Page 1

3 Year Guarantee

*Register online within 30

days. Terms & Conditions apply

Garantie de 3 ans

*Enregistrez votre produit en ligne

dans les 30 jours. Sous réserve des

termes et conditions appliquées

3 Jahre Garantie

*Innerhalb von 30 Tagen online

registrieren. Es gelten die Allgemeinen

Geschäftsbedingungen

3 años de garantía

*Registre su producto online durante

los primeros 30 días. Se aplican

términos y condiciones

3 anni di garanzia

*Registrare il vostro prodotto on-line entro

30 giorni. Termini e condizioni si applicano

3 jaar garantie

*Registreer uw product binnen 30

dagen online. Algemene voorwaarden

zijn van toepassing

www.silverlinetools.com

Page 2

R

E

L

V

L

I

S

AIR

R

A

N

I

N

E

E

G

Air Line Filter Regulator

427596

150ml

Air Line Filter Regulator

Filtre régulateur pour air comprimé

Druckluft-Wartungseinheit mit Filter

Filtro regulador para aire comprimido

Filtro regolatore per aria compressa

Perslucht regelaar

www.silverlinetools.com

Page 3

3

2

1

4

5

6

7

2

Page 4

R

E

V

L

I

S

AIR

R

A

N

G

L

I

N

E

E

Air Line Filter Regulator

English .................. 4

Français ................ 10

®

150ml

Deutsch ................. 16

Español ................. 22

Italiano .................. 28

Nederlands ............ 34

www.silverlinetools.com

3

Page 5

GB

Description of Symbols

The rating plate on your tool may show symbols. These represent

important information about the product or instructions on its use

Wear hearing protection

Wear eye protection

Wear breathing protection

Wear head protection

Wear hand protection

Read instruction manual

DO NOT use with compressed gas cylinders!

Environmental Protection

Air tools should not be disposed of with household

waste. They contain traces of oil and other lubricants.

Please recycle where facilities exist. Check with your

local authority or retailer for recycling advice.

Specification

Fluid type: ...................................................Compressed air

Maximum operating pressure: ....................10bar (145psi)

Adjustable outlet pressure range: ...............0.5 - 8.5bar (7-123psi)

Operating temperature range: .....................5 - 50°C

Air connections: ..........................................G ¼"

Condenser bowl capacity: ...........................150ml

Condenser bowl material: ...........................Polycarbonate

General Safety Warnings

• For multiple hazards, read and understand the safety

instructions before installing, operating, repairing, maintaining,

changing accessories on, or working near this device. Failure

to do so can result in serious bodily injury

• Only qualified and trained operators should install, adjust, or

use this device

• Do not modify this device. Modifications can reduce the

effectiveness of safety measures and increase the risks to the

operator

• Do not discard the safety instructions; give them to the

operator

• Do not use this device if it has been damaged

• Tools shall be inspected periodically to verify that the ratings

and markings required by this part of ISO 11148 are legibly

marked on the tool. The employer/user should contact the

manufacturer to obtain replacement marking labels when

necessary

WARNING: This appliance is not intended for use by persons

(including children) with reduced, physical or mental capabilities

or lack of experience or knowledge unless they have been given

supervision or instruction concerning use of the appliance by a

person responsible for their safety. Children must be supervised

to ensure that they do not play with the appliance.

Projectile Hazards

• Be aware that failure of this device can generate high-velocity

projectiles

• Always wear impact-resistant eye protection during operation

of this device. The grade of protection required should be

assessed for each use

• The risks to others should also be assessed at this time

• Ensure that the device is securely fixed

Workplace Hazards

• Slips, trips and falls are major causes of workplace injury. Be

aware of slippery surfaces caused by use of the tool and also

of trip hazards caused by the air line or hydraulic hose

• This tool is not intended for use in potentially explosive

atmospheres and is not insulated against contact with electric

power

4

Page 6

427596 Air Line Filter Regulator

Additional Safety Instructions for

Pneumatic Devices

Air under pressure can cause severe injury:

• Always shut off air supply, drain hose of air pressure and

disconnect tool from air supply when not in use, before

changing accessories or when making repairs

• Never direct air at yourself or anyone else

• Whipping hoses can cause severe injury. Always check for

damaged or loose hoses and fittings

• Whenever universal twist couplings (claw couplings) are used,

lock pins should be installed and whipcheck safety cables

should be used to safeguard against possible hose-to-tool or

hose-to-hose connection failure

• Do not exceed the maximum air pressure stated on the tool

• Never carry an air tool by the hose

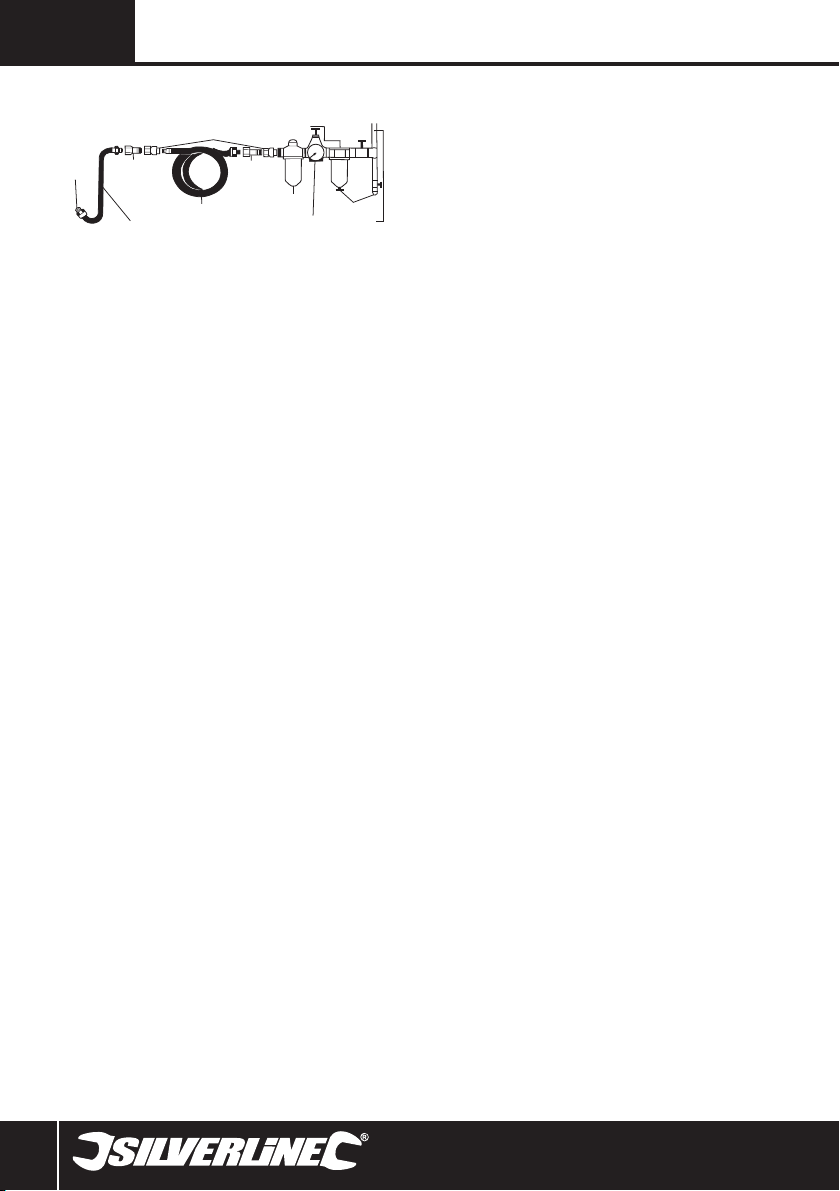

Product Familiarisation

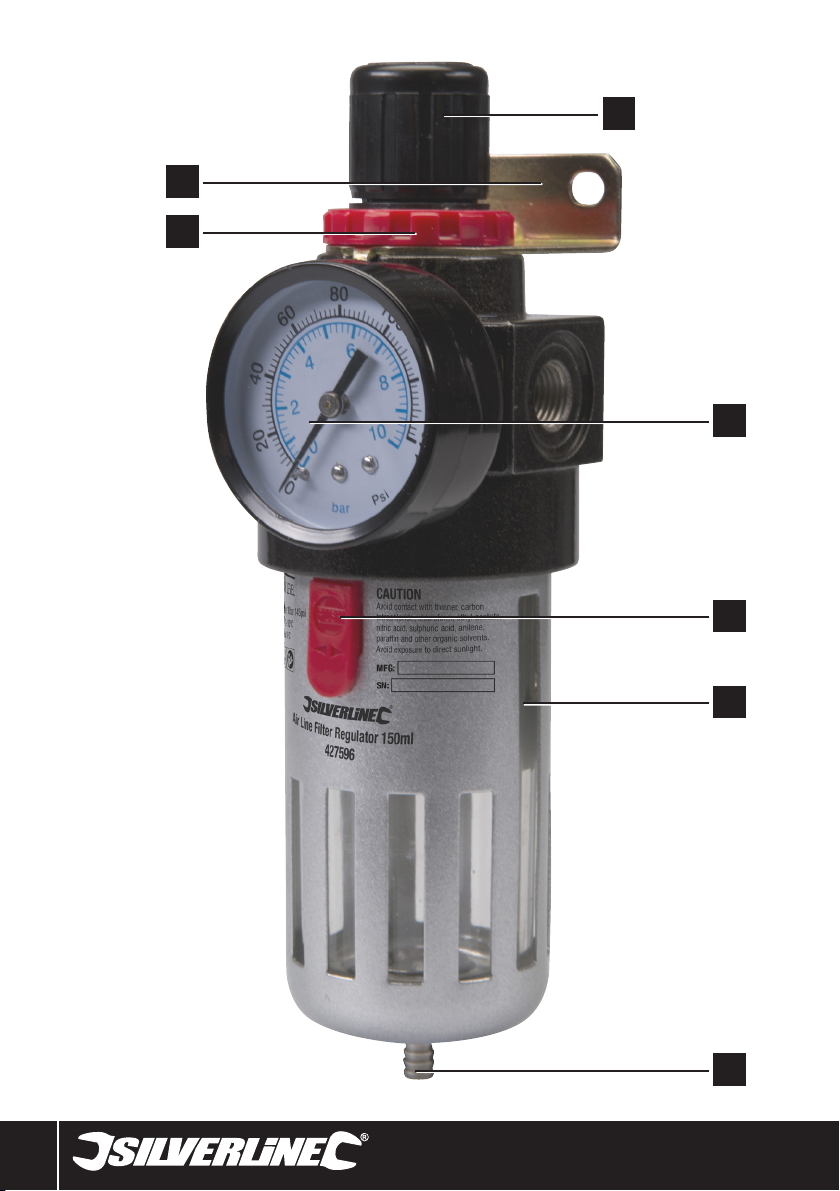

1 Mounting Bracket Locking Ring

2 Mounting Bracket

3 Pressure Control

4 Pressure Gauge

5 Bowl Unlock Button

6 Condenser Bowl

7 Drain Valve

Intended Use

• Combination filter regulator unit for permanent installation

in compressed air lines, to remove foreign matter from the

compressed air, and for setting the air pressure accurately

using the integrated pressure gauge

WARNING: This filter does not produce breathing grade

compressed air!

WARNING: Some water vapour will pass through this unit and

could condense into liquid form downstream, as air temperature

drops. Install an air dryer if water condensation could have a

detrimental effect on the application.

Unpacking Your Device

• Carefully unpack and inspect your tool. Fully familiarise

yourself with all its features and functions

• Ensure that all parts of the tool are present and in good

condition. If any parts are missing or damaged, have such

parts replaced before attempting to use this tool

Before Use

Installation

Note: DO NOT install this filter regulator in locations where it

would be permanently exposed to direct sunlight.

1. Install the Mounting Bracket (2) on a wall, machine housing

or other even surface using two suitable screws (mounting

hardware not included). The Drain Valve (7) must be located

at the bottom of the unit

2. Attach the mounting bracket and Mounting Bracket Locking

Ring (1) as shown in the ‘Product Familiarisation’ image

above. Turn the locking ring clockwise to tighten the thread

3. Apply some PTFE tape (not included) to the screw threads of

the Pressure Gauge (4). This will help to maintain an air tight

seal

Note: Apply PTFE tape tightly and in a clockwise direction, so it

does not come off when the thread is screwed into the tool.

4. Screw the pressure gauge clockwise into the threaded

hole of the regulator body as shown in the ‘Product

Familiarisation’ image above.

Note: Be careful not to cross the threads. Turn gently at first.

Ensure that the dial is correctly positioned when tightening the

pressure gauge.

www.silverlinetools.com

5

Page 7

GB

Air supply connection

RECOIL HOSE

WATER SEPARATION

NIPPLE

OILER

REGULATOR

DRAIN DAILY

AIR SUPPLY

QUICK COUPLER

NIPPLE

TO YOUR

AIR TOOL

LEADER HOSE

WARNING: Ensure that the air system is fully drained and the

compressor is switched off, before connecting the filter regulator.

WARNING: This filter regulator unit must not be used

with compressors that use lubricants containing aromatic

hydrocarbons. Such chemicals would damage and lead to failure

of the polycarbonate Condenser Bowl (6).

IMPORTANT: The arrows on the inlet/outlet ports indicate

direction of air flow. AIR FLOW IS FROM THE COMPRESSOR TO

THE TOOL.

WARNING: For use with motorised air tools an oiler unit must be

fitted downstream of this filter/regulator.

• Connect the filter regulator to the compressor feed, before the

oiler (see diagram below)

Note: For painting applications, e.g. when using spray guns, omit

the oiler

• Do not allow supply pressure to exceed the maximum stated

(see “Specifications”)

• Ensure that water is drained from air system daily

• Ensure that all parts of the system (hoses, couplers, etc.) are

correctly rated for the air pressure to be used

Operation

WARNING: The Condenser Bowl (6) is manufactured from

polycarbonate and must not be exposed to temperatures above

50°C.

Before each use

• Inspect the unit and air hoses for wear or damage, and

replace if necessary. Do not use damaged or leaking hoses or

connections

Adjusting the air pressure

Note: Some air tools have built-in regulators, which are used to

control speed/torque performance. Where a machine does not

have a built-in regulator, the speed/torque can still be adjusted

by varying the pressure on your air supply regulator.

• INCREASE the air pressure by pulling the Pressure Control (3)

up to unlock it, then turning it clockwise. Push the pressure

control back down to lock it again

• DECREASE the pressure by unlocking the pressure control,

then turning it anticlockwise. Push down to lock it again

WARNING: For applications that require a very accurate air

pressure, confirm outlet pressure with a calibrated pressure

gauge.

Draining the condenser bowl

WARNING: Cleaning and draining MUST ONLY be carried out

with the compressor switched off and the air system drained of

pressure.

• The condenser will collect moisture and dirt which, unless

removed, will cause serious corrosion to this device and to

your machines

• Drain the Condenser Bowl (6) daily (or more often where

applicable) by pulling down on the Drain Valve (7) until all

liquid has escaped

Maintenance

WARNING: Always shut off the compressor and depressurise the

air supply before cleaning or carrying out any maintenance.

WARNING: The polycarbonate Condenser Bowl (6) can be

damaged and may fail if exposed to certain solvents or strong

alkaline cleaning agents (either internally or externally).

Cleaning

• Press the Bowl Unlock Button (5), twist the Condenser Bowl

(6) clockwise or anticlockwise until the bayonet connection

unlocks, and remove the bowl

• Wash out using a mild detergent and a lint-free cloth

• Rinse with plenty of clean cold fresh water and dry thoroughly

• To reassemble, first check that the O-ring that seals the bowl

against the body of the unit is clean and undamaged, then

engage the locking bayonet and twist the cup until the unlock

button clicks into its locked position

Disposal

• As with other power tools, air tools should not be disposed of

with household waste

• Air tools may contain traces of tool oil and other lubricants and

so must be recycled accordingly

• Contact your local waste disposal authority for information on

the correct way to dispose of power tools

6

Page 8

427596

Silverline Tools Guarantee

Silverline Tools Guarantee

This Silverline product comes with a 3 year

guarantee

Register this product at silverlinetools.com within 30 days of purchase

in order to qualify for the 3 year guarantee. Guarantee period begins

according to the date of purchase on your sales receipt.

Terms & Conditions

Terms & Conditions

Guarantee period becomes effective from the date of retail purchase as

detailed on your sales receipt.

PLEASE KEEP YOUR SALES RECEIPT

If this product develops a fault within 30 days of purchase, return it to the

stockist where it was purchased, with your receipt, stating details of the

fault. You will receive a replacement or refund.

If this product develops a fault after the 30 day period, return it to:

Silverline Tools Service Centre

PO Box 2988

Yeovil

BA21 1WU, UK

The guarantee claim must be submitted during the guarantee period.

You must provide the original sales receipt indicating the purchase date,

your name, address and place of purchase before any work can be

carried out.

You must provide precise details of the fault requiring correction.

Claims made within the guarantee period will be verified by Silverline Tools

to establish if the deficiencies are related to material or manufacturing of

the product.

Carriage will not be refunded. Items for return must be in a suitably clean

and safe state for repair, and should be packaged carefully to prevent

damage or injury during transportation. We may reject unsuitable or

unsafe deliveries.

All work will be carried out by Silverline Tools or its authorized

repair agents.

The repair or replacement of the product will not extend the period

of guarantee

Defects recognised by us as being covered by the guarantee shall be

corrected by means of repair of the tool, free of charge (excluding carriage

charges) or by replacement with a tool in perfect working order.

Air Line Filter Regulator

Registering your purchase

Registration is made at silverlinetools.com by selecting the Guarantee

Registration button. You will need to enter:-

• Your personal details

• Details of the product and purchase information

Once this information is entered your guarantee certificate will be created

in PDF format for you to print out and keep with your purchase.

Retained tools, or parts, for which a replacement has been issued, will

become the property of Silverline Tools.

The repair or replacement of your product under guarantee provides

benefits which are additional to and do not affect your statutory rights as

a consumer.

What is covered:

The repair of the product, if it can be verified to the satisfaction of Silverline

Tools that the deficiencies were due to faulty materials or workmanship

within the guarantee period.

If any part is no longer available or out of manufacture, Silverline Tools will

replace it with a functional replacement part.

Use of this product in the EU.

What is not covered:

Silverline Tools does not guarantee repairs required as a result of:

Normal wear and tear caused by use in accordance with the operating

instructions eg blades, brushes, belts, bulbs, batteries etc.

The replacement of any provided accessories drill bits, blades, sanding

sheets, cutting discs and other related items.

Accidental damage, faults caused by negligent use or care, misuse,

neglect, careless operation or handling of the product.

Use of the product for anything other than normal domestic purposes.

Change or modification of the product in any way.

Use of parts and accessories which are not genuine Silverline Tools

components.

Faulty installation (except installed by Silverline Tools).

Repairs or alterations carried out by parties other than Silverline Tools or its

authorized repair agents.

Claims other than the right to correction of faults on the tool named in

these guarantee conditions are not covered by the guarantee.

CE Declaration of Conformity

The undersigned: Mr Darrell Morris

as authorised by: Silverline Tools

Declares that the

Identification code: 427596

Description: Air Line Filter Regulator

Conforms to the following Directives:

• Machinery Directive 2006/42/EC

• EN 12100:2010

Notified body: Shanghai Yousende Products Inspection Technology Co.,

Ltd, Shanghai, China

The technical documentation is kept by: Silverline Tools

Date: 07/01/14

Signed by:

Director

Name and address of the manufacturer:

Powerbox Ltd., Boundary Way, Lufton Trading Estate, Yeovil, Somerset,

BA22 8HZ, United Kingdom

www.silverlinetools.com

7

Page 9

F

Description des symboles

La plaque signalétique figurant sur votre outil peut présenter

des symboles. Ces symboles constituent des informations

importantes relatives au produit ou des instructions concernant

son utilisation.

Port de protection auditive

Port de lunettes de sécurité

Port du masque respiratoire

Port du casque

Port de gants

Lire le manuel d’instructions

Ne pas utiliser l’air comprimé des bouteilles à haute

pression

Protection de l’environnement

Les produits électriques usagés ne doivent pas

être jetés avec les ordures ménagères. Veuillez les

recycler dans les centres prévus à cet effet. Pour de

plus amples informations, veuillez contacter votre

municipalité ou point de vente.

Caractéristiques techniques

Type de fluide : .....................................................air comprimé

Pression maximale de fonctionnement : ................ 9,3 bar

Température maximale de fonctionnement : ..........50°

Raccords :.............................................................. G1⁄4"

Capacité du condenseur : ...................................... 150 ml

Matériau du condenseur : ...................................... Polycarbonate

Consignes générales de sécurité

• En ce qui concerne les risques, lire et comprendre les

instructions de sécurité avant d’installer, utiliser, réparer,

entretenir, changer d’accessoires, ou travailler proche de

cet outil. Ne pas respecter les consignes peut engendrer de

sérieuses blessures corporelles.

• Seule une personne qualifiée et formée peut assembler, régler

et utiliser la cet outil.

• N’apporter aucune modification sur cet outil. Des

modifications peuvent diminuer l’efficacité des mesures de

sécurité et augmenter les risques pour l’utilisateur.

• Garder toujours les instructions de sécurité, et les donner à

l’utilisateur.

• Ne pas utiliser cet outil si elle est endommagée.

• Les outils doivent être inspectés régulièrement pour vérifier

la validité des données de l’appareil en fonction de la norme

ISO 11148-8:2011. Ces données doivent être lisibles sur

l’appareil. Il est de la responsabilité de ‘employeur/ utilisateur

de contacter le fabricant pour obtenir le remplacement de la

plaque signalétique si nécessaire.

Attention : Cet appareil n’est pas conçu pour être utilisé par des

personnes (enfants compris) ayant des capacités physiques

ou mentales réduites, ou n’ayant pas la connaissance ou

l’expérience requise, à moins d’être sous la supervision d’une

personne responsable de leur sécurité ou d’avoir reçu les

instructions nécessaires. Les enfants ne doivent pas s’approcher

et jouer avec cet appareil.

Risques de projection

• Il est à savoir qu’un défaut sur la pièce de travail, sur un

accessoire ou sur l’appareil même peut engendrer l’envoi de

projectiles avec une vitesse très importante.

• Toujours porter des protections oculaires résistantes aux

impacts pendant toute la durée d’utilisation de cet outil. Le

grade de protection doit être évalué avant chaque utilisation.

• Les risques pour les autres personnes doivent être également

évalués.

• Vérifier que la pièce de travail soit convenablement stabilisé

pour travailler en toute sécurité.

Risques liés au lieu de travail

• Les causes d’accidents sur le lieu de travail sont souvent dues

à des trébuchements, glissades et chutes. Faites attention sur

les surfaces rendues glissantes par l’utilisation de l’appareil,

ainsi que les risques de trébuchements qui pourraient être

occasionnés par le tuyau d’air et tuyau hydraulique.

• Cet outil n’est pas conçu pour être utilisée en milieu à

atmosphère potentiellement explosif, et n’est pas isolante

contre le contact avec une source électrique.

8

Page 10

427596

Filtre régulateur pour air comprimé

Consignes supplémentaires

relatives aux outils pneumatiques

L’air comprimé peut engendre des blessures graves :

• Toujours couper l’alimentation en air, purger le tuyau d’air et

débrancher l’appareil de l’alimentation en air lorsqu’il n’est

pas utilisé ou lors d’un changement d’accessoires ou avant

toutes réparations.

• Ne jamais diriger l’air vers vous ou d’autres personnes

• Les tuyaux peuvent être une source de dangers en donnant

des coups de fouets. Toujours vérifier le bon état du tuyau et

des raccords.

• Pour toute utilisation de coupleurs universels, utiliser des

goupilles et vérifier les tuyaux pour éviter un mauvais raccord

entre le tuyau et l’appareil.

• Ne jamais dépasser la pression maximale d’air indiquée sur

l’appareil.

• Ne jamais porter l’appareil par le tuyau.

Se familiariser avec le produit

1 Bague de serrage du support de montage

2 Support de montage

3 Contrôle de la pression

4 Manomètre

5 Bouton de déverrouillage du condenseur

6 Condenseur

7 Valve de purge

Usage conforme

Pour des installations sur des circuits d’air comprimé

permanents, afin de filtrer les impuretés de l’air comprimé, et

également régler la pression d’air de façon précise grâce au

manomètre intégré.

ATTENTION : Ce filtre ne produit pas de l’air comprimé respirable

!

ATTENTION : De la vapeur d’eau peut passer dans cet appareil

et se condenser lorsque la température diminue. Installez

un sécheur d’air si la condensation peut être néfaste pour

l’utilisation envisagée.

Déballage

• Déballez le produit avec soin. Veillez à retirer tout le

matériau d’emballage et familiarisez-vous avec toutes les

caractéristiques du produit.

• Si des pièces sont endommagées ou manquantes, faites-les

réparer ou remplacer avant d’utiliser l’appareil.

Avant utilisation

Montage

Remarque : Ne laissez pas le filtre en permanence à la lumière

directe du soleil.

1. Fixez le support de montage (2) sur un mur, boitier de

machine ou autres surfaces plates avec deux vis adéquates

(non fournies). La purge (7) doit être placée vers le bas.

2. Assemblez le support de montage et la bague de serrage

du support de montage (1), comme indiqué sur la photo se

trouvant dans la rubrique ‘Se familiariser avec le produit’.

Tournez la bague dans le sens horaire et serrez bien le pas

de vis.

3. Appliquez de la bande PFTE (non fournie) sur le filetage du

manomètre (4). Ceci permettra d’éviter les fuites d’air.

Remarque : Appliquez la bande PFTE dans le sens horaire, de

sorte qu’elle ne se défasse pas lors du vissage du pas de vis sur

l’appareil.

4. Vissez le manomètre sur le trou fileté du filtre comme

indiqué sur la photo se trouvant dans la rubrique ‘Se

familiariser avec le produit.

Remarque : Faites attention de ne pas entrecroiser les filetages.

Vissez avec précaution dès le début. Assurez-vous que le bouton

soit correctement positionné lorsque vous serrez le manomètre.

www.silverlinetools.com

9

Page 11

F

Connexion de l’air comprimé

SÉPARATION DE L’EAU

RACCORD RAPIDE

COUPLEUR OUTIL

PNEUMATIQUE

RACCORD

TUYAU DE

RACCORDEMENT

FLEXIBLE SERPENTIN

MAMELON

GRAISSEUR

RÉGULATEUR

A PURGER

QUOTIDIENNEMENT

ALIMENTATION EN

AIR COMPRIMÉ

ATTENTION : Assurez-vous que le système d’air est entièrement

purgé et que le compresseur soit éteint avant de branchez le

filtre régulateur.

ATTENTION : Ce filtre régulateur ne doit pas être utilisé avec des

compresseurs utilisant des lubrifiants avec des hydrocarbures

aromatiques. De tels produits chimiques peuvent endommager

et entrainer le non fonctionnement du condenseur (6).

IMPORTANT : Les flèches sur l’entrée et arrivée d’air indiquent le

sens de circulation de l’air, qui se fait du COMPRESSEUR VERS

L’APPAREIL.

ATTENTION : Pour les outils pneumatiques motorisés, un

graisseur doit être utilisé en aval du filtre régulateur.

• Branchez le filtre régulateur sur l’alimentation en air

comprimé, avant le graisseur (voir le schéma ci-dessous)

• Ne laissez pas la pression d’alimentation dépasser la pression

maximale spécifiée. (Voir caractéristiques techniques).

• Vérifiez que l’eau soit drainée quotidiennement

• Vérifiez que toutes les parties du système (tuyaux, coupleurs,

etc) soient adaptés à l’air comprimé utilisé.

Instructions d’utilisation

ATTENTION : Le condenseur (6) est en fait en polycarbonate,

par conséquent il ne peut pas être exposé à des températures

supérieures à 50° C.

Avant chaque utilisation

• Vérifiez que l’appareil et les tuyaux soient en état parfait, et

remplacez-les si nécessaire. N’utilisez jamais de tuyaux ou

raccords endommagés ou qui fuient.

Réglage de la pression d’air

Remarque : Quelques outils pneumatiques ont des régulateurs

intégrés pour contrôler la vitesse ou le couple d’utilisation. Si une

machine n’a pas de régulateur intégré, la vitesse/couple peut se

régler en ajustant la pression de l’air de votre régulateur.

• Pour augmenter la pression d’air, soulevez le contrôle de

la pression (3) pour le débloquer et tournez-le dans le sens

horaire. Poussez le contrôle de pression vers le bas pour le

bloquer.

• Pour diminuer la pression, soulevez le contrôle de la pression

(3) pour le débloquer et tournez-le dans le sens antihoraire.

Poussez le contrôle de pression vers le bas pour le bloquer.

ATTENTION : Pour les utilisations qui requièrent une pression

d’air précise, il est recommandé de brancher un manomètre

étalonné pour confirmer la pression à la sortie.

Purger le condenseur

ATTENTION : Le nettoyage et la purge doivent IMPERATIVEMENT

effectués lorsque le compresseur est éteint et le circuit d’air est

sans résidu de pression.

• Le condenseur récupère l’humidité et la saleté, qui si elles ne

sont pas enlevées, risquent de sérieusement rouiller l’appareil

et vos machines.

• Purgez le condenseur (6) quotidiennement (ou plus si

nécessaire) en tirant la valve de purge (7) vers le bas jusqu’à

ce que tout le liquide se soit échappé.

Entretien

ATTENTION : Eteignez toujours le compresseur et dépressurisez

l’air fourni avant de nettoyer ou effectuer l’entretien de l’appareil.

ATTENTION : Le condenseur en polycarbonate (6) peut être

endommagé ou risque de ne pas fonctionner si exposé à certains

solvants ou des agents de nettoyage à forte teneur en alcalin

(intérieur ou extérieur).

Nettoyage

• Appuyez sur le bouton de déverrouillage du condenseur (5),

tournez le condenseur (6) dans le sens horaire ou antihoraire,

jusqu’à ce que la baïonnette se déclenche, et retirez le

condenseur.

• Nettoyez avec un détergent doux et un chiffon non pelucheux

• Rincez abondamment avec de l’eau froide, et séchez

complètement.

• Avant de remettre le condenseur, vérifiez que le joint torique

soit en bon état et propre. Utilisez le système à baïonnette pour

enclencher bouton de verrouillage du condenseur.

Recyclage

• Comme tous les autres outils électroportatifs, les outils à

air comprimé ne doivent pas être jetés avec les ordures

ménagères.

• Les outils à air comprimé contiennent de l’huile et lubrifiants et

doivent donc être recyclés en conséquence.

• Contactez les autorités locales compétentes en matière de

gestion des déchets pour vous informer de la procédure à

suivre pour recycler les outils électriques et à air comprimé

10

Page 12

Garantie Silverline

Ce produit Silverline bénéficie d’une garantie de

3 ans

Enregistrez ce produit sur le site silverlinetools.com dans les 30 jours

suivant l’achat afin de bénéficier de la garantie de 3 ans. La période de

garantie commence à partir de la date d’achat figurant sur votre facture

d’achat.

Conditions de garantie des outils Silverline

La période de garantie prend effet à compter de la date de l’achat en

magasin, comme indiqué sur votre facture d’achat.

VEUILLEZ CONSERVER VOTRE FACTURE D’ACHAT.

Si ce produit est défectueux pendant les 30 jours qui suivent l’achat,

retournez-le au magasin où vous l’avez acheté, avec votre facture, en

expliquant en détail le problème. Le produit sera remplacé ou vous serez

remboursé(e).

Si ce produit est défectueux après cette période de 30 jours,

retournez-le à :

Silverline Tools Service Centre

PO Box 2988

Yeovil

BA21 1WU, Royaume Uni

Toute demande de service sous garantie doit être soumise pendant la

période de garantie.

Avant toute intervention sous garantie, vous devez présenter la facture

d’achat originale sur laquelle doivent figurer la date d’achat, votre nom, votre

adresse et le lieu d’achat.

Vous devez expliquer en détail la défaillance nécessitant réparation.

Les demandes de service sous garantie faites pendant la période de garantie

seront vérifiées par Silverline Tools pour établir si la défaillance du produit est

liée à un vice de matériau ou de fabrication.

Les frais de port ne seront pas remboursés. Les articles retournés doivent

être convenablement propres et sûrs pour être réparés et devraient être

emballés soigneusement pour éviter tout dommage ou toute blessure

pendant le transport. Nous pouvons refuser les livraisons qui ne sont pas

convenables ou sûres.

Toute intervention sera effectuée par Silverline Tools ou ses agents de

réparation agréés.

La réparation ou le remplacement du produit ne dépassera pas la période

de garantie.

Les anomalies que nous reconnaissons être couvertes par la garantie seront

rectifiées par la réparation de l’outil, sans frais (hormis les frais de port) ou

par son remplacement par un outil en parfait état de fonctionnement.

Filtre régulateur pour air comprimé427596

Enregistrement de votre achat

Visitez silverlinetools.com, sélectionnez le bouton d’enregistrement et

saisissez :

• Vos informations personnelles

• Les informations concernant le produit et l’achat

Vous recevrez le certificat de garantie en format PDF. Veuillez l’imprimer et

le conserver avec votre achat.

Les pièces ou les outils remplacés deviendront la propriété de Silverline Tools.

La réparation ou le remplacement de votre produit sous garantie vous

apporte des avantages ; ces avantages s’ajoutent à vos droits statutaires en

tant que consommateur sans les affecter aucunement.

La présente garantie couvre:

La réparation du produit, s’il peut être vérifié, à la satisfaction de Silverline

Tools, que les défaillances du produit ont été provoquées par un vice de

matériau ou de fabrication au cours de la période de garantie.

Si une pièce n’est plus disponible ou n’est plus fabriquée, Silverline Tools la

remplacera par une pièce de rechange opérationnelle.

Utilisation de ce produit dans l’UE.

La présente garantie ne couvre pas:

Silverline Tools ne garantit pas les réparations nécessaires du produit

engendrées par :

L’usure normale provoquée par l’utilisation conforme aux instructions

d’utilisation, par exemple les lames, les charbons, les courroies, les

ampoules, les batteries, etc.

Le remplacement de tout accessoire fourni tel que les forêts, les lames, les

feuilles abrasives, les outils de coupes et les autres articles associés.

Les dommages et les défaillances accidentels causés par une utilisation ou

un entretien négligent, une mauvaise utilisation, un manque d’entretien ou

une utilisation ou une manipulation imprudente du produit.

L’utilisation du produit à des fins autres que son utilisation domestique normale.

Le moindre changement ou la moindre modification du produit.

L’utilisation de pièces et d’accessoires qui ne sont pas des composants

véritables de Silverline Tools.

Une installation défectueuse (sauf si l’installation a été réalisée par Silverline

Tools).

Les réparations ou les modifications réalisées par des tiers autres que

Silverline Tools ou ses agents de réparation agréés.

Les demandes de service autres que le droit de rectifier les défaillances de

l’outil indiquées dans ces conditions de garantie ne sont pas couvertes par

cette garantie.

Déclaration de conformité CE

Le soussigné : Mr Darrell Morris

Autorisé par : Silverline Tools

Déclare que le produit :

Code d’identification : 427596

Description : Filtre régulateur pour air comprimé

Est conforme aux directives suivantes :

• Directive sur les machines 2006/42/CE

• EN 12100:2010

Organisme notifié : Shanghai Yousende Products Inspection Technology Co.,

Ltd, Shanghai, Chine

La documentation technique est conservée par : Silverline Tools

Date : 07/01/13

Signature :

Directeur général

Nom et adresse du fabricant ou de son représentant agréé :

Powerbox International Ltd, Boundary Way, Lufton Trading Estate, Yeovil,

Somerset, BA22 8HZ Royaume-Uni

www.silverlinetools.com

11

Page 13

D

Beschreibung der Symbole

Auf dem Typenschild des Werkzeugs sind möglicherweise

Symbole abgebildet. Sie vermitteln wichtige Informationen über

das Produkt oder dienen als Gebrauchsanweisung.

Gehörschutz benutzen

Augenschutz benutzen

Atemschutz benutzen

Kopfschutz benutzen

Schutzhandschuhe benutzen

Bedienungsanleitung sorgfältig lesen

NICHT mit Druckgasflaschen betreiben!

Umweltschutz

Druckluftwerkzeuge dürfen nicht über den

Haushaltsmüll entsorgt werden. Geräte enthalten

Spuren von Öl und anderen Schmiermitteln. Nach

Möglichkeit bitte über entsprechende Einrichtungen

entsorgen. Lassen Sie sich bezüglich der

sachgemäßen Entsorgung von Druckluftwerkzeugen

von der zuständigen Behörde oder dem Händler

beraten.

Technische Daten

Flüssigkeitsart ....................................................... Druckluft

Max. Betriebsdruck ................................................ 10 bar (145 psi)

Regelbarer Ausgangsdruckbereich ........................ 0,5–8,5 bar

(7–123 psi)

Betriebstemperaturbereich .................................... 5–50 °C

Anschluss .............................................................. G1/4-Zoll-

Innengewinde

Auffangbehälterkapazität ....................................... 150 ml

Auffangbehältermaterial ........................................ Polykarbonat

Allgemeine Sicherheitshinweise

• Lesen Sie diese Sicherheitshinweise zur Vermeidung

unterschiedlicher Gefahrenquellen aufmerksam durch,

bevor Sie diese Wartungseinheit installieren, bedienen,

reparieren, warten, Zubehörteile anbringen oder in der Nähe

dieser Wartungseinheit arbeiten. Nichtbeachtung kann zu

schwerwiegenden Verletzungen führen.

• Diese Wartungseinheit darf nur von qualifizierten und in der

Bedienung unterwiesenen Personen installiert, eingestellt und

benutzt werden.

• Modifizieren Sie diese Wartungseinheit in keinster Weise.

Modifikationen können dazu führen, dass Schutzeinrichtungen

nicht effektiv funktionieren, wodurch das Risiko für den

Benutzer erhöht wird.

• Werfen Sie diese Sicherheitsanleitung nicht weg, sondern

stellen Sie sie jedem Benutzer zur Verfügung.

• Benutzen Sie diese Wartungseinheit nicht, wenn sie in

irgendeiner Art beschädigt ist.

• Sämtliche Geräte müssen regelmäßig darauf inspiziert werden,

dass von ISO 11148 vorgeschriebene Kennzeichnungen auf

dem Werkzeug bzw. der Wartungseinheit angebracht und noch

lesbar sind. Der Arbeitgeber/Benutzer ist dafür verantwortlich,

gegebenenfalls Ersatzbeschriftungen über den Gerätehersteller

zu beziehen.

WARNUNG! Dieses Gerät darf nicht von Personen (wie z.B.

Kindern) mit eingeschränkten körperlichen oder geistigen

Fähigkeiten oder von Personen ohne Erfahrung im Umgang

mit einem solchen Gerät betrieben werden, außer wenn sie

von einer für ihre persönliche Sicherheit verantwortlichen

Person in der Benutzung unterwiesen worden sind und dabei

beaufsichtigt werden. Kinder müssen beaufsichtigt werden,

um sicherzustellen, dass sie das Gerät nicht als Spielzeug

verwenden.

Risiken durch geschossartige Fragmente

• Seien Sie sich bewusst, dass im Falle eines Versagens der

Wartungseinheit oder ihres Zubehörs und beim Zerbrechen der

Wartungseinheit Hochgeschwindigkeitsgeschosse entstehen

können.

• Tragen Sie bei der Benutzung der Wartungseinheit stets eine

geeignete schlagfeste Schutzbrille. Die Schutzklasse hängt von

der jeweiligen Anwendung ab und muss individuell beurteilt

werden.

• Das Risiko gegenüber dritten Personen und Beistehenden

sollte an dieser Stelle ebenfalls beurteilt werden.

• Vergewissern Sie sich, dass die Wartungseinheit stets sicher

befestigt ist.

Arbeitsplatzgefahren

• Ausrutschen, Stolpern und Fallen sind häufig auftretende Arten

von Arbeitsunfällen. Achten Sie bei der Verwendung dieses

Werkzeugs auf rutschige Untergründe sowie Stolpergefahren,

z.B. durch die Druckluftzuleitung oder Hydraulikschläuche.

• Diese Wartungseinheit ist nicht für den Betrieb in

explosionsgefährdeten Bereichen konzipiert und sie ist nicht

gegen elektrischen Strom isoliert.

12

Page 14

427596

Druckluft-Wartungseinheit mit Filter

Zusätzliche Sicherheitshinweise

für Druckluft-Wartungseinheiten

Druckluft kann schwerwiegende Verletzungen verursachen:

• Schließen Sie stets die Druckluftversorgung, machen Sie den

Schlauch drucklos und entfernen Sie das Werkzeug von der

Druckluftversorgung, wenn es nicht benutzt wird oder Sie

Wartungs- bzw. Reparaturarbeiten durchführen.

• Richten Sie einen Druckluftstrom niemals auf sich selbst oder

auf andere Personen.

• Umherschlagende Schläuche können zu schwerwiegenden

Verletzungen führen. Überprüfen Sie Schläuche und

Verbindungen stets auf Beschädigungen und auf festen Sitz.

• Wenn Verbindungselemente mit Klauenkupplung verwendet

werden, müssen Sicherungsstifte sowie Sicherheitselemente

zur Sicherung gegen Umherschlagen des Schlauches bei

Versagen des schlauch- oder geräteseitigen Verbinders

installiert werden.

• Überschreiten Sie niemals den auf dem Werkzeug

angegebenen maximalen Betriebsdruck.

• Tragen Sie ein Druckluftwerkzeug niemals am Schlauch.

Geräteübersicht

1 Spannzange

2 Sicherheitshebel

3 Auslöser

4 Schnellkupplung

5 Antriebswelle

6 Spannmutter

7 Gabelschlüssel

Bestimmungsgemäße

Verwendung

• Auf dauerhafte Installation in Druckluftsystemen ausgelegte

Wartungseinheit mit Filter zur Entfernung von Fremdkörpern

aus der Druckluft sowie zur präzisen Einstellung des

Luftdrucks über das eingebaute Manometer.

WARNUNG! Diese Filtereinheit gibt keine Druckluft in

Atmungsqualität ab!

WARNUNG! Durch diese Einheit strömt Wasserdampf, der mit

Absinken der Lufttemperatur kondensieren kann. Installieren Sie

einen Lufttrockner, falls sich das Kondenswasser nachteilig auf

die jeweilige Anwendung auswirken würde.

Auspacken der Wartungseinheit

• Packen Sie Ihre Wartungseinheit vorsichtig aus und überprüfen

Sie sie. Machen Sie sich vollständig mit all ihren Eigenschaften

und Funktionen vertraut.

• Vergewissern Sie sich, dass sämtliche Teile der

Wartungseinheit vorhanden und in einwandfreiem Zustand

sind. Sollten Teile fehlen oder beschädigt sein, lassen Sie diese

ersetzen, bevor Sie die Wartungseinheit verwenden.

Vor Inbetriebnahme

Installation

Hinweis: Installieren Sie diese Wartungseinheit NICHT an Orten,

wo sie dauerhaft direkter Sonneneinstrahlung ausgesetzt wäre.

1. Bringen Sie die Halterung (2) mit zwei passenden Schrauben

(Befestigungsmittel nicht im Lieferumfang enthalten) an

einer Wand, einem Maschinengehäuse oder einer anderen

dafür geeigneten Oberfläche an. Das Ablassventil (7) muss

sich dabei unten befinden.

2. Befestigen Sie die Halterung und den Haltering (1) gemäß

„Geräteübersicht“ oben. Drehen Sie den Haltering zum

Anziehen im Uhrzeigersinn.

3. Dichten Sie das Schraubengewinde des Manometers (4) mit

PTFE-Band (nicht im Lieferumfang enthalten) ein, um eine

luftdichte Verbindung zu erhalten.

Hinweis: Wickeln Sie das PTFE-Band fest und im Uhrzeigersinn,

damit es sich bei Einschrauben des Gewindes nicht löst.

4. Schrauben Sie das Manometer (4) gemäß „Geräteübersicht“

im Uhrzeigersinn in den Gewindeausgang am Gehäuse der

Wartungseinheit ein.

www.silverlinetools.com

13

Page 15

D

Hinweis: Achten Sie darauf, dass das Gewinde richtig greift

und setzen Sie es langsam an. Stellen Sie sicher, dass das

Manometer auch nach dem Anziehen richtig positioniert ist.

Anschluss an die Druckluftversorgung

ANSCHLUSSSTÜCK FÜR

DRUCKLUFTGERÄT

SCHNELLKUPPLUNGSADAPTER

NIPPEL

FÜHRUNGSSCHLAUCH

WARNUNG! Schalten Sie stets den Kompressor aus und machen

Sie das Druckluftsystem drucklos, bevor Sie die Wartungseinheit

anschließen.

WARNUNG! Diese Wartungseinheit darf nicht mit Kompressoren

eingesetzt werden, für die aromatische Kohlenwasserstoffe

enthaltende Schmierstoffe verwendet werden. Diese Chemikalien

würden Schäden am Kondensatbehälter (6) verursachen und ihn

unbrauchbar machen.

WICHTIGER HINWEIS: Die Pfeile auf dem Gehäuse zeigen

die korrekte Durchflussrichtung an. DIE LUFT FLIEßT VOM

KOMPRESSOR ZUM WERKZEUG.

WARNUNG! Zur Verwendung von Druckluftwerkzeugen mit

Motor muss eine Ölereinheit hinter dieser Wartungseinheit

montiert sein.

• Montieren Sie die Wartungseinheit hinter Ihrem

Kondensatabscheider und vor dem Druckluftöler (siehe

Schema unten).

Hinweis: Für Lackierarbeiten, z.B. bei Verwendung von

Spritzpistolen, darf kein Druckluftöler verwendet werden!

• Der Druck der Luftversorgung darf den angegebenen

maximalen Arbeitsdruck der Wartungseinheit nicht

überschreiten (siehe Abschnitt „Technische Daten“).

• Sorgen Sie dafür, dass aufgefangene Feuchtigkeit täglich aus

dem Druckluftsystem entleert wird.

• Stellen Sie sicher, dass alle Teile des Druckluftsystems

(inkl. Schläuche, Verbinder usw.) für den angegebenen

Betriebsdruck geeignet sind.

WASSERABSCHEIDUNG

DRUCKLUFTSCHLAUCH

NIPPEL

NEBELÖLER

DRUCKLUFTREGLER

TÄGLICH

ABLASSEN!

DRUCKLUFTZUFUHR

Bedienung

WARNUNG! Der Kondensatbehälter (6) besteht aus Polykarbonat

und darf nicht Temperaturen über 50 °C ausgesetzt werden.

Vor jedem Gebrauch

• Untersuchen Sie die Einheit und alle Luftschläuche auf

Schäden und Verschleiß und ersetzen Sie sie gegebenenfalls.

Keine beschädigten oder undichten Schläuche und

Verbindungsstücke verwenden!

Luftdruck einstellen

Hinweis: Einige Druckluftwerkzeuge verfügen über einen

eingebauten Druckminderer, über den die Drehzahl bzw. das

Drehmoment gesteuert wird. Geräte, die diese Funktion nicht

haben, können über den Druckminderer in der Luftversorgung

gesteuert werden.

DRUCK ERHÖHEN: Ziehen Sie den Druckregler (3) nach

oben, um ihn zu entriegeln. Drehen Sie ihn anschließend im

Uhrzeigersinn. Drücken Sie den Druckregler nach unten, um ihn

in der neuen Einstellung zu verriegeln.

DRUCK VERRINGERN: Ziehen Sie den Druckregler (3) nach

oben, um ihn zu entriegeln. Drehen Sie ihn anschließend im

Gegenuhrzeigersinn. Drücken Sie den Druckregler nach unten,

um ihn in der neuen Einstellung zu verriegeln.

WARNUNG! Bei Anwendungen, die eine äußerst präzise

Einstellung des Luftdrucks erforderlich machen, sollte der

Ausgangsdruck zusätzlich mit einem kalibrierten Druckmesser

überprüft werden.

Kondensatbehälter entleeren

WARNUNG! Reinigung und Entleerung dürfen nur erfolgen, wenn

der Kompressor ausgeschaltet und das Druckluftsystem drucklos

gemacht worden ist.

• Im Kondensatbehälter (6) sammeln sich Feuchtigkeit und

Schmutz, welche zur Korrosion dieser Wartungseinheit und

Ihrer Geräte führen, sofern sie nicht entfernt werden.

• Lassen Sie täglich (bei Bedarf noch häufiger) alle Flüssigkeit

aus dem Kondensatbehälter ab, indem Sie das Ablassventil (7)

nach unten ziehen, bis alle Flüssigkeit ausgetreten ist.

Wartung

WARNUNG! Schalten Sie stets den Kompressor aus und machen

Sie das Druckluftsystem drucklos, bevor Sie Wartungs- oder

Reinigungsarbeiten durchführen.

WARNUNG! Der Kondensatbehälter (6) aus Polykarbonat kann

durch Kontakt (sowohl innen als auch außen) mit bestimmten

Lösungsmitteln und stark alkalischen Reinigungsmitteln

beschädigt und unbrauchbar werden.

Reinigung

• Drücken Sie die Entriegelungstaste (5) und drehen Sie

den Kondensatbehälter (6) im Uhrzeigersinn oder im

Gegenuhrzeigersinn, bis sich der Bajonettverbinder löst.

Nehmen Sie dann den Behälter ab.

• Waschen Sie den Kondensatbehälter mit einem milden

Reinigungsmittel und fusselfreien Lappen aus.

• Spülen Sie ihn anschließend mit reichlich kaltem, sauberem

Wasser aus und trocknen Sie ihn gut ab.

• Um die Einheit wieder zusammenzubauen, vergewissern Sie

sich zunächst, dass der Dichtungsring zwischen dem Behälter

und Gehäuse der Wartungseinheit sauber und unbeschädigt

ist. Lassen Sie dann den Bajonettverschluss greifen und

drehen Sie den Behälter, bis die Entriegelungstaste mit einem

Klickgeräusch einrastet.

Entsorgung

• Druckluftwerkzeuge dürfen wie auch Elektrowerkzeuge nicht

über den Hausmüll entsorgt werden.

• Druckluftwerkzeuge können Spuren von Maschinenöl

und anderen Schmierstoffen enthalten und müssen

dementsprechend der Wiederverwertung zugeführt werden.

• Lassen Sie sich von der zuständigen Behörde bezüglich der

ordnungsgemäßen Entsorgung von Druckluftwerkzeugen

beraten.

14

Page 16

Silverline-Tools-Garantie

Dieser Silverline-Artikel wird mit einer

3-Jahres-Garantie angeboten

Registrieren Sie diesen Artikel unter silverlinetools.com innerhalb von 30

Tagen nach dem Kauf, um die 3-Jahres-Garantie zu aktivieren.

Der Garantiezeitraum beginnt mit dem Kaufdatum auf Ihrem Kaufbeleg.

Garantiebedingungen

Der Garantiezeitraum beginnt mit dem Kaufdatum im Einzelhandel, das auf

dem Kaufbeleg angegeben ist.

BITTE BEWAHREN SIE DEN KAUFBELEG AUF!

Falls dieser Artikel innerhalb von 30 Tagen nach dem Kauf einen Defekt

aufweisen sollte, bringen Sie es bitte mit Ihrem Kaufbeleg zu dem

Fachhändler, bei dem es gekauft wurde, und informieren Sie ihn über die

Mängel. Das Gerät wird daraufhin ersetzt oder der Kaufpreis zurückerstattet.

Falls dieser Artikel nach Ablauf von 30 Tagen nach dem Kauf einen Mangel

aufweist, senden Sie es bitte an:

Silverline Tools Service Centre

PO Box 2988

Yeovil

BA21 1WU, Großbritannien

Der Garantieanspruch muss während der Garantiezeit gestellt werden.

Sie müssen den Originalkaufbeleg mit Angabe des Kaufdatums einreichen

und Ihren Namen und Ihre Adresse sowie den Ort des Kaufs angeben, bevor

etwaige Arbeiten durchgeführt werden können.

Sie müssen genaue Angaben über den zu behebenden Defekt machen.

Alle innerhalb der Garantiefrist gemachten Forderungen werden von Silverline

Tools daraufhin überprüft werden, ob es sich bei den Mängeln um einen

Material- oder Fertigungsfehler handelt.

Versandkosten werden nicht zurückerstattet. Alle Artikel sollten sich in

sauberem und sicherem Zustand befinden und sorgfältig verpackt zur

Reparatur eingeschickt werden, um Schäden oder Verletzungen während des

Transports zu vermeiden. Die Annahme unangemessener oder unsicherer

Lieferungen kann von uns verweigert werden.

Alle Arbeiten werden von Silverline Tools oder seinen autorisierten

Reparaturwerkstätten durchgeführt.

Die Reparatur oder der Ersatz des Artikels führt nicht zur Verlängerung des

Garantiezeitraums.

Mängel, bei denen unsere Prüfung ergibt, dass sie unter die Garantie fallen,

werden durch kostenlose Reparatur des Werkzeugs (ohne Versandkosten)

oder Ersatz durch ein Werkzeug in einwandfreiem Zustand behoben.

Druckluft-Wartungseinheit mit Filter427596

Registrierung Ihres Kaufs

Gehen Sie auf silverlinetools.com, klicken Sie auf „Registrierung“’ und geben

Sie Folgendes ein:

• Ihre persönlichen Angaben

• Produktdetails und Kaufinformationen

Sobald dieser Artikel registriert worden ist, wird Ihre Garantiebescheinigung

im PDF-Format erzeugt. Bitte drucken Sie sie aus und bewahren Sie sie

zusammen mit Ihrem Produkt auf.

Einbehaltene Werkzeuge oder Teile, die ersetzt wurden, gehen in den Besitz

von Silverline Tools über.

Die Reparatur bzw. der Ersatz Ihres Artikels unter dieser Garantie erfolgt

zusätzlich zu Ihren gesetzlichen Rechten als Verbraucher und hat keine

nachteiligen Folgen auf diese.

Durch die Garantie abgedeckt ist:

Die Reparatur des Artikels, nachdem zur Zufriedenheit von Silverline Tools

nachgewiesen wurde, dass der Defekt durch fehlerhaftes Material oder

mangelhafte Arbeitsausführung bedingt ist und in den Garantiezeitraum fällt.

Wenn ein Ersatzteil nicht mehr erhältlich ist oder nicht mehr hergestellt wird,

kann Silverline Tools es gegen einen funktionellen Ersatz austauschen.

Verwendung des Artikels innerhalb der EU.

Durch die Garantie nicht abgedeckt ist:

Silverline Tools garantiert keine Reparaturen, die durch Folgendes

erforderlich geworden sind:

Normale Verschleißerscheinungen, die trotz Verwendung entsprechend

der Bedienungsanleitung entstehen, z.B. an Messern, Bürsten, Riemen,

Glühbirnen, Batterien usw.

Ersatz von mitgeliefertem Zubehör wie etwa Bohrspitzen, Klingen,

Schleifblättern, Schneidscheiben und anderen zugehörigen Teilen.

Unfallschäden und Fehler, die durch unsachgemäße Verwendung oder

Wartung, Missbrauch, Nachlässigkeit oder fahrlässige Bedienung oder

Handhabung des Artikels entstanden sind.

Verwendung des Artikels für andere als normale Haushaltszwecke.

Jegliche Veränderungen oder Modifikationen des Artikels.

Die Verwendung von Teilen oder Zubehör, die keine Originalkomponenten

von Silverline Tools sind.

Fehlerhafte Montage (außer, wenn von Silverline Tools vorgenommen).

Reparaturen oder Änderungen, die von anderen als Silverline Tools oder

seinen autorisierten Reparaturwerkstätten durchgeführt wurden.

Ansprüche, die über die Rechte zur Behebung von Mängeln an dem in

diesen Garantiebedingungen genannten Werkzeug hinausgehen.

EU-Konformitätserklärung

Name des Unterzeichners: Mr. Darrell Morris

Bevollmächtigt durch: Silverline Tools

Erklärt hiermit, dass das Produkt:

Ident.-Nr.: 427596

Produktbeschreibung: Druckluft-Wartungseinheit mit Filter

Den folgenden Richtlinien entspricht:

• Maschinenrichtlinie 2006/42/EG

• EN 12100:2010

Benannte Stelle: Shanghai Yousende Products Inspection Technology Co., Ltd,

Shanghai, China

Techn. Unterlagen bei: Silverline Tools

Datum: 07.01.2014

Unterzeichnet von:

Geschäftsführender Direktor

Name und Anschrift des Herstellers oder seines niedergelassenen

Bevollmächtigten:

Powerbox International Ltd, Boundary Way, Lufton Trading Estate, Yeovil,

Somerset, BA22 8HZ, Großbritannien

www.silverlinetools.com

15

Page 17

ESP

Descripción de los símbolos

Los símbolos siguientes pueden aparecer en la placa de características

de su herramienta. Éstos representan información importante sobre el

producto o instrucciones relativas a su uso.

Lleve protección auditiva

Lleve protección ocular

Lleve protección respiratoria

Lleve un casco de seguridad

Lleve guantes de seguridad

Lea el manual de instrucciones

No utilizar con bombonas de gas comprimido

Protección medioambiental

No elimine las herramientas neumáticas junto con

la basura convencional. Recíclelas en puntos de

reciclaje. Las herramientas neumáticas contienen

restos de lubricante y deben ser desechadas en

puntos de reciclaje adecuados.

Póngase en contacto con la autoridad local encargada

de la gestión de residuos si necesita más información

sobre cómo eliminar este tipo de herramientas

correctamente.

Características técnicas

Tipo de fluido: ..........................................Aire comprimido

Presión máxima operativa:.......................10 bar (145 psi)

Rango de presión de salida ajustable: ......0,5 - 8,5 bar (7 - 123 psi)

Rango de temperatura operativa: .............5 - 50 °C

Conexiones neumáticas: ..........................G ¼"

Capacidad de la cuba del condensador:...150 ml

Material de la cuba del condensador: ......Policarbonato

Instrucciones de seguridad

• Lea todas las instrucciones de seguridad e indicaciones

antes de instalar, utilizar, cambiar accesorios o tareas de

mantenimiento en esta herramienta. El no respetar estas

advertencias e instrucciones puede causar lesiones graves.

• Esta herramienta debe ser utilizada, instalada y ajustada

únicamente por personas cualificadas.

• No modifique nunca esta herramienta. Las modificaciones

pueden reducir la eficacia y la seguridad e incrementar el

riesgo de sufrir lesiones personales.

• No tire las instrucciones de funcionamiento, déselas al usuario.

• No utilice esta herramienta si está dañada.

• Las herramientas deben ser inspeccionadas regularmente

para asegurarse de que las marcas inscritas requeridas por la

directiva ISO 11148 sean completamente legibles. En el caso

de estar dañada, el usuario deberá ponerse en contacto con el

fabricante para su sustitución.

ADVERTENCIA: No permita que los niños, personas

discapacitadas o personas no cualificadas utilicen esta

herramienta. Mantenga esta herramienta fuera del alcance de

los niños.

Riesgos de partículas proyectadas

• Tenga en cuenta que las piezas y accesorios que estén

dañados o sueltos pueden proyectarse hacia el usuario a gran

velocidad.

• Lleve siempre protección ocular resistente a los impactos

cuando utilice esta herramienta. El grado de protección

requerido debe evaluarse dependiendo de cada uso.

• Debe tener en cuenta el riesgo existente para las personas

situadas a su alrededor.

• Asegúrese de que la pieza de trabajo esté sujeta

adecuadamente.

Área de trabajo

• Tenga cuidado con las superficies resbaladizas para no

resbalarse. Tenga especialmente cuidado en no tropezar con

las mangueras hidráulicas. Los resbalones, tropezones y

caídas son las principales causas de lesiones en el trabajo.

• Esta herramienta no está diseñada para trabajar en

atmosferas explosivas ni aisladas contra contacto eléctrico.

16

Page 18

427596

Filtro regulador para aire comprimido

Instrucciones de seguridad

relativas a las herramientas

neumáticas

El aire a presión puede causar lesiones graves:

• Desconecte la herramienta neumática del suministro de

aire antes de proceder a efectuar cualquier trabajo de

mantenimiento o instalación de accesorios.

• No dirija aire a presión hacia usted mismo ni hacia otras

personas.

• Los azotes con mangueras neumáticas pueden causar

lesiones graves. Compruebe siempre el estado de las

mangueras neumáticas, los accesorios y acopladores.

• Cuando utilice acoplamientos universales, deberán instalarse

cierres de seguridad para garantizar una conexión correcta

entre la manguera y la herramienta.

• Nunca exceda la presión máxima indicada en la herramienta.

• Nunca transporte la herramienta neumática sujetándola por

la manguera.

Características del producto

1 Anillo de retención del soporte de montaje

2 Soporte de montaje

3 Control de presión

4 Manómetro

5 Botón de desbloqueo de la cuba

6 Cuba del condensador

7 Válvula de purga

Aplicaciones

• Unidad de regulador del filtro de combinación para su

instalación permanente en líneas de aire comprimido, para

extraer partículas extrañas del aire comprimido, y para ajustar

la presión neumática adecuadamente con el manómetro

integrado.

ADVERTENCIA: Este filtro no produce aire comprimido

respirable.

ADVERTENCIA: Parte del vapor de agua pasará por la unidad y

podría condensarse a líquido aguas abajo, conforme desciende

la temperatura. Instale un secador si la condensación de agua

pudiera tener efectos dañinos sobre la aplicación.

Desembalaje

• Desembale e inspeccione la herramienta con cuidado.

Familiarícese con todas sus características y funciones.

• Asegúrese de que el embalaje contiene todas las partes y que

están en buenas condiciones. Si faltan piezas o están dañadas,

solicite su sustitución antes de utilizar esta herramienta.

Antes de usar

Instalación

Nota: No instale el filtro regulador en áreas con exposición

directa a la luz solar.

1. Monte el soporte de montaje (2) en la pared o en una

superficie plana utilizando dos tornillos (no incluidos). La

válvula de purga (7) debe estar colocada en la parte inferior

de la herramienta.

2. Coloque el soporte de montaje y el anillo de retención del

soporte de montaje (1) tal como se muestra en la imagen

más arriba. Gire el anillo en sentido horario para bloquearlo

en la posición requerida.

3. Coloque cinta PTFE (no incluida) en la rosca del manómetro

(4) para evitar cualquier fuga de aire.

Nota: Coloque siempre la cinta PTFE en sentido horario para

evitar que fugas de aire.

4. Enrosque el manómetro en sentido horario dentro del orificio

tal como se muestra en la figura más arriba.

Nota: Tenga precaución para no dañar la rosca. Comience

enroscando con cuidado. Asegúrese de que el manómetro esté

colocado en la posición correcta.

www.silverlinetools.com

17

Page 19

ESP

CONEXIÓN

SUMINISTRO DE AIRE

Conexión al suministro de aire comprimido

CONEXIÓN A LA HERRAMIENTRA

NEUMÁTICA

UNIÓN

MANGUERA DE

• Nunca sobrepase la presión máxima indicada por el fabricante.

Vea siempre las especificaciones técnicas.

• Asegúrese de drenar el agua diariamente.

• Compruebe que todos los accesorios y componentes de esta

herramienta (acopladores, manguera, etc.) sean compatibles

con la presión utilizada.

SEPARACIÓN DEL AGUA

ACOPLADOR RÁPIDO

MANGUERA

UNIÓN

LUBRICADOR

REGULADOR

DRENAR

DIARIAMENTE

Funcionamiento

ADVERTENCIA: La cuba del condensador (6) está fabricada en

policarbonato y no debe exponerse a temperaturas superiores

a los 50 °C.

Antes de cada uso

• Inspeccione la unidad y las mangueras neumáticas por si

hay desgaste o daños, y reemplácelas si fuera necesario. No

emplee mangueras o conexiones dañadas o con fugas.

Ajuste de la presión neumática

Nota: Ciertas herramientas neumáticas cuentan con reguladores

integrados que se utilizan para controlar la velocidad/

el rendimiento del par de torsión. Cuando una máquina no

cuente con regulador integrado, la velocidad/par de torsión

todavía puede ajustarse variando la presión de su regulador de

suministro neumático.

• AUMENTE la presión neumática tirando del control de presión

(3) hacia arriba para desbloquearlo y, a continuación, gírelo en

sentido horario. Empuje el control de presión de vuelta hacia

abajo para volver a bloquearlo

• REDUZCA la presión desbloqueando el control de presión y, a

continuación, gírelo en sentido antihorario. Vuelva a empujarlo

para bloquearlo de nuevo

ADVERTENCIA: Para aplicaciones que requieran una presión

neumática precisa, confirme la presión de salida con un

manómetro calibrado.

Mantenimiento

ADVERTENCIA: Apague siempre el compresor y despresurice

el suministro de aire antes de limpiar o realizar tareas de

mantenimiento.

ADVERTENCIA: La cuba del condensador (6) de policarbonato

podría dañarse y fallar si se expone a ciertos disolventes

o fuertes agentes alcalinos de limpieza (ya sea interna o

externamente).

Limpieza

• Pulse el botón de desbloqueo de la cuba (5), gire la cuba del

condensador (6) en sentido horario o antihorario hasta que se

desbloquee la conexión de bayoneta, y retire la cuba

• Límpiela con un detergente suave y un paño sin pelusa

• Aclárela con abundante agua limpia y fría y séquela por

completo

• Para volver a montar, compruebe primero que la junta tórica

que sella la cuba contra el cuerpo de la unidad esté limpia y

sin daños y, a continuación, acople la bayoneta de bloqueo y

gire la cuba hasta que el botón de desbloqueo encaje con un

clic en su posición de bloqueo

Eliminación

• No elimine sus herramientas u otro equipo eléctrico o

electrónico junto con la basura convencional. Recíclelos si hay

puntos de reciclaje.

• Las herramientas neumáticas contienen restos de lubricante y

deben ser desechadas en puntos de reciclaje adecuados.

• Póngase en contacto con la autoridad local encargada de la

gestión de residuos si necesita más información sobre cómo

eliminar este tipo de herramientas correctamente.

Purga de la cuba del condensador

ADVERTENCIA: La limpieza y purga SOLO DEBE realizarse con el

compresor apagado y el sistema neumático purgado de presión.

• El condensador acumulará humedad y polvo que, si no se

elimina, provocará corrosión grave a este dispositivo y a sus

máquinas

• Purgue la cuba del condensador (6) a diario (o más a menudo,

si fuera necesario) tirando hacia abajo de la válvula de purga

(7) hasta que haya escapado todo el líquido

18

Page 20

Filtro regulador para aire comprimido427596

Garantía Silverline Tools

Garantía

Este producto Silverline dispone de una garantía de

3 años.

Registre el producto en www.silverlinetools.com antes de que transcurran

30 días a partir de la fecha de compra para obtener la garantía de 3 años.

El periodo de garantía comienza desde la fecha indicada en su recibo de

compra.

Condiciones

El periodo de garantía entra en vigor a partir de la fecha indicada en el recibo

de compra.

GUARDE EL RECIBO DE COMPRA

En caso de que el producto se averíe antes de que transcurran 30 días

desde la fecha de compra, devuélvalo al distribuidor donde lo compró, junto

con el recibo y los detalles de la avería. Le sustituiremos el producto o le

reembolsaremos el importe.

Si el producto se avería después de que transcurran 30 días desde la fecha

de compra, devuélvalo a:

Servicio Técnico Silverline Tools

PO Box 2988

Yeovil

BA21 1WU, Reino Unido.

La reclamación siempre debe presentarse durante el periodo de garantía.

Antes de poder realizar cualquier trabajo de reparación, deberá entregar el

recibo de compra original en el que se indica la fecha de compra, su nombre,

dirección y el lugar donde lo adquirió.

También deberá indicar claramente los detalles del fallo a reparar.

Las reclamaciones presentadas dentro del periodo de garantía deberán

ser verificadas por Silverline Tools para averiguar si las deficiencias son

consecuencia de los materiales o de la mano de obra del producto.

Los gastos de transporte no son reembolsables. Los productos a devolver

deberán estar limpios y en buenas condiciones para su reparación, debiendo

empaquetarse cuidadosamente con el fin de prevenir daños o lesiones

durante el transporte. Nos reservamos el derecho a rechazar envíos

incorrectos o inseguros.

Todas las reparaciones serán realizadas por Silverline Tools o por un servicio

técnico de autorizado.

La reparación o sustitución del producto no prolongará el periodo de garantía.

Si los defectos están cubiertos por la garantía, la herramienta será reparada

sin cargo alguno (salvo los gastos de envío), o bien la sustituiremos por una

herramienta en perfecto estado de funcionamiento.

Registro del producto

Visite: silverlinetools.com, seleccione el botón de registro e indique:

• Sus datos personales

• Detalles del producto e información de compra

El certificado de garantía le será enviado en formato PDF. Imprímalo y

guárdelo con el producto.

Las herramientas o piezas que hayan sido sustituidas serán propiedad de

Silverline Tools.

La reparación o sustitución del producto bajo garantía aporta beneficios

adicionales a sus derechos legales como consumidor, sin afectarlos.

Qué está cubierto:

Silverline Tools deberá comprobar si las deficiencias se deben a materiales o

mano de obra defectuosos dentro del periodo de garantía.

En caso de que cualquier pieza no estuviera disponible o estuviera fuera

de fabricación, Silverline Tools la sustituirá por una pieza funcional con las

mismas características.

Uso del producto en la Unión Europea.

Qué no está cubierto:

Silverline Tools no garantiza las reparaciones causadas por:

Desgaste normal por uso adecuado de la herramienta, por ejemplo hojas,

escobillas, correas, bombillas, baterías, etc...

La sustitución de cualquier accesorio suministrado: brocas, hojas, papel de

lija, discos de corte y otras piezas relacionadas.

Daño accidental, averías debidas a uso o cuidado negligente, uso incorrecto,

negligencia, funcionamiento o manejo indebido del producto.

Utilizar del producto para una finalidad distinta.

Cualquier cambio o modificación del producto.

El uso de piezas y accesorios que no sean recambios originales de Silverline

Tools.

Instalación incorrecta (excepto si fue realizada por Silverline Tools).

Reparaciones o alteraciones realizadas por servicios técnicos no autorizados

por Silverline Tools.

Las reclamaciones distintas a las indicadas en las presentes condiciones de

garantía no estarán cubiertas.

Declaración de conformidad CE

El abajo firmante: Mr Darrell Morris

Autorizado por: Silverline Tools

Declara que el producto:

Código de identificación: 427596

Descripción: Filtro regulador para aire comprimido

Está en conformidad con las directivas:

• Directiva de máquinas 2006/42/CE

• EN 12100:2010

Organismo notificado: Shanghai Yousende Products Inspection Technology Co.,

Ltd, Shanghai, China

La documentación técnica se conserva en: Silverline Tools

Fecha: 07/01/14

Firma:

Director General

Nombre y dirección del fabricante o representante autorizado:

Powerbox Ltd., Boundary Way, Lufton Trading Estate, Yeovil, Somerset,

BA22 8HZ, Reino Unido.

www.silverlinetools.com

19

Page 21

I

Descrizione dei simboli

La targhetta sul vostro strumento può mostrare simboli.

Questi rappresentano importanti informazioni sul prodotto o le

istruzioni sul suo utilizzo.

Indossare la protezione dell'udito

Indossare occhiali protettivi

Indossare protezione delle vie respiratorie

Indossare una protezione per la testa

Indossare la protezione delle mani

Leggere il manuale di istruzioni

NON utilizzare con bombole di gas compresse!

Protezione Ambientale

Utensili ad aria non devono essere smaltiti insieme

ai rifiuti domestici. Essi contengono tracce di olio e

di altri lubrificanti. Riciclare dove esistono strutture

idonei. Verificare con le autorità locali o con il

vostro rivenditore per consigli sul riciclaggio

Specifiche tecniche

Tipo di fluido: ..............................................Aria compressa

Pressione massima d'esercizio: ..................10 bar (145 psi)

Gamma di pressione di uscita regolabile:....0,5 – 8,5 bar (7-123 psi)

Gamma di temperatura d'esercizio: ............5 - 50°C

Collegamenti dell’aria: ................................G ¼"

Capacità coppa condensatore: ....................150 ml

Materiale coppa condensatore: ...................Policarbonato

Sicurezza generale

• Per rischi multipli, leggere e capire le istruzioni di sicurezza

prima di installare, utilizzare, riparare, eseguire la

manutenzione, sostituire gli accessori, o lavorare vicino questo

dispositivo. La mancanza di eseguire queste istruzioni può

provocare gravi lesioni.

• Solo gli operatori qualificati e addestrati devono installare,

regolare o utilizzare questo dispositivo

• Non modificare questo dispositivo. Le modifiche possono

ridurre l'efficacia delle misure di sicurezza e aumentano i

rischi per l'operatore.

• Non gettare le istruzioni di sicurezza, consegnarli all’operatore.

• Non utilizzare questo dispositivo se lo strumento è stato

danneggiato.

• Strumenti sono controllate periodicamente per verificare che

i valori ei marchi richiesti da questa parte della ISO 11148

sono leggibile sullo strumento. Il datore di lavoro / utente deve

contattare il produttore per ottenere le etichette di marcatura

di ricambio in caso di necessità.

ATTENZIONE: Questo apparecchio non è destinato all'uso da

parte di persone (inclusi i bambini) con capacità ridotta, fisici

o mentali, o con mancanza di esperienza o di conoscenza, a

meno che non siano controllati o istruiti all'uso dell'apparecchio

da una persona responsabile della loro sicurezza. I bambini

devono essere sorvegliati per assicurarsi che non giochino con

l'apparecchio

Rischi proiettabili

• Essere consapevoli del fatto che il fallimento di questo

dispositivo può generare proiettili ad alta velocità.

• Indossare sempre protezione degli occhi resistente agli impatti

durante il funzionamento di questo dispositivo. Il grado di

protezione richiesto deve essere valutato per ogni uso.

• I rischi per gli altri dovrebbero essere valutati anche in questo

momento.

• Assicurarsi che questo dispositivo di lavoro sia fissato

saldamente.

Rischi sul luogo di lavoro

• Scivolamento, inciampamento e cadute sono le principali

cause di infortuni sul lavoro. Essere consapevoli di superfici

scivolose causati dall'uso dello strumento e anche di rischi di

viaggio causati dalla linea aerea o tubo idraulico.

• Questo strumento non è destinato ad essere utilizzato in

atmosfera potenzialmente esplosiva e non è isolata dal

contatto con la corrente elettrica.

20

Page 22

427596

Filtro regolatore per aria compressa

Ulteriori istruzioni di sicurezza

per utensili pneumatici

Aria sotto pressione può causare lesioni gravi:

• Chiudere sempre l'alimentazione dell'aria, il tubo di scarico

della pressione dell'aria e scollegare lo strumento dalla rete di

aria quando non è in uso, prima di cambiare gli accessori o in

caso di intervento.

• Non mirare mai l’aria diretta verso se stessi o chiunque altro.

• Tubi sferzati possono causare lesioni gravi. Controllare sempre

per tubi o fissaggi danneggiati o allentati.

• Ogni volta che giunti universali (innesti a denti), vengono usati,

perni di bloccaggio devono essere installati e cavi di sicurezza

devono essere utilizzati per la protezione contro l’errore di

attacco con tubo-a-strumento o attacco tubo-a-tubo.

• Non superare la pressione massima dell'aria indicata

sull'apparecchio.

• Non trasportare mai un utensile pneumatico tramite il tubo.

Familiarizzazione prodotto

1 Anello di bloccaggio della staffa montaggio

2 Staffa di montaggio

3 Controllo della pressione

4 Manometro

5 Pulsante di sblocco della coppa

6 Coppa del condensatore

7 Valvola di scarico

Uso previsto

• Unità combinata di filtro e regolatore per l'installazione

permanente nelle linee dell’aria compressa, per eliminare

eventuali impurità dall'aria compressa, e per l'impostazione di

precisione della pressione dell'aria utilizzando il manometro

integrato

ATTENZIONE: Questo filtro non produce aria compressa di

qualità respirabile!

ATTENZIONE: Un certo quantitativo di vapore acqueo passerà

attraverso questa unità e potrebbe condensarsi a valle sotto

forma liquida, come gocce a temperatura atmosferica. Installare

un essiccatore dell'aria se la condensazione dell'acqua potrebbe

avere un effetto dannoso sull’applicazione. Disimballaggio del

vostro dispositivo

• Disimballare con cura e controllare il tuo strumento. Acquisire

familiarità con tutte le sue caratteristiche e funzioni

• Assicurarsi che tutte le parti dello strumento sono presenti e

in buone condizioni. In caso di parti mancanti o danneggiate,

sostituire tali parti prima di tentare di usare questo strumento

Prima dell’uso

Installazione

NB: non installare questo regolatore filtro in luoghi in cui sarebbe

esposto in modo permanente a luce diretta del sole.

1. Installare la staffa di montaggio (2) su una parete, telaio

della macchina o su un'altra superficie anche utilizzando

due viti adeguate (attrezzi di montaggio non incluse). La

valvola di scarico (8) deve essere situata nella parte inferiore

dell'unità

2. Applicare un po 'di nastro in PTFE (non incluso) per le

filettature del manometro (11). Ciò contribuirà a mantenere

un completo sigillo

NB: Applicare nastro PTFE ermeticamente e in senso orario, in

modo che non si stacca quando il filo è avvitato nell'utensile.

3. Avvitare il manometro in senso orario nel foro filettato

del corpo del regolatore come indicato nell’immagine

'familiarizzazione prodotto' sopra.

NB: Fare attenzione a non incrociare i fili. Girare delicatamente

la prima volta. Assicurarsi che il selettore è posizionato

correttamente quando si serra il manometro.

www.silverlinetools.com

21

Page 23

I

SEPARAZIONE ACQUA

Connessione di alimentazione aria

RACCORDO

TUBO DI GUIDA

ATTACCO RAPIDO

TUBO A RINCOLO

RACCORDO

INGRASSATORE

REGOLATORE

APPROVVIGIONAMENTO IDRICO

SCARICA OGNI

GIORNO

AL VOSTRO UTENSILE

PNEUMATICO

ATTENZIONE: Assicurarsi che il sistema di aria è completamente

scarica e il compressore è spento, prima di collegare l'unità.

ATTENZIONE: Questa unità a regolatore filtro non deve essere

usato con i compressori che utilizzano lubrificanti contenenti

idrocarburi aromatici. Tali sostanze potrebbero danneggiare

e portare al fallimento il contenitore di condensamento in