Page 1

3 Year Guarantee

*Register online within 30

days. Terms & Conditions apply

Garantie de 3 ans

*Enregistrez votre produit en ligne

dans les 30 jours. Sous réserve des

termes et conditions appliquées

3 Jahre Garantie

*Registrieren Sie sich innerhalb von 30

Tagen online. Es gelten die allgemeinen

Geschäftsbedingungen

3 años de garantía

*Regístrese online dentro de 30 días.

Se aplican los términos y condiciones

3 anni di garanzia

*Registrarsi on-line entro 30 giorni.

Termini e Condizioni si applicano

3 Jaar Garantie

*Registreer online binnen 30 dagen.

Algemene voorwaarden van toepassing

www.silverlinetools.com

Page 2

Earth Auger Petrol 49cc

868828

Earth Auger Petrol 49cc

Tarière thermique 49 cm³

Benzinbetriebener 49-cm³-Erdbohrer

Perforador de suelo a gasolina 49 cm³

Trapano Trivella a Benzina 49cc

49 cc benzine grondboor

www.silverlinetools.com

Page 3

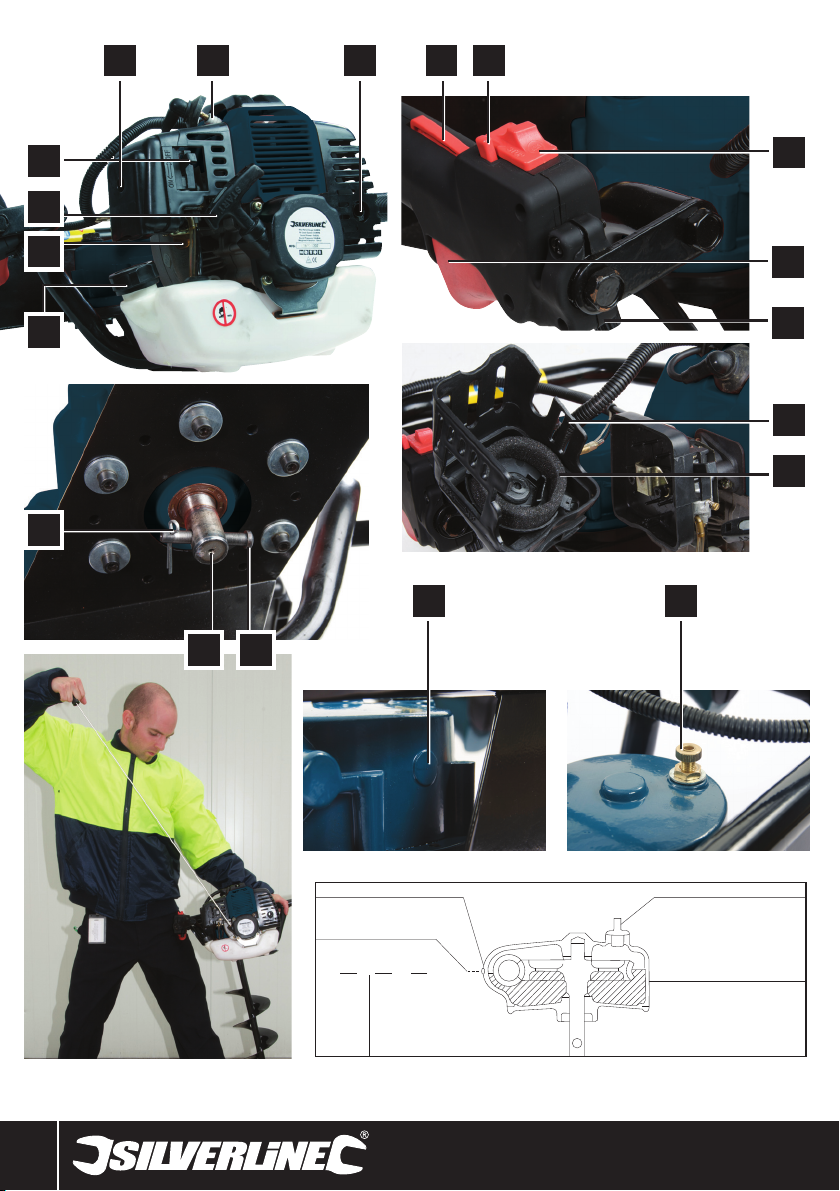

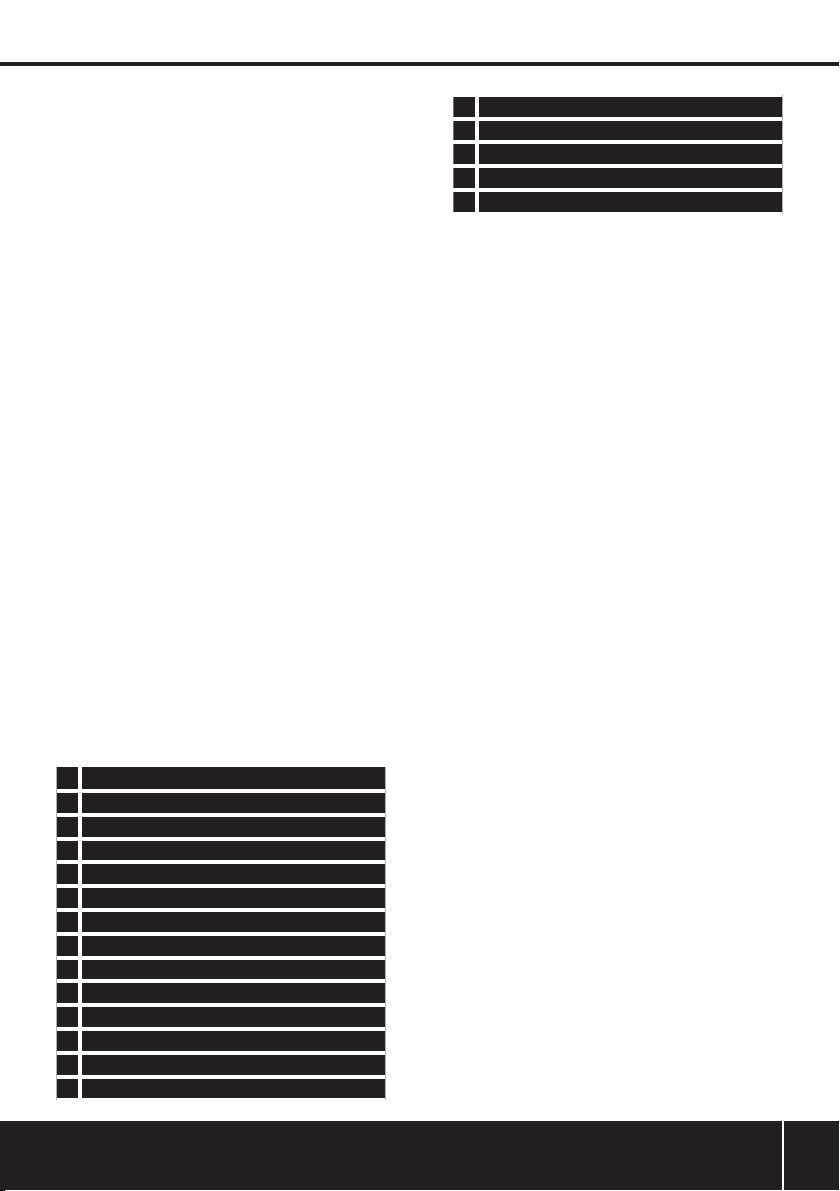

5 7 12 11

6

4

3

2

1

18

10

9

8

13

14

1516

19 17

Fig A.

2

16

Fig B.

Fill Oil Up To Here

15

Gearbox

Fig. B

Page 4

Earth Auger Petrol 49cc

English .................. 4

Français ................ 8

Deutsch ................. 12

®

Español ................. 16

Italiano .................. 20

Nederlands ............ 24

www.silverlinetools.com

3

Page 5

GB

Description of Symbols

The rating plate on your tool may show symbols. These represent important information

about the product or instructions on its use.

Wear hearing protection.

Wear eye protection.

Wear breathing protection.

Wear head protection.

Wear hand protection.

Read instruction Manual.

This product emits poisonous fumes

Conforms to relevant legislation and safety standards.

Recycling and disposal of petrol engine powered

tools, fuel and oil

Tools powered by petrol based internal combustion engines must not be

disposed of with household waste. Such tools should be taken to your local

recycling centre and disposed of according to current environmental protection

requirements in your country.

Specification

Engine size (cc): ..............................................49cc

Fuel type: ........................................................ Unleaded petrol

2 stroke oil fuel mix ratio: ................................ 25:1

Engine power (kW): ......................................... 1.25kW

Output torque (At drive shaft): ......................... 2.25Nm

Idling speed:........................................ ............ 2800rpm

Maximum engine speed: ................................. 8500rpm

Fuel tank capacity: .......................................... 1.2L

Spark plug type: .............................................. BM6A

Spark plug gap: ............................................... 0.6-0.8mm

Gearbox oil type: ............................................. SAE 30

Gearbox oil quantity: ........................................ 200ml

Sound pressure: .............................................. 108dB(A)

Sound power: .................................................. 90dB(A)

Weighted vibration: .........................................15m/s²

Uncertainty: .....................................................2m/s

Weight (without auger bit): ..............................9.3kg

The sound intensity level for the operator may exceed 85dB(A) and

sound protection measures are necessary.

As part of our ongoing product development, specifications of

Silverline products may alter without notice.

2

General Safety Warnings

WARNING Read all safety warnings and all instructions. Failure to follow the warnings

and instructions may result in electric shock, fire and/or serious injury.

Save all warnings and instructions for future reference.

1) Work area safety

a) Keep work area clean and well lit. Cluttered or dark areas invite accidents.

b) Do not operate tools in explosive atmospheres, such as in the presence of

flammable liquids, gases or dust.

c) Keep children and bystanders away while operating a powered tool.

Distractions can cause you to lose control.

2) Personal safety

a) Stay alert, watch what you are doing and use common sense when operating

a powered tool. Do not use a powered tool while you are tired or under

the influence of drugs, alcohol or medication. A moment of inattention while

operating a powered tool may result in serious personal injury.

b) Use personal protective equipment. Always wear eye protection. Protective

equipment such as dust mask, non-skid safety shoes, hard hat, or hearing protection

used for appropriate conditions will reduce personal injuries.

c) Prevent unintentional starting. Ensure the switch is in the off-position when not

operating the tool and make use of other safety features which prevent unintentional

starting

d) Remove any adjusting key or wrench before turning the powered tool on. A

wrench or a key left attached to a rotating part of the tool may result in personal

injury.

e) Do not overreach. Keep proper footing and balance at all times. This enables

better control of the tool in unexpected situations.

f) Dress properly. Do not wear loose clothing or jewelry. Keep your hair, clothing

and gloves away from moving parts. Loose clothes, jewelry or long hair can be

caught in moving parts.

g) If devices are provided for the connection of dust extraction and collection

facilities, ensure these are connected and properly used. Use of dust collection

can reduce dust-related hazards.

WARNING: User exposure to tool vibration can result in loss of sense of touch, numbness,

tingling and reduced ability to grip. Long term exposure can lead to a chronic condition.

If necessary limit the length of time exposed to vibration. Use the figures provided in the

specification relating to vibration if provided to calculate the duration and frequency of

operating the tool. The 2002/44/EC directive relating to vibration in the workplace may

provide useful information even for domestic use of tools. In the first instance of feeling

uncomfortable due to vibration STOP using the tool immediately.

WARNING: Always wear ear protection where the sound level exceeds 85dB(A) and limit the

time of exposure if necessary. If sound levels are uncomfortable even with ear protection stop

using the tool immediately and check the ear protection is correctly fitted and provides the

right level of sound attenuation for the level of sound produced by your tool.

3) Tool use and care

a) Maintain tools. Check for misalignment or binding of moving parts, breakage

of parts and any other condition that may affect the tool’s operation. If

damaged, have the tool repaired before use. Many accidents are caused by

poorly maintained tools.

b) Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp

cutting edges are less likely to bind and are easier to control.

c) Use the tool’s accessories and tool bits etc. in accordance with these

instructions, taking into account the working conditions and the work to be

performed. Use of the tool for operations different from those intended could result

in a hazardous situation.

4) Service

a) Have your tool serviced by a qualified repair person using only identical

replacement parts. This will ensure that the safety of the tool is maintained.

Internal Combustion Safety

Dangerous environment

• Do not use petrol tools in damp or wet conditions, or expose them to rain. Provide

adequate surrounding work space and keep area well lit.

• Do not use petrol tools where there is a risk of explosion or fire from combustible

material, flammable liquids, flammable gases, or dust of an explosive nature

Switch off

• Ensure that the engine has stopped before attaching any accessories to the tool. If the

tool stops unexpectedly ensure that the power is switched off and the engine is not

running before attempting to check the tool

Running-in the engine

• New tools should be used at moderate speed

• Do not maintain high engine speed until the engine is completely run-in

• The engine will not be capable of developing maximum power until the end of the

running-in period

• When first using the tool, periodically stop and check that all nuts and screws are

securely fastened and tighten them as necessary

• Do not use fuels containing methanol or ethanol, as these may cause internal damage

to the fuel tank and fuel lines

4

Page 6

868828 Earth Auger Petrol 49cc

Warning

• Never leave the tool running unattended

• Never leave the machine unattended when parts are still hot

Servicing

• We recommended that your tool is serviced shortly after its first use

• In normal use, have the tool serviced regularly

• Do not modify any of the components of this tool. To do so would invalidate your

guarantee, and could result in injury to yourself or others around you

• Always have your tool serviced at an authorized service centre

Storage

• Clean the tool completely after use

• Be careful not to damage the fuel tank, or fuel lines, when it is placed on the ground

• Ensure that the tool will not be subject to impact damage; any damage could cause the

tool to become unsafe

• Store the tool away from direct sunlight

• Ensure that fuel and oil is stored in a safe place, away from heat, direct sunlight or any

source of ignition

Whenever the machine is likely to be out of use for an extended period of time, proceed

as follows:

• Empty the fuel tank completely

• Protect all metal engine parts from corrosion by coating them with oil

• Remove the spark plug, put a few drops of oil into the cylinder and then pull the recoil

starter 2 to 3 times in order to distribute the oil evenly

• Replace the spark plug

• Never store the machine where children may gain access to it

THIS PRODUCT PRODUCES POISONOUS EXHAUST FUMES AS SOON AS THE ENGINE

IS RUNNING. THESE GASES MAY BE COLOURLESS AND ODOURLESS. TO REDUCE

THE RISK OF SERIOUS OR FATAL INJURY, NEVER R UN THE MACHINE INDOORS, OR IN

POORLY VENTILATED AREAS. ENSURE PROPER VENTILATION WHEN WORKING IN

TRENCHES OR OTHER CONFINED SPACES.

Product Familiarisation

1 Fuel Filler Cap

2 Fuel Priming Bulb

3 Starter Handle

4 Choke Lever

5 Air Filter Housing Screw

6 Spark Plug

7 Exhaust Outlet

8 Max RPM Adjusting Screw

9 Speed Control

10 On/Off Switch

11 Speed Control Lock-On Button

12 Speed Control Safety Catch

13 Air Filter Housing

14 Air Filter Element

15 Gearbox Oil Fill Point

16 Gearbox Oil Level Point

17 Securing Pin

18 Split Pin

19 Output Shaft

*NOTE: The oil fill point assembly is closed when at its maximum height.

Unpacking your Petrol Auger

• Ensure that all parts of your petrol auger are present and in good condition. If any part is

missing, or damaged, contact your retailer and have such parts replaced before

attempting to use this tool.

Assembling your Petrol Auger

• Remove the Split Pin (18) from the Securing Pin (17)

• Remove the Securing Pin (17) from the Output Shaft (19)

• Slide the auger bit (Silverline product codes 633897, 245105, 457044 – not supplied)

over the Output Shaft (19)

• Line up the holes in the auger bit and shaft, then push the Securing Pin (17) through

the hole

• Replace the Split Pin (18) and pull apart its legs, as shown in the main image

Operating the engine

Fuelling

• Always refuel in a safe place, well away from the work area, and any source of heat

or ignition. Avoid any contact with the fuel

• DO NOT SMOKE

• Only add fuel when the engine is stopped and has cooled fully

• Fuel should always be pre-mixed; do not mix fuel in the petrol tank

• Only mix as much fuel as you intend to use

• Always store fuel in a good quality fuel container

• Use the supplied fuel mixing bottle. Fill with petrol until ‘576.92’ on the scale (marked)

and then add 2 stroke oil until level with ‘600’. Replace the lid and shake the bottle

to mix.

NOTE: If you wish to mix a smaller amount of fuel, you will need to carefully manually

measure using the general scale on the bottle. Always try to mix only the amount of fuel

you will actually use.

• Remove the Fuel Filler Cap (1). Fill the tank with fuel mixture to the required level

NOTE: use a funnel such as Silverline code 793799 to avoid spillage

• Replace the Filler Cap (1)

• Make sure that any fuel spillage is properly cleaned up

• Move the petrol auger well away from the fuelling area before starting

the engine

• Keep extra fuel well away from the work area

• The muffler and exhaust will become very hot in operation so ensure inflammable

material doesn’t come into contact with those parts

Priming the engine

• Stand the unit upright on the tip of the auger bit, so that the handles are level with

the ground

• Slowly press and release the Fuel Primer (2)

• Continue until fuel begins to flow down through the clear fuel line and back into the

fuel tank

• Press a few more times until the air bubbles have passed. The fuel system is now

primed and ready

Starting the engine

WARNING: This Petrol Auger will produce toxic fumes from the Exhaust Outlet (7) as

soon as it is running. Never attempt to start the engine indoors, or in any kind of enclosed

space. Always wear proper safety protection: Use of this tool requires goggles, gloves,

ear defenders, face mask, and sturdy clothing. It is also advisable to wear a hard hat and

safety boots

• Set the Choke Lever (4) to the ‘ON’ position if warm

• Set the lever to the ‘OFF’ position if cold

• Set the On/Off Switch (10) to “I”

• Hold the auger as shown in Fig A, ensuring that you have control of the tool

• Pull the Starter Handle (3) firmly, as shown in Fig A

• Pull the starter handle again until the engine runs

IMPORTANT – do not allow the starter handle to snap back into the tool. Return it in a

controlled manner

• Allow the engine to run at idle speed for approx. 30 seconds

• As the engine warms, move the Choke Lever (4) to the ‘ON’ position

IMPORTANT –Allow the engine to warm up slowly for a minimum of 3 minutes before

increasing engine speed. This will improve performance and increase engine life

Running in

• When using the auger for the first time, it is important to run in the engine. This will

improve engine efficiency and performance, and maximise life span

• To run in the engine, leave the engine idling, with minimum use of the throttle, for a

period of approximately 15 minutes on first use. DO NOT INCREASE ENGINE SPEED FOR

THIS PERIOD IF POSSIBLE

NOTE: It is normal to experience distinctive smells during running in, as components heat

up for the first time

Stopping the engine

• Allow the engine to return to idle speed for a minimum of 3 minutes after use before

turning off

• Move the On/Off Switch (10) to the ‘0’ position

www.silverlinetools.com

5

Page 7

GB

Using your Petrol Auger

Controlling the Auger

• Start the engine, as previously described

• To increase the engine speed, press the Safety Catch (12) and then slowly squeeze the

Speed Control (9). Release to slow the engine

NOTE: The output shaft will not rotate when the engine is at idle speed. It begins to rotate

when the engine speed is increased.

• The maximum engine speed can be set by adjusting the Max RPM Adjusting Screw (8).

Turn clockwise to reduce the maximum engine speed

• The Speed Control (9) can be locked on. While holding it in, press the Speed Control

Lock-On Button (11) then release the speed control. Squeeze the Speed Control (9)

again to release

Notes when using the auger

• If possible, maintain a 5m gap between yourself and other people in the work area and

try to work in a way that keeps them in sight while operating

• When operating on an inclined surface, try to work from the side and not below, so if

you lose control of the auger it will not fall towards you

• Ensure the ground is suitable for using an auger and doesn’t contain large rocks or hard

masonry below the surface

Maintenance

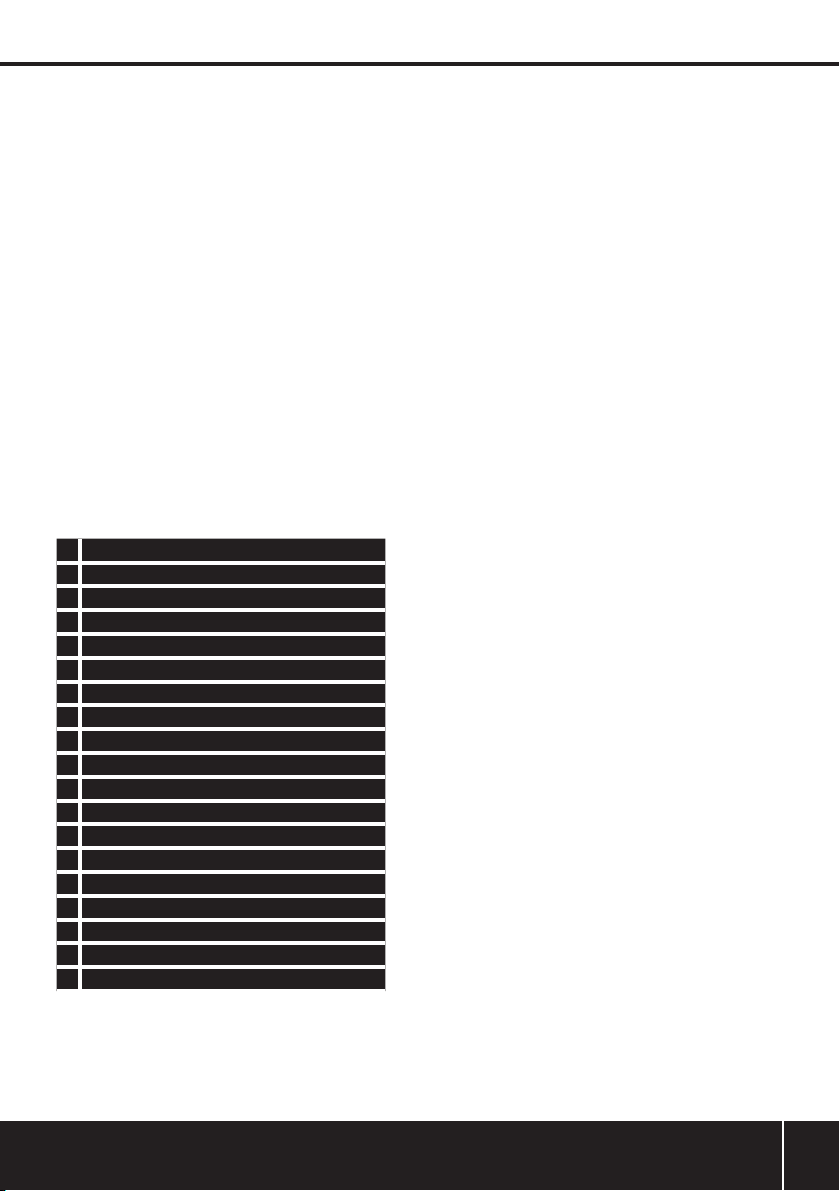

Schedule

Replace Check/adjust/clean

Spark Plug 500

Spark Plug 2000

Air filter 50

Gearbox oil 500

WARNING. Before performing any maintenance on this Auger, stop the engine and

allow to cool down fully.

Checking the spark plug (6)

• Pull the spark plug lead off of the Spark Plug (6)

• Unscrew the spark plug using a suitable wrench

NOTE: Turn anticlockwise to remove the spark plug

• Clean and adjust the spark plug, or replace it according to the maintenance schedule

• Refit the spark plug and tighten by hand. NOTE: Take care not to over tighten the

Spark Plug (6)

• Clean the air filter as recommended in the Maintenance schedule

• Undo the Air Filter Housing Screw (5) using a suitable screwdriver

• Lift off the Air Filter Housing (13)

• Remove the foam Air Filter (14)

• Wash the air filter in a suitable fluid, available from most garden machinery retailers

• Allow it to fully dry

• Refit the air filter and air filter housing and replace the air filter housing screw

Gearbox oil (See fig B)

Changing gearbox oil:

NOTE: Change the gearbox oil as recommended in the maintenance schedule

• Support the auger so that it is level, as though drilling a hole vertically into the ground

• Remove the auger bit as described in ‘Assembling your Petrol Auger’

• Place a suitable oil draining bowl underneath the auger – such as Silverline product

675089

• Using a spanner, remove completely the Gearbox Oil Fill Point (15) assembly

• Tilt the auger through 90 degrees or more to drain the oil from the gearbox

• Once completely drained, transfer to a container and dispose of according to regulations

for waste oil. Do not dispose of oil with normal waste or by using water drainage

facilities

• Return the auger to the level position and support it again

• Pour the correct type and quantity (see specification) of oil into the Gearbox Oil Fill Point

(15) until it is approximately level with the Gearbox Oil Level Point (16) as indicated

in Fig B

• Replace the bolt of the gearbox oil fill point . The assembly is closed when at its

maximum height.

Hours run time

Storage

• Be careful not to hit or cut the fuel tank, or fuel lines, when the unit is placed on the

ground

• Do not let the tool fall, or it may be damaged and become unsafe

• When work is complete, clean the unit completely

• Inspect the entire unit and tubes for damage, including loose or missing components

• Store the unit away from direct sunlight

• Do not store in a nylon bag as this can encourage the formation of mould

• Use a small brush to clean off the outside of the unit and keep the air vents free from

obstructions. Do not use water or a hose to clean the unit

• Ensure that fuel and oil is stored in a safe place, away from heat, direct sunlight, any

source of ignition, and out of reach of children

Storage for an extended period:

Whenever the machine is out of use for an extended period of time, proceed as follows:

• Give the unit an overall cleaning and a thorough check

• Empty the fuel tank completely, then clean the carburettor and lines by running the tool

until it stops from lack of fuel

• Protect all metal engine parts from corrosion by coating them with oil

• Remove the spark plug, add several drops of oil into the cylinder through the spark plug

hole and then pull the recoil starter 2 to 3 times in order to distribute the oil evenly.

Replace the spark plug and spark plug lead

• Clean the air filter as described in the air filter section

Troubleshooting

Power loss or sudden stopping of the engine

• Check whether the fuel tank is empty.

• Check if there is water in the mixture. Drain and rinse the fuel system with petrol.

• Check if the air filter is dirty. Clean the air filter.

Starting a flooded engine

• Disconnect the spark plug lead, and use a spark plug wrench to remove the spark plug

by turning it counter-clockwise.

• If the spark plug is fouled or is soaked with fuel, clean or replace the plug as required.

• Clean excess fuel from the combustion chamber by cranking the engine several times

while the spark plug is removed.

• Install the spark plug and firmly tighten it with the spark plug wrench.

• Repeat the starting procedure as if the engine was already warm.

Recycling and disposal of petrol engine

powered tools, fuel and oil

• Tools powered by petrol based internal combustion engines must not be disposed of

with household waste. Such tools should be taken to your local recycling centre and

disposed of according to current environmental protection requirements in your country.

• Petrol, oil and petrol-oil-mixtures are hazardous waste and have to be treated as such.

Oil and fuel must not be disposed of with household waste. Improper disposal may be

regarded a criminal offence in your country. Contact your local authority or dealer for

correct disposal procedures for oil and old fuels.

6

Page 8

Silverline Tools Guarantee

Earth Auger Petrol 49cc868828

This Silverline product comes with a 3 year

guarantee

Register this product at silverlinetools.com within 30 days of purchase

in order to qualify for the 3 year guarantee. Guarantee period begins

according to the date of purchase on your sales receipt.

Terms & Conditions

Guarantee period becomes effective from the date of retail purchase as

detailed on your sales receipt.

PLEASE KEEP YOUR SALES RECEIPT

If this product develops a fault within 30 days of purchase, return it to the

stockiest where it was purchased, with your receipt, stating details of the

fault. You will receive a replacement or refund.

If this product develops a fault after the 30 day period, return it to:

Silverline Tools Service Centre

PO Box 2988

Yeovil

BA21 1WU, UK

The guarantee claim must be submitted during the guarantee period.

You must provide the original sales receipt indicating the purchase date,

your name, address and place of purchase before any work can be

carried out.

You must provide precise details of the fault requiring correction.

Claims made within the guarantee period will be verified by Silverline Tools

to establish if the deficiencies are related to material or manufacturing of

the product.

Carriage will not be refunded. Items for return must be in a suitably clean

and safe state for repair, and should be packaged carefully to prevent

damage or injury during transportation. We may reject unsuitable or

unsafe deliveries.

All work will be carried out by Silverline Tools or its authorized

repair agents.

The repair or replacement of the product will not extend the period

of guarantee

Defects recognised by us as being covered by the guarantee shall be

corrected by means of repair of the tool, free of charge (excluding carriage

charges) or by replacement with a tool in perfect working order.

Retained tools, or parts, for which a replacement has been issued, will

become the property of Silverline Tools.

Registering your purchase

Registration is made at silverlinetools.com by selecting the Guarantee

Registration button. You will need to enter:-

• Your personal details

• Details of the product and purchase information

Once this information is entered your guarantee certificate will be created

in PDF format for you to print out and keep with your purchase.

The repair or replacement of your product under guarantee provides

benefits which are additional to and do not affect your statutory rights as

a consumer.

What is covered:

The repair of the product, if it can be verified to the satisfaction of Silverline

Tools that the deficiencies were due to faulty materials or workmanship

within the guarantee period.

If any part is no longer available or out of manufacture, Silverline Tools will

replace it with a functional replacement part.

Use of this product in the EU.

What is not covered:

Silverline Tools does not guarantee repairs required as a result of:

Normal wear and tear caused by use in accordance with the operating

instructions eg blades, brushes, belts, bulbs, batteries etc.

The replacement of any provided accessories drill bits, blades, sanding

sheets, cutting discs and other related items.

Accidental damage, faults caused by negligent use or care, misuse,

neglect, careless operation or handling of the product.

Use of the product for anything other than normal domestic purposes.

Change or modification of the product in any way.

Use of parts and accessories which are not genuine Silverline Tools

components.

Faulty installation (except installed by Silverline Tools).

Repairs or alterations carried out by parties other than Silverline Tools or its

authorized repair agents.

Claims other than the right to correction of faults on the tool named in

these guarantee conditions are not covered by the guarantee.

EC Declaration of Conformity

The undersigned: Mr Darrell Morris

as authorised by: Silverline Tools

Declares that the

Description: Earth Auger Petrol 49cc

Product Code: 868828

Conforms to the following Directives:

• Non Road Mobile Machinery Directive 2004/108/EC

• Noise Emission In The Environment By Equipment For Use Outdoors

200/14/EC Annex V

• EMC Directive 2004/108/EC

• ISO22868:2003

• EN ISO 12100-1, EN ISO 12100-2:2003

• EN60204-1:1998, EN55012:2007, EN61000-6-1:2007

The technical documentation is kept by: Silverline Tools

Notified body: BVCE Products Testing

Place of declaration: Shanghai, China

Date: 02/01/13

Signed by:

Director

Name and address of Manufacturer or Authorised representative:

Silverline Tools, Boundary Way, Lufton Trading Estate, Yeovil, Somerset,

BA22 8HZ United Kingdom

www.silverlinetools.com

7

Page 9

F

Description des symboles

La plaque de valeur nominale sur votre outil peut afficher des symboles.

Ces symboles constituent des informations importantes concernant le produit ou des

instructions sur son utilisation.

Port de protection anti-bruit.

Port de lunettes de sécurité.

Port de masques respiratoires.

Protection principale d'usage.

Protection de main d'usage.

Lisez le manuel d’instruction.

Ce produit émet des vapeurs toxiques

Conforme à la réglementation et aux normes de sécurité pertinentes.

Protection de l’environnement

Les outils alimentés par combustion interne par essence ne doivent pas être

rejetés avec les ordures ménagères. De tels outils doivent être amenés dans

un centre de recyclage pour y être recyclés selon les lois en vigueur de la

protection environnementale.

Caractéristiques techniques

Moteur : ....................................................49cc

Carburant : ...............................................Essence sans plomb

Huile 2 temps mélange :...........................25:1

Puissance du moteur : ..............................1,25 kW

Couple de sortie : .....................................2,25 Nm

Vitesse au ralenti : ....................................2800 tr/min

Vitesse maximale : ...................................8500 tr/ min

Capacité du réservoir : .............................1,2 L

Type de bougie : .......................................BM6A

Ecartement des électrodes : .....................0,6-0,8 mm

Huile de la boite de vitesse : .....................SAE 30

Quantité d’huile : ......................................200 ml

Pression acoustique : ...............................108 dB(A)

Puissance acoustique : .............................90 dB(A)

Vibration pondérée : .................................15 m/s²

Incertitude : ..............................................2 m/s²

Poids ( sans tarière) : ................................9,3 kg

L’intensité saine pour l’opérateur peut dépasser 85dB(A) et

mesures de protection de bruit sont nécessaires.

Dans le cadre du développement continu de nos produits, les

caractéristiques techniques des produits Silverline peuvent être

modifiées sans préavis.

Consignes générales de sécurité

AVERTISSEMENT Veuillez lire l’intégralité des consignes de sécurité et des

instructions. Le non-respect de ces consignes et instructions peut entraîner un risque de

choc électrique, d’incendie et/ou se traduire par des blessures graves.

Veuillez conserver ces instructions et consignes de sécurité pour référence

ultérieure.

Sécurité sur la zone de travail

a) Maintenir une zone de travail propre et bien éclairée. Des zones encombrées et

mal éclairées sont sources d’accidents.

b) Ne pas utiliser d’outils dans des environnements explosifs, tels qu’à proximité

de liquides, de gaz ou de poussières inflammables.

c) Eloigner les enfants et les passants pendant l’utilisation d’un appareil

électrique. Ceux-ci peuvent provoquer une perte d’attention et faire perdre la

maîtrise de l’appareil.

Sécurité des personnes

a) Rester vigilent et faire preuve de bon sens lors de la manipulation de l’appareil.

Ne pas utiliser un appareil électrique lorsque l’on se trouve dans un état

de fatigue, ou sous l’influence de drogues, d’alcool ou de médicaments. Un

moment d’inattention pendant l’utilisation d’un outil électrique peut se traduire par

des blessures graves.

b) Porter un équipement de protection approprié. Toujours porter une protection

oculaire. Le port de masque à poussières, chaussures de sécurité antidérapantes,

casque de sécurité et protections antibruit adaptés aux différentes conditions de

travail réduit le risque de blessures corporelles.

c) Eviter tout démarrage accidentel ou intempestif. S’assurer que l’interrupteur

marche-arrêt soit en position d’arrêt lorsque l’appareil n’est utilisé.

d) Enlever toute clé et tout instrument de réglage avant de mettre l’appareil en

marche. Une clé ou un instrument de réglage laissé fixé à un élément en rotation de

l’appareil électrique peut entraîner des blessures physiques.

e) Ne pas essayer d’atteindre une zone hors de portée. Se tenir toujours en

position stable permettant de conserver l’équilibre. Cela permet de mieux

contrôler l’appareil électrique dans des situations inattendues.

f) Porter des vêtements appropriés. Ne pas porter de vêtements amples ou

des bijoux pendants. Eloigner cheveux, vêtements et gants des pièces en

mouvement. Les vêtements amples, les bijoux pendants et cheveux longs peuvent

être happés par les pièces en rotation.

g) Si l’appareil est pourvu de dispositifs destinés au raccord d’équipements

d’extraction et de récupération de la poussière/sciure, s’assurer qu’ils soient

bien fixés et utilisés correctement. L’utilisation de ces dispositifs peut réduire les

risques dus à la poussière.

ATTENTION : L’exposition de l’utilisateur aux vibrations d’un outil peut engendrer la perte

de sens du toucher, des engourdissements, picotements et réduire la préhension de

l’appareil. Des expositions prolongées peuvent engendrer l’apparition chronique de ces

symptômes. Si nécessaire, réduisez le temps d’utilisation de l’outil. Utilisez les cas de

figure avec les caractéristiques relatives aux vibrations, si données, pour calculer la durée

et la fréquence de l’utilisation de l’appareil. Les normes directives 2002/44/CE relatives

aux vibrations sur le lieu de travail peuvent fournir des informations pratiques même pour

un usage domestique. Si dans un premier temps vous commencez à sentir inconfortable à

cause des vibrations, ARRÊTER immédiatement l’utilisation de l’appareil.

ATTENTION : Toujours porter des protections auditives lorsque le niveau sonore excède

80 dB et limiter le temps d’exposition. Si les niveaux sonores ne sont pas assez atténués

avec un casque anti-bruit arrêter l’utilisation de l’appareil, et vérifiez bien que la protection

sonore soit bien appropriée par rapport au niveau sonore.

Utilisation et entretien des appareils

a) Entretien des appareils. Vérifier que les éléments rotatifs soient bien alignés

et non grippés. S’assurer de l’absence de pièces cassées ou endommagées

susceptibles de nuire au bon fonctionnement de l'appareil. Si l’appareil est

endommagé, le faire réparer avant toute utilisation. De nombreux accidents sont

dus à un mauvais entretien d’un outil.

b) Veiller à ce que les outils de coupe soient tenus affûtés et propres. Des outils de

coupe bien entretenus, aux tranchants bien affûtés, sont moins susceptibles de se

gripper et sont plus faciles à contrôler.

c) Utiliser l’appareil, les accessoires et outils à monter conformément à ces

instructions, en tenant compte des conditions de travail et de la tâche à

réaliser. Toute utilisa tion d’un appareil autre que celle pour laquelle il a été conçu

peut entraîner des situations à risque.

Révision

a) Ne faire réparer votre appareil électrique que par un réparateur qualifié

utilisant uniquement des pièces de rechange identiques.

Consignes de sécurité relatives aux

appareils à combustion interne

Environnements dangereux

• Ne pas utiliser un outil à moteur à essence dans un environnement humide et ne

pas l’exposer à la pluie. Prévoir un espace de travail adéquat et assurer un éclairage

correct de la zone.

• Ne pas utiliser l’outil à moteur à essence s’il existe un risque d’explosion ou d’incendie

dû à des matières combustibles, des liquides ou des gaz inflammables, ou à de la

poussière de nature explosive.

Eteindre l’outil avant d’installer un accessoire

• Vérifier que le moteur de l’outil soit arrêté avant la pose d’un accessoire.

• Si l’outil cesse de fonctionner de manière inattendue, vérifier que le moteur soit bien

arrêté avant de procéder à son inspection.

Rodage du moteur

• Lorsque l’outil est neuf, prendre soin de faire tourner le moteur à régimes modérés.

• Ne pas conserver un régime élevé tant que le moteur n’est pas rodé.

8

Page 10

868828 Tarière thermique 49 cm³

• Le moteur ne développe sa pleine puissance qu’à la fin de la période de rodage.

• Avant d’utiliser l’outil pour la première fois et après vous être assuré que le moteur est

arrêté, vérifier le serrage des vis et des écrous.

• N’utiliser aucun carburant contenant du méthanol ou de l’éthanol car ils peuvent

endommager le réservoir et les conduites de carburant.

Avertissement

• Attendre que l’outil se soit complètement arrêté avant de vous en éloigner.

• Ne pas s’éloigner de l’outil tant que certaines de ses pièces sont encore chaudes.

Révisions

• Nous vous conseillons de faire réviser l’outil peu après la première utilisation.

• Par la suite, faire réviser l’outil de manière régulière.

• Ne pas modifier pas les composants de l’outil. Ceci invaliderait non seulement votre

garantie mais pourrait également vous faire courir le risque de vous blesser ou de

blesser d’autres personnes autour de vous.

• Ne faire réviser l’outil que par un centre agréé.

Rangement

• Lorsque vous n’avez plus besoin de l’outil, nettoyez-le soigneusement.

• Lorsque vous posez l’outil sur le sol, veiller à ne pas endommager le réservoir et les

conduites de carburant.

• Veiller à ne pas faire tomber l’outil, ce qui pourrait l’endommager et rendre son

utilisation dangereuse.

• Ranger l’outil à l’abri de la lumière directe du soleil.

• Vérifier que le carburant et l’huile soient conservés dans un endroit sûr, éloigné de toute

source de chaleur, à l’abri de la lumière directe du soleil et de toute source d’étincelle.

• Avant de ranger l’outil pour une période prolongée, procéder comme suit :

• Vider complètement le réservoir de carburant.

• Protéger de la corrosion toutes les pièces métalliques du moteur en y appliquant une

couche d’huile.

• Retirer la bougie, introduire quelques gouttes d’huile dans le cylindre puis tirez 2 ou 3

fois sur le lanceur à rappel pour répartir l’huile uniformément.

• Remettre la bougie en place.

• Ranger toujours la machine hors de portée des enfants.

CET OUTIL PRODUIT DES GAZ D’ÉCHAPPEMENT TOXIQUES DÈS QUE LE MOTEUR

TOURNE. CES GAZ PEUVENT ÊTRE INCOLORES ET INODORES. POUR RÉDUIRE LE

RISQUE D’ACCIDENT GRAVE, VOIRE MORTEL, NE PASL’UTILISEZ À L’INTÉRIEUR NI

DANS UN ENDROIT MAL AÉRÉ. VEILLER À CE QUE LA VENTILATION SOIT SUFFISANTE

LORSQUE VOUS TRAVAILLEZ DANS UNE TRANCHÉE, OU TOUT AUTRE LIEU EXIGU.

Se familiariser avec le produit

1 Bouchon de remplissage de carburant

2 Poire d’amorçage du carburant

3 Poignée de démarrage

4 Levier de starter

5 Vis du logement du filtre à air

6 Bougie

7 Sortie des gaz d’échappement

8 Vis de réglage du régime max.

9 Régulateur de vitesse

10 Interrupteur marche/arrêt

11 Bouton de marche continue du régulateur de vitesse

12 Cran de sûreté du régulateur de vitesse

13 Logement du filtre à air

14 Élément de filtre à air

15 Remplissage d’huile de la boîte de vitesses

16 Point de niveau d’huile de la boîte de vitesses

17 Goupille de serrage

18 Goupille fendue

19 Arbre de sortie

* Lorsque le niveau d’huile est à son maximum, l’orifice de remplissage se ferme.

Déballage

• Déballez le produit avec soin. Veillez à retirer tout le matériau d’emballage et

familiarisez-vous avec toutes les caractéristiques du produit.

• Si des pièces sont endommagées ou manquantes, faites-les réparer ou remplacer avant

d’utiliser l’appareil.

Assemblage de la tarière thermique

• Retirez la goupille fendue (18) de la goupille de serrage (17).

• Retirez la goupille de serrage (17) de l’arbre de sortie (19).

• Faites glisser la mèche (numéros de produit Silverline 633897, 245105, 457044,

non fournis) sur l’arbre de sortie (19).

• Alignez les trous présents sur la mèche et sur l’arbre puis insérez-y la goupille de

serrage (17).

• Réintroduisez la goupille fendue (18) et écartez ses deux branches ainsi qu’il est

visible sur l’image fournie plus haut.

Fonctionnement du moteur

Remplissage du réservoir

• Remplissez toujours l’appareil dans un lieu sûr, mais jamais à proximité du lieu de

travail ou près de toute source de chaleur ou d’inflammation.

• NE PAS FUMER.

• Remplissez le réservoir seulement lorsque le moteur est arrêté et complètement

refroidi.

• Utilisez toujours du carburant pré-mélangé ; ne mélangez pas le carburant dans le

réservoir. Mélangez uniquement la quantité de carburant nécessaire sur le moment.

• Utilisez toujours un jerricane de bonne qualité pour entreposer l’essence.

• Utilisez la bouteille de mélange de carburant. Remplissez la d’essence jusqu’à la

marque ‘576,92’ puis ajoutez l’huile 2 temps jusqu’à la marque ‘600’. Remettez le

bouchon et agiter la bouteille pour bien mélanger.

• Remarque : Si vous souhaitez mélanger une plus petite quantité d’essence, utilisez avec

précaution l’échelle de la bouteille. Essayez toujours de ne mélanger que la quantité

nécessaire.

• Enlevez le bouchon de remplissage de carburant (1). Remplissez le réservoir avec le

mélange de carburant jusqu’au niveau requis.

• REMARQUE – Utilisez un entonnoir tel que celui correspondant au numéro de

produit Silverline 793799 pour éviter les déversements accidentels.

• Remettez le bouchon de remplissage (1) en place.

• Assurez-vous de bien nettoyer tout déversement accidentel.

• Ne démarrez pas l’appareil à l’endroit où le remplissage a été effectué.

• Ne laissez pas le restant de carburant près de la zone où vous travaillez.

Amorçage du moteur

• Tenez l’outil verticalement, sur la pointe de la mèche, de sorte que les poignées soient

parallèles au sol.

• Appuyez lentement sur la poire d’amorçage du carburant (2) puis relâchez-la.

• Continuez ainsi jusqu’à ce que le carburant commence à monter dans les conduites

transparentes et à retourner dans le réservoir de carburant.

• Répétez l’opération jusqu’à ce que toutes les bulles d’air soient passées, après quoi le

système de carburant sera amorcé et prêt à fonctionner.

Démarrage du moteur

AVERTISSEMENT : Cette tarière thermique émettra de la fumée toxique par la sortie

des gaz d’échappement (7) dès sa mise en marche. Ne démarrez jamais cet appareil à

l’intérieur ou dans tout type d’espace clos. Portez toujours des vêtements de protection

appropriés ; cet outil demande le port de lunettes de protection, de gants, d’un casque

antibruit, d’un masque à poussières et de vêtements résistants. Il est également conseillé

de porter un casque et des chaussures de sécurité.

• Mettez le levier de starter (4) sur la position "ON" si le moteur est chaud

• Mettez le levier de starter sur la position "OFF" si le moteur est froid

• Faites passer l’interrupteur marche/arrêt (10) en position « I »

• Tenez la tarière comme il est indiqué sur la Fig. A, en veillant à avoir l’outil bien en main.

• Tirez fermement sur la poignée de démarrage, comme il est indiqué sur la Fig. A.

• Tirez de nouveau sur la poignée de démarrage jusqu’à ce que le moteur tourne.

IMPORTANT – Ne laissez pas la poignée (3) revenir brusquement contre l’outil,

ramenez-là soigneusement en position initiale.

• Laissez le moteur tourner au ralenti pendant 30 secondes environ.

• Une fois que le moteur s’est réchauffé, mettez le levier de starter (4) sur la position

"ON".

IMPORTANT – Laissez le moteur se réchauffer peu à peu pendant un minimum de 3

minutes avant de passer à un régime supérieur. Cela favorisera un meilleur rendement et

une plus longue vie utile du moteur.

Rodage

• Il est important de procéder au rodage du moteur de la tarière thermique lors de sa

première utilisation. Cela permettra d’améliorer son rendement et son efficacité et d’en

prolonger la vie utile.

• Pour roder le moteur, laissez-le marcher au ralenti pendant 15 minutes environ lors de

la première utilisation en utilisant au minimum l’accélérateur. DANS LA MESURE DU

POSSIBLE, NE PAS AUGMENTER LA VITESSE DU MOTEUR PENDANT CETTE PERIODE

DE TEMPS.

www.silverlinetools.com

9

Page 11

F

REMARQUE : Il est normal de percevoir des odeurs inhabituelles durant le rodage du fait

de l’échauffement des composants pour la première fois.

Arrêt du moteur

• Avant d’arrêter le moteur, laissez-le tourner au ralenti pendant un minimum de 3

minutes.

• Faites passer l’interrupteur marche/arrêt (10) en position "O".

Utilisation de votre tarière thermique

Régler la tarière

• Faites démarrer le moteur de la manière indiquée ci-dessus.

• Pour augmenter le régime du moteur, appuyez sur le cran de sûreté (12) et exercez une

légère pression sur le régulateur de vitesse (9). Relâchez-le pour diminuer le régime

du moteur.

REMARQUE : L’arbre de sortie ne tourne pas lorsque le moteur fonctionne au ralenti. Il

commencera à tourner avec l’augmentation du régime du moteur.

• Il est possible de fixer la vitesse maximale du moteur au moyen de la vis de réglage du

régime maximum (8). Faites-la tourner dans le sens des aiguilles d’une montre pour

réduire la vitesse maximale du moteur.

• Il est possible de maintenir le régulateur de vitesse (9) en marche continue. Tout en

maintenant celui-ci activé, appuyez sur le bouton de marche continue du régulateur de

vitesse (11) puis relâchez le régulateur de vitesse. Il vous suffira d’appuyer à nouveau

sur le régulateur de vitesse (9) pour annuler l’opération.

Consignes d’utilisation

• Si possible, maintenez un espace d’environ 5 m entre vous et les personnes aux

alentours de la zone de travail, et travaillez de façon à être en contact visuel avec elles.

• Lorsque vous travaillez sur une surface inclinée, évitez de travailler en aval de la

machine pour qu’elle ne puisse pas retombée sur vous.

• Assurez-vous que le sol soit adéquat à l’utilisation de la tarière, et qu’il n’y a pas de

large roc ou éléments de maçonnerie sous la surface.

Entretien

Programme d’entretien

Changer Vérifier/régler/

nettoyer

Bougie 500

Bougie 2000

Filtre à air 50

Huile de la boîte

de vitesses

AVERTISSEMENT. Avant d’effectuer tout travail d’entretien sur votre tarière thermique,

arrêtez toujours le moteur et laissez-le refroidir complètement.

Vérification de la bougie (6)

• Déconnectez le câble de la bougie.

• Dévissez la bougie à l’aide d’une clé adéquate.

REMARQUE : Tournez la clé dans le sens contraire des aiguilles d’une montre pour

dévisser la bougie.

• Nettoyez et réglez la bougie, ou bien procédez à son remplacement en fonction du

programme d’entretien.

• Remettez la bougie en place et serrez-la à la main. REMARQUE : Prenez soin de ne pas

effectuer un serrage excessif

• Nettoyez le filtre à air suivant les indications du programme d’entretien.

• Dévissez la vis du logement du filtre à air (5) à l’aide d’un tournevis adéquat.

• Sortez le logement du filtre à air (13).

• Retirez le filtre à air en mousse (14).

• Lavez-le dans un liquide approprié, disponible auprès de la plupart des distributeurs

d’outillage de jardin.

• Laissez-le sécher complètement.

• Replacez le filtre (14), le logement du filtre (13) et sa vis (5).

Huile de la boîte de vitesses (voir Fig. B)

Remarque : Changez l’huile de la boite de vitesses comme recommandé dans le tableau

du programme d’entretien

• Enfoncez la tarière dans le sol pour qu’elle soit stable et de niveau.

• Retirez la tarière comme indiquée comme décrit dans ‘Assemblage de la tarière’.

• Placez un récipient adéquat pour sous la tarière pour drainer l’huile, comme par

exemple le produit Silverline 675089.

• Utilisez une clé, retirez complètement le boulon pour le remplissage d’huile de la boîte

de vitesses (15).

• Penchez la tarière sur 90° ou plus pour vider l’huile.

Heures de

fonctionnement

500

• Une fois complètement vidée, transférer l’huile usagée dans un container pour la rejeter

en accordance avec les régulations environnementales sur les huiles usagées. Ne pas

jeter les huiles usagées avec les ordures ménagères ou dans les canalisations d’eau.

• Remettez la tarière de niveau et stabilisez-la

• Verser le bon type d’huile et en quantité nécessaire (comme indiquée par les

caractéristiques techniques) par l’orifice de remplissage (15) jusqu’à ce le point de

niveau d’huile de la boîte de vitesses (16) soit atteint, comme indiqué sur la Fig.B.

• Remettez le boulon du remplissage d’huile de la boîte de vitesses.

Rangement

• Lorsque vous posez l’outil au sol, veillez à ne pas donner de coups et à ne pas

endommager le réservoir ou les conduites de carburant.

• Ne faites jamais tomber l’outil sous peine de l’endommager ou de compromettre sa sécurité.

• Une fois le travail fini, nettoyez à fond la machine.

• Inspectez intégralement la machine et ses conduites afin de déceler toute trace de

dommage, y compris tout composant déboîté, dévissé ou perdu.

• Conservez l’outil à l’abri de la lumière directe du soleil.

• Ne rangez pas la tarière dans un sac de nylon car ceci favoriserait la formation de

moisissures.

• Utilisez une petite brosse pour nettoyer l’extérieur de la machine et prévenir toute

obstruction des orifices de ventilation. Ne nettoyez pas la machine à l’eau ou au jet d’eau.

• Veillez à conserver le carburant et l’huile dans un endroit sûr, à l’abri des sources de

chaleur et d’inflammation, de la lumière directe du soleil et hors de portée des enfants.

Rangement pour une période prolongée

Lorsque la machine doit rester inutilisée pendant de longues périodes de temps, procédez

de la manière suivante.

• Nettoyez et inspectez soigneusement votre tarière.

• Videz intégralement le réservoir de carburant et nettoyez le carburateur et toutes

les conduites en faisant tourner le moteur jusqu’à ce qu’il s’arrête de lui-même par

manque de carburant.

• Protégez de la corrosion toutes les pièces de métal du moteur en y appliquant une

couche d’huile.

• Ôtez la bougie, introduisez plusieurs gouttes d’huile dans le cylindre par le trou de

bougie puis tirez sur la poignée de démarrage 2 ou 3 fois pour que l’huile se répartisse

uniformément. Remettez la bougie et son câble en place.

• Nettoyez le filtre à air de la manière indiquée dans la section correspondante ci-dessus.

Résolution des problèmes

Perte de puissance ou arrêt soudain du moteur

• Vérifiez s’il reste du carburant dans le réservoir.

• Vérifiez qu’il n’y a pas d’eau dans le mélange. Vidangez et rincez le système de

carburant avec de l’essence dans le cas contraire.

• Vérifiez que le filtre à air n’est pas encrassé. Nettoyez-le le cas échéant.

Démarrage d’un moteur noyé

• Déconnectez le câble de la bougie et utilisez une clé adéquate pour enlever la bougie en

la faisant tourner dans le sens contraire des aiguilles d’une montre.

• Si la bougie est encrassée ou imbibée de carburant, lavez-la ou changez-la au besoin.

• Lavez l’excédent de carburant de la chambre de combustion en faisant démarrer le

moteur plusieurs fois tandis que la bougie est retirée.

• Installez la bougie et serrez-la fermement à l’aide de la clé.

• Reprenez la procédure de démarrage comme si le moteur était déjà chaud.

Recyclage des outils à essence,

carburant et huile.

• Les outils alimentés par combustion interne par essence ne doivent pas être

rejetés avec les ordures ménagères. De tels outils doivent être amenés dans un

centre de recyclage pour y être recyclés selon les lois en vigueur de la protection

environnementale.

• Essence, huile, et mélanges d’essence et d’huile sont des résidus à risque et doivent

être traités comme produits dangereux. Les carburants et l’huile ne doivent donc

pas être mélangés avec les ordures ménagères. Ne pas rejeter ces substances

correctement ces substances peut être considéré comme un acte criminel. Contactez

votre revendeur ou la collectivité chargée de la collecte des déchets pour de plus

amples informations concernant le recyclage de ce type de déchet.

10

Page 12

868828 Tarière thermique 49 cm³

Garantie Silverline Tools

Ce produit Silverline bénéficie d’une garantie

de 3 ans

Enregistrez ce produit à silverlinetools.com dans les 30 jours suivant

l’achat afin de bénéficier de la garantie de 3 ans. La période de garantie

commence à partir de la date d’achat figurant sur votre facture d’achat.

Conditions de Garantie des Outils Silverline

La période de garantie prend effet à compter de la date de l’achat en

magasin, comme indiqué sur votre facture d’achat.

VEUILLEZ CONSERVER VOTRE FACTURE D’ACHAT.

Si ce produit est défectueux pendant les 30 jours qui suivent l’achat,

retournez-le au magasin où vous l’avez acheté, avec votre facture, en

expliquant en détail le problème. Le produit sera remplacé ou vous serez

remboursé(e).

Si ce produit est défectueux après cette période de 30 jours,

retournez-le à :

Silverline Tools Service Centre

PO Box 2988

Yeovil

BA21 1WU, Royaume Uni

Toute demande de service sous garantie doit être soumise pendant la

période de garantie.

Avant toute intervention sous garantie, vous devez présenter la facture

d’achat originale sur laquelle doivent figurer la date d’achat, votre nom,

votre adresse et le lieu d’achat.

Vous devez expliquer en détail la défaillance nécessitant réparation.

Les demandes de service sous garantie faites pendant la période de

garantie seront vérifiées par Silverline Tools pour établir si la défaillance du

produit est liée à un vice de matériau ou de fabrication.

Les frais de port ne seront pas remboursés. Les articles retournés doivent

être convenablement propres et sûrs pour être réparés et devraient être

emballés soigneusement pour éviter tout dommage ou toute blessure

pendant le transport. Nous pouvons refuser les livraisons qui ne sont pas

convenables ou sûres.

Toute intervention sera effectuée par Silverline Tools ou ses agents de

réparation agréés.

La réparation ou le remplacement du produit ne dépassera pas la période

de garantie.

Les anomalies que nous reconnaissons être couvertes par la garantie

seront rectifiées par la réparation de l’outil, sans frais (hormis les

frais de port) ou par son remplacement par un outil en parfait état de

fonctionnement.

Enregistrement de votre achat

Visitez silverlinetools.com, sélectionnez le bouton d’enregistrement

et saisissez :

• Vosinformationspersonnelles

• Lesinformationsconcernantleproduitetl’achat

Vous recevrez le Certificat de garantie en format PDF. Veuillez l’imprimer et

le conserver avec votre achat.

Les pièces ou les outils remplacés deviendront la propriété de

Silverline Tools.

La réparation ou le remplacement de votre produit sous garantie vous

apporte des avantages ; ces avantages s’ajoutent à vos droits statutaires

en tant que consommateur sans les affecter aucunement.

La présente garantie couvre:

La réparation du produit, s’il peut être vérifié, à la satisfaction de Silverline

Tools, que les défaillances du produit ont été provoquées par un vice de

matériau ou de fabrication au cours de la période de garantie.

Si une pièce n’est plus disponible ou n’est plus fabriquée, Silverline Tools la

remplacera par une pièce de rechange opérationnelle.

Utilisation de ce produit dans l’UE.

La présente garantie ne couvre pas:

Silverline Tools ne garantit pas les réparations nécessaires du produit

engendrées par :

L’usure normale provoquée par l’utilisation conforme aux instructions

d’utilisation, par exemple les lames, les charbons, les courroies, les

ampoules, les batteries, etc.

Le remplacement de tout accessoire fourni tel que les forêts, les lames, les

feuilles abrasives, les outils de coupes et les autres articles associés.

Les dommages et les défaillances accidentels causés par une utilisation ou

un entretien négligent, une mauvaise utilisation, un manque d’entretien ou

une utilisation ou une manipulation imprudente du produit.

L’utilisation du produit à des fins autres que son utilisation domestique

normale.

Le moindre changement ou la moindre modification du produit.

L’utilisation de pièces et d’accessoires qui ne sont pas des composants

véritables de Silverline Tools.

Une installation défectueuse (sauf si l’installation a été réalisée par

Silverline Tools).

Les réparations ou les modifications réalisées par des tiers autres que

Silverline Tools ou ses agents de réparation agréés.

Les demandes de service autres que le droit de rectifier les défaillances

de l’outil indiquées dans ces conditions de garantie ne sont pas couvertes

par cette garantie.

Déclaration de Conformité CE

Le soussigné: Mr Darrell Morris

Autorisé par: Silverline Tools

Déclare que

Nom/modèle: Tarière thermique 49 cm³

Type/série no: 868828

Puissance nette installée: 1.25kW

Se conforme aux directives suivantes:

• Directive sur les émissions des engins mobiles non routiers 2004/108/CE

• Directive sur les émissions sonores dans l’environnement des matériels

destinés à être utilisés à l’extérieur 2000/14/CE Annexe V

• Directive sur la compatibilité électromagnétique 2004/108/CE

• ISO22868:2003

• EN ISO 12100-1, EN ISO 12100-2:2003

• EN60204-1:1998, EN55012:2007, EN61000-6-1:2007

La documentation technique est enregistrée par: Silverline Tools

Organismes notifiés: BVCE Products Testing

Endroit de la déclaration: Shanghai, China

Date : 02/01/13

Signé par :

Position dans la société : Director

Nom et adresse du fabricant ou représentant autorisé

Silverline Tools Ltd, Boundary Way, Lufton Trading Estate, Yeovil, Somerset,

BA22 8HZ United Kingdom

www.silverlinetools.com

11

Page 13

D

Beschreibung der Symbole

Auf dem Leistungsschild des Werkzeugs sind möglicherweise Symbole

abgebildet. Sie vermitteln wichtige Information über das Produkt oder dienen als

Gebrauchsanweisung.

Gehörschutz tragen

Schutzbrille tragen

Atemschutz tragen.

Kopfschutz tragen

Schutzhandschuhe tragen

Lesen Sie die Bedienungsanleitung aufmerksam durch.

Dieses Produkt gibt giftige Dämpfe ab!

Erfüllt die relevanten Gesetze und Sicherheitsnormen.

Umweltschutz

Werkzeuge mit Verbrennungsmotoren dürfen nicht mit dem Hausmüll

entsorgt werden. Bringen Sie diese zu Ihrem lokalen Recycling- oder

Wertstoffhof, und lassen Sie das Gerät dort in Übereinstimmung mit

geltenden Umweltschutzanforderungen und -gesetzen entsorgen.

Technische Daten

Hubraum : ................................................ 49 cm³

Kraftstoffart:............................................. bleifreies Benzin

Mischungsverhältnis

Zweitaktmischung: .................................. 25:1

Motorleistung: .......................................... 1,25 kW

Drehmoment (Antriebswelle): .................. 2,25 Nm

Leerlaufdrehzahl: ..................................... 2.800 min

Max. Motordrehzahl: ................................ 8.500 min

-1

-1

Kraftstoffbehälterinhalt: ........................... 1,2 Liter

Zündkerze: ............................................... Typ BM6A

Elektrodenabstand: .................................. 0,6 – 0,8 mm

Getriebeöl-Typ: ........................................ SAE 30

Getriebeöl-Menge: ................................... 200 ml

Schalldruckpegel: .................................... 108 dB(A)

Schallleistungspegel: ............................... 90 dB(A)

Hand-Arm-Vibration: ................................ 15 m/s

Unsicherheit: ............................................ 2 m/s

2

2

Gewicht (ohne Bohrer): ............................ 9,3 kg

Der Lautstärkepegel könnte für den Bediener des Bohrers 85

dB(A) übersteigen und es müssen Maßnahmen zum Schallschutz

Als Teil unserer fortlaufenden Produktentwicklung können technische

Daten von Silverline-Produkten ohne Vorankündigung geändert

vorgenommen werden.

werden.

Allgemeine Sicherheitshinweise

WARNUNG! Lesen Sie alle Sicherheitshinweise und Anweisungen. Versäumnisse bei

der Einhaltung der Sicherheitshinweise und Anweisungen können elektrischen Schlag,

Brand und/oder schwere Verletzungen verursachen.

Bewahren Sie alle Sicherheitshinweise und Anweisungen für die Zukunft auf.

1) Arbeitsplatzsicherheit

a) Halten Sie Ihren Arbeitsbereich sauber und gut beleuchtet. Unordnung oder

unbeleuchtete Arbeitsbereiche können zu Unfällen führen.

b) Arbeiten Sie mit dem Werkzeug nicht in explosionsgefährdeter Umgebung, in

der sich brennbare Flüssigkeiten, Gase oder Stäube befinden.

c) Halten Sie Kinder und andere Personen während der Benutzung des Werkzeugs

fern. Bei Ablenkung können Sie die Kontrolle über das Gerät verlieren.

2) Sicherheit von Personen

a) Seien Sie aufmerksam, achten Sie darauf, was Sie tun, und gehen Sie mit

Vernunft an die Arbeit mit einem Werkzeug. Benutzen Sie kein Werkzeug,

wenn Sie müde sind oder unter dem Einfluss von Drogen, Alkohol oder

Medikamenten stehen. Ein Moment der Unachtsamkeit beim Gebrauch des

Werkzeuges kann zu ernsthaften Verletzungen führen.

b) Tragen Sie persönliche Schutzausrüstung und immer eine Schutzbrille.

Das Tragen persönlicher Schutzausrüstung, wie Staubmaske, rutschfeste

Sicherheitsschuhe, Schutzhelm oder Gehörschutz, je nach Art und Einsatz des

Werkzeuges, verringert das Risiko von Verletzungen.

c) Vermeiden Sie eine unbeabsichtigte Inbetriebnahme. Vergewissern Sie sich,

dass das Werkzeug ausgeschaltet ist, wenn es nicht verwendet wird, und dass

andere evtl. vorhandene Einschaltsperren aktiviert sind.

d) Entfernen Sie Einstellwerkzeuge oder Schraubenschlüssel, bevor Sie das

Werkzeug einschalten. Ein Werkzeug oder Schlüssel, der sich in einem drehenden

Geräteteil befindet, kann zu Verletzungen führen.

e) Vermeiden Sie eine unnatürliche Körperhaltung. Sorgen Sie für einen sicheren

Stand und halten Sie jederzeit das Gleichgewicht. Auf diese Weise lässt sich das

Elektrowerkzeug in unerwarteten Situationen besser kontrollieren.

f) Tragen Sie geeignete Kleidung. Tragen Sie keine weite Kleidung oder Schmuck.

Halten Sie Haare, Kleidung und Handschuhe fern von sich bewegenden Teilen.

Lockere Kleidung, Schmuck oder lange Haare können von sich bewegenden Teilen

erfasst werden.

g) Wenn Staubabsaug- und -auffangeinrichtungen montiert werden können,

vergewissern Sie sich, dass diese angeschlossen sind und richtig verwendet

werden. Verwendung einer Staubabsaugung kann Gefährdungen durch Staub

verringern.

WARNUNG: Bei der Benutzung mancher Werkzeuge wird der Benutzer Vibrationen

ausgesetzt, welche zum Verlust des Berührungssinnes, zu Taubheitsgefühl, Kribbeln und

zu einer Verminderung der Handgreifkraft führen können. Langfristige Belastung kann zu

chronischen Beschwerden führen. Begrenzen Sie falls nötig die Exposition zu Vibrationen.

Beurteilen Sie die Vibrationsbelastung unter Zuhilfenahme der Technischen Daten des

jeweiligen Werkzeuges, und bestimmen Sie die zulässige Belastungsdauer und –häufigkeit.

Die EU-Direktive 2002/44/EG enthält Informationen über zulässige Vibrationsbelastung

am Arbeitsplatz und kann auch auf Heimarbeiten angewandt werden. Beenden Sie die

Benutzung eines Werkzeuges sofort, wenn Sie in irgendeiner Art und Weise Unbehagen

aufgrund der Vibrationsbelastung fühlen.

WARNUNG: Tragen Sie in Bereichen wo der Lärmpegel 85 dB(A) überschreitet unbedingt

angemessenen Gehörschutz, und begrenzen Sie die Belastungsdauer wo nötig. Sollte trotz

Gehörschutz Unbehagen irgendeiner Art auftreten, beenden Sie die Arbeit unverzüglich

und überprüfen Sie den Gehörschutz auf korrekten Sitz und Funktion, und stellen Sie

sicher, dass dieser einen angemessenen Schutz für den Lärmpegel bietet, der von den

verwendeten Werkzeugen ausgeht.

3) Werkzeugbenutzung und -pflege

a) Pflegen Sie Werkzeuge mit Sorgfalt. Kontrollieren Sie, ob bewegliche Teile

einwandfrei funktionieren und nicht klemmen, ob Teile gebrochen oder so

beschädigt sind, dass die Funktion des Werkzeuges beeinträchtigt ist. Lassen

Sie beschädigte Teile vor dem Einsatz des Gerätes reparieren. Viele Unfälle

haben ihre Ursache in schlecht gewarteten Werkzeugen.

b) Halten Sie Schneidwerkzeuge scharf und sauber. Sorgfältig gepflegte

Schneidwerkzeuge mit scharfen Schneidkanten verklemmen sich weniger und sind

leichter zu führen.

c) Verwenden Sie Werkzeugzubehör, Einsatzwerkzeuge usw. entsprechend

diesen Anweisungen. Berücksichtigen Sie dabei die Arbeitsbedingungen und

die auszuführende Tätigkeit. Der Gebrauch von Werkzeugen für andere als die

vorgesehenen Anwendungen kann zu gefährlichen Situationen führen.

4) Service

a) Lassen Sie Ihr Werkzeug nur von qualifiziertem Fachpersonal und nur mit

Original-Ersatzteilen reparieren. Damit wird sichergestellt, dass die Sicherheit des

Werkzeuges erhalten bleibt.

Sicherheitshinweise für Geräte mit

Verbrennungsmotoren

Gefährliche Umgebung

• Verwenden Sie Benzinmotorgeräte nie in feuchter oder nasser Umgebung und setzen

Sie sie nie dem Regen aus. Sorgen Sie für einen geeigneten und gut ausgeleuchteten

Arbeitsbereich.

• Benutzen Sie Benzinmotorgeräte nicht an Orten, wo ein Explosions- oder Brandgefahr

aufgrund brennbarer Materialien, entflammbarer Flüssigkeiten, entflammbarer Gase

oder entzündbaren Staubs besteht.

Schützen Sie Ihr Gehör

• Tragen Sie immer einen geeigneten Gehörschutz, wenn der Lautstärkepegel des

Werkzeugs 80 dB überschreitet. Es liegt in der Verantwortung des Benutzers

sicherzustellen, dass auch andere Personen die sich in der Nähe des Arbeitsbereichs

aufhalten, ebenfalls ausreichend geschützt sind.

Schützen Sie Ihre Augen

• Verwenden Sie stets einen geeigneten Augenschutz.

Schützen Sie sich vor Vibrationen

• Tragbare Werkzeuge können Vibrationen erzeugen. Diese Vibrationen können

gesundheitsschädigend sein. Wärmende Handschuhe können zu einer guten

12

Page 14

868828 Benzinbetriebener 49-cm³-Erdbohrer

Durchblutung der Finger beitragen. Tragbare Werkzeuge sollten nie über längere

Zeiträume ohne Pausen verwendet werden.

Vor dem Anschließen von Zubehör ausschalten

• Vergewissern Sie sich, dass der Motor ausgeschaltet ist, bevor Sie Zubehör am

Werkzeug anbringen.

• Wenn das Werkzeug unerwartet anhält, vergewissern Sie sich, dass der Motor nicht

läuft, bevor Sie das Werkzeug untersuchen.

Betrieb des Motors

• Lassen Sie den Motor bei neuen Werkzeugen nur mit mäßiger Drehzahl laufen.

• Benutzen Sie erst dann höhere Motordrehzahlen, wenn der Motor vollständig

eingelaufen ist.

• Der Motor kann seine maximale Leistung erst nach Beendigung der Einlaufzeit erreichen.

• Prüfen Sie vor dem ersten Gebrauch des Werkzeugs, dass alle Muttern und Schrauben

sicher befestigt sind, und ziehen Sie diese gegebenenfalls nach.

• Verwenden Sie keine methanol- oder ethanolhaltigen Kraftstoffe, da diese interne

Schäden an Kraftstoffbehälter und -leitungen verursachen können.

Warnhinweis

• Lassen Sie das Gerät niemals unbeaufsichtigt wenn der Motor noch läuft.

• Lassen Sie das Gerät niemals unbeaufsichtigt wenn Teile der Maschine noch heiß sind.

Wartung

• Es wird empfohlen, dass Sie Ihr Werkzeug kurz nach dem ersten Gebrauch warten lassen.

• Bei normalem Gebrauch muss das Werkzeug regelmäßig gewartet werden.

• Versuchen Sie nicht, Komponenten des Werkzeugs zu modifizieren. Der Versuch, das

Werkzeug zu verändern, führt zum Verlust des Garantieanspruchs und kann außerdem

zu ernsthaften Verletzungen der eigenen oder in der Nähe befindlicher Personen führen.

• Lassen Sie Ihr Werkzeug immer bei einer autorisierten Reparaturwerkstatt warten.

Lagerung

• Reinigen Sie das Gerät nach dem Gebrauch gründlich.

• Achten Sie darauf, dass der Kraftstofftank oder die Kraftstoffleitungen nicht beschädigt

werden, wenn das Werkzeug auf den Boden gestellt wird.

• Sorgen Sie dafür, dass das Gerät nicht durch Schläge oder Stöße beschädigt wird, da

das Gerät sonst möglicherweise nicht länger den Sicherheitsansprüchen genügt.

• Gerät vor direkter Sonneneinstrahlung geschützt lagern.

• Sorgen Sie dafür, dass Kraftstoff und Öl an einem sicheren Ort und geschützt vor Hitze,

direkter Sonneneinstrahlung, allen Zündquellen sowie außer Reichweite von Kindern

aufbewahrt werden.

• Wenn das Gerät längere Zeit nicht benutzt werden wird, gehen Sie wie folgt vor:

• Entleeren Sie den Kraftstofftank vollständig.

• Wischen Sie alle Metalloberflächen und Metallkomponenten des Motors zum Schutz vor

Korrosion mit einem geölten Lappen ab.

• Entfernen Sie die Zündkerze und geben Sie einige Tropfen Öl in den Zylinder. Ziehen Sie

den Starthebel zwei bis drei Mal, um das Öl gleichmäßig zu verteilen.

• Setzen Sie die Zündkerze wieder ein.

• Sorgen Sie dafür, dass Kinder sich keinen Zugang zur Maschine verschaffen können.

DIESES PRODUKT ERZEUGT GIFTIGE ABGASE, SOBALD DER MOTOR LÄUFT. DIESE

GASE KÖNNEN FARB- UND GERUCHLOS SEIN. LASSEN SIE DIE MASCHINE NIEMALS

IN GESCHLOSSENEN RÄUMEN ODER IN SCHLECHT BELÜFTETEN BEREICHEN LAUFEN,

UM DAS RISIKO SCHWERER ODER LEBENSGEFÄHRLICHER VERLETZUNGEN ZU

REDUZIEREN. SORGEN SIE FÜR AUSREICHENDE BELÜFTUNG, WENN IN GRÄBEN ODER

IN ANDEREN BEENGTEN RÄUMEN GEARBEITET WIRD.

Produktübersicht

1 Kraftstoffbehälter-Verschluss

2 Kraftstoffpumpe

3 Startergriff

4 Choke-Hebel

5 Schraube des Luftfiltergehäuses

6 Zündkerze

7 Abgasauslass

8 Max-Drehzahl-Einstellschraube

9 Geschwindigkeitsregler

10 Ein-/Ausschalter

11 Dauerlaufknopf des Geschwindigkeitsreglers

12 Sicherungshebel des Geschwindigkeitsreglers

13 Luftfiltergehäuse

14 Schaumstoff-Luftfiltereinsatz

15 Getriebeöl-Einfüllöffnung

16 Getriebeöl-Kontrollbohrung

17 Sicherungsstift

18 Splint

19 Antriebswelle

*Hinweis: Die Getriebeöl-Einfüllöffnung ist geschlossen, wenn die Schraube so weit

wie möglich heraus steht.

Auspacken des Gerätes

• Vergewissern Sie sich, dass sämtliche Teile Ihres Erdbohrers vorhanden und in

einwandfreiem Zustand sind.

• Sollten Teile fehlen oder beschädigt sein, lassen Sie diese ersetzen, bevor Sie das

Werkzeug verwenden.

Zusammenbau Ihres Benzinbetriebenen

Erdbohrers

• Entfernen Sie den Splint (18) aus dem Sicherungsstift (17).

• Entfernen Sie den Sicherungsstift (17) aus der Antriebswelle (19)

• Schieben Sie den Schlangenbohrer (Silverline-Artikelnummern 633897, 245105 oder

457044 – nicht im Lieferumfang enthalten) über die Antriebswelle (19)

• Richten Sie die Bohrung des Schlangenbohrers mit der der Antriebswelle aus

und schieben Sie anschließend den Sicherungsstift (17) durch die Bohrung.

• Setzen Sie den Splint (18) wieder ein und ziehen Sie seine Schenkel, wie in

der Abbildung dargestellt, auseinander.

Betreiben des Motors

Betanken

• Betanken Sie die Maschine immer an einem sicheren Ort, abseits des Arbeitsbereichs

und fernab von jeglicher Hitze- oder Zündquellen.

• Vermeiden Sie jeglichen Kontakt mit dem Kraftstoff.

• RAUCHEN SIE NICHT!

• Füllen Sie erst Kraftstoff nach, wenn der Motor gestoppt und vollständig abgekühlt ist.

• Der Kraftstoff sollte immer vor dem Betanken gemischt werden.

• Mischen Sie den Kraftstoff nicht im Kraftstoffbehälter des Gerätes.

• Mischen Sie nur so viel Kraftstoff, wie Sie auch verwenden möchten.

• Bewahren Sie Kraftstoff ausschließlich in qualitativ hochwertigen Kraftstoffbehältern auf.

• Verwenden Sie das im Lieferumfang enthaltene Mischgefäß. Befüllen Sie diese mit

576,92 ml Benzin und fügen Sie anschließend Zweitaktöl bis zur 600-ml-Markierung

hinzu. Verschließen Sie die Flasche und schütteln Sie diese, um die Komponenten zu

Mischen.

Hinweis: Falls Sie kleinere Mengen an Kraftstoff an mischen möchten, verwenden Sie

zum Abmessen die Skalen auf dem Mischgefäß. Mischen Sie nur so viel Benzin an, wie Sie

auch verwenden werden.

• Entfernen Sie den Kraftstoffbehälter-Verschluss (1). Füllen Sie den Tank bis zur

notwendigen Füllhöhe mit der Kraftstoffmischung.

Hinweis: Verwenden Sie einen Trichter, wie z.B. Silverline-Artikelnummer 793799, um ein

Verschütten zu vermeiden.

• Setzen Sie den Kraftstoffbehälter-Verschluss (1) wieder auf.

• Entfernen Sie eventuell verschütteten Kraftstoff gründlich.

• Bewegen Sie den benzinbetriebenen Erdbohrer ein gutes Stück von der Stelle weg, an

der Sie ihn betankt haben, bevor Sie den Motor anlassen.

• Bewahren Sie übrigen Kraftstoff nicht in der Nähe des Arbeitsbereichs auf.

• Schalldämpfer und Auspuff werden beim Betrieb sehr heiß. Stellen Sie daher sicher,

dass diese Teile nicht mit brennbaren Materialien in Kontakt kommen.

Startvorbereitung des Motors

• Halten Sie die Maschine senkrecht auf der Spitze des Schlangenbohrers, so dass sich

die Griffe parallel zum Boden befinden.

• Drücken Sie die Kraftstoffpumpe (2) langsam hinein und lassen Sie sie wieder los.

• Wiederholen Sie den Vorgang, bis der Kraftstoff beginnt durch die transparente

Kraftstoffleitung und zurück in den Kraftstofftank zu fließen.

• Drücken Sie die Kraftstoffpumpe (2) noch einige Male, bis keine Luftblasen mehr

zu sehen sind. Die Kraftstoffanlage ist nun vollständig mit Kraftstoff befüllt und

betriebsbereit.

Anlassen des Motors

WARNUNG: Dieser benzinbetriebene Erdbohrer produziert giftige Abgase, die durch den

Abgasauslass (7) austreten, sobald die Maschine läuft. Lassen Sie den Motor ausschließlich

im Freien an und niemals in jeglicher Art von geschlossenen Räumen. Tragen Sie zu Ihrer

Sicherheit immer angemessene Schutzkleidung: Die Bedienung dieses Werkzeugs erfordert

das Tragen einer Schutzbrille, von Handschuhen, Gehörschutz, Atemschutz und robuster

Kleidung. Es wird ebenfalls empfohlen einen Schutzhelm und Sicherheitsschuhe zu tragen.

• Stellen Sie den Choke-Hebel (4) auf „ON“ (EIN), wenn der Motor warm ist.

• Stellen Sie den Hebel auf „OFF“ (AUS), wenn der Motor kalt ist.

• Stellen Sie den Ein-/Ausschalter (10) auf „I“

• Halten Sie den Erdbohrer, wie in Abb. A zu sehen, und stellen Sie sicher, dass Sie die

Kontrolle über das Werkzeug haben.

www.silverlinetools.com

13

Page 15

D

• Ziehen Sie kräftig am Startergriff, wie in Abb. A dargestellt.

• Ziehen Sie den Startergriff erneut, bis der Motor startet.

WICHTIG – lassen Sie den Startergriff (3) nicht in das Werkzeug zurückschnappen, sondern

lassen Sie ihn kontrolliert zurückgleiten.

• Lassen Sie den Motor ca. 30 Sekunden im Leerlauf laufen.

• Wenn der Motor warmgelaufen ist, stellen Sie den Choke-Hebel (4) auf die Position „ON“.

WICHTIG – Lassen Sie den Motor langsam für mindestens 3 Minuten warm laufen, bevor Sie

die Motordrehzahl erhöhen. Dies erhöht die Leistungsfähigkeit und die Lebensdauer des Motors.

Einlaufen des Motors

• Es ist wichtig, dass Sie den Motor einlaufen lassen, wenn Sie die Antriebseinheit zum

ersten Mal verwenden. Dies erhöht die Effizienz und Leistungsfähigkeit des Motors und

maximiert die Lebensdauer.

• Um den Motor einlaufen zu lassen, lassen Sie ihn beim ersten Gebrauch für mindestens

15 Minuten im Leerlauf laufen und geben Sie so wenig Gas wie möglich. WENN

MÖGLICH, ERHÖHEN SIE WÄHREND DIESER ZEIT DIE MOTORDREHZAHL NICHT.

HINWEIS: Es ist normal, dass Sie während des Einlaufens starke Gerüche wahrnehmen, da

sich die Teile zum ersten Mal erhitzen.

Anhalten des Motors

• Lassen Sie den Motor nach Gebrauch für mindestens 3 Minuten im Leerlauf laufen,

bevor Sie ihn ausschalten.

• Stellen Sie den Ein-/Ausschalter (10) auf die Position „O“.

Verwenden des Benzinbetriebenen

Erdbohrers

Steuerung des Erdbohrers

• Starten Sie den Motor, wie weiter oben beschrieben.

• Drücken Sie, um die Motordrehzahl zu erhöhen, den Sicherungshebel (12) und

dann langsam den Geschwindigkeitsregler (9) hinunter. Lassen Sie ihn los, um die

Motordrehzahl wieder zu verringern.

HINWEIS: Wenn der Motor im Leerlauf läuft, dreht sich die Antriebswelle nicht. Sie beginnt

sich zu drehen, wenn die Motordrehzahl erhöht wird.

• Die maximale Motordrehzahl kann durch Einstellen der Max-Drehzahl-Einstellschraube