Page 1

®

Operating Instructions

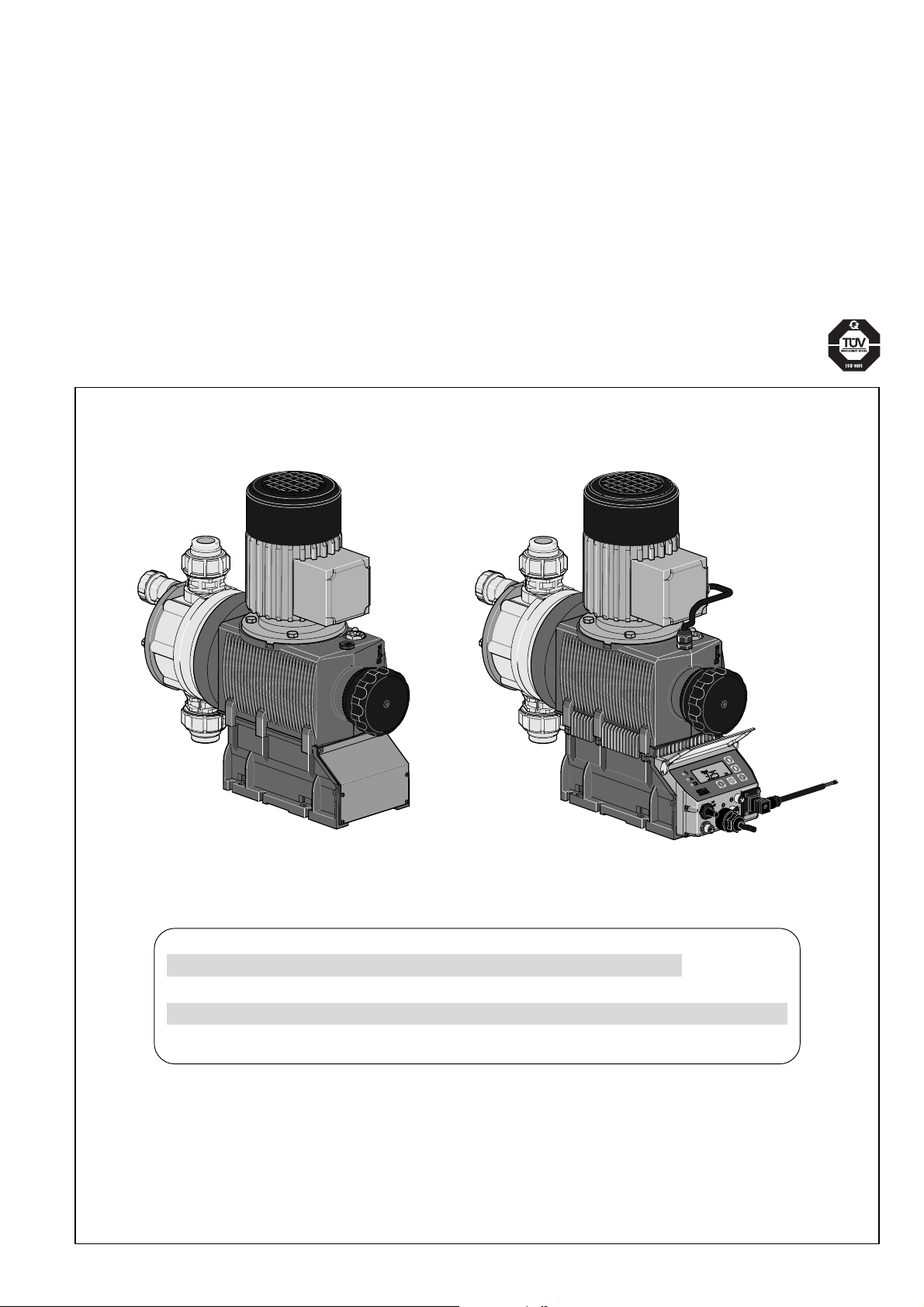

ProMinent® Sigma/ 2

S2Ba (Basic Type)

S2Ca (Control Type)

ProMinent

S2Ba S2Ca

S2Ba

___ ___ ___ ___ ___ ___ ___ ___ ___ ___ ___ ___

S2Ca

___ ___ ___ ___ ___ ___ ___ ___ ___ ___ ___ ___ ___ ___ ___

Please enter the identity code of the device here.

®

Two sets of operating instructions are necessary to ensure the ProMinent

Sigma/ 2 S2Ba or S2Ca metering pumps

are operated safely and reliably for their intended purpose:

This product specific Sigma/ 2 operating instructions manual and the ”General operating instructions

ProMinent

®

motor-driven metering pumps and hydraulic accessories” are only valid if read together!

Please completely read through these operating instructions first! · Do not discard!

The warranty shall be invalidated by damage caused by operating errors!

P

O

T

S

T

R

A

T

S

Part No. 987282 ProMinent Dosiertechnik GmbH · 69123 Heidelberg · Germany BA SI 018 10/03 GB

Page 2

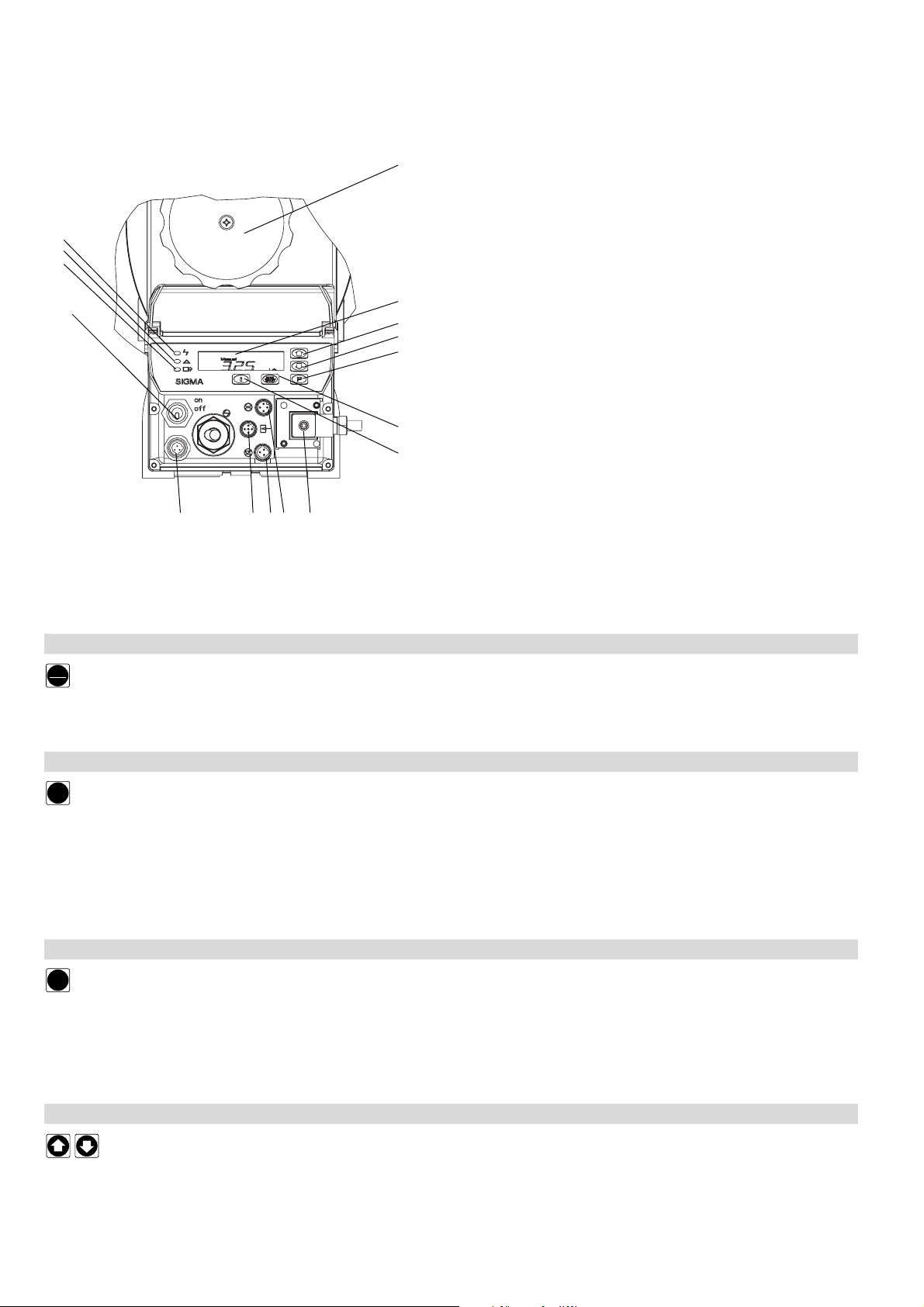

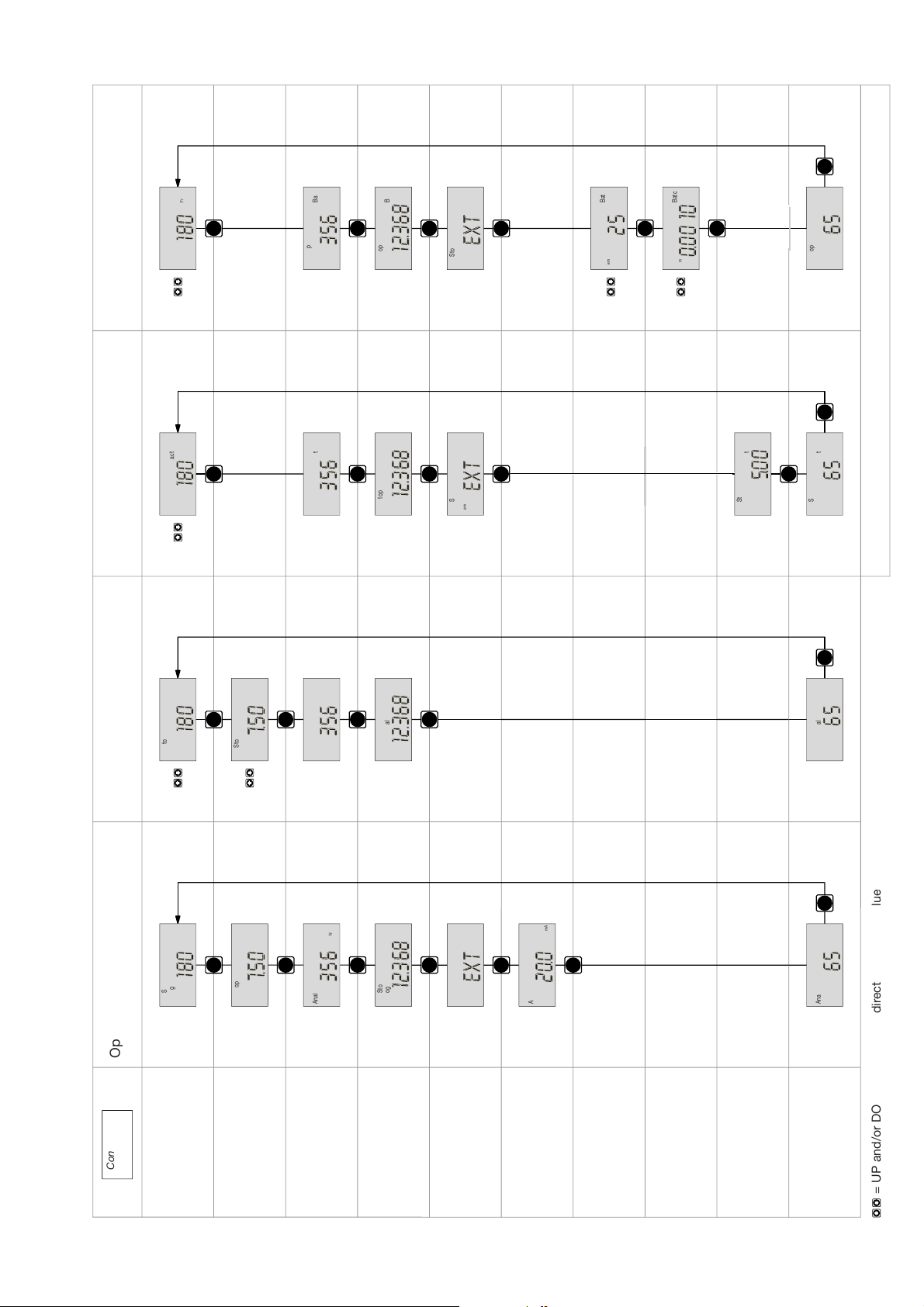

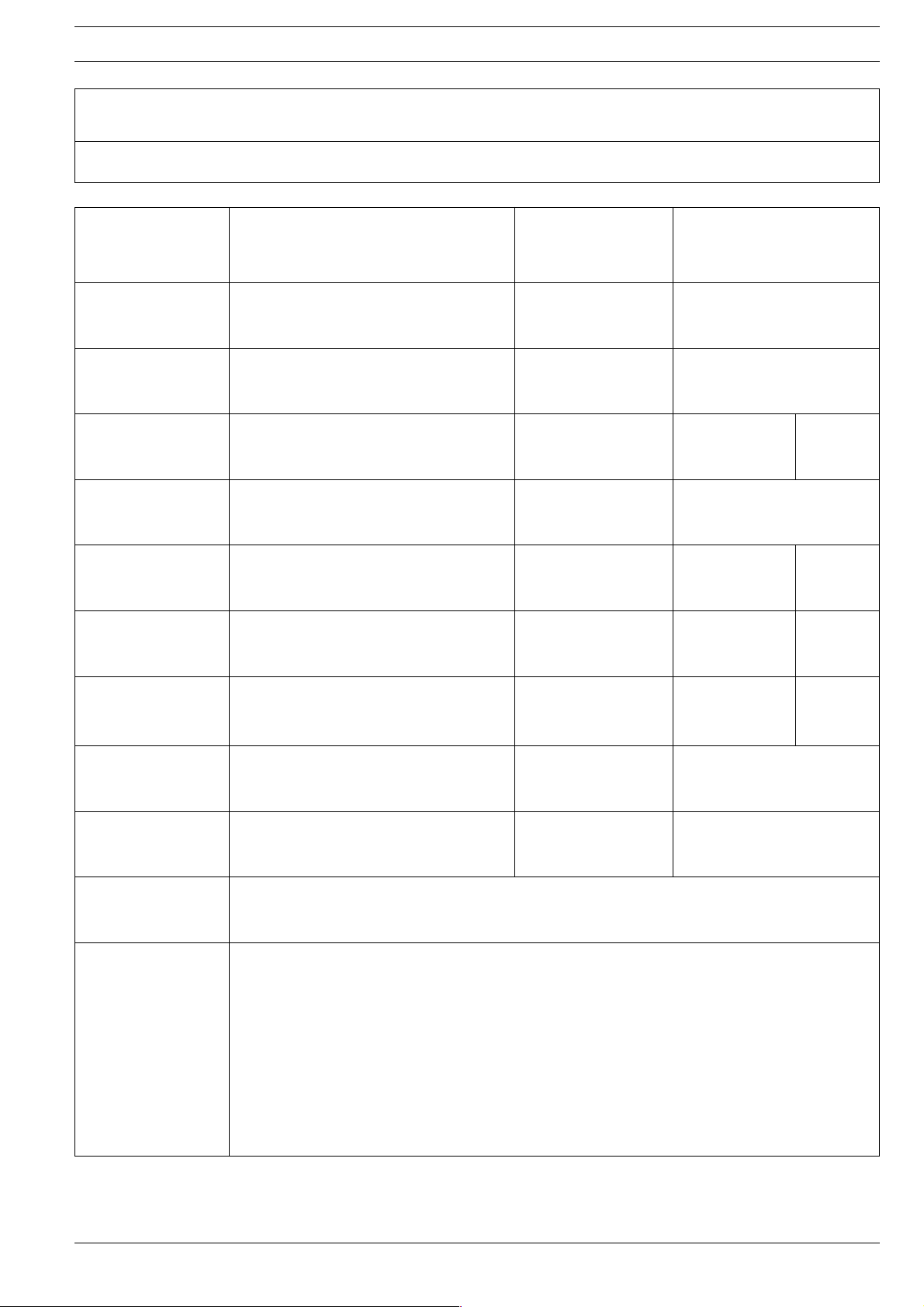

Control elements: overview

3

2

1

16

15 14 13 12 11

Control elements and key functions

4

1 Operating light (green)

5

6

7

8

9

10

2Warning light (yellow)

3 Error warning light (red)

4 Stroke length adjuster

5 LCD display

6 UP key

7 DOWN key

8P key

9 STOP/START key

10 i key

11 Relay output (optional)

12 Metering monitor socket

13 Float switch socket

14 External control socket

15 Diaphragm rupture indicator socket

16 Mains switch

Key functions

In continuous display mode In settings mode

(operating) (settings)

STOP/START key

STOP

START

Press briefly Stop pump, Stop pump,

start pump start pump

P key

P

Press briefly Start batch (in “batch” operating mode only), Confirm entry- jump to next menu

Cancel error option or continuous display

Press for 2 s Change to settings mode --Press for 3 s --- Jump to continuous display

Press for 10 s Software version displayed

Press for 15 s Load factory settings (calibration) ---

i key

i

Press x1 Toggle between continuous displays Toggle between “change individual digits”

and change a figure"

Press x2 --- For “change individual digits”:

jumps to first digit

Arrow keys UP and DOWN

Press separately Change directly alterable values Select other settings,

(until “Set” appears) change individual digit or figure

Press simultaneously Prime (in “stroke rate” permanent display) ---

Page 3

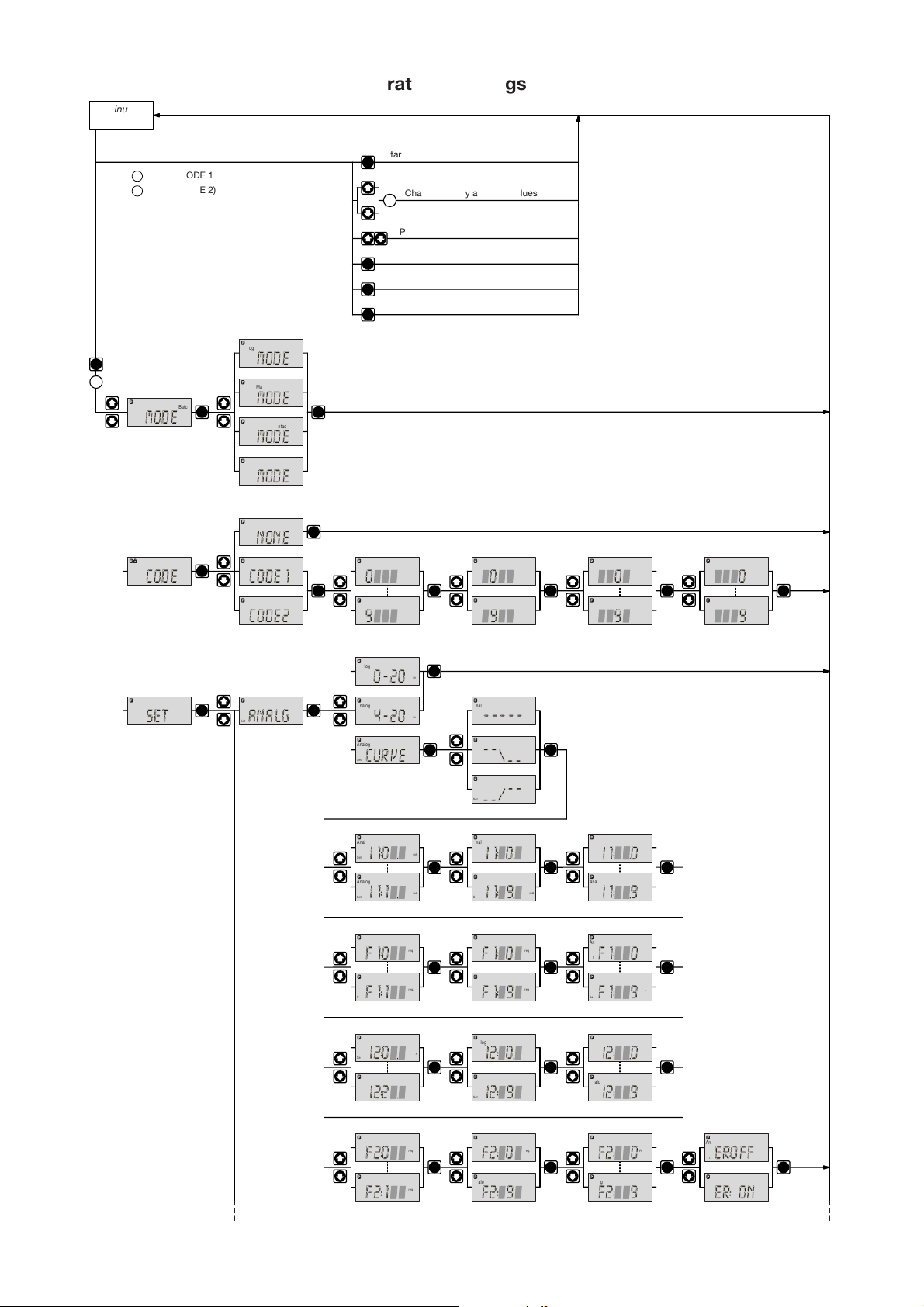

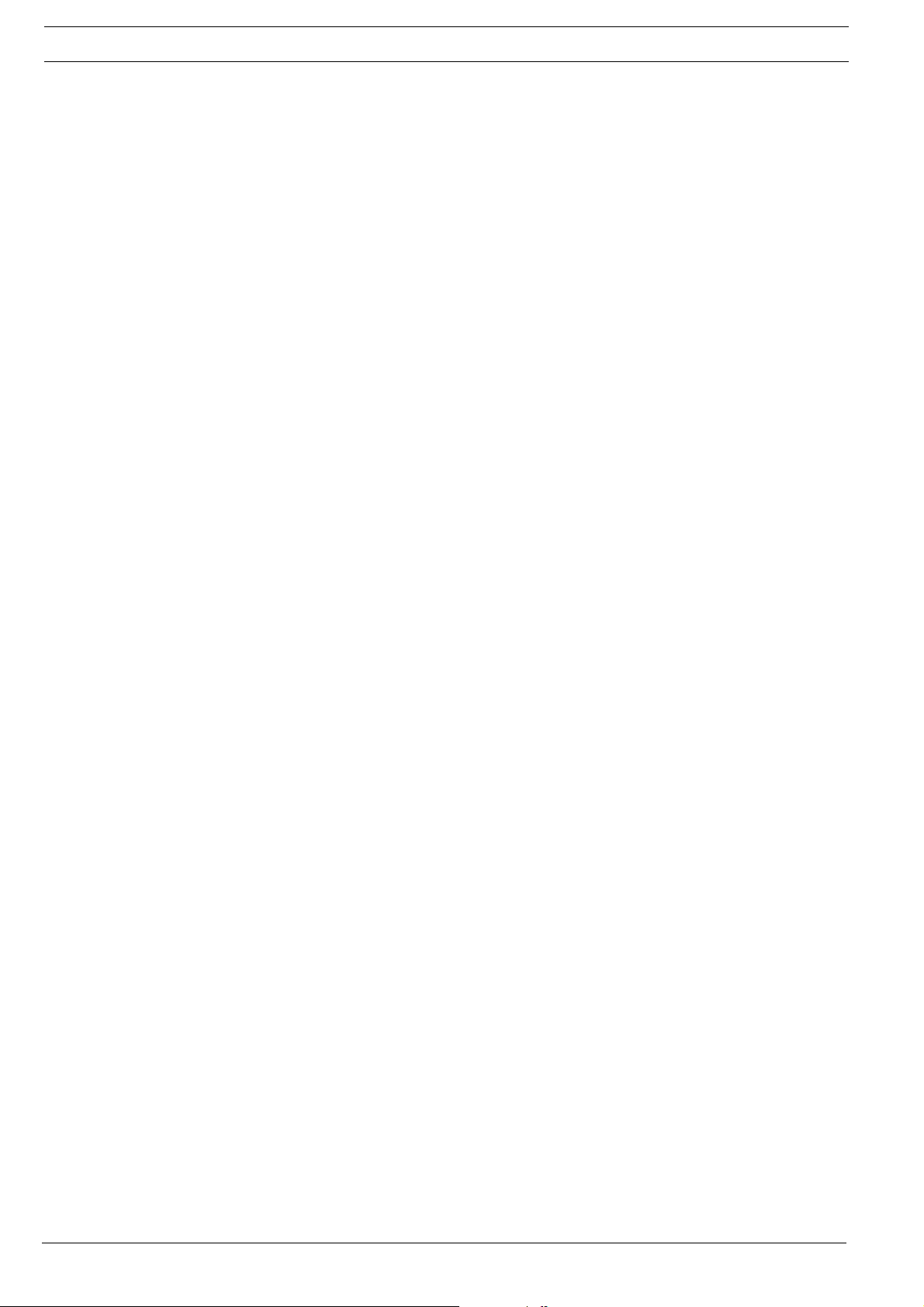

Continuous

display

2 s

P

1

= Lock (CODE 1)

1

= Lock (CODE 2)

2

Batch

ManualAnalog

Contact

edom

p. 44

Analog

edom

Manual

P P

edom

Contact

edom

Batch

edom

enon

Operating-/Settings Diagram

Start/stop pump

STOP

START

Change directly alterable values

2

Prime

Start batch (in"batch" operating mode only)

P

Cancel error

P

Check adjustable values

i

p. 52

Select the operating mode here first,

then carry out the settings in the SET menu.

Exceptions: Timer and PROFIBUS®.

P

p. 51

P

edoc

P

tes

Set

p. 45

1edoc

P

2edoc

P

glana

Analog

Set

Analog

Set

Analog

Set

Analog

Set

Analog

Set

Analog

Set

Analog

Set

0

9

P

0

P

9

P

mA

02o

mA

024

P

evruc

mA

01i

mA

11i

Freq.

01f

Freq.

11f

Analog

Set

-----

Analog

Set

Analog

Set

Analog

Set

P

Analog

Set

Analog

Set

P

Analog

Set

P

mA

01i

P

mA

91i

Freq.

01f

P

Freq.

91f

Analog

Set

Analog

Set

Analog

Set

Analog

Set

0

9

0

P

P

9

mA

01i

P

mA

91i

Freq.

01f

P

Freq.

91f

next page

Analog

Set

Analog

Set

Analog

Set

Analog

Set

mA

02i

mA

22i

Freq.

02f

Freq.

12f

Analog

Set

P

Analog

Set

Analog

Set

P

Analog

Set

mA

02i

mA

92i

Freq.

02f

Freq.

92f

Analog

Set

P

Analog

Set

Analog

Set

P

Analog

Set

mA

02i

P

mA

92i

Freq.

02f

Freq.

92f

Analog

Set

ffore

P

Analog

Set

P

nore

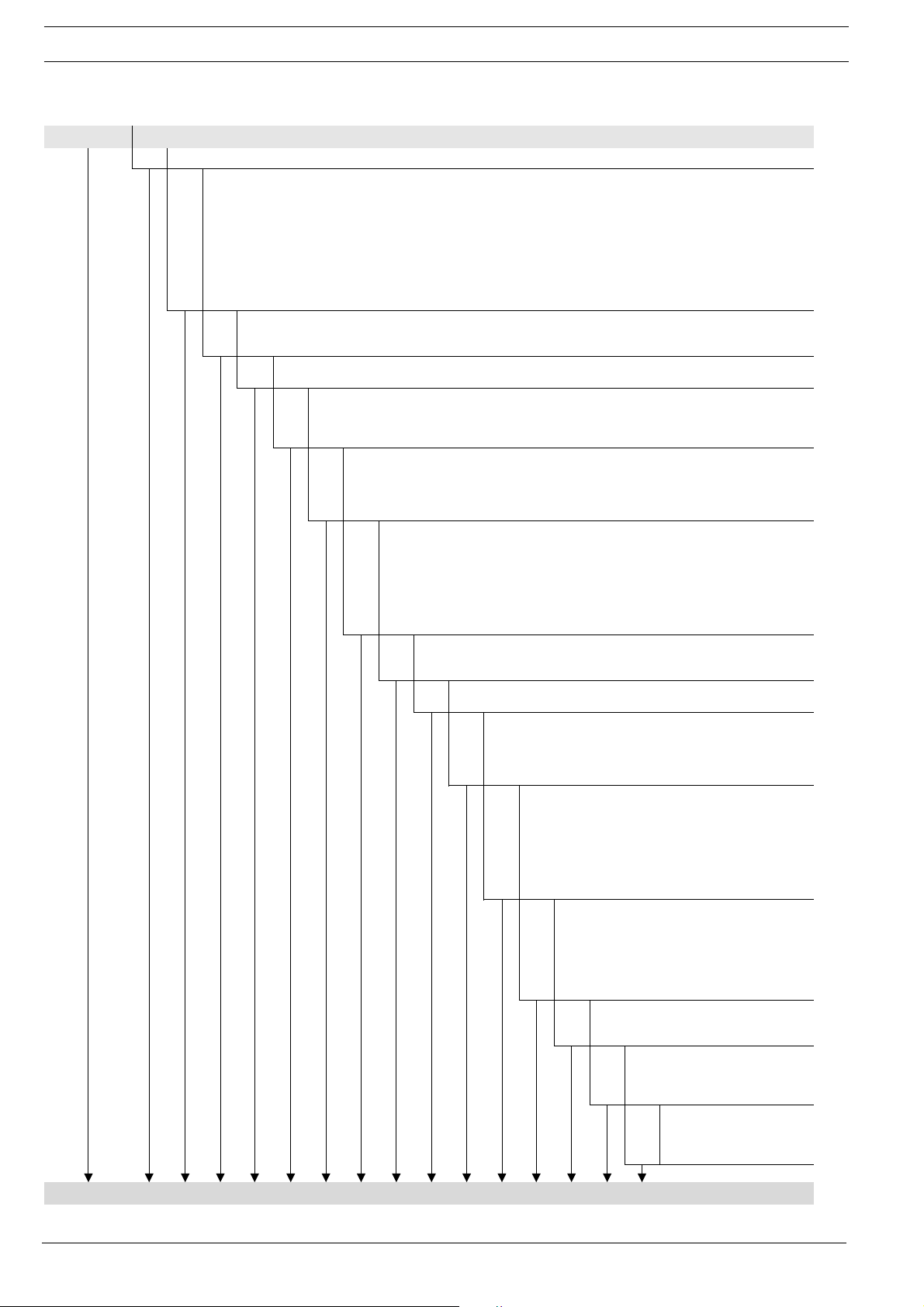

Page 4

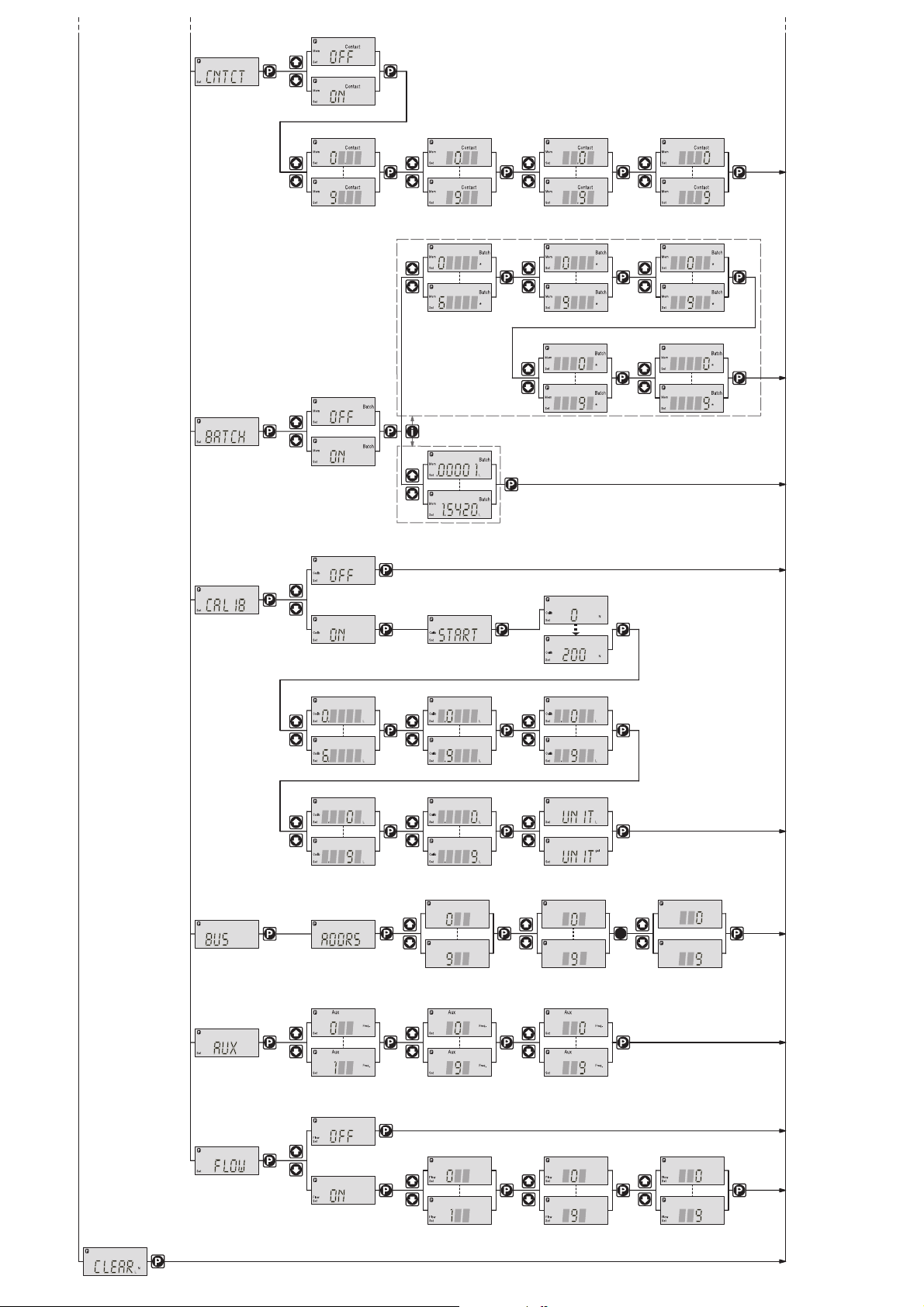

previous page

p. 49

p. 49

Set

p. 50

p. 34

p. 51

Calib

Set

Set

Set

Set

Calib

Set

Set

P

Set

p. 51

p. 51

Page 5

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

#

N

*

Mem

Contact

Stop

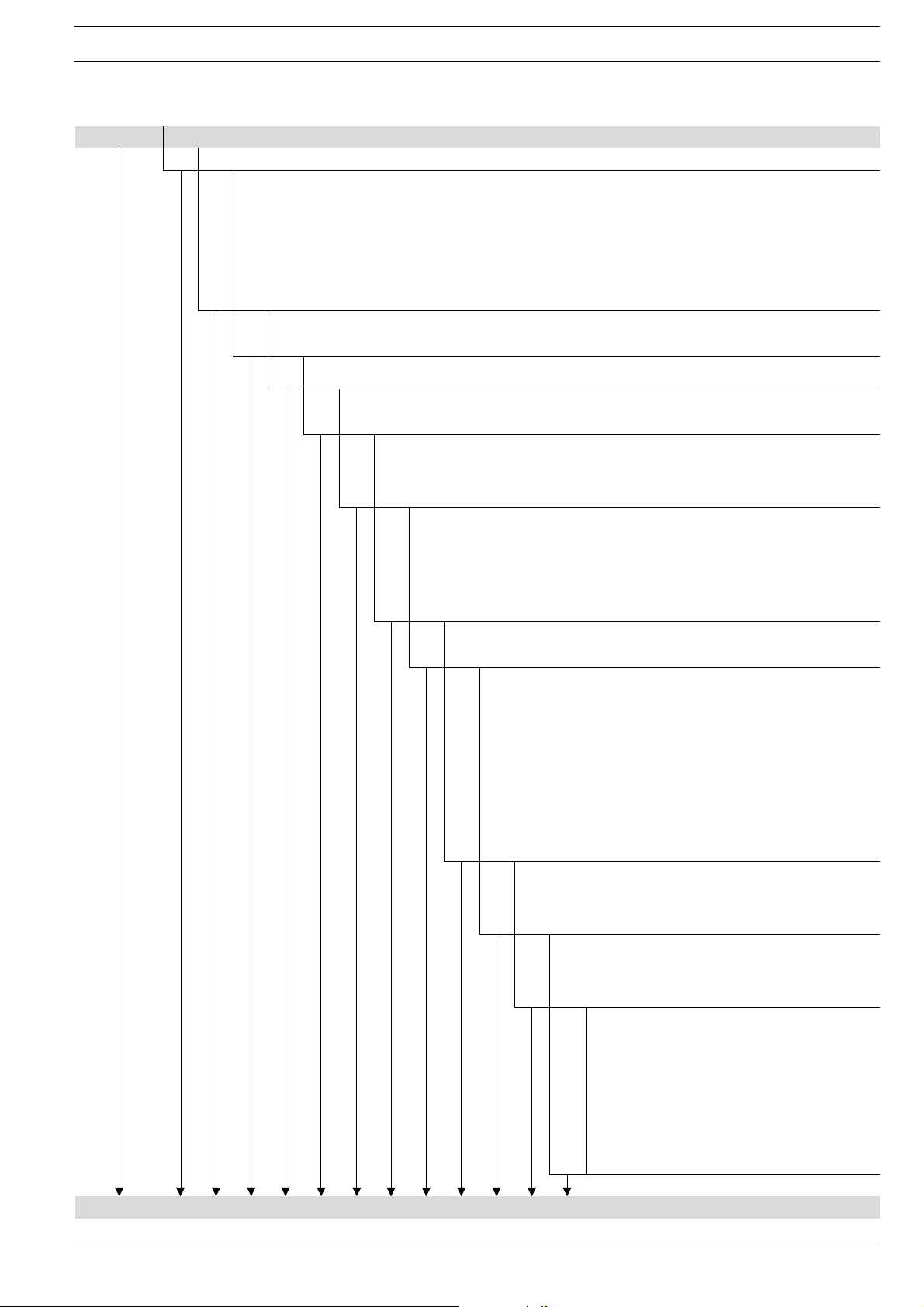

Operating mode "

Analog" 0-20 mA

Stroke rate

Feed rate

To tal stroke number

To tal litres

(feed quantity)

"External" display

Signal current

Strokes remaining

Batch size/

Litres remaining

Factor

"Mem" appears only when "memory" function activated

Stroke length

Operating mode "

Manual"

Continuous display

Operating mode "

Contact" with

memory and tansfer factor 5

Operating mode "

Batch" with

memory and tansfer factor 5

$

#

!

N

Analog

Stop

&$

!

L

Analog

Stop

JN

A

Analog

Stop

mA

Analog

Stop

#$

%

Analog

Stop

#$

%

Manual

Stop

#

$

%

Contact

Stop

#$

%

Batch

Stop

&

Freq.

Manual

Stop

&

Freq.

Contact

Stop

$

#

!

N

Stop

Contact

&

Freq.

Batch

Stop

$

#

!

N

Stop

Batch

#

%

/hL

Manual

Stop

$

#

!

N

Stop

Manual

&$

!

L

Stop

Contact

&$

!

L

Stop

Batch

&$

!

L

Stop

Manual

JN

A

Stop

Contact

Mem

J

N

A

Stop

Batch

Mem

#

N

*

Mem

Batch

Stop

L

*

Mem

Batch

Stop

*

Mem

Batch

Stop

#

*

Mem

Contact

Stop

#

&

Freq.

Analog

Stop

#

%

/hL

Analog

Stop

Continuous

display

= UP and/or DOWN arrow keys, directly alterable values

memory and transfer factor 5

Operating mode ”Batch” with

memory and transfer factor 5

Operating mode ”Contact” with

Page 6

Imprint

Dulcodes UV-Desinfektionsanlage

Page 6

Imprint

®

Operating Instructions for ProMinent

Sigma/ 2 S2Ba/S2Ca

© ProMinent Dosiertechnik GmbH, 2002

ProMinent Dosiertechnik GmbH

Im Schuhmachergewann 5-11

69123 Heidelberg · Germany

info@prominent.de

www.prominent.de

Subject to technical modifications.

ProMinent

®

Page 7

Dulcodes UV-Desinfektionsanlage

1 Notes on safety of ProMinent® metering pumps 11

1.1 Summary of additional safety instructions for the EX version

1.2 General notes 13

1.3 Notes on installation, start-up and operation 13

1.4 Notes on maintenance and repair 14

2Product description S2Ba/S2Ca 15

2.1 Identification of pump type 15

2.2 Design/Functional description 15

Table of contents

Page

Device Identification/Identcode 9

of the pump (in accordance with ATEX) 11

2.2.1 Functional description, drive 15

2.2.2 Stroke movement 16

2.2.3 Metering capacity diagram 17

2.2.4 Functional description, delivery unit 19

2.2.5 Integrated overflow valve with bleeder function 20

2.2.6 Diaphragm rupture sensor 22

3Technical data 25

3.1 Technical data Sigma/ 2 25

3.1.1 Capacity data 25

3.1.2 Dimensions Sigma/ 2 27

3.1.3 Dimensions Sigma/ 2 with stroke adjustment motor 27

3.1.4 Motor data 28

3.1.5 Stroke actuator drive mechanism 28

3.1.6 Stroke adjuster drive mechanism 28

3.1.7 Electrical data, stroke sensor “Sigma” 28

3.1.8 Electrical data, pacing relay “Sigma” 29

3.1.9 Sound intensity level 29

4 Start-up/Maintenance 30

4.1 Start-up 30

4.2 Maintenance 30

4.3 Replacement of wearing parts 31

5 Features of the S2Ca metering pumps 33

5.1 Function description, motors 33

5.2 Function description, controller 33

5.3 Sockets, symbols and wiring diagram 35

5.4 Retrofitting relays 41

ProMinent

®

Page 7

Page 8

Table of contents

Dulcodes UV-Desinfektionsanlage

6 Control elements 42

7 Settings 43

7.1. Check adjustable values 44

7.2 Change to settings mode 44

7.3 Select operating mode (MODE menu) 44

7.4 Settings for operating mode (SET menu) 45

7.4.1 Settings for “manual” operating mode 45

7.4.2 Settings for “analogue” operating mode (ANALG menu) 45

7.4.3 Settings for “contact” operating mode (CONTCT menu) 47

7.4.4 Settings for “batch” operating mode (BATCH menu) 49

7.5 Settings for programmable functions (SET menu) 50

7.5.1 Settings for “calibration” function (CALIB menu) 50

7.5.2 Settings for “auxiliary frequency” function (AUX menu) 51

7.5.3 Settings for the “flow” function (FLOW menu) 51

7.6 Setting code (CODE menu) 51

7.7 Cancel total stroke number or total litres (CLEAR window) 51

8 Operating 52

8.1 Manual operation 52

8.2 Remote control 53

9Troubleshooting 53

10 Decommissioning and disposal 55

11 Spare parts and accessories 56

Annex 57

Motor data sheet 57

EC Declaration of Conformity 58

Exploded diagrams of liquid ends 59

Stroke actuator wiring diagram 63

Wiring diagram, stroke length adjuster 63

Page 8

ProMinent

®

Page 9

Dulcodes UV-Desinfektionsanlage

Dulcodes UV-Desinfektionsanlage

Identcode ordering system

Please enter the identcode on the device label into the grey box below.

S2Ba Sigma Basic Type (S2Ba)

HM Main drive, diaphragm

Pump type: (figures 1+2 = back pressure [bar], figures 3-5 = feed rate [l/h])

16050

16 bar; 50 l/h

16090

16 bar; 90 l/h

16130

16 bar; 130 l/h

12050*

10 bar; 48 l/h

12090*

10 bar; 86 l/h

12030*

10 bar; 125 l/h

07120

7 bar; 120 l/h

07220

7 bar; 220 l/h

04350

4 bar; 350 l/h * for SST versions, max. 12 bar

Liquid end materials:

PV PVDF

SS Stainless steel

Seal material:

T PTFE seal

Diaphragm:

0 Standard diaphragm, PTFE version

1 Double diaphragm with diaphragm rupture indicator (retro fit possible)

Liquid end version:

0 No spring

1 With 2 valve springs, Hastelloy C, 0.1 bar

4 With pressure relief valve, Viton® seal, no valve spring

5 With pressure relief valve, Viton® seal, and valve spring

Hydraulic connection:

0 Standard threaded connector (according to technical data)

1 Union nut and PVC insert

2 Union nut and PP insert

3 Union nut and PVDF insert

4 Union nut and stainless steel insert

7 Union nut and PVDF hose nozzle

8 Union nut and stainless steel hose nozzle

Version:

0 With ProMinent® logo (standard)

1 Without ProMinent® logo

Electrical power supply:

S3 ph, 230 V/400 V 50/60 Hz, 0.18 kW

M1 ph, AC, 230 V/50/60 Hz, 0.18 kW

N1 ph, AC 115 V 60 Hz, 0.18 kW

L3 ph, 230 V/400 V, 50 Hz, (EExe, EExde)

P3 ph, 230 V/400 V, 60 Hz, (EExe, EExde)

R3 ph, variable speed motor, 230/400 V, 0.37 kW

VVariable speed motor with integrated speed control 1 pH,

230 V, 50/60 Hz

Z1 ph, variable speed control set 1 ph, 230 V, 50/60 Hz

1 No motor, with B14 flange (Gr. 71 (DIN))

2 No motor, C 56 flange (NEMA)

3 No motor, B5 Gr. 63 (DIN)

4 No motor, B5, Gr. 70 (DIN)

0 IP 55 (standard)

1 Exe version (II 2G EExe II T3)

2 Exde version (II 2G EExde IIC T4)

AATEX type drive

Identcode ordering system

Motor version:

Stroke sensor:

0 No stroke sensor (standard)

1 with stroke sensor (Hall sensor, no connection cable)

2 Pacing relay (reed relay)

3 Stroke sensor (Namur) intrinsically safe

Stroke length adjustment:

0 Manual (standard)

1 With stroke positioning motor, 230 V/50/60 Hz

2 With stroke positioning motor, 115 V/50/60 Hz

3 With stroke control motor,

0...20 mA 230 V/50/60 Hz

4 With stroke control motor

4...20 mA 230 V/50/60 Hz

5 With stroke control motor

0...20 mA 115 V/50/60 Hz

6 With stroke control motor

4...20 mA 115 V/50/60 Hz

S2Ba ___ ___ ___ ___ ___ ___ ___ ___ ___ ___ ___ ___

Viton® is a registered trademark of DuPont Dow Elastomers.

®

ProMinent

ProMinent

®

Page 9

Page 10

Identcode ordering system

Identcode ordering system

Please enter the identcode on the device label into the grey box below.

S2Ca Sigma Control Type (S2Ca)

HM Power end, diaphragm

Pump typ: (figures 1+2 =back pressure [bar],figures 3-5 =feed rate [l/h])

16050

16 bar; 60 l/h

16090

16 bar; 95 l/h

16130

16 bar; 136 l/h

12050* 10 bar; 60 l/h

12090* 10 bar; 95 l/h

12130* 10 bar; 136 l/h

07120

7 bar; 148 l/h

07220

7 bar; 232 l/h

04350

4 bar; 350 l/h * for SST versions, max. 12 bar

Liquid end materials:

PV PVDF

SS Stainless steel

Seal material:

T PTFE seal

Displacement element:

0 Standard diaphragm

1 Double diaphragm with rupture indicator incorporating “Pump stopping” function

2 Double diaphragm with rupture indicator incorporating “Pump alarm” function

Liquid end version:

0 No springs

1With 2 valve springs,Hastelloy C,0.1 bar

4With relief valve,Viton® seal,no valve spring

5With relief valve,Viton® seal,with valve spring

Hydraulic connection:

0 Standard threaded connector (according to technical data)

1 Union nut and PVC insert

2 Union nut and PP insert

3 Union nut and PVDF insert

4 Union nut and stainless steel insert

7 Union nut and PVDF hose nozzle

8 Union nut and stainless steel hose nozzle

Version:

0 With ProMinent® logo

1 Without ProMinent® logo

Electrical power supply:

U1 ph 100-230 V ±10 %, 50/60 Hz

A2 m European

B2 m Swiss

C2 m Australian

D2 m USA

Dulcodes UV-Desinfektionsanlage

Cable and plug:

Relays:

0 No relay

1 With fault indicating relay (N/C)

3 With fault indicating relay (N/O)

4 As 1 with pacing relay

5 As 3 with pacing relay

F Power relay N/C

G Power relay N/O

Control variant:

0 Manual + external with pulse control

1 Manual + external + pulse control

+ analogue

4 As 0 + process-timer

5 As 1 + process-timer

P PROFIBUS

0 No access code

1 With access code

®

Access code:

Metering monitor:

0 Input with pulse evaluation

1 Input with permanent contact

evaluation

Stroke length

adjustment:

0 Manual

C Manual + calibration

S2Ca ___ ___ ___ ___ ___ ___ ___ ___ ___ ___ ___ ___ ___ ___ ___

Viton® is a registered trademark of DuPont Dow Elastomers.

Page 10

ProMinent

®

Page 11

Dulcodes UV-Desinfektionsanlage

1 Notes on safety of ProMinent® metering pumps

General user instructions

Please read through the following user instructions carefully! They will help you get the best use

out of the operating instruction manual.

The following are highlighted in the text:

• Enumerations

왘 Instructions

Operating guidelines:

NOTE

Notices are intended to make your work easier.

and safety guidelines:

WARNING

Describes a potentially dangerous situation. If not avoided. could cause fatal or serous

injury.

Notes on safety of ProMinent® metering pumps

CAUTION

Describes a potentially dangerous situation. If not avoided. could cause slight or minor

injury or damage to property.

IMPORTANT

Describes a potentially damaging situation. If not avoided. could cause damage to

property.

®

Please also note the guidelines in “General Operating Instruction Manual for ProMinent

Driven Metering Pumps and Hydraulic Accessories”!

EX-pump only: The nameplates affixed to the title page are identical to those on the pump

supplied to enable clear identification on the correct operating instruction manual for the pump.

Please give the order number and the serial number, which you will find on the nameplates of the

pump itself, in the event of any query or spare part order. This facilitates identification of the

pump.

Motor-

1.1 Summary of additional safety instructions for the EX version

of the pump (in accordance with ATEX)

WARNING

• In explosion-threatened workplaces in zone 1, device category II 2G of explosion group II C

the pump may not be operated without the corresponding rating plate (and the corresponding EC conformity declaration) for pumps for explosion-threatened workplaces in

accordance with guideline 94/9/EC of the European guidelines.

•From July 1st, 2003 on, only pumps with the corresponding marking according to EC-Ex-

directive 94/9 may be used in industrial premises with potentially explosive atmospheres.

The explosion group, category and type of protection shown on the marking must

correspond to or exceed the conditions prevailing in the intended area of application.

• All other uses or modifications are prohibited!

• Pumps may never be operated in explosion-threatened workplaces without a correspond-

ing rating plate (and the corresponding EC conformity declaration) for pumps for

explosion-threatened workplaces.

ProMinent

®

Page 11

Page 12

Notes on safety of ProMinent® metering pumps

• Installations in potentially explosive atmospheres must be inspected by an “accredited

qualified” person. This applies in particular also for intrinsically safe electrical circuits.

• Drive motors must be secured by an appropriate motor protection switch. A motor

protection approved for this application must be used for Ex“e”-motors. (Protection

against heating due to overload)

• Observe all relevant standards e.g. DIN EN 60079, DIN EN 50020, DIN VDE 0165 and/or

DIN VDE 0118 “Installing electrical equipment in explosion-threatened areas”!

• When installing the metering pump, observe the directives for the installation of devices

in explosion-threatened areas, e.g. for Europe the European operator’s guideline 99/92/EC

(ATEX137)*, (in Germany implemented via the new operating safety ordinance (Official

Federal Gazette for 2002, Part 1, No. 70, issued in Bonn 2.10.2002))!

* previously ElexV

• Observe documents supplied with individual electric components!

• On principle, metering pumps in potentially explosive atmospheres must be equipped

with a safety overflow valve at the outlet side of the pump (serves as protection against

overheating due to overload and against sparks produced by shock due to overload

which has led to the breakage drive parts.)

• When using with flammable media:

- Diaphragm pumps with mechanically actuated diaphragm: no additional measures

necessary, however, version with diaphragm rupture indicator, version Ex“i”*, must be

used on principle.

- For all metering pumps for metering inflammable media applies: starting up and

emptying only supervised by a competent person.

- Inflammable media may only be lifted with stainless steel liquid ends. - For exceptional

cases, where this is not possible, also PTFE with carbon may be used, our versions TT_

are made of conductive plastics. In this case, special attention must be paid by the

user due to the lower mechanical stability.

• If using the metering pump for Europe e.g. the European operator’s guideline 99/92/EC*

(ATEX 137**), (in Germany implemented via the new operating safety ordinance (Official

Federal Gazette for 2002, Part 1, No. 70, issued in Bonn 2.10.2002) and the German

dangerous chemicals ordinance))!

* previously Ex Vo, Vb F

** previously ATEX118A

• Observe also all relevant standards e.g. DIN EN 60079-10/14 and DIN EN 50020 for

installations in explosion-threatened areas!

• Note all national directives which apply to the installation!

•Wear parts (diaphragms, bearings etc.) of metering pumps used in potentially explosive

atmospheres must be replaced after having completed 90% of their nominal product life.

• The lubricant supply must be regularly checked for lubricated pumps, for instance by

checking the fill level, visual inspection for leakages etc.

• The proper general function, in particular of the drive, must be safeguarded by regular

inspections (leakages, noises, temperatures, possible discoloration due to excess

temperatures....).

• Use original spare parts should exchange become necessary!

• Check that the pressure relief valve downstream from the pump is functioning correctly!

The pressure relief valve must prevent the gearbox from being overloaded and overheating in explosion-threatened workplaces!

• When cleaning plastic parts, attention must be paid to not generating any electrostatic

charge by rubbing excessively. - see danger sign.

• These measures are the minimum protection measures specified by ProMinent. Should

the user know about any further risks, it is his duty to eliminate them by taking

corresponding measures.

Dulcodes UV-Desinfektionsanlage

Page 12

ProMinent

®

Page 13

Dulcodes UV-Desinfektionsanlage

Safety devices

The following safety notice must be affixed to the pump (with PP, PC and PV liquid ends, acrylic

glass cover, ...)

Because of danger of electrostatical

ignition use damp cloth only

EC conformity declaration / certificates

The EC conformity declaration for pumps for explosion-threatened workplaces is supplied with

the pump (the copy of the EC conformity declaration for the pump itself does not apply to pumps

designed for explosion-threatened workplaces).

The EC conformity declarations, the EC series prototype test reports and the operating manuals

for the individual components are also supplied with the pump.

Notes on safety of ProMinent® metering pumps

ATTENTION

for wiping plastic parts!

1.2 General notes

WARNING

• The equipment/devices may only be used for their intended purpose.

•ProMinent® metering pumps must not be assembled with parts which are not tested and

recommended by ProMinent otherwise this can lead to injury to persons and damage to

property for which no liability will be accepted!

• Pumps must be accessible at all times to facilitate operation and maintenance. Access

points must not be obstructed or blocked!

• Before carrying out any maintenance and repair work always drain off and flush out the

liquid end first if hazardous or unknown metered media are used!

• When metering hazardous or unknown liquids, always wear safety clothing (safety

goggles, gloves, ...) when working on the liquid end!

•You must observe the guidelines in this operating instructions manual and the ”General

operating instructions manual for ProMinent® motor-driven metering pumps and hydraulic

accessoires” on assembly, installation and maintenance!

1.3 Notes on installation, start-up and operation

WARNING

• The metering pump can contain water residue in the liquid end as the result of testing at

the factory!

If handling media which must not come in contact with water, all traces of water must be

removed from the liquid end before start-up! For this purpose, turn the pump through

180˚ and drain off the liquid end then flush with a suitable medium from above via the

intake connection!

• Do not connect mains voltage to the control cable!

• When operating the metering pump against a closed shut-off element on the pressure

side or in the event of pressure peaks during the metering stroke, the system pressure

can reach a multiple of the maximum permissible operating pressure that can consequently cause the pressure line to burst!

•To avoid this situation, an overflow is recommended for the purpose of limiting the

maximum permissible operating pressure of the pump or system.

• Do not connect a metal bypass line to the overflow valve on the PVT delivery unit! This

could cause cracks in the delivery unit!

ProMinent

®

Page 13

Page 14

Notes on safety of ProMinent® metering pumps

IMPORTANT

• Set stroke length only with pump in operation!

• Pull the red plug for venting the gear unit during initial operation of the Sigma/ 2 metering

pump (refer to Fig. 2, item 10)!

NOTE

• The pump must be secured in such a way that no vibrations can occur! The valves of the

liquid end must always be positioned vertically in order to ensure trouble-free operation!

• The intake and delivery lines must always be arranged such as to ensure connection at

the liquid end is free of mechanical stress!

The lines must be secured such that no vibrations can occur!

• Only use the clamping rings and hose sockets intended for the relevant hose diameter as

well as original hoses with the specified hose dimensions and wall thickness otherwise

the stability and durability of the connection will not be guaranteed!

Avoid reducing hose sizes!

Observe the permissible pressure of the hoses!

•A vent with return to the supply tank is advisable when metering extremely aggressive or

hazardous media!

In addition, a shut-off valve should be provided on the delivery or intake side!

Dulcodes UV-Desinfektionsanlage

1.4 Notes on maintenance and repair

WARNING

• Only specially trained and authorized persons are permitted to carry out maintenance on

metering pumps and their peripherals!

• If hazardous or unknown metering media are used, always flush out the liquid end first

before carrying out any maintenance and repair work!

• When metering hazardous or unknown liquids, always wear safety clothing (safety

goggles, gloves, ...) when working on the liquid end!

• Always depressurize the delivery line first before carrying out any work on the pump!

Always discharge and flush liquid end!

Observe safety data sheets for metered liquid!

DANGER

• Disconnect power plug or power supply line before opening the plug!

Isolate relay option if applicable!

Check to ensure power is disconnected!

Secure pump while carrying out repairs to ensure it cannot be switched on unintentionally!

• Pumps for metering radioactive media must not be shipped through standard channels!

NOTE

The metering pump must be in a cleaned condition with the liquid end flushed if returned

for repair!

Page 14

ProMinent

®

Page 15

Dulcodes UV-Desinfektionsanlage

2Product description S2Ba/S2Ca

WARNING

Use for intended purpose

• The pump is designed as a liquid medium metering pump; it serves the purpose of

metering liquid medium within the specified line system!

• In explosion-threatened workplaces in zone 1, device category II 2G of explosion group II

C the pump may not be operated without the corresponding rating plate (and the corresponding EC conformity declaration) for pumps for explosion-threatened workplaces in

accordance with guideline 94/9/EC of the European guidelines.

•From July 1st, 2003 on, only pumps with the corresponding marking according to EC-Exdirective 94/9 may be used in industrial premises with potentially explosive atmospheres.

The explosion group, category and type of protection shown on the marking must

correspond to or exceed the conditions prevailing in the intended area of application.

• Operate the pump only within the conditions described in the technical data!

• General restrictions with regard to viscosity limits, chemical resistance and density must

be observed (refer to ProMinent

• All other applications or conversion are prohibited!

• The pump is not designed to meter gaseous media as well as solids.

• For pumps without EX protection: The pump is not suitable for metering combustible

liquids!

• Pumps may never be operated in explosion-threatened workplaces without a corresponding rating plate (and the corresponding EC conformity declaration) for pumps for

explosion-threatened workplaces.

• Only specifically trained and authorized personnel are permitted to operate the pump!

Product description S2Ba/S2Ca

®

chemical resistance list (catalogue or homepage))!

2.1 Identification of pump type

Fig. 1

The identity code and serial number are given in addition to the standard technical specifications.

These two numbers must always be quoted when making any enquiries as they enable distinct

identification of the type of metering pump.

2.2 Design/Functional description

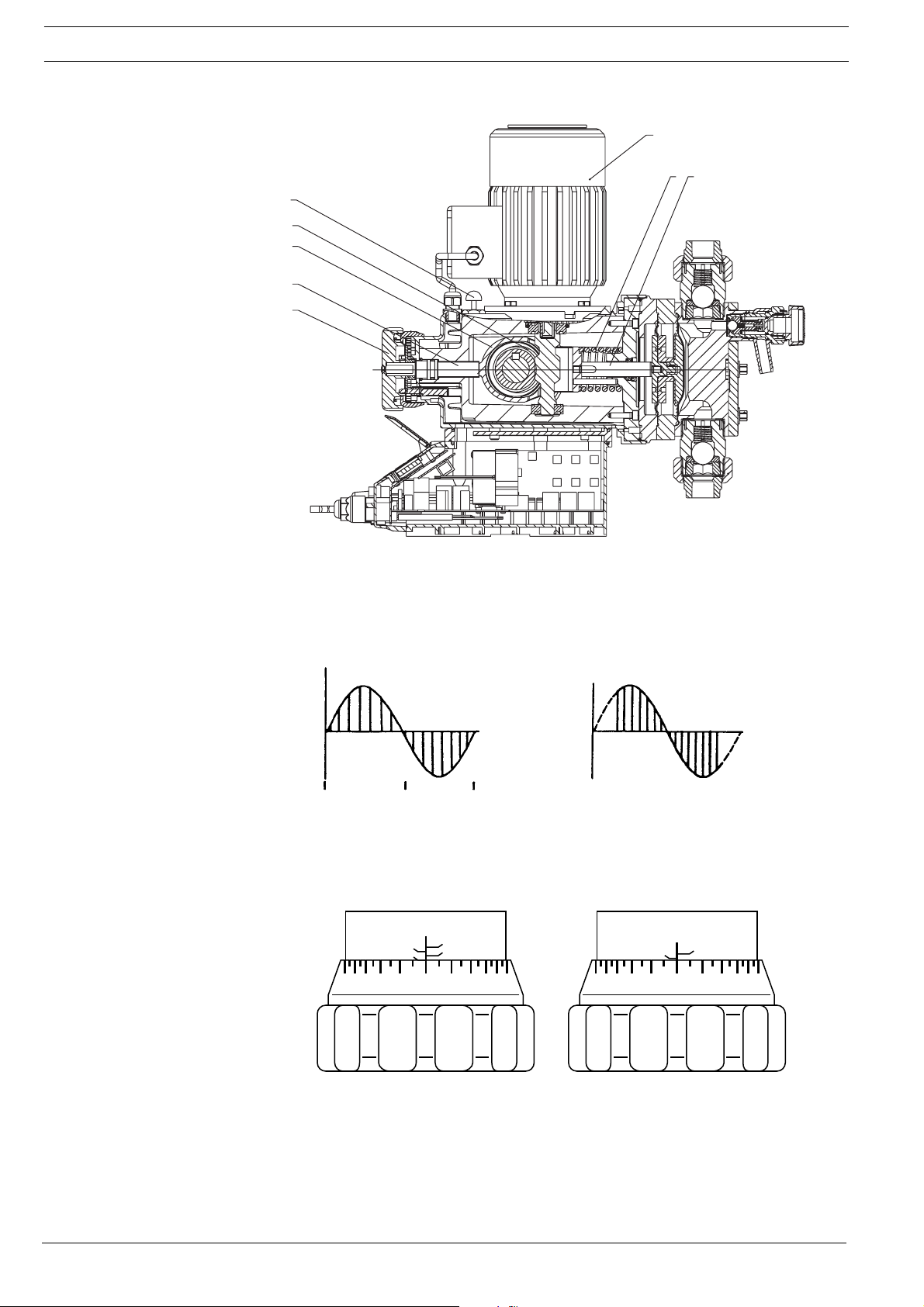

2.2.1 Functional description, drive

The ProMinent® Sigma/ 2 diaphragm-type metering pump is an oscillatory displacement pump

with the stroke length adjustable in steps of 0.5 %. It is driven by electric motor (1). The rotary

drive of the electric motor is stepped down by worm gear and transmitted via the eccentric roller

(3) to the push rod (4) connected to fork (8) and converted into oscillatory movement. Return

spring (5) presses the fork with push rod positively against the eccentric roller thus producing the

return stroke. The stroke is adjusted by means of stroke adjustment knob (6) and spindle (7) by

limiting the return stroke. Stroke movement is transmitted directly to the displacement diaphragm.

Interacting with the valves, this diaphragm produces the overpressure and vacuum in the liquid

end necessary for delivery. Flow is pulsating.

In the basic type, the electric motor is normally a 3-ph extended-range AC motor (refer to Section 3

for other options).

ProMinent

®

Page 15

Page 16

Product description S2Ba/S2Ca

10

3

8

7

6

Dulcodes UV-Desinfektionsanlage

1

5

4

2.2.2 Stroke movement

a) Stroke progression

at max. stroke rate

and stroke length

+ Delivery stroke

– Intake stroke

Stroke speed

0 180 360

Angle reduced stroke length

Set stroke length dependent on the required delivery capacity.

75 %

75%

0

25

50

75

20 0

5

b) At reduced stroke length

0

30 %

30%

25

5

61_01-101_00_25-01

Fig. 2

Fig. 3

0

10

Page 16

NOTE

A large stroke length and low metering frequency should be selected for very viscous

media!

A shorter stroke length and high frequency should be selected to achieve good mixing

properties!

ProMinent

Fig. 4

®

Page 17

Dulcodes UV-Desinfektionsanlage

0

50

100

150

200

250

300

350

400

450

020406080100 120

Q (l/h)

S2Ba HM 04350

S2Ba HM 07220

S2Ba HM 07120

S2Ba HM 12130

S2Ba HM 12090

S2Ba HM 12050

0

50

100

150

200

250

300

350

400

450

500

Q (l/h)

S2Ba HM 04350

S2Ba HM 07220

S2Ba HM 07120

S2Ba HM 12130

S2Ba HM 12090

S2Ba HM 12050

020406080100120

0

50

100

150

200

250

300

350

400

450

500

02468101214

Q (l/h)

S2Ba HM 04350

S2Ba HM 07220

S2Ba HM 07120

S2Ba HM 12130

S2Ba HM 12090

S2Ba HM 12050

0

50

100

150

200

250

300

350

400

450

02468101214

Q (l/h)

S2Ba HM 04350

S2Ba HM 07220

S2Ba HM 07120

S2Ba HM 12130

S2Ba HM 12090

S2Ba HM 12050

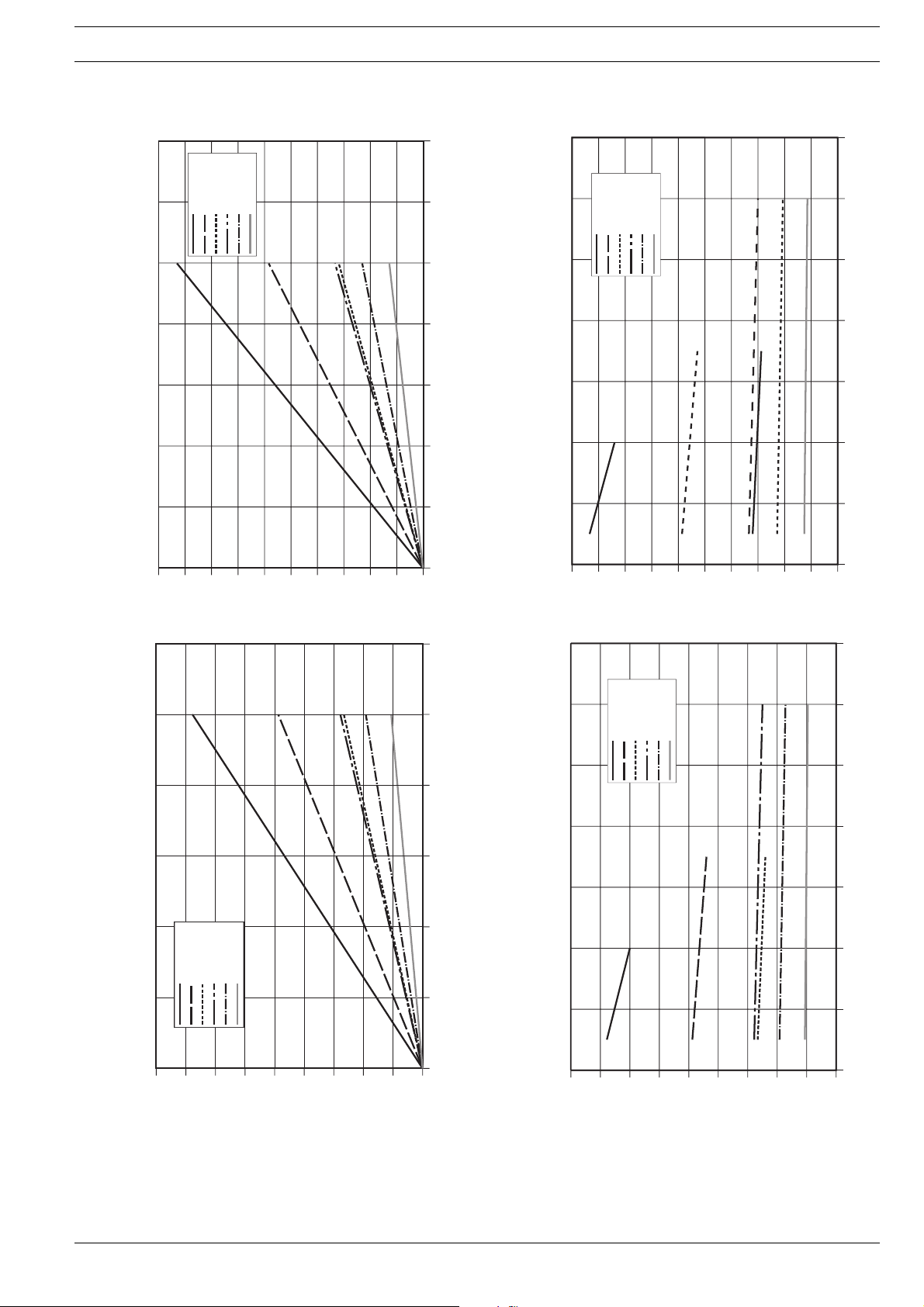

2.2.3 Metering capacity diagram

Product description S2Ba/S2Ca

Metering capacity diagram S2Ba HM (60 Hz)

Stroke length in (%)

pressure in (bar)

Metering capacity diagram S2Ba HM (60 Hz)

ProMinent

Metering capacity diagram S2Ba HM (50 Hz)

®

Stroke length in (%)

pressure in (bar)

Metering capacity diagram S2Ba HM (50 Hz)

Page 17

Page 18

Product description S2Ba/S2Ca

0

50

100

150

200

250

300

350

400

450

02 4 6 8101214

Q (l/h)

S2Ca HM 04350

S2Ca HM 07220

S2Ca HM 07120

S2Ca HM 12130

S2Ca HM 12090

S2Ca HM 12050

16

0

50

100

150

200

250

300

350

400

450

020406080100 120

Q (l/h)

S2Ca HM 04350

S2Ca HM 12130

S2Ca HM 07220

S2Ca HM 12090

S2Ca HM 07120

S2Ca HM 12050

Dulcodes UV-Desinfektionsanlage

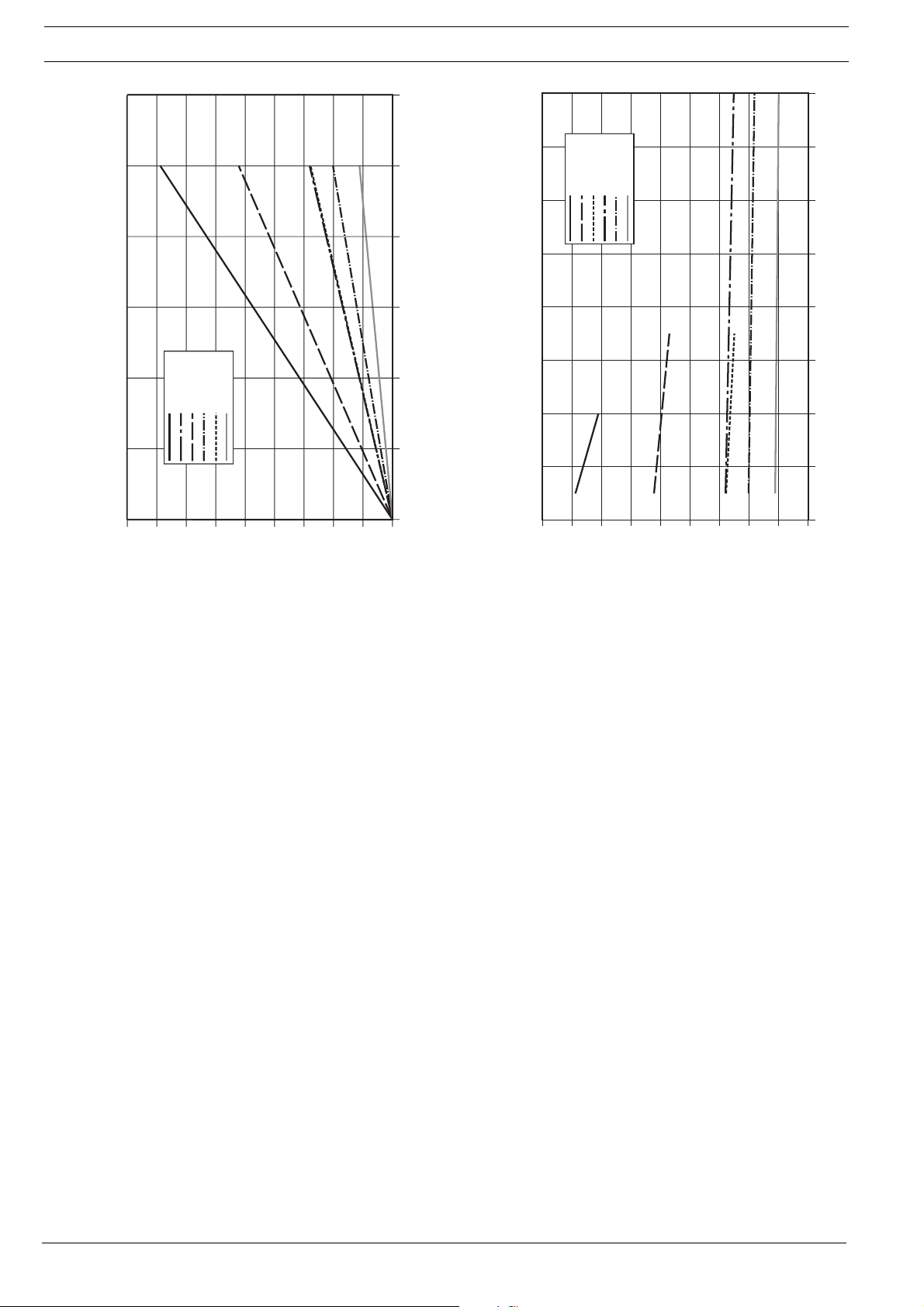

Metering capacity diagram S2Ca HM

Stroke length in (%)

pressure in (bar)

Metering capacity diagram S2Ca HM

Page 18

ProMinent

®

Page 19

Dulcodes UV-Desinfektionsanlage

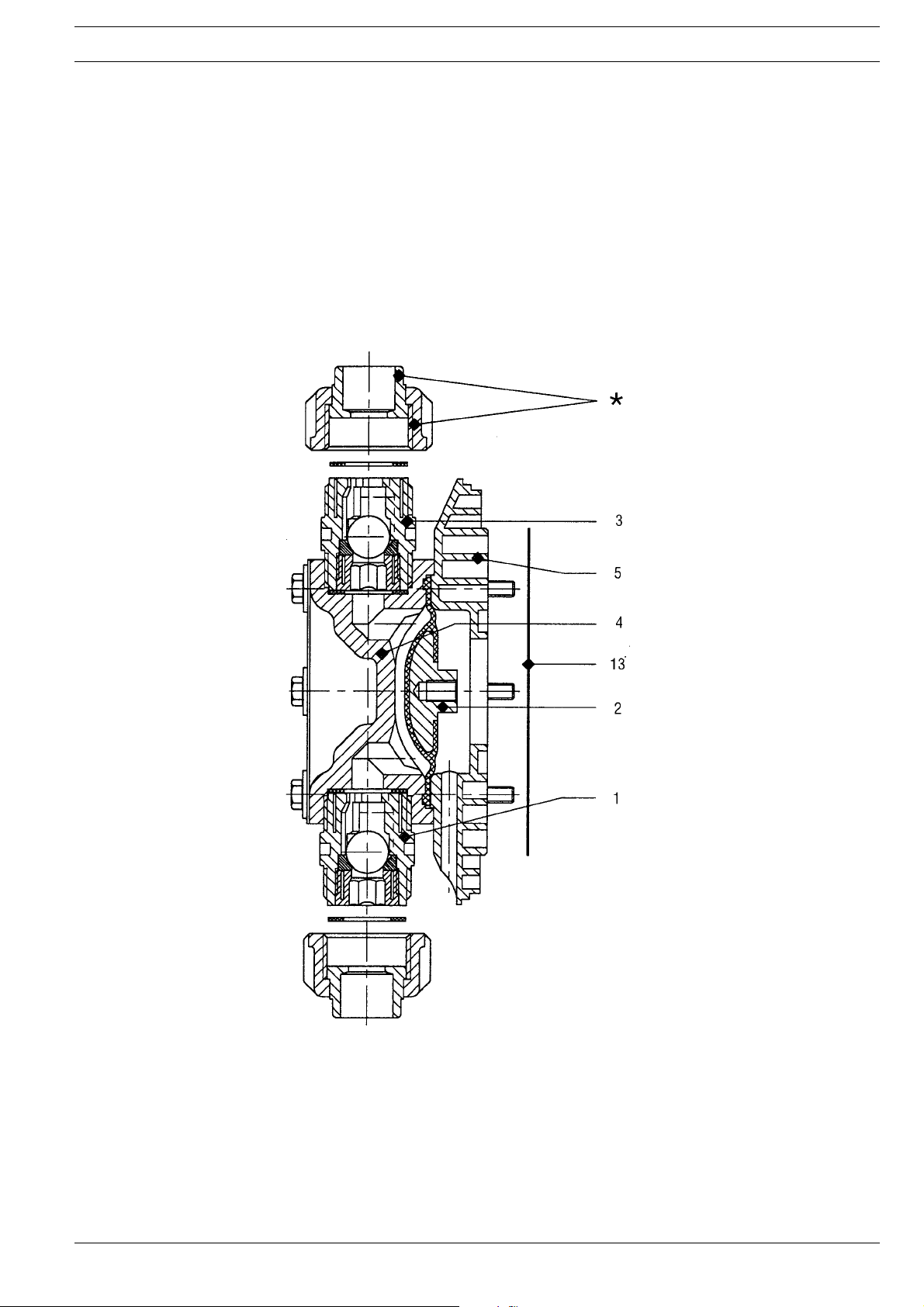

2.2.4 Functional description, delivery unit

The heart of the delivery unit is the DEVELOPAN® metering diaphragm (2). It hermetically seals

the delivery chamber of the liquid end (4) and produces a displacement in the liquid end. The end

disc (5) made of chemically resistant plastic together with safety diaphragm (13) separates the

drive housing from the delivery unit and protects the drive from corrosion in the event of the

diaphragm failing. Delivery is based on the interaction between intake valve (1) and head valve (3)

of the same design together with the diaphragm movement. The valve balls can be supported

with springs for metering viscous media.

The connection dimensions of valves and liquid ends of the same size but with different materials

are identical. These parts can be interchanged as required.

Materials and dimensions are specified in Section 3, Technical data.

Product description S2Ba/S2Ca

ProMinent

Fig. 5

3154-4

®

Page 19

Page 20

Product description S2Ba/S2Ca

2.2.5 Integrated overflow valve with bleeder function

Task:

The task of the overflow valve is to protect the motor and gear unit against impermissible

overpressure caused by the metering pump.

This function is produced by a spring-loaded ball.

A pressure relief mechanism for the bleeder function is provided.

Design and functional description

(refer to Fig. No. 6 and 7)

Initially, the overflow valve illustrated under item 102 operates as a simple directly controlled

safety valve. As soon as the pressure set with spring item 132 is exceeded, the effective pressure

raises ball item 130. The liquid then flows off into the tank via hose connection item 128.

Dulcodes UV-Desinfektionsanlage

134

102

133

137

132

138

139*

111

112

100

110

126

125

127

136

128

130

131

202

203

Overflow valve Sigma/ 2 liquid end, 10 bar PVT Identcode Type: 12050, 12090, 12130

Overflow valve Sigma/ 2 liquid end, 7 bar PVT Identcode Type: 07120, 07220

Overflow valve Sigma/ 2 liquid end, 4 bar PVT Identcode Type: 04350

200

201

117

101

113

116

114

115

118

Fig. 6

3160-4

Page 20

ProMinent

®

Page 21

Dulcodes UV-Desinfektionsanlage

134

102

133

132

138

137

139*

129

126

140

141

125

136

127

128

130

131

202

203

Product description S2Ba/S2Ca

111

112

100

110

200

201

117

101

113

116

114

115

118

Overflow valve Sigma/ 2 liquid end, 16 bar SST Identcode Type: 16050, 16090, 16130

Overflow valve Sigma/ 2 liquid end, 12 bar SST Identcode Type: 12050, 12090, 12130

Overflow valve Sigma/ 2 liquid end, 7 bar SST Identcode Type: 07120, 07220

Overflow valve Sigma/ 2 liquid end, 4 bar SST Identcode Type: 04350

IMPORTANT

• Knob item 139 must be turned in clockwise direction as far as it will go towards ”close“.

• The bypass line must always be closed and must be routed back into the supply tank.

Connection via hose connection item 128.

• Minimal overflow can occur in the bypass line when the valve operates close to the

overpressure function.

The bleeder function is achieved by turning knob item 139 in counterclockwise direction as far as

it will go towards ”open“: Priming aid for starting up pump against pressure. The force of spring

item 132 relieves ball item 130 which is controlled by the lower spring force of bleeder spring

item 133.

IMPORTANT

Once the pump has primed, turn knob item 139 in clockwise direction as far as it will go

towards ”close“! The pump is now operational.

Fig. 7

3161-4

ProMinent

®

Page 21

Page 22

Product description S2Ba/S2Ca

Dulcodes UV-Desinfektionsanlage

Technical data

Corresponding to the type of pump, overflow valves are available for pressure stages p

10, 12 and 16 bar with (1.05 ... 1.15) xp

opening pressure.

nom

nom

Material in contact with metered medium

Material Liquid end Suction/ Seals Balls Springs Integrated

version discharge overload

connector valve

PVT PVDF PVDF PTFE Ceramic / glass* Hastelloy C PDFE/Viton

SST Stainless steel Stainless steel PTFE Stainless steel Hastelloy C Stainless steel/

1.4571/1.4404 1.4581 1.4404 Viton

®

*for 07120, 07220, 04350

Viton® is a registered trademark of DuPont Dow Elastomers.

Use for intended purpose/Use unintended purpose

Use for intended purpose

Protect the dosing pump against unacceptable high overpressure produced by the dosing pump.

Use the overflow value only in connection with liquid with a viscosity of up to max. 200 mPa s.

IMPORTANT

• The ceramic ball and ball seat of the overflow valve are wearing parts. Slight leakage can

occur at the safety valve after a prolonged period of operation. The ball and ball seat

should be replaced if leaks occur.

• The bypass line must always be connected and must be routed back into the supply tank.

Use for unintended purpose

To protect the system from impermissible overpressure.

The pump must not be operated without the bypass line connected.

The bypass line must not be connected in the intake line (the bleeder function will no longer be

guaranteed). The bypass line must be routed back into the supply tank.

4, 7,

®

WARNING

When carrying out maintenance work on the overcurrent valve, pay attention to the

tensioned state of the pressure spring item132! Wear safety goggles!

2.2.6 Diaphragm rupture sensor

Function:

Monitors the seals in the working diaphragm. This liquid end can continue to function for a short

period in emergency mode, i.e. full operating pressure, no leakage, even after diaphragm rupture.

Design and function description (see Fig. 8)

Liquid ends with diaphragm rupture sensors comprise a standard liquid end (item 100) a working

diaphragm (item 200) and an auxiliary diaphragm (item 148) The auxiliary diaphragm is positioned

between the back plate (item 201) and the interim plate (item 147) and forms a sealed

compartment together with the working membrane (item 200).

The leak tightness of the working diaphragm, Item 200, is monitored with a diaphragm failure

detector, Item 104, that triggers a contact signal in the event of diaphragm failure so that the

pump is stopped in the S2Ca and the diaphragm failure is indicated on a LCD.

Page 22

ProMinent

®

Page 23

Dulcodes UV-Desinfektionsanlage

The liquid end can continue to operate in emergency mode, i.e. full operating pressure, no

leakage, even after diaphragm rupture, until the diaphragm has been replaced. We offer two

versions of the S3Ca with diaphragm rupture sensor:

• After a working diaphragm rupture, the pump stops and an ”error“ message/diaphragm sensor

signal is given.

• After a working diaphragm rupture, the pump will continue to run. An ”error“ message/

electrical signal is given.

A function plug is supplied which allows the pump to continue operating after a fault has

occurred (diaphragm rupture, failure of the diaphragm rupture sensor).

WARNING

• EX-pump only: Installations in potentially explosive atmospheres must be inspected by

an “accredited qualified” person. This applies in particular also for intrinsically safe

electrical circuits.

• EX-pump only: observe documents supplied with the sensor!

IMPORTANT

• In the case of the S2Ba, the customer should install a diaphragm rupture signal monitor

and/or ensure that the pump will stop after a diaphragm rupture.

• In the event of diaphragm failure, a contact signal is triggered as from 2 bar system

backpressure.

• Exact pump delivery can no longer be guaranteed after failure of the working diaphragm.

• The auxiliary diaphragm, Item 148, is a wearing part and must be replaced after failure

of the working diaphragm. The diaphragm rupture sensor lens, Item 156, should be

replaced after every diaphragm rupture.

Product description S2Ba/S2Ca

111

112

118

203

204

200

100

110

117

101

113

114

115

103

147

148

149

150

201

159

156

157

155

158

160

104

161

ProMinent

116

FM 130

Identcode Type: 12050, 12090, 12130, 16050, 16090, 16130

FM 350

Identcode Type: 04350, 07120, 07220

®

162

163

Fig. 8

3162-4

Page 23

Page 24

Product description S2Ba/S2Ca

Material in contact with metered medium

Liquid end: Parts of diaphragm failure monitor in contact with medium

PVDF PTFE PVDF

Stainless steel 1.4571 PTFE PVDF

Electrical data for the diaphragm breakage sensor

a) Switch contact

30 V DC/1 A or 125 V AC/0.6 A or 250 V AC/0.3 A

The diaphragm sensor is a N/C relay.

IMPORTANT

Before commencing operation, install the provided diaphragm breakage sensor together

with the gasket (Item159) and make the electrical connections.

NOTE

• For safety reasons it is advisable to connect a safe low voltage (e.g. EN 60335-1 (SELV)).

• The cable priority is arbitrary.

Dulcodes UV-Desinfektionsanlage

Lens, seals Intermediate disc Item 147,

Item 148, 156, 159 intermediate bush Item 150

Blue -

Brown +

b) Namur sensor, intrinsically

5-25 V DC, Namur type and/or DIN 19234, zero volt design.

Rated voltage: 8 V DC (Ri ~ 1 kΩ)

Power consumption:

Active surface, uncovered > 3 mA

Active surface, covered < 2 mA

Rated switching distance: 1.5 mm

The monitor/feeder must be capable of evaluating current changes in order to indicate

diaphragm rupture!

WARNING

• EX-pump only: Installations in potentially explosive atmospheres must be inspected by

an “accredited qualified” person. This applies in particular also for intrinsically safe

electrical circuits.

• EX-pump only: observe documents supplied with the sensor!

IMPORTANT

• Before commencing operation, install the provided diaphragm breakage sensor together

with the gasket (Item159) and make the electrical connections.

• For pump without EX protection: For safety reasons it is advisable to connect a safe low

voltage (e.g. EN 60335-1 (SELV)).

Page 24

ProMinent

®

Page 25

Dulcodes UV-Desinfektionsanlage

Technical data

3Technical data

3.1 Technical data Sigma/ 2

3.1.1 Capacity data

Technical data S2Ba at 50 Hz operation

Feed rate at Max. Suction Admissible Connection Shipping

maximum stroke lift priming suction / weight

back pressure rate pressure discharge

suction side side

Pump type Sigma/ bar l/h ml/stroke strokes/min. m Ws bar G - DN kg

12050 PVT 10 50 11.4 73 7 3 1"-15 15

12050 SST 12 48 11.4 73 7 3 1"-15 20

16050 SST 16 48 11.4 73 7 3 1"-15 20

12090 PVT 10 90 11.4 132 7 3 1"-15 15

12090 SST 12 86 11.4 132 7 3 1"-15 20

16090 SST 16 86 11.4 132 7 3 1"-15 20

12130 PVT 10 130 10.9 198 7 3 1"-15 15

12130 SST 12 125 10.9 198 7 3 1"-15 20

16130 SST 16 125 10.9 198 7 3 1"-15 20

07120 PVT 7 120 27.4 73 5 1 20* 16

07120 SST 7 120 27.4 73 5 1 20* 24

07220 PVT 7 220 27.7 132 5 1 20* 16

07220 SST 7 220 27.7 132 5 1 20* 24

04350 PVT 4 350 29.4 198 5 1 20* 16

04350 SST 4 350 29.4 198 5 1 20* 24

All performance data applies to water at 20 °C.

The suction lift applies when the suction line and liquid end are full and correctly installed.

* Sigma types 07120, 07220 and 04350, the valves used in the liquid end are DN 25 (G1

this tubing (see Technical Data, connection-suction/discharge side) the connector parts to be ordered by Identcode (e.g.

washers) have already been reduced to DN 20, i.e. tubing and accessories can be DN 20.

Technical data S2Ba at 60 Hz operation

Feed rate at Max. Suction Admissible Connection Shipping

maximum stroke lift priming suction / weight

back pressure rate pressure discharge

Pump type Sigma/ bar psi I/h/gph strokes/min. m Ws bar G - DN kg

12050 PVT 10 145 60/ 15.9 87 7 3 1"-15 15

12050 SST 12 174 57/ 15.2 87 7 3 1"-15 20

16050 SST 16 232 57/ 15.2 87 7 3 1"-15 20

12090 PVT 10 145 108/ 28.5 156 7 3 1"-15 15

12090 SST 12 174 103/ 27 156 7 3 1"-15 20

16090 SST 16 232 103/ 27 156 7 3 1"-15 20

12130 PVT 10 145 156/ 41 232 7 3 1"-15 15

12130 SST 12 174 150/ 39.6 232 7 3 1"-15 20

16130 SST 16 232 150/ 39.6 232 7 3 1"-15 20

07120 PVT 7 100 144/ 38 87 5 1 20* 16

07120 SST 7 100 144/ 38 87 5 1 20* 24

07220 PVT 7 100 264/ 69.7 156 5 1 20* 16

07220 SST 7 100 264/ 69.7 156 5 1 20* 24

04350 PVT 4 58 420/ 111 232 5 1 20* 16

04350 SST 4 58 420/ 111 232 5 1 20* 24

All performance data applies to water at 20 °C.

The suction lift applies when the suction line and liquid end are full and correctly installed.

* Sigma types 07120, 07220 and 04350, the valves used in the liquid end are DN 25 (G1

this tubing (see Technical Data, connection-suction/discharge side) the connector parts to be ordered by Identcode (e.g.

washers) have already been reduced to DN 20, i.e. tubing and accessories can be DN 20.

1

/2). Since DN 20 is usually adequate for

suction side side

1

/2). Since DN 20 is usually adequate for

ProMinent

®

Page 25

Page 26

Technical data

Dulcodes UV-Desinfektionsanlage

Technical data S2Ca

Feed rate at Max. Suction Admissible Connection Shipping

maximum stroke lift priming suction / weight

back pressure rate pressure discharge

suction side side

Pump type Sigma/ bar l/h ml/stroke strokes/min. m Ws bar R - DN kg

12050 PVT 10 145 60/ 16 90 7 2 1"-15 17

12050 SST 12 174 60/ 16 90 7 2 1"-15 22

16050 SST 16 232 60/ 16 90 7 2 1"-15 22

12090 PVT 10 145 95/ 25 160 7 2 1"-15 17

12090 SST 12 174 95/ 25 160 7 2 1"-15 22

16090 SST 16 232 95/ 25 160 7 2 1"-15 22

12130 PVT 10 145 136/ 36 200 7 2 1"-15 17

12130 SST 12 174 136/ 36 200 7 2 1"-15 22

16130 SST 16 232 136/ 36 200 7 2 1"-15 22

07120 PVT 7 100 148/ 39 90 5 1 1

1

/2 - 20* 18

07120 SST 7 100 148/ 39 90 5 1 11/2 - 20* 26

07220 PVT 7 100 232/ 61 160 5 1 1

1

/2 - 20* 18

07220 SST 7 100 232/ 61 160 5 1 11/2 - 20* 26

04350 PVT 4 58 350/ 93 200 5 1 11/2 - 20* 18

04350 SST 4 58 350/ 93 200 5 1 1

1

/2 - 20* 26

All performance data applies to water at 20 °C.

The suction lift applies when the suction line and liquid end are full and correctly installed.

* Sigma types 07120, 07220 and 04350, the valves used in the liquid end are DN 25 (G11/2). Since DN 20 is usually adequate for

this tubing (see Technical Data, connection-suction/discharge side) the connector parts to be ordered by Identcode (e.g.

washers) have already been reduced to DN 20, i.e. tubing and accessories can be DN 20.

Materials in contact with chemicals

Material Liquid end Suction/ Seals Balls Springs Integrated

version discharge overload valve

connector

PVT PVDF PVDF PTFE Ceramic / glass* Hastelloy C PDFE/Viton

SST Stainless steel Stainless steel PTFE Stainless steel Hastelloy C Stainless steel/

1.4571/1.4404 1.4581 1.4404 Viton

®

®

* for 07120, 07220 and 04350

Temperature specifications

Permissible storage temperature: –10 to +50 °C

Permissible ambient temperature: –10 to +40 °C

Temperature compatibility (medium temperature) of materials

Material: Long-term at max. Short-term, max. 15 min.

backpressure: at max. 2 bar

PVT 65 °C 100 °C

SST 90 °C 120 °C

The specified temperatures (see above) can be exceeded temporarily, e.g. for sterilisation or

flushing with hot water.

Accuracy

Under constant conditions and in minimum stroke length of 30 % corresponding to following

notes, the reproducibility of the metered quantity is better than ±2 %.

All specifications refer to metered quantities with water at 20 °C and correct installation of the

metering pump.

Page 26

ProMinent

®

Page 27

Dulcodes UV-Desinfektionsanlage

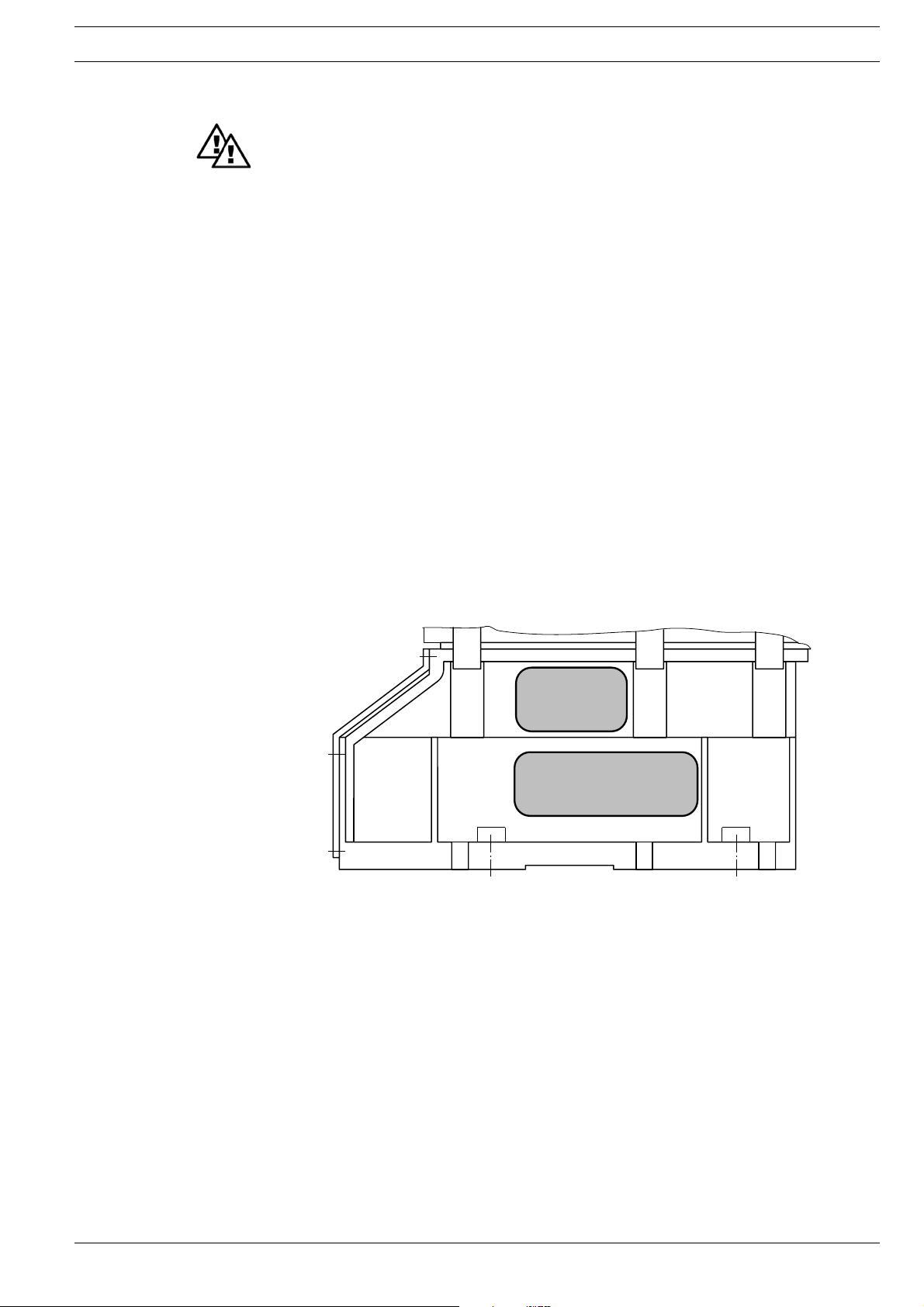

3.1.2 Dimensions Sigma/ 2 (mm)

Technical data

Connection

C

variations

Ø165

B

ØG

A

456/441*

PVDF

PP/PVC/PTFE

185/170*

SS

61_01-101_00_32-73

120

136

+7

28

D/Dl 120

F

Ø 6.5

222

E/El

26.5

79.5

* Dimensions for S2Ba

Model Connector A B C D D1** E E1** F Q G

FM 130 PVT DN 15 265/250* 160 G 1 A 104 124 326/329* 346/349* 82 101

FM 130 SST DN 15 265/250* 160 G 1 A 104 124 326/329* 346/349* 82 101

FM 350 PVT DN 25 304/289* 237 G 1 1/2 A 115 135 337/340* 357/360* 84 148

FM 350 SST DN 25 304/289* 237 G 1 1/2 A 115 135 337/340* 357/360* 84 148

FM 130 = Identcode type 16050,16090,16130 FM 350 = Identcode type 04350,07120,07220

* Dimensions for S2Ba

** Dimensions with diaphragm rupture sensor

Fig. 9

3.1.3 Dimension sheet Sigma/ 2 with stroke adjustment motor

Anschluss-

varianten

218

78

18

100

186

Fig. 10

61_01-101_00_39-73_2_HM

ProMinent

®

Page 27

Page 28

Technical data

Dulcodes UV-Desinfektionsanlage

3.1.4 Motor data

Electrical Data

Motors: Identcode characteristic

3 ph IP 55 230 V/400 V 50 Hz 0.25 kW 1.62/0.94 A S

3 ph IP 55 230 V/400 V 60 Hz 0.25 kW 1.42/0.82 A S

1 ph AC 230 V 50/60 Hz 0.18 kW 1.7/1.5 A M

1 ph AC 115 V 60 Hz 0.18 kW 3.3 A N

3 ph EXe or EXde 230 V/400 V 50 Hz 0.18 kW 1.1/0.7 A L

3 ph EXe or EXde 230 V/400 V 60 Hz 0.18 kW 1.1/0.6 A P

3 ph IP 55 230 V/400 V 50/60 Hz 0.37 kW ...... R Version with external fan

1 PH 230 v; 50/60 Hz and PTC

1 ph IP 55 230 V 50/60 Hz 0.37 kW ..... V Three phase motor with integrated

speed changer, (see chapter 11)

For more details you can request the motor specification sheets. Custom motors and/or custom

motor flanges are available on request.

WARNING

• EX-pump only: Drive motors must be secured by an appropriate motor protection switch.

A motor protection approved for this application must be used for Ex“e”-motors.

(Protection against heating due to overload)

• EX-pump only: motors in EX-areas must be installed and checked by persons with

“recognised skills”!

• EX-pump only: observe the operating manual supplied with the EX motor!

direction

of rotation

Fig. 11

Fuse data

IMPORTANT

• The motors are not fuse-protected. Fit a motor circuit breaker!

When connecting the motor, make sure that it rotates in the correct direction (see Fig. 11

•

Protection against accidental contact and moisture (IP)

Motor: IP 55 DIN EN 60034-5 (in accordance with DIN VDE 0470 Part 1, corresponds to

EN 60529 and IEC 529).

External fan

Notes on the speed-controlled motor with separate fan and temperature monitoring may be

found in the “General Operating Instructions ProMinent

®

Motor-Driven Metering Pumps and

Hydraulic Accessories”.

3.1.5 Stroke actuator drive mechanism

230 V ± 10 % 50/60 Hz 11.7 W

115 V ± 10 % 60 Hz 11.7 W

Cf. “Appendix” for terminal connection diagram.

3.1.6 Stroke adjuster drive mechanism

230 V ± 10 % 50/60 Hz 6.5 W

115 V ± 10 % 60 Hz 6.5 W

).

Page 28

Cf. “Appendix” for terminal connection diagram.

3.1.7 Electrical data, stroke sensor “Sigma”

a) Reed contact (Identcode characteristic “Stroke sensor”: 1)

Pin 1 (white) = 4.5 V to 24 V, max. 10 mA

Pin 2 (brown) = OUT, open collector, 24 V, 20 mA

Pin 3 (green) = GND

Pulse width (low) ≥ 4 ms (depending on gearbox and power frequency)

ProMinent

®

Page 29

Dulcodes UV-Desinfektionsanlage

b) Namur sensor, intrinsically (Identcode characteristic “Stroke sensor”: 3)

WARNING

• EX-pump only: intrinsically safe installations must be installed and checked by persons

with “recognised skills”!

• EX-pump only: observe documents supplied with the sensor!

Technical data

Blue -

Brown +

5-25 V DC, Namur type and/or DIN 19234, zero volt design.

Rated voltage: 8 V DC (R

~ 1 kΩ)

i

Power consumption:

Active surface, uncovered > 3 mA

Active surface, covered < 1 mA

Rated switching distance: 1.5 mm

The monitor/feeder must be capable of evaluating current changes in order to indicate

diaphragm rupture!

3.1.8 Electrical data, pacing relay “Sigma”

Relay input

(power supply for the relay board)

Input voltage Mains frequency Power consumption

200/230 V AC (180-254 V) 50/60 Hz 10 mA (230 V/50 Hz)

100/115 V AC (90-134 V) 50/60 Hz 15 mA (115 V/60 Hz)

24 V DC (20-28 V) - 10 mA at 24 V DC

Relay output

Voltage, max. 24 V DC

Current, max. 100 mA

Hook up duration 100 ms

Standard adjustable

The contacts are zero volt.

3.1.9 Sound intensity level

The sound intensity level is < 70 dB (A)

at maximum stroke, maximum stroking rate, maximum back pressure (water) in accordance with

DIN EN 12639 (noise measurement in fluid pumps)

ProMinent

®

Page 29

Page 30

Start-up/Maintenance

Dulcodes UV-Desinfektionsanlage

4 Start-up/Maintenance

WARNING

• For all metering pumps for metering inflammable media applies: Starting up and

emptying only supervised by a competent person.

IMPORTANT

Observe the safety notes provided in Section 1.

4.1 Start-up

All general guidelines in the accompanying ”General operating instructions ProMinent

®

motordriven metering pumps and hydraulic accessories” apply.

Diaphragm pumps with mechanically actuated diaphragm: no additional measures necessary,

however, version with diaphragm rupture indicator, version Ex“i”*, must be used on principle.

For all metering pumps for metering inflammable media applies: starting up and emptying only

supervised by a competent person.

Inflammable media may only be lifted with stainless steel liquid ends. - For exceptional cases,

where this is not possible, also PTFE with carbon may be used, our versions TT_ are made of

conductive plastics. In this case, special attention must be paid by the user due to the lower

mechanical stability.

4.2 Maintenance

WARNING

• EX-pump only: Wear parts (diaphragms, bearings etc.) of metering pumps used in

potentially explosive atmospheres must be replaced after having completed 90% of their

nominal product life.

• The lubricant supply must be regularly checked for lubricated pumps, for instance by

checking the fill level, visual inspection for leakages etc.

• EX-pump only: check that the pressure relief valve downstream from the pump is

functioning correctly!

The pressure relief valve must prevent the gearbox from being overloaded and

overheating in explosion-threatened workplaces!

• The proper general function, in particular of the drive, must be safeguarded by regular

inspections (leakages, noises, temperatures, possible discoloration due to excess

temperatures....).

• Use original spare parts should exchange become necessary!

• EX-pump only: When cleaning plastic parts, attention must be paid to not generating any

electrostatic charge by rubbing excessively. - see danger sign.

• EX-pump only: metering pumps and their peripheral equipment must be serviced by

specially trained or authorised personnel!

Page 30

IMPORTANT

After loosening the liquid end screws (e.g. to change the valves or diaphragm), the screws

must be retightened clockwise to the specified tightening torque.

What requires maintenance?

• Secure fit of liquid end screws.

• Secure fit of metering lines (intake and delivery sides).

• Secure fit of head valve and intake valve.

• Leakage hole at end disc for moisture (indicates possible diaphragm failure).

• Operate pump continuously for a short period of time in order to check whether it delivers

correctly.

ProMinent

®

Page 31

Dulcodes UV-Desinfektionsanlage

Maintenance intervals

General recommendation for maintenance intervals - every 3 months.

Shorter intervals are recommended if operated under load conditions (e.g. continuous operation).

The gear oil should be changed after approx. 5000 duty hours.

Gear oil ISO viscosity class VG 460, e.g. Mobil Gear 634,

ProMinent Order No. 555325 (Amount of oil approx. 0.5 l).

The metering diaphragm is a wearing part whose service life is dependent on following parameters:

• System backpressure.

• Operating temperature.

• Properties of medium to be metered.

The service life of the diaphragm is restricted in the case of abrasive media. In such cases, it is

recommended to check the diaphragm more frequently and to install a diaphragm failure monitor.

4.3 Replacement of wearing parts

Replacing diaphragm (see exploded diagrams in appendix!)

WARNING

• EX-pump only: metering pumps and their peripheral equipment must be serviced by

specially trained or authorised personnel!

• Always use original spare parts.

Start-up/Maintenance

IMPORTANT

Flush liquid end first in the case of hazardous media. For this purpose, force water or a

suitable flushing agent through the intake connection of the liquid end with a wash bottle.

왘 Set stroke length to zero with the pump running. Switch off pump.

왘 Release the six screws holding the liquid end, detach liquid end together with screws.

왘 Release diaphragm from the push rod by jolting in counterclockwise direction and unscrew.

왘 Screw on new diaphragm until it is firmly seated on the push rod. Mount the dosing head with

screws such that the suction connection lies at the bottom (observe the flow through direction /

arrow marks on the valves). Switch on pump. Set stroke length to 100% and turn in screws

then tighten crosswise to 7.5 ± 0.5 Nm. Check pump for leaks at max. pressure.

ProMinent

®

Page 31

Page 32

Start-up/Maintenance

Dulcodes UV-Desinfektionsanlage

NOTE

The tightening torque of the liquid end screws should be rechecked after 24 hours of

operation.

The tightening torques of the liquid end screws should be checked every 3 months for the

PVT material version.

Fig. 12

GUIDELINE ON VALVE INSTALLATION

In the case of suction problems during installation, place the valves on a firm surface and tap the

PTFE ball seat disk lightly with a brass rod and a hammer weighing about 300 g. Let the valves

operate in the wet state.

approx. 300 g

Brass rod 9 mm diam. x approx. 200 mm

Fig. 13

NOTE

• If suction problems with the pump or leakage at the overcurrent valve are encountered,

first clean the ball and the ball seat disc.

• For media containing particles larger than 0.3 mm it is absolutely essential to install a

filter in the suction line.

Page 32

ProMinent

®

Page 33

Dulcodes UV-Desinfektionsanlage

5 Features of the S2Ca metering pumps

5.1 Function description, motors

The pump has an integrated electronic overload cut-out in all versions. This responds as soon as

the maximum admissible power consumption is reached and stops the motor.

왘 If the motor stops due to a system overload the electronic controller detects the fault and

transmits a message which is displayed on the display panel and at the pump.

왘 The fault signal can be cancelled by pressing the ”P“ key, altering the level for a brief period at

the pause input (switch function) or by reconnecting the pump to the mains.

IMPORTANT

If the motor has been switched off via the electronic overload cut-out, check that the pump

is not continuously overloaded.

NOTE

• The motor is supplied pre-wired.

• The performance data in 3.1.1 are measured with the S2Ba (base model with 3-phase

motor). If the S2Ba has been fitted with a 1-phase motor there may be up to 5 % speed

reduction due to the different motor characteristic curve, i.e. corresponding 5 % reduced

feed rate.

The controller changes over to digital stroking mode at low stroke frequencies! This takes

•

place at stroke frequencies below 1/3 of the maximum stroke frequency. This function is

designed to ensure sufficient cooling of the motor and low stroke frequencies.

Features of the S2Ca metering pumps

Type: 100 – 230 V ± 10 %, 50/60 Hz

at 100 V at 230 V

nominal output 250 W 250 W

nominal current 3.2 A 2.0 A

peak current (in operation)* 10 A 5.5 A

making peak current 12 A 24 A

fuse, internal** 4.0 AT (1.5kA) 4.0 AT (1.5kA)

* internal switching

** Only genuine ProMinent fuses, item no. 732414, may be used!

5.2 Function description, controller

Operating modes Operating modes are selected using the MODE menu (depending upon identity code, some

operating modes may be absent).

“Analogue” operating mode: (Identity code, control variant: analogue)

The stroke rate is controlled via an analogue electrical signal via the “external control” terminal.

Signal processing is pre-selected at the controller.

“Manual” operating mode:

The stroke rate is controlled manually via the controller.

“Contact” operating mode:

This operating mode offers the opportunity to make fine adjustments with small increase/

decrease factors. Dosing can be activated by a pulse via the “external control” terminal or by a

semiconductor element. With the “pulse control” option it is possible to pre-set a feed quantity

(batch) or number of strokes (factor 0.01 to 99.99) via the control unit.

“Batch” operating function:

This operating mode offers the option of working with larger transfer factors (up to 65535).

Metering can be triggered by pressing the P key or a pulse from the “external control” terminal

via a contact or semiconductor element. A batching quantity or number of strokes can be preselected via the control unit.

ProMinent

®

Page 33

Page 34

Features of the S2Ca metering pumps

“PROFIBUS®” mode: (Identity code, control variant: PROFIBUS®)

This operating mode provides the option of controlling the pump via the PROFIBUS® (see

“Supplementary instructions for ProMinent® gamma/ L and ProMinent® Sigma versions with

“PROFIBUS®”).

Functions The following functions can be selected using the SET menu:

“Calibrate” function (Identcode, stroke length adjustment: manual + calibration):

The S3Ca can be operated in all operating modes including in calibrating mode. The

corresponding continuous displays can show the actual feed quantity or the feed rate.

Calibration is maintained within the stroke frequency range 0-180 strokes/ min. Calibration is

also maintained when a stroke frequency is altered up to ±10 % scale divisions.

“Auxiliary frequency” function:

It is possible to set a stroke rate in the SET menu, which may be activated via the “external

control” terminal. This auxiliary frequency overrides all other pre-set stroke rate frequencies.

“Flow” function:

Stops the S2Ca when the flow is insufficient. In the SET menu, the number of failed strokes is

entered after which the pump will be turned off.

The following functions are available as standard:

“Float switch” function:

Information on the liquid level in the feed chemical container is transmitted to the S2Ca. This

option requires the installation of a 2-stage float switch. This is connected to the “float switch”

terminal.

Dulcodes UV-Desinfektionsanlage

“Pause” function:

The S2Ca can be stopped by remote control via the “external control” terminal. The “pause”

function operates only via the “external control” terminal.

The following functions are activated by keystrokes:

“Stop” function:

The S2Ca can be stopped by pressing the STOP/START key without disconnecting from the

mains power supply.

“Prime” function:

Priming (short term feed at maximum frequency) is activated by pressing both arrow keys at

the same time (in “Stroke rate” permanent display).

Optional relay The S2Ca has two connection options (not in PROFIBUS

Optional “fault-indicating relay” or “power relay”:

In the event of fault signals, warning signals or float switch activation signals, connects an

electrical circuit to trigger alarm sirens etc. The relay is retrofitted via an aperture in the power

end.

“Fault indicating and pacing relay” option:

In addition to the fault indicating relay the pacing relay can make a contact with every stroke.

The relay is retrofitted via an aperture in the power end.

Function and error

indicators The operating and error status is shown via the three LEDs and the “error” indicator on the

LCD (see also section 9):

®

version).

Page 34

LCD indicator If a fault occurs “error” will appear along with an additional fault warning.

LED indicator Operating indicator (green)

This indicator is lit as long as the S2Ca is operating correctly. It goes out briefly with every

stroke.

Warning indicator (yellow)

This warning light appears if the S2Ca electronics detect a situation that could lead to a fault,

e.g. “liquid levels low 1st stage”.

Error indicator (red)

This warning light appears if a fault occurs, e.g. “liquid levels low 2nd stage”.

ProMinent

®

Page 35

Dulcodes UV-Desinfektionsanlage

Hierarchy of operating modes, functions and fault statuses

The different operating modes, functions and fault statuses each have a differing effect on

whether and how the S2Ca functions. These effects are given below:

1. Prime

2. Fault, stop, pause

3. Auxiliary frequency

4. Manual, analogue, contact, batch

i.e.

1. “Prime” can be activated in “Stroke rate” permanent display in any pump status

(as long as it is operable)

2. “Fault”, “stop” and “pause” stop all system parts up to “prime”.

3.

The stroke rate of the “auxiliary frequency” always overrides the stroke rates of the operating

modes listed in point 4.

5.3 Sockets, symbols and wiring diagram

Features of the S2Ca metering pumps

4

23

6

7

1

5

(1) Socket for two-stage float switch with advance warning and de-activate function (with

function plug*, not illustrated)

(2) External socket for contact or analogue controller with zero volts deactivation via pause

function (with function plug* - not illustrated)

(3) Metering monitor socket for connection of ProMinent® metering monitor

(4) Mains switch (1-pin)

(5) Relay cable (fault indicating or pacing relay)

(6) Socket for diaphragm rupture sensor

(7) Mains lead with plug

*Must be plugged in unless cable attached.

Fig. 14

ProMinent

®

Page 35

Page 36

Features of the S2Ca metering pumps

Dulcodes UV-Desinfektionsanlage

2

Technical data, relay (control version)

Pump type S2Ca

Relay Fault-indicating relay Fault-indicating relay + pulse generator

3

1

4

Relay type Fault-indicating relay pulse generator Fault-indicating relay

Voltage, max: 250 V 50/60 Hz 24 V DC 24 V 50/60 Hz

Current, max. 2 A (ohmic) 100 mA 100 mA

Hook up duration 100 ms

Behaviour see Identcode see Identcode see Identcode

Service life > 200 000 cycles* > 50 x 106 (10 V 10 mA) > 200 000 cycles

1

4

3

2

yellow/NO

green/NC

white/NO

brown/C

fault indicating relay

pacing relay

Relay type Power relay

Voltage, max. 250 V (50/60 Hz)

Current, max. 16 A (ohmic)

Hook up duration

Behaviour see Identcode

Service life > 30 000 cycles*

2

1

4

green/NC

white/NO

brown/C

* in the case of nominal load

The contacts are zero volt.

N/C fault indicating relay - the relay closes immediately after the power is switched on and opens

in the event of a fault.

N/O fault indicating relay, the relay closes in the event of a fault.

Use suitable interference suppression (e.g. RC glands) when connecting inductive loads.

Page 36

ProMinent

®

Page 37

Dulcodes UV-Desinfektionsanlage

Wiring diagram

View of cable connectors from front

Features of the S2Ca metering pumps

Float switch cable

2 blue/alarm

1 black GND

3 brown pause

Blue and black open

-> alarm signal

Brown and black open

-> alarm signal + pump stops

Metering monitor cable

for

for

Universal signal cable (5-core)

1 brown / pause

Pause function:

External/contact:

2 white/cod

3 blue / analogue

4 black/ GND

5 grey/auxiliary

brown and black closed

-> pump metering

brown and black open

-> alarm + pump stopped

white and black closed

-> start contact for pump

(note pause function:

brown and black closed?)

for

1 brown / 5 V

2 white/cod

3 blue

4 black/ GND

Diaphragm rupture cable

2 blue/alarm

1 black/GND

for

Analogue:

blue, black

-> analogue output 0/4-20 mA

(note pause function:

brown and black closed?)

Auxiliary frequency:

grey and black closed

-> pump metering at pre-set stroking rate

Circuit examples see p. 40

External/contact cable (2 core)

for

ProMinent

Contact open -> alarm

-> pump stops with controller type 0

®

2 brown

4 white

Contact closed -> metering stroke

Page 37

Page 38

Features of the S2Ca metering pumps

Technical data, external contact

Semi-conductor switch elements (e.g. transistors in open-collector circuits) or contactors (relays)

with a residual voltage of -0.7 V can be used as input switch elements.

Controller type 0 (see identity code)

Pin 1 = Pause input (activating function)

Voltage at open contacts: approx. 5 V

Input resistance: 10 kΩ

Controller: – zero volts contact (approx. 0.5 mA)

Pin 2 = Contact input

Voltage at open contacts: approx. 5 V

Input resistance: 10 kΩ

Controller: – zero volts contact (approx. 0.5 mA)

Min. contact duration: 20 ms

Max. pulse frequency: 25 pulses/s

Pin 3 = unused

Pin 4 = GND

Pin 5 = Auxiliary input

Voltage at open contacts: approx. 5 V

Input resistance: 10 kΩ

Controller: – zero volts contact (approx. 0.5 mA)

Controller type 1 (see identity code)

Pin 1 = Pause input (activating function)

Voltage at open contacts: approx. 5 V

Input resistance: 10 kΩ

Controller: – zero volts contact (approx. 0.5 mA)

Pin 2 = Contact input (not active during analogue operation)

Voltage at open contacts: approx. 5 V

Input resistance: 10 kΩ

Controller: – zero volts contact (approx. 0.5 mA)

Min. contact duration: 20 ms

Max. pulse frequency: 25 pulses/s

Pin 3 = Identical to input*

Input load: approx. 120 Ω

Pin 4 = GND

Pin 5 = Auxiliary input

Voltage at open contacts: approx. 5 V

Input resistance: 10 kΩ

Controller: – zero volts contact (approx. 0.5 mA)

– semi-conductor (residual voltage: < 0.7 V)

Dulcodes UV-Desinfektionsanlage

– semi-conductor (residual voltage: < 0.7 V)

– semi-conductor (residual voltage: < 0.7 V)

– semi-conductor (residual voltage: < 0.7 V)

– semi-conductor (residual voltage: < 0.7 V)

– semi-conductor (residual voltage: < 0.7 V)

Page 38

* The metering pump makes its first metering stroke at approx. 0.4 mA (4.4 mA) and starts

continuous operation at approx. 19.2 mA.

ProMinent

®

Page 39

Dulcodes UV-Desinfektionsanlage

Features of the S2Ca metering pumps

Block circuit diagram S2Ca

Empty signal,

warning

Metering

monitor

Flow control

Diaphragm

rupture

sensor

Circuit

examples

overleaf

Inputs

3 brown/pause

2 blue/alarm

1 black/GND

1 brown/5 V

2 white/cod

3 blue

4 black/GND

2 blue/alarm

1 black/GND

3 blue/analogue

2 white/contact

1 brown/pause

4 black/GND

5 grey/auxiliary

Level

monitor

Metering

monitor

Diaphragm

rupture

sensor

External

activation

Pump, Inside

Fault

indicating

relay

Fault

indicating

and

pacing relay

Outputs

VDE cable: