Page 1

Thank you for choosing this product.

This product is guaranteed to be free of defects in materials and workmanship for a period

of 3 years from the purchase date.

If you experience a problem, return the product direct to us, with the original receipt at :

Silverline Tools Limited

PO Box 2988

Yeovil

BA21 1WU

We do not refund carriage. This guarantee is for Great Britain only and does not affect your

statutor

y rights. As you would expect fair wear and tear are not covered.

Users Manual

Air Brush Kit

Product Code 282460

© June 2005

Page 2

Introduction

Carefully read and understand this manual before using this

product. Keep these instructions with the product for future

reference. Ensure all persons who use and service this product

are acquainted with this manual.

General Safety Instructions

It is important to read and understand your instruction manual and

any label attached to the power tool. Learn its application, as well

as it's limitations and the potential hazards associated with this

power tool. Even when used as prescribed it is not possible to

eliminate all residual risk factors. Use with caution.

Keep guards in position

• Always keep guards in position, in good working order, correctly

adjusted and aligned. Never attempt to use a power tool without

any guard supplied with it.

Remove adjusting keys

• Always check to see that keys and adjusting wrenches are

removed from power tool before turning on.

Clean work area

• Accidents occur where benches and work areas are cluttered or

dirty, floors must be kept clear

slippery due to sawdust or wax.

Dangerous environment

• Do not use power tools in damp or wet conditions, or expose

them to rain. Provide adequate surrounding work space and

keep area well lit. Do not use power tools where there is a risk

of explosion or fire from combustible material, flammable

liquids, flammable gases or dust of an explosive nature. When

using power tools avoid contact with any earthed items such as

pipes, radiators, cookers, refrigerators, metal baths and taps.

Children & Pets

• Children and pets should always be kept at a safe distance

from your work. Make your workshop child-proof. Lock tools

away where children can't get access to them. Remove

batteries from cordless tools.

Don't use excess force.

• Your power tool will give you much better service if you do

not use excessive force when using it.

Use the correct power tool

• Don't force, or attempt to use a power tool for a purpose it was

not designed for. Do not use a small tool to do the job of a

heavy duty tool.

Wear correct clothing and footwear.

• Don't wear loose clothing, neckties or jewellery or other items

which may get caught in moving parts. Wear non-slip footwear,

cover or tie back long hair. Use safety footwear if necessary.

Protect your head

• Wear safety goggles at all times, every day glasses are not

sufficient for eye protection, as lenses are not impact resistant

and could shatter. Use an approved face or dust mask when

operation creates dust. Ensure dust extraction equipment is

functioning and correctly used. Hearing protection should be

used if the sound intensity level for the operator could exceed

85dB(A). Use a hard hat where there is a risk of falling objects

or striking your head on low level obstructions.

Protect yourself from vibration.

• Hand held power tools may produce vibration. Vibration can

cause disease. Gloves to keep the operator warm and dry and

therefore maintain good blood circulation in the fingers may

help.

Secure work

• Always secure work. Where practical use a clamp or vice, it

will allow you to use both hands to operate your power tool.

Keep your balance

• Don't over reach, keep proper footing at all times to ensure

correct balance.

Maintain your power tool

• Keep your power tool in good working order, keep tools

sharp and clean for best and safest performance. Ensure

ventilation holes are kept clean and unrestricted at all times.

Always disconnect

• Before changing tools, always ensure they are disconnected

, avoid working where the floor is

from the power source.

A

void accidental starting

•

Make sure the switch is in the OFF position before plugging

in the mains lead.

Accessories

•

The use of any attachment or accessory other than those

mentioned in this manual could result in damage or injury

use of improper accessories could be dangerous.

Never stand on your power tool

• Standing on your power tool or its stand could cause serious

injury if the tool is tipped or if the cutting tool is accidentally

contacted. Do not store materials above or near the tool so that

it is necessary to stand on the tool or its stand to reach them.

Switch off before connecting.

• Ensure the power tool is switched off before connecting to the

power source. If the power tool stops unexpectedly turn the

power switch to off.

Do not abuse the power cord.

• Be sure your cable/extension cable is properly wired and in

good condition. Always replace a damaged cable/extension

cable or have it repaired by a qualified person before using it.

Never yank or pull the cable to disconnect it from the power

socket. Never carry your power tool by it’s cable. Keep the

cable away from damp, heat, oil, solvents, and sharp edges.

Check for damaged or missing parts.

• Before each use check if any part of the power tool is damaged

or missing, check carefully that it will operate properly and

perform its intended function. Check alignment of moving parts

for binding. Any guard or other part that is damaged should be

correctly repaired or replaced. Do not use if the power switch

does not turn the power on and off. Check any other condition

that may affect the safety of the power tool. DO NOT USE IF

DEFECTIVE.

Direction of feed

• Feed work into a blade or cutter against the direction of rotation

of the blade or cutter only.

Don't leave the tool running unattended

• Always wait until your power tool has come to a complete stop

before leaving it and then disconnect from power source.

. The

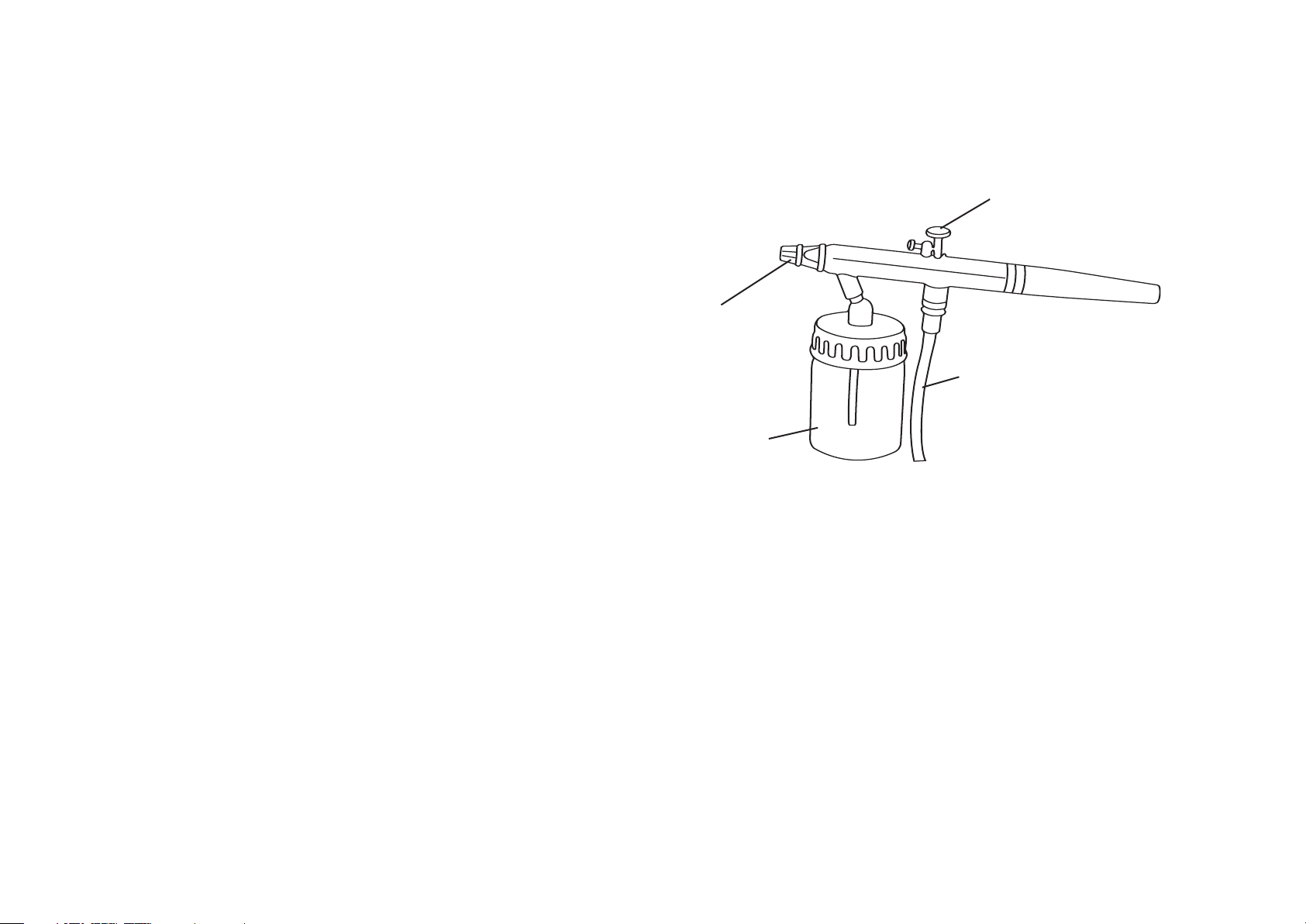

Product Familiarisation

Air Brush Kit

1. Nozzle

2. Finger Lever

3. Air Hose

4. 22cc Paint Bottle

1

4

SPECIFICATION

Nozzle 0.35mm

Capacity 22cc

Average Consumption 0.4-0.7CFM

Air Pressure Required 20-45PSI

ADDITIONAL SAFETY INSTRUCTIONS FOR AIR TOOLS

• Always wear safety goggles or safety glasses.

• Always wear ear protection.

• Always make sure that the machine is switched OFF before

connecting to the air supply.

• Disconnect any machine from the air supply before changing

blades or discs.

• Disconnect any machine from the air supply before performing

any servicing.

• Ensure you keep machines clean and lubricated. Lubrication is

essential to prevent corrosion of internal parts leading to

machine failure.

• Ensure that the machine is oiled daily to prevent corrosion.

Never wear jewellery (not limited to but including. watches,

•

rings, bracelets or necklaces) or loose clothing when operating

air tools.

• Use lightweight coil hoses from the tool to the wall, or

compressor coupling.

• Do not overload the machine. Allowing the machine to work at

its optimum speed prolongs life and is more ef

• Do not increase air pressure above the recommended level,

excessive overload leads to wear of moving parts and possible

tool failure, it can also cause the machine casing to split.

ficient.

2

3

Weight

Min Hose Size 5mm

• Always ensure the machine has fully stopped before putting it

down after use.

• Make sure that the work piece is firmly secured allowing the

operator to control the machine with both hands.

• Ensure that any blades or accessories are rated for use with

the machine.

• Always make sure that blades, discs or other accessories are

correctly secured and fastened before connecting the machine

to an air supply.

• Always fit a whip hose to the air tool.

• Use a straight hose only with spray guns. Do not use coil type

hoses.

• Do not aim the spray gun at people or animals.

• When spraying keep away from heat and naked flames.

• Never spray corrosive or flammable liquids eg. Petrol etc.

Always wear protective equipment including, but not limited to

•

overalls, gloves, facemask etc.

• When spraying it is essential that you have a clean filtered air

supply.

Spray in a well ventilated area or a specialist spray booth.

•

0.7KG

Page 3

OPERA

DO NOT INSTALL

QUICK COUPLING HERE

TO YOUR

AIR TOOL

LEADER HOSE

NIPPLE

QUICK COUPLER

WATER SEPARATION

OILER

NIPPLE

REGULATOR

DRAIN DAILY

AIR SUPPLY

RECOIL HOSE

TING INSTRUCTIONS

Silverline air tools generally operate within a maximum operating

air pressure of 90psi (see specification details).

should be controlled with a combined regulator oil/water filter

ensuring a constant supply of dry air and oil to the machine.

Always check the machines operating pressure and set the

regulator accordingly.

W

ater collects in the compressor tank and this water will cause

serious corrosion to your machines, the tank must be drained on

a daily basis to prevent any water build in the air supply. Dirty

wet air will rapidly corrode the internal working parts of your

machine and shorten its working life significantly

The air pressure

.

Recommended Air Supply

Operation and Use

• Always lubricate the needle with oil at the beginning of the

working day, it will increase working order and durability.

• Never remove the nozzle with pliers always use the correct

size and type of spanner

• Operating pressure is stated in the specification details, perfect

working pressure can vary depending on the density of the

liquid to be sprayed.

• The paint quantity can be adjusted by the needle and by

adjusting the paint control knob.

Filling

Remove the pot from the gun by unscrewing anti-clockwise. Fill

the pot with the desired volume of liquid to be applied. Tightly

screw the pot back on to the gun.

Note. Before connecting the spray gun to the air supply set the

air supply to the correct pressure.

Before spraying mask-up all areas. Avoid taking breaks during

the spraying process as this could allow time for the paint to dry

inside the nozzle and clog the spray gun.

Using Your Air Tool

1. Fill fluid in the cup after thinning appropriately.

2. Hold the airbrush lightly in your hand.

3. By pressing the finger lever, a stream of air emerges. Then

draw it backward gradually for colour atomization.

4. The spray pattern is in accordance with the distance between

the work surface and air brush.

5. For fine line, remove the needle cover and hold the air brush

near the work surface.

MAINTENANCE

1. Empty the fluid cup and wash it out with water.

2. Refill cup with water, then block the needle cover

with a finger and spray. The air flows backward into nozzle,

to clean the paint remaining in the air brush.

TROUBLE SHOOTING

Symptom

Fluttering or spitting. Dry or worn needle

Pattern is an arc. Dust or foreign matter on

Pattern is not evenly

spread.

The centre of the

pattern is too narrow.

Pattern width of fansharp is not enough.

No paint output or very

little.

Problems

packing seat permits air

to seep into fluid passage.

Material container joint

cap leaking.

Packing fluid needle too

loose causing leaking.

air cap clogged horn

holes.

Uneven volume of fluid

from horn holes cause

fluid deviation.

Material builds up on the

outside of the fluid tip or

centre hole or partially

clogs the nozzle orifice.

Loose fluid nozzle

Air pressure is too high.

Material is too thin.

Air pressure is too low

Material too thick.

Fluid passage is clogged

by dirt.

The air holes in the nozzle

of the sprayer are blocked.

Fluid needle stroke is too

small.

Solution

Tighten.

Tighten material

container joint cap.

Tighten or repair them

Remove obstructions

from horn holes or

submerge it in thinner or

suitable solvent and

wipe clean.

Remove obstruction,

never use a wire rod to

unblock the nozzle.

ighten fluid nozzle.

T

Reduce air pressure.

Regulate material

viscosity

.

Increase air pressure.

Regulate material

viscosity

Remove obstructions.

Adjust fluid needle

stroke.

.

.

Loading...

Loading...