Page 1

QuadraTherm® 640i/780i Series

Insertion and In-Line Mass Flow Meters

Preliminary Instruction Manual

Part Number: IM-640i/780i Rev.v1

November 2012

1

Page 2

GLOBAL SUPPORT LOCATIONS: WE ARE HERE TO HELP!

CORPORATE HEADQUARTERS

5 Harris Court, Building L Monterey, CA 93940

Phone (831) 373-0200 (800) 866-0200 Fax (831) 373-4402

www.sierrainstruments.com

EUROPE HEADQUARTERS

Bijlmansweid 2 1934RE Egmond aan den Hoef

The Netherlands

Phone +31 72 5071400 Fax +31 72 5071401

ASIA HEADQUARTERS

Second Floor Building 5, Senpu Industrial Park

25 Hangdu Road Hangtou Town

Pu Dong New District, Shanghai, P.R. China

Postal Code 201316

Phone: + 8621 5879 8521 Fax: +8621 5879 8586

IMPORTANT CUSTOMER NOTICE- OXYGEN SERVICE

Sierra Instruments, Inc. is not liable for any damage or personal injury, whatsoever, resulting from the use

of Sierra Instruments standard mass flow meters for oxygen gas. You are responsible for determining

if this mass flow meter is appropriate for your oxygen application. You are responsible for cleaning

the mass flow meter to the degree required for your oxygen flow application.

© COPYRIGHT SIERRA INSTRUMENTS 2012

No part of this publication may be copied or distributed, transmitted, transcribed, stored in a

retrieval system, or translated into any human or computer language, in any form or by any means,

electronic, mechanical, manual, or otherwise, or disclosed to third parties without the express

written permission of Sierra Instruments. The information contained in this manual is subject to

change without notice.

TRADEMARKS

QuadraTherm™, iTherm™ and iAnywhere™ are trademarks of Sierra Instruments, Inc. Other product

and company names listed in this manual are trademarks or trade names of their respective

manufacturers.

2

Page 3

Table of Contents

Chapter 1: Introduction & Product Description

Product Description

Technical Assistance

............................................................................................................................ 5

...................................................................................................................... 7

.................................................................................... 5

Principle of Operation ........................................................................................................................ 8

iTherm™ Electronics Features

Enclosure Options

........................................................................................................................... 10

............................................................................................................ 9

Chapter 2: Installation & Wiring ........................................................................................................ 11

Installation Overview ....................................................................................................................... 11

Installing the Flow Meter .................................................................................................................. 13

Cold Tap Installation

Hot Tap Installation

........................................................................................................................ 13

......................................................................................................................... 14

Wiring Connections ......................................................................................................................... 17

Input Power Wiring

Alarm Output Wiring

........................................................................................................................ 18

................................................................................................................... 21

Remote Sensor Wiring .................................................................................................................... 24

Chapter 3: Operation & Programming

............................................................................................ 25

Start-up Routine ......................................................................................................................... 26

Level 1: Main Menu ..................................................................................................................... 26

Level 2: Sub-Menu (Password Protected) ..................................................................................... 28

Calibration (Sub-Menu) ............................................................................................................... 29

Calibration (Sub-Menu): Gas Type –“iTherm Dial-A Gas” ............................................................... 30

Calibration (Sub-Menu): Flow Units .............................................................................................. 32

Calibration (Sub-Menu): Temperature Unit .................................................................................... 33

Calibration (Sub-Menu): MenuTune .............................................................................................. 33

Calibration (Sub-Menu): Low Flow Cut Off .................................................................................... 34

Calibration (Sub-Menu): Full Scale Flow ....................................................................................... 35

Process Pressure (Sub-Menu) ..................................................................................................... 35

Process Pressure (Sub-Menu): Pressure Units .............................................................................. 36

Process Pressure Sub-Menu: Process Pressure ............................................................................ 36

Totalizer (Sub-Menu) .................................................................................................................. 37

Totalizer Sub-Menu: Reset Pulse Count ....................................................................................... 37

Totalizer (Sub-Menu): Units Per Pulse .......................................................................................... 39

Totalizer (Sub-Menu): Totalizer On/Off ......................................................................................... 39

Output Adjust (Sub-Menu): Flow, Pressure and Temperature ......................................................... 42

Reference Conditions (Sub-Menu): Standard and Normal .............................................................. 45

Change Password, Change Language .......................................................................................... 45

Restore Factory .......................................................................................................................... 45

Box Car ..................................................................................................................................... 45

Chapter 4: Troubleshooting & Repair

Troubleshooting the Flow Meter

Returning Equipment to Factory

................................................................................................ 49

.................................................................................................... 49

.................................................................................................... 51

Appendix A: Product Specifications ................................................................................................. 52

Appendix B: Smart Interface Installation ........................................................................................... 60

3

Page 4

Warning!

the flow meter nameplate for specific flow meter approvals before any hazardous location installation.

Warning!

permit. The manufacturer of the hot tap equipment and/or the contractor performing the hot tap is

responsible for providing proof of such a permit

Warning!

Warning!

when wiring this unit to a power source and to peripheral devices. Failure to do so could result in injury or

death. All AC power connections must be in accor dance with published CE directives.

Warning!

over-heating of the sensors and/or damage to the electronics.

Warning!

Warning!

Caution!

to any master control system. Adjustments to the electronics will cause direct changes to flow control settings.

Warnings and Cautions

Agency approval for hazardous location installations varies between flow meter models. Consult

Hot tapping must be performed by a trained professional. U.S. regulations often require a hot tap

All wiring procedures must be performed with the power off.

To avoid potential electric shock, follow National Electric Code safety practices or your local code

Do not power the flow meter with the sensor remote (if applicable)wires disconnected. This could cause

Before attempting any flow meter repair, verify that the line is de-pressurized.

Always remove main power before disassembling any part of the mass flow meter.

Before making adjustments to the device, verify the flow meter is not actively monitoring or reporting

Caution!

higher pressure rating as the main pipeline.

Caution!

accuracy of the flow meter. You cannot add or subtract wire length without returning the meter to the

factory for re-calibration.

Caution!

at full gas flow before installing the meter.

Caution!

Caution!

follow these precautions to minimize the risk of damage:

All flow meter connections, isolation valves and fittings for hot tapping must have the same or

Changing the length of cables or interchanging sensors or sensor wiring will affect the

When using toxic or corrosive gases, purge the line with inert gas for a minimum of four hours

The AC wire insulation temperature rating must meet or exceed 80°C (176°F).

Printed circuit boards are sensitive to electrostatic discharge. To avoid damaging the board,

before handling the assembly, discharge your body by touching a

grounded, metal object

handle all cards by their edges unless otherwise required

when possible, use grounded electrostatic discharge wrist straps when handling

sensitive components

4

Page 5

Chapter 1: Introduction & Product Description

From Sierra’s beginning over forty years ago, Founder Dr. John G. Olin was driven by the

vision of supplying industrial customers with the world’s most accurate thermal mass flow

meter. And, he knew it was a “sensor” game.

The development of an industrialized metal-sheathed sensor in the early 80s was Sierra’s

first big step, but Dr. Olin is a driven innovator, and this was only the beginning for

someone who saw “Thermal Mass Flow” as his life’s work. Many successful innovations

followed, but in 1999 Sierra experienced a major breakthrough with the introduction of

their patented no-drift DrySense™ thermal mass velocity sensor. Sierra engineers now

recognized they were on the cusp of realizing Dr. Olin’s vision.

Realizing the Vision: Thermal technology, by its very nature, uses the physics of heat

transfer and and conservation of energy in a closed system to measure mass flow rate. This

means that for a thermal mass flow meter to achieve the greatest accuracy, it must solve

the First Law of Thermodynamics (Heat Energy In = Heat Energy Out) for each data point.

As you can imagine, solving the First Law in a flow instrument was no easy task. By Dr.

Olin’s own accounting, decades of “hard-nosed dedication to excellence” by himself and

Sierra’s engineering team, years of testing, and his stack of yellow note pads over five feet

high, jammed with his handwritten equations and designs, finally yielded the secret in the

form of two revolutionary technologies—QuadraTherm™ and iTherm™, now both

patented worldwide.

The QuadraTherm Sensor: Traditional thermal sensors have two sensors-–one

temperature sensor and one velocity sensor, each in a separate probe. QuadraTherm (the

term “Quad” meaning “four”) introduces four sensors—three precision platinum

temperature sensors and one patented DrySense mass velocity sensor. Performance

improvements never before possible are gained as the QuadraTherm Technology isolates

forced convection (the critical variable for measuring gas mass flow rate) by calculating

and then eliminating unwanted heat-transfer components, like sensor stem conduction, one

of the major causes of false flow readings.

iTherm, the Brains Behind it: iTherm is the true “Brain” of the instrument and a

revolutionary, living, learning algorithm set made possible by today’s hyper-fast

microprocessors and QuadraTherm sensor inputs. iTherm manages changes in gas flow,

temperature and pressure, as well as outside temperature, via a comprehensive heattransfer model. The result of iTherm is a proprietary, fundamentally different gas mass

flow rate calculation using all pertinent variables for the most precise, stable and accurate

mass flow measurement possible.

Website & Downloads

QuadraTherm microsite:

www.sierrainstruments.com/quadratherm

Download this manual:

www.sierrainstruments.com/quadrathermIM

5

Page 6

Features and Benefits

Accuracy (air) +/- 0.5% of reading from 50% to 100% of full scale

+/-0.5% of reading plus 0.5% of full scale from 0% to 50% of full scale

Patented vastly improved thermal sensor element for high accuracy

Patented DrySense™ Technology for long term drift stability; lifetime warranty

Instrument-optimized proprietary iTherm Gas Library for application independence

Sensor design improvements to eliminate downdraft effects from probe

Dial-A-Gas®: change gas and engineering units in the field, on the fly with the push of a

button

Dial-A-Pipe™: Use insertion version on different pipe sizes, set up on the fly with the push of

a button

Multivariable: simultaneous measurement of mass flow rate, process temperature, and

pressure

CE approved

FM approval pending

Digital communications suite pending

Using This Manual

This manual provides information needed to install and operate QuadraTherm 640i

and 780i thermal mass flow meters. The four chapters and two appendices of this

manual cover the following areas:

Chapter 1: Introduction & Product Description

Chapter 2 Installation & Wiring

Chapter 3: Operation & Programming

Chapter 4: Troubleshooting & Repair

Appendix A: Product Specifications

Appendix B: Smart Interface Program (SIP) software

6

Page 7

Warning!

Caution!

This statement appears with information that

is important to protect people and equipment

from damage. Pay very close attention to all

warnings that apply to your application.

This statement appears with information that is

important for protecting your equipment and

performance. Read and follow all cautions that

apply to your application.

Note and Safety Information

We use caution and warning statements throughout this book to draw your

attention to important information.

Receipt of System Components

When receiving a Sierra mass flow meter, carefully check the outside

carton for damage incurred in shipment. If the carton is damaged, notify the local

carrier and submit a report to the factory or distributor. Remove the packing slip

and check that all ordered components are present. Make sure any spare parts

or accessories are not discarded with the packing material. Do not return any

equipment to the factory without first contacting Sierra Customer Service

packing

.

Technical Assistance

If you encounter a problem with your flow meter, review the configuration

information for each step of the installation, operation, and setup procedures.

Verify that your settings and adjustments are consistent with factory

recommendations. Refer to Chapter 4: Troubleshooting, for specific

information and recommendations.

If the problem persists after following the troubleshooting procedures outlined in

Chapter 4, contact Sierra Instruments by fax or by E-mail (see inside front

cover). For urgent phone support you may call (800) 866-0200 or (831) 3730200 between 8:00 a.m. and 5:00 p.m. PST. In Europe, contact Sierra

Instruments Europe at +31 20 6145810. In the Asia-Pacific region, contact

Sierra Instruments Asia at +

Support, make sure to include this information:

86-21-58798521.

The flow range, serial number, and Sierra order number (all

marked on the meter nameplate)

The software version (visible at start up)

When contacting Technical

The problem you are encountering and any corrective action taken

Application information (gas, pressure, temperature and piping

configuration)

7

Page 8

Principle of Operation

Watch a principal of operation video at

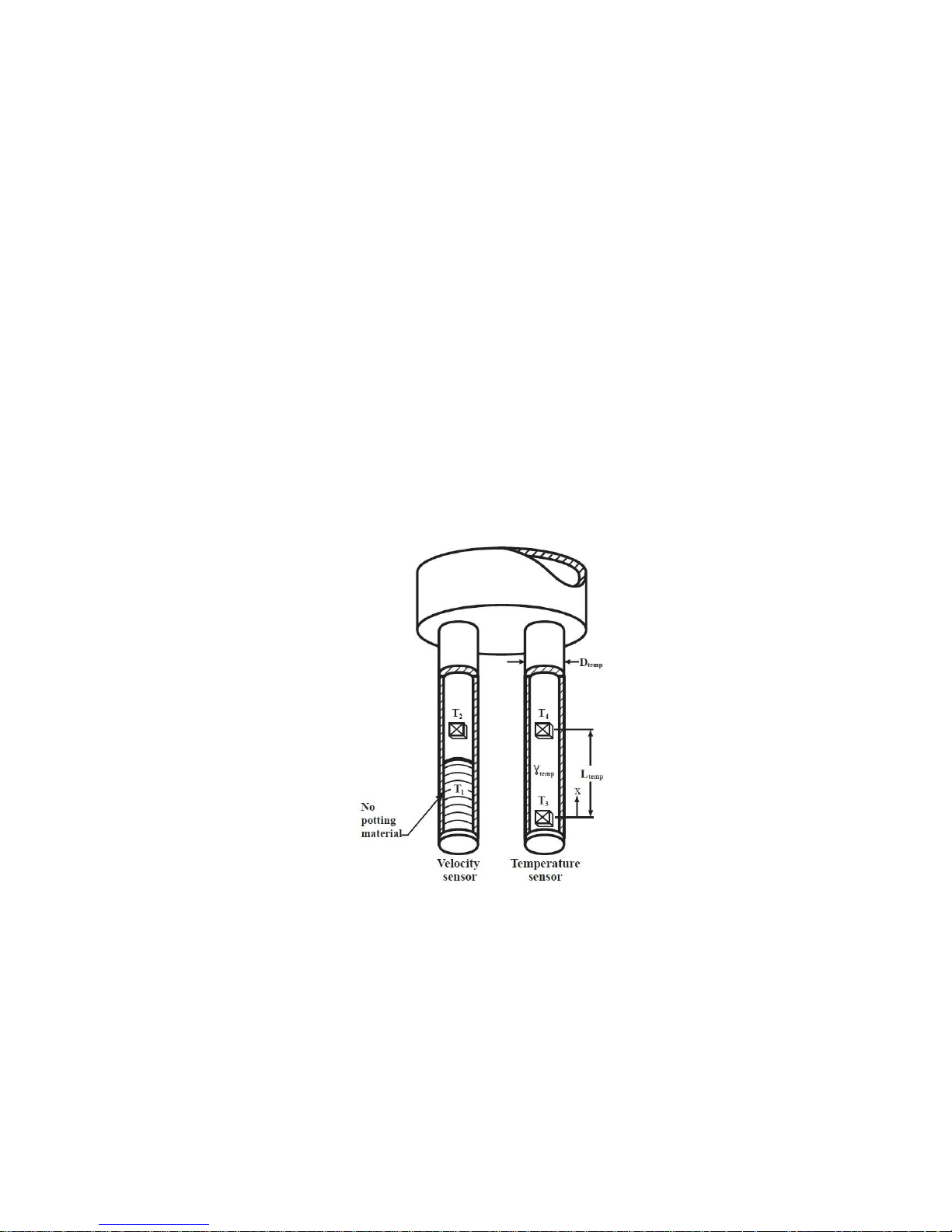

Sierra’s unique QuadraTherm™ sensor probe is responsible for the unsurpassed accuracy,

ruggedness, and reliability of Sierra industrial flow meters. The immersible sensor

consists of four sensing elements–a velocity sensor, a temperature sensor, and two

stem conduction sensors that measure heat lost to the outside.

When power is applied to the flow meter, the transducer electronics heats the velocity

sensor to a constant temperature differential above the gas temperature and measures

the cooling effect of the gas flow. The electrical power required to maintain a constant

temperature differential is directly proportional to the gas mass flow rate. The two

stem conduction sensors ensure that any heat lost is due to this cooling effect, and not

due to conduction to the outside.

The velocity sensor is a reference-grade platinum resistance temperature detector (RTD).

The platinum RTD wire is wound on a rugged ceramic mandrel for strength and stability.

The temperature sensor is clad in 316 stainless steel. The velocity sensor is clad in a

Pt/Ir Alloy.

www.sierrainstruments.com/thermalprincipal

Figure 1-1:640i & 780i Series Sensor Assembly

8

Page 9

iTherm™ Electronics Features

iTherm™ Dial-A-Gas™ Technology

Select gas to be measured

iTherm™ Dial-A-Pipe™ Technology

Set-up pipe dimensions

Units

Select units for mass flow, temperature, and pressure

User Full Scale Flow Rate

Field-configure from 50% to 100% of the factory full scale setting

Alarms

Program high & low or window alarm limits independently for mass flow,

temperature, pressure and totalizer (select one)

MeterTune™ (Span Adjust)

Change the calibration correction factor to compensate for flow profile disturbances or

specific application conditions. The MeterTune™ (span adjust) is a multiplication factor

applied to the flow signal

Dual Output Signals

Two 4-20mA separate linear output signals proportional to flow and

temperature. Optional 4-20mA proportional to pressure if pressure option

selected.

Totalizer

Set up totalizer pulse output

Set Standard Conditions

Chose between, normal, standard and other

Set Password

Set user password

Set Low Flow Cut-off

Force flow to zero at a specified flow rate

View Tag Number

View assigned tag number

Set Language

Set language for display

9

Page 10

View Communications Protocol Parameters

View communications settings: 38,400 Baud rate, no parity, 8 data bits, and 1

stop Bit

ValidCal™ Diagnostics

Review minimum, maximum flow, temperature and pressure and other

diagnostics

Enclosure Options

Flow meter electronics are available mounted directly to the flow body, or remotely

mounted up to 200 feet (60 meters) away. The electronics’ housing may be used indoors

or outdoors.

Display options include a programmable LCD displaying mass flow, temperature,

pressure, totalized flow, Dial-A-Gas, Dial-A-Pipe, MeterTune, and user full scale along

with alarm, reference conditions, serial numbers and tag number. Local operation and reconfiguration is accomplished using the push buttons on the device. Electronics include

non-volatile memory that stores all configuration information. The memory allows the

flow meter to function immediately upon power up, or after an interruption in power.

10

Page 11

Warning!

Agency approval for hazardous location installations varies between flow meter models. Consult the flow meter

nameplate for specific flow

meter approvals before any

hazardous location installation.

Chapter 2: Installation & Wiring

Installation Overview

The 640i and 780i are easy to set up in the field. The flow meter should be inserted

to the centerline of the pipe.

When selecting an installation site, make sure that:

1. Line pressure and temperature will not exceed the flow meter

rating. If ambient temperature exceeds 50°C, remove flow

meter to a cooler area.

2. The location meets the required minimum number of pipe

diameters upstream and downstream of the sensor head

(see Figure 2-1 on the next page)

3. Safe and convenient access with adequate clearance.

.

Also, verify the meter is located where the gas is clean and

dry.

4. Verify that the cable entry into the instrument meets the

FM standard (if required).

5. For remote installations, verify the supplied cable length is

sufficient to connect the flow meter sensor to the remote

electronics. (Do not extend or shorten the supplied cable

between the probe and the electronics.)

6. Also, before installation check your flow system for

anomalies such as:

Leaks

Valves or restrictions in the flow path that could

create disturbances in the flow profile that might

cause unexpected flow rate indications

Heaters that might cause rapid excursions in

the measured temperature

11

Page 12

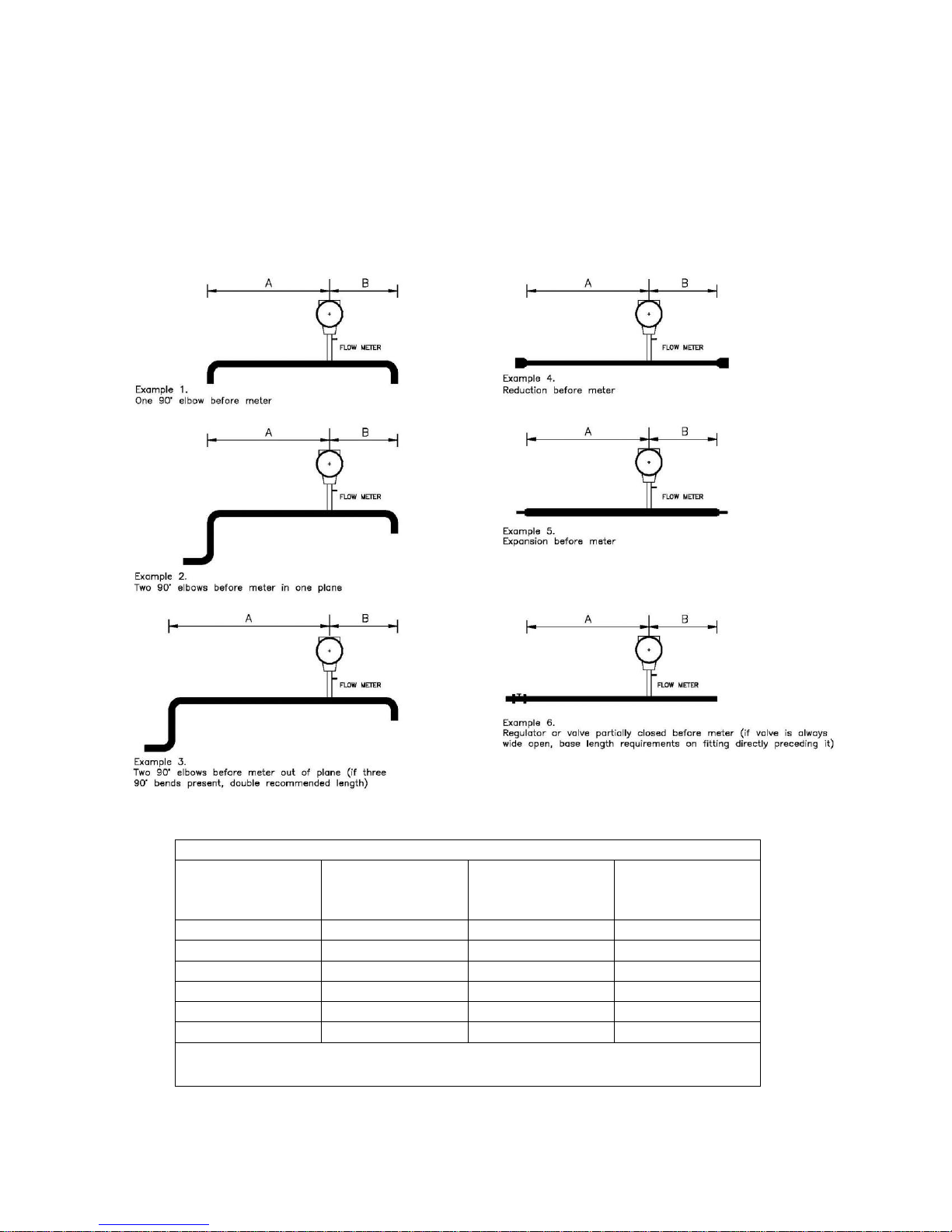

Unobstructed Flow Requirements

640i and 780i Straight Run Requirements

Piping Condition

Example

A-Upstream 640i

Insertion

(1)

A-Upstream 780i

Inline with Flow

Conditioning

(1)

B-Downstream

(2)

1

15D

1D

0D

2

20D

3D

0D 3 40D

3D

0D

4

15D

3D

0D

5

30D

3D

0D 6 40D

5D

0D

Notes: (1) Number of diameters (D) of straight pipe required between upstream disturbance and the flow meter (2) Number of

diameters (D) of straight pipe required downstream of the

flow meter

Select an installation site that will minimize possible distortion in the flow

profile. Valves, elbows, control valves and other piping components may cause

flow disturbances. Check your specific piping condition against the examples

shown below. In order to achieve accurate and repeatable performance install the

flow meter using the recommended number of straight run pipe diameters

upstream and downstream of the sensor.

Figure 2-1: Recommended Pipe Length Requirements for Installation

12

Page 13

Caution!

When using toxic or corrosive gases, purge the

line with inert gas for a

minimum of four hours

at full gas flow before

installing the flow meter.

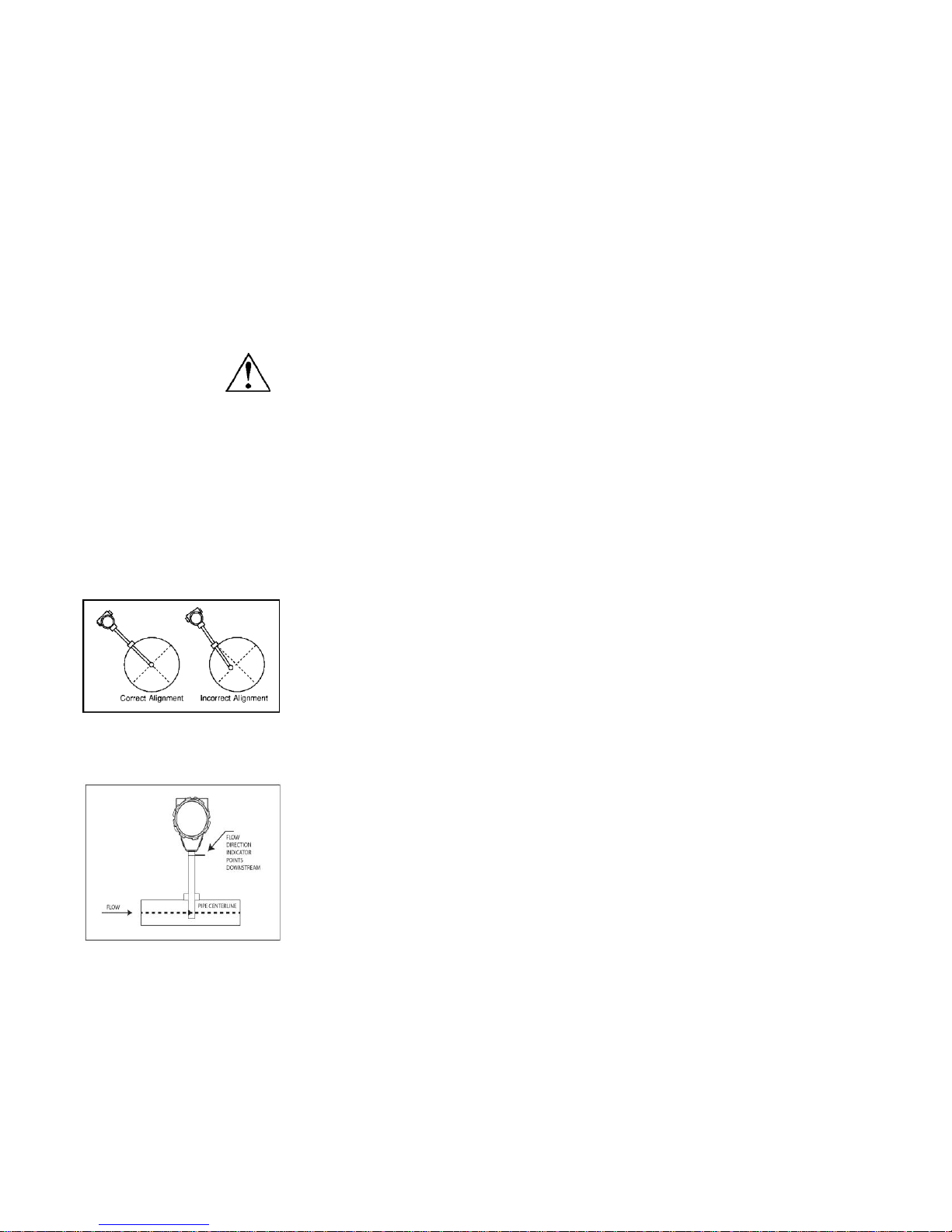

Installing the Flow Meter

NOTE: Probe may enter the pipe

from any direction as long as the

tips are in the center.

When positioning the flow meter, refer to the flow direction indicator attached to the probe. For proper operation, install the meter with the flow

direction indicator pointing downstream in the direction of flow.

Installing the meter opposite this direction will result in inaccurate flow

measurement

Cold Tap Installation

1. Confirm that the installation site meets the minimum upstream and

downstream pipe diameter requirements shown in Figure 2-1.

2. Turn off the flow of process gas. Verify that the line is not pres-

surized.

3. Use a cutting torch or sharp cutting tool to tap into the pipe. The pipe

opening must be at least 0.78 inches in diameter. (Do not attempt to

insert the sensor probe through a smaller hole.)

4. Remove all burrs from the tap. Rough edges may cause flow profile

distortions that could affect flow meter accuracy. Also, obstructions

could damage the sensor assembly when inserting into the pipe.

5. Mount the compression or flange fitting on the pipe. Make sure this

connection is within ±5° perpendicular to the pipe centerline as

shown at left.

6. When installed, cap the fitting. Run a static pressure check on the

connection. If pressure loss or leaks are detected, repair the connection and re-test.

7. Insert the sensor probe through the compression or flange fitting into the

pipe. The correct insertion depth places the centerline of the sensor

access hole in the probe at the pipe’s centerline.

8. Align the sensor head using the flow direction indicator. Adjust the

indicator parallel to the pipe pointing downstream in the direction of

flow.

9. Tighten the fitting to lock the flow meter in position. (When a compression fitting is tightened, the position is permanent unless using

Teflon ferrules.)

13

Page 14

Caution!

All flow meter connec-

tions, isolation valves

and fittings for hot tap-

ping must have the same

or higher pressure rating

as the main pipeline.

Warning!

Hot tapping must be

performed by a trained

professional. U.S. regula-

tions often require a hot

tap permit. The manufac-

turer of the hot tap

equipment and/or the

contractor performing the

hot tap is responsible for

providing proof of such a

Hot Tap Installation

When positioning the flow meter, refer to the flow direction indicator attached to the probe. For proper operation, install the meter with the flow

direction indicator pointing downstream in the direction of flow. Installing the meter opposite this direction will result in inaccurate flow measurement. Low pressure hot taps cannot exceed 150 psia (10 bara) maximum. High pressure hot taps cannot exceed 1000 psia (70 bara) maximum. Make sure the pipe pressure does not exceed these limits before

beginning this procedure.

1. Confirm that the installation site meets the minimum upstream and

downstream pipe diameter requirements shown in Figure 2-1.

2. Calculate the flow meter insertion depth as shown in Figure 2-2 for a

low pressure tap or Figure 2-3 for a high pressure tap.

3. Weld the process connection on the pipe. Make sure the process

connection is within ± 5° perpendicular to the pipe centerline (see

previous page). The pipe opening must be at least 0.88 inches (22

mm) in diameter.

4. Bolt an isolation valve on the process connection. The valve’s full

5. Hot tap the pipe.

6. Close the isolation valve. Run a static pressure. If pressure loss or

7. Insert the sensor probe through the isolation valve into the pipe with

8. Tighten the fittings to lock the flow meter in position.

open bore must be at least 0.88 inches (22 mm) in diameter.

leaks are detected, repair the connection and re-test.

the flow direction indicator parallel to the pipe pointing downstream

in the direction of flow. The correct insertion depth places the sensor

at the pipe’s centerline. Do not force into the pipe.

14

Page 15

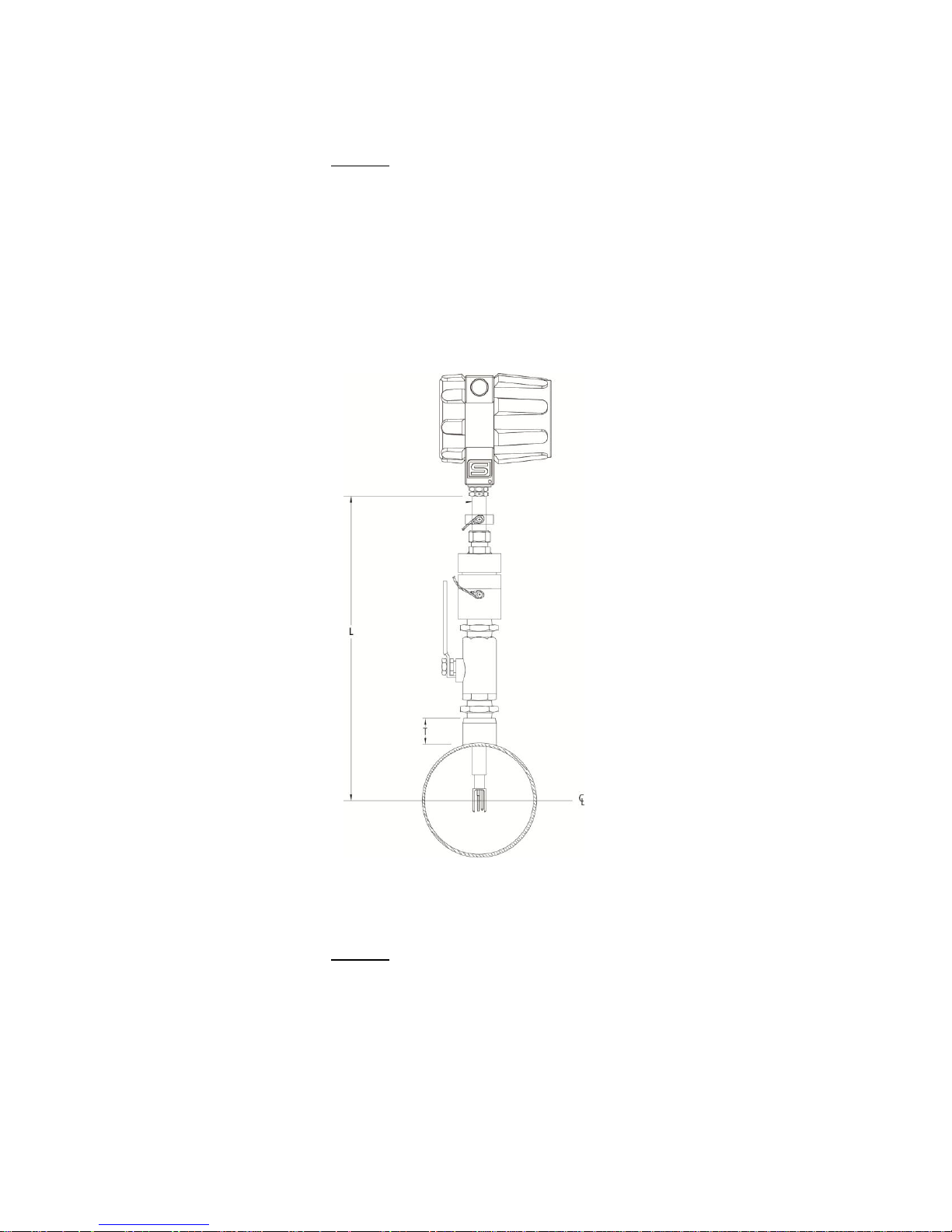

Calculating Insertion Depth for a Low Pressure Tap

Variables

L = Nominal probe length

D = Duct O.D.

C = Duct I.D.

T = Height of “Threadolet” or customer provided “Weldolet”

Formula

L ≥ 12 + D/2 + T

L must be equal or greater than 12 inches plus the height of the

“Threadolet” plus half the duct O.D.

(All dimensions in inches.)

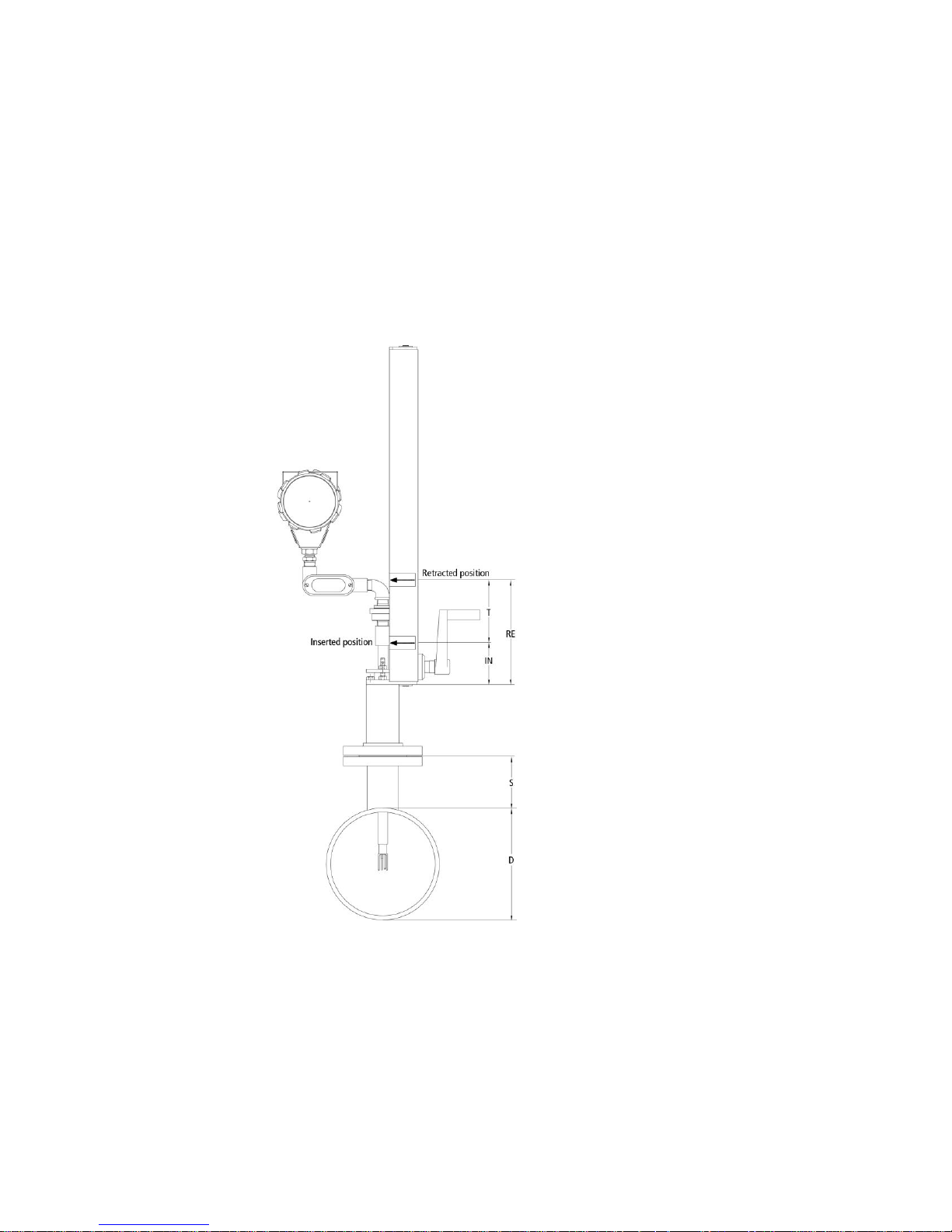

Calculating Insertion Depth for a High Pressure Tap

Figure 2-2: Low Pressure Tap Insertion Depth

Variables

S = Distance from face of mounting flange to outside of duct

D = Duct O.D.

P = Minimum probe length

T = Minimum probe travel

R = Allowable probe travel

IN = Inserted position (marker location)

RE = Retracted position (marker location)

15

Page 16

Formulas

1) P = D/2 + S + 6.75

2) T = D/2 + 0.54

3) R = 28.2 – [actual probe length – S – (D/2)]

4) IN = (actual probe length + 2) – (5.5 + S + D/2)

5) RE = IN + T

(All dimensions in inches.)

(minimum probe length–use next longer whole number length probe)

(must be greater than or equal to T)

Figure 2-3. High Pressure Tap Insertion Depth

16

Page 17

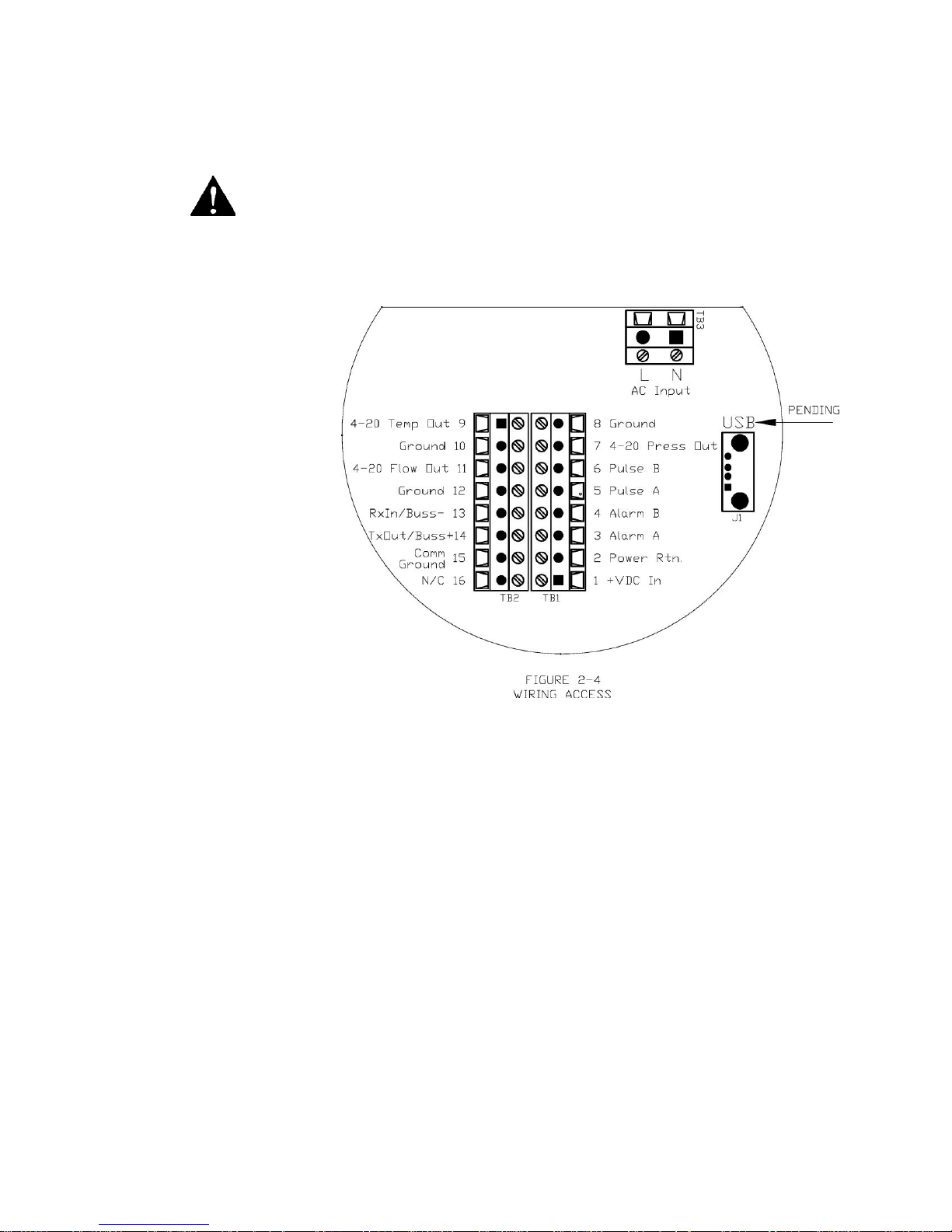

Figure 2-4. Wiring Access

To avoid potential electric

shock, follow National Elec-

tric Code safety practices or

your local code when wiring

this unit to a power source

and to peripheral devices.

Failure to do so could result

in injury or death. All AC

power connections must be

in accordance with pub-

lished CE directives.

Warning!

Wiring Connections

Use the terminal blocks located inside the cap of the flow meter

enclosure for all wiring connections. Make sure to observe all CE

compliance requirements for AC wiring connections given on the next

page.

17

Page 18

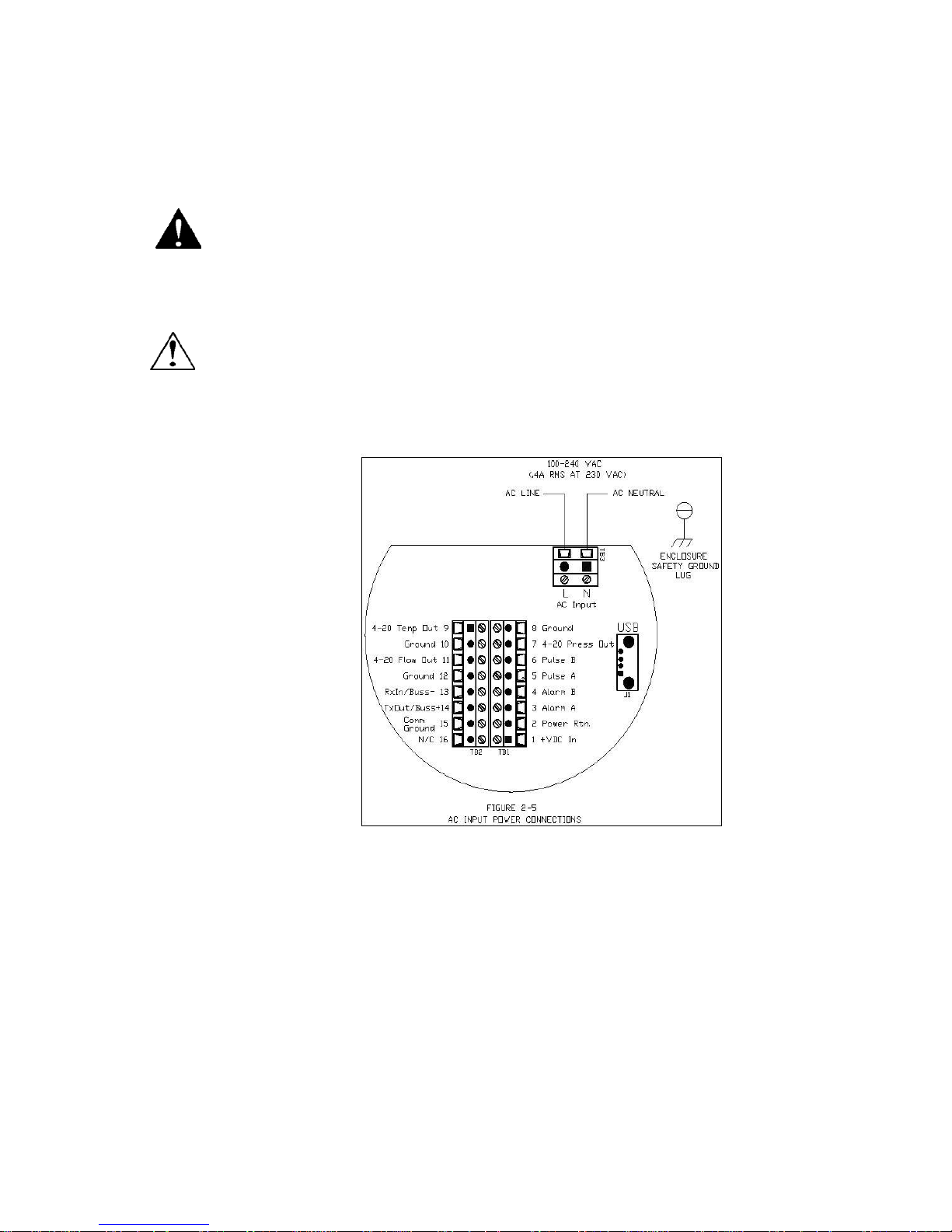

Warning!

All wiring procedures must

be performed with the

power Off.

Caution!

The AC wire insulation tem-

perature rating must meet or

exceed 80 °C (176°F).

Figure 2-5: AC Input Power Connections

Input Power Wiring

AC Power Wiring

The AC power wire size must be 26 to 16 AWG with the wire stripped 1/4

inch (6 mm). Connect 100 to 240 VAC (0.4 Amps RMS at 230 VAC) to the

Neutral and Line terminals on the terminal block. Connect the ground wire

to the safety ground lug. Torque all connections to 4.43 to 5.31 in-lbs (0.5

to 0.6 Nm).

The Hazardous-Area enclosure has two separate conduit entries to maintain

separation between AC input power and output signal wiring. To

eliminate the possibility of noise interference, use a separate cable entry

for the AC power and signal lines.

18

Page 19

Warning!

All wiring procedures must

be performed with the

power Off.

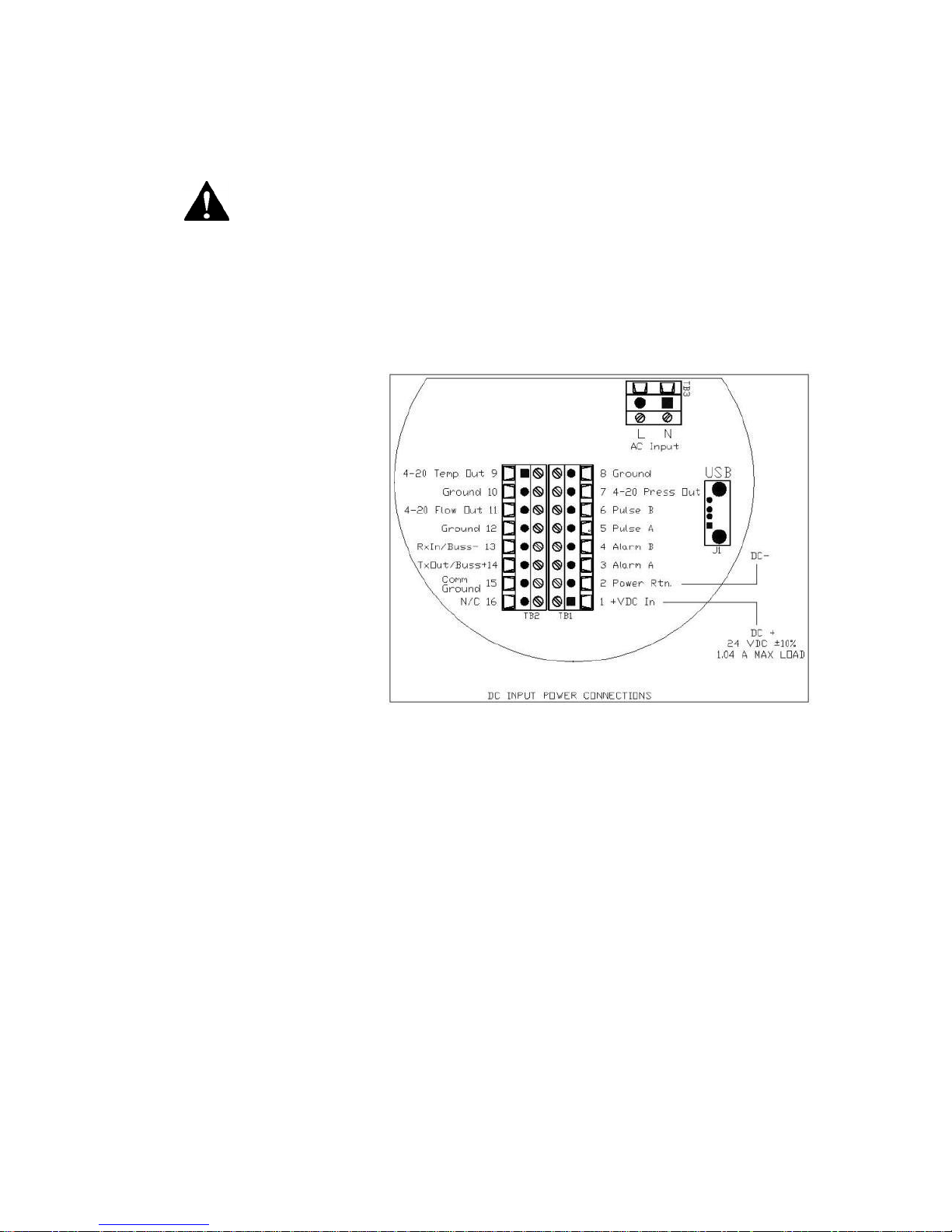

Figure 2-6: DC Input Power Connections

DC Power Wiring

The DC power wire size must be 26 to 16 AWG with the wire stripped 1/4

inch (6 mm). Connect 24 VDC +/- 10% (1.04A load, maximum) to the

terminals marked on the terminal block. Connect the Earth ground wire to

the safety ground log. Torque all connections to 4.43 to 5.31 in-lbs (0.5 to

0.6 Nm).

If conduit seals are used, they must be installed within 18 inches of the

enclosure.

19

Page 20

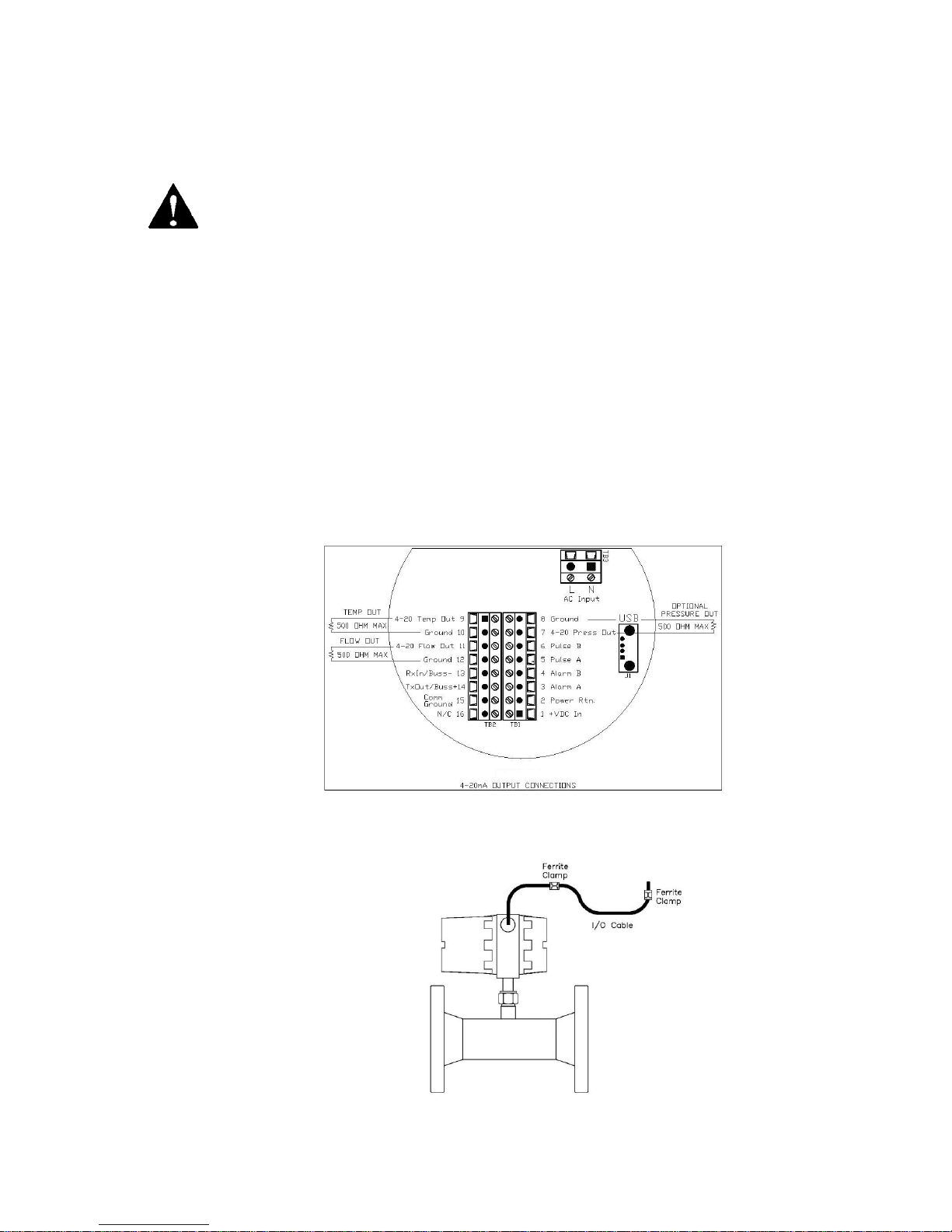

Figure 2-7: 4-20mA Output Connections

Warning!

Do not externally power

the 4-20mA output loop.

It is a self-powered

loop.

Figure: 2-8 Ferrite Installation (Ferrite not required for conduit)

Output Signal Wiring

Output signal cable should be completely screened with a 100% shield.

You must use metal cable glands that provide cable screen clamping. The

cable screen should be connected to the gland and shielded at both ends

over 360 degrees. The shield should be terminated to an earth ground. For

all installations not using metal conduit two ferrite beads should be

added, one on each end of the I/O cable. This is to maintain CE related

EMI/RFI protection. Good quality (Highest impedance at 100MHz)

Broadband ferrites should be used, a solid cylindrical ferrite

(recommended) usually has better performance than a clamp on ferrite.

The ferrites should fit as tight as possible to the OD of your cable.

All QuadraTherm 640i/780i Series flow meters are equipped with calibrated 4-20

mA output signals for both T and P, with an optional 4-20 MA output for pressure.

4-20 mA Output Wiring

The 4-20 mA current loop output is non-isolated. Max load 500 ohms

20

Page 21

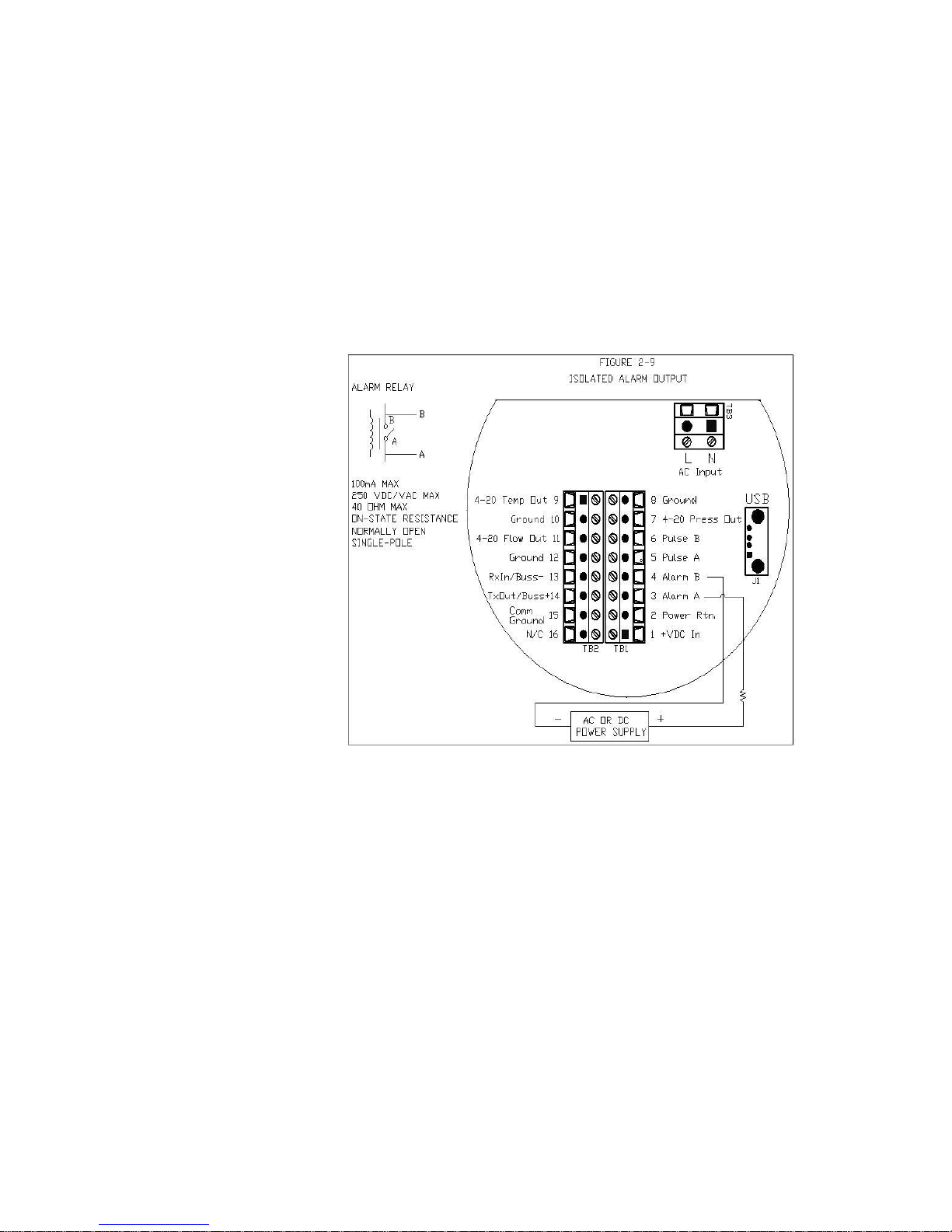

Alarm Output Wiring

Figure 2-9: AC or DC Power Supply

One alarm output contact is included on the flow meter terminal block.

The alarm output is driven by an optical relay that is normally-open

single-pole.

The relay is isolated and requires a separate power supply (isolated) the

voltage of the alarm output is the same as the voltage supplied to the

circuit.

To use an external power supply for an isolated alarm output, connect

as shown in Figure 2-8. You may set low, high or window alarms for

temperature, pressure, totalizer or mass flow

.

21

Page 22

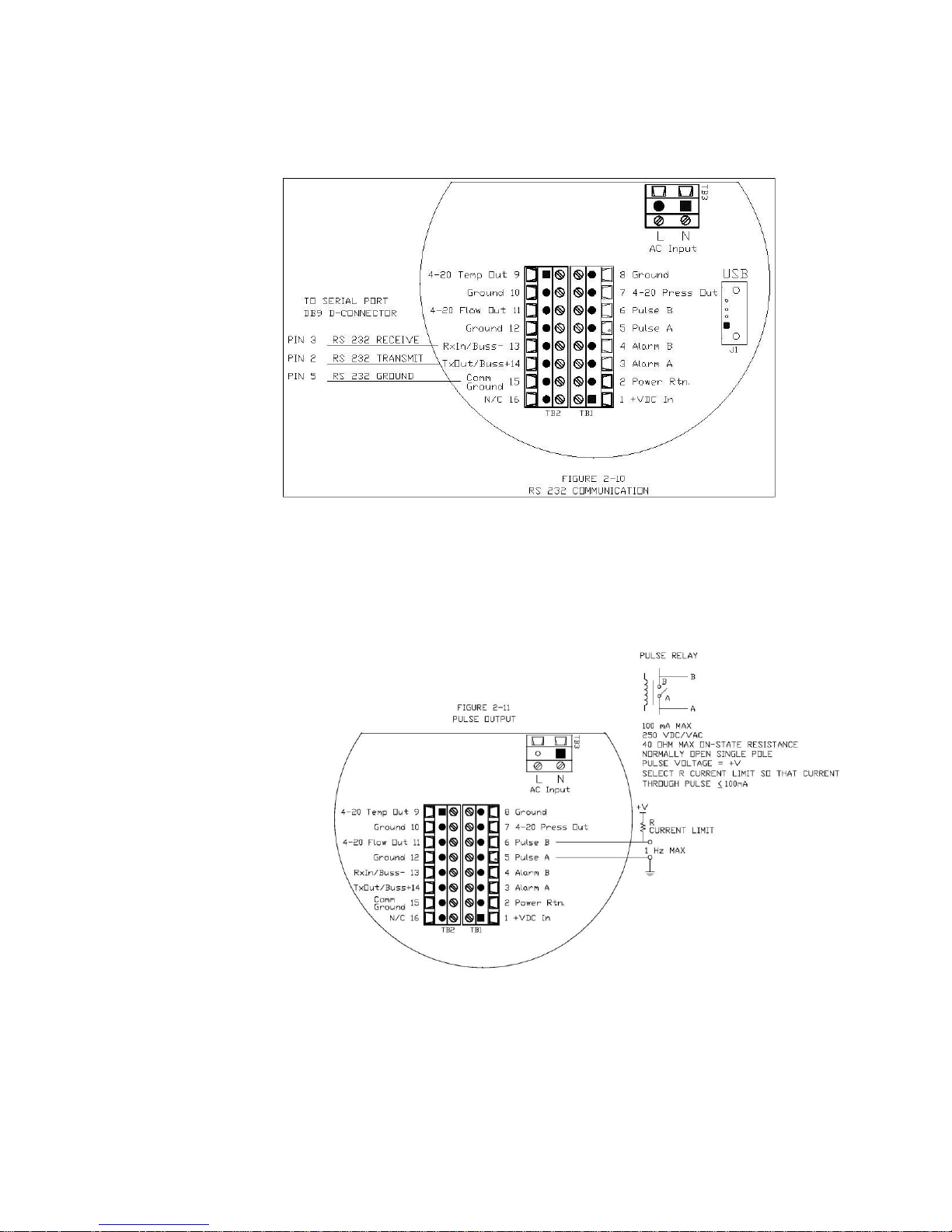

Figure 2-11:Pulse Output

Figure 2-10: RS-232 Communication

RS-232 Wiring

RS-232 provides serial communication. Wire per figure 2-10.

Pulse Output

QuadraTherm provides an adjustable pulse output with a maximum of 1 Hz. Wire per

figure 2-11 below.

22

Page 23

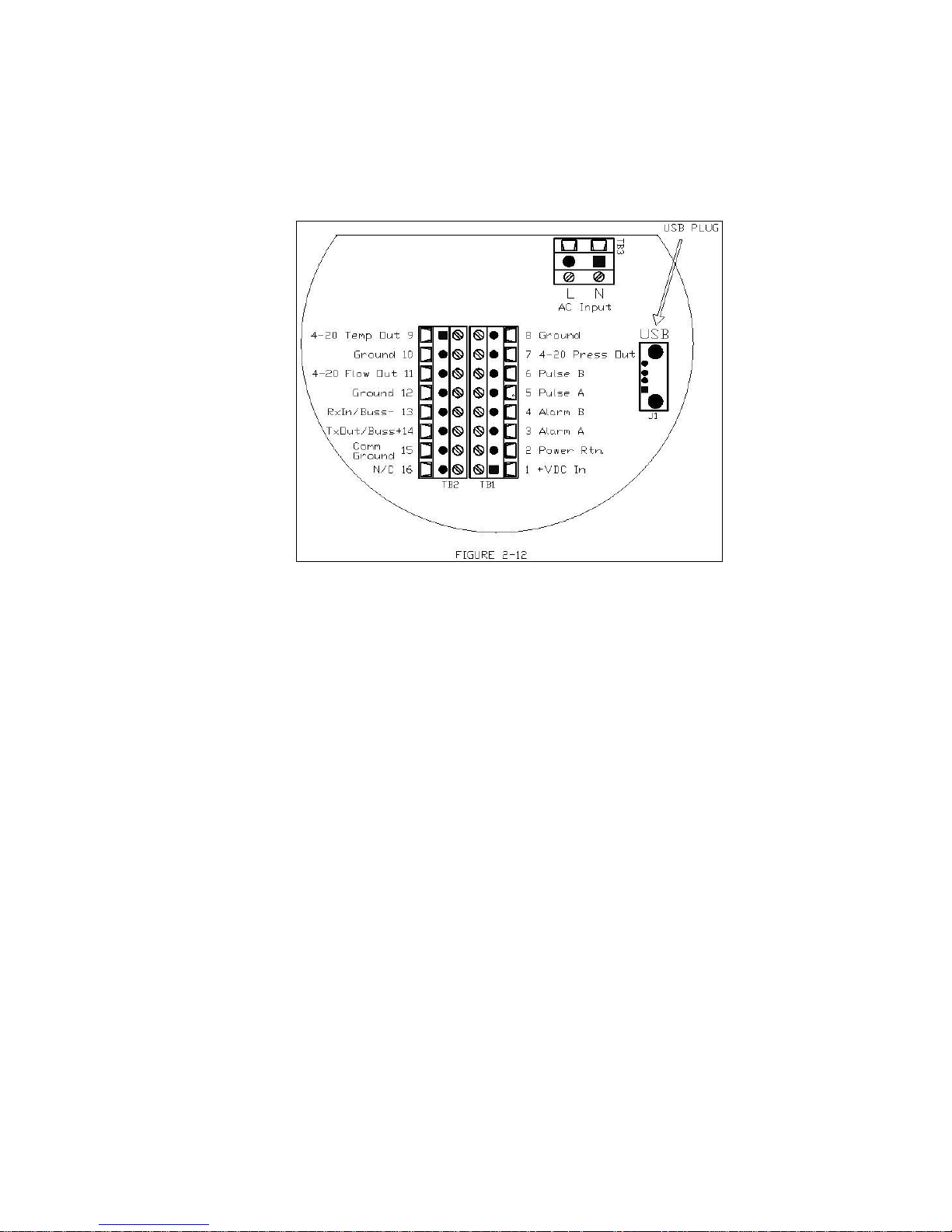

USB Output

Figure 2-12: USB Output (pending)

If supplied, plug your USB adapter into J1, per figure 2-12 (USB pending).

23

Page 24

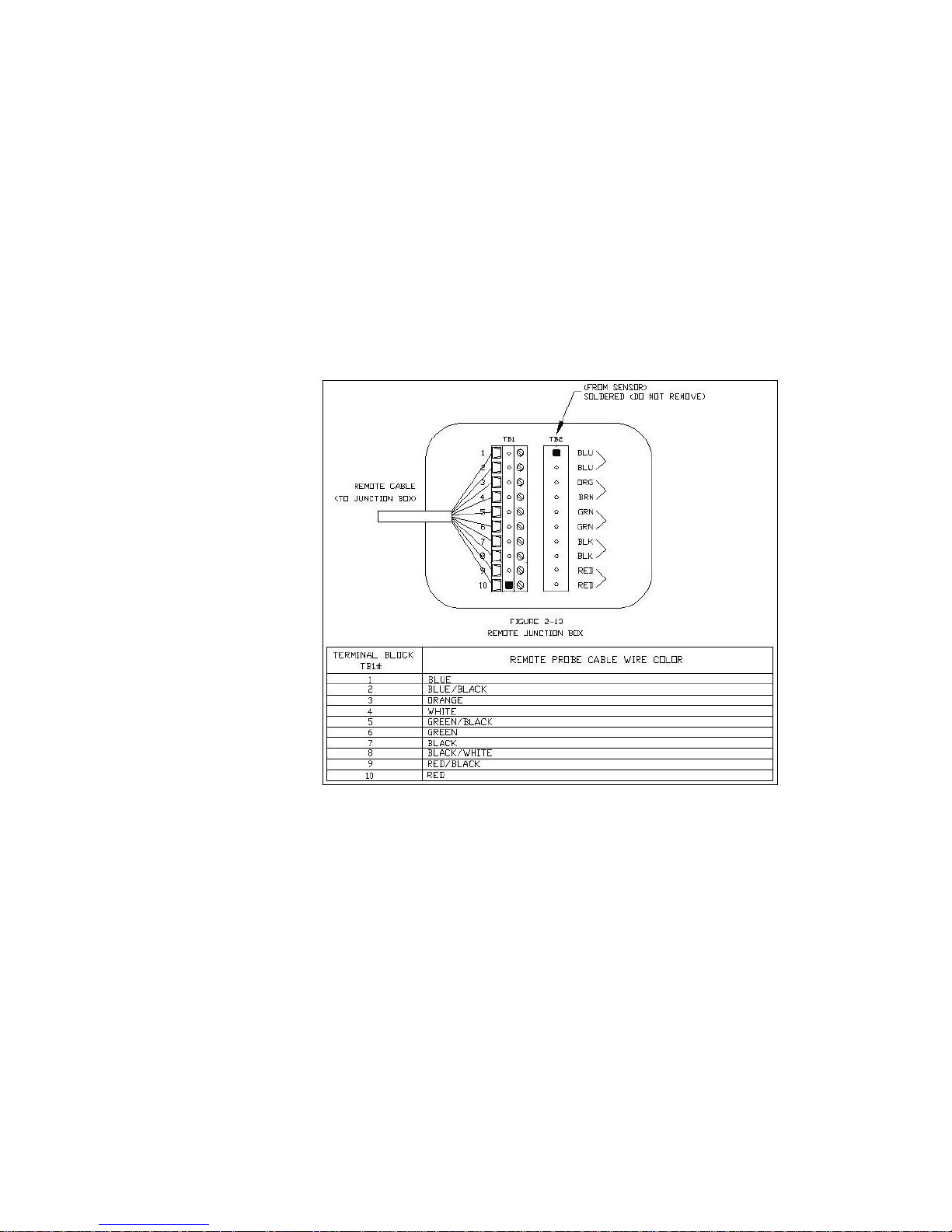

Figure 2-13: Remote Junction Box

Remote Sensor Wiring

When connecting the sensor probe to a remotely mounted flow meter enclosure, use only factory supplied cables. When connecting more than

one meter, do not intermix the sensor probes and electronics. The electronics, sensor probes and interconnecting cables supplied by Sierra Instruments are calibrated as a complete precision mass flow circuit.

To make wiring connections from a sensor probe junction box to a

remotely mounted enclosure, see Figure 2-13.

24

Page 25

Chapter 3: Operation & Programming

General Navigation

In general terms, the menu system consists of a main menu, the set-up menu, a submenu to program each item in the set-up menu, and a series of data entry or pulldown screens with to enter set-up data for each parameter.

Menus may be adjusted using the six buttons on the front of the unit: up , down ,

left , right , enter and escape/cancel , or by using the Smart Interface Program

(SIP) software provided free with the instrument.

Pressing the left button will move the menu selection to the left, or the data entry

field to the left if updating a menu value.

Pressing the right button will move the menu selection to the right, or the data entry

field to the right if updating a menu value.

Pressing the up button will move the menu selection up, or increment the data entry

field if you’re updating a menu value.

For example, if you’re updating a value, and that value is currently set to “0”, pressing

the up key will increase the value to the next logical value, in our example it would

be “1”, then “2”, “3” and so on to “9” then back to “0”

Pressing the down button will move the menu selection down, or decrement the data

entry field if you’re updating a menu value.

For example, if you’re updating a value, and that value is currently set to “9”, pressing

the down key will decrease the value to the next logical value, in our example it

would be “8”, then “7”, “6” and so on to “0” then back to “9”

Pressing the enter key accepts the current value.

Pressing the escape/cancel key returns to the last previous menu, and if you’re

currently editing a value, will cancel any changes you’ve made.

Note: The screen data “flashes” to show that you are actively editing. Pressing

the enter key permanently writes the data to the meters memory.

25

Page 26

640i/780i

V1.0.X

Serial

1234XXXX

Full Scale

100.00 SCFM

Dial-A-Gas

Carbon Dioxide

Tag

1234XXXX

Start-up Routine

Then the meter is first powered up, it will cycle through set-up data. See an example

below of the type of screens you will see.

1. Product Name and Firmware Version. Left is main PCA / right is display PCA

2. Serial Number

3. Full Scale

4. Gas

5. Tag Number

NOTE: All of these values are also displayed on the provided SIP (Smart Interface

Program) software.

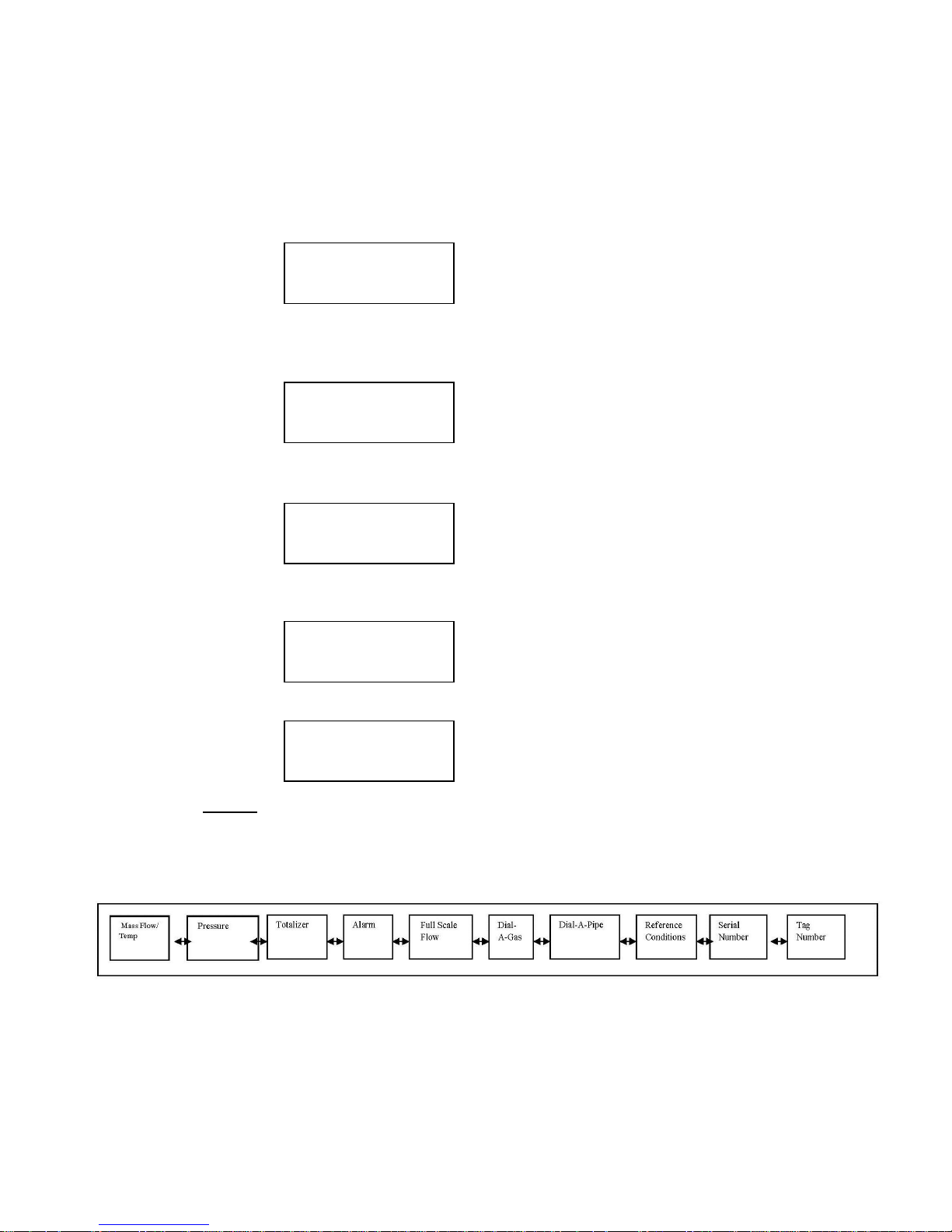

Level 1: Main Menu

Table 3-1: Main Menu Level 1

26

Page 27

0.11 SCFM

97.66 F

Pressure

0.00/psia

Total Units SCF

0.00

Active Alarm

Flow – L (On)

Full Scale Flow

100.00 SCFM

Auto Scroll

Off

Auto Scroll

On

Once set-up data is displayed, the meter will display the flow variables. The instrument will

Auto Scroll through each flow variable. You can turn OFF the Auto Scroll feature by hitting

the down arrow.

Turn Auto Scroll back ON again by hitting the up arrow. Auto Scroll will default back to on

if power is cycled.

The following flow variable screens will Auto Scroll. The data shown below is for example

only:

1. Flow and Temperature

2. Pressure (N/A if option was not ordered)

3. Totalizer (only displayed if turned ON)

You can now cycle through more main menu screens. By entering >, you will see the

additional screens. You can also go back using < at any time or exit to the main screen by

pressing (X).

4. Alarm

5. Full Scale Flow

27

Page 28

Dial-A-Gas

Carbon Dioxide

Ref: Standard

14.695949 / 70.0

Serial

1234XXXX

Tag

1234XXXX

Password

0000

Dial-A-Pipe

ID

6. iTherm Dial-A-Gas (Gas Type)

7. iTherm Dial-A-Pipe

8. Reference Conditions

9. Serial

10. Tag

And finally complete the cycle back to the flow and temperature screen.

Level 2: Sub-Menu (Password Protected)

At this point, you can access various other menus .To enter the next level press the enter key.

You will be requested to enter a password. Default is 0000 and can be reset in a later screen or

using SIP:

Use the up and down buttons to cycle through numbers and left and right buttons to

move to the next digit. Once the correct password has been entered, hit enterand you will

enter the Level 2 Sub-Menu shown in Table 3-2.

28

Page 29

Calibration

(Sub-Menu)

Table 3-2: Level 2 Sub-Menu

Calibration (Sub-Menu)

Navigate to the Calibration Sub Menu, use Table 3-3 below for guidance if necessary.

The calibration menu allows you to set up the meter to match the application.

To start, move down to the next level by pressing the enter key (). From this level, you can

set up Dial-A-Gas and Dial-A-Pipe, as well as flow and temperature units (pressure is optional

and has its own set-up menu to be covered later).

In addition you can adjust the MeterTune (span adjust), full scale flow, low flow cut-off and

view the date the meter was last calibrated. Note that you can also use the Quick Keys or the

function selector of the Smart Interface Program (SIP) provided free with the meter.

Table 3-3: Calibration Sub-Menu

29

Page 30

Dial-A-Gas

Carbon Dioxide

Calibration (Sub-Menu): Gas Type –“iTherm Dial-A Gas”

Use this menu to change and select the gas to be measured. This is called our Dial-A-Gas

feature and is a powerful and unique feature of the 640i/780i.

The display will show gas type and list the currently selected gas.

Navigate to the “Dial-A-Gas” screen. Use Table 3-3: Calibration Sub-Menu for guidance if

necessary.

Once on the “Dial-A-Gas” screen, press enter key once again until the current selected gas

begins to flash. It may take a few seconds to begin to flash.

Use the up and down keys to scroll through the available iTherm Dial-A-Gas menu. The meter

can be pre-configured with four gases from Sierra’s iTherm Gas Library. There are eighteen

gases and gas mixes available from the Sierra iTherm Gas Library. Sierra will continually

update the library as more gases and mixtures become available. New or updated gases can be

downloaded from the library using the SIP program.

Default gases:

Air

Carbon Dioxide

Methane

Nitrogen

Once you have selected the desired gas, press enter key to make the change permanent.

The selection will stop flashing.

You can press the exit several times to climb back up to the main menu level or press to

proceed to the next Calibration Sub-Menu called Dial-A-Pipe ID. We discuss this next.

Calibration (Sub-Menu): Dial-A-Pipe ID, Dial-A-Pipe ID, Dial-A-Type

This instrument can be moved to different pipe sizes and types as needed and perform precision

flow measurement. This capability is called Dial-A-Pipe and is a powerful and unique feature

of the QuadraTherm 640i immersible thermal mass flow meter.

The internal pipe diameter (ID) and pipe type are very important factors when considering flow

profile. The 640i uses internal diameter (ID) and the pipe type to mathematically model the

flow profile and enable Dial-A-Pipe.

Adjustment can also be done using the SIP (Smart Interface Program) Software. It is

recommended to use the SIP to perform Dial-A-Pipe since the process is more automated.

The Dial-A-Pipe process requires 2 steps:

1) Setting Pipe Inner Diameter (ID)

2) Setting Pipe Type

30

Page 31

Dial-A-Pipe ID

6.065000 / In

Dial-A-Pipe

ss-smooth

Step 1(Dial-A-Pipe): Navigate to the “Dial-A-Pipe ID” screen. Use Table 3-3: Calibration

Sub-Menu for guidance if necessary.

The display will show pipe inner diameter in the units selected. In the example below the

inside diameter of the pipe is 6.065000 inches.

Press enter to cause the first digit (the 6 in 6.065000 in our example) to begin flashing. Use

the up and down arrows to select the value 0 to 9. Once done, use the right key to move on to

the selected significant digit. Once the I.D. value is selected, use the up and down keys to

select the desired units.

IMPORTANT: It is vital to use the correct I.D. and units of the pipe where the instrument is

located. If the schedule of the pipe is known, the I.D. can be looked up from pipe tables. If the

pipe outer diameter and wall thickness is known, the I.D. can be calculated. If you do not have

a round pipe, you must enter the equivalent round I.D. There are various methods of

calculating this. Here’s an easy calculation to give you the hydraulic diameter (HD):

Hydraulic Diameter = HD

HD = 4A A= Cross sectional area of duck

P P = Wetted perimeter of duct

I.D. Units:

in: inches

m: meters

mm: millimeters

ft: feet

Step 2 (Dial-A-Pipe Type): Pipe roughness does matter. The friction losses of the gas

moving through the pipe are a major factor in the instruments calculation of the flow profile.

Navigate to the “Pipe Type” screen. Use Table 3-3: Calibration Sub-Menu for guidance if

necessary.

Use this menu screen to complete entering Dial-A-Pipe data. The display will show pipe

roughness and the “type” of pipe. See example below.

Press enter and the type of pipe will begin flashing. Go to the next level down with the

button and select the proper pipe type.

Choices Available:

ss-smooth

ss-normal

ss-rough

31

Page 32

cs-smooth

Flow Units

SCFM

cs-normal

cs-rough

c-fiber

cast-iron

concrete

PVC

Glass

ss-UHP

where:

ss = stainless steel

cs = carbon steel

c-fiber = carbon fiber

UHP = ultra-high purity (5 – 10 Ra finish)

Again, use the up and down keys to select. Choice will flash until the enter key is

pressed. Once the selection is made, the instrument Dial-A-Pipe feature is complete.

You can press the exit several times to climb back up to the main menu level or press to

proceed to the next Calibration Sub-Menu called Flow Units.

Calibration (Sub-Menu): Flow Units

Navigate to the “Flow Units” screen. Use Table 3-3: Calibration Sub-Menu for guidance if

necessary. Use this menu to enter the units for mass velocity or flow. The display will show

the previously selected flow units. For example:

Press enter and the units will begin flashing. Go to the next level with the button and

select the proper pipe type. Again, use the up and down keys to select. The current

choice will flash until the enter key is pressed.

Available Choices:

SCFS, SCFM, SCFH, SCFD, SCFY: Standard Cubic Feet per Second, Minute, Day,

Hour or Year. Standard conditions are set in the Reference Conditions menu.

NCFS, NCFM, NCFH, NCFD, NCFY: Normal Cubic Feet per Second, Minute, Day,

Hour or Year. Normal conditions are set in the Reference Conditions menu.

SM3/sec; min; hr; day; yr: Standard cubic meters per unit time. Standard conditions

are set in the Reference Conditions menu.

NM3/ sec; min; hr; day; yr: Normal cubic meters per unit time. Normal conditions

are set in the Reference Conditions menu.

SLPS,SLPM, SLPH, SLPD, SLPY: standard Liters per unit time. Standard

conditions are set in the Reference Conditions menu.

NLPS,NLPM, NLPH, NLPD, NLPY: normal Liters per unit time. Normal conditions

are set in the Reference Conditions menu.

Lbs/sec; min; hr; day; year: Pounds per unit time.

Kg/sec; min; hour; day; year: Kilograms per unit time.

32

Page 33

SFPS, SFPM, SFPH, SFPD, SFPY: Standard Feet per Second, Minute, Day, Hour or

Temperature Unit

F

MenuTune

1.000000

Year. Note this is a point VELOCITY.

SMPS, SMPM, SMPH, SMPD, SMPY: Standard Meters per Second, Minute, Day,

Hour or Year. Note this is a point VELOCITY.

You can press the exit several times to climb back up to the main menu level or press to

proceed to the next Calibration Sub-Menu called Temperature Units.

Calibration (Sub-Menu): Temperature Unit

Use this menu to enter the units for temperature. Use Table 3-3: Calibration Sub-Menu for

guidance if necessary. The display will show the currently selected temperature unit.

Press enter and the units will begin flashing. Use the up and down keys to select. The

units will flash until the enter key is pressed again.

Choices Available:

F (Fahrenheit)

C (Celsius)

K (Kelvin)

R (Rankine)

Once the temperature units have been selected press enter () to save. You can press the exit

several times to climb back up to the main menu level or press to proceed to the next

Calibration Sub-Menu called Span Value.

Calibration (Sub-Menu): MenuTune

The MenuTune multiplies the meter output by a fixed value, from 0.5000000 to 2.000000.

Displayed MeterTune is for the currently selected gas. This is useful if the meter displays a

known offset from another device or expectation (calculated flow rate for example), and you

want to make the meters “match”.

For instance, assume your process needs a less accurate rotameter that reads 100 SCFM, and

the more accurate 640i or 780i that reads 95 SCFM to align. Enter a span factor of 100/95 =

1.052632. The meter will then multiply by this factor so that the meter output equals the

rotameter output of 100 SCFM. Default is of course 1.000000.

Press enter () and the units will begin flashing. As in previous examples, use the

buttons to enter the desired value, and the enter key () to save the value.

33

Page 34

Low Flow Cut-Off

5.000000

Calibration Date

08/13/2012

You can press the exit several times to climb back up to the main menu level or press to

Full Scale Flow

100.00 SCFM

Low Flow Cut-Off

0.000000

proceed to the next Calibration Sub-Menu called Low Flow Cut Off.

Calibration (Sub-Menu): Low Flow Cut Off

The Low Flow Cut Off value forces both the digital display and the analog output values to

zero/4 mA at a percentage of full scale from 0 to 10% of the full scale value. This is useful

because pipes can show flow when all valves are shut.

The QuadraTherm 640i and 780i are extremely sensitive flow instruments that can pick up

natural convection flows, where thermal gradients cause gas movement inside the piping

system. Phenomenon’s like natural convection will lead to totalization errors.

Displayed value is for the currently selected gas.

Enter the desired low flow cut off as a percentage of the full scale flow. The full scale flow is

calibrated at the factory and is found in the main menu. You can press the exit several times

to climb back up to the main menu . For example, if the full scale flow as found in the main

menu is:

And the meter consistently shows a flow of 2 to 3 SCFM even with all valves closed (and you

are sure there are no leaks), an example is to set the low flow cut off just above to:

This is +/- 5% of the full scale of 100 SCFM. The analog output and the digital display be

0.000000 for any flow below 5.000000 SCFM. The default value for low flow cut off is

0.000000.

Once the low flow cut off has been entered, use the enter key () to save the value. You can

press the exit several times to climb back up to the main menu level or press to proceed to

the next Calibration Sub-Menu called Calibration Date.

Calibration (Sub-Menu): Calibration Date

The Calibration Date is a read-only field that shows when the meter was last factory-calibrated

in MM/DD/YYYY format.

34

Page 35

Full Scale Flow

100.00 SCFM

Sierra recommends recalibration as required by your metrology policy or when the meter

validation routine found in the Smart Interface Program software detects a problem. See Meter

Validation in XXXXXX).

You can press the exit several times to climb back up to the main menu level or press to

proceed to the next Calibration Sub-Menu called Full Scale.

Calibration (Sub-Menu): Full Scale Flow

The full scale value is the flow value that corresponds to 20mA on the Flow 4-20mA analog

output. This value can be adjusted between 50-100% of the original factory calibration full

scale value found on the data tag. Note that accuracy is still based on the original factory

calibration full scale value.

Press enter () and the units will begin flashing. As in previous examples, use the

buttons to enter the desired value, and the enter key () to save the value. This

concludes our review of the Calibration Sub-Menu. Press the exit climb back up to the main

menu.

Process Pressure (Sub-Menu)

Navigate to the Process Pressure Sub Menu, use Table 3-4 below for guidance if necessary.

The QuadraTherm 640i and 780i is a multivariable thermal mass flow meter. It always

measures mass velocity (from which the mass flow rate is derived) and temperature (VT) and

has the optional ability to measure process pressure along with VT, this is called (VTP). The

Process Pressure Sub-Menu allows you to input the desired pressure units.

Table 3-4: Process Pressure Sub-Menu

35

Page 36

Pressure Units

Psia

Process Pressure

14.700154

Process Pressure (Sub-Menu): Pressure Units

Use this menu to enter the units for pressure.

Use the enter key () to drill down to Pressure Units selection. Press enter and the units

will begin flashing. Use the buttons to enter the desired information, and the enter key

() to save the value.

Available units are:

Psia

Psia

Bar A

Bar G

KPa A

KPa G

Kg/CM2 A

Kg/CM2 G

In H2O A

In H2O G

MM H2O A

MM H2O G

Once the pressure units have been selected press the enter key () to save. You can press the

exit several times to climb back up to the main menu level or press to proceed to the next

Sub-Menu called Process Pressure Temperature Units.

Process Pressure Sub-Menu: Process Pressure

Use this menu to enter the process pressure.

This process pressure is used by the instruments iTherm mathematical model to improve gas

properties calculations. Gas properties have a very slight dependence on pressure, so if process

pressure changes appreciably over time this value should be updated to reflect process

conditions (about 0.01% per psi).

The units of the pressure in this menu are the same as what was set in the previous menu. In

the example above, the units are 14.700154 Psia since this is what was set in the pressure units

sub-menu.

This concludes our review of the Process Pressure Sub-Menu. Press the exit climb back up

to the main menu.

36

Page 37

Totalizer (Sub-Menu)

Reset Totalizer

Yes

Reset Pulse Cnt.

349

The Totalizer Sub Menu controls all aspects of the totalizer function. Totalizers are used to

monitor accumulated flow, often for billing and cost allocation purposes. The totalizer submenu is used to turn the totalizer ON or OFF, to reset, and to tell the meter when to send out a

totalizer pulse and what that pulse should look like.

Totalizer (Sub-Menu): Reset Totalizer

Navigate to the Reset Totalizer screen, use Table 3-5 above for guidance if necessary.

Use this menu to reset the totalizer to zero. Press enter () and you will see a flashing

“YES”. Pressing enter () again to reset the totalizer to zero and bring you back to the

Totalizer (Sub-Menu).

In addition, from the screen above you can press the down button to a flashing “NO”.

Pressing enter will return back to the Totalizer (Sub-Menu).

Totalizer Sub-Menu: Reset Pulse Count

If you need to actually set up the totalizer (rather than just reset it to zero), navigate to the Reset

Pulse Count screen, use Table 3-5 above for guidance if necessary.

Use this menu to reset the pulse counter. The pulse count is the count of pulses that went to the

pulse relay since the last reset. This count will match your external counter if they were both

reset at the same time and can be used to verify an external counter. Pulse count X units per

pulse= totalizer count within +/- 1 units per pulse value.

The screen example below, there were 349 pulses since the last reset.

Table 3-5: Totalizer Sub-Menu

37

Page 38

Pulse Width

50 ms

Reset Pulse Cnt.

YES

Reset Pulse Cnt.

0

To reset this to zero, press enter () and a “YES” will appear and flash.

Press enter () again and the pulse counter will be reset. In addition, from the screen above

you can press the down button to a flashing “NO”. Pressing enter () will return back to

the Reset Pulse Count screen. If you answered YES, the count will read zero “0”.

Totalizer (Sub-Menu): Pulse Width

Use this menu to set the width of the pulse in milliseconds. Navigate to the Pulse Width

screen, use Table 3-5 above for guidance if necessary.

The pulse output is an isolated relay contact, so one pulse of for example 50ms closes the

normally open relay for 50ms. Some counters work straight off of the relay contacts closing

and some pull up the relay so when it closes it is a negative 50ms pulse. The 640i and 780i can

use just the contacts or an approximately 10K pull-up resistor.

Choices Available:

On (for testing: closes the normally open relay; default is 50 msec)

Off (for testing, opens the relay; default is 50 msec)

50 ms

100 ms

250 ms

In the screen example above, the pulse width will close the isolated normally open contacts for

50ms, the frequency of the pulse varies with flow rate and units per pulse value (see below) but

cannot exceed 1Hz maximum.

Press enter () and the units will begin flashing. Press the up button or down button to

choose the desired pulse. Next, press the enter key () to save. You can press the exit

several times to climb back up to the main menu level or press to proceed to the next SubMenu called Units Per Pulse.

38

Page 39

Units per pulse

1.700000

Totalizer

ON

Totalizer (Sub-Menu): Units Per Pulse

Use this menu to select the units per pulse. Navigate to the Units Per Pulse screen, use Table

3-5 above for guidance if necessary. Note the maximum frequency at which the totalizer

can count is 1 pulse per second, or 1 Hz. This puts a limit on the units per pulse and makes

resolution dependent on flow rate.

For example: Assume the maximum flow rate is 100 SCFM and you want the totalizer to pulse

every 5 SCF. Since the flow is 100 SCFM, it will take 5/100 minutes, or 3 seconds to totalize 5

SCF. That is acceptable since the totalizer takes longer than 1 second to accumulate SCF.

Assume that now you want more resolution, so you would like the totalizer to pulse every 1

SCF. Since the flow is 100 SCFM, it will take 1/100 minutes, or 0.6 seconds to totalize 1 SCF.

Since the instrument’s totalizer is 1 Hz. It can’t pulse any faster than a maximum rate of once

per second (1 Hz).

In this example, the best units per pulse would be 1.7 SCF; that is just over the 1 HZ maximum

sampling rate.

Press enter () and the units will begin flashing. As in previous examples, use the

buttons to enter the desired value, and the enter key () to save the value.

Press to proceed to the Totalizer On/Off screen or press the exit several times to climb

back up to the main menu level.

NOTE: The units of the totalizer are the same as entered in the units menu (minus the time

since this is an accumulation and not a rate).

Totalizer (Sub-Menu): Totalizer On/Off

Use this menu to turn the totalizer On or Off. Use Table 3-5 for guidance if necessary. Press

enter () and the variable will begin flashing. As in previous examples, use the buttons

to select On or Off, and press enter () to save the value.

Note: The Totalizer can only be used when mass units are being used. For example, Lbs/Hr or

Kg/Hr.

39

Page 40

Totalizer set up in now complete. This concludes our review of the Totalizer (Sub-Menu).

Active Alarm

Flow

Press exit to climb back up to the main menu.

Alarm (Sub-Menu)

The alarm sub menu controls all aspects of the 640i and 780i Alarm feature. The instrument

can be set to alarm on one of the following variables: Flow, Pressure, Temperature or Totalizer.

The instrument alarm can be set on one of the following conditions: Low, High or Window.

The Window alarm becomes active when the parameter reads higher OR lower than the set

point (when it is outside of its “operating window”).

Table 3-6: Alarm Sub Menu

Alarm (Sub-Menu): Active Alarm

Navigate to the Active Alarm screen, use Table 3-6 above for guidance if necessary. Press

enter and the variable will begin flashing. In the screen example below, the active alarm is

“Flow”.

Use the buttons to select On or Off, and press enter () to save the value.

Alarm Choices Available:

Flow

Pressure

Temperature

Totalizer

Off

On (use only to test the alarm relay)

40

Page 41

NOTE: Only one alarm can be active at any one time. The alarm relay is a normally open

Active Mode

Low

isolated contact. The alarm is tripped when the relay closes.

You can press the exit several times to climb back up to the main menu level or press to

proceed to the next Sub-Menu called Alarm Mode.

Alarm (Sub-Menu): Alarm Mode

Navigate to the Alarm Mode screen, use Table 3-6 above for guidance if necessary. Press

enter and the variable will begin flashing. In the screen example below, the active alarm

condition is “Low”.

Use the buttons to select On or Off, and press enter () to save the value.

Available Choices:

High

Low

Window

Off

On

Alarms (Sub-Menu)

The Alarms (Sub Menu) allows you to set the Low and High alarm values for Flow, Pressure,

Temperature, and Totalizer.

Table 3-6.1: Flow Alarms (Sub Menu)

41

Page 42

We will set a low flow alarm to demonstrate the Alarms function. Navigate to the Flow Alarms

Low (SCFM)

000010.000000

(Sub Menu) screen, use Table 3-6.1 above for guidance if necessary. Assume that you already

set the Active Alarm to “Flow” and the alarm condition is set to go off on a “Low” flow. The

Flow Alarms (Sub Menu) allows you to set the actual alarm setpoint along with hysteresis.

Press enter () and the units will begin flashing. As in previous examples, use the

buttons to enter the desired numeric value, and the enter key () to save the value.

In the example screen below, 10 SCFM has been entered. The units were already set in the

units menu.

If you wanted to now set a High alarm, press the right key and the High alarm setup screen

will appear.

Note: If you wanted to set the active alarm on pressure, temperature or totalizer (instead of

flow), press the right key to reach the appropriate sub-menu and use the buttons to

enter the desired numeric value, and the enter key () to save the value

This concludes our review of the Calibration Sub-Menu. Press the exit climb back up to the

main menu.

Output Adjust (Sub-Menu): Flow, Pressure and Temperature

The QuadraTherm® 640i and 780i comes standard with linear 4 to 20 mA analog outputs for

flow and temperature. If the pressure option is selected, a third linear 4 to 20 mA analog output

is provided for pressure.

Use the output adjust menu to view, test, or adjust the 4 and 20 mA raw digital DAC counts

value for these parameters as well as to view or adjust the pressure and temperature values that

Table 3-7: Output (Sub Menu)

42

Page 43

correspond to 4 and 20mA. Zero flow always corresponds to 4mA and full scale flow always

Flow 4 mA

11373

Flow 4 mA

11373 - Testing

Flow 20 mA

56643

corresponds to 20mA.

All values in the output menu have been calibrated and set at the factory. You only need to

enter these screens if you wish to view, adjust, or test any of the values.

Setting Up: 4-20 mA Outputs

We will set Flow 4-20 mA to demonstrate this function. The same routines apply for setting up

Pressure 4-20 mA and Temperature 4-20 mA.

Flow 4 mA : View, Test, Adjust

Navigate to the Flow 4 mA screen in the Output (Sub Menu), use Table 3-7 above for

guidance if necessary. From this menu, press enter to get to the flow 4 mA setup screen.

This numeric value is the DAC value that produces 4 mA on the analog flow output. In the

example screen DAC is 11373. Press enter () and the units will begin flashing. Increasing

this value will raise the 4 mA output and decreasing this value will lower the 4 mA output. Use

the buttons to enter the desired numeric value, and the enter key () to save the

value.

You can then use the down button to force/test flow 4 mA output and hit the up button to

stop the force/test. It will flash testing until you stop the test. You can repeat this process, if

desired, until you achieve the desired result.

Flow 20 mA : View, Test, Adjust

Navigate to the Flow 20 mA screen in the Output (Sub Menu), use Table 3-7 above for

guidance if necessary. From the Flow 4 mA screen, pressing the right button will send you

to the view, test, or adjust screen for 20 mA value.

This value is the DAC value that produces 20 mA on the analog flow output. In the example

screen DAC is 56643. Press enter ()and the units will begin flashing. Increasing this value

will raise the 20 mA output and decreasing this value will lower the 20 mA output. Use the

buttons to enter the desired numeric value, and the enter key to save the value.

You can then use the down button to force/test flow 20 mA output and hit the up button to

stop the force/test. It will flash testing until you stop the test. You can repeat this process, if

43

Page 44

desired, until you achieve the desired result.

Pressure Low

0.00

Pressure High

30.00

Temperature Low

32.00

Flow 20 mA

56643 - Testing

NOTE: The engineering units are as set in the Calibration (Sub Menu). Go to that section for

more detailed information.

In the example above, assume full scale flow is 100 SCFM. As a result, a 20 mA output equals

100 SCFM and 4 mA output equals 0.00000 SCFM. These values are fixed for flow. The

output is linear between these two points, in this example, if we had a flow of 50 SCFM, the

output would be 12 mA.

Once you have completed viewing, testing, and adjusting the flow, pressure, and temperature

4-20 mA DAC values press the right key to reach the appropriate sub-menu and use the

buttons to enter the desired numeric value, and the enter key () to save the value

Getting 4 to 20 mA for Temperature and Pressure

If you wanted to set the 4 to 20 mA active alarm on pressure and temperature (instead of flow).

The pressure units above are the current pressure units you ordered or that you have changed in

the process pressure sub-menu. In the example above if your pressure units are psia then 0.00

psia would correspond to the pressure 4mA output. Press enter key () and use the left right

up and down keys to modify this value if desired and then press the enter key () to accept.

Press the right key to continue to the pressure high value that corresponds to the 20mA output.

In the example above, if your pressure units are psia then 30.00 psia would correspond to the

pressure 20mA output. Press enter key () and use the left right up and down keys to modify

this value if desired and then press the enter key () to accept. If you change this value be

sure not to enter a Pressure High value greater than the full scale of the pressure option you

ordered or you would be over the range of the transducer. If you change these pressure

low/high values the pressure accuracy is still based on the original +/-1% of full scale of the

Pressure transducer option ordered. Press the right key to continue to the temperature low value

that corresponds to the 4mA output.

The temperature units above are the current temperature units you ordered or that you have

changed in the calibration sub-menu. In the example above, if your temperature units are °F

then 32.00 °F would correspond to the temperature 4mA output. Press enter key () and use

44

Page 45

the left right up and down keys to modify this value if desired and then press the enter key ()

Temperature High

212.00

Ref. Con.

(Sub Menu)

Standard Temp.

70.000000 / F

Standard Press.

14.695949 / Psia

to accept. Press the right key to continue to the temperature high value that corresponds to the

20mA output.

In the example above, if your temperature units are °F then 212.00 °F would correspond to the

temperature 20mA output. Press enter key () and use the left right up and down keys to

modify this value if desired and then press the enter key () to accept. If you change these

temperature low/high values the temperature accuracy is still based on the original +/-1°C

specification.

In the above examples, from 32.00° F to 212.00° F or from 0 to 30 psia would correspond to

the 4 and 20mA analog outputs for temperature and pressure. These values are dependent upon

your process. Finally, exit back to the set-up menu and right to reference conditions.

Reference Conditions (Sub-Menu): Standard and Normal

Use this menu to establish the reference conditions as specified in the units menu. Navigate to

the Reference Conditions (Sub Menu), use Table 3-8 below for guidance if necessary.

Press enter () once and then use the buttons to select “Standard” or “Normal” .

45

Page 46

Table 3-8: Reference Conditions (Sub Menu)

Standard Temp.

70.000000 / F

Standard Press.

14.695949 / Psia

Normal Temp.

0.000 / C

Normal Press.

101.325/KPa A

For example, SCFM (Standard Cubic Feet per Minute) is commonly used in the United States.

The S = Standard in SCFM and is referenced to 70°F (21.1°C) and 14.696 Psia (or 1

atmosphere).

In Europe, Nm3/hr (Normal Cubic Meters per Hour) is commonly used. The N = Normal and

is generally referenced to 0°C and 101.32 KPa A(or 1 atmosphere).

Once a “Standard” or “Normal” selection has been made press enter () again to go to the

adjust screen.

From here you can adjust instrument reference conditions . To adjust, press () again and the

units will begin flashing. As in previous examples, use the buttons to enter the

desired value, and press enter () to save the value.

Once you are done press the enter key () to save. You can press the exit several times to

climb back up to the main menu level or press to proceed to the next Sub-Menu called

Diagnostics.

Diagnostics (Sub-Menu)

In the Diagnostics Sub-Menu, you can read the maximum and minimum: flow, pressure &

temperature.

Navigate to the Diagnostics (Sub Menu), use Table 3-9 below for guidance if necessary.

Use the left and right buttons to view these values. These are the maximum and minimum

values that the flow meter has measured. Press the exit button several times to climb back

up to the main menu level or press to proceed to the next Sub-Menu called Change Password

(Sub Menu).

NOTE: Extensive diagnostics are available via the Smart Interface Program (SIP) software.

46

Page 47

Table 3-9: Diagnostics (Sub Menu)

Change Password

1234

Change Language

US-English

Change Password (Sub-Menu)

Use this menu to set or change a password. Navigate to the Change Password (Sub Menu), use

Table 3-9 above for guidance if necessary.

A password is required to access the set-up sub menu’s. Press enter () and the four digit

password units will begin flashing. As in previous examples, use the buttons to enter

the desired value, and press enter () to save the value.

The default password is 0000. If you have lost your password and can’t gain needed access to

the setup screens, you can contact our service department for a password that would allow you

to access the setup screens and setup a new password.

You can press the exit several times to climb back up to the main menu level or press to

proceed to the next Sub-Menu called Change Language.

Change Language (Sub-Menu)

Navigate to the Change Language (Sub Menu), use Table 3-9 above for guidance if

necessary.

Use this menu to change the displayed language. Use SIP program to download latest

languages to your device.

You can press the exit several times to climb back up to the main menu level or press to

proceed to the next Sub-Menu called Restore Factory.

47

Page 48

Caution!

Before attempting any flow

meter repair, verify that the

line is not pressurized.

Caution!

Always remove main power

before disassembling any

part of the mass flow meter.

Restore Factory

YES

Box Car

020

Restore Factory (Sub-Menu):

Use this menu to restore all parameters to the original factory conditions. This will undo any

changes you have made.

Navigate to the Box Car (Sub Menu), use Table 3-9 above for guidance if necessary.

Press enter () and the YES will begin flashing. As in previous examples, use the

buttons to enter YES or NO, and press the enter key () to save.

You can press the exit several times to climb back up to the main menu level or press to

proceed to the next Sub-Menu called Box Car.

Box Car (Sub-Menu):

Use this menu to view or change your current box car value. Navigate to the Change Language

(Sub Menu), use Table 3-9 above for guidance if necessary.

This value is a smoothing or averaging function of the indicated flow rate. This value can be

from 1 to 200. Increasing this value will smooth-out the indicated flow rate more and slow

down the time response slightly.

Decreasing this value will make the indicated flow noisier, but will also speed up the response

time slightly.

Press enter () and the units will begin flashing. As in previous examples, use the

buttons to enter the desired value, and the enter key () to save the value.

Hit the exit key to return to the main top menu.

48

Page 49

Chapter 4: Troubleshooting & Repair

Troubleshooting the Flow Meter

Begin hardware troubleshooting by verifying the following facilities issues are correct. These areas impact system operation and must be

corrected prior to performing any flow meter inspections.

1. Verify the incoming power to the flow meter is present and of the

correct voltage and polarity.

2. Check the flow meter wiring for correct connections as described

in Chapter 2.

3. Verify the flow meter is installed with the correct number of upstream and downstream pipe diameters as shown on page 2-2.

4. Verify the flow direction indicator is correctly aligned pointing

downstream of flow.

5. Make sure there are no leaks in the line being measured.

After verifying the factors above, follow the troubleshooting procedures

outlined on the next page. If you need to return the flow meter to the

factory, see page 4-3 for return shipping instructions

.

49

Page 50

Flow rate below meter’s minimum

flow rating

Flow has exceeded the maximum

range of the flow meter

Contact factory for instructions

Set the user full scale to equal the factory full scale

Reduce flow below the maximum range

shown on the meter’s nameplate or contact the factory for re-calibration advice

No power Turn on power to the flow meter

Problem Possible Cause Solution

Velocity measurement is Very erratic or non-uniform flow Follow installation requirements shown

erratic or fluctuating in Chapter 2

Velocity measurement

seems too high or low

Flow meter installed with less than

required minimum pipe diameters

upstream and downstream of the

sensor

Insertion sensor probe not mounted

securely

Sensor component broken Return to factory for replacement

Malfunction in system Return to factory for evaluation

electronics

Ground loop Check wiring, see Chapter 2

Moisture present in gas flow Install a water trap or filter upstream of

Sensor assembly not aligned correctly to flow

Sensor probe not inserted to the

proper depth

Follow installation requirements shown

in Chapter 2

Sensor probe must be mounted securely without vibration

the flow sensor

Correct alignment with the flow indicator

pointing downstream in the direction of

flow

Verify sensing point is located on the

centerline of the pipe

No response to flow from

sensor assembly

using the Smart Interface software.

Low flow cutoff too high Correct low flow cutoff programming

Flow profile distortions Try to find another location for the meter

Extremely turbulent flow Do not place the meter near a ventilator,

static mixer or valve

Sensor failure Return to factory for evaluation

Printed circuit assembly defective Return to factory for evaluation

50

Page 51

Returning Equipment to Factory

Factory Calibration—All Models

Sierra Instruments maintains a fully-equipped calibration laboratory. All measuring and test

equipment used in the calibration of Sierra transducers are traceable to NIST Standards.

Sierra is ISO-9001 registered and conforms to the requirements of ANSI/NCSL-Z540 and

ISO/IEC Guide 25.

Instructions for Returning Your Instrument for Service

The following information will help you return your instrument to Sierra Instruments'

Factory Service Center and will ensure that your order is processed promptly. Prices may