Page 1

Guaranteed Forever

*Register online within 30

days. Terms & Conditions apply

Garantie à vie

*Enregistrez votre produit en ligne

dans les 30 jours. Sous réserve des

termes et conditions appliquées

Lebenslange Garantie

*Registrieren Sie sich innerhalb von 30

Tagen online. Es gelten die allgemeinen

Geschäftsbedingungen

www.silverlinetools.com

Garantía de por vida

*Regístrese online dentro de 30 días.

Se aplican los términos y condiciones

Garanzia a vita

*Registrarsi on-line entro 30 giorni.

Termini e Condizioni si applicano

Levenslange garantie

*Registreer online binnen 30 dagen.

Algemene voorwaarden van toepassingg

Page 2

633936

Dovetail Jig 300mm

Dovetail Jig 300mm

Gabarit pour queues d'aronde 300 mm

Zinkenfräsgerät, 300 mm

300mm Width Capacity

Plantilla para juntas cola de milano 300 mm

Mortasatrice a coda di rondine 300 mm

Zwaluwstaart freesmal

www.silverlinetools.com

Page 3

3

2

4

1

3

4

2

5

6

8

6

9

7

8

10

9

Fig A

Fig B

Fig C

2

Page 4

®

Dovetail Jig 300mm

300mm Width Capacity

English .................. 4

Français ................ 8

Deutsch ................. 12

Español ................. 16

Italiano .................. 20

Nederlands ............ 24

www.silverlinetools.com

3

Page 5

GB

Specification

Template: ................................................... 12.7mm (½")

Guide bush (not included): .......................... 11.1mm (7⁄16")

Router cutter (not included): ....................... 6.35mm (¼")

shank -12.7mm (½") x 14˚ dovetail

Maximum material thickness: .................... 32mm

Horizontal width range: .............................. 140 – 300mm

Vertical width range:...................................150 – 275mm

Weight: ....................................................... 9.5kg

Safety Warnings

WARNING Read all safety warnings and all instructions. Failure to

follow the warnings and instructions may result in electric shock, fire and/

or serious injury.

Save all warnings and instructions for future reference.

Work Area Safety

a) Keep work area clean and well lit. Cluttered or dark areas invite

accidents.

b) Do not operate tools in explosive atmospheres, such as in the

presence of flammable liquids, gases or dust.

c) Keep children and bystanders away while operating a powered

tool. Distractions can cause you to lose control.

Personal Safety

a) Stay alert, watch what you are doing and use common sense

when operating a powered tool. Do not use a powered tool

while you are tired or under the influence of drugs, alcohol or

medication. A moment of inattention while operating a powered tool

may result in serious personal injury.

b) Use personal protective equipment. Always wear eye protection.

Protective equipment such as dust mask, non-skid safety shoes, hard

hat, or hearing protection used for appropriate conditions will reduce

personal injuries.

c) Prevent unintentional starting. Ensure the switch is in the off-

position when not operating the tool and make use of other safety

features which prevent unintentional starting.

d) Remove any adjusting key or wrench before turning the powered

tool on. A wrench or a key left attached to a rotating part of the tool

may result in personal injury.

e) Do not overreach. Keep proper footing and balance at all times.

This enables better control of the tool in unexpected situations.

f) Dress properly. Do not wear loose clothing or jewelry. Keep your

hair, clothing and gloves away from moving parts. Loose clothes,

jewelry or long hair can be caught in moving parts.

g) If devices are provided for the connection of dust extraction and

collection facilities, ensure these are connected and properly

used. Use of dust collection can reduce dust-related hazards.

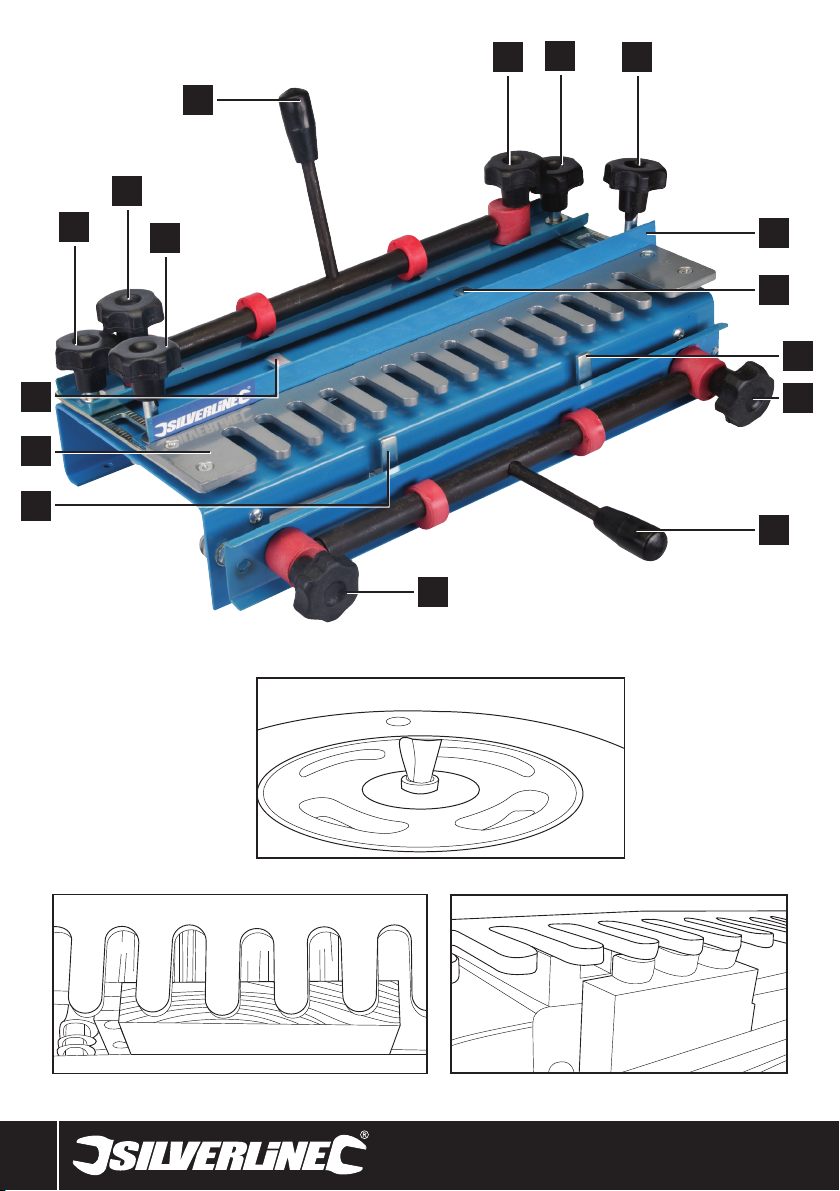

Product Familiarisation

1 Horizontal Clamping Lever

2 Horizontal Clamping Knobs

3 Template Position Knobs

4 Fence Position Knobs

5 Fence

6 Horizontal Stop Bar

7 Template

8 Vertical Stop Bar

9 Vertical Clamping Knobs

10 Vertical Clamping Lever

Unpacking and assembly

• Carefully unpack the dovetail jig, and remove all packaging materials.

Beware of sharp edges

• The Horizontal Clamping Lever (1) and the Vertical Clamping Lever (10)

are supplied loose. The levers should be securely screwed into the

threaded holes provided so that, when clamped, the horizontal lever is

behind the jig and the vertical lever is down away from the Template (7)

4

Page 6

633936 Dovetail Jig 300mm

Mounting

• This dovetail jig should always be securely mounted to the front edge of

a sturdy workbench before use

• The jig should be fixed to the bench using wood screws through the four

small holes in the jig frame

• If a permanent installation is not required the jig may be mounted to a

board that can be easily clamped to a workbench. It is important the

board is long enough so the clamps do not obstruct use of the jig

Operating Instructions

WARNING: The cutter must not contact any part of the jig. Always use the

correct-sized guide bush and cutter. Incorrect sizes will make an un-usable

joint and may damage the jig.

Configuring your router

Note: These instructions are specific to the recommended router

accessories to use with this dovetail jig. Use of other accessories to create

other joints is possible but beyond the scope of this manual.

The jig is compatible with both ¼" and ½" routers including equivalent

metric sizes. The router may need an additional collet or reducer so it can

accept ¼" router bits.

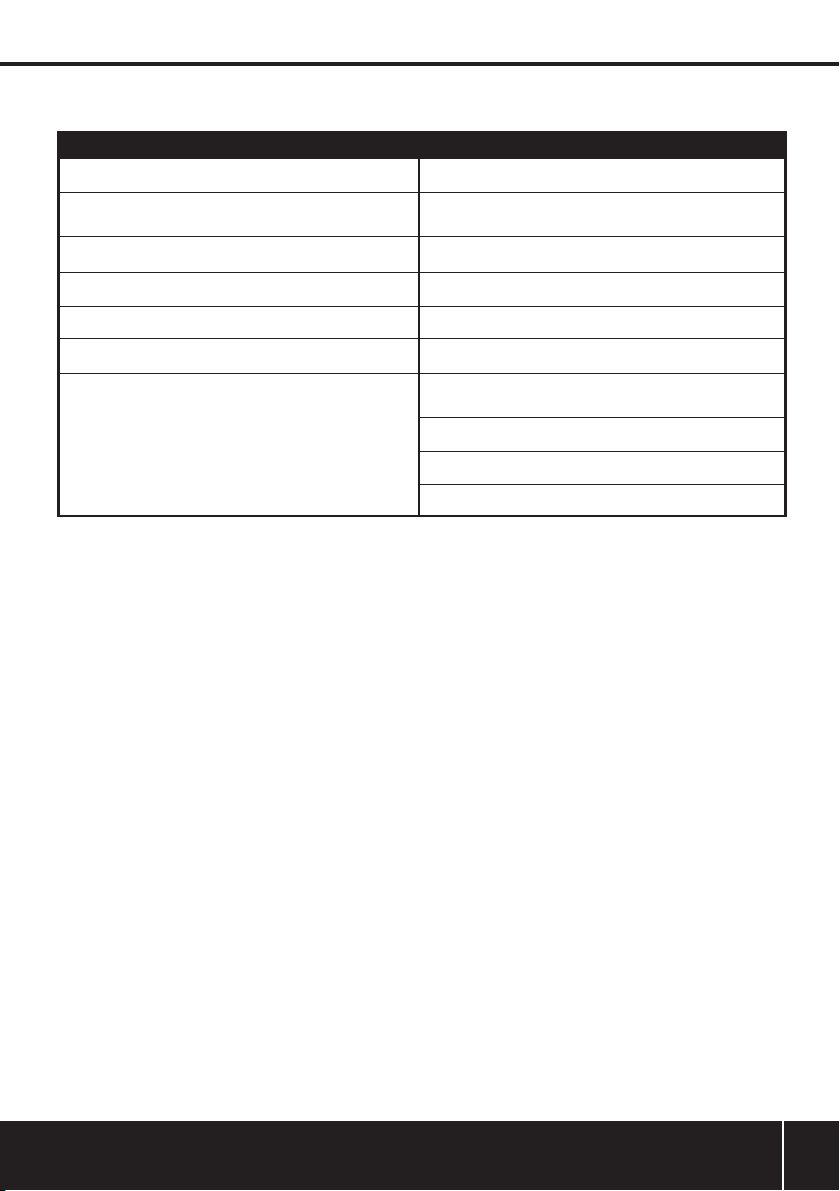

1. Fit a base to your router that will allow fitment of guide bushes

2. Install a guide bush of 11.1-12mm or 7⁄16" outer diameter so that the

router can move smoothly between the slots of the ½" Template (7).

The guide bush depth must not exceed the thickness of the template

3. Fit a 12.7mm (1⁄2") dovetail 14° cutter with a ¼" shank. The dovetail

cutter height needs to be set so that the cutting blades will not contact

the template in use but the cutting blade starts cutting at the surface

of the wood. The dovetail cutter should be approximately 17mm

height from the base plate of the router. See Fig A

Preparation

This jig is suitable for the creation of dovetail joints needed for drawers,

boxes and chests. The information presented below is general guidance

only. Familiarisation with this jig over time is necessary to achieve the

desired results. Fine adjustment of some measurements is required to get

an exact fit.

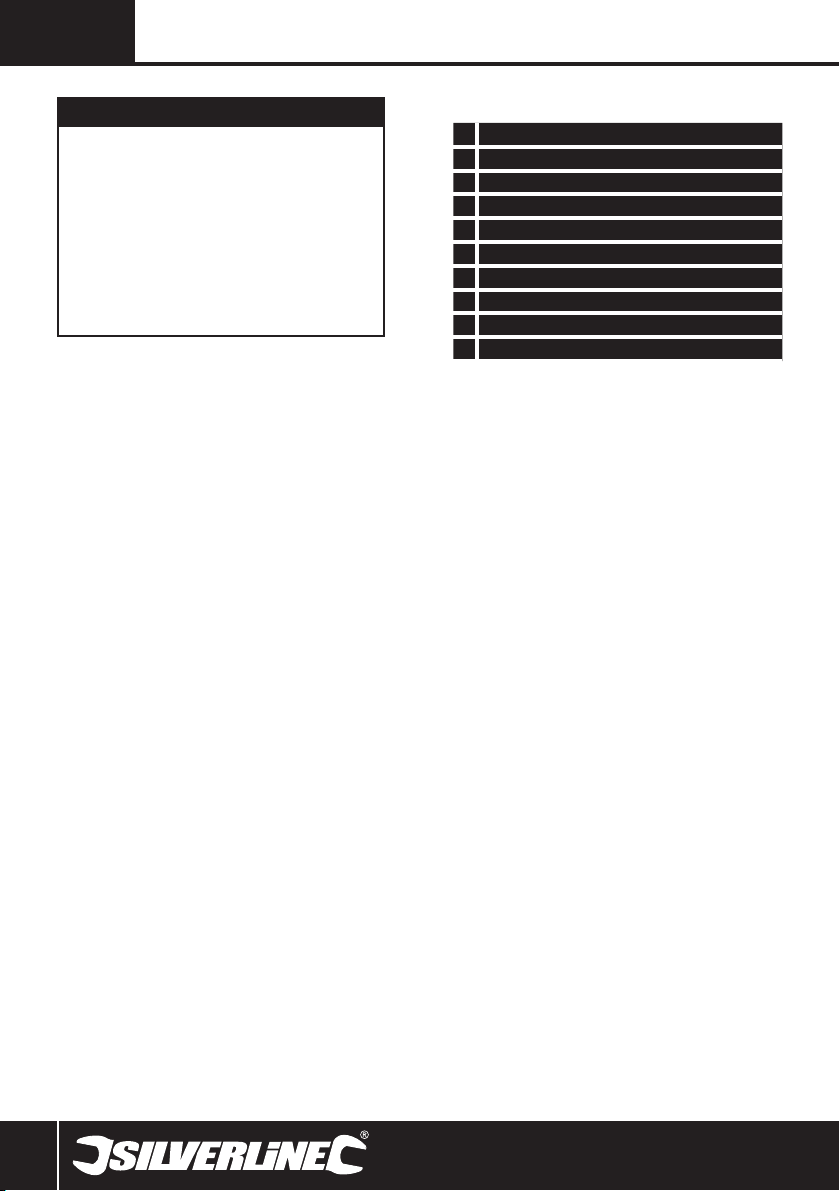

The jig is used to create both the tails and pins of the dovetail joint in one

process. This is achieved by using an offset position between two clamped

pieces of wood. See fig B which shows the wood position for four tails of

the dovetail joint on the vertical wood before cutting and fig C which shows

three tails of the dovetail joints after cutting. The sides of the slots where

the tail fits into are the pins.

• Wood must be cut to the correct size, with square cut ends. Allow for the

depth of the joint when calculating wood sizes

• Use a pencil to label the wood indicating front, back, left, right, inside,

outside and any other information that might assist in cutting the wood

correctly. For example, write matching numbers on the ends of the

wood to be joined together, and note which end is for tails and which

part is pins

Important: The use of a square is recommended to ensure that correct

angles are achieved in all stages of setting up the dovetail jig. Accurate

alignment of the wood is crucial to achieving a good quality joint. Practising

with scrap material is highly recommended to develop accuracy when

using the jig.

Setting the vertical and horizontal stop bars

Note: A spanner (not supplied) is required to adjust the Horizontal Stop Bars

(6) and the Vertical Stop Bars (8).

1. Loosen the Horizontal Clamping Knobs (2) and Vertical Clamping

Knobs (9), and raise the Horizontal Clamping Lever (1) and the Vertical

Clamping Lever (10) to allow access to the stop bars adjustment nuts

easily

2. Set the left-hand Horizontal Stop Bar (6) to a position where the

Template (7) indicates a suitable place for the first dovetail joint female

slot for the size of the wood so that the dovetail joints are evenly

spaced across the wood. The left-hand Vertical Stop Bar (8) should be

set so that it is positioned 12.7mm (½") to the right of the Horizontal

Stop Bar (6). This is the offset which is approximately the width of a

finger of the template

• The initial horizontal stop bar position in relation to the template fingers

may vary slightly depending on how much border is required. The border

is the distance from the edge of the vertical wood to the first dovetail tail.

The offset between the two pieces of wood is always the thickness of a

template finger 12.7mm (1⁄2") in order to line up two equal width pieces

of wood after jointing. Once cut, the wood in Fig B will have a smaller

border than that in Fig C

• Use the right-hand side horizontal and vertical stop bars to secure and

align larger pieces of wood more centrally in the jig. The right-hand side

stop bars can also be used in preference to the left-hand side or used for

another two pieces of wood secured at the same time as the left side so

two dovetail joints can be made in one operation

• When securing two sets of wood, the left-hand or right-hand side

Horizontal Clamping Knobs (2) and Vertical Clamping Knobs (9) can

be used instead of the Horizontal Clamping Lever (1) and the Vertical

Clamping Lever (10) to allow releasing or fitting of wood to the left or

right side only without affecting the position of the wood already fitted

on the other side

• Once the stop bars are in the correct offset position lining up the two

pieces of wood exactly level when jointed, avoid adjusting the stop

bar position again. This is only possible if the same size wood is being

worked on. Alternatively, once the correct offset position has been found

between the horizontal and vertical stop bars, an offset spacer can be

made from a small piece of wood to that exact measurement. This will

enable the offset position to be set quickly and accurately even when

using different size pieces of wood

Clamping and positioning the wood

1. Pull the Horizontal Clamping Lever (1) towards the back of the jig,

loosen the two Horizontal Clamping Knobs (2) and slide the horizontal

piece of wood into the jig from the rear

2. The wood should pass underneath the fence (5) and the Template

(7). The left-hand side of the wood should be lying against the left

Horizontal Stop Bar (6) and the front of the wood should be level with

the front of the main body of the jig to allow for the vertically placed

wood to be positioned in front of it (Fig B)

3. Tighten the Horizontal Clamping Knobs (2) so the clamp is very close

to the surface of the wood. Recheck the position of the wood and pull

the horizontal clamping lever towards the front of the jig to secure the

wood

• The clamp needs to be set so that operating the clamping lever allows

the wood to be inserted and secured without additional use of the

clamping knobs

• Do not force the clamping lever if there is too much resistance when

operating. Loosen the clamping knobs to adjust it to the optimum setting

that holds the wood securely but does not put unnecessary strain on the

clamping mechanism to prevent it being damaged

4. Pull the Vertical Clamping Lever (10) up so it is in the unclamped

position and loosen the Vertical Clamping Knobs (9)

5. If the vertical piece of wood has already been cut for the joint at the

other end, make sure the wood is inserted in the correct way. Once

the dovetail joint is cut the vertical wood in the jig fits to the horizontal

wood at 180° to its cut position, as if hinged at the cut position and

rotated 180° upwards

www.silverlinetools.com

5

Page 7

GB

6. Insert the vertical piece of wood from below into the front of the jig.

The wood should pass behind the front clamp assembly, and be in

contact with the vertical edge of the frame

7. Position the left side of the wood against the left-hand side Vertical

Stop Bar (8)

8. As per the horizontal clamp adjust the clamp so that the wood can be

inserted and secured simply by operating the clamping lever

9. Align the vertical wood so the height is parallel with the horizontal

wood as shown in Fig B

10.Move the vertical clamping lever to the down position to lock the

wood in place

Adjusting of the template position

To adjust the position of the Template (7) to allow for correct positioning

loosen the Template Position Knobs (3) and adjust the template position to

suit the thickness of the wood making sure the template is even on both

sides. The tips of the template should be approximately 2.5mm back from

the front edge of the vertical piece of wood. Ensure the template is kept

parallel with the jig body.

Adjusting the fence

The fence controls how deep the female dovetail slots are by limiting the

movement of the base of the router. There are no set values of distance as

this value depends on the size of the router base and the thickness of the

wood. The formula for this is:

Distance = (2 x thickness of vertical wood) + (½ width of router base)

– (cutter radius)

This is measured from the fence to the end of the fingers on the Template

(7). If you have used the recommended ½" dovetail cutter, the cutter radius

value will be 6.35mm (1⁄4")

Note: If using a router without a completely round base (possibly a router

that has 2 flat sides to its base) measure the distance from the centre of

the base to the edge closest to the centre of the base. When operating the

router remember to work to the base side you have measured to. If you set

to the widest distance of the base there is a risk of the cutter coming into

contact with the jig if you then use the side of the base closest to the cutter.

Cutting a dovetail joint

1. Ensure both the router and jig are set up using the instructions above,

including using scrap wood in the jig if this is your first dovetail joint

2. Wear any necessary personal protective equipment including a face

mask especially if there is any risk of toxic particles (for example, from

man-made composite woods)

3. Set the router to a speed that does not exceed that of the maximum

speed of the dovetail cutter

4. Place the router onto the Template (7) with the router cutter not

touching the wood but close to it in an ideal position to start cutting

5. Hold the router securely and turn on, allow the motor to reach full

speed

6. Carefully begin cutting, allowing the router guide bush to follow the

slots of the template, entering the slot on the left side and following

the curve of the slot so that the guide bush is against the right side

of the slot when leaving the slot. Do not cut into slots individually but

instead cut in one process carefully going around the shape of the

template. The end result will look like Fig C

7. While operating the router make sure the cutter does not contact any

part of the jig and do not lift the router while cutting. Once the cut

is complete, switch off the router and allow the cutter time to stop

rotating before removing carefully from the template

• Once the cut has been made, remove the wood from the jig and check

the joint. A correctly cut joint should be neither too loose nor too tight to

connect. Using a light mallet can be used to tap the joint into place if it

is a tight joint.

• If the joint is not correct or if more practising is required, saw off the ends

of the test pieces so they can be used again

Optional Accessories

Contact your Silverline stockist for a range of accessories suitable for use

with this product including;

245122 – 10 Piece Guide Bush Set in Case (including a 11.1mm (7⁄16")

guide bush)

792084 – 12 Piece ¼" Router Bit Set (including a ½" 14° dovetail cutter)

656577 – 24 Piece ¼" Router Bit Set (including a ½" 14° dovetail cutter)

Maintenance

Keep your dovetail jig clean. Do not allow dust to build up around the jig.

Clean regularly with a soft brush or vacuum, clean resin off with a suitable

solvent

6

Page 8

Troubleshooting

Dovetail joint is not at a 90° angle Recheck that wood is correctly fitted and clamped

Dovetail Jig 300mm633936

Problem Solution

Dovetail joint is at an angle with the two pieces of wood not level but slightly

Where jointed the two pieces of wood are slightly stepped and not level

Splintering of the wood as the cutter leaves the workpiece

angled apart

The dovetail pins are too long or short

Dovetail joint too tight

Dovetail joint too loose

Recheck that the angle of wood to the Horizontal Stop Bars and Vertical Stop

Bars is correct using a square and the angle between the stop bars is correct

Offset of the stop bar needs adjustment

Fence position needs adjustment towards or away from the Template (7)

decrease the dovetail cutter height from the router base

increase the dovetail cutter height from the router base

Clamp another piece of wood over the vertical wood if possible to prevent

Scribe a line across the wood at the cut height to prevent splintering

splintering

More careful router operation

Cut with the grain

www.silverlinetools.com

7

Page 9

F

Caractéristiques techniques

Ecart entre dents du peigne : ..................... 12,7mm (½")

Bague de copiage (non fourni) : .................. 11,1 mm (7⁄16")

Fraise queue d’aronde (non fournie) : ......... Queue de

6,35mm (¼") ; 12,7 mm (½") x 14˚

Epaisseur maximale du matériau : ............. 32 mm

Plage de largeur horizontale : ..................... de 140 à 300 mm

Plage de largeur verticale : ......................... de 150 à 275 mm

Poids : ........................................................ 9,5 kg

Consignes générales de sécurité

AVERTISSEMENT Veuillez lire l’intégralité des consignes de sécurité

et des instructions. Le non-respect de ces consignes et instructions peut

entraîner un risque de choc électrique, d’incendie et/ou se traduire par des

blessures graves.

Veuillez conserver ces instructions et consignes de sécurité pour

référence ultérieure.

Sécurité sur la zone de travail

a) Maintenir une zone de travail propre et bien éclairée. Des zones

encombrées et mal éclairées sont sources d’accidents.

b) Ne pas utiliser d’outils dans des environnements explosifs,

tels qu’à proximité de liquides, de gaz ou de poussières

inflammables.

c) Eloigner les enfants et les passants pendant l’utilisation d’un

appareil électrique. Ceux-ci peuvent provoquer une perte d’attention

et faire perdre la maîtrise de l’appareil.

Sécurité des personnes

a) Rester vigilent et faire preuve de bon sens lors de la manipulation

de l’appareil. Ne pas utiliser un appareil électrique lorsque l’on

se trouve dans un état de fatigue, ou sous l’influence de drogues,

d’alcool ou de médicaments. Un moment d’inattention pendant

l’utilisation d’un outil électrique peut se traduire par des blessures

graves.

b) Porter un équipement de protection approprié. Toujours porter

une protection oculaire. Le port de masque à poussières, chaussures

de sécurité antidérapantes, casque de sécurité et protections antibruit

adaptés aux différentes conditions de travail réduit le risque de

blessures corporelles.

c) Eviter tout démarrage accidentel ou intempestif. S’assurer que

l’interrupteur marche-arrêt soit en position d’arrêt lorsque

l’appareil n’est utilisé.

d) Enlever toute clé et tout instrument de réglage avant de mettre

l’appareil en marche. Une clé ou un instrument de réglage laissé fixé

à un élément en rotation de l’appareil électrique peut entraîner des

blessures physiques

e) Ne pas essayer d’atteindre une zone hors de portée. Se tenir

toujours en position stable permettant de conserver l’équilibre.

Cela permet de mieux contrôler l’appareil électrique dans des

situations inattendues.

f) Porter des vêtements appropriés. Ne pas porter de vêtements

amples ou des bijoux pendants. Eloigner cheveux, vêtements et

gants des pièces en mouvement. Les vêtements amples, les bijoux

pendants et cheveux longs peuvent être happés par les pièces en

rotation

g) Si l’appareil est pourvu de dispositifs destinés au raccord

d’équipements d’extraction et de récupération de la poussière/

sciure, s’assurer qu’ils soient bien fixés et utilisés correctement.

L’utilisation de ces dispositifs peut réduire les risques dus à la

poussière.

Se familiariser avec le produit

1 Levier de serrage horizontal

2 Molettes de serrage horizontal

3 Molette de positionnement du peigne

4 Molette de positionnement du guide

5 Guide

6 Butée d’arrêt horizontal

7 Peigne

8 Butée d’arrêt vertical

9 Molettes de serrage vertical

10 Levier de serrage vertical

Déballage et assemblage

• Déballez le gabarit à queue d'aronde avec précaution, en prenant soin

de retirer tout le matériau d'emballage. Faites attention aux arêtes

coupantes.

• Les leviers de serrage (1) et (10) sont livrés démontées. Ces leviers

doivent se visser solidement dans les trous filetés présents sur les barres

de serrage : de cette façon, le levier horizontal se trouve sur l’arrière de

l’appareil et le levier vertical placé en bas du peigne (7).

8

Page 10

633936 Gabarit pour queues d'aronde 300 mm

Assemblage

• Avant utilisation, le gabarit doit être solidement fixé sur le bord antérieur

d'un établi robuste.

• Quatre trous de montage sont prévus sur le châssis du gabarit pour

permettre sa fixation sur l’établi à l'aide de vis à bois.

• Si vous ne voulez pas fixer définitivement le gabarit sur un établi, vous

pouvez le fixer sur une planche pour le fixer avec des serre-joints sur

l’établi. Il est important que la planche soit assez longue pour que les

serre-joints ne gênent l’utilisation du gabarit.

Instructions d’opération

ATTENTION : La fraise ne doit pas venir en contact avec aucun élément

du gabarit.

Utilisez toujours une bague de copiage et une fraise de dimensions

appropriées. Une fraise inadaptée risque de produire un assemblage nonutilisable et d'occasionner des dommages sur le gabarit.

Régler votre défonceuse

Remarque : Ces instructions sont spécifiques aux accessoires

recommandés pour l’utilisation de ce gabarit. L’utilisation d’autres

accessoires pour créer d’autres assemblages n’est pas du ressort de ce

manuel.

Le gabarit est compatible avec les défonceuses 1⁄4" et 1⁄2" y compris avec

les tailles métriques équivalentes. La défonceuse peut nécessiter une

pince de serrage supplémentaire ou une bague de réduction pour utiliser

des fraises 1⁄4".

1. Placez une embase sur votre défonceuse pour installer les bagues

de copiage.

2. Installez la bague de copiage de diamètre extérieure de 11,1 mm

(7⁄16") pour que la défonceuse puisse se déplacer facilement entre les

espaces du peigne 1⁄2" (7). La profondeur de la bague de copiage ne

doit pas être supérieure à l’épaisseur du peigne.

3. Installez la fraise à queue d’aronde de 12,7 mm (½") x 14˚ à

emmanchement 1⁄4". Le réglage de la hauteur de cette fraise doit se

faire de sorte que les tranchants ne rentrent pas en contact avec le

peigne, mais qu’ils puissent commencer à couper la surface du bois.

La fraise à queue d’aronde doit être approximativement à 17 mm de

l’embase de la défonceuse. Voir Fig.A.

Préparation

Ce gabarit est conçu pour la réalisation d’assemblage en queue d’aronde

pour des tiroirs, caisses et coffres. Les informations données ci-dessous

ne sont que des instructions générales. Se familiariser et acquérir de

l’expérience avec ce produit est nécessaire pour obtenir le résultat voulu.

Le réglage fin de certaines mesures est primordial pour un assemblage

parfait.

Ce gabarit permet de réaliser le tenon et la rainure en une seule opération.

Ceci s’effectue en utilisant une position décalée entre deux pièces de bois

jointes. La Fig. B montre la position du bois pour la réalisation des tenons

avant la coupe, et la Fig. C montre les trois tenons après la coupe, ainsi

qu’une des rainures se trouvant sur la pièce de bois horizontale.

• Les pièces de bois à usiner doivent avoir été préalablement coupées à la

taille finale souhaitée, avec des chants à l’équerre. Tenez compte de la

profondeur de l’assemblage lors du calcul des dimensions des pièces.

• Utilisez un crayon pour indiquer l’avant, l’arrière, côté gauche et droit,

intérieur et extérieur de la pièce pour effectuer une coupe du bois

précise. Utilisez par exemple des numéros sur les extrémités du bois

à assembler ensemble, pour savoir quel tenon s’assemble sur quelle

rainure.

Important : L’utilisation d’une équerre peut être utile pour obtenir les

angles corrects, mais aussi pour toutes les étapes de configuration de

l’appareil. Les alignements corrects des pièces de bois sont primordiaux

pour un assemblage parfait. Il est recommandé de s’entrainer sur des

morceaux de chute afin d’utiliser cet outil avec précision.

Régler les butées d’arrêt vertical et horizontal

Remarque : Une clé (non fournie) est requise pour régler les butées d’arrêt

horizontal (6) et les butées d’arrêt vertical (8)

1. Desserrez les molettes de serrage horizontal (2) et vertical (9), et

levez le levier de serrage horizontal et vertical (1 et 10) pour accéder

facilement aux écrous de réglages des butées d’arrêt.

2. Placez la butée d’arrêt horizontal gauche de sorte que le peigne (7)

puisse permettre de réaliser une première rainure convenablement

placé sur la pièce et ainsi obtenir un assemblage bien centré et

espacé sur la longueur de la pièce. La butée d’arrêt verticale gauche

(8) devrait être placée à 12,7 mm (1⁄2") de la butée d’arrêt horizontal(6).

Ceci est le décalage, qui est approximativement la largeur des dents

du peigne.

• Le positionnement initial de la butée d’arrêt horizontale par rapport aux

dents du peigne peut légèrement varier selon la longueur de bordure. La

bordure est la distance du bord vertical du bois à la première rainure. Le

décalage entre les deux pièces de bois est toujours la largeur d’une dent

du peigne (12,7 mm) de façon à aligner les deux largeurs des pièces de

bois entre-elles après l’assemblage. Une fois la coupe réalisée, la pièce

de bois de la Fig.B a une bordure plus petite que celle de la Fig.C.

• Utilisez les butées d’arrêt droite, vertical et horizontal, pour aligner

et centrer les plus grandes pièces de bois avec le gabarit. Les butées

droites peuvent être également, selon votre commodité, utilisée à la

place des gauches. Ou être utilisées en même temps si vous souhaitez

faire deux assemblages en une seule fois.

• Si vous effectuez deux assemblages en même temps, les molettes de

serrage vertical et horizontal (2 et 9) peuvent être utilisées à la place des

leviers de serrage (1 et 10 ) pour relâcher ou fixer une pièce de bois sans

avoir à modifier la position des pièces de bois du second assemblage.

• Une fois les butées d’arrêt en place avec le correct décalage, avec les

pièces de bois de l’assemblage de niveau, évitez de les re-régler. Ceci

est seulement possible si les pièces de bois sont de même dimension.

Autrement, une fois le décalage paramétré, vous pouvez fabriquer

une entretoise en bois à la dimension exacte du décalage. Ceci vous

permettra de régler le gabarit rapidement et précisément lors des

prochaines utilisations même avec des pièces de bois de taille différente.

Fixer et positionner une pièce de bois.

1. Tirez le levier de serrage horizontal (1) vers l’arrière du gabarit,

desserrez les deux molettes de serrage (2), et faites glisser la pièce de

bois horizontale depuis l’arrière du gabarit.

2. La pièce de bois doit passer sous le guide (5) et sous le peigne (7). Le

côté gauche de la pièce de bois doit être en contact contre la butée

d’arrêt horizontal gauche (6), et l’avant de la pièce de bois doit être

de niveau avec le côté avant du gabarit, pour être par la suite, être de

niveau avec la pièce de bois verticale.

3. Resserrez les molettes de serrage horizontal (2) de sorte que la presse

soit proche de la surface du bois. Revérifiez la position du bois et tirez

le levier de serrage horizontal vers l’avant du gabarit pour maintenir le

bois en place.

• Le serrage doit être réglé de sorte que lorsque vous actionnez le levier de

serrage, vous puissiez insérer et fixer la pièce de bois sans avoir à utiliser

les molettes de serrages.

• Ne forcez pas sur le levier de serrage s’il y a trop de résistance lors de

son utilisation. Desserrez les molettes de serrage de façon à trouver

le réglage parfait permettant d’activer le levier de serrage sans avoir à

forcer dessus (et risquer d’endommager le système), tout en maintenant

la pièce de bois bien fixée.

4. Soulevez le levier de serrage vertical (10) pour le mettre en position

relâchée, et desserrez les molettes de serrage vertical (9).

5. Si la pièce de bois verticale a déjà été coupée pour l’assemblage

sur l’autre extrémité, soyez bien sûr d’insérer la pièce de bois dans

le bon sens. Une fois la coupe effectuée, la pièce verticale s’aligne

parfaitement avec la pièce horizontale si mises bout à bout.

6. Insérez la pièce de bois par le bas sur l’avant du gabarit. La pièce de

bois doit donc se trouver entre le tampon du levier de serrage et le

bord vertical du gabarit.

www.silverlinetools.com

9

Page 11

F

7. Positionnez le bord gauche de la pièce de bois contre la butée d’arrêt

vertical (8).

8. Tout comme le serrage horizontal, faites un réglage du serrage de

sorte que la pièce de bois puisse s’insérer et être fixée en utilisant

simplement le levier de serrage.

9. Alignez le bord de la pièce verticale avec celui de la pièce horizontale,

comme indiqué sur la Fig.B

10.Abaissez le levier de serrage vertical pour maintenir la pièce de bois.

Régler la position du peigne

Pour régler la position du peigne (7), desserrez les molettes de

positionnement du peigne. Positionnez le peigne en fonction de l’épaisseur

du bois et assurez-vous qu’il soit bien centré par rapport aux extrémités

de la pièce de bois. Les dents du peigne doivent être approximativement à

2,5 mm du bord de la pièce verticale. Assurez-vous que le peigne soit bien

parallèle par rapport au châssis du gabarit.

Régler le guide

Le guide contrôle la profondeur des rainures en stoppant le mouvement

de l ‘embase de la défonceuse. Pour connaitre la distance à laquelle le

guide doit être placé, il faut prendre en compte la taille de la défonceuse et

l’épaisseur du bois. Cette distance se calcule de la façon suivante :

Distance = (épaisseur du bois vertical x 2) + (largeur de l’embase de

la défonceuse x 0,5 )- (rayon de la fraise)

Cette distance est celle se trouvant entre le guide et l’extrémité des dents

du peigne (7). Si vous utilisez la fraise ½" recommandée pour queue

d’aronde, le rayon de la fraise est de 6,35 mm

Remarque : Si vous utilisez une défonceuse avec une embase qui n’est

pas totalement ronde (possédant deux faces droites), mesurez la distance

avec le côté le plus proche du centre de la défonceuse. En utilisant la

défonceuse, rappelez-vous de travailler avec le côté de l’embase avec

lequel vous avez effectué la mesure. Si vous mesurez la distance avec le

côté le plus éloigné de l’embase, il y a un risque que la fraise vienne en

contact avec le gabarit si par après, vous utilisez le côté le plus proche

du centre.

Effectuer la coupe pour un assemblage à queue d’aronde

1. Assurez-vous de régler la défonceuse et le gabarit comme indiqué

dans ci-dessus. Pour une première utilisation il est recommandé

d’effectuer un test sur un morceau de chute.

2. Portez les équipements personnels de sécurité, ainsi qu’un masque

respiratoire en cas de présence de particules toxiques (par exemple

dans les bois composites)

3. Régler la vitesse de la défonceuse pour qu’elle ne dépasse pas la

vitesse maximale de la fraise

4. Placez la défonceuse sur le peigne (7) avec la fraise ne touchant pas le

bois, mais assez proche pour bien commencer la coupe.

5. Maintenez bien la défonceuse, mettez en marche, et attendez que le

moteur atteigne sa pleine vitesse

6. Commencez à couper avec précaution, en faisant suivre la bague

de copiage entre les dents du peigne en allant de la gauche vers la

droite. Réalisez la coupe en une seule passe et sans pause. Le résultat

obtenu ressemble à celui de la Fig. C

7. En utilisant la défonceuse, vérifiez bien que la fraise ne rentre pas en

contact avec le gabarit, et ne soulevez pas la défonceuse pendant la

coupe. Une fois la coupe terminée, éteignez la défonceuse et attendez

l’arrêt total de la fraise avant de la retirer.

• Une fois la coupe terminée, retirez la pièce de bois du gabarit et vérifiez

l’assemblage. Un assemblage correct ne sera ni trop lâche, ni trop serré.

Utilisez un maillet si l’assemblage est trop serré.

• Si l’assemblage n’est pas correct ou si vous vous entrainez, sciez les

extrémités des pièces pour qu’elles puissent être réutilisées de nouveau.

Accessoires optionnels

Contactez votre revendeur Silverline pour une grande variété d’accessoires

compatible avec ce produit, tels que :

245122 - Coffret de 10 bagues de copiage pour défonceuse (comprenant la

bague de copiage 11,1 mm)

792084 - Coffret de 12 fraises à défoncer carbure de tungstène 1⁄4"

(comprenant la fraise 1⁄4" pour queue d’aronde)

656577 – Coffret de 24 fraises à défoncer TCT 1⁄4"

Entretien

Gardez votre gabarit toujours propre. Ne laissez pas la poussière

s’accumuler sur le gabarit. Nettoyez régulièrement avec une brosse souple

ou avec un aspirateur, et enlevez la résine avec un solvant adéquat.

10

Page 12

633936 Gabarit pour queues d'aronde 300 mm

En cas de problème

Problème Solution

L’assemblage n’est pas à 90° Vérifiez comment le bois est positionné et serré

Le joint est légèrement incliné Vérifiez l’angle d’inclinaison de la pièce de bois et que les leviers horizontal et

Les deux pièces de bois ne sont pas alignées

Les tenons sont trop courts ou trop longs

L’assemblage est trop serré

L’assemblage est trop lâche

Si possible, fixez une autre pièce de bois sur le bois vertical

Le bois éclate lorsque la fraise ressort

Faites une entaille le long de la pièce à la hauteur de la fraise

vertical soient bien réglés

Réglez la butée d’arrêt horizontal

Replacez le peigne correctement

Réduisez la hauteur de la fraise

Augmentez la hauteur de la fraise

Maniez la défonceuse avec plus de précaution

Coupez dans le sens du bois

www.silverlinetools.com

11

Page 13

D

Spezifikation

Schablone: ................................................. ½ Zoll (12,7 mm)

Führungshülse

(nicht im Lieferumfang enthalten): ..............7⁄16 Zoll (11,1 mm)

Fräser (nicht im Lieferumfang enthalten): ... ¼ Zoll Schaft

(6,35 mm): ½ Zoll (12,7 mm) x 14˚ Schwalbenschwanz

Maximale Materialstärke: ........................... 32 mm

Horizontale Breite: ...................................... 140 – 300 mm

Vertikale Breite: .......................................... 150 – 275 mm

Gewicht: ..................................................... 9,5 kg

Sicherheitshinweise

WARNUNG! Lesen Sie alle Sicherheitshinweise und Anweisungen.

Versäumnisse bei der Einhaltung der Sicherheitshinweise und Anweisungen

können elektrischen Schlag, Brand und/oder schwere Verletzungen

verursachen.

Bewahren Sie alle Sicherheitshinweise und Anweisungen für die

Zukunft auf.

Arbeitsplatzsicherheit

a) Halten Sie Ihren Arbeitsbereich sauber und gut beleuchtet.

Unordnung oder unbeleuchtete Arbeitsbereiche können zu Unfällen

führen.

b) Arbeiten Sie mit dem Werkzeug nicht in explosionsgefährdeter

Umgebung, in der sich brennbare Flüssigkeiten, Gase oder Stäube

befinden.

c) Halten Sie Kinder und andere Personen während der Benutzung

des Werkzeugs fern. Bei Ablenkung können Sie die Kontrolle über

das Gerät verlieren.

Sicherheit von Personen

a) Seien Sie aufmerksam, achten Sie darauf, was Sie tun, und gehen

Sie mit Vernunft an die Arbeit mit einem Werkzeug. Benutzen

Sie kein Werkzeug, wenn Sie müde sind oder unter dem Einfluss

von Drogen, Alkohol oder Medikamenten stehen. Ein Moment der

Unachtsamkeit beim Gebrauch des Werkzeuges kann zu ernsthaften

Verletzungen führen.

b) Tragen Sie persönliche Schutzausrüstung und immer eine

Schutzbrille. Das Tragen persönlicher Schutzausrüstung, wie

Staubmaske, rutschfeste Sicherheitsschuhe, Schutzhelm oder

Gehörschutz, je nach Art und Einsatz des Werkzeuges, verringert das

Risiko von Verletzungen.

c) Vermeiden Sie eine unbeabsichtigte Inbetriebnahme.

Vergewissern Sie sich, dass das Werkzeug ausgeschaltet ist,

wenn es nicht verwendet wird, und dass andere evtl. vorhandene

Einschaltsperren aktiviert sind.

d) Entfernen Sie Einstellwerkzeuge oder Schraubenschlüssel, bevor

Sie das Werkzeug einschalte. Ein Werkzeug oder Schlüssel, der sich

in einem drehenden Geräteteil befindet, kann zu Verletzungen führen.

e) Vermeiden Sie eine unnatürliche Körperhaltung. Sorgen Sie für

einen sicheren Stand und halten Sie jederzeit das Gleichgewicht.

Auf diese Weise lässt sich das Elektrowerkzeug in unerwarteten

Situationen besser kontrollieren.

f) Tragen Sie geeignete Kleidung. Tragen Sie keine weite Kleidung

oder Schmuck. Halten Sie Haare, Kleidung und Handschuhe fern

von sich bewegenden Teilen. Lockere Kleidung, Schmuck oder

lange Haare können von sich bewegenden Teilen erfasst werden.

g) Wenn Staubabsaug- und -auffangeinrichtungen montiert werden

können, vergewissern Sie sich, dass diese angeschlossen sind

und richtig verwendet werden. Verwendung einer Staubabsaugung

kann Gefährdungen durch Staub verringern.

Geräteübersicht

1 Horizontaler Spannhebel

2 Horizontale Feststellschrauben

3 Schablonenpositionsschrauben

4 Anschlagpositionsschrauben

5 Anschlag

6 Horizontale Anschlagsleiste

7 Schablone

8 Vertikale Anschlagsleiste

9 Vertikale Feststellschrauben

10 Vertikaler Spannhebel

Auspacken und Zusammenbau

• Das Schwalbenschwanzfräsgerät vorsichtig auspacken und alle

Verpackungsmaterialien entfernen. Vorsicht bei scharfen Kanten!

• Der horizontale Spannhebel (1) und der vertikale Spannhebel (10)

werden lose geliefert. Die Hebel müssen sicher in die Gewindelöcher

eingeschraubt werden, damit sich beim Spannen der horizontale Hebel

hinter dem Fräsgerät und der vertikale Hebel nach unten weg von der

Schablone (7) befindet.

12

Page 14

633936 Zinkenfräsgerät, 300 mm

Montage

• Dieses Schwalbenschwanz Fräsgerät sollte vor Gebrauch immer sicher

an der Vorderkante einer festen Werkbank befestigt sein.

• Das Fräsgerät sollte mittels Holzschrauben in den vier kleinen Löchern

des Geräterahmens an der Werkbank befestigt sein.

• Falls eine permanente Installation nicht erforderlich ist, kann das

Fräsgerät an einem Brett montiert werden, damit dieses leicht in eine

Werkbank geklemmt werden kann. Achten Sie darauf, dass das Brett

lang genug ist, damit die Klemmen nicht die Benutzung des Fräsgeräts

behindern.

Bedienungsanleitung

ACHTUNG! Die Schneide darf nicht mit irgendeinem Teil des Geräts in

Berührung kommen. Stets die passende Führungshülse und Schneide

benutzen. Falsche Größen produzieren unbrauchbare Fräsverbindungen und

können das Gerät beschädigen.

Einstellung der Oberfräse

Hinweis: Diese Anweisungen sind speziell für das Zubehör der

empfohlenen Oberfräse, das mit dieser Schwalbenschwanzfräse benutzt

werden sollte. Die Anwendung anderen Zubehörs zur Herstellung anderer

Fräsverbindungen ist möglich, geht aber über den Rahmen dieses

Handbuches hinaus.

Das Fräsgerät ist kompatibel mit ¼-Zoll- und ½-Zoll-Oberfräsen inklusive

der entsprechenden metrischen Größe. Die Oberfräse könnte eine weitere

Spannzange benötigen, um ¼-Zoll-Fräser zu akzeptieren.

1. Befestigen Sie eine Grundplatte an Ihre Oberfräse, die einen Einbau

der Führungshülsen ermöglicht.

2. Montieren Sie eine Führungshülse mit einem Außendurchmesser von

11,1 - 12 mm, bzw. 7⁄16 Zoll, damit die Oberfräse glatt zwischen den

Schlitzen der 0,5 mm (½ Zoll) Schablone (7) laufen kann. Die Tiefe der

Führungshülse darf nicht die Dichte der Schablone überschreiten.

3. Einen 12,7 mm (1⁄2 Zoll) 14°-Schwalbenschwanz-Fräser in einer

¼-Zoll-Spannzange montieren. Die Höhe der Schwalbenschwanz

Schneide muss so eingestellt werden, dass die Schneidmesser nicht

in Berührung mit der benutzten Schablone geraten, sondern so, dass

das Schneidmesser auf der Oberfläche des Holzstücks schneiden.

Die Schwalbenschwanz Schneide sollte ca. 17 mm hoch von der

Grundplatte der Oberfräse eingestellt sein. Siehe Abb. A.

Vorbereitung

Dieses Fräsgerät eignet sich zur Herstellung von

Schwalbenschwanzverbindungen, die für Schubladen, Kästen und Truhen

erforderlich sind. Die u. g. Informationen dienen nur als allgemeiner

Ratschlag. Es ist notwendig sich mit diesem Fräsgerät über einen Zeitraum

hinweg vertraut zu machen, um die gewünschten Ergebnisse zu erzielen.

Feineinstellungen mancher Maße sind erforderlich, um eine exakte

Einpassung zu erzielen.

Das Fräsgerät wird benutzt, um die Enden und Stifte der

Schwalbenschwanzverbindung in einem Vorgang herzustellen. Das

wird durch Nutzung einer Ausgleichsposition zwischen den beiden

eingespannten Holzstücken erreicht. Siehe Abb. B, welche die Holzposition

für vier Enden der Schwalbenschwanzverbindung auf dem vertikalen

Holzstück vor dem Schneiden zeigt, und Abb. C, welche die drei Enden der

Schwalbenschwanzverbindung nach dem Schneiden zeigt. Die Seiten der

Schlitze, wo die Enden eingepasst sind, sind die Stifte.

• Das Holz muss auf die richtige Größe zugeschnitten werden mit

quadratisch zugeschnittenen Enden. Berücksichtigen Sie die Tiefe der

Verbindung bei der Berechnung der Holzgrößen.

• Nehmen Sie einen Bleistift, um das Holzstück auf der Vorder- und

Rückseite, links, rechts, auf der Innen- und Außenseite, und um alle

weiteren Informationen zu markieren, die dabei helfen könnten, das

Holzstück korrekt zuzuschneiden. Schreiben Sie z. B. die passenden

Zahlen auf die Enden des Holzstückes, die miteinander verbunden

werden sollen, und beachten Sie, welches Ende für die Enden und

welches für die Stifte ist.

Wichtiger Hinweis: Es wird empfohlen ein Quadrat zu benutzen, damit

gewährleistet wird, dass die korrekten Winkel in allen Stadien der

Einstellung der Schwalbenschwanzfräse eingehalten werden. Eine präzise

Ausrichtung des Holzstückes ist notwendig, um eine qualitativ gute

Verbindung zu erzielen. Das vorherige Üben mit einem Probeholzstück wird

äußerst empfohlen, um eine Genauigkeit bei der Benutzung dieser Fräse

entwickeln zu können.

Einstellung der vertikalen und horizontalen Anschlagleisten

Hinweis: Ein Schraubenschlüssel (nicht mitgeliefert) ist erforderlich, um

die horizontalen Anschlagleisten (6) und die vertikalen Anschlagleisten (8)

einzustellen.

1. Die horizontalen Feststellschrauben (2) und vertikalen

Feststellschrauben (9) lockern, und den horizontalen Spannhebel (1)

und den vertikalen Spannhebel (10) anheben, für einen leichteren

Zugang zu den Einstellmuttern der Anschlagleisten.

2. Die linke, horizontale Anschlagleiste (6) in der Position einstellen,

in der die Schablone (7) einen geeigneten Platz für die erste

Schwalbenschwanzverbindungsbuchse für diese Holzgröße anzeigt,

damit die Schwalbenschwanzverbindungen gleichmäßig über das

Holzstück verteilt werden. Die linke, vertikale Anschlagleiste (8) sollte

so eingestellt werden, damit sie 12,7 mm (½ Zoll) rechts von der

horizontalen Anschlagleiste (6) positioniert ist. Dies ist der Ausgleich,

der ungefähr eine Fingerbreite der Schablone beträgt.

• Die erste horizontale Anschlagsleistenposition in Bezug auf die

Schablonenfinger kann leicht variieren, je nachdem wie viel Rand

erforderlich ist. Der Rand ist die Strecke zwischen der Kante des

vertikalen Holzstückes bis zum ersten Schwalbenschwanz. Der

Ausgleich zwischen den beiden Holzstücken ist immer die Dichte eines

Schablonenfingers 12,7 mm (1⁄2 Zoll), um zwei gleich breite Holzteile nach

dem Ausfugen miteinander auszurichten. Nachdem es gefräst wurde,

wird das Holzstück in Abb. B einen schmaleren Rand als in Abb. C haben.

• Die rechten, horizontalen und vertikalen Anschlagleisten benutzen, um

größere Holzstücke zentraler im Fräsgerät zu sichern und auszurichten.

Die rechten Anschlagleisten können auch statt der Linken benutzt

werden oder sie können für zwei weitere Holzstücke benutzt werden,

um sie zur gleichen Zeit wie die Linken zu sichern, damit zwei

Schwalbenschwanzverbindungen in einem Vorgang erstellt werden

können.

• Beim Sichern von zwei Paar Holzstücken können die linken oder

die rechten horizontalen Feststellschrauben (2) und die vertikalen

Feststellschrauben (9) benutzt werden, statt des horizontalen

Spannhebels (1) und des vertikalen Spannhebels (10), um die Freigabe,

bzw. Einpassung des Holzstückes nur an die linke oder rechte Seite zu

ermöglichen ohne die Position des Holzstückes zu beeinträchtigen, das

bereits auf der anderen Seite eingepasst ist.

• Nachdem die Anschlagleisten in der korrekten Ausgleichposition sind und

die beiden Holzstücke exakt gerade beim Ausfugen ausgerichtet sind,

eine erneute Einstellung der Anschlagleistenposition vermeiden. Das ist

nur möglich, wenn die gleiche Holzgröße benutzt wird. Alternativ kann,

nachdem die korrekte Ausgleichsposition zwischen der horizontalen und

der vertikalen Anschlagleiste gefunden wurde, ein Ausgleichsstandhalter

aus einem kleineren Stück Holz für dieses exakte Maß hergestellt

werden. Das ermöglicht die schnelle und präzise Einstellung der

Ausgleichsposition, wenn verschieden große Holzstücke benutzt werden.

www.silverlinetools.com

13

Page 15

D

Festklemmen und Positionierung des Holzstückes

1. Den horizontalen Spannhebel (1) zur Rückseite des Fräsgeräts ziehen,

die horizontalen Feststellschrauben (2) lockern und das horizontale

Holzstück von hinten in das Fräsgerät einschieben.

2. Das Holzstück sollte unter dem Anschlag (5) und der Schablone (7)

durchlaufen. Die linke Seite des Holzstückes sollte bündig gegen die

linke Anschlagleiste (6) liegen und die Vorderseite des Holzstückes

sollte gerade mit der Vorderseite des Fräsgeräts liegen, damit das

vertikal platzierte Holzstück davor positioniert werden kann (Abb. B).

3. Die horizontalen Feststellschrauben (2) festziehen, damit die Klemme

sehr dicht an der Oberfläche des Holzstückes liegt. Erneut die Position

des Holzstückes überprüfen und den horizontalen Spannhebel zur

Vorderseite des Fräsgeräts ziehen, um das Holzstück zu sichern.

• Die Klemme muss eingestellt werden, damit die Bedienung des

Spannhebels es ermöglicht, dass das Holzstück eingeschoben und

gesichert werden kann ohne weiter die Feststellschrauben zu benutzen.

• Den Spannhebel nicht forcieren, wenn zu viel Widerstand bei der

Bedienung besteht. Die Feststellschrauben lockern, um sie zur

optimalen Einstellung einzustellen, die das Holzstück sicher fixiert, aber

nicht unnötigerweise Kraft auf den Klemm-Mechanismus ausübt, um

eventuelle Schäden hieran zu vermeiden.

4. Den vertikalen Spannhebel (10) nach oben ziehen, damit er in der

ungespannten Position ist und die vertikalen Feststellschrauben (9)

lockern.

5. Falls das vertikale Holzstück bereits für die Verbindung am

anderen Ende geschnitten wurde, bitte dabei beachten, dass das

Holzstück dann auf die korrekte Art eingeführt wird. Nachdem die

Schwalbenschwanzverbindung gefräst wurde, passt das vertikale

Holzstück bei 180° in seine Schnittposition, als ob es an der

Schnittposition aufgehängt und 180° nach oben gedreht ist.

6. Das vertikale Holzstück von unten in die Vorderseite des Fräsgeräts

einschieben. Das Holzstück sollte hinter dem vorderen Spannaufbau

vorbeilaufen und in Kontakt mit der vertikalen Kante des Rahmens

liegen.

7. Die linke Seite des Holzstückes gegen die linke Seite der vertikalen

Anschlagleiste (8) positionieren.

8. Wie bei der horizontalen Spanne die Klemme so einstellen, dass das

Holzstück einfach durch Bedienung des Spannhebels eingeführt und

gesichert werden kann.

9. Das vertikale Holzstück so ausrichten, dass die Höhe parallel mit dem

horizontalen Holzstück verläuft wie in Abb. B gezeigt.

10.Den vertikalen Spannhebel in die untere Position bewegen, um das

Holzstück festzuklemmen.

Einstellung der Schablonenposition

Zur Einstellung der Position der Schablone (7), um eine korrekte

Positionierung zu ermöglichen, die Schablonenpositionsschrauben

(3) lockern und die Schablonenposition auf die geeignete Dichte des

Holzstückes einstellen, dabei darauf achten, dass die Schablone auf beiden

Seiten gleich ist. Die Spitzen der Schablone sollten ca. 2,5 mm hinter der

Vorderkante des vertikalen Holzstückes liegen. Darauf achten, dass die

Schablone parallel mit dem Fräsgerät liegt.

Einstellung des Anschlags

Der Anschlag kontrolliert wie tief die Schwalbenschwanzbuchsen sind,

indem die Bewegung der Grundplatte der Oberfräse einschränkt wird.

Es gibt keine Sollwerte für die Distanz, da dieser Wert von der Größe der

Grundplatte der Oberfräse und der Dichte des Holzes abhängig ist. Die

Formel hierfür ist:

Distanz = (2 x Dichte des vertikalen Holzstücks) + (½ Breite der

Grundplatte der Oberfräse) – (Schneide Radius)

Dies wird gemessen vom Anschlag bis zum Ende der Finger auf der

Schablone (7). Falls Sie die empfohlene ½-Zoll-Schwalbenschwanzschneide

benutzt haben, wird der Schneideradiuswert 6,35 mm (1⁄4 Zoll) betragen.

Hinweis: Wenn eine Oberfräse ohne eine komplett runde Grundplatte (evtl.

eine Oberfräse, die 2 flache Seiten an ihrer Grundplatte hat) benutzt wird,

die Distanz von der Mitte der Grundplatte bis zur Kante am dichtesten zur

Mitte der Grundplatte messen. Bei Bedienung der Oberfräse beachten zur

Grundseite, die bemessen wurde, zu arbeiten. Falls sie auf die breiteste

Distanz der Grundplatte eingestellt wurde, besteht das Risiko, dass die

Schneide mit dem Fräsgerät in Berührung kommt, wenn man dann die

Seite der Grundplatte am dichtesten zur Schneide benutzt.

Fräsen einer Schwalbenschwanzverbindung

1. Gewährleisten, dass die Oberfräse und das Fräsgerät gemäß der

o.g. Anweisungen eingestellt wurden, inklusive zur Benutzung

von Probeholzstücken im Fräsgerät, falls Sie zum ersten Mal eine

Schwalbenschwanzverbindung herstellen.

2. Alle erforderlichen Schutzausrüstungen tragen, inklusive einer

Gesichtsmaske, insbesondere, wenn ein Risiko an giftigen Partikeln

besteht (z. B. von künstlichen Verbundhölzern).

3. Die Oberfräse auf eine Geschwindigkeit einstellen, welche nicht

die der maximalen Geschwindigkeit der Schwalbenschwanzfräse

überschreitet.

4. Die Oberfräse auf die Schablone (7) führen, wobei die Schneide der

Oberfräse nicht das Holz berühren darf, aber dicht am Holzstück dran

liegt in einer idealen Position, um mit dem Fräsen zu beginnen.

5. Die Oberfräse sicher halten und einschalten, warten bis der Motor die

volle Geschwindigkeit erreicht hat.

6. Vorsichtig mit dem Fräsen beginnen, der Führungshülse der Oberfräse

ermöglichen, den Schlitzen entlang der Schablone zu folgen, auf der

linken Seite in die Schlitze einfräsen und der Kurve des Schlitzes

folgen, damit die Führungshülse gegen die rechte Seite des Schlitzes

liegt, wenn dieser Schlitz verlassen wird. Nicht einzeln in die Schlitze

fräsen, sondern stattdessen in einem Vorgang vorsichtig um die Form

der Schablone herum fräsen. Das Endergebnis wird wie in Abb. C

aussehen.

7. Bei Bedienung der Oberfräse darauf achten, dass die Schneide nicht

mit irgendeinem Teil des Fräsgeräts in Berührung kommt und die

Oberfräse nicht beim Fräsen anheben. Nachdem der Schnitt beendet

ist, die Oberfräse ausschalten und warten bis die Schneide sich nicht

mehr dreht, ehe das Holzstück vorsichtig von der Schablone entfernt

wird.

• Nachdem der Schnitt gemacht wurde, das Holzstück von der Fräse

entfernen und die Verbindung prüfen. Eine korrekt gefräste Verbindung

sollte weder zu lose noch zu fest zu verbinden sein. Ein leichter

Gummihammer kann benutzt werden um die Verbindung zurecht zu

hämmern bis sie eine dichte Verbindung ergibt.

• Falls die Verbindung nicht richtig ist oder wenn mehr Übung erforderlich

ist, die Enden der Teststücke absägen, damit die Holzstücke erneut

benutzt werden können.

Optionales Zubehör

Wenden Sie sich an Ihren Silverline Händler für eine Auswahl an Zubehör,

das für dieses Produkt geeignet ist, inklusive:

245122 – 10-tlg. Führungshülsenset im Aufbewahrungskasten (inklusive

einer 11,1-mm- (7⁄16-Zoll-) Führungshülse)

792084 – 12-teiliges ¼-Zoll-Fräserset (inklusive eines ½-Zoll-14°Schwalbenschwanz-Fräsers)

656577 -24-teiliges ¼-Zoll-Fräserset (inklusive eines ½-Zoll-14°Schwalbenschwanz-Fräsers)

Wartung

Das Schwalbenschwanzfräsgerät sauber halten. Darauf achten, dass

sich kein Staub rund um das Fräsgerät anhäuft. Regelmäßig mit einer

weichen Bürste oder dem Staubsauger reinigen, Harz mit einem geeigneten

Lösemittel entfernen.

14

Page 16

633936 Zinkenfräsgerät, 300 mm

Fehlersuche

Problem Lösung

Die Schwalbenschwanzverbindung ist nicht in einem 90° Winkel.

Erneut überprüfen, dass das Holzstück korrekt eingepasst und festgeklemmt

wurde.

Die Schwalbenschwanzverbindung ist in einem Winkel zu den beiden

Holzstücken, nicht gerade aber leicht angewinkelt voneinander.

Wo sie miteinander verbunden sind, sind die beiden Holzstücke leicht abgestuft

Die Schwalbenschwanzstifte sind zu lang oder zu kurz.

Die Schwalbenschwanzverbindung ist zu fest.

Die Schwalbenschwanzverbindung ist zu lose.

Das Holz splittert, wenn die Schneide es verlässt.

und nicht gerade.

Erneut überprüfen, dass der Winkel des Holzstücks zu den horizontalen

Anschlagleisten und den vertikalen Anschlagleisten korrekt ist durch

Anwendung eines Quadrats und überprüfen, dass der Winkel zwischen den

Die Ausrichtung der Anschlagleiste muss eingestellt werden.

Die Anschlagposition muss zur Schablone (7) in oder von ihr weg eingestellt

Die Höhe der Schwalbenschwanz Schneide von der Grundplatte der Oberfräse

Die Höhe der Schwalbenschwanz Schneide von der Grundplatte der Oberfräse

Ein weiteres Holzstück über das vertikale Holzstück klemmen, falls möglich, um

Eine Linie quer über das Holz in der Schnitthöhe zeichnen, um eine Splitterung

Anschlagleisten korrekt ist.

werden.

senken.

erhöhen.

die Splitterung zu vermeiden.

Die Oberfräse vorsichtiger bedienen.

zu vermeiden.

Den Holzfaserverlauf entlang fräsen.

www.silverlinetools.com

15

Page 17

ESP

Características técnicas

Paso del peine: ........................................... 12,7 mm (½")

Casquillo copiador (no incluido): ................. 11,1 mm (7⁄16")

Fresa (no incluida): ..................................... Vástago 6,35 mm

(¼") - 12,7 mm (½") x 14˚ cola de milano

Grosor máximo del material: ...................... 32 mm

Intervalo de anchura horizontal: ................. 140 – 300 mm

Intervalo de anchura vertical: ..................... 150 – 275 mm

Peso: .......................................................... 9,5 kg

Instrucciones generales de

seguridad

ADVERTENCIA: Lea todas las advertencias de seguridad e

instrucciones. No respetar estas advertencias e instrucciones puede

causar descargas eléctricas, incendios y/o lesiones graves.

Conserve estas instrucciones de seguridad para futuras referencias.

Seguridad en el área de trabajo

a) Mantenga el área de trabajo limpia y bien iluminada. Las áreas

desordenadas y oscuras invitan a que se produzcan accidentes.

b) No utilice herramientas eléctricas en atmósferas explosivas,

como por ejemplo en presencia de líquidos, gases o polvos

inflamables.

c) Mantenga alejados a los niños y a las personas que se

encuentren a su alrededor mientras esté trabajando con una

herramienta eléctrica. Las distracciones pueden hacerle perder el

control de la herramienta.

Seguridad personal

a) Manténgase alerta, fíjese en lo que está haciendo y use el sentido

común cuando esté utilizando una herramienta eléctrica. No

use una herramienta eléctrica si se encuentra cansado o bajo la

influencia de drogas, alcohol o medicamentos. Un momento de

distracción mientras esté utilizando una herramienta eléctrica puede

provocar lesiones corporales graves.

b) Use equipo de protección personal. Use siempre protección

ocular. El uso de equipamientos de seguridad tales como máscara

antipolvo, calzado de seguridad antideslizante, casco duro y

protecciones auditivas adecuadas reducirá el riesgo de lesiones

corporales.

c) Evite el arranque accidental. Asegúrese de que el interruptor está

en la posición de apagado antes de enchufar la herramienta.

d) Retire las llaves de ajuste antes de encender la herramienta

eléctrica. Una llave de ajuste que se ha dejado colocada en una parte

móvil de la herramienta eléctrica puede causar lesiones corporales.

e) No adopte posturas forzadas. Manténgase en posición firme y en

equilibrio en todo momento. De este modo, podrá controlar mejor la

herramienta eléctrica en situaciones inesperadas.

f) Vístase adecuadamente. No lleve ropa holgada ni joyas. Mantenga

el pelo, la ropa y los guantes alejados de las piezas móviles. La

ropa holgada, las joyas o el pelo largo pueden quedar atrapados en

las piezas móviles.

g) Si dispone de conexión a sistemas de extracción y recolección

de polvo, asegúrese de que estén conectados y se usen

correctamente.

Características del producto

1 Palanca horizontal

2 Perillas de la barra horizontal

3 Perilla de ajuste del peine

4 Perillas de ajuste de la guía

5 Guía

6 Tope horizontal

7 Plantilla

8 Tope vertical

9 Perillas de ajuste vertical

10 Palanca vertical

Desembalaje

• Desembale e inspeccione la herramienta con cuidado. Tenga cuidado con

los cantos afilados.

• Esta herramienta se suministra con la palanca horizontal (1) y vertical

(10) aflojadas. Antes de utilizar la plantilla deberá atornillar las palancas

en sus agujeros correspondientes. La palanca vertical debe colocarse en

la parte posterior de la plantilla, la palanca vertical debe colocarse en la

parte frontal de la plantilla (7).

16

Page 18

633936 Plantilla para juntas cola de milano 300 mm

Montaje

• Esta plantilla debe montarse firmemente sobre un banco de trabajo

resistente.

• La plantilla debe fijarse al banco de trabajo introduciendo los cuatro

tornillos de madera a través de los orificios situados en la carcasa de

la plantilla.

• Si desea instalar la plantilla temporalmente, utilice un trozo de madera y

abrazaderas para sujetarla sobre su banco de trabajo.

Instrucciones de funcionamiento

ADVERTENCIA: La fresa nunca debe entrar en contacto con la plantilla.

Utilice siempre un casquillo copiador y una fresa del tamaño adecuado; si

utiliza una fresa incorrecta, las juntas quedarán mal realizadas y dañará

la plantilla.

Configuración de la fresadora

Nota: Estas instrucciones están basadas en la utilización de accesorios

recomendados para esta plantilla. El uso de otros accesorios puede variar

los métodos y pasos descritos a continuación.

Esta plantilla es totalmente compatible con fresadoras de 12,7 mm (1⁄2") y 6

mm (1⁄4"). Es probable que necesite utilizar una pinza de apriete adicional o

un reductor cuando desee utilizar fresas de 1⁄4" (6 mm).

1. Coloque una placa en su fresadora para instalar los casquillos

copiadores.

2. Instale un casquillo copiador con diámetro exterior de 11,1 – 12

mm (7⁄16") para que la fresa de 12,7 mm (1⁄2") pueda moverse

adecuadamente a través de la ranuras de la plantilla (7). El grosor del

casquillo nunca debe superar el grosor del peine de la plantilla.

3. Coloque una fresa para juntas cola de milano de 12,7 mm (1⁄2") 14°

y vástago de 6 mm (1⁄4"). La altura de la fresa debe ajustarse para

que no entre en contacto con la plantilla. La fresa debe colocarse

aproximadamente a 17 mm de la base de la fresadora. Ver Fig. A.

Preparación

Esta plantilla está diseñada para realizar juntas cola de milano en cajones,

cajas y objetos similares. La información indicada a continuación es

solamente orientativa. Para obtener resultados profesionales deberá

familiarizarse antes con las funciones de esta herramienta y tomar las

medidas exactas.

Esta plantilla se utiliza para realizar juntas cola de milano mediante un

sólo corte. Esto tipo de corte se realiza colocando 2 trozos de maderas

diferentes y desplazándolas ligeramente. La Fig. B. muestra la posición

adecuada de las piezas de madera antes de realizar el corte definitivo

mostrado en la Fig. C.

• La madera debe cortarse al tamaño correcto. Tenga en cuenta la

profundidad de la junta y el tamaño de la madera antes de realizar un

corte.

• Utilice un lápiz para nombrar todos los lados de la pieza de madera (parte

posterior, frontal, izquierda, derecha, interior, exterior). También puede

marcar con números las juntas a cortar.

IMPORTANTE: Se recomienda el uso de una escuadra para comprobar el

ángulo antes de ajustar definitivamente la plantilla. Para conseguir un corte

de calidad es imprescindible que las piezas de madera estén correctamente

alineadas. Practique antes con un trozo de madera desechable hasta

conseguir el resultado deseado.

Ajuste de los topes verticales y horizontales

Nota: Para ajustar los topes horizontales (6) y verticales (8) necesitará

utilizar una llave (no incluida).

1. Afloje las perillas de la barra horizontal (2) y vertical (9) y eleve la

palanca horizontal (1) y vertical (10) para acceder a las tuercas de los

topes fácilmente.

2. Ajuste el tope horizontal izquierdo (6) hasta que la plantilla (7) este

colocada para realizar la primera junta hembra. El tope vertical

izquierdo (8) debe estar colocado a 12,7 mm (1⁄2") del tope horizontal

derecho (6). Esta es la anchura aproximada que tiene una de las

espigas del peine de la plantilla.

• La posición del tope horizontal en relación con la espiga del peine puede

variar dependiendo del tipo de borde requerido. El borde es la distancia

que existe entre el canto de la pieza de madera y la primera junta de

espiga. El espacio entre las dos piezas de madera es igual que el grosor

del primer corte 12,7 mm (1⁄2") para alinear dos piezas con la misma

anchura. Una vez realizado el corte, la madera mostrada en la Fig. B

tendrá un borde más pequeño que la de la Fig. C.

• Utilice el tope horizontal y vertical derecho para fijar y alinear piezas de

madera largas en el centro de la plantilla. Los topes derechos también

pueden utilizarse junto con otras dos piezas de madera adicionales para

realizar dos cortes simultáneamente.

• Cuando sujete dos piezas de madera, puede utilizar las perillas de la

barra horizontal (2) y vertical (9) en lugar de la palanca horizontal (1) y

vertical (10) para ajustar la pieza de madera hacia la izquierda o derecha

sin tener que variar la posición de las piezas de madera del lado opuesto.

• Se recomienda no volver a ajustar los topes después de haberlos

colocado y alineado con las piezas de madera. Alternativamente, una

vez haya obtenido el espacio requerido entre el los topes verticales y

horizontales, puede utilizar un trozo de madera como espaciador para

utilizarlo como plantilla en piezas de madera de diferente grosor.

Sujeción y colocación de la pieza de madera

1. Deslice la palanca horizontal (1) hacia la parte posterior de la plantilla,

afloje las 2 perillas de la barra horizontal (2) y deslice la pieza de

madera a través de la parte posterior de la plantilla.

2. La pieza de madera debe pasar por debajo de la guía y la plantilla (7).

El lado izquierdo de la pieza de madera debe apoyarse sobre la parte

derecha del tope horizontal (6), la parte frontal debe de estar alineada

con la plantilla para que la madera vertical pueda colocarse en la parte

frontal de la plantilla (Fig. B).

3. Apriete las perillas de la barra horizontal (2). Compruebe que la pieza

de madera esté en la posición adecuada, a continuación, tire de la

palanca horizontal para fijar la pieza de madera.

• Las abrazaderas deben de ajustarse para que la pieza de madera pueda

introducirse sin necesidad de utilizar las perillas ajuste.

• No intente nunca forzar la palanca. Afloje las perillas de ajuste hasta que

la pieza de madera quede sujeta sin forzar el mecanismo de sujeción

para evitar dañar la herramienta.

4. Tire de la palanca vertical (10) hacia arriba para desbloquearla y afloje

las perillas de ajuste vertical (9).

5. Asegúrese de introducir la pieza de madera vertical correctamente

cuando esta haya sido cortada previamente en uno de los lados. Una

vez haya realizado el corte cola de milano, la pieza de madera vertical

deberá encajar perfectamente en ángulo de 180° sobre la ranura de la

pieza de madera horizontal.

6. Coloque la pieza de madera vertical en la parte frontal de la plantilla.

La pieza de madera debe pasar por detrás de las abrazaderas

frontales y debe estar en contacto con el borde vertical de la plantilla.

7. Coloque la pieza de madera contra el tope vertical (8).

8. Ajuste las perillas de ajuste para que la pieza de madera pueda

introducirse adecuadamente pero sin obstruir el mecanismo de

palanca.

9. Alinee la pieza de madera vertical con la pieza horizontal tal como se

muestra en la Fig. B.

10.Baje la palanca para sujetar la pieza de madrera en la posición

requerida.

www.silverlinetools.com

17

Page 19

ESP

Ajuste de la plantilla

Para ajustar la posición de la plantilla (7), afloje las perillas de ajuste del

peine (3) y ajuste la plantilla dependiendo del grosor de la pieza de madera.

Las puntas del peine de la plantilla deben de estar a 2,5 mm del borde de

la pieza de madera vertical. Asegúrese de que el peine esté paralelo a la

plantilla en todo momento.

Ajuste de la guía

La guía sirve para limitar el movimiento de la base de la fresadora y la

profundidad del corte hembra. No existen distancias predefinidas, el ajuste

correcto dependerá del tamaño de la base redonda de su fresadora y del

grosor de la pieza de madera. Puede calcular la distancia utilizando esta

fórmula:

Distancia= (grosor de la pieza de madera vertical x 2) + (1⁄2 anchura de

la base de la fresadora) - (el radio de la fresa)

Las medidas se deben tomar desde la guía hasta el final del peine de la

plantilla (7). Cuando utilice una fresa para cola de milano de 12,7 mm (1⁄2"),

el radio de la fresa será de 6,35 mm (1⁄4").

Nota: Cuando utilice una fresadora sin base redonda (con 2 bases planas),

deberá medir la distancia desde el centro de la base hasta el borde más

cercano al centro de la base. Recuerde que deberá utilizar la fresadora

que ha medido previamente. Si utiliza la fresadora por la parte más ancha

de la base podría correr el riesgo de que la fresa entre en contacto con la

plantilla.

Realizar una junta cola de milano

1. Compruebe que la fresadora y la plantilla estén ajustadas

correctamente. Si es necesario, se recomienda practicar primero con

un trozo de madera desechable.

2. Lleve puesto equipo de protección personal adecuado, incluido

mascara respiratoria. Algunas partículas pueden ser tóxicas,

especialmente en maderas sintéticas.

3. Ajuste la velocidad de la fresadora y asegúrese de que no exceda la

velocidad máxima de la fresa.

4. Coloque la fresadora sobre la plantilla (7) sin que la fresa entre en

contacto con la pieza de madera.

5. Sujete la fresadora firmemente y deje que el motor alcance su

velocidad máxima.

6. Comience el corte, deje que el casquillo copiador se desplace a través

las ranuras del peine de la plantilla. Comience el corte de izquierda a

derecha. Realice el corte entero en una sola pasada y sin pausas. El

resultado final será similar a la imagen de la Fig. C.

7. Asegúrese de que la fresa nunca entre en contacto con ninguna parte

de la platilla. Nunca levante la fresadora mientras esté cortando. Una

vez realizado el corte, deje que la fresa se detenga completamente

antes de sacar la fresadora de la plantilla.

• Después de cada corte, retire la pieza de madera y compruebe la junta.

Los encajes de la junta no deben de estar ni muy sueltos ni tampoco

muy apretados. Utilice un martillo para golpear ligeramente y encajar

ambas juntas.

• Si la junta no es correcta, corte el trozo de la junta y practique en la

misma pieza hasta conseguir el ajuste correcto.

Accesorios opcionales

Existen gran variedad de accesorios para esta herramienta disponibles a

través de su distribuidor Silverline más cercano.

245122 - Juego de 10 casquillos copiadores, incluido casquillo de 11,1

mm (7⁄16").

792084- Juego de 12 fresas TCT de 1⁄4" (incluye fresa para cola de milano

½" 14°).

656577 – Juego de 24 fresas TCT de 1⁄4" (incluye fresa para cola de milano

½" 14°).

Mantenimiento

Mantenga la plantilla siempre limpia. No deje que el polvo se acumule en

la herramienta. Limpie la herramienta regularmente con un cepillo suave o

una aspiradora. Limpie los restos de resina con un disolvente adecuado.

18

Page 20

633936 Plantilla para juntas cola de milano 300 mm

Solución de problemas

Problema Solución

La junta cola de milano no está en un ángulo de 90°. Compruebe que la pieza de madera esté colocada y sujeta adecuadamente.

La junta cola de milano está ligeramente inclinada.

Al unir las juntas las 2 piezas de maderas no están alineadas.

Las espigas de la junta son muy largas o demasiado cortas.

La junta queda muy estrecha.

La junta queda demasiado suelta.

Astillas en la pieza de madera al retirar la fresa.

Compruebe el ángulo de inclinación de la pieza de madera y que los topes

horizontales y verticales estén colocados adecuadamente.

Ajuste el espacio del tope horizontal.

Ajuste la guía más lejos o cerca de la plantilla (7).

Disminuya la altura de la fresa desde la base de su fresadora.

Incremente la altura de la fresa desde la base de su fresadora.

Coloque una pieza de madera adicional sobre la pieza de madera vertical.

Frese con más precaución.

Marque previamente una línea de corte en la pieza de madera.

Asegúrese de realizar el corte con las cuchillas de la fresa.

www.silverlinetools.com

19

Page 21

I

Specifiche tecniche

Sagoma: ..................................................... 12.7mm

Boccola di guida (non inclusa): ................... 11.1mm

Fresa per scanalatura (non inclusa): ........... 6.35mm -

codolo -12.7mm x 14˚ coda di rondine

Spessore massimo pezzo: .......................... 32mm

Raggio larghezza orizzontale: ..................... 140 – 300mm

Raggio larghezza verticale: ......................... 150 – 275mm

Peso: .......................................................... 9.5kg

Norme generali di sicurezza

AVVERTENZA: Leggere ed assimilare tutte le istruzioni. La non

osservanza delle seguenti istruzioni può causare scosse elettriche, incendi

e/o lesioni gravi.

Conservare tutte le avvertenze di pericolo e le istruzioni operative per

ogni esigenza futura.

Area di lavoro

a) Mantenere l’area di lavoro pulita e adeguatamente illuminata. Il

disordine e le zone di lavoro non illuminate possono essere fonte di

incidenti.

b) Non usare gli elettroutensili in presenza di atmosfere esplosive,

come liquidi, gas e polveri infiammabili.

c) Tenere altre persone e i bambini a distanza di sicurezza durante

l’impiego dell’utensile elettrico. Eventuali distrazioni potrebbero far

perdere il controllo dell’utensile all’operatore.

Sicurezza elettrica

a) È importante concentrarsi su ciò che si sta facendo e usare il

buon senso quando si utilizza uno strumento alimentato. Non

utilizzare uno strumento di potenza quando si è stanchi o sotto l'effetto

di droghe, alcol o medicinali. Un attimo di distrazione durante la guida

di uno strumento alimentato può provocare gravi lesioni personali.

b) Utilizzare i dispositivi di protezione. Indossare sempre protezioni

per gli occhi. Dispositivi di protezione come la maschera antipolvere,

scarpe di sicurezza anti-scivolo, casco, oppure protezione acustica

nelle condizioni appropriate potrà ridurre il rischio di ferite.

c) Evitare l'accensione involontaria. Assicurarsi che l'interruttore è in

posizione OFF quando non si utilizza lo strumento e fare uso di altre

caratteristiche di sicurezza che impediscono l'avviamento involontario

d) Rimuovere qualsiasi chiave di regolazione prima di accendere

lo strumento. Una chiave lasciata collegata alla parte sinistra di una

parte rotante della macchina può provocare lesioni personali.

e) Non sbilanciarsi. Tenere i piedi, in equilibrio in ogni momento.

Questo consente un migliore controllo dello strumento in situazioni

impreviste.

f) Indossare un abbigliamento adatto. Non indossare abiti larghi

o gioielli. Tenere i capelli, i vestiti ed i guanti lontani da pezzi in

movimento. Vestiti larghi, gioielli o capelli lunghi potranno impigliarsi

nelle parti in movimento.

g) Se i dispositivi sono previsti per il collegamento di aspirazione