Page 1

Sierra Instruments Instruction Manual Smart-Trak® 2 Series 100

Smart-Trak® 2 Series 100

Mass Flow Meters and Controllers

INSTRUCTION MANUAL

IM-100-ST2, Revision: D

January 2012

1

Page 2

Sierra Instruments Instruction Manual Smart-Trak® 2 Series 100

GLOBAL SUPPORT LOCATIONS: WE ARE HERE TO HELP!

CORPORATE HEADQUARTERS

5 Harris Court, Building L Monterey, CA 93940

Phone (831) 373-0200 (800) 866-0200 Fax (831) 373-4402

www.sierrainstruments.com

EUROPE HEADQUARTERS

Bijlmansweid 2 1934RE Egmond aan den Hoef

The Netherlands

Phone +31 72 5071400 Fax +31 72 5071401

ASIA HEADQUARTERS

Rm. 618, Tomson Centre, Bldg A, 188 Zhang Yang Road

Pu Dong New District, Shanghai, P.R. China

Phone: + 8621 5879 8521 Fax: +8621 5879 8586

IMPORTANT CUSTOMER NOTICE: OXYGEN SERVICE

Sierra Instruments, Inc. is not liable for any damage or personal injury, whatsoever, resulting from the use of

Sierra Instruments standard mass flow meters or controllers for oxygen gas. You are responsible for

determining if this mass flow meter or controller is appropriate for your oxygen application. You are

responsible for cleaning the mass flow meter or controll er to the degree required for your oxygen flow

application.

© COPYRIGHT SIERRA INSTRUMENTS 2010

No part of this publication may be copied or distributed, transmitted, transcribed, st ored in a retrieval system,

or translated into any human or com puter language, in any form or by any means, electronic, mechanical,

manual, or otherwise, or disclosed to third parties without the expre ss written permission of Sierra Instruments.

The information contained in this manual is subject to change without notice.

TRADEMARKS

®

Smart-Trak

product and company names listed in this manual are trademarks or trade names of their respective

manufacturers.

100 Series and Dial-A-Gas™ is a Registered Trademark of Sierra Instruments, Inc. Other

2

Page 3

Sierra Instruments Instruction Manual Smart-Trak® 2 Series 100

Table of Contents

Chapter 1: Introduction .................................................................................................... 5

Welcome to the future of gas flow measurement! ......................................................... 5

Using This Manual ................................................................................................................. 5

Safety Information ................................................................................................................. 6

Receipt of your instrument ..................................................................................................... 7

The Smart-Trak 2 Flow Sensing Principle............................................................................. 9

Chapter 2: Installation ....................................................................................................... 9

Before You Begin Installation ............................................................................................. 11

Pre-Installation Check List .................................................................................................. 12

Installing the Instrument—Plumbing ................................................................................... 12

Compression Fittings ..................................................................................................... 13

VCO Fittings................................................................................................................... 13

VCR Fittings ................................................................................................................... 14

1/4 Inch Female NPT ..................................................................................................... 14

Installing your Instrument—Mechanical Mounting ............................................................ 15

Installing your Instrument—Electrical Connections ........................................................... 16

Figure 2-3: HD DB-15 Connector Pin Configuration (on the instrument) .................. 18

Figure 2-4: Wiring Definitions for Optional Communication Cable ........................... 18

Figure 2-5: Power Supply Requirements ......................................................................... 19

Chapter 3: Analog Operation .................................................................................... 22

Analog Operation, Mass Flow Controller ........................................................................ 23

Smart-Trak 2 Features...................................................................................................... 24

Setpoint Adjustment......................................................................................................... 24

Changing the Output or Setpoint Signals ......................................................................... 24

Over-Range Condition ..................................................................................................... 24

Manual Valve Override—Valve Close ............................................................................ 25

Manual Valve Override—Valve Purge Function ............................................................ 25

Important Notes About Purging ....................................................................................... 25

Purging Non-Reactive Gases: .......................................................................................... 25

Purging Reactive Gases: .................................................................................................. 25

Chapter 4: Digital Operation with Pilot Module ...................................................... 27

Introduction to Pilot Module Features and Capabilities .................................................. 27

Pilot Module Operation, Mass Flow Controllers ................................................................. 29

Pilot Module Operation, Mass Flow Controllers: ................................................................ 30

Making Changes Using the Lower Level Screens:...................................................................... 38

Lost Passwords and General Customer Service: ....................................................................... 47

Chapter 5: Digital Operation RS-232 & Smart-Trak 2 Software

Power Up Your Instrument ......................................................................................... 48

Power Up Your Computer .......................................................................................... 51

Loading the Smart-Trak 2 Software ........................................................................... 51

Connecting Smart-Trak 2 to Your Computer ............................................................. 52

...................... 48

3

Page 4

Sierra Instruments Instruction Manual Smart-Trak® 2 Series 100

If your computer has a serial port… .................................................................................... 51

If your computer has no serial port, but has a USB port….................................................. 53

If you plan to control more than one Smart-Trak 2 instrument from your computer… ...... 53

Running The Smart-Trak 2 Software ............................................................................... 55

Chapter 6: Technical Support & Service .................................................................. 68

Factory Calibration—All Models .................................................................................... 70

Instructions for Returning Your Instrument for Service .................................................. 70

Appendix A: Gas Tables & K-Factors

Appendix B: Product Specifications

Appendix C: Flow Chart for Pilot Module User Interface

Appendix D: PIN Configuration

Appendix E: Product Dimensions and Mounting

Appendix F: Micro-Trak

Appendix G: Smart-Trak Basic Commands

4

Page 5

Sierra Instruments Instruction Manual Smart-Trak® 2 Series 100

CHAPTER 1: INTRODUCTION

Welcometothefutureofgasflowmeasurement!

This manual is your guide to Smart-Trak 2. Visit the Sierra Instruments website

www.sierrainstruments.com any time for more information about this product.

The Smart-Trak 2 instruments offer a variety of features for ease of operation.

Among these features:

9 Dial-A-Gas: allows a user to change from among 10 gases while maintaining

accuracy.

9 The Optional Pilot Module: control electronics that offers both display and

control options at the user’s fingertips.

9 Digital Electronics: maximum performance with minimum noise plus

exceptional tuning capability.

9 Choice of Analog Communications Options and RS-232 with every Smart-

Trak 2 instrument.

9 Flexible Design with many functions that can be re-configured on-site by the

user.

9 Compact Footprint that allows Smart-Trak 2 to fit almost anywhere.

9 Wide range of sizes for gas flow from 0.1 sccm to 1400 slpm.

9 And many more

Using This Manual

This manual is organized into six chapters:

• Chapter 1: Introduction and Theory of Operation.

• Chapter 2: Installation, Plumbing & Wiring instructions.

• Chapter 3: Analog Operation.

• Chapter 4: Digital Operation with the Optional Pilot Module.

• Chapter 5: Digital Operation with RS-232 & Smart-Trak 2 Software.

• Chapter 6: Technical Support and Service.

5

Page 6

Sierra Instruments Instruction Manual Smart-Trak® 2 Series 100

There are also 6 Appendices:

• Appendix A: Smart-Trak 2 Pre-Programmed gases, Conversion

Formula and Gas Tables.

• Appendix B: Product Specifications, useful Optional Parts &

Accessories

• Appendix C: Flowchart for the Pilot Module.

• Appendix D: PIN Configuration of the mini-D connector

• Appendix E: Dimensional Drawings & Mounting Instructions

• Appendix F: Special Instructions for Installation and Operation of the

Micro-Trak ultra-low flow instruments.

Throughout this manual, we use the word instrument as a generic term to

represent all models of Sierra Instruments’ Smart-Trak 2 Series 100 mass flow

meters and controllers.

SAFETY INFORMATION

Caution and warning statements are used throughout this book to draw your

attention to important information.

Warning!

This statement appears with information that

is important to protect people and equipment

from damage. Pay very close attention to all

warnings that apply to your application.

Caution!

This statement appears with information that is

important for protecting your equipment and

performance. Read and follow all cautions that

apply to your application.

6

Page 7

Sierra Instruments Instruction Manual Smart-Trak® 2 Series 100

RECEIPT OF YOUR INSTRUMENT

When receiving the instrument, carefully check the outside packing carton for

damage that may have incurred during shipment. If the carton is damaged, notify

the local carrier and submit a report to the factory or distributor. Remove the

packing slip and check that all ordered components are present and match your

specifications (as ordered). Make sure any spare parts or accessories are not

discarded with the packing material. Do not return any equipment to the factory

without first contacting one of Sierra’s Technical Support Centers:

USA (Headquarters) Customer Service:

TOLL FREE: 800-866-0200

PHONE: 831-373-0200

FAX: 831-373-4402

EMAIL: service@sierrainstruments.com

European Customer Service:

PHONE: +31 72 5071400

FAX: +31 72 5071401

EMAIL: service@sierra-instruments.nl

Asia Customer Service:

PHONE: + 8621 5879 8521

FAX: +8621 5879 8586

EMAIL: www.sierra-asia.com

7

Page 8

Sierra Instruments Instruction Manual Smart-Trak® 2 Series 100

DEFINITIONS USED IN THIS MANUAL

The following terms are used frequently in this manual. They are presented here

with their definitions for your information.

Setpoint—The command or control signal supplied to a flow controller is called its

setpoint. The controller will maintain the flow at this value.

Full scale—The highest flow that an instrument will meter within its specified

accuracy. It is often possible for an instrument to measure a flow beyond its full

scale value, but the accuracy of this measurement may be outside of published

specifications.

Purge—The Smart-Trak 2 Mass Flow Controller is supplied with the ability to open

the valve far beyond the full scale position to allow them to be cleaned. This is

usually accomplished by blowing clean, dry nitrogen through the instrument. When

the valve is opened to this cleaning position, it is said to be in the Purge mode.

LFE—Laminar Flow Element (LFE) or bypass generates pressure drop forcing a

small fraction of the total flow to pass through the sensor capillary tube.

8

Page 9

Sierra Instruments Instruction Manual Smart-Trak® 2 Series 100

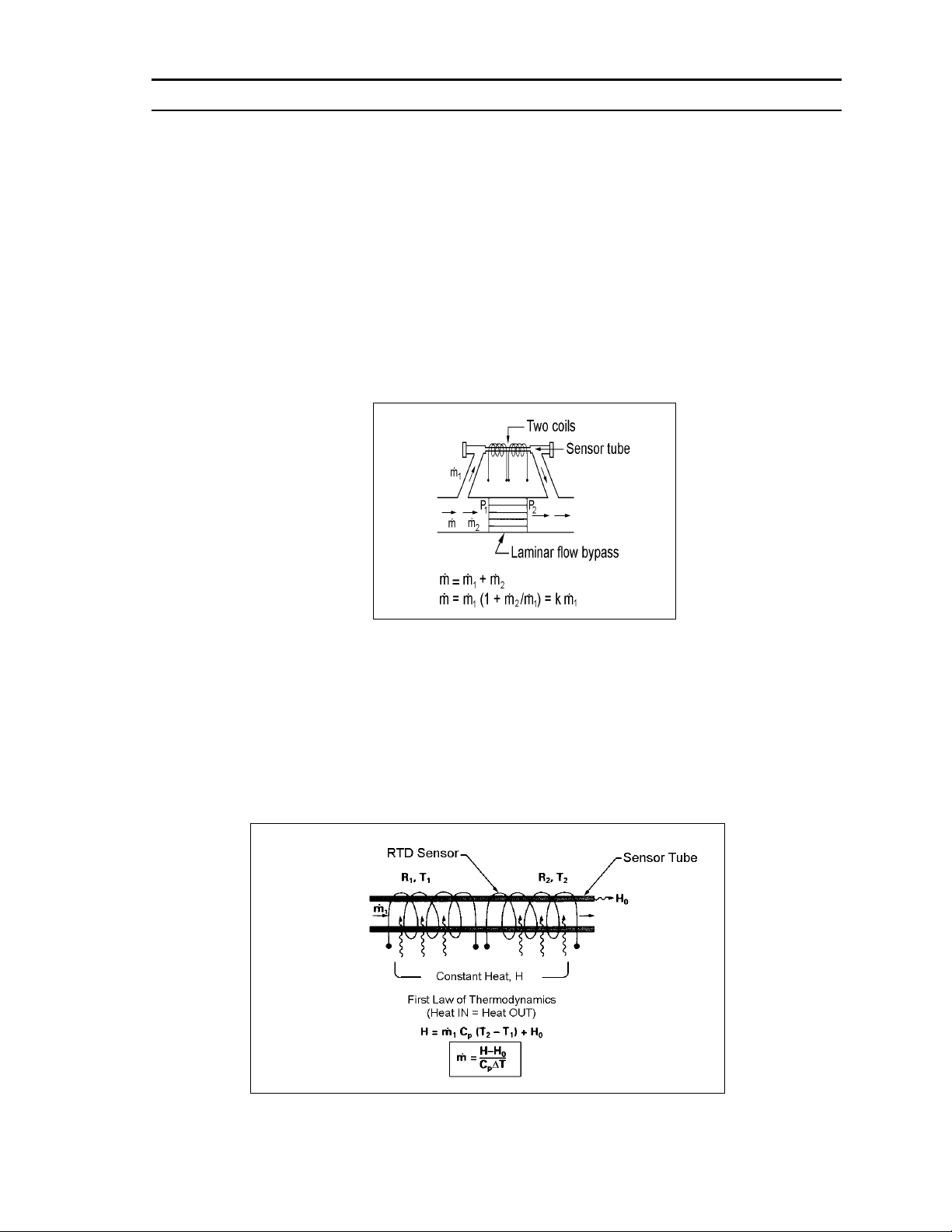

THE SMART-TRAK 2 FLOW SENSING PRINCIPLE

The operating principle of the Smart-Trak 2 instruments is based on heat transfer

and the first law of thermodynamics. During operation process gas enters the

instrument’s flow body and divides into two flow paths, one through the sensor

tube, and the other through the laminar flow bypass. The laminar flow bypass (often

called LFE which stands for “laminar flow element”) generates a pressure drop, P1–

P2, forcing a small fraction of the total flow to pass through the sensor tube (m1).

Figure 1-1. Flow Paths through the Instrument

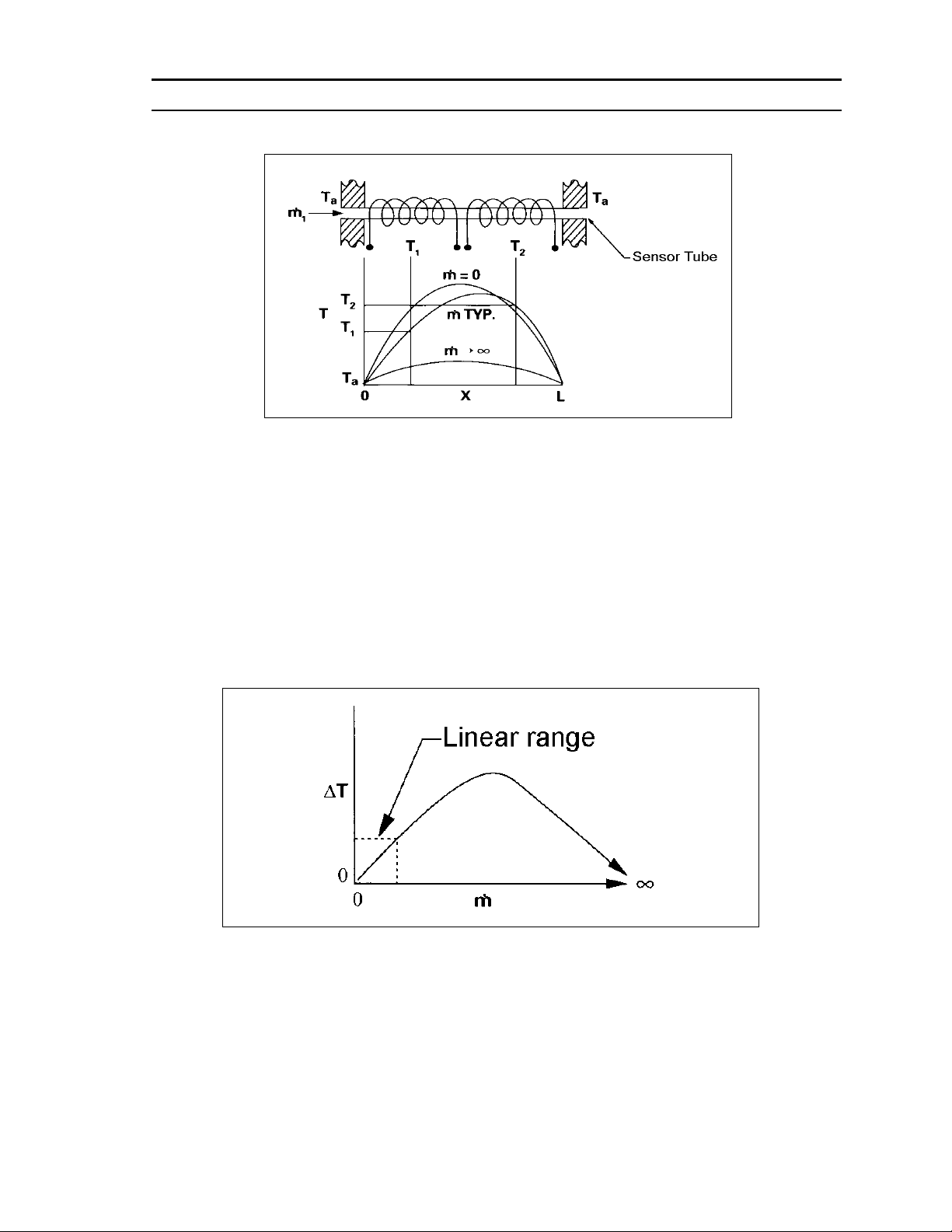

Two resistance temperature detector (RTD) coils around the sensor tube direct a

constant amount of heat (H) into the gas stream. During operation, the gas mass

flow carries heat from the upstream coil to the downstream coil. The resulting

temperature difference (∆T) is measured by the Smart-Trak 2 microprocessor.

From this, Smart-Trak 2 calculates the output signal. Since the molecules of the gas

carry away the heat, the output signal is linearly proportional to gas mass flow.

Figure 1-2. Flow Measuring Principle

9

Page 10

Sierra Instruments Instruction Manual Smart-Trak® 2 Series 100

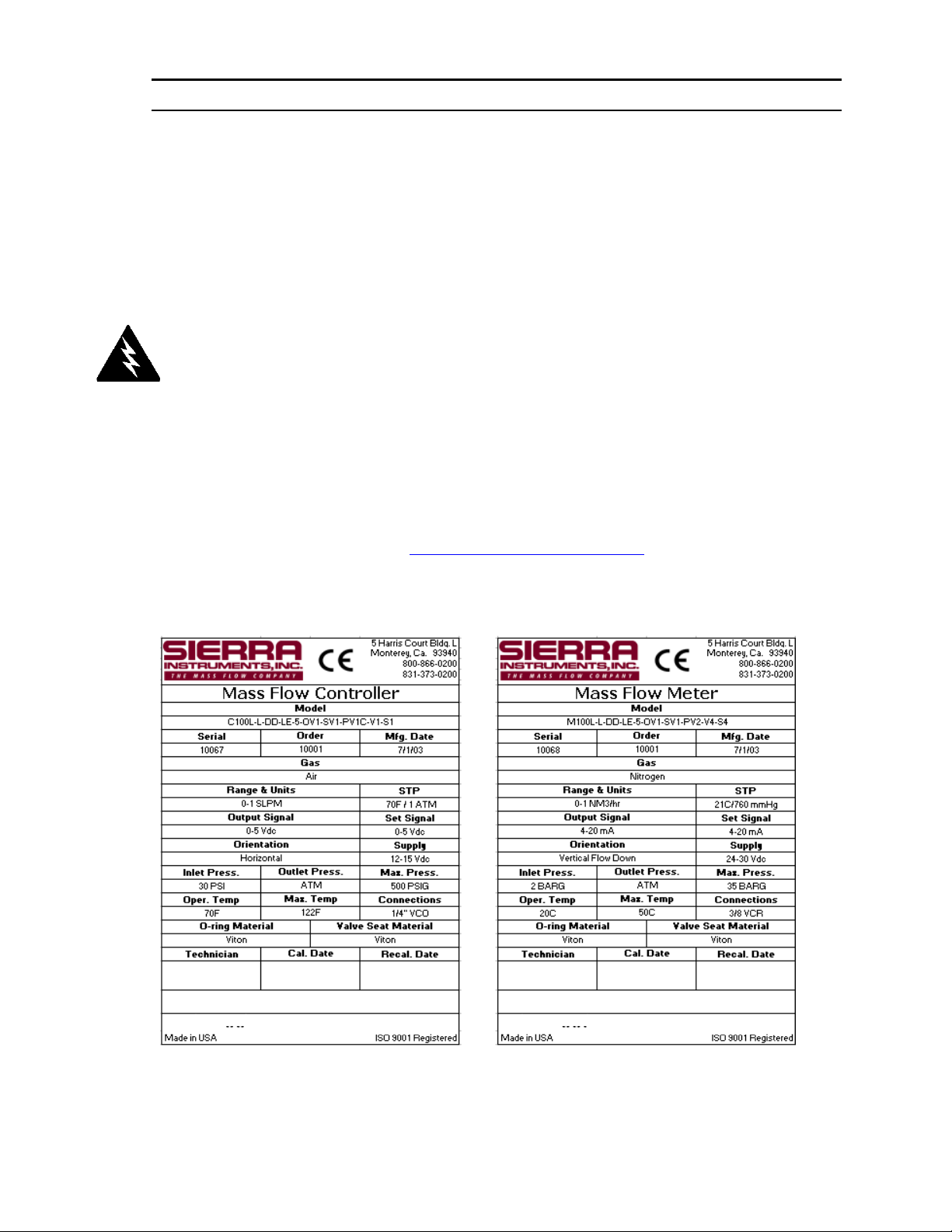

Figure 1-3. Sensor Temperature Distribution

Figures 1-2 and 1-3 show the mass flow through the sensor tube as inversely

proportional to the temperature difference of the coils. The coils are legs of a bridge

circuit with an output voltage in direct proportion to the difference in the coils’

resistance; the result is the temperature difference (∆T). Two other parameters, heat

input (H) and coefficient of specific heat (Cp) are both constant. Through careful

design and attention to these parameters, this output signal is made linear over the

transducer’s normal operating range (Figure 1-4). As a result, the measured flow

through the sensor tube is directly proportional to the gas flow in the main body.

Figure 1-4. Linear Range of the Transducer’s Output Signal

In the Smart-Trak 2 mass flow controllers, the gas which flows through the

monitoring section is precisely regulated by the built-in electromagnetic valve. The

normally closed valve is similar to an on/off solenoid valve, except that the current

to the valve coil, and hence the magnetic field, is modulated so that the

ferromagnetic valve armature, or valve plug, assumes the exact height above the

valve’s orifice required to maintain the valve’s command flow (set point). The

result is excellent resolution.

10

Page 11

Sierra Instruments Instruction Manual Smart-Trak® 2 Series 100

Before You Begin Installation

Warning!

Injury can result if line

pressure exceeds the

maximum rating of

500 psig (34 barg).

CHAPTER 2 INSTALLATION

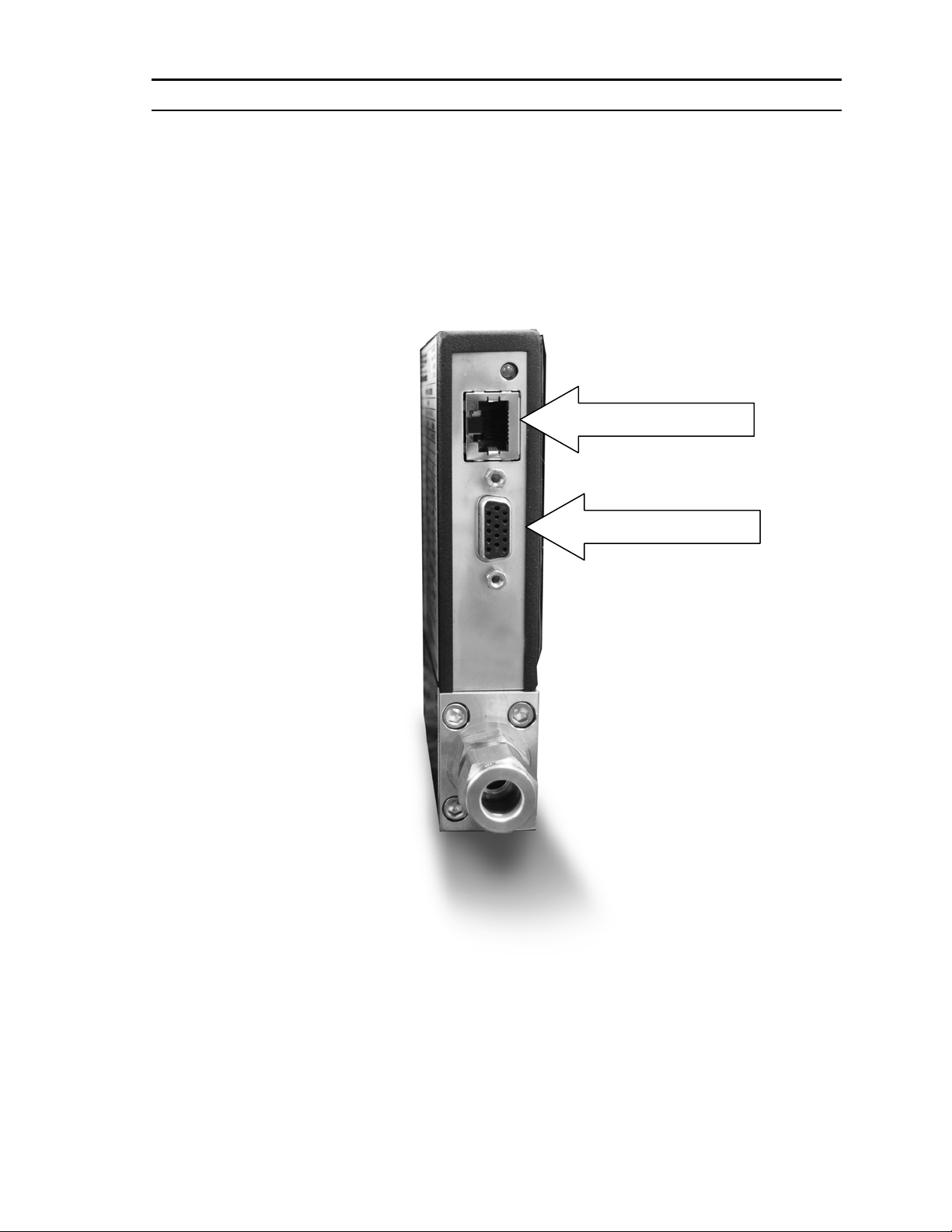

Before installing the instrument, ensure that the installation site conforms to the

specific operating parameters recorded on the instrument’s Data Label. The Data

Label is mounted on the back of the instrument electronics enclosure (see sample

Data Labels in Figure: 2-1). This is critical because each instrument is configured

for a specific application range. Please review the gas or gases, the mounting

orientation, the maximum flow range(s), the inlet and outlet pressure(s), and the

operating temperature(s). The line pressure should not exceed 500 psig (34 barg).

The temperature should not exceed 122°F (50°C). The minimum operating

temperature is 32°F (0°C) and ambient temperature is 0-50°C. If your application

exceeds any of these parameters, contact your Sierra Sales Agent before

installation. You may also contact one of Sierra’s Technical Support Centers.

FACTORY USA: TOLL FREE: 800-866-0200 or PHONE: 831-373-0200 or FAX:

831-373-4402 or EMAIL: service@sierrainstruments.com

Figure 2-1: Examples of Smart-Trak 2 Data Labels

11

Page 12

Sierra Instruments Instruction Manual Smart-Trak® 2 Series 100

Pre-Installation Check List

1. Double-check to be sure that the O-ring material used in your

instrument is compatible with the gas to be measured. The O-ring

material used in your Smart-Trak 2 can be found in the Data Label. See

Appendix A for a table of elastomer compatibility with a wide variety of

gases.

2. Sierra strongly recommends you install an in-line filter upstream of the

instrument. Recommended filter size: 10 micron. A 10 micron filter is

available from Sierra as an accessory. See Appendix B or contact your local

Sierra distributor.

3. Do not locate the instrument in areas subject to sudden temperature

changes, excessive moisture or near equipment radiating significant

amounts of heat. Be sure to allow adequate space for cable connectors and

wiring.

4. For controllers, use a properly sized pressure regulator. Make sure the

pressure regulator is not too small or too big. There can be no restrictions

(such as valves, tubing or pipe internal diameters, reducers, etc.) upstream or

downstream of the controller with a dimension that is less than the valve

orifice diameter. To determine orifice diameter, consult the calibration

certificate included with your instrument. If restricted, controller will not

reach full scale.

5. Output Signals: The Smart-Trak 2 has two analog outputs that are linearly

proportional to the gas mass flow rate, one voltage and one current. Choose

from 0-20 mA or 4-20 mA for current plus one voltage signal: 0-5 VDC or

0-10 VDC or 1-5 VDC. The output signals specified at time of order will be

indicated on the data label. You may change among the current and the

voltage output signal at your discretion after receipt of the instrument using

the Pilot Module or the Smart-Trak 2 Software (see Chapters 4 & 5).

Changing the output signals has no influence on the instrument’s accuracy.

6. The CAT-5 connector on the side of the Smart-Trak 2 is NOT an Ethernet

connector. It is for use with the optional Remote Pilot Module. Do not plug

an Ethernet cable here as damage may result. Keep this connector covered if

possible whenever it is not in use.

7. The instrument has specific power supply requirements. See the table

later in this chapter for a complete listing of power requirements.

Installing the Instrument—Plumbing

Smart-Trak 2 instruments are supplied with compression, VCO®, VCR®, or female

NPT process connections. To ensure a successful installation, inlet and outlet tubing

12

Page 13

Sierra Instruments Instruction Manual Smart-Trak® 2 Series 100

should be clean prior to plumbing the instrument into the system. The shipping caps

covering the inlet/outlet fittings should not be removed until immediately before

installation.

Follow the installation instructions that are applicable to your instrument’s process

connection. Ensure that the tubing is free from burrs or sharp rims that may result

from cutting.

CAUTION: Before use, all plumbing should be checked carefully for leaks,

especially at the connecting fittings. All instruments are leak-tested prior to

shipping. It is not a requirement to leak test your instrument. Do not use liquid

leak detectors such as Snoop

Trak 2. Instead, monitor pressure decay.

®

to search for leaks inside or outside the Smart-

Compression Fittings

1. Position the instrument with the

flow direction arrow pointing in the

direction of flow.

2. Verify the position of the front and

back ferrule. Insert the tubing into

the fitting. Be sure that the tubing rests firmly on the shoulder of the fitting

and that the nut is finger-tight. Scribe the nut at the six o’clock position.

3. While holding the fitting body steady with a backup wrench, tighten the nut

1-1/4 turns, watching the scribe mark make one complete revolution and

continue to the nine o’clock position. For 1/16-inch, 1/8-inch and 3/16-inch

(2, 3 and 4 mm) sizes, tighten only 3/4 turns from finger-tight. Do not over-

tighten!

4. If you use flexible tubing (Example: Polyflow) use an “Insert” (see

www.swagelok.com)

5. Check the system’s entire flow path thoroughly for leaks. Do not use liquid

leak detectors. Instead, monitor pressure decay. Exposing the instrument to

leak detector fluid may cause damage.

VCO Fittings

1. Position the instrument with the flow direction arrow pointing in the

direction of flow.

2. Tighten the nut finger-tight, and then 1/8 turn tighter with a wrench. Do not

over-tighten!

13

Page 14

Sierra Instruments Instruction Manual Smart-Trak® 2 Series 100

3. Check the system’s entire flow path thoroughly for leaks. Do not use liquid

leak detectors. Instead, monitor pressure decay. Exposing the instrument to

leak detector fluid may cause damage.

VCR Fittings

1. Position the instrument with the flow direction arrow pointing the direction

of flow.

2. Install new gaskets that are compatible with the gas to be used.

3. Tighten the nut finger-tight, and then 1/8 turn tighter with a wrench. Do not

over-tighten!

4. Check the system’s entire flow path thoroughly for leaks. Do not use liquid

leak detectors. Instead, monitor pressure decay. Exposing the instrument to

leak detector fluid may cause damage.

1/4InchFemaleNPT

1. Position the instrument with the flow direction arrow pointing the direction

of flow.

2. Apply high quality Teflon tape to the male NPT fitting. Alternatively, use a

high quality paste pipe thread sealant suitable for the application and gas,

and apply this compound to the inlet and outlet fittings. Avoid getting the

tape or the thread sealant onto the first two threads to keep it out of your

process gas.

3. Tighten each fitting by hand. Then, tighten no more than one (1) turn. Do

not over-tighten.

4. Check the system’s entire flow path thoroughly for leaks. Do not use liquid

leak detectors. Instead, monitor pressure decay. Exposing the instrument to

leak detector fluid may cause damage.

14

Page 15

Sierra Instruments Instruction Manual Smart-Trak® 2 Series 100

Installing your Instrument—Mechanical Mounting

Mounting your Instrument

The base plate or bottom of the instrument has 4 mounting holes. Two are SAE

thread and two are metric thread. For location and dimensions, please see Appendix

E.

Your Smart-Trak 2 instrument is made from premium 316 stainless steel. As a result,

it may require substantial mounting brackets to properly support its weight. Exercise

caution when installing to avoid damage or injury.

Mounting the Optional Remote Pilot Module

If you have the optional Remote Pilot Module control unit, you have several

mounting options.

1. Wall or Panel mounting—your Remote Pilot Module may be mounted to a

flat surface using the supplied plate and 2 special “shoulder” screws.

Simply screw the shoulder screws into the plate. Then, attach the plate to

the wall by driving 2 screws (not included) through the 2 large central holes.

MAKE SURE THE UP ARROW IMPRINTED ON THE MOUNTING

BRACKET POINTS UPWARD. Your Remote Pilot Module will slip onto

the shoulder screws. Push against the plate and then down. To remove,

push up and pull. Attach the CAT-5 cable to the socket on the bottom of the

Remote Pilot Module.

2. Rack mounting—to mount your Remote Pilot Module to a standard 19”

laboratory rack, first purchase a “blank” panel from your industrial supplier.

Decide where the Remote Pilot Module will be attached, then follow the

procedure listed above for wall mounting. When you are ready, insert the

CAT-5 cable into the socket in the Remote Pilot Module.

3. Desktop mounting—the Remote Pilot Module will sit on a desk in a

fashion that makes it convenient to view and operate. Insert the CAT-5

cable into the socket in the back of the Module. Use the cable as a

“kickstand.” Gently bend the cable to recline the Remote Pilot Module to

an angle suitable for easy viewing. Alternately, you can lay the Remote

Pilot Module on its back and insert the CAT-5 cable into the socket in the

bottom.

15

Page 16

Sierra Instruments Instruction Manual Smart-Trak® 2 Series 100

Installing your Instrument—Electrical Connections

All electrical connections for your Smart-Trak 2 instrument are made on the left

(inlet) side panel. See Figure 2-2: Smart-Trak 2 Connections below for the location

of all connections. Note that the CAT-5 connector is not an ethernet connector.

CAT 5

HD DB 15

Figure 2-2: Smart-Trak 2 connections

16

Page 17

Sierra Instruments Instruction Manual Smart-Trak® 2 Series 100

Smart-Trak 2 is provided with a high density 15-pin D Connector called an “HD

DB-15” located on the side of the enclosure and either one of our optional preassembled communications cables or an empty mating connector. Power must be

supplied to the HD DB-15 connector. Other features may be accessed there as well.

The pin numbers and assignments for the HD DB-15 connector are shown in Figure

2-3: HD DB-15 Connector Pin Configuration (on the instrument). The

corresponding colors of the optional communication cable wires and the functions

of each are listed in Figure 2-4: Wiring Definitions for Optional Communication

Cable. The connections for input power, analog output signal and analog input

signal (controllers only) are all made at the HD DB-15 connector. There is a

second copy of these 2 figures in Appendix D for your convenience

17

Page 18

Sierra Instruments Instruction Manual Smart-Trak® 2 Series 100

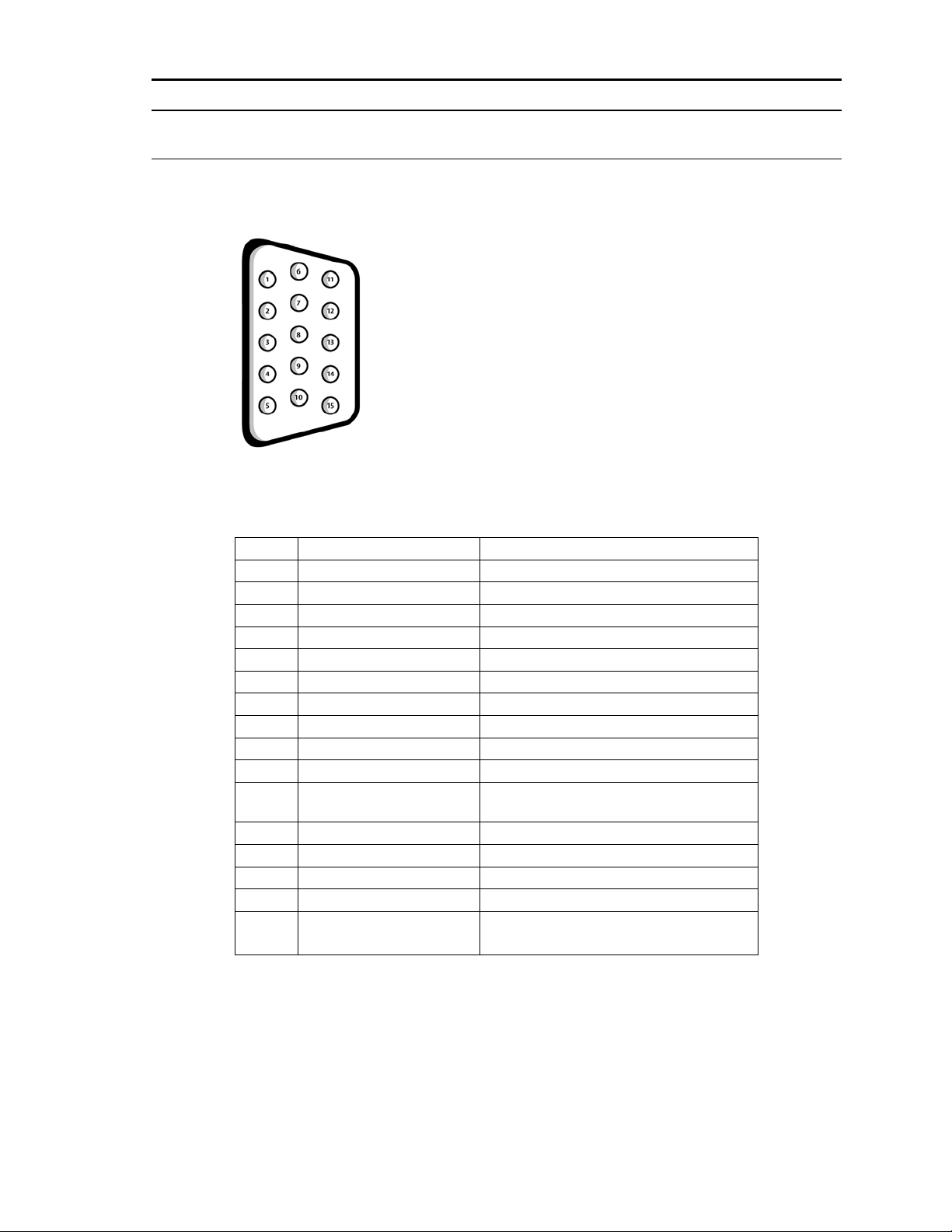

Figure2‐3:HDDB‐15ConnectorPinConfiguration(ontheinstrument)

Figure2‐4:WiringDefinitionsforOptionalCommunicationCable

Pin # Wire Color in Cable Function

1. Brown Analog Ground/Output

2. Red 0-5 VDC Output (or 0-10, 1-5 VDC)

3. Orange Analog Ground/RS232

4. Pink Valve Override Purge

5. Yellow Power Return (-)

6. Green Power Input (+)

7. Green/White RS-232 Transmit (out)

8. Blue Setpoint

9. Purple Not Used

10. Gray Analog Ground/Setpoint

11. White Reference Voltage

(5 VDC External Setpoint & Valve Purge)

12. Black Valve Override Close

13. Brown/white RS-232 Receive (in)

14. Red/white 4-20 mA Output

15. Red/Black Not Used

Shield Wire

(no insulation)

Chassis (Earth) Ground

Note: Pins 1, 3, and 10 are connected together inside the

instrument. Do not tie these grounds together outside the

instrument. Must have one connection per analog ground.

Recommended use listed.

18

Page 19

Sierra Instruments Instruction Manual Smart-Trak® 2 Series 100

Instrument Power:

The Smart-Trak 2 requires a 15-24 VDC power supply. If you are using the power

supply supplied by Sierra, connect it to the 15-pin HD DB-15 connector on the side of

the instrument. If you are supplying your own power source, it must be a regulated

15-24 VDC with ripple not to exceed 100 mV peak-to-peak. It must be capable of

producing the current specified for the appropriate voltage shown in Figure 2-5: Power

Supply Requirements. Apply power as follows: positive (+) to the green (pin 6) and

negative (-) to the yellow (pin 5) wires. The instrument is polarity sensitive. If you

reverse this wiring, the instrument will not be damaged, but it will not function.

Instrument Grounding:

The Smart-Trak 2 has very high levels of RFI and EMI shielding built into the metal

electronics cover (meets or exceeds the CE Standard EN 61326-1; 2006). To maintain

the integrity of this CE rating, it is critical that a path be provided for any residual

internal noise to exit the instrument or it may register on the outputs. Grounding

provides this path.

To properly ground your instrument, secure the chassis to solid earth ground using the

mounting holes on the bottom of the flow body. If the instrument will be used without

permanent mounting (on a laboratory bench, for instance) then, using the provided

cable, connect the shield wire (no insulation) to earth ground in your facility. If you

purchased a Sierra power supply, a ground wire is provided for your convenience.

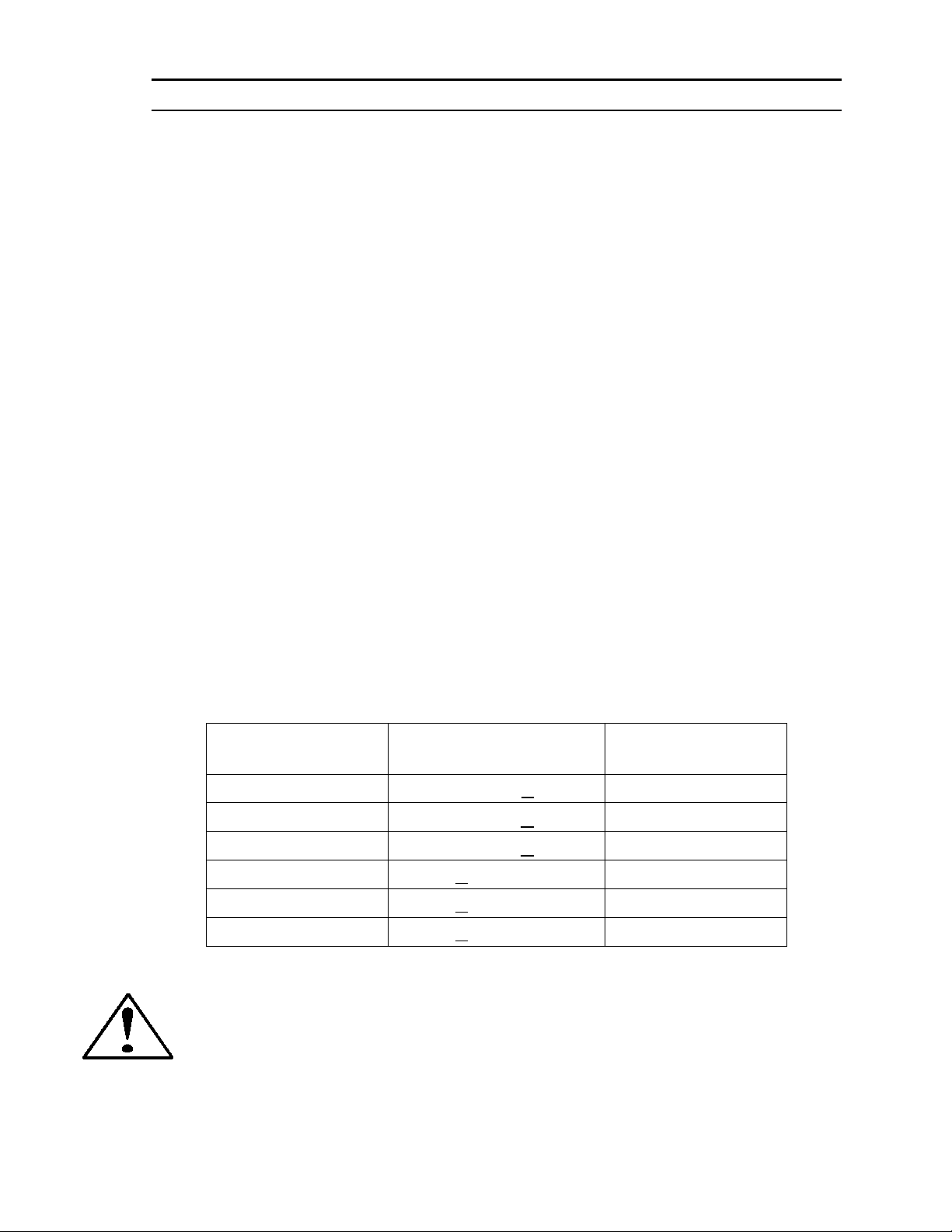

Figure 2-5: Power Supply Requirements

Instrument Type Recommended Input

Voltage

Minimum Current

Required (mA)

M100L Meter 15-24 VDC (+ 10%) 230

M100M Meter

M100H Meter

15-24 VDC (+

15-24 VDC (+

10%)

10%)

230

230

C100L Controller 24 + 10% VDC 500

C100M Controller 24 + 10% VDC 800

C100H Controller 24 + 10% VDC 1260

NOTE: The Compod™ adds an additional 100mA to the ST2 current ratings.

CAUTION: This instrument is not a loop-powered device! Do NOT apply power

to the 4-20 mA output or input connections.

19

Page 20

Sierra Instruments Instruction Manual Smart-Trak® 2 Series 100

Analog Output Signals:

• Output Signal—Voltage: Measure the voltage output signal across the red (pin 2)

wire and any of the analog grounds: brown (pin 1), orange (pin 3) or gray (pin 10).

The minimum load is 1000 Ohms. We recommend pin 1. DO NOT USE THE SAME

ANALOG GROUND FOR CURRENT OUTPUT, SETPOINT OR RS232.

• Output Signal—Current: Measure the current output signal, 4-20 mA or 0-20 mA,

across the red/white stripe (pin 14) wire and any of the analog grounds: pin 1, 3, or

10. The maximum load is 500 Ohms. We recommend pin 1. DO NOT USE THE

SAME ANALOG GROUND FOR VOLTAGE OUTPUT, SETPOINT OR RS232.

For Mass Flow Controllers, the following analog features are also

available at the HD DB-15 connector:

Setpoint: To transmit an analog setpoint, supply the voltage or current signal (check

the data label and/or setting) across the blue (pin 8) wire and pin 10.

Valve Close: To force the valve closed, connect the black (pin 12) wire to pin 10

Purge: To force the valve to its maximum open position which we call “Purge,”

connect the pink (pin 4) wire to the white (pin 11) wire. Note that this will allow

much greater flow than the rated full-scale value.

For Digital Communication Using Your Personal Computer:

You can communicate with your instrument using the Smart-Trak 2 Software

package and

your PC running the Windows operating system. Simply connect the light green (pin 7)

wire, the brown/white stripe (pin 13) wire and one of the analog grounds (pin 1,3, or 10)

to a standard DB-9 connector according to Figure 2-6: Digital Communication.

Figure 2-6: Digital Communication

RS-232 Transmit (pin 7) to DB-9 pin #2

RS-232 Receive (pin 13) to DB-9 pin #3

Analog ground (pin 3) to DB-9 pin #5

20

Page 21

Sierra Instruments Instruction Manual Smart-Trak® 2 Series 100

NOTE: Transit and Receive may need to be reversed, depending on which type of

device or cable is connected. (No damage will result—attempt communication after

reversal.

With the connections in Figure 2-6 in place, plug the DB-9 connector into an appropriate

serial port on your PC.

To minimize the potential for RF interference, it is recommended to shield these wires.

Use a metal DB-9 connector and connect one end of the shield to the DB-9 shell and the

other end to the outer shell of the Smart-Trak 2 HD DB-15 connector.

CAUTION: The CAT-5 connector on the side of the Smart-Trak 2 is NOT an

Ethernet connector. It is for use with the optional Remote Pilot Module or CRN

cable. Do not plug an Ethernet cable here as damage may result.

21

Page 22

Sierra Instruments Instruction Manual Smart-Trak® 2 Series 100

CHAPTER 3: ANALOG OPERATION

Your Smart-Trak 2 instrument may be operated in three different ways:

THREE CONTROL OPTIONS

A. Analog Input/Output Operation (This Chapter): Using analog input/output signals

at the 15-pin mini-D connector.

B. Digital Operation with Pilot Module (Chapter 4): Using the optional Pilot Module.

C. Digital Operation with RS-232 and Smart-Trak 2 Software (Chapter 5): Using the

RS-232 link, the supplied Smart-Trak 2 Software package, and a PC-style

computer running Windows operating system.

This chapter will discuss the first of these—Analog Operation. Please see subsequent

chapters for other options.

Regardless of control options, the standard output for all Smart-Trak 2 instruments are

two linear analog output signals corresponding to 0% to 100% of the mass flow fullscale range. Please note that one of these output signals is a current signal of either 4-20

or 0-20 mA. The other is a voltage signal of 0-5 VDC, 0-10 VDC or 1-5 VDC. You can

choose any combination of these signals at any time in your facility.

For mass flow controllers, one input signal of 4-20 mA, 0-20 mA, 0-5 VDC, 0-10 VDC

or 1-5 VDC (selectable by user) may be chosen to set the gas mass flow rate to any

desired value within the range of the device. This input signal must be a direct linear

representation of 0% to 100% of the desired gas mass flow full-scale value. For the

location of these signals on the HD DB-15 connector, refer to Figure 2-4 or Appendix D.

Analog Operation, Mass Flow Meter

After your instrument is installed and the system has undergone a complete leak check

as discussed in detail in Chapter 2, you are ready to supply power.

Power Your Instrument: Provide adequate power per Figure 2-5. Apply power using

Sierra’s power supply or your own power source. The green LED at the top of the inlet

side will light to confirm power. If your instrument has a Pilot Module, it will begin its

start-up cycle. See Chapter 4 for details on Pilot Module operation. NOTE:

recommended you connect power to the Smart-Trak 2, and then power your supply

(plug into wall or switch on). The opposite may cause the unit to take longer to power

on. Let the instrument warm up for at least 15 minutes for optimal performance.

Your Smart-Trak 2 instrument is now ready for use!

It is highly

22

Page 23

Sierra Instruments Instruction Manual Smart-Trak® 2 Series 100

Analog Operation, Mass Flow Controller

After your instrument is installed and the system has undergone a complete leak

check as discussed in detail in Chapter 2, follow these steps:

1. The valve will remain closed until power is supplied. See Chapter 2 for

wiring instructions. Remember that the valve in the Smart-Trak 2 is not a

positive shut-off device. When power is applied, the flow control valve will

operate per any instructions it receives. When the Smart-Trak 2 is delivered, the

valve will be in the Automatic (Normal) state and the Pilot Module or analog

signal will provide the correct zero setpoint reference for the instrument. As a

result, the valve will be closed. However, upon subsequent power-ups, the

valve will return to the state it was in the last time the instrument was operated.

CAUTION: If you do not know the value of the setpoint or the valve state

given to the Smart-Trak 2 when it was last operated, you must assume that

the valve will open when power is applied. Take necessary precautions.

You may use the Pilot Module or the Smart-Trak 2 Software to check the

setpoint or the valve state currently on your instrument. See Chapter 4 or

Chapter 5 for information on Setpoint and Valve State.

2. Power Your Instrument: Provide adequate power per Figure 2-5. Apply power

using Sierra’s power supply or your own power source. The green LED at the

top of the inlet side will light to confirm power. If your instrument has a Pilot

Module, it will begin its start-up cycle. See Chapter 4 for details on Pilot

Module operation. NOTE: It is highly recommended you connect power to the

Smart-Trak 2, and then power your supply (plug into wall or switch on). The

opposite may cause the unit to take longer to power on. Let the instrument warm

up for at least 15 minutes for optimal performance.

3. Adjust the controller setpoint to the desired flow rate by supplying an

appropriate signal (mA or VDC). The effective control range of the unit is 2%

to 100% of the calibrated full scale flow range. Automatic shut-off occurs at

1.9% of the factory full scale calibrated range unless specifically modified at

time of order. Smart-Trak 2 will immediately begin accurately monitoring and

controlling the gas mass flow rate. Let the instrument warm up for at least 15

minutes for optimal performance.

Your Smart-Trak 2 instrument is now ready for use!

23

Page 24

Sierra Instruments Instruction Manual Smart-Trak® 2 Series 100

Smart-Trak 2 Features

Setpoint Adjustment

The setpoint (command) input signal you supply to Smart-Trak 2 must be a direct

linear representation of 0% to 100% of the mass flow full-scale value. Apply the

setpoint signal from pin 8 to any of the analog grounds (see Chapter 2 for wiring

details). A setpoint value of 0 VDC or mA (or 1 VDC or 4 mA) will regulate the

flow to 0% and a setpoint value of 5.00 VDC (or 10 VDC or 20 mA) will adjust the

flow to 100% of the instrument’s full scale range.

When the setpoint (command) signal is applied, the flow controller will reach the

setpoint value within two seconds to within ±2% of the selected flow rate.

CAUTION: DO NOT LEAVE A SETPOINT APPLIED FOR AN

EXTENDED PERIOD OF TIME TO A CONTROLLER WHEN THE

GAS SUPPLY IS SHUT OFF OR BLOCKED. Damage may result and the

instrument will become hot to the touch. Instead, see below for use of the

“Valve Close” feature which allows you to disable the valve while

maintaining the setpoint signal. This may be set by the Pilot Module, the

Smart-Trak 2 Software, or an external analog signal.

Changing the Output or Setpoint Signals

To modify the analog output or setpoint signals (from 4-20mA to 0-10Vdc, for

example), you must use the Pilot Module or the Smart-Trak 2 Software. The data

label will indicate the form these signals had when the instrument was last

calibrated. We strongly recommend that you adapt the data label if the

configuration is changed for future reference. See Chapter 4 or 5 for the necessary

procedure.

Over-Range Condition

If the mass flow rate exceeds the full-scale range listed on the Smart-Trak 2 data

label (see samples on page 2-1), the output signal will measure above full-scale.

However, the device has not been calibrated for flows in excess of the calibrated

full scale value and the value will be both non-linear and inaccurate if an over-range

condition exists. Please be aware that the analog outputs can exceed full scale by as

much as 20%, or more.

Once the over-range condition has been removed, it may take up to 30 seconds for

the Smart-Trak 2 to recover and resume normal operation. An over-range condition

will not

harm the instrument.

24

Page 25

Sierra Instruments Instruction Manual Smart-Trak® 2 Series 100

Manual Valve Override—Valve Close

Manual valve override is provided for all Sierra mass flow controllers. This feature

includes both a valve close command and a valve maximum open command (called

purge). When the valve is directed to close or to purge, it will no longer respond to

a setpoint command.

FOR VALVE CLOSE: connect pin 12 to analog ground

Remember that the valve in the Smart-Trak 2 is not a positive shut-off device.

The Controller will return to normal automatic operation about 4 seconds

after pin 12 is left floating.

Manual Valve Override—Valve Purge Function

The purge function opens the controller valve completely for the purpose of quickly

flushing unwanted gas from the flow path. When the valve is opened for purging, it

allows flows far in excess of the rated full scale of the controller.

FOR VALVE PURGE: connect pin 4 to pin 11.

CAUTION: PURGE MODE ALLOWS FAR MORE GAS TO FLOW THROUGH

THE CONTROLLER! BEFORE USING VALVE PURGE OPERATION, INSURE

PROPER DOWNSTREAM CAPACITY AND VENTILATION.

IMPORTANT NOTES ABOUT PURGING

Purging Non-Reactive Gases:

Purge your Smart-Trak 2 with clean, dry nitrogen for a minimum of two hours.

Purging Reactive Gases:

One of the following methods may be used:

Cycle purge. This is done by alternately evacuating and purging the

instrument for 2 to 4 hours with clean, dry nitrogen.

Purge the instrument with clean, dry nitrogen for 18 to 24 hours.

Evacuate the instrument for 18 to 24 hours.

25

Page 26

Sierra Instruments Instruction Manual Smart-Trak® 2 Series 100

IMPORTANT SAFETY NOTES ABOUT PURGING

WARNING: When toxic or corrosive gases are used,

purge unit thoroughly with inert dry gas before

disconnecting from the gas line to prevent personnel

from being injured when coming in contact with the

instrument.

WARNING: If an instrument used with a toxic or

corrosive gas is returned to the factory, a Material

Safety Data Sheet (MSDS) must be enclosed &

attached to the outside of the box to alert Sierra

personnel of the potential hazard. Also, make sure the

inlet & outlet are securely sealed.

26

Page 27

Sierra Instruments Instruction Manual Smart-Trak® 2 Series 100

CHAPTER 4: Digital Operation with Pilot Module

Your Smart-Trak 2 instrument may be operated in three different ways:

THREE CONTROL OPTIONS

A. Analog Input/Output Operation (Chapter 3): Using analog

input/output signals at the HD DB-15 connector.

B. Digital Operation with Pilot Module (This Chapter): Using the

optional Pilot Module.

C. Digital Operation with RS-232 and Smart-Trak 2 Software

(Chapter 5): Using the RS-232 Smart-Trak 2 Software package and a

computer running the Windows operating system.

This chapter will discuss the second of these—Digital Operation with the optional

Pilot Module. Please see alternate chapters for other options.

Although you have chosen to use the optional Pilot Module, please note that all the

Analog control functions are still available on your instrument. Consult Chapter 3

for details on Analog operation. Also, computer control using the RS-232

communication is available. See Chapter 5 for details on operation with a computer.

CAUTION—If RS-232 digital communication is to be used in conjunction with the

Pilot Module, the HD DB15 connector must be properly wired with a three wire

serial DB9 cable to your computer. Often, this is done with the same HD DB15 that

supplies power to your instrument. You can run both RS-232 communication and

Pilot Module communications in parallel, but the unit will only respond to one set of

commands at a time. DO NOT attempt to control the unit simultaneously with both

the Pilot Module and the computer, this can lock up the unit.

Introduction to Pilot Module Features and Capabilities

The optional Pilot Module functions as both display and a control unit for your

Smart-Trak 2 instrument. The standard Pilot Module is available mounted directly

on the face of your instrument or as a handheld / remote mountable control interface

attached to the Smart-Trak 2 via a detachable cable.

27

Page 28

Sierra Instruments Instruction Manual Smart-Trak® 2 Series 100

If your instrument has a standard Pilot Module mounted locally on the face of the

unit, no additional set-up is required. See picture below.

On the other hand, if your instrument has a Remote Pilot Module, attach one end of

the included Category 5 (CAT 5, also called RJ-45) connecting cable into the jack

at the top of the instrument’s left side, immediately above the HD DB-15 connector.

Next, place the other end into one of the two matching jacks on the Pilot Module.

For your convenience, Sierra has provided two jacks—one on the back and one on

the bottom of the Remote Pilot Module. You may use whichever jack is most

convenient for your application as they both have identical functions.

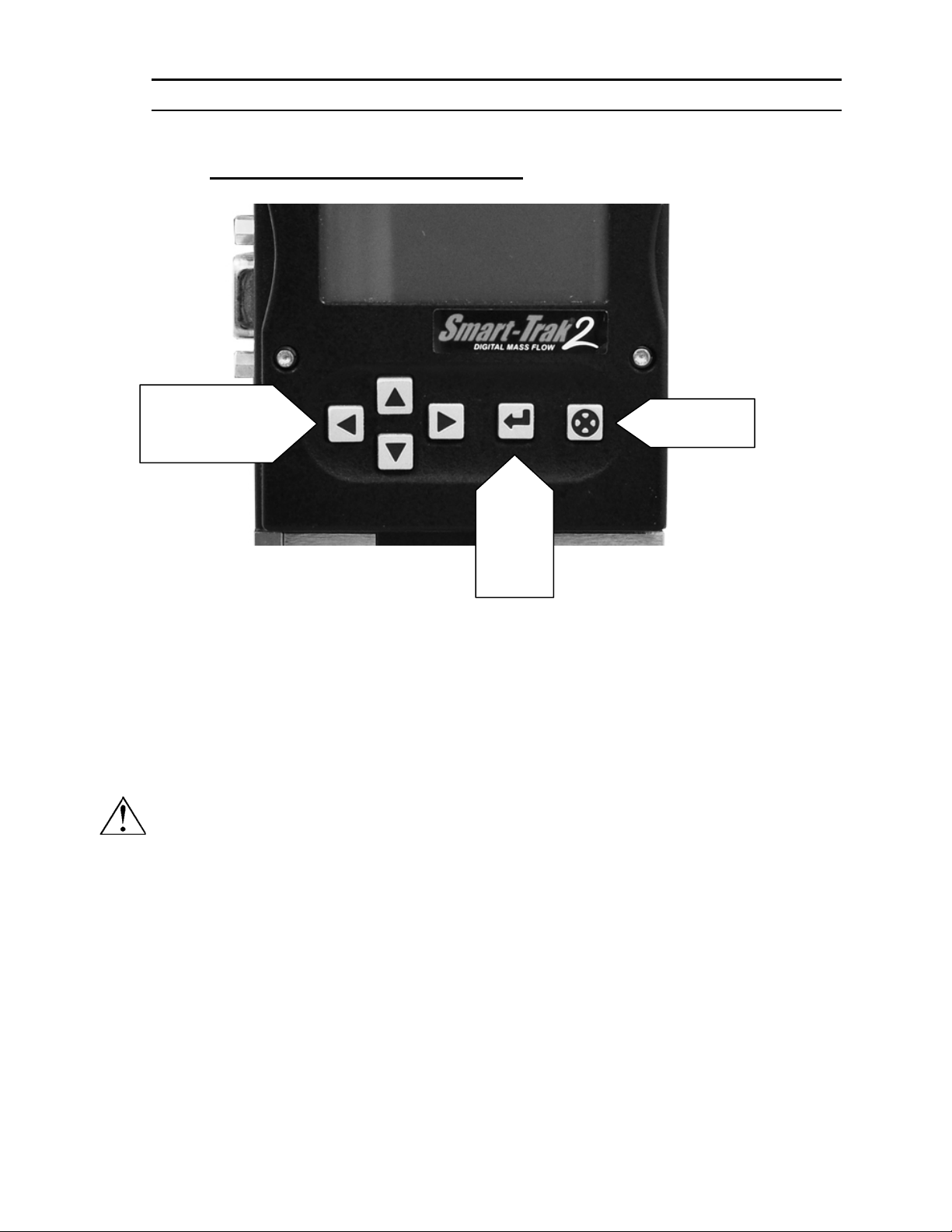

The Pilot Module includes a large LCD graphic display screen and six buttons. The

LCD will show a variety of information and the buttons can be used to view and

modify this information. The convenient buttons are:

Left arrow

Right arrow

Up arrow

Down arrow

Enter button

Escape button

28

Page 29

Sierra Instruments Instruction Manual Smart-Trak® 2 Series 100

These are shown in the photo below:

Up, Down

Left, Right

Pilot Module Operation, Mass Flow Meter

Caution!

The Smart-Trak 2 is

not a loop-powered

device. Do not

apply power to the

4-20 mA outputs.

Assuming no gas is flowing, after another 5-10 seconds the display will read:

Escape

Enter

After your instrument is installed and the system has undergone a complete leak check

as discussed in detail in Chapter 2, follow these steps:

1. Power Up Your Instrument: Apply power to your instrument. See Chapter 2,

Figure 2-5: Power Supply Requirements. When power is first applied, the Pilot

Module will display:

Version

2.04X

Read Parameters

Mass Flow

0.000 sl/m

29

Page 30

Sierra Instruments Instruction Manual Smart-Trak® 2 Series 100

Air

NOTE: If gas is flowing the Pilot Module will immediately begin to accurately

display the gas mass flow rate on the LCD panel. If you have chosen alternate units

or another gas, the display will show the selected units instead of the above.

2. Open the gas supply: Smart-Trak 2 is now ready to monitor the gas mass flow

rate. Let the instrument warm up for at least 15 minutes for optimal

performance.

Your Smart-Trak 2 instrument is now ready for use!

Pilot Module Operation, Mass Flow Controllers

After your instrument is installed and the system has undergone a complete leak

check as discussed in detail in Chapter 2, follow these steps:

1. The valve will remain closed until power is supplied. See Chapter 2

for wiring instructions.

CAUTION: Remember that the valve in the Smart-Trak 2 is not a guaranteed

positive shut-off device. For dangerous applications, Sierra recommends use of

an external shut-off safety valve.

When power is applied, the flow control valve will operate per the instructions it

receives from the Pilot Module. When the Smart-Trak 2 is delivered, the valve will

be in the Automatic (Normal) state and the Pilot Module will provide the correct

zero setpoint reference. As a result, the valve will be closed. However, the valve

will return to the state it was in the last time the instrument was operated.

WARNING: If you do not know the setpoint or the valve state of the Mass

Flow Controller before it was shut down, you must assume that the valve will

open when power is applied. TAKE NECESSARY PRECAUTIONS.

2. Power Up Your Instrument: Apply power to your instrument using

Sierra’s power supply or your own input power source. See Chapter 2,

Figure 2-5: Power Supply Requirements. When power is first applied,

the Pilot Module will display:

Version

2.04X

Read Parameters

If no gas is flowing, after another 5-10 seconds the display will read:

30

Page 31

Sierra Instruments Instruction Manual Smart-Trak® 2 Series 100

Mass Flow

0.000 sl/m

Air

NOTE: If gas is flowing and the Pilot Module has a setpoint greater than zero, it

will immediately begin to accurately display the gas mass flow rate on the LCD

panel. If you have chosen alternate units or another gas, the display will show the

selected units instead of those above.

3. Open the gas supply. Smart-Trak 2 is now ready to monitor and

control the gas mass flow rate. The display will show 0.000 until it is

given a setpoint. Let the instrument warm up for at least 15 minutes for

optimal performance.

Your Smart-Trak 2 instrument is now ready for use!

CAUTION: DO NOT LEAVE A SETPOINT APPLIED FOR AN EXTENDED

PERIOD OF TIME TO A CONTROLLER WHEN THE GAS SUPPLY IS

SHUT OFF OR BLOCKED. Damage may result and the instrument will become

hot to the touch. Instead, see below for use of the “Valve Close” feature which

allows you to disable the valve while maintaining the setpoint signal. This may be

set by the Pilot Module, the Smart-Trak 2 Software, or an external analog signal.

Using the Pilot Module Menus & User Interface

The features of the Pilot Module can be considered in three groups:

1 Upper Level Screens: display information (no password is required to view this

information). These include:

Mass flow rate

Gas (10 options pre-programmed)

Engineering units (mass per unit time)

Current Setpoint with units

Source of Setpoint (analog or digital and type)

Valve operation mode (normal, valve close or purge)

Current meter full scale value with units (user selectable)

31

Page 32

Sierra Instruments Instruction Manual Smart-Trak® 2 Series 100

2 Lower Level Screens: permit changes to instrument operation. They are password

protected. These include:

Setpoint value

Engineering units

Gas

Valve operation

Source of the setpoint signal

Form of the output signals

Full scale of the instrument

Password

Zero

Span

3 Maintenance Features:

Re-boot the Smart-Trak 2 microprocessor. Press the LEFT ARROW,

DOWN ARROW, ENTER, AND ESCAPE keys at the same time.

Move the decimal point. Navigate to the “change the setpoint” menu. Press

ENTER to make one of the digits flash. While it is flashing, press ESCAPE at the same

time you press LEFT ARROW or RIGHT ARROW.

Return all parameters to the factory default values. Navigate to the

“Change the Setpoint” menu. Press LEFT ARROW, UP ARROW, and ENTER at the

same time. Choose “yes” to restore factory default settings.

If you are trying to navigate using the pilot but the message appears,

“Must be in Pilot Mode,” use the LEFT ARROW from this screen to navigate to the

“Change Setpoint Source” and change to “Pilot / RS-232.” Escape and try again.

32

Page 33

Sierra Instruments Instruction Manual Smart-Trak® 2 Series 100

Map of the Pilot Module Interface

The Pilot Module user interface is presented below in a graphical format. Once you

have some familiarity with the user interface, you may find you want to make a

copy of this and keep it with the instrument for reference. You can find a larger

version of this Flow Chart in Appendix C.

33

Page 34

Sierra Instruments Instruction Manual Smart-Trak® 2 Series 100

The seven Upper Level Screens display a variety of information. You are able to

move between the screens by pressing the left or right arrows. No password is

required for the Upper Level Screens.

Mass Flow Screen

When the instrument is powered up, or whenever the escape button is pressed, it

always returns to the Mass Flow Screen. This screen displays the mass flow rate,

the engineering units and your gas choice. It looks something like this:

Mass Flow

0.000 sl/m

Air

Setpoint Screen

Pushing the right arrow takes you to the Setpoint Screen. The Setpoint Screen

displays the current setpoint given to the controller, the engineering units and the

source of the setpoint signal.

The source of the setpoint can be:

• Pilot Module/RS-232

• 4-20 mA

• 1-5 Vdc

• 0-5 Vdc

• 0-10 Vdc

For operation with the Pilot Module, the display will look something like this:

Setpoint

10.00

Pilot Module/RS-232

If this screen does not show “Pilot Module/RS-232” at the bottom, you will not be

able to give the controller a setpoint command from the Pilot Module because the

instrument is waiting for an analog setpoint. See section below titled “Change

Setpoint Source Screen” to change the source of the setpoint signal. Alternately,

you may supply an analog setpoint to the HD DB-15 connector (see Chapter 3).

sl/m

34

Page 35

Sierra Instruments Instruction Manual Smart-Trak® 2 Series 100

Valve Position Screen (Mass Flow Controllers only)

Pushing the right arrow again takes you to the Valve Position Screen, if you have a

Mass Flow Controller. This screen will display the current state of the Smart-Trak 2

valve.

The state of the valve can be:

1. Closed (Remember that the Smart-Trak 2 is not a positive shut-off device).

2. Purge--Maximum Open (recommended 120% of the calibrated full scale

value, but can be much more and can be dangerous)

3. Automatic (the normal position, where the controller responds to a setpoint

signal).

WARNING: The flow rate in Purge is much greater than the

calibrated full scale value and as a result can be dangerous.

For normal operation of the flow controller, this screen should display:

Valve

Automatic

Normal

If this is visible, the instrument will automatically control flow as soon as a setpoint

is given to it. If this screen displays Closed or Purge, the instrument has been

placed into an override position and it will not respond to any setpoint signal. The

valve state may be changed using the “Change Valve Operation” as described on

page 4-16.

Full Scale Screen

Pressing the right arrow again takes you to the Full Scale Screen. This screen

displays the current

displays the gas. Note that this is not necessarily the factory calibrated full scale

value. The screen will display:

full scale value of the instrument with engineering units. It also

Full Scale

10.00

To change the full scale value, see the section below titled “Change Full Scale

Screen.” Pressing the right arrow again takes you back to the Mass Flow Screen.

sl/m

Nitrogen

35

Page 36

Sierra Instruments Instruction Manual Smart-Trak® 2 Series 100

Lower Level Screens (Changing Parameters)

Getting to the Lower Level Screens:

Your instrument is password protected so that unauthorized personnel will be

unable to change the operating parameters of Smart-Trak 2. To enter the Lower

Level Screens at any time you must first supply the correct password.

Password Screen: By pressing the “enter” key from any of the Upper Level

Screens you will come to the Password Screen. (If you do not know if you are in an

Upper Level Screen, press escape and you always automatically go to the Mass

Flow Screen in the Upper Level) The display will show:

Enter Password

0000

The first digit will blink. At this point, you must enter the correct password to gain

access to the Lower Level Screens.

9 If the instrument is being operated for the first time or if no password has ever

been set on the instrument: You can use the factory default password. The factory

default password is “0000.” To proceed to the Lower Level Screens by using the

factory default password, simply press the “enter” key a second time. If you want

rapid access to permit regular changes to your instrument and you do not desire a

password, this is the fastest way to enter the lower level.

9 If You Have a Password: If you have already set a password, enter it now. To

enter the password, push the up arrow to increase the blinking digit or the down

arrow to decrease the blinking digit. To move to the next digit, press the left or

right arrow and repeat the process. When you have selected your four digit

password, press the enter key.

9 If You Want to Set a New Password: If you want to change the password, you

must first get to the Lower Level Screens. Proceed by entering your known

password or if no password has ever been set on the instrument, us the factory

default password. Follow the instructions in the “Change Password Screen” section

found later in this chapter.

If the password you have entered is correct, you will enter the Lower Level at the

Change Setpoint Value Screen.

36

Page 37

Sierra Instruments Instruction Manual Smart-Trak® 2 Series 100

If the password is not correct, the display will show:

Access Denied

Press any button

To continue

When you press any button, you will return to the Mass Flow Screen in the Upper Level.

Press the “enter” key to try again.

LOST PASSWORDS & GENERAL CUSTOMER SERVICE: If you lose your

password, it will be necessary to contact one of Sierra’s Technical Support Centers.

Email Customer Service: service@sierrainstruments.com

FACTORY USA Customer Service:

TOLL FREE: 800-866-0200

PHONE: 831-373-0200

FAX: 831-373-4402

EMAIL: service@sierrainstruments.com

European Customer Service:

PHONE: +31 72 5071400

FAX: +31 72 5071401

EMAIL: service@sierra-instruments.nl

Asia Customer Service:

PHONE: + 8221 5879 8521

FAX: +8621 5879 8586

EMAIL: www.sierra-asia.com

37

Page 38

Sierra Instruments Instruction Manual Smart-Trak® 2 Series 100

Making Changes Using the Lower Level Screens:

The ten Lower Level Screens are at the heart of Dial-A-Gas, allowing you complete

control of your Smart-Trak 2 instrument. It is possible to make several changes on

different Lower Level Screens before exiting.

For example, you could change between one of the ten pre-programmed gases,

change the engineering units, and change the setpoint all in one visit to the Lower

Level Screens. The Smart-Trak 2 will make each adjustment as you complete it.

At any time, you may press the escape button to return to the Upper Level.

Change Setpoint Value Screen

This screen is the entry point to the Lower Level. As soon as a correct password is

entered, you will arrive here. If you are already in the Lower Level Screens, push

the right or left arrow until you reach the Change Setpoint Value screen. The

display will show:

Change Setpoint

00.00 sl/m

Air

This is the position where you can change the setpoint value of the mass flow

controller. To make a change to the displayed value, press the enter key. The first

number in the display will blink. Use the up and down arrows to change the value

of this digit or the left and right arrows to move to another digit. For example, if

you wish to enter a setpoint of 12.5 sl/m, push the “up” arrow once when the first

digit is blinking. You will see:

Change Setpoint

10.00 sl/m

Air

Next, press the “right” arrow so that the second digit blinks. Push the up arrow

twice. You will now see:

Change Setpoint

12.00 sl/m

Air

Press the right arrow again. The first digit after the decimal point will now blink.

Press the up arrow 5 times until you see:

38

Page 39

Sierra Instruments Instruction Manual Smart-Trak® 2 Series 100

Caution!

The Smart-Trak 2 will not

allow you to enter a

setpoint greater than the

current full scale value

set on the instrument.

Change Setpoint

12.50 sl/m

Air

Now that you have made your selection, press the enter key. The display from our

example will show:

Change Setpoint

12.50 sl/m

Air

If you are finished or wish to observe the changes you have made on the LCD

panel, press the escape key to return to the Upper Level Mass Flow Screen.

If you prefer to make additional changes, use the left and right arrow keys to move

to other Lower Level Screens.

Note: If you enter a Setpoint that exceeds the full scale value (displayed in the “Full

Scale” screen in the Upper Level), the Smart-Trak 2 will automatically modify this

value to equal the current full scale value. For example, if the current full scale value

of your instrument is 10 slpm and you have entered a setpoint of 15 slpm, the SmartTrak 2 will modify your setpoint to 10 slpm when you implement the change. The

Setpoint Value screen will show 10 slpm, not 15 slpm.

Change Units Screen

If you are already in the Lower Level Screens, push the right or left arrow until you

reach the Change Units screen. To get to this screen at any time, Press Escape—

Press Enter—type password and Press Enter. Then, press the Right or Left arrow

until you reach the Change Units Screen

The display will show:

.

Change Units

sl/m

39

Page 40

Sierra Instruments Instruction Manual Smart-Trak® 2 Series 100

If you wish to change the engineering units, press the enter button at this point. The

“mass units” will begin to blink. Use the up or down arrows to select an alternate

unit. You can choose from the following mass units:

sl

NL

g

kg

lb

scc

Ncc

SCF

3

NM

3

SM

When you are satisfied, push the left or right arrow. You will now see the “time

unit” blink. Use the up or down arrows to select your choice of time units. You can

choose from the following time units:

m (minutes)

H (hours)

S (seconds)

When you are finished, press the enter button again. You will see:

Change Units

XXX/x

You can make additional changes by using the left and right arrow keys to move to

other Lower Level Screens. You may also choose to press the escape key to return

to the Upper Level Screens and to observe your change.

NOTE: If a small unit is chosen, the device might not be able to display the valve

and might show 9999. You might need to restore factory defaults. See Maintenance

Functions starting on page 47.

Change Gas Screen (Dial-A-Gas)

If you are already in the Lower Level Screens, push the right or left arrow until you

reach the Change Gas screen. To get to this screen at any time: Press Escape—Press

Enter—type password and Press Enter. Then, press the Right or Left arrow until

you reach this screen. The display will show:

Change Gas

Nitrogen

40

Page 41

Caution!

The Smart-Trak 2

valve is not a positive

shut-off device.

Sierra Instruments Instruction Manual Smart-Trak® 2 Series 100

If you wish to change the gas used in the instrument, press enter. The name of the

gas will blink. Use the up and down arrows to make your selection. When you

reach the desired gas, press enter. You will see:

Change Gas

XXXX

You can make additional changes by using the left and right arrow keys to move to

other Lower Level Screens. You may also choose to press the escape key to return

to the Upper Level Screens and to observe your change.

Note: your instrument comes with 10 pre-programmed standard gases. These are

listed in the Specifications in Appendix B. Smart-Trak 2 may be ordered with

alternate gases programmed. If your device was so ordered, you may choose from

these 10 gases instead. You may see the 10 gases programmed in your instrument

by using this screen and simply scrolling up or down.

Change Valve Operation-Close, Purge

If you are already in the Lower Level Screens, push the right or left arrow until you

reach the Change Valve Operation screen. To get to this screen at any time: Press

Escape—Press Enter—enter password and Press Enter. Then, press the Right or

Left arrow until you reach this screen. The display will show:

Change Valve

Operation

Automatic

From this screen you may set the valve to open all the way (“Purge”), force the

valve to remain closed until further changes are made (“Valve Closed”) or set the

valve to control flow when it receives a setpoint from some source (“Automatic”).

To make a change to the valve operation, press the enter key. Use the up and down

arrows to make your selection. When you are satisfied, press the enter key again.

You will see:

Change Valve

Operation

XXXXX

You can make additional changes by using the left and right arrow keys to move to

other Lower Level Screens. You may also choose to press the escape key to return

to the Upper Level Screens.

41

Page 42

Sierra Instruments Instruction Manual Smart-Trak® 2 Series 100

Note: The valve will move to the desired position immediately when you press the

enter key.

IMPORTANT SAFETY NOTES ABOUT PURGING

WARNING: When toxic or corrosive gases are used, purge

unit thoroughly with inert dry gas before disconnecting from

the gas line to prevent personnel from being injured when

coming in contact with the instrument. Chapter 3 discusses

how to purge your instrument. Always neutralize any toxic

gas trapped inside the instrument before removing it from

the gas line.

WARNING: The flow rate in Purge is much greater than the

calibrated full scale value and as a result can be dangerous.

Change Setpoint Source Screen (mass flow controllers only)

If you are already in the Lower Level Screens, push the right or left arrow until you

reach the Change Setpoint Source screen. To get to this screen at any time: Press

Escape—Press Enter—enter password and Press Enter. Then, press the Right or

Left arrow until you reach this screen. The Change Setpoint Source screen allows

you to re-configure the location and type of the setpoint for the Smart-Trak 2

controller. If you intend to supply the setpoint command signal from the Pilot

Module or a computer using the RS-232 link, the display must show:

Change Setpoint

Source

Pilot/RS232

If, instead of using the Pilot Module or the RS-232 link, you prefer to supply an

analog setpoint signal to the Smart-Trak 2, press the enter button. “Pilot/RS232”

will begin to blink. Use the up and down arrows to make your selection from the

following choices:

0-5 VDC

0-10 VDC

1-5 VDC

42

Page 43

Sierra Instruments Instruction Manual Smart-Trak® 2 Series 100

4-20 mA

Pilot/RS232

When you are satisfied, press enter. You will see:

Change Setpoint

Source

X-XX XX

You can make additional changes by using the left and right arrow keys to move to

other Lower Level Screens. You may also choose to press the escape key to return

to the Upper Level Screens.

Caution: If you change the source of the setpoint to an analog

value, you will not be able to control your Smart-Trak 2 mass flow

controller via the Pilot Module or the RS-232 link.

Change Output Signals Screen

If you are already in the Lower Level Screens, push the right or left arrow until you

reach the Change Output Signals screen. To get to this screen at any time: Press

Escape—Press Enter—enter password and Press Enter. Then, press the Right or

Left arrow until you reach this screen

Change Output

. The display will show:

Signals

0-5 VDC/4-20 mA

Here you can re-configure the analog output signals for the instrument. The SmartTrak 2 always outputs one current signal of 4-20mA but the voltage signal may be

selected using this screen. Use the up and down arrows to make your selection.

You can choose between:

0-5VDC and 4-20mA

0-10VDC and 4-20mA

1-5VDC and 4-20mA

When you are finished making your selection, press enter. The screen will read:

43

Page 44

Sierra Instruments Instruction Manual Smart-Trak® 2 Series 100

Change Output

Signals

X-XX XX/X-XX XX

You can make additional changes by using the left and right arrow keys to move to

other Lower Level Screens. You may also choose to press the escape key to return

to the Upper Level Screens.

Change Full Scale Screen

If you are already in the Lower Level Screens, push the right or left arrow until you

reach the Change Full Scale screen. To get to this screen at any time: Press

Escape—Press Enter—enter password and Press Enter. Then, press the Right or

Left arrow until you reach this screen. The display will show:

Change Full Scale

XX.XX sl/m

Air

This screen allows you to re-range the outputs of your instrument. You may select

any full-scale value between 100% and 50% of the displayed maximum value (this

is the factory full-scale calibration value).

The new full-scale value that you select will re-define the analog outputs of the

instrument. The 20 mA signal and the corresponding voltage signal (5 VDC, 1-5

VDC or 10 VDC) will now represent this new full-scale value.

Caution: Changing the full-scale value of the instrument does not affect the

accuracy.

The accuracy is always ±1% of the original factory full-scale calibration value.

Caution: For any instrument, if a value greater than the factory full scale

calibration value is entered on this screen, the Smart-Trak 2 will modify the

requested value to equal the factory full scale calibration value.

If you choose to change the full-scale value, press the enter key. The first digit will

blink. Use the up and down arrows to adjust the value of the digit or the left and

right arrows to choose another digit. When you have completed your modification,

press the enter key. The display will show:

Change Full Scale

XX.XX sl/m

Air

44

Page 45

Sierra Instruments Instruction Manual Smart-Trak® 2 Series 100

You can make additional changes by using the left and right arrow keys to move to

other Lower Level Screens. You may also choose to press the escape key to return

to the Upper Level Screens.

Change Span Screen

If you are already in the Lower Level Screens, push the right or left arrow until you

reach the Change Span screen. To get this screen at any time: Press Escape—Press

Enter—enter password and Press Enter. Then, press the Right or Left arrow until

you reach this screen.

From this screen you can change the instrument’s span distance by a percentage

factor ratio. For example, if your meter is reading 1% high of reading, change span

to 0.990 (99.0%) and the full scale value should be reduced by 1%. If your

controller is controlling 1% below of reading, the same change will bring it in. If

the meter is reading 1% low (controller controls 1% high), then change span to

1.010 (101.0%). The display will show:

Change Span

1.000

Air

To make a change, press the enter key. The first digit will begin to blink. Use the

up and down arrows to modify this digit or the left and right arrows to choose

another digit. When you are satisfied, press enter. The display will show:

Change Span

X.XXX

Air

Keep in mind that you can change the span for each individual gas, thus, a change

in the span to one gas will not affect the span of another gas. You can make

additional changes by using the left and right arrow keys to move to other Lower

Level Screens. You may also choose to press the escape key to return to the Upper

Level Screens.

Zero Meter Screen

If you are already in the Lower Level Screens, push the right or left arrow until you

reach the Zero Meter screen. To get this screen at any time: Press Escape—Press

Enter—enter password and Press Enter. Then, press the Right or Left arrow until

you reach this screen.

45

Page 46

Sierra Instruments Instruction Manual Smart-Trak® 2 Series 100

From this screen you can change the zero flow bridge differential value to match

the zero flow conditions of your application. Mount (or place) the instrument where

it is intended to be used, minding orientation, tilt, etc.; The accuracy of this function

is dictated on how close to operating conditions the unit is when the meter is

zeroed. The display will show:

Zero Meter

Confirm zero flow

Then press enter

Once you push enter, the unit will monitor the sensor bridge differential value. The

display will show:

Zero Meter

Confirm zero flow

New Zero

Upon pressing the enter key again, the unit will record the bridge differential value

to the zero flow condition, leaving you with a freshly “zeroed” instrument! You can

make additional changes by using the left and right arrow keys to move to other

Lower Level Screens. You may also choose to press the escape key to return to the

Upper Level Screens.

Change Password Screen

If you are already in the Lower Level Screens, push the right or left arrow until you

reach the Change Password screen. To get to this screen at any time: Press

Escape—Press Enter—enter password and Press Enter. Then, press the Right or

Left arrow until you reach this screen.

From this screen you can change the instrument password from the factory default

to any four-digit password of your choice. The display will show the factory default

password of four zero’s: “0000”. The display will show:

Change Password

0000

To make a change, press the enter key. The first digit will begin to blink. Use the

up and down arrows to modify this digit or the left and right arrows to choose

another digit. When you are satisfied, press enter. The display will show:

Change Password

0000

46

Page 47

Sierra Instruments Instruction Manual Smart-Trak® 2 Series 100

You can make additional changes by using the left and right arrow keys to move to

other Lower Level Screens. You may also choose to press the escape key to return

to the Upper Level Screens.

Caution: Once you change the Password, you will not be able to enter the

Lower Level without it. Be certain the new password is recorded.

Lost Passwords and General Customer Service

The “creator” password is 6363- this will override all other passwords. If this does

not work, it will be necessary to contact one of Sierra’s Technical Support Centers.

Email Customer Service: service@sierrainstruments.com

FACTORY USA Customer Service:

TOLL FREE: 800-866-0200

PHONE: 831-373-0200

FAX: 831-373-4402

EMAIL: service@sierrainstruments.com

European Customer Service:

PHONE: +31 72 5071400

FAX: +31 72 5071401

EMAIL: service@sierra-instruments.nl

Asia Customer Service:

PHONE: + 8221 5879 8521

FAX: +8621 5879 8586

EMAIL: www.sierra-asia.com

47

Page 48

Sierra Instruments Instruction Manual Smart-Trak® 2 Series 100

CHAPTER 5: Digital Operation RS-232 & Smart-Trak 2

Software

Your Smart-Trak 2 instrument may be operated in three different ways:

THREE CONTROL OPTIONS

A. Analog Input/Output Operation (Chaper 3): Using analog input/output signals

at the 15-pin mini- D connector.