUAL DEL USUARIO

Bomba portátil

rociadora / para uso general

Installation/Operation/Parts

For further operating, installation,

or maintenance assistance:

Call 1-800-468-7867

English . . . . . . . . . . . . . . . Pages 2-7

Installation/Fonctionnement/Pièces

Pour plus de renseignements

concernant l’utilisation,

l’installation ou l’entretien,

Composer le

1 (800) 468-7867

Français . . . . . . . . . . . . Pages 8-13

Instalación/Operación/Piezas

Para mayor información sobre el

funcionamiento, instalación o

mantenimiento de la bomba:

Llame al 1-800-468-7867

Español . . . . . . . . . . .Paginas 14-19

©2005 SIM590 (Rev. 9/13/05)

293 Wright St., Delavan, WI 53115

Phone:

1-800-468-7867

1-800-546-7867

Fax:

1-800-390-5351

Web Site:

http://www.simerpump.com

Page 2

Safety 2

For parts or assistance, call Simer Customer Service at 1-800-468-7867 / 1-800-546-7867

READ AND FOLLOW

SAFETY INSTRUCTIONS!

This is the safety alert symbol. When you see this

symbol on your pump or in this manual, look for

one of the following signal words and be alert to the

potential for personal injury.

warns about hazards that will cause serious

personal injury, death or major property damage if

ignored.

warns about hazards that can cause serious

personal injury, death or major property damage if

ignored.

warns about hazards that will or can cause

minor personal injury or property damage if ignored.

The label NOTICE indicates special instructions which

are important but not related to hazards.

Carefully read and follow all safety instructions in this

manual and on pump.

Keep safety labels in good condition.

Replace missing or damaged safety labels.

GENERAL SAFETY

1. To avoid risk of serious bodily injury and property

damage, read the safety instructions carefully before

installing this pump.

2. Follow local and/or national plumbing and electrical

codes when installing the pump.

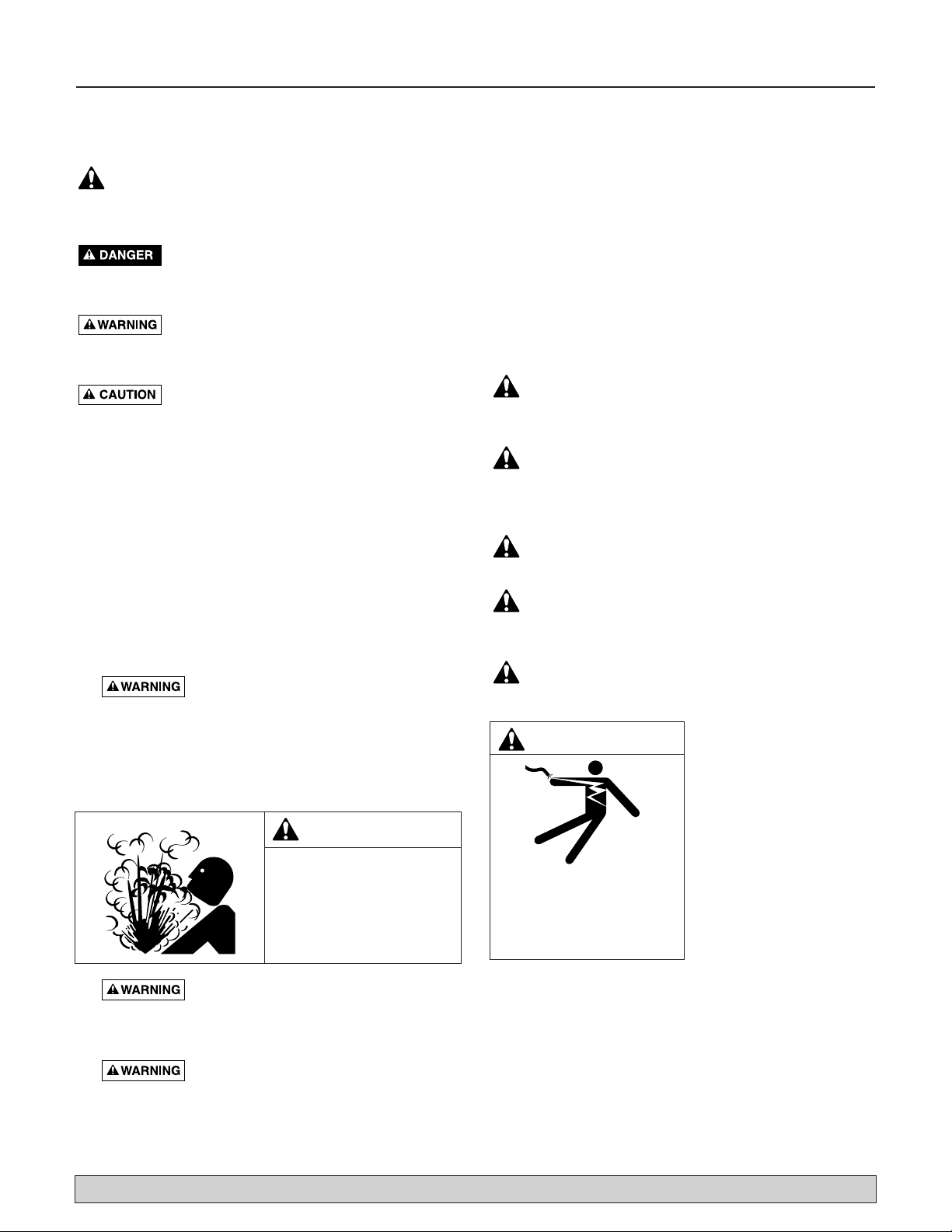

3. Hazardous Pressure. The pump body

may explode if used as a booster pump unless a

relief valve capable of passing the full pump flow at

60 PSI (414 kPa) is installed. Never run the pump

dry. To do so can damage internal parts, overheat

pump (which can cause burns to people handling or

servicing pump), and will void warranty!

4. Risk of fire or explosion. To avoid risk

of fire and explosion, Pump Water Only with this

pump. Do not use this pump in an atmosphere that

might contain flammable fumes or vapors.

5. Burn Hazard. If water is trapped in the

pump during operation it may turn to steam.

Trapped steam can lead to explosion and burns.

Never run the pump with the outlet closed or

obstructed.

6. If used with a well for potable water, always disinfect

the well and test the water for purity before using.

Check with your local health department for testing

procedures.

7. Complete pump and piping must be protected against

freezing. Freezing will cause damage and void the

warranty.

8. This pump is not designed, nor intended, for the

pumping of chemicals or corrosive liquids. Pump

water only with this pump.

9. Do not run pump dry. If the pump is dry, damage will

result and void the warranty.

ELECTRICAL SAFETY

The pump is supplied with a 3-conductor grounding type cord. Connect only to a properly ground-

ed, GFCI protected outlet. Do not lift the pump by the

electrical cord.

Match the motor voltage and the power supply

voltage. The supply voltage must be within +/- 10%

of the motor nameplate voltage. Incorrect voltage can

cause fire or seriously damage the motor and will void

the warranty. If in doubt, consult a licensed electrician.

The pump is non-submersible. Keep the motor dry

at all times. Do not wash the motor. Do not

immerse. Protect the motor from wet weather.

If using an extension cord, use only a UL approved

indoor/outdoor, 3-wire, grounding type cord. Do

not allow any part of the cord or the receptacle ends to

sit in water or in damp locations.

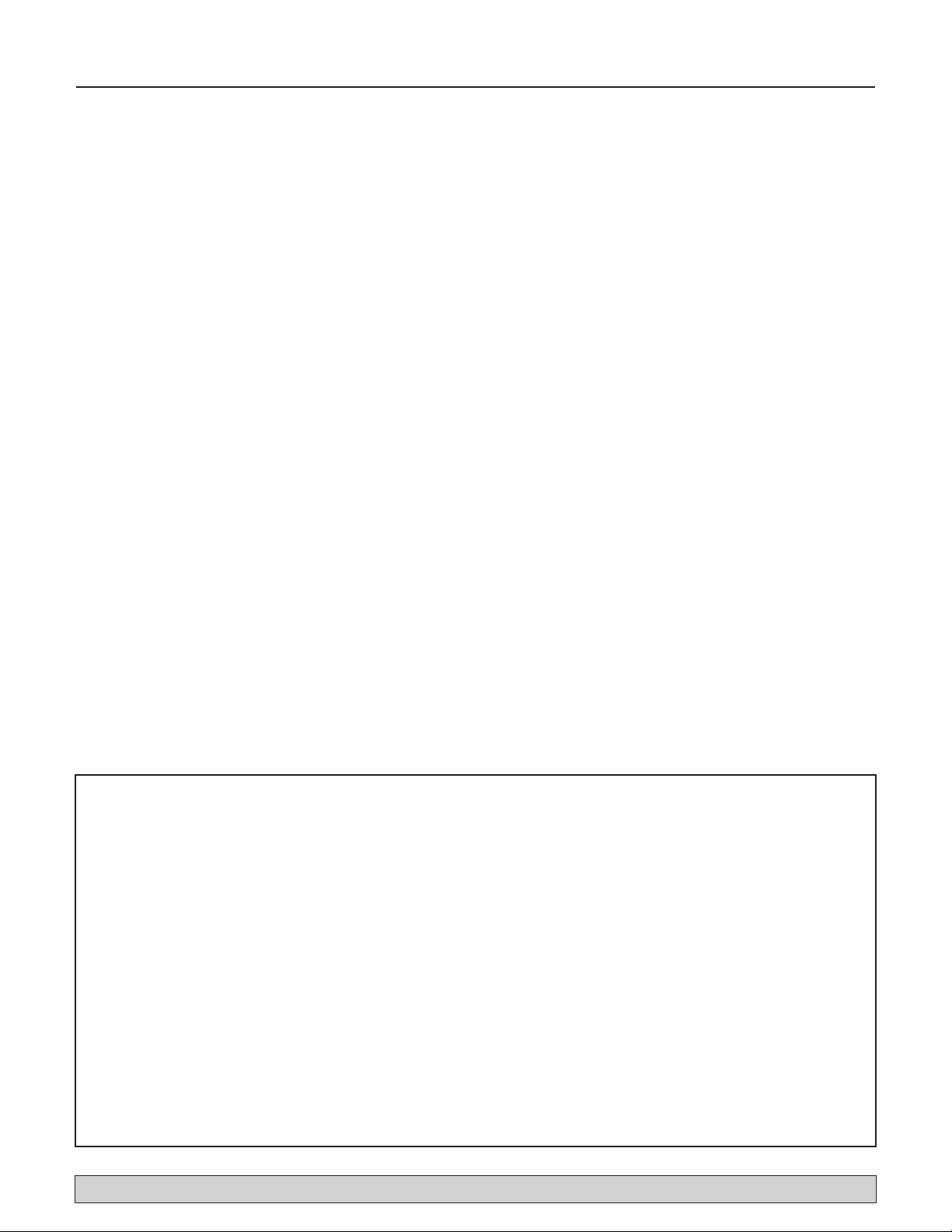

Unplug the pump before servicing. To avoid fatal

shocks, proceed as follows if the pump needs

servicing.

A. Disconnect the power

to the pump outlet box

before pulling the

pump plug. Modern

motors are designed

to operate at high

temperatures. To avoid

burns when servicing

pump, allow it to cool

for 20 minutes after

shut-down before

handling.

B. Take extreme care

when changing fuses.

To reduce the chance of

fatal electrical shocks, DO NOT stand in water or put

your finger in the fuse socket.

C. Ground the pressure switch or motor before before

running this pump.

D. Plug pump into a Ground Fault Circuit Interrupter

(GFCI) protected grounded outlet only.

WARNING

Hazardous voltage. Can

shock, burn, or cause death.

Ground pump before connecting

to power supply. Disconnect

power before working on pump,

motor or tank.

WARNING

Hazardous pressure!

Install pressure relief

valve in discharge pipe.

Release all pressure on

system before working on

any component.

Page 3

Table of Contents 3

Page

General Safety .....................................................................................................2

Warranty..............................................................................................................3

Installation ......................................................................................................4, 5

Operation ........................................................................................................5, 6

Troubleshooting ...................................................................................................6

Repair Parts .........................................................................................................7

For parts or assistance, call Simer Customer Service at 1-800-468-7867 / 1-800-546-7867

SIMER warrants to the original consumer purchaser (“Purchaser”) of its products

that they are free from defects in material or workmanship.

If within twelve (12) months from the date of the original consumer purchase

any such product shall prove to be defective, it shall be repaired or replaced at

SIMER’s option, subject to the terms and conditions set forth below. Your original receipt of purchase is required to determine warranty eligibility.

Exceptions to the Twelve (12) Month Warranty

Five (5) Year Warranty:

If within five (5) years from original consumer purchase any Pre-Charge water

system tank shall prove to be defective, it shall be repaired or replaced at

SIMER’s option, subject to the terms and conditions set forth below.

General Terms and Conditions

Purchaser must pay all labor and shipping charges necessary to replace product

covered by this warranty. This warranty shall not apply to acts of God, nor shall

it apply to products which, in the sole judgement of SIMER, have been subject

to negligence, abuse, accident, misapplication, tampering, alteration; nor due

to improper installation, operation, maintenance or storage; nor to other than

normal application, use or service, including but not limited to, operational failures caused by corrosion, rust or other foreign materials in the system, or operation at pressures in excess of recommended maximums.

Requests for service under this warranty shall be made by returning the defective product to the Retail outlet or to SIMER as soon as possible after the discovery of any alleged defect. SIMER will subsequently take corrective action as

promptly as reasonably possible. No requests for service under this warranty

will be accepted if received more than 30 days after the term of the warranty.

This warranty sets forth SIMER’s sole obligation and purchaser’s exclusive remedy for defective products.

SIMER SHALL NOT BE LIABLE FOR ANY CONSEQUENTIAL, INCIDENTAL, OR

CONTINGENT DAMAGES WHATSOEVER.

THE FOREGOING WARRANTIES ARE EXCLUSIVE AND IN LIEU OF ALL

OTHER EXPRESS WARRANTIES. IMPLIED WARRANTIES, INCLUDING BUT

NOT LIMITED TO THE IMPLIED WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE, SHALL NOT EXTEND BEYOND THE

DURATION OF THE APPLICABLE EXPRESS WARRANTIES PROVIDED HEREIN.

Some states do not allow the exclusion or limitation of incidental or consequential damages or limitations on how long an implied warranty lasts, so the

above limitations or exclusions may not apply to you. This warranty gives you

specific legal rights and you may also have other rights which vary from state

to state.

Simer Limited Warranty

SIMER • 293 Wright St. • Delavan, WI U.S.A. 53115

Phone: 1-800-468-7867 / 1-800-546-7867 • Fax: 1-800-390-5351

Page 4

For parts or assistance, call Simer Customer Service at 1-800-468-7867 / 1-800-546-7867

Installation 4

SPECIFICATIONS

Power Supply Required. ...................................115 Volts

Motor Duty ...................................................Continuous

Circuit Requirement (minimum) .....................15.0 Amps

Discharge Adapter .......................................................1"

SHALLOW WELL JET PUMP

INSTALLATIONS:

• Have a vertical depth of 25’ or less.

• Have one pipe from the well to the pump case.

• Can be installed in a bored or drilled well, or in a

driven well.

REPLACING AN OLD PUMP

Hazardous voltage. Can shock, burn or

kill. Disconnect power to pump before working on

pump or motor.

This pump can replace shallow well jet pump, Model

3825. This will require reusing the pressure switch and

wiring the pump to the switch.

1. Drain and remove the old pump. Check the old pipe

for scale, lime, rust, etc., and replace it if necessary.

2. Install the pump in the system. Make sure that all

pipe joints in the suction pipe are air-tight as well as

water tight.

If the suction pipe can suck air, the

pump will not be able to pull water from the well.

3. Adjust the pump mounting height so that the plumbing connections do not put a strain on the pump

body. Support the pipe so that the pump body does

not take the weight of piping or fittings.

This completes the well plumbing for your new shallow well jet pump. Please go to Page 6 for

discharge pipe and tank connections.

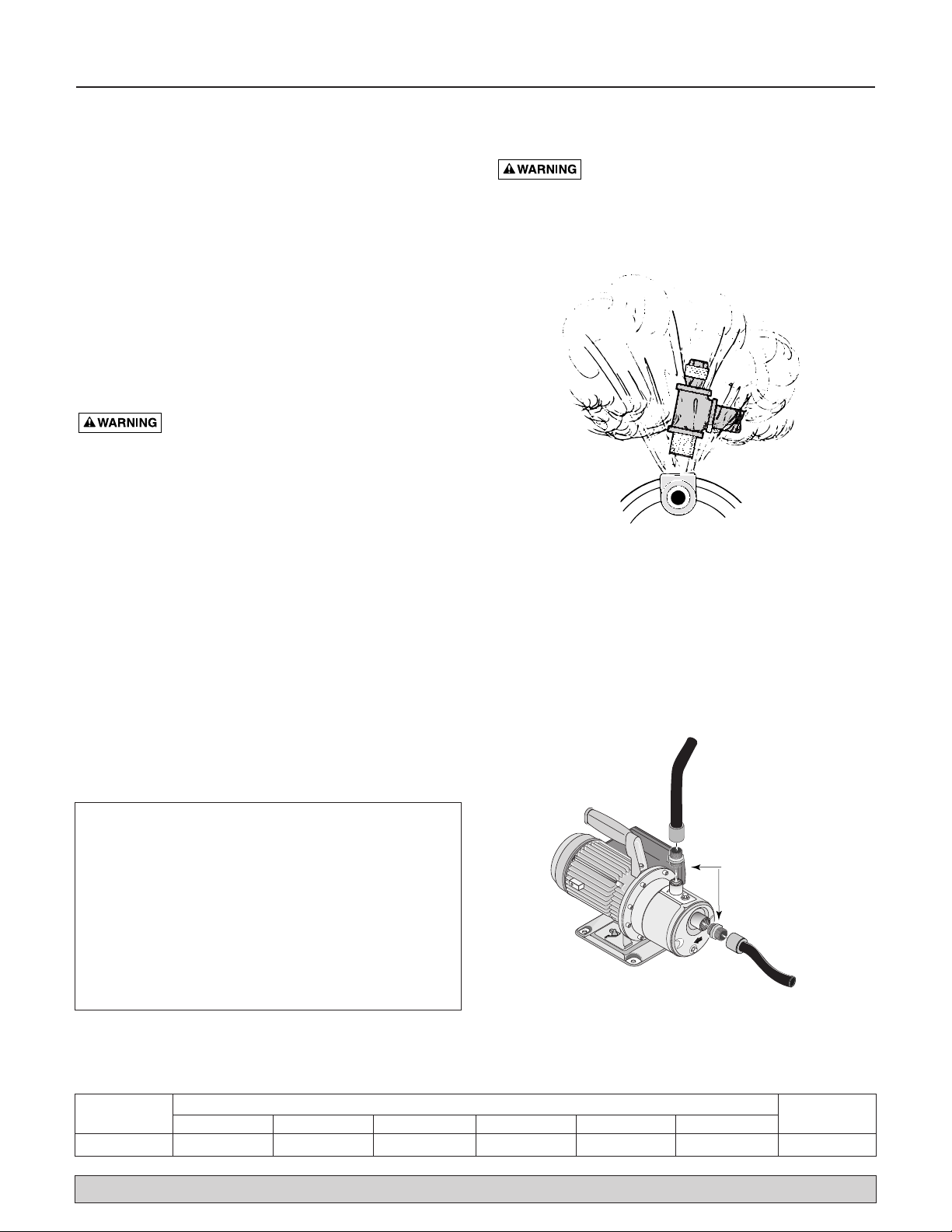

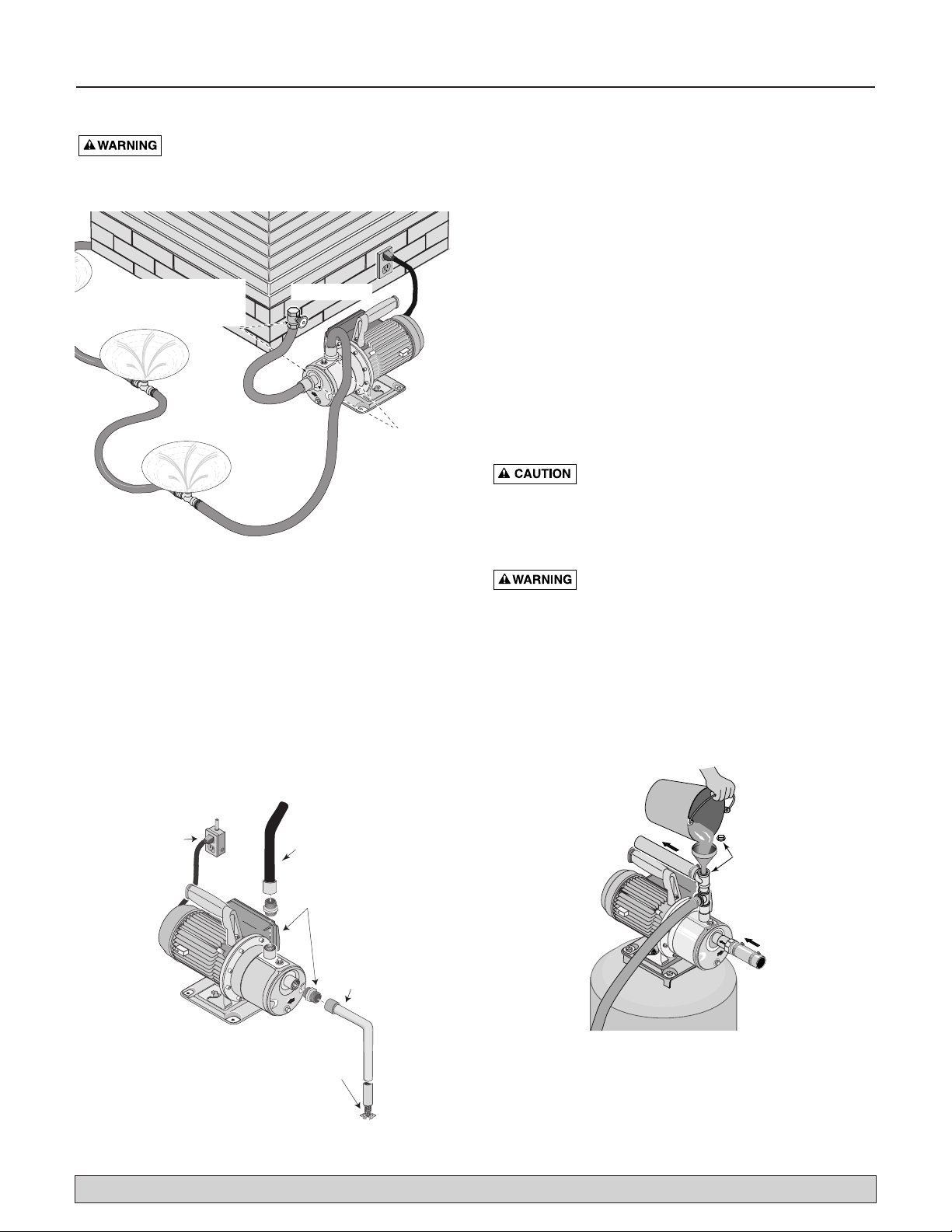

BOOSTING CITY WATER PRESSURE

Hazardous pressure. Never run the pump

against a closed discharge. To do so can boil the water

inside the pump, causing hazardous pressure in the

pump causing the risk of explosion and possibly scalding persons nearby. See Figure 1.

When using the pump as a high-pressure washer, use

only a reinforced high pressure hose or pipe for the discharge line.

When using a garden hose, install adapters to the pump

suction and the discharge. The suction hose will require

two female ends. Either use a standard washing machine

supply hose or modify a short piece of standard 1" garden hose as a suction line (See Figure 2).

Output Pressure Maximum

Model 0 10 20 30 40 50 PSI

2825ss 10 8.5 8.0 7.5 7.0 6.0 80

PERFORMANCE

Sealing Pipe Joints

Use only Teflon tape for making all threaded

connections to the pump itself. Do not use pipe

joint compounds on plastic pumps: they can

react with the plastic in pump components.

Make sure that all pipe joints in the suction pipe

are air tight as well as water tight.

If the suction

pipe can suck air, the pump will not be able to

pull water from the well.

1117 0993

Figure 1: Do Not Run Pump With Outlet Shut Off

Hose Adapters

Figure 2: Hose adapter installation

Page 5

For parts or assistance, call Simer Customer Service at 1-800-468-7867 / 1-800-546-7867

Installation / Operation 5

Hazardous pressure. Do not shut off the

hose or the sprinklers while the pump is running. The

hose or sprinkler head may explode.

PIPING

Both the suction and discharge ports are tapped for 1"

BSP threads. If using hoses, use hose adapters. See

Figure 2. Do not use a hose on the suction if pumping

from lakes, streams or ponds. The hose will collapse and

cause pump failure. Install a strainer with a foot valve on

the end of the suction line. Inspect and clean the strainer

frequently (Figure 4).

NOTICE: An air leak in the suction pipe may draw air in

although no water leaks out. Make sure there are no air

leaks or air pockets in the suction pipe.

PRIMING/OPERATION

NOTICE: Do not run the pump dry. Running the pump

without water can damage the impeller and may damage

the seal, causing leaking or flooding, and will void

warranty.

All suction connections must be airtight. Make sure the

suction lift is not more than 25 feet (7.6M). Fill the pump

body through the priming port before starting the pump.

Start the pump; it should pump water in under 10 minutes (depending on the length of the suction hose and

the height of the pump above water).

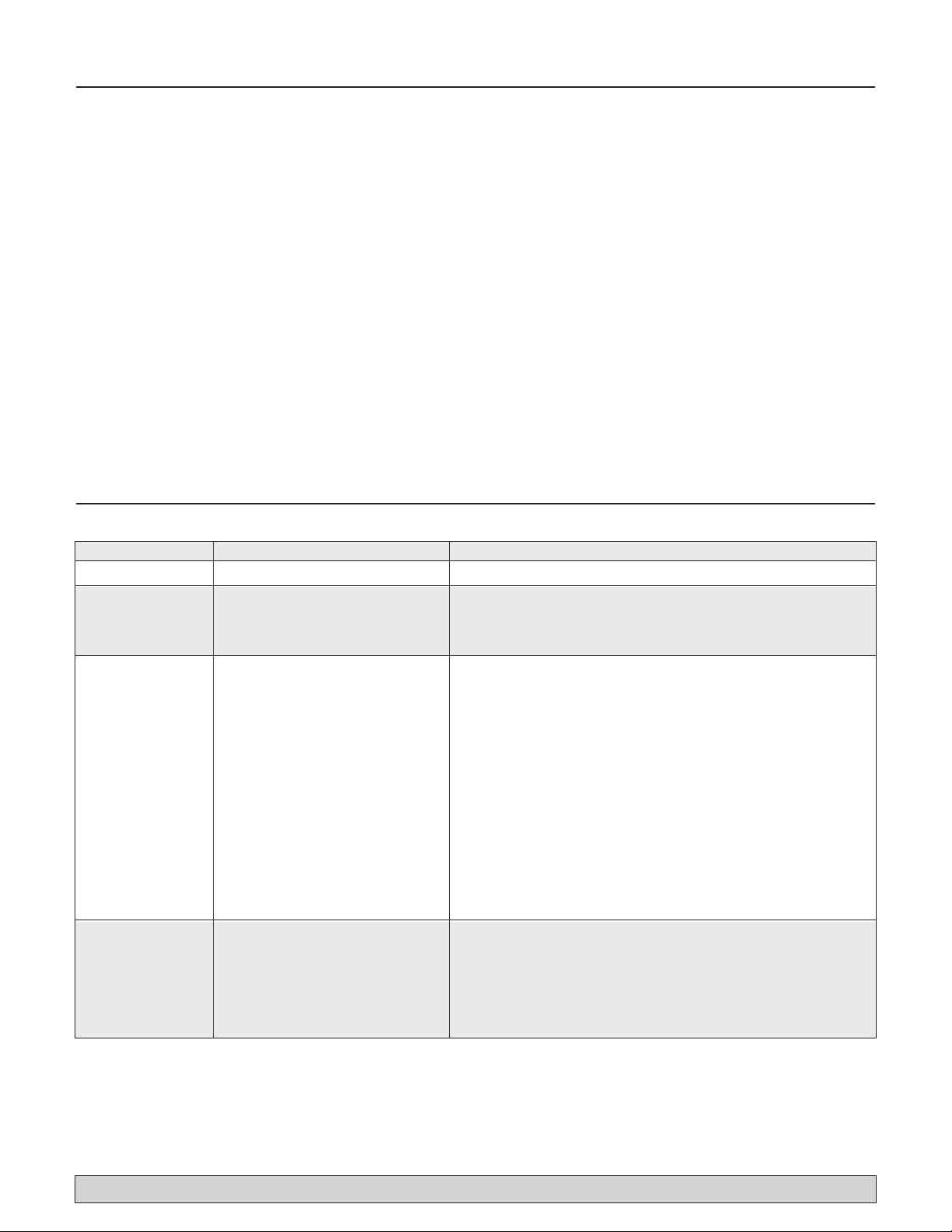

PREPARING TO START THE PUMP

(REFER TO FIGURE 5)

Risk of burns. Never run pump dry.

Running the pump without water may cause the pump to

overheat, damaging the seal and possibly causing burns

to persons handling the pump. Fill the pump with water

before starting.

Hazardous Pressure. Never run the pump

against closed discharge. To do so can boil water inside

pump, causing hazardous pressure in unit, risk of explosion and possibly scalding persons handling pump.

1. Remove the priming plug from the priming tee and

fill the pump. Fill all piping between the pump and

the well and make sure that all piping in the well is

full. If you have also installed a priming tee in the

suction piping, remove the plug from the tee and fill

the suction piping. See Figure 5.

Figure 3: Connect pump to a spigot for use with sprinklers. Connect with adapters supplied with pump

115V, GFCI

Protected,

Grounded

Outlet Box

Discharge Line

(Garden Hose or

Rigid Pipe)

Suction Line

(Garden Hose or

Rigid Pipe)

Foot valve with

strainer (clean

frequently)

Hose

Adapters

Figure 4: Strainer and foot valve installation

Remove the

plug and

fill the pump

and the piping

through the

priming tee.

Figure 5: Prime the Pump

Connect the Pump Inlet

to the Water Faucet

for use with Sprinklers.

Water Faucet

Hose

Adapters

3942 0401

Page 6

Operation 6

For parts or assistance, call Simer Customer Service at 1-800-468-7867 / 1-800-546-7867

2. Replace all fill plugs.

3. Power on! Start the pump. If you don’t have water

after 2 or 3 minutes, stop the pump and remove the

fill plugs. Refill the pump and piping. You may have

to repeat this several times in order to get all of the

trapped air out of the piping. A pump lifting water 25’

may take as long as 15 minutes to prime.

4. After the pump has built up pressure in the system

and shut off, check the pressure switch operation by

opening a faucet or two and running enough water

out to bleed off pressure until the pump starts. The

pump should start when the pressure drops to 30 PSI

and stop when the pressure reaches 50 PSI. Run the

pump through one or two complete cycles to verify

correct operation. This will also help clean the system

of dirt and scale dislodged during installation.

Congratulations on a successful installation.

If you were unsuccessful, please refer to the

Troubleshooting section (below) or call our customer service technical staff at 1-800-468-7867.

Troubleshooting

SYMPTOM POSSIBLE CAUSE(S) CORRECTIVE ACTION

Motor will not run Fuse is blown or circuit breaker tripped DISCONNECT POWER;Replace fuse or reset circuit breaker.

Motor runs hot and Voltage is too low Check voltage being supplied to the pump.

the overload kicks

off or the does not

run and only hums.

Motor runs but no Pump during new installation did In new installation:

water is delivered* not pick up prime through:

1. Improper priming 1. Re-prime according to instructions.

2. Air leaks 2. Check all connections on suction line, with soapy water or

shaving cream.

3. Leaking foot valve 3. Replace foot valve.

4. Pipe size is too small 4. Re-pipe using size of suction and discharge ports on pump.

Pump has lost prime through: In installation already in use:

1. Air leaks 1. Check all connections on suction line and shaft seal with soapy water.

2. Water level below suction pipe inlet 2. Lower suction line into water and re-prime. If receding water level

in well exceeds 25’ (7.6M), a deep well pump is needed.

Impeller is plugged Clean impeller.

Foot valve is stuck shut Replace the foot valve.

Pipes are frozen Thaw pipes.

Foot valve and/or strainer are Raise the foot valve and/or strainer above bottom of water source.

buried in sand or mud Clean foot valve and strainer.

*Pump does not Water being pumped is lower than A deep well jet will may needed if the water being pumped is more than

deliver water to full estimated 25’ (7.6M) depth to water.

capacity

Steel piping (if used) is corroded or Replace with plastic pipe where possible, otherwise with new steel pipe.

limed, causing excess friction

Piping is too small in size Re-pipe using size of suction and discharge ports on pump.

Pump not being supplied with Add additional well points.

enough water

* (Note:

Stop pump;

then check prime

before looking for

other causes.

Unscrew

priming

plug and see if water

is in priming hole).

Page 7

Repair Parts 7

For parts or assistance, call Simer Customer Service at 1-800-468-7867 / 1-800-546-7867

Key No. Part Description No. Used Part Number

1 Pump Body 1 723S2290

2 O-Ring, Drain Plug 2 111P0990

3 Drain Plug 2 121P2100

4 O-Ring, Nozzle 1 111P0480

5 Diffuser, Venturi, Nozzle Assembly 1 101P2840

6 Impeller 1 731S2220

7 Mechanical Seal, Assembly 1 ZBR00010

8 O-Ring, Pump Body 1 111P1190

9 Flange 1 101P1290

10 Intermediate Support 1 731P0170

11 Handle 1 101P1450

12 Washer, Handle 1 121P1500

13 Screw, Handle 1 121P1600

14 Lock Nut, Handle 1 121P0950

15 Water Singer 1 102P0540

16 Handle Grip, Handle 1 102P1650

17 Fan,Cooling 1 102P0570

18 Fan Cover 1 721S1090

19 Power Cord 1 191P0560

20 Screws, Capacitor Holder 11 121P2060

21 Grounding Lug 1 171P4070

22 Capacitor Box W/ Cover 1 102P2830

23 Capacitor 1 171P5430

24 O-Ring, Capacitor Box 1 111P1350

25 Washer, Ground Screw 1 121P0090

26 Lockwasher, Ground Screw 1 121P0920

27 Screw, Ground 1 121P1280

28 Base Assembly 1 ZBR05420

29 Screw, Pump Body 6 121P0340

8

7

6

17

23

18

19

20

24

22

27

3985 0501

5

4

3

2

1

16

13

12

29

2

3

11

10

9

15

14

21

22

25

26

28

Page 8

Sécurité 8

Pour obtenir des pièces ou de l’aide, appeler le Service à la clientèle Simer en composant le 1 800 468-7867/1 800 546-7867

LIRE ET OBSERVER TOUTES CES

INSTRUCTIONS DE SÉCURITÉ !

Ce symbole indique qu’il faut être prudent. Lorsque ce

symbole apparaît sur la pompe ou dans cette Notice,

rechercher une des mises en garde qui suivent, car elles

indiquent un potentiel possible de blessures corporelles.

avertit d’un danger qui causera des blessures

corporelles, la mort ou des dommages matériels importants si

on l’ignore.

avertit d’un danger qui risque de causer des

blessures corporelles, la mort ou des dommages matériels

importants si on l’ignore.

avertit d’un danger qui causera ou qui ris-

quera de causer des blessures corporelles, la mort ou des dommages matériels importants si on l’ignore.

Le mot REMARQUE indique des instructions spéciales et importantes n’ayant aucun rapport avec les dangers.

Lire attentivement toutes les consignes de sécurité contenues

dans cette Notice ou collées sur la pompe.

Garder les autocollants en bon état concernant les consignes de

sécurité.

Les remplacer s’ils manquent ou s’ils ont été endommagés.

CONSIGNES DE SÉCURITÉ GÉNÉRALES

1. Pour éviter tout risque de blessures corporelles graves et des

dommages matériels importants, lire attentivement ces consignes

de sécurité avant de procéder à l’installation de la pompe.

2. Pour installer cette pompe, respecter les codes de la plomberie

et de l’électricité de la municipalité et du gouvernement fédéral.

3. Pression dangereuse. Le corps de la pompe

peut exploser si la pompe est utilisée en tant que pompe de

surpression, à moins qu’une soupape de sûreté pouvant laisser passer le débit maximum de la pompe de 414 kPa (60

lb/po

2

) soit posée. Ne jamais faire fonctionner la pompe à

sec, sinon elle risque de surchauffer, ses joints risquent d’être

endommagés et les personnes qui la manipuleront risquent de

se brûler. Cette pratique annule aussi la garantie.

4. Risque d’incendie ou d’explosion. Pour

empêcher tout risque d’incendie ou d’explosion, ne pomper

que de l’eau avec cette pompe. Ne pas utiliser cette pompe

dans une atmosphère contenant des vapeurs inflammables.

5. Risque de brûlures. Toute eau restée

emprisonnée dans la pompe pendant qu’elle fonctionne

risque de se transformer en vapeur et de provoquer une

explosion et des brûlures. Ne jamais faire fonctionner la

pompe si son refoulement est fermé ou bouché.

6. Si cette pompe est utilisée pour pomper l’eau potable d’un puits,

toujours désinfecter le puits et, avant d’utiliser l’eau, la faire

analyser pour s’assurer de sa pureté. Pour procéder à l’analyse

de l’eau, s’adresser au Service de santé de la municipalité

7. La pompe et les tuyauteries doivent être protégées contre le

gel. Le gel causera des dommages, ce qui annulera la

garantie.

8. Cette pompe n’est pas conçue ni prévue pour pomper des

produits chimiques ni des corrosifs liquides. Ne pomper que

de l’eau avec cette pompe.

9. Ne pas faire fonctionner cette pompe à sec, sinon elle sera

endommagée, ce qui annulera la garantie.

CONSEILS DE SÉCURITÉ

CONCERNANT L’ÉLECTRICITÉ

Cette pompe est livrée avec un cordon électrique à 3 conducteurs, dont un de mise à la terre. Ne brancher ce cor-

don que dans une prise de courant adéquatement mise à terre et

protégée par un disjoncteur de fuite à la terre. Ne pas lever cette

pompe par son cordon électrique.

Faire correspondre la tension du moteur avec la celle d’alimentation. La tension d’alimentation doit correspondre à

±10 % de la tension indiquée sur la plaque signalétique du

moteur. Une mauvaise tension risque de causer un incendie,

voire de graves dommages au moteur, ce qui annulera la garantie.

En cas de doute, consulter un électricien qualifié.

Cette pompe n’est pas submersible. Toujours garder son

moteur sec. Ne pas le laver ni l’immerger. Protéger son

moteur contre les intempéries.

Si on doit utiliser un cordon prolongateur, n’utiliser qu’un

cordon prolongateur à 3 conducteurs dont un de mise à la

terre. Ce cordon doit être approuvé UL pour utilisation à l’intérieur et à l’extérieur. Ne pas jamais laisser une partie du cordon

prolongateur ni ses extrémités fiche et prise reposer dans l’eau ou

dans un endroit humide.

Avant d’intervenir sur la pompe, la débrancher du courant

qui l’alimente. Pour éviter tout risque de subir des secouss-

es électriques mortelles, procéder comme il est indiqué ci-dessous

si on doit intervenir sur la pompe.

A. Couper le courant alimentant la prise de courant avant

d’intervenir sur la pompe. Les

moteurs modernes sont conçus

pour fonctionner par des températures élevées. Pour ne pas

se brûler lorsqu’on intervient

sur la pompe, laisser son

moteur refroidir pendant

20 minutes après avoir

arrêté la pompe et avant

de la manipuler.

B. Il faut être extrêmement

prudent lorsqu’on remplace

un fusible. Pour réduire les

risques de secousses électriques mortelles, NE PAS se

tenir dans l’eau et ne pas met-

tre un doigt dans la douille du fusible.

C. Mettre à la terre le pressostat ou le moteur avant de démarrer

la pompe.

D. Ne brancher la pompe que dans une prise de courant

adéquatement mise à la terre protégée par un disjoncteur de

fuite à la terre.

Tension dangereuse. Peut

entraîner des chocs, des

brûlures ou causer la mort.

Mettre la pompe à la terre avant

de la brancher. Couper le

courant électrique avant de travailler sur la pompe, le moteur

ou le réservoir.

Pression dangereuse!

Poser une soupape de sûreté

sur le tuyau de refoulement.

Dissiper toute la pression

du système avant d’intervenir

sur un composant.

ATTENTION

AVERTISSEMENT

AVERTISSEMENT

Page 9

Table des matières 9

Pages

Consignes de sécurité ..........................................................................................8

Garantie...............................................................................................................9

Installation ...................................................................................................10, 11

Fonctionnement ...........................................................................................11, 12

Recherche des pannes .......................................................................................12

Pièces de rechange ...........................................................................................13

Pour obtenir des pièces ou de l’aide, appeler le Service à la clientèle Simer en composant le 1 800 468-7867/1 800 546-7867

SIMER garantit à l’acheteur-utilisateur initial de ses produits (“Acheteur”) contre tout défaut

de fabrication et de matériaux.

Tout produit reconnu défectueux dans les douze (12) mois qui suivent la date d’achat d’origine

sera remplacé ou réparé à la discrétion de SIMER, selon les conditions stipulées ci-dessous. La

preuve d’achat est exigée pour déterminer l’admissibilité à la garantie.

Exceptions à la garantie de douze (12) mois

Garantie de quatre-vingt-dix (90) jours :

Si, dans les quatre-vingt-dix (90) jours à compter de la date d’achat par le consommateur d’origine, une pompe adaptable sur perceuse, une pompe d’amorçage ou une cartouche de filtre à

eau en ligne s’avérait être défectueuse, elle sera remplacée, conformément aux conditions stipulées ci-dessous.

Garantie de deux (2) ans :

Si, dans les deux (2) ans à compter de la date d’achat par le consommateur d’origine, une

pompe d’assèchement submersible de 1/3 ch ou modèle de FP2800DCC s’avérait être

défectueuse, elle sera réparée ou remplacée, au choix de SIMER, conformément aux termes et

conditions stipulés ci-dessous.

Garantie de trois (3) ans :

Si, dans les trois (3) ans à compter de la date d’achat par le consommateur d’origine, une pompe

de puits submersible de 4 pouces ou une pompe d’assèchement submersible de 1/2 ch s’avérait

être défectueuse, elle sera réparée ou remplacée, au choix de SIMER, conformément aux termes

et conditions stipulés ci-dessous.

Garantie de cinq (5) ans :

Si, dans les cinq (5) ans à compter de la date d’achat par le consommateur d’origine, un réservoir de système d’eau préchargé s’avérait être défectueux, il sera réparé ou remplacé, au choix

de SIMER, conformément aux termes et conditions stipulés ci-dessous.

Conditions générales

L’Acheteur s’engage à payer tous les frais de main-d’œuvre et d’expédition nécessaires au

remplacement du produit couvert par la garantie. Cette garantie ne couvrira pas les cas de

force majeure, et ne s’appliquera pas aux produits qui, du seul avis de SIMER, ont fait l’objet

de négligence, d’utilisation abusive ou incorrecte, d’accident, de modification ou d’altération

; ni aux produits qui n’ont pas été installés, utilisés, entreposés ou entretenus correctement ;

ni à ceux qui n’ont pas été utilisés ou entretenus normalement, y compris, mais sans s’y limiter, aux produits ayant des pannes de fonctionnement causées par la corrosion, la rouille ou

autre corps étranger dans le système, ou à des produits ayant fonctionné à des pressions dépassant la limite maximale recommandée.

Les demandes de service en vertu de la présente garantie seront faites en retournant le produit

défectueux au détaillant ou à SIMER dès la découverte de tout défaut allégué. Simer prendra alors

les mesures correctives aussi rapidement qu’il est raisonnablement possible. Aucune demande de

service en vertu de la présente garantie ne sera acceptée si elle est reçue plus de 30 jours après

l’expiration de la dite garantie.

La présente garantie énonce la totalité des obligations de SIMER et le seul recours possible de

l’Acheteur dans le cas de produits défectueux.

SIMER NE SERA TENU RESPONSABLE D’AUCUN DOMMAGE INDIRECT, ACCIDENTEL OU

FORTUIT QUEL QU’IL SOIT.

LES PRÉSENTES GARANTIES SONT EXCLUSIVES ET TIENNENT LIEU DE TOUTE AUTRE GARANTIE EXPRESSE. LES GARANTIES IMPLICITES, Y COMPRIS, MAIS SANS S’Y LIMITER, LES

GARANTIES IMPLICITES AYANT TRAIT À LA COMMERCIABILITÉ ET À L’ADAPTATION À UN

USAGE PARTICULIER, NE DÉPASSERONT PAS LA DURÉE DES GARANTIES EXPRESSES APPLICABLES STIPULÉES DANS LES PRÉSENTES.

Certaines provinces n’autorisent pas d’exclure ou de limiter les dommages fortuits ou indirects ou

de limiter la durée d’une garantie implicite ; il se peut donc que les limitations ou exclusions cidessus ne s’appliquent pas à votre cas. La présente garantie vous donne des droits juridiques spécifiques et vous pouvez en avoir d’autres qui varient d’une province à l’autre.

Garantie limitée Simer

SIMER • 293 Wright Street • Delavan, WI U.S.A. 53115

Téléphone: 1-800-468-7867 / 1-800-546-7867 • Télécopieur: 1-800-390-5351

Courrier électronique: info@simerwater.com • Site Web: http://www.simerwater.com

Page 10

Pour obtenir des pièces ou de l’aide, appeler le Service à la clientèle Simer en composant le 1 800 468-7867/1 800 546-7867

Installation 10

CARACTÉRISTIQUES

Courant électrique requis ................................................115 volts

Fonctionnement du moteur ..............................................Continu

Circuit requis (minimal)...............................................15 ampères

Adaptateur de refoulement.....................................................1 po

INSTALLATION DE LA POMPE

À ÉJECTEUR SUR UN PUITS PEU

PROFOND

• La profondeur verticale entre la pompe et l’eau pompée ne

doit pas dépasser 7, 60 mètres (25 pieds).

• N’utiliser qu’un seul tuyau entre le puits et le corps de la

pompe.

• Cette pompe peut pomper l’eau d’un puits foré ou d’une

pointe filtrante.

REMPLACEMENT DE LA

POMPE EXISTENTE

Tension dangereuse. Risque de secousses élec-

triques, de brûlures, voire de mort. Avant d’intervenir sur la

pompe ou le moteur, couper le courant qui les alimente.

Cette pompe peut remplacer la pompe à éjecteur pour puits peu

profonds, modèle 3825. Cela requiert la réutilisation du manostat

et le câblage de la pompe au commutateur.

1. Vider toute l’eau de l’ancienne pompe avant de la déposer.

Vérifier la tuyauterie à la recherche de dépôts de tartre, de

chaux, de rouille, etc. Remplacer la tuyauterie au besoin.

2. Brancher la pompe sur le système. S’assurer que tous les raccords du tuyau d’aspiration sont bien étanches, aussi bien à

l’air qu’à l’eau.

Si le tuyau d’aspiration aspire de l’air, la

pompe ne pompera pas l’eau du puits.

3. Régler la hauteur de la pompe de façon que les raccords de

plomberie n’exercent aucune contrainte sur son corps.

Supporter les tuyaux de façon que le corps de la pompe ne

subisse pas le poids de la tuyauterie, ni celui des raccords.

Le branchement du tuyau d’aspiration sur la pompe à

éjecteur pour puits peu profond neuve est terminé. Se

reporter à la page 6 pour procéder aux branchements du

tuyau de refoulement et du réservoir.

AUGMENTATION DE LA

PRESSION DE L’EAU COURANTE

Pression dangereuse. Ne jamais faire fonction-

ner la pompe contre un refoulement fermé, sinon l’eau risque de

bouillir à l’intérieur de la pompe, une accumulation dangereuse

de pression risque de se produire, un danger d’explosion peut

s’ensuivre et les personnes se trouvant à proximité risquent d’être

ébouillantées. (Se reporter à la figure 1).

Si on utilise cette pompe en tant que nettoyeur haute pression, la

brancher que sur un tuyau de refoulement souple haute pression

renforcé ou un tuyau rigide.

Si on utilise un tuyau d’arrosage, poser des adaptateurs sur l’aspiration et le refoulement de la pompe. Le tuyau souple d’aspiration devra comporter deux embouts femelles. Utiliser soit un

tuyau souple de laveuse standard soit un petit morceau de tuyau

d’arrosage standard de 1 po en tant que tuyau d’aspiration. (Se

reporter à la Figure 2).

Pression de refoulement lb/po

2

Modèle 0 10 20 30 40 50 (maxi)

2825ss 10 8,5 8,0 7,5 7,0 6,0 80

RENDEMENTS

Étanchéité des raccords des tuyaux

Utiliser du ruban en téflon pour procéder à tous les

raccordements filetés sur la pompe. Ne pas utiliser de

pâte pour raccords filetés sur les pompes en plastique. Cette pâte réagira avec les composants en plas-

tique de la pompe. S’assurer que tous les raccords du

tuyau d’aspiration sont bien étanches, aussi bien à

l’air qu’à l’eau.

Si le tuyau d’aspiration aspire de l’air,

la pompe ne pompera pas l’eau du puits

1117 0993

Figure 1: Ne pas faire fonctionner la pompe si le

refoulement est fermé

Hose Adapters

Figure 2: Branchement des adaptateurs de tuyau souple

Adaptateurs

de tuyau souple

Page 11

Pour obtenir des pièces ou de l’aide, appeler le Service à la clientèle Simer en composant le 1 800 468-7867/1 800 546-7867

Installation / Fonctionnement 11

Pression dangereuse. Ne pas fermer la sortie

du tuyau souple ni les arroseurs pendant que la pompe fonctionne, sinon le tuyau souple ou la tête des arroseurs risque

d’exploser.

TUYAUTERIE

Les orifices d’aspiration et de refoulement sont dotés de filets

intérieurs BSP de 1 po. Utiliser des adaptateurs si on utilise des

tuyaux souples. Se reporter à la Figure 2. Pour pomper l’eau d’un

lac, d’un ruisseau ou d’un étang, ne pas brancher un tuyau souple

sur l’aspiration de la pompe, sinon il s’aplatira et la pompe

tombera en panne. Poser une crépine et un clapet de pied à l’extrémité du d’aspiration. Inspecter et nettoyer fréquemment la

crépine. (Se reporter à la Figure 4).

REMARQUE : Toute prise d’air du tuyau d’aspiration empêchera

la pompe de pomper, même s’il n’y a pas de fuites d’eau.

S’assurer qu’il n’y a pas de prises d’air ni de poches d’air dans le

tuyau d’aspiration.

AMORÇAGE ET FONCTIONNEMENT

REMARQUE : Ne pas faire fonctionner la pompe à sec sinon son

impulseur et son joint risquent d’endommager ce qui causera des

fuites ou une inondation. Cette pratique annule également la

garantie.

Tous les raccords d’aspiration doivent être étanches. S’assurer que

la hauteur géométrique d’aspiration est inférieure à 7,60 m (25

pi). Avant de démarrer la pompe, remplir son corps par l’orifice

d’amorçage. Démarrer la pompe. Elle doit pomper de l’eau dans

les 10 minutes qui suivent (en fonction de la longueur du tuyau

souple d’aspiration et de la hauteur à laquelle elle est située par

rapport à l’eau).

PRÉPARATION AVANT DE DÉMARRER

LA POMPE (FIGURE 5)

Risque de brûlures. Ne jamais faire fonction-

ner la pompe à sec, sinon elle risque de surchauffer, ses joints

risquent d’être endommagés et les personnes qui la manipuleront

risquent de se brûler. Remplir la pompe d’eau avant de la démarrer.

Pression dangereuse. Risque d’explosion. Ne

jamais faire fonctionner la pompe si le refoulement est fermé,

sinon l’eau risque de bouillir à l’intérieur de la pompe et causer

une pression dangereuse, un danger d’explosion et les personnes

qui manipuleront la pompe risqueront d’être ébouillantées.

1. Déposer le bouchon du té d’amorçage, puis faire le plein de

la pompe. Faire le plein de toutes les tuyauteries branchées

entre la pompe et le puits et s’assurer aussi que toutes les

tuyauteries descendant dans le puits sont pleines d’eau. Si un

té d’amorçage a été posé sur le tuyau d’aspiration, déposer

son bouchon, puis faire le plein du tuyau d’aspiration. Se

reporter à la Figure 5.

Figure 3: Pour utiliser cette pompe avec des arroseurs,

la brancher sur un robinet. Utiliser les adaptateurs

livrés avec la pompe

115V, GFCI

Protected,

Grounded

Outlet Box

Discharge Line

(Garden Hose or

Rigid Pipe)

Suction Line

(Garden Hose or

Rigid Pipe)

Foot valve with

strainer (clean

frequently)

Hose

Adapters

Figure 4: Branchement de la crépine et du clapet de

pied

Remove the

plug and

fill the pump

and the piping

through the

priming tee.

Figure 5: Amorçage de la pompe

Si on utilise cette pompe avec

des arroseurs, brancher son

tuyau d’arrivée sur un robinet

d’eau.

Robinet d’eau

Adaptateurs

de tuyau souple

Prise de courant

de 115 volts à

trois trous dont

un de mise à la

terre protégée par

un disjoncteur de

fuite à la terre

Tuyau de refoulement

(d’arrosage ou rigide)

Adaptateurs de

tuyau souple

Tuyau d’aspiration

(Souple renforcé

ou rigide)

Clapet de pied et

crépine (À nettoyer

fréquemment)

Déposer le bouchon,

puis faire le plein de la

pompe et du tuyau par

le té d’amorçage.

Connect the Pump Inlet

to the Water Faucet

for use with Sprinklers.

Water Faucet

Hose

Adapters

3942 0401

ATTENTION

Page 12

Fonctionnement 12

Pour obtenir des pièces ou de l’aide, appeler le Service à la clientèle Simer en composant le 1 800 468-7867/1 800 546-7867

2. Reposer tous les bouchons d’amorçage.

3. Établir le courant. Démarrer la pompe. Elle doit pomper l’eau

dans les 2 à 3 minutes qui suivent. Sinon l’arrêter, puis déposer les bouchons d’amorçage. Refaire le plein de la pompe et

des tuyaux. Il faudra peut-être répéter cette opération

plusieurs fois jusqu’à ce que tout l’air emprisonné dans les

tuyaux soit chassé. Si la pompe pompe l’eau d’une hauteur

de 7,60 (25 pi), il lui faudra peut-être 15 minutes pour

s’amorcer.

4. Dés que la pression sera accumulée dans le système et que la

pompe se sera arrêtée, vérifier le fonctionnement du pressostat en ouvrant un ou deux robinets du système et en les laissant couler suffisamment longtemps pour que la pression se

dissipe et que la pompe redémarre. Elle doit démarrer dès

que la pression chute à 207 kPa (30 lb/po

2

) et s’arrêter dès

qu’elle atteint 345 kPa (50 lb/po

2

). Faire fonctionner la pompe

pendant un ou deux cycles complets pour confirmer son bon

fonctionnement et chasser du système toute la saleté et tout le

tartre qui se seraient détachés pendant l’installation.

Félicitations pour une installation réussie.

Si l’installation n’est pas réussie, se reporter à la Section «

Recherche des pannes » ou appeler un technicien de notre service à la clientèle en composant le 1- 800 -468-7867.

Recherche des pannes

INCIDENTS CAUSES PROBABLES REMÈDES

Le moteur ne Le fusible est fondu ou le COUPER L’ARRIVÉE DE COURANT; Remplacer le fusible ou

fonctionne pas disjoncteur est sauté réenclencher le disjoncteur.

Le moteur chauffe et le La tension est trop basse Vérifier la tension alimentant la pompe.

dispositif de protection

contre les surcharges

se déclenche ou bien

le moteur ne fonctionne

pas ou fait un bruit de

bourdonnement

Le moteur fonctionne, Dans le cas d’une installation neuve, Dans le cas d’une installation neuve :

mais l’eau n’est pas la pompe ne s’est pas amorcée :

pompée * 1. À cause d’un mauvais amorçage 1. Réamorcer la pompe conformément aux instructions.

2. Parce qu’il y a des prises d’air 2. Avec du savon ou de la crème à raser, vérifier tous les raccords du

tuyau d’aspiration.

3. Parce que le clapet de pied fuit 3. Remplacer le clapet de pied.

4. Parce que le diamètre du tuyau 4. Remplacer le tuyau par un dont le diamètre est le même que celui

est trop petit des orifices d’aspiration et de refoulement de la pompe.

La pompe s’est désamorcée : Dans le cas d’une installation déjà en service :

1. Parce qu’il y a des prises d’air 1. Avec du savon, vérifier tous les raccords du tuyau d’aspiration

et le joint de l’arbre.

2. Parce que le niveau de l’eau est plus 2. Abaisser le tuyau d’aspiration dans l’eau. Réamorcer la pompe. Si,

bas que la prise d’eau du tuyau dans le puits, l’eau baisse à plus de 7,60 mètres (25 pieds), utiliser

d’aspiration une pompe pour puits profond.

L’impulseur est bouché Le nettoyer.

Le clapet de pied est grippé. Le remplacer.

Les tuyaux sont gelés Les dégeler.

Le clapet de pied ou la crépine sont Les relever plus haut que la source d’eau. Les nettoyer.

enfouis dans le sable ou la boue

*La pompe ne pompe Le niveau de l’eau est plus bas que Un éjecteur pour puits profond est peut-être requis si le niveau de l’eau

pas à pleine capacité celui estimé dans le puits est à plus de 7,60 mètres (plus de 25 pieds).

Le tuyau en acier (le cas échéant) est Dans la mesure du possible, le remplacer par un tuyau en plastique.

corrodé ou bouché par la chaux, ce Sinon, poser un tuyau en acier neuf.

qui cause un frottement excessif

Le diamètre du tuyau est trop petit Le remplacer par un tuyau dont le diamètre est le même que celui des

orifices d’aspiration et de refoulement de la pompe.

La pompe n’est pas suffisamment Ajouter plus de pointes filtrantes.

alimentée en eau

(REMARQUE :

Arrêter la pompe.

Vérifier l’amorçage

avant de rechercher

toute autre cause.

Dévisser le bouchon

d’amorçage et voir

s’il y a de l’eau dans

le trou d’amorçage).

Page 13

Pièces de rechange 13

Pour obtenir des pièces ou de l’aide, appeler le Service à la clientèle Simer en composant le 1 800 468-7867/1 800 546-7867

Réf. Désignation Qté Numéro de pièces

1 Corps de la pompe 1 723S2290

2 Joint torique du bouchon de vidage 2 111P0990

3 Bouchon de vidage 2 121P2100

4 Joint torique éjecteur 1 111P0480

5 Ensemble diffuseur, venturi et éjecteur 1 101P2840

6 Impulseur 1 731S2220

7 Joint mécanique complet 1 ZBR00010

8 Joint torique du corps de la pompe 1 111P1190

9 Bride 1 101P1290

10 Support intermédiaire 1 731P0170

11 Poignée 1 101P1450

12 Rondelle de la poignée 1 121P1500

13 Vis de la poignée 1 121P1600

14 Écrou de la poignée 1 121P0950

15 Déflecteur d’eau 1 102P0540

16 Poignée 1 102P1650

17 Ventilateur de refroidissement 1 102P0570

18 Carter du ventilateur 1 721S1090

19 Cordon électrique 1 191P0560

20 Vis du support du condensateur 11 121P2060

21 Borne de mise à la terre 1 171P4070

22 Boîtier du condensateur, y compris le couvercle 1 102P2830

23 Condensateur 1 171P5430

24 Joint torique du boîtier du condensateur 1 111P1350

25 Rondelle de la vis de mise à la terre 1 121P0090

26 Rondelle-frein de la vis de mise à la terre 1 121P0920

27 Vis de mise à la terre 1 121P1280

28 Socle 1 ZBR05420

29 Vis du corps de la pompe 6 121P0340

8

7

6

17

23

18

24

22

27

5

4

3

2

1

16

13

12

29

2

3

11

10

9

15

14

21

22

25

26

28

19

20

3985 0501

Page 14

Seguridad 14

Si necesita repuestos o asistencia llame al Servicio al Cliente de Simer, 1-800-468-7867/1-800-546-7867

¡LEA Y SIGA LAS

INSTRUCCIONES DE SEGURIDAD!

Este es el símbolo de alerta de seguridad. Cuando vea este

símbolo en su bomba o en este manual, busque alguna de

las siguientes palabras de advertencia y esté alerta a la posibilidad

de lesiones personales:

advierte acerca de los peligros que provo-

carán lesiones personales graves, muerte o daños materiales considerables si se ignoran.

advierte acerca de los peligros que

pueden

provocar

lesiones personales graves, muerte o daños

materiales considerables si se ignoran.

advierte acerca de los peligros que provo-

carán o podrán

provocar

lesiones personales o daños materiales

menores si se ignoran.

La etiqueta AVISO indica instrucciones especiales que son impor-

tantes pero que no están relacionadas con los peligros.

Lea y siga cuidadosamente todas las instrucciones de seguridad

en este manual y en la bomba.

Mantenga las etiquetas de seguridad en buen estado.

Reemplace las etiquetas de seguridad faltantes o dañadas.

SEGURIDAD GENERAL

1. Para evitar el peligro de lesiones corporales y daños materi-

ales graves, lea las instrucciones de seguridad con atención

antes de instalar esta bomba.

2. Cuando instale la bomba, observe los códigos de plomería y

de electricidad locales y/o nacionales.

3. Presión Peligrosa. La bomba puede

explotar si se usa como bomba de refuerzo, a menos que se

haya instalado una válvula de desahogo capaz de pasar todo

el caudal de la bomba a 60 PSI (414 kPa). Nunca deje marchar la bomba en seco. De lo contrario podrá dañar las

piezas internas, y sobrecalentar la bomba (lo cual provocará

quemaduras a las personas que estén manipulando o reparando la bomba), ¡y anulará la garantía!

4. Peligro de incendio o de explosión.

Para evitar el peligro de incendio y de explosión, bombee

sólo agua con esta bomba. No la use en atmósferas que

puedan contener vapores o gases inflamables.

5. Peligro de quemadura. Si queda atra-

pada agua en la bomba durante la operación, se podrá convertir en vapor. El vapor atrapado puede provocar explosiones

y quemaduras. Nunca deje marchar la bomba con la salida

cerrada u obstruida.

6. Si se usa en un pozo para agua potable, siempre desinfecte el

pozo y haga una prueba de la pureza de agua antes de usarla. Verifique los procedimientos de prueba con su departamento de sanidad local.

7. Tanto la bomba como los tubos deben estar protegidos contra

heladas. Las heladas provocarán daños y anularán la garantía.

8. Esta bomba no ha sido diseñada ni concebida para bombear

sustancias químicas o líquidos corrosivos. Bombee sólo agua

con esta bomba.

9. No deje marchar la bomba en seco. Si la bomba está seca,

ocurrirán daños y la garantía quedará anulada.

SEGURIDAD ELÉCTRICA

La bomba viene provista de un cordón con 3 conductores

con puesta a tierra. Conéctela solamente a un tomacorri-

ente debidamente puesto a tierra y protegido por un disyuntor de

escape a tierra (GFCI). No levante la bomba por medio del

cordón eléctrico.

Asegúrese de que el voltaje del motor y el voltaje de suministro de corriente correspondan. El voltaje de suministro

debe estar entre +/- 10% del voltaje de la placa de fábrica del

motor. Un voltaje incorrecto puede provocar incendios o daños

graves al motor y anulará la garantía. En caso de duda, consulte a

un electricista certificado.

La bomba no es sumergible. Mantenga el motor seco en

todo momento. No lave el motor. No lo sumerja. Proteja el

motor en climas húmedos.

Si usa un cordón de alargue, use sólo un cordón trifilar

aprobado por UL para interiores/exteriores, con conexión

de puesta a tierra. No permita que ninguna parte del cordón o

del receptáculo quede en el agua o en lugares húmedos.

Desenchufe la bomba antes de realizar trabajos de mantenimiento o de reparación. Para evitar choques fatales,

proceda de la siguiente manera si es necesario reparar la bomba.

A. Desconecte la corriente

eléctrica a la caja de salida de

la bomba antes de desenchufar la bomba. Los motores

modernos han sido diseñados

para funcionar a alta temperatura. Para evitar quemaduras

cuando se repare la bomba,

permita que se enfríe por unos

20 minutos después de haberla

apagado, antes de realizar el

trabajo.

B. Tenga mucho cuidado

cuando cambie los fusibles.

Para reducir la posibilidad de

choques eléctricos fatales, NO

se pare sobre el agua ni ponga

sus dedos en el portafusible.

C. Conecte el manóstato o el motor a tierra antes de hacer mar-

char esta bomba.

D. Enchufe la bomba sólo en un tomacorriente puesto a tierra

con un disyuntor de escape a tierra (GFCI).

Tensión peligrosa. Puede

provocar choques, quemaduras o muerte.

Conecte la bomba a tierra antes

de conectarla al suministro de

corriente eléctrica. Desconecte

la corriente antes de trabajar en

la bomba, el motor o el tanque.

¡Presión peligrosa! Instale una

válvula de desahogo de presión

en la tubería de descarga.

Libere toda la presión en el sistema antes de trabajar con

cualquiera de sus componentes.

PELIGRO

ADVERTENCIA

PRECAUCIÓN

ADVERTENCIA

ADVERTENCIA

ADVERTENCIA

ADVERTENCIA

ADVERTENCIA

Page 15

Índice 15

Page

Seguridad General .............................................................................................14

Garantía.............................................................................................................15

Instalación ..................................................................................................16, 17

Operación ...................................................................................................17, 18

Localización de fallas ........................................................................................18

Piezas de repuesto ............................................................................................19

Si necesita repuestos o asistencia llame al Servicio al Cliente de Simer, 1-800-468-7867/1-800-546-7867

Simer garantiza al comprador consumidor original (“Comprador”) de sus productos, que éstos se

encuentran libres de defectos de material o mano de obra

.

Si dentro de los doce (12) meses de la fecha original de la compra cualquiera de los productos

demostrara estar defectuoso, el mismo será reparado o reemplazado, a opción de Simer con sujeción a los términos y condiciones expuestos a continuación. Se requiere su recibo original de

compra para determinar si se encuentra bajo garantía.

Excepciones a la Garantía por Doce (12) Meses

Garantía de noventa (90) días

Si se comprueba que una Bomba de Perforación, una Bomba de Émbolo Buzo o un Cartucho

de Filtro de Agua en línea, tienen defectos, dentro de los noventa (90) días a partir de la compra del consumidor original, éstos serán reemplazados, sujeto a las condiciones indicadas a

continuación.

Garantía de dos (2) años

Si se comprueba que una Bomba Sumergible de Sumidero de 1/3 CV o Modelo FP2800DCC

tiene defectos, dentro de los dos (2) años a partir de la compra del consumidor original, ésta

será reparada o reemplazada, a opción de SIMER, sujeto a los términos y a las condiciones indicadas a continuación.

Garantía de tres (3) años

Si se comprueba que una Bomba Sumergible de Pozo de 4”, o una Bomba Sumergible de

Sumidero de 1/2 CV tienen defectos, dentro de los tres (3) años a partir de la compra del consumidor original, éstas serán reparadas o reemplazadas, a opción de SIMER, sujeto a los términos y a las condiciones indicadas a continuación.

Garantía de cinco (5) años

Si se comprueba que un tanque precargado del sistema de agua tiene defectos, dentro de los

cinco (5) años a partir de la compra del consumidor original, éste será reparado o reemplazado, a opción de SIMER, sujeto a los términos y a las condiciones indicadas a continuación.

Términos y Condiciones Generales

El comprador debe pagar todos los gastos de mano de obra y transporte necesarios para reemplazar el producto cubierto por esta garantía. Esta garantía no se aplicará a hechos de fuerza mayor, ni se aplicará a los productos que, a juicio exclusivo de Simer, hayan sido objeto

de negligencia, abuso, accidente, aplicaciones contraindicadas, manejo indebido, alteraciones; ni debido a instalación, funcionamiento, mantenimiento o almacenaje incorrectos; ni a

ninguna otra cosa que no sea su aplicación, uso o servicio normales, incluyendo, pero no limitado a, fallas operacionales causadas por corrosión, oxidación u otros elementos extraños

en el sistema, o funcionamiento a presión por encima del máximo recomendado.

Los pedidos de servicio bajo los términos de esta garantía serán efectuados mediante la devolución del producto defectuoso al Vendedor o a Simer, tan pronto como sea posible, después de localizado cualquier supuesto defecto. Simer tomará luego acción correctiva, tan

pronto como sea razonablemente posible. Ningún pedido de servicio bajo esta garantía será

aceptado si se recibe más de 30 días después del término de la garantía.

Esta garantía establece la obligación única de Simer y el remedio exclusivo del comprador en

el caso de productos defectuosos.

Simer NO SERÁ RESPONSABLE POR NINGÚN DAÑO CONSECUENTE, INCIDENTAL O

CONTINGENTE DE NINGUNA NATURALEZA.

LAS GARANTÍAS ANTERIORES SON EXCLUSIVAS Y REEMPLAZAN CUALESQUIERA OTRAS

GARANTÍAS EXPRESAS. LAS GARANTÍASIMPLÍCITAS, INCLUYENDO, PERO NO LIMITADAS A, LAS GARANTÍAS IMPLÍCITAS DE COMERCIABILIDAD Y APTITUD PARA UN

PROPÓSITO EN PARTICULAR, NO DEBERÁN EXCEDER EL PERÍODO DE DURACIÓN DE

LAS GARANTÍAS EXPRESAS APLICABLES AQUÍ PROVISTAS.

Algunos estados no permiten la exclusión o limitación de daños incidentales o consecuentes

ni las limitaciones respecto a la duración de garantías implícitas; de modo que las limitaciones o exclusiones precedentes pueden no aplicarse en su caso. Esta garantía le concede derechos legales específicos. Usted puede tener, además, otros derechos que varían de un estado a otro.

Garantía limitada de Simer

SIMER • 293 Wright St. • Delavan, WI U.S.A. 53115

Teléfono: 1-800-468-7867 / 1-800-546-7867 • Fax: 1-800-390-5351

e-Mail (correo electrónico): info@simerwater.com • Dirección web: http://www.simerwater.com

Page 16

Si necesita repuestos o asistencia llame al Servicio al Cliente de Simer, 1-800-468-7867/1-800-546-7867

Installación 16

ESPECIFICACIONES

Suministro de potencia requerido ................................115 Voltios

Servicio del motor ...........................................................Continuo

Requisito de circuito (mínimo)................................15.0 amperios

Adaptador de descarga ...............................................................1"

INSTALACIONES DE LA BOMBA

DE CHORRO EN POZOS POCO

PROFUNDOS

• La profundidad vertical debe ser de 25 pies o menor.

• Se debe tener una tubería desde el pozo a la caja de la

bomba.

• Se puede instalar en un pozo perforado o taladrado, o en un

pozo hincado.

REEMPLAZO DE UNA BOMBA USADA

Tensión peligrosa. Puede causar choque,

quemaduras o muerte. Desconecte la corriente eléctrica hacia la

bomba antes de trabajar con la bomba o con el motor.

Esta bomba puede reemplazar la bomba de chorro para pozos

poco profundos, Modelo 3825. Se deberá volver a usar el

manóstato y cablear la bomba al mismo.

1. Drene y saque la bomba usada. Verifique que las tuberías

antiguas no tengan restos de oxidación, cal, herrumbre, etc.

y cámbielas de ser necesario.

2. Instale la bomba en el sistema. Asegúrese de que todas las

uniones de las tuberías en la tubería de aspiración estén herméticas y estancas. Si la tubería de aspiración puede aspirar

aire, la bomba no podrá extraer agua desde el pozo.

3. Ajuste la altura de montaje de la bomba para que las conexiones de plomería no ejerzan presión sobre la unidad de la

bomba. Apoye las tuberías de manera que la unidad de la

bomba no deba soportar el peso de las tuberías o de los

accesorios.

Usted acaba de completar la tubería del pozo para su nueva

bomba de chorro para pozos poco profundos. Pase a la

página 6 para la información sobre las conexiones de la

tubería de descarga y del tanque.

REFUERZO DE LA PRESIÓN

DE LAS AGUAS PÚBLICAS

Presión Peligrosa. Nunca haga marchar

la bomba contra una descarga cerrada ya que esto hará que el

agua dentro de la bomba hierva, provocando una presión peligrosa en la bomba, con riesgo de explosión y la posibilidad de

escaldar a personas cercanas. Consulte la Figura 1.

Cuando use la bomba para lavar a alta presión, emplee solamente una manguera o tubería reforzada para alta presión como

línea de descarga. Cuando use una manguera de jardín, instale

adaptadores en la aspiración y la descarga de la bomba. La

manguera de aspiración requerirá dos extremos hembra. Use una

manguera de suministro estándar para lavarropas o modifique un

trozo corto de una manguera de jardín estándar de 1" como

línea de aspiración (Consulte la Figura 2).

Presión de salida Máximas PSI

Modelo 0 10 20 30 40 50 (libras por pulgada cuadrada)

2825ss 10 8.5 8.0 7.5 7.0 6.0 80

DESEMPEÑO

Cómo sellar las juntas de tuberías

Use solamente cinta de teflón para hacer las conexiones roscadas a la bomba. No use compuestos para

juntas de tuberías en bombas de plástico; éstas

pueden reaccionar con el plástico en los componentes de la bomba. Asegúrese de que todas las juntas de tubería en la tubería de aspiración sean herméticas y estancas.

Si la tubería de aspiración puede

aspirar aire, la bomba no podrá extraer agua del pozo.

1117 0993

Figura 1: No haga marchar la bomba con la salida cerrada

Hose Adapters

Figura 2: Instalación del adaptador de manguera

Adaptadores

de manguera

ADVERTENCIA

ADVERTENCIA

Page 17

Si necesita repuestos o asistencia llame al Servicio al Cliente de Simer, 1-800-468-7867/1-800-546-7867

Installación / Operación 17

Presión Peligrosa. No cierre la manguera

ni los rociadores mientras la bomba esté funcionando, ya que la

manguera o el cabezal rociador pueden explotar.

TUBERÍA

Tanto los orificios de aspiración como de descarga están fileteados

para roscas de 1" BSP. Si emplea mangueras, use adaptadores de

manguera. Consulte la Figura 2. No use una manguera en la

aspiración si está bombeando desde lagos, corrientes de agua o

estanques. La manguera se desplomará y la bomba fallará. Instale

una criba con una válvula de pie en el extremo de la línea de

aspiración. Inspeccione y limpie la criba con frecuencia (Figura 4).

AVISO: Una fuga de aire en la tubería de aspiración puede introducir aire aunque no haya fuga de agua. Verifique que no haya

fugas de aire ni bolsas de aire en la tubería de aspiración.

CEBADURA / OPERACIÓN

AVISO: No permita que la bomba marche en seco, ya que si la

bomba marcha sin agua, se puede dañar el impulsor y el sello,

provocando fugas o inundaciones, y la garantía quedará anulada.

Todas las conexiones de aspiración deben ser herméticas.

Verifique que la altura de aspiración no supere los 25 pies

(7.6 m). Llene la unidad de la bomba por el orificio de cebadura

antes de encender la bomba.

Encienda la bomba; deberá bombear agua en menos de 10 minutos (dependiendo del largo de la manguera de aspiración y de la

altura de la bomba sobre el agua).

PREPARACIÓN PARA ENCENDER LA

BOMBA (CONSULTE LA FIGURA 5)

Peligro de quemadura. Nunca haga mar-

char la bomba en seco. Si la bomba marcha sin agua puede

provocar sobrecalentamiento, puede dañar el sello y, posiblemente, provoque quemaduras a las personas que la estén manipulando. Llene la bomba con agua antes de encenderla.

Presión peligrosa. Nunca haga marchar

una bomba hacia una descarga cerrada, ya que eso puede hacer

hervir el agua dentro de la bomba, produciendo una presión peligrosa en la unidad, un riesgo de explosión y posibles escaldaduras a las personas que estén manipulando la bomba.

1. Saque el tapón de cebadura del Te de cebadura y llene la

bomba (ver la figura 5). Llene toda la tubería entre la bomba

y el pozo, asegurándose de que toda la tubería en el pozo

esté llena. Si también ha instalado un Te de cebadura en la

tubería de aspiración, saque el tapón del Te y llene la tubería

de aspiración. Consulte la Figura 5.

Figura 3: Conecte la bomba a una espiga para usar con

los rociadores. Conecte con los adaptadores suministrados con la bomba

115V, GFCI

Protected,

Grounded

Outlet Box

Discharge Line

(Garden Hose or

Rigid Pipe)

Suction Line

(Garden Hose or

Rigid Pipe)

Foot valve with

strainer (clean

frequently)

Hose

Adapters

Figura 4: Instalación de la criba y de la válvula de pie

Remove the

plug and

fill the pump

and the piping

through the

priming tee.

Figura 5: Cebadura de la bomba

Conecte el grifo de agua

de admisión de la bomba

al grifo de agua para

usar con los rociadores

Grifo de agua

Adaptadores

de manguera

Caja de salida de

115 V, puesta a

tierra, protegida

por un GFCI

Línea de descarga

(manguera de

jardín o tubo rígido)

Adaptadores

de manguera

Válvula de pie con criba

(limpiar frecuentemente)

Línea de aspiración

(manguera de jardín

o tubo rígido)

Saque el tapón y

llene la bomba y la

tubería a través del

Te de cebadura.

ADVERTENCIA

Connect the Pump Inlet

to the Water Faucet

for use with Sprinklers.

Water Faucet

3942 0401

Hose

Adapters

PRECAUCIÓN

ADVERTENCIA

Page 18

Operación 18

Si necesita repuestos o asistencia llame al Servicio al Cliente de Simer, 1-800-468-7867/1-800-546-7867

2. Vuelva a colocar todos los tapones de llenado.

3. ¡Actívela! Encienda la bomba. Si no se obtiene agua después

de 2 ó 3 minutos, detenga la bomba y retire los tapones de

llenado. Vuelva a llenar la bomba y la tubería. Es posible que

deba repetir esto varias veces para sacar todo el aire atrapado

en la tubería. La cebadura de una bomba que levanta agua a

25 pies, puede demorar hasta 15 minutos.

4. Después de que la bomba haya producido presión en el sistema y esté apagada, verifique la operación del manóstato

abriendo un grifo o dos y dejando correr suficiente agua

como para descargar la presión hasta que la bomba se

encienda. La bomba se deberá encender cuando la presión

caiga a 30 PSI y se deberá detener cuando la presión alcance

las 50 PSI. Haga marchar la bomba por uno o dos ciclos

completos para verificar que esté funcionando correctamente.

Esto también le ayudará a limpiar el sistema del polvo y la

oxidación acumulados durante la instalación.

Felicitaciones por una instalación exitosa.

Si no tuvo éxito, consulte la sección de Localización de Fallas (a

continuación) o llame a nuestro personal técnico de atención al

cliente, al 1-800-468-7867.

Localización de fallas

SÍNTOMA POSIBLE(S) CAUSA(S) ACCIÓN CORRECTIVA

El motor no marcha Fusible quemado o disyuntor disparado DESCONECTE LA CORRIENTE ELÉCTRICA; Reemplace el fusible

o reposicione el disyuntor.

El motor marcha y se El voltaje es demasiado bajo Verifique el voltaje suministrado a la bomba.

recalienta y la

protección contra

sobrecarga se dispara o

no marcha y solamente

zumba

El motor marcha pero La bomba durante una instalación En una nueva instalación:

no entrega agua* nueva no se cebó debido a:

1. Cebadura incorrecta 1. Vuelva a cebar según las instrucciones.

2. Fugas de aire 2. Verifique todas las conexiones en la línea de aspiración con agua

jabonosa o con crema de afeitar.

3. Fugas en la válvula de pie 3. Reemplace la válvula de pie.

4. El tamaño del tubo es 4. Reemplace la tubería por tubos del tamaño de los orificios de

demasiado pequeño aspiración y de descarga en la bomba.

La bomba ha perdido cebadura debido a: En instalaciones que ya estén en uso:

1. Fugas de aire 1. Verifique todas las conexiones en la línea de aspiración y el sello

del eje con agua jabonosa.

2. Nivel del agua debajo de la 2. Baje la línea de aspiración dentro del agua y vuelva a cebar. Si el nivel

admisión de la tubería de aspiración del agua que se retira supera los 25’ (7.6 m), se necesitará una bomba

para pozos profundos.

El impulsor está obstruido Limpie el impulsor.

La válvula de pie está atascada en Reemplace la válvula de pie.

la posición cerrada

Las tuberías están congeladas Descongele las tuberías.

La válvula de pie y/o la criba están Eleve la válvula de pie y/o la criba por encima del fondo de la fuente de

enterradas en arena o lodo agua. Limpie la válvula de pie y la criba.

*La bomba no entrega El agua que se bombea es menor Es posible que se necesite un chorro para pozos profundos si el agua que

agua a toda capacidad de lo estimado se bombea está a más de 25’ (7.6 m) de profundidad al agua.

La tubería de acero (si se usó) está Reemplace por una tubería de plástico en donde sea posible, de lo

corroída u oxidada, provocando un contrario por una nueva tubería de acero.

exceso de fricción

El tamaño de la tubería es Coloque una nueva tubería usando el tamaño debido en función de los

demasiado pequeño orificios de aspiración y de descarga en la bomba.

La bomba no está recibiendo Agregue puntos filtrantes adicionales.

suficiente agua

* (Nota:

Detenga la

bomba;

luego verifique la cebadura

antes de buscar otras

causas. Destornille el

tapón de cebadura y

verifique si hay agua

en el orificio de

cebadura).

Page 19

Piezas de repuesto 19

Si necesita repuestos o asistencia llame al Servicio al Cliente de Simer, 1-800-468-7867/1-800-546-7867

Clave No. Descripción de la pieza Cantidad Número de pieza

1 Unidad de la bomba 1 723S2290

2 Aro tórico, tapón de desagüe 2 111P0990

3 Tapón de desagüe 2 121P2100

4 Aro tórico, tobera 1 111P0480

5 Unidad de difusor, venturi y tobera 1 101P2840

6 Impulsor 1 731S2220

7 Unidad de sello mecánico 1 ZBR00010

8 Aro tórico, Unidad de la bomba 1 111P1190

9 Brida 1 101P1290

10 Soporte intermedio 1 731P0170

11 Manija 1 101P1450

12 Arandela, Manija 1 121P1500

13 Tornillo, Manija 1 121P1600

14 Contratuerca, Manija 1 121P0950

15 Deflector del agua 1 102P0540

16 Agarradera de la manija, Manija 1 102P1650

17 Ventilador, refrigerante 1 102P0570

18 Cubierta del ventilador 1 721S1090

19 Cordón eléctrico 1 191P0560

20 Tornillos, Soporte del capacitor 11 121P2060

21 Saliente de puesta a tierra 1 171P4070

22 Caja del capacitor con cubierta 1 102P2830

23 Capacitor 1 171P5430

24 Aro tórico, Caja del capacitor 1 111P1350

25 Arandela, Tornillo de puesta a tierra 1 121P0090

26 Contratuerca, Tornillo de puesta a tierra 1 121P0920

27 Tornillo, Tierra 1 121P1280

28 Unidad de base 1 ZBR05420

29 Tornillo, Unidad de la bomba 6 121P0340

8

7

6

17

23

18

24

22

27

3985 0501

5

4

3

2

1

16

13

12

29

2

3

11

10

9

15

14

21

22

25

26

28

19

20

Page 20

Loading...

Loading...