Page 1

Guaranteed Forever

*Register online within 30

days. Terms & Conditions apply

Garantie à vie

*Enregistrez votre produit en ligne

dans les 30 jours. Sous réserve des

termes et conditions appliquées

Lebenslange Garantie

*Innerhalb von 30 Tagen online

registrieren. Es gelten die Allgemeinen

Geschäftsbedingungen

www.silverlinetools.com

Garantía de por vida

*Regístrese online dentro de 30 días.

Se aplican los términos y condiciones

Garanzia a vita

*Registrare il vostro prodotto on-line entro

30 giorni. Termini e condizioni si applicano

Levenslange garantie

*Registreer uw product binnen 30

dagen online. Algemene voorwaarden

zijn van toepassing

Page 2

4 Ton

Cable Puller Heavy Duty

598501

Cable Puller Heavy Duty

Palan-tendeur de traction

Schwerlast-Greifzug

www.silverlinetools.com

Polipasto de tracción resistente

Tenditore resistente del cavo

'Heavy-Duty' treklier

Page 3

2

3

6

7

4 5

1

Fig 1

8

2

Page 4

4 Ton

Cable Puller Heavy Duty

English .................. 4

Français ................ 8

Deutsch ................. 12

®

Español ................. 16

Italiano .................. 20

Nederlands ............ 24

www.silverlinetools.com

3

Page 5

GB

Description of Symbols

The rating plate on your tool may show symbols. These represent important

information about the product or instructions on its use

Wear hearing protection

Wear eye protection

Wear breathing protection

Wear head protection

Wear hand protection

Read instruction manual

WARNING: Moving parts can cause crush and cut injuries

Conforms to relevant legislation and safety standards

Specification

Max. pulling capacity: ............................................4000kg

Cable diameter: .....................................................5.5mm x 3m

Ratchet system: ..................................................... Double

Leverage ratio: ....................................................... 15:1

Note: Pulling capacity is given as a rolling load on a level surface.

Exercise extreme caution and do not overload, particularly on

‘deadweight’ loads.

General Safety Warnings

WARNING Read all safety warnings and all instructions. Failure to

follow the warnings and instructions may result in a serious injury.

WARNING: This tool is not intended for use by persons

(including children) with reduced, physical or mental

capabilities or lack of experience or knowledge unless they have been

given supervision or instruction concerning use of the tool by a person

responsible for their safety. Children must be supervised to ensure that

they do not play with the tool.

Save all warnings and instructions for future reference.

Work area safety

a) Keep work area clean and well lit. Cluttered or dark areas invite

accidents.

b) Do not operate tools in explosive atmospheres, such as in the

presence of flammable liquids, gases or dust.

c) Keep children and bystanders away while operating or using this

tool. Distractions can cause you to lose control.

Personal safety

a) Stay alert, watch what you are doing and use common sense

when operating or using this tool. Do not operate or use the tool

while you are tired or under the influence of drugs, alcohol or

medication. A moment of inattention while operating or using the tool

may result in serious personal injury. Work sensibly at all times with

regular breaks if necessary.

b) Use personal protective equipment. Always wear eye protection.

Protective equipment such as dust mask, non-skid safety shoes, hard

hat, or hearing protection used for appropriate conditions will reduce

personal injuries.

c) Remove any adjusting key or wrench before operating the tool. A

wrench or a key left attached to a rotating part of the tool may result

in personal injury.

d) Do not overreach. Keep proper footing and balance at all times.

This enables better control of the tool in unexpected situations.

e) Dress properly. Do not wear loose clothing or jewelry. Keep your

hair, clothing and gloves away from moving parts. Loose clothes,

jewelry or long hair can be caught in moving parts.

Tool use and care

IMPORTANT: Tools used outdoors may require more regular cleaning and

surface treatment to prevent corrosion, as well as replacement grease or oil

on moving parts to maintain them in good working condition.

a) Maintain tools. Check for misalignment or binding of moving

parts, breakage of parts and any other condition that may affect

the tool’s operation. If damaged, have the tool repaired before

use. Many accidents are caused by poorly maintained tools.

b) Keep cutting tools sharp and clean. Properly maintained cutting

tools with sharp cutting edges are less likely to bind and are easier

to control.

c) Use the tool’s accessories and tool bits etc. in accordance with

these instructions, taking into account the working conditions

and the work to be performed. Use of the tool for operations

different from those intended could result in a hazardous situation.

Service

a) Have your tool serviced or repaired by a qualified repair person

using only identical replacement parts. This will ensure that the

safety of the tool is maintained.

4

Page 6

Pulling Tool Safety

Ensure your cable puller is maintained in a safe working condition. Observe

the following important guidance:

• Before each use, check the condition of the equipment. Pay particular

attention to cables and locking mechanisms

• Cables should be free from kinks and should not show any evidence of

fraying or cutting

• Locking mechanisms should work freely and should be clean of

excessive dirt or grease

• Ensure the safety latches on the hooks are closed and the load is secure

before pulling commences

• Test all safety devices (including automatic) before use

• DO NOT attempt to pull items around or over a corner

• DO NOT wrap cable around any object and hook it back on itself

• DO NOT OVERLOAD: Ensure the weight of all loads is within the capacity

of this equipment (see specification)

• DO NOT LIFT with this puller. This equipment is not designed to hoist

• When pulling, allow for rolling resistance which will significantly increase

the weight of an object – particularly in cases when pulling through mud,

snow or water

• Take into account any angle of incline over which the load will be pulled

• Use an adequate sling, eyebolt or other attachment on the load to be

pulled and ensure that there is a positive engagement of the puller hook

to the load

• Do not use a pipe, lever or other device to lengthen the handle for

additional leverage; the pulley may fail, causing damage and/or personal

injury

• Under no circumstances use pulling equipment to pull people or objects

with people attached

• Do not modify any pulling equipment. Any attempt to tamper with this

equipment will invalidate its guarantee, and could result in serious injury

to yourself or others around you

• Pulling equipment should be inspected by a qualified person at least once

each year and the results of the inspection recorded in an inspection

book for future reference

• If you are in any way unsure about the safe method of using this

equipment, do not use it

Cable Puller Heavy Duty598501

www.silverlinetools.com

5

Page 7

GB

Product Familiarisation

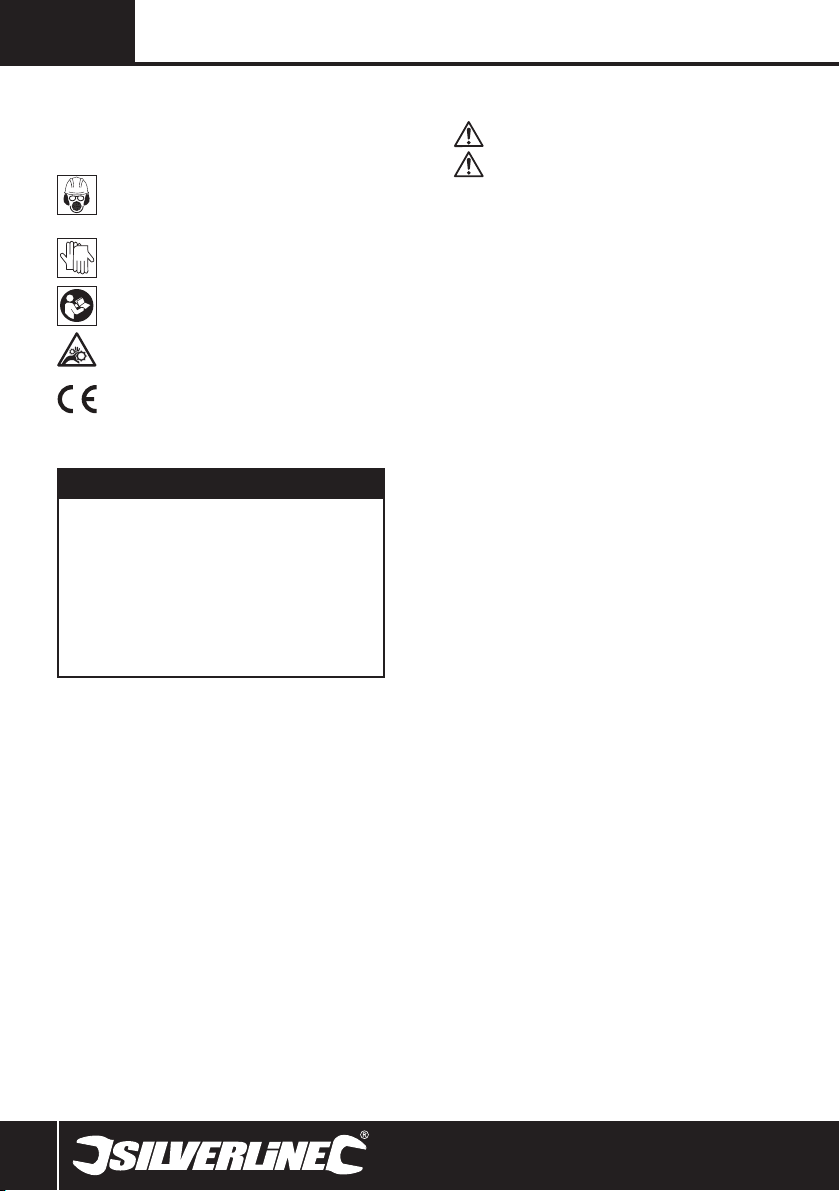

1. Fixed Hook

2. Safety Bar

3. Ratchet Lock Lever

4. Ratchet Teeth

5. Ratchet Drive Spring

6. Cable

7. Cable Hook

8. Handle

Unpacking Your Tool

Carefully unpack and inspect your tool. Fully familiarise yourself with all

features and functions of it

Ensure that all parts of the tool are present and in good condition. If any

parts are missing or damaged, have such parts replaced before attempting

to use this tool

Operation

Attaching the Cable Puller

• Attach the Fixed Hook (1) onto the item to be pulled. Ensure the total load

will not exceed 4 ton

• Check the item is securely attached and the Safety Bar (2) is closed

• Slide the Ratchet Drive Spring (5) across to the disengaged position so

that the handle does not engage the Ratchet Teeth (4)

• Press the Ratchet Lock Lever (3) and unwind sufficient Cable (6) from

the spool to attach the Cable Hook (7) to the anchor position. Release

the ratchet lock lever. Ensure hook is securely attached and safety bar

is closed

Pulling

• Slide the Ratchet Drive Spring (5) across to the engaged position so that

the handle engages the ratchet teeth

• Crank the Handle (8) backwards and forwards to tension the cable and

pull the load

Releasing the tension

1. Slide the Ratchet Drive Spring (5) across to the disengaged position so

that the handle does not engage the Ratchet Teeth (4) (Fig 1)

2. Crank the Handle (8) to operate the reverse step mechanism. Each crank

will step the ratchet back one tooth

3. Repeat until enough slack has been provided so that you can remove the

hooks

4. Ensure load is stable and secure before removing hooks

WARNING: When releasing tension, avoid abrupt handle movements.

Apply pressure to the handle evenly and with a smooth action.

Abrupt movements can cause the load to shift, making it unstable

Maintenance and Storage

• Keep the Cable Puller clean and in good order. Store with the cable fully

wound on the spool

• Carry out a visual inspection every time the Cable Puller is used and

listen for any unusual sounds during operation

• Store in a safe, secure and dry place out of the reach of children

• Never disassemble the Cable Puller

• Inspect the mechanism before every use

6

Page 8

598501 Cable Puller Heavy Duty

Silverline Tools Guarantee

This Silverline product comes with a forever

guarantee

Register this product at www.silverlinetools.com within 30 days of

purchase in order to qualify for the forever guarantee. Guarantee period

begins according to the date of purchase on your sales receipt.

Registering your purchase

Registration is made at silverlinetools.com by selecting the Guarantee

Registration button. You will need to enter:-

• Your personal details

• Details of the product and purchase information

Once this information is entered your guarantee certificate will be created

in PDF format for you to print out and keep with your purchase.

Terms & Conditions

Guarantee period becomes effective from the date of retail purchase as

detailed on your sales receipt.

PLEASE KEEP YOUR SALES RECEIPT

If this product develops a fault within 30 days of purchase, return it to the

stockist where it was purchased, with your receipt, stating details of the

fault. You will receive a replacement or refund.

If this product develops a fault after the 30 day period, return it to:

Silverline Tools Service Centre

PO Box 2988

Yeovil

BA21 1WU, UK

The guarantee claim must be submitted during the guarantee period.

You must provide the original sales receipt indicating the purchase date,

your name, address and place of purchase before any work can be

carried out.

You must provide precise details of the fault requiring correction.

Claims made within the guarantee period will be verified by Silverline Tools

to establish if the deficiencies are related to material or manufacturing of

the product.

Carriage will not be refunded. Items for return must be in a suitably clean

and safe state for repair, and should be packaged carefully to prevent

damage or injury during transportation. We may reject unsuitable or

unsafe deliveries.

All work will be carried out by Silverline Tools or its authorized

repair agents.

The repair or replacement of the product will not extend the period

of guarantee

Defects recognised by us as being covered by the guarantee shall be

corrected by means of repair of the tool, free of charge (excluding carriage

charges) or by replacement with a tool in perfect working order.

Retained tools, or parts, for which a replacement has been issued, will

become the property of Silverline Tools.

The repair or replacement of your product under guarantee provides

benefits which are additional to and do not affect your statutory rights as

a consumer.

What is covered:

The repair of the product, if it can be verified to the satisfaction of Silverline

Tools that the deficiencies were due to faulty materials or workmanship

within the guarantee period.

If any part is no longer available or out of manufacture, Silverline Tools will

replace it with a functional replacement part.

Use of this product in the EU.

What is not covered:

Silverline Tools does not guarantee repairs required as a result of:

Normal wear and tear caused by use in accordance with the operating

instructions eg blades, brushes, belts, bulbs, batteries etc.

The replacement of any provided accessories drill bits, blades, sanding

sheets, cutting discs and other related items.

Accidental damage, faults caused by negligent use or care, misuse,

neglect, careless operation or handling of the product.

Use of the product for anything other than normal domestic purposes.

Change or modification of the product in any way.

Use of parts and accessories which are not genuine Silverline Tools

components.

Faulty installation (except installed by Silverline Tools).

Repairs or alterations carried out by parties other than Silverline Tools or its

authorized repair agents.

Claims other than the right to correction of faults on the tool named in

these guarantee conditions are not covered by the guarantee.

EC Declaration of Conformity

The undersigned: Mr Darrell Morris

as authorised by: Silverline Tools

Declares that

Identification code: 598501

Description: Cable Puller Heavy Duty

Conforms to the following directives and standards:

• Machinery Directive 2006/42/EC

• EN 12100:2010

• EN 1492-2:2000+A1:2008

Notified body: Ente Certificazione Macchine, Ningbo, China

The technical documentation is kept by: Silverline Tools

Date: 2/08/2013

Signed:

Director

Name and address of the manufacturer:

Powerbox, Boundary Way, Lufton Trading Estate, Yeovil, Somerset,

BA22 8HZ, United Kingdom

www.silverlinetools.com

7

Page 9

F

Description des symboles

La plaque signalétique figurant sur votre outil peut présenter des symboles.

Ces symboles constituent des informations importantes relatives au produit

ou des instructions concernant son utilisation.

Port de protection auditive

Port de lunettes de sécurité

Port de masques respiratoires

Port du casque

Port de gants

Lire le manuel d’instructions

ATTENTION : les pièces mobiles peuvent engendrer des

écrasements et des coupures.

Conforme à la réglementation et aux normes de sécurité

pertinentes

Caractéristiques techniques

Max. capacité de traction : .............................................4000 kg

Câble : ...........................................................................5,5 mm x 3 m

Cliquet : ........................................................................Double

Rapport de démultiplication : ......................................... 15:1

Remarque : la capacité de traction est donnée par rapport à une charge

roulante. Faites extrêmement attention de ne pas travailler en surcharge,

et particulièrement avec un système de poids mort.

Consignes générales de sécurité

ATTENTION : Veuillez lire l’intégralité des consignes de sécurité

et des instructions. Le non-respect de ces consignes et instructions

peut entraîner un risque de choc électrique, d’incendie et/ou se traduire par

des blessures graves.

ATTENTION : Cet appareil n’est pas conçu pour être utilisé par des

personnes (enfants compris) ayant des capacités physiques ou

mentales réduites, ou n’ayant pas la connaissance ou l’expérience requise,

à moins d’être sous la supervision d’une personne responsable de leur

sécurité ou d’avoir reçu les instructions nécessaires. Les enfants ne doivent

pas s’approcher et jouer avec cet appareil.

Veuillez conserver ces instructions et consignes de sécurité pour

référence ultérieure.

Sécurité sur la zone de travail

a) Maintenir une zone de travail propre et bien éclairée. Des zones

encombrées et mal éclairées sont sources d’accidents.

b) Ne pas utiliser d’outils dans des environnements explosifs,

tels qu’à proximité de liquides, de gaz ou de poussières

inflammables.

c) Eloigner les enfants et les passants pendant l’utilisation d’un

appareil électrique. Ceux-ci peuvent provoquer une perte d’attention

et faire perdre la maîtrise de l’appareil.

Sécurité des personnes

a) Rester vigilent et faire preuve de bon sens lors de la manipulation

de l’appareil. Ne pas utiliser un appareil électrique lorsque

l’on se trouve dans un état de fatigue, ou sous l’influence de

drogues, d’alcool ou de médicaments. Un moment d’inattention

pendant l’utilisation d’un outil électrique peut se traduire par des

blessures graves.

b) Porter un équipement de protection approprié. Toujours porter

une protection oculaire. Le port de masque à poussières,

chaussures de sécurité antidérapantes, casque de sécurité et

protections antibruit adaptés aux différentes conditions de travail

réduit le risque de blessures corporelles.

c) Enlever toute clé et tout instrument de réglage avant de mettre

l’appareil en marche. Une clé ou un instrument de réglage laissé fixé

à un élément en rotation de l’appareil peut entraîner des blessures.

d) Ne pas essayer d’atteindre une zone hors de portée. Se tenir

toujours en position stable permettant de conserver l’équilibre.

Cela permet de mieux contrôler l’appareil électrique dans des

situations inattendues.

e) Porter des vêtements appropriés. Ne pas porter de vêtements

amples ou des bijoux pendants. Eloigner cheveux, vêtements

et gants des pièces en mouvement. Les vêtements amples, les

bijoux pendants et cheveux longs peuvent être happés par les

pièces en rotation

Utilisation et entretien des appareils

Important : Des appareils utilisé à l’extérieur peuvent demander un

entretien plus régulier, particulièrement un traitement anticorrosion

des surfaces, ainsi que le graissage ou la lubrification des éléments

mobiles pour garder le produit en bonne condition

a) Entretien des appareils. Vérifier que les éléments rotatifs

soient bien alignés et non grippés. S’assurer de l’absence de

pièces cassées ou endommagées susceptibles de nuire au bon

fonctionnement de l'appareil. Si l’appareil est endommagé, le

faire réparer avant toute utilisation. De nombreux accidents sont

dus à un mauvais entretien d’un outil.

b) Veiller à ce que les outils de coupe soient tenus affûtés et

propres. Des outils de coupe bien entretenus, aux tranchants bien

affûtés, sont moins susceptibles de se gripper et sont plus faciles à

contrôler.

c) Utiliser l’appareil, les accessoires et outils à monter

conformément à ces instructions, en tenant compte des

conditions de travail et de la tâche à réaliser. Toute utilisation d’un

appareil autre que celle pour laquelle il a été conçu peut entraîner des

situations à risque.

8

Page 10

598501 Palan-tendeur de traction

Révision

a) Ne faire réparer ou entretenir votre appareil électrique que

par un réparateur qualifié utilisant uniquement des pièces de

rechange identiques.

Consignes de sécurité relatives

aux outils de traction

Veillez à conserver le bon état de fonctionnement et de sécurité de votre

palan. Veuillez observer les consignes ci-dessous :

• Avant toute utilisation, vérifiez l’état de l’équipement. Soyez

particulièrement attentif aux câbles et aux mécanismes de blocage.

• Veillez à ce que les câbles ne soient ni vrillés ni coudés et qu’ils ne

présentent aucun signe d’effilochage ou de coupure.

• Vérifiez que les mécanismes de blocage fonctionnent sans entrave et

restent exempts de présence excessive de graisse et d’encrassement.

• Testez tous les dispositifs de sécurité (y compris les dispositifs

automatiques) préalablement à l’utilisation.

• NE PAS tenter de tirer un objet s’il y a un coin

• NE PAS entourer le câble autour de l’objet et de de crocheter sur

lui-même

• NE PAS surcharger : vérifier que le poids de toute charge soit compatible

avec la capacité de cet équipement (voir les caractéristiques techniques).

• NE PAS effectuer de levage. Cet équipement n’est pas conçu pour hisser.

• Lors de l’opération de traction, pensez à la résistance de roulement qui

augmente le poids de l’objet, surtout dans les cas de tractions sur de la

boue, neige ou eau.

• Prenez en considération les angles d’inclination pour la traction.

• Utilisez une élingue, piton ou autres systèmes de fixations adéquates

pour la charge et vérifiez le bon fonctionnement du crochet sur le point

d’attache de la charge.

• N’utilisez pas de barre ou de levier pour rallonger la poignée et

augmenter la force d’appui. Cela peut provoquer un mauvais

fonctionnement du palan, l’endommager, et provoquer des blessures.

• Sous aucune circonstance, ne pas utiliser les équipements de traction,

pour tirer des personnes ou des objets sur lesquels des personnes sont

attachées.

• Ne modifiez pas votre équipement de traction. Toute tentative de

modification de l’équipement entraînera une invalidation de sa garantie

et pourrait engendrer un risque de blessures graves chez l’utilisateur

comme chez les personnes présentes à proximité de l’équipement.

• Les équipements de traction doivent être soumis à une révision annuelle

par une personne qualifiée et les résultats de l’inspection consignés dans

un livret approprié pour référence ultérieure.

• Si vous n’êtes pas certains de la bonne utilisation de cet équipement

dans les conditions de sécurité optimales, ne pas l’utiliser.

www.silverlinetools.com

9

Page 11

F

Présentation du produit

1. Crochet fixe

2. Linguet

3. Levier de blocage du cliquet

4. Dents du cliquet

5. Ressort d’entraînement du cliquet

6. Câble

7. Crochet sur câble

8. Manette

Déballage

Déballez le produit avec soin. Veillez à retirer tout le matériau d’emballage

et familiarisez-vous avec toutes les caractéristiques du produit.

Si des pièces sont endommagées ou manquantes, faites-les réparer ou

remplacer avant d’utiliser l’appareil.

Sécurité à l’usage

• N’essayez PAS de tendre/tracter des objets en faisant passer le câble

sur un angle/coin.

• N’enroulez PAS le câble autour d’un objet et ne le raccrochez pas sur

lui-même.

• NE PAS SURCHARGER L’EQUIPEMENT : vérifiez que le poids total

des charges ne dépasse pas la capacité de traction de l’appareil (cf.

caractéristiques techniques).

• Lors des opérations de traction ou tension, tenez compte de la force de

résistance au roulement, qui entrainera une augmentation significative

du poids de l’objet, notamment lors de traction dans la boue, la neige

ou l’eau.

• Tenez compte de toute pente sur laquelle la charge doit être tractée.

• Assurez-vous que les linguets des crochets soient bien fermés et que la

charge soit bien arrimée avant de commencer à tracter.

• Utilisez une élingue, un œillet fileté ou tout autre dispositif de fixation

approprié pour la charge à tracter et assurez-vous que le crochet du

palan soit bien engagé avec la charge.

• N’essayez pas de prolonger la manette à l’aide d’un tuyau, levier ou

autre dispositif pour accroître l’effet de levier car ceci pourrait entraîner

une défaillance de l’appareil, avec un risque de dommages matériels et/

ou corporels.

• Les équipements de traction ne sont en aucune circonstance destinés

à être utilisés sur des personnes ou pour tracter des objets contenant

des personnes.

• Cet équipement est conçu pour des activités de traction, il N’EST PAS

DESTINÉ AU LEVAGE.

• Si vous n’êtes pas certain de la manière avec laquelle employer cet

équipement, ne l’utilisez pas.

Fonctionnement

Rattacher le palan-tendeur

• Attachez le crochet fixe (1) sur l’objet à tirer/tracter. Assurez-vous que la

charge totale ne dépasse pas 4 tonnes.

• Vérifiez que l’objet soit bien rattaché et que le linguet (2) soit fermé.

• Repoussez vers l’intérieur la partie du cliquet sur laquelle est fixé le

ressort d’entraînement du cliquet (5) pour la déboîter de sorte que la

manette ne soit plus en prise avec les dents du cliquet (4).

• Appuyez sur le levier de blocage du cliquet (3) et déroulez suffisamment

de câble (6) de l’enroulement pour pouvoir attacher le crochet sur câble

(7) à la position d’ancrage. Relâchez le levier de blocage du cliquet.

Assurez-vous que le crochet soit bien attaché et que le linguet soit fermé.

Traction

• Faites revenir la partie du cliquet sur laquelle est fixé le ressort

d’entraînement du cliquet (5) dans la position emboîtée de sorte que la

manette revienne en prise avec les dents du cliquet.

• Actionnez la manette (8) plusieurs fois que tendre le câble et tirer la

charge.

Détendre le câble

• Repoussez vers l’intérieur la partie du cliquet sur laquelle est fixé le

ressort d’entraînement du cliquet (5) pour la déboîter de sorte que la

manette ne soit plus en prise avec les dents du cliquet (4) (Fig 1).

• Actionnez la manette (8) pour activer le mécanisme en sens inverse.

Chaque actionnement fera remonter le cliquet d’un cran.

• Continuez l’opération jusqu’à ce que le câble soit suffisamment détendu

pour pouvoir retirer confortablement les crochets.

• Vérifiez que la charge soit stable et en position sure avant de retirer les

crochets.

ATTENTION : lors de la détente, évitez les actionnements brusques de la

manette. Exercez une pression uniforme sur la manette, sans à-coups.

Tout mouvement brusque peut entraîner un écart de la charge, ce qui

pourrait la rendre instable.

Entretien et rangement

• Veillez à garder le palan-tendeur propre et en bon état de marche.

Prenez-soin de rembobiner complètement le câble avant de ranger

l’équipement.

• Inspectez le palan-tendeur après chaque utilisation et tenez compte de

tout bruit anormal pendant l’utilisation

• Conservez l’équipement dans un endroit sûr et hors de portée des

enfants.

• Ne démontez jamais le palan-tendeur

• Inspectez le mécanisme avant chaque utilisation

10

Page 12

598501 Palan-tendeur de traction

Garantie Silverline Tools

Ce produit Silverline bénéficie d’une garantie

de 3 ans

Enregistrez votre produit sur www.silverlinetools.com dans les 30 jours

suivant l’achat pour pouvoir bénéficier de la garantie de 3 ans. La période

de garantie commence à partir de la date d’achat figurant sur votre facture

d’achat.

Enregistrement de votre achat

Sur le site silverlinetools.com, sélectionnez le bouton d’enregistrement

et saisissez :

• Vos informations personnelles,

• Les informations concernant le produit et l’achat.

Vous recevrez le Certificat de garantie au format PDF. Veuillez l’imprimer et

le conserver avec votre achat.

La période de garantie prend effet à compter de la date de l’achat en

magasin, indiquée sur votre facture d’achat.

VEUILLEZ CONSERVER VOTRE FACTURE D’ACHAT.

Si ce produit est défectueux pendant les 30 jours qui suivent l’achat,

retournez-le au magasin où vous l’avez acheté, avec votre facture, en

expliquant en détail le problème. Le produit sera remplacé ou vous serez

remboursé(e).

Si ce produit est défectueux après cette période de 30 jours,

retournez-le à :

Silverline Tools Service Centre

PO Box 2988

Yeovil

BA21 1WU

Royaume-Uni

Toute demande de service sous garantie doit être soumise pendant la

période de garantie.

Avant toute intervention sous garantie, veuillez présenter la facture d’achat

originale et indiquer la date d’achat, votre nom, votre adresse et le lieu

d’achat.

Veuillez expliquer en détail la défaillance nécessitant la réparation.

Les demandes de service sous garantie faites pendant la période de

garantie seront vérifiées par Silverline Tools pour établir si la défaillance du

produit est liée à un vice de matériau ou de fabrication.

Les frais de port ne seront pas remboursés. Les articles retournés doivent

se trouver dans un état de propreté et offrir une sécurité suffisante

pour permettre les travaux de réparation et doivent avoir été emballés

soigneusement pour éviter tout dommage ou toute blessure pendant le

transport. Nous pouvons refuser les livraisons qui ne sont pas convenables

ou sûres.

Toute intervention sera effectuée par Silverline Tools ou ses agents de

réparation agréés.

La réparation ou le remplacement du produit n’allongera pas la période

de garantie.

Les anomalies que nous reconnaissons être couvertes par la garantie

seront rectifiées par la réparation de l’outil, sans frais (hormis les

frais de port) ou par son remplacement par un outil en parfait état de

fonctionnement.

Déclaration de conformité CE

Le soussigné : Mr Darrell Morris

Autorisé par : Silverline Tools

Déclare que le produit :

Code d’identification : 598501

Description : Palan-tendeur de traction

Est conforme aux directives suivantes :

• Directives relatives à la machinerie : 2006/42/CE

• EN 12100:2010

• EN 1492-2:2000+A1:2008

Conditions de garantie des outils Silverline

Les pièces ou les outils remplacés deviendront la propriété de

Silverline Tools.

La réparation ou le remplacement de votre produit sous garantie vous

apporte des avantages ; ces avantages s’ajoutent à vos droits statutaires

en tant que consommateur sans les affecter aucunement.

La présente garantie couvre :

La réparation du produit, s’il peut être vérifié, à la satisfaction de Silverline

Tools, que les défaillances du produit ont été provoquées par un vice de

matériau ou de fabrication au cours de la période de garantie.

L’utilisation de ce produit dans l’UE

Si une pièce n’est plus disponible ou n’est plus fabriquée, Silverline Tools la

remplacera par une pièce de rechange opérationnelle.

La présente garantie ne couvre pas :

Silverline Tools ne garantit pas les réparations du produit engendrées par :

L’usure normale provoquée par l’utilisation conforme aux instructions

d’utilisation, concernant par exemple les lames, les charbons, les

courroies, les ampoules, les batteries, etc.

Le remplacement de tout accessoire fourni tel que les forets, les lames, les

feuilles abrasives, les outils de coupes et autres articles associés.

Les dommages et les défaillances accidentels causés par des négligences

d’utilisation ou d’entretien, une utilisation impropre, une utilisation ou une

manipulation inconsidérée du produit.

L’utilisation du produit à des fins autres que son utilisation domestique

normale.

La moindre modification ou altération du produit.

L’utilisation de pièces et d’accessoires qui ne sont pas des composants

d’origines Silverline Tools.

Une installation défectueuse (sauf si l’installation a été réalisée par

Silverline Tools).

Les réparations ou les modifications réalisées par des tiers autres que

Silverline Tools ou ses agents de réparation agréés.

Toute demande de service autre que le droit de rectifier les défaillances

de l’outil indiquées dans les présentes conditions de garantie ne sont pas

couvertes par la présente garantie.

Organisme notifié : Ente Certificazione Macchine, Ningbo, Chine

La documentation technique est conservée par : Silverline Tools

Date : 02/08/2013

Signature :

Directeur général

Nom et adresse du fabricant ou de son représentant agréé :

Powerbox, Boundary Way, Lufton Trading Estate, Yeovil, Somerset,

BA22 8HZ Royaume-Uni

www.silverlinetools.com

11

Page 13

D

Beschreibung der Symbole

Auf dem Leistungsschild des Werkzeugs sind möglicherweise Symbole

abgebildet. Sie vermitteln wichtige Informationen über das Produkt oder

dienen als Gebrauchsanweisung.

Gehörschutz tragen

Augenschutz tragen

Atemschutz tragen

Kopfschutz tragen

Schutzhandschuhe tragen

Handbuch sorgfältig lesen

WARNUNG! Risiko von Quetsch- und Schnittverletzungen

durch bewegliche Teile!

Erfüllt die entsprechenden rechtlichen Vorschriften

und Sicherheitsnormen

Technische Daten

Max. Zugkapazität: ................................................4000 kg

Stahlseildurchmesser: ...........................................5,5 mm x 3 m

Ratschensystem: ................................................... Zweigang

Hebelverhältnis: .....................................................15:1

Hinweis: Die Zugkapazität bezieht sich auf eine bewegliche Ladung

auf ebener Fläche. Extreme Vorsicht muß angewandt werden, die

Vorrichtung nicht zu überlasten, speziell bei statischen Lasten.

Allgemeine Sicherheitshinweise

WARNUNG! Lesen Sie alle Sicherheitshinweise und Anweisungen.

Versäumnisse bei der Einhaltung der Sicherheitshinweise und

Anweisungen können schwere Verletzungen verursachen.

WARNUNG: Dieses Werkzeug darf nicht von Personen (wie

z.B. Kindern) mit eingeschränkten körperlichen oder geistigen

Fähigkeiten oder von Personen ohne Erfahrung im Umgang

mit einem solchen Werkzeug betrieben werden, außer wenn sie von

einer für ihre persönliche Sicherheit verantwortlichen Person in der

Benutzung unterwiesen worden sind und dabei beaufsichtigt werden.

Kinder müssen beaufsichtigt werden, um sicherzustellen, dass sie das

Werkzeug nicht als Spielzeug verwenden.

Bewahren Sie alle Sicherheitshinweise und Anweisungen für die

Zukunft auf.

Arbeitsplatzsicherheit

a) Halten Sie Ihren Arbeitsbereich sauber und gut beleuchtet.

Unordnung oder unbeleuchtete Arbeitsbereiche können zu Unfällen

führen.

b) Arbeiten Sie mit dem Werkzeug nicht in explosionsgefährdeter

Umgebung, in der sich brennbare Flüssigkeiten, Gase oder Stäube

befinden.

c) Halten Sie Kinder und andere Personen während der Benutzung

des Werkzeugs fern. Bei Ablenkung können Sie die Kontrolle über

das Werkzeug verlieren.

Sicherheit von Personen

a) Seien Sie aufmerksam, achten Sie darauf, was Sie tun, und gehen

Sie mit Vernunft an die Arbeit mit einem Werkzeug. Benutzen

Sie kein Werkzeug, wenn Sie müde sind oder unter dem Einfluss

von Drogen, Alkohol oder Medikamenten stehen. Ein Moment der

Unachtsamkeit beim Gebrauch des Werkzeuges kann zu ernsthaften

Verletzungen führen. Arbeiten Sie stets konzentriert und legen Sie bei

Bedarf regelmäßig Pausen ein.

b) Tragen Sie persönliche Schutzausrüstung und immer eine

Schutzbrille. Das Tragen persönlicher Schutzausrüstung, wie

Staubmaske, rutschfeste Sicherheitsschuhe, Schutzhelm oder

Gehörschutz, je nach Art und Einsatz des Werkzeuges, verringert das

Risiko von Verletzungen.

c) Entfernen Sie Einstellwerkzeuge oder Schraubenschlüssel, bevor

Sie die Arbeit mit dem Werkzeug aufnehmen. Ein Werkzeug oder

Schlüssel, der sich in einem drehenden Werkzeugteil befindet, kann zu

Verletzungen führen.

d) Vermeiden Sie eine unnatürliche Körperhaltung. Sorgen Sie für

einen sicheren Stand und halten Sie jederzeit das Gleichgewicht.

Auf diese Weise lässt sich das Werkzeug in unerwarteten Situationen

besser kontrollieren.

e) Tragen Sie geeignete Kleidung. Tragen Sie keine weite Kleidung

oder Schmuck. Halten Sie Haare, Kleidung und Handschuhe fern

von sich bewegenden Teilen. Lockere Kleidung, Schmuck oder lange

Haare können von sich bewegenden Teilen erfasst werden.

Werkzeugbenutzung und -pflege

WICHTIGER HINWEIS: Im Freien benutzte Werkzeuge bedürfen

gegebenenfalls häufigerer Reinigung und gründlicherer Oberflächenpflege,

um Korrosion zu verhindern. Bewegliche Teile müssen zudem öfter

geschmiert werden, damit der einwandfreie Betriebszustand gewährleistet ist.

a) Pflegen Sie Werkzeuge mit Sorgfalt. Kontrollieren Sie, ob

bewegliche Teile einwandfrei funktionieren und nicht klemmen,

ob Teile gebrochen oder so beschädigt sind, dass die Funktion

des Werkzeuges beeinträchtigt ist. Lassen Sie beschädigte Teile

vor dem Einsatz des Werkzeugs reparieren. Viele Unfälle haben ihre

Ursache in schlecht gewarteten Werkzeugen.

b) Halten Sie Schneidwerkzeuge scharf und sauber. Sorgfältig

gepflegte Schneidwerkzeuge mit scharfen Schneidkanten verklemmen

sich weniger und sind leichter zu führen.

c) Verwenden Sie Werkzeugzubehör, Einsatzwerkzeuge usw.

entsprechend diesen Anweisungen. Berücksichtigen Sie dabei

die Arbeitsbedingungen und die auszuführende Tätigkeit.

Der Gebrauch von Werkzeugen für andere als die vorgesehenen

Anwendungen kann zu gefährlichen Situationen führen.

12

Page 14

598501 Schwerlast-Greifzug

Service

a) Lassen Sie Ihr Werkzeug nur von qualifiziertem Fachpersonal

und nur mit Original-Ersatzteilen warten und reparieren. Damit

wird sichergestellt, dass die Sicherheit des Werkzeuges erhalten bleibt.

Sicherheitshinweise für

Zugwerkzeuge

Stellen Sie sicher, dass Ihr Zugwerkzeug stets gewartet ist und sich in

betriebstüchtigem Zustand befindet. Beachten Sie die folgenden wichtigen

Hinweise:

• Beurteilen Sie den Zustand des Gerätes vor jeder Benutzung. Achten Sie

besonders auf das Stahlseil und die Verriegelungsmechanismen.

• Die Stahlseile müssen knickfrei sein und dürfen keine Anzeichen von

Ausfransen, Abschürfungen, Einschnitten oder anderen Beschädigungen

aufweisen.

• Verriegelungsmechanismen müssen freigängig sein und frei von

Schmutz und übermäßigen Mengen von Schmiermitteln.

• Stellen Sie sicher, dass die Sicherheitsfallen an den Zughaken vollständig

geschlossen sind, und die Last gesichert ist, bevor Sie mit dem

Zugvorgang beginnen.

• Testen Sie alle Schutzvorrichtungen (inklusive automatischer) vor der

Benutzung auf korrekte Funktion.

• Ziehen Sie Gegenstände NICHT über oder um eine Ecke herum.

• Wickeln Sie das Stahlseil nicht um Gegenstände herum, und haken Sie

das Seil nicht an sich selbst ein.

• NICHT ÜBERLASTEN: Stellen Sie sicher, dass das Gewicht aller Ladungen

sich innerhalb der Gerätespezifikationen befindet (siehe Technische

Daten).

• Benutzen Sie diese Zugvorrichtung keinesfalls zum Heben. Das Gerät ist

nicht als Hebezeug geeignet.

• Bedenken Sie den beim Ziehen auftretenden Rollwiderstand, welcher das

Gewicht der Ladung erheblich erhöht. Dies gilt besonders wenn Objekte

über oder durch Schlamm, Schnee oder Wasser gezogen werden.

• Beachten Sie jegliche Steigung, über welche die Last gezogen werden

muss.

• Benutzen Sie ein geeignetes Hebeband, eine Augenschraube oder

einen anderen geeignete Anschlag für die Last, und achten Sie auf gute

Befestigung der Zughaken.

• Benutzen Sie keinesfalls Rohre oder anderweitige Vorrichtungen um den

Hebel zu verlängern. Das Zugwerkzeug kann dadurch versagen, was zu

Sach- und/oder Personenschaden führen kann.

• Verwenden Sie diese Zugvorrichtung keinesfalls für Personen, oder um

Objekte zu bewegen die mit Personen in Kontakt stehen.

• Zugwerkzeuge dürfen nicht modifiziert werden. Veränderungen an

diesem Werkzeug führen zum Erlöschen der Garantie und können

ernsthafte Verletzungen der eigenen oder umstehender Personen zur

Folge haben.

• Zugwerkzeuge sollten mindestens einmal jährlich durch eine qualifizierte

Fachkraft geprüft und die Ergebnisse zur späteren Referenz in ein

Inspektionsbuch eingetragen werden.

• Sollten Sie in irgendeiner Weise unsicher sein, wie dieses Gerät auf

sicherer Art und Weise zu benutzen ist, verwenden Sie es nicht.

www.silverlinetools.com

13

Page 15

D

Geräteübersicht

1 Befestigungshaken

2 Sicherheitsbügel

3 Ratschen-Feststellhebel

4 Ratschen-Verzahnung

5 Ratschen-Antriebsfeder

6 Stahlseil

7 Seilhaken

8 Handgriff

Auspacken des Gerätes

Packen Sie Ihr Gerät vorsichtig aus und überprüfen Sie es. Machen Sie sich

vollständig mit allen seinen Eigenschaften und Funktionen vertraut.

Vergewissern Sie sich, dass sämtliche Teile des Werkzeugs vorhanden und

in einwandfreiem Zustand sind. Sollten Teile fehlen oder beschädigt sein,

lassen Sie diese ersetzen, bevor Sie das Gerät verwenden.

Benutzung

Greifzug befestigen

• Befestigen Sie den Befestigungshaken (1) an der zu bewegenden Last.

Stellen Sie sicher, daß die Gesamtbelastung 4 Tonnen nicht überschreiten

wird.

• Überprüfen Sie, daß das Objekt sicher befestigt, und der Sicherheitsbügel

(2) geschlossen ist.

• Rücken Sie die Ratschen-Antriebsfeder (5) aus, so daß der Hebel nicht

mit den Ratschen-Zähnen (4) in Verbindung steht.

• Drücken Sie den Ratschen-Feststellhebel (3) und wickeln Sie

ausreichend Stahlseil (6) ab, um den Seilhaken (7) an seiner

Verankerungsstelle befestigen zu können. Bringen Sie den RatschenFesttellhebel zurück in seine Ursprungsposition und stellen Sie sicher,

daß der Haken sicher befestigt, und der Sicherheitsbügel geschlossen ist.

Ziehvorgang

• Rücken Sie die Ratschen-Antriebsfeder (5) in die Ratschen-Zähne (4)

hinein.

• Bewegen Sie den Hebel (8) vorwärts und rückwärts, um das Stahlseil zu

spannen und anschließend die Ladung zu ziehen.

Zugverbindung entspannen

• Rücken Sie die Ratschen-Antriebsfeder (5) aus, so daß der Hebel nicht

mit den Ratschen-Zähnen (4) in Verbindung steht (Abb 1).

• Benutzen Sie den Hebel (8) um den Mechanismus schrittweise rückwärts

zu bewegen. Jede Hebelbewegung wird die Ratsche um einen Zahn

zurück bewegen.

• Wiederholen Sie diesen Vorgang, bis genug Durchhang hergestellt

worden ist, um die Haken zu entfernen.

• Vergewissern Sie sich, dass die Ladung sicher steht, bevor die Haken

entfernt werden.

WARNUNG! Vermeiden Sie beim Entspannen abrupte Hebelbewegungen.

Bewegen Sie den Hebel gleichmäßig und kontinuierlich. Abrupte

Bewegungen können dazu führen, daß die Ladung abrutscht oder

instabil wird.

Wartung und Lagerung

• Halten sie den Greifzug sauber und in gutem Allgemeinzustand. Lagern

Sie ihn mit komplett aufgerolltem Stahlseil.

• Inspizieren Sie den Greifzug vor jeder Benutzung und achten Sie auf

ungewöhnliche Geräusche während der Benutzung.

• Lagern Sie das Gerät an einem sicheren, trockenen Ort, außer der

Reichweite von Kindern.

• Demontieren Sie den Greifzug nicht.

• Inspizieren Sie den Mechanismus vor jeder Benutzung.

14

Page 16

598501 Schwerlast-Greifzug

Silverline Tools Garantie

Dieses Silverline-Produkt wird mit einer 3-JahresGarantie angeboten

Registrieren Sie dieses Produkt unter silverlinetools.com innerhalb von

30 Tagen nach dem Kauf, um die 3-Jahres-Garantie zu aktivieren. Der

Garantiezeitraum beginnt mit dem Kaufdatum auf Ihrem Kaufbeleg.

Registrierung Ihres Kaufs

Gehen Sie zu: silverlinetools.com, wählen Sie den Link Registrierung und

geben Sie Folgendes ein:

• Ihre persönlichen Angaben

• Produktdetails und Kaufinformationen

Sobald dieses Produkt registriert worden ist, wird Ihre

Garantiebescheinigung im PDF-Format erzeugt. Bitte drucken Sie sie aus

und bewahren Sie sie zusammen mit Ihrem Produkt auf.

Garantiebedingungen für Silverline Tools

Der Garantiezeitraum beginnt mit dem Kaufdatum im Einzelhandel, das auf

dem Kaufbeleg angegeben ist.

BITTE BEWAHREN SIE IHREN KAUFBELEG AUF

Falls dieses Produkt innerhalb von 30 Tagen nach dem Kauf einen

Defekt aufweisen sollte, bringen Sie es bitte mit Ihrem Kaufbeleg zu dem

Fachhändler, bei dem es gekauft wurde, und informieren Sie ihn über die

Mängel. Das Gerät wird ersetzt oder der Kaufpreis zurückerstattet.

Falls dieses Produkt nach Ablauf von 30 Tagen nach dem Kauf einen Mangel

aufweist, senden Sie es an:

Silverline Tools Service Centre

PO Box 2988

Yeovil

BA21 1WU, Großbritannien

Der Garantieanspruch muss während der Garantiezeit gestellt werden.

Sie müssen den Originalkaufbeleg mit Angabe des Kaufdatums einreichen

und Ihren Namen und Ihre Adresse sowie den Ort des Kaufs angeben, bevor

etwaige Arbeiten durchgeführt werden können.

Sie müssen genaue Angaben über den zu behebenden Defekt machen.

Alle innerhalb der Garantiefrist gemachten Forderungen werden von

Silverline Tools daraufhin überprüft werden, ob es sich bei den Mängeln um

einen Material- oder Fertigungsfehler handelt.

Versandkosten werden nicht zurückerstattet. Alle Produkte sollten sich

in sauberem und sicherem Zustand befinden und sorgfältig verpackt zur

Reparatur eingeschickt werden, um Schäden oder Verletzungen während

des Transports zu vermeiden. Die Annahme ungeeigneter oder unsicherer

Lieferungen kann von uns verweigert werden.

Alle Arbeiten werden von Silverline Tools oder seinen autorisierten

Reparaturwerkstätten durchgeführt.

Die Reparatur oder der Ersatz des Produkts führt nicht zur Verlängerung des

Garantiezeitraums.

Mängel, bei denen unsere Prüfung ergibt, dass sie unter die Garantie fallen,

werden durch kostenlose Reparatur des Werkzeugs (ohne Versandkosten)

oder Ersatz durch ein Werkzeug in einwandfreiem Zustand behoben.

Einbehaltene Werkzeuge oder Teile, die ersetzt wurden, gehen in den Besitz

von Silverline Tools über.

Die Reparatur bzw. der Ersatz Ihres Produkts unter dieser Garantie erfolgt

zusätzlich zu Ihren gesetzlichen Rechten als Verbraucher und hat keine

nachteiligen Folgen auf diese.

Durch die Garantie abgedeckt ist:

Die Reparatur des Produkts, nachdem zur Zufriedenheit von Silverline Tools

nachgewiesen wurde, dass der Defekt durch fehlerhaftes Material oder

mangelhafte Arbeitsausführung bedingt ist und in den Garantiezeitraum fällt.

Wenn ein Ersatzteil nicht mehr erhältlich ist oder nicht mehr hergestellt

wird, kann Silverline Tools es gegen einen funktionellen Ersatz austauschen.

Verwendung des Produkts innerhalb der EU.

Durch die Garantie nicht abgedeckt ist:

Silverline Tools garantiert keine Reparaturen, die durch Folgendes

erforderlich geworden sind:

Normale Verschleißerscheinungen, die trotz Verwendung entsprechend

der Bedienungsanleitung entstehen, z.B. an Messern, Bürsten, Riemen,

Glühbirnen, Batterien usw.

Ersatz von mitgeliefertem Zubehör wie etwa Bohrspitzen, Messern,

Sandpapier, Schneidscheiben und anderen zugehörigen Teilen.

Unfallschäden und Fehler, die durch unsachgemäße Verwendung oder

Wartung, Missbrauch, Nachlässigkeit oder fahrlässige Bedienung oder

Handhabung des Produkts entstanden sind.

Verwendung des Produkts für andere als normale Haushaltszwecke.

Jegliche Veränderungen oder Modifikationen des Produkts.

Die Verwendung von Teilen oder Zubehör, die keine Originalkomponenten

von Silverline Tools sind.

Fehlerhafte Montage (außer, wenn von Silverline Tools vorgenommen).

Reparaturen oder Änderungen, die von anderen als Silverline Tools oder

seinen autorisieren Reparaturwerkstätten durchgeführt wurden.

Ansprüche, die über die Rechte zur Behebung von Mängeln an dem in

diesen Garantiebedingungen genannten Werkzeug hinausgehen.

EG-Konformitätserklärung

Name des Unterzeichners: Mr Darrell Morris

Bevollmächtigt durch: Silverline Tools

Erklärt hiermit, dass das Produkt:

Ident.-Nr.: 598501

Produktbeschreibung: Schwerlast-Greifzug

Den folgenden Richtlinien entspricht:

• Maschinenrichtlinie 2006/42/EG

• EN 12100:2010

• EN 1492-2:2000+A1:2008

Benannte Stelle: Ente Certificazione Macchine, Ningbo, China

Techn. Unterlagen bei: Silverline Tools

Datum: 02/08/2013

Unterzeichnet von:

Geschäftsführender Direktor

Name und Anschrift des Herstellers oder seines

niedergelassenen Bevollmächtigten:

Powerbox, Boundary Way, Lufton Trading Estate, Yeovil, Somerset,

BA22 8HZ, Großbritannien

www.silverlinetools.com

15

Page 17

ESP

Descripción de los símbolos

Los símbolos siguientes pueden aparecer en la placa de características de

su herramienta. Éstos representan información importante sobre el producto

o instrucciones relativas a su uso

Lleve protección auditiva

Lleve protección ocular

Lleve protección respiratoria

Lleve un casco de seguridad

Lleve guantes de seguridad

Lea el manual de instrucciones

ADVERTENCIA: Los mecanismos móviles de esta herramienta

pueden causar cortes y lesiones personales

Conforme a las normas de seguridad y a la legislación

correspondientes

Características técnicas

Max. capacidad de trabajo:.................................................4000 kg

Diámetro del cable:.....................................................5,5 mm x 3 mm

Sistema de trinquete:....................................................Doble

Relación de transmisión:...............................................15:1

NOTA: La capacidad de trabajo está basada en una superficie

nivelada. Tenga cuidado en no sobrecargar la herramienta,

especialmente en cargas con peso muerto.

Instrucciones generales de

seguridad

ADVERTENCIA: Lea todas las advertencias de seguridad e

instrucciones. No respetar estas advertencias e instrucciones puede

causar lesiones graves.

ADVERTENCIA: No permita que los niños, personas discapacitadas

o personas no cualificadas utilicen esta herramienta. Mantenga

esta herramienta fuera del alcance de los niños.

Conserve estas instrucciones de seguridad para futuras referencias.

Seguridad en el área de trabajo

a) Mantenga el área de trabajo limpia y bien iluminada. Las áreas

desordenadas y oscuras invitan a que se produzcan accidentes.

b) No utilice herramientas eléctricas en atmósferas explosivas,

como por ejemplo en presencia de líquidos, gases o polvos

inflamables.

c) Mantenga alejados a los niños y a las personas que se

encuentren a su alrededor mientras esté trabajando con una

herramienta eléctrica. Las distracciones pueden hacerle perder el

control de la herramienta.

Seguridad personal

a) Manténgase alerta, fíjese en lo que está haciendo y use el

sentido común cuando esté utilizando una herramienta. No use

una herramienta si se encuentra cansado o bajo la influencia

de drogas, alcohol o medicamentos. Un momento de distracción

mientras esté utilizando una herramienta puede provocar lesiones

graves. Realice pausas y descanse cuando sea necesario.

b) Use equipo de protección personal. Use siempre protección

ocular. El uso de equipamientos de seguridad tales como máscara

antipolvo, calzado de seguridad antideslizante, casco duro y

protecciones auditivas adecuadas reducirá el riesgo de lesiones

corporales.

c) Retire las llaves de ajuste antes de utilizar la herramienta. Una

llave de ajuste que se ha dejado colocada en una parte móvil de la

herramienta eléctrica puede causar lesiones corporales.

d) No adopte posturas forzadas. Manténgase en posición firme y en

equilibrio en todo momento. De este modo, podrá controlar mejor la

herramienta eléctrica en situaciones inesperadas.

e) Vístase adecuadamente. No lleve ropa holgada ni joyas.

Mantenga el pelo, la ropa y los guantes alejados de las piezas

móviles. La ropa holgada, las joyas o el pelo largo pueden quedar

atrapados en las piezas móviles.

Uso y mantenimiento

IMPORTANTE: Las herramientas utilizadas en exteriores deben limpiarse

regularmente y tratarse con productos anticorrosión. Para mantener la

herramienta en buen estado, lubrique las piezas móviles con grasa o aceite

adecuado.

a) Mantenga sus herramientas. Revise que no haya piezas en

movimiento mal alineadas o trabadas, piezas rotas o cualquier

otra condición que pueda afectar el funcionamiento de la

herramienta. Si encuentra aluna pieza dañada, haga reparar la

herramienta antes de utilizarla. Muchos accidentes son causados

por herramientas eléctricas que carecen de un mantenimiento

adecuado.

b) Mantenga las herramientas de corte siempre afiladas y limpias.

Las herramientas de corte correctamente afiladas son menos

propensas a trabarse y son más fáciles de controlar.

c) Utilice la herramienta, los accesorios, brocas etc. de acuerdo

con estas instrucciones, teniendo en cuenta las condiciones y el

trabajo que necesite realizar. El uso de la herramienta eléctrica para

tareas distintas de aquellas para las que fue diseñada podría causar

una situación peligrosa.

Servicio

a) Lleve siempre su herramienta eléctrica a un servicio técnico

cualificado y utilice únicamente piezas de recambio idénticas.

Esto garantizará un funcionamiento óptimo y seguro de su

herramienta.

16

Page 18

598501 Polipasto de tracción resistente

Instrucciones de seguridad

relativas a los polipastos de

tracción

Asegúrese de que el polipasto de tracción esté en buenas condiciones de

trabajo. Lea atentamente las instrucciones indicadas a continuación:

• Compruebe el estado de esta herramienta antes de usarla. Preste

especial atención a los cables y los mecanismos de cierre.

• Los cables deben estar libres de torceduras y no mostrar ninguna

evidencia de deshilachado o corte.

• Los mecanismos de cierre deben trabajar libremente y estar limpios de

exceso de suciedad o grasa.

• Asegúrese de que el seguro de los ganchos está cerrado y la carga esté

bien sujeta antes de comenzar la tarea.

• Compruebe todos los dispositivos de seguridad (incluyendo los

automáticos) antes de su uso.

• NO tire de objetos alrededor de ángulos o esquinas.

• NO enrolle el cable alrededor de un objeto para luego engancharlo sobre

si mismo.

• NO SOBRECARGUE la herramienta: Asegúrese de que el peso total de la

carga esté dentro de la capacidad de trabajo de esta herramienta (vea

las características técnicas).

• NO LEVANTE objetos con este polipasto. Este equipo no ha sido diseñado

para levantar cargas.

• Cuando arrastre o tire de objetos, tenga en cuenta de que la resistencia

al rodar aumentará significativamente el peso del objeto, especialmente

en casos de tracción en lodo, nieve o agua.

• Tenga en cuenta la inclinación del suelo sobre el cual la carga se está

operando.

• Utilice una eslinga, un perno de anilla u otro dispositivo y asegúrese de

que el gancho este bien sujeto a la carga.

• No trate de utilizar un tubo, palanca u otro dispositivo para alargar el

mango, ya que puede producir un fallo en el mecanismo, causando

posibles daños materiales y personales.

• Nunca utilice este equipo para sacar a personas o para tirar de objetos

en los cuales se encuentren personas.

• No modifique el polipasto de tracción. Cualquier intento de alterar esta

herramienta invalidará su garantía y podría provocar lesiones graves a

usted y a las personas que se encuentren a su alrededor.

• El polipasto de tracción deberá ser inspeccionado por una persona

cualificada al menos una vez al año y los resultados de la inspección

deberán registrarse en un libro de inspecciones para servir de referencia

en el futuro.

• Si no está seguro de como utilizar esta herramienta de forma adecuada,

no la utilice. Compruebe todos los dispositivos de seguridad (incluyendo

los automáticos) antes de su uso.

• Si alguna de las partes de esta herramienta se encuentra dañada o

desgastada, deberá repararse con piezas de recambio originales en un

centro de servicio autorizado.

• El polipasto de tracción deberá ser inspeccionado por una persona

cualificada al menos una vez al año y los resultados de la inspección

deberán registrarse en un libro de inspecciones para servir de referencia

en el futuro.

• No modificar el polipasto de tracción. Cualquier intento de alterar este

equipo invalidará su garantía y podría provocar lesiones graves a usted y

a las personas que se encuentren a su alrededor.

www.silverlinetools.com

17

Page 19

ESP

Características del producto

1 Gancho de fijación

2 Seguro

3 Palanca de bloqueo del trinquete

4 Dientes del trinquete

5 Resorte de accionamiento de trinquete

6 Cable

7 Gancho del cable

8 Mango

Desembalaje

Desembale e inspeccione la herramienta con cuidado. Familiarícese con

todas sus características y funciones.

Asegúrese de que el embalaje contiene todas las partes y que están en

buenas condiciones. Si faltan piezas o están dañadas, solicite su sustitución

antes de utilizar esta herramienta.

Instrucciones de funcionamiento

Como conectar el polipasto de tracción

1. Conecte el gancho de fijación (1) sobre la carga. Asegúrese de que el

peso total de la carga no exceda 4 toneladas.

2. Compruebe la carga está correctamente amarrada y el seguro (2)

cerrado.

3. Deslice el resorte de accionamiento del trinquete (5) hasta la posición

de desconexión para que el mango no se conecte a los dientes del

trinquete (4).

4. Pulse la palanca de bloqueo del trinquete (3) y desenrolle suficiente cable

(6) de la bobina para conectar el gancho (7) a la posición de anclaje.

Suelte la palanca de bloqueo del trinquete. Asegúrese de que el gancho

está bien conectado y el seguro cerrado.

Tirar

1. Deslice el resorte de accionamiento del trinquete (5) hasta la posición de

conexión para que el mango se conecte con los dientes del trinquete.

2. Accione el mango (8) hacia delante y atrás para tensar el cable y tirar

de la carga.

Soltar tensión

1. Deslice el resorte de accionamiento del trinquete (5) hasta la posición de

desconexión para que el mango no se conecte a los dientes del trinquete

(4) (Fig 1).

2. Accione el mango (8) para operar el mecanismo de movimiento invertido.

Cada accionamiento del mango hará que el trinquete vuelva atrás sobre

un diente.

3. Repita el procedimiento hasta que obtenga suficiente holgura para

permitirle quitar el gancho.

4. Asegúrese de que la carga sea estable y haya sido asegurada antes de

quitar los ganchos.

ADVERTENCIA: Cuando libere tensión, evite realizar movimientos bruscos.

Aplique presión al mango de manera uniforme y con una acción suave. Los

movimientos bruscos pueden hacer que la carga se mueva, haciendo por lo

tanto que sea inestable.

Mantenimiento Y Almacenaje

• Mantenga el polipasto de tracción limpio y en buen estado. Guárdelo con

el cable completamente enrollado en la bobina.

• Inspeccione el polipasto de tracción después de cada uso y compruebe

que no haya ruidos extraños durante la operación.

• Guárdelo en un lugar seguro y seco, fuera del alcance de los niños.

• No desmonte nunca el polipasto de tracción.

• Inspeccione el mecanismo antes de cada uso.

18

Page 20

598501 Polipasto de tracción resistente

Garantía Silverline Tools

Garantía

Este producto Silverline dispone de una garantía de

3 años.

Registre el producto en www.silverlinetools.com antes de que transcurran

30 días a partir de la fecha de compra para obtener la garantía de 3 años.

El periodo de garantía comienza desde la fecha indicada en su recibo de

compra.

Condiciones

El periodo de garantía entra en vigor a partir de la fecha indicada en el recibo

de compra.

GUARDE EL RECIBO DE COMPRA

En caso de que el producto se averíe antes de que transcurran 30 días

desde la fecha de compra, devuélvalo al distribuidor donde lo compró, junto

con el recibo y los detalles de la avería. Le sustituiremos el producto o le

reembolsaremos el importe.

Si el producto se avería después de que transcurran 30 días desde la fecha

de compra, devuélvalo a:

Servicio Técnico Silverline Tools

PO Box 2988

Yeovil

BA21 1WU, Reino Unido.

La reclamación siempre debe presentarse durante el periodo de garantía.

Antes de poder realizar cualquier trabajo de reparación, deberá entregar el

recibo de compra original en el que se indica la fecha de compra, su nombre,

dirección y el lugar donde lo adquirió.

También deberá indicar claramente los detalles del fallo a reparar.

Las reclamaciones presentadas dentro del periodo de garantía deberán

ser verificadas por Silverline Tools para averiguar si las deficiencias son

consecuencia de los materiales o de la mano de obra del producto.

Los gastos de transporte no son reembolsables. Los productos a devolver

deberán estar limpios y en buenas condiciones para su reparación, debiendo

empaquetarse cuidadosamente con el fin de prevenir daños o lesiones

durante el transporte. Nos reservamos el derecho a rechazar envíos

incorrectos o inseguros.

Todas las reparaciones serán realizadas por Silverline Tools o por un servicio

técnico de autorizado.

La reparación o sustitución del producto no prolongará el periodo de garantía.

Registro del producto

Visite: silverlinetools.com, seleccione el botón de registro e indique:

• Sus datos personales

• Detalles del producto e información de compra

El certificado de garantía le será enviado en formato PDF. Imprímalo y

guárdelo con el producto.

Si los defectos están cubiertos por la garantía, la herramienta será reparada

sin cargo alguno (salvo los gastos de envío), o bien la sustituiremos por una

herramienta en perfecto estado de funcionamiento.

Las herramientas o piezas que hayan sido sustituidas serán propiedad de

Silverline Tools.

La reparación o sustitución del producto bajo garantía aporta beneficios

adicionales a sus derechos legales como consumidor, sin afectarlos.

Qué está cubierto:

Silverline Tools deberá comprobar si las deficiencias se deben a materiales o

mano de obra defectuosos dentro del periodo de garantía.

En caso de que cualquier pieza no estuviera disponible o estuviera fuera

de fabricación, Silverline Tools la sustituirá por una pieza funcional con las

mismas características.

Uso del producto en la Unión Europea.

Qué no está cubierto:

Silverline Tools no garantiza las reparaciones causadas por:

Desgaste normal por uso adecuado de la herramienta, por ejemplo hojas,

escobillas, correas, bombillas, baterías, etc...

La sustitución de cualquier accesorio suministrado: brocas, hojas, papel de

lija, discos de corte y otras piezas relacionadas.

Daño accidental, averías debidas a uso o cuidado negligente, uso incorrecto,

negligencia, funcionamiento o manejo indebido del producto.

Utilizar del producto para una finalidad distinta.

Cualquier cambio o modificación del producto.

El uso de piezas y accesorios que no sean recambios originales de Silverline

Tools.

Instalación incorrecta (excepto si fue realizada por Silverline Tools).

Reparaciones o alteraciones realizadas por servicios técnicos no autorizados

por Silverline Tools.

Las reclamaciones distintas a las indicadas en las presentes condiciones de

garantía no estarán cubiertas.

Declaración de conformidad CE

El abajo firmante: Mr Darrell Morris

Autorizado por: Silverline Tools

Declara que el producto:

Código de identificación: 598501

Descripción: Polipasto de tracción resistente

Está en conformidad con las directivas:

• Directiva de máquinas 2006/42/CE

• EN 12100:2010

• EN 1492-2:2000+A1:2008

Organismo notificado: Ente Certificazione Macchine, Ningbo, China

La documentación técnica se conserva en: Silverline Tools

Fecha: 02/08/2013

Firma:

Director General

Nombre y dirección del fabricante o representante autorizado:

Powerbox, Boundary Way, Lufton Trading Estate, Yeovil, Somerset,

BA22 8HZ, Reino Unido.

www.silverlinetools.com

19

Page 21

I

Descrizione dei simboli

La targhetta identificativa del vostro elettroutensile potrebbe riportare

dei simboli. Tali simboli sono una rappresentazione grafica che mira a

evidenziare importanti informazioni sul prodotto o istruzioni per il suo

utilizzo corretto e sicuro.

Indossare protezioni per l’udito

Indossare protezioni per gli occhi

Indossare una protezione per le vie respiratorie.

Indossare una protezione per la testa

Indossare protezioni per le mani

Leggere il manuale d’uso

ATTENZIONE: parti in movimento possono causare lesioni di

taglio e frantumazioni

Il prodotto è conforme alle vigenti normative e norme di

sicurezza applicabili

Caratteristiche tecniche

Max. capacità di tiro: .............................................4000 kg

Diametro: .............................................................. 5,5 mm x 2,5 m

Sistema cricchetto: ...............................................Doppio

Ratio di sollevamento: ........................................... 15:01

Nota: Capacità di tiro è data come un carico di rotolamento su

una superficie piana. Prestare la massima attenzione e non

sovraccaricare, in particolare su carichi a "portata lorda".

Norme generali di sicurezza

AVVERTENZA Leggere tutte le avvertenze di pericolo e le istruzioni.

La mancata osservanza delle avvertenze e istruzioni può provocare

un grave infortunio.

ATTENZIONE: Questo strumento non è inteso per l'uso da parte di

persone (inclusi i bambini) con capacità ridotta, fisici o mentali o con

mancanza di esperienza o di conoscenza, a meno che non siano

attentamente sorvegliate e istruite sull’utilizzo dello strumento da parte di

una persona responsabile della loro sicurezza. I bambini devono essere

sorvegliati per assicurarsi che non giochino con l'utensile.

Conservare tutte le avvertenze e le istruzioni per riferimenti futuri.

Sicurezza dell'area di lavoro

a) Mantenere l'area di lavoro pulita e ben illuminata. Il disordine o

zone scure invitano gli incidenti.

b) Non utilizzare utensili in atmosfere esplosive, ad esempio in

presenza di liquidi infiammabili, gas o polveri.

c) Tenere lontani i bambini ed altre persone durante il

funzionamento o utilizzo di questo strumento. Le distrazioni

possono causare la perdita di controllo.

Sicurezza personale

a) È importante concentrarsi su ciò che si sta facendo e usare il

buon senso quando si opera o si usa questo strumento. Non far

operare o utilizzare lo strumento quando si è stanchi o sotto

l'effetto di droghe, alcol o medicinali. Un attimo di distrazione

durante l’esecuzione o l'utilizzo dello strumento può provocare

gravi lesioni personali. Lavora sensibilmente in ogni momento con

pause regolari, se necessario.

b) Utilizzare dispositivi di protezione individuale. Indossare sempre

occhiali di protezione. Attrezzature di protezione tra quali maschere

antipolvere, scarpe di sicurezza antiscivolo, casco o protezioni oculari

ridurranno il rischio di lesioni personali.

c) Togliere gli attrezzi di regolazione o la chiave inglese prima di

utilizzare lo strumento. Un utensile o una chiave che si trovi in una

parte rotante della macchina può provocare lesioni personali.

d) Non sporgersi. Mantenere sempre la posizione e l'equilibrio in

ogni momento. Questo consente un migliore controllo dello strumento

in situazioni impreviste.

e) Vestirsi in modo adeguato. Non indossare abiti larghi o gioielli.

Tenere i capelli, i vestiti ed i guanti lontani da pezzi in movimento.

Vestiti lenti, gioielli o capelli lunghi possono impigliarsi nelle parti in

movimento.

Uso e cura

IMPORTANTE: Strumenti utilizzati all'aperto possono richiedere una pulizia

più regolare ed il trattamento di superficie per evitare la corrosione, così

come la sostituzione di grasso o di olio sulle parti in movimento al loro

mantenimento in buone condizioni di lavoro.

a) Mantenimento strumenti. Controllare il funzionamento legame di

parti in movimento, la rottura di parti e di ogni altra condizione

che può influenzare il funzionamento dello strumento. Se

danneggiato, avere lo strumento riparato prima dell'uso. Numerosi

incidenti vengono causati da una scarsa manutenzione.

b) Mantenere gli utensili da taglio affilati e puliti. Utensili da taglio

ben tenute con bordi affilati, sono meno soggetti al bloccaggio e

sono più facili da controllare.

c) Utilizzare gli accessori dello strumento, attrezzi, ecc. in

conformità con queste istruzioni, tenendo conto delle condizioni

di lavoro ed il lavoro da svolgere. L'impiego di utensili per usi diversi

da quelli consentiti potrà dar luogo a situazioni di pericolo.

Servizio

a) Far eseguire la manutenzione o fate riparare il vostro

strumento da una persona di riparazione qualificato utilizzando

esclusivamente pezzi di ricambio originali. Ciò farà sì che la

sicurezza dell'utensile viene mantenuta.

20

Page 22

598501 Tenditore resistente del cavo

Sicurezza per tira-cavi

Assicuratevi che il vostro tira-cavi è mantenuto in condizioni di lavoro

sicuro. Osservare le seguenti indicazioni importanti:

• Prima di ogni utilizzo, controllare lo stato delle apparecchiature. Prestare

particolare attenzione ai cavi e ai meccanismi di bloccaggio

• I cavi devono essere privi di pieghe e non deve presentare alcun segno

di usura o di taglio

• I meccanismi di bloccaggio devono lavorare liberamente e devono essere

pulite di un eccesso di sporco o grasso

• Assicurarsi che i fermi di protezione sui ganci sono chiuse e che il carico

è sicuro prima che si inizia di tirare

• Verificare tutti i dispositivi di sicurezza (compresi automatico) prima

dell'uso

• NON tentare di estrarre gli elementi intorno o su un angolo

• Non avvolgere il cavo intorno a qualsiasi oggetto e agganciarlo su se

stessa

• Non sovraccaricare: Assicurarsi che il peso di tutti i carichi è alla portata

di questa apparecchiatura (vedi specifiche tecniche)

• Non sollevare con questo tiracavi. Questo apparecchio non è progettato

per l’uso di paranco

• Quando si tira, consentire la resistenza al rotolamento che aumenterà

significativamente il peso di un oggetto - in particolare nei casi in cui si

tira nel fango, neve o acqua

• Prendere in considerazione qualsiasi angolo di inclinazione su cui il

carico viene tirato

• Utilizzare un elastico adeguato, bullone a occhio o altro allegamento sul

carico da essere tirato e garantire che ci sia un ingaggio positivo del tira

gancio al carico

• Non utilizzare un tubo, leva o altro dispositivo per allungare il manico

per un ulteriore effetto leva, la puleggia può fallire, causando danni e / o

lesioni personali

• In nessun caso utilizzare attrezzature da tiro per tirare persone o cose

con la gente attaccata

• Non modificare le apparecchiature di trazione. Qualsiasi tentativo di

manomettere l'apparecchiatura invalida la garanzia e potrebbe provocare

gravi lesioni a voi stessi o gli altri intorno a voi

• Attrezzature da tiro deve essere controllato da personale qualificato

almeno una volta ogni anno e i risultati del controllo devono essere

registrate in un libro di ispezione per riferimento futuro

• Se non si è sicuri sul metodo sicuro di utilizzare questo dispositivo, non

ne fate uso

www.silverlinetools.com

21

Page 23

I

Conoscenza del prodotto

1 Gancio fisso

2 Barra di sicurezza

3 Leva di blocco

4 Denti del cricchetto

5 Molla a cricchetto

6 Cavo

7 Gancio Filo

8 Maniglia

Disimballaggio

Disimballare con cautela e ispezionare il vostro strumento. Familiarizzarsi a

pieno con tutte le sue caratteristiche e funzioni.

Assicurarsi che tutte le parti dell’utensile siano presenti e in buone

condizioni. In caso di parti mancanti o danneggiate, sostituirle prima di

tentare di usare questo utensile.

Funzionamento

Collegamento del cavo da traino

• Fissare il gancio fisso (1) sul punto da essere tirato. Assicurarsi che il

carico totale non superi 4 tonnellate

• Verificare che l’utensile sia ben fisso e la barra di sicurezza (2) sia chiusa

• Far scorrere la molla a cricchetto (5) fino alla posizione di disimpegno in

modo che la maniglia non coinvolga i denti di arresto (4)

• Premere la leva di bloccaggio a cricchetto (3) e distendere cavo

sufficiente (6) dalla bobina per fissare il gancio del cavo (7) in posizione

di ancoraggio. Rilasciare la leva di blocco a cricchetto. Assicurarsi che il

gancio sia ben fisso e che la barra di sicurezza sia chiusa

Traino

• Inserire la molla (5) fino alla posizione impegnata in modo che la maniglia

impegna i denti di arresto

• Girare la manovella (8) avanti e indietro per tendere il cavo e tirare il

carico

Rilasciando la tensione

• Far scorrere la molla(5) fino alla posizione di disimpegno in modo che la

maniglia non coinvolga i denti di arresto (4) (Fig 1)

• Girare la manovella (8) per azionare il meccanismo di passo d'inversione

contabile. Ogni manovella farà un passo indietro di un dente del

cricchetto

• Ripetere l'operazione fino a quando spazio sufficiente è stato fornito in

modo che è possibile rimuovere i ganci

• Assicurarsi che il carico sia stabile e sicuro prima di rimuovere ganci

AVVERTENZA: Quando si rilascia la tensione, evitare movimenti bruschi

della maniglia. Applicare una pressione alla maniglia in modo uniforme e

con un'azione regolare. Movimenti bruschi possono causare il carico di

spostarsi, rendendolo instabile

Manutenzione e conservazione

• Tenere il tiracavi pulito e in ordine. Conservare con il cavo

completamente avvolto sulla bobina

• Eseguire un controllo visivo ogni volta che il cavo viene utilizzato e

ascoltare per eventuali rumori insoliti durante il funzionamento

• Conservare in un luogo sicuro e asciutto, fuori dalla portata dei bambini

• Non smontare mai il tiracavi

• Controllare il meccanismo prima di ogni utilizzo

22

Page 24

598501 Tenditore resistente del cavo

Garanzia Silverline Tools

Garanzia Silverline Tools

Questo prodotto Silverline è protetto da una

Questo prodotto Silverline è protetto da una

garanzia a vita

garanzia di 3 anni

Per attivare la garanzia a vita è necessario registrare il prodotto sul sito

Per attivare la garanzia di 3 anni è necessario registrate il prodotto sul