Page 1

3 Year Guarantee

*Register online within 30

days. Terms & Conditions apply

Garantie de 3 ans

*Enregistrez votre produit en ligne

dans les 30 jours. Sous réserve des

Conditions Générales d’utilisation

3 Jahre Garantie

*Registrieren Sie sich innerhalb von 30

Tagen online. Es gelten die allgemeinen

Geschäftsbedingungen

3 años de garantía

*Regístrese online dentro de 30 días.

Se aplican los términos y condiciones

3 anni di garanzia

*Registrarsi on-line entro 30 giorni.

Termini e Condizioni si applicano

3 Jaar Garantie

*Registreer online binnen 30 dagen.

Algemene voorwaarden van toepassing

www.silverlinetools.com

Page 2

R

E

L

V

L

I

S

AIR

R

A

N

I

N

E

E

G

771422

20 Gauge

Air Narrow Crown Stapler 22mm

Air Narrow Crown Stapler 22mm

Agrafeuse pneumatique

à agrafes étroites 22 mm

Druckluftklammergerät für

Schmalrückenklammern, 22 mm

www.silverlinetools.com

Grapadora neumática

para grapas estrechas 22mm

Graffatrice pneumatica

a corona stretta 22 mm

Pneumatische nietmachine,

22 mm

Page 3

3

1

2

8

4

6

7

5

2

Page 4

R

E

V

L

L

I

I

S

AIR

R

N

E

E

A

G

N

®

20 Gauge

Air Narrow Crown Stapler 22mm

English .................. 4

Français ................ 8

Deutsch ................. 12

Español ................. 16

Italiano .................. 20

Nederlands ............ 24

www.silverlinetools.com

3

Page 5

GB

Description of Symbols

The rating plate on your tool may show symbols. These represent important

information about the product or instructions on its use.

Wear hearing protection

Wear eye protection

Wear breathing protection

Wear head protection

Wear hand protection

Read instruction manual

Conforms to relevant legislation and safety standards

Specification

Weight: ....................................................1.10kg

Required pressure: ..................................60-100psi

Staple size: ..............................................20 Gauge

Staple length: ..........................................10-22mm

Staple capacity: .......................................100pces

Air inlet: ...................................................1⁄4" BSP

Sound pressure: ......................................88dB

Vibration level: .........................................2.19m/s

The sound intensity level for the operator may exceed 85dB(A) and

sound protection measures are necessary.

As part of our ongoing product development, specifications of

Silverline products may alter without notice.

2

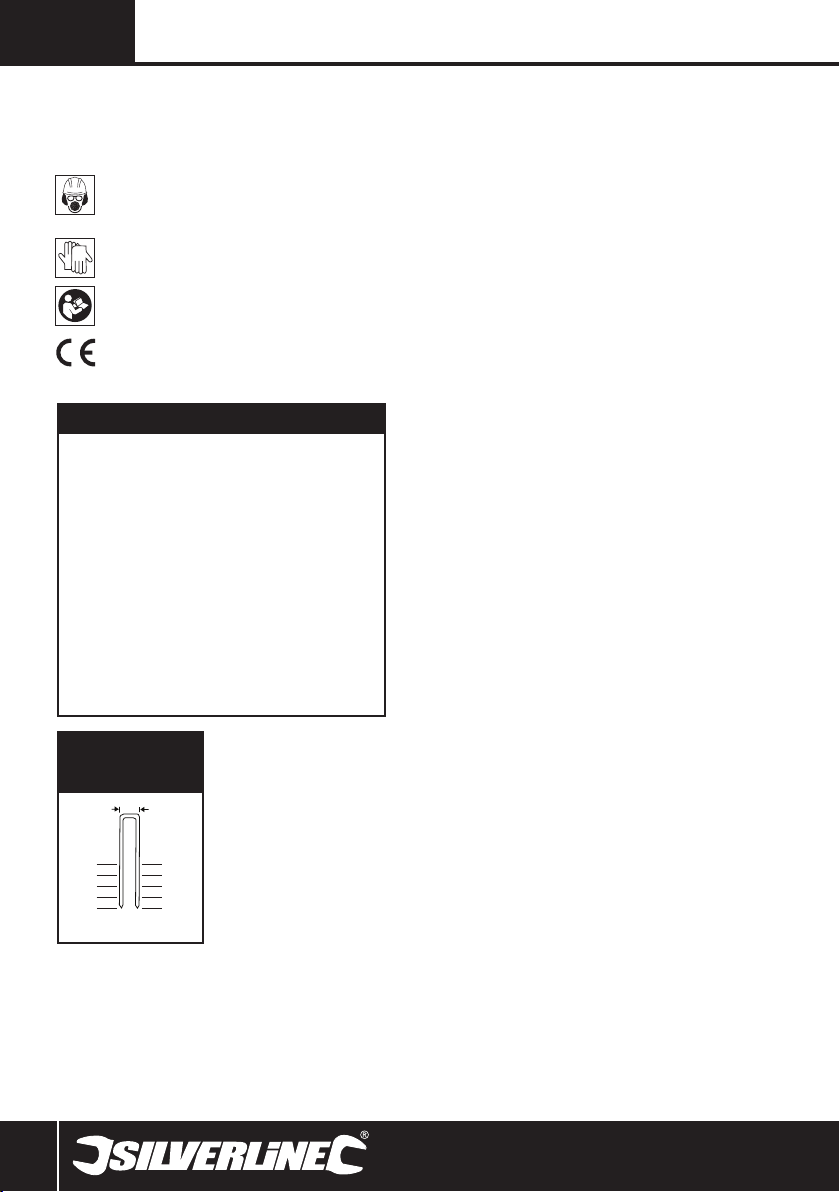

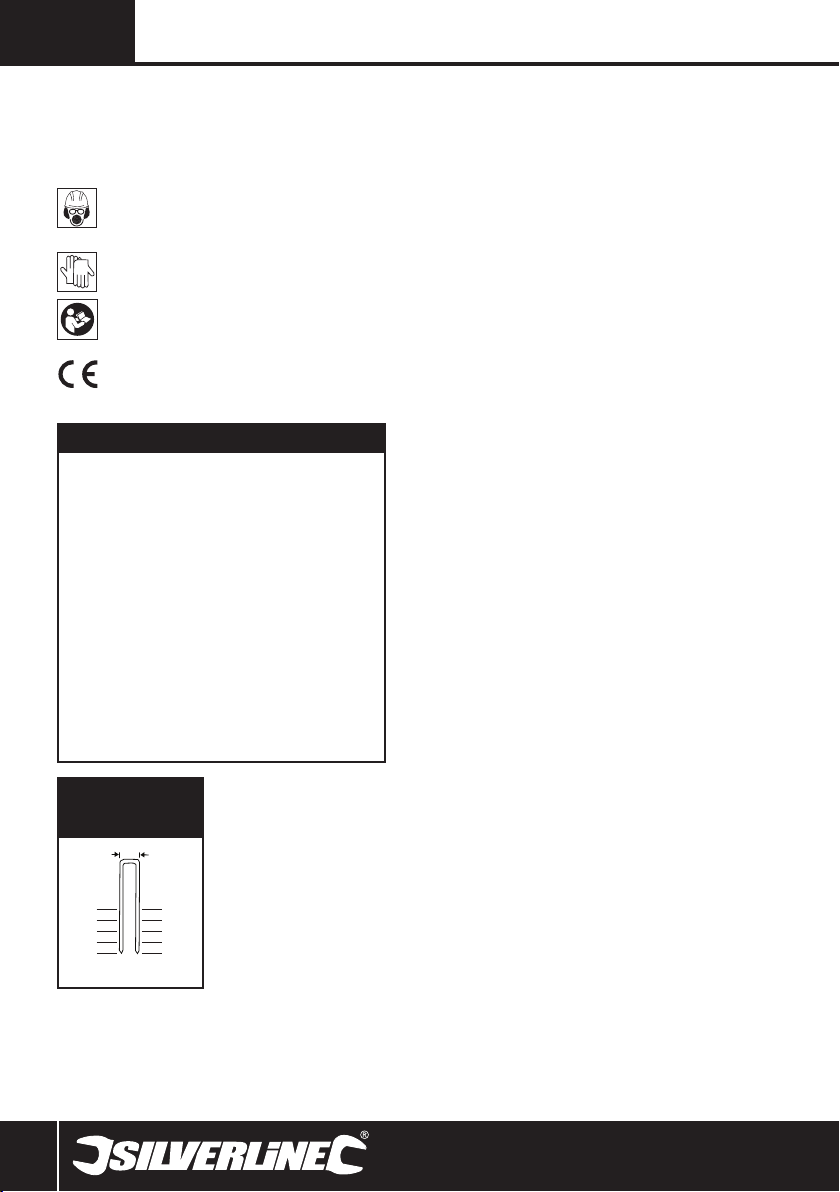

Staple

Specification

5.2mm (0.2”)

10mm

3/8”

1/2”

13mm

5/8”

16mm

3/4”

19mm

7/8”

22mm

1.2 x 0.6mm

(0.047”) (0.024”)

20Ga.

General Safety

Carefully read and understand this manual and any label attached to

the tool before use. Keep these instructions with the product for future

reference. Ensure all persons who use this product are fully acquainted

with this manual.

Even when used as prescribed it is not possible to eliminate all residual risk

factors. Use with caution. If you are at all unsure of the correct and safe

manner in which to use this tool, do not attempt to use it.

Keep guards in position

• Where guards exist keep them in position, in good working order,

correctly adjusted and aligned. Never attempt to use a tool if any of

the supplied guards are missing. If any guards are damaged, replace

before use

Remove adjusting keys

• Where adjusting keys exist, ensure they are removed prior to using the

tool. Always check to see that keys and adjusting devices are removed

from the tool before use

Clean the work area

• Accidents can occur where benches and work areas are cluttered or

dirty. Keep floors clear and avoid working where the floor is slippery. If

working outdoors, be aware of all potential slip and trip hazards before

using this tool

Trained, competent persons

• This tool should be used by trained, competent persons only

Children and pets

• Keep children and pets at a safe distance from the work area. Lock tools

away where children cannot gain access

Use the correct tool

• Do not force or attempt to use a tool for a purpose for which it was not

designed. This tool is not intended for industrial use

Wear suitable clothing and footwear

• Do not wear loose fitting clothing, neckties, jewellery, or other

items which may become caught. Wear non-slip footwear or, where

appropriate, footwear with protective toe caps. Long hair should be

covered or tied back

Keep your balance

• Do not over-reach. Keep proper footing at all times and do not use tools

when standing on an unstable surface

Accessories

• The use of any attachment or accessory, other than those mentioned in

this manual, could be dangerous and result in damage or injury, and may

invalidate your warranty

Never stand on your tool

• Standing on your tool or its stand could cause serious injury if the tool

is tipped or collapses. Do not store materials above or close to the tool

in such a way that a person might stand on the tool to reach the stored

items

Secure work

• Where possible, always secure work. If appropriate, use a clamp or vice

so that both hands are free to operate the tool

Check for damaged or missing parts

• Before each use, check if any part of the tool is damaged or missing.

Carefully check that it will operate properly and perform its intended

function. Check alignment of moving parts for binding. Any guard or other

part that is damaged should be immediately repaired or replaced by an

authorised service centre. DO NOT USE IF DEFECTIVE

4

Page 6

Air Narrow Crown Stapler 22mm771422

Air Tool Safety

Dangerous environment

• Always ensure there is adequate clear space around the work area. Only

use spraying tools in a well ventilated area or a specialist spray booth. Be

aware that air hoses can present a trip hazard; always lay hoses in a way

that minimises hazards

Protection from vibration

• Hand-held air tools may produce vibration and should not be used for

long periods without a break. Vibration can cause disease. Gloves may

help to maintain good blood circulation in the fingers.

Maintain your air tool

• Ensure that you keep air tools clean and lubricated. Lubrication is

essential to prevent corrosion of internal parts, which could lead to

machine failure

Always disconnect

• Always ensure the air tool is switched OFF before connecting to air

supply. Be aware that air tools may hold residual pressure after use.

Always bleed air pressure from the tool after shutting off air supply

• Ensure fasteners are correctly fitted before reconnecting to the air supply

• Disconnect an air tool from the air supply before inserting fasteners,

attachments or performing any servicing

• Always ensure that your air tool has fully stopped functioning before

putting it down

Use the correct air hose

• Use a correctly rated air hose appropriate to the compressor and this

product

Protective equipment

• Wear appropriate safety equipment, including eye, ear and hand

protection

Use of air staplers/nailers

• Do not aim this tool at people or animals

• Always wear appropriate protective equipment including but not limited

to overalls, gloves, etc

• It is the user’s responsibility to ensure that any other persons in

the vicinity of the work area are also equipped with the appropriate

protective equipment

Do not abuse the machine

• Do not overload the machine. Allowing the machine to work at its

optimum speed is safer and prolongs its service life

• Do not increase air pressure above the recommended level; excessive

pressure leads to wear of moving parts, possible failure and may cause

the machine casing to split

• Do not attempt to modify air tools. Any attempt to modify this air tool

could result in serious injury to you or others, and will invalidate its

warranty

Product Familiarisation

1 Trigger

2 Air Inlet / 1⁄4" BSP Quick Connector

3 Bottle of Air Tool Oil

4 Magazine Latch

5 Magazine Cover

6 Safety Catch

7 Hex Keys

8 Screws

www.silverlinetools.com

5

Page 7

GB

Unpacking Your Tool

• Carefully unpack and inspect your tool. Fully familiarise yourself with all

its features and functions

• Ensure that all parts of the tool are present and in good condition. If

any parts are missing or damaged, have such parts replaced before

attempting to use this tool

Operating Instructions

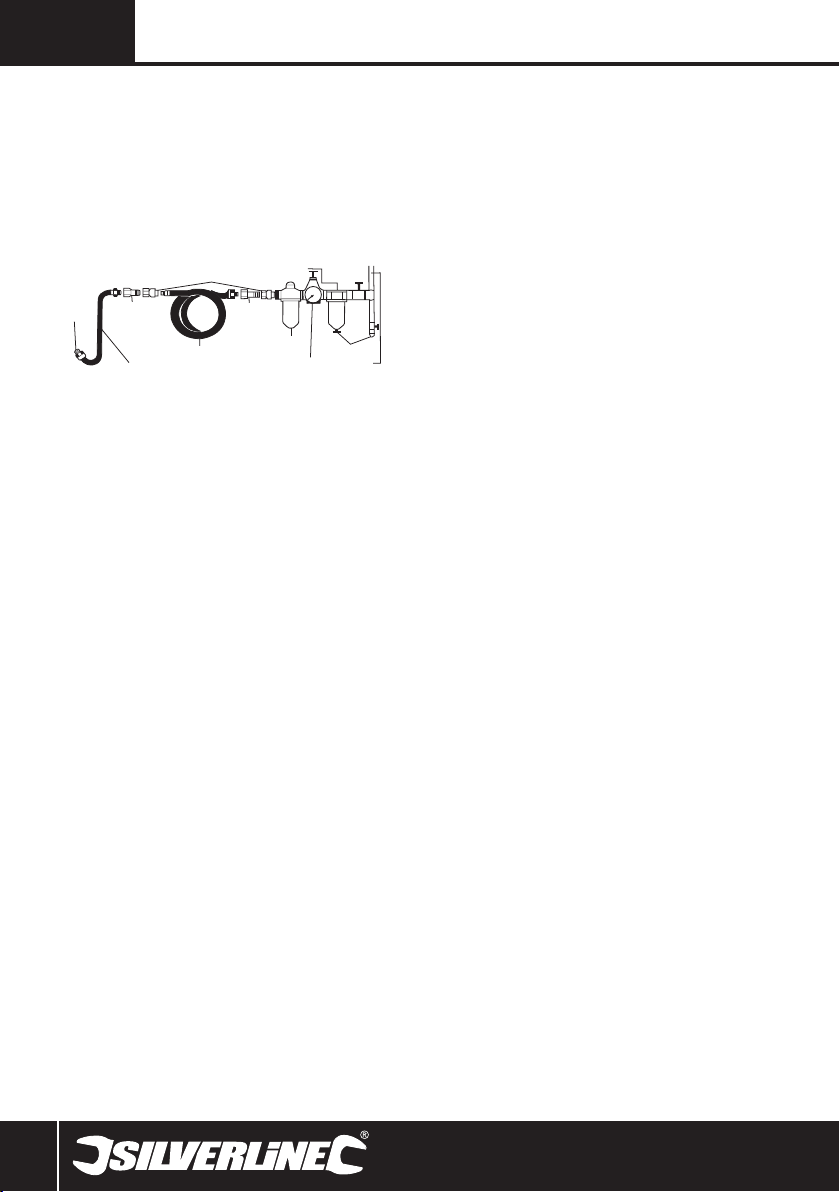

Air Supply Connection

QUICK COUPLER

NIPPLE

TO YOUR

AIR TOOL

LEADER HOSE

This tool should be connected to a clean air supply, with in-line oiler and

water separator

• Do not allow supply pressure to exceed the maximum stated in the

specifications

• Ensure that all parts of the system (hoses, couplers, etc) are correctly

rated for the air pressure to be used

• Ensure that condensate is drained from air system daily

Preparing the tool

• A ¼" bayonet quick connector is supplied with this tool. The connector is

a screw fit into the Air Inlet / 1⁄4" BSP Quick Connector (2). Applying PTFE

tape to the screw threads will help to maintain an air tight seal. Air lines

fitted with matching ¼" connectors will now be a push fit

• With the quick connector pointing uppermost, pour a few drops of Air Tool

Oil (3) into connector and allow it to run down into the mechanism

Checking the safety catch

Warning: Always disconnect the tool from the air supply before any

adjustment or maintenance is carried out.

• Ensure that there are no fasteners in the magazine

• The Safety Catch (6) should move in and out with no obstruction

To test the safety catch is working correctly:

1. Connect the tool to the air supply

2. Push the Safety Catch (6) against a piece of wood without pulling the

Trigger (1). The tool must not fire. If the tool fires, it must be repaired

before any further use

3. Hold the tool away from the piece of wood. The Safety Catch (6) should

return to the original position

4. Pull the Trigger (1). The tool must not fire. If the tool fires, it must be

repaired before any further use

5. Push the Safety Catch (6) against the piece of wood, but this time pull

the Trigger (1). The tool should fire. This indicates normal operation

Loading the magazine

Warning: Always disconnect the tool from the air supply before any loading,

adjustment or maintenance is carried out.

• Open the Magazine Latch (4) and pull open the Magazine Cover (5)

• Insert fasteners into the magazine ensuring the point of the fastener is

facing forward (away from the handle of the tool).

• Close the Magazine Cover (5) until the Magazine Latch (4) is fully secured

(you will hear a 'click')

Operating

IMPORTANT: Always fire a test staple into a similar piece of material to

ensure that the staple penetrates to the correct depth. Use the regulator to

adjust the air pressure. Reducing the pressure will reduce the depth that

the staple penetrates.

RECOIL HOSE

WATER SEPARATION

NIPPLE

REGULATOR

OILER

DRAIN DAILY

AIR SUPPLY

1. Connect tool to air supply

2. Hold the tool firmly up to the material so that the Safety Catch (6) is

depressed

3. Gently squeeze the Trigger (1) until the staple is fired. Release the

trigger and check that it has penetrated the material correctly

Clearing Jams

Warning: Always disconnect the tool from the air supply before any

adjustment or maintenance is carried out.

Fastener jammed in magazine

1. Open Magazine Latch (4) and open the Magazine Cover (5)

2. Remove the obstruction using pliers

3. Reload magazine and close securely

Fastener jammed in plate area

1. Remove Screws (8) and then remove nose cover using Hex Keys (7)

supplied. The safety lever can now be removed. Remove screws and

remove main plate

2. Remove the obstruction using pliers

3. Re-assemble the nose plates and check the operation of the safety

lever before using the tool

Maintenance

IMPORTANT: There is very little that can go wrong with your air tool. Note

that when an air tool fails to work, it is generally because the internal

workings have corroded due to residues of dirty wet air and failure to follow

the maintenance instructions given below.

EVERY DAY, before use, with the machine disconnected from the air supply,

pour the equivalent of a tablespoon of oil into the air intake. Operate the

machine at low speed to thoroughly lubricate all internal workings.

If the machine is in constant use or used for long periods at a time, a

combined filter/lubricator must be fitted. There must be an air filter fitted

at all times.

Contact your retailer for suitable air tool oil. DO NOT UNDER ANY

CIRCUMSTANCES USE NORMAL ENGINE OIL.

NOTE: Failure to comply with the operating and maintenance instructions

may invalidate the guarantee.

6

Page 8

771422 Air Narrow Crown Stapler 22mm

Silverline Tools Guarantee

This Silverline product comes with a 3 year

guarantee

Register this product at www.silverlinetools.com within 30 days of

purchase in order to qualify for the 3 year guarantee. Guarantee period

begins according to the date of purchase on your sales receipt.

Registering your purchase

Registration is made at silverlinetools.com by selecting the Guarantee

Registration button. You will need to enter:-

• Your personal details

• Details of the product and purchase information

Once this information is entered your guarantee certificate will be created

in PDF format for you to print out and keep with your purchase.

Terms & Conditions

Guarantee period becomes effective from the date of retail purchase as

detailed on your sales receipt.

PLEASE KEEP YOUR SALES RECEIPT

If this product develops a fault within 30 days of purchase, return it to the

stockist where it was purchased, with your receipt, stating details of the

fault. You will receive a replacement or refund.

If this product develops a fault after the 30 day period, return it to:

Silverline Tools Service Centre

PO Box 2988

Yeovil

BA21 1WU, UK

The guarantee claim must be submitted during the guarantee period.

You must provide the original sales receipt indicating the purchase date,

your name, address and place of purchase before any work can be

carried out.

You must provide precise details of the fault requiring correction.

Claims made within the guarantee period will be verified by Silverline Tools

to establish if the deficiencies are related to material or manufacturing of

the product.

Carriage will not be refunded. Items for return must be in a suitably clean

and safe state for repair, and should be packaged carefully to prevent

damage or injury during transportation. We may reject unsuitable or

unsafe deliveries.

All work will be carried out by Silverline Tools or its authorized

repair agents.

The repair or replacement of the product will not extend the period

of guarantee

Defects recognised by us as being covered by the guarantee shall be

corrected by means of repair of the tool, free of charge (excluding carriage

charges) or by replacement with a tool in perfect working order.

Retained tools, or parts, for which a replacement has been issued, will

become the property of Silverline Tools.

EC Declaration of Conformity

The undersigned: Mr Darrell Morris

as authorised by: Silverline Tools

Declares that the

Name/ model: Air Narrow Crown Stapler 22mm

Type/ serial no: 771422

Conforms to the following Directives:

• Machinery Directive 2006/42/EC

• EN792-13/A1:2008

The repair or replacement of your product under guarantee provides

benefits which are additional to and do not affect your statutory rights as

a consumer.

What is covered:

The repair of the product, if it can be verified to the satisfaction of Silverline

Tools that the deficiencies were due to faulty materials or workmanship

within the guarantee period.

If any part is no longer available or out of manufacture, Silverline Tools will

replace it with a functional replacement part.

Use of this product in the EU.

What is not covered:

Silverline Tools does not guarantee repairs required as a result of:

Normal wear and tear caused by use in accordance with the operating

instructions eg blades, brushes, belts, bulbs, batteries etc.

The replacement of any provided accessories drill bits, blades, sanding

sheets, cutting discs and other related items.

Accidental damage, faults caused by negligent use or care, misuse,

neglect, careless operation or handling of the product.

Use of the product for anything other than normal domestic purposes.

Change or modification of the product in any way.

Use of parts and accessories which are not genuine Silverline Tools

components.

Faulty installation (except installed by Silverline Tools).

Repairs or alterations carried out by parties other than Silverline Tools or its

authorized repair agents.

Claims other than the right to correction of faults on the tool named in

these guarantee conditions are not covered by the guarantee.

The technical documentation is kept by: Silverline Tools

Notified body: Jiangsu TUV Product Service Ltd

Place of declaration: Shanghai, China

Date: 06/09/11

Signed by:

Director

Name and address of Manufacturer or Authorised representative:

Silverline Tools, Boundary Way, Lufton Trading Estate, Yeovil, Somerset,

BA22 8HZ United Kingdom

www.silverlinetools.com

7

Page 9

F

Description des symboles

La plaque signalétique figurant sur votre outil peut présenter des symboles.

Ces symboles constituent des informations importantes relatives au produit

ou des instructions concernant son utilisation.

Port de protection auditive

Port de lunettes de sécurité

Port de masques respiratoires

Port du casque

Port de gants

Lire le manuel d’instructions

Conforme à la réglementation et aux normes de sécurité

pertinentes

Caractéristiques techniques

Poids: ......................................................1,10 kg

Pression requise: .....................................4,1 – 6,9 bar

Taille de la couronne des agrafes: ...........5,2 mm

Longueur des pattes des agrafes: ...........10-22 mm

Epaisseur des pattes des agrafes: ...........1,2 x 0,6 mm

Capacité du chargeur: .............................100 agrafes

Raccord pneumatique: ............................1⁄4" BSP

Pression sonore: ......................................88 dB

Niveau de vibrations: ...............................2,19 m/s

L’intensité sonore peut dépasser 85 dB(A) et il est recommandé que

l’opérateur prenne des mesures de protection sonore.

Du fait de l’évolution constante de notre développement produits, les

caractéristiques techniques des produits Silverline peuvent changer

sans notification préalable.

Caractéristiques

des agrafes

5.2mm (0.2”)

10mm

3/8”

1/2”

13mm

5/8”

16mm

3/4”

19mm

7/8”

22mm

1.2 x 0.6mm

(0.047”) (0.024”)

20Ga.

2

Consignes générales de sûreté

Lisez attentivement ce manuel ainsi que toute étiquette apposée sur l’outil

et assurez-vous d’en comprendre le sens avant utilisation. Rangez ces

consignes avec l’outil, pour référence ultérieure. Assurez-vous que toute

personne venant à utiliser cet outil ait attentivement pris connaissance de

ce manuel.

Sachez qu’utiliser un outil conformément aux prescriptions ne garantit

pas l’élimination de tous les facteurs de risque. Procédez avec prudence.

N’utilisez pas cet outil si vous avez des doutes quant à la manière sûre et

correcte de procéder.

Gardez les éléments de protection en place

• Gardez les éléments de protection en place, en bon état de

fonctionnement, correctement ajustés et alignés. N’utilisez jamais un

outil si l’un des éléments de protection fournis est manquant. Si l’un

des éléments de protection est endommagé, remplacez-le avant toute

utilisation

Retirez les clés de réglage

• Assurez-vous que les clés et autres dispositifs de réglage aient été retirés

de l’outil avant utilisation

Nettoyez la zone de travail

• Des établis et zones de travail encombrés ou sales sont sources

d’accidents ; de même, le sol doit être dégagé et il est recommandé

d’éviter de travailler sur un sol glissant. En cas de travail à l’extérieur,

appréciez les risques de faux pas ou de chute avant d’utiliser l’outil

Personnes compétentes

• Ce produit doit être utilisé par des personnes compétentes ou ayant reçu

une formation adéquate

Enfants et animaux

• Maintenez une distance de sécurité entre les enfants ou les animaux et

votre zone de travail. Rangez les outils dans un lieu sûr fermé à clé, hors

de portée des enfants

Utilisation correcte de l’outil

• Ne tentez pas d’utiliser un outil à des fins pour lesquelles il n’est pas

conçu. Cet outil n’est pas conçu pour un usage industriel

Port de vêtements et de chaussures adaptés

• Ne portez pas de vêtements amples, cravate, bijoux ou autres

éléments susceptibles d’être happés. Au besoin, portez des chaussures

antidérapantes ou équipées d’une coque de protection des orteils. Les

cheveux longs doivent être couverts ou noués vers l’arrière

Conservez l’équilibre

• Ne tentez pas de travailler dans des endroits hors de portée, gardez un

bon appui en permanence, n’utilisez pas d’outil lorsque vous êtes sur

une surface instable

Accessoires

• L’utilisation de tout équipement ou accessoires différant de ceux

mentionnés dans ce manuel peut être dangereuse, entraîner des

dommages matériels ou des blessures et annulera votre garantie

Ne vous tenez pas sur l’outil

• En vous appuyant ou en montant sur l’outil ou sur son support, vous

encourez des blessures graves s’il venait à basculer ou à s’affaisser.

Veillez à na pas ranger de matériel au-dessus ou à proximité de l’outil

et de telle sorte qu’il faille s’appuyer sur l’outil ou sur son support pour

atteindre ce matériel

Immobilisez la pièce à travailler

• Dans la mesure du possible, immobilisez la pièce sur laquelle vous

travaillez. Si cela est possible, utilisez un étau ou un serre-joint de

manière à disposer des deux mains pour manier l’outil

Assurez-vous qu’aucune pièce ne soit endommagée ou

manquante

• Avant chaque utilisation, assurez-vous qu’aucune pièce ne

soit manquante ou endommagée ; assurez-vous également du

fonctionnement correct et de la bonne marche des fonctions voulues.

Vérifiez l’alignement des pièces mobiles et l’absence de grippage. Toute

protection et autre pièce endommagées doivent être immédiatement

réparées ou remplacées par un centre de service agréé. N’UTILISEZ

JAMAIS UN OUTIL DEFECTUEUX

8

Page 10

771422 Agrafeur pneumatique à agrafes étroites 22 mm

Consignes de sûreté relatives aux

outils pneumatiques

Environnements dangereux

• Assurez-vous de disposer d’un espace suffisamment dégagé autour de

la zone de travail

• Sachez que les tuyaux flexibles d’alimentation en air comprimé peuvent

représenter un danger de trébuchage. Veillez à les disposer de manière à

réduire autant que possible ce danger

Protégez-vous des vibrations

• Les outils électriques portatifs produisent des vibrations. Les vibrations

peuvent provoquer des maladies. En conservant la chaleur, des gants

portés par l’utilisateur peuvent lui permettre de maintenir une bonne

circulation sanguine dans les doigts. Les outils portatifs ne doivent pas

être utilisés pendant de longues périodes sans marquer une pause

Entretenez votre outil pneumatique

• Assurez-vous de maintenir la propreté et la bonne lubrification de vos

outils pneumatiques. Une bonne lubrification est essentielle pour éviter

la corrosion des pièces internes de l’appareil, susceptible d’entraîner un

dysfonctionnement de l’appareil

Débranchez l’outil avant tout changement

• Assurez-vous toujours que votre outil pneumatique soit en position

éteinte avant de le brancher à l’alimentation en air comprimé. Sachez

que les outils pneumatiques peuvent conserver une pression résiduelle

après utilisation. Purgez toujours la pression d’air de l’outil après avoir

fermé l’alimentation en air comprimé

• Assurez-vous que les éléments de fixation (clous, agrafes, etc.) soient

correctement insérés avant de rebrancher l’appareil à l’alimentation en

air comprimé

• Débranchez toujours l’outil de l’alimentation en air comprimé avant toute

insertion d’éléments de fixation, tout montage d’accessoire ou travail

d’entretien

• Assurez-vous toujours que votre outil pneumatique se soit complètement

arrêté de fonctionner avant de le déposer

Utilisez un tuyau flexible d’air comprimé adapté

• Utilisez un tuyau conforme et adapté au compresseur et à l’appareil à

air comprimé

Portez un équipement de protection

• Portez toujours un équipement de protection adapté, notamment lunettes

et gants de sécurité ainsi que protections de l’audition

Utilisation des agrafeuses/cloueuses

• Ne dirigez pas l’appareil sur une personne ou un animal

• Portez toujours un équipement de protection adapté comprenant entre

autres combinaison adaptée, gants, etc

• Il relève de la responsabilité de l’utilisateur de s’assurer que toute

personne présente à proximité de la zone de travail soit également

pourvue d’un équipement protecteur adapté

Ménagez l’appareil

• Ne surchargez pas l’appareil. En laissant l’appareil fonctionner à sa

vitesse optimale, vous prolongerez sa durée utile et bénéficierez d’un

meilleur rendement

• N’employez pas de pression d’air comprimé supérieure au niveau

recommandé. Une pression excessive peut entraîner une usure précoce

des pièces en rotation et favoriser les dysfonctionnements. Elle peut

également conduire à une fissure du carter

• Ne tentez pas de modifier un outil pneumatique. Toute tentative de

modification de votre outil annulera sa garantie et pourrait entraîner des

blessures graves sur vous-même ou les personnes se trouvant autour

de vous

Présentation du produit

1 Gâchette

2 Raccord rapide arrivée d’air 1⁄4" BSP

3 Flacon d’huile pour outils pneumatiques

4 Loquet du chargeur

5 Carter du chargeur

6 Palpeur de sécurité

7 Clés mâles

8 Vis

www.silverlinetools.com

9

Page 11

F

Déballage

• Déballez le produit avec soin. Veillez à retirer tout le matériau

d’emballage et familiarisez-vous avec toutes les caractéristiques du

produit

• Si des pièces sont endommagées ou manquantes, faites-les réparer ou

remplacer avant toute utilisation

Instructions d’utilisation

Raccord à l’alimentation en air comprimé

COUPLEUR OUTIL

PNEUMATIQUE

Cet outil doit être raccordé à une arrivée d’air comprimé propre, pourvu

d’un lubrificateur et d’un séparateur d’eau.

• L’alimentation en air comprimé ne doit jamais dépasser la pression

maximale préconisée dans les caractéristiques techniques ci-dessus.

• Assurez-vous que la pression nominale de toutes les pièces du système

(tuyaux souples, raccords, etc.) correspondent à la pression d’air

préconisée

• Assurez-vous que les liquides condensés soient évacués

quotidiennement du système pneumatique

RACCORD

TUYAU DE

RACCORDEMENT

Préparation de l’outil

• Un raccord rapide ¼" à baïonnette est livré avec cet outil. Ce raccord

se fixe dans l’arrivée d’air (2) par simple action de vissage. L’application

d’un adhésif PTFE sur le pas de vis permettra de conserver une

bonne étanchéité à l’air. Les arrivées d’air équipées de raccords ¼"

correspondants se fixeront alors par simple enfoncement

• Tournez le raccord rapide vers le haut, versez quelques gouttes d’huile

pour outils pneumatiques (3) dans le raccord et laissez l’huile couler dans

le mécanisme

Contrôle du palpeur de sécurité

Avertissement. Veillez à toujours débrancher l’outil de la source

d’alimentation en air avant de procéder à toute opération de réglage ou

d’entretien sur l’outil.

• Assurez-vous que le chargeur est vide

• A ce stade, vous devriez pouvoir faire entrer / sortir le palpeur de sécurité

(6) sans difficulté

Pour vérifier le bon fonctionnement du palpeur de sécurité :

1. Raccorder l’outil à la source d’alimentation en air

2. Poussez le palpeur de sécurité (6) contre une pièce de bois, sans

appuyer sur la gâchette (1). L’outil ne devrait pas déclencher de tir.

Dans le cas contraire, faites réparer l’outil avant de le remettre en

service

3. Éloignez l’outil de la pièce de bois. Le palpeur de sécurité (6) devrait

revenir à la position initiale

4. Appuyez sur la gâchette (1). L’outil ne devrait pas déclencher de tir.

Dans le cas contraire, faites réparer l’outil avant de le remettre en

service

5. Poussez le palpeur de sécurité (6) contre la pièce de bois, en appuyant

cette fois-ci sur la gâchette (1). Si l’outil déclenche un tir, il fonctionne

normalement

Remplir le chargeur

Avertissement. Veillez à toujours débrancher l’outil de la source

d’alimentation en air avant de procéder à toute opération de réglage,

d’entretien ou de remplissage du chargeur.

• Débloquez le loquet du chargeur (4) et ouvrez le carter du chargeur (5)

RACCORD RAPIDE

FLEXIBLE SERPENTIN

SÉPARATION DE L’EAU

MAMELON

GRAISSEUR

RÉGULATEUR

A PURGER

QUOTIDIENNEMENT

ALIMENTATION EN

AIR COMPRIMÉ

• Insérez les agrafes dans le chargeur, en veillant à ce que les pointes

des agrafes soient tournées vers l’avant (du côté opposé à la poignée

de l’outil)

• Refermez le carter du chargeur (5) jusqu’à ce que le loquet s’enclenche

(4) à fond (vous entendrez un déclic)

Maniement

IMPORTANT. Vérifiez toujours la conformité de la longueur de pénétration

de la fixation. Sur un matériau similaire à votre matériau de travail,

introduisez une agrafe d’essai à l’aide de la machine ; réglez le régulateur

si nécessaire pour ajuster la pression pneumatique au niveau souhaité.

Réduire la pression permet de réduire la profondeur de pénétration de

l’agrafe.

1. Raccordez l’outil à la source d’alimentation en air.

2. Tenez fermement l’outil contre le matériau à agrafer, de manière à ce

que le palpeur de sécurité (6) se rétracte

3. Appuyez légèrement sur la gâchette (1) jusqu’à ce que l’agrafe soit

éjectée. Relâchez la gâchette et vérifiez que l’agrafe soit correctement

enfoncée dans le matériau

Élimination des blocages

Avertissement. Veillez à toujours débrancher l’outil de la source

d’alimentation en air avant de procéder à toute opération de réglage ou

d’entretien sur l’outil.

Blocage d’une agrafe dans le chargeur

1. Ouvrez le loquet du chargeur (4) et ouvrez le carter du chargeur (5)

2. Retirez le blocage à l’aide de pinces.

3. Rechargez le chargeur et refermez l’outil

Blocage d’une agrafe au niveau de la plaque

1. Retirez les vis (8) et retirez le couvercle frontal à l’aide des clés mâles

(7). Le palpeur de sécurité peut ensuite être retiré. Retirez les vis et la

plaque principale

2. Retirez le blocage à l’aide de pinces

3. Remontez les plaques frontales et vérifiez le fonctionnement du

palpeur de sécurité avant d’utiliser l’outil

Entretien

IMPORTANT : Il y a très peu de raisons pour que votre outil pneumatique

tombe en panne ; les pannes d’outils pneumatiques relèvent généralement

de la corrosion des pièces internes due à de l’air sale et humide et au non

respect des consignes ci-dessous.

ENTRETIEN AU QUOTIDIEN : débranchez l’outil de la source d’alimentation

en air, versez l’équivalent d’une cuillère à soupe d’huile dans l’entrée d’air.

Faites fonctionner la machine à vitesse réduite, pour bien en lubrifier les

pièces internes.

Si la machine est en utilisation constante, ou en utilisation ponctuelle mais

pendant des périodes prolongées, elle doit être munie d’une unité filtre/

lubrificateur combinée. Un filtre à air doit être installé en permanence.

Votre distributeur saura vous conseiller l’huile à utiliser. NE SOYEZ JAMAIS

TENTÉ, QUELLES QUE SOIENT LES CIRCONSTANCES, D’UTILISER DE

L’HUILE MOTEUR ORDINAIRE.

NOTA : Le non respect des consignes d’utilisation et d’entretien pourrait

invalider la garantie de l’outil.

10

Page 12

771422 Agrafeur pneumatique à agrafes étroites 22 mm

Garantie Silverline Tools

Ce produit Silverline bénéficie d’une garantie

de 3 ans

Enregistrez ce produit à www.silverlinetools.com dans les 30 jours suivant

l’achat afin de bénéficier de la garantie de 3 ans. La période de garantie

commence à partir de la date d’achat figurant sur votre facture d’achat.

Enregistrement de votre achat

Visitez silverlinetools.com, sélectionnez le bouton d’enregistrement

et saisissez :

• Vosinformationspersonnelles

• Lesinformationsconcernantleproduitetl’achat

Vous recevrez le Certificat de garantie en format PDF. Veuillez l’imprimer et

le conserver avec votre achat.

Conditions de Garantie des Outils Silverline

La période de garantie prend effet à compter de la date de l’achat en

magasin, comme indiqué sur votre facture d’achat.

VEUILLEZ CONSERVER VOTRE FACTURE D’ACHAT.

Si ce produit est défectueux pendant les 30 jours qui suivent l’achat,

retournez-le au magasin où vous l’avez acheté, avec votre facture, en

expliquant en détail le problème. Le produit sera remplacé ou vous serez

remboursé(e).

Si ce produit est défectueux après cette période de 30 jours,

retournez-le à :

Silverline Tools Service Centre

PO Box 2988

Yeovil

BA21 1WU, Royaume Uni

Toute demande de service sous garantie doit être soumise pendant la

période de garantie.

Avant toute intervention sous garantie, vous devez présenter la facture

d’achat originale sur laquelle doivent figurer la date d’achat, votre nom,

votre adresse et le lieu d’achat.

Vous devez expliquer en détail la défaillance nécessitant réparation.

Les demandes de service sous garantie faites pendant la période de

garantie seront vérifiées par Silverline Tools pour établir si la défaillance du

produit est liée à un vice de matériau ou de fabrication.

Les frais de port ne seront pas remboursés. Les articles retournés doivent

être convenablement propres et sûrs pour être réparés et devraient être

emballés soigneusement pour éviter tout dommage ou toute blessure

pendant le transport. Nous pouvons refuser les livraisons qui ne sont pas

convenables ou sûres.

Toute intervention sera effectuée par Silverline Tools ou ses agents de

réparation agréés.

La réparation ou le remplacement du produit ne dépassera pas la période

de garantie.

Les anomalies que nous reconnaissons être couvertes par la garantie

seront rectifiées par la réparation de l’outil, sans frais (hormis les

frais de port) ou par son remplacement par un outil en parfait état de

fonctionnement.

Les pièces ou les outils remplacés deviendront la propriété de

Déclaration de conformité CE

Le soussigné : Mr Darrell Morris

Autorisé par : Silverline Tools

Déclare que le produit :

Nom/modèle : Agrafeuse pneumatique à agrafes étroites 22 mm-

Nº de série/Type : 771422

Est conforme aux directives suivantes :

• Directive sur les machines 2006/42/EC

• EN792-13/A1:2008

Silverline Tools.

La réparation ou le remplacement de votre produit sous garantie vous

apporte des avantages ; ces avantages s’ajoutent à vos droits statutaires

en tant que consommateur sans les affecter aucunement.

La présente garantie couvre:

La réparation du produit, s’il peut être vérifié, à la satisfaction de Silverline

Tools, que les défaillances du produit ont été provoquées par un vice de

matériau ou de fabrication au cours de la période de garantie.

Si une pièce n’est plus disponible ou n’est plus fabriquée, Silverline Tools la

remplacera par une pièce de rechange opérationnelle.

Utilisation de ce produit dans l’UE.

La présente garantie ne couvre pas:

Silverline Tools ne garantit pas les réparations nécessaires du produit

engendrées par :

L’usure normale provoquée par l’utilisation conforme aux instructions

d’utilisation, par exemple les lames, les charbons, les courroies, les

ampoules, les batteries, etc.

Le remplacement de tout accessoire fourni tel que les forêts, les lames, les

feuilles abrasives, les outils de coupes et les autres articles associés.

Les dommages et les défaillances accidentels causés par une utilisation ou

un entretien négligent, une mauvaise utilisation, un manque d’entretien ou

une utilisation ou une manipulation imprudente du produit.

L’utilisation du produit à des fins autres que son utilisation domestique

normale.

Le moindre changement ou la moindre modification du produit.

L’utilisation de pièces et d’accessoires qui ne sont pas des composants

véritables de Silverline Tools.

Une installation défectueuse (sauf si l’installation a été réalisée par

Silverline Tools).

Les réparations ou les modifications réalisées par des tiers autres que

Silverline Tools ou ses agents de réparation agréés.

Les demandes de service autres que le droit de rectifier les défaillances

de l’outil indiquées dans ces conditions de garantie ne sont pas couvertes

par cette garantie.

La documentation technique est conservée par : Silverline Tools

Organisme notifié : Jiangsu TUV Product Service Ltd

Lieu de la déclaration : Shanghai, Chine

Date : 06/09/11

Signature :

Directeur

Nom et adresse du fabricant ou de son représentant agréé :

Silverline Tools, Boundary Way, Lufton Trading Estate, Yeovil, Somerset,

BA22 8HZ Royaume-Uni

www.silverlinetools.com

11

Page 13

D

Beschreibung der Symbole

Auf dem Leistungsschild des Werkzeugs sind möglicherweise Symbole

abgebildet. Sie vermitteln wichtige Informationen über das Produkt oder

dienen als Gebrauchsanweisung.

Gehörschutz tragen

Augenschutz tragen

Atemschutz tragen

Kopfschutz tragen

Handschutz tragen

Bedienungsanleitung sorgfältig lesen

Erfüllt die entsprechenden rechtlichen Vorschriften und

Sicherheitsnormen

Technische Daten

Gewicht: ..................................................1,10 kg

Erforderlicher Druck: ...............................4,1–6,9 bar

Klammerlänge: ........................................10–22 mm

Klammerrücken:. .....................................5,2 mm

Klammerschenkel:...................................1,2 x 0,6 mm

Klammerkapazität: ..................................100 Stück

Druckluftanschluss: .................................1⁄4" BSP

Schalldruckpegel: ....................................88 db

Vibrationspegel: .......................................2,19 m/s

Der Schallintensitätspegel kann für den Bediener 85 dB(A)

übersteigen und Lärmschutzmaßnahmen sind notwendig.

Aufgrund der fortlaufenden Weiterentwicklung unserer Produkte

können sich die technischen Daten von Silverline-Produkten ohne

vorherige Ankündigung ändern..

Befestigungsmittel:

Schmalrückenklammern

5.2mm (0.2”)

10mm

3/8”

1/2”

13mm

5/8”

16mm

3/4”

19mm

7/8”

22mm

1.2 x 0.6mm

(0.047”) (0.024”)

20Ga.

2

Allgemeine Sicherheitshinweise

Betreiben Sie das Gerät erst, wenn Sie diese Bedienungsanleitungen und

alle am Werkzeug angebrachten Etiketten sorgfältig gelesen und verstanden

haben. Bewahren Sie alle Anleitungen mit dem Gerät zum späteren

Nachschlagen auf. Vergewissern Sie sich, dass alle Benutzer dieses

Produkts diese Bedienungsanleitung vollständig verstanden haben.

Auch wenn dieses Gerät wie vorgeschrieben verwendet wird, ist es nicht

möglich, sämtliche Restrisiken auszuschließen. Mit Vorsicht verwenden.

Sollten Sie sich in irgendeiner Weise unsicher bezüglich der sachgemäßen

und sicheren Benutzung dieses Werkzeugs sein, verwenden Sie es nicht.

Arbeitsbereich sauber halten

• Unordnung oder Schmutz auf Werkbänken und im Arbeitsbereich

können zu Unfällen führen. Böden freihalten und Arbeiten auf rutschigem

Untergrund vermeiden. Bei Arbeiten im Freien vor der Verwendung des

Werkzeugs auf mögliche Ausrutsch- und Stolpergefahren achten

Halten Sie die Schutzvorrichtungen in Position

• Halten Sie die Schutzvorrichtungen stets in Position, in gutem

Arbeitszustand sowie sachgemäß befestigt und ausgerichtet.

Verwenden Sie ein Werkzeug niemals, wenn eine der mitgelieferten

Schutzvorrichtungen fehlt. Ersetzen Sie ggf. beschädigte

Schutzvorrichtungen vor dem Gebrauch

Alle Einstellwerkzeuge entfernen

• Vergewissern Sie sich stets, dass alle Einstellwerkzeuge und

Schraubenschlüssel vor dem Betrieb des Werkzeugs entfernt wurden

Geeignete Benutzer

• Dieses Produkt sollte nur von geschulten und kompetenten Personen

benutzt werden

Kinder und Haustiere

• Kinder und Haustiere müssen einen sicheren Abstand zum Arbeitsbereich

einhalten. Schließen Sie Werkzeuge an einem Ort ein, zu dem Kinder

keinen Zugriff haben

Nur geeignete Werkzeuge verwenden

• Überlasten und zweckentfremden Sie das Werkzeug nicht, sondern

verwenden Sie es ausschließlich für den vorgesehenen Zweck. Dieses

Werkzeug ist nicht für industriellen Gebrauch bestimmt

Geeignete Bekleidung und Schuhe tragen

• Tragen Sie keine weite Bekleidung, Krawatten, Schmuck oder

Gegenstände, die vom Werkzeug erfasst werden könnten. Tragen Sie

rutschfestes Schuhwerk oder, wenn erforderlich, Sicherheitsschuhe

mit Stahlkappe. Lange Haare sollten bedeckt oder im Nacken

zusammengebunden werden

Gleichgewicht halten

• Vermeiden Sie eine unnatürliche Körperhaltung, sorgen Sie für einen

sicheren Stand und halten Sie stets das Gleichgewicht. Verwenden Sie

keine Werkzeuge, wenn Sie auf instabilem Untergrund stehen

Zubehör

• Die Verwendung von Einsatzwerkzeug oder Zubehör, das nicht in dieser

Bedienungsanleitung erwähnt ist, kann zu Schäden oder Verletzungen

sowie zum Erlöschen Ihrer Garantie führen

Stellen Sie sich niemals auf Ihr Werkzeug

• Wenn Sie auf Ihrem Werkzeug oder dessen Stand stehen, kann dies

durch Umkippen oder Zusammenbrechen zu ernsthaften Verletzungen

führen. Bewahren Sie keine Gegenstände oberhalb oder rund um das

Werkzeug auf, um zu verhindern, dass das Werkzeug oder dessen Stand

als Trittleiter benutzt wird

Werkstück sichern

• Sofern möglich muss das Werkstück fest eingespannt werden.

Verwenden Sie gegebenenfalls Spannvorrichtungen oder einen

Schraubstock, damit beide Hände zur Bedienung des Werkzeugs frei sind

12

Page 14

771422 Druckluftklammergerät für Schmalrückenklammern, 22 mm

Auf Schäden oder fehlende Teile prüfen

• Prüfen Sie vor der Verwendung, ob Teile des Produkts beschädigt sind

oder fehlen. Vergewissern Sie sich sorgfältig, dass es für die vorgesehene

Arbeit geeignet ist und sachgemäß funktioniert. Kontrollieren Sie, dass

bewegliche Teile einwandfrei ausgerichtet sind und nicht klemmen.

Sämtliche beschädigte Schutzhauben oder andere beschädigte

Teile müssen sofort durch einen autorisierten Vertragskundendienst

repariert oder ersetzt werden. NIEMALS BESCHÄDIGTES WERKZEUG

VERWENDEN

Sicherheitshinweise für

Druckluftwerkzeuge

Gefährliche Arbeitsumgebung

• Achten Sie immer darauf, dass ausreichend freier Raum um den

Arbeitsbereich verfügbar ist. Beachten Sie, dass Luftschläuche eine

Stolpergefahr darstellen können. Legen Sie Schläuche stets so, dass die

Gefahr möglichst gering gehalten wird

Schützen Sie sich vor Vibrationen

• Tragbare Druckluftwerkzeuge können Schwingungskräfte erzeugen und

sollten nicht ohne Pausen über längere Zeiträume verwendet werden.

Vibrationen können gesundheitsschädigend sein. Handschuhe können zu

einer guten Durchblutung der Finger beitragen

Druckluftwerkzeug instandhalten

• Stellen Sie sicher, dass Ihre Druckluftwerkzeuge sauber und

ordnungsgemäß geschmiert sind. Die Schmierung ist unerlässlich, um

eine Korrosion der Innenteile zu vermeiden, die zu Maschinenausfall

führen könnte

Ausschalten nicht vergessen

• Sorgen Sie stets dafür, dass das Druckluftwerkzeug ausgeschaltet ist,

bevor Sie es an die Druckluftquelle anschließen. Beachten Sie, dass

Druckluftwerkzeuge nach der Verwendung noch Restdruck enthalten

können. Lassen Sie nach dem Abstellen der Druckluftquelle stets den

Luftdruck aus dem Gerät ab

• Vergewissern Sie sich, dass sämtliche Verbindungselemente richtig

angebracht sind, bevor Sie das Gerät an die Druckluftquelle anschließen

• Trennen Sie Druckluftwerkzeuge stets von der Druckluftquelle, bevor

Sie Verbindungselemente oder anderes Zubehör anbringen oder

Wartungsarbeiten durchführen

• Stellen Sie stets sicher, dass der Betrieb des Druckluftwerkzeugs

vollständig eingestellt wurde, bevor Sie es ablegen

Den richtigen Luftschlauch verwenden

• Verwenden Sie einen Luftschlauch mit einem für den Kompressor und

dieses Gerät zulässigen Leistungsbereich

Schutzausrüstung

• Tragen Sie geeignete Schutzausrüstung einschließlich Augen-, Gehörund Handschutz

Verwendung von Druckluftnagel- und

Druckluftklammergeräten

• Richten Sie dieses Gerät nicht auf Menschen oder Tiere

• Tragen Sie stets geeignete Schutzausrüstung einschließlich, jedoch nicht

beschränkt auf Schutzanzüge, Handschuhe usw

• Es liegt in der Verantwortung des Benutzers, dafür zu sorgen, dass

allen in der Nähe des Arbeitsbereichs befindlichen Personen ebenfalls

angemessene Schutzausrüstung zur Verfügung steht

Gerät nicht unsachgemäß verwenden

• Überlasten Sie das Gerät nicht. Der Betrieb bei optimaler Drehzahl ist

sicherer und verlängert die Lebensdauer des Werkzeugs

• Erhöhen Sie den Luftdruck nicht über das empfohlene Maß hinaus.

Übermäßiger Druck führt zum Verschleiß der beweglichen Teile und

kann zum Ausfall des Geräts führen. Zudem kann das Werkzeuggehäuse

dadurch reißen

• Versuchen Sie nicht, Druckluftwerkzeuge zu modifizieren.

Modifikationsversuche führen zum Erlöschen der Garantie und können

zu schwerwiegenden Verletzungen des Bedieners oder umstehender

Personen führen

Geräteübersicht

1 Auslöser

2 Lufteinlass mit ¼"-BSP-Schnellkupplung

3 Flasche Druckluftwerkzeugöl

4 Magazinverriegelung

5 Magazinabdeckung

6 Sicherheitssperre

7 Innensechskantschlüssel

8 Schrauben

www.silverlinetools.com

13

Page 15

D

Vor Inbetriebnahme

• Packen Sie Ihr Werkzeug vorsichtig aus und überprüfen Sie es. Machen

Sie sich vollständig mit all seinen Eigenschaften und Funktionen vertraut

• Vergewissern Sie sich, dass sämtliche Teile des Werkzeugs vorhanden

und in einem guten Zustand sind. Sollten Teile fehlen oder beschädigt

sein, lassen Sie diese ersetzen, bevor Sie das Werkzeug verwenden

Bedienungsanleitung

Druckluftanschluss

ANSCHLUSSSTÜCK FÜR

DRUCKLUFTGERÄT

Dieses Werkzeug ist an eine Druckluftquelle mit sauberer Luft und einem in

Reihe geschalteten Öler und Wasserfiltereinheit anzuschließen.

• Die Zuluft darf nicht die in den Technischen Daten aufgeführte

Höchstgrenze überschreiten

• Vergewissern Sie sich, dass sich alle Bestandteile des Systems

(Schläuche, Kupplungen usw.) im für den zu verwendenden Luftdruck

zulässigen Leistungsbereich befinden

• Sorgen Sie dafür, dass das Kondensat täglich aus dem Druckluftsystem

abgelassen wird

SCHNELLKUPPLUNGSADAPTER

NIPPEL

FÜHRUNGSSCHLAUCH

DRUCKLUFTSCHLAUCH

Vorbereitung des Gerätes

• Mit dem Gerät wird eine ¼”-Bajonett-Schnellkupplung geliefert. Es

handelt sich dabei um eine Schraubverbindung für den Lufteinlass bzw.

die ¼”-BSP-Schnellkupplung (2). Durch Umwickeln mit PTFE-Band

lassen sich die Schraubgewinde luftdicht abdichten. Luftleitungen mit

passenden ¼“-Kupplungen werden so zu Steckverbindungen

• Tröpfeln Sie ein paar Tropfen Druckluftwerkzeugöl (3) in die Kupplung,

während die Schnellkupplung nach oben gerichtet ist, und lassen Sie es

in den Mechanismus laufen

Kontrollieren der Sicherheitssperre

Warnhinweis: Trennen Sie das Gerät stets von der Druckluftversorgung,

bevor Sie Einstellungs- oder Wartungsarbeiten vornehmen.

• Stellen Sie sicher, dass das Magazin leer ist

• Die Sicherheitssperre (6) muss sich ohne Behinderung hinein- und

herausbewegen

Funktionsüberprüfung der Sicherheitssperre:

1. Schließen Sie das Gerät an die Druckluftversorgung an

2. Drücken Sie die Sicherheitssperre (6) gegen ein Stück Holz, ohne den

Auslöser (1) zu betätigen. Das Gerät darf nicht auslösen. Falls das

Gerät dennoch auslöst, muss es vor dem weiteren Gebrauch repariert

werden

3. Nehmen Sie das Gerät vom Holzstück. Die Sicherheitssperre (6) sollte

jetzt in ihre ursprüngliche Stellung zurückkehren

4. Betätigen Sie den Auslöser (1). Das Gerät darf nicht auslösen. Falls

das Gerät dennoch auslöst, muss es vor dem weiteren Gebrauch

repariert werden

5. Drücken Sie die Sicherheitssperre (6) erneut gegen ein Stück Holz,

aber betätigen Sie diesmal den Auslöser (1). Das Gerät sollte nun

auslösen. Dies zeigt an, dass das Gerät normal arbeitet

Laden des Magazins

Warnhinweis: Trennen Sie das Gerät stets von der Druckluftversorgung,

bevor Sie es bestücken oder Einstellungs- oder Wartungsarbeiten

vornehmen.

• Lösen Sie die Magazinverriegelung (4) und öffnen Sie dann die

Magazinabdeckung (5)

WASSERABSCHEIDUNG

NIPPEL

NEBELÖLER

DRUCKLUFTREGLER

TÄGLICH ABLASSEN!

DRUCKLUFTQUELLE

• Legen Sie Befestigungsmittel in das Magazin ein und achten Sie dabei

darauf, dass die Spitzen der Heftklammern nach vorne gerichtet sind

(d.h. vom Gerätegriff fortweisen)

• Schließen Sie die Magazinabdeckung (5), bis die Verriegelung (4) mit

einem Klickgeräusch voll eingerastet ist

Bedienung

WICHTIGER HINWEIS: Treiben Sie stets eine Heftklammer zunächst

probeweise in einen ähnlichen Werkstoff, um zu überprüfen, dass die

Befestigungsmittel weit genug eindringen. Verändern Sie bei Bedarf den

Luftdruck mithilfe des Reglers. Durch Reduzieren des Drucks wird auch die

Eindringtiefe der Heftklammer verringert.

1. Schließen Sie das Gerät an die Druckluftversorgung an

2. Drücken Sie das Gerät fest an das Werkstück, so dass die

Sicherheitssperre (6) niedergedrückt wird

3. Betätigen Sie behutsam den Auslöser (1), bis die Heftklammer

ausgestoßen wird. Geben Sie den Auslöser frei und prüfen Sie, ob die

Heftklammer weit genug in den Werkstoff eingedrungen ist.

Verklemmungen beseitigen

Warnhinweis: Trennen Sie das Gerät stets von der Druckluftversorgung,

bevor Sie Einstellungs- oder Wartungsarbeiten vornehmen.

Befestigungsmittel steckt im Magazin fest

1. Lösen Sie die Magazinverriegelung (4) und öffnen Sie dann die

Magazinabdeckung (5)

2. Entfernen Sie die festsitzende Heftklammer mit einer Zange

3. Laden Sie das Magazin wieder und verschließen Sie es sicher

Befestigungsmittel steckt im Plattenbereich fest

1. Entfernen Sie die Schrauben (8) und nehmen Sie dann die

Frontabdeckung mithilfe der Innensechskantschlüssel (7) ab. Die

Sicherheitssperre kann jetzt gelöst werden. Entfernen Sie die

Schrauben und die Hauptplatte

2. Entfernen Sie die festsitzende Heftklammer mit einer Zange

3. Montieren Sie die Frontplatten wieder und überprüfen Sie das

Funktionieren der Sicherheitssperre, bevor Sie das Gerät verwenden

Wartung

WICHTIGER HINWEIS: Im Allgemeinen kann Ihrem Druckluftwerkzeug

nicht viel passieren. Wenn es nicht ordnungsgemäß funktionieren sollte,

liegt dies meist daran, dass die Innenteile aufgrund schmutzig-feuchter Luft

korrodiert sind, sowie daran, dass die nachfolgenden Anweisungen nicht

befolgt wurden.

Träufeln Sie jeden Tag vor Inbetriebnahme bei von der Luftzufuhr

getrenntem Gerät einen Esslöffel Druckluftwerkzeugöl in den Lufteinlass.

Betreiben Sie das Gerät bei niedriger Geschwindigkeit, damit alle Innenteile

gründlich geschmiert werden.

Falls das Gerät regelmäßig oder längere Zeit durchgehend verwendet wird,

muss ein kombinierter Filter-Öler eingesetzt werden. Es muss stets ein

Luftfilter installiert sein.

Wenden Sie sich für geeignetes Druckluftwerkzeugöl an Ihren Händler.

VERWENDEN SIE UNTER KEINEN UMSTÄNDEN NORMALES MOTORENÖL!

HINWEIS: Nichtbefolgung der Betriebs- und Wartungsanleitungen kann zum

Erlöschen der Garantie führen.

14

Page 16

771422 Druckluftklammergerät für Schmalrückenklammern, 22 mm

Silverline Tools Garantie

Dieses Silverline Produkt beinhaltet eine

3-Jahre-Garantie

Registrieren Sie dieses Produkt unter www.silverlinetools.com innerhalb

von 30 Tagen nach dem Kauf, um die 3-Jahre-Garantie zu nutzen. Die

Garantiezeit beginnt mit dem Kaufdatum auf Ihrem Kaufbeleg.

Registrieren Sie Ihren Kauf

Gehen Sie zu: silverlinetools.com, wählen Sie den Link Registrierung und

geben Sie Folgendes ein:

• IhrepersönlichenAngaben

• ProduktdetailsundKaunformationen

Das Garantiezertifikat wird Ihnen im PDF-Format zugeschickt. Bitte

drucken Sie es aus und bewahren Sie es zusammen mit Ihrem Produkt auf.

Garantiebedingungen für Silverline Tools

Die Garantiezeit beginnt mit dem Datum des auf dem Kaufbeleg

angegebenen Einzelhandelskaufs.

BITTE BEWAHREN SIE IHREN KAUFBELEG AUF

Falls dieses Produkt innerhalb von 30 Tagen nach dem Kauf einen Defekt

aufweisen sollte, bringen Sie es bitte mit Ihrem Kaufbeleg und unter

Angabe des Fehlers zu dem Fachhändler, bei dem es gekauft wurde,

zurück. Sie erhalten einen Ersatz oder eine Erstattung.

Falls dieses Produkt nach den 30 Tagen nach dem Kauf einen Defekt

aufweist, schicken Sie es zurück an:

Silverline Tools Service Centre

PO Box 2988

Yeovil

BA21 1WU, U.K.

Der Garantieanspruch muss während der Garantiezeit gestellt werden.

Sie müssen den Originalkaufbeleg mit Angabe des Kaufdatums einreichen,

Ihren Namen und Ihre Adresse sowie den Ort des Kaufs angeben, bevor

Schritte eingeleitet werden können.

Sie müssen genaue Einzelheiten des zu behebenden Defekts angeben.

Ansprüche, die während der Garantiezeit gestellt werden, werden von

Silverline Tools überprüft, um nachzuweisen, dass der Defekt durch

fehlerhaftes Material oder Herstellung des Produkts bedingt ist.

Transportkosten werden nicht erstattet. Eingereichte Produkte sollten

sich in einem zur Reparatur geeigneten sauberen und sicheren Zustand

befinden und sorgfältig verpackt werden, damit es beim Transport nicht

zu Schäden oder Verletzungen kommen kann. Wir können die Annahme

ungeeigneter oder unsicherer Lieferungen verweigern.

Alle Arbeiten werden von Silverline Tools oder den von Silverline Tools

ernannten Reparaturbeauftragten durchgeführt.

Die Reparatur oder der Ersatz des Produkts wird die Garantiezeit nicht

erweitern.

Defekte, die von uns als unter die Garantie fallend erachtet werden,

werden entweder durch kostenlose Reparatur des Werkzeugs (exklusive

Transportkosten) oder durch Ersatz durch ein Werkzeug in einwandfreiem

Zustand behoben.

Einbehaltene Werkzeuge oder Teile, für die ein Ersatz ausgegeben wurde,

werden zu Eigentum von Silverline Tools.

Die Reparatur bzw. der Ersatz Ihres Produkts unter dieser Garantie erfolgt

zusätzlich zu Ihren gesetzlichen Rechten als Verbraucher und hat keine

nachteiligen Folgen auf diese.

Was abgedeckt ist:

Die Reparatur des Produkts, nachdem zur Zufriedenheit von Silverline Tools

nachgewiesen wurde, dass der Defekt durch fehlerhaftes Material oder

mangelhafte Arbeitsausführung während der Garantiezeit bedingt ist.

Wenn ein Ersatzteil nicht mehr erhältlich ist oder nicht mehr hergestellt

wird, kann Silverline Tools es gegen einen funktionellen Ersatz

austauschen.

Gebrauch des Produkts in der EU.

Was nicht abgedeckt ist:

Silverline Tools garantiert keine Reparaturen, die erforderlich sind

aufgrund von:

Normale Verschleißerscheinungen, die durch einen der

Bedienungsanleitung entsprechenden Gebrauch entstehen, z.B. an

Messern, Bürsten, Riemen, Glühbirnen, Batterien usw.

Der Ersatz von mitgeliefertem Zubehör wie etwa Bohrspitzen, Messer,

Sandpapier, Schneidscheiben und anderen zugehörigen Artikeln.

Unfallschäden, Defekte verursacht durch: unsachgemäßen Gebrauch,

unzureichende Wartung oder nachlässige Bedienung bzw. Handhabung

des Produkts.

Verwendung des Produkts für andere als normale häusliche Zwecke.

Produktänderungen oder -modifikationen jeglicher Art.

Durch den Gebrauch von Zubehörteilen, die keine echten Silverline Tools-

Teile sind, entstandene Defekte.

Fehlerhafte Installation (außer, wenn von Silverline Tools installiert).

Reparaturen oder Änderungen, die von anderen als Silverline Tools oder

seinen autorisieren Reparaturbeauftragten durchgeführt wurden.

Forderungen anderer Art als dem Recht auf Behebung von Defekten des

Produkts im Rahmen dieser Bedingungen fallen nicht unter die Garantie.

Konformitätserklärung

Name des Unterzeichners: Mr Darrell Morris

Bevollmächtigter: Silverline Tools

Erklärt, dass das Produkt:

Name/Gerätetyp: Druckluftklammergerät für Schmalrückenklammern, 22 mm

Bauart/Seriennummer: 771422

Mit den folgenden Richtlinien übereinstimmt:

• Maschinenrichtlinie 2006/42/EC

• EN792-13/A1:2008

Techn. Unterlagen bei: Silverline Tools

Benannte Stelle: Jiangsu TUV Product Service Ltd

Ort: Shanghai, China

Datum: 06/09/11

Unterschrift:

Direktor

Name und Anschrift des Herstellers oder seines niedergelassenen

Bevollmächtigten:

Silverline Tools, Boundary Way, Lufton Trading Estate, Yeovil, Somerset,

BA22 8HZ Großbritannien

www.silverlinetools.com

15

Page 17

ESP

Descripción de los símbolos

Los símbolos siguientes pueden aparecer en la placa de características

de su herramienta. Éstos representan información importante sobre el

producto o instrucciones relativas a su uso.

Lleve protección auditiva

Lleve protección ocular

Lleve protección respiratoria

Lleve un casco de seguridad

Lleve guantes de seguridad

Lea el manual de instrucciones

Conforme a las normas de seguridad y a la

legislación correspondientes

Características técnicas

Peso: .......................................................1,10 kg

Presión requerida: ...................................4,1 - 6,9 bar

Tamaño de la corona de las grapas: ........5,2 mm

Longitud de las patas de las grapas: .......10-22 mm

Espesor de las patas de las grapas: ........1,2 x 0,6 mm

Capacidad del cargador: ..........................100 grapas

Entrada de aire: .......................................1⁄4" BSP

Presión sonora:........................................88 dB

Nivel de vibración: ...................................2,19 m/s

El nivel de intensidad sonora para el operador puede exceder

85 dB(A) y se recomiendan medidas de protección sonora.

En el marco de nuestro continuo programa de desarrollo de

productos, los datos técnicos de los productos Silverline pueden

cambiar sin previo aviso.

2

Características

de la grapas

5.2mm (0.2”)

10mm

3/8”

1/2”

13mm

5/8”

16mm

3/4”

19mm

7/8”

22mm

1.2 x 0.6mm

(0.047”) (0.024”)

20Ga.

Instrucciones generales de

seguridad

Lea cuidadosamente y asegúrese de entender este manual y cualquier

etiqueta antes de usar. Guarde estas instrucciones con el producto para

poderlas consultar en el futuro. Asegúrese de que todas las personas que

utilizan este producto están completamente familiarizadas con este manual.

Incluso cuando se esté utilizando según lo prescrito, no es posible eliminar

todos los factores de riesgo residuales. Utilice con precaución. Si está

inseguro de la manera correcta y segura en la cual utilizar este producto,

no intente utilizarlo.

Mantenga las protecciones en posición

• Mantenga siempre los dispositivos de protección en posición, en un

buen orden de trabajo, correctamente alineados y ajustados. Nunca

intente utilizar una herramienta si le falta alguna de las protecciones

suministradas. Si alguna protección está dañada, reemplácela antes

de usar

Quite las llaves de ajuste

• Compruebe siempre para verificar que las llaves y los dispositivos de

ajuste se han quitado de la herramienta antes de usar

Limpie el área de trabajo

• Pueden ocurrir accidentes si los bancos y las áreas de trabajo tienen

demasiada aglomeración de utensilios o están sucios. Los pisos se

deben mantener limpios, evitando trabajar donde el piso esté resbaladizo.

Si trabaja al aire libre, cerciórese de todos los posibles peligros como

resbalarse o tropezar antes de usar esta herramienta

Usuarios competentes

• Este producto sólo debe ser utilizado por personas formadas y

competentes

Niños y animales domésticos

• Los niños y los animales domésticos deben mantenerse siempre a una

distancia de seguridad de su área de trabajo. Guarde las herramientas

con llave lejos del alcance de los niños

Use la herramienta correcta

• No fuerce ni intente utilizar una herramienta para un propósito para el

que no fue diseñado. Esta herramienta no ha sido diseñada para uso

industrial

Lleve prendas y calzado adecuados

• No lleve ropa floja, corbatas, joyas o cualquier otro objeto que pudiese

quedar atrapado. Lleve calzado antirresbaladizo o, cuando se precise,

calzado con puntera protectora. El pelo largo se debe cubrir o anudarse

en coleta atrás

Mantenga su equilibrio

• Evite posturas arriesgadas. Trabaje sobre una base firme y mantenga el

equilibrio en todo momento. No utilice herramientas cuando esté sobre

una superficie inestable

Accesorios

• El uso de cualquier acoplamiento o accesorio diferente de los

mencionados en este manual podría ocasionar daños o lesiones. El uso

de accesorios incorrectos podría ser peligroso, e invalidará su garantía

No se suba nunca al aparato

• Subirse al aparato o su plataforma puede provocar graves heridas si

el aparato bascula o se viene abajo. No almacene materiales sobre o

cerca del aparato de modo que sea necesario subirse al aparato o su

plataforma para alcanzarlos

Asegure la pieza de trabajo

• Asegure siempre la pieza de trabajo; si resulta apropiado use un tornillo

de banco o abrazadera

Compruebe si hay piezas dañadas o faltan piezas

• Antes de cada uso, compruebe si la pieza de este producto está

dañada o se ha perdido, compruebe cuidadosamente que funcionará

correctamente y que realiza su función prevista. Verifique la alineación

de las piezas móviles para asegurar que no estén agarrotadas. Repare

inmediatamente cualquier protección u otra pieza que esté dañada o

solicite a un centro de servicio autorizado que la recambie. NO UTILICE

EL APARATO SI ESTÁ DEFECTUOSO

16

Page 18

771422 Grapadora neumática para grapas estrechas 22 mm

Aspectos de seguridad relativos

a las herramientas neumáticas

Entorno peligroso

• Asegúrese siempre de que haya espacio despejado adecuado alrededor

de la zona de trabajo. Tenga en cuenta que las mangueras neumáticas

pueden representar un peligro de tropiezo; disponga siempre las

mangueras de manera que los peligros sean reducidos al mínimo

Protéjase de la vibración

• Las herramientas neumáticas de uso manual pueden producir vibración.

La vibración puede causar enfermedades. Los guantes para mantener

al operador caliente pueden ayudar a mantener la buena circulación

sanguínea en los dedos

Mantenimiento de su herramienta neumática

• Asegúrese de mantener sus herramientas neumáticas limpias y

lubricadas. La lubricación es esencial para prevenir la corrosión de las

piezas internas, lo cual podría causar el fallo de la máquina

Desconecte siempre

• Asegúrese siempre de que su herramienta neumática esté apagada

antes de conectarla a un suministro de aire. Tenga en cuenta que las

herramientas neumáticas pueden retener presión residual después de

ser utilizadas. Purgue siempre la presión neumática de la herramienta

antes de cortar el suministro de aire

• Asegúrese siempre de que los elementos de fijación (clavos, grapas,

etc.) estén bien insertados antes de volver a conectar la herramienta al

suministro de aire

• Desconecte la herramienta neumática del suministro de aire antes de

proceder a efectuar cualquier trabajo de mantenimiento, o inserción de

clavos o grapas o instalación de accesorio

• Asegúrese siempre de que su herramienta neumática haya dejado de

funcionar antes de depositarla

Utilice una manguera de aire correcta

• Utilice una manguera para aire comprimido que sea adaptada al

compresor y al producto utilizado

Equipo de protección

• Lleve siempre equipo de protección apropiado, especialmente lentes o

gafas de seguridad, guantes de seguridad y una protección auditiva

Uso de las grapadoras/clavadoras

• No dirija el aparato hacia personas o animales

• Lleve siempre equipo de protección apropiado como por ejemplo un

mono de trabajo, guantes, etc.

• Es responsabilidad del usuario asegurarse de que otras personas que

puedan encontrarse en las cercanías del área de trabajo también van

equipadas con equipo de protección personal adecuado

No maneje la máquina de manera abusiva

• No sobrecargue la máquina de manera abusiva Si se procura que la

máquina funcione a su velocidad óptima, se prolongará su vida útil y

surtirá más eficacia

• No incremente la presión neumática sobre el nivel recomendado, ya

que una presión excesiva causará desgaste de las piezas móviles y

posible fallo resultante. También puede causar la rotura de la carcasa

de la máquina

• No intente modificar las herramientas neumáticas. Cualquier intento

de modificar la herramienta invalidará la garantía y puede provocarle

lesiones graves a usted o a los que le rodean

Presentación del product

1 Gatillo

2 Entrada de aire con conector rápido 1⁄4" BSP

3 Botella de aceite para herramientas neumáticas

4 Cierre del cargador

5 Tapa del cargador

6 Cierre de seguridad

7 Llaves allen

8 Tornillos

www.silverlinetools.com

17

Page 19

ESP

Antes del uso

• Desembale e inspeccione la herramienta con cuidado. Familiarícese con

todas sus características y funciones

• Asegúrese de que el embalaje contiene todas las partes y que están

en buenas condiciones. Si faltan piezas o están dañadas, solicite su

sustitución antes de utilizar esta herramienta

Instrucciones de funcionamiento

Conexión al suministro de aire

UNIÓN

MANGUERA DE

CONEXIÓN

ACOPLADOR RÁPIDO

MANGUERA DEL RETROCESO

CONEXIÓN AL APARATP

NEUMÁTICO

Esta herramienta debe conectarse a un suministro de aire limpio y seco,

con un engrasador y un separador de agua en línea.

• No deje que la presión de suministro supere la establecida en las

características técnicas más arriba

• Asegúrese de que todas las piezas del sistema (mangueras,

acoplamientos, etc.) tienen la presión nominal correspondiente a la que

se va a usar

• Asegúrese de vaciar diariamente el condensado del sistema de aire

Preparación de la herramienta

• Con la herramienta se suministra un conector rápido a bayoneta de ¼".

El conector se atornilla en la entrada de aire (2). Si se aplica cinta de

PTFE a la rosca, se mantiene mejor la estanqueidad al aire. Las líneas de

aire con conectores de ¼" se conectarán por simple presión

• Con el conector rápido hacia arriba, ponga unas gotas de aceite para

herramientas neumáticas (3) en el conector y deje que penetre en el

mecanismo

Comprobación del cierre de seguridad

Advertencia. Desconecte siempre la herramienta de la fuente de aire antes

de realizar cualquier ajuste o labor de mantenimiento.

• Asegúrese de que el cargador esté vacío

• El cierre de seguridad (6) debe entrar y salir sin restricciones.

Para comprobar el correcto funcionamiento del cierre de

seguridad:

1. Conecte la herramienta a la fuente de aire

2. Empuje el cierre de seguridad (6) contra un trozo de madera sin

apretar el gatillo (1). La herramienta no debe dispararse. En caso de

que se dispare, deberá repararse antes de usarla

3. Aleje la herramienta del trozo de madera. El cierre de seguridad (6)

deberá volver a la posición original

4. Apriete el gatillo (1). La herramienta no debe dispararse. En caso de

que se dispare, deberá repararse antes de usarla

5. Empuje el cierre de seguridad (6) contra el trozo de madera, pero esta

vez apriete el gatillo (1). La herramienta se dispara, lo cual indica un

funcionamiento normal

Cargar el cargador

Advertencia. Desconecte siempre la herramienta de la toma de aire antes

de realizar cualquier ajuste o labor de mantenimiento o carga.

• Abra el cierre del cargador (4) y tire de la tapa del cargador (5) para

abrirlo

• Introduzca las grapas en el cargador asegurándose de que las puntas

queden hacia adelante (en el sentido opuesto a la empuñadura de la

herramienta)

• Cierre la tapa del cargador (5) hasta que el cierre (4) quede totalmente

cerrado (haciendo un ‘clic’ audible)

SEPARACIÓN DEL AGUA

UNIÓN

ENGRASDOR

REGULADOR

PURGUE

DIARIAMENTE

SUMINISTRO DE AIRE

Funcionamiento

IMPORTANTE. Compruebe siempre que la penetración de la grapa sea

la correcta. Empleando un material similar, dispare una grapa de prueba

usando si fuera necesario el regulador para ajustar la presión del aire al

nivel deseado. Al reducir la presión se reduce la penetración de la grapa.

Conecte la herramienta a la fuente de aire.

1. Conecte la herramienta a la fuente de aire

2. Sujete la herramienta firmemente contra el material de forma que el

cierre de seguridad (6) esté apretado

3. Apriete suavemente el gatillo (1) hasta que se dispare la grapa. Suelte

el gatillo y compruebe que haya penetrado el material correctamente

Eliminación de bloqueos

Advertencia. Desconecte siempre la herramienta de la toma de aire antes

de realizar cualquier ajuste o labor de mantenimiento.

Sujetador atascado en el cargador

1. Abra el cierre del cargador (4) y la tapa del cargador (5)

2. Quite la obstrucción con unas tenacillas

3. Vuelva a poner el cargador y ciérrelo firmemente

Grapa atascada en la parte de la placa

1. Quite los tornillos (8) y quite la tapa delantera. Ahora puede quitar el

cierre de seguridad. Saque los tornillos y retire la placa principal

2. Quite la obstrucción con unas tenacillas

3. Vuelva a poner las placas delanteras y compruebe el funcionamiento

del cierre de seguridad antes de utilizar la herramienta

Mantenimiento

IMPORTANTE: Hay muy pocas razones para que la herramienta neumática

funcione mal. Si deja de funcionar se debe generalmente a que se ha

producido corrosión interna como consecuencia del aire húmedo sucio y de

no haber seguido las instrucciones que se dan más abajo.

TODOS LOS DÍAS: Desconecte la fuente de aire y ponga una cucharada de

aceite en la toma de aire. Haga funcionar la máquina a baja velocidad para

lubricar a fondo el mecanismo interior.

Si la herramienta se utiliza constantemente o si se usa durante periodos

largos, debe montarse un filtro / lubricador combinado. Debe siempre tener

montado un filtro de aire.

Si no está seguro del tipo de aceite que utilizar, consulte a su

distribuidor. NO USE ACEITE NORMAL PARA MOTORES BAJO NINGUNA

CIRCUNSTANCIA.

NOTA: El incumplimiento de las instrucciones de uso y mantenimiento

puede invalidar la garantía.

18

Page 20

771422 Grapadora neumática para grapas estrechas 22 mm

Garantía de Silverline Tools

Garantía Silverline Tools

Este producto Silverline viene con una garantía de

3 años

Registre el producto en www.silverlinetools.com antes de que transcurran

30 días a partir de la fecha de compra para poder acogerse a la garantía

de 3 años. El periodo de garantía comienza en la fecha de compra que

consta en el comprobante.

Registro de la compra

Visite: silverlinetools.com y seleccione el botón de registro, introduciendo:

• Susdatospersonales

• Detallesdelproductoeinformacióndecompra

El Certificado de Garantía le será enviado en formato PDF. Imprímalo y

guárdelo con el producto.

Condiciones

El periodo de garantía entra en vigor en la fecha de compra que consta en

el recibo de ventas.

GUARDE EL RECIBO DE VENTAS

En caso de que el producto se averíe antes de que transcurran 30 días

desde la fecha de compra, devuélvalo al distribuidor donde lo compró,

junto con el recibo y los detalles de la avería. Recibirá una sustitución o

un reembolso.

Si el producto se avería después de que transcurran 30 días desde la fecha

de compra, devuélvalo a:

Centro de Servicio de Silverline Tools

PO Box 2988

Yeovil

BA21 1WU, Reino Unido

La reclamación bajo garantía debe presentarse durante el periodo de

garantía.

Antes de poder realizar cualquier trabajo de reparación, deberá entregar

el recibo de compra original en el que se indica la fecha de compra, su

nombre, dirección y el lugar donde lo adquirió.

También deberá indicar claramente los detalles del fallo a reparar.

Las reclamaciones presentadas dentro del periodo de garantía deberán ser