Page 1

3 Year Guarantee

*Register online within 30

days. Terms & Conditions apply

Garantie de 3 ans

*Enregistrez votre produit en ligne

dans les 30 jours. Sous réserve des

termes et conditions appliquées

3 Jahre Garantie

*Registrieren Sie sich innerhalb von 30

Tagen online. Es gelten die allgemeinen

Geschäftsbedingungen

3 años de garantía

*Regístrese online dentro de 30 días.

Se aplican los términos y condiciones

3 anni di garanzia

*Registrarsi on-line entro 30 giorni.

Termini e Condizioni si applicano

3 Jaar Garantie

*Registreer online binnen 30 dagen.

Algemene voorwaarden van toepassing

www.silverlinetools.com

Page 2

R

E

L

V

L

I

S

AIR

R

A

G

N

I

N

E

E

633548

5

PCE

Air Tools & Compressor Accessories Kit

5pce Air Tools & Compressor Accessories Kit

5 Accessoires outils pneumatiques et compresseurs

Druckluftwerkzeug u. Kompressor-Zubehör, 5-tlg. Satz

Juego de 5 herramientas neumáticas y accesorios

Kit di Compressione a 5pz

5-delige perslucht compressor accessoire set

www.silverlinetools.com

Page 3

AIR

S

I

L

V

E

R

L

I

N

E

R

A

N

G

E

911

11

3

10

6

8

5

1

2

4

2

Page 4

R

E

V

L

L

I

S

AIR

R

A

G

N

I

N

E

E

®

5

PCE

Air Tools & Compressor Accessories Kit

English .................. 4

Français ................ 8

Deutsch ................. 12

Español ................. 16

Italiano .................. 20

Nederlands ............ 24

www.silverlinetools.com

3

Page 5

GB

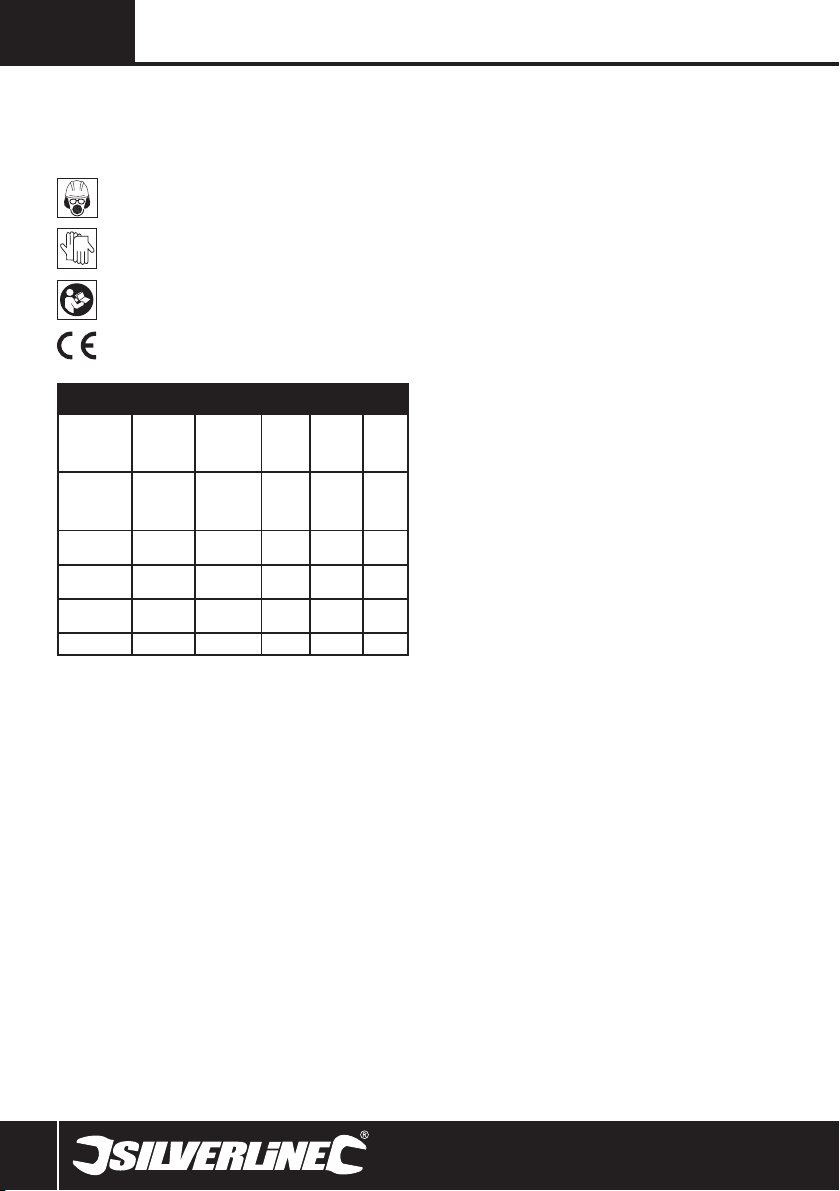

Description of Symbols

The rating plate on your tool may show symbols. These represent important

information about the product or instructions on its use

Wear hearing protection

Wear eye protection

Wear breathing protection

Wear head protection

Wear hand protection

Read instruction manual

Conforms to relevant legislation and safety standards

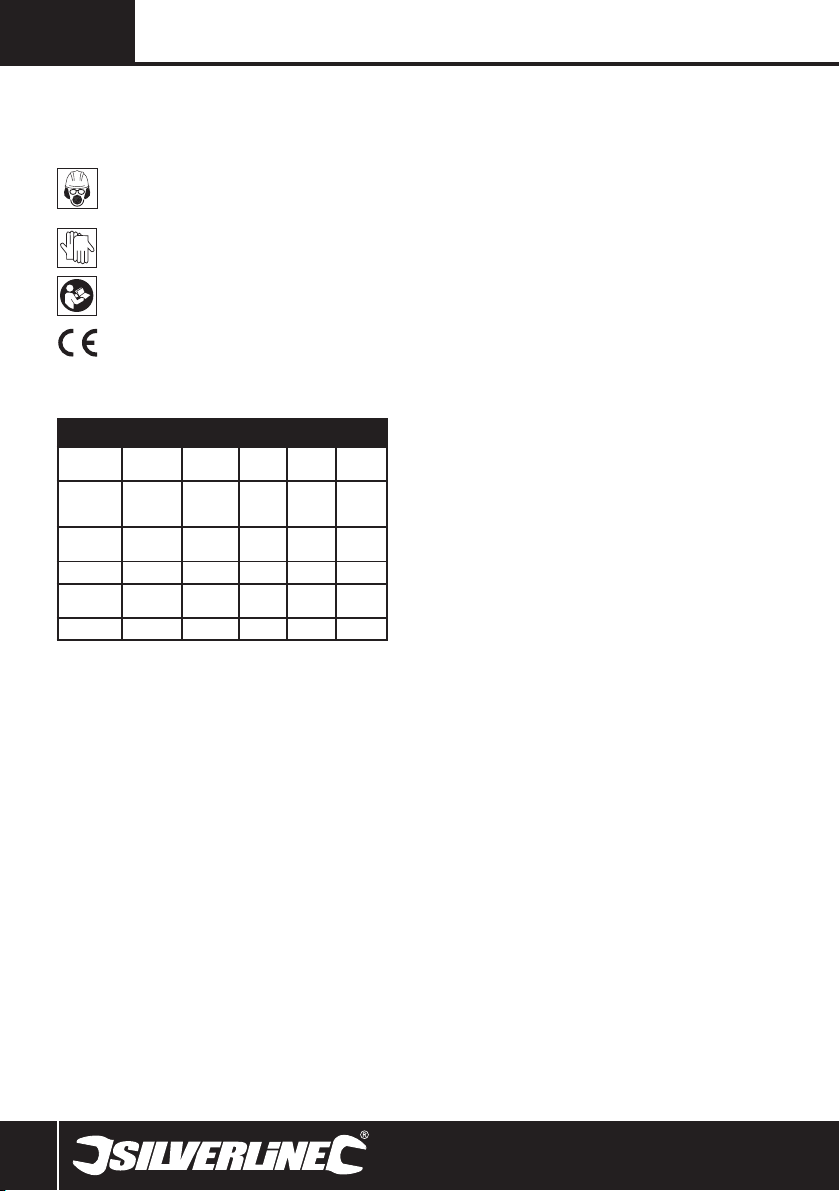

Specification

Spray Gun

Degreasing

Working

55psi (3.5

Pressure

Air

Consumption*

Fluid Capacity 750ml 900ml N/A N/A N/A

Fluid Delivery

110-200ml/

Nozzle 1.5mm 4.5mm N/A 2.0mm N/A

55psi (3.5

Bar)

3-6CFM 3-6CFM 6-9CFM 3-6CFM N/A

min

*CFM figures based on SCFM figures and approximate figures only

Silverline Tools reserves the right to alter product specifications without notice.

Even when used as prescribed it is not possible to eliminate all residual risk

factors. Use with

caution. If you are at all unsure of the correct and safe manner in which to use this

product, do not attempt to use it.

Tyre

Inflator

0-60psi

(0-4

Bar)

Blow

Gun

30-90psi

(2-6

Bar)

Gun

Bar)

- N/A N/A N/A

Hose

120psi (8

Bar) Max

Pressure

As part of our on-going product development, specifications of Silverline products

may alter without notice.

Carefully read and understand this manual and any label before use. Even when

used as prescribed it is not possible to eliminate all residual risk factors. Use with

caution.

Carefully read and understand this manual and any label attached to the tool

before use. Keep these instructions with the product for future reference. Ensure

all persons who use this product are fully acquainted with this manual.

If you are at all unsure of the correct and safe manner in which to use this tool, do

not attempt to use it.

General Safety Warnings

WARNING Read all safety warnings and all instructions. Failure to follow the

warnings and instructions may result in electric shock, fire and/or serious injury

Save all warnings and instructions for future reference.

Work area safety

• Keep work area clean and well lit. Cluttered or dark areas invite accidents

• Do not operate tools in explosive atmospheres, such as in the presence of

flammable liquids, gases or dust

• Keep children and bystanders away while operating a powered tool.

Distractions can cause you to lose control

Personal safety

• Stay alert, watch what you are doing and use common sense when

operating a powered tool. Do not use a powered tool while you are tired

or under the influence of drugs, alcohol or medication. A moment of

inattention while operating a powered tool may result in serious personal injury

• Use personal protective equipment. Always wear eye protection. Protective

equipment such as dust mask, non-skid safety shoes, hard hat, or hearing

protection used for appropriate conditions will reduce personal injuries

• Prevent unintentional starting. Ensure the switch is in the off-position when

not operating the tool and make use of other safety features which prevent

unintentional starting

• Remove any adjusting key or wrench before turning the powered tool

on. A wrench or a key left attached to a rotating part of the tool may result in

personal injury

• Do not overreach. Keep proper footing and balance at all times. This

enables better control of the tool in unexpected situations

• Dress properly. Do not wear loose clothing or jewelry. Keep your hair,

clothing and gloves away from moving parts. Loose clothes, jewelry or long

hair can be caught in moving parts

• If devices are provided for the connection of dust extraction and collection

facilities, ensure these are connected and properly used. Use of dust

collection can reduce dust-related hazards

WARNING: User exposure to tool vibration can result in loss of sense of touch,

numbness, tingling and reduced ability to grip. Long term exposure can lead to a

chronic condition. If necessary limit the length of time exposed to vibration. Use the

figures provided in the specification relating to vibration if provided to calculate the

duration and frequency of operating the tool. The 2002/44/EC directive relating to

vibration in the workplace may provide useful information even for domestic use

of tools. In the first instance of feeling uncomfortable due to vibration STOP using

the tool immediately

WARNING: Always wear ear protection where the sound level exceeds 80dB and

limit the time of exposure if necessary. If sound levels are uncomfortable even

with ear protection stop using the tool immediately and check the ear protection

is correctly fitted and provides the right level of sound attenuation for the level of

sound produced by your tool

Tool use and care

• Maintain tools. Check for misalignment or binding of moving parts,

breakage of parts and any other condition that may affect the tool’s

operation. If damaged, have the tool repaired before use. Many accidents

are caused by poorly maintained tools

• Keep cutting tools sharp and clean. Properly maintained cutting tools with

sharp cutting edges are less likely to bind and are easier to control

• Use the tool’s accessories and tool bits etc. in accordance with these

instructions, taking into account the working conditions and the work

to be performed. Use of the tool for operations different from those intended

could result in a hazardous situatio

Service

• Have your tool serviced by a qualified repair person using only identical

replacement parts. This will ensure that the safety of the tool is maintained

4

Page 6

5pce Air Tools & Compressor Accessories Kit633548

Air Tool Safety

Dangerous environment

• Ensure there is adequate clear space around the work area. Only use spraying

tools in a well-ventilated area or a specialist spray booth. Be aware that air

hoses can present a trip hazard; always lay hoses in a way that minimises

hazards.

Protect your eyes

• Always wear safety goggles or safety glasses.

Protect your hearing

• Always wear ear protection.

Protection from vibration

• Hand-held air tools may produce vibration and should not be used for long

periods without a break. Vibration can cause disease. Gloves may help to

maintain good blood circulation in the fingers.

Protective clothing

• Always wear appropriate protective equipment including but not limited to

overalls, gloves, facemask etc.

• It is the user’s responsibility to ensure that other persons in the vicinity of the

work area are also equipped with the appropriate protective equipment.

Use the correct air hose

• Use lightweight hose to connect the tool to the air compressor.

• Most air tools should be fitted with a coil hose; only use a straight hose with

spray guns.

• When spraying, ensure that the gun is connected to a clean, filtered air supply.

Always disconnect

• Ensure that your air tool has completely stopped functioning before putting

it down.

• Disconnect an air tool from the air supply before performing any servicing, or

changing any blades, discs, or other attachments.

• Ensure the air tool is switched OFF before connecting to air supply. Be aware

that air tools may hold residual pressure after use. Always bleed air pressure

from the tool after shutting off air supply.

Do not abuse the tool

• Do not overload the tool. Allowing the machine to work at its optimum speed is

more efficient and prolongs its service life.

• Do not increase air pressure above the recommended level; excessive pressure

leads to wear of moving parts, possible failure and may cause the tool casing

to split.

• Do not attempt to modify air tools. Any attempt to modify this air tool could

result in serious injury to you or others, and will invalidate its warranty.

Use of spray guns

• Do not aim a spray gun at people or animals!

• When spraying keep away from heat and naked flames!

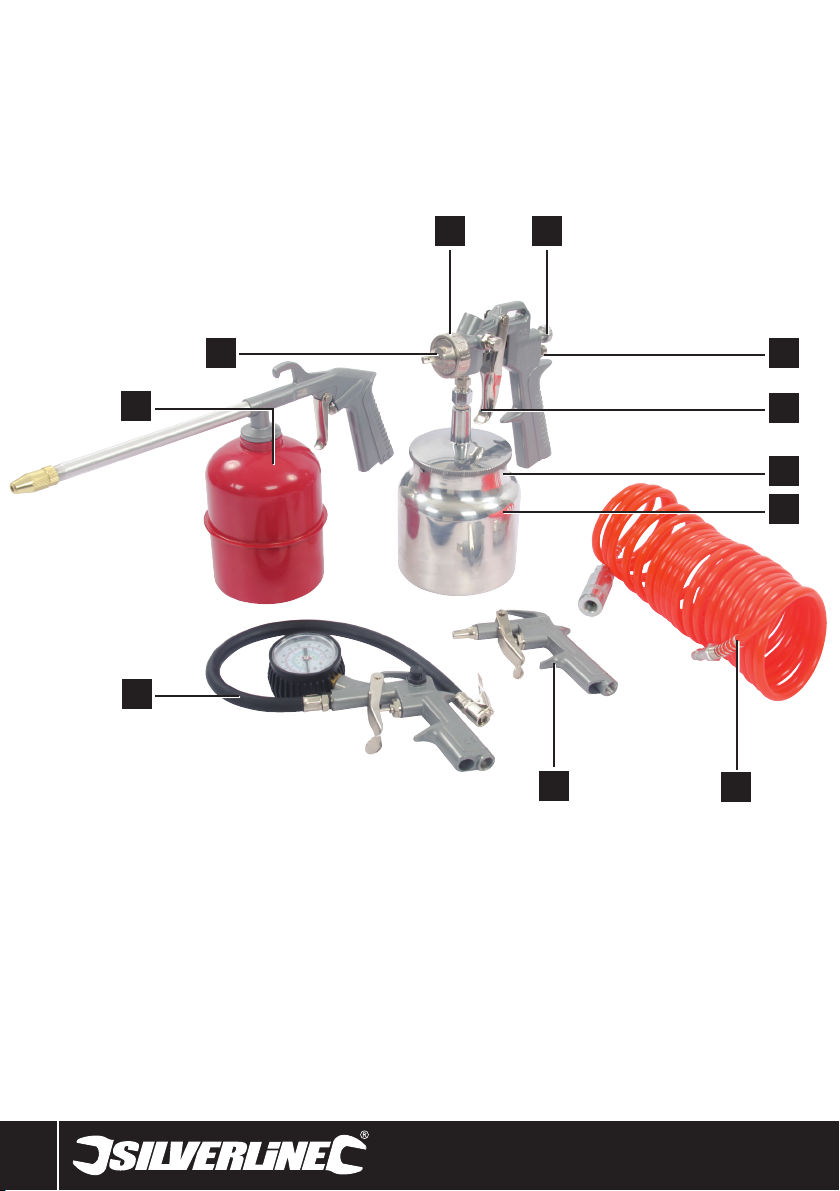

Product Familiarisation

1 Tyre Inflator

2 Blow Gun

3 Degreasing & Undercoating Gun

4 Recoil Air Hose

5 Spray Gun

6 Trigger

7 Nozzle

8 Canister

9 Trigger Restrictor

10 Pattern Control Knob

11 Air Cap

www.silverlinetools.com

5

Page 7

GB

Unpacking Your Tool

• Carefully unpack and inspect your tool. Fully familiarise yourself with all its

features and functions

• Ensure that all parts of the tool are present and in good condition. If any parts

are missing or damaged, have such parts replaced before attempting to use

this tool

Operating Instructions

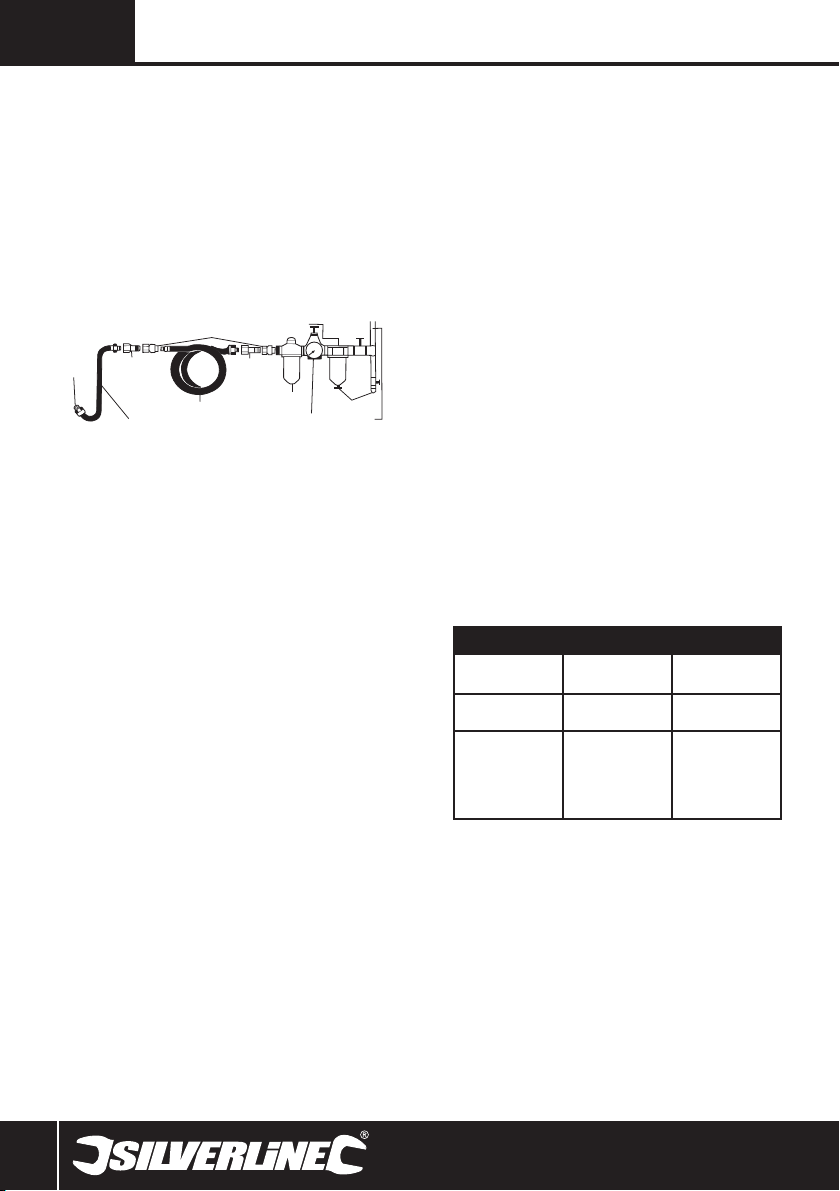

NOTE: Check that all connections are secure, and that line pressure does not

exceed the stated maximum pressure for the tool to be used.

See diagram below for recommended air connection which shows a fitted air filter

removing moisture from the air line. If vibration is apparent during operation of any

of these tools, the use of a rubber whip/leader hose is recommended.

RECOIL HOSE

WATER SEPARATION

NIPPLE

OILER

REGULATOR

NIPPLE

LEADER HOSE

QUICK COUPLER

TO YOUR

AIR TOOL

If the quick connectors are not pre-fitted to the tools, fit them by screwing them

into the bottom of the handles of each tool. To eliminate any air leaks the use of

PTFE tape may be required around the thread of the quick connectors.

Blow Gun

• To operate the Blow Gun (2) connect to the air-line and press the trigger. This

tool is useful for cleaning swarf or dust from worktops or recessed areas

Tyre Inflator

1. To operate the Tyre Inflator (1), connect to air-line, and to tyre valve

2. To inflate the tyre, squeeze the trigger. Be aware that the inflation rate is

high - do not over-inflate and damage the tyre

3. To check tyre pressure, release the trigger and the gauge will display the

current pressure. While inflating, regularly check the gauge by releasing

the trigger

Note: During inflation, the pressure shown on the gauge is the airline pressure,

not the tyre pressure.

Degreasing & Undercoating Gun

NOTE: Always disconnect the Degreasing & Undercoating Gun (3) from the air

supply before filling the Canister (8)

1. Unscrew the Canister (8) from the trigger/nozzle assembly

2. Fill the canister with a suitable fluid (this product is suitable for use with a

wide range of oils, cleaning and rustproofing liquids)

3. Replace the trigger/nozzle assembly securely onto the canister

4. To operate the degreasing gun, squeeze the trigger

• The Nozzle (7) can be adjusted to vary the spray pattern. Unscrew the locking

collar to allow adjustment of the main nozzle. Adjust the nozzle and then rotate

the locking collar to secure the nozzle. The viscosity of the liquid will affect the

spray pattern

• Correct adjustment of the nozzle and the air pressure level for the liquid used

will allow you to find the ideal spray pattern for your intended application, for

example undercoating

Spray Gun

Filling

1. Always disconnect the Spray Gun (5) from the air supply before filling

2. Paint should always be pre-mixed and thinned according to the paint

manufacturer’s guidance for use with air spray guns or similar equipment

3. Remove the Canister (8) by unscrewing from its lid. The canister can then be

filled

4. Refit the canister and tighten

Set Up

1. Connect the spray gun to the air supply. It is important to provide clean,

filtered air to the spray gun. If you have an inline oiler switch it off and make

sure water is filtered from the air line. Any oil or water in the airline will

contaminate the paint

2. To change the orientation of the spray pattern slightly unscrew the Air Cap

(11) and rotate the Nozzle (7) to the desired orientation and then re-tighten

the air cap

3. To adjust the shape of the spray pattern, rotate the Pattern Control Knob (10)

DRAIN DAILY

AIR SUPPLY

4. To adjust and limit the paint delivery rate, adjust the Trigger Restrictor (9)

which controls the allowable movement of the trigger and therefore the

maximum flow rate

Painting

• Prepare by ensuring you are wearing appropriate safety equipment, and ensure

any surfaces that do not require painting are masked off

• Prime the sprayer by spraying away from the intended surface until paintspraying consistency is achieved

• It is important to ensure the paint is sprayed at the correct distance from the

workpiece, and that consistency in both distance and speed is maintained

throughout

• Depending on the surface to be painted, you may need to start spraying before

the gun is passed over the surface, to ensure an even coat is applied

• Do not overload the surface with too much paint, otherwise the paint may run

• Allow the paint to dry slightly before applying a second coat

• Do not allow the paint to dry in the gun - always clean the gun immediately

after use

Cleaning

• Remove the Canister (8), and drain out any remaining paint

• Pour a suitable cleaning agent into the canister and re-attach to the paint gun

• Shake the gun to release paint from inside the canister

• Reconnect the gun to the air supply and set to a high flow rate. Spray onto

scrap material until the spray becomes clear. Repeat if necessary

• For a more thorough clean unscrew the air cap and remove the nozzle, then

soak in a cleaning agent

• Remove any remaining paint with a small, stiff, brush. Do not attempt to clean

air passageways with a metal object

• Remove the needle by fully unscrewing the Trigger Restrictor (9). Clean the

needle, and check that it is not bent or damaged

• When thoroughly clean and dry, reassemble the gun, and store in a dry place

• It may be necessary to lubricate the needle to maintain working condition of the

tool. Use a suitable lubricant sparingly and flush through the tool with a cleaning

solution afterwards to make sure no lubricant residue can contaminate the paint

Troubleshooting

Note: Before checking other causes, make sure there are no air leaks in the main

air line or fittings at the compressor or tool end

Symptom Possible Cause Remedy

Volume of paint being

sprayed very low

Excessive paint being

sprayed

Inconsistency of paint

being sprayed

Air pressure low Increase air pressure

Air pressure high Decrease air pressure

Blockage in air

hole of Canister (8),

blocked nozzle or poor

assembly

Unblock air hole in

lid of canister and

clean spray gun and

re-assemble correctly.

Also needle may

require lubrication

6

Page 8

5pce Air Tools & Compressor Accessories Kit633548

Silverline Tools Guarantee

This Silverline product comes with a 3 year

guarantee

Register this product at www.silverlinetools.com within 30 days of

purchase in order to qualify for the 3 year guarantee. Guarantee period

begins according to the date of purchase on your sales receipt.

Terms & Conditions

Guarantee period becomes effective from the date of retail purchase as

detailed on your sales receipt.

PLEASE KEEP YOUR SALES RECEIPT

If this product develops a fault within 30 days of purchase, return it to the

stockist where it was purchased, with your receipt, stating details of the

fault. You will receive a replacement or refund.

If this product develops a fault after the 30 day period, return it to:

Silverline Tools Service Centre

PO Box 2988

Yeovil

BA21 1WU, UK

The guarantee claim must be submitted during the guarantee period.

You must provide the original sales receipt indicating the purchase date,

your name, address and place of purchase before any work can be

carried out.

You must provide precise details of the fault requiring correction.

Claims made within the guarantee period will be verified by Silverline Tools

to establish if the deficiencies are related to material or manufacturing of

the product.

Carriage will not be refunded. Items for return must be in a suitably clean

and safe state for repair, and should be packaged carefully to prevent

damage or injury during transportation. We may reject unsuitable or

unsafe deliveries.

All work will be carried out by Silverline Tools or its authorised

repair agents.

The repair or replacement of the product will not extend the period

of guarantee

Defects recognised by us as being covered by the guarantee shall be

corrected by means of repair of the tool, free of charge (excluding carriage

charges) or by replacement with a tool in perfect working order.

Retained tools, or parts, for which a replacement has been issued, will

become the property of Silverline Tools.

EC Declaration of Conformity

The undersigned: Mr Darrell Morris

as authorised by: Silverline Tools

Declares that the

Description: 5pce Air Tools & Compressor Accessories Kit

Product Code: 633548

Conforms to the following Directives:

• MachineryDirective2006/42/EC

• EN1953:1998+A1:2009

• EN792

Registering your purchase

Registration is made at silverlinetools.com by selecting the Guarantee

Registration button. You will need to enter:-

• Your personal details

• Details of the product and purchase information

Once this information is entered your guarantee certificate will be created

in PDF format for you to print out and keep with your purchase.

The repair or replacement of your product under guarantee provides

benefits which are additional to and do not affect your statutory rights as

a consumer.

What is covered:

The repair of the product, if it can be verified to the satisfaction of Silverline

Tools that the deficiencies were due to faulty materials or workmanship

within the guarantee period.

If any part is no longer available or out of manufacture, Silverline Tools will

replace it with a functional replacement part.

Use of this product in the EU.

What is not covered:

Silverline Tools does not guarantee repairs required as a result of:

Normal wear and tear caused by use in accordance with the operating

instructions eg blades, brushes, belts, bulbs, batteries etc.

The replacement of any provided accessories drill bits, blades, sanding

sheets, cutting discs and other related items.

Accidental damage, faults caused by negligent use or care, misuse,

neglect, careless operation or handling of the product.

Use of the product for anything other than normal domestic purposes.

Change or modification of the product in any way.

Use of parts and accessories which are not genuine Silverline Tools

components.

Faulty installation (except installed by Silverline Tools).

Repairs or alterations carried out by parties other than Silverline Tools or its

authorised repair agents.

Claims other than the right to correction of faults on the tool named in

these guarantee conditions are not covered by the guarantee.

The technical documentation is kept by: Silverline Tools

Notified body: Intertek Testing Services

Place of declaration: Shanghai, China

Date: 27/11/12

Signed by:

Director

Name and address of Manufacturer or Authorised representative:

Silverline Tools, Boundary Way, Lufton Trading Estate, Yeovil, Somerset, BA22 8HZ United

Kingdom

www.silverlinetools.com

7

Page 9

F

Description des symboles

La plaque signalétique figurant sur votre outil peut présenter des symboles. Ces

symboles constituent des informations importantes relatives au produit ou des

instructions concernant son utilisation.

Port de protection auditive

Port de lunettes de sécurité

Port du masque respiratoire

Port du casque

Port de gants

Lire le manuel d’instructions

Conforme à la réglementation et aux normes de sécurité pertinentes

Caractéristiques techniques

Pistolet de

Pistolet

pulvérisateur

Pression de

fonctionnement

Consommation

d’air

Capacité de

liquide

Débit du fluide

Les valeurs de débit d’air sont données à titre indicatif

Silverline Tools se réserve le droit de modifier les spécifications des produits sans

préavis.

Même en cas d’utilisation conforme aux prescriptions, on ne peut pas éliminer

complètement tous les risques résiduels. Utilisez avec précaution. En cas de doute

sur la manière correcte et sûre d’utiliser ce produit, ne l’utilisez pas

110-200ml/

Buse 1.5mm 4.5mm N/A 2.0mm N/A

dégraissage

et peinture

sous-couche

3.5 bar 3.5 bar 0-4 bar 2-6 bar

85 - 170

l/min

750ml 900ml N/A N/A N/A

min

Gonfleur

Soufflette Tuyau

de pneu

85 - 170

170-255

l/min

85 – 170

l/min

l/min

- N/A N/A N/A

Max

pres-

sure

8 bar

N/A

Du fait de l’évolution constante de notre développement produits, les

caractéristiques techniques des produits Silverline peuvent changer sans

notification préalable.

Lisez attentivement ce manuel ainsi que toute étiquette avant l’utilisation. Sachez

qu’utiliser un outil conformément aux prescriptions, n’élimine pas tout facteur de

risque résiduel. Utilisez avec prudence.

Gardez ce manuel pour toute référence ultérieure. Assurez-vous que toutes les

personnes qui utilisent ce produit ont pris entièrement pris connaissance et

compris les instructions.

Si vous n’êtes pas sûre comment utiliser cet appareil en toute sécurité, ne l’utilisez

pas.

Consignes générales de sécurité

AVERTISSEMENT Veuillez lire l’intégralité des consignes de sécurité et des

instructions. Le non-respect de ces consignes et instructions peut entraîner un

risque de choc électrique, d’incendie et/ou se traduire par des blessures graves.

Veuillez conserver ces instructions et consignes de sécurité pour référence

ultérieure.

Sécurité sur la zone de travail

• Maintenir une zone de travail propre et bien éclairée. Des zones

encombrées et mal éclairées sont sources d’accidents.

• Ne pas utiliser d’outils dans des environnements explosifs, tels qu’à

proximité de liquides, de gaz ou de poussières inflammables.

• Eloigner les enfants et les passants pendant l’utilisation d’un appareil

électrique. Ceux-ci peuvent provoquer une perte d’attention et faire perdre la

maîtrise de l’appareil.

Sécurité des personnes

• Rester vigilent et faire preuve de bon sens lors de la manipulation de

l’appareil. Ne pas utiliser un appareil électrique lorsque l’on se trouve

dans un état de fatigue, ou sous l’influence de drogues, d’alcool ou

de médicaments. Un moment d’inattention pendant l’utilisation d’un outil

électrique peut se traduire par des blessures graves.

• Porter un équipement de protection approprié. Toujours porter une

protection oculaire. Le port de masque à poussières, chaussures de sécurité

antidérapantes, casque de sécurité et protections antibruit adaptés aux

différentes conditions de travail réduit le risque de blessures corporelles.

• Eviter tout démarrage accidentel ou intempestif. S’assurer que l’interrupteur

marche-arrêt soit en position d’arrêt lorsque l’appareil n’est utilisé.

• Enlever toute clé et tout instrument de réglage avant de mettre l’appareil

en marche. Une clé ou un instrument de réglage laissé fixé à un élément en

rotation de l’appareil électrique peut entraîner des blessures physiques

• Ne pas essayer d’atteindre une zone hors de portée. Se tenir toujours en

position stable permettant de conserver l’équilibre. Cela permet de mieux

contrôler l’appareil électrique dans des situations inattendues.

• Porter des vêtements appropriés. Ne pas porter de vêtements amples ou

des bijoux pendants. Eloigner cheveux, vêtements et gants des pièces

en mouvement. Les vêtements amples, les bijoux pendants et cheveux longs

peuvent être happés par les pièces en rotation.

• Si l’appareil est pourvu de dispositifs destinés au raccord d’équipements

d’extraction et de récupération de la poussière/sciure, s’assurer qu’ils

soient bien fixés et utilisés correctement. L’utilisation de ces dispositifs peut

réduire les risques dus à la poussière.

ATTENTION : L’exposition de l’utilisateur aux vibrations d’un outil peut engendrer

la perte de sens du toucher, des engourdissements, picotements et réduire

la préhension de l’appareil. Des expositions prolongées peuvent engendrer

l’apparition chronique de ces symptômes. Si nécessaire, réduisez le temps

d’utilisation de l’outil. Utilisez les cas de figure avec les caractéristiques relatives

aux vibrations, si données, pour calculer la durée et la fréquence de l’utilisation

de l’appareil. Les normes directives 2002/44/CE relatives aux vibrations sur le

lieu de travail peuvent fournir des informations pratiques même pour un usage

domestique. Si dans un premier temps vous commencez à sentir inconfortable à

cause des vibrations, ARRÊTER immédiatement l’utilisation de l’appareil.

ATTENTION : Toujours porter des protections auditives lorsque le niveau sonore

excède 80 dB et limiter le temps d’exposition. Si les niveaux sonores ne sont

pas assez atténués avec un casque anti-bruit arrêter l’utilisation de l’appareil, et

vérifiez bien que la protection sonore soit bien appropriée par rapport au niveau

sonore.

Utilisation et entretien des appareils

• Entretien des appareils. Vérifier que les éléments rotatifs soient bien

alignés et non grippés. S’assurer de l’absence de pièces cassées ou

endommagées susceptibles de nuire au bon fonctionnement de l'appareil.

Si l’appareil est endommagé, le faire réparer avant toute utilisation. De

nombreux accidents sont dus à un mauvais entretien d’un outil.

8

Page 10

633548 5 Accessoires outils pneumatiques et compresseurs

• Veiller à ce que les outils de coupe soient tenus affûtés et propres. Des

outils de coupe bien entretenus, aux tranchants bien affûtés, sont moins

susceptibles de se gripper et sont plus faciles à contrôler.

• Utiliser l’appareil, les accessoires et outils à monter conformément à ces

instructions, en tenant compte des conditions de travail et de la tâche

à réaliser. Toute utilisation d’un appareil autre que celle pour laquelle il a été

conçu peut entraîner des situations à risque.

Révision

• Ne faire réparer votre appareil électrique que par un réparateur qualifié

utilisant uniquement des pièces de rechange identiques.

Consignes de sûreté relatives aux

outils pneumatiques

Environnements dangereux

• Assurez-vous de disposer d’un espace suffisamment dégagé autour de la zone

de travail. Sachez que les tuyaux flexibles d’alimentation en air comprimé

peuvent représenter un danger de trébuchage. Veillez à les disposer de manière

à réduire autant que possible ce danger.

Protégez vos yeux

• Portez toujours des lunettes de sécurité.

Protégez votre ouïe

• Portez toujours des protections auditives

Protégez-vous des vibrations

• Les outils électriques portatifs produisent des vibrations et ne doivent pas être

utilisés pendant de longues périodes sans marquer de pause. Les vibrations

peuvent en effet provoquer des maladies. En conservant la chaleur, des gants

portés par l’utilisateur peuvent lui permettre de maintenir une bonne circulation

sanguine dans les doigts.

Portez un équipement de protection

• Portez toujours un équipement de protection adapté, comprenant entre autres

une combinaison de travail, des gants, un masque, etc.

• Il est de la responsabilité de l’utilisateur de s’assurer que toute personne

se trouvant à proximité de la zone de travail soit également pourvue d’un

équipement de sécurité approprié.

Utilisez un tuyau flexible d’air comprimé adapté

• Utilisez des tuyaux flexibles légers pour raccorder l’outil au compresseur d’air.

• La plupart des outils pneumatiques demandent l’utilisation d’un flexible

serpentin ; les flexibles droits ne doivent être employés qu’avec les pistolets

pulvérisateurs.

• Avant toute pulvérisation, assurez-vous que le pistolet soit raccordé à une

alimentation en air propre et filtré.

Débranchez l’outil avant tout changement

• Assurez-vous toujours que votre outil pneumatique se soit complètement arrêté

de fonctionner avant de le déposer.

• Débranchez toujours l’outil de l’alimentation en air comprimé avant tout

travail d’entretien, de réparation ou avant changer lames, disques et autres

accessoires.

• Assurez-vous toujours que votre outil pneumatique soit en position éteinte

avant de le brancher à l’alimentation en air comprimé. Sachez que les outils

pneumatiques peuvent conserver une pression résiduelle après utilisation.

Purgez toujours la pression d’air de l’outil après avoir fermé l’alimentation en

air comprimé.

Ménagez l’appareil

• Ne surchargez pas l’appareil. En laissant l’appareil fonctionner à sa vitesse

optimale, vous prolongerez sa durée utile et bénéficierez d’un meilleur

rendement

• N’employez pas une pression d’air comprimé supérieure au niveau

recommandé. Une pression excessive peut entraîner une usure précoce des

pièces en rotation et favoriser les dysfonctionnements. Elle peut également

conduire à une fissure du carter

• Ne tentez pas de modifier un outil pneumatique. Toute tentative de modification

de votre outil pourrait entraîner des blessures graves sur vous-même ou les

personnes se trouvant autour de vous et annulera sa garantie.

vous et annulera sa garantie.

Utilisation des pistolets à peinture

• Ne dirigez pas le pistolet à peinture vers une personne ou un animal

• Lors de la pulvérisation de peinture, tenez-vous à l’écart des sources de chaleur

et des flammes nues.

Présentation du produit

1 Gonfleur de pneu

2 Soufflette

3 Pistolet de dégraissage et de peinture sous-couche

4 Tuyau spirale

5 Pistolet pulvérisateur

6 Gâchette

7 Buse

8 Cartouche

9 Bouton de réglage de fluide

10 Bouton de réglage du jet d’air

11 Obturateur d’air

Déballage

• Déballez le produit avec soin. Veillez à retirer tout le matériau d’emballage et

familiarisez-vous avec toutes les caractéristiques du produit.

• Si des pièces sont endommagées ou manquantes, faites-les réparer ou

remplacer avant d’utiliser l’appareil.

www.silverlinetools.com

9

Page 11

F

Instructions d’utilisationn

Remarque : Vérifier tous les branchements soient corrects, et que la pression de

fonctionnement ne dépasse pas la pression maximale indiquée pour l’utilisation

de l’appareil.

Voir le diagramme ci-dessous pour un branchement recommandé d’air comprimé,

qui indique également le branchement d’un filtre à air pour supprimer l’humidité

dans le circuit d’air. Si des vibrations apparaissent durant l’utilisation d’un de ces

outils, il est recommandé d’utiliser des tuyaux en caoutchouc.

SÉPARATION DE L’EAU

RACCORD RAPIDE

COUPLEUR OUTIL

PNEUMATIQUE

Si les raccords rapides ne sont pas pré-montés sur les outils, fixez-les en les

vissant sur la partie basse de la poignée de chaque accessoire. Pour éviter et

éliminer les fuites, utiliser de la bande de PTFE sur le filetage du raccord rapide.

La soufflette

Brancher la soufflette (2) sur le circuit d’air et appuyer sur la gâchette. Cet outil est

très utile pour nettoyer la poussière ou les copeaux.

Gonfleur de pneu

• Pour faire fonctionner le gonfleur de pneu (1), raccordez-le à la ligne d’air, et à

la valve du pneu.

• Pour gonfler le pneu, appuyez sur la gâchette. Attention, le taux de gonflage est

important : ne pas surgonfler le pneu, cela pourrait l’endommager.

• Pour vérifier la pression du pneu, relâchez la gâchette. Le manomètre indiquera

la pression actuelle du pneu. Lors du gonflage, vérifier régulièrement le

manomètre en relâchant la gâchette

Remarque : Pendant le gonflage, la pression indiquée par le manomètre est la

pression du circuit d’air, pas celle du pneu.

Dégraissage et peinture sous-couche

Remarque : Toujours débrancher le pistolet de dégraissage et de peinture sous-

couche (3) de l’alimentation en air avant de remplir la cartouche (8)

1. Dévissez la cartouche de l’ensemble gâchette/buse.

2. Remplissez la cartouche avec un liquide de dégraissage approprié (cet

3. Remettez en place l’ensemble gâchette/buse en le fixant solidement.

4. Pour faire fonctionner le pistolet de dégraissage, appuyez sur la gâchette (6).

• La buse (7) permet de régler la diffusion. Dévisser la bague de serrage pou

permettre le réglage de la buse principale. Une fois réglée, revisser la bague de

serrage. Il est à noter que la viscosité du liquide influe sur sa diffusion.

• Un réglage correct de buse et du niveau de pression d’air vous permettra de

trouver la meilleure diffusion possible en fonction de la tâche à effectuer.

RACCORD

TUYAU DE

RACCORDEMENT

appareil est utilisable avec différentes huiles, liquide de nettoyage et

d’antirouille)

Le pistolet pulvérisateur

Remplissage

1. Débranchez toujours le pistolet pulvérisateur (5) de l’alimentation en air

avant de le remplir.

2. La peinture doit être toujours pré mélangée et filtrée en respectant les

instructions du fabricant.

3. Enlevez la cartouche (8) en la dévissant de son couvercle. La cartouche

pourra alors être remplie.

4. Remettez en place la cartouche et serrez-la.

Installation

1. Raccordez le pistolet pulvérisateur à l’alimentation en air. Il est important

de fournir un air filtré et propre. Si vous disposez d’un graisseur en ligne,

assurez-vous qu’il soit éteint et que le séparateur d’eau fonctionne bien. La

présence d’huile et d’eau contamine la peinture

2. Pour changer l’orientation du ventilateur, dévisser l’obturateur d’air (11) et

faites pivoter la buse (7) dans la position désirée. Revisser l’obturateur d’air.

3. Pour modifier la diffusion d’air du ventilateur, faites tourner le bouton de

réglage de jet d’air (10).

4. Pour régler le débit correct du liquide, manœuvrez le bouton de réglage de

fluide (9) qui influe sur l’usage de la gâchette puis sur le niveau du débit

maximum.

FLEXIBLE SERPENTIN

MAMELON

GRAISSEUR

RÉGULATEUR

A PURGER

QUOTIDIENNEMENT

ALIMENTATION EN

AIR COMPRIMÉ

Peinture

• Assurez-vous de porter les équipements de sécurité nécessaires et que les

surfaces qui ne vont pas être peintes, soient protégées.

• Amorcer le pulvérisateur sans le diriger vers la surface de travail, jusqu’à ce la

diffusion de la peinture soit homogène.

• Déplacez toujours le pistolet avec une vitesse uniforme et d’une distance

correct de la surface de travail, pour assurer une couverture uniforme.

• Selon la surface de travail à peindre, exercez-vous à peindre avant de

commencer un travail important.

• Ne pas surcharger la surface avec trop de peinture car elle risque de couler

• Laissez la peinture sécher lentement avant d’appliquer une seconde couche.

• Ne laissez pas la peinture sécher dans le pistolet. Nettoyez toujours le pistolet

immédiatement après utilisation

Nettoyage

• Enlevez la cartouche (8), et vidangez la peinture restante.

• Versez un produit de nettoyage approprié dans la cartouche, et fixez-la à

nouveau sur le pistolet de peinture.

• Secouez le pistolet pour détacher la peinture à l’intérieur de la cartouche.

• Rebranchez le pistolet à l’alimentation en air, et pulvérisez de la peinture sur

une chute de matériau jusqu’à ce que le jet de pulvérisation devienne bien clair.

Répétez si nécessaire.

• Enlevez l’obturateur d’air (11) et trempez le dans du produit de nettoyage.

• Enlevez la peinture résiduelle avec une petite brosse à poils raides. Ne tentez

pas de nettoyer les passages d’air avec un objet métallique, le bouchon de

peinture pourrait alors devenir définitivement endommagé.

• Enlevez le pointeau en dévissant complètement le bouton de réglage de fluide

(9). Nettoyez le pointeau, et vérifiez qu’il n’est pas courbé ou endommagé.

• Une fois que le pistolet est complètement nettoyé et séché, remontez-le et

rangez-le dans un endroit sec

• Il peut être utile de lubrifier le pointeau pour garder l’outil en bonne condition

de fonctionnement. Utilisez un lubrifiant adéquat en petite quantité, puis rincer

abondamment avec une solution nettoyante pour être sûr d’éliminer tout résidu

de lubrifiant qui pourrait contaminer la peinture.

En cas de problème

Remarque : Vérifiez toujours dans un premier temps s’il n’y a pas de fuites d’air

au niveau du circuit ou au niveau des branchements sur les accessoires ou le

compresseur.

Symptômes Causes

Solutions

possibles

Volume de diffusion de

peinture faible

Diffusion excessive de

la peinture

Diffusion de la peinture

non homogène

Pression d’air faible Augmenter la pression

Pression d’air trop

importante

Trou d’air de la

cartouche bouchée,

buse bouchée ou

mauvais assemblage

Diminuer la pression

Déboucher le trou

d’air du couvercle

de la cartouche et

nettoyer le pistolet

et réassembler

correctement. Il

est possible que le

pointeau ait besoin

d’être lubrifié

10

Page 12

633548 5 Accessoires outils pneumatiques et compresseurs

Garantie Silverline Tools

Ce produit Silverline bénéficie d’une garantie

de 3 ans

Enregistrez votre produit sur www.silverlinetools.com dans les 30 jours

suivant l’achat pour pouvoir bénéficier de la garantie de 3 ans. La période

de garantie commence à partir de la date d’achat figurant sur votre facture

d’achat.

Enregistrement de votre achat

Sur le site silverlinetools.com, sélectionnez le bouton d’enregistrement

et saisissez :

• Vosinformationspersonnelles,

• Lesinformationsconcernantleproduitetl’achat.

Vous recevrez le Certificat de garantie au format PDF. Veuillez l’imprimer et

le conserver avec votre achat.

La période de garantie prend effet à compter de la date de l’achat en

magasin, indiquée sur votre facture d’achat.

VEUILLEZ CONSERVER VOTRE FACTURE D’ACHAT.

Si ce produit est défectueux pendant les 30 jours qui suivent l’achat,

retournez-le au magasin où vous l’avez acheté, avec votre facture, en

expliquant en détail le problème. Le produit sera remplacé ou vous serez

remboursé(e).

Si ce produit est défectueux après cette période de 30 jours,

retournez-le à :

Silverline Tools Service Centre

PO Box 2988

Yeovil

BA21 1WU

Royaume-Uni

Toute demande de service sous garantie doit être soumise pendant la

période de garantie.

Avant toute intervention sous garantie, veuillez présenter la facture d’achat

originale et indiquer la date d’achat, votre nom, votre adresse et le lieu

d’achat.

Veuillez expliquer en détail la défaillance nécessitant la réparation.

Les demandes de service sous garantie faites pendant la période de

garantie seront vérifiées par Silverline Tools pour établir si la défaillance du

produit est liée à un vice de matériau ou de fabrication.

Les frais de port ne seront pas remboursés. Les articles retournés doivent

se trouver dans un état de propreté et offrir une sécurité suffisante

pour permettre les travaux de réparation et doivent avoir été emballés

soigneusement pour éviter tout dommage ou toute blessure pendant le

transport. Nous pouvons refuser les livraisons qui ne sont pas convenables

ou sûres.

Toute intervention sera effectuée par Silverline Tools ou ses agents de

réparation agréés.

La réparation ou le remplacement du produit n’allongera pas la période

de garantie.

Les anomalies que nous reconnaissons être couvertes par la garantie

seront rectifiées par la réparation de l’outil, sans frais (hormis les

frais de port) ou par son remplacement par un outil en parfait état de

fonctionnement.

Déclaration de conformité CE

Le soussigné : Mr Darrell Morris

Autorisé par : Silverline Tools

Déclare que le produit :

Description : 5 Accessoires outils pneumatiques et compresseurs

Code du produit : 633548

Est conforme aux directives suivantes :

• Directive sur les machines 2006/42/CE

• EN1953:1998+A1:2009

• EN 792

Conditions de garantie des outils Silverline

Les pièces ou les outils remplacés deviendront la propriété de

Silverline Tools.

La réparation ou le remplacement de votre produit sous garantie vous

apporte des avantages ; ces avantages s’ajoutent à vos droits statutaires

en tant que consommateur sans les affecter aucunement.

La présente garantie couvre :

La réparation du produit, s’il peut être vérifié, à la satisfaction de Silverline

Tools, que les défaillances du produit ont été provoquées par un vice de

matériau ou de fabrication au cours de la période de garantie.

L’utilisation de ce produit dans l’UE

Si une pièce n’est plus disponible ou n’est plus fabriquée, Silverline Tools la

remplacera par une pièce de rechange opérationnelle.

La présente garantie ne couvre pas :

Silverline Tools ne garantit pas les réparations du produit engendrées par :

L’usure normale provoquée par l’utilisation conforme aux instructions

d’utilisation, concernant par exemple les lames, les charbons, les

courroies, les ampoules, les batteries, etc.

Le remplacement de tout accessoire fourni tel que les forets, les lames, les

feuilles abrasives, les outils de coupes et autres articles associés.

Les dommages et les défaillances accidentels causés par des négligences

d’utilisation ou d’entretien, une utilisation impropre, une utilisation ou une

manipulation inconsidérée du produit.

L’utilisation du produit à des fins autres que son utilisation domestique

normale.

La moindre modification ou altération du produit.

L’utilisation de pièces et d’accessoires qui ne sont pas des composants

d’origines Silverline Tools.

Une installation défectueuse (sauf si l’installation a été réalisée par

Silverline Tools).

Les réparations ou les modifications réalisées par des tiers autres que

Silverline Tools ou ses agents de réparation agréés.

Toute demande de service autre que le droit de rectifier les défaillances

de l’outil indiquées dans les présentes conditions de garantie ne sont pas

couvertes par la présente garantie.

La documentation technique est conservée par : Silverline Tools

Organisme notifié : Intertek Testing Services

Lieu de la déclaration : Shanghai, Chine

Date : 27/11/12

Signature :

Directeur général

Nom et adresse du fabricant ou de son représentant agréé :

Silverline Tools, Boundary Way, Lufton Trading Estate, Yeovil, Somerset, BA22 8HZ

Royaume-Uni

www.silverlinetools.com

11

Page 13

D

Beschreibung der Symbole

Auf dem Leistungsschild des Werkzeugs sind möglicherweise Symbole abgebildet.

Sie vermitteln wichtige Informationen über das Produkt oder dienen als

Gebrauchsanweisung.

Gehörschutz tragen

Augenschutz tragen

Atemschutz tragen

Kopfschutz tragen

Schutzhandschuhe tragen

Bedienungsanleitung sorgfältig lesen

Erfüllt die entsprechenden rechtlichen Vorschriften und

Sicherheitsnormen

Technische Daten

l/min

(3 – 6

cfm)

110 –

min

Ent-

Reifen-

fettungs-

85 – 170

(3 – 6 cfm)

füller

pistole

0 – 4 bar

3,5 bar

(0 – 60

(55 psi)

psi)

170 – 255

l/min

l/min

(6 – 9

cfm)

--- --- --- ---

Spritzpistole

Arbeits-

3,5 bar

druck

(55 psi)

85 – 170

Luftdurch-

satz*

Flüssig-

keits-

kapazität

verbrauch

*cfm-Werte basieren auf gerundeten scfm-Werten

Aufgrund der fortlaufenden Weiterentwicklung unserer Produkte können sich die

technischen Daten von Silverline-Produkten ohne vorherige Ankündigung ändern.

Auch wenn dieses Gerät wie vorgeschrieben verwendet wird, ist es nicht möglich,

sämtliche Restrisiken auszuschließen. Mit Vorsicht verwenden. Sollten Sie sich

unsicher sein, wie dieses Gerät sicher zu verwenden ist, benutzen Sie es nicht!

750 ml 900 ml --- --- ---

Flüssig-

keits-

200 ml/

Düse 1,5 mm 4,5 mm --- 2,0 mm w

Druckluft-

pistole

2 – 6 bar

(30 – 90

psi)

85 – 170

l/min

(3 – 6

cfm)

Druckluft-

Spiral-

schlauch

8 bar

(120 psi)

Maximal-

druck

---

Betreiben Sie das Gerät nicht, bevor Sie nicht diese Bedienungsanleitung und alle

Etiketten sorgfältig gelesen und verstanden haben. Bewahren Sie diese Anleitung

für zukünftiges Nachschlagen zusammen mit dem Gerät auf. Stellen Sie sicher,

dass alle Personen, die dieses Gerät verwenden, die Anleitungen vollständig

gelesen und verstanden haben. Auch wenn dieses Gerät wie vorgeschrieben

verwendet wird, ist es nicht möglich, sämtliche Restrisiken auszuschließen. Mit

Vorsicht verwenden. Sollten Sie sich unsicher sein, wie dieses Gerät sicher zu

verwenden ist, benutzen Sie es nicht!

Allgemeine Sicherheitshinweise

WARNUNG! Lesen Sie alle Sicherheitshinweise und Anweisungen.

Versäumnisse bei der Einhaltung der Sicherheitshinweise und Anweisungen

können elektrischen Schlag, Brand und/oder schwere Verletzungen verursachen.

Bewahren Sie alle Sicherheitshinweise und Anweisungen für die Zukunft auf.

Arbeitsplatzsicherheit

• Halten Sie Ihren Arbeitsbereich sauber und gut beleuchtet. Unordnung oder

unbeleuchtete Arbeitsbereiche können zu Unfällen führen.

• Arbeiten Sie mit dem Werkzeug nicht in explosionsgefährdeter Umgebung,

in der sich brennbare Flüssigkeiten, Gase oder Stäube befinden.

• Halten Sie Kinder und andere Personen während der Benutzung des

Werkzeugs fern. Bei Ablenkung können Sie die Kontrolle über das Gerät

verlieren.

Sicherheit von Personen

• Seien Sie aufmerksam, achten Sie darauf, was Sie tun, und gehen Sie mit

Vernunft an die Arbeit mit einem Werkzeug. Benutzen Sie kein Werkzeug,

wenn Sie müde sind oder unter dem Einfluss von Drogen, Alkohol oder

Medikamenten stehen. Ein Moment der Unachtsamkeit beim Gebrauch des

Werkzeuges kann zu ernsthaften Verletzungen führen.

• Tragen Sie persönliche Schutzausrüstung und immer eine Schutzbrille.

Das Tragen persönlicher Schutzausrüstung, wie Staubmaske, rutschfeste

Sicherheitsschuhe, Schutzhelm oder Gehörschutz, je nach Art und Einsatz des

Werkzeuges, verringert das Risiko von Verletzungen.

• Vermeiden Sie eine unbeabsichtigte Inbetriebnahme. Vergewissern Sie sich,

dass das Werkzeug ausgeschaltet ist, wenn es nicht verwendet wird, und dass

andere evtl. vorhandene Einschaltsperren aktiviert sind.

• Entfernen Sie Einstellwerkzeuge oder Schraubenschlüssel, bevor Sie

das Werkzeug einschalten. Ein Werkzeug oder Schlüssel, der sich in einem

drehenden Geräteteil befindet, kann zu Verletzungen führen.

• Vermeiden Sie eine unnatürliche Körperhaltung. Sorgen Sie für einen

sicheren Stand und halten Sie jederzeit das Gleichgewicht. Auf diese Weise

lässt sich das Elektrowerkzeug in unerwarteten Situationen besser kontrollieren.

• Tragen Sie geeignete Kleidung. Tragen Sie keine weite Kleidung oder

Schmuck. Halten Sie Haare, Kleidung und Handschuhe fern von sich

bewegenden Teilen. Lockere Kleidung, Schmuck oder lange Haare können von

sich bewegenden Teilen erfasst werden.

• Wenn Staubabsaug- und -auffangeinrichtungen montiert werden können,

vergewissern Sie sich, dass diese angeschlossen sind und richtig

verwendet werden. Verwendung einer Staubabsaugung kann Gefährdungen

durch Staub verringern.

WARNUNG: Bei der Benutzung mancher Werkzeuge wird der Benutzer Vibrationen

ausgesetzt, welche zum Verlust des Berührungssinnes, zu Taubheitsgefühl,

Kribbeln und zu einer Verminderung der Handgreifkraft führen können. Langfristige

Belastung kann zu chronischen Beschwerden führen. Begrenzen Sie falls nötig

die Exposition zu Vibrationen. Beurteilen Sie die Vibrationsbelastung unter

Zuhilfenahme der Technischen Daten des jeweiligen Werkzeuges, und bestimmen

Sie die zulässige Belastungsdauer und –häufigkeit. Die EU-Direktive 2002/44/

EG enthält Informationen über zulässige Vibrationsbelastung am Arbeitsplatz und

kann auch auf Heimarbeiten angewandt werden. Beenden Sie die Benutzung eines

Werkzeuges sofort, wenn Sie in irgendeiner Art und Weise Unbehagen aufgrund

der Vibrationsbelastung fühlen.

WARNUNG: Tragen Sie in Bereichen wo der Lärmpegel 80 dB überschreitet

unbedingt angemessenen Gehörschutz, und begrenzen Sie die Belastungsdauer

wo nötig. Sollte trotz Gehörschutz Unbehagen irgendeiner Art auftreten, beenden

Sie die Arbeit unverzüglich und überprüfen Sie den Gehörschutz auf korrekten Sitz

und Funktion, und stellen Sie sicher, dass dieser einen angemessenen Schutz für

den Lärmpegel bietet, der von den verwendeten Werkzeugen ausgeht.

Werkzeugbenutzung und -pflege

• Pflegen Sie Werkzeuge mit Sorgfalt. Kontrollieren Sie, ob bewegliche Teile

einwandfrei funktionieren und nicht klemmen, ob Teile gebrochen oder

so beschädigt sind, dass die Funktion des Werkzeuges beeinträchtigt ist.

Lassen Sie beschädigte Teile vor dem Einsatz des Gerätes reparieren. Viele

Unfälle haben ihre Ursache in schlecht gewarteten Werkzeugen.

• Halten Sie Schneidwerkzeuge scharf und sauber. Sorgfältig gepflegte

Schneidwerkzeuge mit scharfen Schneidkanten verklemmen sich weniger und

sind leichter zu führen.

12

Page 14

633548 Druckluftwerkzeug u. Kompressor-Zubehör, 5-tlg. Satz

• Verwenden Sie Werkzeugzubehör, Einsatzwerkzeuge usw. entsprechend

diesen Anweisungen. Berücksichtigen Sie dabei die Arbeitsbedingungen

und die auszuführende Tätigkeit. Der Gebrauch von Werkzeugen für andere

als die vorgesehenen Anwendungen kann zu gefährlichen Situationen führen.

Service

• Lassen Sie Ihr Werkzeug nur von qualifiziertem Fachpersonal und nur mit

Original-Ersatzteilen reparieren. Damit wird sichergestellt, dass die Sicherheit

des Werkzeuges erhalten bleibt.

Sicherheitshinweise für

Druckluftwerkzeuge

Gefährliche Arbeitsumgebung

• Achten Sie immer darauf, dass ausreichend freier Raum um den Arbeitsbereich

verfügbar ist. Verwenden Sie Spritzwerkzeuge nur in gut belüfteten Bereichen

oder speziellen Spritzkabinen. Beachten Sie, dass Luftschläuche eine

Stolpergefahr darstellen können. Legen Sie Schläuche stets so, dass die Gefahr

möglichst gering gehalten wird.

Augen schützen

• Tragen Sie immer eine Schutzbrille.

Gehör schützen

• Tragen Sie immer einen Gehörschutz.

Schutz vor Vibrationen

• Tragbare Druckluftwerkzeuge können Schwingungskräfte erzeugen und sollten

nie über längere Zeiträume ohne Pausen verwendet werden. Vibrationen können

gesundheitsschädigend sein. Handschuhe können zu einer guten Durchblutung

der Finger beitragen.

Schutzkleidung

• Tragen Sie stets geeignete Schutzausrüstung einschließlich, aber nicht

beschränkt auf Arbeitsschutzanzüge, Handschuhe, Gesichtsmasken usw.

• Es liegt in der Verantwortung des Benutzers, dafür zu sorgen, dass allen in

der Nähe des Arbeitsbereichs befindlichen Personen ebenfalls angemessene

Schutzausrüstung zur Verfügung steht.

Den richtigen Luftschlauch verwenden

• Verwenden Sie zwischen Werkzeug und Wand- bzw. Kompressorkupplung

immer leichte Schläuche.

• Die meisten Druckluftwerkzeuge sollten mit einem Spiralschlauch verwendet

werden; für Spritzpistolen muss jedoch ein glatter Schlauch verwendet werden.

• Beim Sprühen ausschließlich saubere, gefilterte Druckluft verwenden.

Ausschalten nicht vergessen

• Stellen Sie stets sicher, dass der Betrieb des Druckluftwerkzeugs vollständig

eingestellt wurde, bevor Sie es ablegen.

• Trennen Sie Druckluftwerkzeuge stets von der Druckluftquelle, bevor Sie

Wartungsarbeiten daran durchführen oder Klingen, Teller und andere Aufsätze

austauschen.

• Stellen Sie stets sicher, dass das Druckluftwerkzeug ausgeschaltet ist, bevor Sie

es an die Druckluftquelle anschließen. Beachten Sie, dass Druckluftwerkzeuge

nach dem Gebrauch noch Restdruck enthalten können. Lassen Sie nach dem

Abstellen der Druckluftquelle stets den Luftdruck aus dem Gerät ab.

Gerät nicht unsachgemäß verwenden

• Überlasten Sie das Gerät nicht. Der Betrieb bei optimaler Drehzahl verlängert die

Lebensdauer des Werkzeugs und steigert die Effizienz.

• Erhöhen Sie den Luftdruck nicht über das empfohlene Maß hinaus. Übermäßiger

Druck führt zum Verschleiß der beweglichen Teile und kann zum Ausfall des

Geräts führen. Zudem kann das Werkzeuggehäuse dadurch reißen.

• Versuchen Sie nicht, Druckluftwerkzeuge zu modifizieren.

Modifikationsversuche führen zum Erlöschen der Garantie und können

schwerwiegende Verletzungen des Bedieners oder umstehender Personen

verursachen.

Verwendung von Spritzpistolen

• Richten Sie Spritzpistolen weder auf Menschen noch auf Tiere.

• Halten Sie sich beim Sprühen von Hitzequellen und offenen Flammen fern.

Produktübersicht

1 Reifenfüller

2 Druckluftpistole

3 Entfettungspistole (Flüssigkeits-Sprühpistole)

4 Druckluft-Spiralschlauch

5 Spritzpistole

6 Auslöser

7 Düse

8 Behälter

9 Durchflussmengen-Regler

10 Regler für Sprühmustereinstellung

11 Düsenhalterring

Auspacken des Gerätes

• Packen Sie Ihr Werkzeug vorsichtig aus und überprüfen Sie es. Machen Sie sich

vollständig mit allen seinen Eigenschaften und Funktionen vertraut.

• Vergewissern Sie sich, dass sämtliche Teile des Werkzeugs vorhanden und in

einwandfreiem Zustand sind. Sollten Teile fehlen oder beschädigt sein, lassen

Sie diese ersetzen, bevor Sie das Werkzeug verwenden.

www.silverlinetools.com

13

Page 15

D

Bedienungsanleitung

HINWEIS: Vergewissern Sie sich vor Beginn der Arbeit, dass alle Verbindungen

gesichert sind, und dass der Betriebsdruck den zulässigen Arbeitsdruck des

jeweiligen Werkzeuges nicht überschreitet.

Nachfolgende Abbildung zeigt die empfohlene Druckluftinstallation mit

Wartungseinheit zur Entfernung von Feuchtigkeit aus der Druckluftversorgung. Die

Verwendung eines Anschluss-Schlauchstückes („Leader Hose“) aus Gummi wird

empfohlen, wenn bei der Verwendung eines der Werkzeuge Vibrationen auftreten.

ANSCHLUSSSTÜCK FÜR

DRUCKLUFTGERÄT

Falls die Schnellkupplungen nicht an den Werkzeugen vorinstalliert sind, müssen

diese in die Handgriffe der jeweiligen Werkzeuge eingeschraubt werden. Die

Gewinde der Schnellkupplungen sind mit PTFE-Band einzudichten.

Druckluftpistole

• Verbinden Sie die Druckluftpistole (2) mit der Luftversorgung und drücken Sie

zur Verwendung den Auslöser. Dieses Werkzeug ist nützlich zur Entfernung von

Spänen oder Staub von Werkbänken, aus schwer zugänglichen Bereichen, usw.

Reifenfüller

1. Verbinden Sie den Reifenfüller (1) mit der Luftversorgung und dem Ventil des

aufzupumpenden Reifens.

2. Drücken Sie den Auslöser um Luft in den Reifen zu pumpen. Achten Sie

darauf den Reifen nicht zu überfüllen, da das Gerät einen hohen Luftstrom

liefert.

3. Lassen Sie den Auslöser los, um den aktuellen Reifendruck auf dem

Manometer ablesen zu können. Unterbrechen Sie den Füllvorgang in

regelmäßigen Abständen, um diese Überprüfung durchzuführen.

Hinweis: Während des Füllens, d.h. bei gedrücktem Auslöser, zeigt das

Manometer den Betriebsdruck in der Luftversorgung des Gerätes an und NICHT

den Reifendruck!

Entfettungspistole (Flüssigkeits-Sprühpistole)

HINWEIS: Entfernen Sie die Entfettungspistole (3) stets von der

Druckluftversorgung bevor Sie den Behälter (8) befüllen!

1. Schrauben Sie den Behälter (8) von der Handgriffeinheit ab.

2. Befüllen Sie den Behälter mit der zu verwendenden Flüssigkeit

(das Gerät kann mit einer Vielzahl unterschiedlicher Entfettungs- u.

Konservierungsmittel, sowie Schmierstoffen verwendet werden).

3. Befestigen Sie den Behälter ordnungsgemäß an der Handgriffeinheit.

4. Drücken Sie zur Benutzung der Entfettungspistole den Auslöser.

• Das Sprühmuster kann über die Düse (7) eingestellt werden. Lösen Sie dazu

zunächst die Kontermutter auf dem Düsengewinde. Stellen Sie anschließend

das gewünschte Sprühverhalten ein und fixieren Sie die Einstellung danach

durch festziehen der Kontermutter. Bedenken Sie, dass die Viskosität der zu

sprühenden Flüssigkeit das Sprühmuster beeinflussen wird.

• Das korrekte Anpassen von Düse und Luftdruck ermöglicht die Einstellung des

für das jeweilige Sprühmedium optimalen Sprühmusters.

SCHNELLKUPPLUNGSADAPTER

NIPPEL

FÜHRUNGSSCHLAUCH

Spritzpistole

Befüllen

1. Entfernen Sie die Spritzpistole (5) stets von der Druckluftversorgung bevor

Sie den Behälter befüllen!

2. Verwendete Lacke sollte stets nach Angaben des Lackherstellers vorbereitet

und zur Verwendung mit Spritzpistolen verdünnt werden.

3. Entfernen Sie den Behälter (8) indem Sie den Deckel abschrauben. Er kann

anschließend befüllt werden.

4. Bringen Sie den Behälter wieder fest an.

Vorbereiten

1. Verbinden Sie die Spritzpistole mit der Luftversorgung. Es ist wichtig, dass

die Pistole mit sauberer gefilterter Druckluft versorgt wird. Falls in Ihrer

Druckluftversorgung ein Öler integriert ist, schalten Sie diesen aus und

stellen Sie sicher, dass Feuchtigkeit trotzdem durch Filtration entfernt wird.

Jegliches in der Druckluft verbleibende Öl wird den Lack kontaminieren!

2. Lösen Sie den Düsenhalterring (11) etwas, um in der Lage zu sein die Düse

(7) zu drehen und damit die grobe Richtung des Sprühmusters einzustellen.

Ziehen Sie den Düsenhalterring nach erfolgter Einstellung wieder handfest

an.

3. Um die Form des Sprühmusters einzustellen, muss der

Sprühmustereinstellungs-Regler (10) verstellt werden.

4. Über den Durchflussmengen-Regler (9) kann die Durchflussrate an Lack

WASSERABSCHEIDUNG

DRUCKLUFTSCHLAUCH

NIPPEL

NEBELÖLER

DRUCKLUFTREGLER

TÄGLICH

ABLASSEN!

DRUCKLUFTQUELLE

angepasst werden. Dieser Regler limitiert den Verfahrweg des Auslösers und

bestimmt dadurch die maximale Durchflussmenge.

Lackieren

• Bereiten Sie sich auf das Lackieren vor indem Sie sicherstellen, dass Sie

die erforderliche persönliche Schutzausrüstung tragen, sowie dass nicht zu

lackierende Bereiche abgeklebt worden sind.

• Machen Sie die Spritzpistole betriebsbereit indem Sie zunächst vom zu

lackierenden Objekt entfernt sprühen bis ein konstantes Sprühmuster erreicht

wurde.

• Die Einhaltung des korrekten Abstandes von Spritzpistole zum Werkstück, sowie

das Aufrechterhalten einer gleichmäßigen Arbeitsgeschwindigkeit sind für ein

hochwertiges Lackierungsergebnis sehr wichtig.

• Je nach zu bearbeitender Oberfläche kann es notwendig sein schon vor

der Werkstückkante mit dem Sprühen zu beginnen um eine gleichmäßige

Oberfläche zu erzeugen.

• Tragen Sie keinesfalls zu viel Lack auf, da es sonst zu Nasenbildung kommt.

• Lassen Sie Lackschichten vor dem Auftragen weiterer Schichten stets

antrocknen.

• Reinigen Sie die Spritzpistole unmittelbar nach der Benutzung, und sorgen Sie

dafür, dass Lack niemals innerhalb des Gerätes antrocknet.

Reinigen

• Nehmen Sie den Behälter (8) ab, und entfernen Sie jeglichen verbleibenden

Lack.

• Füllen Sie eine geeignete Reinigungsflüssigkeit in den Behälter, und bringen Sie

diesen wieder an der Handgriffeinheit an.

• Schütteln Sie die Spritzpistole um Lack von der Innenseite des Behälters zu

lösen.

• Verbinden Sie die Spritzpistole mit der Luftversorgung und stellen Sie einen

hohen Durchfluss ein. Sprühen Sie auf Restmaterial bis das austretende

Material klar wird. Wiederholen Sie den Reinigungsvorgang falls nötig.

• Entfernen Sie den Düsenhalterring, entnehmen Sie alle Düsenkomponenten und

weichen Sie alle Teile in Reinigungslösung ein, um eine gründlichere Reinigung

durchzuführen.

• Entfernen Sie verbleibende Lackreste mit einer kleinen starren Bürste.

Verwenden Sie zur Reinigung von Luftwegen niemals Metallobjekte.

• Schrauben Sie den Durchflussmengen-Regler (9) aus der Handgriffeinheit

heraus, und entnehmen Sie die Nadel und Feder. Reinigen Sie diese, und

überprüfen Sie vor dem Zusammenbau, dass die Nadel weder verbogen noch

anderweitig beschädigt ist.

• Nach gründlicher Reinigung und Trocknung sollte die Spritzpistole wieder

komplett montiert und zusammengebaut an einem trockenen Ort gelagert

werden.

• Es kann nötig sein die Nadel mit einem geeigneten Schmiermittel zu behandeln.

Sprühen Sie danach jedoch ein geeignetes Reinigungsmittel durch die

Spritzpistole, um jegliche Verunreinigung von lackführenden Komponenten zu

entfernen und eine Kontaminierung des Lackes zu verhindern.

Fehlerbehebung

Hinweis: Überprüfen Sie das Druckluftsystem auf Leckagen bevor Sie an anderer

Stelle nach Fehlern suchen.

Symptom Mögliche Ursache Lösung

LackSprühvolumen sehr

gering

LackSprühvolumen

zu hoch

Ungleichmäßiger

Lackaustritt beim

Sprühen

Luftdruck zu gering Erhöhen Sie den

Luftdruck zu hoch Verringern Sie den

Druckausgleichsöffnung

des Behälters (8)

blockiert, Düse verstopft

oder Werkzeug falsch

montiert

Luftdruck

Luftdruck

Reigen Sie die

Druckausgleichsöffnung

auf der Oberseite des

Behälterdeckels, reinigen

Sie die Spritzpistole

und setzen Sie diese

vorschriftsmäßig

zusammen. Ein

Schmieren der Nadel

könnte ebenfalls

notwendig sein.

14

Page 16

633548 Druckluftwerkzeug u. Kompressor-Zubehör, 5-tlg. Satz

Silverline Tools Garantie

Silverline-Tools-Garantie

Dieses Silverline-Produkt wird mit einer 3-JahresGarantie angeboten

Registrieren Sie dieses Produkt unter silverlinetools.com innerhalb von

30 Tagen nach dem Kauf, um die 3-Jahres-Garantie zu aktivieren. Der

Garantiezeitraum beginnt mit dem Kaufdatum auf Ihrem Kaufbeleg.

Registrierung Ihres Kaufs

Gehen Sie auf silverlinetools.com, klicken Sie auf ‚Registrierung’ und

geben Sie Folgendes ein:

• IhrepersönlichenAngaben

• ProduktdetailsundKaunformationen

Sobald dieses Produkt registriert worden ist, wird Ihre

Garantiebescheinigung im PDF-Format erzeugt. Bitte drucken Sie sie aus

und bewahren Sie sie zusammen mit Ihrem Produkt auf.

Garantiebedingungen

Der Garantiezeitraum beginnt mit dem Kaufdatum im Einzelhandel, das auf

dem Kaufbeleg angegeben ist.

BITTE BEWAHREN SIE IHREN KAUFBELEG AUF

Falls dieses Produkt innerhalb von 30 Tagen nach dem Kauf einen

Defekt aufweisen sollte, bringen Sie es bitte mit Ihrem Kaufbeleg zu dem

Fachhändler, bei dem es gekauft wurde, und informieren Sie ihn über die

Mängel. Das Gerät wird ersetzt oder der Kaufpreis zurückerstattet.

Falls dieses Produkt nach Ablauf von 30 Tagen nach dem Kauf einen Mangel

aufweist, senden Sie es an:

Silverline Tools Service Centre

PO Box 2988

Yeovil

BA21 1WU, Großbritannien

Der Garantieanspruch muss während der Garantiezeit gestellt werden.

Sie müssen den Originalkaufbeleg mit Angabe des Kaufdatums einreichen

und Ihren Namen und Ihre Adresse sowie den Ort des Kaufs angeben, bevor

etwaige Arbeiten durchgeführt werden können.

Sie müssen genaue Angaben über den zu behebenden Defekt machen.

Alle innerhalb der Garantiefrist gemachten Forderungen werden von

Silverline Tools daraufhin überprüft werden, ob es sich bei den Mängeln um

einen Material- oder Fertigungsfehler handelt.

Versandkosten werden nicht zurückerstattet. Alle Produkte müssen sich

in sauberem und sicherem Zustand befinden und sorgfältig verpackt zur

Reparatur eingeschickt werden, um Schäden oder Verletzungen während

des Transports zu vermeiden. Die Annahme ungeeigneter oder unsicherer

Lieferungen kann von uns verweigert werden.

Alle Arbeiten werden von Silverline Tools oder seinen autorisierten

Reparaturwerkstätten durchgeführt.

Die Reparatur oder der Ersatz des Produkts führt nicht zur Verlängerung des

Garantiezeitraums.

Mängel, bei denen unsere Prüfung ergibt, dass sie unter die Garantie fallen,

werden durch kostenlose Reparatur des Werkzeugs (ohne Versandkosten)

oder Ersatz durch ein Werkzeug in einwandfreiem Zustand behoben.

Einbehaltene Werkzeuge oder Teile, die ersetzt wurden, gehen in den Besitz

von Silverline Tools über.

Die Reparatur bzw. der Ersatz Ihres Produkts unter dieser Garantie erfolgt

zusätzlich zu Ihren gesetzlichen Rechten als Verbraucher und hat keine

nachteiligen Folgen auf diese.

Durch die Garantie abgedeckt ist:

Die Reparatur des Produkts, nachdem zur Zufriedenheit von Silverline Tools

nachgewiesen wurde, dass der Defekt durch fehlerhaftes Material oder

mangelhafte Arbeitsausführung bedingt ist und in den Garantiezeitraum fällt.

Wenn ein Ersatzteil nicht mehr erhältlich ist oder nicht mehr hergestellt

wird, kann Silverline Tools es gegen einen funktionellen Ersatz austauschen.

Verwendung des Produkts innerhalb der EU.

Durch die Garantie nicht abgedeckt ist:

Silverline Tools garantiert keine Reparaturen, die durch Folgendes

erforderlich geworden sind:

Normale Verschleißerscheinungen, die trotz Verwendung entsprechend

der Bedienungsanleitung entstehen, z.B. an Messern, Bürsten, Riemen,

Glühbirnen, Batterien usw.

Ersatz von mitgeliefertem Zubehör wie etwa Bohrspitzen, Messern,

Sandpapier, Schneidscheiben und anderen zugehörigen Teilen.

Unfallschäden und Fehler, die durch unsachgemäße Verwendung oder

Wartung, Missbrauch, Nachlässigkeit oder fahrlässige Bedienung oder

Handhabung des Produkts entstanden sind.

Verwendung des Produkts für andere als normale Haushaltszwecke.

Jegliche Veränderungen oder Modifikationen des Produkts.

Die Verwendung von Teilen oder Zubehör, die keine Originalkomponenten

von Silverline Tools sind.

Fehlerhafte Montage (außer, wenn von Silverline Tools vorgenommen).

Reparaturen oder Änderungen, die von anderen als Silverline Tools oder

seinen autorisieren Reparaturwerkstätten durchgeführt wurden.

Ansprüche, die über die Rechte zur Behebung von Mängeln an dem in

diesen Garantiebedingungen genannten Werkzeug hinausgehen.

EG-Konformitätserklärung

Name des Unterzeichners: Mr Darrell Morris

Bevollmächtigt durch: Silverline Tools

Erklärt hiermit, dass das Produkt:

Beschreibung: Druckluftwerkzeug u. Kompressor-Zubehör, 5-tlg. Satz

Artikelnummer: 633548

Mit den folgenden Richtlinien übereinstimmt:

• Maschinenrichtlinie 2006/42/EG

• EN1953:1998+A1:2009

• EN792

Techn. Unterlagen bei: Silverline Tools

Benannte Stelle: Intertek Testing Services

Ort: Shanghai, China

Datum: 27.11.2012

Unterzeichnet von:

Geschäftsführender Direktor

Name und Anschrift des Herstellers oder seines Bevollmächtigten:

Silverline Tools, Boundary Way, Lufton Trading Estate, Yeovil, Somerset, BA22 8HZ,

Großbritannien

www.silverlinetools.com

15

Page 17

ESP

Descripción de los símbolos

Los símbolos siguientes pueden aparecer en la placa de características

de su herramienta. Éstos representan información importante sobre el

producto o instrucciones relativas a su uso.

Lleve protección auditiva

Lleve protección ocular

Lleve protección respiratoria

Lleve un casco de seguridad

Lleve guantes de seguridad

Lea el manual de instrucciones

Conforme a las normas de seguridad y a la

legislación correspondiente

Características técnicas

Pistola de

Pistola de

desen-

pintura

grasado

Presión de

3,5 Bar 3,5 Bar 0 - 4 Bar 2 - 6 Bar

aire

Consumo

85 – 170

de aire

Capacidad

de fluido

Caudal de

fluido

Boquilla 1,5 mm 4,5 mm N/A 2,0 mm N/A

85 – 170

l/min

l/min

750 ml 900 ml N/A N/A N/A

110 - 200

ml/min

- N/A N/A N/A

*Las cifras indicadas en esta tabla son aproximadas.

Silverline Tools se reserva el derecho a modificar las especificaciones del producto

sin previo

aviso. Incluso cuando se esté utilizando según lo prescrito, no es posible eliminar

todos los factores de riesgo residuales. Utilice esta herramienta con precaución. Si

no está completamente seguro de como utilizar esta herramienta correctamente,

no la utilice.

Inflador de

neumáticos

85 – 255

l/min

Pistola de

aire com-

primido

85 – 170

l/min

Manguera

flexible

8 Bar

(máx.)

N/A

Como parte de nuestra política de desarrollo de productos, los datos técnicos de

los productos Silverline pueden cambiar sin previo aviso.

Lea cuidadosamente y asegúrese de entender este manual y cualquier otra

indicación antes de usar este producto. Guarde estas instrucciones con el producto

para poderlas consultar en el futuro. Asegúrese de que todas las personas que

utilizan este producto están completamente familiarizadas con este manual.

Incluso cuando se esté utilizando según lo prescrito, no es posible eliminar

todos los factores de riesgo. Utilice esta herramienta con precaución. Si no está

completamente seguro de como utilizar esta herramienta correctamente, no

intente utilizarla.

Instrucciones generales de

seguridad

ADVERTENCIA Lea todas las advertencias de seguridad e instrucciones. El no

respetar estas advertencias e instrucciones puede causar descargas eléctricas,

incendios y/o lesiones graves.

Conserve estas instrucciones de seguridad para futuras referencias.

Seguridad en el área de trabajo

• Mantenga el área de trabajo limpia y bien iluminada. Las áreas

desordenadas y oscuras invitan a que se produzcan accidentes.

• No maneje herramientas eléctricas en atmósferas explosivas, como por

ejemplo en presencia de líquidos, gases o polvos inflamables.

• Mantenga alejados a los niños y a las personas que estén presentes

mientras esté trabajando con una herramienta eléctrica. Las distracciones

pueden hacerle perder el control de la herramienta.

Seguridad personal

• Manténgase alerta, fíjese en lo que está haciendo y use el sentido común

cuando esté utilizando una herramienta eléctrica. No use una herramienta

eléctrica si se encuentra cansado o bajo la influencia de drogas, alcohol

o medicamentos. Un momento de distracción mientras esté utilizando una

herramienta eléctrica puede provocar lesiones corporales graves.

• Use equipo de protección personal. Use siempre protección ocular. El

uso de equipamientos de seguridad tales como máscara antipolvo, calzado

de seguridad antideslizante, casco duro y protecciones auditivas adecuadas

reducirá el riesgo de lesiones corporales.

• Evite el arranque accidental. Asegúrese de que el interruptor está en la

posición de apagado antes de enchufar la herramienta.

• Quite toda llave de ajuste o de tuercas antes de encender la herramienta

eléctrica. Una llave de tuercas o de ajuste que se ha dejado colocada en una

parte móvil de la herramienta eléctrica puede causar lesiones corporales.

• No adopte posturas forzadas. Manténgase en posición firme y en

equilibrio en todo momento. De este modo, podrá controlar mejor la

herramienta eléctrica en situaciones inesperadas.

• Vístase adecuadamente. No lleve ropa holgada ni joyas. Mantenga el pelo,

la ropa y los guantes alejados de las piezas móviles. La ropa holgada, las

joyas o el pelo largo pueden quedar atrapados en las piezas móviles.

• Si dispone de conexión a sistemas de extracción y recolección de polvo,

asegúrese de que estén conectados y se usen correctamente. El uso de

estos dispositivos puede reducir los riesgos producidos por la inhalación de

polvo.

ADVERTENCIA: La vibración producida al utilizar herramientas eléctricas durante

periodos de tiempo prolongados puede provocar adormecimiento, hormigueo

y disminución de tacto en las manos. Utilizar herramientas continuamente

durante largos periodos de tiempo puede ocasionar lesiones crónicas. Utilice las

indicaciones y los datos de vibración proporcionado por cada fabricante para

calcular el tiempo máximo de exposición. De acuerdo con la directiva 2002/44/

CE todas las áreas de trabajo deben disponer de información relativa a las

vibraciones. PARE inmediatamente su herramienta eléctrica en caso de notar

alguna contradicción.

ADVERTENCIA: Se recomiendan usar medidas de protección sonora cuando