Page 1

OWNER’S MANUAL

Shallow Well Jet Pumps

NOTICE D’UTILISATION

293 Wright Street, Delavan, WI 53115

Phone: 1-800-468-7867

Fax: 1-800-390-5351

Web Site: SimerPump.com

Pompes à éjecteur pour puits

peuprofonds

MANUAL DEL USUARIO

Bombas de chorro para pozos

poco profundos

2805E-02, 2810E-02

Installation/Operation/Parts

For further operating, installation, or

maintenance assistance:

Call 1-800-468-7867

English. . . . . . . . . . . Pages 2-10

© 2011 SIM929 (4/7/11)

Installation/Fonctionnement/Pièces

Pour plus de renseignements

concernant l’utilisation,

l’installation ou l’entretien,

Composer le 1 (800) 468-7867

Français. . . . . . . . . Pages 11-19

Instalación/Operación/Piezas

Para mayor información sobre el

funcionamiento, instalación o

mantenimiento de la bomba:

Llame al 1-800-468-7867

Español . . . . . . . Paginas 20-28

Page 2

Safety 2

Important Safety Instructions

SAVE THESE INSTRUCTIONS - This manual contains

important instructions that should be followed during

installation, operation, and maintenance of the product.

Save this manual for future reference.

This is the safety alert symbol. When you see this

symbol on your pump or in this manual, look for one of

the following signal words and be alert to the potential

for personal injury!

indicates a hazard which, if not avoided, will

result in death or serious injury.

indicates a hazard which, if not avoided,

could result in death or serious injury.

indicates a hazard which, if not avoided,

could result in minor or moderate injury.

NOTICE

Carefully read and follow all safety instructions in this

manual and on pump.

Keep safety labels in good condition.

Replace missing or damaged safety labels.

addresses practices not related to personal injury.

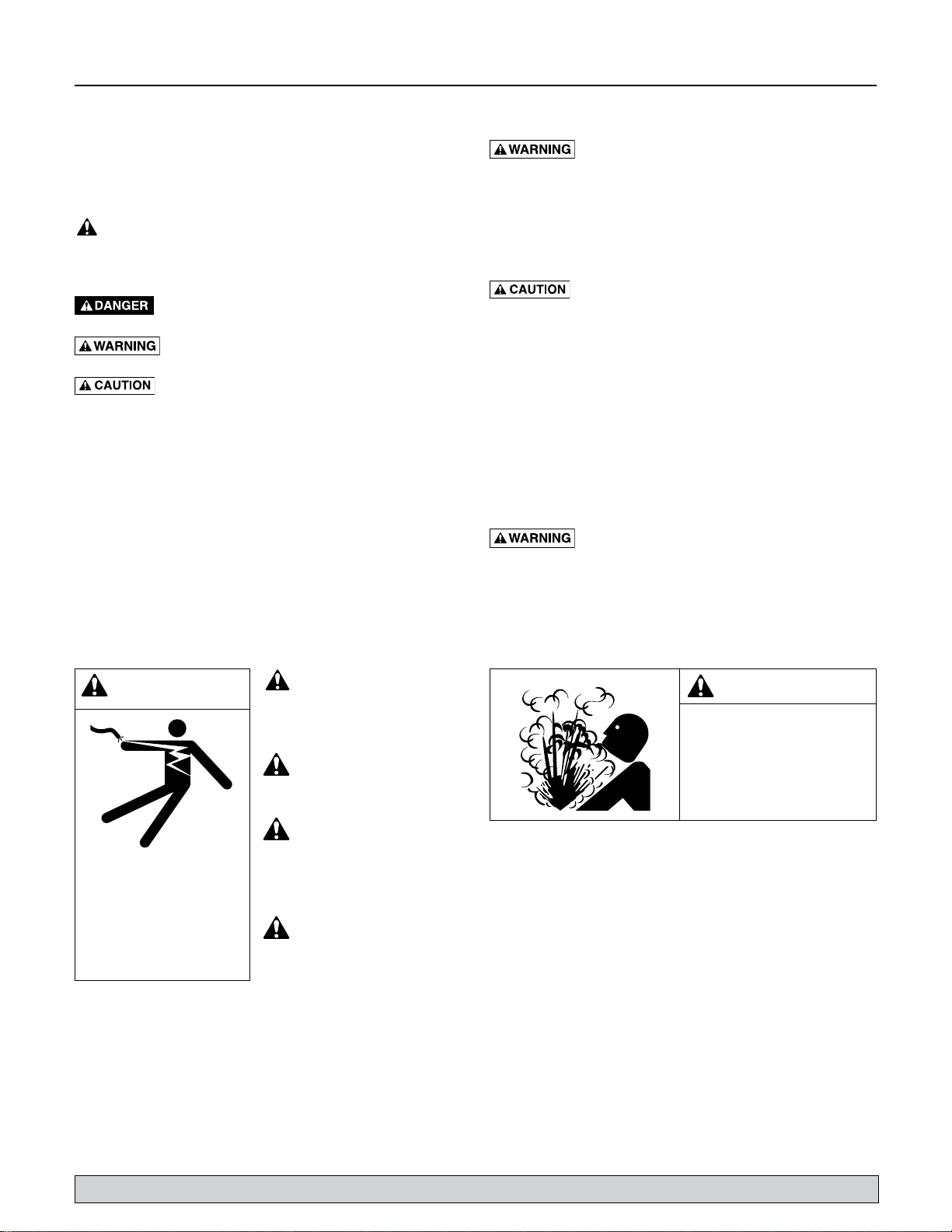

Electrical Safety

Capacitor voltage may be hazardous.

To discharge motor capacitor, hold insulated handle

screwdriver BY THE HANDLE and short capacitor

terminals together. Do not touch metal screwdriver blade

or capacitor terminals. If in doubt, consult a qualified

electrician.

General Safety

Do not touch an operating motor. Modern

motors are designed to operate at high temperatures. To

avoid burns when servicing pump, allow it to cool for

20minutes after shut-down before handling.

Do not allow pump or any system component to freeze.

To do so will void warranty.

Pump water only with this pump.

Periodically inspect pump and system components.

Wear safety glasses at all times when working on pumps.

Keep work area clean, uncluttered and properly lighted;

store properly all unused tools and equipment.

Keep visitors at a safe distance from the work areas.

Pump body may explode if used as a

booster pump unless relief valve capable of passing full

pump flow at 75 psi is installed.

WARNING

Hazardous voltage.

Can shock, burn, or

cause death.

Ground pump before

connecting to power

supply. Disconnect power

before working on pump,

motor or tank.

Wire motor for correct

voltage. See “Electrical”

section of this manual

and motor nameplate.

Ground motor before

connecting to power

supply.

Meet National Electrical

Code, Canadian

Electrical Code, and

local codes for all

wiring.

Follow wiring

instructions in this

manual when

connecting motor to

power lines.

WARNING

Hazardous pressure!

Install pressure relief

valve in discharge pipe.

Release all pressure on

system before working on

any component.

For parts or assistance, call Simer Customer Service at 1-800-468-7867

Page 3

Warranty 3

Retain Original Receipt For Your Records

Limited Warranty

SIMER warrants to the original consumer purchaser (“Purchaser” or “You”) of its products that they are free from defects in material and workmanship

for a period of twelve (12) months from the date of the original consumer purchase.

If, within twelve (12) months from the original consumer purchase, any such product shall prove to be defective, it shall be repaired or replaced at

SIMER’s option, subject to the terms and conditions set forth below. The original purchase receipt and product warranty information label are required

to determine warranty eligibility. Eligibility is based on purchase date of original product – not the date of replacement under warranty. The warranty is

limited to repair or replacement of product only – Purchaser pays all removal, installation, labor, shipping, and incidental charges.

For parts or troubleshooting assistance, DO NOT return product to your retail store. Contact SIMER Customer Service at 1-800-468-7867.

Claims made under this warranty shall be made by returning the product (except sewage pumps, see below) to the retail outlet where it was purchased

immediately after the discovery of any alleged defect. SIMER will subsequently take corrective action as promptly as reasonably possible. No requests

for service will be accepted if received more than 30 days after the warranty expires.

Warranty does not apply to products used in commercial/rental applications.

Sewage Pumps

DO NOT return a sewage pump (that has been installed) to your retail store. Contact SIMER Customer Service. Sewage pumps that have seen service

and been removed carry a contamination hazard with them.

If your sewage pump has failed:

• Wearrubbergloveswhenhandlingthepump;

• Forwarrantypurposes,returnthepump’scordtagandoriginalreceiptofpurchasetotheretailstore;

• Disposeofthepumpaccordingtolocaldisposalordinances.

Exceptions to the Twelve (12) Month Limited Warranty

Product Warranty Period

BW85P,CM10,CMK,M40,M40P 90 days

2300,2310,2330,2520ULST,2943,2955,2956,2957,2960,5023SS,A5500 2 Years

4”SubmersibleWellPumps,2945,2958,2975PC,2985,3075SS,3983,3984 3 Years

Pre-ChargeWaterSystemTank,3985,3986,3988,3989 5Years

3963,3995,3997 Lifetime

General Terms and Conditions

You must pay all labor and shipping charges necessary to replace product covered by this warranty. This warranty does not apply to the following: (1)

actsofGod;(2)productswhich,inSIMER’ssolejudgement,havebeensubjecttonegligence,abuse,accident,misapplication,tampering,oralteration;

(3)failuresduetoimproperinstallation,operation,maintenanceorstorage;(4)atypicalorunapprovedapplication,useorservice;(5)failurescaused

by corrosion, rust or other foreign materials in the system, or operation at pressures in excess of recommended maximums.

This warranty sets forth SIMER’s sole obligation and purchaser’s exclusive remedy for defective products.

SIMER SHALL NOT BE LIABLE FOR ANY CONSEQUENTIAL, INCIDENTAL, OR CONTINGENT DAMAGES WHATSOEVER.

THE FOREGOING WARRANTIES ARE EXCLUSIVE AND IN LIEU OF ALL OTHER EXPRESS AND IMPLIED WARRANTIES, INCLUDING BUT NOT LIMITED

TO THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. THE FOREGOING WARRANTIES SHALL NOT

EXTEND BEYOND THE DURATION PROVIDED HEREIN.

Some states do not allow the exclusion or limitation of incidental or consequential damages or limitations on how long an implied warranty lasts, so

the above limitations or exclusions may not apply to You. This warranty gives You specific legal rights and You may also have other rights which vary

from state to state.

SIMER • 293 Wright Street • Delavan, WI U.S.A. 53115

Phone: 1-800-468-7867 • Fax: 1-800-390-5351 • Web Site: simerpump.com

Page 4

Installation 4

To Household

Water System

Typical pump

Pump Priming

Tee and Plug

Priming

Tee and

Plug

Drive point

below water

level

Check

Valve

Drive

Coupling

Drive

Point

shown herein

not to scale

Figure 1: Driven Point Installation

To Household

Water System

Pump Priming

Tee and Plug

Suction Pipe

From Well

Priming

Tee and

Plug

Replacing An Old Pump

Hazardous voltage. Disconnect power to pump before

working on pump or motor.

1. Drain and remove the old pump. Check the old pipe for scale, lime,

rust, etc., and replace it if necessary.

2. Install the pump in the system. Make sure that all pipe joints in the

suction pipe are air-tight as well as water tight. If the suction pipe can

suck air, the pump will not be able to pull water from the well.

3. Adjust the pump mounting height so that the plumbing connections do

not put a strain on the pump body. Support the pipe so that the pump

body does not take the weight of piping or fittings.

You have just completed the well plumbing for your new shallow well jet

pump. Please go to Page 6 for discharge pipe and tank connections.

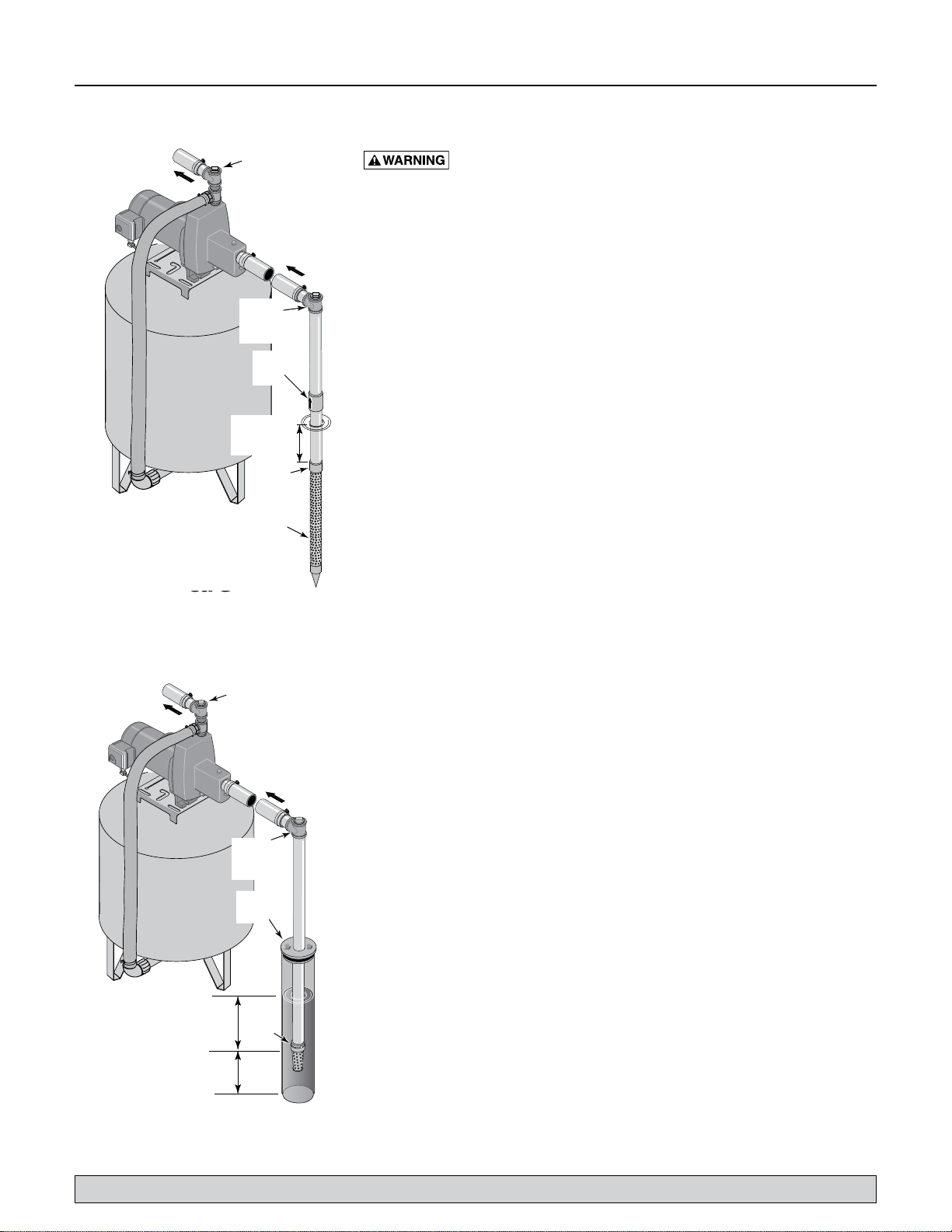

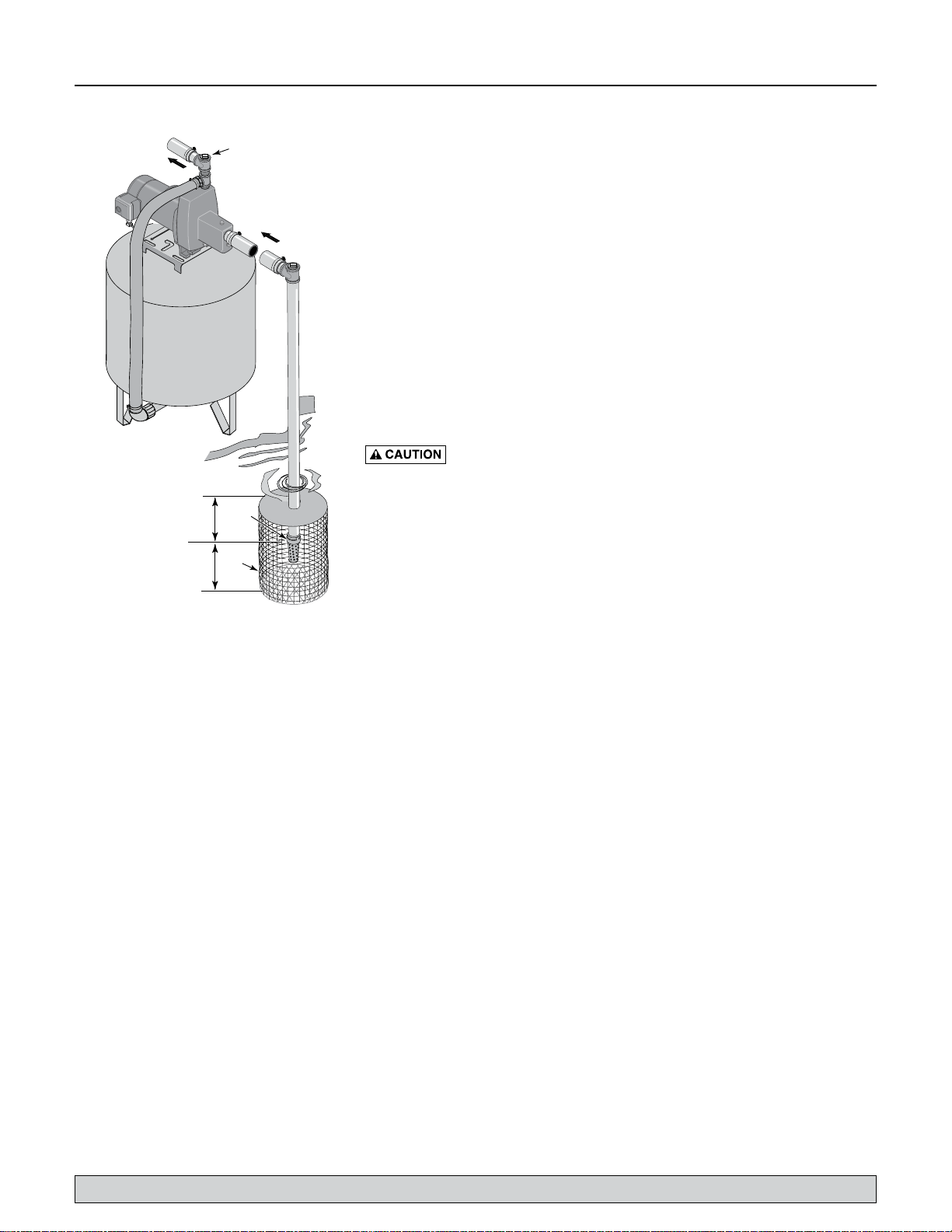

Well Point (Driven Point) Installation (Figure 1)

1. Drive the well, using “drive couplings” and a “drive cap”. “Drive

fittings” are threaded all the way through and allow the pipe ends to

butt against each other so that the driving force of the maul is carried

by the pipe and not by the threads. The ordinary fittings found in

hardware stores are not threaded all the way through the fitting and can

collapse under impact. “Drive fittings” are also smoother than standard

plumbing fittings, making ground penetration easier.

2. Mount the pump as close to the well as possible.

3. Use the fewest possible fittings (especially elbows) when connecting

the pipe from the well point to the pump suction port. The suction pipe

should be at least as large as the suction port on the pump (include

a check valve if your pump is not equipped with one – see Figure

1). Support the pipe so that there are no dips or sags in the pipe, so

it doesn’t strain the pump body, and so that it slopes slightly upward

from the well to the pump (high spots can cause air pockets which can

air lock the pump). Seal the suction pipe joints with 1Teflon™ tape or

a Teflon™ based pipe joint compound. Joints must be air- and watertight. If the suction pipe can suck air, the pump cannot pull water from

the well. If one well point does not supply enough water, consider

connecting two or three well points to one suction pipe.

You have just completed the suction piping for your new shallow well jet

pump. Please go to Page 6 for discharge pipe and tank connections.

1

E. I. DuPont de Demours and Company Corporation, Delware

Sanitary

Well Seal

Foot

10'

Min.

Valve

5–10'

Figure 2: Cased Well Installation

For parts or assistance, call Simer Customer Service at 1-800-468-7867

Cased Well Installation, 2” or Larger Casing (Figure2)

1. Mount the pump as close to the well as possible.

2. Assemble the foot valve, strainer, and well pipe (see Figure 2). Make

sure that the foot valve works freely.

3. Lower the pipe into the well until the strainer is five feet above the

bottom of the well. It should also be at least 10 feet below the well’s

water level while the pump is running in order to prevent the pump

from sucking air. Install a sanitary well seal.

Page 5

Installation 5

To Household

Water System

5–10'

10'

Min.

Pump Priming

Tee and Plug

Suction Pipe

From Well

Foot

Valve

Screen

Figure 3: Surface Water Installation

4. Install a priming tee, priming plug, and suction pipe to the pump

(see Figure 2). Connect the pipe from the well to the pump suction

port, using the fewest possible fittings – especially elbows – as fittings

increase friction in the pipe (however, include a foot valve – see

Figure2). The suction pipe should be at least as large as the suction

port on the pump. Support the pipe so that there are no dips or sags

in the pipe, so it doesn’t strain the pump body, and so that it slopes

slightly upward from the well to the pump (high spots can cause air

pockets which can air lock the pump). Seal the suction pipe joints with

Teflon™ tape or a Teflon™ based pipe joint compound. Joints must be

air- and water-tight. If the suction pipe can suck air, the pump cannot

pull water from the well.

You have just completed the suction piping for your new shallow well jet

pump. Please go to Page 6 for discharge pipe and tank connections.

Installation for Surface Water (Figure 3)

Possible contamination. Do not use surface water for drinking.

The installation shown could be used for sprinkler applications.

1. The pump should be installed as close to the water as possible, with

the fewest possible fittings (especially elbows) in the suction pipe.

The suction pipe should be at least as large as the suction port on

thepump.

2. Assemble a foot valve and suction pipe (see Figure 3). Make sure that

the foot valve works freely. Use Teflon™ tape or a Teflon™-based

pipe joint compound on threaded pipe joints. Protect the foot valve

assembly from fish, trash, etc, by installing a screen around it (see

Figure 3).

3. Lower the pipe into the water until the strainer is five feet above the

bottom. It should also be at least 10 feet below the water level in order

to prevent the pump from sucking air.

4. Install a priming tee, priming plug, and suction pipe to the pump (see

Figure 3). Support the pipe so that there are no dips or sags in the pipe,

so it doesn’t strain the pump body, and so that it slopes slightly upward

from the well to the pump (high spots can cause air pockets which can

air lock the pump). Seal the suction pipe joints with Teflon™ tape or

a Teflon™ based pipe joint compound. Joints must be air- and watertight. If the suction pipe can suck air, the pump cannot pull water from

thewell.

You have just completed the plumbing for your new shallow well jet pump.

Please go to Page 6 for discharge pipe and tank connections.

For parts or assistance, call Simer Customer Service at 1-800-468-7867

Page 6

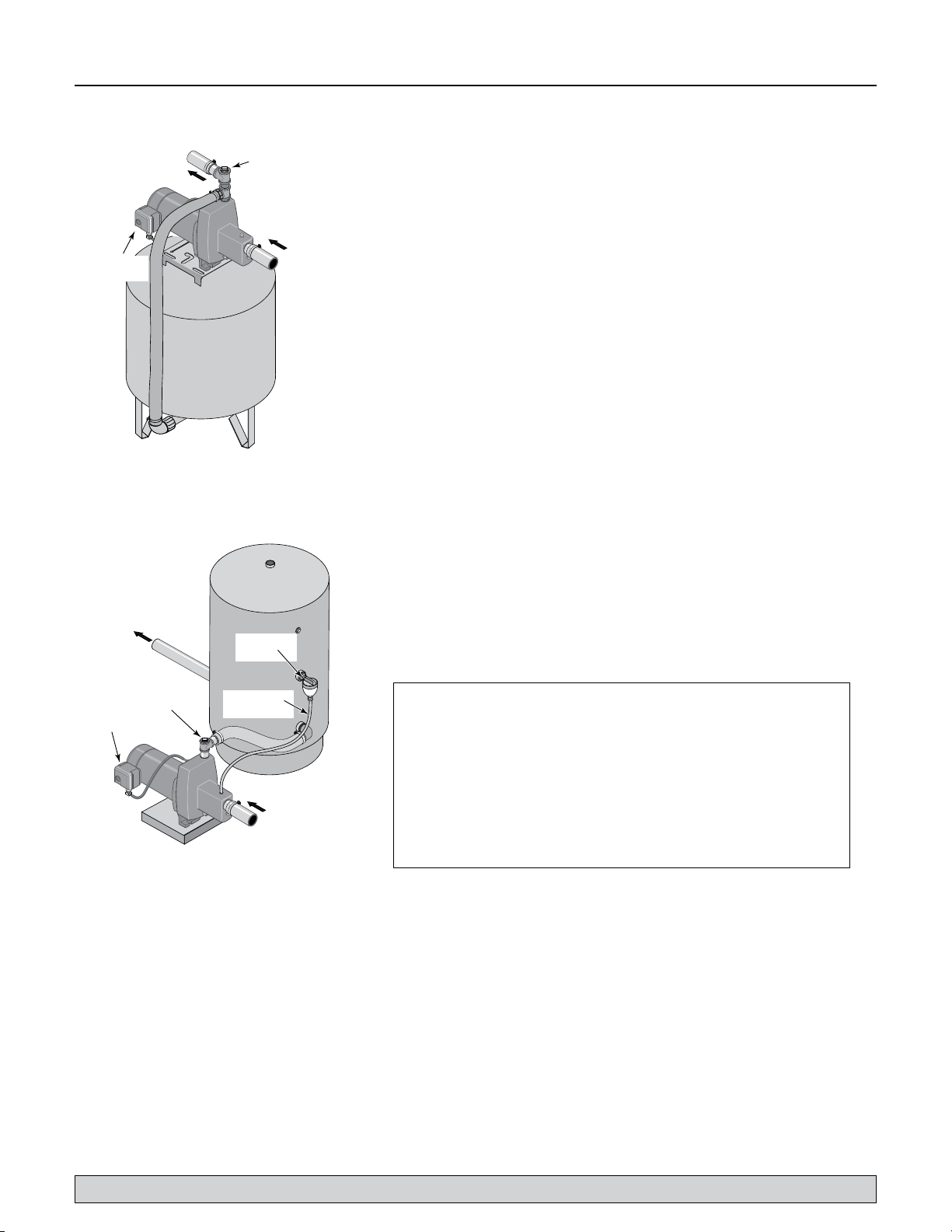

Discharge Pipe and Pressure Tank Connections 6

To Household

Water System

Pressure

Switch

Pump Priming

Tee and Plug

From

Well

Figure 4: Pre-charged Tank Connections

To Household

Water System

Air Volume

Control

Pump

Pressure

Switch

Priming Tee

and Plug

Air Volume

Control Tube

From

Well

Figure 5: Standard Tank Connections

Pre-Charge Tank Connection (Figure 4)

1. Install two tees in the pump discharge port (see Figure 4). The pipe size

must be at least as large as the discharge port.

2. Run a pipe or reinforced hose from one arm of the first tee to the port

on the pre-charged tank.

3. Connect the other end of the discharge tee to your plumbing system.

Cap the tee with a threaded plug or a pressure gauge.

4. Check the pre-charge of air in the tank with an ordinary tire gauge. The

pre-charge should be 2 PSI less than the cut-in setting of the pump’s

pressure switch. The pre-charge is measured when there is no water

pressure in the tank. Your new pump has a 30/50 PSI switch, so adjust

the tank pre-charge pressure to 28 PSI.

Congratulations! You have just completed the tank connection for your jet

pump. Please go to Page 7 for electrical hookup.

Standard Tank Connection (Figure 5)

1. Install one tee in the pump discharge port (see Figure 5).

2. Run a pipe from the pump discharge port to the inlet port of your tank.

The pipe size must be at least as large as the discharge port.

3. Install a tee in the suction pipe near the pump. Install a reducer

bushing down to 1/8” NPT in the tee. Run tubing from the tee to the

port on the AVC mounted on the tank. Seal all joints with Teflon™

tape. See instructions provided with the tank and the AVC for details.

Congratulations! You have just completed the tank connection for your jet

pump. Please go to Page 7 for electrical hookup.

Sealing Pipe Joints

Use only

making all threaded connections to the pump itself. Do not

use pipe joint compounds on plastic pumps: they can react

with the plastic in pump components. Make sure that all pipe

joints in the suction pipe are air tight as well as water tight. If

the suction pipe can suck air, the pump will not be able to pull

water from the well.

1

E. I. DuPont de Demours and Company Corporation, Delware

1

Teflon™ tape or Teflon™ based joint compounds for

For parts or assistance, call Simer Customer Service at 1-800-468-7867

Page 7

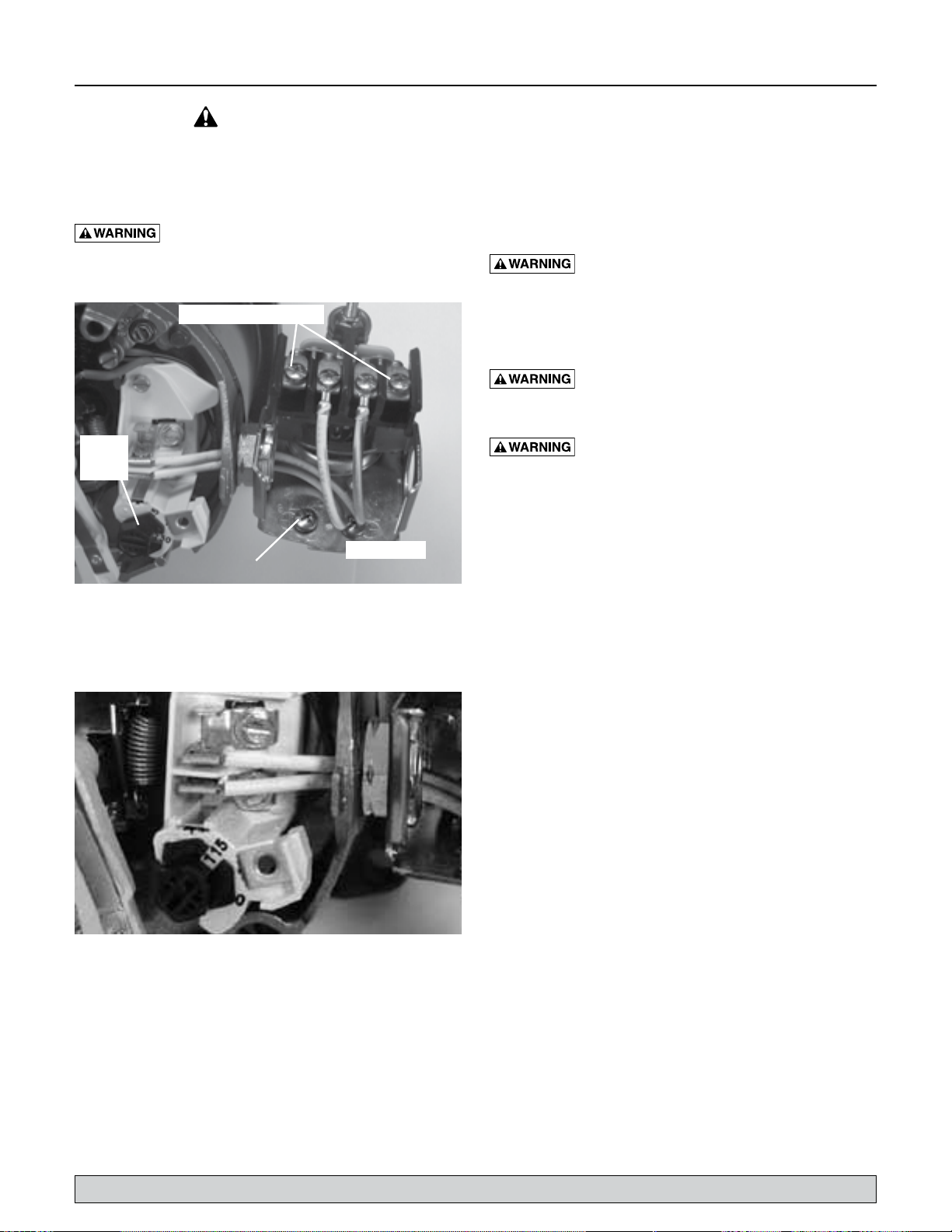

Electrical 7

Disconnect power before working on pump, motor, pressure switch, or wiring.

Motor Switch Settings

NOTICE: 1/2 HP motors are dual voltage and are factory set to 115V. 3/4 & 1 HP motors are also dual voltage, but are

factory set to 230V. Motor terminal board (located under the motor end cover) should look like that shown below. Use

the instructions to set your motor to match your power source.

Never connect a motor set to 115V to a 230V power source.

Dial Type Voltage Selector

Voltage is set to 230 volts. To change to 115 volts:

Power Supply Connections

Voltage

Change

Dial

Pressure Switch

Ground Wire Connection

Figure 6: Voltage set to 230 volts, Dial Type

1. Make sure power is off.

2. Turn the dial counter-clockwise until 115 shows in

the dial window as shown in Figure 7.

Figure 7: Voltage set to 115 volts, Dial Type

3. Attach the incoming power leads to the two outer

screws on the pressure switch as shown in Figure 6.

4. Attach the ground wire to the grounding connections

as shown in Figure 6.

5. If there are other wires, they should be capped.

6. Reinstall the pressure switch and motor end covers.

Hazardous voltage. Can shock, burn, or

kill. Connect ground wire before connecting power

supply wires. Use the wire size (including the ground

wire) specified in the wiring chart. If possible, connect

the pump to a separate branch circuit with no other

appliances on it.

Explosion hazard. Do not ground to a gas

supply line.

Wiring Connections

Fire hazard. Incorrect voltage can cause

a fire or seriously damage the motor and voids the

warranty. The supply voltage must be within ±10% of the

motor nameplate voltage.

NOTICE: Dual-voltage motors may be set for 115V

or 230V. If necessary, reset the motor to the desired

voltage, as shown. Do not alter the wiring in single

voltagemotors.

Install, ground, wire, and maintain your pump in

compliance with the National Electrical Code (NEC) or

the Canadian Electrical Code (CEC), as applicable, and

with all local codes and ordinances that apply. Consult

your local building inspector for code information.

Connection Procedure:

1. Connect the ground wire first as shown in Figure 6.

The ground wire must be a solid copper wire at least

as large as the power supply wires.

2. There must be a solid metal connection between the

pressure switch and the motor for motor grounding

protection. If the pressure switch is not connected

to the motor, connect the green ground screw in the

switch to the green ground screw under the motor

end cover. Use a solid copper wire at least as large

as the power supply wires.

3. Connect the ground wire to a grounded lead in a

service panel, to a metal underground water pipe, to

a metal well casing at least ten feet (3m) long, or to

a ground electrode provided by the power company

or the hydro authority.

4. Connect the power supply wires to the pressure

switch as shown in Figure 6.

You have just completed the wiring for your pump.

Please go to Page 8 for startup preparations.

For parts or assistance, call Simer Customer Service at 1-800-468-7867

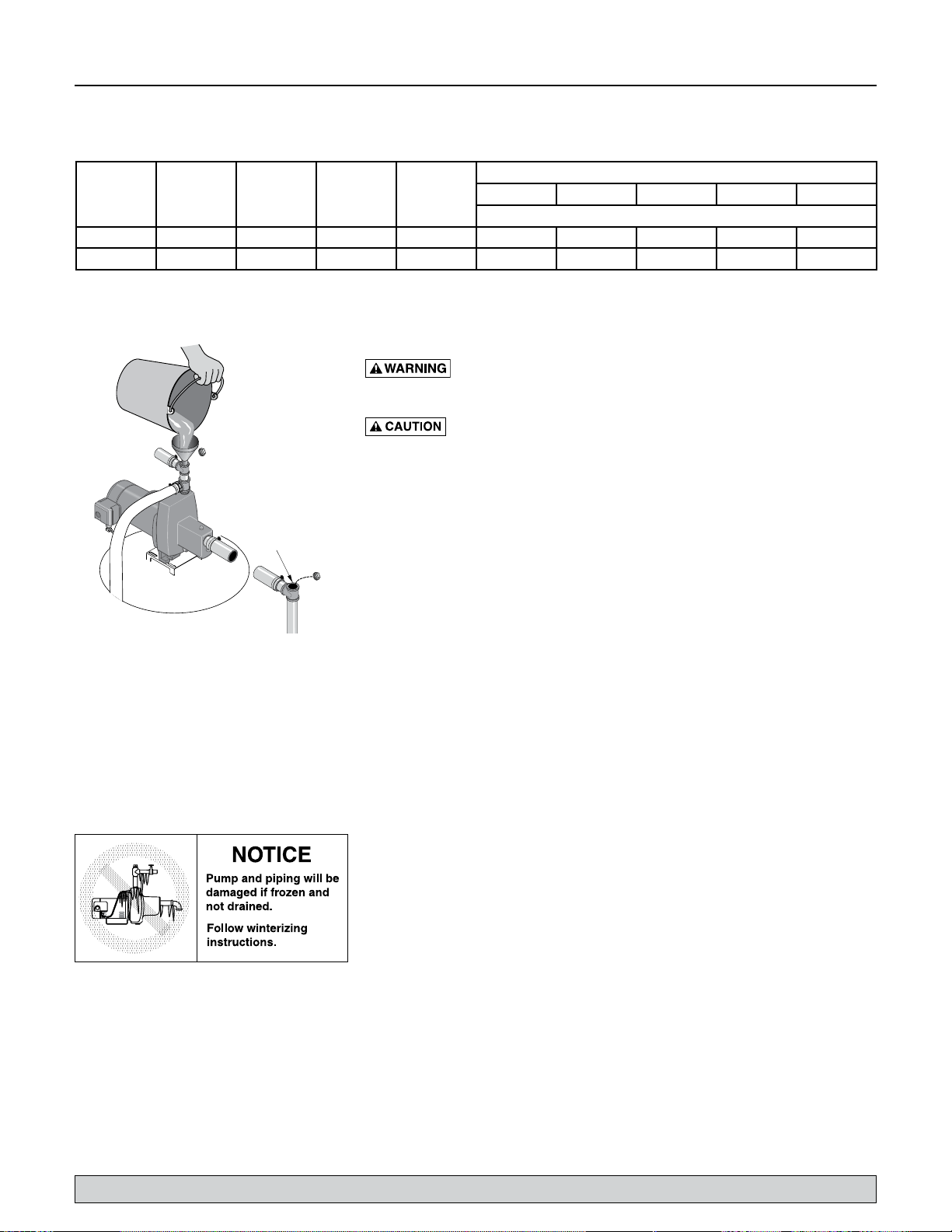

Page 8

Electrical 8

Wiring Chart – Recommended Wire and Fuse Sizes

DISTANCE IN FEET FROM MOTOR TO SUPPLY

Model Motor HP Volts

2805E-02 1/2 115/230 9.9/4.95 15/15 14/14(2/2) 14/14(2/2) 12/14(3/2) 10/14(5.5/2) 10/12(5.5/3)

2810E-02 3/4 115/230 12.4/6.2 20/15 12/14(3/2) 10/14(5.5/2) 8/14(8.4/2) 6/12(14/3) 6/12(14/3)

Max. Load

Amp

Branch Fuse

Rating Amp

Preparing to Start the Pump

Priming

Explosion hazard. Never run pump against closed discharge.

To do so can boil water inside pump, causing hazardous pressure in unit,

risk of explosion and possibly scalding persons handling pump.

Fill pump

and piping

through

priming tee.

Figure 8: Prime the Pump

Can fill downpipe

separately through

2nd priming tee.

pump to overheat, damaging seal and possibly causing burns to persons

handling pump. Fill pump with water before starting.

1. Remove the priming plug from the pump and fill the pump, fill all

piping between the pump and the well, and make sure that all piping

in the well is full. If you have also installed a priming tee in the suction

piping, remove the plug from the tee and fill the suction piping.

2. Replace all fill plugs.

3. Power on! Start the pump. If you don’t have water after 2 or 3 minutes,

stop the pump and remove the fill plugs. Refill the pump and piping.

You may have to repeat this several times in order to get all the trapped

air out of the piping. A pump lifting water 25’ may take as long as

15minutes to prime.

4. After the pump has built up pressure in the system and shut off, check

the pressure switch operation by opening a faucet or two and running

enough water out to bleed off pressure until the pump starts. The pump

should start when pressure drops to 30 PSI and stop when pressure

reaches 50 PSI. Run the pump through one or two complete cycles to

verify correct operation. This will also help clean the system of dirt and

scale dislodged during installation.

Never run pump dry. Running pump without water may cause

0 - 100 101 - 200 201 - 300 301 - 400 401 - 500

AWG WIRE SIZE (mm2)

Winterizing the Pump

To prepare the pump for freezing temperatures:

1. Shut off power to the pump.

2. Relieve system pressure. Open a faucet and let it drain until water

stops flowing.

3. Drain the pump. Your pump may have a separate drain plug. Remove

this plug and let it drain.

Your pump may only have a plug or connection on the side of the

pump. Remove this and let the pump drain. Some water will remain in

the pump. A small amount of water left in the pump will not harm it if

it freezes.

For parts or assistance, call Simer Customer Service at 1-800-468-7867

Page 9

Troubleshooting 9

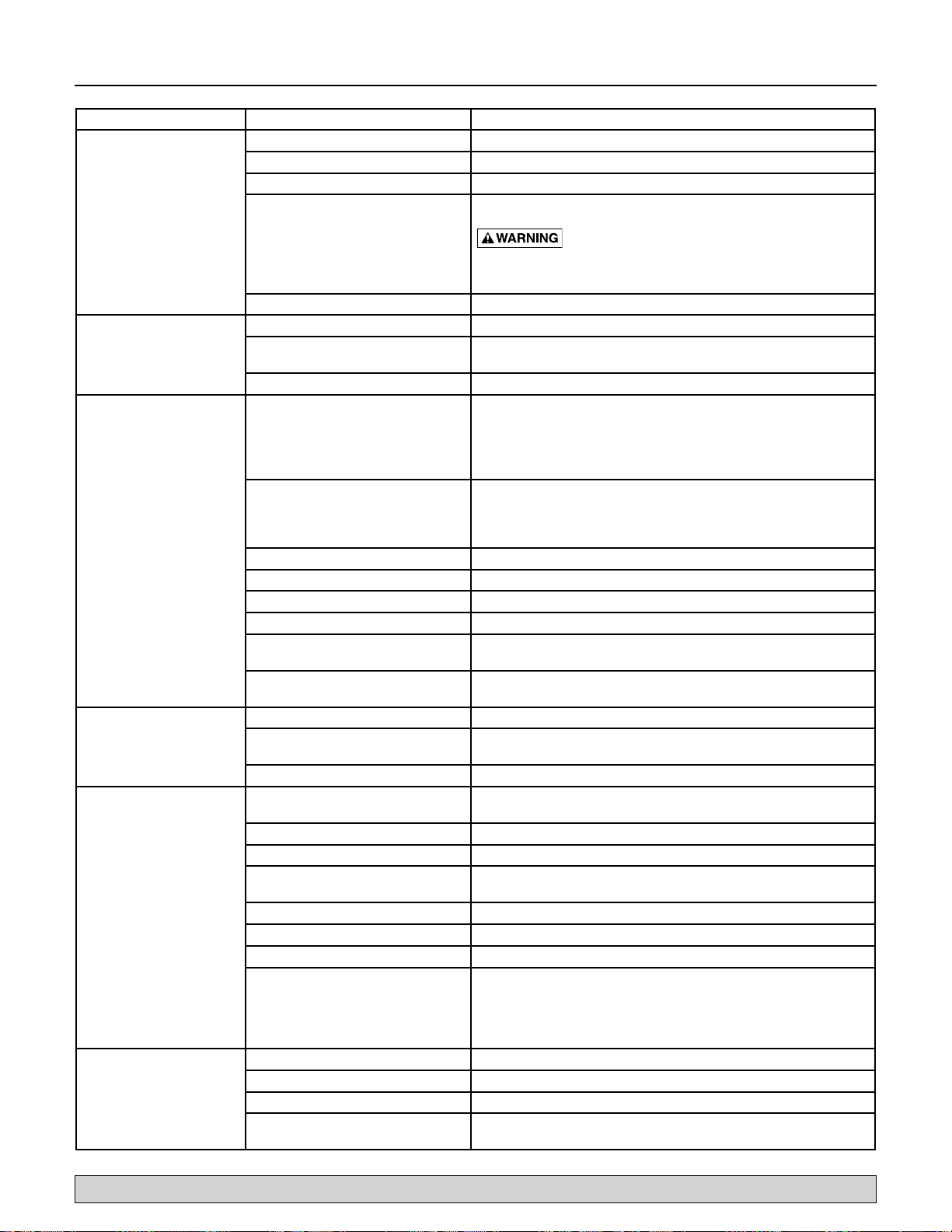

Symptom Possible Cause(s) Corrective Action

Motor will not run Disconnect switch is off Be sure switch is on.

Fuse is blown or circuit breaker tripped Replace fuse or reset circuit breaker.

Starting switch is defective DISCONNECT POWER; Replace starting switch.

Wires at motor are loose, disconnected, or

wired incorrectly

Pressure switch contacts are dirty DISCONNECT POWER and file contacts with emery board or nail file.

Motor runs hot and overload

kicks off

Motor runs but no water is

delivered*

* Stop pump; then check

prime before looking for

other causes. Unscrew

priming plug and see if

water is in priming hole.

Pump does not deliver water

to full capacity (Also check

point 3 immediately above)

Pump delivers water but does

not shut off or pump cycles

too frequently

Air spurts from faucets Pump is picking up prime When pump has picked up prime, it should pump solid water with no air.

Motor is wired incorrectly Refer to instructions on wiring.

Voltage is too low Check with power company. Install heavier wiring if wire size is too small (See

Pump cycles too frequently See section below on too frequent cycling.

Pump in new installation did not pick up

prime through:

1. Improper priming

2. Air leaks

3. Leaking foot valve or check valve

Pump has lost prime through:

1. Air leaks

2. Water level below suction pipe inlet

Foot valve or strainer is plugged Clean foot valve or strainer.

Ejector or impeller is plugged Clean ejector or impeller.

Check valve or foot valve is stuck shut Replace check valve or foot valve.

Pipes are frozen Thaw pipes. Bury pipes below frost line. Heat pit or pump house.

Foot valve and/or strainer are buried in

sand or mud

Water level is too low for shallow well

setup to deliver water

Water level in well is lower than estimated A new nozzle and venturi combination may be needed.

Steel piping (if used) is corroded or limed,

causing excess friction

Piping is too small in size Use larger piping.

Pressure switch is out of adjustment or

contacts are welded together

Faucets have been left open Close faucets.

Venturi, nozzle or impeller is clogged Clean venturi, nozzle or impeller.

Standard pressure tank is waterlogged and

has no air cushion

Pipes leak Check connections.

Foot valve leaks Replace foot valve.

Pressure switch is out of adjustment Adjust or replace pressure switch.

Air charge too low in pre-charged tank

Leak in suction side of pump Suction pipe is sucking air. Check joints for leaks with soapy water.

Well is gaseous Consult factory about installing a sleeve in the well.

Intermittent over-pumping of well. (Water

drawn down below foot valve.)

Refer to instructions on wiring (Page 9). DISCONNECT POWER; check and

tighten all wiring.

Capacitor voltage may be hazardous. To discharge capacitor,

hold insulated handle screwdriver BY THE HANDLE and short capacitor

terminals together. Do not touch metal screwdriver blade or capacitor terminals.

If in doubt, consult a qualified electrician.

Electrical / Wiring Chart).

In new installation:

1. Re-prime according to instructions.

2. Check all connections on suction line, AVC, and ejector with soapy water or

shaving cream.

3. Replace foot valve or check valve.

In installation already in use:

1. Check all connections on suction line and shaft seal.

2. Lower suction line into water and re-prime. If receding water level in well

exceeds 25’ (7.6M), a deep well pump is needed.

Raise foot valve and/or strainer above bottom of water source. Clean foot valve

and strainer.

A deep well jet will be needed if your well is more than 25’ (7.6M) depth to

water.

Replace with plastic pipe where possible, otherwise with new steel pipe.

DISCONNECT POWER; adjust or replace pressure switch.

Drain tank to air volume control port. Check AVC for defects. Check all

connections for air leaks.

DISCONNECT POWER and open faucets until all pressure is relieved. Using

tire pressure gauge, check air pressure in tank at valve stem located on the tank.

If less than pressure switch cut-in setting (30-50 PSI), pump air into tank from

outside source until air pressure is 2 PSI less than cut-in setting of switch. Check

air valve for leaks (use soapy solution) and replace core if necessary.

Lower foot valve if possible, otherwise restrict pump discharge.

For parts or assistance, call Simer Customer Service at 1-800-468-7867

Page 10

Repair Parts 10

1

2

16

15

14

3

4

5

6

7

12

13

17

11

8

9A

9B

2331 0296

9

10

10

10

Item Description Qty. 2810E-02 2805E-02

1 Motor (-L) 1 J218-590PKG J218-582A-115PKG

2 Water Slinger 1 17351-0009 17351-0009

3 Seal Plate Assembly 1 N3-9 N3-9

4 Gasket, Seal Plate 1 N20-35 N20-35

5 Shaft Seal 1 U109-6A U109-6A

6 Impeller 1 J105-42P J105-40P

7 Volute Diffuser 1 L1-25P L1-25P

8 Gasket, Diffuser 1 N20-34 N20-34

9 Pump Body Assembly 1 N176-38F N176-38

9A Venturi (1) N32P-75 N32P-66

9B Nozzle (1) N34P-21 (#47) N34P-17 (#43)

10 Pipe Plug, 1/4” NPT Hex Hd. 3 § §

11 Barbed Fitting, 1/4” NPT 1 U111-211T U111-211T

12 Barbed Elbow, 1/4” NPT 1 U111-212T –

13 Tube, 1/4”x14-1/2” 1 U37-672P U37-672P

14 Pressure Switch 1 U217-1202 U217-1202

15 Locknut, 1/2” 1 U36-112ZP U36-112ZP

16 Connector 1 L43-5C L43-5C

17 Capscrew 3/8-16x1-1/4” Lg. Hex Hd. 4 § §

§ Standard hardware item; purchase locally.

For parts or assistance, call Simer Customer Service at 1-800-468-7867

Page 11

Sécurité 11

Di rectives de sécurité importantes

Conservez ces directives – Ce manuel renferme d’importantes

directives qu’il faut suivre durant l’installation et l’entretien de

lapompe.

Ce symbole

symbole apparaît sur la pompe ou dans cette Notice, rechercher

une des mises en garde qui suivent, car elles indiquent un

potentiel de blessures corporelles!

Le mot signal

évité, causera la mort ou des blessures graves.

Le mot signal

pas évité, pourrait causer la mort ou des blessures graves.

Le mot signal

évité, pourrait causer des blessures mineures ou modérées.

Le mot AVIS est utilisé pour les pratiques qui ne sont pas reliées

aux blessures personnelles.

Lire attentivement toutes les consignes de sécurité contenues dans

cette Notice ou collées sur la pompe.

Garder les autocollants de sécurité en bon état;

les remplacer s’ils manquent ou s’ils ont été endommagés.

Sécurité concernant l’électricité

dangereuse. Pour décharger le condensateur du moteur, tenir

un tournevis à manche isolé PAR LE MANCHE et mettre en

court-circuit les bornes du condensateur. Ne pas toucher la lame

métallique du tournevis ni les bornes du condensateur. En cas de

doute, consulter un électricien qualifié.

indique qu’il faut être prudent. Lorsque ce

indique un danger qui, s’il n’est pas

indique un risque qui, s’il n’est

indique un risque qui, s’il n’est pas

La tension du condensateur peut être

Sécurité générale

Ne pas toucher un moteur qui fonctionne.

Les moteurs modernes sont conçus pour fonctionner par

des températures élevées. Pour ne pas se brûler lorsque l’on

interviendra sur la pompe, la laisser refroidir pendant 20 minutes

après l’avoir arrêtée avant de latoucher.

Ne pas laisser geler la pompe ni aucun autre élément du système,

sinon la garantie sera annulée.

Ne pomper que de l’eau avec cette pompe.

Périodiquement, inspecter la pompe et tous les éléments

dusystème.

Toujours porter des lunettes de sécurité lorsque l’on intervient sur

une pompe.

Garder la zone de travail propre, non encombrée et bien éclairée;

tous les outils et tout l’équipement non utilisés doivent être

entreposés correctement.

Ne pas laisser les visiteurs s’approcher de la zone detravail.

Le corps de la pompe peut exploser si la

pompe est utilisée en tant que pompe de surpression, à moins

qu’une soupape de sûreté pouvant laisser passer le débit maximum

de la pompe à 75 lb/po

2

soit posée.

AVERTISSEMENT

Câbler le moteur en

fonction de la bonne

tension. Voir la Section

«Électricité» de cette

Notice et la plaque

signalétique du moteur.

Mettre à la terre le

moteur avant de le

Tension dangereuse.

Risque de secousses

électriques, de brûlures,

voire de mort.

Mettre à la terre la pompe

avant de la brancher sur le

courant électrique. Couper

l’arrivée de courant avant

d’intervenir sur la pompe, sur

le moteur ou sur le réservoir.

brancher sur le courant

électrique.

Conforme au Code

national de l’électricité,

au Code canadien de

l’électricité et aux codes

municipaux pour tous

les câblages.

Respecter les instructions de câblage figurant dans

cette Notice lorsque l’on branche le moteur sur

une ligne haute tension.

AVERTISSEMENT

Pression dangereuse!

Poser une soupape de sûreté

sur le tuyau de refoulement.

Dissiper toute la pression

du système avant d’intervenir

sur un élément.

Pour les services des pièces ou d’assistance, appeler le service à la clientèle Simer en composant le 1(800)468-7867

Page 12

Garantie 12

Conserver l’original du reçu pour toute référence ultérieure

Garantie limitée

SIMER garantit à l’acheteur/au consommateur d’origine (l’Acheteur) que ses produits sont exempts de tout vice de matériau et de fabrication. Cette

garantie est valable pendant douze (12) mois à partir de la date d’achat d’origine.

Si, dans les douze (12) mois suivant la date d’achat d’origine, un produit se révèle défectueux, il sera réparé ou remplacé, à la discrétion de SIMER,

conformément aux modalités et conditions exposées ci-dessous. Le reçu de l’achat d’origine et l’étiquette d’information sur la garantie sont requis pour

déterminer la recevabilité de la réclamation au titre de la garantie. La recevabilité de la réclamation se base sur la date de l’achat d’origine du produit, et

non sur la date d’un éventuel remplacement sous garantie. La garantie est limitée à la réparation ou au remplacement du produit uniquement. L’Acheteur

assume les frais de retrait, d’installation, de transport et tous les frais accessoires.

Pour obtenir des pièces ou de l’aide technique, NE PAS retourner le produit au détaillant. Contacter le service à la clientèle de SIMER

au 1-800-468-7867.

Les réclamations au titre de cette garantie doivent être effectuées en retournant le produit (à l’exception des pompes d’eaux d’égout, voir ci-dessous) au

détaillant où il a été acheté, et ce, immédiatement après la découverte de la défaillance supposée. SIMER prendra les mesures correctives nécessaires

dans un délai rapide et raisonnable. Aucune demande de réparation ne sera acceptée plus de 30 jours après l’expiration de la garantie.

Cette garantie ne s’applique pas aux produits utilisés à des fins commerciales ou de location.

Pompes d’eaux d’égout

NE PAS RETOURNER une pompe d’eaux d’égout (qui a été installée) au détaillant. Communiquer avec le service à la clientèle de SIMER. Les pompes

d’eaux d’égout qui ont été utilisées, puis retirées présentent un risque de contamination.

En cas de défaillance de la pompe d’eaux d’égout :

• Porterdesgantsencaoutchoucpourmanipulerlapompe.

• Àdesfinsdegarantie,retournerl’étiquettefigurantsurlecordondelapompeetl’originaldureçuaudétaillant.

• Mettrelapompeaurebutconformémentàlaréglementationlocale.

Exceptions à la garantie limitée de douze (12) mois

Produit Période de garantie

BW85P,CM10,CMK,M40,M40P 90 jours

2300,2310,2330,2520ULST,2943,2955,2956,2957,2960,5023SS,A5500 2 ans

Pompepourpuitssubmersiblesde4pouces,2945,2958,2975PC,2985,3075SS,3983,3984 3 ans

Réservoirpréchargédesystèmed’eau,3985,3986,3988,3989 5ans

3963,3995,3997 Àvie

Modalités et conditions générales

L’Acheteur doit payer tous les frais de main d’œuvre et de transport nécessaires au remplacement du produit garanti couvert par cette garantie.

Cettegarantienes’appliquepasàcequisuit:(1)Lescatastrophesnaturelles;(2)Lesproduitsqui,selonSIMER,ontfaitl’objetd’unenégligence,

d’uneutilisationabusive,d’unaccident,d’unemauvaiseapplicationoud’unealtération;(3)Lesdéfaillancesduesàuneinstallation,une

utilisation,unentretienouunentreposageinappropriés;(4)Uneapplication,uneutilisationouuneréparationatypiqueounonapprouvée;(5)Les

défaillances causées par la corrosion, la rouille ou d’autres matériaux étrangers au système, ou par une utilisation à une pression supérieure au

maximum recommandé.

Cette garantie établit la responsabilité unique de SIMER et le recours exclusif de l’Acheteur en cas de produit défectueux.

SIMER NE POURRA TRE TENUE RESPONSABLE DE TOUT DOMMAGE INDIRECT OU CONSÉCUTIF QUEL QU’IL SOIT.

LES PRÉSENTES GARANTIES SONT EXCLUSIVES ET REMPLACENT TOUTE AUTRE GARANTIE EXPRESSE OU IMPLICITE, Y COMPRIS, MAIS SANS

S’YLIMITER,CELLEDEQUALITÉMARCHANDEOUD’APTITUDEDUPRODUITÀUNEMPLOIPARTICULIER.LESPRÉSENTESGARANTIESNE

PEUVENTSEPROLONGERAU-DELÀDELAPÉRIODEDEGARANTIEINDIQUÉEICI.

Certains États ne permettent pas l’exclusion ou la limitation des dommages indirects ou consécutifs, ni les limitations relatives à la durée des garanties

implicites. Par conséquent, il se peut que les limitations ou les exclusions ci-dessus ne s’appliquent pas. Cette garantie procure des droits juridiques

précis à l’Acheteur. Cependant, il est possible de bénéficier d’autres droits, qui varient selon l’État.

SIMER • 293 Wright Street • Delavan, WI U.S.A. 53115

Téléphone : 1 800 468-7867 • Télécopieur : 1 800 390-5351 • Site Web : SimerPump.com

Page 13

Installation 13

Vers le système d’eau

de la maison

Manomètre et orifice

d’amorçage

Remplacement d’une ancienne pompe

Tension dangereuse. Couper l’arrivée de courant à la pompe avant

d’intervenir sur la pompe ou sur le moteur.

1 ° Vider toute l’eau de l’ancienne pompe; déposer l’ancienne pompe. Vérifier

l’ancienne tuyauterie à la recherche de dépôts de tartre, de chaux, de rouille, etc.;

la remplacer selon le besoin.

2 ° Brancher la pompe sur le système. S’assurer que tous les raccords du tuyau

d’aspiration sont bien étanches, aussi bien à l’air qu’à l’eau. Si le tuyau d’aspiration

aspire de l’air, la pompe ne pompera pas l’eau du puits.

Té

d’amorçage

et bouchon

3 ° Régler la hauteur de montage de la pompe de façon que les raccords de plomberie

n’exercent aucune contrainte sur le corps de la pompe. Supporter les tuyaux

de façon que le corps de la pompe ne supporte pas le poids de la tuyauterie ni

Clapet

anti-retour

desraccords.

Le branchement de cette pompe à éjecteur neuve pour puits profonds sur la tuyauterie

du puits est maintenant terminé. Passer à la page 15 pour le branchement de la

Raccord

d’enfoncement

de la pointe

filtrante

tuyauterie de refoulement et sur un réservoir.

Installation de la pointe filtrante (Figure 1)

1 ° Enfoncer la pointe dans le sol, en utilisant des «raccords d’enfoncement» et des

Pointe

filtrante

Pas à

l’échelle

Figure 1: Installation avec une

pointefiltrante

Vers le système

d’eau de la maison

Manomètre et orifice

d’amorçage

Tuyau d’aspiration

venant du puits

Tuyau

d’aspiration

venant du puits

Joint sanitaire

du puits

«chapeaux de battage». Les «raccords d’enfoncement» sont filetés sur toute leur

longueur, ce qui permet aux extrémités des tuyaux de venir en butée l’une contre

l’autre de façon que la force d’enfoncement du maillet soit absorbée par le tuyau et

non pas par les filets. Les raccords ordinaires que l’on trouve dans les quincailleries

ne sont pas filetés sur toute leur longueur et ils risquent de s’écraser sous l’impact

des coups. Les «raccords d’enfoncement» sont également plus lisses que les

raccords de plomberie standard, ce qui leur permet de pénétrer plus facilement

dans le sol.

2 ° Monter la pompe aussi près que possible du puits.

3 ° Utiliser le moins possible de raccords (en particulier des coudes) lorsque l’on

branche la tuyauterie de la pointe filtrante sur l’orifice d’aspiration de la pompe.

Le diamètre du tuyau d’aspiration doit être au moins aussi grand que le diamètre

de l’orifice d’aspiration de la pompe (y compris le clapet anti-retour si la pompe

n’en comporte pas un - voir la Figure 1). Supporter le tuyau de façon qu’il ne soit

pas cintré afin qu’il n’exerce pas de contraintes sur le corps de la pompe; de plus,

il doit être légèrement incliné vers le haut, du puits jusqu’à la pompe (les points

hauts risquent de causer des poches et des bouchons d’air dans la pompe). Rendre

étanches les raccords du tuyau d’aspiration avec du ruban 1Téflon™ ou une pâte

pour raccords filetés à base de Téflon™. Les raccords doivent être étanches à l’air et

à l’eau. Si le tuyau d’aspiration aspire de l’air, la pompe ne pompera pas l’eau du

puits. Si une pointe filtrante ne fournit pas suffisamment d’eau, considérer brancher

deux ou trois pointes filtrantes sur un même tuyau d’aspiration.

Le branchement de cette pompe à éjecteur neuve pour puits profonds sur la tuyauterie

du puits est maintenant terminé. Passer à la page 15 branchement pour la tuyauterie de

refoulement et sur un réservoir.

1

E. I. DuPont de Demours and Company Corporation, Delware

Installation sur un puits à tubage de 2 pouces de

diamètre ou plus grand

Au moins

5 à 10 pi

10 pi

Clapet

de pied

Figure 2 : Installation dans un puits

àtubage

Pour les services des pièces ou d’assistance, appeler le service à la clientèle Simer en composant le 1(800)468-7867

1 ° Monter la pompe aussi près que possible du puits.

2 ° Brancher le clapet de pied, la crépine et le tuyau du puits (voir la Figure 2).

S’assurer que le clapet de pied fonctionne librement.

3 ° Abaisser le tuyau dans le puits jusqu’à ce que la crépine soit à cinq pieds du fond

du puits. Pour que la pompe n’aspire pas d’air, la crépine doit être au moins à

10pieds sous le niveau de l’eau du puits pendant que la pompe fonctionne. Poser

un joint sanitaire de puits.

(Figure 2)

Page 14

Installation 14

Vers le système d’eau

de la maison

Au moins

10 pied

5 à 10 pi

Figure 3 : Installation pour les eaux

desurface

Té d’amorçage de la

pompe avec bouchon

ou manomètre

Tuyau d’aspiration

venant du puits

Clapet

de

pied

Crépine

4 ° Poser le té d’amorçage, le bouchon d’amorçage et le tuyau d’aspiration sur

la pompe (voir la Figure 2). Brancher le tuyau provenant du puits sur l’orifice

d’aspiration de la pompe en utilisant le moins possible de raccords - en particulier

des coudes - étant donné que les raccords augmentent le frottement de l’eau

dans les tuyaux (il faut toutefois ajouter un clapet de pied — voir la Figure 2). Le

diamètre du tuyau d’aspiration doit être au moins aussi grand que le diamètre de

l’orifice d’aspiration de la pompe. Supporter le tuyau de façon qu’il ne soit pas

cintré afin qu’il n’exerce pas de contraintes sur le corps de la pompe; de plus,

il doit être légèrement incliné vers le haut, du puits jusqu’à la pompe (les points

hauts risquent de causer des poches et des bouchons d’air dans la pompe). Rendre

étanches les raccords du tuyau d’aspiration avec du ruban Téflon™ ou une pâte

pour raccords filetés à base de Téflon™. Les raccords doivent être étanches à l’air

et à l’eau. Si le tuyau d’aspiration aspire de l’air, la pompe ne pompera pas l’eau

dupuits.

Le branchement de cette pompe à éjecteur neuve pour puits profonds sur la tuyauterie

du puits est maintenant terminé. Passer à la page 15 pour le branchement de la

tuyauterie de refoulement et sur un réservoir.

Installation dans le cas d’eaux en surface (Figure 3)

Ne pas boire l’eau de surface. L’installation montrée peut être utilisée

pourl’arrosage.

1 ° Monter la pompe aussi près que possible du puits en utilisant le moins possible de

raccords (en particulier des coudes) sur le tuyau d’aspiration. Le diamètre du tuyau

d’aspiration doit être au moins aussi grand que le diamètre de l’orifice d’aspiration

de la pompe.

2 ° Assembler le clapet de pied et le tuyau d’aspiration (voir la Figure 3). S’assurer que

le clapet de pied fonctionne librement. Utiliser du ruban Téflon™ ou de la pâte

pour raccords filetés à base de Téflon™ sur les raccords filetés. Poser une crépine

autour du clapet de pied pour le protéger contre les poissons, les déchets, etc. (voir

la Figure3).

3 ° Abaisser le tuyau dans le puits jusqu’à ce que la crépine soit à cinq pieds du fond

du puits. Pour que la pompe n’aspire pas d’air, la crépine doit être au moins à

10pieds sous le niveau de l’eau du puits pendant que la pompe fonctionne.

4 ° Poser le té d’amorçage, le bouchon d’amorçage et le tuyau d’aspiration sur la

pompe (voir la Figure 3). Supporter le tuyau de façon qu’il ne soit pas cintré afin

qu’il n’exerce pas de contraintes sur le corps de la pompe; de plus, il doit être

légèrement incliné vers le haut, du puits jusqu’à la pompe (les points hauts risquent

de causer des poches et des bouchons d’air dans la pompe). Rendre étanches les

raccords du tuyau d’aspiration avec du ruban Téflon™ ou une pâte pour raccords

filetés à base de Téflon™. Les raccords doivent être étanches à l’air et à l’eau. Si le

tuyau d’aspiration aspire de l’air, la pompe ne pompera pas l’eau du puits.

Le branchement de cette pompe à éjecteur neuve pour puits profonds sur la tuyauterie

du puits est maintenant terminé. Passer à la page 15 pour le branchement de la

tuyauterie de refoulement et sur un réservoir.

Pour les services des pièces ou d’assistance, appeler le service à la clientèle Simer en composant le 1(800)468-7867

Page 15

Branchements du tuyau de refoulement 15

Vers le système

d’eau de la maison

Manocontacteur

Té d’amorçage de la

pompe avec bouchon

ou manomètre

En provenance

du puits

Figure 4 : Branchements sur un

réservoirpréchargé

Vers le système

d’eau de la maison

Contrôleur

d’air

Té d’amorçage de la

pompe avec bouchon

ou manomètre

Manocontacteur

Tube du

contrôleur d’air

Branchement sur un réservoir préchargé (Figure 4)

1 ° Poser deux tés dans l’orifice de refoulement de la pompe (voir la Figure 4). Le

diamètre du tuyau doit être au moins aussi grand que le diamètre de l’orifice

derefoulement.

2 ° Poser un tuyau rigide ou un tuyau souple renforcé entre une des branches du

premier té et l’orifice du réservoir préchargé.

3 ° Brancher l’autre extrémité du té de refoulement sur le système de la plomberie.

Boucher le té avec un bouchon fileté ou un manomètre.

4 ° Vérifier la précharge d’air dans le réservoir avec un manomètre pour pneu.

La précharge doit être de 2 lb/po

2

inférieure au réglage de la pression

d’enclenchement du manocontacteur de la pompe. La précharge se mesure

lorsqu’il n’y a pas de pression d’eau dans le réservoir. Cette pompe neuve est

équipée d’un manocontacteur 30/50 lb/po

devra donc être réglée à 28 lb/po

2

.

2

; la pression de précharge du réservoir

Félicitations! Le branchement de la pompe à éjecteur sur le réservoir est

maintenantterminé.

Passer à la page 16 pour les branchements électriques.

Branchement sur un réservoir standard (Figure 5)

1 ° Poser un té dans l’orifice de refoulement de la pompe (voir la Figure 5).

2 ° Poser un tuyau entre l’orifice de refoulement de la pompe et l’orifice d’admission

du réservoir. Le diamètre du tuyau doit être au moins aussi grand que le diamètre

de l’orifice de refoulement de la pompe.

3 ° Poser un té dans le tuyau d’aspiration près de la pompe. Poser une bague de

réduction jusqu’à 1/8 po NPT dans le té. Poser un tube entre le té et l’orifice

du contrôleur d’air monté sur le réservoir. Sceller tous les joints avec du ruban

Téflon™. Se reporter aux instructions fournies avec le réservoir et le contrôleur d’air

pour plus de détails.

Félicitations! Le branchement de la pompe à éjecteur sur le réservoir est

maintenantterminé.

Passer à la page 16 pour les branchements électriques.

En provenance

Figure 5 : Branchements sur un

réservoirstandard

du puits

N’utiliser que du ruban

filetés à base de Téflon™ pour procéder à tous les raccords filetés sur la

pompe. Ne pas utiliser de pâte pour raccords filetés sur les pompes en

plastique : cette pâte peut réagir avec les éléments en plastiques de la

pompe. S’assurer que tous les raccords du tuyau d’aspiration sont bien

étanches, aussi bien à l’air qu’à l’eau. Si le tuyau d’aspiration aspire de

l’air, la pompe ne pompera pas l’eau du puits.

1

E. I. DuPont de Demours and Company Corporation, Delware

Étanchéité des raccords des tuyaux

1

Téflon™ ou de la pâte d’étanchéité pour raccords

Pour les services des pièces ou d’assistance, appeler le service à la clientèle Simer en composant le 1(800)468-7867

Page 16

Électricité 16

Débrancher le courant électrique avant d’intervenir sur la pompe, le moteur, le manostat ou le câblage.

Réglages de l’interrupteur du moteur

AVIS : Les moteurs de 1/2 cheval sont des moteurs bitension. Ils ont été réglés en usine pour fonctionner sur le courant de 115 V. Les

moteurs de 3/4 et de 1 cheval sont des moteurs bitension. Ils ont été réglés en usine pour fonctionner sur le courant de 230 V. La plaquette

de connexions des moteurs (logée sous le couvercle arrière du moteur) ressemble à une de celles illustrées ci-dessous. Se reporter aux

instructions pour régler le moteur conformément à la source d’énergie.

Ne jamais brancher un moteur réglé à 115 V à une source d’alimentation de 230 V.

Sélecteur de tension à cadran

La tension est réglée en usine à 230 V. Pour passer au courant

de115V :

Bornes de branchement électrique

Cadran de

sélection

de tension

Manocontacteur

Borne du fil de mise à la terre

Figure 6 : Tension réglée à 230 V sur sélecteur àcadran

1. S’assurer que le courant est coupé.

2. Tourner le cadran dans le sens des aiguilles d’une montre

jusqu’à ce que le nombre 115 soit visible dans la fente du

cadran (figure 7).

Figure 7 : Tension réglée à 115 V sur sélecteur àcadran

3. Fixer les fils d’arrivée de courant aux deux vis extérieures du

manostat (figure 6).

4. Relier le fil de terre aux bornes de raccord de mise à la terre

(figure 6).

5. S’il y a d’autres fils, leurs bouts doivent être isolés.

6.

Reposer les couvercles d’extrémité du moteur et du

manostat.

Tension dangereuse. Risque de secousses

électriques, de brûlures, voire la mort. Brancher le fil de terre avant

de brancher les fils de tension. Utiliser des fils de calibre spécifié

(y compris le fil de terre) dans le tableau de câblage. Dans la

mesure du possible, brancher la pompe sur un circuit séparé, sur

lequel aucun autre appareil ne sera branché.

Risque d’explosion. Ne pas mettre à la terre sur

une conduite de gaz.

Connexions des fils

Risque d’incendie. L’utilisation d’une mauvaise

tension risque de causer un incendie ou d’endommager gravement

le moteur et d’annuler la garantie. La tension d’alimentation

doit correspondre à ± 10 % de la tension figurant sur la plaque

signalétique du moteur.

AVIS : Les moteurs bi-tension peuvent fonctionner sur le courant

de 115 ou de 230 V. Au besoin, régler le moteur sur la tension

désirée, comme il est indiqué. Ne pas modifier le câblage des

moteurs fonctionnant sur une tension.

Installer la pompe, la mettre à la terre, la câbler et l’entretenir

conformément au National Electrical Code (NEC) ou au

Code canadien de l’électricité, selon le cas, et conformément

à tous les codes et décrets en vigueur de la municipalité.

Consulter l’inspecteur des bâtiments de la localité pour plus de

renseignements sur les codes.

Méthodes de connexion :

1 ° Brancher tout d’abord le fil de mise à la terre, comme il est

illustré à la Figure6. Le fil de mise à la terre doit être un fil

de cuivre massif d’un diamètre au moins aussi gros que le

diamètre des fils de tension.

2 ° Il doit y avoir un raccordement en métal solide entre le

manostat et le moteur pour une protection à la terre du

moteur. Si le manostat n’est pas branché sur le moteur,

brancher la vis verte de mise à la terre du manostat sur la vis

verte de mise à la terre qui se trouve sous le couvercle du

moteur. Utiliser un fil de cuivre massif ayant un diamètre au

moins aussi gros que celui des fils de tension.

3 ° Brancher le fil de mise à la terre sur le fil de mise à la terre du

tableau de distribution, sur un tuyau métallique d’eau enterré,

sur le tubage d’un puits en métal ayant au moins 10 pieds

(3m) de long, ou sur une électrode de mise à la terre que

fournira la compagnie d’électricité.

4 ° Brancher les fils de tension sur le manostat, comme il est

illustré à la Figure6.

Le câblage de la pompe est maintenant terminé.

Se reporter à la page 17 pour les préparations avant le démarrage.

Pour les services des pièces ou d’assistance, appeler le service à la clientèle Simer en composant le 1(800)468-7867

Page 17

Électricité 17

Tableau de câblage - Câbles et diamètres des fusibles recommandés

Puissance

Modele

2805E-02 1/2 115/230 9.9/4.95 15/15 14/14(2/2) 14/14(2/2) 12/14(3/2) 10/14(5.5/2) 10/12(5.5/3)

2810E-02 3/4 115/230 12.4/6.2 20/15 12/14(3/2) 10/14(5.5/2) 8/14(8.4/2) 6/12(14/3) 6/12(14/3)

du moteur

en ch

Tension

Charge max.

en ampères

Fusible

Intensité en

ampères

Distance en pieds entre le moteur et le courant d’alimentation

0 - 100 101 - 200 201 - 300 301 - 400 401 - 500

Diamètre du fil -calibre awg (mm2)

Préparations avant le démarrage de la pompe

Amorçage

Ne jamais faire fonctionner la pompe contre un refoulement fermé,

sinon l’eau risque de bouillir à l’intérieur de la pompe, une accumulation dangereuse

de pression risque de se produire, un danger d’explosion risque de s’ensuivre et les

Faire le plein de

la pompe et de la

tuyauterie par le té

d’amorçage.

Le tuyau de descente peut

être rempli séparément par

le té d’amorçage.

Figure 8 : Amorçage de la pompe

personnes qui manipuleront la pompe pourront peut-être être ébouillantées.

Ne jamais faire fonctionner la pompe à sec. Faire fonctionner la pompe

sans eau risque de causer une surchauffe de la pompe, d’endommager les joints et,

possiblement, causer des brûlures aux personnes qui manipuleront la pompe. Faire le

plein d’eau de la pompe avant de la démarrer.

1 ° Déposer le bouchon d’amorçage de la pompe et faire le plein de la pompe et de

tous les tuyaux branchés entre la pompe et le puits et s’assurer que tous les tuyaux

du puits sont pleins. Si un té d’amorçage a déjà été posé sur le tuyau d’aspiration,

le déposer du té et faire le plein de la tuyauterie d’aspiration. Se le figura 8.

2 ° Reposer tous les bouchons de remplissage.

3 ° Établir le courant! Démarrer la pompe. S’il n’y a pas de présence d’eau après

2ou 3 minutes de fonctionnement, arrêter la pompe et déposer les bouchons de

remplissage. Refaire le plein de la pompe et de la tuyauterie. Cette opération devra

peut-être être répétée plusieurs fois de façon à chasser tout l’air emprisonné dans

la tuyauterie. Il faudra jusqu’à 15 minutes pour qu’une pompe aspirant de l’eau à

25pieds s’amorce.

4 ° Après que la pression se sera accumulée dans le système et que la pompe se

sera arrêtée, vérifier le fonctionnement du manocontacteur en ouvrant un ou

deux robinets du système; laisser couler suffisamment d’eau pour dissiper la

pression jusqu’à ce que la pompe redémarre. La pompe doit redémarrer lorsque

la pression chute à 30 lb/po

2

et s’arrêter lorsque la pression atteint 50 lb/po2. Faire

fonctionner la pompe pendant un ou deux cycles complets pour confirmer son bon

fonctionnement. Ceci permettra également de nettoyer le système de toute la saleté

et de tout le tartre qui se seront détachés pendant l’installation.

ATTENTION

La pompe et les tuyaux

peuvent être endommagés

s’ils gèlent parce qu’ils

n’auront pas été vidés.

Observer les instructions

concernant l’hivérisation.

Hivérisation de la pompe

Pour préparer la pompe pour l’hiver:

1° Couper le courant qui l’alimente.

2° Dissiper la pression du système. Ouvrir un robinet et attendre que l’eau

cesse de couler.

3° Vider la pompe en déposant son bouchon de vidange. Laisser toute l’eau

se vider.

La pompe peut être munie d’un bouchon ou d’un branchement sur son côté.

Déposer l’un ou l’autre pour vider la pompe. Un peu d’eau peut rester dans la

pompe. Cela ne l’endommagera pas si elle vient à geler.

Pour les services des pièces ou d’assistance, appeler le service à la clientèle Simer en composant le 1(800)468-7867

Page 18

Diagnostic des pannes 18

Symptômes Causes probables Remèdes

Le moteur ne tourne pas Le sectionneur est ouvert S’assurer que le sectionneur est enclenché.

Le fusible est sauté ou le disjoncteur est déclenché Remplacer le fusible ou réenclencher le disjoncteur.

L’interrupteur de démarrage est défectueux COUPER L’ARRIVÉE DE COURANT; remplacer l’interrupteur de démarrage.

Le moteur chauffe et le

dispositif de protection

contre les surcharges

sedéclenche

Le moteur fonctionne

mais la pompe ne

débitepasd’eau *

* AVIS : Arrêter la

pompe, puis vérifier

l’amorçage avant

de rechercher toute

autrecause.

Dévisser le bouchon

d’amorçage et voir si le

trou d’amorçage contient

de l’eau.

La pompe ne débite pas à

pleine capacité.

(Vérifier aussi les

3points immédiatement

précités)

La pompe débite mais

ne s’arrête pas ou

bien pelle fonctionne

tropfréquemment

L’air jaillit des robinets

dusystème

Les fils côté moteur sont desserrés, débranchés ou

mal branchés

Les contacts du pressostat sont sales COUPER L’ARRIVÉE DE COURANT, puis nettoyer les contacts avec un morceau de toile émeri ou

Le moteur est mal câblé Se reporter aux instructions concernant le câblage.

La tension est trop faible S’adresser à la compagnie d’électricité. Poser des câbles plus gros si le diamètre des fils est trop

La pompe fonctionne trop fréquemment. Se reporter ci-dessous si la pompe démarre trop fréquemment.

Dans une installation nouvelle, la pompe ne s’est

pas amorcée à cause :

1. D’un mauvais amorçage

2. De prises d’air

3. De fuites du clapet de non retour ou du clapet

de pied.

La pompe s’est désamorcée :

1. À cause de prises d’air

2. Parce que le niveau d’eau est plus bas que la

prise d’eau du tuyau d’aspiration.

Le clapet de pied ou la crépine sont bouchés Nettoyer le clapet de pied ou la crépine.

L’éjecteur ou l’impulseur sont bouchés Nettoyer l’éjecteur ou l’impulseur.

Le clapet de non retour ou le clapet de pied sont

grippés en position fermée

Les tuyauteries sont gelées. Dégeler les tuyauteries. Enterrer les tuyauteries sous le point de gélivation. Chauffer la fosse ou le

Le clapet de pied et/ou la trémie sont enfouis dans

le sable ou la boue

Dans le cas d’un puits peu profond, le niveau de

l’eau est trop bas pour que la pompe débite

Le niveau de l’eau du puits est plus bas que

celuiestimé

La tuyauterie en acier (le cas échéant) est corrodée

ou bouchée par la chaux, ce qui cause un

frottement excessif

Le diamètre des tuyaux est trop petit Utiliser des tuyaux de plus grand diamètre.

Le pressostat est déréglé ou bien ses contacts sont

soudés ensemble

Les robinets du système sont restés ouverts Les fermer.

Le venturi, la buse ou l’impulseur sont bouchés Nettoyer le venturi, la buse ou l’impulseur.

Le réservoir sous pression standard est saturé d’eau

et n’a plus de coussin d’air

Les tuyaux fuient Vérifier les raccords.

Le clapet de pied fuit Remplacer le clapet de pied.

Le pressostat est déréglé Régler ou remplacer le pressostat.

La charge d’air dans le réservoir préchargé est

tropbasse

La pompe s’amorce Lorsque la pompe sera amorcée, tout l’air sera chassé.

Prise d’air côté aspiration de la pompe Le tuyau d’aspiration aspire de l’air. Vérifier tous les raccords. S’assurer qu’ils sont bien serrés.

Le puits est gazeux S’adresser à l’usine pour la possibilité d’installer un manchon dans le puits.

Surpompage intermittent du puits. (L’eau

estpompée plus bas que le clapet de pied.)

Se reporter aux instructions sur le câblage (page 24). COUPER L’ARRIVÉE DE COURANT; vérifier

tout le câblage et le resserrer.

condensateur du moteur, tenir un tournevis à manche isolé PAR LE MANCHE et mettre en courtcircuit les bornes du condensateur. Ne pas toucher la lame métallique du tournevis ni les bornes

du condensateur. En cas de doute, consulter un électricien qualifié.

une lame à ongles.

petit (voir Électricité/Tableau de câblage).

Dans le cas d’une installation neuve :

1. Réamorcer la pompe conformément aux instructions.

2. Vérifier tous les raccords de la conduite d’aspiration, du régulateur de volume d’air et

del’éjecteur.

3. Remplacer le clapet de pied ou le clapet de non retour.

Dans le cas d’une installation déjà en utilisation :

1. Vérifier tous les raccords de la conduite d’aspiration et le joint de l’arbre.

2. Abaisser la conduite d’aspiration dans l’eau et réamorcer la pompe. Si, dans le puits, la surface

libre jusqu’à l’eau dépasse 7,60mètres (25pieds), utiliser une pompe pour puits profond.

Remplacer le clapet de non retour ou le clapet de pied.

bâtiment où se trouve la pompe.

Relever le clapet de pied et/ou la crépine plus haut que le fond de la source d’eau. Nettoyer le

clapet de pied et la crépine.

Utiliser un éjecteur pour puits profonds si la surface libre jusqu’à l’eau dans ce puits est supérieure

à 7,60mètres (25pieds).

Une nouvelle combinaison buse et venturi est peut-être requise.

Dans la mesure du possible, remplacer par des tuyaux en plastique, sinon poser des tuyaux en

acierneufs.

COUPER L’ARRIVÉE DE COURANT; régler le pressostat ou le remplacer.

Penser à l’idée d’utiliser une pompe à éjecteur pour puits profonds. Vider le réservoir jusqu’à

l’orifice du régulateur de volume d’air. Vérifier le régulateur de volume d’air à la recherche de

défectuosités. S’assurer que les raccords n’aspirent pas d’air.

COUPER L’ARRIVÉE DE COURANT et ouvrir les robinets du système jusqu’à ce que toute la

pression soit dissipée. À l’aide d’un manomètre pour pneus, vérifier la pression d’air dans le

réservoir par la tige de la valve qui se trouve sur le réservoir. Si la pression est inférieure au

réglage de fonctionnement du pressostat entre (206 et 344,7 kPa [30 et 50 lb/po

l’air dans le réservoir à partir d’une source extérieure jusqu’à ce que la pression d’air soit de

2 lb/po2 inférieure au réglage de déclenchement du pressostat. S’assurer que la valve ne fuit pas

(l’enduire d’une solution savonneuse); remplacer l’obus de la valve au besoin.

Dans la mesure du possible, abaisser le clapet de pied. Sinon, limiter le refoulement de la pompe.

La tension du condensateur peut être dangereuse. Pour décharger le

2

]), pomper de

Pour les services des pièces ou d’assistance, appeler le service à la clientèle Simer en composant le 1(800)468-7867

Page 19

Pièces de rechange 19

1

2

16

15

14

3

4

5

6

7

12

13

17

11

8

9A

9B

2331 0296

10

Réf. Désignation de pièces Qté 2810E-02 2805E-02

1 Moteur (-L) 1 J218-590PKG J218-582A-115PKG

2 Déflecteur d’eau 1 17351-0009 17351-0009

3 Plaque d’étanchéité 1 N3-9 N3-9

4 Joint plat de la plaque d’étanchéité 1 N20-35 N20-35

5 Joint de l’arbre 1 U109-6A U109-6A

6 Impulseur 1 J105-42P J105-40P

7 Diffuseur de la volute 1 L1-25P L1-25P

8 Joint plat du diffuseur 1 N20-34 N20-34

9 Corps de la pompe 1 N176-38F N176-38

9A Venturi (1) N32P-75 N32P-66

9B Buse (1) N34P-21 (#47) N34P-17 (#43)

10 Bouchon fileté de 1/4 de pouce NPT à tête hexagonale 3 § §

11 Raccord cannelé de 1/4 de pouce NPT 1 U111-211T U111-211T

12 Coude cannelé de 1/4 pouce NPT 1 U111-212T –

13 Tube de 1/4 de pouce x 14 1/2 pouces 1 U37-672P U37-672P

14 Pressostat 1 U217-1202 U217-1202

15 Écrou de 1/2 pouce 1 U36-112ZP U36-112ZP

16 Raccord 1 L43-5C L43-5C

17 Vis d’assemblage à tête hexagonale de 3/8 - 16 x 1 1/4 pouce de long. 4 § §

§ Pièces courantes. À acheter localement.

9

10

10

Pour les services des pièces ou d’assistance, appeler le service à la clientèle Simer en composant le 1(800)468-7867

Page 20

Seguridad 20

In strucciones importantes

deseguridad

Guarde estas instrucciones - Este manual contiene instrucciones

importantes que se deben seguir durante la instalación y el

mantenimiento del bombas de sumidero.

Este es un símbolo de alerta sobre la seguridad. Cuando vea

este símbolo en su bomba o en este manual, busque para ver si

hay alguna de las siguientes palabras de señal y esté alerta a la

posibilidad de lesiones personales.

indica un riesgo que, de no evitarse, provocará la

muerte o lesiones de gravedad.

indica un riesgo que, de no evitarse, podría

provocar la muerte o lesiones de gravedad.

indica un riesgo que, de no evitarse, podría

provocar lesiones leves o moderadas.

AVISO hace referencia a una práctica no relacionada con una

lesión física.

Lea y siga cuidadosamente todas las instrucciones de seguridad

en este manual y en la bomba.

Mantenga las etiquetas de seguridad en buenas condiciones.

Reemplace las etiquetas de seguridad faltantes o dañadas.

Seguridad electrica

El voltaje del capacitor puede ser peligroso.

Para descargar el capacitor del motor, tome un desatornillador con

mango aislado POR EL MANGO y ponga en corto las terminales

del capacitor. No toque la superficie de metal del desatornillador

ni las terminales del capacitor. Si tiene alguna duda, consulte a un

electricista calificado.

Seguridad general

No toque un motor en operación. Los

motores modernos están diseñados para operar a temperaturas

altas. Para evitar quemaduras al realizar el servicio a una bomba,

déjela enfriar por 20 minutos después de apagarla.

No permita que la bomba o cualquier componente del sistema se

congele. Hacerlo invalidará la garantía.

Utilice esta bomba sólo para agua.

Inspeccione la bomba y los componentes del

sistemaperiódicamente.

Utilice gafas de seguridad durante todo el tiempo mientras trabaje

en la bomba.

El área de trabajo se debe mantener limpia, ordenada y con

iluminación adecuada; guarde las herramientas y el equipo que no

utilice en el lugar apropiado.

Mantenga a los visitantes a una distancia segura de las áreas

detrabajo.

El cuerpo de la bomba puede explotar si se

utiliza como una bomba propulsora a menos que se instale una

válvula de alivio que sea capaz de pasar todo el flujo de la bomba

a 75 psi.

ADVERTENCIA

Voltaje peligroso. Puede

ocasionar conmoción,

quemaduras e incluso

la muerte.

Conecte la bomba a tierra

antes de conectarla a la

alimentación eléctrica.

Desconecte la alimentación

de energía antes de trabajar

en la bomba, el motor

o el tanque.

Conecte el motor al

voltaje correcto. Vea la

sección “Electricidad”

en este manual y la

placa del motor.

Conecte el motor a

tierra antes de

conectarlo a la

alimentación de

energía.

Cumpla con las

indicaciones del Código

Nacional Eléctrico, el

de Canadá y los códigos

locales para toda la

conexión eléctrica.

Siga las instrucciones de

conexión eléctrica en

este manual al conectar

el motor a las líneas de

energía eléctrica.

ADVERTENCIA

Presión peligrosa!

Instale una válvula de alivio

de presión en la tubería

de descarga.

Libere toda la presión en el

sistema antes de trabajar en

alguno de los componentes.

Para refacciones o asistencia, llame a Simer Servicios al Cliente al: 1 800 468-7867.

Page 21

Garantía 21

Guarde el recibo original para culaquier referencia posterior

Garantía limitada

SIMER le garantiza al comprador consumidor original (el “Comprador” o “Usted”) de sus productos, que éstos estarán libres de defectos en materiales

y en mano de obra por un período de doce (12) meses, a partir de la fecha de la compra original del consumidor.

Si dentro de los doce (12) meses a partir de la fecha de la compra inicial del consumidor, se comprueba que cualquiera de esos productos es

defectuoso, éste será reparado o reemplazado, a la discreción de SIMER, sujeto a los términos y a las condiciones indicadas a continuación. Se

necesitará su recibo de compra original y la etiqueta de información sobre la garantía del producto, para determinar la admisibilidad de la garantía.

La admisibilidad se basa en la fecha de compra del producto original - no en la fecha de reemplazo bajo la garantía. La garantía está limitada a la

reparación o el reemplazo del producto solamente - El comprador pagará todos los costos de remoción, instalación, mano de obra y envío necesarios,

así como todo costo adicional asociado.

Si necesita piezas o resolución de problemas, NO regrese el producto a la tienda minorista. Llame el Servicio a la Clientela de SIMER

al 1-800-468-7867.

Las reclamaciones bajo esta garantía se deberán realizar mediante la devolución del producto (excepto en el caso de las bombas cloacales, ver a

continuación) a la tienda minorista en donde se haya adquirido, inmediatamente después de haber descubierto un supuesto defecto. SIMER entonces

tomará la medida correctiva tan pronto como sea razonablemente posible. No se aceptarán solicitudes de servicio, si se reciben más de 30 días

después del vencimiento de esta garantía.

Esta garantía no es válida para productos que se utilicen para fines comerciales o de alquiler.

Bombas cloacales

NO devuelva una bomba cloacal (que se haya instalado) a su tienda minorista. Comuníquese con el Departamento de Atención al Cliente de SIMER.

Las bombas cloacales que hayan estado en servicio y se hayan removido pueden representar un peligro de contaminación.

Si su bomba cloacal ha fallado:

• Useguantesdecauchocuandomanipulelabomba;

• Paralosfinesdelagarantía,devuelvalaetiquetadelcordóndelabombayelrecibodecompraoriginalalatiendaminorista;

• Descartelabombacumpliendocontodaslasnormaslocalesquecorrespondanparasueliminación.

Excepciones para la garantía limitada de doce (12) meses

Producto Período de garantía

BW85P,CM10,CMK,M40,M40P 90 días

2300,2310,2330,2520ULST,2943,2955,2956,2957,2960,5023SS,A5500 2 años

Bombasdepozosumergiblesde4”,2945,2958,2975PC,2985,3075SS,3983,3984 3 años

Tanqueprecargadodelsistemadeagua,3985,3986,3988,3989 5años

3963,3995,3997 De por vida

Términos y condiciones generales

Usted deberá pagar por todos los gastos de mano de obra y de envío necesarios para reemplazar el producto cubierto por esta garantía. Esta garantía

no se aplicará en las siguientes situaciones: (1) caso de fuerza mayor (2) productos que, a sólo juicio de SIMER hayan sido sometidos a negligencia,

abuso,accidente,malaaplicación,manejoindebidooalteraciones;(3)fallasdebidoainstalación,operación,mantenimientooalmacenamiento

inadecuados;(4)aplicaciones,usososerviciosquenoseannormalesoaprobados;(5)fallasprovocadasporcorrosión,herrumbreuotrosmateriales

extraños en el sistema, o una operación a presiones que excedan los máximos recomendados.

Esta garantía establece la única obligación de SIMER y el recurso exclusivo del Comprador con respecto a los productos defectuosos.

SIMER NO SE HARÁ RESPONSABLE DE NINGÚN DA—O CONSECUENTE, INCIDENTAL O CONTINGENTE.

LAS GARANTÍAS QUE ANTECEDEN SON EXCLUSIVAS Y REEMPLAZAN TODA OTRA GARANTÍA EXPLÍCITA O IMPLÍCITA, INCLUYENDO PERO SIN

LIMITARSE A LAS GARANTÍAS IMPLÍCITAS DE COMERCIABILIDAD E IDONEIDAD PARA UN FIN ESPECÍFICO. LAS GARANTÍAS QUE ANTECEDEN NO

SE EXTENDERÁN MÁS ALLÁ DE LA DURACIÓN PROVISTA EN LA PRESENTE.

Algunos Estados no permiten la exclusión o limitación de daños incidentales o consecuentes o de limitaciones de tiempo sobre garantías implícitas, de

modo que es posible que las limitaciones o exclusiones que preceden no correspondan en su caso. Esta garantía le otorga derechos legales específicos

y es posible que Usted también tenga otros derechos que pueden variar de un Estado al otro.

SIMER • 293 Wright Street • Delavan, WI U.S.A. 53115

Teléfono: 1-800-468-7867 • Fax: 1-800-390-5351 • Sitio Web: SimerPump.com

Page 22

Instalación 22

Al sistema doméstico

de agua

Te de cebadura de la

bomba con tapón o

manómetro

Reemplazo de una bomba vieja

Voltaje peligroso. Desconecte la alimentación de energía de la

bomba antes de trabajar en ella o en el motor.

1. Drene y quite la bomba vieja. Revise la tubería vieja por si estuviera oxidada,

tuviera cal o moho, etc., y reemplácela si es necesario.

2. Instale la bomba en el sistema. Asegúrese de que todas las uniones de los tubos en

la tubería de succión están unidas herméticamente y son impermeables al agua. Si

la tubería de succión puede succionar aire, la bomba no podrá jalar agua del pozo.

3. Ajuste la altura de montaje de la bomba de modo que las conexiones de plomería

“T” y tapón

para cebar

Válvula

“check”

no ocasionen un esfuerzo de deformación sobre el cuerpo de la bomba. Dele el

soporte adecuado a los tubos de modo que el cuerpo de la bomba no reciba todo

el peso de la tubería o los herrajes.

Usted acaba de terminar las conexiones de plomería del pozo de su nueva bomba de

chorro para pozo poco profundo. Consulte la página 24 para realizar las conexiones del

tanque y de la tubería de descarga.

Punto de hincar

debajo del nivel

No está

aescala

del agua

Manguito de

tubería de

hincar

Punto de

hincar

Instalacion del punto del pozo (punto de hincar)

(Figura1)

1. Hinque el pozo utilizando “manguitos de tubería de hincar” y una “caperuza para

la hinca”. Las “conexiones de perforar” están roscadas a todo lo largo y permiten

que los extremos de la tubería empalmen para que la fuerza de perforación del

mazo sea soportada por la tubería y no por el enroscado. Las conexiones ordinarias

que se encuentran en las tlapalerías no están roscadas a todo lo largo y se pueden

colapsar por el impacto. Las “conexiones de hincado” también son más suaves que

Figura 1 - instalación del punto

de hincar

las conexiones de plomería comunes, y esto facilita la penetración en el suelo.

2. Monte la bomba tan cerca del pozo como sea posible.

3. Utilice el menor número de conexiones posible (especialmente codos) al conectar

la tubería desde el punto del pozo al orificio de succión de la bomba. La tubería

de succión debe ser por lo menos del mismo tamaño que el orificio de succión

Al sistema doméstico

de agua

Te de cebadura de

la bomba con tapón

o manómetro

en la bomba (incluya una válvula “check” si su equipo no está equipado con una)

- Vea la Figura 1. Soporte la tubería para que no haya inclinaciones verticales o

hundimientos en ella a fin de que no se ejerza tensión sobre el cuerpo de la bomba

y con el propósito de que no se incline ligeramente hacia arriba desde el pozo

hacia la bomba (los puntos altos pueden ocasionar que se formen bolsas de aire

Tubería de succión

del pozo