Page 1

3 Year Guarantee

*Register online within 30

days. Terms & Conditions apply

Garantie de 3 ans

*Enregistrez votre produit en ligne

dans les 30 jours. Sous réserve des

termes et conditions appliquées

3 Jahre Garantie

*Innerhalb von 30 Tagen online

registrieren. Es gelten die Allgemeinen

Geschäftsbedingungen

www.silverlinetools.com

3 años de garantía

*Registre su producto online durante

los primeros 30 días. Se aplican

términos y condiciones

3 anni di garanzia

*Registrare il vostro prodotto on-line entro

30 giorni. Termini e condizioni si applicano

3 jaar garantie

*Registreer uw product binnen 30

dagen online. Algemene voorwaarden

zijn van toepassing

Page 2

R

E

V

L

I

S

AIR

R

A

N

L

I

N

E

E

G

598446

75mm

Air Cut-Off Tool

Air Cut-Off Tool

Disqueuse droite pneumatique

Druckluft-Trennschleifer

www.silverlinetools.com

Amoladora recta neumática

Strumento tagliante pneumatico

Pneumatische slijper

Page 3

10

3

1

2

Fig. A

9

4

8

5

7

6

2

Page 4

R

E

V

L

I

S

AIR

R

A

N

G

L

I

N

E

E

®

75mm

Air Cut-Off Tool

English .................. 4

Français ................ 10

Deutsch ................. 16

Español ................. 22

Italiano .................. 28

Nederlands ............ 34

www.silverlinetools.com

3

Page 5

GB

Description of Symbols

The rating plate on your tool may show symbols. These represent important

information about the product or instructions on its use.

Wear hearing protection

Wear eye protection

Wear breathing protection

Wear head protection

Wear hand protection

Read instruction Manual

DO NOT use with compressed gas cylinders!

Conforms to relevant legislation and safety standards

Environmental Protection

Air tools must not be disposed of with household waste. Air

tools may contain traces of tool oil and other lubricants and so

must be recycled accordingly

Specification

Maximum operating pressure: ........................... 6.3bar (90psi)

Air consumption: ...............................................170L/min (6cfm)

Air inlet: .............................................................¼" BSP, supplied with

two male airline quick connectors (EN-6 ‘UK’ and EQ-4 ‘European’ types)

Minimum hose diameter:...................................9.5mm (3⁄8")

No load speed: ..................................................20,000min

Disc dimensions: ...............................................75 x 10 x 2mm

(3" discs)

Angle: ................................................................0°

Spindle thread: ..................................................M6 (female)

Weight ............................................................... 0.77kg

Noise and vibration information:

Level of sound pressure according to Machinery directive 2006/42/EC:

Sound pressure: ...............................................LPA = 84dB(A)

Sound power: ................................................... LWA = 95dB(A)

Uncertainty: .......................................................K = 3dB

The sound intensity level for the operator may exceed 85dB(A) and

sound protection measures are necessary.

Vibration total values (triax vector sum) according to Machinery directive

2006/42/EC:

Vibration emission value: .................................. ah = 1.68m/s

Uncertainty: .......................................................K = 1.5m/s

As part of our ongoing product development, specifications of

Silverline products may alter without notice.

-1

2

2

Noise and Vibration

• Sound and vibration levels in the specification are determined according

to ISO 28927-3. The figures given can be used to compare similar tools

tested to this standard. These figures may be used to assess exposure to

noise and vibration levels.

• The figures represent normal use for the tool in normal working

condition. A poorly maintained, incorrectly assembled or misused tool

may produce increased levels of noise and vibration. The total working

period that you can operate this tool must factor in periods where the

tool is idle or switched off. Allow frequent rest breaks when operating

this tool.

• It is in the interest of users to maximise their safety using the correct

safety equipment, like ear defenders that protect against loud or

repetitive noise, and anti-vibration gloves that minimise vibration.

Do not operate the tool with your hands below a normal comfortable

temperature, as vibration will have a greater effect.

Sound

• The noise directive was introduced to protect against the risk to health

and safety arising or likely to arise from exposure to noise and risk of

hearing. The Directive can be used to define noise exposure and the

physical parameters, such as peak sound pressure and daily and weekly

exposure level. Particular attention should be taken to exposure level

and duration.

• For more information on the Noise Directives 2003/10/EC and 2000/14/

EC, please visit The European Agency for Safety and Health at work -

www.osha.europa.eu.

Vibration

• The European Physical Agents (Vibration) Directive 2002/44/EC was

introduced to control the exposure of vibration at work. The Directive

enables users of tools to make informed decisions on the amount of time

spent working. Those who regularly operate high vibration equipment

over a sustained period of time are at a higher risk of health problems.

ISO 28927-3 measures vibration in three directions which is known as

tri-axial or vector sum measurement. When operating high vibration

equipment, ensure not to exceed exposure levels. For more details on

The Vibration Directive 2002/44/EC please visit The European Agency for

Safety and Health at work -www.osha.europa.eu

General Safety Warnings

• For multiple hazards, read and understand the safety instructions before

installing, operating, repairing, maintaining, changing accessories on, or

working near this tool. Failure to do so can result in serious bodily injury

• Only qualified and trained operators should install, adjust, or use this tool

• Do not modify this tool. Modifications can reduce the effectiveness of

safety measures and increase the risks to the operator

• Do not discard the safety instructions; give them to the operator

• Do not use this tool if it has been damaged

• Tools shall be inspected periodically to verify that the ratings and

markings required by this part of ISO 11148 are legibly marked on

the tool. The employer/user should contact the manufacturer to obtain

replacement marking labels when necessary

WARNING: This appliance is not intended for use by persons (including

children) with reduced, physical or mental capabilities or lack of experience

or knowledge unless they have been given supervision or instruction

concerning use of the appliance by a person responsible for their safety.

Children must be supervised to ensure that they do not play with the

appliance.

Projectile Hazards

• Be aware that failure of the workpiece or accessories, or even of the

inserted tool itself, can generate high-velocity projectiles

• Always wear impact-resistant eye protection during operation of this tool.

The grade of protection required should be assessed for each use

• For overhead work, wear a safety helmet

• The risks to others should also be assessed at this time

• Ensure that the workpiece is securely fixed

• Entanglement Hazards

4

Page 6

Air Cut-Off Tool598446

• Choking, scalping and/or lacerations can occur if loose clothing, personal

jewellery, neck wear, hair or gloves are not kept away from the tool and

its accessories

Operating Hazards

• Use of the tool can expose the operator’s hands to hazards, including

cuts, abrasions and heat

• Wear suitable gloves to protect hands

• Operators and maintenance personnel should be physically able to

handle the bulk, weight and power of the tool

• Hold the tool correctly; be ready to counteract normal or sudden

movements and have both hands available

• Maintain a balanced body position and secure footing

• Release the start-and-stop device in the case of an interruption of the

energy supply

• Use only lubricants recommended by the manufacturer

• Personal protective safety glasses should be used; suitable gloves and

protective clothing are recommended

• Inspect the cutting disc before each use. Do not use if cracked or broken

or if it has been dropped

• Avoid direct contact with moving parts in order to prevent pinching or

cutting of hands or other body parts.

• Wear suitable gloves to protect hands

• Never switch the tool on or off whilst the disc is in contact with the

workpiece

• There is a risk of electrostatic discharge if used on plastic and other

non-conductive materials

• Potentially explosive atmospheres can be caused by dust and fumes

resulting from cutting or grinding

• Always use dust extraction or suppression systems which are suitable for

the material being processed

Repetitive Motions Hazards

• When using this tool to perform work-related activities, the operator can

experience discomfort in the hands, arms, shoulders, neck or other parts

of the body

• While using this tool, the operator should adopt a comfortable posture

whilst maintaining secure footing and avoiding awkward or off-balance

postures. The operator should change posture during extended tasks; this

can help avoid discomfort and fatigue

• If the operator experiences symptoms such as persistent or recurring

discomfort, pain, throbbing, aching, tingling, numbness, burning

sensations or stiffness, these warning signs should not be ignored.

The operator should inform the employer and consult a qualified health

professional

Accessory Hazards

• Disconnect the tool from the energy supply before fitting or changing the

inserted tool or accessory

• Avoid direct contact with the inserted tool during and after use, as it can

be hot or sharp

• Use only sizes and types of accessories and consumables that are

recommended by the manufacturer of this tool; do not use other types or

sizes of accessories or consumables

• Grinding discs should not be used

• Check that the maximum operating speed of the cutting disc is higher

than the rated speed of the tool

Workplace Hazards

• Slips, trips and falls are major causes of workplace injury. Be aware

of slippery surfaces caused by use of the tool and also of trip hazards

caused by the air line or hydraulic hose

• This tool is not intended for use in potentially explosive atmospheres and

is not insulated against contact with electric power

• Ensure that there are no electrical cables, gas pipes, etc., which can

cause a hazard if damaged by use of the tool

Dust and Fume Hazards

• Dust and fumes generated when using this tool can cause ill health

(for example cancer, birth defects, asthma and/or dermatitis); risk

assessment and implementation of appropriate controls for these

hazards are essential

• Risk assessment should include dust created by the use of the tool and

the potential for disturbing existing dust

• Operate and maintain this tool as recommended in these instructions, to

minimise dust or fume emissions

• Direct the exhaust so as to minimise disturbance of dust in a dust-filled

environment

• Where dust or fumes are created, the priority should be to control them

at the point of emission

• All integral features or accessories for the collection, extraction or

suppression of airborne dust or fumes should be correctly used and

maintained in accordance with the manufacturer’s instructions

• Select, maintain and replace the consumable/inserted tool as

recommended in the instruction handbook, to prevent an unnecessary

increase in dust or fumes

• Use respiratory protection in accordance with employer's instructions

and as required by occupational health and safety regulations

Noise Hazards

• Exposure to high noise levels can cause permanent, disabling hearing

loss and other problems, such as tinnitus (ringing, buzzing, whistling or

humming in the ears). Therefore, risk assessment and implementation of

appropriate controls for these hazards are essential

• Appropriate controls to reduce the risk can include actions such as

damping materials to prevent workpieces from ‘ringing’

• Use hearing protection in accordance with employer's instructions and as

required by occupational health and safety regulations

• Operate and maintain this tool as recommended in the instruction

handbook, to prevent an unnecessary increase in the noise level

• Select, maintain and replace the consumable/inserted tool as

recommended in the instruction handbook, to prevent an unnecessary

increase in noise

• If the tool has a silencer, always ensure it is in place and in good working

order when the tool is being operated

Vibration Hazards

• This information shall draw attention to vibration hazards that have not

been eliminated by design and construction and remain as residual

vibration risks. It shall enable employers to identify the circumstances

in which the operator is likely to be at risk from vibration exposure If

the vibration-emission value obtained using ISO 28927-3 does not

adequately represent the vibration emission in the intended uses (and

foreseeable misuses) of the machine, additional information and/or

warnings shall be supplied to enable the risks arising from vibration to be

assessed and managed.

• Exposure to vibration can cause disabling damage to the nerves and

blood supply of the hands and arms

• Wear warm clothing when working in cold conditions and keep your

hands warm and dry

• If you experience numbness, tingling, pain or whitening of the skin in

your fingers or hands, stop using the sander or polisher, inform your

employer and consult a physician

• Operate and maintain the sander or polisher as recommended in the

instruction handbook, to prevent an unnecessary increase in vibration

levels

• Hold the tool with a light but safe grip, taking account of the required

hand reaction forces, because the risk from vibration is generally greater

when the grip force is higher

www.silverlinetools.com

5

Page 7

GB

Additional Safety Instructions

for Pneumatic Power Tools

• Air under pressure can cause severe injury:

• Always shut off air supply, drain hose of air pressure and disconnect tool

from air supply when not in use, before changing accessories or when

making repairs

• Never direct air at yourself or anyone else

• Whipping hoses can cause severe injury. Always check for damaged or

loose hoses and fittings

• Whenever universal twist couplings (claw couplings) are used, lock

pins should be installed and whipcheck safety cables should be used

to safeguard against possible hose-to-tool or hose-to-hose connection

failure

• Do not exceed the maximum air pressure stated on the tool

• Never carry an air tool by the hose

Grinding Tool Safety

• Always wear appropriate personal protective equipment. When using a

grinder, adequate eye protection, ear defenders and breathing protection

must be worn

• Reset the guard if the work angle or the position of the person operating

the machine changes. Seek professional guidance if you are unsure

how to operate the guards or any other safety features of the machine

correctly

• DO NOT operate a grinder without the appropriate guards in place

• Grinding tool accessories must be mounted, used and stored in

compliance with the manufacturer’s recommendations

• Only use cutting discs in the size stated in this instruction manual.

Attempting to use any other accessory or attachment is extremely

dangerous and could lead to serious injury

• Use the correct type of cutting disc for the task and material being

worked on. Check the label on the disc or accessory to find out if it is

appropriate to use on the workpiece

• The maximum speed of the cutting disc or other accessory must always

be higher than the maximum speed of the machine on which they are

mounted

• Do not use any form of spacers or adapters in an attempt to make an

incorrectly sized disc fit your machine

• Ensure that the cutting disc is fitted correctly and securely before use.

Run the machine with the disc or accessory fitted, but without load,

for a reasonable time before attempting to cut. If excessive vibration

occurs, stop the machine, investigate and correct the cause before use.

Seek professional guidance if you are in doubt about how to operate the

machine safely

• All discs and accessories must be checked before installation. If a disc

is damaged in any way, such as by being chipped, fractured, warped or

misshapen, DO NOT USE AND DISCARD. If you are unsure about whether

a disc is safe to operate, DO NOT USE AND DISCARD

• Always ensure that accessories are suitable to use. Check the expiry

date on the label. Resin-based cutting discs CANNOT SAFELY BE USED

beyond their expiry date

• Do not allow discs to become wet or contaminated with oil. If you

suspect that a disc has degraded in storage, or if you are unsure about

whether its expiry date has passed, DO NOT USE AND DISCARD

• Do not attempt to cut magnesium or any alloy that has high magnesium

content

• Do not attempt to make cuts that exceed the maximum cutting depth

of the disc

• Hold the machine appropriately to ensure that debris produced does not

land on skin or clothing

• Discs will continue to rotate for some time after the machine has

been switched off. Allow the moving parts to stop completely without

interference. Do not try to stop the machine by holding an object against

the disc. NEVER place the grinder down until the disc has completely

stopped moving

• A grinding disc will gradually wear down during use, reducing its size. If

a disc becomes too small to work with easily, stop using it and replace

it with a new disc

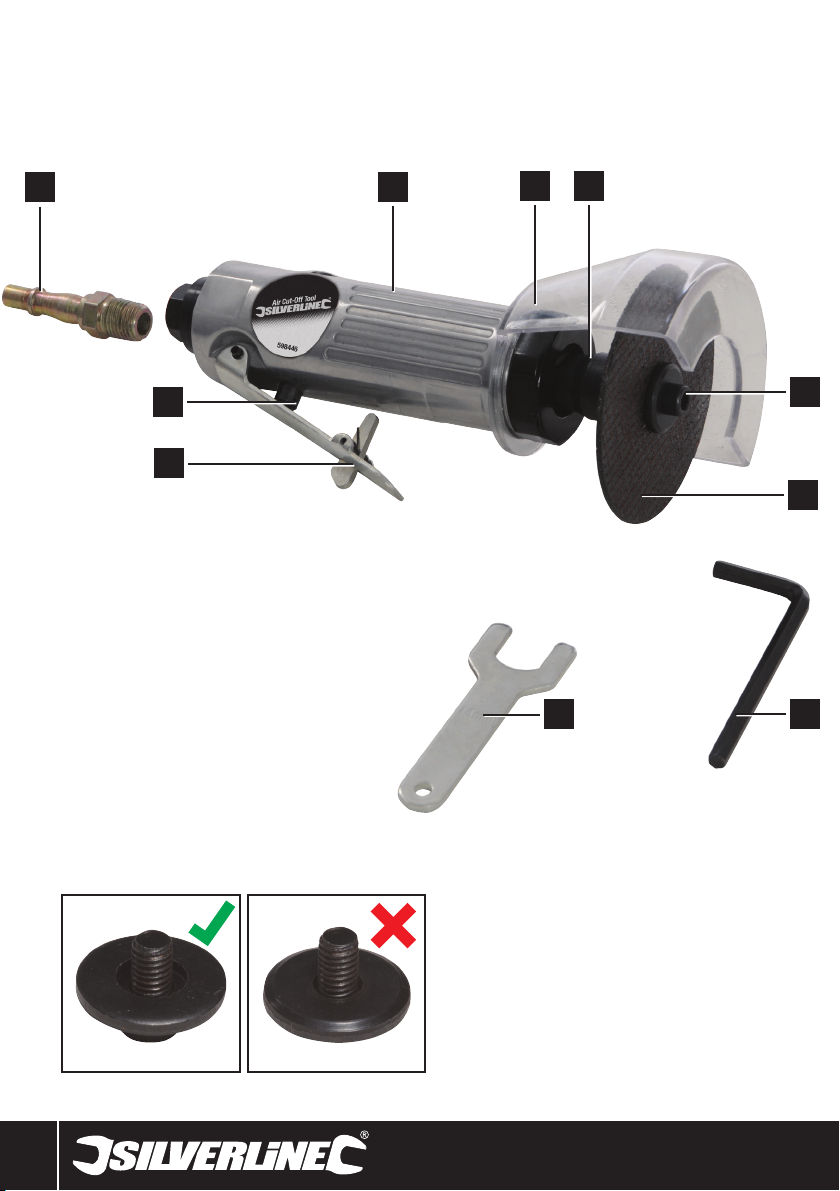

Product Familiarisation

1 Body / Handle

2 Guard

3 Spindle

4 Bolt & Washer

5 Cutting Disc (not supplied)

6 5mm Hex Key

7 14mm Spanner

8 Safety Catch

9 Speed Control

10 Quick Connector

6

Page 8

598446 Air Cut-Off Tool

Intended Use

• Rotating cut-off tool, powered by compressed air from a compressor, for

cutting of metal (mainly thin sheet metal, nuts/bolts, car bodywork etc.).

Unpacking Your Tool

• Carefully unpack and inspect your tool. Fully familiarise yourself with all

its features and functions

• Ensure that all parts of the tool are present and in good condition. If

any parts are missing or damaged, have such parts replaced before

attempting to use this tool

Before Use

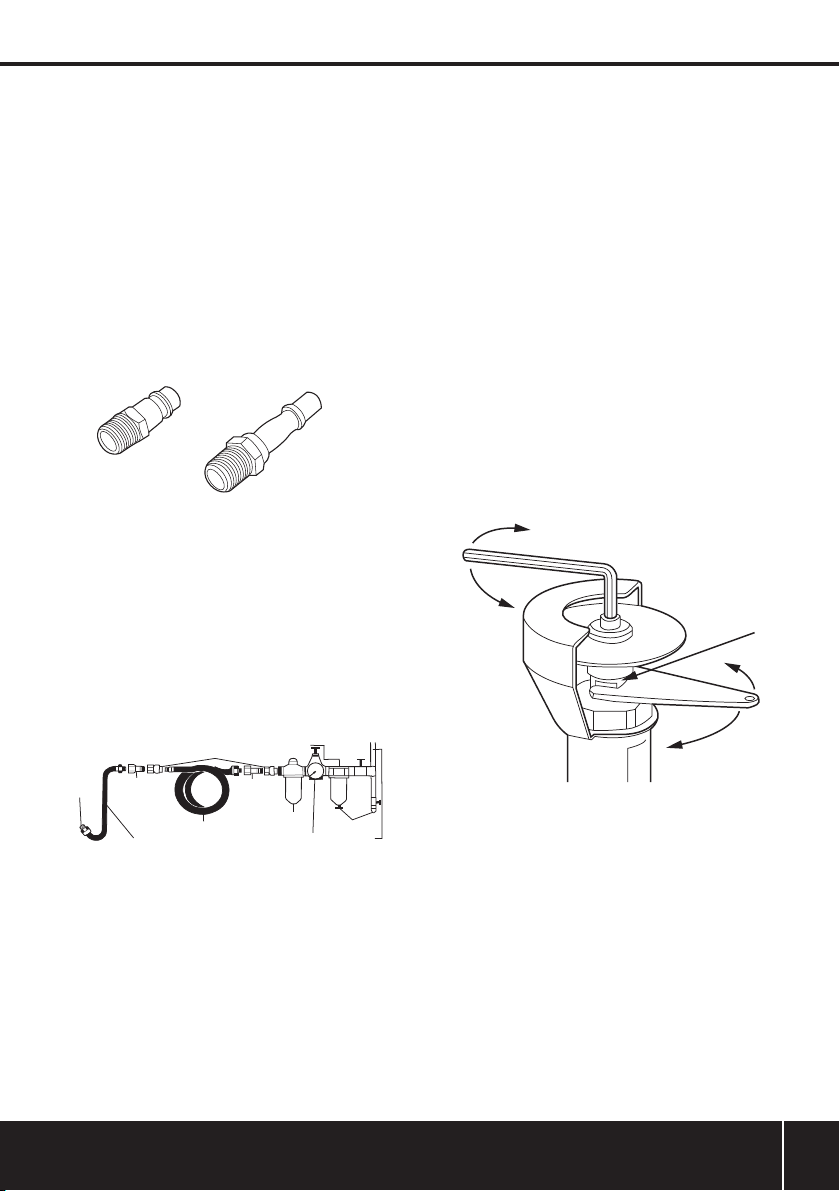

Fitting the quick connector

Note: This tool is supplied with two different male airline quick connectors:

EQ-4 – commonly used in Europe

EN-6 – mainly used in the UK

EQ-4

Europe

• Please choose the connector that is compatible with the airline system

you are using, and install as outlined below:

1. Apply some PTFE tape (not included) to the screw threads of the Quick

Connector (10). This will help to maintain an air-tight seal

Note: Apply PTFE tape tightly and in a clockwise direction, so it does not

come off when the thread is screwed into the tool.

2. Remove the protective plug from the air inlet

3. Using a spanner (not included) screw the quick connector into the air

inlet located at the base of the handle

4. Connect to airline, pressurise carefully and carry out a leak check (e.g.

by spraying small amounts of soapy water on to the outside of the

connectors)

• Air lines fitted with matching female quick connectors will now be a push

fit to the tool

Air supply connection

QUICK COUPLER

NIPPLE

TO YOUR

AIR TOOL

LEADER HOSE

• This tool should be connected to a clean, dry air supply with inline oiler

and water separator

• Do not allow supply pressure to exceed the maximum stated (see

“Specifications”)

• Ensure that water is drained from air system daily

• Ensure that all parts of the system (hoses, couplers, etc.) are correctly

rated for the air pressure to be used

RECOIL HOSE

EN-6

UK

WATER SEPARATION

NIPPLE

REGULATOR

OILER

DRAIN DAILY

AIR SUPPLY

Setting tool power

• The maximum tool speed/power can be adjusted by reducing/increasing

the air supply pressure within the range specified in ‘Specifications’

• Whilst working with the tool, speed adjustments can be made via the

Speed Control Trigger (9)

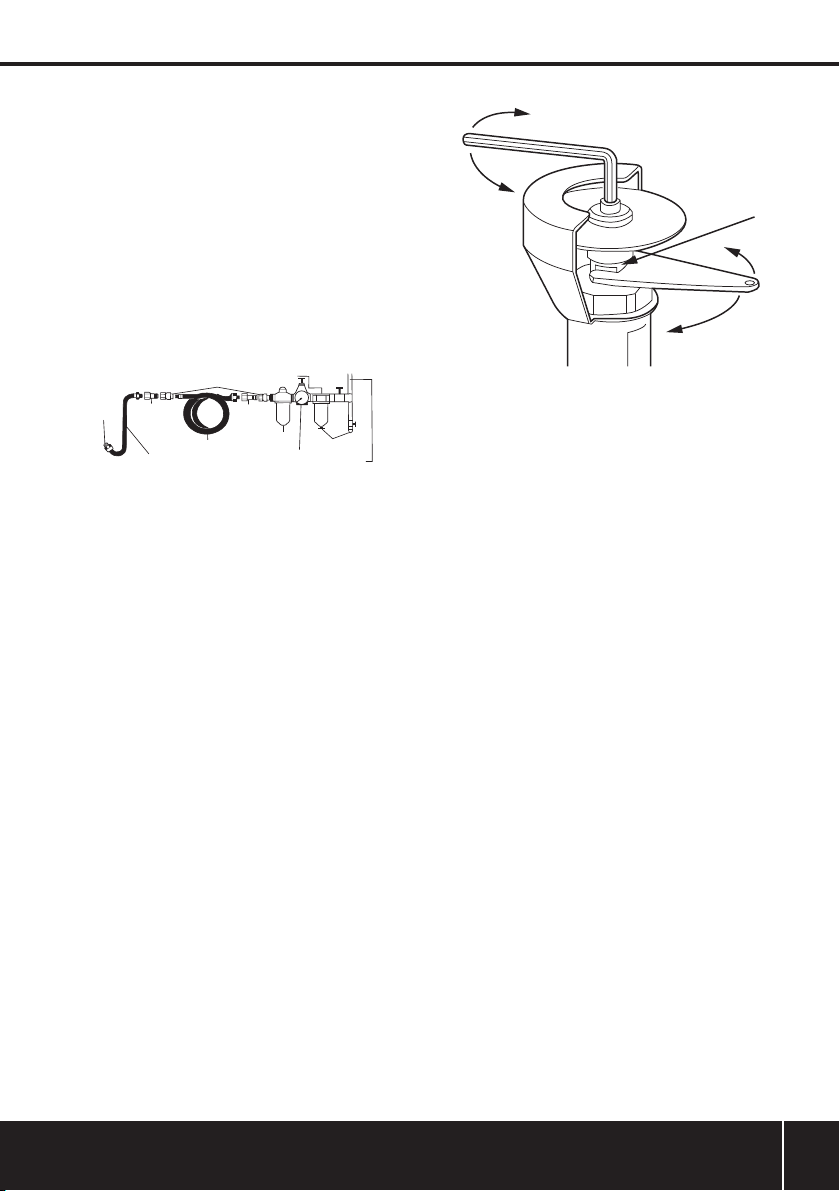

Fitting a cutting disc

WARNING: Always disconnect the tool from the air supply before fitting or

removing a cutting disc.

1. Slot the Spanner (7) over the Spindle (3) so that it grips the two flat

faces (see Fig. B). The spindle should be held securely and not able to

rotate

2. Use the Hex Key (6) to unscrew the Bolt & Flange (4)

3. Remove the disc if in place

4. Fit a new disc of correct size (see ‘Specifications’), following the

manufacturer’s guidance for direction of rotation

Note: Unless otherwise stated, the metal ring at the centre of the disc

should face the Spindle (3).

5. Re-fit the Bolt & Flange (4) in the correct orientation (see Fig. A),

ensuring it is not deformed, burred or notched, and tighten using the

spanner and hex key

WARNING: A damaged flange may cause irregular pressure on the disc, and

may cause it to break.

WARNING: DO NOT overtighten. The direction of rotation will prevent the

bolt from becoming loose.

6. Spin the Cutting Disc (5) by hand to check it is secure and correctly

aligned

Tighten

Fig.B

Loosen

Spindle (3)

Tighten

Loosen

Adjusting the guard

Note: Inspect the guard before every use, and replace if damaged.

WARNING: This tool must NEVER be operated without the guard in place

and correctly positioned.

• Depending in the application and work angle, the position f the guard

must be adjusted, to always be located between the disc and the user:

1. Use the Hex Key (6) to loosen the guard clamping screw

2. Adjust guard position and re-tighten screw

WARNING: DO NOT overtighten. Overtightening may damage the guard.

Operation

WARNING: DO NOT switch the machine on/off when the disc is in contact

with the workpiece. Always allow the motor to reach its full speed before

applying load, and to stop completely before placing the grinder down.

Always hold the machine securely, using both hands, on the handles

provided.

www.silverlinetools.com

7

Page 9

GB

Note: Do not apply too much pressure to the machine whilst grinding.

Excessive pressure does not result in more effective removal of material,

but will cause premature wear of the grinding disc and increase wear and

tear on the machine.

WARNING: This is a cutting device only. DO NOT attempt to use it for

sideways grinding, as axial force will cause the cutting disc to shatter.

1. Hold the tool by its Handle (1) and turn it so the open side of the Guard

(2) is facing away from you. Your thumb should wrap around the

Handle (1) and your fingers should sit on the Speed Control Trigger (9)

2. Disengage the Safety Catch (8) and gently squeeze the trigger towards

the handle

3. The Cutting Disc (5) will begin to spin. Squeeze the trigger further to

increase the speed, slightly release to decrease the speed

4. With the disc spinning at the required speed, slowly move the disc

towards the workpiece to be cut and gently engage the material

WARNING: When the disc begins to cut, it will force the tool to move

sideways. Make sure you have a firm grip on the tool and are ready to

counteract this.

5. As the disc begins to cut, take note of the direction of the waste

material being ejected. It should be going away from you, and not

towards any person or object to which it may cause damage

6. To stop the tool, remove the disc from the workpiece, fully release the

trigger and allow the safety catch to re-engage

Note: DO NOT allow the tool to run in ‘idle rotation’ for an extended period of

time. This will shorten its life.

WARNING: Be aware that air tools may hold residual pressure after use.

Always bleed air pressure from the tool after shutting off air supply.

Accessories

• Accessories for this tool including cutting discs (product code 633551)

are available from your Silverline stockist. Spare parts can be obtained

from your Silverline dealer or www.toolsparesonline.com

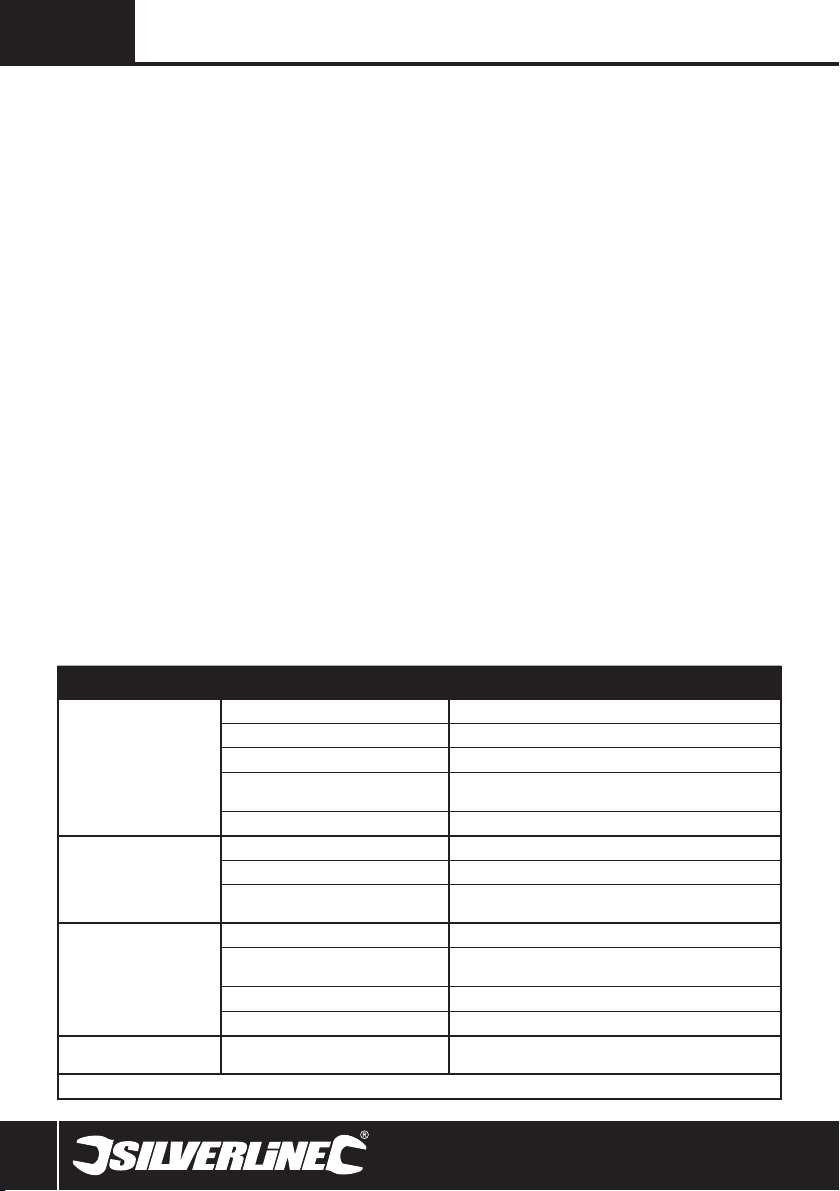

Troubleshooting

Maintenance

WARNING: Always disconnect from the air supply and depressurise before

cleaning or carrying out any maintenance.

Cleaning

• Keep your tool clean at all times. Dirt and dust will cause internal parts

to wear quickly, and shorten the machine’s service life. Clean the body of

your machine with a soft brush, or dry cloth

IMPORTANT: There is very little that can go wrong with your air tool and it

should be noted that when an air tool fails to work it is generally because

the internal workings have corroded due to dirty, wet air and failure to

follow the instructions given below.

Daily maintenance procedure: Disconnect from the air supply, pour the

equivalent of a tablespoon of oil into the air intake. Operate the machine at

low speed to thoroughly lubricate all internal workings.

• If the machine is in constant use or used for long periods at a time, a

combined filter/lubricator must be fitted. There must be an air filter fitted

at all times

• Use air tool oil only. DO NOT UNDER ANY CIRCUMSTANCES USE NORMAL

ENGINE OIL

• Failure to comply with the operating and maintenance instructions may

invalidate the guarantee

Storage

• Store this tool carefully in a secure, dry place out of the reach of children

Disposal

• As with other power tools, air tools should not be disposed of with

household waste

• Air tools may contain traces of tool oil and other lubricants and so must

be recycled accordingly

• Contact your local waste disposal authority for information on the correct

way to dispose of power tools

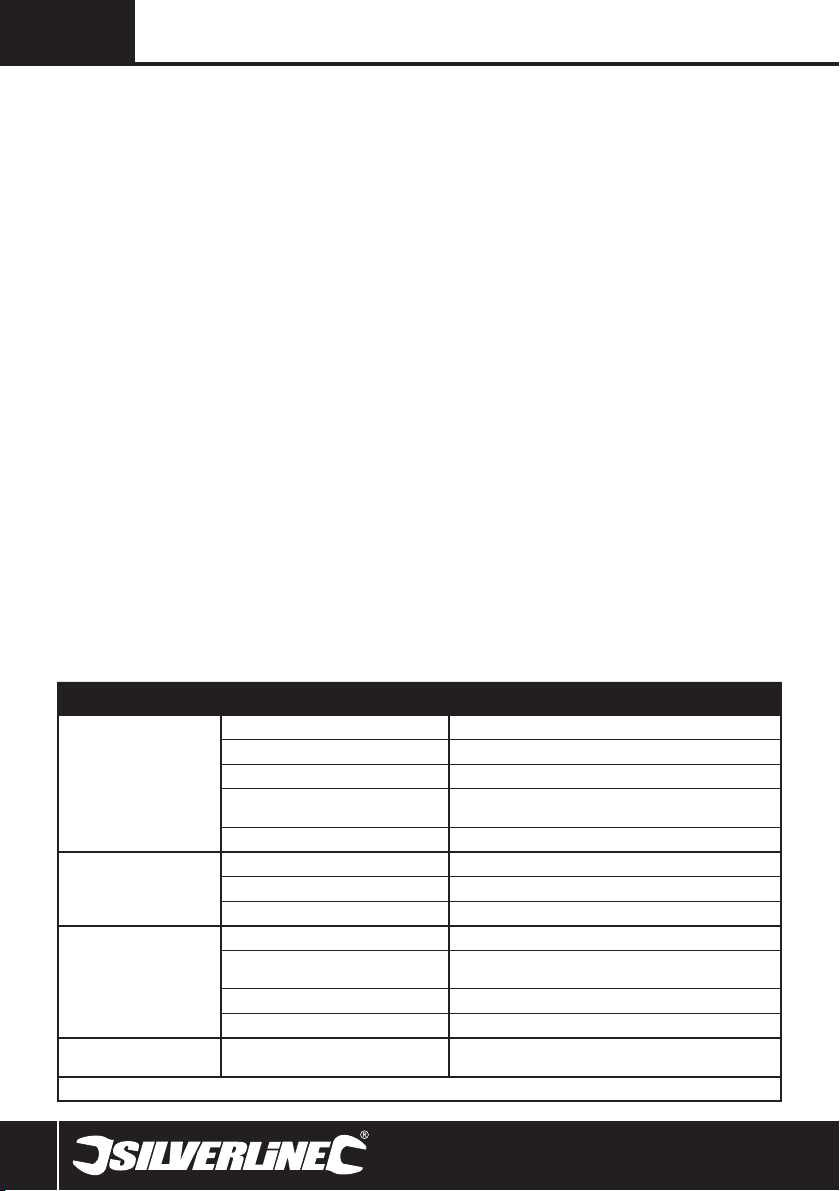

Problem Possible Cause Solution

Pressure incorrect Set the correct air pressure according to the specification

Dirt within the mechanism Pour oil into air inlet as per maintenance instructions

Tool operating slowly

Tool seized

Strong vibrations when tool is

switched on

Tool will not stop after trigger is

fully released

Air blockage Operate tool in short bursts to clear blockage

Air leak Check all fittings and hose for air leaks and correct issue by re-

Blockage in gauze mesh filter Remove Quick Connector (10) and clean mesh filter

Dirt or rust in mechanism Try ‘Tool operating slowly’ solutions

Dirt or rust in mechanism Tap tool gently with a soft mallet

Dirt or rust in mechanism Free mechanism by rotating drive manually when disconnected from

Cutting disc fitted incorrectly Remove disc, inspect for damage and refit

Cutting disc damaged (cracks, deformations

or splinters)

Flange damaged (burred or notched) Replace flange

Spindle bent Have the tool repaired by an authorised Silverline service centre

Throttle valve O-ring or valve seat damaged Have the tool repaired at an authorised Silverline service centre

If the above troubleshooting solutions fail, contact your dealer or an authorised Silverline service centre.

tightening, using PTFE tape or replacing

air line

Replace cutting disc

8

Page 10

598446 Air Cut-Off Tool

Silverline Tools Guarantee

Silverline Tools Guarantee

This Silverline product comes with a 3 year

guarantee

Register this product at www.silverlinetools.com within 30 days of

purchase in order to qualify for the 3 year guarantee. Guarantee period

begins according to the date of purchase on your sales receipt.

Registering your purchase

Registration is made at silverlinetools.com by selecting the Guarantee

Registration button. You will need to enter:-

• Your personal details

• Details of the product and purchase information

Once this information is entered your guarantee certificate will be created

in PDF format for you to print out and keep with your purchase.

Terms & Conditions

Guarantee period becomes effective from the date of retail purchase as

detailed on your sales receipt.

PLEASE KEEP YOUR SALES RECEIPT

If this product develops a fault within 30 days of purchase, return it to the

stockist where it was purchased, with your receipt, stating details of the

fault. You will receive a replacement or refund.

If this product develops a fault after the 30 day period, return it to:

Silverline Tools Service Centre

PO Box 2988

Yeovil

BA21 1WU, UK

The guarantee claim must be submitted during the guarantee period.

You must provide the original sales receipt indicating the purchase date,

your name, address and place of purchase before any work can be

carried out.

You must provide precise details of the fault requiring correction.

Claims made within the guarantee period will be verified by Silverline Tools

to establish if the deficiencies are related to material or manufacturing of

the product.

Carriage will not be refunded. Items for return must be in a suitably clean

and safe state for repair, and should be packaged carefully to prevent

damage or injury during transportation. We may reject unsuitable or

unsafe deliveries.

All work will be carried out by Silverline Tools or its authorized

repair agents.

The repair or replacement of the product will not extend the period

of guarantee

Defects recognised by us as being covered by the guarantee shall be

corrected by means of repair of the tool, free of charge (excluding carriage

charges) or by replacement with a tool in perfect working order.

Retained tools, or parts, for which a replacement has been issued, will

become the property of Silverline Tools.

The repair or replacement of your product under guarantee provides

benefits which are additional to and do not affect your statutory rights as

a consumer.

What is covered:

The repair of the product, if it can be verified to the satisfaction of Silverline

Tools that the deficiencies were due to faulty materials or workmanship

within the guarantee period.

If any part is no longer available or out of manufacture, Silverline Tools will

replace it with a functional replacement part.

Use of this product in the EU.

What is not covered:

Silverline Tools does not guarantee repairs required as a result of:

Normal wear and tear caused by use in accordance with the operating

instructions eg blades, brushes, belts, bulbs, batteries etc.

The replacement of any provided accessories drill bits, blades, sanding

sheets, cutting discs and other related items.

Accidental damage, faults caused by negligent use or care, misuse,

neglect, careless operation or handling of the product.

Use of the product for anything other than normal domestic purposes.

Change or modification of the product in any way.

Use of parts and accessories which are not genuine Silverline Tools

components.

Faulty installation (except installed by Silverline Tools).

Repairs or alterations carried out by parties other than Silverline Tools or its

authorized repair agents.

Claims other than the right to correction of faults on the tool named in

these guarantee conditions are not covered by the guarantee.

CE Declaration of Conformity

The undersigned: Mr Darrell Morris

as authorised by: Silverline Tools

Declares that

Identification code: 598446

Description: Air Cut-Off Tool

Conforms to the following directives and standards:

• Machinery Directive 2006/42/EC

• EN 792-7:2001+A1:2008

Notified body: Intertek Testing Services, Shanghai, China

The technical documentation is kept by: Silverline Tools

Date: 11/06/13

Signed:

Director

Name and address of the manufacturer:

Powerbox International Ltd, Boundary Way, Lufton Trading Estate, Yeovil,

Somerset, BA22 8HZ United Kingdom

www.silverlinetools.com

9

Page 11

F

Description des symboles

La plaque signalétique figurant sur votre outil peut présenter des symboles.

Ces symboles constituent des informations importantes relatives au produit

ou des instructions concernant son utilisation.

Port de protection auditive

Port de lunettes de sécurité

Port de masque respiratoire

Port du casque

Port de gants

Lire le manuel d’instructions

Ne pas utiliser avec des bouteilles à air comprimé

Conforme à la réglementation et aux normes de sécurité en

vigueur

Protection de l’environnement

Les produits à air comprimé usagés ne doivent pas être jetés

avec les ordures ménagères. Veuillez les recycler dans les

centres prévus à cet effet. Pour de plus amples informations,

veuillez contacter votre municipalité ou point de vente.

Caractéristiques techniques

Pression maximale de fonctionnement : 6,3 bar

Consommation d’air : ............................ 170 L/min

Arrivée d’air : ......................................... Raccord 1⁄4"

BSP fourni avec deux raccords rapides (type anglais EN-6

et européen EQ-4)

Diamètre minimum du tuyau : ............... 9,5 mm

Vitesse à vide : ...................................... 20,000 min

Dimensions du disque : ......................... 75 x 10 x 2 mm

Angle : ................................................... 0º

Poids : ................................................... 0,77 kg

Informations sur le niveau sonore et vibratoire

Niveau de la pression acoustique en accordance avec la

directive sur les machines 2006/42/CE

Pression acoustique : LPA ....................... 84 dB(A)

Puissance acoustique : LWA .................... 95 dB(A)

Incertitude K : ........................................ 3 dB

L’intensité sonore peut dépasser 85 dB(A) et il est

nécessaire que l’utilisateur prenne des mesures de

protection auditive.

Valeur totale des vibrations (somme vectorielle sur trois axes)

en accordance avec la directive sur les machines 2006/42/

CE.

Valeur des émissions vibratoires : ......... ah = 1,68 m/s

Incertitude : ........................................... K= 1,5 m/s²

Du fait de l’évolution constante de notre développement

produit, les caractéristiques des produits Silverline

peuvent changer sans notification préalable.

-1

2

Niveau sonore et vibratoire

Les niveaux sonores et vibratoires des caractéristiques techniques sont

déterminés en fonction de la norme ISO 28927 – 3. Ces données peuvent

être utilisées pour comparer des outils similaires et testés selon cette

norme. Ces données peuvent être aussi pour estimer l’exposition aux

niveaux sonores et vibratoires.

Ces données correspondent à un usage normale de l’appareil, et ce

dans des conditions de travail normales. Un appareil mal entretenu, mal

assemblé ou mal utilisé peut augmenter les niveaux sonores et vibratoires.

La durée totale d’utilisation sur laquelle vous utilisez l’appareil doit prendre

en compte les périodes ou l’appareil est éteint ou à l’arrêt. Faites des

pauses régulièrement lorsque vous utilisez cette appareil.

C’est dans l’intérêt de l’utilisateur d’assurer au maximum sa sécurité en

s’équipant de protection de sécurité comme des casques anti- bruit qui

protègent contre les bruits répétitifs et forts, et des gants anti-vibration

pour diminuer les effets vibratoires. Ne pas utilisez cet appareil avec vos

mains sous des conditions en dessous de températures normales, car

l’effet vibratoire en est accentué.

Le niveau sonore

La directive sur les émissions sonores a été introduite pour protéger contre

les risques sur la santé, améliorer la sécurité et prévenir les risques de

pertes auditives par l’exposition aux émissions sonores. Cette directive

peut être utilisée pour définir l’exposition sonore et les paramètres

physiques, tels que les niveaux de pression acoustique, les niveaux

quotidiens et hebdomadaires d’exposition. Une attention particulière doit

être portée au niveau d’exposition et de la durée. Pour plus d’informations

sur la directive des émissions sonores 2003/10/CE et 2000/14/CE, visitez

le site http://osha.europa.eu/fr

Le niveau vibratoire

La directive relative à l’exposition des travailleurs aux risques dus aux

agents physiques 2002/44/CE a été introduite pour contrôler l’exposition

aux vibrations au travail. Cette directive permet aux utilisateurs d’évaluer la

durée d’utilisation de l’appareil. Les personnes utilisant des équipements à

effet vibratoire élevé pendant de longues périodes sont plus exposées aux

risques sur la santé. La norme ISO 28927 – 3 mesure les vibrations selon

trois axe , par la somme vectorielle triaxiale. Lors de l’utilisation d’appareil

à haut effet vibratoire, assurez-vous de ne pas dépasser les niveaux

d’expositions. Pour plus d’informations sur la directive à l’exposition aux

vibrations, consultez le site http://osha.europa.eu/fr.

Consignes générales de sécurité

• En ce qui concerne les risques, lire et comprendre les instructions

de sécurité avant d’installer, utiliser, réparer, entretenir, changer

d’accessoires, ou travailler proche de cet outil. Ne pas respecter les

consignes peut engendrer de sérieuses blessures corporelles.

• Seule une personne qualifiée et formée peut assembler, régler et utiliser

la cet outil.

• N’apporter aucune modification sur cet outil. Des modifications peuvent

diminuer l’efficacité des mesures de sécurité et augmenter les risques

pour l’utilisateur.

• Garder toujours les instructions de sécurité, et les donner à l’utilisateur.

• Ne pas utiliser cet outil si elle est endommagée.

• Les outils doivent être inspectés régulièrement pour vérifier la validité

des données de l’appareil en fonction de la norme ISO 11148-8:2011.

Ces données doivent être lisibles sur l’appareil. Il est de la responsabilité

de ‘employeur/ utilisateur de contacter le fabricant pour obtenir le

remplacement de la plaque signalétique si nécessaire.

Attention : Cet appareil n’est pas conçu pour être utilisé par des personnes

(enfants compris) ayant des capacités physiques ou mentales réduites, ou

n’ayant pas la connaissance ou l’expérience requise, à moins d’être sous la

supervision d’une personne responsable de leur sécurité ou d’avoir reçu les

instructions nécessaires. Les enfants ne doivent pas s’approcher et jouer

avec cet appareil.

Risques de projection

• Il est à savoir qu’un défaut sur la pièce de travail, sur un accessoire

ou sur l’appareil même peut engendrer l’envoi de projectiles avec une

vitesse très importante.

10

Page 12

598446 Disqueuse droite pneumatique

• Toujours porter des protections oculaires résistantes aux impacts

pendant toute la durée d’utilisation de cet outil. Le grade de protection

doit être évalué avant chaque utilisation.

• Pour les travaux à effectuer au-dessus de la tête, porter un casque de

sécurité.

• Les risques pour les autres personnes doivent être également évalués.

• Vérifier que la pièce de travail soit convenablement stabilisé pour

travailler en toute sécurité.

Risques d’enchevêtrement

• Etouffements, lacérations et ou déchirures peuvent être provoques avec

le port de vêtements amples, de bijoux, colliers, et si les cheveux ou

des gants ne sont pas maintenus hors de portee de l’appareil et de ses

accessoires.

Risques liés à l’utilisation

• L’utilisation de l’appareil peut exposer les mains à des risques de

coupures, égratignures ou des inflammations.

• Porter des gants de protection adéquats

• Les utilisateurs et le personnel d’entretien doivent être physiquement

capables de manipuler cet appareil de par son volume, poids et

puissance.

• Maintenez l’appareil convenablement de façon à répondre aux

mouvements normaux et d’anticiper les mouvements soudains de

l’outil.

• Travailler avec une posture stable.

• Relâcher le dispositif de marche/arrêt en cas de coupure d’alimentation.

• Utiliser les lubrifiants recommandés par le fabricant.

• Des protections oculaires personnelles doivent être portées. Des gants et

vêtements de protection sont également recommandés.

• Inspecter le disque avant toute utilisation. Ne pas l’utiliser s’il est fissuré,

cassé ou s’il est tombé.

• Eviter le contact avec la ponceuse en marche pur éviter des pincements

et coupures sur les mains ou autres parties du corps. Porter des gants

adéquats

• Ne jamais mettre en marche ou éteindre l’appareil lorsque si le disque

est appliqué sur la pièce de travail.

• Des décharges électrostatiques peuvent se produire en cas d’utilisation

sur du plastiques ou d’autres matériaux non conducteurs.

• Le ponçage ou le meulage peut engendrer de la poussière et des

émanations, et créer des zones à atmosphère potentiellement explosives.

• Toujours utiliser un système d’extraction de la poussière adéquat a cet

appareil.

Risques liés aux mouvements répétitifs

• L’utilisation à bon escient de cet outil peut engendrer des sensations de

gêne sur les mains, bras, épaules, cou et autres parties du corps.

• Lors de son utilisation, il est important de garder une posture stable et

d’éviter toute posture pouvant engendrer un déséquilibre. Pour éviter

une sensation de gêne ou de fatigue lors de longues utilisations, changer

de posture.

• Si un utilisateur ressent des symptômes de façon récurrente ou

persistante, comme la gêne, élancement, douleur, picotement,

engourdissement, sensation de brûlure, raideur, ces avertissements

doivent être pris sérieusement. L’utilisateur doit avertir son employeur et

consulter professionnel de la santé qualifié.

Risques liés aux accessoires

• Débrancher toujours l’appareil de sa source d’alimentation avant

d’insérer ou de changer d’accessoire.

• Eviter tout contact direct avec les accessoires insérés sur l’outil car ils

peuvent être chaud ou tranchant.

• Utiliser uniquement les tailles et types d’accessoires recommandés par

le fabricant.

• Les meules ne doivent pas être utilisées.

• Vérifier que la vitesse maximale du disque soit supérieure à celle

indiquée sur la ponceuse.

Risques liés au lieu de travail

• Les causes d’accidents sur le lieu de travail sont souvent dues à des

trébuchements, glissades et chutes. Faites attention sur les surfaces

rendues glissantes par l’utilisation de l’appareil, ainsi que les risques

de trébuchements qui pourraient être occasionnés par le tuyau d’air et

tuyau hydraulique.

• Cet outil n’est pas conçu pour être utilisée en milieu à atmosphère

potentiellement explosif, et n’est pas isolante contre le contact avec une

source électrique.

• Vérifier qu’il n’y a pas de câbles électriques, de conduites de gaz, etc.

qui pourraient représentés un risque en cas d’endommagement par

l’utilisation de l’outil.

Risques liés à la poussière et aux émanations.

• La poussière et les émanations produites lors de l’utilisation de l’appareil

peuvent provoquer des maladies (comme le cancer, asthme, dermatite et

d'anomalies congénitales).

• L’évaluation des risques doit inclure la poussière produite lors de

l’utilisation de l’outil, ainsi que le déplacement de la poussière déjà

existant crée par de l’utilisation de l’outil.

• Faire fonctionner et entretenir l’appareil sont recommandés dans ces

instructions pour la poussière et les émanations.

• Dirigé la sortie de la poussière de façon à limiter le déplacement de la

poussière dans un milieu poussiéreux.

• Lorsque de la poussière et des émanations sont créés, la priorité doit

être de les contrôler à la source de l’émission.

• Tous les systèmes d’extraction de la poussière ou des systèmes de

pulvérisation d'eau anti-poussière/émanations doivent être correctement

utilise en fonction des instructions du fabricant.

• Choisir, entretenir et remplacer les accessoires recommandés dans le

manuel d’utilisation pour éviter une augmentation de la production de

poussière et d’émanations.

• Utiliser les protections respiratoires en accordance avec les instructions

de l’employeur ainsi qu’avec la réglementation en matière de santé et

de sécurité.

Risques liés aux émissions sonores

• L’exposition à des niveaux sonores élevés peut entrainer des pertes

auditives permanentes ou autres problèmes, comme l’acouphène

(bourdonnement, sifflement ou grésillement dans les oreilles). Par

conséquent, il est primordial d’évaluer les risques et d’implémenter les

mesures de contrôle nécessaires pour éviter ces risques.

• Une mesure de contrôle pour réduire ces risques peut être d’utiliser

des matériaux amortissants pour atténuer les sons aigus sur la pièce

de travail.

• Porter des protections auditives en accordance avec les instructions de

l’employeur ainsi qu’avec la réglementation en matière de santé et de

sécurité.

• Utiliser et entretenir l’appareil comme indiqué dans le manuel

d’utilisation pour éviter une augmentation inutile du niveau sonore.

• Si l’appareil possède un silencieux, vérifier qu’il soit en bonne condition

et bien installée sur l’outil pour un bon fonctionnement.

Risques liés aux vibrations

• Les consignes d’utilisation doivent stipuler que la conception et

la fabrication de l’appareil n’élimine pas totalement les risques

vibratoires, et donc qu’il existe toujours des risques. Les données

vibratoires de l’appareil doivent permettre à l’employeur d’évaluer dans

quelles situations l’utilisateur est exposé a des risques vibratoires. Si

les données relatives aux émissions vibratoires lors d’une utilisation

adéquate de l’appareil ne correspondent pas à celles de la norme ISO

28927-3, des informations ou avertissements supplémentaires doivent

être donnés pour que les risques soient évalués et contrôlés.

• L’exposition aux vibrations peut provoquer des lésions nerveuses et des

vaisseaux sanguins des bras et des mains.

• Porter des vêtements chauds lors d’utilisation des conditions de

températures froides et garder vos mains chaudes et sèches.

• En cas d’engourdissement, picotement, douleur ou blanchiment de

la peau sur les doigts ou la main, arrêter l’utilisation de la ponceuse/

polisseuse, prévenir votre employeur et consulter un médecin.

www.silverlinetools.com

11

Page 13

F

• Utiliser et entretenir la ponceuse/polisseuse comme indiqué dans le

manuel d’utilisation pour éviter une augmentation inutile du niveau

sonore.

• Tenir l’appareil sans trop serrer, mais assez pour travailler en toute

sécurité en fonction de la tâche à effectuer car les risques liés aux

vibrations augmentent plus l’outil est tenu fermement.

Consignes supplémentaires

relatives aux outils pneumatiques

L’air comprimé peut engendre des blessures graves :

• Toujours couper l’alimentation en air, purger le tuyau d’air et débrancher

l’appareil de l’alimentation en air lorsqu’il n’est pas utilisé ou lors d’un

changement d’accessoires ou avant toutes réparations.

• Ne jamais diriger l’air vers vous ou d’autres personnes

• Les tuyaux peuvent être une source de dangers en donnant des coups de

fouets. Toujours vérifier le bon état du tuyau et des raccords.

• Pour toute utilisation de coupleurs universels, utiliser des goupilles

et vérifier les tuyaux pour éviter un mauvais raccord entre le tuyau et

l’appareil.

• Ne jamais dépasser la pression maximale d’air indiquée sur l’appareil.

• Ne jamais porter l’appareil par le tuyau.

Consignes de sécurité relatives

aux outils de meulage

• Portez toujours un équipement de protection individuelle adéquat.

L’utilisation d’un outil de meulage demande le port de lunettes de

protection, d’un casque anti-bruit et d’un masque anti-poussière.

• Repositionnez le garde de protection si l’angle de travail ou la position de

l’utilisateur change.

• N’hésitez pas de demander l’assistance d’un professionnel au cas de

doute sur l’utilisation des gardes ou tout autre aspect de la sécurité

d’utilisation de ce produit.

• N’utilisez jamais de meuleuse dépourvue de ses éléments de protection.

• Les accessoires de la meuleuse doivent être installés, utilisés et rangés

selon les instructions du fabricant.

• N’utilisez que des disques de la taille prescrite dans ce manuel.

L’utilisation de tout accessoire inadapté est extrêmement dangereuse et

représente un risque de blessures graves.

• Utilisez les disques à tronçonner adapté à la tâche et au matériau.

Vérifiez l’étiquette du disque ou de l’accessoire pour en connaitre la

compatibilité pour une utilisation avec votre pièce de travail.

• La vitesse maximale du disque à tronçonner doit toujours être supérieure

à la vitesse maximale de la machine sur laquelle elle est montée.

• N’utilisez pas d’entretoise pour forcer le montage d’un disque inadapté

sur votre machine.

• Assurez-vous le disque soit correctement posé et fixé avant l’utilisation.

Faites tourner la machine avec le disque posé, sans charge, pendant

un certain temps avant d’entreprendre la découpe. S’il apparaît une

vibration excessive, arrêter la machine et remédier à la cause avant

utilisation. N’hésitez pas de demander l’assistance d’un professionnel

au cas de doute sur l’utilisation des gardes ou tout autre aspect de la

sécurité d’utilisation de ce produit.

• Examinez les disques à tronçonner avant l’utilisation. Si un disque est

endommagé de quelque manière que ce soit (écaillé, fracturé, etc.), NE

L’UTILISEZ PAS. Jetez le disque et remplacez-le. Si vous n’êtes pas sûr

de l’état du disque, NE L’UTILISEZ PAS et jetez-le.

• Vérifiez que les accessoires sont en bon état d’utilisation et vérifiez la

date d’expiration se trouvant sur l’étiquette. Des disques à tronçonner

dont la date d’expiration est dépassée, ne peuvent pas être utilisés en

toute sécurité.

• N’exposez pas les disques à l’humidité et à la graisse. Si vous

soupçonnez qu’un disque s’est dégradé pendant son entreposage, NE

L’UTILISEZ PAS.

• N’entreprenez pas de tronçonner ni de meuler du magnésium ni aucun

alliage contenant une forte proportion de magnésium.

• N’entamez pas de coupe dépassant la profondeur maximale de coupe

du disque.

• Maintenez la machine de façon à éviter de recevoir des débris sur la

peau ou vos vêtements.

• La machine continue à tourner pendant un certain temps après avoir

été éteinte. Laissez la machine s’arrêter d’elle-même. Ne l’arrêtez pas

en calant le disque contre un quelconque objet. NE déposez JAMAIS la

meuleuse avant l’arrêt complet du disque.

• Un disque de meulage s’use à l’usage et sa taille diminue. Une fois que le

disque est trop usé pour pouvoir travailler confortablement, remplacez-le.

Présentation du produit

1 Corps / Poignée

2 Carter de protection

3 Arbre

4 Boulon et rondelle

5 Disque de coupe (non fourni)

6 Clé mâle 5 mm

7 Clé de serrage 14 mm

8 Cran de sécurité

9 Régulateur de vitesse

10 Raccord rapide

Utilisation appropriée

• Outil de coupe rotatif alimenté par air comprimé, pour couper le métal ( le

plus souvent des feuilles de métal, boulons et écrous, carrosserie etc… ).

Déballage

• Déballez le produit avec soin. Veillez à retirer tout le matériau

d’emballage et familiarisez-vous avec toutes les caractéristiques du

produit.

• Si des pièces sont endommagées ou manquantes, faites-les réparer ou

remplacer avant d’utiliser l’appareil.

Avant utilisation

Montage du raccord rapide

Remarque : Cet outil est fourni avec deux raccords rapides mâles pour la

conduite d’air :

EQ-4 , généralement utilisé en Europe

EN-6 , utilisé principalement au Royaume-Uni

EQ-4

Europe

EN-6

UK

12

Page 14

598446 Disqueuse droite pneumatique

• Choisissez un raccord rapide compatible avec la conduite d’air utilisée, et

montez- le de la façon suivante :

1. Appliquez une bande de PTFE (non fournie) sur le filetage du raccord

pour conserver une meilleure étanchéité. Les conduites d’air pourvues

d’un raccord ¼” coordonné s’emmancheront par simple pression sur

le raccord de l’appareil.

Remarque : appliquez la bande PFTE en la serrant bien et dans le sens

horaire pour que la bande reste bien en place lorsque le raccord sera vissez

sur l’appareil.

2. Retirez le bouchon protecteur de l’arrivée d’air

3. En utilisant une clé (non fournie), vissez le raccord rapide sur l’arrivée

d’air située sur la base de la poignée.

4. Alimentez le circuit d’air en pressurisant avec précaution, et vérifiez

qu’il n’y pas de fuite (par exemple en vaporisant un peu d’eau

savonneuse sur les raccords).

• Les conduites d’air avec des raccords rapides femelles peuvent s’insérer

maintenant sur l’appareil.

Connexion de l’air comprimé

COUPLEUR OUTIL

PNEUMATIQUE

• Cet outil doit être branché à une alimentation en air comprimé propre et

sec, pourvue d’un graisseur en ligne et d’un séparateur d’eau.

• Ne laissez pas la pression d’alimentation dépasser la pression maximale

spécifiée. (Voir caractéristiques techniques).

RACCORD

TUYAU DE

RACCORDEMENT

SÉPARATION DE L’EAU

RACCORD RAPIDE

FLEXIBLE SERPENTIN

MAMELON

GRAISSEUR

RÉGULATEUR

A PURGER

QUOTIDIENNEMENT

ALIMENTATION EN

AIR COMPRIMÉ

• Vérifiez que l’eau soit drainée quotidiennement

• Vérifiez que toutes les parties du système (tuyaux, coupleurs, etc) soient

adaptés à l’air comprimé utilisé.

Réglage de la puissance

• La vitesse/puissance peut être réglée en augmentant ou en réduisant la

pression de l’air fournie en fonction des ‘caractéristiques techniques’.

• Lors de l’utilisation de l’appareil, la vitesse peut se contrôler grâce à la

gâchette (9)

Montage du disque de coupe

Attention : Débranchez toujours l’appareil de l’alimentation en air avant de

monter ou démonter un disque de coupe

1. Placez la clé (7) sur l’arbre (3) en s’assurant qu’elle soit bien sur les

deux faces plates (voir Fig.B). L’arbre doit être maintenu de sorte qu’il

ne tourne pas.

2. Utilisez la clé à 6 pans pour dévisser le boulon et la bride (4)

3. Enlevez le disc s’il est en place

4. Montez le nouveau disque ayant une taille adéquate (voir

caractéristiques techniques), en suivant les instructions du fabricant

pour le sens de rotation.

Remarque : Sauf indiqué, la bague métallique au centre du disque doit faire

face à l ‘arbre (3).

5. Réassemblez le boulon et la bride(4) dans le bon sens (voir Fig.A), en

s’assurant que cet ensemble ne soit pas déformé, voilé, entaillé, et

resserrez avec la clé à six pans.

ATTENTION : une bride endommagée peut exercer une pression irrégulière

sur le disque et se casser

ATTENTION : Ne sur- serrez pas. Le sens de rotation empêchera le boulon

de devenir lâche.

6. Faites tourner le disque manuellement et vérifiez qu’il soit bien fixé et

correctement aligné.

Serrez

Fig.B

Desserrez

Arbre

Serrez

Desserrez

Réglage de la protection

Remarque : Inspectez la protection avant utilisation, et remplacez-le si

endommagé.

ATTENTION : L’appareil ne doit utiliser sans la protection en place et

correctement positionnée.

• Selon la tâche à effectuer et l’angle de travail, la position de la protection

doit être réglée de sorte qu’elle se trouve entre le disque et l’utilisateur.

1. Utilisez la clé à six pans pour desserrer la vis de fixation.

2. Réglez la position et resserrez la vis.

ATTENTION : Ne pas sur-serrer, cela peut endommager la protection.

Instruction d’utilisation

ATTENTION : Ne pas mettre en marche ou éteindre l’appareil lorsque le

disque est en contact avec la pièce de travail. Laissez toujours le moteur

atteindre sa vitesse maximale avant de commencer à travailler, et attendez

toujours son arrêt complet avant de reposer la disqueuse. Tenez toujours

l’appareil fermement, avec les deux mains sur les poignées.

Remarque : Ne pas exercer trop de pression sur l’appareil lors du meulage.

Une pression excessive n’enlève pas plus rapidement le matériau, mais cela

usera plus rapidement le disque et l’appareil.

ATTENTION : Cet outil est un appareil de coupe uniquement. N’essayez pas

de l’utiliser pour meuler de côté, car cela pourrait faire éclater le disque.

1. Maintenez l’appareil par sa poignée (1) et tournez-le de sorte que

l’ouverture de la protection (2) ne soit pas dirigée vers vous. Votre

pouce doit être placé autour de la poignée de l’appareil (1) et les

doigts doivent être sur la gâchette de contrôle de la vitesse (9).

2. Désenclenchez le cran de sécurité (1), et appuyez sur la gâchette.

3. Le disque de coupe commencera à tourner. Appuyez plus sur la

gâchette pour augmenter la vitesse, relâchez légèrement pour la

diminuer.

4. Avec le disque tournant à la vitesse requise, approchez doucement

vers la pièce de travail, et l’amener sur le matériau.

ATTENTION : Lorsque le disque commence à couper, l’outil aura tendance

à aller de côté. Maintenez fermement l’appareil pour contrecarrer se

déplacement.

5. Lors de la coupe, assurez-vous que la poussière et les débris de

matériaux ne soient pas rejetés vers vous ou d’autres personnes, ainsi

qu’à des objets pouvant être endommagés.

6. Pour arrêter l’appareil, retirez l’appareil de la pièce de travail, relâchez

complètement la gâchette pour enclencher le cran de sécurité.

Remarque : Ne laissez pas tourner la clé à cliquet dans le vide pour de

longue période. Cela réduit sa durabilité.

ATTENTION : De l’air comprimé résiduel peut rester dans l’appareil après

utilisation. Purgez toujours l’air de l’appareil après avoir éteint l’alimentation

en air.

www.silverlinetools.com

13

Page 15

F

Accessoires

• Les accessoires de cet appareil, comme les disques de coupes

(633551) sont disponibles depuis votre revendeur Silverline. Des pièces

de rechange peuvent être obtenues également depuis le site www.

toolspareonline.com.

Entretien

ATTENTION : Débranchez toujours l’appareil de l’alimentation en air et

purgez l’air avant de le nettoyer ou de l’entretenir

Nettoyage

• Gardez l’appareil propre. La poussière et la saleté provoquent l’usure

rapide des éléments internes de l’appareil et réduit sa durabilité. Utilisez

une brosse souple ou un chiffon sec pour le nettoyage. Si possible,

nettoyez les orifices de ventilation à l’air comprimé propre et sec

ATTENTION : Débranchez toujours l’appareil de l’alimentation en air et

purgez l’air avant de le nettoyer ou de l’entretenir.

Important : Il est important d’effectuer l’entretien régulier de l’outil pour

éviter que la saleté, humidité provoque la corrosion des éléments internes,

qui pourrait engendrer un mauvais fonctionnement de votre appareil.

Entretien quotidien : L’outil étant débranché de l’alimentation en air,

verser quelques gouttes d’huile dans la prise d’air. Faites fonctionner l’outil

brièvement à faible vitesse afin de lubrifier tous les éléments internes.

• Si l’appareil est utilisé constamment ou pendant de longues périodes

d’affilée, il faut l’équiper d’un filtre/lubrificateur combiné. Un filtre à air

doit être installé en permanence.

• Utiliser de l’huile pour air comprimé : N’UTILISEZ EN AUCUN CAS DE

L’HUILE MOTEUR CLASSIQUE.

• Le non-respect des instructions d’utilisation et d’entretien peut annuler

la garantie.

Rangement

Ranger cet outil dans un endroit sûr, sec et hors portée des enfants

Recyclage

• Comme tous les autres outils électroportatifs, les outils à air comprimé

ne doivent pas être jetés avec les ordures ménagères.

• Les outils à air comprimé contiennent de l’huile et lubrifiants et doivent

donc être recyclés en conséquence.

• Contactez les autorités locales compétentes en matière de gestion des

déchets pour vous informer de la procédure à suivre pour recycler les

outils électriques et à air comprimé

En cas de problème

Problème Cause possible Solution

Pression incorrecte Réglez la pression d’air en fonction des caractéristiques techniques

Saleté dans le mécanisme Versez de l’huile dans l’arrivée d’air selon les instructions d’entretien

Lenteur de fonctionnement

Outil grippé

Fortes vibrations lorsque

l’appareil est en marche

L’appareil ne s’arrête plus, même

en relâchant la gâchette

Si les solutions ne donnent aucun résultat, contactez votre revendeur ou un centre de réparation agrée Silverline.

Blocage de l’air Faites fonctionner l’appareil per petits à-coups pour le déboucher

Fuite d’air Vérifiez tous les raccords : resserrez, ou utilisez de la bande PFTE ou

Blocage dans le filtre grillagé à gaze Retirez le raccord rapide et nettoyez le filtre

Saleté ou rouille dans le mécanisme Essayez les solutions de ‘lenteur de fonctionnement’

Saleté ou rouille dans le mécanisme Frappez légèrement l’appareil avec un maillet

Saleté ou rouille dans le mécanisme Débranchez l’alimentation en air et faites tourner le mécanisme à la main

Le disque n’est pas monté correctement Retirez le disque, repérez d’éventuels dommages et remontez le disque

Le disque de coupe est endommagé

(déformations, fissures etc.)

Bride endommagée (voilée ou entaillée) Remplacez la bride

Arbre courbé Faites réparer l’appareil dans un centre agrée Silverline

Le joint torique de la gâchette, ou support du

joint endommagé

remplacez la pièce nécessaire

Remplacez le disque

Faites réparer l’appareil dans un centre agrée Silverline

14

Page 16

598446 Disqueuse droite pneumatique

Garantie Silverline Tools

Ce produit Silverline bénéficie d’une garantie

de 3 ans

Enregistrez ce produit à www.silverlinetools.com dans les 30 jours suivant

l’achat afin de bénéficier de la garantie de 3 ans. La période de garantie

commence à partir de la date d’achat figurant sur votre facture d’achat.

Enregistrement de votre achat

Visitez silverlinetools.com, sélectionnez le bouton d’enregistrement

et saisissez :

• Vos informations personnelles

• Les informations concernant le produit et l’achat

Vous recevrez le Certificat de garantie en format PDF. Veuillez l’imprimer et

le conserver avec votre achat.

Conditions de Garantie des Outils Silverline

La période de garantie prend effet à compter de la date de l’achat en

magasin, comme indiqué sur votre facture d’achat.

VEUILLEZ CONSERVER VOTRE FACTURE D’ACHAT.

Si ce produit est défectueux pendant les 30 jours qui suivent l’achat,

retournez-le au magasin où vous l’avez acheté, avec votre facture, en

expliquant en détail le problème. Le produit sera remplacé ou vous serez

remboursé(e).

Si ce produit est défectueux après cette période de 30 jours,

retournez-le à :

Silverline Tools Service Centre

PO Box 2988

Yeovil

BA21 1WU, Royaume Uni

Toute demande de service sous garantie doit être soumise pendant la

période de garantie.

Avant toute intervention sous garantie, vous devez présenter la facture

d’achat originale sur laquelle doivent figurer la date d’achat, votre nom,

votre adresse et le lieu d’achat.

Vous devez expliquer en détail la défaillance nécessitant réparation.

Les demandes de service sous garantie faites pendant la période de

garantie seront vérifiées par Silverline Tools pour établir si la défaillance du

produit est liée à un vice de matériau ou de fabrication.

Les frais de port ne seront pas remboursés. Les articles retournés doivent

être convenablement propres et sûrs pour être réparés et devraient être

emballés soigneusement pour éviter tout dommage ou toute blessure

pendant le transport. Nous pouvons refuser les livraisons qui ne sont pas

convenables ou sûres.

Toute intervention sera effectuée par Silverline Tools ou ses agents de

réparation agréés.

La réparation ou le remplacement du produit ne dépassera pas la période

de garantie.

Les anomalies que nous reconnaissons être couvertes par la garantie

seront rectifiées par la réparation de l’outil, sans frais (hormis les

frais de port) ou par son remplacement par un outil en parfait état de

fonctionnement.

Les pièces ou les outils remplacés deviendront la propriété de

Silverline Tools.

La réparation ou le remplacement de votre produit sous garantie vous

apporte des avantages ; ces avantages s’ajoutent à vos droits statutaires

en tant que consommateur sans les affecter aucunement.

La présente garantie couvre:

La réparation du produit, s’il peut être vérifié, à la satisfaction de Silverline

Tools, que les défaillances du produit ont été provoquées par un vice de

matériau ou de fabrication au cours de la période de garantie.

Si une pièce n’est plus disponible ou n’est plus fabriquée, Silverline Tools la

remplacera par une pièce de rechange opérationnelle.

Utilisation de ce produit dans l’UE.

La présente garantie ne couvre pas:

Silverline Tools ne garantit pas les réparations nécessaires du produit

engendrées par :

L’usure normale provoquée par l’utilisation conforme aux instructions

d’utilisation, par exemple les lames, les charbons, les courroies, les

ampoules, les batteries, etc.

Le remplacement de tout accessoire fourni tel que les forêts, les lames, les

feuilles abrasives, les outils de coupes et les autres articles associés.

Les dommages et les défaillances accidentels causés par une utilisation ou

un entretien négligent, une mauvaise utilisation, un manque d’entretien ou

une utilisation ou une manipulation imprudente du produit.

L’utilisation du produit à des fins autres que son utilisation domestique

normale.

Le moindre changement ou la moindre modification du produit.

L’utilisation de pièces et d’accessoires qui ne sont pas des composants

véritables de Silverline Tools.

Une installation défectueuse (sauf si l’installation a été réalisée par

Silverline Tools).

Les réparations ou les modifications réalisées par des tiers autres que

Silverline Tools ou ses agents de réparation agréés.

Les demandes de service autres que le droit de rectifier les défaillances

de l’outil indiquées dans ces conditions de garantie ne sont pas couvertes

par cette garantie.

Déclaration de conformité CE

Le soussigné : Mr Darrell Morris

Autorisé par : Silverline Tools

Déclare que le produit :

Code d’identification : 598446

Description : Disqueuse droite pneumatique

Est conforme aux directives suivantes :

• Directive sur les machines 2006/42/CE

• EN 792-7:2001+A1:2008

Organisme notifié : Intertek Testing Services, Shanghai, China

La documentation technique est conservée par : Silverline Tools

Date : 11/06/13

Signature :

Directeur général

Nom et adresse du fabricant ou de son représentant agréé :

Powerbox International Ltd, Boundary Way, Lufton Trading Estate, Yeovil,

Somerset, BA22 8HZ Royaume-Uni

www.silverlinetools.com

15

Page 17

D

Beschreibung der Symbole

Auf dem Leistungsschild des Werkzeugs sind möglicherweise Symbole

abgebildet. Sie vermitteln wichtige Informationen über das Produkt oder

dienen als Gebrauchsanweisung.

Gehörschutz tragen

Augenschutz tragen

Atemschutz tragen

Kopfschutz tragen

Schutzhandschuhe tragen

Bedienungsanleitung sorgfältig lesen

NICHT mit Pressluftflaschen betreiben

Erfüllt die entsprechenden rechtlichen Vorschriften und

Sicherheitsnormen

Umweltschutz

Druckluftwerkzeuge dürfen nicht über den Haushaltsmüll

entsorgt werden. Geräte enthalten Spuren von Öl und anderen

Schmiermitteln. Nach Möglichkeit bitte über entsprechende

Einrichtungen entsorgen. Lassen Sie sich bezüglich der

sachgemäßen Entsorgung von Druckluftwerkzeugen von der

zuständigen Behörde oder dem Händler beraten.

Technische Daten

Max. Betriebsdruck ......................................6,3 bar (90 psi)

Luftverbrauch ..............................................142 l/min

Druckluftanschluss.................................. ....1⁄4 Zoll BSP; zwei

Bajonett-Schnellkupplungen (EN-6 für Großbritannien und EQ-4 für

Kontinentaleuropa) im Lieferumfang enthalten

Mindestschlauchdurchmesser ..................... 9,5 mm (3⁄8 Zoll)

Leerlaufdrehzahl ..........................................20,000 min

Scheibenabmessungen ...............................75 x 10 x 2 mm

(3-Zoll-Scheiben)

Winkel .........................................................0°

Spindelgewinde: ..........................................M6 (Innengewinde)

Gewicht: ......................................................0,77 kg

Geräusch- und Vibrationsinformationen:

Schalldruckpegel gemäß Maschinenrichtlinie 2006/42/EG:

Schalldruckpegel .........................................LPA = 84 dB(A)

Schallleistungspegel ....................................LWA = 95 dB(A)

Unsicherheit.................................................K = 3 dB

Der Schallintensitätspegel kann für den Bediener 85 dB(A)

übersteigen und Lärmschutzmaßnahmen sind notwendig.

Gesamtvibrationswerte (Triax-Vektorsumme) gemäß

Maschinenrichtlinie 2006/42/EG:

Schwingungsemissionswert ........................ ah = 1,68 m/s

Unsicherheit.................................................K = 1,5 m/s

Aufgrund der fortlaufenden Weiterentwicklung unserer Produkte

können sich die technischen Daten von Silverline-Produkten ohne

vorherige Ankündigung ändern.

-1

2

2

Schall und Vibrationen

Die in den Technischen Daten angegebenen Geräusch- und

Vibrationsinformationen werden nach ISO 28927-3 bestimmt. Diese

Angaben können zum Vergleich ähnlicher Werkzeuge dienen, die nach

demselben Standard geprüft wurden. Die Angaben können auch zur

Beurteilung der Schall- und Vibrationsbelastung verwendet werden.

Die angegebenen Werte entsprechen einer normalen Benutzung des

Werkzeugs unter normalen Arbeitsbedingungen. Schlecht gewartete,

falsch montierte und unsachgemäß verwendete Werkzeuge können

erhöhte Schallpegel und Vibrationswerte aufweisen. Bei der Bestimmung

der Gesamtverwendungsdauer des Werkzeugs müssen Ruhe- und

Stillstandzeiten berücksichtigt werden. Planen Sie regelmäßige

Arbeitspausen bei der Verwendung dieses Werkzeuges ein.

Es liegt im Interesse des Benutzers, seine eigene Sicherheit durch

Tragen angemessener persönlicher Schutzausrüstung zu erhöhen,

einschließlich Gehörschutz gegen lauten und wiederholten Lärm sowie

Anti-Vibrationshandschuhen zur Verringerung der Vibrationsbelastung.

Verwenden Sie dieses Werkzeug nicht mit kalten Händen, da Vibrationen

bei Temperaturen unter dem individuellen Komfortbereich eine stärkere

Wirkung zeigen.

Schall

Die Lärmschutzrichtlinie wurde zur Gewährleistung der Arbeitssicherheit

und zum Schutz der Gesundheit vor Auswirkungen oder wahrscheinlichen

Auswirkungen von Schallbelastung und Hörverlust eingeführt. Diese

Richtlinie definiert Schallbelastung und physikalische Parameter wie

Spitzenschalldruck sowie Tages- und Wochenbelastungswerte. Besondere

Aufmerksamkeit gilt dem Belastungsgrad und der Belastungsdauer. Weitere

Informationen zu den Lärmschutzrichtlinien 2003/10/EG und 2000/14/

EG finden Sie auf den Seiten der Europäischen Agentur für Sicherheit und

Gesundheitsschutz am Arbeitsplatz: www.osha.europa.eu.

Vibrationen

Die EU-Vibrationsrichtlinie 2002/44/EG wurde zur Kontrolle der

Vibrationsbelastung am Arbeitsplatz eingeführt. Die Richtlinie ermöglicht

es dem Werkzeugbenutzer, auf Kenntnis der Sachlage beruhende

Entscheidungen über seine Arbeitsdauer zu treffen. Personen, die

regelmäßig und über längere Zeiträume hinweg mit vibrationsstarken

Geräten arbeiten, sind einem höheren Erkrankungsrisiko ausgesetzt. Nach

ISO 28927-3 werden Vibrationen in drei Raumrichtungen gemessen,

was unter dem Begriff Triax-Vektorsummen-Bestimmung bekannt ist.

Stellen Sie beim Gebrauch von Geräten mit hoher Vibrationsbelastung

sicher, die zulässigen Belastungsgrenzwerte nicht zu überschreiten.

Weitere Informationen zur EU-Vibrationsrichtlinie finden Sie auf den Seiten

der Europäischen Agentur für Sicherheit und Gesundheitsschutz am

Arbeitsplatz: www.osha.europa.eu.

Allgemeine Sicherheitshinweise

• Lesen Sie diese Sicherheitshinweise zur Vermeidung unterschiedlicher

Gefahrenquellen aufmerksam durch, bevor Sie dieses Werkzeug

installieren, bedienen, reparieren, warten, Zubehörteile anbringen oder

in der Nähe dieses Werkzeuges arbeiten. Nichtbeachtung kann zu

schwerwiegenden Verletzungen führen.

• Dieses Werkzeug darf nur von qualifizierten und in der Bedienung

unterwiesenen Personen installiert, eingestellt und benutzt werden.

• Modifizieren Sie dieses Werkzeug in keinster Weise. Modifikationen

können dazu führen, dass Schutzeinrichtungen nicht effektiv

funktionieren, wodurch das Risiko für den Benutzer erhöht wird.

• Werfen Sie diese Sicherheitsanleitung nicht weg, sondern stellen Sie sie

jedem Benutzer zur Verfügung.

• Benutzen Sie dieses Werkzeug nicht, wenn es in irgendeiner Art

beschädigt ist.

• Werkzeuge müssen regelmäßig darauf inspiziert werden, dass von ISO

11148 vorgeschriebene Kennzeichnungen auf dem Werkzeug angebracht

und noch lesbar sind. Der Arbeitgeber/Benutzer ist dafür verantwortlich,

gegebenenfalls Ersatzbeschriftungen über den Gerätehersteller zu

beziehen.

WARNUNG! Dieses Gerät darf nicht von Personen (wie z.B. Kindern) mit

eingeschränkten körperlichen oder geistigen Fähigkeiten oder von Personen