Page 1

OWNER’S MANUAL

Smart Geyser

TM

Submersible Utility Pump

NOTICE D’UTILISATION

Smart Geyser

MD

Pompe utilité submersibles

MANUAL DEL USUARIO

Smart Geyser

MR

Bomba submergibles

de uso general

Installation/Operation/Parts

For further operating, installation,

or maintenance assistance:

Call 1-800-468-7867

English . . . . . . . . . . . . . . . Pages 2-4

Installation/Fonctionnement/Pièces

Pour plus de renseignements

concernant l’utilisation,

l’installation ou l’entretien,

Composer le

1 (800) 468-7867

Français . . . . . . . . . . . . . Pages 5-7

Instalación/Operación/Piezas

Para mayor información sobre el

funcionamiento, instalación o

mantenimiento de la bomba:

Llame al 1-800-468-7867

Español . . . . . . . . . . . .Paginas 8-10

©2005 SIM566 (Rev. 6/13/07)

293 Wright St., Delavan, WI 53115

Phone:

1-800-468-7867

1-800-546-7867

Fax:

1-800-390-5351

MODEL 2330-03

®

3671 0300 INT SIM

Page 2

Safety 2

For parts or assistance, call Simer Customer Service at 1-800-468-7867 / 1-800-546-7867

GENERAL SAFETY

Electrically powered utility pumps normally give many

years of trouble-free service when correctly installed,

maintained, and used. However, unusual circumstances

(interruption of power to the pump, dirt/debris, flooding

that exceeds the pump’s capacity, electrical or mechanical failure in the pump, etc.) may prevent your pump

from functioning normally. To prevent possible water

damage due to flooding, consult your retailer about a

secondary AC pump, a DC backup pump, and/or a high

water alarm. See the “Troubleshooting Chart” in this

manual for information about common pump problems

and remedies. For more information, see your retailer or

call Simer customer service at 1-800-468-7867.

1. Know the pump application, limitations, and potential hazards.

Do not use in explosive atmospheres.

Pump water only with this pump. Failure to follow

this warning can result in personal injury and/or

property damage.

2. Make certain power source conforms to requirements

of your equipment.

3. Disconnect power before servicing.

4. Release all pressure within system before servicing

any component.

5. Drain all water from system before servicing.

6. Secure discharge line before starting pump. An unsecured discharge line will whip, possibly causing personal injury and/or property damage.

7. Check hoses for weak or worn condition before each

use, making certain all connections are secure.

8. Periodically inspect pump and system components.

Keep pump and system free of debris and foreign

objects. Perform routine maintenance as required.

9. Provide means of pressure relief on pumps whose discharge line can be shut-off or obstructed.

10.Personal Safety:

a. Wear safety glasses at all times when working

with pumps.

b. Keep work area clean, uncluttered and properly

lighted – replace all unused tools and equipment.

c. Keep visitors at a safe distance from the work

area.

d. Make workshop child-proof – with padlocks, mas-

ter switches, and by removing starter keys.

11. When wiring an electrically driven pump, follow all

electrical and safety codes, as well as most recent

National Electrical Code (NEC) and Occupational

Safety and Health Act (OSHA).

Pump motor is equipped with an automatic resetting thermal protector and may restart

unexpectedly.

12. Risk of electric shock. This equipment is

only for use on 115 volt (single phase) and is

equipped with an approved 3-conductor cord and 3prong, grounding-type plug.

To reduce risk of electric shock, be certain that it is connected to properly grounded,

grounding-type receptacle.

Where a 2-prong wall receptacle is encountered, it

must be replaced with properly grounded 3-prong

receptacle installed in accordance with the National

Electrical Code and local codes and ordinances.

13.All wiring should be performed by a qualified

electrician.

14.Protect electrical cord from sharp objects, hot surfaces, oil, and chemicals. Avoid kinking cord. Replace

or repair damaged or worn cords immediately.

15.Use wire of adequate size to minimize voltage drop

at motor. Refer to most recent National Electrical

Code.

16.Do not touch an operating motor. Modern motors can

operate at high temperatures.

SPECIFICATIONS

Power supply required................................115V, 60 HZ.

Liquid Temp. Range..............................Max. 77°F (25°C)

Operation Position ...............................................Vertical

Individual Branch Circuit Required ....................15 Amp

Operating Depth Beginning min.........................3/4"

(water level) Ending max.............................1/4"

Discharge ...............................................1" NPT (25 mm)

DESCRIPTION

The submersible pump is designed for water removal in

home applications. Pump can be used for emergency

service and dewatering. Unit is constructed of hi-impact

corrosion resistant plastic. Screened inlet prevents large

solids from entering pump.

NOTICE: This unit is not designed for applications involving salt water or brine! Use with salt water or brine will

void warranty.

PERFORMANCE

GPH (LPH) AT TOTAL FEET (M)

3' 5' 10' 15' 18' 20' 22'

(0.91) (1.52) (3.05) (4.57) (5.49) (6.09) (6.70)

1600 gal 1524 gal 1260 gal 924 gal 648 gal 372 gal 0 gal

(6 057 L) (5 769 L) (4 770 L) (3 498 L) (2 453 L) (1 408 L) (0 L)

Page 3

For parts or assistance, call Simer Customer Service at 1-800-468-7867 / 1-800-546-7867

Installation / Operation 3

INSTALLATION

Do not use power cord to lift motor.

Always use handle.

1. Pump should be located and should rest on level

solid foundation. Do not suspend pump by means of

discharge pipe or power cord. Keep pump inlet

screen clear.

2. Thread outlet pipe into pump body carefully to avoid

stripping or crossing threads.

a. To install with garden hose, install adapter pro-

vided with pump.

NOTICE: To keep friction as low as possible,

hose must be 5/8" or larger. Keep hose as short as

possible.

b. To install with rigid pipe, use plastic pipe. Wrap

thread with Teflon tape or use Plasto Joint Stik*.

Screw pipe into pump hand tight +1 - 1-1/2

turns.

3. If, in your application, backflow is a problem when

the pump stops, prevent it by installing a 1" NPT

check valve in the pump discharge.

4. Power Supply: Pump is designed for 115V., 60 HZ.

operation and requires an individual branch circuit

of 15 amperes or more capacity. It is supplied with a

3-wire cord set with grounding-type plug for use in a

3-wire, grounded outlet. 3 wire extension cord, of at

least 14 AWG (2mm2) size is suggested, with larger

sizes for runs over 25 ft (7M). For safety, pump

should always be electrically grounded to a suitable

electrical ground such as a grounded water pipe or a

properly grounded metallic raceway, or ground wire

system. Do not cut off the round grounding prong.

The pump motor is equipped with

automatic resetting thermal protector and may

restart unexpectedly. Protector tripping is indication

of motor overloading as a result of operating pump

at low heads (low discharge restriction), excessively

high or low voltage, inadequate wiring, incorrect

motor connections, or a defective motor or pump.

OPERATION

Risk of burns or death from electric shock.

Do not handle pump or pump motor with wet hands or

when standing on wet or damp surface, or in water.

Disconnect power from pump before handling, servicing, or attempting to repair pump.

* Lake Chemical Co., Chicago, Illinois

The Smart GeyserTMis fully automatic in operation. The

“smart” controller starts the pump every 2-1/2 minutes

and causes it to run for 5 seconds. If it senses that there

is no water to the pump, it stops. If it senses water, it

continues to run until the water is pumped down to 1/4"

deep, and then it stops. It then goes into a

7-minute quick-detection cycle, starting 4 times the first

minute, twice the second minute, and once a minute for

the next 5 minutes. If by the last check it has not detected water, it resumes its cycle (running 5 seconds every

2-1/2 minutes) until it senses water again.

NOTICE: When you plug the pump into the wall outlet,

it will start and run for 5 seconds. It will then cycle as

described above.

If the unit is put in the water and started, interrupting the

water flow into the pump during the 5-second watersensing run will cause it to wait 2-1/2 minutes before

restarting (instead of 15 seconds).

1. The motor is equipped with an automatically resetting thermal overload protector. If the motor gets too

hot, the overload protector will stop the motor

before it is damaged. When the motor has cooled

sufficiently, the overload protector will reset itself

and the motor will restart.

NOTICE: If the overload protector stops the pump

repeatedly, disconnect the power from the pump and

check it to find the problem. Low voltage, long extension cords, clogged impeller, too much back pressure

in the discharge hose (as when pumping through 50’

(15 M) of coiled hose), or extended running of pump

with no load, can all cause overheating.

2. The water being pumped cools the motor, allowing

the pump to run continuously at any depth of water

above 1/4". However, if the motor overload stops the

pump, allow it to cool for one hour before restarting.

Motor will not restart before the overload has cooled.

AIRLOCKS

When a pump airlocks, it runs but does not move any

water. An airlock will cause the pump to overheat and

fail. This pump has an anti-airlock hole in the bottom of

the pump body. If you suspect an airlock, unplug the

pump, clean out the anti-airlock hole with a paper clip

or piece of wire, and restart the pump.

NOTICE: If the outlet of the discharge hose/pipe is

submerged you must have a 1/8" hole in the discharge

hose/pipe to prevent airlock. This hole must be open to air.

NOTICE: If you move the pump or the pump airlocks, be

sure to drain the hose before trying to restart the pump.

Page 4

Repair Parts / Troubleshooting 4

For parts or assistance, call Simer Customer Service at 1-800-468-7867 / 1-800-546-7867

TROUBLESHOOTING

Risk of electrical shock and sudden start.

Disconnect electrical power to pump before attempting to troubleshoot or work on it.

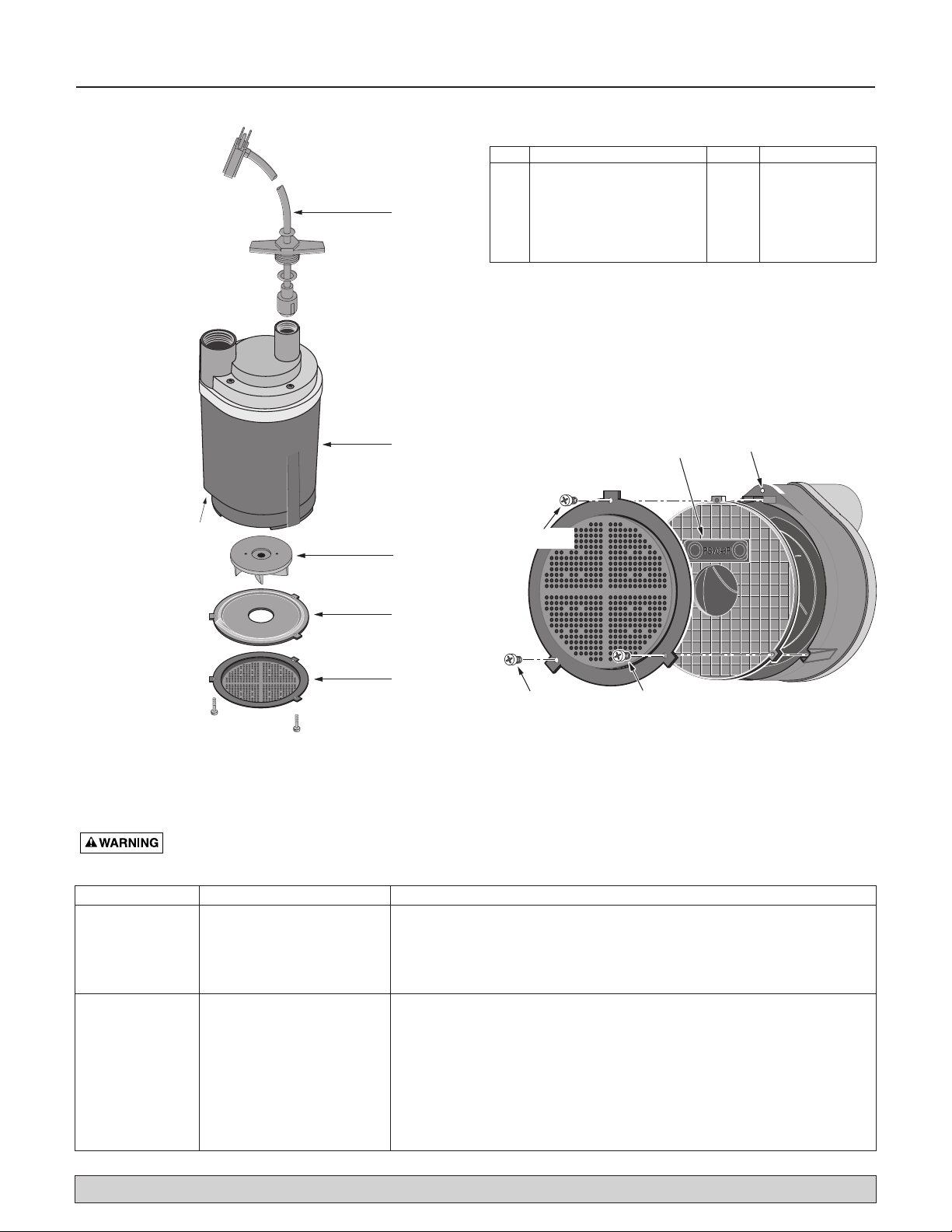

REPAIR PARTS

Key Part Description Qty. Part No.

1 Screen 1 PS8-6P

2 Shield 1 PS70-3P

3 Impeller 1 PS5-25P

4 Motor 1 **

5 Power Cord 1 PS117-51-TSU

• Garden Hose Adapter 1 FT0013-43

NOTICE: To purchase a check valve, call Customer Service at

1-800-468-7867 and order part number PW73-63.

** If motor fails, replace entire pump.

• Not Illustrated.

SYMPTOM POSSIBLE CAUSE(S) CORRECTIVE ACTION

Pump won’t Blown fuse If blown, replace with fuse of proper size

start or run

Low line voltage If voltage under recommended minimum, check size of wiring

from main switch on property. If OK, contact power company.

Defective motor Replace pump

Impeller Remove screen, locate source of binding

Pump operates Low line voltage Use only 14 gauge or larger extension cords. Use short extension cords

but delivers little when necessary

or no water

Something caught in impeller Clean out impeller

Small diameter garden hose Use larger diameter garden hose or 1" flexible pipe. Eliminate any

or long discharge line excess hose. Short hoses work best

Check valve installed without Drill a 1/16" - 1/8" (1.6 - 3.2 mm) dia. hole between pump

vent hole discharge & check valve

Air lock Turn off pump for a few seconds, clean out anti-airlock hole and restart pump

Coils or bends in hose Straighten hose

3rd

Anti-Airlock

Hole

Tighten 1st

Orient Part Number with

Anti-Airlock Hole as shown

2nd

Assemble Screen and Shield as shown.

5

4

Anti-Airlock

Hole

3

2

1

5125 0905

Page 5

Sécurite 5

Pour obtenir des pièces ou de l’aide, appeler le Service à la clientèle Simer en composant le 1 800 468-7867/1 800 546-7867

SÉCURITÉ GÉNÉRALE

Normalement, les électropompes de utilité fournissent de nombreuses années de service sans incident si elles sont bien

posées, entretenues et utilisées. Toutefois, certaines circonstances inhabituelles (interruption du courant alimentant la

pompe, saletés/débris dans le puisard, envahissement par l’eau

dépassant le débit de pompage de la pompe, panne mécanique

ou électrique de la pompe, etc.) peuvent empêcher la pompe

de fonctionner normalement. Pour empêcher toute possibilité

de dommages causés suite à un envahissement par l’eau, consulter le marchand de chez qui la pompe a été achetée concernant la pose d’une pompe de puisard secondaire, d’une pompe

de puisard de secours fonctionnant sur le courant continu et/ou

d’une alarme de niveau haut d’eau. Se reporter au «Tableau de

recherche des pannes» de cette Notice pour tout renseignement

concernant les problèmes courants des pompes de utilité et

comment y remédier. Pour plus de renseignements, s’adresser

au marchand ou appeler le service à la clientèle Simer en composant le 1 800 468-7867.

1. Connaître les applications, limitations et dangers éventuels

de la pompe.

Ne pas utiliser dans un environnement

explosif. N’utiliser la pompe que pour pomper de l’eau.

Ignorer cet avertissement peut provoquer des blessures

corporelles et/ou des dommages matériels.

2. Veiller à ce que la source d’alimentation électrique est conforme aux exigences de votre équipement.

3. Débrancher l’alimentation en courant avant de passer à

l’entretien.

4. Relâcher toute la pression existant à l’intérieur du système

avant de passer à l’entretien de tout élément de la pompe.

5. Evacuer toute l’eau du système avant d’effectuer tout entretien.

6. Fixer la voie de déversement avant de mettre la pompe en

marche. Une voie de déversement mal fixée se mettra à

fouetter causant éventuellement des blessures corporelles

et/ou des dommages matériels.

7. Avant chaque utilisation, vérifier que les tuyaux ne sont pas

faibles ou usés, en s’assurant que tous les raccords sont

fixés.

8. Périodiquement, inspecter la pompe et tous les éléments de

l’ensemble. Procéder à un entretien périodique selon le

besoin.

9. Permettre que la pression exercée sur les pompes soit

libérée afin d’éviter que les voies de déversement ne se ferment ou s’obstruent.

10. Sécurité personnelle:

a. Porter des lunettes protectrices à tout moment pendant

le maniement de la pompe.

b. Maintenir la zone de travail propre, en ordre et

correctement éclairée. Ranger tous les outils et

matériels non utilisés.

c. Maintenir les visiteurs à une distance prudente de la

zone de travail.

d. Veiller à ce que les enfants soient écartés des dangers

de l’atelier: avec des cadenas et des interrupteurs

maîtres, et en ôtant les clés de démarrage.

11. Pendant le câblage d’une pompe à fonctionnement

électrique, suivre tous les codes de sécurité et d’électricité,

ainsi que le dernier code électrique national en vigueur et

l’acte relatif à la sécurité et la santé en milieu de travail, le

cas échéant (OSHA).

Le moteur de la pompe est équipé d’un

protecteur thermique à remise en marche automatique qui

peut se mettre en route brusquement.

12. Risque d’électrocution. Ce matériel ne

doit être utilisé que sur du 115 volts (monophasé) et il est

équipé d’un câble conducteur à 3 dents approuvé et d’une

prise à 3 dents à masse.

Pour réduire les risques d’électrocution,

veiller à ce qu’il soit correctement relié à un réceptacle à

la masse.

Dans le cas où un réceptacle à 2 dents est en place, il doit

être remplacé par un réceptacle à 3 dents à la masse monté

conformément au code électrique national et aux arrêtés

locaux.

13. Le câblage devrait être exécuté par un électricien qualifié.

14. Mettre le cable électrique à l’abri d’objets tranchants,

surfaces chaudes, huile et produits chimiques. Éviter qu’il

ne soit tortillé. Remplacer ou réparer immédiatement les

câbles endommagés ou usés.

15. Utiliser des câbles de taille appropriée pour minimiser les

baisses de tension du moteur. Se référer au code électrique

national.

16. Ne pas toucher un moteur en marche. Les moteurs peuvent

fonctionner par les températures élevées.

CARACTÉRISTIQUES TECHNIQUES

Alimentation requise...............................................115V, 60HZ

Température du liquide (gamme) ....................Max. 25°C (77°F)

Position en marche ......................................................Verticale

Circuit de dérivation individuel requis..........................15 amp.

Profondeur durant

fonctionnement Début min. ...................19,1mm (3/4")

(niveau d’eau) Fin max...........................6,4mm (1/4")

Déversement ..................................................................1" NPT

DESCRIPTION

La pompe submersible est conçue pour éliminer l’eau des habitations. Elle peut être utilisée pour les services d’urgence et

évacuer l’eau. Cette pompe est construite en plastique à résistance élevée aux chocs et à la corrosion. L’admission, qui est

munie d’une crépine, empêche les matières solides de pénétrer

dans la pompe.

NOTA : Cette pompe n’est pas conçue pour pomper de l’eau

salée ni de la saumure! La garantie sera annulée si cette pompe

est utilisée pour pomper de l’eau salée ou de la saumure.

RENDEMENT

LPH (GPH) À UN NOMBRE TOTAL DE MÈTRES (PIEDS)

0,91 1,52 3,05 4,57 5,49 6,09 6,70

(3') (5') (10') (15') (18') (20') (22')

6 057 L 5 769 L 4 770 L 3 498 L 2 453 L 1 408 L 0 L

(1600 gal)(1524 gal)(1260 gal) (924 gal) (648 gal) (372 gal) (0 gal)

Page 6

Installation / Fonctionnement 6

MONTAGE

Ne pas utiliser le câble d’alimentation pour

lever le moteur. Toujours faire usage des poignées.

1. La pompe devrait être placée, et reposer, sur une base

solide et équilibrée. Ne pas suspendre la pompe par le

conduit de déversement ou le câble d’alimentation.

Maintenir le filtre à l’admission propre.

2. Visser soigneusement le conduit de sortie sur le corps de la

pompe soigneusement pour éviter d’arracher ou de fausser

les filets.

a. Pour la pose avec un tuyau d’arrosage, poser l’adapta-

teur fourni avec la pompe.

NOTA : Pour garder le frottement au minimum, le

diamètre du tuyau doit être de 5/8 de pouce au minimum et aussi court que possible.

b. Pour l’équiper d’un tuyau rigide, utiliser un conduit en

plastique. Recouvrir les filets de ruban téflon ou de

*Plasto Joint Stik. Visser manuellement le conduit sur la

pompe de +1 -1,5 tour.

3. Si, en fonction de l’utilisation, le refoulement représente

un problème lorsque la pompe s’arrête, poser un clapet

antiretour de 1 pouce NPT côté refoulement de la pompe.

4. Source d’alimentation: La pompe est conçue pour du 115V

et 60HZ et requiert un circuit de dériviation individuel de

15 ampères ou plus. Elle est fournie avec un câble à 3 fils

métalliques et une prise à la masse pour une sortie à la

masse à 3 fils. Une rallonge à 3 fils métalliques, d’au moins

2mm2 (14 AWG) est suggérée, avec une taille supérieure si

la longueur doit dépasser 7m (25 pieds). Pour des raisons

de sécurité, la pompe doit toujours être mise à la masse à

un sol adéquate, avec un conduit d’eau, une canalisation

métallique ou un système métallique reliés à la masse.Ne

pas couper la dent ronde de mise à la masse.

Le moteur de la pompe est équipé d’un protecteur thermique de remise en marche automatique qui peut

se mettre en route subitement. Le déclenchement du protecteur indique que le moteur est surchargé à la suite d’un

fonctionnement avec: de faibles hauteurs (faible restriction de

déversement), une tension excessivement faible ou élevée, un

câblage incorrecte, de mauvais raccords au moteur ou un

moteur ou une pompe défectueux.

FONCTIONNEMENT

Des secousses électriques risquent de causer

des brûlures, voire la mort. Ne pas manipuler la pompe ni le

moteur lorsqu'on a les mains humides ou lorsqu'on se tient sur

une surface humide ou dans l'eau. Couper le courant avant de

manipuler la pompe, de l'entretenir ou d'essayer de la réparer.

*Lake Chemical Co., Chicago, Illinois, Êtats-Unis

Le fonctionnement de la pompe Smart GeyserMDest entièrement

automatique. Le contrôleur «intelligent» démarre la pompe

toutes les 2-1/2 minutes et la fait fonctionner pendant 5 secondes. Si le contrôleur détecte que la pompe n’aspire pas d’eau, il

l’arrêtera. Si le contrôleur détecte de l’eau, il continuera de faire

fonctionner la pompe jusqu’à ce que l’eau soit pompée jusqu’à

une profondeur de 1/4 de pouce, puis il arrêtera la pompe. La

pompe passe ensuite dans un cycle de détection rapide de 7

minutes, qui se répète 4 fois lors de la première munute, deux

fois lors de la deuxième minute et une fois para minute pour les

5 prochaines minutes. Si, lors de la dernière vérification, la

pompe ne détecte pas d’eau, elle reprend son cycle normal

(c’est-à-dire qu’elle fonctionnera 5 seconds toutes les 2 1/2 minutes) jusqu’à ce qu’elle détecte de nouveau de l’eau.

NOTA : Lorsque la pompe sera branchée dans la prise de

courant électrique, elle démarrera et fonctionnera pendant 5

secondes. Le contrôleur fera ensuite fonctionner la pompe

comme il est décrit ci-dessus.

Si la pompe est mise dans l’eau, puis qu’on la démarre et qu’ensuite on interrompt le débit dans la pompe pendant son fonctionnement de détection d’eau de 5 secondes, la pompe attendra 2 1/2 minutes avant de redémarrer (au lieu de 15 seconds).

1. Le moteur est équipé d'un protecteur contre les surcharges

thermiques à réenclenchement automatique. Si le moteur

surchauffe, le protecteur contre les surcharges arrêtera le

moteur avant qu'il soit endommagé. Dès que le moteur

aura suffisamment refroidi, le protecteur contre les surcharges réenclenchera le moteur qui redémarrera.

NOTA : Si le protecteur contre les surcharges arrête la

pompe de façon répétitive, débrancher la pompe et déterminer le problème. Une basse tension, des cordons prolongateurs trop longs, un impulseur bouché, une contre-pression trop importante dans le tuyau de refoulement (comme

pomper de l'eau dans un tuyau enroulé ayant jusqu'à 50

pieds [15 mètres]) ou un fonctionnement prolongé à vide

de la pompe causera une surchauffe.

2. L'eau pompée refroidit le moteur, ce qui permet à la pompe

de fonctionner continuellement à condition que la profondeur

de l'eau soit supérieure à 1/4 de pouce. Toutefois, si une surcharge du moteur arrête la pompe, le laisser refroidir pendant

une heure avant de le redémarrer. Le moteur ne redémarrera

pas tant que la surcharge n'aura pas refroidi.

BOUCHON D'AIR

Si un bouchon d’air se forme dans la pompe, elle fonctionnera

mais ne débitera pas d’eau. Un bouchon d’air causera la surchauffe de la pompe, puis sa panne. Un trou antibouchon d’air

a été pratiqué à la partie inférieure du corps de cette pompe. Si

l’on soupçonne un bouchon d’air, débrancher la pompe, nettoyer le trou antibouchon d’air avec un trombone ou un

morceau de fil de fer, puis redémarrer la pompe.

REMARQUE : Si la sortie du tuyau rigide ou du tuyau souple de

refoulement est immergée, un trou de 1/8 de po devra être

percé dans le tuyau rigide ou le tuyau souple de refoulement

pour empêcher la formation de bouchons d’air. Ce trou doit

toujours être ouvert à l’air libre.

REMARQUE : Si la pompe est déplacée ou s’il y a un bouchon

d’air dans la pompe, s’assurer de vidanger le tuyau avant de

tenter de redémarrer la pompe.

Pour obtenir des pièces ou de l’aide, appeler le Service à la clientèle Simer en composant le 1 800 468-7867/1 800 546-7867

Page 7

Piéces de rechange / Recherche des pannes 7

Pour obtenir des pièces ou de l’aide, appeler le Service à la clientèle Simer en composant le 1 800 468-7867/1 800 546-7867

PIÈCES DE RECHANGE

Rèf. Description Qté N° de pièce

1 Filtre 1 PS8-6P

2 Protecteur 1 PS70-3P

3 Roue hélice 1 PS5-25P

4 Moteur 1 **

5 Câble d’alimentation 1 PS117-51-TSU

• Adaptateur pour tuyau

de jardinage 1 FT0013-43

REMARQUE : Pour acheter un clapet antiretour, appeler le service à la clientèle au 1 (800) 365-6832 et commander le

numéro de pièce suivant : PW73-63.

** Si le moteur tombe en panne, remplacer la pompe.

• Non represénté.

SYMPTÔMES CAUSE(S) PROBABLE(S) ACTION CORRECTIVE

La pompe ne Le fusible a sauté S’il a sauté, le remplacer avec un fusible de la taille appropriée

démarre pas La tension est faible Si la tension est inférieure au minimum recommandé, vérifier la taille du

câblage depuis l’interrupteur principal sur place. Si tout est en règle,

contacter la compagnie d’électricité

Le moteur est défectueux Remplacer la pompe

Roue hélice Déposer la crépine et localiser la source du coincement

La pompe La tension est faible N’utiliser que des cordons prolongateurs de calibre 14 ou plus gros. Dans la

fonctionne mais mesure du possible, utiliser des cordons prolongateurs de courte longueur

elle déverse peu Quelque chose obstrue Nettoyer la roue hélice

ou pas d'eau la roue hélice

Tuyau d’arrosage de petit Utiliser un tuyau souple de 1 pouce ou un tuyau d’arrosage de plus grand

diamètre ou conduite de diamètre. Éliminer toute longueur de tuyau souple en trop. Des tuyaux

refoulement longue souples courts fonctionnent mieux

le clapet antiretour monté Percer un trou d’un diamètre de 1,6 - 3,2mm (1/16" - 1/8") entre la voie de

sans trou d’évent déversement de la pompe et le clapet antiretour

Bouchon d'air Arrêter la pompe pendant quelques secondes, nettoyer le trou antibouchon

d’air, puis redémarrer la pompe

Le tuyau est enroulé en Le redresser

serpentin ou plié

RECHERCHE DES PANNES

Risque de secousses électriques et de démarrages soudains.

Débrancher la pompe de la prise de courant avant de la réparer ou de l’entretenir.

Antibouchon

d’air

Assembler le filtre et le protecteur tel qu’illustré.

Aligner le numéro de pièce au trou

antibouchon tel qu’illustré

Tr o u antibouchon d’air

Reserrer le 1

er

2

ième

3

ième

5

Anti-Airlock

Hole

5125 0905

4

3

2

1

Orient Part Number with

Anti-Airlock Hole as shown

3rd

Tighten 1st

2nd

Anti-Airlock

Hole

Page 8

Seguridad 8

Si necesita repuestos o asistencia llame al Servicio al Cliente de Simer, 1-800-468-7867/1-800-546-7867

SEGURIDAD GENERAL

Las bombas de uso general con accionamiento eléctrico, generalmente brindan muchos años de servicio sin problema cuando se las instala, mantiene y emplea correctamente. Sin embargo, circunstancias inusuales (como la interrupción de la corriente hacia la bomba, suciedad/escombros en el sumidero,

inundación que supera la capacidad de la bomba, fallas eléctricas o mecánicas en la bomba, etc.) pueden evitar que la

bomba funcione normalmente. Para evitar posibles daños causados por el agua y debidos a inundaciones, consulte con su

fontanero sobre la posibilidad de instalar un bomba secundaria

de CA para el sumidero, una bomba de CC de repuesto para el

sumidero, y/o una alarma de nivel alto de agua. Consulte la

“Tabla de localización de fallas” en este manual para obtener

información sobre los problemas comunes con bombas de uso

general y sus soluciones. Para mayor información, acuda con

su representante de ventas o llame al centro de servicio a

clientes Simer al 1-800-468-7867.

1. Sepa cuál es la aplicación de la bomba, sus limitaciones y

los peligros potenciales.

No use en ambiente explosivas. Utilice la

bomba sólo con agua. Si no se respeta esta advertencia se

pueden producir lesiones personales o daños materiales.

2. Asegurarse de que la fuente de alimentación se ajuste a las

especificaciones de sus equipos.

3. Desconecte la corriente antes de efectuar el servicio.

4. Alivie toda la presión dentro del sistema antes de efectuar

el servicio de un componente.

5. Drene todo el agua del sistema antes de efectuar el servicio.

6. Asegurar la línea de descarga antes de arrancar la bomba.

Si no se sujeta, dará latigazos, causando posibles lesiones

personales y daños materiales.

7. Examine las mangueras antes de usarlas para ver si están

debilitadas o desgastadas, asegurandose que todas las

conexiones estén bien fijas.

8. Inspeccione periódicamente la bomba y los componentes del

sistema. Manténgalos limpios de basuras y objetos foráneos.

Realice el mantenimiento de rutina según sea necesario.

9. Disponga de medios de aliviar la presión en bombas cuya

línea de descarga pueda cerrarse o taponarse.

10. Seguridad personal:

a. Lleve puestas gafas de seguridad en todo momento

cuando trabaje con las bombas.

b. Mantenga limpia el área de trabajo, despejada y bien

iluminada. Aparte todas las herramientas y equipos que

no esté usando.

c. No deje que se acerquen otras personas a la zona de

trabajo.

d. Asegure el taller a prueba de niños. Use candados,

interruptores generales y saque las llaves de arranque.

11. Cuando conecte una bomba de impulsión eléctrica, respete

todos los códigos eléctricos y de seguridad, así como otros

más recientes como el Código Eléctrico Nacional (NEC) y

la Ley de Seguridad e Higiene en el Trabajo (OSHA).

El motor de la bomba está equipado con un

protector térmico de reposición automática y puede volver

a arrancar de forma inesperada.

12. Riesgo de descarga eléctrica. Esta unidad

sólo se debe usar con corriente de 115 V (monofásica) y

está equipada con un cable aprobado de 3 conductores y

un enchufe de 3 clavijas con linea a tierra.

Para disminuir el riesgo de una descarga

eléctrica, asegúrase que esté enchufada a un receptáculo

conectado a tierra de forma adecuada. En casos en que se

disponga de una toma de corriente de pared para 2 clavijas, debe reemplazarse por un receptáculo para 3 clavijas

conectado a tierra de forma adecuada e instalado según el

Código Eléctrico Nacional y los códigos y ordenanzas

locales.

13. Todas las conexiones eléctricas deben ser hechas por un

electricista capacitado.

14. Proteja el cable eléctrico de objetos afilados, superficies

calientes, aceite y productos químicos. Evite enredar el

cable. Reemplace o repare inmediatamente los cables

dañados o gastados.

15. Use cable del tamaño adecuado para reducir a un mínimo

la caída de voltaje en el motor. Consulte códigos al dia

como el Código Eléctrico Nacional (NEC).

16. No toque el motor en funcionamiento. Los motores pueden

funcionar a temperaturas altas.

ESPECIFICACIONES

Corriente requerida ................................................115V, 60 Hz

Rango temperatura del líquido .......................Máx. 25°C (77°F)

Posición de operación ...................................................Vertical

Requiere un ramal individual.............................................15 A

Nivel de operación Mín. inicial ..................19,1 mm (3/4")

(nivel de agua) Máx. final ......................6,4 mm (1/4")

Descarga ........................................................................1" NPT

DESCRIPCIÓN

La bomba sumergible ha sido diseñada para la remoción de

agua en aplicaciones residenciales. La bomba se puede usar

para servicios de emergencia y desagüe. La unidad está construida en plástico anticorrosivo de gran resistencia. La

admisión con tamiz impide que partículas sólidas grandes

entren en la bomba.

AVISO: Esta unidad no ha sido diseñada para uso con agua

salada o salubre. El uso con agua salada o salubre anulará la

garantía.

RENDIMIENTO

LPH (GPH) A METROS (PIES) TOTALES

0,91 1,52 3,05 4,57 5,49 6,09 6,70

(3') (5') (10') (15') (18') (20') (22')

6 057 L 5 769 L 4 770 L 3 498 L 2 453 L 1 408 L 0 L

(1600 gal)(1524 gal)(1260 gal) (924 gal) (648 gal) (372 gal) (0 gal)

Page 9

Instalación / Operación 9

INSTALACIÓN

No levante el motor por el cordón de alimentación. Use siempre la manija.

1. La bomba debe estar colocada y apoyada sobre una superficie maciza y nivelada. No cuelgue la bomba por el tubo

de descarga o cordón de alimentación. Mantenga limpio el

filtro de entrada de la bomba.

2. Enrosque con cuidado el tubo de salida al cuerpo de la

bomba para no desgastar o dañar la rosca.

a. Para instalar con manguera de jardín, instale el adapta-

dor provisto con la bomba.

AVISO: Para mantener la fricción reducida a un mínimo,

la manguera debe tener un diámetro de 5/8" o más

grande. La manguera debe ser tan corta como sea posible.

b. Para instalar con una tubería rígida, use tubería de plástico.

Envuelva la rosca con cinta de teflón o use Plasto Joint

Stik*. Enrosque la tubería en la bomba con la mano entre +

1 y 1 1/2 vueltas.

3. Si, en su aplicación, el retroflujo es un problema cuando la

bomba se detiene, evítelo instalando una válvula de retención de 1" NPT en la descarga de la bomba.

4. Fuente de alimentación: La bomba está diseñada para

operar a 115V y 60 Hz y requiere un ramal individual de

15 amperes o más de capacidad. Dispone de un cable de 3

conductores con un enchufe con linea a tierra para usar en

una toma de corriente conectada a tierra de 3 conductores.

Se recomienda un cordón prolongador de 3 conductores, o

de calibre 14 AWG (2 mm

2

) como mínimo, y tamaños mayores para tramos superiores a 7 m (25 pies). Por razones de

seguridad, la bomba debe estar conectada siempre a una

tierra eléctrica adecuada tal como una tubería de agua

conectada a tierra o una canalización eléctrica metálica

conectada a tierra de forma adecuada o un sistema de

cables conectado a tierra. No corte la clavija redondeada

de tierra.

El motor de la bomba está equipado con un

protector térmico de reposición automática y puede volver

a arrancar de forma inesperada. La desconexión del

protector es señal de que el motor está sobrecargado

como resultado de operar la bomba a bajas alturas de elevación (baja restricción de descarga), voltaje muy alto o

muy bajo, conexiones inadecuadas, conexiones incorrectas

del motor o defectos en el motor o la bomba.

OPERACIÓN

Riesgo de quemaduras o muerte como resultado

de choques eléctricos. No maneje la bomba ni el motor de la

bomba con manos húmedas o cuando esté parado sobre

superficies húmedas o mojadas, o sobre agua. Desconecte la

corriente eléctrica de la bomba antes de realizar trabajos de

mantenimiento o reparaciones en la bomba.

* Lake Chemical Co., Chicago, Illinois, Estados Unidos de America

El funcionamiento de la Smart GeyserMRes totalmente automático. El controlador "inteligente" enciende la bomba cada 2-1/2

minutos y hace que marche por 5 segundos. Si detecta que no

hay flujo de agua hacia la bomba, se detiene. Si detecta agua,

continúa funcionando hasta que haya bombeado agua hasta

una profundidad de 1/4" y luego se detiene. Luego pasa a un

ciclo de detección rápida de 7 minutos, comenzando 4 veces

durante el primer minuto, dos veces durante el segundo minuto

y una vez por minuto durante los próximos 5 minutos. Si

cuando llega a la última verificación, aún no ha detectado

agua, volverá a pasar por este ciclo (funcionando por 5 segundos cada 2-1/2 minutos) hasta que vuelva a detectar agua.

AVISO: Cuando enchufe la bomba en el tomacorriente, se

encenderá y funcionará por 5 segundos. Luego comenzará el

ciclo que se describe arriba.

Si la unidad se coloca en el agua y se pone en funcionamiento,

interrumpiendo el flujo de agua hacia la bomba durante la

operación de detección de agua de 5 segundos, ésta esperará 21/2 minutos antes de volver a comenzar (en lugar de 15 segundos).

1. El motor viene equipado con un protector de sobrecarga

térmica que se vuelve a graduar automáticamente. Si el

motor se recalienta, el protector de sobrecarga detiene el

motor antes de que se perjudique. Cuando el motor se ha

enfriado lo suficiente, el protector de sobrecarga se gradúa

automáticamente y vuelve a arrancar el motor.

AVISO: Si el protector de sobrecarga detiene la operación

de la bomba repetidamente, desconecte la corriente eléctrica de la bomba e inspeccione para encontrar el problema.

Tensiones bajas, cables largos de alargamiento, impulsores

bloqueados, demasiada presión en la manguera de descarga (como en los casos en que se bombea a través de 50

pies - 15 metros - de manguera enredada), o una

operación prolongada de la bomba sin carga, pueden

causar recalentamiento.

2. El agua que se bombea enfría el motor, lo que permite que la

bomba continúe funcionando a cualquier profundidad de

agua por encima de 1/4 de pulgada. Sin embargo, si la sobrecarga del motor detiene la bomba, deje que se enfríe por una

hora antes de volver a encenderla. El motor no volverá a funcionar antes de que la sobrecarga se haya enfriado.

BOLSAS DE AIRE (“AIRLOCK”)

Cuando el flujo de la bomba disminuye o se para debido a bolsas de aire, la bomba marcha pero no mueve agua. Una bolsa

de aire puede hacer que la bomba se recaliente y falle. Esta

bomba posee un orificio “anti-airlock” en el fondo del cuerpo

de la bomba para eliminar las bolsas de aire. Si usted sospecha

que hay una bolsa de aire, desenchufe la bomba, limpie el orificio “anti-airlock” con un clip de papel o un trozo de alambre

y vuelva a activarla.

AVISO: Si la salida de la manguera/tubería de descarga

está sumergida, se deberá tener un orificio de 1/8” en la

manguera/tubería de descarga para evitar la creación de

bolsas de agua. Este orificio debe estar abierto al aire.

AVISO: Si mueve la bomba o si hay bolsas de aire en la bomba,

asegúrese de drenar la manguera antes de tratar de volver a encender la bomba

Si necesita repuestos o asistencia llame al Servicio al Cliente de Simer, 1-800-468-7867/1-800-546-7867

Page 10

Repuestos / Localización de fallas 10

Si necesita repuestos o asistencia llame al Servicio al Cliente de Simer, 1-800-468-7867/1-800-546-7867

REPUESTOS

Clave Descripción Cant. N° de Pieza

1 Filtro 1 PS8-6P

2 Protector térmico 1 PS70-3P

3 Impulsor 1 PS5-25P

4 Motor 1 **

5 Cordón de alimentación 1 PS117-51-TSU

• Adaptador de manguera

de jardín 1 FT0013-43

AVISO: Para adquirir una válvula de retención, llame al

Departamento de Atención al Cliente, 1-800-365-6832 y

encargue el repuesto PW73-63.

** Si el motor falla, reemplace la bomba.

• No ilustrado.

SÍNTOMA CAUSAS PROBABLES SOLUCIÓN

La bomba no Fusible fundido Si está fundido, reemplácelo por un fusible del tamaño adecuado

arrancao no Bajo voltaje de línea Si el voltaje es inferior al mínimo recomendado, compruebe el tamaño de los

funciona cables procedentes del interruptor principal de las instalaciones. Si está bien,

consulte con la compañía eléctrica

Motor defectuoso Reemplace la bomba

Impulsor Retire la criba, ubique la fuente del atascamiento

La bomba Bajo voltaje de línea Use únicamente cables de extensión de calibre 14. Use cables de extensión

funcionapero cortos cuando sea necesario

no suministra Objeto atascado en el rodete Limpie el impulsor

agua o muy Manguera de jardín de Use una manguera de jardín de mayor diámetro o un tubo flexible de 1".

poca agua diámetro chico o línea de Deseche el exceso de manguera. Las mangueras cortas funcionan mejor

descarga larga

Examine la válvula instalada Taladre un agujero de 1,6 a 3,2 mm (1/16" a 1/8") de diámetro entre la de

sin respiradero scarga de la bomba y la válvula de retención

Bolsa de aire (disminución Apague la bomba por unos segundos, limpie el orificio “anti-airlock” y

de flujo) luego vuelva a activarla

Espirales o dobleces en Enderece la manguera

la manguera

LOCALIZACIÓN DE FALLAS

Riesgo de choque eléctrico y arranque repentino. Desconecte la corriente eléctrica a la bomba antes de

tratar de localizar una falla o de realizar trabajos en la misma.

Ensamble la pantalla y el casco según se ilustra.

Orificio “anti-airlock”

Dirija el número de la pieza con el

orificio anti-airlock según se ilustra

Orificio anti-airlock

Apriete 1o.

2o. 3o.

5

Anti-Airlock

Hole

5125 0905

Orient Part Number with

4

3

2

1

Anti-Airlock Hole as shown

Tighten 1st

3rd

2nd

Anti-Airlock

Hole

Page 11

11

ATTACH ORIGINAL RECEIPT HERE FOR WARRANTY CONSIDERATION.

SIMER warrants to the original consumer purchaser (“Purchaser”) of its products that they are free from defects in material or workmanship.

If within twelve (12) months from the date of the original consumer purchase any such product shall prove to be defective, it shall be repaired or replaced at SIMER’s

option, subject to the terms and conditions set forth below.Your original receipt of purchase is required to determine warranty eligibility.

Exceptions to the Twelve (12) Month Warranty

Product/Model No. Warranty Period

M40P, M40, BW85P, CM10, CMK 90 days

2330, 2300, 2310, 2955, 2956, 2957, 2960, A5500 2 Years

4" Submersible Well Pumps, 3984, 3983, 2975PC, 2958, 2985, 3075SS 3 Years

Pre-Charge Water System Tank, 3986, 3985, 2956 5 Years

3988, 3995, 3997, 3963 Lifetime

General Terms and Conditions

Purchaser must pay all labor and shipping charges necessary to replace product covered by this warranty. This warranty shall not apply to acts of God, nor shall

it apply to products which, in the sole judgement of SIMER, have been subject to negligence, abuse, accident, misapplication, tampering, alteration; nor due to

improper installation, operation, maintenance or storage; nor to other than normal application, use or service, including but not limited to, operational failures

caused by corrosion, rust or other foreign materials in the system, or operation at pressures in excess of recommended maximums.

Requests for service under this warranty shall be made by returning the defective product to the Retail outlet or to SIMER as soon as possible after the discov-

ery of any alleged defect. SIMER will subsequently take corrective action as promptly as reasonably possible. No requests for service under this warranty will be

accepted if received more than 30 days after the term of the warranty.

This warranty sets forth SIMER’s sole obligation and p

urchaser’s exclusive remedy for defective products.

SIMER SHALL NOT BE LIABLE FOR ANY CONSEQUENTIAL, INCIDENTAL, OR CONTINGENT DAMAGES WHATSOEVER.

THE FOREGOING WARRANTIES ARE EXCLUSIVE AND IN LIEU OF ALL OTHER EXPRESS WARRANTIES. IMPLIED WARRANTIES, INCLUDING BUT NOT

LIMITED TO THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, SHALL NOT EXTEND BEYOND THE

DURATION OF THE APPLICABLE EXPRESS WARRANTIES PROVIDED HEREIN.

Some states do not allow the exclusion or limitation of incidental or consequential damages or limitations on how long an implied warranty lasts, so the above

limitations or exclusions may not apply to you.This warranty gives you specific legal rights and you may also have other rights which vary from state to state.

SIMER • 293 Wright Street • Delavan, WI U.S.A. 53115

Phone: 1-800-468-7867/1-800-546-7867 • Fax: 1-800-390-5351

E-Mail: info@simerpumps.com • Web Site: http://www.simerpumps.com

ATTACHER LE REÇU D'ORIGINE ICI À DES FINS DE GARANTIE

SIMER garantit à l’acheteur-utilisateur initial de ses produits (“Acheteur”) contre tout défaut de fabrication et de matériaux.

To ut produit reconnu défectueux dans les douze (12) mois qui suivent la date d’achat d’origine sera remplacé ou réparé à la discrétion de

SIMER, selon les conditions stipulées ci-dessous. La preuve d’achat est exigée pour déterminer l’admissibilité à la garantie.

Exceptions à la garantie de douze (12) mois

Produits/Node modèle Période de garantie

M40P, M40, BW85P, CM10, CMK 90 jours

2330, 2300, 2310, 2955, 2956, 2957, 2960, A5500 2 ans

Pompe pour puits submersibles de 4 pouces, 3984, 3983, 2975PC, 2958, 2985, 3075SS 3 ans

Réservoir préchargé de système d’eau, 3986, 3985, 2956 5 ans

3988, 3995, 3997, 3963 À vie

Conditions générales

L’Acheteur s’engage à payer tous les frais de main-d’œuvre et d’expédition nécessaires au remplacement du produit couvert par la garantie. Cette garantie ne couvrira pas les cas de

force majeure, et ne s’appliquera pas aux produits qui, du seul avis de SIMER, ont fait l’objet de négligence, d’utilisation abusive ou incorrecte, d’accident, de modification ou d’altération ; ni aux produits qui n’ont pas été installés, utilisés, entreposés ou entretenus correctement ; ni à ceux qui n’ont pas été utilisés ou entretenus normalement, y compris, mais sans

s’y limiter, aux produits ayant des pannes de fonctionnement causées par la corrosion, la rouille ou autre corps étranger dans le système, ou à des produits ayant fonctionné à des pressions dépassant la limite maximale recommandée.

Les demandes de service en vertu de la présente garantie seront faites en retournant le produit défectueux au détaillant ou à SIMER dès la déco

uverte de tout défaut allégué. SIMER prendra

alors les mesures correctives aussi rapidement qu’il est raisonnablement possible. Aucune demande de service en vertu de la présente garantie ne sera acceptée si elle est reçue plus de 30

jours après l’expiration de la dite garantie.

La présente garantie énonce la totalité des obligations de SIMER et le seul recours possible de l’Acheteur dans le cas de produits défectueux.

SIMER NE SERA TENU RESPONSABLE D’AUCUN DOMMAGE INDIRECT, ACCIDENTEL OU FORTUIT QUEL QU’IL SOIT.

LES PRÉSENTES GARANTIES SONT EXCLUSIVES ET TIENNENT LIEU DE TOUTE AUTRE GARANTIE EXPRESSE. LES GARANTIES IMPLICITES, Y COMPRIS, MAIS SANS S’Y

LIMITER, LES GARANTIES IMPLICITES AYANT TRAIT À LA COMMERCIABILITÉ ET À L’ADAPTATION À UN USAGE PARTICULIER, NE DÉPASSERONT PAS LA DURÉE DES GARANTIES EXPRESSES APPLICABLES STIPULÉES DANS LES PRÉSENTES.

Certaines provinces n’autorisent pas d’exclure ou de limiter les dommages fortuits ou indirects ou de limiter la durée d’une garantie implicite ; il se peut donc que les limitations ou exclusions

ci-dessus ne s’appliquent pas à votre cas. La présente garantie vous donne des droits juridiques spécifiques et vous pouvez en avoir d’autres qu

i varient d’une province à l’autre.

SIMER • 293 Wright Street • Delavan, WI U.S.A. 53115

Téléphone: 1-800-468-7867/1-800-546-7867 • Télécopieur: 1-800-390-5351

Courrier électronique: info@simerpumps.com • Site Web: http://www.simerpumps.com

Page 12

ADHÍERA AQUÍ EL RECIBO ORIGINAL PARA VALIDACION DE GARANTÍA

SIMER garantiza al comprador consumidor original (“Comprador”) de sus productos, que éstos se encuentran libres de defectos de material o mano de obra

.

Si dentro de los doce (12) meses de la fecha original de la compra cualquiera de los productos demostrara estar defectuoso, el mismo será reparado o reemplazado, a opción de

SIMER

con sujeción a los términos y condiciones expuestos a continuación. Se requiere su recibo original de compra para determinar si se encuentra bajo garantía.

Excepciones a la Garantía por Doce (12) Meses

Producto/Modelo No. Período de garantía

M40P, M40, BW85P, CM10, CMK 90 días

2330, 2300, 2310, 2955, 2956, 2957, 2960, A5500 2 años

Bombas de pozo sumergibles de 4”, 3984, 3983, 2975PC, 2958, 2985, 3075SS 3 años

Tanque precargado del sistema de agua, 3986, 3985, 2956 5 años

3988, 3995, 3997, 3963 De por vida

Términos y Condiciones Generales

El comprador debe pagar todos los gastos de mano de obra y transporte necesarios para reemplazar el producto cubierto por esta garantía. Esta garantía no se aplicará a hechos de

fuerza mayor, ni se aplicará a los productos que, a juicio exclusivo de

SIMER

, hayan sido objeto de negligencia, abuso, accidente, aplicaciones contraindicadas, manejo indebido, alteraciones; ni debido a instalación, funcionamiento, mantenimiento o almacenaje incorrectos; ni a ninguna otra cosa que no sea su aplicación, u so o servicio normales, incluyendo, pero

no limitado a, fallas operacionales causadas por corrosión, oxidación u otros elementos extraños en el sistema, o funcionamiento a presión por encima del máximo recomendado.

Los pedidos de servicio bajo los términos de esta garantía serán efectuados mediante la devolución del producto defectuoso al Vendedor o a

SIMER

, tan pronto como sea posible, des-

pués de localizado cualquier supuesto defecto.

SIMER

tomará luego acción correctiva, tan pronto como sea razonablemente posible. Ningún pedido de servicio bajo esta garantía será

aceptado si se recibe más de 30 días después del término de la garantía.

Esta garantía establece la obligación única de

SIMER

y el remedio exclusivo del comprador en el caso de productos defectuosos.

SIMER

NO SERÁ RESPONSABLE POR NINGÚN DAÑO CONSECUENTE, INCIDENTAL O CONTINGENTE DE NINGUNA NATURALEZA.

LAS GARANTÍAS ANTERIORES SON EXCLUSIVAS Y REEMPLAZAN CUALESQUIERA OTRAS GARANTÍAS EXPRESAS. LAS GARANTÍASIMPLÍCITAS, INCLUYENDO, PERO NO

LIMITADAS A, LAS GARANTÍAS IMPLÍCITAS DE COMERCIABILIDAD Y APTITUD PARA UN PROPÓSITO EN PARTICULAR, NO DEBERÁN EXCEDER EL PERÍODO DE DURACIÓN

DE LAS GARANTÍAS EXPRESAS APLICABLES AQUÍ PROVISTAS.

Algunos estados no permiten la exclusión o limitación de daños incidentales o consecuentes ni las limitaciones respecto a la duración de garantías implícitas; de modo que las limitaciones o exclusiones precedentes pueden no aplicarse en su caso. Esta garantía le concede derechos legales específicos. Usted puede tener, además, otros derechos que varían de

un estado a otro.

SIMER • 293 Wright Street • Delavan, WI U.S.A. 53115

Teléfono: 1-800-468-7867/1-800-546-7867 • Fax: 1-800-390-5351

e-Mail (correo electrónico): info@simerpumps.com • Dirección web: http://www.simerpumps.com

12

Loading...

Loading...