Page 1

3 Year Guarantee

*Register online within 30

days. Terms & Conditions apply

Garantie de 3 ans

*Enregistrez votre produit en ligne

dans les 30 jours. Sous réserve des

termes et conditions appliquées

3 Jahre Garantie

*Innerhalb von 30 Tagen online

registrieren. Es gelten die Allgemeinen

Geschäftsbedingungen

3 años de garantía

*Registre su producto online durante

los primeros 30 días. Se aplican

términos y condiciones

3 anni di garanzia

*Registrarsi on-line entro 30 giorni.

Termini e Condizioni si applicano

3 jaar garantie

*Registreer uw product binnen 30

dagen online. Algemene voorwaarden

zijn van toepassing

www.silverlinetools.com

Page 2

AIR

S

I

L

V

E

R

L

I

N

E

R

A

N

G

E

280mm

Air Grease Gun 400cc

427558

Air Grease Gun 400cc

Pistolet graisseur pneumatique 400 cm3

Druckluft-Fettpresse, 400 cm3

www.silverlinetools.com

Pistola de engrase neumática 400 cm3

Pistola pneumatica a grasso 400cc

3

Pneumatische vetspuit, 400 cm

Page 3

11

2

3

1

4

5

10

6

9

8

2

7

Page 4

R

E

V

L

I

S

AIR

R

A

N

G

L

I

N

E

E

®

280mm

Air Grease Gun 400cc

English .................. 4

Français ................ 10

Deutsch ................. 16

Español ................. 22

Italiano .................. 28

Nederlands ............ 34

www.silverlinetools.com

3

Page 5

GB

Description of Symbols

The rating plate on your tool may show symbols. These represent important

information about the product or instructions on its use.

Wear hearing protection.

Wear eye protection.

Wear breathing protection.

Wear head protection.

Wear hand protection.

Read instruction Manual.

DO NOT use with compressed gas cylinders!

Conforms to relevant legislation and safety standards

Environmental Protection

Air tools should not be disposed of with household waste. They

contain traces of oil and other lubricants. Please recycle where

facilities exist. Check with your local authority or retailer for recycling

advice.

Specification

Operating pressure range: .....................2.0-6.3bar

(30-90psi)

Air consumption: ..................................approx. 113L/min

(4cfm) at 6.3bar

(90psi)

Air inlet: ................................................¼" BSP, supplied

with two male airline quick connectors (EN-6 'UK' and EQ-4

'European' types)

Minimum hose diameter: .....................9.5mm (3/8")

Capacity:...............................................400cm3 (Bulk)

Grease outlet pressure: ........................approx. 60-190bar

(900-2700psi)

Chamber length: ...................................280mm

Net weight: ...........................................1.45kg

As part of our ongoing product development, specifications of

Silverline products may alter without notice.

General Safety

• For multiple hazards, read and understand the safety instructions before

installing, operating, repairing, maintaining, changing accessories on, or working

near this tool. Failure to do so can result in serious bodily injury

• Only qualified and trained operators should install, adjust, or use this tool

• Do not modify this tool. Modifications can reduce the effectiveness of safety

measures and increase the risks to the operator

• Do not discard the safety instructions; give them to the operator

• Do not use this tool if it has been damaged

• Tools shall be inspected periodically to verify that the ratings and markings

required by this part of ISO 11148 are legibly marked on the tool. The employer/

user should contact the manufacturer to obtain replacement marking labels

when necessary

WARNING: This appliance is not intended for use by persons (including children)

with reduced, physical or mental capabilities or lack of experience or knowledge

unless they have been given supervision or instruction concerning use of the

appliance by a person responsible for their safety. Children must be supervised to

ensure that they do not play with the appliance.

Projectile hazards

• Be aware that failure of the workpiece or accessories, or even of the inserted

tool itself, can generate high-velocity projectiles

• Always wear impact-resistant eye protection during operation of this tool. The

grade of protection required should be assessed for each use

• For overhead work, wear a safety helmet

• The risks to others should also be assessed at this time

• Ensure that the workpiece is securely fixed

Operating hazards

• Use of the tool can expose the operator’s hands to hazards, including cuts,

abrasions and heat

• Wear suitable gloves to protect hands

• Operators and maintenance personnel should be physically able to handle the

bulk, weight and power of the tool

• Hold the tool correctly; be ready to counteract normal or sudden movements

and have both hands available

• Maintain a balanced body position and secure footing

• Release the start-and-stop device in the case of an interruption of the energy

supply

• Use only lubricants recommended by the manufacturer

• Personal protective safety glasses should be used; suitable gloves and

protective clothing are recommended

• Inspect the spouts before each use. Do not use if cracked or broken or if it has

been dropped

• There is a risk of electrostatic discharge if used on plastic and other nonconductive materials

Repetitive motions hazards

• When using this tool to perform work-related activities, the operator can

experience discomfort in the hands, arms, shoulders, neck or other parts of

the body

• While using this tool, the operator should adopt a comfortable posture whilst

maintaining secure footing and avoiding awkward or off-balance postures. The

operator should change posture during extended tasks; this can help avoid

discomfort and fatigue

• If the operator experiences symptoms such as persistent or recurring

discomfort, pain, throbbing, aching, tingling, numbness, burning sensations or

stiffness, these warning signs should not be ignored. The operator should inform

the employer and consult a qualified health professional

Accessory hazards

• Disconnect the tool from the energy supply before fitting or changing the

inserted tool or accessory

• Use only sizes and types of accessories and consumables that are

recommended by the manufacturer of this tool; do not use other types or sizes

of accessories or consumables

4

Page 6

Air Grease Gun 400cc427558

Workplace hazards

• Slips, trips and falls are major causes of workplace injury. Be aware of slippery

surfaces caused by use of the tool and also of trip hazards caused by the air

line or hydraulic hose

• This tool is not intended for use in potentially explosive atmospheres and is not

insulated against contact with electric power

Dust and fume hazards

• Dust and fumes generated when using this tool can cause ill health (for

example cancer, birth defects, asthma and/or dermatitis); risk assessment and

implementation of appropriate controls for these hazards are essential

• Risk assessment should include dust created by the use of the tool and the

potential for disturbing existing dust

• Operate and maintain this tool as recommended in these instructions, to

minimise dust or fume emissions

• Direct the exhaust so as to minimise disturbance of dust in a dust-filled

environment

• Where dust or fumes are created, the priority should be to control them at the

point of emission

• Use respiratory protection in accordance with employer's instructions and as

required by occupational health and safety regulations

Additional Safety Instructions for

Pneumatic Power Tools

Air under pressure can cause severe injury:

• Always shut off air supply, drain hose of air pressure and disconnect tool from

air supply when not in use, before changing accessories or when making

repairs

• Never direct air at yourself or anyone else

• Whipping hoses can cause severe injury. Always check for damaged or loose

hoses and fittings

• Whenever universal twist couplings (claw couplings) are used, lock pins should

be installed and whipcheck safety cables should be used to safeguard against

possible hose-to-tool or hose-to-hose connection failure

• Do not exceed the maximum air pressure

• Never carry an air tool by the hose

Product Familiarisation

1 Grease Nipple

2 Grease Gun

3 Trigger

4 Quick Connector

5 Plunger Handle

6 Plunger Release

7 Chamber

8 Flexible Spout

9 Rigid Spout

10 Filler Pump Nozzle

11 Bleed Valve

www.silverlinetools.com

5

Page 7

GB

Intended Use

• Grease dispensing gun, powered by compressed air from a compressor,

suitable for bulk and cartridge grease, ideal for lubricating vehicles, agricultural

machines and industrial equipment.

Unpacking Your Tool

Carefully unpack and inspect your tool. Familiarise yourself with all its features

and functions.

Ensure that all parts of the tool are present and in good condition. If any parts are

missing or damaged, have such parts replaced before attempting to use this tool.

Before Use

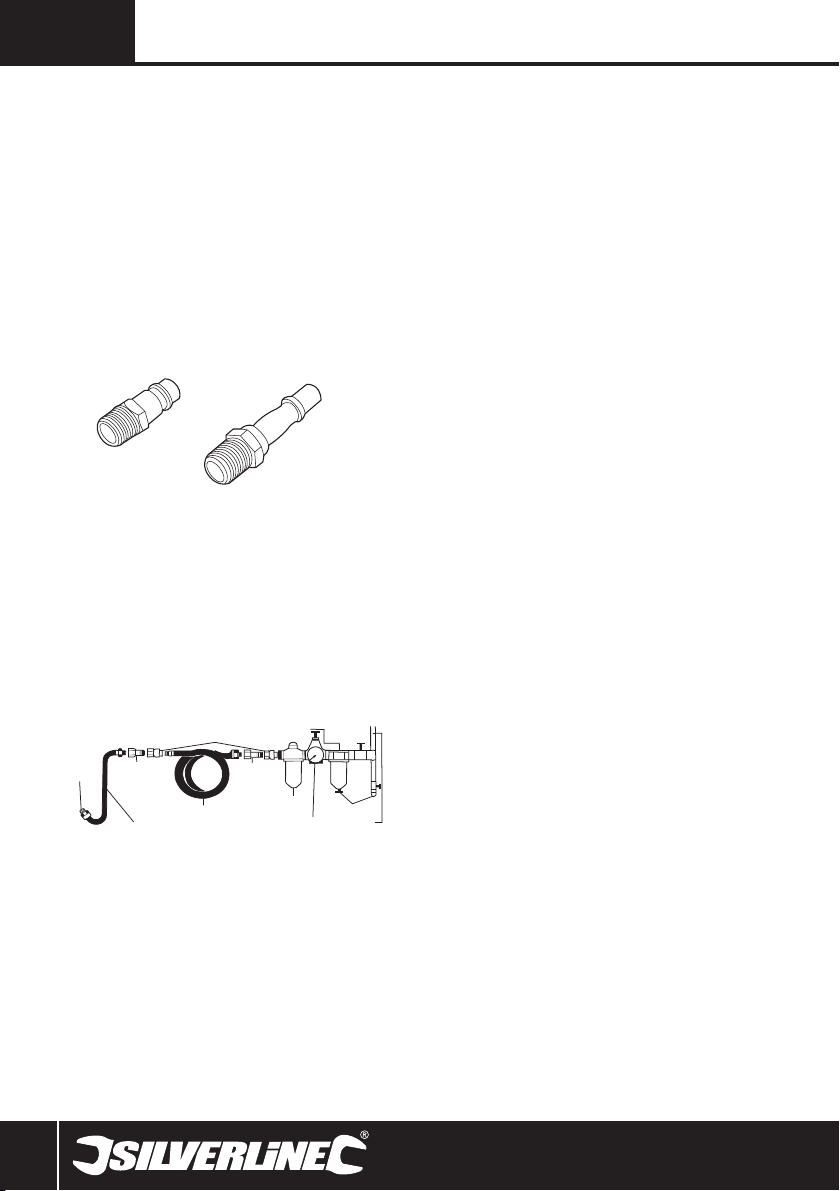

Fitting the quick connector

Note: This tool is supplied with two different male airline quick connectors:

EQ-4 – commonly used in Europe

EN-6 – mainly used in the UK

EQ-4

Europe

• Please choose the connector that is compatible with the airline system you are

using, and install as outlined below:

1. Apply some PTFE tape (not included) to the screw threads of the Quick

Connector (4). This will help to maintain an air-tight seal

Note: Apply PTFE tape tightly and in a clockwise direction, so it does not come off

when the thread is screwed into the tool.

2. Remove the protective plug from the air inlet

3. Using a spanner (not included) screw the quick connector into the air inlet

located at the base of the handle

4. Connect to airline, pressurise carefully and carry out a leak check (e.g. by

spraying small amounts of soapy water on to the outside of the connectors)

• Air lines fitted with matching female quick connectors will now be a push fit

to the tool

Air supply connection

QUICK COUPLER

NIPPLE

TO YOUR

AIR TOOL

LEADER HOSE

• This tool should be connected to a clean, dry air supply with inline oiler and

water separator

• Do not allow supply pressure to exceed the maximum stated (see

‘Specifications’)

• Ensure that water is drained from air system daily

• Ensure that all parts of the system (hoses, couplers, etc.) are correctly rated for

the air pressure to be used

Setting tool power

• The speed/pressure with which grease is expelled can be adjusted by reducing/

increasing the air supply pressure within the range specified in ‘Specifications’

RECOIL HOSE

EN-6

UK

WATER SEPARATION

NIPPLE

REGULATOR

OILER

DRAIN DAILY

AIR SUPPLY

Filling with grease

WARNING: Avoid spillages! Clean up spilled grease immediately and DO NOT allow

grease to enter the environment. Spilled grease may cause surfaces to become

slippery, causing a slipping hazard.

Note: Before using this tool, the user should consider the implications of using

grease cartridges. Over time, the use of cartridges will cause the seal of the

plunger mechanism to wear, affecting the gun’s performance so that it will not seal

when being filled with grease directly.

1. Ensure the grease gun is disconnected from the air supply before you begin

2. Unscrew the Chamber (7) from the body of the Grease Gun (2)

Installing a cartridge

1. Pull the Plunger Handle (5) back so that it is fully extended

2. Remove any packaging from the cartridge

3. Insert the cartridge fully into the chamber, as directed on the cartridge

4. Screw the chamber securely back onto the gun

5. Press the Plunger Release (6) to release the plunger mechanism

Filling from a container

1. Pull the Plunger Handle (5) back so that it is fully extended

2. Use a spatula to pack the grease directly into the chamber, taking care not to

accidentally press the Plunger Release (6)

3. Once filled, clean any excess from the edge of the chamber

4. Screw the chamber securely back onto the gun

5. Press the plunger release to release the plunger mechanism

Loading from a filler pump

Note: This is general guidance for a filler pump. Read the instructions provided

with your filler pump in combination with these when filling.

1. Pull the Plunger Handle (5) back so that it is fully extended

2. Hold the grease gun vertically so the Filler Pump Nozzle (10) is at the top and

the plunger release can’t be accidentally operated

3. Insert the filler plug on the end of the hose from the filler pump into the filler

pump nozzle

4. Operate the filler pump pumping mechanism to load the grease

5. Stop pumping when the required grease is loaded or if there is noticeable

resistance to loading

6. Disconnect the filler plug from the filler pump nozzle and wipe the nozzle

7. Press the Plunger Release (6) to release the plunger mechanism

Note: When only partially loading the chamber, carefully control the spring plunger

mechanism so that when the plunger release is pressed, you continue to hold the

plunger handle in order to control the descent of the plunger mechanism.

Bleeding the grease chamber

• After filling, remove any pockets of air trapped in the chamber:

1. Disconnect from the air supply

2. Check that the plunger is released. If not, depress the ratchet release

3. Unscrew the Chamber (7) from the body of the Grease Gun (2) 1 to 1-1/2

turns

4. Draw back the Plunger Handle (5) fully

5. Push plunger handle all the way in again

6. Retighten the chamber

7. Depress the Bleed Valve (11) several times to let the air escape

Attaching a spout

1. Ensure the Grease Nipple (1) is clean

2. Connect the required spout by screwing the threaded end into the grease

nipple

3. To remove a spout, unscrew it from the grease nipple

6

Page 8

427558 Air Grease Gun 400cc

Operation

WARNING: Ensure you are using the correct grease for the individual application,

i.e. the type of grease recommended by the manufacturer of the device to be

lubricated (vehicle, machine part, etc.).

WARNING: Avoid spillage! Clean up spilled grease immediately and DO NOT allow

grease to enter the environment. Spilled grease may cause surfaces to become

slippery, causing a hazard.

1. Connect to suitable air supply – See ‘Recommended air supply’ (above)

2. Pull the trigger to activate the air tool

3. Grease will be dispensed from the spout

4. When you have finished using the grease gun, disconnect the tool from the

air supply

WARNING: Be aware that air tools may hold residual pressure after use. Always

bleed air pressure from the tool after shutting off air supply.

Maintenance

WARNING: Always disconnect from the air supply and depressurise before

cleaning or carrying out any maintenance.

Cleaning

• Keep your tool clean at all times. Dirt and dust will cause internal parts to wear

quickly, and shorten the machine’s service life. Clean the body of your machine

with a soft brush, or dry cloth

IMPORTANT: There is very little that can go wrong with your air tool and it should

be noted that when an air tool fails to work it is generally because the internal

workings have corroded due to dirty, wet air and failure to follow the instructions

given below.

After every use: Disconnect from the air supply, pour a small amount of oil into

the air intake.

• If the machine is in constant use or used for long periods at a time, a combined

filter/lubricator must be fitted. There must be an air filter fitted at all times

• Use air tool oil. DO NOT UNDER ANY CIRCUMSTANCES USE NORMAL ENGINE OIL

• Failure to comply with the operating and maintenance instructions may

invalidate the guarantee

Storage

• Store this tool carefully in a secure, dry place out of the reach of children

Disposal

• Empty all remaining grease into a sealed container prior to recycling the tool,

and dispose of grease according to laws and regulations

• As with other power tools, air tools should not be disposed of with household

waste

• Air tools may contain traces of tool oil and other lubricants and so must be

recycled accordingly

• Contact your local waste disposal authority for information on the correct way to

dispose of grease and power tools

www.silverlinetools.com

7

Page 9

GB

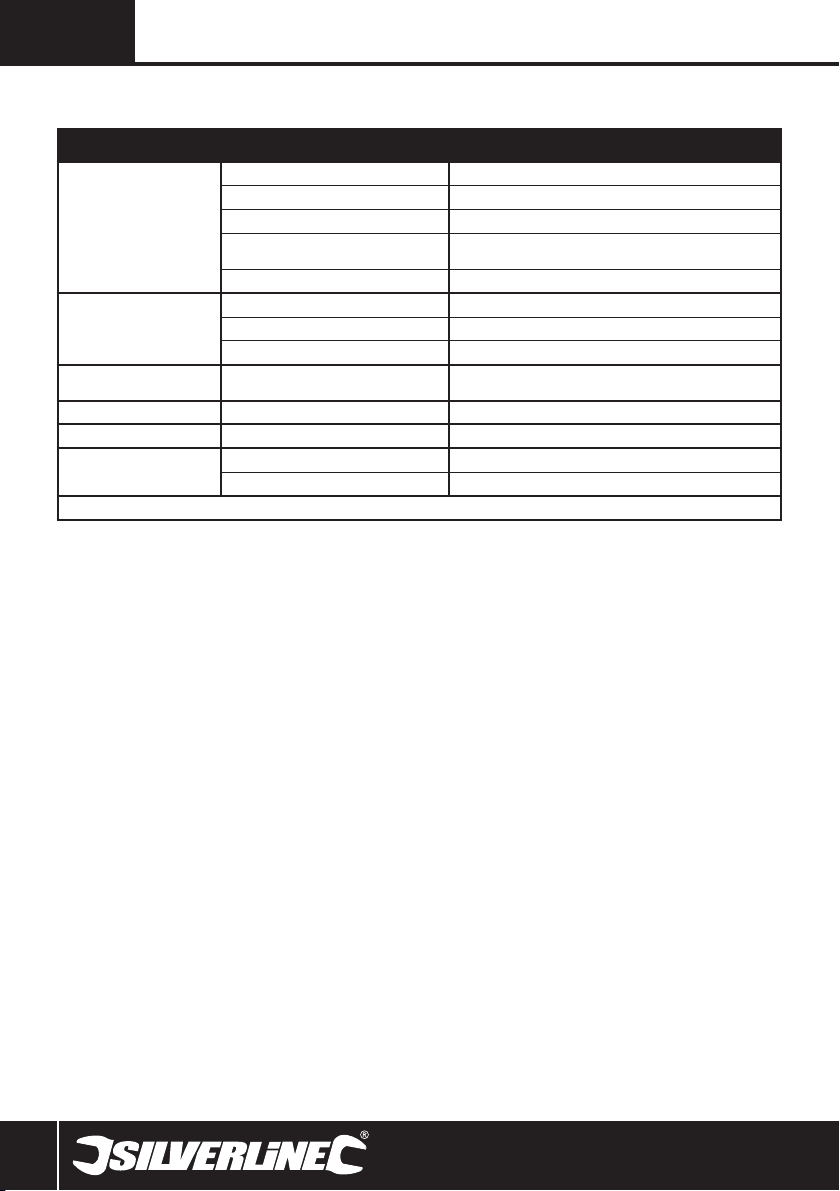

Troubleshooting

Problem Possible Cause Solution

Pressure incorrect Set the correct air pressure according to the specification

Dirt within the mechanism Pour oil into air inlet as per maintenance instructions

Tool operating slowly

Tool seized

Tool will not stop after trigger is

fully released

Gun fails to operate Air pocket Follow ‘Bleeding the grease chamber’ instructions above

No grease dispensed Plunger mechanism not released Press the Plunger Release (6)

Low amount of grease being

dispensed

Air blockage Operate tool in short bursts to clear blockage

Air leak Check all fittings and hose for air leaks and correct issue by re-tightening, using

Blockage in gauze mesh filter Remove Quick Connector (4) and clean mesh filter

Dirt or rust in mechanism Try ‘Tool operating slowly’ solutions

Dirt or rust in mechanism Tap tool gently with a soft mallet

Dirt or rust in mechanism Free mechanism by rotating drive manually when disconnected from air line

Throttle valve O-ring or valve seat damaged Have the tool repaired at an authorised Silverline service centre

Compressor pressure low Increase compressor air pressure within the range specified in ‘Specifications’

Grease level in chamber low Re-fill chamber

If the above troubleshooting solutions fail, contact your dealer or an authorised Silverline service centre.

PTFE tape or replacing

8

Page 10

427558 Air Grease Gun 400cc

Silverline Tools Guarantee

This Silverline product comes with a 3 year

guarantee

Register this product at www.silverlinetools.com within 30 days of

purchase in order to qualify for the 3 year guarantee. Guarantee period

begins according to the date of purchase on your sales receipt.

Registering your purchase

Registration is made at silverlinetools.com by selecting the Guarantee

Registration button. You will need to enter:-

• Your personal details

• Details of the product and purchase information

Once this information is entered your guarantee certificate will be created

in PDF format for you to print out and keep with your purchase.

Terms & Conditions

Guarantee period becomes effective from the date of retail purchase as

detailed on your sales receipt.

PLEASE KEEP YOUR SALES RECEIPT

If this product develops a fault within 30 days of purchase, return it to the

stockist where it was purchased, with your receipt, stating details of the

fault. You will receive a replacement or refund.

If this product develops a fault after the 30 day period, return it to:

Silverline Tools Service Centre

PO Box 2988

Yeovil

BA21 1WU, UK

The guarantee claim must be submitted during the guarantee period.

You must provide the original sales receipt indicating the purchase date,

your name, address and place of purchase before any work can be

carried out.

You must provide precise details of the fault requiring correction.

Claims made within the guarantee period will be verified by Silverline Tools

to establish if the deficiencies are related to material or manufacturing of

the product.

Carriage will not be refunded. Items for return must be in a suitably clean

and safe state for repair, and should be packaged carefully to prevent

damage or injury during transportation. We may reject unsuitable or

unsafe deliveries.

All work will be carried out by Silverline Tools or its authorized

repair agents.

The repair or replacement of the product will not extend the period

of guarantee

Defects recognised by us as being covered by the guarantee shall be

corrected by means of repair of the tool, free of charge (excluding carriage

charges) or by replacement with a tool in perfect working order.

Retained tools, or parts, for which a replacement has been issued, will

become the property of Silverline Tools.

The repair or replacement of your product under guarantee provides

benefits which are additional to and do not affect your statutory rights as

a consumer.

What is covered:

The repair of the product, if it can be verified to the satisfaction of Silverline

Tools that the deficiencies were due to faulty materials or workmanship

within the guarantee period.

If any part is no longer available or out of manufacture, Silverline Tools will

replace it with a functional replacement part.

Use of this product in the EU.

What is not covered:

Silverline Tools does not guarantee repairs required as a result of:

Normal wear and tear caused by use in accordance with the operating

instructions eg blades, brushes, belts, bulbs, batteries etc.

The replacement of any provided accessories drill bits, blades, sanding

sheets, cutting discs and other related items.

Accidental damage, faults caused by negligent use or care, misuse,

neglect, careless operation or handling of the product.

Use of the product for anything other than normal domestic purposes.

Change or modification of the product in any way.

Use of parts and accessories which are not genuine Silverline Tools

components.

Faulty installation (except installed by Silverline Tools).

Repairs or alterations carried out by parties other than Silverline Tools or its

authorized repair agents.

Claims other than the right to correction of faults on the tool named in

these guarantee conditions are not covered by the guarantee.

CE Declaration of Conformity

The undersigned: Mr Darrell Morris

as authorised by: Silverline Tools

Declares that

Identification code: 427558

Description: Air Grease Gun 400cc

Conforms to the following directives and standards:

• Machinery Directive 2006/42/EC Annex 1

Notified body: Intertek Testing Services, Shanghai, China

The technical documentation is kept by: Silverline Tools

Date: 23/05/13

Signed:

Director

Name and address of the manufacturer:

Powerbox International Ltd, Boundary Way, Lufton Trading Estate, Yeovil,

Somerset, BA22 8HZ United Kingdom

www.silverlinetools.com

9

Page 11

F

Description des symboles

La plaque signalétique figurant sur votre outil peut présenter des symboles.

Ces symboles constituent des informations importantes relatives au produit ou des

instructions concernant son utilisation.

Port de protection auditive

Port de lunettes de sécurité

Port du masque respiratoire

Port du casque

Port de gants

Lire le manuel d’instructions

Ne pas utiliser l’air comprimé des bouteilles à haute pression

Conforme à la règlementation et aux normes européennes de sécurité

pertinentes

Protection de l’environnement

Les produits électriques usagés ne doivent pas être jetés avec les

ordures ménagères. Veuillez les recycler dans les centres prévus à

cet effet. Pour de plus amples informations, veuillez contacter votre

municipalité ou point de vente.

Caractéristiques techniques

Plage de la pression

de fonctionnement : ..............................2,0-6,3 bars

(30-90 psi)

Consommation d'air : ...........................approx. 113 L/min

(4 cfm) pour 6,3 bars

(90 psi)

Entrée d'air : .........................................¼" BSP, fourni avec

deux raccords rapides mâles pour conduite d'air (de type

EN-6 pour le Royaume-Uni et EQ-4 pour l'Europe)

Diamètre minimum du tuyau : ..............9,5 mm (3/8")

Capacité :..............................................400 cm3 (Volume)

Pression de sortie de la graisse : ..........approx. 60-190 bars

(900-2 700 psi)

Longueur de la chambre : ....................280 mm

Poids net : ............................................1,45 kg

Du fait de l’évolution constante de nos produits, les caractéristiques

des produits Silverline peuvent changer sans notification préalable.

Consignes générales de sécurité

• En ce qui concerne les risques, lire et comprendre les instructions de sécurité

avant d’installer, utiliser, réparer, entretenir, changer d’accessoires, ou travailler

proche de cet outil. Ne pas respecter les consignes peut engendrer de sérieuses

blessures corporelles.

• Seule une personne qualifiée et formée peut assembler, régler et utiliser la

cet outil.

• N’apporter aucune modification sur cet outil. Des modifications peuvent

diminuer l’efficacité des mesures de sécurité et augmenter les risques pour

l’utilisateur.

• Garder toujours les instructions de sécurité, et les donner à l’utilisateur.

• Ne pas utiliser cet outil si elle est endommagée.

• Les outils doivent être inspectés régulièrement pour vérifier la validité des

données de l’appareil en fonction de la norme ISO 11148-8:2011. Ces données

doivent être lisibles sur l’appareil. Il est de la responsabilité de ‘employeur/

utilisateur de contacter le fabricant pour obtenir le remplacement de la plaque

signalétique si nécessaire.

ATTENTION : Cet appareil n’est pas conçu pour être utilisé par des personnes

(enfants compris) ayant des capacités physiques ou mentales réduites, ou n’ayant

pas la connaissance ou l’expérience requise, à moins d’être sous la supervision

d’une personne responsable de leur sécurité ou d’avoir reçu les instructions

nécessaires. Les enfants ne doivent pas s’approcher et jouer avec cet appareil.

Risques de projection

• Il est à savoir qu’un défaut sur la pièce de travail, sur un accessoire ou sur

l’appareil même peut engendrer l’envoi de projectiles avec une vitesse très

importante.

• Toujours porter des protections oculaires résistantes aux impacts pendant toute

la durée d’utilisation de cet outil. Le grade de protection doit être évalué avant

chaque utilisation.

• Pour les travaux à effectuer au-dessus de la tête, porter un casque de sécurité.

• Les risques pour les autres personnes doivent être également évalués.

• Vérifier que la pièce de travail soit convenablement stabilisé pour travailler en

toute sécurité.

Risques liés à l’utilisation

• L’utilisation de l’appareil peut exposer les mains à des risques de coupures,

égratignures ou des inflammations.

• Porter des gants de protection adéquats

• Les utilisateurs et le personnel d’entretien doivent être physiquement capables

de manipuler cet appareil de par son volume, poids et puissance.

• Maintenez l’appareil convenablement de façon à répondre aux mouvements

normaux et d’anticiper les mouvements soudains de l’outil.

• Travailler avec une posture stable.

• Relâcher le dispositif de marche/arrêt en cas de coupure d’alimentation.

• Utiliser les lubrifiants recommandés par le fabricant.

• Des protections oculaires personnelles doivent être portées. Des gants et

vêtements de protection sont également recommandés.

• Vérifiez l’état du bec avant chaque utilisation. Ne l’utilisez pas s’il est fendu,

cassé ou s’il est tombé.

• Des décharges électrostatiques peuvent se produire en cas d’utilisation sur du

plastiques ou d’autres matériaux non conducteurs.

Risques liés aux mouvements répétitifs

• L’utilisation à bon escient de cet outil peut engendrer des sensations de gêne

sur les mains, bras, épaules, cou et autres parties du corps.

• Lors de son utilisation, il est important de garder une posture stable et d’éviter

toute posture pouvant engendrer un déséquilibre. Pour éviter une sensation de

gêne ou de fatigue lors de longues utilisations, changer de posture.

• Si un utilisateur ressent des symptômes de façon récurrente ou persistante,

comme la gêne, élancement, douleur, picotement, engourdissement, sensation

de brûlure, raideur, ces avertissements doivent être pris sérieusement.

L’utilisateur doit avertir son employeur et consulter professionnel de la santé

qualifié.

Risques liés aux accessoires

• Débrancher toujours l’appareil de sa source d’alimentation avant d’insérer ou

de changer d’accessoire.

• Utiliser uniquement les tailles et types d’accessoires recommandés par le

fabricant.

10

Page 12

427558 Pistolet graisseur pneumatique 400 cm³

Risques liés au lieu de travail

• Les causes d’accidents sur le lieu de travail sont souvent dues à des

trébuchements, glissades et chutes. Faites attention sur les surfaces rendues

glissantes par l’utilisation de l’appareil, ainsi que les risques de trébuchements

qui pourraient être occasionnés par le tuyau d’air et tuyau hydraulique.

• Cet outil n’est pas conçu pour être utilisée en milieu à atmosphère

potentiellement explosif, et n’est pas isolante contre le contact avec une source

électrique.

Risques liés à la poussière et aux émanations

• La poussière et les émanations produites lors de l’utilisation de la ponceuse/

polisseuse peuvent provoquer des maladies (comme le cancer, asthme,

dermatite et d'anomalies congénitales).

• L’évaluation des risques doit inclure la poussière produite lors de l’utilisation

de l’outil ainsi que le déplacement de la poussière déjà existant crée par de

l’utilisation de l’outil.

• Faire fonctionner et entretenir cet outil sont recommandés dans ces

instructions pour la poussière et les émanations.

• Dirigé la sortie de la poussière de façon à limiter le déplacement de la poussière

dans un milieu poussiéreux.

• Lorsque de la poussière et des émanations sont créés, la priorité doit être de

les contrôler à la source de l’émission.

• Utiliser les protections respiratoires en accordance avec les instructions de

l’employeur ainsi qu’avec la réglementation en matière de santé et de sécurité.

Consignes supplémentaires

relatives aux outils pneumatiques

L’air comprimé peut engendre des blessures graves :

• Toujours couper l’alimentation en air, purger le tuyau d’air et débrancher

l’appareil de l’alimentation en air lorsqu’il n’est pas utilisé ou lors d’un

changement d’accessoires ou avant toutes réparations.

• Ne jamais diriger l’air vers vous ou d’autres personnes

• Les tuyaux peuvent être une source de dangers en donnant des coups de

fouets. Toujours vérifier le bon état du tuyau et des raccords.

• Pour toute utilisation de coupleurs universels, utiliser des goupilles et vérifier les

tuyaux pour éviter un mauvais raccord entre le tuyau et l’appareil.

• Ne jamais dépasser la pression maximale d’air indiquée sur l’appareil.

• Ne jamais porter l’appareil par le tuyau.

Familiarisation avec le produit

1 Embout de graissage

2 Pistolet de graissage

3 Détente

4 Raccord rapide

5 Poignée du plongeur

6 Gâchette de sécurité du plongeur

7 Chambre

8 Tige flexible

9 Tige rigide

10 Buse de la pompe de remplissage

11 Vanne de purge

www.silverlinetools.com

11

Page 13

F

AIR COMPRIMÉ

Usage conforme

• Pistolet graisseur pneumatique, utilisant de l'air comprimé fourni par un

compresseur, adapté pour les cartouches de graisse ou pour remplissage

par pompage, idéal pour la lubrification de véhicules, machines agricoles et

équipements industriels.

Déballage

Déballez le produit avec soin. Veillez à retirer tout le matériau d’emballage et

familiarisez-vous avec toutes les caractéristiques du produit.

Si des pièces sont endommagées ou manquantes, faites-les réparer ou remplacer

avant d’utiliser l’appareil.

Avant utilisation

Montage du raccord rapide

Remarque : Cet outil est fourni avec deux raccords rapides mâles pour la conduite

d’air :

EQ-4 , généralement utilisé en Europe

EN-6 , utilisé principalement au Royaume-Uni

EQ-4

Europe

• Choisissez un raccord rapide compatible avec la conduite d’air utilisée, et

montez- le de la façon suivante :

1. Appliquez une bande de PTFE (non fournie) sur le filetage du raccord pour

conserver une meilleure étanchéité. Les conduites d’air pourvues d’un

raccord ¼” coordonné s’emmancheront par simple pression sur le raccord

de l’appareil.

Remarque : appliquez la bande PFTE en la serrant bien et dans le sens horaire

pour que la bande reste bien en place lorsque le raccord sera vissez sur l’appareil.

2. Retirez le bouchon protecteur de l’arrivée d’air

3. En utilisant une clé (non fournie), vissez le raccord rapide sur l’arrivée d’air

située sur la base de la poignée.

4. Alimentez le circuit d’air en pressurisant avec précaution, et vérifiez qu’il n’y

pas de fuite (par exemple en vaporisant un peu d’eau savonneuse sur les

raccords).

• Les conduites d’air avec des raccords rapides femelles peuvent s’insérer

maintenant sur l’appareil.

Connexion de l’air comprimé

RACCORD RAPIDE

COUPLEUR OUTIL

PNEUMATIQUE

• Cet outil doit être branché à une alimentation en air comprimé propre et sec,

pourvue d’un graisseur en ligne et d’un séparateur d’eau.

• Ne laissez pas la pression d’alimentation dépasser la pression maximale

spécifiée. (Voir caractéristiques techniques).

• Vérifiez que l’eau soit drainée quotidiennement

• Vérifiez que toutes les parties du système (tuyaux, coupleurs, etc) soient

adaptés à l’air comprimé utilisé.

Réglage de la puissance de l'outil

• La vitesse/pression avec laquelle la graisse est expulsée peut être réglée en

diminuant/augmentant la pression de l'alimentation d'air dans la plage décrite

dans les « Spécifications ».

RACCORD

TUYAU DE

RACCORDEMENT

FLEXIBLE SERPENTIN

EN-6

UK

SÉPARATION DE L’EAU

MAMELON

GRAISSEUR

RÉGULATEUR

A PURGER

QUOTIDIENNEMENT

ALIMENTATION EN

Remplissage avec de la graisse

AVERTISSEMENT : Évitez les déversements ! Nettoyez immédiatement tout

déversement de graisse et NE LAISSEZ PAS la graisse pénétrer l'environnement.

Les déversements de graisse peuvent rendre les surfaces glissantes, causant ainsi

un danger de glissade.

Remarque : Avant d'utiliser cet outil, l'utilisateur doit envisager les incidences de

l'utilisation de cartouches de graisse. Au fil du temps, l'utilisation de cartouches

provoquera l'usure de l'étanchéité du mécanisme du plongeur, ce qui affectera

la performance du pistolet et le rendra difficile à fermer hermétiquement lorsqu'il

sera rempli directement avec de la graisse.

1. Assurez-vous que le pistolet est débranché de l'alimentation d'air avant de

commencer.

2. Dévissez la chambre (7) du corps du pistolet de graissage (2).

Installation d'une cartouche

1. Tirez la poignée du plongeur (5) en arrière de façon à ce qu'elle soit

complètement déployée.

2. Retirez tout emballage de la cartouche.

3. Insérez complètement la cartouche dans la chambre, tel qu'indiqué sur la

cartouche.

4. Revissez solidement la chambre au pistolet.

5. Appuyez sur la gâchette de sécurité (6) pour débloquer le plongeur.

Remplissage avec un conteneur

1. Tirez la poignée du plongeur (5) en arrière de façon à ce qu'elle soit

complètement déployée.

2. Utilisez une spatule afin de tasser la graisse directement dans la chambre, en

prenant soin de ne pas appuyer sur la gâchette de sécurité (6).

3. Une fois la chambre remplie, nettoyez tout excédent qui apparaîtrait au bord

de la chambre.

4. Revissez solidement la chambre au pistolet.

5. Appuyez sur la gâchette de sécurité pour débloquer le plongeur.

Remplissage avec une pompe de remplissage

Remarque : Il s'agit d'un guide général sur les pompes de remplissage. Au

moment du remplissage, lisez les instructions fournies avec votre pompe de

remplissage en plus de celles-ci.

1. Tirez la poignée du plongeur (5) en arrière de façon à ce qu'elle soit

complètement déployée.

2. Maintenez le pistolet de graissage verticalement de façon à ce que la buse

de la pompe de remplissage (10) se trouve en haut et que la gâchette de

sécurité ne puisse pas être actionnée accidentellement.

3. Insérez le bouchon de remplissage à l'extrémité du tuyau en le faisant aller

de la pompe de remplissage à la buse de la pompe de remplissage.

4. Actionnez le mécanisme de pompage de la pompe de remplissage pour

pomper la graisse.

5. Arrêtez de pomper lorsque la quantité de graisse requise est atteinte ou que

vous ressentez une résistance lors du pompage.

6. Retirez le bouchon de remplissage de la buse de la pompe de remplissage et

nettoyez la buse.

7. Appuyez sur la gâchette de sécurité (6) pour débloquer le plongeur.

Remarque : Lorsque vous ne remplissez que partiellement la chambre, contrôlez

attentivement le mécanisme de ressort du plongeur de façon à ce que, si vous

appuyez sur la gâchette de sécurité, vous puissiez continuer à tenir la poignée du

plongeur pour contrôler la descente du mécanisme du plongeur.

Purge de la chambre de graissage

• Après le remplissage, retirez toute poche d'air piégée dans la chambre:

1. Débranchez l'alimentation d'air.

2. Vérifiez que la sécurité du plongeur n'est pas activée. Si c'est le cas, appuyez

sur la gâchette de sécurité.

3. Dévissez la chambre (7) du corps du pistolet de graissage (2) d'un tour à un

tour et demi.

4. Tirez la poignée du plongeur (5) complètement vers l'arrière.

5. Enfoncez de nouveau complètement la poignée du plongeur.

6. Resserrez la chambre.

7. Appuyez sur la vanne de purge (11) plusieurs fois pour que l'air puisse

s'échapper.

Fixation d'une tige

1. Assurez-vous que l'embout de graissage (1) est propre.

2. Connectez la tige requise en vissant l'extrémité filetée à l'embout de

graissage.

3. Pour retirer une tige, dévissez-la de l'embout de graissage.

12

Page 14

427558 Pistolet graisseur pneumatique 400 cm³

Instructions d’utilisation

AVERTISSEMENT : Assurez-vous que vous utilisez la graisse adéquate pour une

application individuelle, par ex. le type de graisse recommandé par le fabricant de

l'appareil à lubrifier (véhicule, pièce mécanique, etc.).

AVERTISSEMENT : Évitez les déversements ! Nettoyez immédiatement tout

déversement de graisse et NE LAISSEZ PAS la graisse pénétrer l'environnement.

Les déversements de graisse peuvent rendre les surfaces glissantes, causant

ainsi un danger.

1. Raccordez à une alimentation d'air appropriée – Consultez « Alimentation

d'air recommandée » (ci-dessus)

2. Appuyez sur la détente pour activer l'outil pneumatique.

3. La graisse sortira par la tige.

4. Lorsque vous avez fini d'utiliser le pistolet de graissage, débranchez l'outil

de l'alimentation d'air.

AVERTISSEMENT : Sachez que les outils pneumatiques peuvent garder de la

pression résiduelle après utilisation. Purgez toujours la pression d'air présente

dans l'outil après avoir coupé l'alimentation d'air.

Entretien

ATTENTION : Débranchez toujours l’appareil de l’alimentation en air et purgez l’air

avant de le nettoyer ou de l’entretenir.

Nettoyage

• Gardez l’appareil propre. La poussière et la saleté provoquent l’usure rapide

des éléments internes de l’appareil et réduit sa durabilité. Utilisez une brosse

souple ou un chiffon sec pour le nettoyage. Si possible, nettoyez les orifices de

ventilation à l’air comprimé propre et sec.

Important : Il est important d’effectuer l’entretien régulier de l’outil pour éviter

que la saleté, humidité provoque la corrosion des éléments internes, qui pourrait

engendrer un mauvais fonctionnement de votre appareil.

Entretien quotidien : L’outil étant débranché de l’alimentation en air, verser

quelques gouttes d’huile dans la prise d’air. Faites fonctionner l’outil brièvement à

faible vitesse afin de lubrifier tous les éléments internes.

• Si l’appareil est utilisé constamment ou pendant de longues périodes d’affilée,

il faut l’équiper d’un filtre/lubrificateur combiné. Un filtre à air doit être installé

en permanence.

• Utiliser de l’huile pour air comprimé : N’UTILISEZ EN AUCUN CAS DE L’HUILE

MOTEUR CLASSIQUE.

• Le non-respect des instructions d’utilisation et d’entretien peut annuler la

garantie.

Rangement

• Ranger cet outil dans un endroit sûr, sec et hors portée des enfants

Recyclage

• Vidangez tout restant de graisse dans un récipient fermant hermétiquement

avant de recycler l'appareil, et jetez la graisse dans le respect des

réglementations en matière d'environnement.

• Comme tous les autres outils électroportatifs, les outils à air comprimé ne

doivent pas être jetés avec les ordures ménagères.

• Les outils à air comprimé contiennent de l’huile et lubrifiants et doivent donc

être recyclés en conséquence.

• Contactez les autorités locales compétentes en matière de gestion des déchets

pour vous informer de la procédure à suivre pour recycler les outils électriques

et à air comprimé

www.silverlinetools.com

13

Page 15

F

Dépannage

Problème Cause possible Solution

Pression incorrecte Réglez la pression d'air correcte selon les spécifications.

Saleté dans le mécanisme Versez de l'huile dans l'entrée d'air conformément aux instructions d'entretien.

Outil fonctionnant lentement

Outil bloqué

Outil qui ne s'arrête pas après le

relâchement complet de la détente

Pistolet qui ne fonctionne pas Poche d'air Suivez les instructions de « Purge de la chambre à graisse » ci-dessus.

Graisse qui ne sort pas Mécanisme du plongeur non relâché Appuyez sur la gâchette de sécurité (6).

Quantité de graisse versée trop faible

Si les solutions de dépannage ci-dessus échouent, contactez votre revendeur ou un centre de service agréé Silverline.

Blocage de l'air Actionnez l'outil en lui donnant de brèves pulsations afin d'éliminer le blocage.

Fuite d'air Vérifiez tous les raccords et tuyaux à la recherche de fuite et réglez les

Blocage du filtre en tamis métallique Retirez le raccord rapide (4) et nettoyez le filtre.

Saleté ou rouille dans le mécanisme Essayez les solutions proposées dans « Outil fonctionnant lentement ».

Saleté ou rouille dans le mécanisme Donnez des petits coups sur l'outil à l'aide d'un maillet doux.

Saleté ou rouille dans le mécanisme Libérez le mécanisme en le faisant tourner manuellement après l'avoir

Joint torique du pointeau ou siège de vanne

endommagé

Pression du compresseur faible Augmentez la pression du compresseur en fonction de la plage établie dans

Niveau de graisse dans la chambre faible Remplissez la chambre.

problèmes en les resserrant à l'aide d'un ruban PTFE ou en les remplaçant.

débranché de la conduite d'air.

Faites réparer l'outil dans un centre de service agréé Silverline.

les « Spécifications ».

14

Page 16

427558 Pistolet graisseur pneumatique 400cm

Garantie Silverline

Ce produit Silverline bénéficie d’une garantie de

3 ans

Enregistrez ce produit sur le site silverlinetools.com dans les 30 jours

suivant l’achat afin de bénéficier de la garantie de 3 ans. La période de

garantie commence à partir de la date d’achat figurant sur votre facture

d’achat.

Enregistrement de votre achat

Visitez silverlinetools.com, sélectionnez le bouton d’enregistrement et

saisissez :

• Vos informations personnelles

• Les informations concernant le produit et l’achat

Vous recevrez le certificat de garantie en format PDF. Veuillez l’imprimer et

le conserver avec votre achat.

Conditions de garantie des outils Silverline

La période de garantie prend effet à compter de la date de l’achat en

magasin, comme indiqué sur votre facture d’achat.

VEUILLEZ CONSERVER VOTRE FACTURE D’ACHAT.

Si ce produit est défectueux pendant les 30 jours qui suivent l’achat,

retournez-le au magasin où vous l’avez acheté, avec votre facture, en

expliquant en détail le problème. Le produit sera remplacé ou vous serez

remboursé(e).

Si ce produit est défectueux après cette période de 30 jours,

retournez-le à :

Silverline Tools Service Centre

PO Box 2988

Yeovil

BA21 1WU, Royaume Uni

Toute demande de service sous garantie doit être soumise pendant la

période de garantie.

Avant toute intervention sous garantie, vous devez présenter la facture

d’achat originale sur laquelle doivent figurer la date d’achat, votre nom,

votre adresse et le lieu d’achat.

Vous devez expliquer en détail la défaillance nécessitant réparation.

Les demandes de service sous garantie faites pendant la période de

garantie seront vérifiées par Silverline Tools pour établir si la défaillance du

produit est liée à un vice de matériau ou de fabrication.

Les frais de port ne seront pas remboursés. Les articles retournés doivent

être convenablement propres et sûrs pour être réparés et devraient être

emballés soigneusement pour éviter tout dommage ou toute blessure

pendant le transport. Nous pouvons refuser les livraisons qui ne sont pas

convenables ou sûres.

Toute intervention sera effectuée par Silverline Tools ou ses agents de

réparation agréés.

La réparation ou le remplacement du produit ne dépassera pas la période

de garantie.

Les anomalies que nous reconnaissons être couvertes par la garantie

seront rectifiées par la réparation de l’outil, sans frais (hormis les

frais de port) ou par son remplacement par un outil en parfait état de

fonctionnement.

Les pièces ou les outils remplacés deviendront la propriété de Silverline

Tools.

La réparation ou le remplacement de votre produit sous garantie vous

apporte des avantages ; ces avantages s’ajoutent à vos droits statutaires

en tant que consommateur sans les affecter aucunement.

La présente garantie couvre:

La réparation du produit, s’il peut être vérifié, à la satisfaction de Silverline

Tools, que les défaillances du produit ont été provoquées par un vice de

matériau ou de fabrication au cours de la période de garantie.

Si une pièce n’est plus disponible ou n’est plus fabriquée, Silverline Tools la

remplacera par une pièce de rechange opérationnelle.

Utilisation de ce produit dans l’UE.

La présente garantie ne couvre pas:

Silverline Tools ne garantit pas les réparations nécessaires du produit

engendrées par :

L’usure normale provoquée par l’utilisation conforme aux instructions

d’utilisation, par exemple les lames, les charbons, les courroies, les

ampoules, les batteries, etc.

Le remplacement de tout accessoire fourni tel que les forêts, les lames, les

feuilles abrasives, les outils de coupes et les autres articles associés.

Les dommages et les défaillances accidentels causés par une utilisation ou

un entretien négligent, une mauvaise utilisation, un manque d’entretien ou

une utilisation ou une manipulation imprudente du produit.

L’utilisation du produit à des fins autres que son utilisation domestique

normale.

Le moindre changement ou la moindre modification du produit.

L’utilisation de pièces et d’accessoires qui ne sont pas des composants

véritables de Silverline Tools.

Une installation défectueuse (sauf si l’installation a été réalisée par

Silverline Tools).

Les réparations ou les modifications réalisées par des tiers autres que

Silverline Tools ou ses agents de réparation agréés.

Les demandes de service autres que le droit de rectifier les défaillances

de l’outil indiquées dans ces conditions de garantie ne sont pas couvertes

par cette garantie.

3

Déclaration de conformité CE

Le soussigné : Mr Darrell Morris

Autorisé par : Silverline Tools

Déclare que le produit :

Code d’identification : 427558

Description : Pistolet graisseur pneumatique 400 cm³

Est conforme aux directives suivantes :

• Directive sur les machines 2006/42/CE Annex 1

Organisme notifié : Intertek Testing Services, Shanghai, Chine

La documentation technique est conservée par : Silverline Tools

Date : 23/05/13

Signature :

Directeur général

Nom et adresse du fabricant ou de son représentant agréé :

Powerbox International Ltd, Boundary Way, Lufton Trading Estate, Yeovil,

Somerset, BA22 8HZ Royaume-Uni

www.silverlinetools.com

15

Page 17

D

Beschreibung der Symbole

Auf dem Typenschild des Werkzeugs sind möglicherweise Symbole abgebildet.

Sie vermitteln wichtige Informationen über das Produkt oder dienen als

Gebrauchsanweisung.

Gehörschutz benutzen

Augenschutz benutzen

Atemschutz benutzen

Kopfschutz benutzen

Schutzhandschuhe benutzen

Bedienungsanleitung sorgfältig lesen

NICHT mit Druckgasflaschen betreiben!

Erfüllt die einschlägigen Rechtsvorschriften und Sicherheitsnormen

Umweltschutz

Druckluftwerkzeuge dürfen nicht über den Haushaltsmüll entsorgt

werden. Geräte enthalten Spuren von Öl und anderen Schmiermitteln.

Nach Möglichkeit bitte über entsprechende Einrichtungen entsorgen.

Lassen Sie sich bezüglich der sachgemäßen Entsorgung von

Druckluftwerkzeugen von der zuständigen Behörde oder dem Händler

beraten.

Technische Daten

Erforderlicher Betriebsdruck: .................2,0-6,3 bar

(30-90 psi)

Luftverbrauch: ......................................ca. 113 l/min bei

6,3 bar (90 psi)

Druckluftanschluss: ..............................1/4 Zoll BSP; zwei

Bajonett-Schnellkupplungen (EN-6 für Großbritannien und

EQ-4 für Kontinentaleuropa) im Lieferumfang enthalten

'European' types)

Mindestschlauchdurchmesser: .............9,5 mm

Füllvolumen:.........................................400 cm3 (loses Fett)

Ausgangsdruck: ...................................ca. 60–190 bar

(900–2700 psi)

Behälterlänge: ......................................280 mm

Gerätegewicht: .....................................1,45 kg

Aufgrund der fortlaufenden Weiterentwicklung unserer Produkte

können sich die technischen Daten von Silverline-Produkten ohne

vorherige Ankündigung ändern.

Allgemeine Sicherheitshinweise

• Lesen Sie diese Sicherheitshinweise zur Vermeidung unterschiedlicher

Gefahrenquellen aufmerksam durch, bevor Sie dieses Werkzeug installieren,

bedienen, reparieren, warten, Zubehörteile anbringen oder in der Nähe dieses

Werkzeuges arbeiten. Nichtbeachtung kann zu schwerwiegenden Verletzungen

führen.

• Dieses Werkzeug darf nur von qualifizierten und in der Bedienung

unterwiesenen Personen installiert, eingestellt und benutzt werden.

• Modifizieren Sie dieses Werkzeug in keinster Weise. Modifikationen können

dazu führen, dass Schutzeinrichtungen nicht effektiv funktionieren, wodurch das

Risiko für den Benutzer erhöht wird.

• Werfen Sie diese Sicherheitsanleitung nicht weg, sondern stellen Sie sie jedem

Benutzer zur Verfügung.

• Benutzen Sie dieses Werkzeug nicht, wenn es in irgendeiner Art beschädigt ist.

• Werkzeuge müssen regelmäßig darauf inspiziert werden, dass von ISO 11148

vorgeschriebene Kennzeichnungen auf dem Werkzeug angebracht und noch

lesbar sind. Der Arbeitgeber/Benutzer ist dafür verantwortlich, gegebenenfalls

Ersatzbeschriftungen über den Gerätehersteller zu beziehen.

WARNUNG! Dieses Gerät darf nicht von Personen (wie z.B. Kindern) mit

eingeschränkten körperlichen oder geistigen Fähigkeiten oder von Personen

ohne Erfahrung im Umgang mit einem solchen Gerät betrieben werden, außer

wenn sie von einer für ihre persönliche Sicherheit verantwortlichen Person in

der Benutzung unterwiesen worden sind und dabei beaufsichtigt werden. Kinder

müssen beaufsichtigt werden, um sicherzustellen, dass sie das Gerät nicht als

Spielzeug verwenden.

Risiken durch geschossartige Fragmente

• Seien Sie sich bewusst, dass im Falle eines Versagens des Werkzeugs

oder seines Zubehörs und beim Zerbrechen des Werkstücks

Hochgeschwindigkeitsgeschosse entstehen können.

• Tragen Sie bei der Benutzung des Werkzeugs stets eine geeignete schlagfeste

Schutzbrille. Die Schutzklasse hängt von der jeweiligen Anwendung ab und

muss individuell beurteilt werden.

• Tragen Sie bei Überkopfarbeiten einen Schutzhelm.

• Das Risiko gegenüber dritten Personen und Beistehenden sollte an dieser Stelle

ebenfalls beurteilt werden.

• Vergewissern Sie sich, dass das Werkstück stets sicher befestigt ist.

Betriebsrisiken

• Bei der Benutzung dieses Werkzeugs können die Hände des Benutzers

Gefahren, die Schnitt- und Schürfwunden sowie Verbrennungen hervorrufen

können, ausgesetzt sein.

• Schützen Sie Ihre Hände durch Tragen geeigneter Schutzhandschuhe.

• Bediener und Wartungspersonal müssen körperlich in der Lage sein, die

Masse und das Gewicht des Werkzeugs sowie die bei dessen Verwendung

auftretenden Kräfte handhaben zu können.

• Halten Sie das Werkzeug vorschriftsmäßig; seien Sie jederzeit bereit, plötzliches

Ausschlagen abzufangen und haben Sie stets beide Hände am Werkzeug.

• Achten Sie auf eine gut ausbalancierte Körperposition und sorgen Sie für einen

sicheren Stand.

• Schalten Sie das Werkzeug im Falle eines plötzlichen Ausfalls der

Energieversorgung immer am Schalter aus.

• Verwenden Sie ausschließlich vom Hersteller empfohlene Schmiermittel.

• Das Tragen einer Schutzbrille ist Pflicht; geeignete Schutzhandschuhe und

Arbeitsschutzkleidung werden dringend empfohlen.

• Begutachten Sie die Abschmierrohre/-schläuche vor jeder Benutzung.

Verwenden Sie diese nicht, falls sie Risse aufweisen, anderweitig beschädigt

oder heruntergefallen sind. Tra gen Sie geeignete Schutzhandschuhe.

• Bei der Verwendung mit Kunststoffen und anderen elektrisch nicht leitfähigen

Materialien kann es zu elektrostatischer Aufladung kommen.

Risiken durch wiederholte Bewegungsabläufe

• Bei der Arbeit mit diesem Werkzeug ist es möglich, dass der Benutzer

Unbehagen in den Händen, Armen, Schultern, im Nacken oder in anderen

Körperteilen verspürt.

• Der Benutzer muss während der Arbeit mit diesen Werkzeug darauf achten,

stets eine bequeme Körperposition mit festem Stand einzuhalten; unbequeme

Positionen und Positionen, die zum Verlust des Gleichgewichtes führen

können, sind zu vermeiden. Der Benutzer sollte seine Körperposition bei länger

andauernden Arbeiten in regelmäßigen Abständen verändern, um Ermüdung

und Unwohlsein vorzubeugen.

• Warnsignale wie bleibendes oder wiederauftretendes Unbehagen, akutes

oder anhaltendes Schmerzgefühl, Pochen, Kribbeln, Taubheit, Brennen oder

Versteifungen dürfen nicht ignoriert werden. Der Arbeitgeber muss umgehend

informiert und ein qualifizierter Arbeitsmediziner hinzugezogen werden.

16

Page 18

427558 Druckluft-Fettpresse, 400 cm3

Risiken durch Zubehörteile

• Trennen Sie das Gerät stets von der Energieversorgung, bevor Sie Zubehörteile

anbringen oder austauschen.

• Verwenden Sie ausschließlich vom Gerätehersteller empfohlenes Zubehör und

kompatible Verbrauchsmaterialien; verwenden Sie keine Zubehörteile oder

Verbrauchsmaterialien in anderen Größen.

Arbeitsplatzgefahren

• Ausrutschen, Stolpern und Fallen sind häufig auftretende Arten von

Arbeitsunfällen. Achten Sie bei der Verwendung dieses Werkzeugs auf rutschige

Untergründe sowie Stolpergefahren, z.B. durch die Druckluftzuleitung oder

Hydraulikschläuche.

• Dieses Gerät ist nicht für den Betrieb in explosionsgefährdeten Bereichen

konzipiert und es ist nicht gegen elektrischen Strom isoliert.

Risiken durch Staub und Rauch

• Durch Benutzung dieses Werkzeugs entstehender Staub und Rauch ist

gesundheitsschädlich (und kann u.a. Krebs, Geburtsschäden, Asthma

und Dermatitis verursachen). Eine Risikoanalyse und die Einführung von

Maßnahmen zur Kontrolle der Gesundheitsbelastung sind unerlässlich.

• In der Risikoanalyse muss sowohl durch die Benutzung des Werkzeuges

erzeugter als auch bestehender Staub berücksichtigt werden.

• Um Staubemissionen möglichst gering zu halten, verwenden Sie das Gerät wie

in dieser Anleitung beschrieben und halten Sie es entsprechend instand.

• Richten Sie den Staubaustritt so aus, dass bestehender Staub nicht aufgewirbelt

wird.

• Bei Ausführen von stauberzeugenden Arbeiten muss der Staub bereits bei der

Emission kontrolliert werden.

• Verwenden Sie Atemschutz in der von Ihrem Arbeitgeber vorgeschriebenen Art

und Weise bzw. in Übereinstimmung mit geltenden Arbeitsschutzrichtlinien.

Zusätzliche Sicherheitshinweise

für druckluftbetriebene

Werkzeuge

Druckluft kann schwerwiegende Verletzungen verursachen:

• Schließen Sie stets die Druckluftversorgung, machen Sie den Schlauch drucklos

und entfernen Sie das Werkzeug von der Druckluftversorgung, wenn es nicht

benutzt wird oder Sie Wartungs- bzw. Reparaturarbeiten durchführen.

• Richten Sie einen Druckluftstrom niemals auf sich selbst oder auf andere

Personen.

• Umherschlagende Schläuche können zu schwerwiegenden Verletzungen führen.

Überprüfen Sie Schläuche und Verbindungen stets auf Beschädigungen und

auf festen Sitz.

• Wenn Verbindungselemente mit Klauenkupplung verwendet werden,

müssen Sicherungsstifte sowie Sicherheitselemente zur Sicherung gegen

Umherschlagen des Schlauches bei Versagen des schlauch- oder geräteseitigen

Verbinders installiert werden.

• Überschreiten Sie niemals den maximalen Betriebsdruck.

• Tragen Sie ein Druckluftwerkzeug niemals am Schlauch.

Geräteübersicht

1 Schmiernippel

2 Druckkopf

3 Abzugshebel

4 Schnellkupplung

5 Schubstange

6 Sperrhebel

7 Fettbehälter

8 Abschmierschlauch

9 Abschmierrohr

10 Befüllstutzen

11 Entlüftungsventil

www.silverlinetools.com

17

Page 19

D

Bestimmungsgemäße

Verwendung

• Mit Druckluft aus einem Kompressor betriebenes, loses Fett oder Fett

aus Fettkartuschen ausgebendes Pumpwerkzeug zum Schmieren von

Kraftfahrzeugen, landwirtschaftlichen Maschinen und Industrieanlagen.

Auspacken des Gerätes

Packen Sie Ihr Werkzeug vorsichtig aus und überprüfen Sie es. Machen Sie sich

vollständig mit allen seinen Eigenschaften und Funktionen vertraut.

Vergewissern Sie sich, dass sämtliche Teile des Werkzeugs vorhanden und in

einwandfreiem Zustand sind. Sollten Teile fehlen oder beschädigt sein, lassen Sie

diese ersetzen, bevor Sie das Werkzeug verwenden.

Vor Inbetriebnahme

Schnellkupplung anbringen

Hinweis: Der Lieferumfang dieses Werkzeugs umfasst zwei verschiedene

Druckluft-Schnellkupplungen:

EQ-4: Verwendung vor allem in Kontinentaleuropa

EN-6: Verwendung vor allem in Großbritannien

EQ-4

Europe

• Bitte wählen Sie die mit dem von Ihnen verwendeten Druckluftsystem

kompatible Schnellkupplung und richten Sie sich nach der folgenden

Installationsanleitung:

1. Dichten Sie das Schraubengewinde der Schnellkupplung (4) mit PTFE-Band

(nicht mitgeliefert) ein, um eine luftdichte Verbindung zu erhalten.

Hinweis: Wickeln Sie das PTFE-Band fest und im Uhrzeigersinn, damit es sich bei

Einschrauben des Gewindes nicht löst.

2. Entfernen Sie den Schutzstopfen aus dem Druckluftanschluss.

3. Schrauben Sie die Schnellkupplung mit einem Gabelschlüssel (nicht

mitgeliefert) in den Druckluftanschluss unten am Handgriff.

4. Verbinden Sie die Schnellkupplung mit der Druckluftversorgung, bringen Sie

sie vorsichtig unter Druck und prüfen Sie die Verbindung auf Dichtigkeit (z.B.,

indem Sie die Außenseiten der Verbindungsstücke mit wenig Seifenwasser

besprühen).

• Schnellkupplungen mit passendem Innengewinde lassen sich nun auf das

Werkzeug aufstecken.

Anschluss an die Druckluftversorgung

ANSCHLUSSSTÜCK FÜR

DRUCKLUFTGERÄT

• Dieses Werkzeug ist zum Anschluss an eine Druckluftversorgung vorgesehen,

die über eine Wartungseinheit mit Wasserabscheider und Druckluftöler verfügt

und saubere, trockene Druckluft liefert.

• Der Druck der Luftversorgung darf den angegebenen maximalen Arbeitsdruck

des Gerätes nicht überschreiten (siehe Abschnitt „Technische Daten“).

• Sorgen Sie dafür, dass aufgefangene Feuchtigkeit täglich aus dem

Druckluftsystem entleert wird.

• Stellen Sie sicher, dass alle Teile des Druckluftsystems (inkl. Schläuche,

Verbinder usw.) für den angegebenen Betriebsdruck geeignet sind.

SCHNELLKUPPLUNGSADAPTER

NIPPEL

DRUCKLUFTSCHLAUCH

FÜHRUNGSSCHLAUCH

EN-6

UK

WASSERABSCHEIDUNG

NIPPEL

NEBELÖLER

DRUCKLUFTREGLER

TÄGLICH

ABLASSEN!

DRUCKLUFTZUFUHR

Geräteleistung einstellen

• Die Geschwindigkeit bzw. der Druck, mit der/dem das Schmierfett ausgegeben

wird, lässt sich einstellen, indem der Zuluftdruck innerhalb des laut

„Technischen Daten“ zulässigen Druckbereichs verringert bzw. erhöht wird.

Befüllung mit Schmierfett

WARNUNG! Verschütten vermeiden! Beseitigen Sie verschüttetes Schmierfett

sofort und sorgen Sie dafür, dass kein Schmierfett in die Umwelt gelangt.

Verschüttetes Schmierfett kann zu rutschigen Oberflächen führen, so dass

Ausrutschgefahr besteht.

Hinweis: Vor Gebrauch dieses Werkzeugs ist zu berücksichtigen, dass die

Verwendung von Fettkartuschen im Laufe der Zeit zu einem Verschleiß der

Kolbendichtung führt. Dies beeinträchtigt das Betriebsverhalten der Fettpresse

derart, dass die Dichtung beim direkten Befüllen mit Schmierfett nicht mehr

schließt.

1. Sorgen Sie vor Beginn dafür, dass die Fettpresse nicht an die Druckluftquelle

angeschlossen ist.

2. Schrauben Sie den Druckkopf (2) vom Fettbehälter (7) ab.

Fettkartusche einsetzen

1. Ziehen Sie die Schubstange (5) vollständig zurück.

2. Nehmen Sie die Fettkartusche aus der Verpackung und entfernen Sie

jegliches Verpackungsmaterial.

3. Setzen Sie die Kartusche entsprechend den Anweisungen auf der Kartusche

komplett in den Fettbehälter (7) ein.

4. Schrauben Sie den Druckkopf (2) wieder fest auf den Fettbehälter auf.

5. Drücken Sie zum Lösen der Schubstange den Sperrhebel (6).

Mit losem Fett befüllen

1. Ziehen Sie die Schubstange (5) vollständig zurück.

2. Geben Sie das Schmierfett mit Hilfe eines geeigneten Spachtels direkt in

den Behälter. Achten Sie dabei darauf, nicht versehentlich den Sperrhebel

(6) zu betätigen.

3. Nach dem Befüllen überschüssiges Schmierfett vom Rand des Behälters

entfernen.

4. Schrauben Sie den Druckkopf (2) wieder fest auf den Fettbehälter auf.

5. Drücken Sie zum Lösen der Schubstange den Sperrhebel.

Über ein Fettfüllgerät befüllen

Hinweis: Das im Folgenden beschriebene Vorgehen dient lediglich zur

Orientierung. Bitte befolgen Sie zum Befüllen neben dieser Anleitung die mit Ihrer

Füllpumpe gelieferten Anweisungen.

1. Ziehen Sie die Schubstange (5) vollständig zurück.

2. Halten Sie die Fettpresse mit dem Befüllstutzen (10) nach oben, so dass der

Sperrhebel nicht versehentlich betätigt werden kann.

3. Führen Sie den Einfüllstutzen am Schlauchende der Füllpumpe in den

Befüllstutzen der Fettpresse.

4. Betätigen Sie zum Befüllen der Fettpresse mit Schmierfett den

Pumpmechanismus der Füllpumpe.

5. Beenden Sie den Pumpvorgang, wenn die gewünschte Menge Schmierfett

eingefüllt ist bzw. wenn es beim Befüllen zu spürbarem Widerstand kommt.

6. Lösen Sie den Einfüllstutzen vom Befüllstutzen und wischen Sie die Düse ab.

7. Betätigen Sie zum Lösen der Schubstange den Sperrhebel (6).

Hinweis: Wenn der Behälter nicht vollständig befüllt werden soll, halten Sie die

Schubstange stets gut fest, damit Sie auch beim Drücken des Sperrhebels volle

Kontrolle über den Kolben behalten und dieser sich nicht zu schnell absenkt.

Lufteinschlüsse im Fettbehälter entfernen

• Nach der Befüllung alle Lufteinschlüsse im Fettbehälter wie folgt entfernen:

1. Trennen Sie das Werkzeug von der Druckluftquelle.

2. Sorgen Sie dafür, dass die Schubstange gelöst ist. Betätigen Sie ggf. den

Sperrhebel.

3. Schrauben Sie den Fettbehälter (7) mit einer bis eineinhalb Umdrehungen

vom Druckkopf (2) los.

4. Ziehen Sie die Schubstange (5) vollständig zurück.

5. Schieben Sie die Schubstange wieder ganz ein.

6. Schrauben Sie den Fettbehälter wieder am Druckkopf fest.

7. Drücken Sie wiederholt das Entlüftungsventil (11), um die Luft entweichen zu

lassen.

18

Page 20

427558 Druckluft-Fettpresse, 400 cm3

Abschmierrohr/-schlauch anbringen

1. Sorgen Sie dafür, dass der Schmiernippel (1) sauber ist.

2. Setzen Sie den benötigten Abschmierschlauch bzw. das Abschmierrohr ein,

indem Sie das Gewinde in den Schmiernippel einschrauben.

3. Zum Entfernen des Schlauches bzw. Rohrs schrauben Sie ihn/es aus dem

Schmiernippel aus.

Bedienung

WARNUNG! Achten Sie darauf, stets das für die jeweilige Anwendung richtige

Schmierfett zu verwenden, d.h. die vom Hersteller des zu schmierenden Gerätes

(Fahrzeugs, Maschinenteils usw.) empfohlene Schmierfettart.

WARNUNG! Verschütten vermeiden! Beseitigen Sie verschüttetes Schmierfett

sofort und sorgen Sie dafür, dass kein Schmierfett in die Umwelt gelangt.

Verschüttetes Schmierfett kann zu rutschigen Oberflächen führen, so dass

Ausrutschgefahr besteht.

1. Schließen Sie das Gerät an eine geeignete Druckluftquelle an – siehe

„Empfohlene Druckluftkomponenten“ (oben).

2. Zum Aktivieren des Werkzeugs drücken Sie den Abzugshebel (3).

3. Auf diese Weise wird Schmierfett durch den Abschmierschlauch bzw. das

Abschmierrohr abgegeben.

4. Unterbrechen Sie nach Beendigung der Arbeit die Druckluftzufuhr zum Gerät.

WARNUNG! Beachten Sie, dass Druckluftwerkzeuge auch nach der Verwendung

noch Restdruck enthalten können. Lassen Sie nach dem Abstellen der Luftzufuhr

stets den verbleibenden Luftdruck aus dem Gerät ab.

Wartung

WARNUNG! Trennen Sie das Gerät stets von der Druckluftversorgung und lassen

Sie den Druck ab, bevor Sie Wartungs- oder Reinigungsarbeiten durchführen.

Reinigung

• Halten Sie Ihr Gerät stets sauber. Durch Schmutz und Staub verschleißen die

Innenteile schnell und die Lebensdauer des Gerätes wird verkürzt. Säubern Sie

das Gerätegehäuse mit einer weichen Bürste oder einem trockenen Tuch.

WICHTIGER HINWEIS: Ihr Druckluftwerkzeug ist im Allgemeinen sehr

störungsunanfällig. Falls es nicht ordnungsgemäß funktioniert, ist dies in

den meisten Fällen auf die Korrosion von Innenteilen, hervorgerufen durch

verschmutzte feuchte Luft, sowie auf Nichtbeachtung der nachfolgenden

Anweisungen zurückzuführen.

Nach jedem Gebrauch: Trennen Sie das Gerät von der Druckluftzufuhr und

träufeln Sie einige Tropfen Druckluftwerkzeugöl in den Druckluftanschluss.

• Bei Dauerbetrieb des Werkzeugs muss eine Druckluftwartungseinheit mit

Filter-/Öler-Kombination verwendet werden. Es ist stets mindestens eine

Filtrationseinheit zu verwenden.

• Verwenden Sie ausschließlich Spezialöl für Druckluftgeräte. BENUTZEN SIE

UNTER KEINEN UMSTÄNDEN NORMALES MOTORENÖL.

• Das Nichtbeachten dieser Anweisungen kann zum Erlöschen der Garantie

führen.

Lagerung

• Bewahren Sie dieses Gerät sorgfältig an einem sicheren, trockenen Ort

außerhalb der Reichweite von Kindern auf.

Entsorgung

• Entleeren Sie vor Entsorgung des Werkzeugs sämtliche Schmierfettreste

in einen verschließbaren Behälter und entsorgen Sie das Schmierfett

vorschriftsmäßig.

• Druckluftwerkzeuge dürfen wie auch Elektrowerkzeuge nicht über den

Hausmüll entsorgt werden.

• Druckluftwerkzeuge können Spuren von Maschinenöl und anderen

Schmierstoffen enthalten und müssen dementsprechend der Wiederverwertung

zugeführt werden.

• Lassen Sie sich von der zuständigen Behörde bezüglich der ordnungsgemäßen

Entsorgung von Druckluftwerkzeugen beraten.

www.silverlinetools.com

19

Page 21

D

Fehlerbehebung

Problem Mögliche Ursache Abhilfe

Falscher Luftdruck Korrekten Luftdruck einstellen (siehe „Technische Daten“)

Schmutz im Mechanismus Öl gemäß Wartungsanweisung in Druckluftanschluss träufeln

Gerät läuft nur langsam

Gerät festgelaufen

Gerät hält auch nach vollständiger

Freigabe des Auslösers nicht an

Fettpresse funktioniert nicht Lufteinschluss Siehe Abschnitt „Lufteinschlüsse im Fettbehälter entfernen“

Kein Schmierfett ausgegeben Schubstange nicht gelöst Sperrhebel lösen

Geringe Menge Schmierfett

ausgegeben

Falls sich das Problem trotz der hier genannten Abhilfemöglichkeiten nicht beheben lässt, wenden Sie sich an Ihren Fachhändler oder einen von Silverline

Luftstau Gerät in kurzen Schüben betreiben, um Blockade zu beseitigen

Luftaustritt Alle Verschraubungen und Schlauch auf Undichtigkeit prüfen und Leckagen

Blockade im Siebfilter Schnellkupplung entfernen und Siebfilter reinigen

Schmutz oder Rost im Mechanismus Siehe Abhilfe zu „Gerät läuft nur langsam”

Schmutz oder Rost im Mechanismus Gerät leicht mit einem weichen Gummihammer abklopfen

Schmutz oder Rost im Mechanismus Gerät von Druckluftzufuhr trennen und Mechanismus durch Drehen des

O-Ring der Drosselklappe oder Ventilsitz beschädigt Gerät bei einem von Silverline zugelassenen Kundendienst reparieren lassen

Kompressordruck zu niedrig Luftdruck im Kompressor innerhalb des laut „Technischen Daten” zulässigen

Zu wenig Schmierfett in Fettbehälter Fettbehälter auffüllen

zugelassenen Kundendienst..

durch Nachziehen, Verwendung von PTFE-Band oder Ersetzen der Teile

beseitigen

Antriebs per Hand lösen

Druckbereichs erhöhen

20

Page 22

427558 Druckluft-Fettpresse, 400 cm3

Silverline-Tools-Garantie

Dieser Silverline-Artikel wird mit einer

3-Jahres-Garantie angeboten

Registrieren Sie diesen Artikel unter silverlinetools.com innerhalb von 30

Tagen nach dem Kauf, um die 3-Jahres-Garantie zu aktivieren.

Der Garantiezeitraum beginnt mit dem Kaufdatum auf Ihrem Kaufbeleg.

Registrierung Ihres Kaufs

Gehen Sie auf silverlinetools.com, klicken Sie auf „Registrierung“ und

geben Sie Folgendes ein:

• Ihre persönlichen Angaben

• Produktdetails und Kaufinformationen

Sobald dieses Produkt registriert worden ist, wird Ihre

Garantiebescheinigung im PDF-Format erzeugt. Bitte drucken Sie sie aus

und bewahren Sie sie zusammen mit Ihrem Produkt auf.

Garantiebedingungen

Der Garantiezeitraum beginnt mit dem Kaufdatum im Einzelhandel, das auf

dem Kaufbeleg angegeben ist.

BITTE BEWAHREN SIE DEN KAUFBELEG AUF!

Falls dieser Artikel innerhalb von 30 Tagen nach dem Kauf einen Defekt

aufweisen sollte, bringen Sie es bitte mit Ihrem Kaufbeleg zu dem

Fachhändler, bei dem es gekauft wurde, und informieren Sie ihn über die

Mängel. Das Gerät wird daraufhin ersetzt oder der Kaufpreis zurückerstattet.

Falls dieser Artikel nach Ablauf von 30 Tagen nach dem Kauf einen Mangel

aufweist, senden Sie es bitte an:

Silverline Tools Service Centre

PO Box 2988

Yeovil

BA21 1WU, Großbritannien

Der Garantieanspruch muss während der Garantiezeit gestellt werden.

Sie müssen den Originalkaufbeleg mit Angabe des Kaufdatums einreichen

und Ihren Namen und Ihre Adresse sowie den Ort des Kaufs angeben, bevor

etwaige Arbeiten durchgeführt werden können.

Sie müssen genaue Angaben über den zu behebenden Defekt machen.

Alle innerhalb der Garantiefrist gemachten Forderungen werden von

Silverline Tools daraufhin überprüft werden, ob es sich bei den Mängeln

um einen Material- oder Fertigungsfehler handelt.

Versandkosten werden nicht zurückerstattet. Alle Artikel sollten sich in

sauberem und sicherem Zustand befinden und sorgfältig verpackt zur

Reparatur eingeschickt werden, um Schäden oder Verletzungen während

des Transports zu vermeiden. Die Annahme unangemessener oder

unsicherer Lieferungen kann von uns verweigert werden.

Alle Arbeiten werden von Silverline Tools oder seinen autorisierten

Reparaturwerkstätten durchgeführt.

Die Reparatur oder der Ersatz des Artikels führt nicht zur Verlängerung

des Garantiezeitraums.

Mängel, bei denen unsere Prüfung ergibt, dass sie unter die Garantie fallen,

werden durch kostenlose Reparatur des Werkzeugs (ohne Versandkosten)

oder Ersatz durch ein Werkzeug in einwandfreiem Zustand behoben.

Einbehaltene Werkzeuge oder Teile, die ersetzt wurden, gehen in den Besitz

von Silverline Tools über.

Die Reparatur bzw. der Ersatz Ihres Artikels unter dieser Garantie erfolgt

zusätzlich zu Ihren gesetzlichen Rechten als Verbraucher und hat keine

nachteiligen Folgen auf diese.

Durch die Garantie abgedeckt ist:

Die Reparatur des Artikels, nachdem zur Zufriedenheit von Silverline Tools

nachgewiesen wurde, dass der Defekt durch fehlerhaftes Material oder

mangelhafte Arbeitsausführung bedingt ist und in den Garantiezeitraum fällt.

Wenn ein Ersatzteil nicht mehr erhältlich ist oder nicht mehr hergestellt

wird, kann Silverline Tools es gegen einen funktionellen Ersatz austauschen.

Verwendung des Artikels innerhalb der EU.

Durch die Garantie nicht abgedeckt ist:

Silverline Tools garantiert keine Reparaturen, die durch Folgendes

erforderlich geworden sind:

Normale Verschleißerscheinungen, die trotz Verwendung entsprechend

der Bedienungsanleitung entstehen, z.B. an Messern, Bürsten, Riemen,

Glühbirnen, Batterien usw.

Ersatz von mitgeliefertem Zubehör wie etwa Bohrspitzen, Klingen,

Schleifblättern, Schneidscheiben und anderen zugehörigen Teilen.

Unfallschäden und Fehler, die durch unsachgemäße Verwendung oder

Wartung, Missbrauch, Nachlässigkeit oder fahrlässige Bedienung oder

Handhabung des Artikels entstanden sind.

Verwendung des Artikels für andere als normale Haushaltszwecke.

Jegliche Veränderungen oder Modifikationen des Artikels.

Die Verwendung von Teilen oder Zubehör, die keine Originalkomponenten

von Silverline Tools sind.

Fehlerhafte Montage (außer, wenn von Silverline Tools vorgenommen).

Reparaturen oder Änderungen, die von anderen als Silverline Tools oder

seinen autorisierten Reparaturwerkstätten durchgeführt wurden.

Ansprüche, die über die Rechte zur Behebung von Mängeln an dem in

diesen Garantiebedingungen genannten Werkzeug hinausgehen.

EG-Konformitätserklärung