Page 1

OPERATOR’S MANUAL

Version 4.xx

Laser Beam Analyzer

Models LBA-300/400/500PC

Models LBA-700/708/710/712/714PC

For Windows® 2000 and Windows® XP Pro

Spiricon, Inc.

60 W 1000 N

Logan, Utah 84321

Phone 435-753-3729

Fax 435-753-5231

E-mail, Sales: sales@spiricon.com

E-mail, Service: service@spiricon.com

© Copyright 2005, Spiricon Inc., All rights reserved.

Operator’s Manual LBA-PC

Doc. No. 10654-001, Rev 4.10

1

Page 2

NOTICE

Spiricon Inc. reserves the right to make improvements and changes to the product described in this

manual at any time and without notice. While Spiricon Inc. has taken every precaution in the

preparation of this product Spiricon Inc. assumes no responsibility for errors or omissions that might

cause or contribute to a loss of data.

Spiricon Inc. makes no guarantee that any one brand or model of Personal Computer will be compatible

with any or all of the capabilities in the LBA-PC application software or hardware, either now or in the

future.

Operator’s Manual LBA-PC

2

Page 3

Table of Contents

OPERATOR’S MANUAL __________________ 1

Version 4.xx ____________________________________________ 1

Laser Beam Analyzer __________________________________ 1

Models LBA-300/400/500PC_____________________________ 1

Models LBA-700/708/710/712/714PC __________________ 1

For Windows® 2000 and Windows® XP Pro ____________________ 1

© Copyright 2005, Spiricon Inc., All rights reserved. __________________ 1

NOTICE 2

Chapter 1 INTRODUCTION ___________________________________ 11

1.1 General Information ______________________________________________ 11

1.2 System Requirements_____________________________________________ 11

1.3 Optional Equipment ______________________________________________ 12

1.4 Specifications ___________________________________________________ 13

1.5 Safety Considerations _____________________________________________ 14

1.5.1 Optical Radiation Hazards ____________________________________________ 14

1.5.2 Electrical Hazards __________________________________________________ 14

Chapter 2 EQUIPMENT SETUP ________________________________ 15

2.1 Equipment Setup ________________________________________________ 15

2.1.1 Step 1 Installation of the Frame Grabber Board ________________________ 15

2.1.2 Step 2 Camera Connections ________________________________________ 18

2.1.2.1 Analog Cameras_______________________________________________________ 19

2.1.2.2 Digital Cameras _______________________________________________________ 19

2.1.3 Step 3 LBA-PC Software Installation __________________________________ 19

2.1.4 Step 4 Start LBA-PC _______________________________________________ 20

2.1.5 Step 5 Configure Camera Type ______________________________________ 21

2.1.6 Step 6 Collect Data _______________________________________________ 21

2.1.7 Step 7 Sample Configurations _______________________________________ 21

2.2 Error Messages __________________________________________________ 22

2.3 Optional Equipment ______________________________________________ 24

2.4 Connections_____________________________________________________ 24

2.4.1 Camera Power _____________________________________________________ 25

2.4.2 Shutter Controls Signals _____________________________________________ 25

2.4.3 Trigger Out _______________________________________________________ 26

2.4.4 Pass/Fail Out ______________________________________________________ 26

2.4.5 Trigger In ________________________________________________________ 26

2.4.6 Video In __________________________________________________________ 26

2.5 Camera Control Cables ____________________________________________ 26

2.6 Special Setup for Pyrocam I Operation _______________________________ 27

2.6.1 Pyrocam I with Non-Digital LBA-PC’s ___________________________________ 27

LBA-300/400/500/708/710/712/714PC w/o digital camera option ______________________ 27

2.6.1.1 Pyrocam I Setup Requirements: __________________________________________ 27

2.6.1.2 Setup requirements for LBA-PC with pyrocam cameras: _______________________ 28

Operator’s Manual LBA-PC

Doc. No. 10654-001, Rev 4.10

3

Page 4

2.6.1.3

2.6.1.4 Image synchronization considerations _____________________________________ 29

Some Restrictions apply when interfaced to a Pyrocam I ______________________ 28

2.6.2 Pyrocam I with Digital LBA-PC’s _______________________________________ 29

2.6.2.1 Pyrocam I setup requirements:___________________________________________ 29

2.6.2.2 LBA-500/7XXPC-D Setup requirements: ____________________________________ 30

2.6.2.3 Image Synchronization Considerations _____________________________________ 31

Chapter 3 MENUS AND DIALOG BOXES _________________________ 32

3.1 File. . . Drop Down Menu Selections _________________________________ 32

3.1.1 File | Load. . . _____________________________________________________ 32

.lb3/4/5/7 Files _____________________________________________________________ 32

.lba Files ____________________________________________________________________ 32

.lbb Files ____________________________________________________________________ 32

.lbc Files ____________________________________________________________________ 32

3.1.1.1 Load Frame Dialog Box _________________________________________________ 33

3.1.1.2 Special Frame Numbers_________________________________________________ 34

3.1.1.3 Drag and Drop Data Frame Loading _______________________________________ 34

3.1.2 File | Save As… ____________________________________________________ 34

3.1.2.1 Save As … Dialog Box __________________________________________________ 35

3.1.3 Export Image… to a disk file__________________________________________ 35

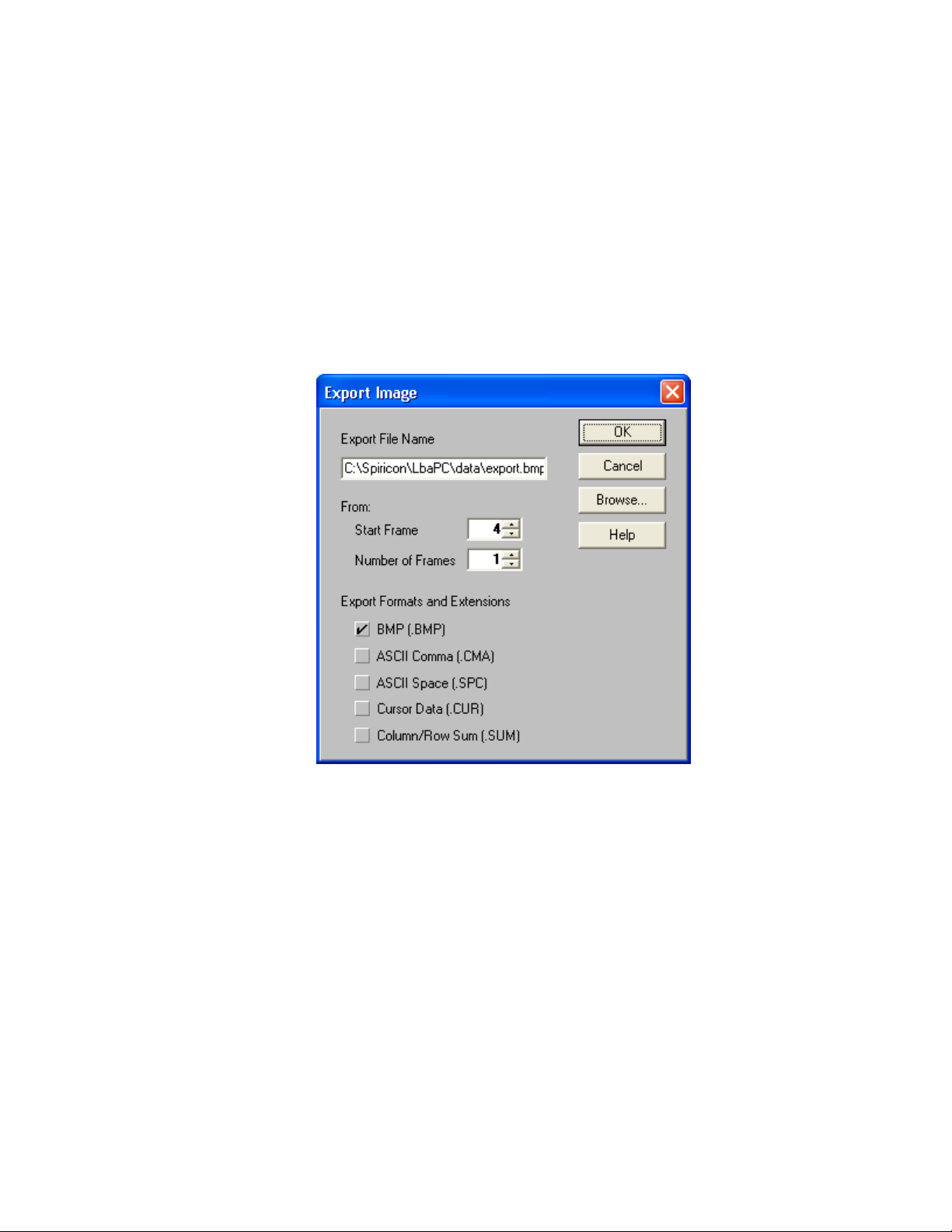

3.1.3.1 Export Image… dialog box ______________________________________________ 36

3.1.4 Save Config… to a file _______________________________________________ 37

3.1.5 Restore Config… from a file __________________________________________ 37

3.1.6 Set Reference, copy the current to the reference frame ____________________ 37

3.1.7 Generate Gain _____________________________________________________ 38

3.1.7.1 How to generate gain __________________________________________________ 38

3.1.7.2 What is Gain Correction?________________________________________________ 38

3.1.7.3 What Disables Gain Correction? __________________________________________ 38

3.1.8 File | Load Gain… __________________________________________________ 39

3.1.9 File | Save Gain As… ________________________________________________ 39

3.1.10 Gain Off/On _________________________________________________ 39

3.1.11 File | Logging... ______________________________________________ 39

3.1.11.1 Beginning and Terminating Logging _______________________________________ 40

3.1.11.2 Data, Results & Export Logging, dialog box _________________________________ 40

3.1.11.3 Logging Method_______________________________________________________ 41

3.1.11.4 Pass/Fail Filter ________________________________________________________ 42

3.1.12 Implications of Combining Logging, Statistics, Post Processing and Block

Capture 42

3.1.12.1 Combinations using Logging, Statistics and Block Mode _______________________ 43

3.1.12.2 Combinations using Logging, Statistics and Post Processing. ___________________ 43

3.1.13 File | Print… _____________________________________________________ 44

3.1.14 File | Print Setup...________________________________________________ 45

3.1.15 File | Exit _______________________________________________________ 45

3.1.16 File | Save FROG as… __________________________________________ 45

3.1.16.1 Save FROG as…Dialog Box ______________________________________________ 46

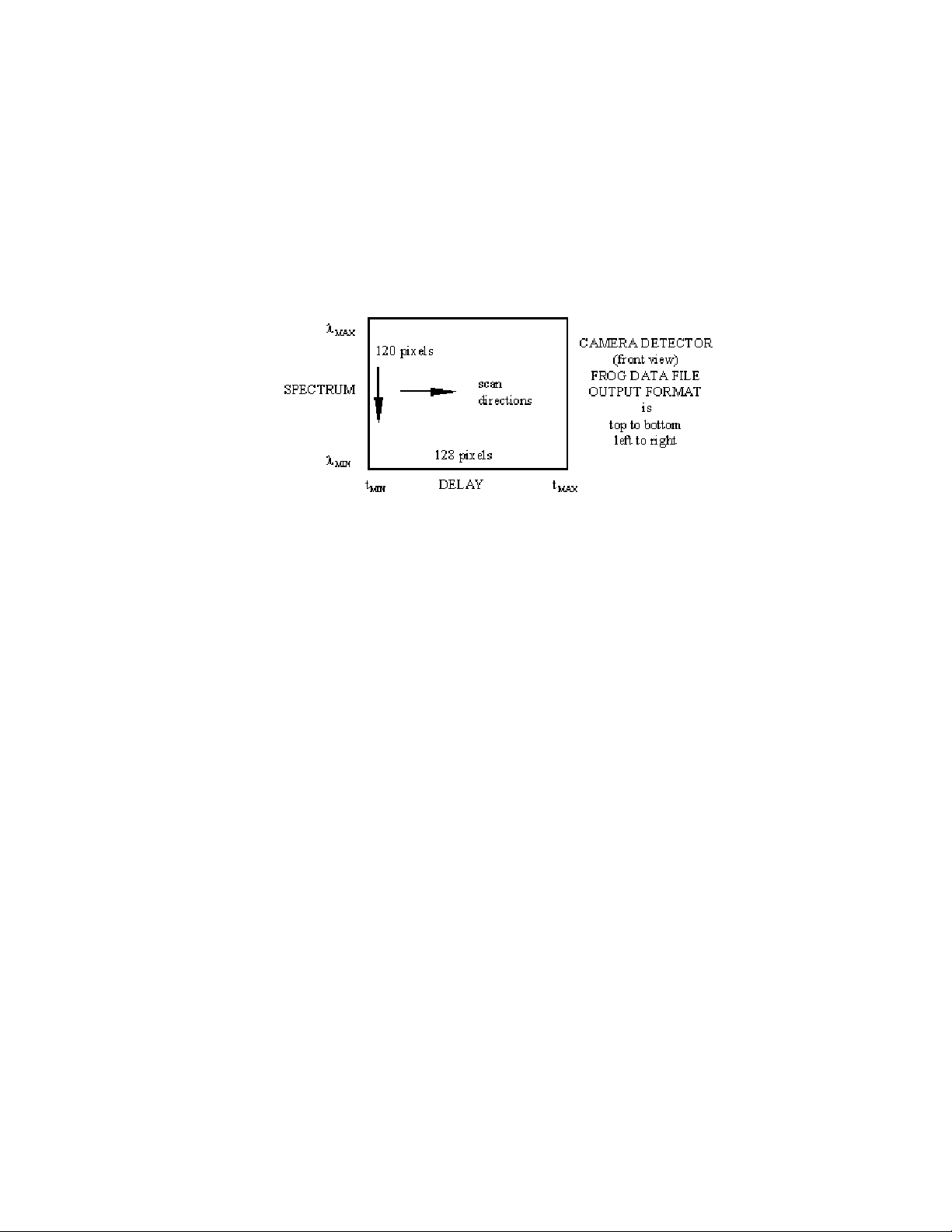

3.1.16.2 FROG Data Orientation _________________________________________________ 47

3.1.16.3 FROG Data Collection Tips ______________________________________________ 47

3.2 Options... Drop Down Menu Selections _______________________________ 49

3.2.1 Hide/Show; Capture, Display, Aperture Toolbar __________________________ 49

Operator’s Manual LBA-PC

4

Page 5

3.2.2 Aperture... display and define apertures ________________________________ 49

3.2.2.1 Aperture Shapes ______________________________________________________ 49

3.2.2.2 How to create a Drawn Aperture _________________________________________ 50

3.2.2.3 Drag and Drop Apertures _______________________________________________ 50

3.2.2.4 Using Auto Apertures___________________________________________________ 51

3.2.2.5 Display Beam Width ___________________________________________________ 51

3.2.3 Camera... selection and display resolution _______________________________ 52

3.2.3.1 Camera type selection. _________________________________________________ 52

3.2.3.2 Creating a new Camera Type ____________________________________________ 52

3.2.3.3 Resolution and Frame Size ______________________________________________ 53

3.2.3.4 Frame Buffer Size _____________________________________________________ 54

3.2.3.5 Am I using Virtual Memory yet? __________________________________________ 55

3.2.3.6 Sync Source __________________________________________________________ 55

3.2.3.7 Pixel Scale, Pixel Units__________________________________________________ 56

3.2.3.8 Gamma Correction_____________________________________________________ 56

3.2.3.9 Lens ________________________________________________________________ 57

3.2.3.10 Special Camera Settings ________________________________________________ 57

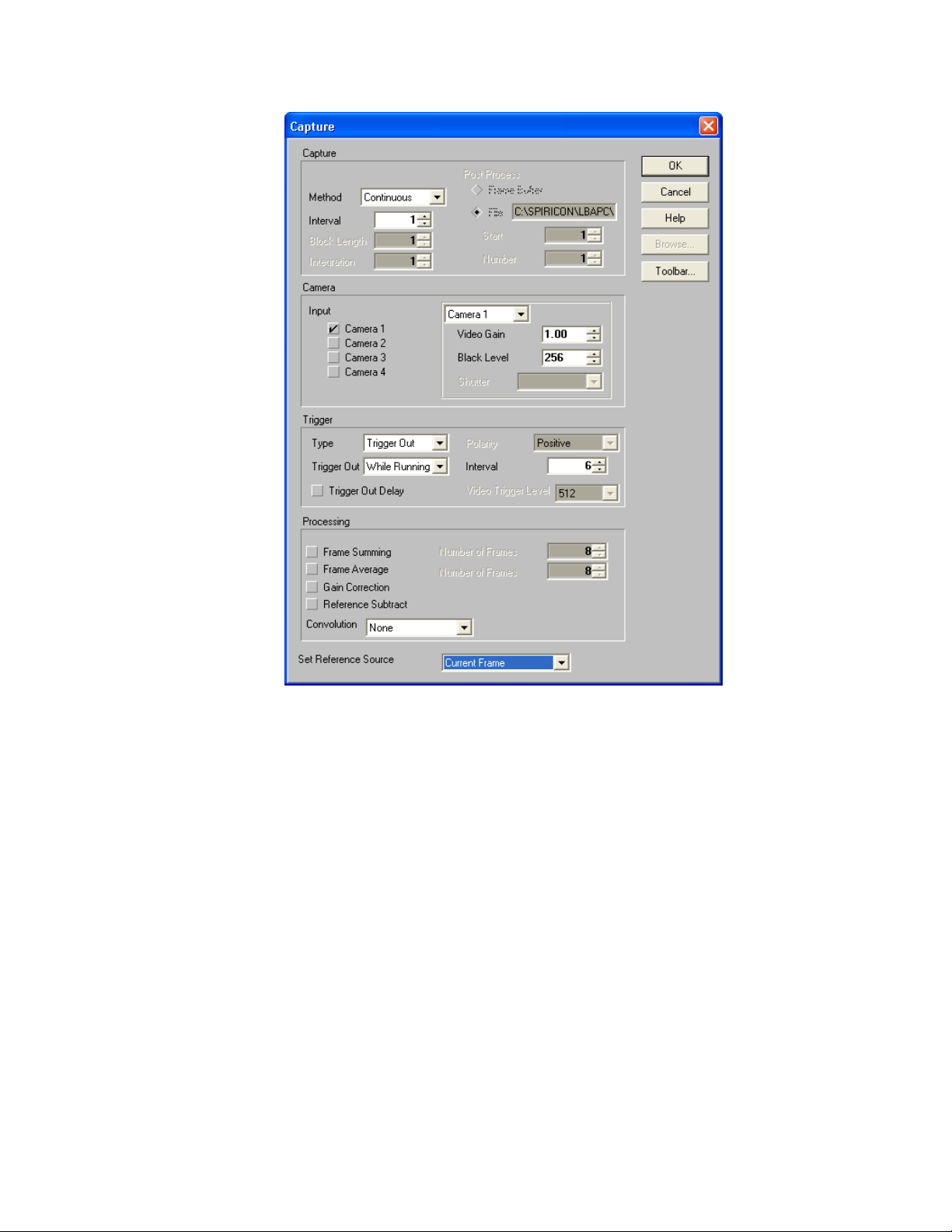

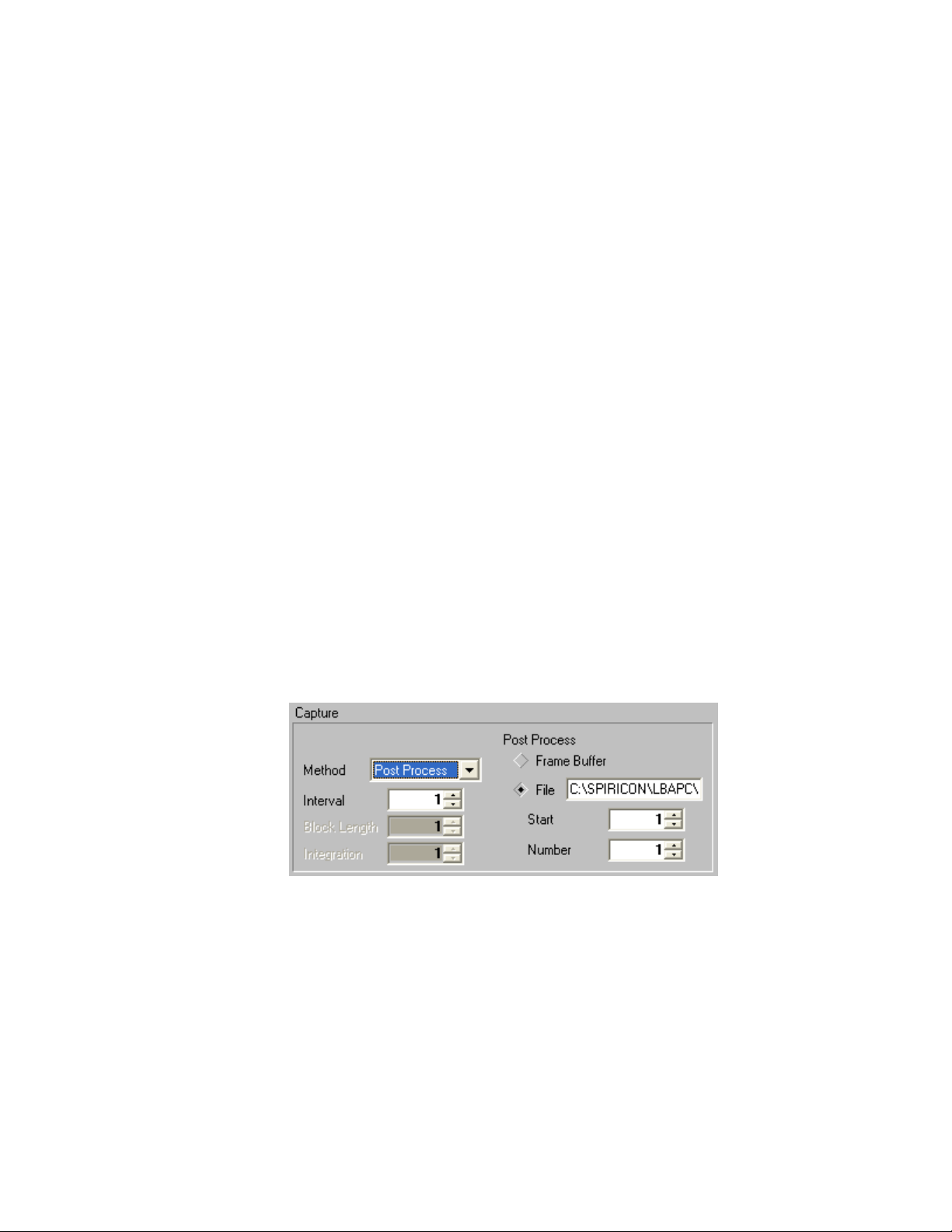

3.2.4 Capture... define acquisition method and processing ______________________ 57

3.2.4.1 Capture _____________________________________________________________ 58

3.2.4.2 Capture Interval_______________________________________________________ 60

3.2.4.3 Camera _____________________________________________________________ 60

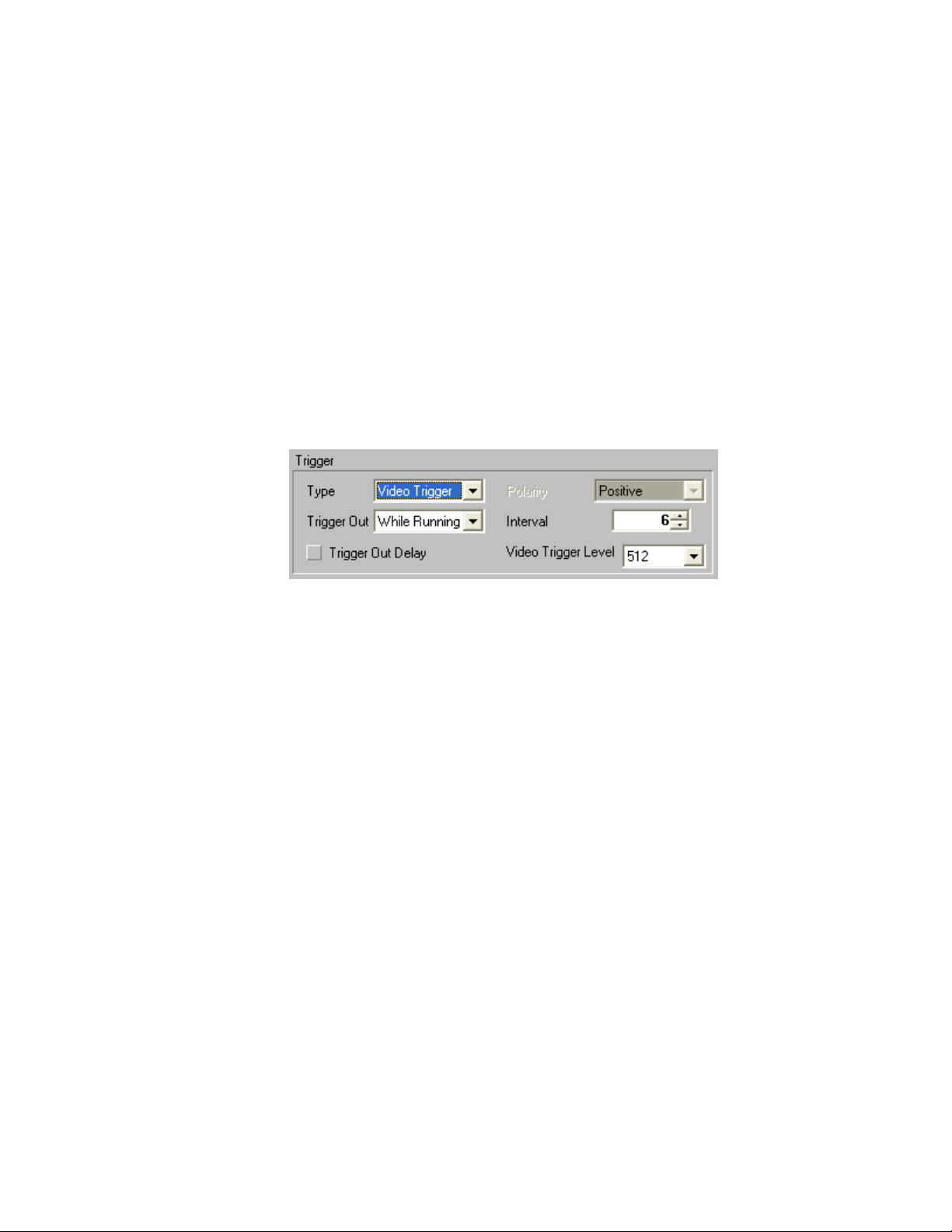

3.2.4.4 Trigger ______________________________________________________________ 62

3.2.4.5 Processing ___________________________________________________________ 64

3.2.4.6 Frame Summing __________________________________________________ 65

3.2.4.7 Frame Average ___________________________________________________ 65

3.2.4.8 Gain Correction ___________________________________________________ 65

3.2.4.9 Reference Subtraction ______________________________________________ 65

3.2.4.10 Convolution __________________________________________________________ 66

3.2.5 Capture Toolbar... design the toolbar contents ___________________________ 66

3.2.5.1 Logging _________________________________________________________ 67

3.2.5.2 Print ____________________________________________________________ 67

3.2.5.3 Write Protect _____________________________________________________ 67

3.2.6 Computation... Energy calibration select results items _____________________ 67

3.2.6.1 Energy of Beam _______________________________________________________ 67

3.2.6.2 Energy Calibration Procedure ____________________________________________ 68

3.2.6.3 Quantitative display, on/off______________________________________________ 68

3.2.6.4 Beam Width Method ___________________________________________________ 69

3.2.6.5 Elliptical _____________________________________________________________ 71

3.2.6.6 Gauss Fit ____________________________________________________________ 71

3.2.6.7 Top Hat _____________________________________________________________ 71

3.2.6.8 Divergence___________________________________________________________ 72

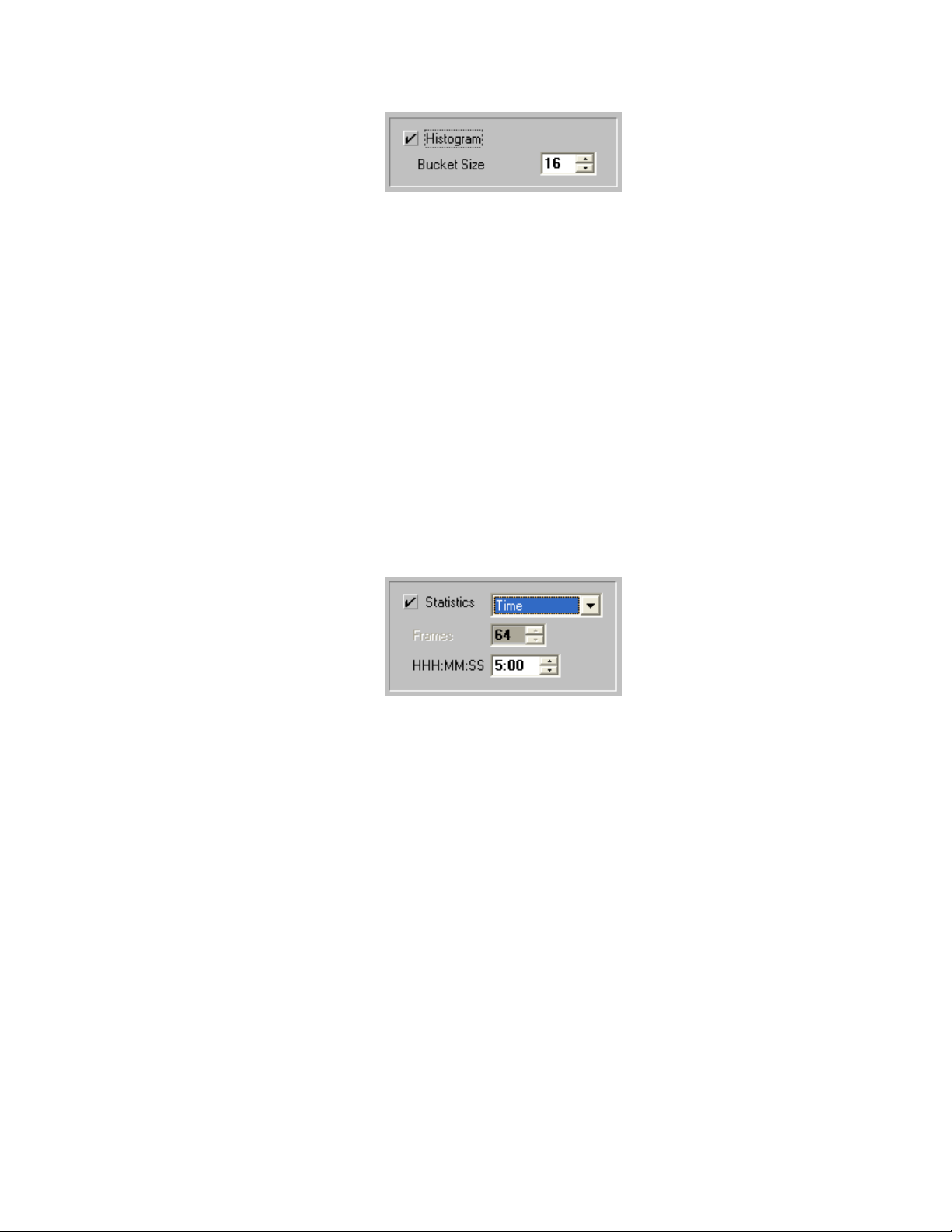

3.2.6.9 Histogram ___________________________________________________________ 73

3.2.6.10 Statistics_____________________________________________________________ 74

3.2.7 Beam Display... define the beam display ________________________________ 75

3.2.7.1 Beam View _______________________________________________________ 76

3.2.7.2 Cursors______________________________________________________________ 76

Operator’s Manual LBA-PC

Doc. No. 10654-001, Rev 4.10

5

Page 6

3.2.7.3

3.2.7.4 Origin Location________________________________________________________ 77

3.2.7.5 Beam Colors__________________________________________________________ 78

3.2.7.6 Z Axis Scale __________________________________________________________ 78

3.2.7.7 Beam Display _________________________________________________________ 79

3.2.7.8 Set Reference Source __________________________________________________ 80

3.2.7.9 Display Thresholds_____________________________________________________ 81

3.2.7.10 Color Bar ________________________________________________________ 81

3.2.7.11 Copy Image to Clipboard ___________________________________________ 82

3.2.7.12 Copy Image to Wallpaper ___________________________________________ 82

3.2.7.13 2D Only Beam Display Items_____________________________________________ 82

3.2.7.14 3D only______________________________________________________________ 83

Cursor Orientation _____________________________________________________ 76

3.2.8 Beam Display Toolbar _______________________________________________ 85

3.2.9 Beam Stability _____________________________________________________ 85

3.2.9.1 Main Controls_________________________________________________________ 86

3.2.9.2 Strip Chart Controls ____________________________________________________ 87

3.2.9.3 Peak/Centroid Scatter Plot and Histogram __________________________________ 89

3.2.10 Create Palette… __________________________________________________ 94

3.2.10.1 Saving the Palette _____________________________________________________ 96

3.2.10.2 Save Colors __________________________________________________________ 96

3.2.10.3 Load Colors __________________________________________________________ 97

3.2.10.4 Clearing Colors________________________________________________________ 97

3.2.11 Password Lockout ________________________________________________ 98

3.3 Pass/Fail... Drop Down Menu Selections ______________________________ 98

3.3.1 Pass/Fail... enable and define its operation ______________________________ 98

3.3.1.1 PASS or FAIL results ___________________________________________________ 99

3.3.1.2 Pass/Fail Units ________________________________________________________ 99

3.3.1.3 Pass/Fail dialog boxes __________________________________________________ 99

3.3.2 Quantitative Pass/Fail _______________________________________________ 99

3.3.2.1 Min Fluence __________________________________________________________ 99

3.3.2.2 Centroid ____________________________________________________________ 100

3.3.3 Elliptical Pass/Fail _________________________________________________ 100

3.3.3.1 Orientation__________________________________________________________ 100

3.3.4 Gauss Pass/Fail ___________________________________________________ 100

3.3.5 Top Hat Pass/Fail _________________________________________________ 100

3.3.5.1 Top Hat Fluence _____________________________________________________ 101

3.3.5.2 Divergence Pass/Fail __________________________________________________ 101

3.4 Window... Drop Down Menu Selections ______________________________ 101

3.4.1 Tile_____________________________________________________________ 102

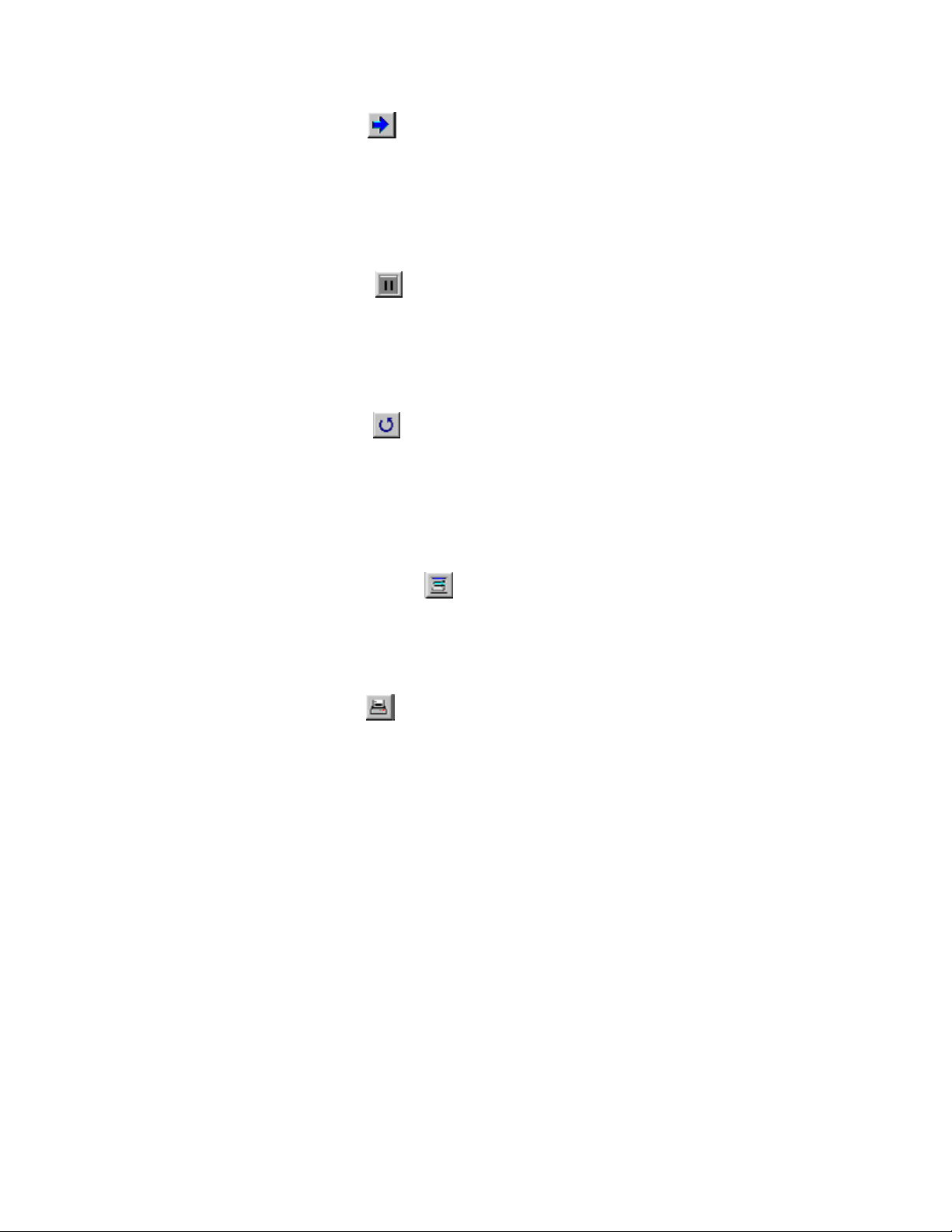

3.5 Start!/Stop!... A Toggle Menu Action Item____________________________ 102

3.6 Ultracal! Menu Action Item________________________________________ 102

3.6.1 How to Ultracal! __________________________________________________ 102

3.6.2 What Disables Ultracal! _____________________________________________ 103

3.7 AutoExposure!… Menu Action Item _________________________________ 103

3.7.1 AutoExposure! Operation ___________________________________________ 103

3.7.2 AutoExposure Interacts with Ultracal __________________________________ 103

Chapter 4 DISPLAY WINDOWS ______________________________ 106

4.1 Main Window __________________________________________________ 106

Operator’s Manual LBA-PC

6

Page 7

4.2 The Beam Display Window________________________________________ 106

4.2.1 Frame Comment __________________________________________________ 107

4.2.2 Shortcuts ________________________________________________________ 109

4.3 The Results Display Window ______________________________________ 109

4.3.1 Shortcuts ________________________________________________________ 110

4.4 The Pan/Zoom Display Window ____________________________________ 111

4.4.1 Hardware Zooming ________________________________________________ 111

4.4.1.1 Analog Camera Zooming _______________________________________________ 112

4.4.1.2 Digital Camera Zooming _______________________________________________ 113

4.4.2 Soft Zooming_____________________________________________________ 113

4.4.3 Panning _________________________________________________________ 113

4.4.4 Zooming and Panning Constraints ____________________________________ 114

4.5 The Tilt/Rotate Display Window ____________________________________ 114

4.6 The Histogram Display Window ____________________________________ 115

4.7 Shortcuts using the Mouse ________________________________________ 116

4.7.1 Shortcut to the Computations Dialog Box ______________________________ 116

4.7.2 Shortcut to the Beam Display Dialog Box _______________________________ 116

4.7.3 Shortcut to the Capture Toolbar Dialog Box_____________________________ 116

4.7.4 Shortcut to the Capture Dialog Box ___________________________________ 116

4.7.5 Shortcut to the Beam Display Toolbar Dialog Box ________________________ 116

4.7.6 Shortcut to the Beam Display Dialog Box _______________________________ 116

4.7.7 Shortcut to the Aperture Dialog Box___________________________________ 116

Chapter 5 TRIGGERING TYPES & CAPTURING METHODS __________ 118

5.1 Triggering the LBA-PC ___________________________________________ 118

5.1.1 A Note to Pulse Laser Users _________________________________________ 118

5.1.2 Trigger Type CW __________________________________________________ 119

5.1.2.1 Interlaced Cameras ___________________________________________________ 119

5.1.2.2 Non-interlaced Cameras _______________________________________________ 119

5.1.3 Type Trigger Out__________________________________________________ 119

5.1.3.1 Trigger Interval ______________________________________________________ 119

5.1.3.2 Trigger Delay ________________________________________________________ 120

5.1.3.3 CCD Frame Transfer Camera, Interlaced __________________________________ 120

5.1.3.4 CCD Interline and Full Frame Transfer Camera, Interlaced ____________________ 120

5.1.3.5 CMOS Camera, Interlaced ______________________________________________ 120

5.1.3.6 Tube Camera, Interlaced_______________________________________________ 120

5.1.3.7 CCD Frame and Interline Transfer Cameras, Non-interlaced (Progressive scan) ___ 121

5.1.3.8 CMOS, CID Line Transfer and Tube Cameras, Non-Interlaced (Progressive scan) __ 121

5.1.4 Type Trigger In ___________________________________________________ 121

5.1.4.1 CCD Frame Transfer Camera, Interlaced __________________________________ 121

5.1.4.2 CCD Interline and Full Frame Transfer Camera, Interlaced ____________________ 121

5.1.4.3 CCD Frame and Interline Transfer Cameras, Non-Interlaced (Progressive scan) ___ 121

5.1.5 Type Video Trigger ________________________________________________ 121

5.1.5.1 CCD Frame and Interline Transfer Cameras, Interlaced_______________________ 122

5.2 Capture Methods and Rate Control _________________________________ 122

5.2.1 Programming the Capture Interval ____________________________________ 122

5.2.1.1 With Trigger Type set to CW____________________________________________ 122

5.2.1.2 With Trigger Type set to Trigger Out _____________________________________ 123

5.2.1.3 Trigger Type set to Video Trigger with the LBA firing the laser_________________ 123

5.2.1.4 Trigger Type set to Video Trigger without the LBA firing the laser ______________ 123

Operator’s Manual LBA-PC

Doc. No. 10654-001, Rev 4.10

7

Page 8

5.3 Integration Control ______________________________________________ 123

5.3.1 Integration Operation ______________________________________________ 124

5.4 Digital Camera Operations ________________________________________ 124

5.4.1 Digital Camera Control _____________________________________________ 124

5.4.1.1 Digital Camera Binning Effects __________________________________________ 124

5.4.1.2 Digital Camera ROI Formating __________________________________________ 125

5.4.1.3 Digital Camera Exposure Controls________________________________________ 125

5.4.1.4 Digital Camera Triggering ______________________________________________ 125

5.4.1.5 Digital Camera Gain and Black Level Control _______________________________ 126

Chapter 6 COMPUTATIONS _________________________________ 128

6.1 Computational Accuracy __________________________________________ 128

6.2 Numerical Formats ______________________________________________ 128

6.3 Beam Presentation Affects Results__________________________________ 129

6.4 Manual Background Energy Nulling _________________________________ 129

6.4.1 What is Ultracal! __________________________________________________ 129

6.5 Clip Level______________________________________________________ 130

6.6 Total Energy ___________________________________________________ 130

6.7 Percent in Aperture______________________________________________ 131

6.8 Peak and Min __________________________________________________ 131

6.9 Peak Location __________________________________________________ 131

6.10 Centroid Location______________________________________________ 131

6.11 Beam Widths and Diameters _____________________________________ 132

6.11.1 D4-Sigma Method _______________________________________________ 132

6.11.2 Knife Edge Method_______________________________________________ 133

6.11.3 Percent of Energy Method _________________________________________ 134

6.11.4 Percent of Peak Method___________________________________________ 134

6.12 Elliptical beam ________________________________________________ 134

6.13 Gauss Fit ____________________________________________________ 135

6.14 Whole Beam fit equations _______________________________________ 136

6.15 X/Y or Major/Minor line fit equations ______________________________ 136

6.16 Deviation of Fit________________________________________________ 137

6.17 Correlation of Fit ______________________________________________ 137

6.18 Top Hat _____________________________________________________ 138

6.18.1 Top Hat Mean and Standard Deviation _______________________________ 139

6.18.2 Top Hat Minimum and Maximum intensities ___________________________ 139

6.19 Top Hat Factor ________________________________________________ 139

6.20 Effective Area and Effective Diameter______________________________ 141

6.21 Far-Field Divergence Angle computations___________________________ 141

6.21.1 The Focal Length Method _________________________________________ 141

6.21.2 The Far-Field Method_____________________________________________ 142

6.22 Histogram____________________________________________________ 142

6.23 Statistics_____________________________________________________ 143

6.24 Frame Averaging ______________________________________________ 144

6.25 Frame Summing_______________________________________________ 144

6.26 Gamma Correction _____________________________________________ 145

6.27 Convolution __________________________________________________ 146

Operator’s Manual LBA-PC

8

Page 9

Chapter 7 DIGITAL CAMERA OPTION__________________________ 148

7.1 Digital Camera Option____________________________________________ 148

7.2 I/O Connections ________________________________________________ 148

7.3 Digital Camera Advanced Timing Setup ______________________________ 152

7.3.1 Transfer Mode ____________________________________________________ 152

7.3.2 Scan Mode_______________________________________________________ 152

7.3.3 Vertical Start _____________________________________________________ 152

7.3.4 Vertical Size ______________________________________________________ 153

7.3.5 Horizontal Start ___________________________________________________ 153

7.3.6 Horizontal Size____________________________________________________ 153

7.4 Digital Camera and Ultracal Operation_______________________________ 154

Chapter 8 REMOTE OPERATION ______________________________ 156

8.1 Remote Operation_______________________________________________ 156

8.2 How to Disable Remote Operation __________________________________ 156

Chapter 9 ACTIVE X _______________________________________ 158

9.1 Introduction ___________________________________________________ 158

9.2 Using ActiveX __________________________________________________ 158

9.2.1 Microsoft Excel ___________________________________________________ 158

9.2.2 Visual Basic (Visual Studio)__________________________________________ 159

9.2.3 LabVIEW ________________________________________________________ 160

9.3 Properties, Methods, and Events ___________________________________ 160

9.3.1 Properties _______________________________________________________ 161

9.3.1.1 AppInfo ____________________________________________________________ 161

9.3.1.2 Running ____________________________________________________________ 161

9.3.1.3 OperationComplete ___________________________________________________ 161

9.3.1.4 OperationError_______________________________________________________ 162

9.3.1.5 NewFrame, HoldNewFrame_____________________________________________ 162

9.3.1.6 FrameData, FrameWidth, FrameHeight ___________________________________ 162

9.3.1.7 PixelHScale, PixelVScale _______________________________________________ 162

9.3.1.8 FrameMonth, FrameDay, FrameYear _____________________________________ 162

9.3.1.9 FrameHour, FrameMinute, FrameSecond, FrameMilliseconds __________________ 162

9.3.1.10 CursorX, CursorY, CursorZ______________________________________________ 162

9.3.1.11 CrosshairX, CrosshairY, CrosshairZ _______________________________________ 163

9.3.1.12 CursorDelta _________________________________________________________ 163

9.3.1.13 EnergyOfBeam_______________________________________________________ 163

9.3.1.14 Bitmap _____________________________________________________________ 163

9.3.1.15 FrameNumber _______________________________________________________ 163

9.3.1.16 Results _____________________________________________________________ 164

9.3.1.17 Quantitative Results __________________________________________________ 164

9.3.1.18 Elliptical Results______________________________________________________ 165

9.3.1.19 Gauss Fit Results _____________________________________________________ 165

9.3.1.20 Top Hat Results ______________________________________________________ 166

9.3.1.21 Divergence Results ___________________________________________________ 167

9.3.1.22 Statistics Results _____________________________________________________ 167

9.3.1.23 Pass/Fail Results _____________________________________________________ 168

9.3.2 Methods_________________________________________________________ 169

9.3.2.1 LoadConfig__________________________________________________________ 169

9.3.2.2 Open ______________________________________________________________ 169

9.3.2.3 OpenIndex __________________________________________________________ 170

9.3.2.4 Start _______________________________________________________________ 170

Operator’s Manual LBA-PC

Doc. No. 10654-001, Rev 4.10

9

Page 10

9.3.2.5

9.3.2.6 Ultracal_____________________________________________________________ 170

9.3.2.7 Auto Exposure _______________________________________________________ 171

Stop _______________________________________________________________ 170

9.3.3 Events __________________________________________________________ 171

9.3.3.1 OnNewFrame________________________________________________________ 171

9.3.3.2 OnOperationComplete _________________________________________________ 172

9.4 DCOM ________________________________________________________ 172

9.4.1 Remote Access ___________________________________________________ 173

9.4.1.1 Server (LBA-PC) Computer _____________________________________________ 173

9.4.1.2 Client (Application) Computer ___________________________________________ 174

9.4.2 If you have a problem______________________________________________ 175

Chapter 10 REMOTE GPIB OPERATION _________________________ 177

10.1 Introduction __________________________________________________ 177

10.2 Hardware and Software Requirements _____________________________ 177

10.3 Remote GPIB Setup ____________________________________________ 177

10.4 Command Formats and Responses ________________________________ 179

10.4.1 IEEE 488.1 Command Support _____________________________________ 179

10.4.2 IEEE 488.2 Common Commands____________________________________ 180

10.4.3 LBA-PC Command and Data Formats ________________________________ 180

10.4.4 Establishing Remote Control _______________________________________ 181

10.5 Configuration Commands _______________________________________ 182

10.5.1 Restore and Save Configuration Files ________________________________ 182

10.5.1.1 LDC - Restore Config… ________________________________________________ 182

10.5.1.2 SDC - Save Config… __________________________________________________ 182

10.5.2 Configuration Commands _________________________________________ 183

10.6 Transfer Commands____________________________________________ 186

10.6.1 Transferring Raw Data____________________________________________ 186

10.6.1.1 RCC?, RCR? - Read Cursor Transfer ______________________________________ 187

10.6.1.2 RDD? - Read Frame Transfer ___________________________________________ 189

10.6.2 Transferring Data Files ___________________________________________ 190

10.6.2.1 FRM? - Download Data Frame __________________________________________ 191

10.6.2.2 FRM - Upload Data Frame______________________________________________ 192

10.6.2.3 LDD - Read Data File__________________________________________________ 193

10.6.2.4 SDD - Save Data File __________________________________________________ 194

10.6.2.5 RDR? - Read Results __________________________________________________ 195

10.6.2.6 LOG - Logging _______________________________________________________ 197

10.6.2.7 FST? - Transferring Status Information ___________________________________ 198

10.6.3 PFS? - Pass/Fail Status _____________________________________________ 200

10.7 COORDINATE SYSTEMS ________________________________________ 200

10.7.1 Spatial Coordinates ______________________________________________ 200

10.7.2 Pan/Zoom Window Detector Coordinates _____________________________ 201

10.7.2.1 DIS - Set Manual Origin Location ________________________________________ 202

10.7.2.2 PAN - Set Capture Window Location______________________________________ 202

10.7.3 Frame Coordinates _______________________________________________ 204

10.7.4 Beam Window World Coordinates ___________________________________ 205

10.8 ERROR MESSAGES_____________________________________________ 206

10.9 SERVICE REQUEST ____________________________________________ 209

10.9.1 Service Request Response_________________________________________ 209

Operator’s Manual LBA-PC

10

Page 11

Chapter 1 INTRODUCTION

1.1 General Information

The Spiricon, Laser Beam Analyzer, Models LBA-300/400/500/700/708/710/712/714PC, is a low cost, PC

based product for use in modern Pentium generation personal computers with high performance PCI

bus architecture. It provides all the essential features needed for laser beam analysis. Some of these

features are:

• High-speed high-resolution false color beam intensity profile displays in both 2D and 3D.

• Operates in Windows 2000, XP Professional, or higher operating systems.

• Numerical beam profile analysis employing advanced patented calibration algorithms.

• User selectable choices for making beam width measurement, including Second Moment

methods.

• Pass/fail testing available on most measured parameters.

• Both Whole beam and Linear Gaussian fits to beam data.

• Top Hat measurements based on the beam profile or a user defined area or line.

• Signal-to-noise ratio improvement through averaging and background subtraction.

• Frame summing for cumulative effect analysis.

• Statistical Analysis of all measured parameters.

• Beam Stability analysis.

• Histogram display and results.

• Post processing capabilities.

• Both Drawn and Auto Aperturing for isolating beam data.

• Both Results and Data logging capabilities.

• Flexible printing options for hard copy generation.

• Two Divergence measurement techniques.

1.2 System Requirements

A complete LBA-PC system consists of the following equipment:

1. The Spiricon LBA-PC frame grabber card, with software.

2. A CCD style camera, or a Spiricon Pyrocam III pyroelectric camera.

3. A Pentium style or compatible PC with:

a) High speed PCI bus, one slot available.

®

b) A Pentium

c) Graphics accelerator card (support for 1024 x 768 minimum).

or Pentium Pro® or equivalent processor based motherboard.

d) At least 256 MB of main memory, 512 MB recommended.

e) At least 15 MB of hard disk space available. Much more (>1 GB) if you want to log data files.

Operator’s Manual LBA-PC

Doc. No. 10654-001, Rev 4.10

11

Page 12

f) A high resolution color monitor.

g) Windows

®

2000 or Windows® XP Professional operating system with at least 64MB of main

memory.

h) A CD-ROM Drive.

i) A PC compatible mouse & keyboard.

Pentium and Pentium Pro are registered trademarks of Intel Corporation.

Windows 2000 and Windows XP Pro are registered trademarks of Microsoft Corporation.

Notice: PC operating system, component and hardware manufactures are constantly revising their products.

Therefore Spiricon, Inc. makes no guarantee that any one brand or model of Personal Computer will be compatible

with any or all of the features contained in the LBA-PC application, either now or in the future.

1.3 Optional Equipment

1. Four-camera adapter, allows you to choose between 1 of 4 connected analog cameras or

automatically cycle between them.

2. Digital Camera adapter, allows you to interface the output from an RS-422 or LVDS digital camera.

3. A printer with appropriate Windows compatible drivers.

4. LBS-100, BA-VIS, -NIR, or -BB Laser Beam Attenuator.

Most laser beam energy will need to be attenuated before applying it to the camera sensor.

Attenuation requirements vary greatly depending upon application. Spiricon offers optional equipment

for beam attenuation. Consult your Spiricon Representative or call Spiricon's Sales Department for

further information.

Operator’s Manual LBA-PC

12

Page 13

1.4 Specifications

ENVIRONMENTAL

Operating Temperature: 0 °C to +50 °C

Storage Temperature: -55 °C to +75 °C

Humidity: 95% non-condensing

POWER REQUIREMENTS

PCI bus loading: +5 Vdc @ 350 mA., +3.3Vdc @ 50mA.

+12 Vdc @ 140 mA.* (w/o camera)

-12 Vdc @ 110 mA.

Power consumption: 4.75 watts (w/o camera)

*Total PCI load on +12 Vdc w/camera not to exceed 500 mA.

WEIGHT

Net: Approximately 0.23 kg (0.5 lb.)

Shipping: Approximately 1.4 kg (3 lb.)

INSTRUMENT CHARACTERISTICS

Video Input: 75 ohm Termination, ±5 volts dc max

Trigger Input: edge sensitive (positive or negative), max input +12 Vdc, lower

threshold 1.1Vdc, upper threshold 2.5 Vdc, minimum pulse

width 10µs.

Trigger Output: +5 or +12 Vdc (positive or negative),

pulse width 700µs +/- 70µs.

Video Gain Adjust .8 to 1.4 w/ LBA-7XX; .8 to ~5 w/LBA-300/400/500

Pass/Fail Output +5 or +12 Vdc positive pulse, 250ms

Shutter Control Outputs TTL positive logic

Operator’s Manual LBA-PC

Doc. No. 10654-001, Rev 4.10

13

Page 14

1.5 Safety Considerations

While the LBA-PC does not present the operator with any safety hazards, this instrument however is

intended for use with laser systems. Therefore, the operator should be protected from any hazards

that the laser system may present. The greatest hazards associated with laser systems are damage to

the eyes and skin due to laser radiation.

1.5.1 Optical Radiation Hazards

With almost any camera used with the LBA-PC, the optical radiation at the camera sensor is low

enough to be considered relatively harmless. However, usage of this instrument may require the

operator to work in the optical path itself where exposure to hazards may be sufficient to warrant the

use of protective equipment.

Unless the laser’s optical path is enclosed, at least to the point where the beam is attenuated for use

with the camera system, the operator should be protected against accidental exposure. Exposure to

personnel other than the operator must also be considered. Exposure hazards include reflected

radiation as well as the direct beam. When working with an unenclosed beam path, it is advisable to

do so with the laser not operating, or operating at reduced power levels. Whenever there is risk of

dangerous exposure, protective eye shields and clothing should be used.

1.5.2 Electrical Hazards

The LBA-PC utilizes only low voltages, derived from the PCI bus in the host PC computer, therefore it

posses no risk of electrical shock.

When installing or removing the LBA-PC frame grabber card, the power to the computer should

always be disconnected.

The computer should always be operated with its covers in place and in accordance with its

manufacture’s recommendations.

Your computer should always be operated with a properly grounded AC power cord.

If your camera has its own power supply, then follow its manufacture’s operating procedures for safe

operation.

Operator’s Manual LBA-PC

14

Page 15

Chapter 2 EQUIPMENT SETUP

2.1 Equipment Setup

This chapter describes how to get started using your LBA-PC. Follow these steps:

Step 1) Install your LBA-PC frame grabber card into your PC.

Step 2) Hook up your camera.

Step 3) Turn on the system and setup your windows environment.

Step 4) Launch the LBA-PC windows application.

Step 5) Configure the LBA-PC for your camera type.

Step 6) Begin collecting data from your camera.

Step 7) Other Configurations

Note: If you purchased your LBA-PC from Spiricon with a computer system and installation, then steps 1, 3, and 5

will have been done for you, and you can skip those steps.

2.1.1 Step 1 Installation of the Frame Grabber Board

This installation procedure applies to the following Spiricon products:

LBA-300PC

LBA-400PC (-D)

LBA-500PC (-D)

LBA-7XXPC (-D)

LBA-PC-PIII

CAUTION

Electrostatic Discharge can result in permanent damage

to electronic equipment. Always ground yourself by

touching the system cabinet before beginning the

following procedure. We strongly recommend using an

antistatic wrist strap attached to earth ground.

To install your LBA-PC frame grabber card, disconnect the AC power from your computer. Remove

the cover from your computer as described in your computers technical manual. Locate your PCI bus

slots. Most PC’s will have either 3 or 4 PCI slots. Select an unused PCI slot and remove the rear filler

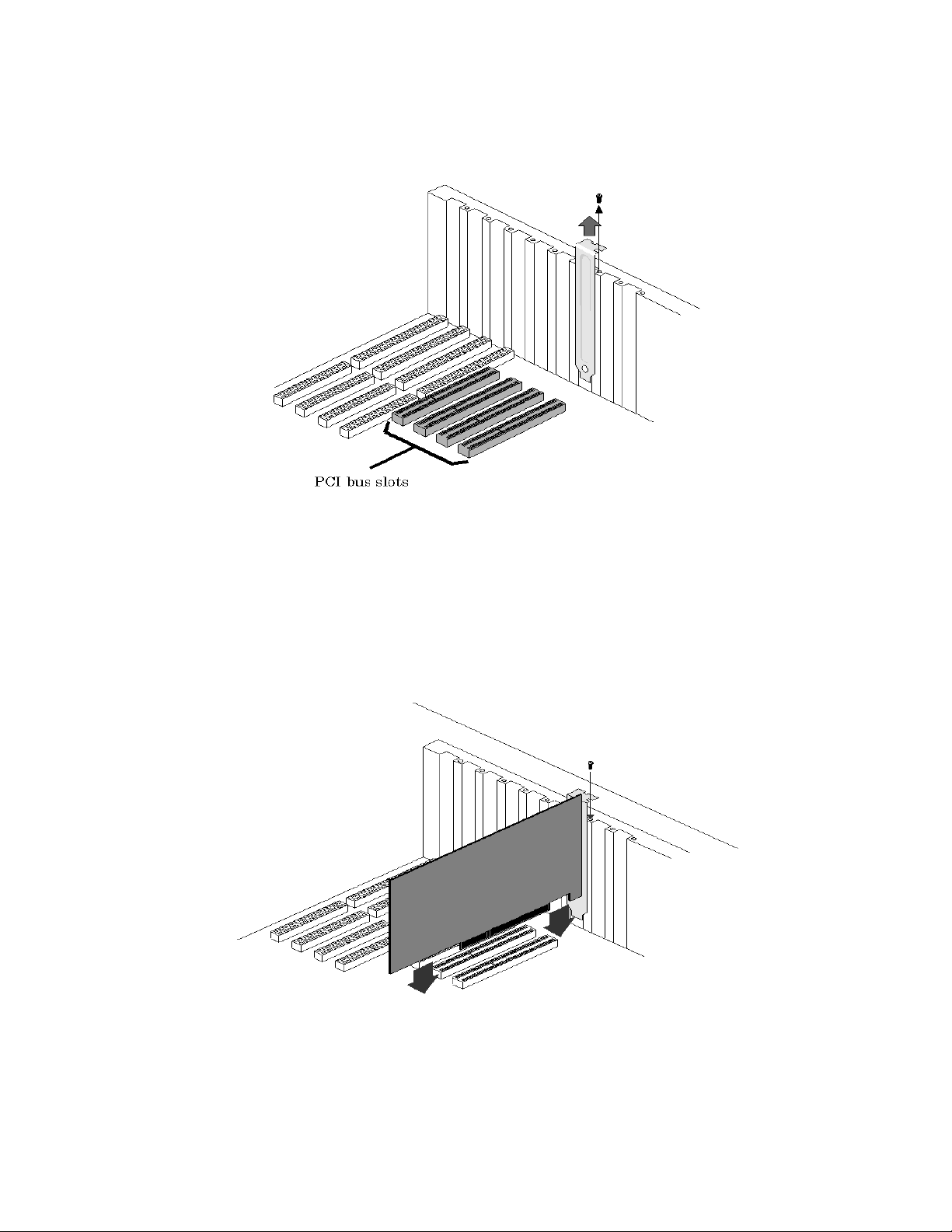

bracket associated with that slot. (See figure below)

Operator’s Manual LBA-PC

Doc. No. 10654-001, Rev 4.10

15

Page 16

Note: If you purchased the optional 4 camera adapter, or the optional digital adapter then make sure that the slot

immediately to the left (viewed from the front of your PC) of the above PCI slot is also empty, and remove its rear

filler bracket also.

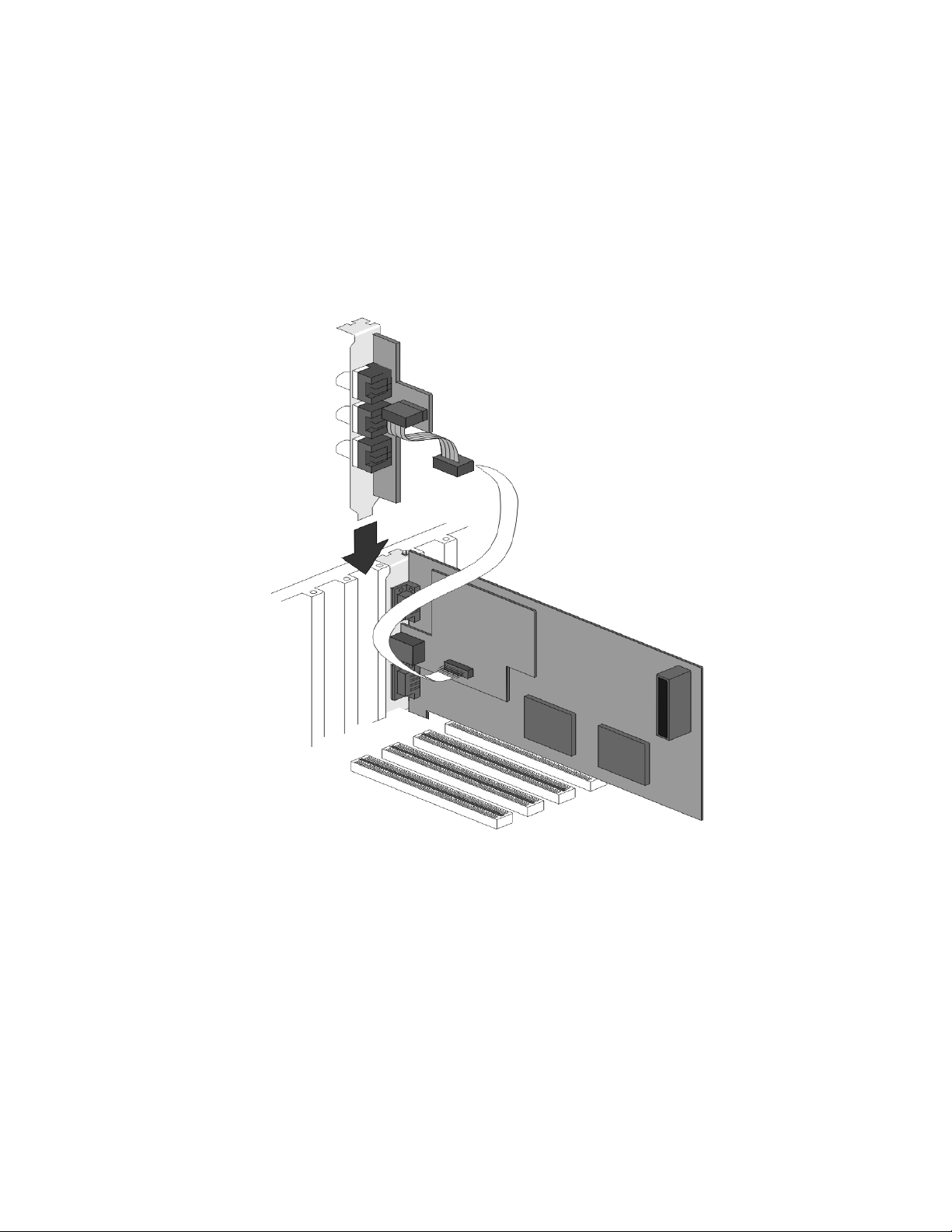

Figure 1

Carefully plug your LBA-PC frame grabber card into the PCI slot. Make sure that it is fully seated in

the PCI connector. Secure the end bracket with the screw that held in the filler plate. (See figure

below)

Figure 2

Operator’s Manual LBA-PC

16

Page 17

The optional adapters use the rear panel opening, but do not plug into any of the PC expansion slots. Rather it is

provided with a short ribbon cable that plugs into the frame grabber card. (See figures below) Slide the adapter

into the rear opening and plug its cable into the frame grabber card. Secure the adapter bracket to the rear panel

with the screw that held in the filler plate.

Four Camera Option

Figure 3

Operator’s Manual LBA-PC

Doc. No. 10654-001, Rev 4.10

17

Page 18

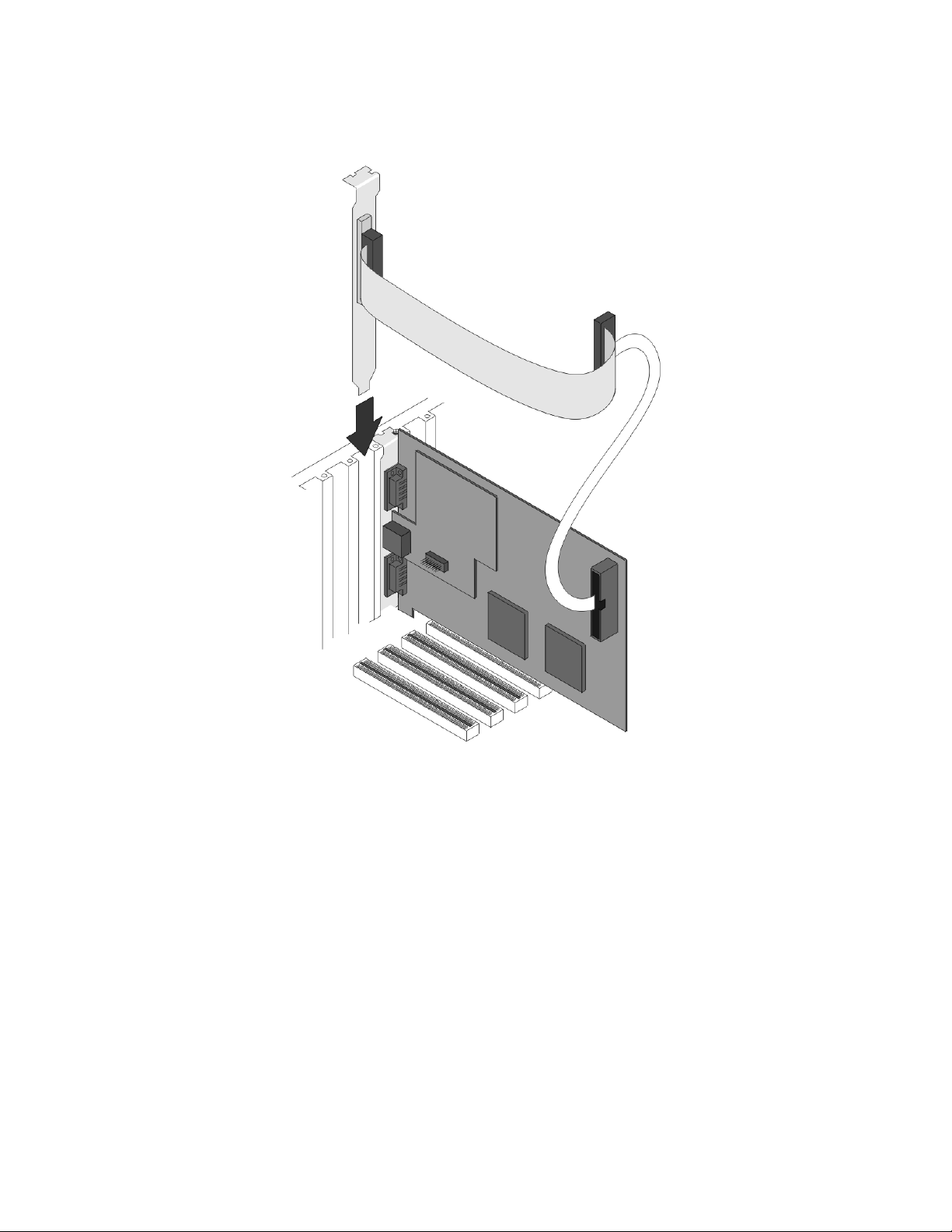

Digital Camera Option

Figure 4

Replace the cover of your computer. Restore the AC power to your computer.

Note: The location of the connectors may vary depending upon which frame grabber model is being installed. The

older LBA-400/500 series has a slightly different arrangement but the concept remains the same.

2.1.2 Step 2 Camera Connections

If you purchased a Pyrocam III to use with LBA-PC, disregard this section and refer to your Pyrocam

III Installation Guide. To use LBA-PC with your Pyrocam III you must launch LBA-PC from the

Pyrocam III Control Console.

Operator’s Manual LBA-PC

18

Page 19

2.1.2.1 Analog Cameras

Connect the video out from your camera to the BNC connector on the LBA-PC frame grabber

card. This is the camera 1 input channel. If you have the 4-camera adapter option, then camera

2’s input is at the top, 3 in the middle, and 4 at the bottom of the adapter bracket assembly.

If you purchased your camera from Spiricon, you may have been provided with a Camera Control

Cable. This cable will usually provide power to your camera, and also control signals for your

camera’s electronic shutter (if it has one). Plug this cable between the appropriate 9-pin

connector on the frame grabber card, and into your camera. If you have the 4-camera adapter,

the additional cameras will need to be powered from an external power supply.

Your camera may also be supplied with a separate power supply. If so, connect it according to

the instructions provided with the camera.

2.1.2.2 Digital Cameras

Connect the digital output from your camera to the SCSI-2 type connector on the digital camera

adapter provided with the LBA-PC frame grabber card. If you purchased your camera from

Spiricon, you may have been provided with a Camera Control Cable. The cable will provide the

digital data connection to your camera, and may control signals for your camera’s electronic

shutter (if it has one).

Your camera may also be supplied with a separate power supply. Connect it according to the

instructions provided with the camera. Digital cameras may require additional software to control

the camera. Check with the camera manufacture and follow their instructions.

2.1.3 Step 3 LBA-PC Software Installation

After the frame grabber is physically installed in the computers PCI slot, and the PC is rebooted,

windows may tell you that it has found new hardware and ask you to install its driver. If this occurs

exit out of the found new hardware wizard without installing a driver and instead allow the LBA-PC

installation application to load the necessary files and drivers. After the installation application has

run, the hardware should be installed properly and you will not see the found new hardware wizard.

If problems do occur during the installation and the drivers are not properly installed, windows will

launch the new hardware wizard after the installation. If this situation should occur, tell the wizard to

search automatically for the necessary drivers, finish the wizard and reboot.

Here are two ways to install LBA-PC in Windows XP; the second method will also work for Windows

2000. Choose only one of the following:

First Method (Windows XP):

Step 1) Start Windows.

Step 2) Close all other Windows applications.

Step 3) Place the Spiricon CD into your CD-ROM drive.

Step 4) Windows XP will open a dialog that asks: “What do you want Windows to do?”

Step 5) Click “Open folder to view files”! Windows will open a folder in the CD’s root directory

showing folders for each of the shipped Spiricon applications.

Step 6) Double click the “LBA-PC” folder to open it.

Operator’s Manual LBA-PC

Doc. No. 10654-001, Rev 4.10

19

Page 20

Step 7) Double click the file in the LBA-PC folder named “Setup.exe” to launch the install. (The

windows file extensions, for this folder, must be set to viewable to see the “exe”

extension.)

Step 8) Follow the instructions in the installation dialogs.

Step 9) Reboot when installation is complete.

Step 10) LBA-PC should now be installed.

Second Method (Windows 2000 or XP):

Step 11) Start Windows.

Step 12) Close all other Windows applications.

Step 13) Place the CD in the CD-ROM drive

Step 14) Click Cancel when Windows asks you, “What do you want to do?

Step 15) From the Taskbar, click on Start, and then Run…

Step 16) In the Open line type: R:\LBA-PC\setup.exe and press <Enter> (Where “R” is the letter

of your CD-ROM drive).

Step 17) Follow the directions given in the installation dialogs.

Step 18) Reboot when installation is complete.

Step 19) LBA-PC should now be installed.

Note: After the installation is completed, The install dialogs will ask you if you want to restart windows, you must

answer yes to allow windows to restart and load the drivers, otherwise LBAPC will not function properly.

Note: Be sure to look at the LBA-PC ReadMe.txt file, before starting the LBA-PC application. This will bring you

up to date with any last minute information regarding the current version of the program.

The following Windows display settings may need adjustment to accommodate the LBA-PC

Application. Use Control Panel, Display, and Settings tab to make these adjustments:

• Screen resolution should be set for a minimum display size of 1024x768, bigger is better.

• Color Quality should be set to a minimum of 256 colors.

2.1.4 Step 4 Start LBA-PC

It’s recommended that you read portions of this operator’s manual to become familiar with the

operation and capabilities of the LBA-PC. The operator’s manual may be found on the installation disk

in PDF format. The PDF may also be found on the Spiricon web site at www.spiricon.com, just

following the LBA-PC product links. To start the Laser Beam Analyzer application go to windows

taskbar and select:

Start, Programs>, Spiricon>, LBA-PC>, LBA-PC.

Operator’s Manual LBA-PC

20

Page 21

2.1.5 Step 5 Configure Camera Type

You should now have the LBA-PC application window on your monitor. The default configuration is

for a basic CW laser setup. This will allow you to verify that your camera and hardware are operating

correctly. If you received any error or warning messages while starting the LBA-PC application, refer

to the Error Messages section in this chapter before proceeding.

Before you can begin to collect data from your camera you must select the correct camera type. To

do this click Options, Camera..., and then click on the Camera drop down arrow. Select the

camera type that matches (or most closely matches) your specific camera, then click on OK.

To save this setup configuration... Click File, then Save Config...; enter a file name for this

configuration, then click OK. This file name has now become your new default configuration file.

This default will remain, from one program startup to the next, until you save or restore a new

configuration file; at which time, the last loaded or saved configuration becomes the default.

2.1.6 Step 6 Collect Data

Click the Start! menu item to begin collecting data from the camera. The frame display window

should immediately start changing colors corresponding to the intensity of the light reaching the

camera sensor, and the beam profile displays should change from a flat line in proportion to the light

intensity at the cursors.

If the room light is bright enough and/or the camera is sensitive enough, the frame display window

may be entirely white as the horizontal and vertical profile displays move upward and to the right,

respectively. If this is the case, reduce the amount of light reaching the camera sensor by shading it

with your hand. You should be able to obtain the entire range of colors shown on the color bar along

the right side of the display window. If you are using a camera with a lens, you should be able to

obtain a recognizable image by adjusting the lens f-stop and focus.

2.1.7 Step 7 Sample Configurations

You are probably now ready to try looking at a laser, and to go exploring the many operating options

of the LBA-PC.

CAUTION

Before you expose your camera to your laser beam, make sure that

the power/energy of your laser is well below the damage threshold

of your camera’s photo imager. You may also need to attenuate

your beam to bring it into a range that will prevent your camera’s

imager from saturating.

To help you get started, we have created a set of configuration files that you can restore. These

configuration files will adapt the LBA for a variety of basic operating modes.

However, these configuration files do not know which particular camera you are using. Therefore you

must select the appropriate camera to complete your setup. To select a camera, you will have to

repeat the procedure in Step 5.

Operator’s Manual LBA-PC

Doc. No. 10654-001, Rev 4.10

21

Page 22

The factory-supplied configuration files are write protected, so that you cannot accidentally lose or

overwrite them. Each of these file names begin with a ~ (tilde), for easy identification. Some

examples of these files are:

~lbapc.cfg The original default configuration.

~cw_basc.cfg A CW laser setup w/ basic results.

~cw_gaus.cfg A CW laser setup w/ Gauss Fit results.

~cw_hist.cfg A CW laser setup w/ Histogram display.

~cw_fram.cfg A CW laser setup w/ 8 frame averaging.

~cw_elip.cfg A CW laser setup w/ elliptical results.

~vt_toph.cfg Video trigger mode for a pulsed laser w/ Top Hat results enabled.

~to5gaus.cfg A Trigger Output at 5 Hz to fire a pulsed laser w/ Gauss Fit results.

~PYROCAM.cfg For use with Pyrocam I’s w/o digital camera option.

~PYRODIG.cfg For use with Pyrocam I’s w/ digital camera option.

2.2 Error Messages

The explanations of the following error messages assume that you are Windows savvy. If you find that

after reading an error message’s meaning, you still do not know what to do, then contact Spiricon’s

Service department for assistance.

You may encounter the following error messages:

LBA-PC device driver not found.

LBA-PC set to Off-Line mode

This error usually indicates that your LBA-PC frame grabber is either not installed or is not working. If

the frame grabber card is not detected by Windows then the device driver will not be loaded when the

system starts. This error may also indicate that the device driver was not properly installed. To

determine the cause, do the following:

Windows 2000

• Click on… Start, Settings, Control Panel.

Or for Windows XP

• Click on… Start, Control Panel.

Then for Both

• Double click on the System icon.

• Select the Hardware tab.

• Click on the Device Manager button.

Operator’s Manual LBA-PC

22

Page 23

• Click on the Sound, video and game controllers listing.

• If the LBA-PC frame grabber was detected, and the device driver was not loaded you will see a

category called Unknown in the edit box listing of the Device Manager. If this occurs, double

click on the Unknown icon. You should see an entry called PCI Card. This indicates that the

device driver was not properly installed. To correct this problem, re-install the LBA-PC software.

• If you did not see the Unknown icon, then Windows did not detect the LBA-PC frame grabber

card. Check to see that your frame grabber card is properly installed. Sometimes PCI card slots

are defective, so you might also try another slot if all else seems to be in order.

If this device driver is not found, the LBA-PC program will complete loading, but the software will be

forced to the Off-Line mode. This means you can only view files and perform Post Processing of data

from and/or to data files.

Device Drive vX.XX detected.

LBA-PC requires vY.YY.

LBA-PC set to Off-Line mode.

If your current device driver version does not match the current LBA-PC version you will get this

message. This may occur if you have upgraded your LBA-PC application, but continue to use an old

device driver. Normally this should not happen, as the installation will install a new device driver

version with each upgrade. The LBA-PC application program will complete loading, but the software will

be forced to the Off-Line mode. This means you can only view files and perform Post Processing of

data from and/or to data files.

Unable to load LCA program file.

File Not Found.

This message will precede the following error message if the lcaXXX.exo file is not found or is not in the

same path as the LBA-PC application.

LBA-PC frame grabber

detected, but cannot initialized.

LBA-PC set to Off-Line mode.

The LBA-PC frame grabber contains a programmable LCA device. If this device fails to program during

application initialization, the above error message will occur. Contact the Spiricon Service Department

for assistance. The LBA-PC application program will complete loading, but the software will be forced

to the Off-Line mode. This means you can only view files and perform Post Processing of data from

and/or to data files.

Not Enough Memory for Frame Capture.

LBA-PC set to Off-Line mode.

Operator’s Manual LBA-PC

23

Doc. No. 10654-001, Rev 4.10

Page 24

The device driver was unable to allocate enough memory in order to capture video frames. This may

occur the first time you boot the computer after installing the Frame Grabber card. Try rebooting the

computer. If the error continues to occur you will need to add memory to the computer. LBA-PC

requires a minimum 256 MB of main memory, 512 MB is recommended. If the error occurs after

adding memory then contact the Spiricon Service Department.

Frame Grabber not found.

LBA-PC set to Off-Line mode.

Your LBA-PC frame grabber card is either not installed, or not working. The LBA-PC application

program will complete loading, but the software will be forced to the Off-Line mode. This means you

can only view files and perform Post Processing of data from and/or to data files. Check to see that

your Frame Grabber card is properly installed. Contact the Spiricon Service Department for further

assistance.

Not a valid LBA-PC data file.

You are attempting to load a file that is not in a format that the LBA-PC can recognize. See loadable

file types.

2.3 Optional Equipment

Optional equipment can include the following items:

License: Multi-user site software license

Adapter: 4 Camera adapter

Digital Camera adapter

Camera: Selected camera, specify type

Interface cable

BNC cable

Camera manual (if supplied by camera manufacturer)

Camera power supply (if supplied by camera manufacturer)

Computer: PC compatible, Pentium or equivalent

Attenuator: Model LBS-100, BA-VIS, -NIR, or -BB beam attenuator

2.4 Connections

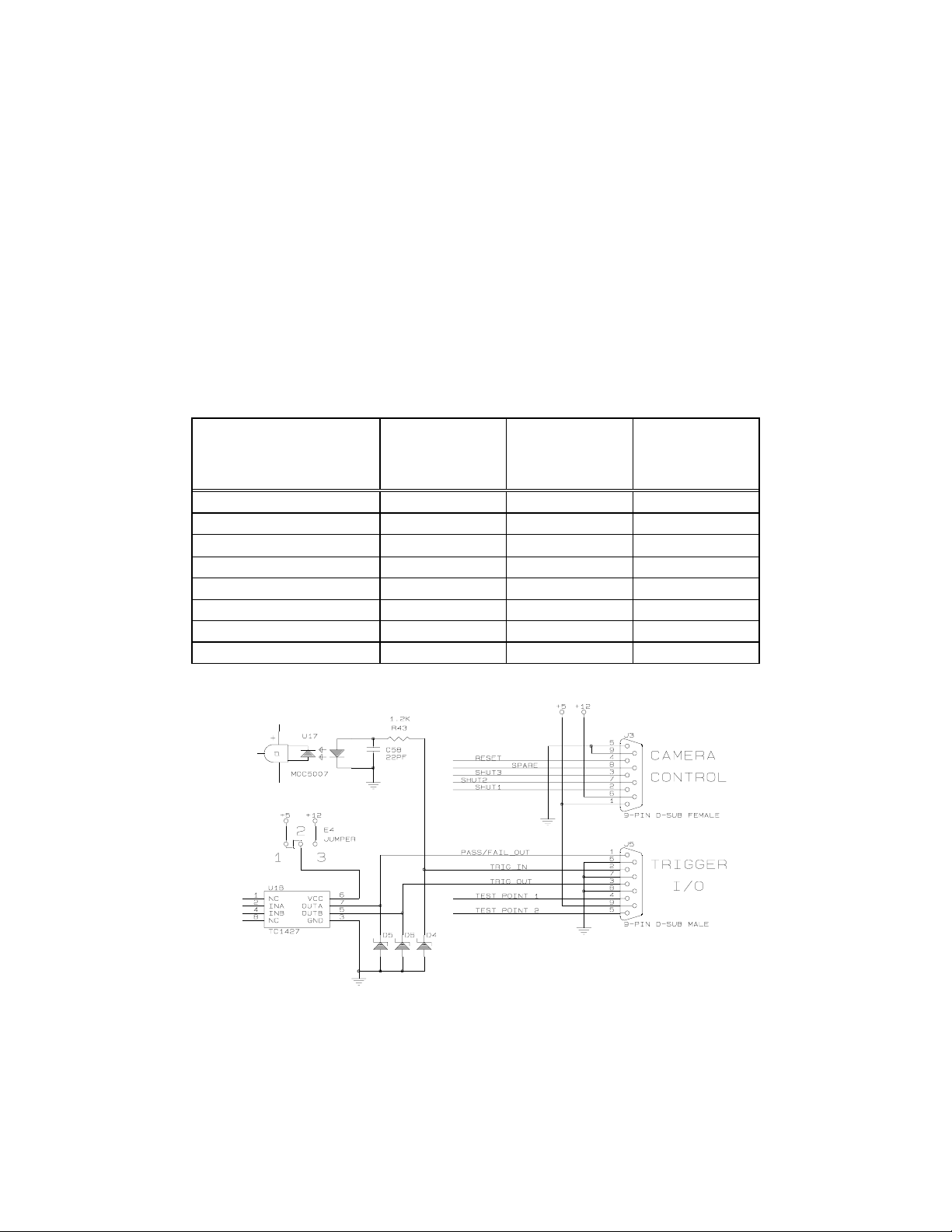

This topic describes the Camera Control (upper, 9 pin D-sub, female) and Trigger I/O (lower, 9 pin Dsub male) connectors on the LBA-PC rear panel. The schematic shown below describes the circuits on

these connectors. See the Specifications section for the respective drive limits of these signals.

Operator’s Manual LBA-PC

24

Page 25

2.4.1 Camera Power

If your camera is a low power CCD style that runs on +12Vdc, then it may be powered from

connector J1 (J3 on LBA-3/4/500 frame grabbers) pin 6 (+12Vdc) and pin 5 (gnd).

Caution: Do not attempt to power more than ONE camera from the LBA-PC.

2.4.2 Shutter Controls Signals

The electronic shutter control signals are provided on as SHUT1, SHUT2, and SHUT3. These are TTL

level drive outputs. The Logic is positive true. The shutter settings are listed in the 8 lines of the

Shutter drop down edit control found in the main menu Options > Camera > Advanced dialog

box. The labeling of the shutter lines can be user modified to match the settings of a particular

camera. The line locations however, always correspond to the following TTL output drive levels:

Shutter Line

Edit control

Top line 1 0 0 0

2 0 0 1

3 0 1 0

4 0 1 1

5 1 0 0

6 1 0 1

7 1 1 0

Bottom line 8 1 1 1

SHUT3

(J1 pin 3)

(J3 on 3/4/500)

SHUT2

(J1 pin 7)

(J3 on 3/4/500)

SHUT1

(J1 pin 2)

(J3 on 3/4/500)

Frame Grabber Pin-out

Figure 5

Operator’s Manual LBA-PC

Doc. No. 10654-001, Rev 4.10

25

Page 26

2.4.3 Trigger Out

Connector J2 (J5 on LBA-3/4/500 frame grabbers) pin 3 is the Trigger Out signal. This signal is factory set to output +5Vdc pulses. You can change this signal to +12Vdc level pulses by moving Jumper E1 (E4 on LBA-3/4/500 frame grabbers) to bridge pins 2-3.

Note: Jumper E1 (E4) controls the output signal level for both Trigger Out and Pass/Fail Out. Jumper position 1-2

yields a +5Vdc level; position 2-3 yields a +12Vdc level.

2.4.4 Pass/Fail Out

Connector J5 (J2 on LBA-7XX frame grabbers) pin 1 is the Pass/Fail Out signal. This signal is factory set to output +5Vdc pulses. You can change this signal to +12Vdc level pulses by moving Jumper E1(E4) to bridge pins 2-3. To enable this signal and select its mode of operation see the Pass/Fail menu topic.

Note: Jumper E1 (E4) controls the output signal level for both Trigger Out and Pass/Fail Out. Jumper position 1-2

yields a +5Vdc level; position 2-3 yields a +12Vdc level

.

2.4.5 Trigger In

Connector J2 (J5 on LBA-3/4/500 frame grabbers) pin 2 is where you apply the Trigger In signal. This input must be only a positive voltage with respect to ground. But you can pulse it with either a high going or a low going pulse. You can program the Trigger In Polarity to respond to either a positive (rising) or negative (falling) edge of this input signal.

2.4.6 Video In

The BNC connector (not shown above) is where you input either RS-170 or CCIR formatted black and

white video. The video input is terminated into 75 ohms. This is Camera input number 1. If you

have purchased the 4 camera option, three additional BNC connectors are provided on a separate

bracket assembly. These BNC connectors provide inputs for cameras number 2, 3 and 4 (top to

bottom).

2.5 Camera Control Cables

Many cameras shipped by Spiricon will be supplied with a Camera Control Cable. Connect this cable

between the camera and connector J1, (J3 on LBA-3/4/500 frame grabbers) the upper 9-pin D-sub

female. This cable will usually provide power to the camera, as well as permit the LBA-PC to control a

camera’s electronic shutter, if it has one. Cameras that derive power from a source other than the LBAPC will not usually be supplied with this cable.

If you are using the 4-camera option, any additional cameras must be powered from an external

source. To provide control of the shutter of any additional cameras, a special cable must be made that

connects all of the shutter inputs of the cameras in parallel. If you plan on using the automatic camera

sequencing you may also need a special cable to synchronize (genloc) the cameras.

Operator’s Manual LBA-PC

26

Page 27

2.6 Special Setup for Pyrocam I Operation

You must use special setups if you want to successfully interface your Pyrocam I with a Model LBA-PC

frame grabber system. It is strongly recommended that you first become familiar with the operating

characteristics of both your Pyrocam I and LBA-PC before attempting to operate them together.

To operate your Pyrocam I with a model LBA-300PC or a LBA-400/500/708/710/712/714PC without a

digital camera option, see section 2.12.1.

To operate your Pyrocam I with model LBA-500PC-D or a model LBA-7XXPC-D, with the digital camera

option, see section 2.12.2.

2.6.1 Pyrocam I with Non-Digital LBA-PC’s

LBA-300/400/500/708/710/712/714PC w/o digital camera option

2.6.1.1 Pyrocam I Setup Requirements:

2.6.1.1.1 Configure Video Output

The Pyrocam must be configured to output monochrome video in CCIR format. To do this,

Dip Switch number 6 must be in the ON position. See Chapter 6 and Appendix A-6 in your

Pyrocam Operator’s Manual for details.

2.6.1.1.2 Configure Gain and Vertical Scale

Do not operate the Pyrocam I with the Gain switch set in the 10 position or with the

Vertical Scale set in the Auto or Manual x8 positions. Use only the 1 or 3 Gain setting and

Manual x1, x2 or x4 settings. The LBA will not be able to Ultracal in the gain equals 10 or

scale x8 setting positions, and the Ultracal will not remain valid if the Pyrocam is in the Auto

scale mode.

Note: You will need to temporarily attach your Pyrocam to either a VGA or a monochrome monitor to observe the

Vertical Scale settings.

2.6.1.1.3 Configure MONO/DIG/VGA switch to MONO position.

2.6.1.1.4 Install Video Cable

Connect the Pyrocam’s Video Output BNC to the Video Input BNC on the LBA-PC.

All other operating requirements for the Pyrocam I are still applicable, and must be set up

correctly. Don’t forget to periodically calibrate your Pyrocam.

Hint: First set up your Pyrocam to operate in one of its stand-alone configurations, and then connect it to the LBAPC only after you’re sure that it is operating satisfactorily with your laser.

Operator’s Manual LBA-PC

Doc. No. 10654-001, Rev 4.10

27

Page 28

2.6.1.2 Setup requirements for LBA-PC with pyrocam cameras:

Two files are provided for configuring the LBA to a Pyrocam I. They are ~PYROCAM.CFG and

~PYROCAM.CAM.

2.6.1.2.1 Setting up the Pyrocam Configuration.

Go to File. . . Restore Config. . . and set the configuration to ~PYROCAM.CFG.

2.6.1.2.2 Setting the camera type to Pyrocam

Go to Options. . . Camera dialog box and set the Camera selection to ~PYROCAM.CAM.

This may already have happened when you did the previous step.

The ~PYROCAM.CAM file is absolutely required for correct operation with your Pyrocam. The

~PYROCAM.CFG configuration is a good starting point configuration.

You will undoubtedly need to make changes to your configuration to suit your application.

Do so, and then save off your new configurations into new <filename>.cfg config files.

Remember the ~PYROCAM files are read only; so don’t try to use those file names.

2.6.1.3 Some Restrictions apply when interfaced to a Pyrocam I

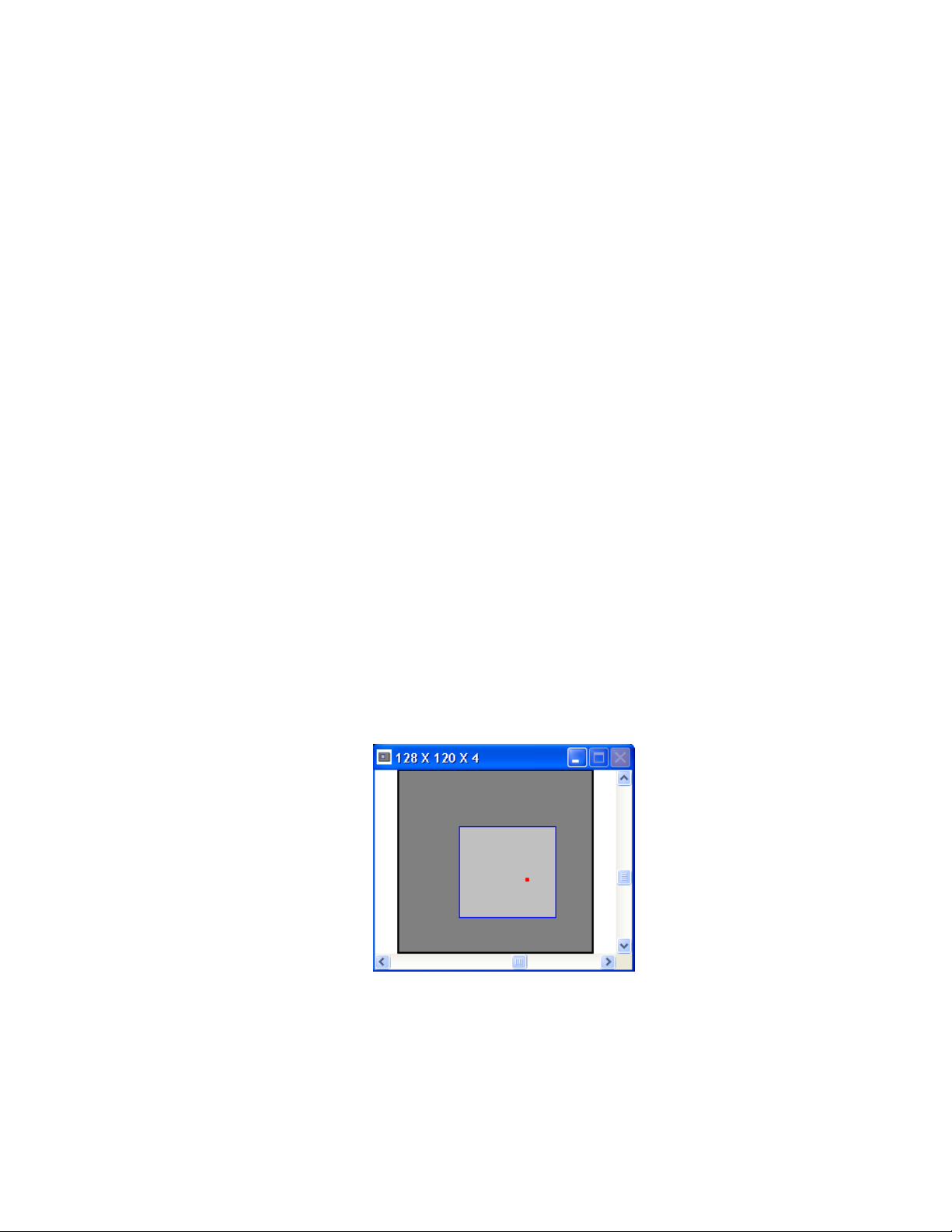

2.6.1.3.1 Frame resolution restrictions

While you are not restricted from setting your frame Resolution to 512x480x1, it is not a

good idea. Keep your Resolution setting set to 128x120x4. Remember the Pyrocam creates

a 124x124 sized image, so setting higher resolutions only wastes memory and slows down

operations.

2.6.1.3.2 Zooming restrictions

In keeping with the above, do not use Hardware zooming. Only use Soft zooming, i.e.

double-right-mouse click in the Zoom window.

2.6.1.3.3 Restricted pixel regions

Because of the image size difference between the LBA and the Pyrocam I, as noted above,

the LBA will clip off 4 rows from the Pyrocam; two on top, and two on the bottom. Also the

LBA will have 4 dark columns; two on the left edge, and two along the right.

2.6.1.3.4 Scale and resolution restrictions

Note also that the Pixel Scale setting is set to 25mm, not 100mm, which is the actual pixel

scale of the Pyrocam I. This is because the image output by the Pyrocam in CCIR mode is 4

times over scanned in both the x and y directions. Thus the LBA’s 1x resolution comes out to

be 1/4th the 4x resolution. Keep this in mind if you plan to change the scaling because of

placing the beam altering optics in the beam path.

Operator’s Manual LBA-PC

28

Page 29

2.6.1.3.5 Camera settings restrictions

Under no circumstances, make any changes to the Advanced. . . Camera settings for the

Pyrocam I.

2.6.1.4 Image synchronization considerations

The Pyrocam I’s CCIR video output is always producing video images at the rate of 25 frames per

second. Furthermore, it only changes output image after acquiring and processing a new image.

Thus the rate of a new output beam image is a function of many variables, including Pulse or

Chop rates, image processing time, and results computational times.

If you are using a Pulsed laser with your Pyrocam I, the Pyrocam will continue to output the

image of the last laser pulse that it receives. As a result, your LBA will continue to collect data

frames that are multiples of the last pulse received by the Pyrocam. To relieve this, you may

want to set up a Trigger input to the LBA. This will cause, at the most, only one image to be

acquired for each Laser Pulse. This can be a tricky situation since the Pyrocam does take a little

time to process each image, and that time will vary somewhat from image to image. Also, if your

laser is triggered faster than the Pyrocam can acquire and update its CCIR display, it will skip

pulses. Thus the LBA can still end up acquiring multiples of some of the processed pulses. You

can also try the solution described below for the Chopped-operating mode.

The exact same type of problem occurs in Chopped mode. The chop frequencies must be either

24Hz or 48Hz. Thus, the CCIR image can never be updating as fast as the chopper is triggering

the Pyrocam. Consequently, the CCIR output is always creating multiple frames of the same

beam profile. In this case, you may want to set the LBA’s Capture interval to a value that will

eliminate or reduce multiple frame captures.

2.6.2 Pyrocam I with Digital LBA-PC’s

LBA-500/7XXPC-D w/ Digital Camera Option

2.6.2.1 Pyrocam I setup requirements:

To use this interface method, your LBA-500/7XXPC must be equipped with the digital camera

option (-D), and your Pyrocam I must be of a later design that has digital output capability. Early

versions of the Pyrocam were not equipped with digital outputs. If your Pyrocam I does not have

a 50 pin connector on its rear cover it can not be interfaced as a digital camera. However, you

can still interface it by using the analog method described in the LBA-300PC interface topic.

Alternately, you can contact Spiricon’s service department and arrange to have your Pyrocam I

upgraded with digital camera output capability.

NOTICE: When interfacing with a Pyrocam I, DO NOT USE THE ULTRACAL! Feature of the LBA-PC. Rather, it

is ESSENTIAL that you periodically re-calibrate the Pyrocam I. Calibrating the Pyrocam I is the only calibration

that should be used with this type of interface.

Operator’s Manual LBA-PC

Doc. No. 10654-001, Rev 4.10

29

Page 30

2.6.2.1.1 Set video switch

The Pyrocam must be set to output digital video. This is accomplished by setting the

MONO/DIG/VGA switch to the LBA position. See Chapter 6 in your Pyrocam Operator’s

Manual.

2.6.2.1.2 Connect cable

Connect the Pyrocam’s digital output to the digital input connector of the LBA-500PC. A

special interface cable is required to make this connection. If you ordered your Pyrocam I,

LBA-PC and LBA-Digital Option together as a system, then a cable was supplied.

2.6.2.1.3 Pyrocam settings

With the Pyrocam set to the DIG mode, the Vertical Scale setting has no effect on the

output. However, the Gain switch is still operating and can be set to any position. All other

operating requirements for the Pyrocam I are still applicable, and must be set up correctly.

Don’t forget to periodically Calibrate your Pyrocam.

Hint: First set up your Pyrocam to operate in one of its stand-alone configurations, and then connect it to the LBAPC only after you’re sure that it is operating satisfactorily with your laser.

2.6.2.2 LBA-500/7XXPC-D Setup requirements:

Two files are provided for configuring the LBA-PC digital interface to a Pyrocam I. They are

~PYRODIG.CFG and ~PYRODIG.CAM.

2.6.2.2.1 Set the Pyrocam configuration

Go to file. . . Restore Config. . . and set the configuration to ~PYRODIG.CFG.

2.6.2.2.2 Set the camera options

Go to Options. . . Camera dialog box and set the Camera selection to ~PYRODIG.CAM.

This may already have happened when you did the previous step.

The ~PYRODIG.CAM file is absolutely required for correct operation with your Pyrocam. The

~PYRODIG.CFG configuration is a good starting point configuration.

You will undoubtedly need to make changes to your configuration to suit your application.

Do so, and then save off your new configurations into new <filename>.cfg config file.

Remember the ~PYRODIG files are read only, so don’t try to use those file names.

Under no circumstances make any changes to the Advanced… Camera settings for the

Pyrocam I.

Operator’s Manual LBA-PC

30

Page 31

2.6.2.3 Image Synchronization Considerations

The Pyrocam I’s Digital Output only produces an image each time new data is available. It will

not continuously output the same frame repeatedly. Thus, the rate of new output beam images

is a function of the Pulse or Chopping rate and image processing time. For this reason, you

should operate the LBA-500PC in Video Trigger mode only.

If you are using a Pulsed laser with your Pyrocam I, the Pyrocam will attempt to output a new

image with each laser pulse, however, depending upon the pulse rate, it may not be able to keep

up.

The exact same type of problem occurs in Chopped mode. The chop frequencies must be either

24Hz or 48Hz. The Pyrocam may be able to keep up at 24Hz, but will lose some frames at 48Hz.

Operator’s Manual LBA-PC

Doc. No. 10654-001, Rev 4.10

31

Page 32

Chapter 3 MENUS AND DIALOG BOXES

3.1 File. . . Drop Down Menu Selections

3.1.1 File | Load. . .

A saved data file can be loaded into the frame buffer for display and results processing. Four types of

data file formats are supported and are delineated by their file extension labels. The results obtained

from these file types are not all of equal merit, however. The origin and meaning of these file types

are as follows:

.lb3/4/5/7 Files

Is the native file extension denoting a data file created by the LBA-PC. The number indicates

that the data was created by either the LBA-300 (8-bit frame grabber), -400 (10 bit frame

grabber), –500 (12 bit frame grabber), or with a new –7XX (multi-format frame grabber). If the

saved file was generated using Ultracal processing then the results obtained when loading and

viewing this file type are of high quality.

.lba Files

Is the native file extension denoting a data file created by the LBA-100A. If the saved file was

generated using Autocal processing then the results obtained when loading and viewing this file

type are of high quality. All of these files produce images that are 120 x 120 pixels.

.lbb Files

.lbc Files

Is the native file extension denoting a data file created by the LBA-100A. All file types of this

designation are created without the benefit of any calibration, and thus can not be relied upon

for accurate results. All of these files produce images that are 256 x 240 pixels.

Is the native file extension denoting a data file created by the LBA-100A. All file types of this

designation are created without the benefit of any calibration, and thus can not be relied upon

for accurate results. All of these files produce images that are 512 x 480 pixels.

NOTICE:

File Compatibility with New versions of LBA-PC Software.

We will try very hard to make all future releases of the LBA-PC

application backwards compatible with all prior .lb3/4/5 file

formats. However, we cannot guarantee that new versions will

produce .lb3/4/5 files that will be backward compatible with older

versions.

Operator’s Manual LBA-PC

32

Page 33

Beginning with release v2.50, any of the three .lb3, .lb4, and .lb5

file types can be read by any of the LBA-300/400/500PC model

types. However, the new .lb4 and .lb5 file types cannot be read by

software released prior to v2.5.

Beginning with release v4.00, any of the three .lb3, .lb4, and .lb5

file types can be read by any of the LBA-7XXPC model types.

However, the new .lb7 file types cannot be read by software

released prior to v4.00.

Data files can contain one or more frames of data. Each frame of data is called a Record.

Embedded in each Record is all the information necessary to accurately reproduce the original frame.

Pixel scale, Camera type, Zoom and Pan location, energy and Ultracal values etc. are saved within

each Record.

Note: If you load an LBA-100A record that used a different camera setup than the one you currently have

configured, then one or more of the following can occur:

• If the Camera type file is available, it will be loaded and replace the current settings. See Camera

type selection.

• If the Camera type file is available, but the pixel scale or resolution settings do not agree with the

current settings, it will be loaded and the Pixel Scale and Resolution settings changed to match

the data file values.

• If the Camera type file is not available, the camera type will be set to NONE, and the Pixel Scale

and resolution will be changed to that required of the Data File.

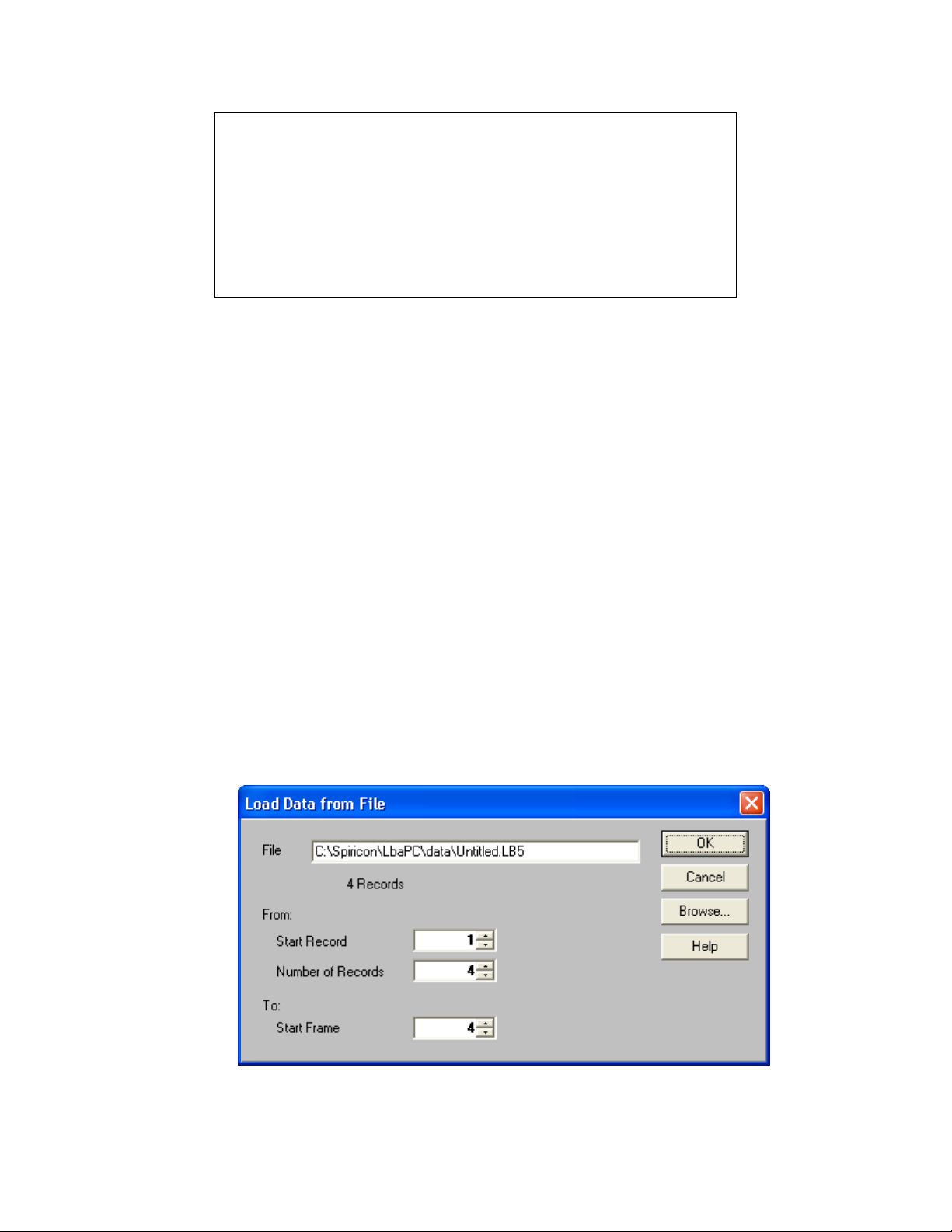

3.1.1.1 Load Frame Dialog Box

Enter the drive:\paths\and <filename>.lbx of the File that you want to load. Press Browse... if

your not sure of the file’s name or location, and wish to search for it.

Figure 6

Operator’s Manual LBA-PC

Doc. No. 10654-001, Rev 4.10

33

Page 34

If the file that you are loading contains multiple records, enter the starting number of the record

that you want to begin loading from, in the edit box labeled Start Record.

Enter the Number of Records that you want to Load. You can enter a value of 0, or 1 to the

number of records in the file. A value of 0 means all the records in the file.

Records can only be loaded sequentially from the Start Record position. If you specify a

greater number of records than you have frame buffer space available, the loading process will

fill the buffer and then wrap around leaving the last records transferred in the frame buffer. See

setting the frame buffer size in 3.2.3.4.

In Start Frame, enter the location in the frame buffer where you wish to begin depositing the file

records. Multiple frames will load from that location upward, skipping any locations that are

Write Protected.

3.1.1.2 Special Frame Numbers