Page 1

SIGMA

MRX SERIES

ANALOG AND DIGITAL

MID-SIZE MATRIX ROUTING SYSTEM

OPERATORS MANUAL

SIGMA ELECTRONICS, INC.

P.O. BOX 448

1027 COMMERCIAL AVENUE

EAST PETERSBURG, PA 17520-0448

(717) 569-2681

(MAR’ 03)

Page 2

UNPACKING

PHYSICAL INSPECTION

Inspect your packages and equipment for any damage that might have occurred during shipping. If damage

has occurred, save the shipping cartons. Report the damage to the shipping company and notify Sigm a

Electronics, Inc.

STANDARD SHIPPING CONFIGURATION

Each MRX system will be shipped in multiple cart ons. Video and Audio frames are shipped, each in their

own carton, with all modules installed. Power supply frames and the required power supplies are shipped in

the same carton. The accessory box (where this manual was located) containing all power interface cables,

accessories, connectors and documentation is shipped inside the power fr am e shipping carton.

Control panels ordered with a system are shipped in separ ate cartons. The external power supply for the

control panel is in the same carton as the control panel.

i

Page 3

SIGMA MRX SERIES

ANALOG AND DIGITAL MID-SIZE MATRIX ROUTING SYSTEM

OPERATOR’S MANUAL

TABLE OF CONTENTS

UNPACKING.......................................................................................................................................................................................i

PHYSICAL INSPECTION...............................................................................................................................................................i

STANDARD SHIPPING CONFIGURATION.................................................................................................................................i

TABLE OF CONTENTS..................................................................................................................................................................... ii

INSTALLATION AND OVERVIEW.................................................................................................................................................1

GENERAL OPERATING REQUIREMENTS................................................................................................................................1

ENVIRONMENTAL...................................................................................................................................................................1

Ambient temperature/Ventilation.............................................................................................................................................1

Humidity ..................................................................................................................................................................................1

Rack-mounting.........................................................................................................................................................................1

Audio Frame placement...........................................................................................................................................................1

POWER........................................................................................................................................................................................1

INTERCONNECT WIRING ...........................................................................................................................................................2

AUDIO FRAME - ANALOG.....................................................................................................................................................2

AUDIO FRAME - DIGITAL......................................................................................................................................................2

VIDEO FRAME - ANALOG.......................................................................................................................................................3

VIDEO FRAME - DIGITAL.......................................................................................................................................................3

POWER FRAME.........................................................................................................................................................................3

SYSTEM CONTROL INTERFACE .......................................................................................................................................3

POWER MODULE..................................................................................................................................................................4

REAR SUPPORTS ..........................................................................................................................................................................5

Rear Support Installation Instructions..........................................................................................................................................5

CONTROL PANEL.........................................................................................................................................................................6

APPENDIX A – SCI PROTOCOL AND INTERFACE...................................................................................................................A1

INTRODUCTION.....................................................................................................................................................................A1

Control Panel Interface..........................................................................................................................................................A1

Serial Control Interface....................................................................................................... .................................................. A1

Vertical Interval Switching ................................................................................................................................................... A1

SCI Configuration Switches..................................................................................................... ............................................. A1

Control Levels.......................................................................................................................................................................A1

RS232 PROTOCOL COMMANDS ........................................................................................................................................A2

SPECIAL COMMANDS..........................................................................................................................................................A4

RS422/485 PROTOCOL COMMANDS ................................................................................................................................. A6

SERIAL CONTROL AND MODE SWITCHES......................................................................................................................A7

JUMPER SELECTION............................................................................................................................................................. A8

9 PIN 'D' RS-422/485 WIRING................................................................................................................................................ A8

9 PIN 'D' RS-232 PIN ASSIGNMENT..................................................................................................................................... A9

RS-232C WIRING..................................................................................................................................................................A10

APPENDIX B - SPECIFICATIONS ................................................................................................................................................ B1

SYSTEM CONTROL INTERFACE MODULE (MRX-SCI).................................................................................................. B1

ANALOG VIDEO FRAME (MRX-24V, MRX-32V).............................................................................................................. B1

ANALOG AUDIO FRAME (MRX-24A, MRX-32A) ............................................................................................................. B1

DIGITAL VIDEO FRAME (MRX-DVF).................................................................................................................................B2

DIGITAL AUDIO FRAME – Balanced (MRX-TDAF)........................................................................................................... B2

DIGITAL AUDIO FRAME – Unbalanced (MRX-CDAF).......................................................................................................B3

POWER SUPPLY FRAME (MRX-PSF).................................................................................................................................. B3

MECHANICAL........................................................................................................................................................................ B3

ii

Page 4

INSTALLATION AND OVERVIEW

GENERAL OPERATING REQUIREMENTS

ENVIRONMENTAL

Ambient temperature/Ventilation

The MRX Switching System is designed to operate as specified when the ambient temperature is kept

within the range of 0°C to 50°C. Ventilation slots are provided on the fr ont and sides of the frames to assist

in the removal of the excess heat generated in t he nor mal operation of the units. These ventilation slot s

must not be blocked. Sigma Elect r onics will consider block ing of these slots, to be a custom, design

modification by the user. Custom design modifications void the Sigma Electronics warranty.

Humidity

Excessive humidity is harmful to electronic equipment . It is expected that the user will monitor and control

the relative humidity of the operating environm ent to maintain levels acceptable for the operation of this

equipment.

Rack-mounting

All frames and control panels are intended to be mounted in standard 19” EIA equipment racks. Prior to

installing an MRX Series f rame into a rack, the front panel must be removed. To rem ove the front panel,

grasp the handles and pull fir mly away from the f rame. T he front panel should completely detach from the

ballstuds.

Audio Frame placement

Due to the susceptibility of all audio circuitry to int er ference from power sources, the audio frame should be

located as far away from power sources as possible.

POWER

The MRX Switching System is designed to operate in all standard com mercial power environments

providing input voltage between 100VAC and 240VAC ± 10%. Voltages outside of this range may or may

not be tolerated by the equipment for a period of time but will, in any case, be considered a violation of the

warranty.

1

Page 5

2

Page 6

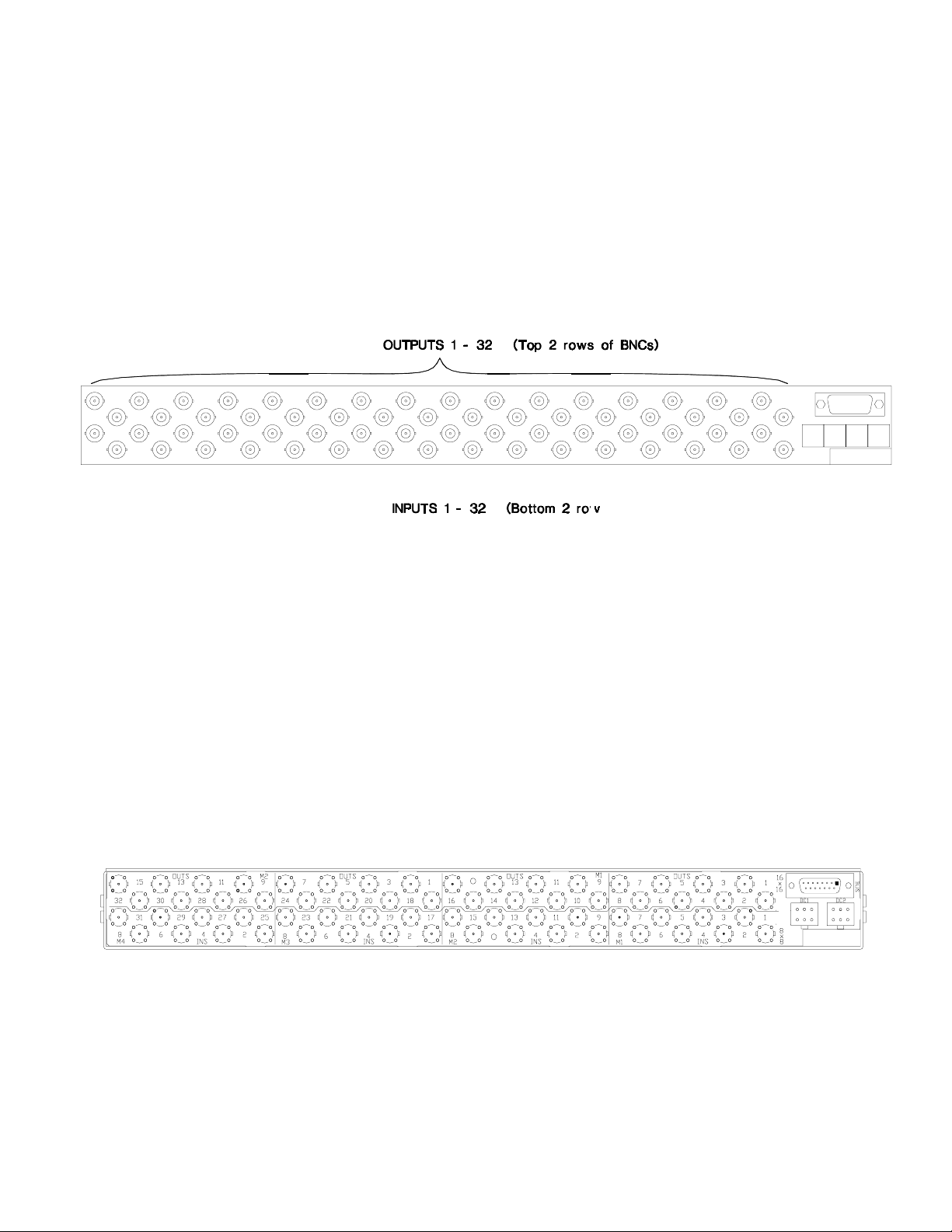

VIDEO FRAME - ANALOG

Video signals are connected to the video frame via BNC jacks on the rear panel. Connect the

source video cables to the corresponding input BNCs on t he rear of the frame. The MRX routing switcher

must be the terminating device in the system. All video modules provide the video source with proper 75Ω

termination. All active video outputs must be terminated in 75Ω. (BNC’s for outputs that are beyond the

configured matrix size do not need to be ter minated.)

The figure below shows the rear of a system configur ed as a 32 X 32 switcher. In this configuration,

the bottom two rows of BNC’s are used as t he video input connectors. T he 32 BNC’s that m ake up the t op

two rows are the video output connectors. All 32 output BNC’s need to be terminated. Use a 75Ω load to

terminate any unused output.

3

Page 7

To ensure that the SCI has power at all times, the control module is connected to every power

module output. This guarant ees that if any functional power supply module is installed, the SCI will have

power supplied to it. In addition, as long as there is m or e t han one operating power supply in the power

frame, the SCI has redundant power capability.

CONTROL BUS WIRING

The data bus connection is provided on the rear of each power frame at the SCI interface panel.

Ribbon cables with 15 Pin D-type connectors are used as Bus connectors. T hese Bus connectors are used

to transmit the control data f rom the SCI to all system f ram es. All systems will be provided with enough bus

cable assemblies to meet the req uirements of the system plus an expansion connector. Fram e placement

within the racks will determine the required leng th of t he bus cable. If custom leng th cables are req uired for

a specific application, Sigma Electr onics I nc can accom modate special cable requirements.

POWER MODULE

All power is supplied to t he audio and video frames from the power f rame through the supplied DC

power cables. Although all power modules are identical, some positions within the f rame are dedicated to

supply power to digital audio or video frames and other positions are to supply analog frames. For

applications where redundancy is requir ed, each power fr ame can hold two digit al and two analog assig ned

supplies.

After the power supply modules are plugged into t he power frame’s slots, install the power cables

into the rear of each supply and then connect to t he rear of the appropriat e fr ame, analog or digital. Analog

power cables are terminated with 4-pin connectors and digital power cables are terminated with 6-pin

connectors. Ensure t hat an analog power supply is used to supply an analog frame and a digital power

supply is used to supply a digital frame.

Additional DC input power connectors are provided on each analog and digital f rame. Redundant

analog or digital power supplies may be mounted in the power fram e and connected to the audio or video

frames via this connector. The redundant connector on the r ear of the analog f rame is labeled DC2- I. The

redundant connector on the rear of the digital frame is labeled DC 2.

*NOTE: If one analog video frame

cables as follows: Connect one 4-pin power supply cable from the power supply frame to the video frame

connector DC1-I. Connect one 4-pin power supply cable from the power supply frame to the audio f rame

connector DC1-I. Connect one 4-pin power supply cable from the video fr ame connector DC1-O

audio frame connector DC1-I

.

and two analog audio frames are used, connect the power supply

to the 2nd

4

Page 8

REAR SUPPORTS

Depending upon the installation, it may be necessary to install the included rear mounting f rame supports.

These supports are designed to allow connection to rear rails positioned between 19 and 30 inches from the

front supports. T o inst all, follow the directions below.

Rear Support Installation Instructions

Refer to illustration below for r eference letters.

1. Prior to installation of the frame into the rack, attach an extender bar (A); the flat piece with the

countersunk holes at one end; to each side of the f rame using the f our (4) supplied #8- 32 undercut,

flathead screws (B) throug h the countersunk holes and into the threaded inserts in the side of the

frame. NOTE: Undercut, flathead screws must be used to provide adequate clearance and pr oper

fit.

2. Install the frame into the equipment rack, securing the front mounting brackets with the supplied

#10-24 plastic-coated, rack-mount ing screws. For shorter f ront to back rack-mounting applications,

be certain both extender bars are positioned between the vertical, rear mounting rack rails.

3. Install both rear mounting brackets (C) over the end of the extender bars with the angled portion

pointing toward the outside.

4. Secure the rear mounting bracket © to the rear of the rack using #10-24 plastic-coated, rackmounting screws.

5. Install at least one of the supplied #8-32 panhead scr ews (D) through the extender bar and into the

threaded inserts in the mounting bracket on each side. For greater security, an additional screw

may be installed where possible.

Rear Support Installation (right side only shown)

5

Page 9

CONTROL PANEL

T o initiate the switching operation, data must be input into the SCI. One way to input this data is

through a control panel. The MRX system is capable of utilizing many different control panels available

from Sigma Electronics, Inc.

The dat a from the control panels is transf erred to the SCI via a communication line. References to

this line are typically abbreviated to COMM line. This coaxial cable is connected between either the COMM

1 or COMM 2 BNC on the SCI interface on the rear of the power frame, and the COMM connection on the

rear of the control panel. Bot h connectors provide an identical interface to the SCI.

Several control panels may be added to the COMM Line as system requirements dictate. Additional

panels are added by installing BNC “T” connectors in t he coax path. Coaxial cable paths f or either COMM 1

or COMM2 are recommended to be less than 2000 total feet. This coaxial path should NOT be terminated

in a 75Ω load.

Electronics Inc.

6

Page 10

APPENDICES

Page 11

APPENDIX A – SCI PROTOCOL AND

INTERFACE

INTRODUCTION

The SCI serial interface card is the heart of

the Sigma MRX Series mid-size matrix routing

system. The SCI functions as the controller

between the user and the switcher crosspoints. A

switch can be generated one of two ways: by a

remote control panel or by the serial port.

Control Panel Interface

On the rear of t he main frame are two BNCs

labeled "COMM 1" and "COMM 2". Coaxial

control lines connect the COMM ports to the

remote control panels. Multiple control panels

may be supported by the SCI. The 64 different

panel addresses allow each panel to have a

unique polling address. This prevents conf licts of

transaction informat ion during a poll between the

SCI and a specific address. The SCI

systematically polls the control panel addresses to

request transaction data. When polled, data

present at the control panel is transmitted to the

SCI via the coax cable. The SCI interprets and

executes the instruction. After a panel is polled,

the SCI transmits an update of the transaction to

all the system control panels. In this way there is

a positive feedback for each tr ansaction.

Serial Control Interface

The second method of control is thr ough the

serial port. The SCI can support eit her RS-232 or

RS-422 protocols. Selection of RS-232 is

obtained by placing the dual 9 Pin jumper on JP2

(factory default). To select RS-422 the jumper

must be moved to JP1. Serial communications is

achieved with very simple and straightforward

ASCII commands. The interrupt driven

communications link will respond immediately

whenever a command is issued from an external

serial device. When the com mand is received, it is

interpreted and executed. The SCI will issue a

response of "OK" to the sending device upon

completion of each transaction. If the command

was invalid the SCI will transmit a "?". The

response can be disabled if required.

Vertical Interval Switching

The SCI is capable of generating a vertical

interval switch. To do this a reference sig nal must

be present at the "REF IN" BNC. This sig nal can

be either a composite video signal (1 Vp-p) or a

composite sync pulse (-4vpp). The SCI will use

this reference to determine the vertical interval

switch. If no “REF IN” signal is present the SCI

will execute the switch as soon as it is interpreted.

SCI Configuration Switches

There are three switches located on the front

on the SCI-MRX circuit board. S1 is a mom entary

push button switch labeled "RESET". This switch

functions as a microprocessor hardware reset that

forces the processor to restart from a default

setup condition. The SCI will reset all cr osspoints,

every output will be set to input 1. An S1 reset will

clear all entries in the internal salvo tables and

panel restrictions in the SCI m emor y. Reset must

be used with care. Refer to the CTRL-W

command before implementing a system reset

with S1.

The 12-position DIP switch, S2, provides

system configuration. System configuration

includes serial port baud rate, switcher input

range, output range, protocol logical addressing

and number of control levels. Refe r to the tables

provided in this manual.

The four-position switch, S3 is used to select

the Numeric/Alpha mode, enable/disable

hardware handshaking and control panel

scanning.

Control Levels

The SCI-MRX supports four or eight control

levels. Rotary switches on the front of the audio

and video boards control level assignments for

each output group. Level 1, typically assigned to

the video modules, is designated with an A in the

ASCII protocol. Level 2, typically assigned to the

audio modules, is designated with letter B in the

protocol.

The separation of signals into levels allows

the router’s logic to switch one level without

affecting any other level. Using level control

allows the operator to switch a video signal to a

given destination without changing the audio

signal for that destination. This is referred t o as a

breakaway switch.

As well, the operator may

source video and audio from two different

source devices. With the use of level control

the video source is preset on its level and

audio is preset on a different level. At the

TAKE command the two different source

signals switch to a common destination. This

is referred to as a split mode switch.

A1

Page 12

APPENDIX A – SCI PROTOCOL AND INTERFACE

RS232 PROTOCOL COMMANDS

The following commands may be issued from

a computer/terminal keyboard or other similar

communication control device. This protocol is

supported by various control systems provided by

other control system manufacturers. Standard

ASCII characters are used to create the command

strings. The SCI-MRX is not case sensitive, and

therefore does not care if capital or lower case

letters are used. Please not e that spaces are not

used in any command strings.

COMMAND: Audio-Follow-Video sw i tch

IxxxOxxx {RETURN/ENTER}

The 'I' represents INPUT and the 'O'

OUTPUT. The 'xxx' represents the one to three

digit number of the respective INPUT and

OUTPUT. Leading zeros are optional. Valid

INPUT numbers for the SCI are 1 to 128. Valid

OUTPUT numbers are 1 to 128. To generate a

TAKE command, press the RETURN/ ENTER key

on the keyboard. When the SCI receives the

request and executes the change, it will respond

with an ASCII message 'OK' (unless disabled see "N/Y" command explanation).

COMMAND: BREAKAWAY

AxxxOxxx {RETURN/ENTER}

In this command only the requested input

Level (A) will change causing that level to

breakaway from the other levels. The 'A' could

actually be A,B,C,D,E,F,G or H. These eight

letters represent the control levels 1-8

respectively. So an "A" would correspond to

Level 1, a "D" would represent Level 4 and so

on.. The 'Oxxx' is the OUTPUT or destination

number.

COMMAND: SPLIT:

BxxxCxxxOxxx OR DxxxAxxxOxxx

COMMAND: STATUS

Any OUTPUT’s status can be obtained by

entering the following protocol sequence:

Sxxx {RETURN/ENTER}

The 'S' represents STATUS and the 'xxx'

represents the one to three digit ASCI I number of

the OUTPUT. Any leading zeros are optional.

Press RETURN/ENTER to generate execution.

The SCI will respond with the following ASCII

message:

Output xxx, L1 xxx, L2 xxx, L3 xxx, L4 xxx, L5

xxx, L6 xxx, L7 xxx, L8 xxx

This will all print on one line on t he terminal

video screen. The 'xxx' will indicate the one to

three digit ASCII num ber for the OUT PUT and all

the sources for LEVEL 1 t o 4 or 1 to 8 in an eight

level system.

COMMAND: STATUS ALL

A global status can also be generated. This

will give the STATUS for all t he active OUTPUTS.

By default, those OUTPUTS not yet addressed

will be indicated as having INPUT 01 selected.

SA {RETURN/ENTER}

The 'S' represents STATUS and the 'A'

represents ALL. As always, press the

RETURN/ENTER key to execute the command.

The SCI will respond with the following:

L1 L2 L3 L4 L5 L6 L7 L8 OUT

xxx xxx xxx xxx xxx xxx xxx xxx xxx

xxx xxx xxx xxx xxx xxx xxx xxx xxx

xxx xxx xxx xxx xxx xxx xxx xxx xxx

The current INPUT STATUS for all levels of

each OUTPUT will be listed. The number of

outputs to which the SCI DIP switches are set

(see SCI DIP switch settings) will limit t he number

of outputs displayed.

In these examples, the inputs for two levels

are assigned different sources, but both will go to

the same OUTPUT or destinat ion. Again, it is not

necessary to supply the leading zero in assigning

source or destination numbers. B17C03O04 or

B17C3O4 will both perform the same switch.

Order and number of levels does not matter.

Any combination of levels in any order is valid.

For example, D09B21A2C11O9 is a valid

sequence.

Anytime an invalid or incomplete message is

sent to the SCI, it will respond with an ASCII '?'

unless this response is disabled (see "N/Y"

command). This will occur for each group of

invalid characters it receives. The

RETURN/ENTER key is the delimiter between

commands. Therefore, invalid characters will not

cause a '?' response until the RETURN/ENTER

key has been sent.

A2

Page 13

APPENDIX A – SCI PROTOCOL AND INTERFACE

COMMAND: MATRIX SETUP REQUEST

The input/output matrix setup information of

the system can be displayed. To do this, send the

following command:

? {RETURN/ENTER}

The SCI will respond with the following

message:

AVAILABLE OUTPUTS ARE: xxx

AVAILABLE INPUTS ARE: xxx

where 'xxx' is the number of inputs and

outputs set at the SCI DIP switches.

COMMAND: DISABLE RESPONSE

Responses generated by the SCI can be

disabled with the following command. The

command is:

CTRL-N

This will prevent all SCI responses. No

carriage return is required.

COMMAND: ENABLE RESPONSE

At any time, the responses can be resumed.

The command is:

CTRL-Y

Again, no carriage return is needed. Please

note this process differs from the XON/XOFF

routine. In that case, the responses are held in a

buffer and then all pending messages are sent

upon receiving the XON command. In this case,

the messages are simply discarded and no record

of them is kept. In this way, it is possible to tailor a

program to allow only a status response but inhibit

all other SCI messages.

The SCI will respond by sending a carriage

return and linefeed to move the cursor on the

screen to the beginning of the next line.

The SCI always gives priority to commands

over responses. All commands are executed

before any responses are sent. This assures the

fastest processing of a change request.

COMMAND: DISABLE CONTROL PANELS

It is possible to disable the remote control

panels and give exclusive attention to the serial

port for improved response tim e to incoming serial

commands. To halt the scanning of panels press:

PD {CARRIAGE RETURN}

The response is "Panels Inactive." This will

cause the polling and updating of any remote

panels to stop. This command is especially useful

to improve SCI efficiency in systems where

control panels are not used. Also, this command

can be used to temporarily disable the panel

scan, execute time critical serial transactions, and

then re-enable the panel scan with the next

command.

COMMAND: ENABLE CONTROL PANELS

To re-enable the control panel scan routines

press:

PE {CARRIAGE RETURN}

The response is "Panels Active." Now the

SCI is fully functional again and t he panels will be

updated and polled as before. Caref ul tailoring of

programming will allow maximum efficiency in

executing serial commands in those applications

where execution time is especially critical.

COMMAND: CONTROL PANEL STATUS

COMMAND: CLEAR ENTRY

Whenever a wrong key is accidentally

pressed or a command needs to be changed, the

current command can be cleared by pressing the

SPACEBAR. This is always true as long as the

RETURN/ENTER key has not yet been pressed.

All keystrokes made since the last entry of the

RETURN/ENTER key will be erased. The

CANCEL command is automatic and does not

require the RETURN/ENTER key to be pressed.

The format is:

{SPACEBAR}

The current control panel status can be

determined by pressing:

PS {CARRIAGE RETURN}

This will yield the response of Panels Active

or Panels Inactive depending on the current

state.

A3

Page 14

APPENDIX A – SCI PROTOCOL AND INTERFACE

SPECIAL COMMANDS

There are several special commands

available that should be used with care.

COMMAND: SYSTEM HARD REBOOT

It is possible to force a system r eset from t he

serial port, duplicating the function of the RESET

switch on the front of the SCI. All outputs are

reassigned to source 1, all previously stored data

is cleared, all salvo information is erased, and the

system will then reboot as though a power-on

condition occurred. This hard reboot comm and is:

COMMAND: HALT DATA TRANSMIT

The SCI supports the XON/XOFF protocol.

This is a method, through sof tware, of halting and

resuming transmission of data. The XOFF is

activated by holding the Control k ey and pressing

'S' (CTRL-S). This will halt data transmission..

Incoming commands are still executed during an

XOFF. It is the responses generated by the SCI

that are not sent. They are held in a message

buffer until an XON is received. Like the CANCEL

command, XOFF is automatic and does not

require the RETURN/ENTER key to be pressed.

CTRL - C

Note no carriage return is required.

COMMAND: SYSTEM SOFT REBOOT

This is a less destructive reset. This method

will force the internal watchdog timer to r estart the

system as though a power-on condition had

occurred. No crosspoint or salvo table inf ormat ion

is lost. Upon this reset the DIP switch settings of

the SCI are read. It is useful to use this reset

command when changing the DIP switches

without requiring a power down of the SCI. This

soft reboot command is:

CTRL - W

Again, no carriage retur n is r equired.

COMMAND: CONDENSED STATUS

It is possible to get the status of the system in

a condensed format. There are two possible

methods. The first is in binary and the second is in

packed BCD. The advantage here is a minimal

number of bytes are issued from the port and it is

a very efficient method of g aining the status from

within an external control program. Since these

characters may be non-printing ASCII character s

it is not useful to use in a terminal package.

The command for a condensed status in

binary is:

SB {RETURN/ENTER}

The command for a condensed BCD status

is:

SC {RETURN/ENTER}

For a detailed explanation of the byte

sequence please contact Sigma Electronics

software department.

COMMAND: RESUME DATA TRANSMIT

XON is activated by holding the Control key

and pressing 'Q' (CTRL-Q). This will resume

transmission of data from the SCI. All pending

responses are sent out the serial port in the same

sequence in which they were received and stored.

Like the CANCEL and XOFF command, XON is

automatic and does not require the

RETURN/ENTER key to be pressed.

SALVO COMMANDS

The SCI-MRX is capable of int ernally storing

ten different salvos. A salvo provides a method of

switching multiple commands at one time. This

“grouping” of switches eliminates delay of

switching from the first step to the last step in a

multi-step switch. There are commands that

pertain exclusively to the creation, edit and

execution of a salvo.

The ten distinct Salvo symbols are as followsSymbol Keyboard Command

! Shift 1 Salvo 1

@ Shift 2 Salvo 2

# Shift 3 Salvo 3

$ Shift 4 Salvo 4

% Shift 5 Salvo 5

^ Shift 6 Salvo 6

& Shift 7 Salvo 7

* Shift 8 Salvo 8

( Shift 9 Salvo 9

) Shift 0 Salvo 10 (EAS)

SHIFT 1 through SHIFT 0 correspond to

salvo 1 through salvo 10. W hen act ivating a salvo

the first character in the command must be the

salvo designator symbol; !, @, #, $, %, ^, &, *, (,

or ). The Salvo stored as Salvo 10 will execute

upon a closure applied to the EAS screw

terminals on the rear of the master frame. This

provides an automatic response to an Emergency

Alert System alarm.

A4

Page 15

APPENDIX A – SCI PROTOCOL AND INTERFACE

COMMAND: STORE SALVO

COMMAND: SALVO STATUS ALL

Creating a transaction to be st ored in a salvo

is done exactly as a regular transaction except the

salvo symbol is the leading character. The

following example will store this transaction in

salvo 2 (@):

@A10C3O19 {RETURN/ENTER}

This is a split mode transaction stored in

salvo number 2 (@ = SHIFT 2),change level 1 (A)

to source ten (10) and level 3 (C) to source three

(3) of output (O) ninet een ( 19).

Multiple switches may occur upon a single

salvo command. This allows multiple input to

output switches to be preloaded and then switch

simultaneously upon the execution of the salvo. A

typical multiple output salvo would be entered like

the following string of commands;

! I 01 O 01 {RETURN/ENTER}

! I 02 O 02 {RETURN/ENTER}

! I 03 O 03 {RETURN/ENTER}

! I 04 O 04 {RETURN/ENTER}

! I 05 O 05 {RETURN/ENTER}

! I 06 O 06 {RETURN/ENTER}

! I 07 O 07 {RETURN/ENTER}

! I 08 O 08 {RETURN/ENTER}

! I 09 O 09 {RETURN/ENTER}

! I 10 O 10 {RETURN/ENTER}

! I 11 O 11 {RETURN/ENTER}

! I 12 O 12 {RETURN/ENTER}

! I 13 O 13 {RETURN/ENTER}

! I 14 O 14 {RETURN/ENTER}

! I 15 O 15 {RETURN/ENTER}

! A 16 B 64 O 16 {RETURN/ENTER}

(No spaces are used between any commands.)

This salvo command is set for Salvo 1 (!) and

switches inputs (I) one to fifteen (1 - 15) to outputs

(0) one to fifteen (1 - 15) respectively. The last

step of salvo 1 performs a split switch of input

level 1 (A) from source sixteen (16) and input

level 2 (B) from source sixty-four (64) to output

(O) sixteen (16). The salvo command is f inished

with Return/Enter. The number of possible

transactions in a salvo is equal to the number of

outputs in the system. You can only change each

output once in any particular salvo. Switch

commands do not need to be in num erical order.

If multiple comm ands are entered for one output,

only the last command for that output will be

visualized after the execution of the salvo.

The status of a salvo can be examined by

prefixing the status command with the salvo

symbol.

!SA {RETURN/ENTER}

The example provided is for salvo 1 (!). This

example provides the status (S) for all outputs (A).

The difference between a normal status check

and a salvo status check is anytime a level is not

assigned (such as in a breakaway), the

unassigned inputs will display dashes "---" to

indicate these input levels will not be affected by

the salvo. The dashed lines would appear at

levels 3 (C) and 4 (D) of output 16 for the sample

salvo 1 given in the previous command

paragraph.

COMMAND: SALVO STATUS SINGLE OUT

Within each salvo a specific output can be

checked for the status.

#S9 {RETURN/ENTER}

The example command f or salvo 3 (#) would

yield the current status (S) for out put nine (9).

COMMAND: SALVO ERASE (clear)

There are six commands available to erase a

salvo or portions of a salvo. To erase an entire

salvo use the following command.

$Z {RETURN/ENTER}

In the example above, the command will take

salvo 4 ($) erase (Z) the entire contents:

To erase only a specific output , use the

command with an output limiter attached.

@Z14 {RETURN/ENTER}

This example for salvo 2 (@) erases (Z) all

input assignments for output fourteen (14).

A range of outputs within a salvo can be

erased as a group.

!Z11-18 {RETURN/ENTER}

This example for salvo 1 (!) erases (Z) all

input assignments for output s eleven (11) through

(-) eighteen (18).

It is possible to erase only one level of a

salvo. The following command erases only the

level designated for all transactions listed in the

command string.

A5

Page 16

APPENDIX A – SCI PROTOCOL AND INTERFACE

@ZB {RETURN/ENTER}

COMMAND: EXECUTE PRESET SALVO

The example above for salvo 2 (@) will erase

(Z) all level 2 (B) entries for each output specified

in the salvo.

It is also possible to erase a level for a

specific output within a salvo.

#ZC9 {RETURN/ENTER}

The example above for salvo 3 (#) erases (Z)

the level 3 (C) input assignment for output nine

(9).

A command is available to erase a level

within a range of outputs for a par ticular level.

#ZA12-19 {RETURN/ENTER}

The example above for salvo 3# will erase (Z)

all entries for level 1 (A), beginning with output

twelve (12) through (-)and including output

nineteen (19).

COMMAND: EXECUTE SALVO

A salvo can be executed immediately by

choosing the proper salvo symbol and using the

execute command.

!X {RETURN/ENTER}

The example above is the salvo 1 (!) execute

(X) command.

COMMAND: PRESET SALVO

The command to PRESET a salvo, but not

execute it, allows the system to queue a system

for an immediate preloaded switch upon the

execute command.

$P {RETURN/ENTER}

The example above for salvo 4 ($) presets

(P) and holds the salvo. During a salvo preset

condition, no other salvo can be accessed.

Neither edits nor system transactions are

permitted.

options: execute the salvo, cancel the salvo or

request a status. This is true whether it is a

command from the serial port or a control panel.

All other switch commands are ignored during a

salvo preset.

A salvo preset has an internal timer of

approximately 30 seconds. If a preset salvo is not

executed within this time, it will automatically be

canceled and a salvo cancel message will be sent

out the serial port.

There are essentially only three

To execute a preset salvo, choose the salvo

number/symbol of the preset salvo.

$ {RETURN/ENTER}

The example above will execute salvo 4 ($),

which was in the preset mode.

COMMAND: CANCEL PRESET SALVO

A preset salvo can be canceled.

$Q {RETURN/ENTER}

The sample above takes a preset condition

for salvo 4 ($) and releases (Q, quit) it. This

cancellation of the preset salvo allows normal

transactions to resume.

RS422/485 PROTOCOL COMMANDS

Unlike the RS232 commands, the RS422/485

protocol allows for multiple devices to be

connected to a computer/terminal at the same

time. In order for the computer/terminal to

communicate with a device in RS422/485, it must

first tell the device to listen. T his is the purpose of

the logic address. The SCI has f our DIP switches

reserved for setting the device's logic address.

Valid addresses for the SCI are 01-07 (an

address of 00 indicates that RS-232 is being

used).

The format for RS-422/485 protocol is

identical to that of RS232 with one exception. Any

RS422/485 command must be have the pref ix of

a forward slash (/). The f orward slash is required

on all commands including special commands like

XON/XOFF.

/xx

The slash (/) is the precursor, and t he 'xx' is

the logic address of the device. This is ALWAYS

a TWO DIGIT NUMBER.

For example, to generate a typical audiofollow-video switch use the sequence below.

/xxIyyyOzzz {RETURN/ENTER}

The forward slash ( /) precedes the SCI's two

digit logic address 'xx', the input number is

represented by one, two or three digits 'yyy' and

the output or destination is represented by the

one, two or three digit 'zzz'.

A6

Page 17

APPENDIX A – SCI PROTOCOL AND INTERFACE

SERIAL CONTROL AND MODE SWITCHES

The system configuration DIP switches S2 and S3 are located on the front edge of the SCI-MRX printed circuit board.

The power supply fram e holds the SCI-MRX m odule. Remove the front panel of the fram e to access the switches. The

momentary push-button reset switch S1 is positioned next to S3. See INTRODUCTION for details.

This chart sets the communications Baud Rate.

S2,1 S2,2 Baud Rate

ON ON 9600

OFF ON 19200

ON OFF 38400

OFF OFF 57600

This chart sets the number of switcher inputs (sources).

S2,3 S2,4 S2,5 Input Range

ON ON ON 01 - 16

OFF ON ON 01 - 32

ON OFF ON 01 - 48

OFF OFF ON 01 - 64

ON ON OFF 01 - 80

OFF ON OFF 01 - 96

ON OFF OFF 01 - 112

OFF OFF OFF 01 - 128

This chart sets the number of switcher outputs (destinations).

S2,6 S2,7 S2,8 Output Range

ON ON ON 01 - 16

OFF ON ON 01 - 32

ON OFF ON 01 - 48

OFF OFF ON 01 - 64

ON ON OFF 01 - 80

OFF ON OFF 01 - 96

ON OFF OFF 01 - 112

OFF OFF OFF 01 - 128

This chart indicates protocol format and logical address.

S2,9 S2,10 S2,11 Logic Address

ON ON ON RS-232∗

OFF ON ON 01

ON OFF ON 02

OFF OFF ON 03

ON ON OFF 04

OFF ON OFF 05

ON OFF OFF 06

OFF OFF OFF 07

Use address 00 for RS-232. All other settings are for RS-422 operation.

Control Level Control Panel Type Handshaking Reserved Panel Scan

S2, 12 Levels S3,1 Panel Type S3.2 Handshaking S3.3 S3.4 Panel Scan

ON 8 ON Numeric ON Enabled Reserved ON Scan ALL

OFF 4 OFF Alpha OFF Disabled OFF Scan Active

NOTE 1 - Fixed serial communications parameters are: 8 Character bits 1 Stop bit No Parity

NOTE 2 - Synchronous mode switching occurs on line 10 in NTSC and line 7 in PAL when reference is supplied.

The Dip switch s ettings below are conf igured f or a 4 level

32x32 matrix using RS-232 protocol at 38,400 baud rate.

Off [down] / ON [up]

1

2

3

4

5

6

7

8

9

10

11

12

S2

1

2

3

4

S3

R

E

S

E

T

A7

Page 18

APPENDIX A – SCI PROTOCOL AND INTERFACE

JUMPER SELECTION

SERIAL PORT COMMUNICATION FORMAT

RS-232 SELECTION JP2, 9 position jumper with header attached, factory default.

RS-422/485 SELECTION JP1, 9 position jumper, move header from JP2 to this position for RS-422/485.

J4, RS-422/RS-485 selector, factory default is RS-422

J5, Delete for RS-422 and RS-232 (factory default), Add for RS-485

J6, Delete for RS-422 and RS-232 (factory default), Add for RS-485

Reserved Function JP3, programming interface for U6 (factory reserved)

9 PIN 'D' RS-422/485 WIRING

PIN # FUNCTION∗ DIRECTION

1 Ground --- 2 Transmit A Output ( TX Data - )

3 Receive B Input ( RCV Data + )

4 Receive Common --- 5 N/C --- 6 Tra nsmit Common --- 7 Transmit B Output ( TX Data + )

8 Receive A Input ( RCV Data - )

9 Frame Ground ----

∗(Same as standard: ANSI/SMPTE 207M/1984)

A8

Page 19

APPENDIX A – SCI PROTOCOL AND INTERFACE

9 PIN 'D' RS-232 PIN ASSIGNMENT

PIN # FUNCTION∗ DIRECTION

1 N/C --- 2 RECEIVE DATA INPUT to SCI-MRX

3 TRANSMIT DATA OUTPUT from SCI-MRX

4 DATA TERMINAL READY OUTPUT from SCI-MRX

5 SIGNAL GROUND N/A

6 DATA SET READY INPUT to SCI-MRX

7 READY TO SEND OUTPUT from SCI-MRX

8 CLEAR TO SEND INPUT to SCI-MRX

9 N/C ----

T he Pin assignments noted are per the RS-232 standard. Although the standard defines the

use of twenty five (25) Pins, only nine (9) are required for PC serial communications. Of those nine

pins, only seven are required for communication to the SCI when handshaking is required. If

handshaking is not required only three pins will be active. There is no need to jumper the

handshaking pins when unused. Consult the control device manufacturer’s data sheet to determine

proper wiring.

PIN OUT

5 1

9

8 7 6

SCI-MRX Serial Port

2 3 4

A9

Page 20

APPENDIX A – SCI PROTOCOL AND INTERFACE

RS-232C WIRING

SCI-MRX 9 PIN 'D'

SERIAL PORT SERIAL PORT

PIN SIGNAL CONNECTIONS CONNECTIONS

DESIGNATION (COMM 1-DCE) (COMM 2-DTE)

1- N/C N/C N/C

2- RECEIVE DATA (RXD) [INPUT] RXD OR TXD

3- TRANSMIT DATA (TXD) [OUTPUT] TXD OR RXD

4- DATA TERMINAL READY (DTR) [OUTPUT] CTS CTS

5- SIGNAL GROUND GROUND GROUND

6- DATA SET READY (DSR) [INPUT] RTS RTS

7- READY TO SEND (RTS) [OUTPUT] DSR DSR

8- CLEAR TO SEND (CTS) [INPUT] DTR DTR

9- N/C N/C N/C

Although the RS-232C standard def ines the use of 25 pins, only nine of those are needed for basic PC

serial communications. Of those nine, only seven are required for serial communications with the SCI-MRX.

The above wiring chart is typical for most IBM and compatible type PC's. However, it is always best to check

with the manufacturer's wiring specifications to determine exact pin assignments before beginning. This is

especially true if using COMM 1, since some manufacturers use a 9 pin 'D' connector instead of a 25 pin 'D'.

Regardless of t he connector, the signal connections are the same. RXD and TXD are reversed depending

upon whether the serial port is configured as a DTE (data terminal equipment) or a DCE (data communications

equipment).

If the control equipment does not require handshaking, there is no need to jumper the pins on the SCI-MRX. When handshaking

is not required only 3 pins will be used: TXD, RXD and Signal Ground. All other pins will have no connection.

A10

Page 21

APPENDIX B - SPECIFICATIONS

SYSTEM CONTROL INTERFACE MODULE (MRX-SCI)

Data Transmission System................................RS-232 & RS-422

Serial Port Baud Rate........................................Up to 57.6 Kb baud

Control Levels....................................................Four or eight

Communication Line..........................................Coaxial, up to 2000 feet

Control Panels...................................................Up to 64 on 2 Comm. Lines

Number of Salvos..............................................Four, from Master Control Panel

Protocol .............................................................Simple ASCII, supports Xon/Xoff

External Sync Reference...................................Composite Sync or Blackburst

Connectors ........................................................(2) BNC for Comm. Line & External Sync.

..........................................................................9 Pin “D” for Serial Port

ANALOG VIDEO FRAME (MRX-24V, MRX-32V)

Input Impedance................................................75Ω, terminated

Input Level.........................................................1.4V p-p maximum

Input Coupling....................................................DC

Input Return Loss ..............................................35dB minimum to 5MHz

Input DC Offset..................................................±0.3V

Tilt, field and line................................................<1% maximum

Output Impedance.............................................75Ω, source terminated

Output Level......................................................1.4V p-p maximum

Output Coupling.................................................DC

Differential Phase ..............................................<0.15° @ 4.43MHz, 10-90% APL

Differential Gain.................................................<0.15% @ 4.43MHz %, 10-90% APL

Frequency Response.........................................±0.1dB from DC to 25 MHz

Bandwidth..........................................................50 MHz

Input Gain Variation...........................................<±0.15 dB maximum

Crosstalk ..........................................................>40 dB below 1V p-p @ 5 MHz

Hum & Noise......................................................-65 dB rms., below 1Vp-p

Connectors ........................................................BNC

ANALOG AUDIO FRAME (MRX-24A, MRX-32A)

Input Impedance................................................30 KΩ, balanced

Input Level.........................................................+24 dBu, maximum

Output Level......................................................+24 dBu max. into 600Ω

..........................................................................+26 dBu max. into high impedance

Output Impedance .............................................100Ω, balanced

Frequency Response.........................................±0.1 dB 10 Hz to 30 KHz, any level

..........................................................................±0.25 dB to 100 KHz

Hum & Noise......................................................< -90 dBu with 22KHz low-pass filter

Total Harmonic Distortion...................................<0.05% maximum, worst case @ +24 dBu

Crosstalk............................................................ 90 dB min. below referenced channel 10Hz to 20kHz,

............................................................................... all inputs driven, 600Ω loads. 110 dB typ.

Gain...................................................................Unity ±0.2 dB, 600Ω termination

Connectors......................................................................3 Pin pluggable t erminals

Page 22

APPENDIX B - SPECIFICATIONS

DIGITAL VIDEO FRAME (MRX-DVF)

Signal Type........................................................ SMPTE 259M

Connectors ........................................................75 Ohm BNC

Inputs.................................................................32, single-ended, terminated, 800mV p-p

Input return loss.................................................15 dB min. from 5 MHz to 270 MHz

Equalization.......................................................Auto, 750 feet, with Belden 1694A or equiv.

Outputs..............................................................32, 800mV p-p max. (+/-10%)

Output return loss..............................................15 dB min. from 5 MHz to 270 MHz

Output DC offset................................................0.0 V +/- 0.5 V

Rise and Fall time..............................................0.4ns < tr < 1.50ns, 20% to 80% (rise time)

..........................................................................0.4ns < tf < 1.50ns, 20% to 80% (fall time)

..........................................................................| tr - tf | < 0.5ns (difference of tr and tf < 0.5ns)

Overshoot..........................................................maximum 10% of total amplitude

Serial Jitter.........................................................500ps p-p max.

Reclocking.........................................................Automatic

Electrical length .................................................11ns typical

Operating temperature.......................................0 to 50 degrees Celsius

DIGITAL AUDIO FRAME – Balanced (MRX-TDAF)

Signal Type........................................................ AES-3 1992

Connectors ........................................................3 pin removable terminal block

Inputs.................................................................32, differential, terminated, 7V p-p max.

Transformer Coupled, AES- 3 1992

Input impedance................................................110 ohms (+/-20%) from 0.1 MHz to 6.0 MHz

Input cable length ..............................................500 feet maximum

Outputs..............................................................32, differential, 7V p-p max. (4.3Vp-p typical)

Transformer Coupled, AES- 3 1992

Output impedance..............................................110 ohms (+/-20%) from 0.1 MHz to 6.0 MHz

Output Rise and Fall time...................................5ns < tr < 30ns, 10% to 90% (rise time)

5ns < tf < 30ns, 10% to 90% (fall time)

Serial Data Rates...............................................3.072 Mb/s max. (Fs = 48 kHz max.)

Serial Data Jitter................................................±20ns p-p max.

Reclocking.........................................................Automatic

Input common mode rejection............................7V peak from DC to 20 kHz

Output common mode noise..............................30 dB min. below signal from DC to 6 MHz

Electrical length .................................................80ns typical

Operating temperature.......................................0 to 50 degrees Celsius

B2

Page 23

APPENDIX B - SPECIFICATIONS

DIGITAL AUDIO FRAME – Unbalanced (MRX-CDAF)

Signal Type........................................................ AES-3id 1995

Connectors ........................................................75 Ohm BNC

Inputs.................................................................32, single-ended, terminated, 1V p-p max.

Input return loss.................................................15 dB min. from 0.1 MHz to 6.0 MHz

Input impedance................................................75 ohms from 0.1 MHz to 6.0 MHz

Input cable length ..............................................1000 feet maximum

Outputs..............................................................32, single-ended, 1V p-p max.

Output return loss..............................................15 dB min. from 0.1 MHz to 6.0 MHz

Output impedance..............................................75 ohms from 0.1 MHz to 6.0 MHz

Output Rise and Fall time...................................30ns < tr < 44ns, 10% to 90% (rise time)

30ns < tf < 44ns, 10% to 90% (fall time)

Serial Data Rates...............................................3.072 Mb/s max. ( Fs = 48 kHz max.)

Serial Data Jitter................................................±20ns p-p max.

Reclocking.........................................................Automatic

Electrical length .................................................80ns typical

Operating temperature.......................................0 to 50 degrees Celsius

POWER SUPPLY FRAME (MRX-PSF)

AC Input Voltage................................................100-240 VAC, 50-60 Hz

AC Input Connectors..........................................3 pin IEC (2 total per frame)

Power Supply Type............................................AC-DC Switching, forced air cooling

Removable Supply Model Name........................MRX-PSU

Max. Removable Supplies..................................2 in non-redundant configuration

4 in redundant configuration

DC Outputs........................................................2 per MRX-PSU (8 total per frame)

DC Output Connectors.......................................4 pin for MRX Analog

6 pin for MRX Digital

DC Output Voltage.............................................±18VDC for MRX Analog

Dual +18VDC for MRX Digital

AC Input Power..................................................85W Supplying Maximum Load for MRX Digital

Includes MRX-DVF and MRX-TDAF (or CDAF)

60W Supplying Maximum Load for MRX Analog

Includes MRF-V and two frames of MRF-A

120W Supplying Max. Load for MRX Analog & Digital

Operating temperature.......................................0 to 50 degrees Celsius

MECHANICAL

Switch and Power Frame...................................1 RU 1.75” H x 19” W x 10” D

Master Control Panel (SYX &SYX-3232) ...........2 RU 3.5” H x 19” W x 2.5” D

Single Bus Panels (SBX-32)..............................2 RU 3.5” H x 19” W x 2.5” D

Alpha-Numeric (ANX) .......................................1 RU 1.75” H x 19” W x 2.5” D

Rapid Take Panel (RTX-32)...............................1 RU 1.75” H x 19” W x 2.5” D

B3

Loading...

Loading...