Sierra Profibus DP 600 Series, Profibus DP 760S, Profibus DP 640S, Profibus DP 700 Series, Profibus DP 780S-UHP Instruction Manual

Page 1

600/700 Series Profibus DP

Instruction Manual

Profibus DP Device Specification for Models:

640S, 760S, 780S, and 780S-UHP

Thermal Mass Flow Meters

Part Number: IM600/700 ProfibusDP Rev.V1

May 2013

Page 2

GLOBAL SUPPORT LOCATIONS: WE ARE HERE TO HELP!

CORPORATE HEADQUARTERS

5 Harris Court, Building L Monterey, CA 93940

Phone (831) 373-0200 (800) 866-0200 Fax (831) 373-4402

www.sierrainstruments.com

EUROPE HEADQUARTERS

Bijlmansweid 2 1934RE Egmond aan den Hoef

The Netherlands

Phone +31 72 5071400 Fax +31 72 5071401

ASIA HEADQUARTERS

Second Floor Building 5, Senpu Industrial Park

25 Hangdu Road Hangtou Town

Pu Dong New District, Shanghai, P.R. China

Postal Code 201316

Phone: + 8621 5879 8521 Fax: +8621 5879 8586

IMPORTANT CUSTOMER NOTICE- OXYGEN SERVICE

Sierra Instruments, Inc. is not liable for any damage or personal injury, whatsoever, resulting from the use of Sierra Instruments standard mass

flow meters for oxygen gas. You are responsible for determining if this mass flow meter is appropriate for your oxygen application. You

are responsible for cleaning the mass flow meter to the degree required for your oxygen flow application.

© COPYRIGHT SIERRA INSTRUMENTS 2012

No part of this publication may be copied or distributed, transmitted, transcribed, stored in a retrieval system, or translated into any

human or computer language, in any form or by any means, electronic, mechanical, manual, or otherwise, or disclosed to third parties

without the express written permission of Sierra Instruments. The information contained in this manual is subject to change without

notice.

TRADEMARKS

SteelMass™, ChlorineTrak™, and FlatTrak™ are trademarks of Sierra Instruments, Inc. Other product and company names listed in this

manual are trademarks or trade names of their respective manufacturers.

Page 3

!

Warnings and Cautions

Warning!

nameplate for specific flow meter approvals before any hazardous location installation.

Warning!

manufacturer of the hot tap equipment and/or the contractor performing the hot tap is responsible for providing proof of such a

permit.

Warning!

Warning!

to a power source and to peripheral devices. Failure to do so could result in injury or death. All AC power connections must be in

accordance with published CE directives.

Warning!

sensors and/or damage to the electronics.

Warning!

Warning!

Agency approval for hazardous location installations varies between flow meter models. Consult the flow meter

Hot tapping must be performed by a trained professional. U.S. regulations often require a hot tap permit. The

All wiring procedures must be performed with the power off.

To avoid potential electric shock, follow National Electric Code safety practices or your local code when wiring this unit

Do not power the flow meter with the sensor remote (if applicable) wires disconnected. This could cause over-heating of the

Before attempting any flow meter repair, verify that the line is de-pressurized.

Always remove main power before disassembling any part of the mass flow meter.

Caution!

control system. Adjustments to the electronics will cause direct changes to flow control settings.

Before making adjustments to the device, verify the flow meter is not actively monitoring or reporting to any master

Caution!

as the main pipeline.

Caution!

You cannot add or subtract wire length without returning the meter to the factory for re-calibration.

Caution!

before installing the meter.

Caution!

Caution!

precautions to minimize the risk of damage:

All flow meter connections, isolation valves and fittings for hot tapping must have the same or higher pressure rating

Changing the length of cables or interchanging sensors or sensor wiring will affect the accuracy of the flow meter.

When using toxic or corrosive gases, purge the line with inert gas for a minimum of four hours at full gas flow

The AC wire insulation temperature rating must meet or exceed 80°C (176°F).

Printed circuit boards are sensitive to electrostatic discharge. To avoid damaging the board, follow these

before handling the assembly, discharge your body by touching a grounded, metal object

handle all cards by their edges unless otherwise required

when possible, use grounded electrostatic discharge wrist straps when handling sensitive components

Page 4

Warning!

Caution!

This statement appears with information that

is important to protect people and equipment

from damage. Pay very close attention to all

warnings that apply to your application.

This statement appears with information that is

important for protecting your equipment and

performance. Read and follow all cautions that

apply to your application.

!

Note and Safety Information

We use caution and warning statements throughout this book to draw your attention to

important information.

Receipt of System Components

When receiving a Sierra mass flow meter, carefully check the outside

packing

carton for

damage incurred in shipment. If the carton is damaged, notify the local carrier and submit a

report to the factory or distributor. Remove the packing slip and check that all ordered

components are present. Make sure any spare parts or accessories are not discarded with

the packing material. Do not return any equipment to the factory without first contacting

Sierra Customer Service

.

Technical Assistance

If you encounter a problem with your flow meter, review the configuration information for

each step of the installation, operation, and setup procedures. Verify that your settings

and adjustments are consistent with factory recommendations. Installation and

troubleshooting information can be found in the SteelMass™ 640S and FlatTrak™ 780S

(includes 760S and 780S-UHP) Series product manuals.

If the problem persists after following the troubleshooting procedures outlined in the 640S or

780S product manuals, contact Sierra Instruments by fax or by E-mail (see inside front

cover). For urgent phone support you may call (800) 866-0200 or (831) 373-0200 between

8:00 a.m. and 5:00 p.m. PST. In Europe, contact Sierra Instruments Europe at +31 20

6145810. In the Asia-Pacific region, contact Sierra Instruments Asia at +

When contacting Technical Support, make sure to include this information:

86-21-58798521.

The flow range, serial number, and Sierra order number (all marked on

the meter nameplate)

The software version (visible at start up)

The problem you are encountering and any corrective action taken

Application information (gas, pressure, temperature and piping configuration)

4

Page 5

Table of Contents

Chapter 1: Introduction ................................................................................................................... 6

Set Up Quick Step Plan ............................................................................................................................... 6

Chapter 2: Field bus installation .................................................................................................... 7

Fieldbus Connector ..................................................................................................................................... 7

Cable ........................................................................................................................................................... 7

Termination .................................................................................................................................................. 9

Status Leds .................................................................................................................................................. 9

Status LED: .................................................................................................................................................. 9

Slave Address ........................................................................................................................................... 10

Dip Switch ................................................................................................................................................... 10

Server Assigned Address ........................................................................................................................... 11

Set Address (126) ....................................................................................................................................... 11

Chapter 3: Configuration .............................................................................................................. 12

GSD File .................................................................................................................................................... 12

Cyclic Data Overview ................................................................................................................................ 12

Cyclic Data Explained ................................................................................................................................ 13

Syscon Software ........................................................................................................................................ 14

Import Device Description Files ................................................................................................................. 14

Configure A Slave ...................................................................................................................................... 15

Create A New Document And Insert A Master: ......................................................................................... 15

Auto Addressing ........................................................................................................................................ 16

Insert A Slave To The System. .................................................................................................................. 17

Download Configuration ............................................................................................................................ 18

Check The Configuration ........................................................................................................................... 20

Kepserverex 4.0 ........................................................................................................................................ 22

GSD File .................................................................................................................................................... 30

5

Page 6

Chapter 1: Introduction

This manual will explain how to add a Sierra flow meter to a Profibus DP network using the Profibus

DP interface. The interface allows access to all relevant data available in the flow meter.

Set Up Quick Step Plan

To successfully add the flow meter to a Profibus DP network you need the following:

Profibus network with a DP master

GSD file

Bitmap files

Connection cable

Power supply (for the flow meter)

Setup steps:

Load GSD

Copy bitmaps

Add slave device to system

Set slave configuration

Set slave station address

Download configuration

Test configuration

6

Page 7

Chapter 2: Field bus installation

PB-GND

3

PB-A (green)

PB-B (red)

EARTH

5

PB-5V

2

Fieldbus

Connector

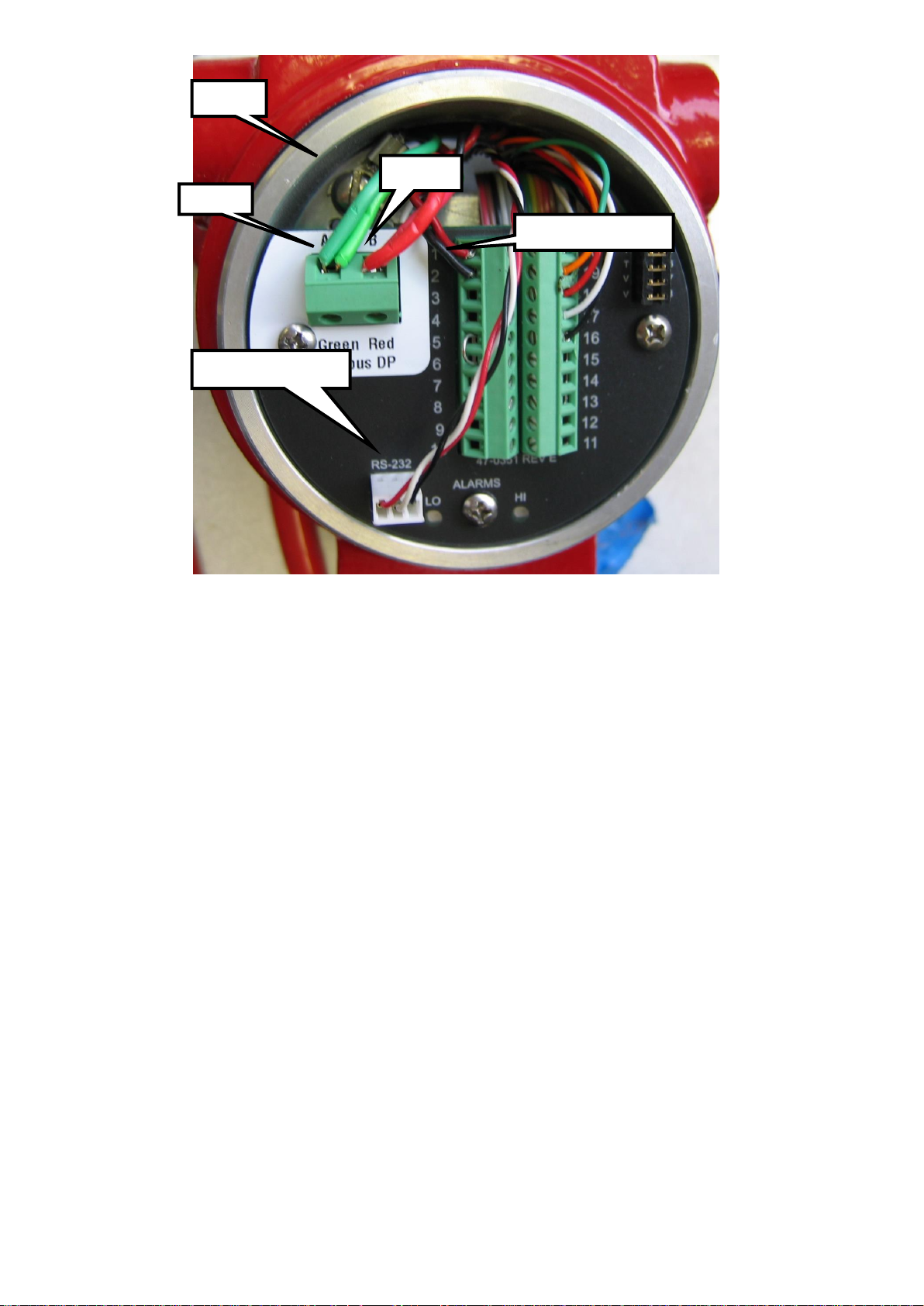

All fieldbus connection for your Smart Meter is made on the right side:

Fieldbus Connector

The Profibus DP network is connected to the chassis female M12 connector (B-coded). The connector

has the following pin configuration:

(Front view)

The Profibus DP network can be connected with a special terminal block connection. This must be

requested at the time of ordering. The down side of this is the PB-5V and PB-GND will not be

available to power a terminator. You should also pull 2 Profibus cables to maintain the daisy chain

topography, to avoid spur lines.

7

Page 8

PB-A

PB-B

Earth

Meter DC Power

RS232 cable

Cable

Profibus cables are shielded twisted-pair copper cables which differ from each other in the type of

wire (fixed/flexible) and/or sheath. The two inner cores of a Profibus cable have green and red

insulation. The specifications in this chapter are primarily intended to provide a general introduction

and describe the cable properties to be considered (see also IEC 61784-5-3). A good cabling guide can

be found online at: http://verwertraining.com/wp-content/uploads/InstallationGuideV9_2.pdf .

The cable must conform to the following specifications:

Impedance: 150 Ohm (nominal) at frequencies from 3 to 20 MHz.

Cable capacitance: < 30 pF per meter.

Core diameter: > 0,34 mm², corresponds to AWG 22.

Cable type: twisted pair cable. 1x2 or 2x2 or 1x4 lines.

Resistance: < 110 Ohm per km.

Signal attenuation: max. 9 dB over total length of line section.

Shielding: CU shielding braid or shielding braid and shielding foil.

Max. Bus length: 200 m at 1500 Kbit/s, up to 1,2 km at 93,75 Kbit/s.

8

Page 9

Termination

Status

Description

Flashing green/red

Initializing

Steady green

Device operational

Flashing red

Recoverable hardware failure

Steady red

Hardware failure – attention required

Status

LED

Network

LED

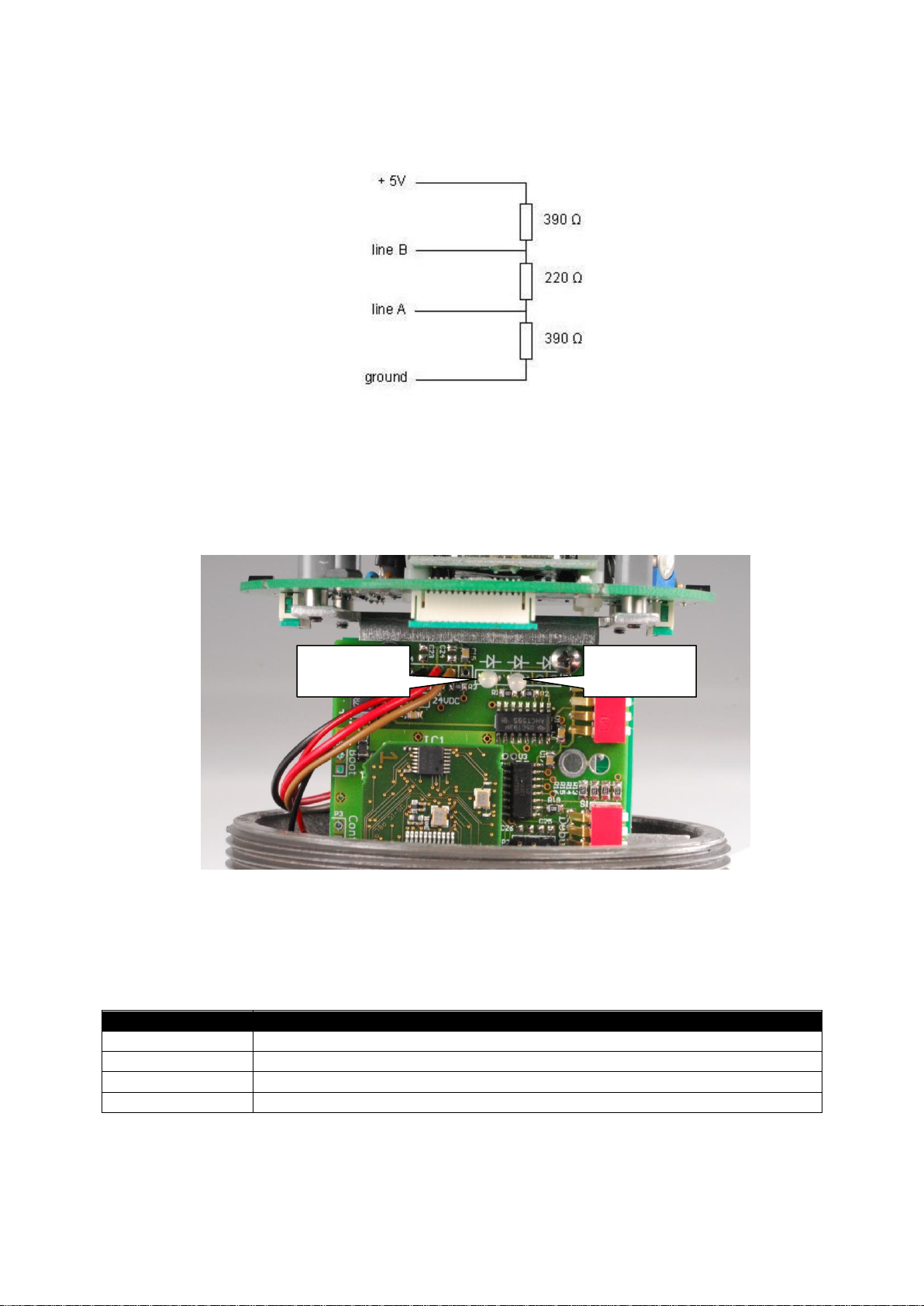

The Profibus physical layer is based on RS-485, and therefore termination resistors are needed at both

ends of the network. The image below shows how to connect the terminators:

Ready-made terminators are available for easy installation.

Status Leds

The interface has two multi-color LED’s mounted inside the enclosure to indicate the status. To access

the LED’s, remove the front cap.

The left LED shows the status of the interface, the right LED shows the network status.

Status LED:

Network LED:

9

Page 10

Status

Description

Off

Not online – waiting for configuration

Steady green

Data exchange

Flashing red

Connection lost

LSB

1 2 4 8

MSB

16 32 64 128

Slave Address

Once the interface is installed, the slave address of the interface can be set. Default instruments will be

delivered with slave address 126. This address has been agreed by the Profibus organization to be free

for installing new devices to the bus. Changing the station address is done in two ways, either through

a dip switch or through the master.

Dip Switch

The dip switches are located inside the meter. Remove the display cover to expose the switches:

The dip switch is binary encoded with the LSB (lowest bit) on the left side. The switch is only read

during power-up.

The switch becomes active when the slider is moved upwards. Here some examples of some addresses

(1 = on/up, 0 = off/down):

10

Page 11

Address

ID

Dip Switch

1 2 3 4 1 2 3 4

1

1|0|0|0||0|0|0|0

14

0|1|1|1||0|0|0|0

60

0|0|1|1||1|1|0|0

125

1|0|1|1||1|1|1|0

Note: An address set with the dip switch has the highest priority and the slave address will use this

address when powering up!

Server Assigned Address

It is possible to change the address of the unit through the server. Perform the following steps to

change the address:

1. Assign a new address from the server

2. Set the dip switch to 128 (pin 8 on) or higher.

The assigned address will be used each time that the unit is powered.

Set Address (126)

It is possible to force the address of the unit to 126. Set the dip switch to zero and power cycle the unit.

The address is set to 126. The address can be changed by the server if needed. Do keep in mind that if

the dip switch remains set to zero, the address will be set to 126 at each power-up.

11

Page 12

Chapter 3: Configuration

Data

Address

Description

Size

(bytes)

Format

0

Flow

4

REAL

4

Totalizer

4

REAL

8

User full scale

4

REAL

12

Factory full scale

4

REAL

16

K-factor

4

REAL

20

Serial number

12

ASCII

32

Flow unit

5

ASCII

37

Totalizer unit

3

ASCII

40

Status

2

INT

42 bytes

GSD File

Each Profibus DP instrument comes with its own GSD-file. The GSD file can be obtained from the

documents and downloads page (http://www.sierrainstruments.com/products/downloads/profibus-dp ).

The GSD file contains the instrument specifications telling the master configuration software which

facilities/features the instrument offers to the Profibus system.

The GSD-file is a text-file containing:

Identification info:

o Model name: “SteelMass™ 640S - Profibus”

o Vendor name: “Sierra Instruments Inc.”

o Identification number: 0x013E

o Bitmap device: “640S_dev”

o Bitmap diagnostics: “640S_dia”

o Bitmap SF: “640S_spf”

(Bitmap files are used in configuration software to indicate instrument status)

Revision numbers

Hardware characteristics:

o VPC3+C dependable properties

Software characteristics:

o Supported features of Profibus: Freeze, Sync, auto baud rate detection

Maximum bus data lengths

Size of used data buffers

Modules with cyclic input / output variables for the instrument.

Cyclic Data Overview

The following table shows the cyclic input & output buffer supported by the device. Module 1 has 42

bytes in of process data in, and 12 bytes out. The actual data address will depend on preceding

devices on your bus. The matrix example below shows the actual data addresses, assuming the

640S/780S is the first device on your Profibus network.

Incoming Cyclic Data (Slave To Master Module 1)

12

Page 13

Data

Address

Description

Size

(bytes)

Format

0

Reset totalizer

4

REAL

4

User full scale

4

REAL

8

K-factor

4

REAL

12 bytes

Outgoing Cyclic Data (Master To Slave Module 1)

Cyclic Data Explained

Flow (R):

Data type: 32 bit floating point (LSB – MSB)

Description: The actual flow as measured by the instrument

Totalizer (R):

Data type: 32 bit floating point (LSB – MSB)

Description: Accumulated flow

User full scale (R):

Data type: 32 bit floating point (LSB – MSB))

Description: The user full scale value allows you to re-range the instrument. Any value between

50% and 100% of the factory full scale is allowed. The new value will also redefine the analog

outputs of the instrument (when used). The 20mA/5 VDC will represent the new full scale value.

Factory Full Scale (R):

Data type: 32 bit floating point (LSB – MSB)

Description: Factory full scale value of the instrument.

K-Factor (R):

Data type: 32 bit floating point (LSB – MSB)

Description: K-factor which can be used to adjust the flow reading

Serial Number (R):

Data type: 16 bits ASCII

Description: Serial number of the instrument (12 characters).

Flow Unit (R):

Data type: 16 bits ASCII

Description: Flow unit of the instrument (5 characters).

Totalizer Unit (R):

Data type: 16 bits ASCII

Description: Totalizer unit of the instrument (3 characters).

Status (R):

Data type: 16 bit integer

Description: Status indicates if the quality of the data in the registers (0 = bad, 1 = good).

Reset Totalizer (W):

Data type: 32 bit floating point (LSB – MSB)

Description: Accumulated flow

13

Page 14

K-Factor (W):

Data type: 32 bit floating point (LSB – MSB)

Description: K-factor which can be used to adjust the flow reading

User Full Scale (W):

Data type: 32 bit floating point (LSB – MSB))

Description: The user full scale value allows you to re-range the instrument. Any value between

50% and 100% of the factory full scale is allowed. The new value will also redefine the analog

outputs of the instrument (when used). The 20mA/5 VDC will represent the new full scale value.

Syscon Software

Sycon is a tool for the configuration of a Fieldbus network using a Hilscher CIF50-PB master. You

may be using different configuration software and hardware Master. However you will need to

accomplish the same functions. No specific slave DTMs of the equipment are available, which are

generated from the device description files, called generic slave DTMs.

Online diagnostic indicators and auto-scan function for the reading of network participants assist in the

commissioning of the network.

This guide will explain step by step how to configure the system to support various fieldbus slaves on

a Hilscher CIF50-PB master.

Before starting make sure that the necessary device description files (GSD & bit maps) are available in

your device catalog. These are available on our web site.

Import Device Description Files

In order to use a fieldbus device its properties need to be added to the server. This is done by

importing the device description files into Sycon.

Start Sycon and create a new document (File -> New)

A dialog window appears asking to select a fieldbus. For this example select Profibus:

The main window is loaded. Go to the file menu and select “Copy GSD”:

14

Page 15

Add master here

Locate the desired GSD file and load it. The GSD data is added to the Sycon library but it isn’t

available yet. Quit the program and restart it to make it available.

Configure A Slave

Create A New Document And Insert A Master:

Place the master at the top of the line. A dialog window appears where a master needs to be selected

from a list. The list shows every type of master supported by Sycon. Select the Profibus master which

has been installed on the PC:

15

Page 16

Leave the station address set to zero. Press the “Add” button and then the “OK” button.

A window pops up showing the driver linked to the selected master. Press “Yes” to use the hardware.

Note: The board ID number changes when extra PCI cards are added to the PC. Older configurations

must be checked before trying to run them.

Auto Addressing

The master needs to be set to auto addressing. Click on the master and from the file menu select

“Settings -> Master configuration”:

Make sure the “Auto addressing” is checked:

16

Page 17

Add slave here

Insert A Slave To The System.

File menu: Insert -> Slave. Place it below the master:

Set the slave filter to “Sierra Instruments Inc.”. Select the desired GSD file, press the “Add” button,

set the slave address and description to match the slave and press the “OK” button.

17

Page 18

Note: If no slave device appears in the window then the GSD file hasn’t been copied into Sycon.

Double click on the added slave in the main window. The slave configuration window appears:

Select the desired modules by double clicking on the module name. Press the “OK” button.

When done save the new configuration to disk (File -> save as).

Download Configuration

The configuration needs to be downloaded to the master (Online -> Download):

18

Page 19

A pop-up may appear warning you that the communication may stop:

Press “Yes” to continue. The data is downloaded to the master:

The system is ready to be used.

19

Page 20

Check The Configuration

To make sure things are working start the debug mode:

If everything is working correctly then the line between the master and the slave will be green and the

bit map shows a green check:

Double click on the slave to see the diagnostic status:

20

Page 21

Press the “OK” button and leave the debug mode (Online -> Stop Debug Mode).

Should the line be red (error) then double click the slave to find out what the problem is:

The diagnostic window gives an indication of a problem, wrong address here:

21

Page 22

In this case the slave is deactivated. Check the address of “Slave1” to see if it matches with the

physical address of the hardware slave.

Correct any error. If the slave address in the configuration is incorrect, adjust it and download the

configuration.

Kepserverex 4.0

You may be using different server software or a PLC. This example shows how to use the

KepserverEx 4.0 free demo software on a windows PC. For your convenience we put a copy on our

web site.

After you have installed the KepserverEx software start a new project.

Click to add a channel.

Give the channel a name. Click Next.

22

Page 23

Choose a Master, we are using a Hilscher CIF50 master. Click, Next.

The defaults will work, click Next.

Chose the board and type, click next.

23

Page 24

You’ll need to import the setup .pb file that we created earlier in Syscon. You may browse to the

location where you saved it. Click on the Browse button.

Browse the 640S flowmeter.pb you just created in Sycon. Once highlighted, click Open.

24

Page 25

You should see this warning.

You can review the summary of the new channel you just created.

You may now add your first slave device. Click on “Click to add a device”

25

Page 26

Give your new device a name.

Set the device ID. ID# 0 was already used for the master, so chose #1.

26

Page 27

The next 2 screens will be fine as default, click next. Choose the device type. Click next.

Review the new device summary, click next.

27

Page 28

Click Finish, you have now created a new device for your network.

You will now need create a Tag to access each piece of Cyclic data, as specified in chapter 3.2. Click

on “Click to add a static tag” and fill in the boxes as above.

The example above is for the flow:

28

Page 29

Flow (R):

Data type: 32 bit floating point (MSB – LSB) Should this be LSB-MSB?

Description: The actual flow as measured by the instrument

Because you only have one device on your network, and the Flow is “Instance ID1”, the Data Address

would be 0. If there were other save devices in your network you would need to add the last Address

of the previous device to the starting address of the new device.

Add a tag name. Address 0 with the data type, in this case IO D 0 S. (32 bit float, byte swapped). Add

a description. Set the Client access to Read Only. Click OK.

Kepserver has a very simple Quick Client that can be used to read and write to device tags. Click the

Hammer icon to start the quick client. When you highlight the profibus master.C100_1 tag, you can

read the flow data (4.756) and quality of the communications.

29

Page 30

GSD File

GSD File Text:

#Profibus_DP

;

; Sierra Instruments Inc.

;

; Version 1.0

;

; This GSD-File is intended for the Smart Meter 640S

; This Unit supports DPV0

;

; Outgoing Cyclic data (slave to master)

;

; Instance ID | Description | Size (bytes) | Format

;---------------+-----------------------+---------------+------; 1 | Flow | 4 | REAL

; 2 | Totalizer | 4 | REAL

; 3 | User full scale | 4 | REAL

; 4 | Factory full scale | 4 | REAL

; 5 | K-factor | 4 | REAL

; 6 | Serial Number | 12 | ASCII

; 7 | Flow unit | 5 | ASCII

; 8 | Totalizer unit | 3 | ASCII

; 9 | Status | 2 | INT

;

; Incoming Cyclic data (master to slave)

;

; Instance ID | Description | Size (bytes) | Format

;---------------+-----------------------+---------------+------; 10 | Reset totalizer | 4 | REAL

; 11 | User full scale | 4 | REAL

; 12 | K-factor | 4 | REAL

;

GSD_Revision = 4

;

Vendor_Name = "Sierra Instruments, Inc."

Model_Name = "Smart Meter 640S - Profibus"

Revision = "V1.0"

Ident_Number = 0x0e13

Protocol_Ident = 0

Station_Type = 0

FMS_supp = 0

Hardware_Release = "Revision H"

Software_Release = "V6.0"

;

9.6_supp = 1

19.2_supp = 1

45.45_supp = 1

93.75_supp = 1

187.5_supp = 1

500_supp = 1

1.5M_supp = 1

3M_supp = 1

6M_supp = 1

12M_supp = 1

;

30

Page 31

MaxTsdr_9.6 = 60

MaxTsdr_19.2 = 60

MaxTsdr_45.45 = 60

MaxTsdr_93.75 = 60

MaxTsdr_187.5 = 60

MaxTsdr_500 = 100

MaxTsdr_1.5M = 150

MaxTsdr_3M = 250

MaxTsdr_6M = 450

MaxTsdr_12M = 800

;

Redundancy = 0

Implementation_Type = "VPC3+C"

Bitmap_Device = "640S_De"

Bitmap_Diag = "640S_Di"

Bitmap_SF = "640S_Sf"

;

Freeze_Mode_supp = 1

Sync_Mode_supp = 1

Auto_Baud_supp = 1

Set_Slave_Add_supp = 1

Min_Slave_Intervall = 1

;

Modular_Station = 0

;

Fail_Safe = 0

Slave_Family = 0 ; General

Max_Diag_Data_Len = 6

;

DPV1_Slave = 1

C1_Read_Write_supp = 0

Max_Initiate_PDU_Length = 52

C2_Read_Write_supp = 1

C2_Max_Data_Len = 80

C2_Response_Timeout = 300

C2_Read_Write_required = 1

C2_Max_Count_Channels = 2

;

DPV1_Data_Types = 0

;

Max_User_Prm_Data_Len = 0

;

; <Module-Definition-List>

Module = "42 bytes in, 12 bytes out" 0xc0,0x8b,0xa9

1

EndModule

31

Page 32

GSD File Cert:

32

Loading...

Loading...