Page 1

Model S5832SG

Control Panel

8 to 32 Zones

Installation

Instructions

Downloaded from: http://www.guardianalarms.net

Page 2

Table of Contents

Page 3

Table of Contents

Compliance and Regulatory Information ....................i

Installing and Connecting the Control Panel ..... 1 - 5

Sierra S5832SG PC Board Layout.............................. 1

Mounting the Panel.................................................. 1 - 2

Panel Setup and Installation ....................................... 1

Earth Ground ............................................................... 1

Mounting the Enclosures .............................................. 2

S5832S Enclosure (Small) ....................................... 2

S5832 Enclosure (Large) .......................................... 2

Backup Battery ................................................................ 3

Sierra Accessory Loading ............................................ 3

AH Requirements for Backup ...................................... 3

Determining Standby Battery Requirements ........ 3

AC Power ......................................................................... 3

Output Terminals ............................................................ 4

External Bell Supervision ............................................. 4

Keypad Wiring ................................................................ 4

Sierra Accessory Wiring Distances......................... 4

Keypad Addressing .................................................... 5

Connecting an Auxiliary Keypad (J8) .................... 5

Zone Terminals ............................................................... 5

On-Board Relay Terminals (TB2) ................................ 5

Programming the Panel ........................................ 8 - 10

Remote Programming (RPS)........................................ 8

Direct Connect ............................................................. 8

Keypad Activated RPS......................................... 8 - 9

Programming With an LED Keypad ............................ 9

Programming With an Alphanumeric Keypad ........ 1 0

Quick Programming Mode ......................................1 0

Menu Programming Mode ...................................... 1 0

Programming With an Icon Keypad.......................... 1 0

Installer Mode Options, (Block 0) ..................... 11 - 12

Installer Walk-Test ........................................................ 1 1

Event Memory ............................................................... 1 1

Event Memory Codes...............................................1 1

Custom Messages........................................................ 1 2

Test Report ..................................................................... 12

Test Report with Audibles ........................................... 1 2

Audible Test ................................................................... 1 2

Entry Delay Test ............................................................ 1 2

Exit Delay Test .............................................................. 1 2

Transmit Walk-Test Queue Reports .......................... 1 2

RPS Callback ................................................................ 1 2

Battery Test .................................................................... 1 2

Accessories .............................................................. 5 - 7

S5050 Relay/Event Memory Module.................... 5 - 6

Switch Settings............................................................ 6

Switch Configuration ................................................. 6

S5058 Zone Expansion Module.................................. 6

ZEM Addressing.......................................................... 6

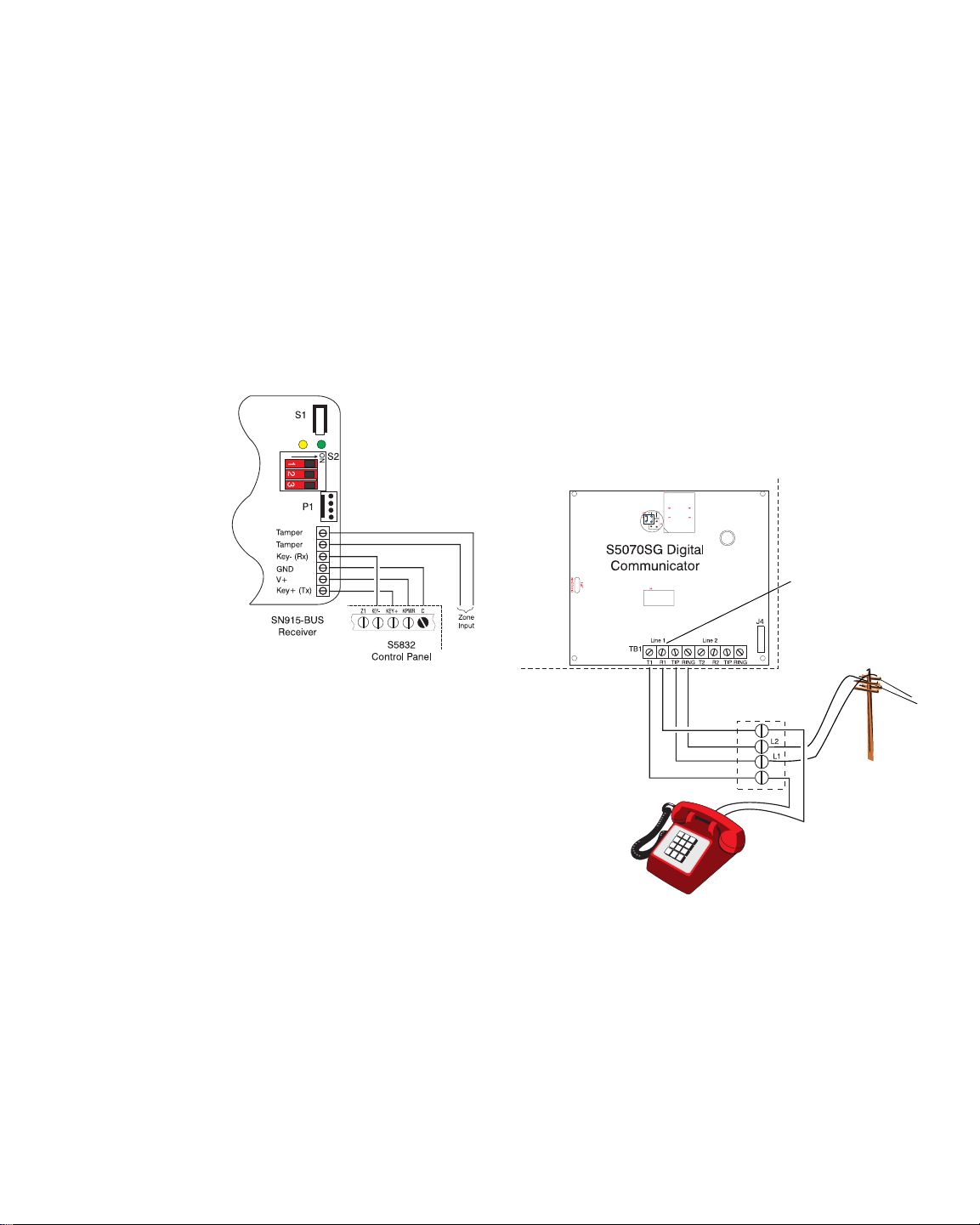

SN915-BUS SpreadNet Receiver ............................... 7

SN990/991 SpreadNet Keypad/Remote ................... 7

SN961 SpreadNet Keyfob ............................................ 7

Digital Communicator ............................................. 7 - 8

Removing/Installing the Digital Communicator ....... 7

Digital Communicator Terminal Connections..... 7 - 8

Terminal Connections ................................................... 8

Programming Summary ...................................... 13 - 39

Block 1: Code Option Programming ............... 13 - 14

Block 2: Zone Configuration Programming ... 14 - 16

Block 3: Armed System Programming ............ 16 - 21

Block 4: Digital Communicator Programming 21 - 25

Block 5: Reporting Digits Programming ......... 25 - 29

Block 6: Real Time Clock Programming .................3 0

Block 7: Auxiliary Devices Programming....... 31 - 34

Block 8: SpreadNet Programming ............................ 3 5

Block 9: Partition (Area) Programming .......... 35 - 37

Block 10: User Code Programming ................ 37 - 39

Page 4

Country Specific Compliance Information

Singapore

The following hardware and programming guidelines are required

for installation of this system in Singapore.

Hardware Requirements:

1. The Digital Communicator must be Model S5070SG or S5070SG-2.

Programming Requirements:

1. Dial Type (Block 4, CL 101) must be programmed for DTMF only.

2. Dial Attempts (Block 4, CL 102) must not be programmed to more

than 10.

Malaysia

The following hardware and programming guidelines are required

for installation of this system in Malaysia.

Hardware Requirements:

1. The Digital Communicator must be Model S5070SG or S5070SG-2.

Programming Requirements:

1. Dial Attempts (Block 4, CL 102) must not be programmed to more

than 3.

Standby Battery Information

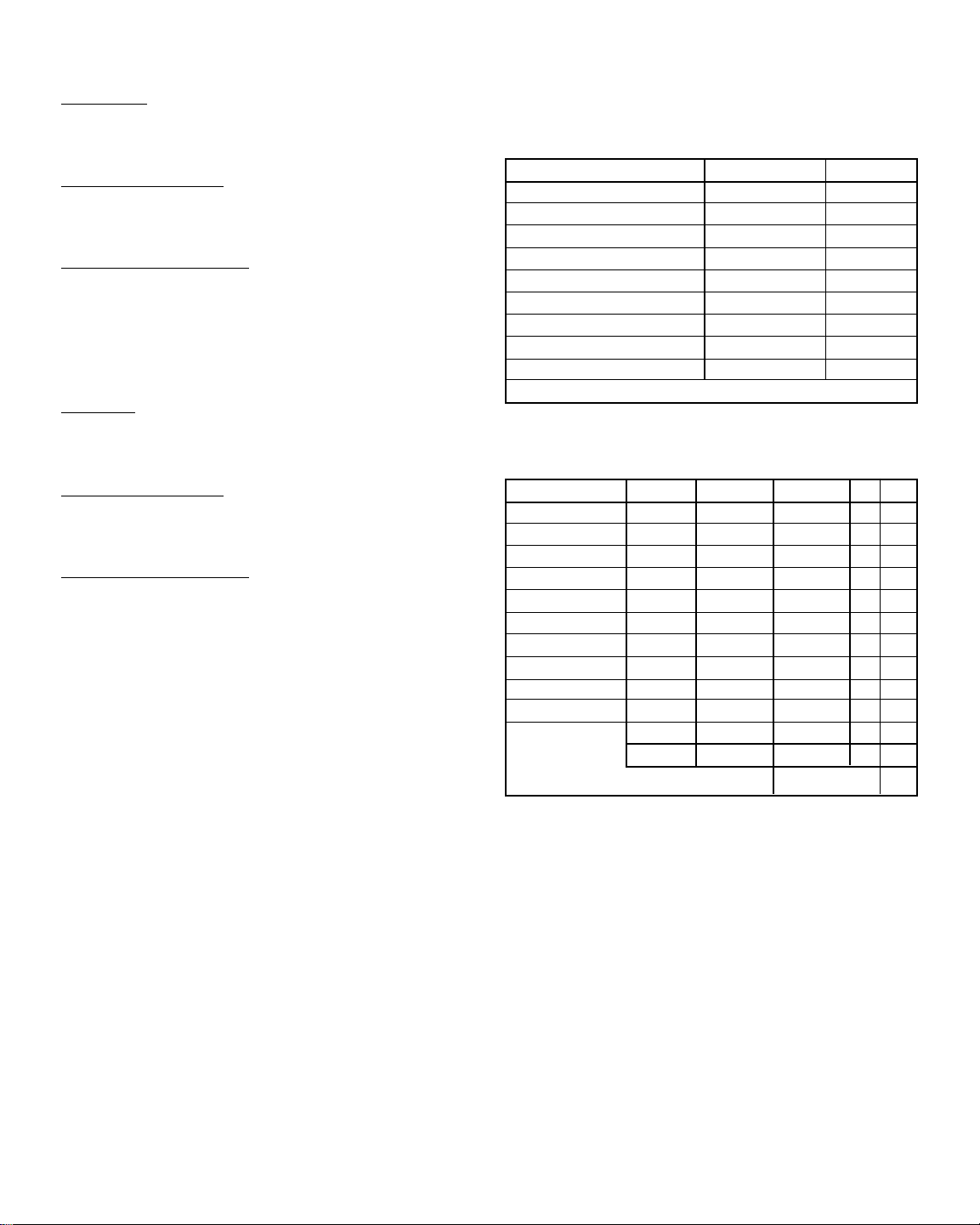

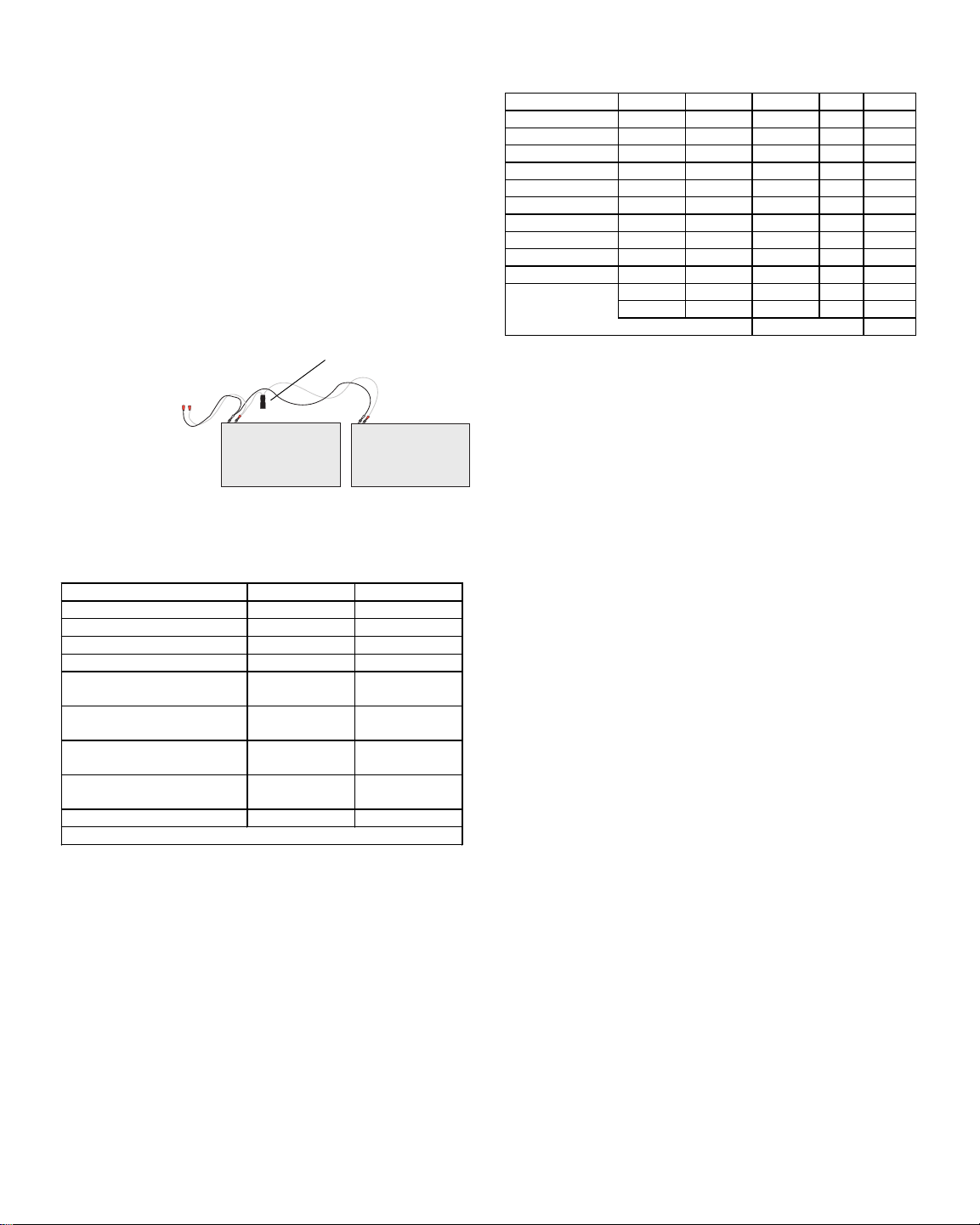

The Table and worksheet below provide the installer with the information necessary to determine the AH rating and battery requirements for any particular installation.

Sierra Accessory Loading

Product current consumption Max. Standby Max. Active

S5832 Control Panel 125 mA 125 mA

S5010 Alpha Keypad 30 mA 50 mA

S5020 LED Keypad 30 mA 50 mA

S5030 Icon Keypad 30 mA 50 mA

S5050 REMM (up to 2) 100 mA (each) 100 mA

S5058 ZEM (up to 3) 40 mA (each) 40 mA**

S5070 Single-line Dialer 35 mA 60 mA

S5070-2 Dual-line Dialer 35 mA 70 mA

SN915-BUS RF Receiver 125 mA 170 mA

**ZEM VOUT terminals can supply up to 300 mA (max.)

Table A - Standby Battery Loading

AH Requirements for Backup

Product/Device 4-Hour 24-Hour 72-Hour Qty Total

S5832SG 0.5 AH 3.0 AH 9.0 AH

S5010 0.12 AH 0.72 AH 2.16 AH

S5020 0.12 AH 0.72 AH 2.16 AH

S5030 0.12 AH 0.72 AH 2.16 AH

S5050 0.4 AH 2.4 AH 7.2 AH

S5058 0.16 AH 0.96 AH 2.88 AH

S5070(-2) 0.14 AH 0.84 AH 2.52 AH

SN915-BUS 0.5 AH 3.0 AH 9.0 AH

Sensor (10 mA) 0.04 AH 0.24 AH 0.72 AH

Sensor (25 mA) 0.1 AH 0.6 AH 1.8 AH

Bell/Siren (5 min) 0.085 AH 0.085 AH 0.085 AH

Bell/Siren (15 min) 0.225 AH 0.225 AH 0.225 AH

* Bell/Siren current may be 0.7 - 1.0 A Total AH Required

Table B - AH Requirements

Determining Standby Battery Requirements

To calculate the size (AH rating) of your system's Backup Battery,

enter the Number (Qty) of devices of each type in the chart above.

Multiply the number of devices times the AH rating for the desired

backup period (Qty x AH = Total) and enter the total in the last

column. To determine the total AH rating of the battery, add all

values in the last column.

Total current from all sensors must be considered when calculating AH rating. For example:

i

10 sensors @ 10 mA = 100 mA

4 sensors @ 25 mA = 100 mA

Total current all sensors = 200 mA

Page 5

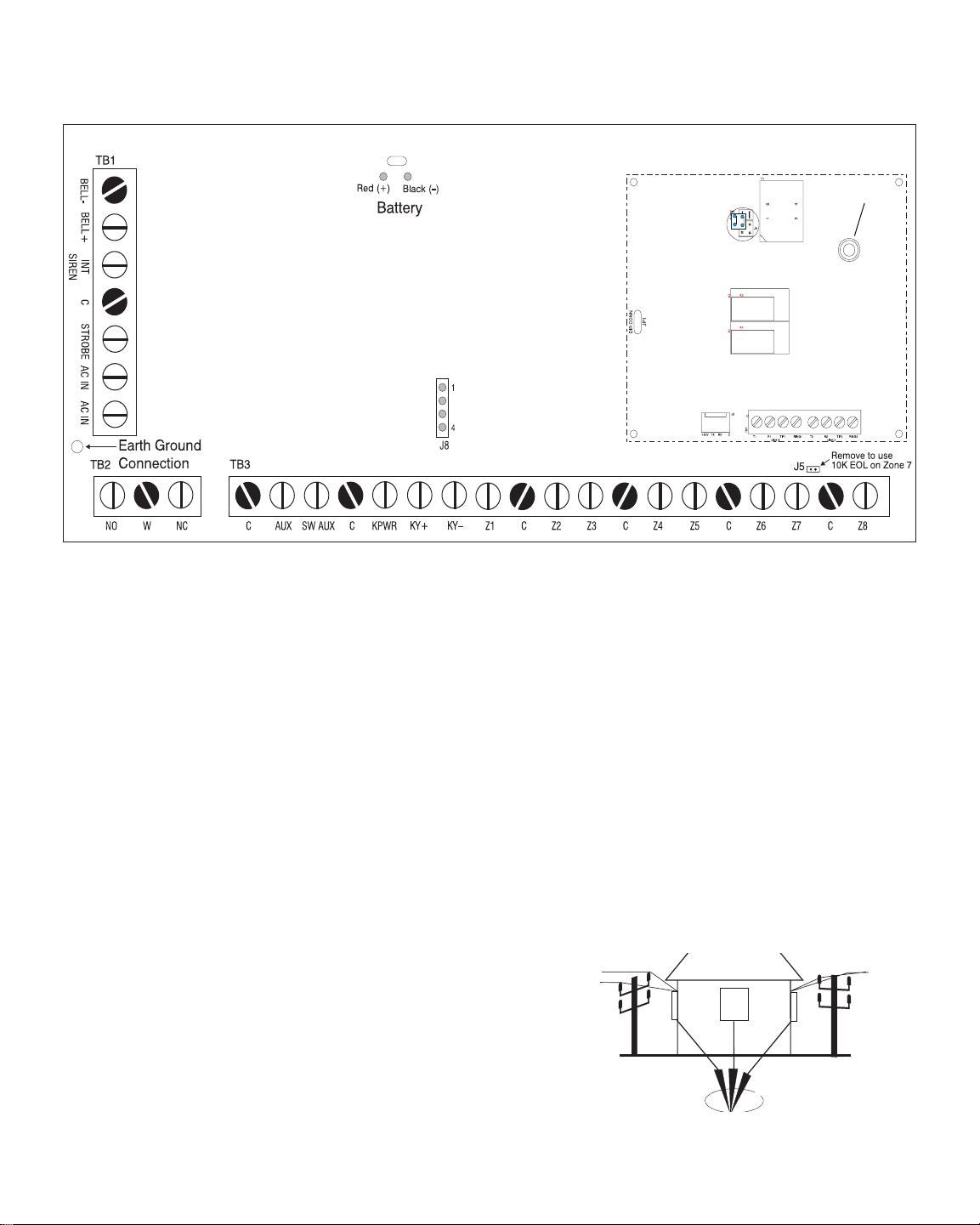

S5832SG Terminal Layout

Figure 1

S5832SG PCB Terminal Layout

Nylon retaining

screw

Introduction

This manual contains basic information and programming information for the Sierra Model S5832SG control panel.

For additional information regarding programming and

applications, refer to the Expanded Programming section of the S5090 Sierra Reference Manual.

Mounting the Panel

The Sierra S5832SG should be mounted in a location

which allows convenient access to AC power, telephone connections, and earth ground (see Figure 2).

Remove the knock-outs, if necessary.

Mark the screw mounting holes on the wall, using

the cabinet as a template.

Mount the cabinet at the desired height and pass

the cables through the knock-outs.

Mount the circuit board to the stand-offs. The standoffs are factory installed. The metal stand-off (lower

left corner) has a panhead screw to be used for connecting earth ground.

Connect the earth ground wire (green with yellow

stripe) to the board (see Figure 1) and cabinet. The

earth ground wire will connect to the upper hinge

when using the large enclosure and to the lower

hinge on the small enclosure.

Panel Setup and Installation

The first step in any installation process is careful planning

of the installation. Install the Sierra Model S5832SG in a

location as close as possible to power and phone lines. The

control panel is designed to operate as a local panel, with an

optional plug-on digital communicator.

Earth Ground

To ensure the effectiveness of the lightning and transient

protection circuits, the control panel must be connected to

"Earth Ground". Ideally, this should be a common ground to

the power lines, telephone system, and security system.

This type of ground, called a "Unified Earth Ground", provides the best protection. The ground connection, from a

grounding rod, cold water pipe or other established ground

point, is made to the green/yellow jacketed wire, providing a

ground to the panel housing.

Power

Lines

Figure 2

Connecting to

Earth Ground

Control

Panel

Power Line

Earth Ground

Unified Earth Ground

with Bonded Ground Roots

Telephone

Earth Ground

Telephone

Lines

1

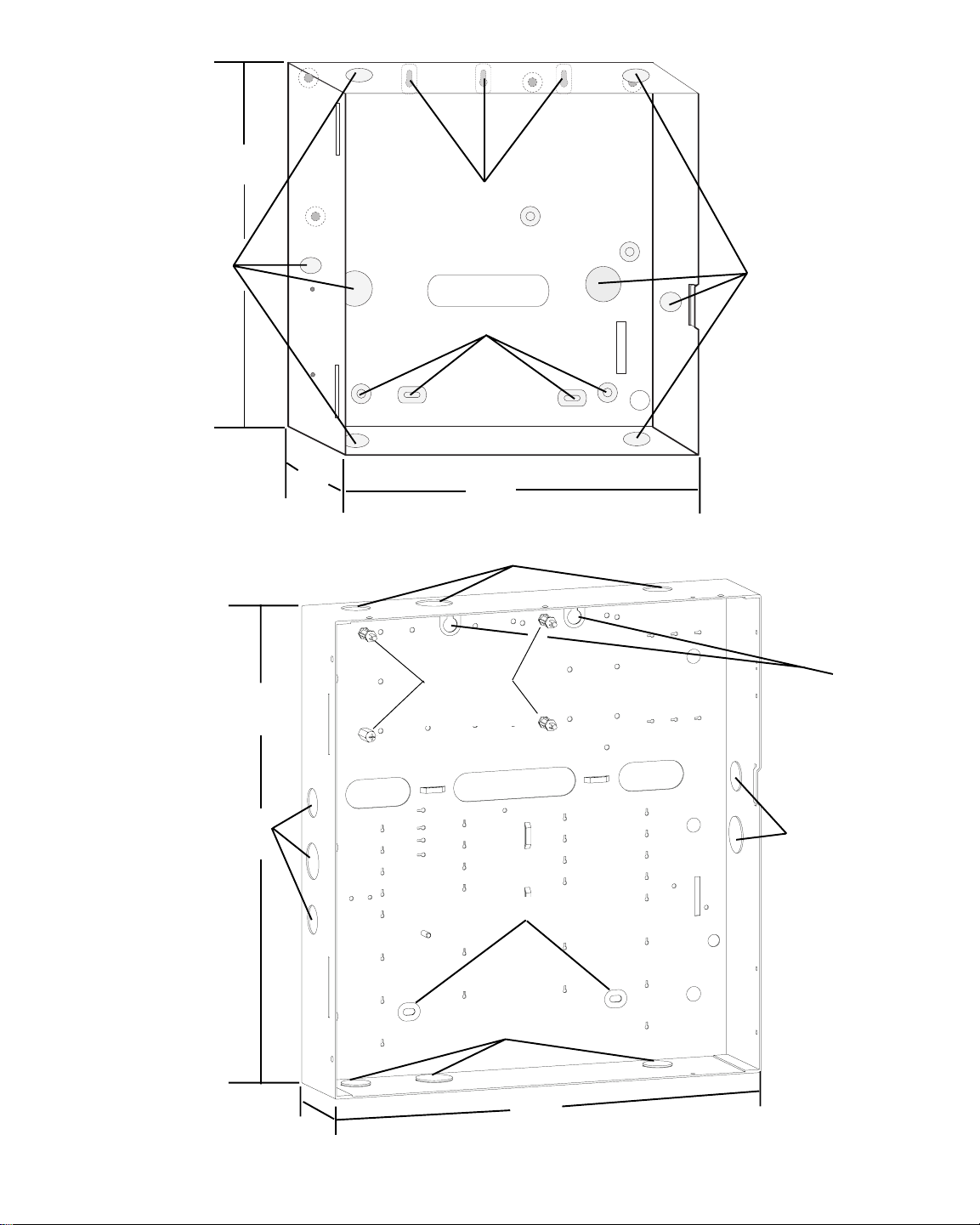

Page 6

261 mm

10.25"

Housing Mounting Holes

Wiring Knock-outs

Figure 3 (a)

Mounting the S5832S

Enclosure

372 mm

14.65"

80 mm

3.15"

Housing Mounting Holes

266 mm

10.5"

Wiring Knock-outs

To p

PCB Mounting

Hardware

(see page 1

for details)

Wiring Knock-outs

Housing

Mounting Holes

Wiring Knock-outs

Figure 3 (b)

Mounting the S5832

Enclosure

Left side

80 mm

3.15"

Housing Mounting Holes

Wiring Knock-outs

Bottom

348 mm

13.7"

2

Wiring Knock-outs

Right side

Page 7

Backup Battery

The system employs one or more 6.5 AH (Model 1265) or 7.0

AH (Model 1270) sealed lead-acid storage battery. Connect

the battery to the control panel PCB via the red (+) and black

(-) leads. The battery should be replaced every 3 - 5 years.

When connecting two or more batteries in parallel, use the

Model S5054 Auxiliary Battery Harness. Both batteries must

have the same AH (Ampere-Hour) rating and should have

the same lot number or date code. Figure 4, below, shows

correct method for wiring the batteries in parallel.

NOTE: Up to 2 batteries may be connected in parallel to

obtain the desired standby (backup) time.

Self-resetting

To S5053 LSM

or S5832SG

Control Panel

C & K Model

1265 or 1270

Figure 4

Connecting two Batteries in Parallel

circuit

C & K Model

1265 or 1270

Sierra Accessory Loading

Product Current Consumption Max. Standby Max. Active

S5832SG Control Panel 125 mA 125 mA

S5010 Alpha Keypad 30 mA 50 mA

S5020 Icon Keypad 30 mA 50 mA

S5030 LED Keypad 30 mA 50 mA

S5050 REMM (up to 2)

(Relay/Event Memory Module)

S5058 ZEM (up to 3)

(Zone Expansion Module)

S5070 Single-line Digital

Communicator

S5070-2 Dual-line Digital

Communicator

SN915-BUS RF Receiver 125 mA 170 mA

** ZEM VOUT Terminals can supply up to 300 mA (max.)

Table 1 - Standby Battery Loading

100 mA (each) 100 mA

40 mA (each) 40 mA**

35 mA 60 mA

35 mA 70 mA

AH Requirements for Backup

Product/Device 4-Hour 24-Hour 72-Hour Qty. Total

S5832SG 0.5 AH 3.0 AH 9.0 AH

S5010 0.12 AH 0.72 AH 2.16 AH

S5020 0.12 AH 0.72 AH 2.16 AH

S5030 0.12 AH 0.72 AH 2.16 AH

S5050 0.4 AH 2.4 AH 7.2 AH

S5058 0.16 AH 0.96 AH 2.88 AH

S5070 (-2) 0.14 AH 0.84 AH 2.52 AH

SN915-BUS 0.5 AH 3.0 AH 9.0 AH

Sensor (10 mA) 0.04 AH 0.24 AH 0.72 AH

Sensor (25 mA) 0.1 AH 0.6 AH 1.8 AH

Bell/Siren (5 min) 0.085 AH 0.085 AH 0.085 AH

Bell/Siren (15 min) 0.225 AH 0.225 AH 0.225 AH

* Bell/Siren current may be 0.7 1.0 A Total AH Required

Table 2 - AH Requirements

Determining Standby Battery Requirements

To calculate the size (AH rating) of your system's Backup

Battery, enter the Number (Qty) of devices of each type in

the chart above. Multiply the number of devices times the

AH rating for the desired backup period (Qty x AH = Total)

and enter the total in the last column. To determine the

total AH rating of the battery, add all values in the last

column.

Total current from all sensors must be considered when

calculating AH rating. For example:

10 sensors @ 10 mA = 100 mA

4 sensors @ 25 mA = 100 mA

Total current all sensors = 200 mA

AC Power

The Sierra S5832SG receives its power from a 16.5 VAC 40

VA transformer. Connect the transformer to the AC In terminals on TB1 of the PCB (see Figure 1), using 18 AWG (1.02

mm) wire. (Some systems may have the transformer and

mains fuse block installed and pre-wired from the factory.)

Connect the AC transformer to an unswitched receptacle.

Do not share the secondary of the transformer with other

devices.

NOTE: AC input requirements may vary by country. Refer to

the Compliance section for additional wiring information.

Table 1 shows the current requirements for the Sierra

S5832SG control panel and accessories. Additional information about Standby Battery requirements and Audible

times may be found in Table 2 - AH Requirements, at the top

of the next column.

3

Page 8

Output Terminals

Table 3 shows the Output Terminals of the S5832SG, with

the Voltage and Current Range of each Output. The Table

also shows the maximum combined current for related outputs.

INT

Voltage

Range Curr ent

8.4 14.9 V 0.75 A

8.4 14.9 V 2.0 A

Function Terminal

Strobe

Output

Internal

Siren

External

Siren

Auxiliary

Power

Switched

Auxiliary

Power

Keypad

Power

Zone 8 Z8 8.5 14.0 V 0.03 A 0.03 A 2-wire Smoke Detectors

STROBE 8.4 14.9 V 0.75 A

SIREN

BELL+

BELL-

AUX 8.4 14.9 V 1.0 A

SW AUX 8.4 14.9 V 0.3 A

KPWR 8.4 14.9 V 1.0 A

Table 3

Output Terminal limits

Combined

Current Comments

(3.0 A with

Battery)

1.5 A

Specifically designed to

drive strobes with high

in-rush currents.

Typically used to drive

sirens mounted inside

the premises.

Supervised Siren Output

typically used to drive

bells, sirens, and other

high current devices

outside the premises.

Used to drive sensors,

etc.

Used to drive lat ching

devices like glassbreak

detectors or four-wire

smoke detectors that

must be reset.

Used to power keypads,

REMMs, ZEMs, and

SN915 RF Receiver.

Keypad Wiring (cont.)

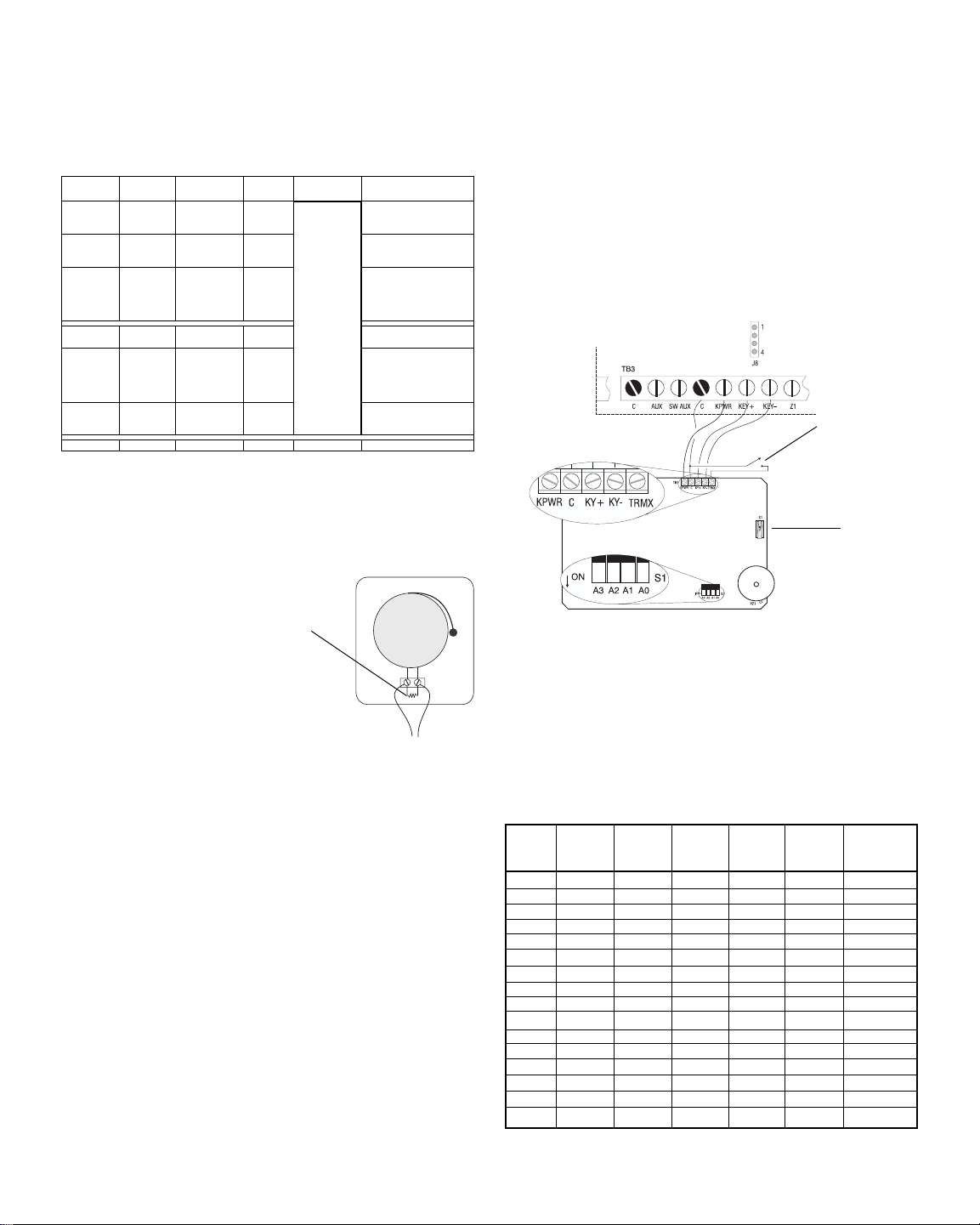

Figure 6, below, shows the connections for wiring the Sierra

Keypad to the Control Panel and connecting the optional

Terminate Exit Delay switch. Switch S1, in the lower righthand corner, is used for keypad addressing (see Table 5).

NOTE: If the keypad tampers are active (and programmed

in Block 3, Cmd Loc 044 - 045), tamper signals will be sent

to the control panel via the keypad bus. Keypad tamper

(hardwired keypads only) report routing is programmed in

Block 4, Cmd Loc 158. Keypad trouble conditions are also

reported on the keypad bus and the routing is defined in

Block 4, Cmd Loc 159.

Optional Terminate

Exit Delay Switch

External Bell Supervision

The circuit connection shown in Figure 5 is used only when

External Bell Line Supervision is required. For Bell

Line Supervision, the bell

must be equipped with an

9.X 2.2K Ohm

EOL

internal diode.

To Bell Output Terminals

on Control Panel

Figure 5 - Bell Supervision Wiring

Keypad Wiring

The Sierra S5832SG uses four terminals for powering and

communicating with the keypads and other devices via the

keypad data bus. The terminal connections are as follows:

KPWR This terminal supplies +12 VDC to power the key-

pads or accessories.

KY+ One half of the differential keypad data bus. This

terminal combined with the KY- terminal provides

communication between the various devices and

the control panel.

KY- Used in conjunction with the KY+ terminal for data

communications on the keypad data bus.

C Common (ground) terminal for Power return.

TRMX Optional Terminate Exit Delay switch connected

between this terminal and C terminal. When active

(Block 7, CL 012), closing the exit delay switch will

short the TRMX terminal and skip all but the last 5

seconds of the exit delay.

Tamper Switch

Figure 6

Connecting the Keypad Terminals

Sierra Accessory Wiring Distances

The Table shown below shows the maximum wiring distances for the Sierra accessories based upon total load current drawn from each run. Refer to the Accessory Loading

Table on page 3 for load requirements.

NOTE: Total wire distance for all devices combined not to

exceed 2440 M.

Max Load 0.40 mm 0.51 mm 0.64 mm 0.81 mm 1.02 mm 1.29 mm

per run (26 AWG) (24 AWG) (22 AWG) (20 AWG) (18 AWG) (16 AWG)

(mA) M (Ft.) M (Ft.) M (Ft.) M (Ft.) M (Ft.) M (Ft.)

50 121 (395) 192 (629) 305 (1000) 490 (1605) 774 (2538) 1225 (4016)

100 60 (198) 96 (314) 153 (500) 245 (803) 387 (1269) 612 (2008)

150 40 (132) 64 (210) 102 (333) 163 (535) 258 (846) 408 (1339)

200 30 (99) 48 (157) 76 (250) 122 (401) 194 (635) 306 (1004)

250 24 (79) 38 (126) 61 (200) 98 (321) 155 (508) 245 (803)

300 20 (66) 32 (105) 51 (167) 82 (268) 129 (423) 204 (669)

350 17 (56) 27 (90) 44 (143) 70 (229) 111 (363) 175 (574)

400 15 (49) 24 (79) 38 (125) 61 (201) 97 (317) 153 (502)

450 13 (44) 21 (70) 34 (111) 54 (178) 86 (282) 136 (446)

500 12 (40) 19 (63) 31 (100) 49 (161) 77 (254) 122 (402)

550 11 (36) 17 (57) 28 (91) 45 (146) 70 (231) 111 (365)

600 10 (33) 16 (52) 25 (83) 41 (134) 65 (212) 102 (335)

700 9 (28) 14 (45) 22 (71) 35 (115) 55 (181) 87 (287)

800 8 (25) 12 (39) 19 (63) 31 (100) 48 (159) 77 (251)

900 6 (22) 10 (35) 17 (55) 27 (89) 43 (141) 68 (223)

1000 6 (20) 9 (31) 15 (50) 24 (80) 39 (127) 61 (201)

Table 4

Maximum Wiring Distance for Sierra Accessories

4

Page 9

Keypad Addressing

The S5832SG control panel will support up to 16 hardwired

keypads. Each keypad must have a different address, with

addresses ranging from 1 - 16. (Figure 6 shows the location

of the switch used to address the keypad.) Table 5 lists the

switch settings for S1 for each keypad address.

Addr A0 A1 A2 A3

1 on off off off

2 off on off off

3 on on off off

4 off off on off

5 on off on off

6 off on on off

7 on on on off

8 off off off on

Table 5

Keypad Addressing

Addr A0 A1 A2 A3

9 on off off on

10 off on off on

11 on on off on

12 off off on on

13 on off on on

14 off on on on

15 on on on on

16 off off off off

Each keypad (Alphanumeric, Icon, or LED) may draw up to

50 mA of current. Once connected, the control panel will

automatically recognize the presence of the keypad.

Connecting an Auxiliary Keypad (J8)

The S5832SG Control Panel also has a 4-pin Molex® connector (J8) for attaching an auxiliary keypad to the panel for

on-site programming. The connector (J8) is located on the

PCB above the Keypad Data Bus terminals (see Figure 6,

on page 4).

The connections to J8 are as follows:

Pin 1 Common (ground) for Power return.

Pin 2 Supplies +12 VDC to power the keypad.

Pin 3 KY+ on the differential keypad data bus.

Pin 4 KY on the differential keypad data bus.

Pins 1 and 2 supply power and ground, while pins 3 and 4

provide communication between the panel and the keypad.

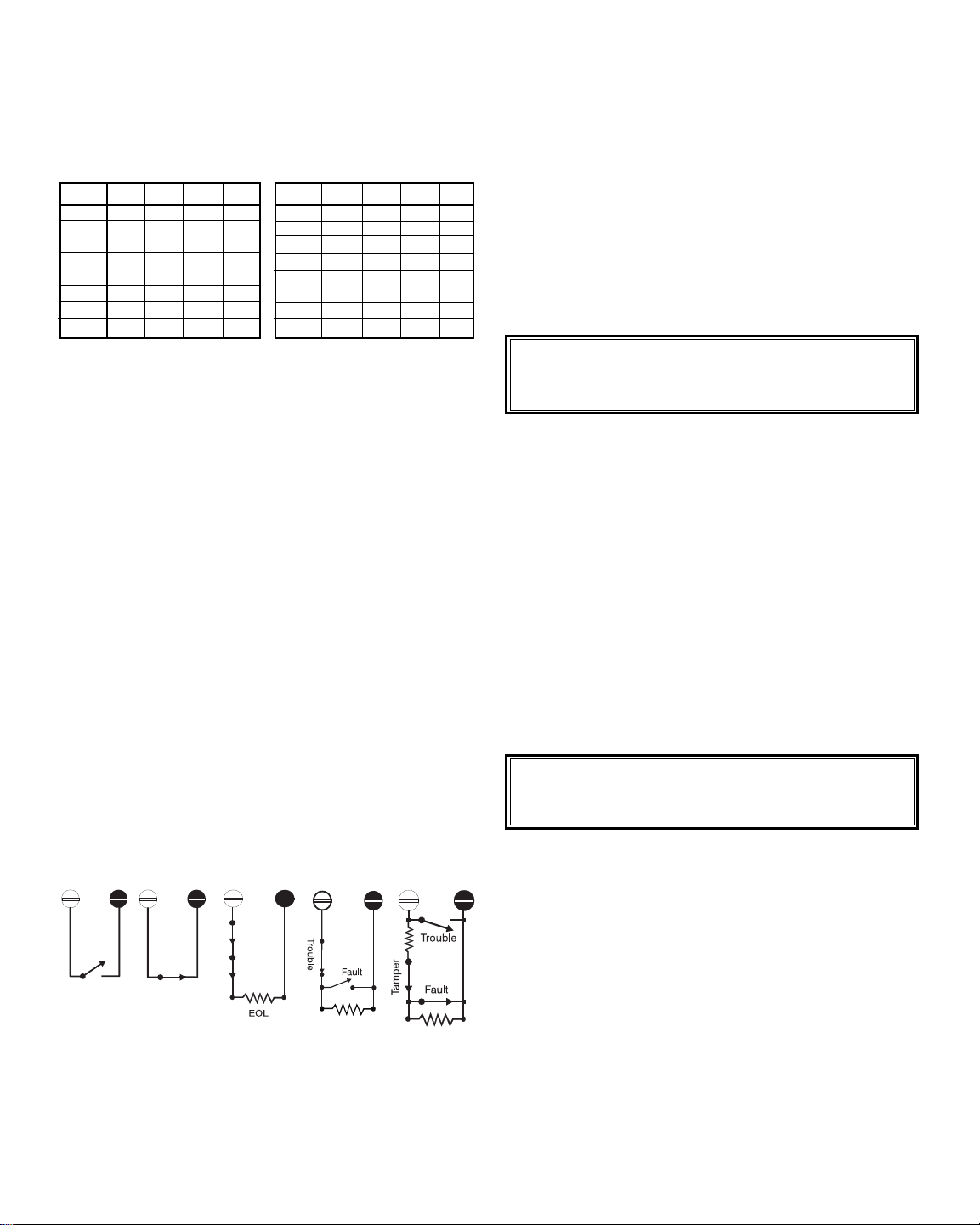

The N.O. and N.C. zone configurations do not provide for

supervision of the detection devices.

The following configurations provide supervision of the detection devices:

EOL: This zone configuration uses a single EOL resistor to

detect the following conditions: Normal (2.2K), Fault (open

or short).

Supervised EOL: This zone configuration uses a single EOL

resistor to detect the following conditions: Normal (2.2K), Fault

(short), or Trouble (open).

Tamper: This zone configuration uses two EOL resistors to

detect four different zone conditions: Normal (2.2K), Fault

(4.4K), Trouble (short), or Tamper (open).

NOTE: For devices requiring a 10K Ohm EOL resistor,

use Zone 7 and remove jumper J5. (See page 1, Figure

1 for jumper location.)

On-Board Relay Terminals (TB2)

The Sierra S5832EB has a single-pole, double-throw (Form

C) relay mounted on the PCB. Connections to the relay are

made at TB2. (Refer to Figure 1 for relay terminal location.)

The on-board relay may be configured as Normally Open

(N.O.) or Normally Closed (N.C.) and can switch up to 1 A of

current at 12 VDC. For programming options, refer to Block 7,

Command Location (CL) 001.

Accessories

The Sierra S5832SG supports a variety of accessories which

communicate with the panel through the keypad data bus.

These accessories can include up to two Model S5050 Relay/Event Memory Modules (REMM), up to three Model

S5058 Zone Expansion Modules (ZEM), and a Model SN915BUS SpreadNet

®

RF Receiver.

Zone Terminals

The basic configuration of the S5832SG can support up

to 8 hardwired zones. Zone 8 is a powered loop for use

with two-wire smoke detectors. This loop is current-limited at 30 mA.

a) N.O.

Normally

Open

Figure 7

Zone Configurations

b) N.C.

Normally

Closed

c) EOL

End-of-Line

Resistor

Zones may be configured with Normally Open (N.O.) or Normally Closed (N.C.) contacts (although not recommended).

d) EOL,

Supervised

e) 2x EOL

4-state

supervision

Caution: When connecting accessories to the system,

use care not to exceed rated outputs. (See Table 1

on page 3 for Accessory loading information.)

S5050 Relay/Event Memory Module

The Sierra S5832SG control panel will support up to two

Model S5050 REMMs connected to the keypad data bus.

NOTE: Trouble conditions and tampers, if enabled, are reported via the keypad bus. Refer to Block 4, CL 158 and

159, respectively, for report routing information.

Power for the S5050 REMM is obtained by connecting the

KPWR terminal on the REMM PCB to either the KPWR or

AUX terminal on the control panel. For the power return,

connect the C terminal on the REMM to the C terminal on

the control panel. The GND terminal on the REMM PCB is

used to connect the REMM to Earth Ground.

Adding one REMM will increase Event Memory storage capability from 60 events to 250 events. Adding a second

REMM will increase the storage capacity to 500 events.

5

Page 10

The REMM also has five independently programmable relays. The relay programming options are explained in the

programming summary, Block 7.

The AUX terminal on the S5050 REMM is capable of supplying up to 100 mA of output current to power sensors and

other devices.

NOTE: Total combined current from the relays and AUX

output terminal may not exceed 100 mA.

Refer to the S5050 REMM Installation Instructions (P/

N 5-051-453-00) for additional information regarding the

set up, configuration, and operation of the S5050 REMM.

Figure 8

The S5050 Relay/Event Memory Module (REMM) PCB Layout

Switch Settings

The S5050 REMM has five (5) dip switches (S1-1 thru S14 and S2-1) which can be used to provide AUX power to

the relay outputs. The default setting for each switch is

OFF. In this position, each relay uses the switched (S)

and common (C) terminals. Each relay is independently

programmable by the installer.

With the switch in the ON position, the +12 VDC AUX

power is applied to the respective Relay switched (S) output terminal (see Figure 9, below).

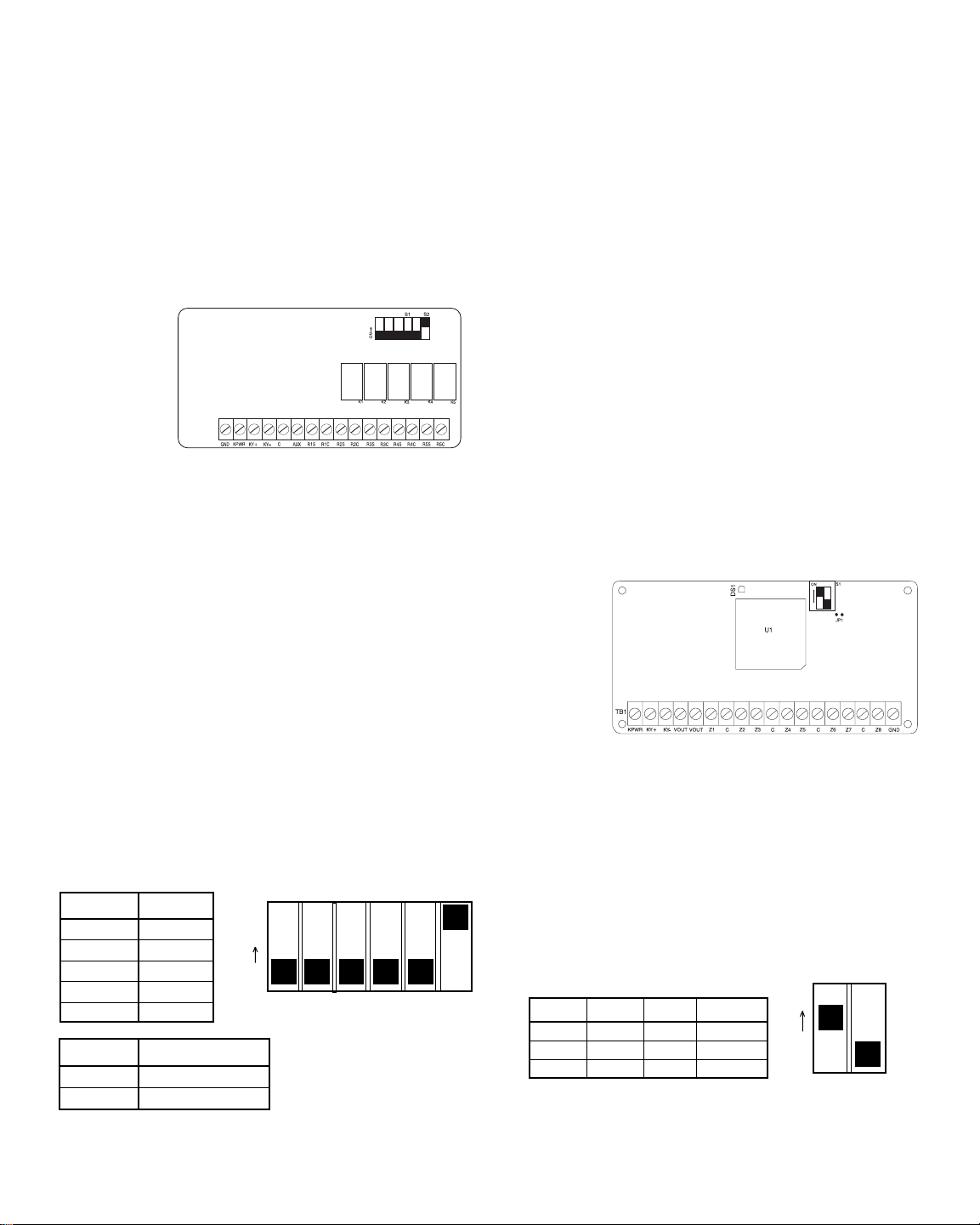

S5058 Zone Expansion Module

The Sierra S5832SG control panel has eight hardwired

zones and may be expanded up to 32 zones. Eight additional hardwire zones are obtained by connecting an

S5058 Zone Expansion Module to the keypad data bus.

Up to three S5058 ZEMs may be connected, providing a

total of 24 additional zones.

NOTE: Trouble conditions and tampers, if enabled, are reported via the keypad bus. The report routing is defined in

Block 4, CL 158 and 159, respectively.

Power is supplied by connecting the KPWR terminal on

the S5058 ZEM PCB to the KPWR or AUX terminal on the

control panel and the C terminal on the ZEM to the C terminal on the control panel. The GND terminal on the ZEM

PCB is for connecting earth ground to the ZEM.

There are two VOUT terminals (connected in parallel),

which can provide up to 300 mA of output current to power

sensors or other devices.

Each S5058 ZEM will support up to 8 hardwired zones. If

a zone is programmed as a SpreadNet zone (see Block

2, CL 111 - 142), it is not available for use as a hardwired

zone.

Additional setup and wiring information is available in the

S5058 Zone Expansion Module Installation Instructions (P/N 5-051-454-00).

Switch Configuration

Figure 9, below, shows the relationship of the switches to

the relays on the REMM.

S2-2 is used to address the REMM. Leave S2-2 in the ON

position for REMM #1. Change S2-2 to the OFF position

to address REMM #2.

Switch Relay

S1-1 R1S

S1-2 R2S

S1-3 R3S

S1-4 R4S

S2-1 R5S

S1-1 S1-2 S1-3 S1-4 S2-1 S2-2

ON

Switch REMM

S2-2 ON = REMM #1

S2-2 OFF = REMM #2

Figure 9

REMM Switch Settings (shown in default position)

Figure 10

S5058 Zone Expansion Module (ZEM) PCB Layout

ZEM Addressing

S1-1 and S1-2 are used to address the ZEMs. The ZEM address determines which zones are added to the S5832SG

control panel.

Figure 11, below, shows the switch settings to address the

ZEMs. ZEM #1 is used to add zones 9 - 16; ZEM #2 adds

zones 17 - 24; and ZEM #3 adds zones 25 - 32.

ON

S1-1 S1-2

Addr. S1-1 S1-2 Zones

1 on off 9 - 16

2 off on 17 - 24

3 on on 25 - 32

Figure 11

Addressing the ZEM

6

Page 11

SN915-BUS SpreadNet Receiver

The SpreadNet SN915-BUS Bus Receiver connects to the

keypad bus and provides the communication link for all

SpreadNet keypads/keyfobs and zone transmitters.

NOTE: Tamper and trouble conditions, if enabled, are reported via the keypad bus. The report routing is specified in

Block 4, CL 158 and 159, respectively. Low Battery Report

Routing for the SpreadNet Transmitters is programmed in

Block 4, CL 157.

Power for the SN915-BUS may be supplied from either the

KPWR or AUX and C terminals on the control panel to the V+

and GND terminals on the SpreadNet Receiver (see Figure

12).

For additional information on wiring and configuration of the

SN915-BUS Receiver, refer to the SN915-BUS Installation

Instructions (P/N 5-051-440-00).

Digital Communicator Connections

Removing/Installing the Digital Communicator

The digital communicator plugs into the control panel PCB

and is secured by a nylon retaining screw.

To remove the digital communicator:

1) Remove AC and DC power from the control panel.

2) Locate and remove the nylon screw. The screw is located

near the upper right-hand corner of the digital communicator PCB. (See page 1, Figure 1.) Use a #1 phillips

head screwdriver to remove the retaining screw.

3) Unplug the digital communicator from the control panel.

To install the digital communicator:

1) Ensure that AC and DC power have been removed from

the control panel.

2) Carefully plug the digital communicator into the control

panel PCB. Misalignment of the pins could damage the

control panel.

3) Replace the nylon retaining screw.

4) Apply power.

Digital Communicator Telephone Connections

Figure 12

Connecting the SN915-BUS

SN990/991 SpreadNet Keypad/Remote

The control panel can support up to eight SpreadNet keypads. There are two different models available, the SN990KEYPAD and SN991-REMOTE. Both devices are battery

operated and communicate with the panel through the

SpreadNet SN915-BUS RF Receiver.

SpreadNet keypads provide one-way communication only

and do not display any panel status information.

Additional information on the SpreadNet keypad and remote

may be found in the SN990/991 Installation Instructions (P/N

5-051-556-00).

SN961 SpreadNet Keyfob

The control panel can have up to eight SpreadNet keyfobs.

Each keyfob will be associated with a specific user number

and will arm, home arm, or disarm the system just like the

user code. The keyfob will communicate with the control panel

via the keypad bus.

SpreadNet keyfob allows one-way communication only and

cannot display any panel status information.

For information on programming the SpreadNet keyfob, refer

to the SN900-PROG Operating Manual (P/N 5-051-136-00

Rev C or later).

Line #1

Figure 13

Telephone Connections

The Sierra S5832SG control panel can support either a oneor two-line plug-on digital communicator.

The digital communicators have four terminals for connection to the telephone lines. These terminals are labelled:

Tip, Ring, T1, and R1. The single-line digital communicator

has one set of terminals and the dual-line digital communicator has two sets of terminals. Figure 13 shows how to connect the digital communicator to the incoming phone lines

and the house phones using either a single-line or a dualline digital communicator.

7

Page 12

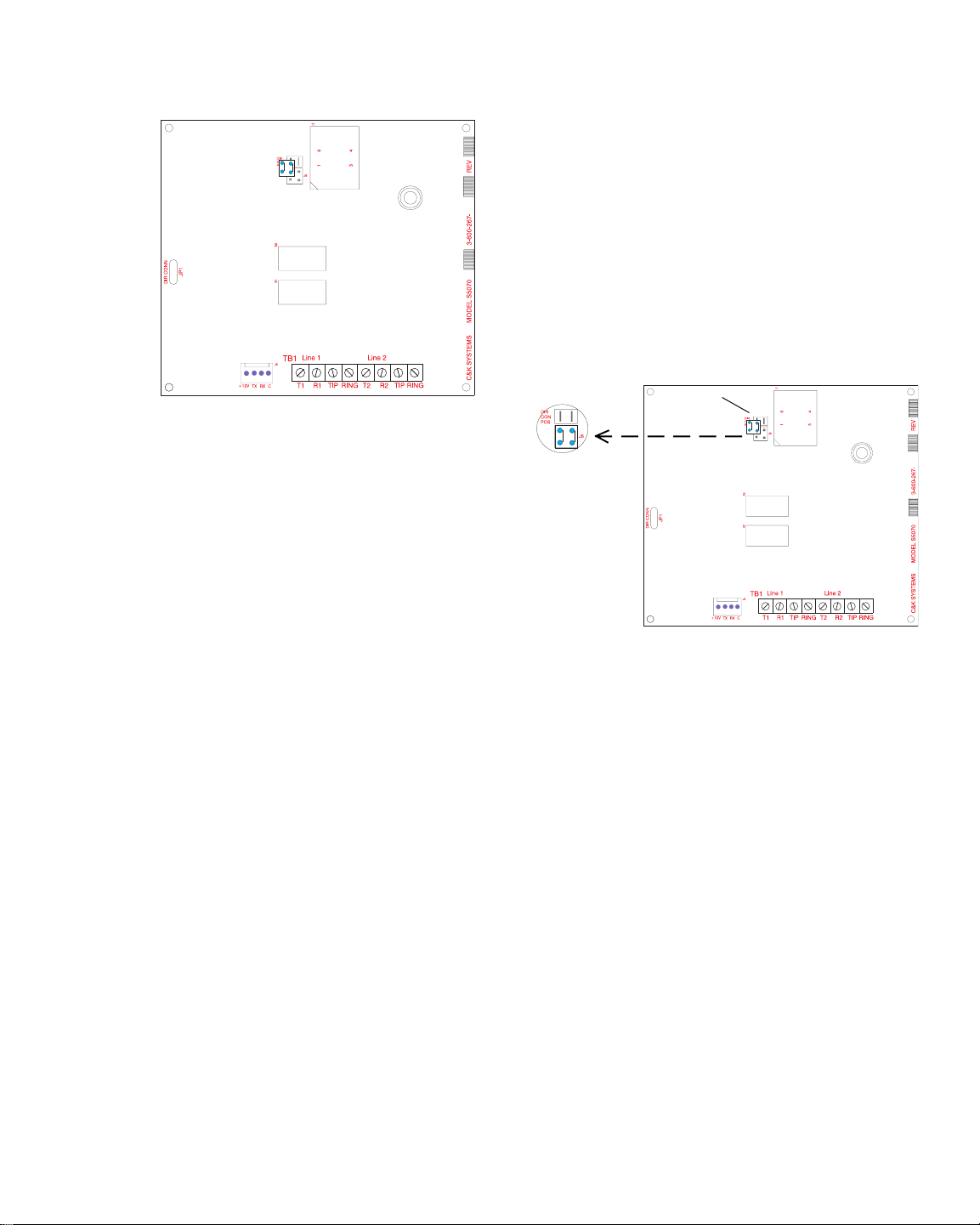

Figure 14, below, shows the layout of the S5070SG-2 dualline digital communicator. The terminals for line 2 are labelled Tip, Ring, T2, and R2.

Remote Programming (RPS)

Remote Programming of the Sierra S5832SG control

panel is available with the Commander II software. The

remote programming session can be initiated locally from

the keypad or remotely by the Commander II software.

Setup for Direct Connect to the S5832SG

The procedure for initiating Direct Connect with your

model of Digital Communicator is outlined below.

1. When using Direct Connect, connect the telco cable

from the line side of the modem to the Tip and Ring

terminals on the Digital Communicator (Line 1 only).

2. Move the jumper (J6) to the enabled position, as shown

in Figure 15, below.

3. Start Commander II and open the Panel menu. Select

the Connect option and then click on Direct Connect.

Figure 14

S5070US-2 Dual-line digital communicator

Terminal Connections

Connect the Sierra S5832SG digital communicator to the

telephone line, as shown in Figure 13 (on previous page),

using an approved, 6 or 8 conductor telephone cable (not

included). Connect the cable to the control panel as follows:

Red = Ring Brown = Seized Tip (T1)

Green = Tip Blue & Orange = Tamper

Grey = Seized Ring (R1) Yellow & Black = Not Used

Programming the Panel

The Sierra S5832SG control panel may be programmed

from any keypad connected to the keypad data bus. Connector J8 (see Figure 1) is also available to temporarily connect a keypad, if desired, for programming the panel. The

panel can also be programmed, either remotely or on-site,

using the Commander II software.

The Command Locations used to store the programming

options of the Sierra S5832SG control panel are divided into

10 sections. Each section is called a Block. The configuration of the control panel determines which Blocks are programmed.

All keypad programming is done from the Installer Programming Mode. To enter the Installer Programming Mode, press

and hold the [1] key for 2 seconds.

When programming with an Alphanumeric keypad, you must

select the appropriate language for your panel, followed by

the [Home] key. The icon and LED keypads do not require

the [Home] key to be pressed. On the LED keypad, all LEDs

are off to indicate that you must enter the installer code.

Next, enter the 6-digit installer code. The default installer

code is [0-1-2-3-4-5]. On the Alphanumeric keypad, press

the [Home] key to use Menu Programming or the [Bypass]

key to use Quick Programming. You are now in installer programming mode.

To exit the Installer Programming Mode, press and hold the

[CANCEL] key for 2 seconds. This will exit the programming

mode and reset the panel.

Direct Connect

Disabled

Direct Connect

Enabled

Figure 15

Direct Connect using the S5070SG Digital Communicator

4. Enable the Direct Connect jumper (see Figure 15) and

initiate the Direct Connect function in Commander II.

When you hear the modem tones, momentarily short

the Direct Connect pads located on the left-hand side

of the digital communicator PCB. You should hear the

seize relay energize to indicate connection.

5. Commander II should indicate that the connection has

been established. You are now ready to program the

panel.

6. Be sure to return the jumper to its original position

when the RPS session is completed.

Keypad Activated RPS

The following conditions must be met before starting a

keypad activated RPS session:

1. The RPS Phone Number must be programmed into

Block 4, CL 085 - 100;

2. Keypad RPS Enable (Block 4, CL 106) must be programmed for Yes (2);

3. RPS/Modem Types (Block 4, CL 107) must match the

configuration of the Commander II software;

4. The phone lines must be connected to the Tip and Ring

terminals on the digital communicator (Line 1 only);

and

8

Page 13

Keypad Activated RPS (cont.)

5. Commander II must be running at the remote site.

If the above conditions are met, you are now ready to ini-

tiate the RPS session from an Alphanumeric keypad.

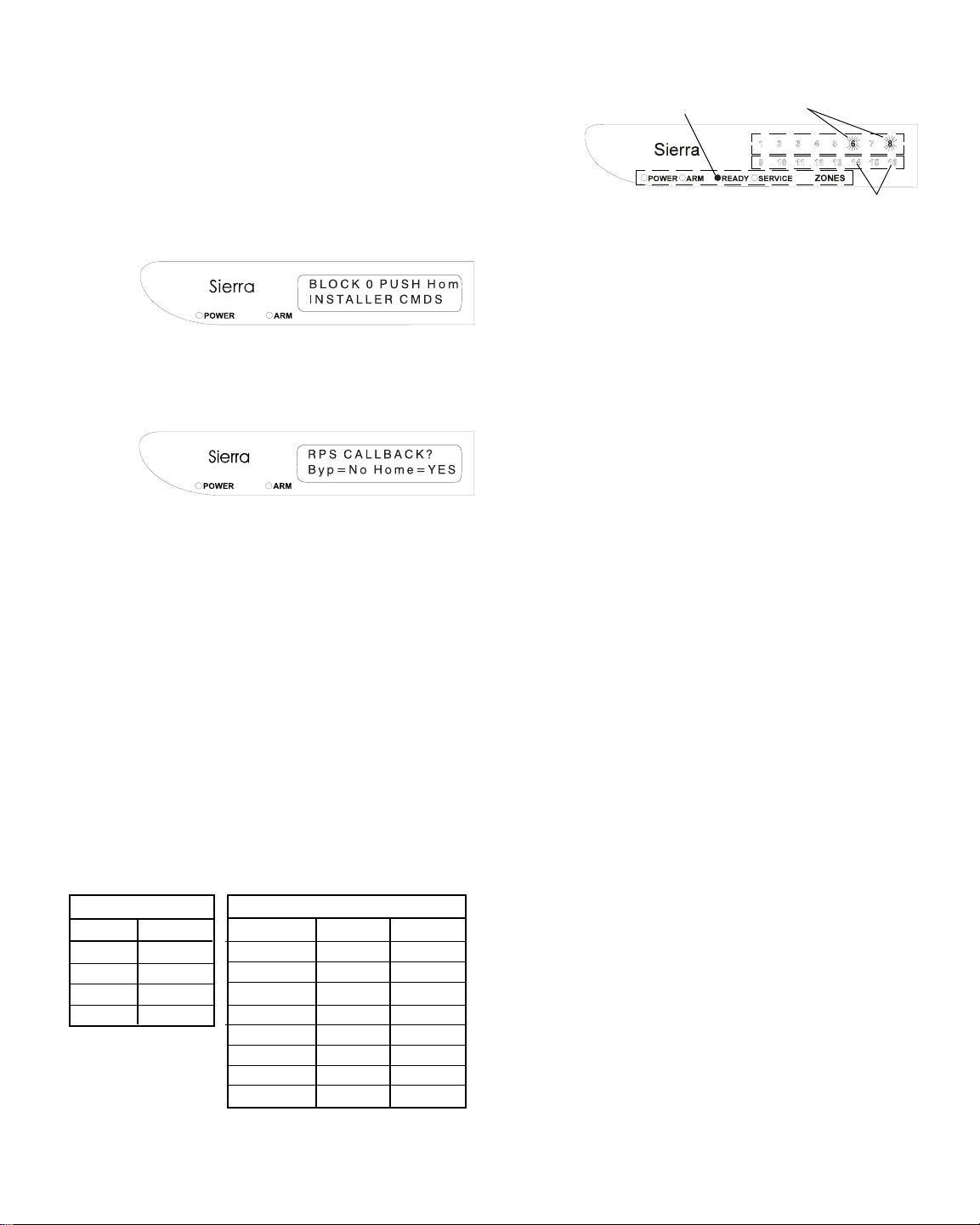

1. Using an Alphanumeric Keypad, enter the Installer

Mode Programming (see Programming With an Alphanumeric Keypad on page 10). Select the Menu Programming Mode and go to Block 0 (Installer

Commands). Press the [Home] key to accept.

Figure 16

Accessing Installer Commands (Block 0)

Programming With an LED Keypad (cont.)

Block # (steady)

Figure 18

Reading Programming Data on the LED Keypad

There are three keys used to access and enter data into the

control panel from the keypad. They are the [Bypass],

[Home], and [Cancel] keys. The function of each key is explained in the next column.

Cmd Loc 005

(flashing)

Program Data

(steady)

2. Scroll through the options, using the [Bypass] key until

you get to the RPS Callback? option (option 10).

Figure 17

Activating Keypad RPS

3. Press [Home] to activate the RPS feature.

Programming With an LED Keypad

You may use an LED keypad to program the control panel.

The LED display on the keypad is used to display all pro-

gramming information: Block Number, Command Location,

and Data. The Block Number is displayed using the Power,

Arm, Ready, and Service LEDs. Command Locations are displayed using the LEDs for zones 1 - 8. The LEDs representing zones 9 - 16 are used to display the program data. Table

6, below, lists the relative value for each LED.

Upon entering the installer programming mode, all LEDs

will be off. The installer must then enter the installer code

[0-1-2-3-4-5]. The system will then go to Block 1, Command

Location 001 and display the data stored at that location.

The LEDs in the currently active field will blink (if any are lit)

indicating that the data may be edited.

Block Numbers Zone LEDs

LED Value Cmd Loc Data Value

Service 1 8 16 1

Ready 2 7 15 2

Arm 4 6 14 4

Power 8 5 13 8

41216

31132

21064

1 9 128

Table 6

Reading the LEDs

Key Function

[Bypass] Moves the cursor between the Block, Com-

mand Location (Cmd Loc), and Data fields.

Press the [Bypass] key a fourth time to return

the cursor to the Cmd Loc field.

[Home] This key has several functions, depending

upon the field being edited and the data entered at the keypad.

If the Cmd Loc field is active, press the [Home]

key to increment to the next Loc. You may also

enter a new Cmd Loc and press the [Home]

key to move to that Loc. The LEDs for zones 9

- 16 display will show the data stored in the

new Loc.

If the Data field is active, pressing the [Home]

key will write the data in the display to the Cmd

Loc indicated. The system will also be incremented to the next Cmd Loc. The Data field

will remain active.

If the Block field is active, press the [Home]

key to increment to the next Block and reset

the Cmd Loc to 001. You may also enter the

number of the desired Block (1 - 10 or 0 - 10

for the Alphanumeric keypad), followed by the

[Home] key to go to that Block.

[Cancel] The [Cancel] key allows you to undo changes

to the programming, provided you have not

stored the data. Once the data has been written to memory (by pressing the [Home] key),

you cannot use the [Cancel] key to recover the

original data.

If the data has not been changed and the Cmd

Loc field is active, pressing the [Cancel] key

will decrement to the previous Cmd Loc. If the

Block field is active, pressing the [Cancel] key

will decrement to the previous Block.

CAUTION: Pressing and holding the [Cancel] key for 2

seconds will Exit Programming Mode.

9

Page 14

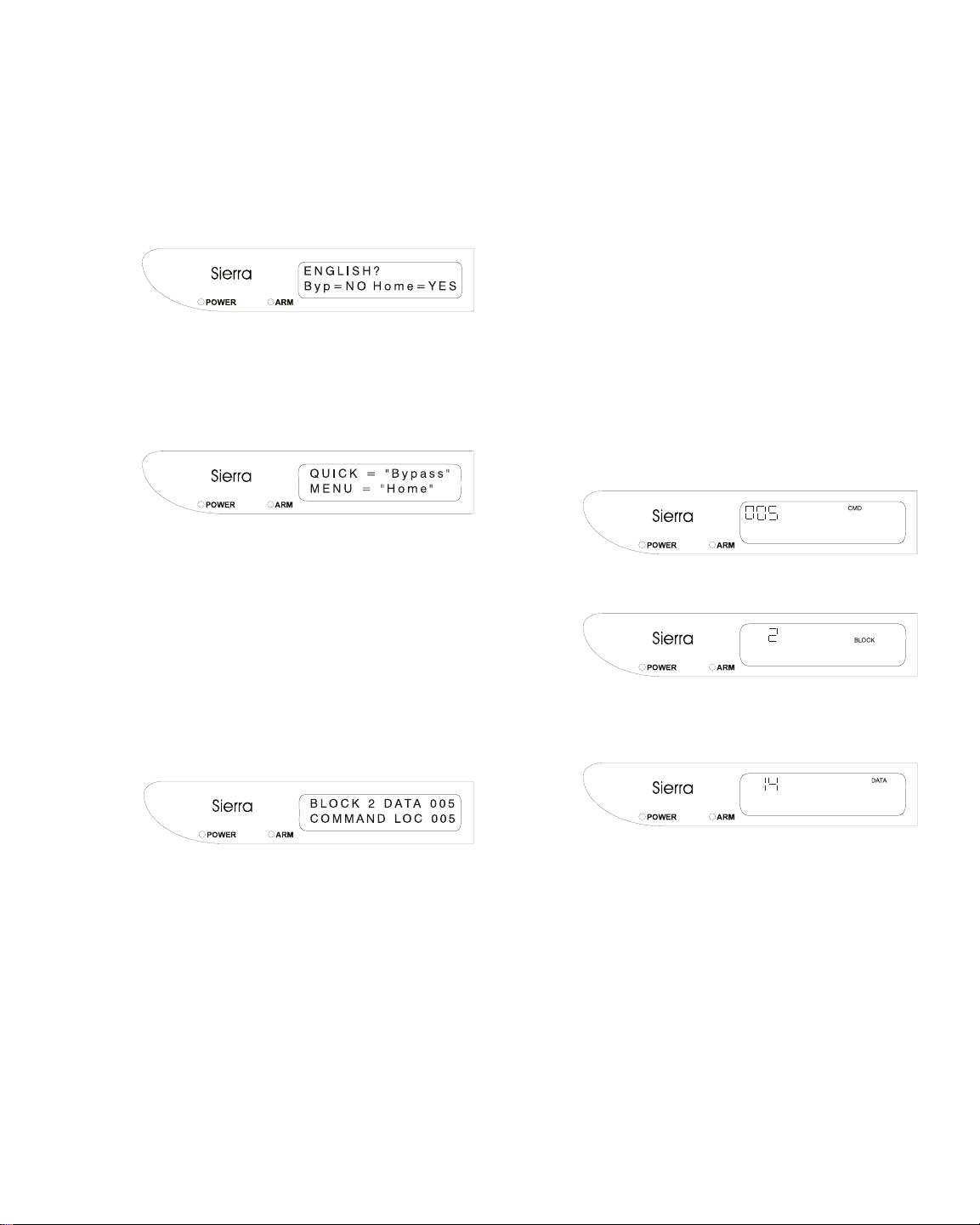

Programming With an Alpha Keypad

Upon entering the installer programming mode, the display

will ask you which language you wish to use for programming the panel. Each panel supports three languages, one

of which is English. The other languages are determined by

the model number of the panel. The Alphanumeric keypad

provides two panel programming options: Quick or Menu

programming. Both options use a combination of text and

numbers in the LCD display.

Figure 19

Selecting the Language on the Alphanumeric Keypad

Once a valid installer code has been entered, the installer

has the option of using either the Quick or Menu Programming mode to enter data into the panel. Each method is

explained below.

Figure 20

Selecting the Programming Mode with the Alphanumeric Keypad

Quick Programming Mode

Using the Quick Programming mode, you can easily go

directly to any Cmd Loc (Blocks 1 - 10 only; the Installer

Commands, Block 0, are not available in Quick programming mode). This allows you to view or edit any of the

data programmed into the panel.

The Alphanumeric display will show the Block Number (1

- 10) and Programmed Data (varies by location) on the

top line of the display, with the Command Location (varies by Block) shown on the bottom line.

Programming With an Alpha Keypad (cont.)

Key Function

[Bypass] Used to scroll through the different Menu op-

tions and levels.

[Home] If the PRG> prompt is displayed, this key will

write the data currently displayed to memory

and increment to the next program position.

If the Menu has additional options in submenus, this key will move to the next submenu.

[Cancel] Cancel the operation, if the data has not been

written to memory. If you are in a sub-menu,

this key will back up one level.

CAUTION: Pressing and holding the Cancel key for 2

seconds will Exit Programming Mode.

Programming With an Icon Keypad

The display on the keypad consists of a 3-digit display for

showing numbers (Blocks, Cmd Locs, and Data) and fixed

text for indicating the type of data displayed.

Figure 22

Reading Command Location on the Icon Keypad

Figure 23

Displaying Block Data on the Icon Keypad

Data will be displayed using only the digits required.

Figure 21

Reading Programming Data on the Alphanumeric Keypad

The [Bypass], [Home], and [Cancel] keys are used to

move between fields and to edit the data in each field, as

outlined previously.

Menu Programming Mode

The Menu Programming mode uses menu options and

descriptions to guide you easily through the panel programming. You can scroll through the Blocks by pressing the [Bypass] key or go directly to any Block by pressing the desired key (0 - 10), followed by the [Home] key.

The same three keys ([Bypass], [Home], and [Cancel])

are used in the Menu Programming mode, with slight

variations.

Figure 24

Viewing Program Data on the Icon Keypad

The [Bypass], [Home], and [Cancel] keys are used to move

between fields and to edit the data in each field, as outlined

previously.

10

Page 15

Installer Mode Options, (Block 0)

There are 10 Installer Mode Options which are available

from the Menu mode. These options allow the installer to test

the various aspects of the system's operation, program the

Custom Messages used by the Alphanumeric keypads, and

start keypad activated RPS.

To access the Block 0 Commands, press and hold the [1] key

for 2 seconds. Use the [Home] and [Bypass] keys to select

the desired language. When prompted, enter your [Installer

Code]. Then press the [Home] key to select Menu mode.

Upon entering the Menu mode, pressing either [0] or [Bypass] will take you to the first of the Block 0 options.

Installer Walk-Test

The first option available from the Block 0 Commands is the

Walk-Test? option. To use this option, press [Home]. To proceed to the next option, press [Bypass].

After installation, the installer can perform a system WalkTest. Using this option, the installer can test the operation of

each zone in the system.

While in the Installer Walk-Test Mode, the zones faulted during the current Walk-Test session will be annunciated at the

keypad and continuously displayed. This memory will be

purged when exiting Walk-Test Mode.

Event Memory

The second Block 0 Command available is Event Memory.

Press [Home] to access the Event Memory option or [Bypass] to scroll to the next option.

After selecting Event Memory?, the display will ask if you

wish to Display Event Memory. To display the contents of

the Event Memory, press [Home]. If you wish to Erase Event

Memory, press [Bypass], then press [Home].

Event Memory stores all events which have occurred since

the panel was initially installed or the memory was last

cleared. The Sierra S5832SG control panel has an internal

Event Memory capable of storing up to 60 events with time

and date stamping. By adding the Relay/Event Memory Module, the memory capability may be expanded to either 250

events (1 module) or 500 events (2 modules).

Events are viewed in chronological order (oldest to newest)

by pressing the [1] key. Events may be viewed in reverse

order (newest to oldest) by pressing the [4] key.

Table 7 shows the Event Codes displayed by the LED and

Icon keypads. The event codes are displayed using the zone

LEDs (LED keypad) or the 3-digit display (Icon keypad). The

Sierra Reference Manual contains additional information on

reading the codes with the LED keypad. The events are listed

in numerical order.

Event Memory Codes

Event

Code Description

1 Zone is/was in alarm

2 Zone is/was tampered

3 Zone is/was in trouble

4 Zone alarm/tamper restored

5 Zone has been bypassed

6 Zone Unbypassed

7 Area X disarmed by User Y

8 Area X armed by User Y

9 User Walk-test started

10 User Walk-test completed

11 Alarm in Area X canceled by User Y

12 Comm Fail Receiver X

13 Comm Fail restore Receiver X

14 AC power fail

15 AC power restored

16 Low Battery (Control Panel)

17 Low Battery restored (Control Panel)

18 Master User changed User Code Y

19 Primary phone line cut

20 Primary phone line cut restored

21 Secondary phone line cut

22 Secondary phone line cut restored

23 Emergency/medical alarm (hard or soft zone)

24 Emergency/medical alarm restored (hard / soft)

25 Panic/police alarm (hard or soft zone)

26 Panic/police alarm restore (hard / soft)

27 Fire alarm (hard or soft zone)

28 Fire alarm restore (hard / soft)

29 Begin Installer Programming (local)

30 Installer Programming completed (local)

31 Supervisory failure Zone X (SpreadNet)

32 Supervisory failure restore Zone X (SpreadNet)

33 Low Battery Zone X (SpreadNet)

34 Low Battery restore Zone X (SpreadNet)

35 Watchdog reset (panel reset)

36 Bell failure (Siren loop open or short)

37 Bell failure restored

38 Exit fail, Zone X still faulted at end of Exit Delay

39 Duress code entered for Area X

40 Kidwatch open failure (Kidwatch time expired)

41 Begin RPS programming

42 RPS connection failure

43 RPS programming successful

44 Test Report (manual or automatic)

45 Trouble Zone X restored

46 User Y override of Auto Arming

47 Tamper Zone X restored

48 Ground Fault

49 Ground Fault restored

50 Brown Out

51 Brown Out restored

52 Peripheral communications trouble

53 Peripheral communications trouble restored

Table 7

Event Memory Codes

11

Page 16

Custom Messages

Alphanumeric keypads have the ability to display customized messages. These messages are stored in the control

panel's nonvolatile memory.

To program the Custom Messages, use the [Bypass] key to

scroll to the Custom Messages? screen. Press the [Home]

key to display the first Custom Message (EDIT TROUBLE

MSG).

There are 41 Custom Messages available. The Edit Trouble

Message, 32 Zone Messages, and 8 Area Messages.

To assist you in entering the Custom Messages, a programming template is included with the keypad. The template

is shown below and the operation of the keys is described

at the top of the next page.

123

456

7

Bypass

Figure 25

The Alphanumeric Keypad Programming Template

To enter a Message or Label, use the following key commands:

Key Function

[2] Scroll forward through characters/symbols

[8] Scroll backward through characters/symbols

[4] Move cursor left one character

[6] Move cursor right one character

[Cancel] Cancel current changes and restore pre-

vious message, or scroll up one message

[Home] Write message to memory and scroll down

one message

In addition, other numbers on the keypad enable you to

quickly move to special places in the alphabet. These

special keys are:

[1] Jump to the space character

[3] Jump to the number 0

[7] Jump to the letter A

[9] Jump to the letter a

NOTE: The [Cancel] key will only restore previous mes-

sages if the message has not been written to

memory using the [Home] key.

89

0Home CANCEL

Test Report

Following the Custom Messages option is the Send Test

Report option. Selecting this option will initiate a Test Re-

port to the Central Station. The keypad will display a message indicating the success or failure of the Report.

Test Report with Audibles

This option generates a Test Report to the Central Station with all local audibles (internal and external sirens)

sounding for the duration of the Test Report attempt.

Pressing any key during the Test Report period will turn

the sirens off. The system will provide feedback to confirm the success or failure of the Report.

Audible Test

This option turns on all local audibles (internal and external sirens) for a period of 5 seconds.

Entry Delay Test

Using this option, the installer can test the Entry Delay to

ensure that a user has sufficient time to enter the premises and disarm the system without generating an alarm.

To begin the test, scroll to the Entry Delay Tst screen

and press [Home]. Then fault the Entry zone to begin the

delay.

Exit Delay Test

Using this option, the installer can test the Exit Delay to

ensure that a user has sufficient time to arm the system

and leave the premises without generating an alarm. To

begin the test, scroll to the Exit Delay Test screen and

press [Home]. The Exit delay will begin immediately.

Transmit Walk-Test Queue Reports

Walk-Test events stored in Event Memory during the current session will be transmitted to the Central Station.

The system will provide feedback to confirm the success

or failure of the Report.

RPS Callback

Using this option, the installer can initiate an RPS session from the Keypad.

Battery Test

This option allows the installer to perform a Battery Test

on the system. The test starts when you press the [Home]

key. The system will exit the installer programming mode

and reset the panel. The test takes approximately two minutes to complete. The battery status will be displayed only

if a Low Battery condition exists.

12

Page 17

Programming Summary - Sierra Model S5832SG

Block 1 - Code Option Programming

This programming block is divided into 80 Command Locations (CL 001 - 080). This Block used to program the Installers

Code (001-006), Default Installer Code on Power Up (007), Require Installer Code for Direct Connect via RPS (008), and to

set up the User Code parameters. The parameters include setting Maid Code, Duress, and Kidwatch.

Installer Code

Cmd Loc 001 002 003 004 005 006

Default 0 1 2 3 4 5

Range 0 - 9 0 - 9 0 - 9 0 - 9 0 - 9 0 - 9

Default Installer Code on Power Up?

Cmd Loc 007

Default 2

Range 1 - 2

Installer Code Required on Direct Connect RPS?

Cmd Loc 008

Default 2

Range 1 - 2

Maid Code Enable (by Area)

Cmd Loc 009 010 011 012 013 014 015 016

Default 0 0 0 0 0 0 0 0

Area 1 2 3 4 5 6 7 8

Range 0 - 255 (CL 009)

0 - 127 (CL 010 - 016)

Maid Code Hours, Temporary Access, Area 1

Cmd Loc 017

Default 12

Range 0 - 254

Duress Code Enable (By Area)

Cmd Loc 018

Default 0

Range 0 - 255

Comments

This is a 6-digit code which is required to allow access to installer programming mode. The code is programmed 1 digit per Cmd Loc.

Comments

If enabled (programmed as 2), this restores the Installer

Code to the default value (see CL 001 - 006) following a

power failure/restoral.

Comments

If enabled, the Installer Code (CL 001 - 006) is required

when programming the panel with the direct connect RPS

function of COMMANDER II.

Comments

The Maid Code may be specified by active days of

the week and by individual areas. Area 1 may also

use keypad activation for temporary access.

NOTE: Maid Code Enable programming deter-

mines when the Maid Code may be used for disarming the system. The Maid code is always available to

arm the system.

Options:

1No

2Yes

Options:

1No

2Yes

Options:

0 Disabled

1 Saturday

2 Friday

4 Thursday

8 Wednesday

16 Tuesday

32 Monday

64 Sunday

128 By Keypad

Comments

This option is used in conjunction with keypad activation of the Maid Code

for area 1 only. Duration of the active period is from the time of activation by

grand master user (user #1) or area master (user #12). To disable keypad

(temporary) activation, program this location with 0.

Comments

If the system is divided into areas, this option determines if the duress code associated with a specific

area is active. Refer to the Sierra S5090 Reference

Manual (P/N 5-051-528-01), Block 9 programming

for details on assigning user codes to areas.

Options:

0 Disabled

1 Area 1

2 Area 2

4 Area 3

8 Area 4

16 Area 5

32 Area 6

64 Area 7

128 Area 8

Kidwatch Enable

Cmd Loc 019

Default 0

Range 0, 129 - 255

Keypad Lockout Enable

Cmd Loc 020

Default 1

Range 1 - 3

Comments

If used, this option must be enabled (program

value > 128) and have the appropriate days of

the week programmed. The Kidwatch timer is

programmed from Block 6, CL 006 - 009. The

same start and end times are used for all days

when the Kidwatch feature is active.

NOTE: If enabled, the Kidwatch code must be

entered if Area 1 is armed during the Kidwatch

window (see Block 6, CL 006 - 009).

Comments

If enabled, 10 consecutive keystrokes without producing a valid user code will cause a keypad

delay starting at 15 seconds and doubling each

time up to a maximum of 240 seconds (4 min).

13

Options:

0 Disabled

1 Saturday

2 Friday

4 Thursday

8 Wednesday

16 Tuesday

32 Monday

64 Sunday

128 Enable (Master)

Options:

1 Disabled

2 When Disarmed

3 Always Active

Page 18

Block 1 - Code Option Programming (cont.)

User Code Privileges (User # 1 - 60)

Cmd Loc 021 022 023 024 025 026 027 028

User # 1 2 3 4 5 6 7 8

Cmd Loc 029 030 031 032 033 034 035 036

User # 9 10 11 12 13 14 15 16

Cmd Loc 037 038 039 040 041 042 043 044

User # 17 18 19 20 21 22 23 24

Cmd Loc 045 046 047 048 049 050 051 052

User # 25 26 27 28 29 30 31 32

Cmd Loc 053 054 055 056 057 058 059 060

User # 33 34 35 36 37 38 39 40

Cmd Loc 061 062 063 064 065 066 067 068

User # 41 42 43 44 45 46 47 48

Cmd Loc 069 070 071 072 073 074 075 076

User # 49 50 51 52 53 54 55 56

Cmd Loc 077 078 079 080

User # 57 58 59 60

Default 15 (All CL)

Range 0 - 47 (All CL)

Comments

These programming Options determine which

Options the user is authorized to perform.

Some user codes may have alternate functions. (See Block 9 - Partition Programming

in the Sierra Reference Manual for additional

information.)

Language Program Value

English 0

Spanish 16

Italian 32

** Limited Functions are user number specific.

They may include relay operation, restricted

SN device operation, and some end-user

functions.

Options:

0 Limited Functions**

1 Disarm

2 Arm

4 Bypass

8 Open/Close Rpt

16 Lang. Code opt. 1

32 Lang. Code opt. 2

Block 2 - Zone Configuration Programming

Block 2 is divided into 160 Command Locations (CL 001 - 160) which are used to program the characteristics of each of the zones

in the control panel. The features include Delay Times, Zone Type, Zone Restoral Type, Zone Response Time, Audible Cadence,

Circuit Type, Chime Enable, Shunt Enable, and Home Arm Shunt List. The soft zone programming uses CL 155 - 160.

Entry Delay #1

Cmd Loc 001

Default 20

Range 10 - 255 (Seconds)

Comments

This establishes the first of two delay times for entry zones. Time is entered

in seconds.

Entry Delay #2

Cmd Loc 002

Default 40

Range 10 - 255 (Seconds)

Exit Delay

Cmd Loc 003

Default 60

Range 20 - 255 (Seconds)

Zone Type (Zones 1 - 32)

Cmd Loc 004 005 006 007 008 009 010 011

Zone # 1 2 3 4 5 6 7 8

Default 1 3 3 5 5 5 5 10

Cmd Loc 012 013 014 015 016 017 018 019

Zone # 9 10 11 12 13 14 15 16

Cmd Loc 020 021 022 023 024 025 026 027

Zone # 17 18 19 20 21 22 23 24

Cmd Loc 028 029 030 031 032 033 034 035

Zone # 25 26 27 28 29 30 31 32

Default 0 (CL 012 - 035)

Range 0 - 15 (All CL)

Zone Restoral Type (Zones 1 - 32)

Cmd Loc 036 037 038 039 040 041 042 043

Zone # 1 2 3 4 5 6 7 8

Cmd Loc 044 045 046 047 048 049 050 051

Zone # 9 10 11 12 13 14 15 16

Cmd Loc 052 053 054 055 056 057 058 059

Zone # 17 18 19 20 21 22 23 24

Cmd Loc 060 061 062 063 064 065 066 067

Zone # 25 26 27 28 29 30 31 32

Default 2 (All CL)

Range 1 - 5 (All CL)

Comments

This establishes the second of two delay times for entry zones. Time is

entered in seconds.

Comments

This establishes the delay time for exit zones. The time programmed into

this location should allow the user to use the exit farthest from the keypad.

Time is entered in seconds.

Comments

These programming

Options determine the

zone type for each zone

(hardwired or wireless)

in the system.

Options:

0 Disabled

1 Entry Delay 1/Exit

2 Entry Delay 2/Exit

3 Interior Instant

4 Interior Delay 2

5 Instant (Perim.)

6 Day Buzzer/Inst

7 Day Buzzer/Delay

8 Day Bell/Inst

9 Day Bell/Delay

10 24-Hr. BA

11 Fire (FA)

12 Tamper

13 Panic/Hold-Up

14 Emergency-Med

15 Keyswitch **

** If the Zone Type is programmed as Keyswitch, then Zone Restoral

Type (Block 2, CL 036 - 067) will be programmed using Option #2

values.

Comments

Option #1 values are

used for all zone types

except Keyswitch.

Keyswitch zones will

use the second set of

Options. Default value

for keyswitch is 2

(Arm/Disarm).

Option Set #1

1 Disabled

2 Return to normal

3 Return to normal

and bell silenced

4 Return to normal

and not armed

5 User code entry

(zone may remain

faulted)

Option Set #2

1 Disabled

2 Arm/Disarm

3 Arm Only

4 Disarm Only

5 N/A

14

Page 19

Block 2 - Zone Configuration Programming (cont.)

Zone Response Time (Zones 1 - 8)

Cmd Loc 068 069 070 071 072 073 074 075

Zone # 1 2 3 4 5 6 7 8

Cmd Loc 076 (Zone Expander Module #1)

Zone # 9 thru 16

Cmd Loc 077 (Zone Expander Module #2)

Zone # 17 thru 24

Cmd Loc 078 (Zone Expander Module #3)

Zone # 25 thru 32

Default 2 (All CL)

Range 1 - 2 (All CL)

Audible Cadence (Zones 1 - 32)

Cmd Loc 079 080 081 082 083 084 085 086

Zone # 1 2 3 4 5 6 7 8

Cmd Loc 087 088 089 090 091 092 093 094

Zone # 9 10 11 12 13 14 15 16

Cmd Loc 095 096 097 098 099 100 101 102

Zone # 17 18 19 20 21 22 23 24

Cmd Loc 103 104 105 106 107 108 109 110

Zone # 25 26 27 28 29 30 31 32

Default 3 (All CL)

Range 1 - 7 (All CL)

Zone Circuit Type (Zones 1 - 32)

Cmd Loc 111 112 113 114 115 116 117 118

Zone # 1 2 3 4 5 6 7 8

Cmd Loc 119 120 121 122 123 124 125 126

Zone # 9 10 11 12 13 14 15 16

Cmd Loc 127 128 129 130 131 132 133 134

Zone # 17 18 19 20 21 22 23 24

Cmd Loc 135 136 137 138 139 140 141 142

Zone # 25 26 27 28 29 30 31 32

Default 3 (All CL)

Range 1 - 6 (All CL)

Comments

These Options select the zone response time (in milliseconds) of zones 1 - 8 and zones available from

the S5058 Zone Expansion Module.

All zones on the S5058 ZEM use the same response time.

Comments

These options program the operation of the internal and external

sounders. Both internal and external sounders will operate together.

Programming options 5 and 6 also

limit the duration of the sounder

outputs.

Exceptions are: Keyswitch/SpreadNet Arming Annunciation (Block 3,

CL 051) and Ringback (Block 4,

CL 115).

Comments

Tamper zones use 2 EOL resistors and may

detect 4 discreet conditions (normal, fault/

alarm, trouble, and tamper).

If any zone is designated as a SpreadNet

zone, it will automatically be ignored as a

hardwired zone.

For devices requiring 10K EOL resistor, use zone 7 and remove J5. Refer

to the S5090 Sierra Reference Manual for additional information.

Options:

1 Keypad Buzzer

2 Pulsing Sounder (1.5s on/off)

3 Steady Sounder

4 Temporal Code 3 (0.5s on/

0.5s off 2x, 0.5s on/ 1.5s off)

5 On 1 Min./Off 30s

(repeated twice)

6 On 1 Min./Off 30s

(repeated 5x)

7 Silent

Options:

Options:

1 250 mS

2 500 mS

1 Normally Closed

2 Normally Open

3 EOL

4 Supervised EOL

5 Tamper (2 EOL)

6 SpreadNet RF

Chime Enable

Zones: 1 - 8 9 - 16 17 - 24 25 - 32

Cmd Loc 143 144 145 146

Default 0 0 0 0

Range 0 - 255 0 - 255 0 - 255 0 - 255

Zone Bypass Enable

Zones: 1 - 8 9 - 16 17 - 24 25 - 32

Cmd Loc 147 148 149 150

Default 255 255 255 255

Range 0 - 255 0 - 255 0 - 255 0 - 255

Comments

If programmed for chime, these zones will

sound at the keypad when the control panel

is disarmed and the zone is faulted. It is used

for delay, interior, and instant zones only. The

program value is a total of all zones in the

group which will have Chime enabled.

Comments

These four command locations determine

which zones a user may manually bypass (if

authorized in Block 1, CL 021 - 080).

Zone bypass enable is divided into groups

of 8 zones each. The program value is a total

of all zones in the group which may be bypassed.

15

Options:

0 Disabled

1 Zone 1 9 17 25

2 Zone 2 10 18 26

4 Zone 3 11 19 27

8 Zone 4 12 20 28

16 Zone 5 13 21 29

32 Zone 6 14 22 30

64 Zone 7 15 23 31

128 Zone 8 16 24 32

Options:

0 Disabled

1 Zone 1 9 17 25

2 Zone 2 10 18 26

4 Zone 3 11 19 27

8 Zone 4 12 20 28

16 Zone 5 13 21 29

32 Zone 6 14 22 30

64 Zone 7 15 23 31

128 Zone 8 16 24 32

Page 20

Block 2 - Zone Configuration Programming (cont.)

Home Arm Bypass List

Zones: 1 - 8 9 - 16 17 - 24 25 - 32

Cmd Loc 151 152 153 154

Default 0 0 0 0

Range 0 - 255 0 - 255 0 - 255 0 - 255

Soft Zone Enable (Medical, Police, and Fire)

Key: Med Police Fire

Cmd Loc 155 156 157

Default 1 1 1

Range 1 - 2 1 - 2 1 - 2

Soft Zone Audible Cadence

Key: Med Police Fire

Cmd Loc 158 159 160

Default 3 2 4

Range 1 - 7 1 - 7 1 - 7

Comments

These four (4) command locations determine

which zones will be automatically bypassed

when the user home arms the system.

The home arm bypass list is divided into

groups of 8 zones each. The value entered is

the total of all zones in the group to be automatically bypassed.

Options:

0 Disabled

1 Zone 1 9 17 25

2 Zone 2 10 18 26

4 Zone 3 11 19 27

8 Zone 4 12 20 28

16 Zone 5 13 21 29

32 Zone 6 14 22 30

64 Zone 7 15 23 31

128 Zone 8 16 24 32

Comments

If enabled, press and hold any of the soft zone keys for two

seconds to report an alarm condition (see also Block 4, CL

148 (Report Routing)). The local sounder (Block 2, CL 158 -

160) will also be activated.

Comments

These Options program the operation of the internal and external

sounders in response to the Medical, Police, and Fire (soft zone)

keys. Both internal and external

sounders will operate together. Programming Options 5 and 6 also limit

the duration of the sounder outputs.

Options:

1 Keypad Buzzer

2 Pulsing Sounder (1.5S on/off)

3 Steady Sounder

4 Temporal Code 3 (0.5S on/

0.5S off 2x, 0.5 S on/ 1.5 S off)

5 On 1 Min./ Off 30S

(repeated twice)

6 On 1 Min./ Off 30S

(repeated 5x)

7 Silent

Options:

1No

2Yes

Block 3 - Armed System Programming

This Block is divided into 54 Command Locations (CL 001 - 054). This Block allows the installer to set the Arming Type, Enable

Autohome, and set the three Quick functions. In addition, the Installer can select the Keypad functions, Cross-Zoning and

Double-Knock functions, Auto Arming and Disarming, and other miscellaneous functions.

Arming Type

Cmd Loc 001

Default 1

Range 1 - 3

Autohome Enable

Cmd Loc 002

Default 1

Range 1 - 2

Quick Arming Enable

Cmd Loc 003

Default 2

Range 1 - 2

SpreadNet Single Button Disarming Enable

Cmd Loc 004

Default 2

Range 1 - 2

Quick Exit Enable

Cmd Loc 005

Default 1

Range 1 - 2

Comments

This option determines the conditions necessary

in order to arm the system (zone status, etc.).

For additional details on arming options, refer to

the S5090 Reference Manual.

Comments

If enabled, arming the system without exiting the premises

will cause the system to automatically home arm (bypass all

zones programmed in Block 2, CL 151 - 154). Perimeter

zones will be armed with all delays active.

Comments

If enabled, quick arming allows the user to arm the system

without entering a user code. Quick arming pertains to full

arming, home arming, and instant arming. System delays

programmed for those functions will be in effect. (See the

S5090 Reference Manual for details on arming features.)

Comments

If enabled, allows the system to be disarmed using the Disarm button on a SpreadNet SN991-REMOTE or SN961KEYFOB. With this option enabled, the Door button on the

SN991-REMOTE or SN990-KEYPAD may also be used to

activate a relay (see Block 7, CL 001 - 011, option 2).

Comments

If enabled, quick exit allows the user to Home arm the system and then leave the premises at a later time, without the

need to disarm and re-arm the system. Pressing and holding the [Home] key for two seconds will invoke the quick exit

function.

Options:

1 Goof-Proof

2 Force Arming

3 Chirp-Alert

Options:

1No

2Yes

Options:

1No

2Yes

Options:

1No

2Yes

Options:

1No

2Yes

16

Page 21

Block 3 - Armed System Programming (cont.)

Quick Bypass Enable

Cmd Loc 006

Default 1

Range 1 - 2

Home Arm Exit Delay Enable

Cmd Loc 007

Default 1

Range 1 - 2

4X Exit Delay Extension Enable

Cmd Loc 008

Default 2

Range 1 - 2

Chirp-Alert on Exit Fail

Cmd Loc 009

Default 2

Range 1 - 2

Low Battery Arming

Cmd Loc 010

Default 2

Range 1 - 2

Comments

If enabled, quick bypass allows any user to bypass zones

without entering a user code. To bypass a zone, press the

[Bypass] key followed by the 2-digit code for the zone to be

bypassed.

Comments

If enabled, the exit delay (Block 2, CL 003) will start when a

user presses and holds the [Home] key for two seconds. If

disabled, the exit delay will be ignored and the system will

home arm instantly.

Comments

If enabled, the exit delay (Block 2, CL 003) will restart if the

delay zone is faulted a second or subsequent time during

the exit delay. The exit delay may be restarted up to 4 times.

Comments

If enabled, all sounders (internal and external) will chirp for

three seconds at the start of the entry delay (Block 2, CL

001 or 002).

Comments

If enabled, allows the system to be armed even if the backup battery is low.

Options:

1No

2Yes

Options:

1No

2Yes

Options:

1No

2Yes

Options:

1No

2Yes

Options:

1No

2Yes

Keypad Buzzer During Exit Delay

Cmd Loc 011

Default 2

Range 1 - 2

Keypad Buzzer During Entry Delay

Cmd Loc 012

Default 2

Range 1 - 2

Keypad LED Status

Cmd Loc 013

Default 1

Range 1 - 3

Cross-Zoning List

Zones: 1 - 8 9 - 16 17 - 24 25 - 32

Cmd Loc 014 015 016 017

Default 0 0 0 0

Range 0 - 255 0 - 255 0 - 255 0 - 255

Comments

If enabled, the keypad buzzer sounds during the exit delay.

The keypad buzzer rate is faster during the last 10 seconds

of the exit delay.

Comments

If enabled, the keypad buzzer sounds during the entry delay. The keypad buzzer rate is faster during the last 10

seconds of the entry delay.

Comments

This option controls the zone

and status displays of the

LED keypad.

NOTE: The Power and Arm

LEDs on all keypads operate the same.

Comments

If programmed for cross-zoning, any two

of the zones listed here must be violated

while armed in order for an alarm condition

to register.

If the system is divided into areas, both

zones in alarm must be within the same area.

NOTE: Fire, delay, and keyswitch zones

are ignored if placed on the cross-zone list.

Options:

1 Always display arm and zone status

2 Status always on while disarmed. If

armed, status displayed for 30 secs.

3 Display arm and zone status for 30

seconds following User Code entry.

Options:

0 Disabled

1 Zone 1 9 17 25

2 Zone 2 10 18 26

4 Zone 3 11 19 27

8 Zone 4 12 20 28

16 Zone 5 13 21 29

32 Zone 6 14 22 30

64 Zone 7 15 23 31

128 Zone 8 16 24 32

Options:

1No

2Yes

Options:

1No

2Yes

Double-Knock List

Zones: 1 - 8 9 - 16 17 - 24 25 - 32

Cmd Loc 018 019 020 021

Default 0 0 0 0

Range 0 - 255 0 - 255 0 - 255 0 - 255

Comments

Zones listed here must be violated twice

(or any two zones must be faulted) within

a 30-second period in order for an alarm

condition to register.

If the system is divided into areas, the

alarms must be within the same area.

NOTE: Fire, delay, and keyswitch zones

are ignored if placed on this list.

17

Options:

0 Disabled

1 Zone 1 9 17 25

2 Zone 2 10 18 26

4 Zone 3 11 19 27

8 Zone 4 12 20 28

16 Zone 5 13 21 29

32 Zone 6 14 22 30

64 Zone 7 15 23 31

128 Zone 8 16 24 32

Page 22

Block 3 - Armed System Programming (cont.)

Auto-Arming Enable (Area)

Cmd Loc 022

Default 0

Range 0 - 255

Auto-Arming Time (Hours)

Cmd Loc 023

Default 0

Range 0 - 23

Auto-Arming Time (Minutes)

Cmd Loc 024

Default 0

Range 0 - 59

Auto-Disarming Enable (Area)

Cmd Loc 025

Default 0

Range 0 - 255

Auto-Disarming Enable (Day of Week)

Cmd Loc 026

Default 0

Range 0 - 127

Auto-Disarming Time (Hours)

Cmd Loc 027

Default 0

Range 0 - 23

Auto-Disarming Time (Minutes)

Cmd Loc 028

Default 0

Range 0 - 59

Swinger Alarm Lockout Limit

Cmd Loc 029

Default 0

Range 0 - 15

Audible Output Limits

Cmd Loc 030

Default 2

Range 1 - 3

Comments

Auto-Arming may be enabled for any or all partitions. If

enabled, the system will be automatically armed each

day at the time specified in Block 3, CL 023 and 024. All

partitions will auto-arm using the same timer.

When programming the time of day for auto-arming,

use the 24-hour format. (Add 12 hours for afternoon

and evening times.)

The internal sounder will sound a warning two minutes and again at one minute prior to the Automatic

Arming of the system.

Comments

This will automatically disarm the partitions indicated

according to the information programmed into Block

3, CL 026 - 028. The value programmed is a total of all

areas to auto-disarm within the system.

Comments

This will automatically disarm the areas specified

in Block 3, CL 025. Auto-disarm will occur on the

days programmed (Block 3, CL 026) and at the

time specified (Block 3, CL 027 - 028). The value

programmed in Block 3, CL 026 is the total of all

days to auto-disarm the system.

When programming the time of day for auto-disarming, use the 24-hour format. (Add 12 hours for

afternoon and evening times.)

Options:

0 Disabled

1 Area 1

2 Area 2

4 Area 3

8 Area 4

16 Area 5

32 Area 6

64 Area 7

128 Area 8

Options:

0 Disabled

1 Area 1

2 Area 2

4 Area 3

8 Area 4

16 Area 5

32 Area 6

64 Area 7

128 Area 8

Options:

0 Disabled

1 Saturday

2 Friday

4 Thursday

8 Wednesday

16 Tuesday

32 Monday

64 Sunday

Comments

Limits the number of alarm signals reported and/or annunciated during an

armed period. Additional alarms will not be indicated. Setting the limit to

zero (0) indicates unlimited signals reported. In partitioned systems, this

limit pertains to ALL partitions (areas).

Comments

Determines the number of times the

sounders (bells) will indicate an alarm

condition during an armed period.

Options:

1 Unlimited Local Audibles.

2 One Audible per Zone.

3 One Audible per Area.

Fire Verification Enable

Cmd Loc 031

Default 1

Range 1 - 4

AC Power Loss Delay Before Report (Minutes)

Cmd Loc 032

Default 15

Range 1 - 255

Battery Test Interval (Hours)

Cmd Loc 033

Default 24

Range 0 - 24

Comments

Determines if powered loop

(zone 8) or switched aux

power will be reset for fire

alarm verification.

Options:

1 No Verification

2 Powered Loop Verify Only

3 Switched Aux Verify Only

4 Powered Loop and Switched Aux

Comments

Specifies the number of minutes AC power must be interrupted before an

AC power fail report is sent.

Comments

The interval (in hours) between battery tests. If programmed for 0, the test

is disabled. This test is conducted each time the system is reset. Additional

tests follow the test interval specified.

18

Page 23

Block 3 - Armed System Programming (cont.)

Sounder Turn-On Delay Following Alarm (Seconds)

Cmd Loc 034

Default 0

Range 0 - 255

Comments

Number of seconds that elapse following an alarm condition before the

internal siren/external bell sounds. The keypad buzzer is active during this

period.

Strobe/Siren Disable with Low Battery

Cmd Loc 035

Default 2

Range 1 - 2

Phone Line Cut or Comm Fail Indication (Silent

to Audible)

Cmd Loc 036

Default 1

Range 1 - 2