Page 1

Ultrasonic Transducers

XCT-8

Operating Instructions 03/2010

Page 2

Safety Guidelines: Warning notices must be observed to ensure personal safety as well as that of

others, and to protect the product and the connected equipment. These warning notices are

accompanied by a clarification of the level of caution to be observed.

Qualified Personnel: This device/system may only be set up and operated in conjunction with this

manual. Qualified personnel are only authorized to install and operate this equipment in accordance with

established safety practices and standards.

Unit Repair and Excluded Liability:

• The user is responsible for all changes and repairs made to the device by the user or the user’s

agent.

• All new components are to be provided by Siemens Milltronics Process Instruments Inc.

• Restrict repair to faulty components only.

• Do not reuse faulty components.

Warning: Cardboard shipping package provides limited humidity and moisture protection. This product

can only function properly and safely if it is correctly transported, stored, installed, set up, operated, and

maintained.

This product is intended for use in industrial areas. Operation of this equipment in a residential area

may cause interference to several frequency based communications.

Note: Always use product in accordance with specifications.

Copyright Siemens Milltronics Process

Disclaimer of Liability

Instruments Inc. 2010. All Rights Reserved

This document is available in bound version and in

electronic version. We encourage users to purchase

authorized bound manuals, or to view electronic

versions as designed and authored by Siemens

Milltronics Process Instruments Inc. Siemens

Milltronics Process Instruments Inc. will not be

responsible for the contents of partial or whole

reproductions of either bound or electronic versions.

While we have verified the contents of this

manual for agreement with the instrumentation

described, variations remain possible. Thus we

cannot guarantee full agreement. The contents

of this manual are regularly reviewed and

corrections are included in subsequent editions.

Please check the website shown below for the

latest manual revisions.

We welcome all suggestions for improvement.

Technical data subject to change.

MILLTRONICS®is a registered trademark of Siemens Milltronics Process Instruments Inc.

Contact SMPI Technical Publications European Authorized Representative

at the following address:

Technical Publications Siemens AG

Siemens Milltronics Process Instruments Inc. Industry Sector

1954 Technology Drive, P.O. Box 4225 76181 Karlsruhe

Peterborough, Ontario, Canada, K9J 7B1 Deutschland

Email: techpubs.smpi@siemens.com

• For a selection of Siemens Milltronics level measurement manuals, go to:

www. siemens.com/level. Choose Instructions and Manuals under the More Info list.

• For a selection of Siemens Milltronics weighing manuals, go to:

www. siemens.com/weighing. Choose Support, and then Manuals / Operating Instructions.

© Siemens Milltronics Process Instruments Inc. 2010

Page 3

Introduction

This product is intended for use in industrial areas. Operation of this

equipment in a residential area may cause interference to several

frequency based communications.

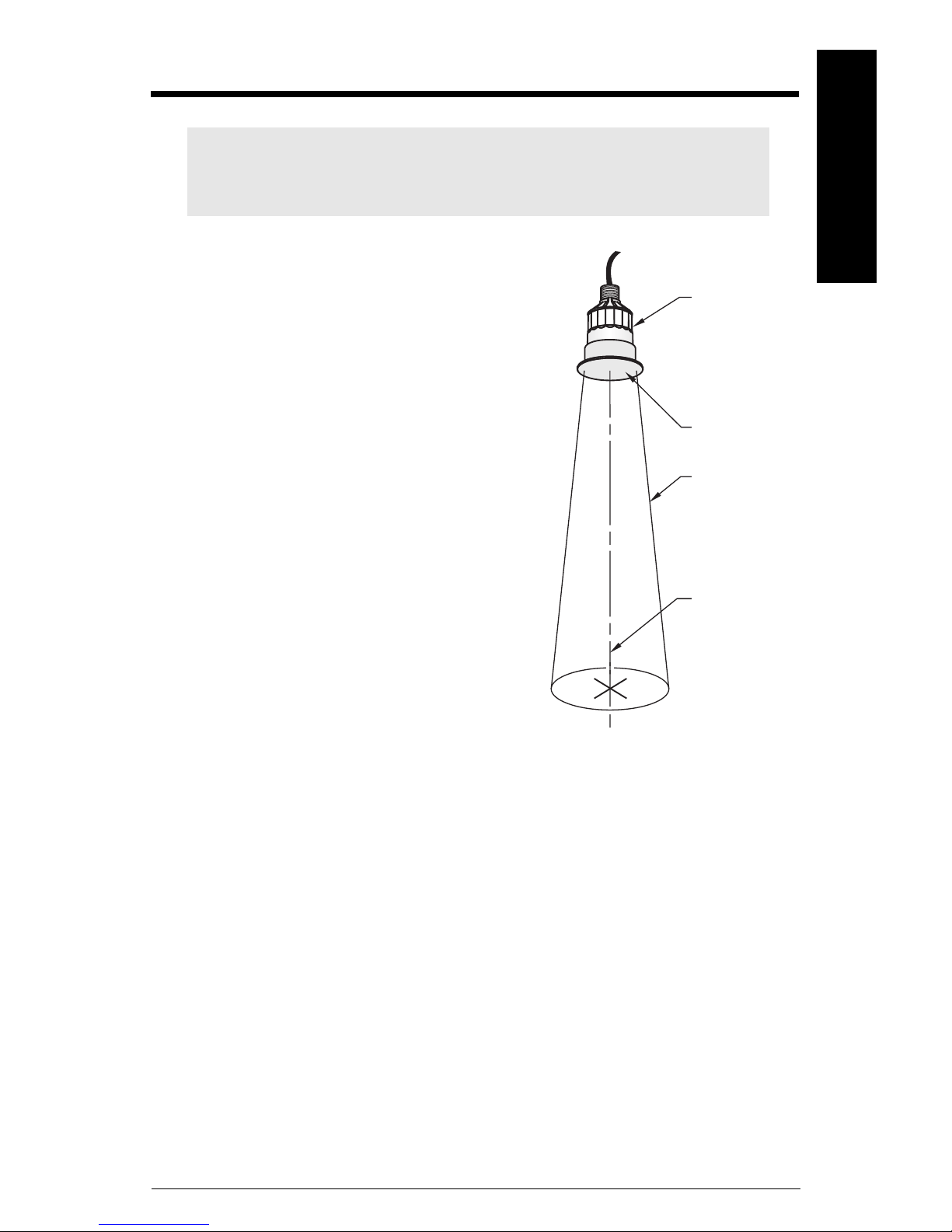

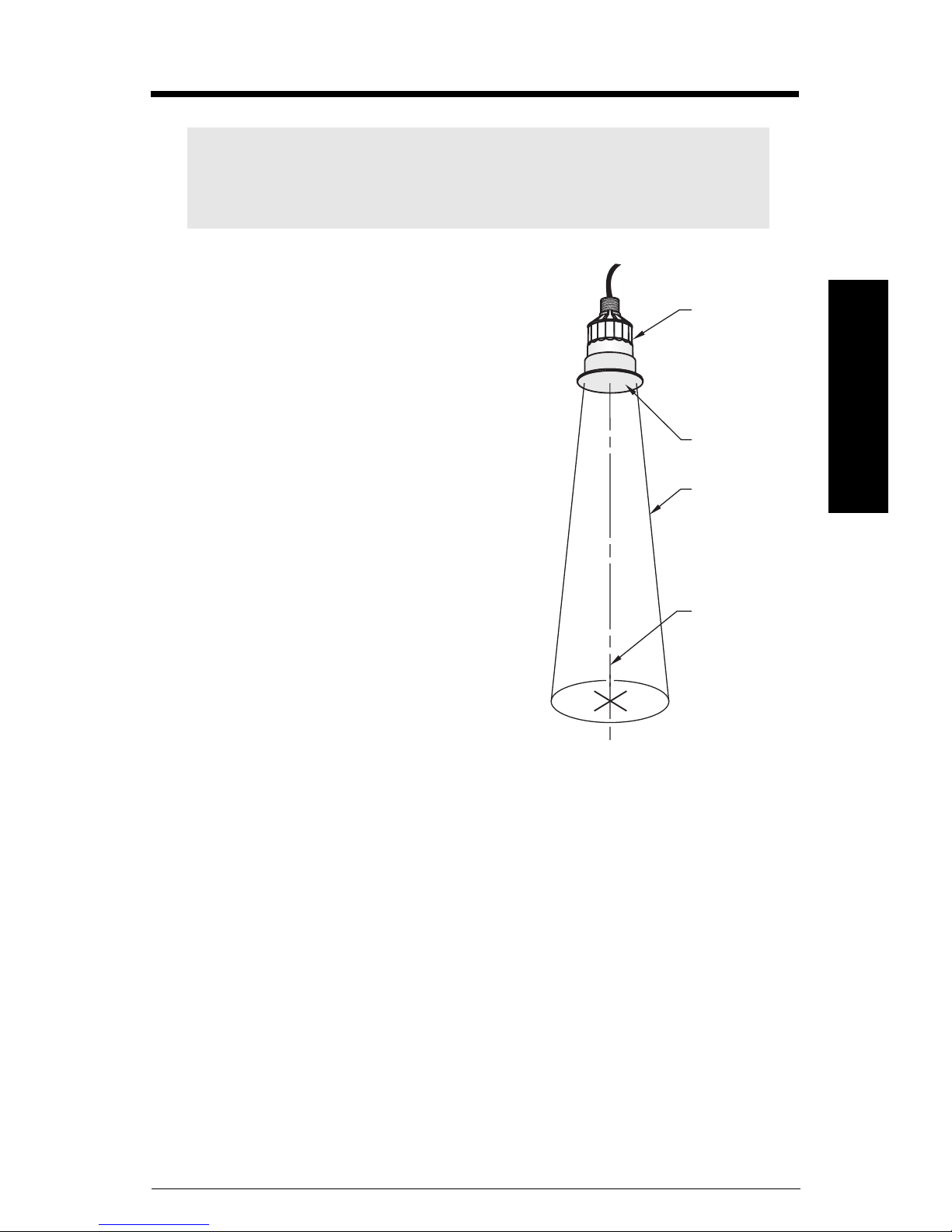

The Echomax XCT-8 transducer operates in

association with Siemens Milltronics ultrasonic

level monitoring products.

The transducer converts electrical pulses

provided by the transceiver to ultrasonic pulses

used for measurement and converts the ultrasonic

echoes back into an electrical signal. The signal is

interpreted by the Siemens Milltronics transceiver

using the patented Sonic Intelligence® algorithms

developed by Siemens Milltronics. The ultrasonic

pulse reduces in power by – 3 dB in a 12° cone

from the transducer face. Keep objects out of this

cone path to reduce the chance of false echoes

being recorded.

English

transducer

transducer

face

– 3 dB

boundary

The XCT-8 transducer incorporates an integral

temperature sensor that reports the ambient

temperature to the transceiver. The connection is

transparent because the ultrasonic and

temperature components of the transducer use

the same leads. This ensures that the Siemens

Milltronics transceiver can automatically

compensate and adjust the speed of sound

constant for varying temperatures.

The PTFE face allows it to be used in the food industry in intense clean-in-place

applications.

Transceivers

The XCT-8 Sanitary transducer is compatible with the following:

• MiniRanger Plus

• MultiRanger 100/200

•HydroRanger 200

• SITRANS LU 01

• SITRANS LU 02

• SITRANS LU 10

•AiRanger SPL

•AiRanger DPL

•AiRanger XPL

axis of

transmission

perpendicular to

transducer face

7ML19985HX62 XCT-8 Sanitary Transducer– INSTRUCTION MANUAL Page EN-1

Page 4

General Guidelines

WARNING: Materials of construction are chosen based on their

chemical compatibility (or inertness) for general purposes. For exposure

to specific environments, check with chemical compatibility charts

English

before installing.

Note: PVDF and PTFE are resistant to attack from most chemicals under the

described operating conditions. However, for exposure to specific environments,

check with chemical compatibility charts before installing the XCT-8 Transducer

in your application.

Maintenance

The XCT-8 requires no special maintenance or cleaning.

Unit Repair and Excluded Liability

All changes and repairs must be done by qualified personnel and applicable safety

regulations must be followed. Please note the following:

• The user is responsible for all changes and repairs made to the device by the user or

by the user’s agent.

• All new components to be provided by Siemens Milltronics Process Instruments Inc.

• Restrict repair to faulty components only.

• Do not re-use faulty components.

Page EN-2 XCT-8 Sanitary Transducer– INSTRUCTION MANUAL 7ML19985HX62

Page 5

Specifications

Measurement Range

• 0.6 m (2 ft) to 8.0 m (26 ft). Dependent on application conditions.

Temperature Range

• – 40 to 125 °C (–40 to 260 °F) at 0.6 m (2 ft)

Beam Angle

•12°

Frequency

•44 kHz

Environmental

• Location: indoor / outdoor

• Ambient temperature: – 40 to 125 °C (–40 to 260 °F)

• Altitude 2000 m maximum

• Pollution degree 4

English

Pressure

• 200 kPa (29 psi)

Temperature Sensor

•Internal

Enclosure

• PVDF with PTFE transducer face

• PTFE flange / ferrule

Mounting

• Base: 4” sanitary fitting clamp

• Conduit: 1” NPT thread or 1” BSP

Cable

• 2-wire twisted pair / braided and foil shielded, 0.55 mm2 (20 AWG), PVC jacket

• Maximum cable run: 365 m (1200 ft)

Approvals

•CE •CSA

7ML19985HX62 XCT-8 Sanitary Transducer– INSTRUCTION MANUAL Page EN-3

US/C

•C-TICK

Page 6

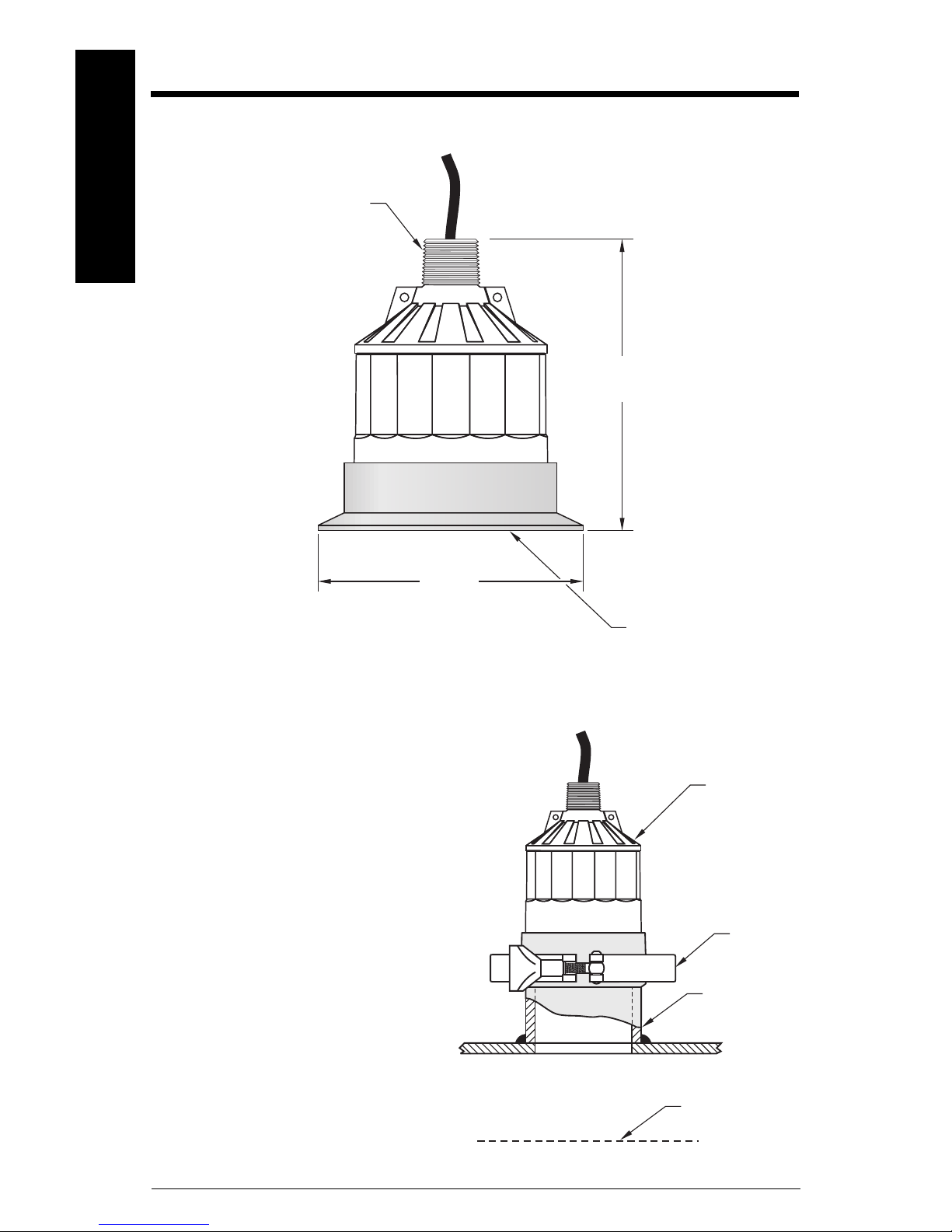

Outline and Dimensions

”

English

1” BSP

or

1” NPT

122 mm

(4.8”)

119 mm

(4.68”)

Ferrule Considerations

The primary customer requirement is

a 4" sanitary ferrule welded to a short

standpipe on the top of the tank. The

inner standpipe wall and ends must

be smooth and free of burrs, ridges,

or seams, and

applicable regulations.

The standpipe extension between

the mating ferrule and the tank top

cannot be longer than the blanking

distance as determined by the

Siemens Milltronics transceiver. The

blanking distance is the minimum

possible measurement range listed in

Specifications

the

must comply with all

on page 3.

radiating PTFE face

XCT-8

transducer

sanitary

clamp

standpipe

topped with 4

ferrule

Do not over tighten the mounting.

Hand tightening of the mounting

hardware is sufficient.

Page EN-4 XCT-8 Sanitary Transducer– INSTRUCTION MANUAL 7ML19985HX62

blanking

distance

Page 7

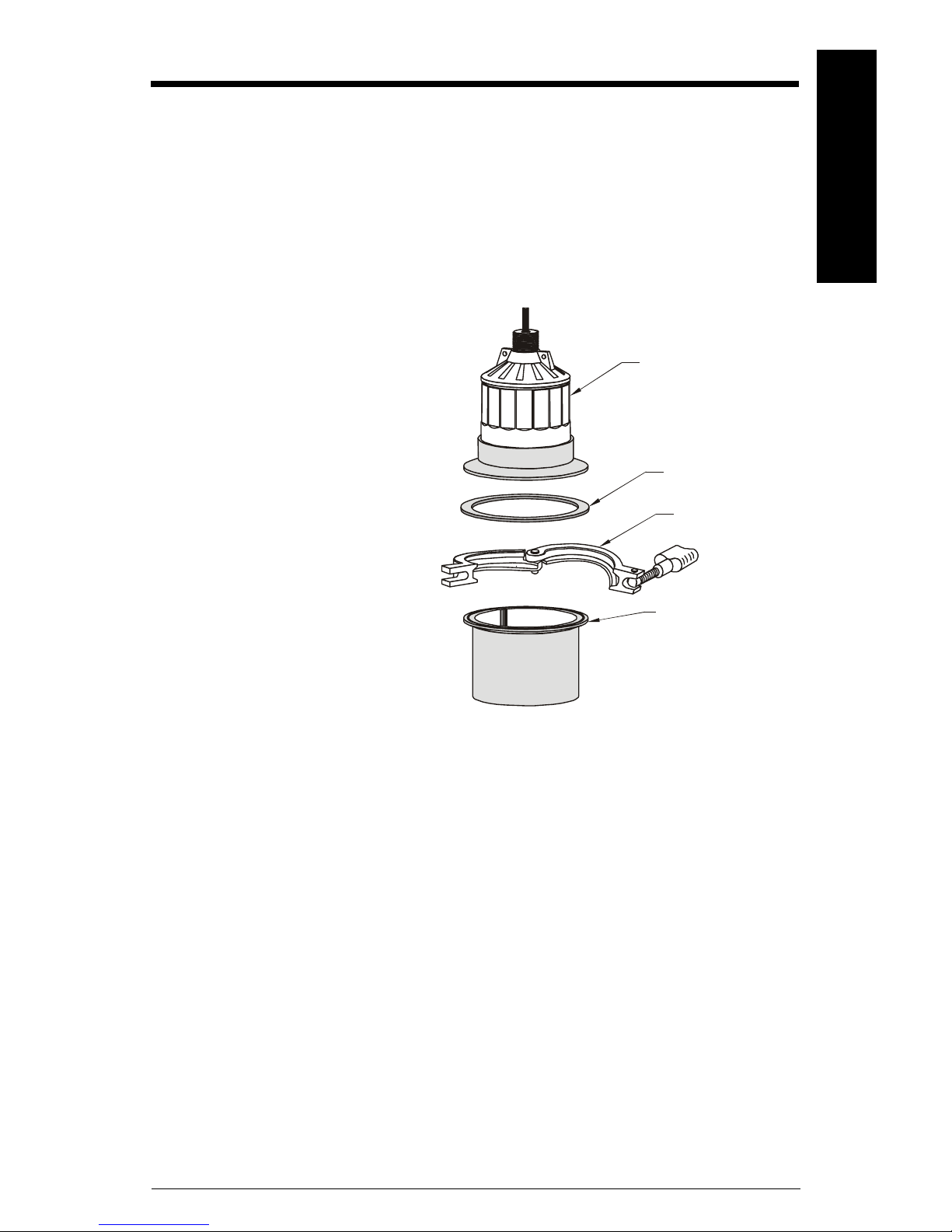

Mounting

Mount the transducer so that it is above the maximum material level by more than the

blanking value to ensure that accurate results are achieved. Refer to the associated

transceiver manual for information on setting the blanking value.

The transducer must be mounted so that the axis of transmission is perpendicular to the

measured surface to get the most reliable signal. See

for an example.

Always use an isolation gasket

(customer supplied) when

mounting the XCT-8. This gasket

reduces ultrasonic energy

coupling to the mounting

hardware.

Transducer must be mounted on a

4” ferrule. Do not mount by conduit

threads.

After applying the sanitary clamp,

adjust the clamp as required to

seal the transducer to the vessel

ferrule. Do not over tighten the

mounting. Hand tightening of the

mounting hardware is sufficient.

Transducer Placement

XCT - 8 transducer

isolating gasket

(customer

supplied)

sanitary clamp

4” sanitary ferrule

on page 7

English

• sanitary clamp – Siemens

Milltronics 7ML1830-1BR

May be substituted with a

clamp meeting these

specifications:

• 4” single hinge, sanitary clamp

• 4.820” interior diameter

•300 psi rated

• sanitary ferrule – customer supplied

Refer to the associated transceiver manual for details on blanking, standpipe length, and

wiring.

7ML19985HX62 XCT-8 Sanitary Transducer– INSTRUCTION MANUAL Page EN-5

Page 8

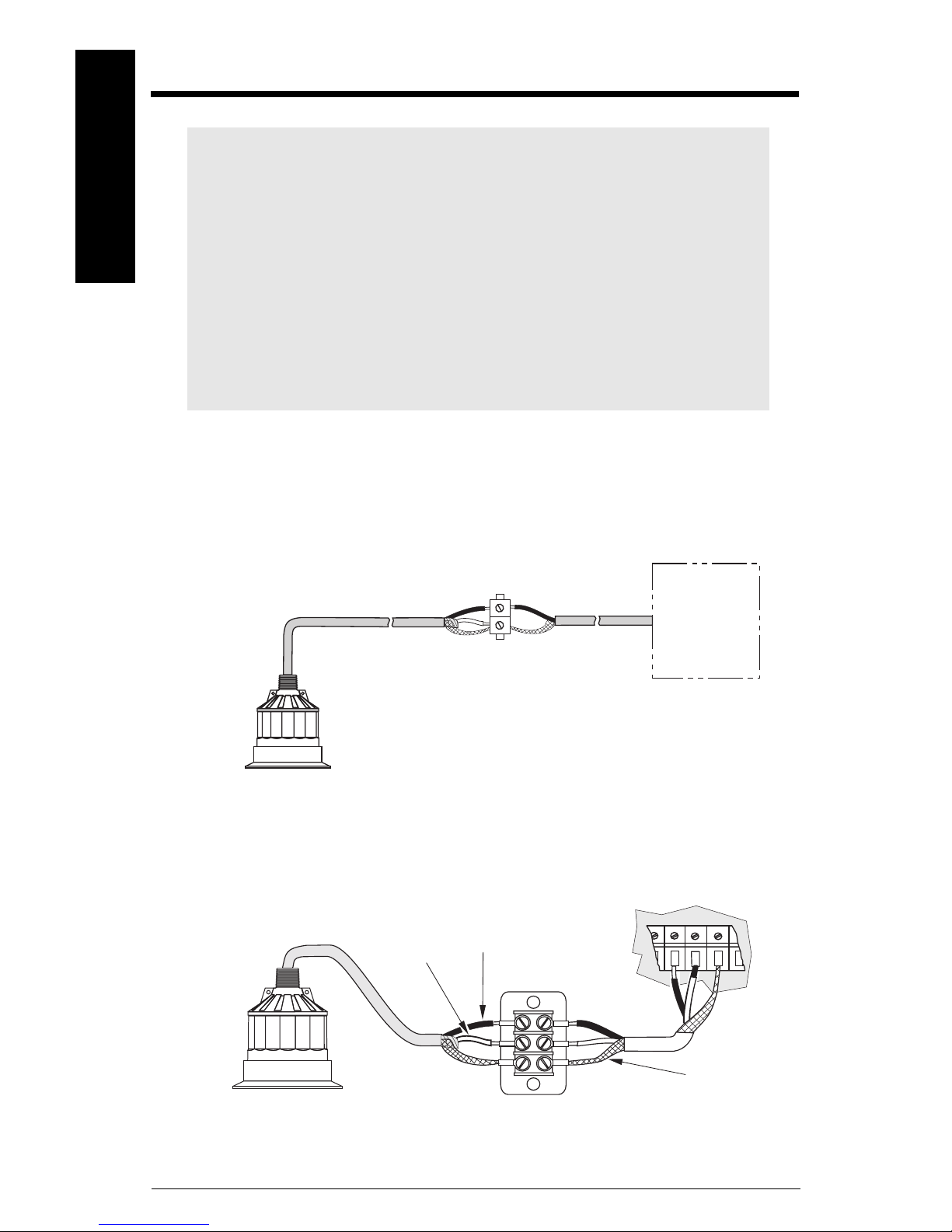

Interconnection

Notes:

• Installation shall only be performed by qualified personnel and in accordance

English

Cable Extension

with local governing regulations.

• Do not route cable openly. Run cable separately in a grounded metal conduit

to protect it from ambient electrical noise.

• Use the supplied shielded, 3-wire cable to connect the transducer to the

Siemens Milltronics transceiver. Supplied cable lengths are 1 m (3 ft).

• Seal all thread connections to prevent the ingress of moisture.

• Do not run cable near high voltage or current runs, contacts, or SCR control

drives.

• The terminal blocks on the transceiver are described in the transceiver

manual.

Applies to the MiniRanger Plus and SITRANS LU/AiRanger series of transceivers.

Connect the supplied cable to a junction box and use RG–62 A/U coaxial cable from there

to the transceiver. This setup is effective for combined runs up to 365 m (1200 ft).

Siemens

Milltronics

transceiver

junction box

Twisted Pair Extension

Applies to the MultiRanger 100/200 transceiver. Extend the cable using 18 AWG shielded /

twisted pair.

black

white

Page EN-6 XCT-8 Sanitary Transducer– INSTRUCTION MANUAL 7ML19985HX62

drain / shield

junction box

Page 9

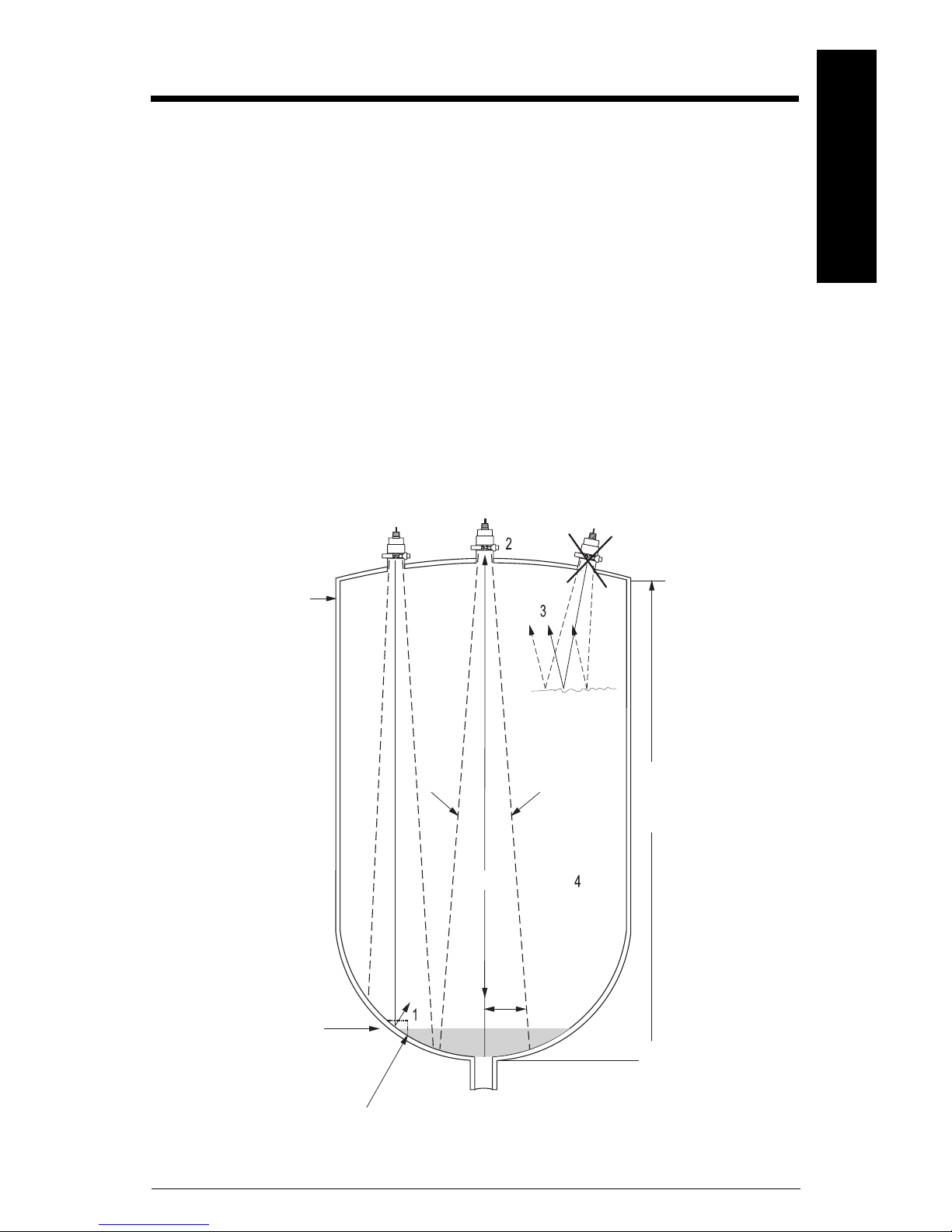

Application

A

Transducer Placement

Locations (See diagram below for reference)

A: Primary location

The preferred location and to be used when possible. The center of the tank generally

gives the most reliable readings as there are fewer obstructions, minimizing false echoes.

B: Alternate location

The alternate location and used if the centre of the tank is already in use or if the tank

roof cannot hold the transducer safely.

C: Poor location

The avoided location. The echoes will reflect away from the transducer face.

English

maintain full fluid

level for full or

offset calibration.

Do not allow

.

material to enter

the blanking zone.

B

C

beam angle

span: distance between

Empty and Full levels in

measurement process.

empty level for B

location. Below this

level the echo reflects

away from the

transducer.

may require target to

obtain empty reading.

7ML19985HX62 XCT-8 Sanitary Transducer– INSTRUCTION MANUAL Page EN-7

run

tank manufacturer’s

empty level.

discharge

Page 10

Placement Notes

Please refer to the tank diagram on the previous page to locate the reference numbers

cited below.

1. Beam should not detect bin bottom.

English

If this occurs use range extension parameters (on transceivers where available) to omit

false echoes. The XCT- 8 transducer operates with a beam angle of 12° and has a rise to

run ratio of approximately 10:1. This means that for every 1m (3.3 ft.) of tank height you

must allow for 0.1m (0.3 ft.) of material surface to reflect the ultrasonic pulses. In most

tanks the transducer should be centered as much as possible (without interference from

inlet) for optimum reading range.

2. Sound beam must be perpendicular to liquid surface.

When mounting the standpipe and ferrule you must ensure that the transducer face is

parallel with the liquid surface.

3. Echo has missed an improperly leveled transducer.

Similar to Note 2, ensure that the standpipe and ferrule are mounted so that the

transducer is face level with the measured liquid.

4. Calibrate under normal conditions.

When performing an empty or full calibration, the tank must contain its normal vapour

and be at its normal temperature.

Notes:

• The transducer is to be used only in the manner outlined in this instruction

manual.

• This transducer is recommended for use with liquids only.

Process Temperature Variations

The PTFE facing is constructed to allow for intense "clean-in-place" applications. When

installing the XCT-8 transducer into a system that uses a high temperature "clean-inplace" process you must account for temperature variations in the transducer.

The temperature sensor’s time constant is 45 minutes. This means that it takes 45 minutes

to change 63.2% of the temperature difference between the transducer and ambient.

Consult your engineering handbook for details on temperature constants.

Page EN-8 XCT-8 Sanitary Transducer– INSTRUCTION MANUAL 7ML19985HX62

Page 11

Einleitung

Dieses Produkt ist vorgesehen zum Gebrauch in Industrieumgebungen. Bei Verwendung in Wohngebieten kann es zu Störungen von

verschiedenen Funkanwendungen kommen.

Die Ultraschallsensoren Baureihe Echomax XCT-8

werden zusammen mit Siemens Milltronics Ultra-

schall-Füllstandmessumformern betrieben.

Der Sensor wandelt die elektrische Energie des

Sendeimpulses vom Messumformer in akustische

Energie um. Die akustische Energie des Echos wird

dann wieder in elektrische Energie für den Messumformer zurückgewandelt. Zur Auswertung des

Signals verwendet der Siemens Milltronics Messumformer die von Siemens Milltronics entwickelte,

patentierte Sonic Intelligence®. Die Leistung des

Ultraschallimpulses nimmt am 12° Schallkegel von

der Sendefläche um –3 dB ab. Innerhalb dieses

Kegels dürfen sich keine Gegenstände befinden,

die als Störechos ausgewertet werden könnten.

Ultraschallsensor

Deutsch

Sensor-

sendefläche

-3db Grenzlinie

Die XCT-8 Sensoren sind mit einem integrierten

Temperaturfühler ausgestattet. Dieser meldet dem

Messumformer die Temperatur am Ultraschallsensor. Der Anschluss ist eindeutig, sowohl Ultraschallals auch Temperaturkomponenten des Sensors verwenden dieselben Adern in der Leitung. Dies

ermöglicht dem Siemens Milltronics Messumformer eine automatische Kompensation der Schallgeschwindigkeitskonstante bei Temperaturschwankungen.

Die Sensorsendefläche aus PTFE ermöglicht den Einsatz des Sensors in Applikationen mit

Reinigungszyklen der Lebensmittelindustrie.

Übertragungsachse, senkrecht zur

Sensorsendefläche

Messumformer

Die XCT-8 Sanitärsensoren sind mit folgenden Messumformern kompatibel:

• MiniRanger Plus

• MultiRanger 100/200

•HydroRanger 200

• SITRANS LU 01

• SITRANS LU 02

• SITRANS LU 10

•AiRanger SPL

•AiRanger DPL

•AiRanger XPL

7ML19985HX62 XCT-8 Sanitärsensor– BETRIEBSANLEITUNG Seite DE-1

Page 12

Allgemeine Richtlinien

WARNUNG: Die Werkstoffe werden entsprechend ihrer chemischen

Beständigkeit (oder Trägheit) für allgemeine Zwecke gewählt. Bei Einsatz

in besonderen Umgebungen prüfen Sie vor Installation die chemische

Beständigkeit anhand einschlägiger Tabellen.

Hinweis: PVDF und PTFE sind unter den beschriebenen Einsatzbedingungen

gegen die meisten Chemikalien beständig. Vor der Installation des XCT-8

Sensors sollten Sie jedoch, bei Einsatz in besonderen Umgebungen, zunächst

die chemische Beständigkeit anhand einschlägiger Tabellen prüfen.

Wartung

Deutsch

Der XCT-8 erfordert keine besondere Wartung oder Reinigung.

Gerätereparatur und Haftungsausschluss

Alle Änderungen und Reparaturen müssen von qualifiziertem Personal unter Beachtung

der jeweiligen Sicherheitsbestimmungen vorgenommen werden. Bitte beachten Sie:

• Der Anwender ist für alle vom Anwender oder seinem Bevollmächtigten

durchgeführten Änderungen und Reparaturen am Gerät verantwortlich.

• Alle neuen Bauteile sind von Siemens Milltronics Process Instruments Inc. bereit zu

stellen.

• Reparieren Sie lediglich defekte Bauteile.

• Defekte Bauteile dürfen nicht wiederverwendet werden.

Seite DE-2 XCT-8 Sanitärsensor– BETRIEBSANLEITUNG 7ML19985HX62

Page 13

Technische Daten

Messbereich

• 0,6 m (2 ft) bis 8,0 m (26 ft). Applikationsabhängig.

Temperaturbereich

• – 40 bis 125 °C (–40 bis 260 °F) bei 0,6 m (2 ft)

Schallkegel

•12°

Frequenz

•44 KHz

Umgebungsbedingungen

• Montage: innen / im Freien

• Umgebungstemperatur: –40 bis 125 °C (–40 bis 260 °F)

• Höhe max. 2000 m

• Verschmutzungsgrad 4

Deutsch

Druck

• 200 kPa (29 psi)

Temperaturfühler

• Integriert

Gehäuse

• PVDF mit Sensorsendefläche aus PTFE

• PTFE Flansch / Gegenflansch

Montage

• Sockel: 4" Clamp-Anschluss

• Leitung: 1" NPT Gewinde oder 1" BSP

Kabel

• 2-adrig verdrilltes Paar/Litze, geschirmt, 0,55 mm2 (20 AWG) PVC-Mantel

• Max. Kabellänge: 365 m (1200 ft)

Zulassungen

•CE •CSA

7ML19985HX62 XCT-8 Sanitärsensor– BETRIEBSANLEITUNG Seite DE-3

•C-TICK

US/C

Page 14

Maßbilder

Deutsch

1” BSP

oder

1” NPT

122 mm

(4,8”)

Gegenflansch

Kundenanforderung ist ein 4" SanitärGegenflansch, der an ein kurzes

Standrohr oben auf dem Behälter

angeschweißt wird. Die Innenseite

des Standrohrs muss glatt sein (ohne

Schweiß-, Gussnähte oder sonstige

Verstrebungen) und allen gültigen

Richtlinien entsprechen.

Die Höhe des Standrohrs vom

Gegenflansch bis zur Behälterdecke

darf die im Siemens Milltronics Messumformer bestimmte Nahbereichsausblendung nicht überschreiten. Die

Nahbereichsausblendung entspricht

dem minimalen Abstand zum zu messenden Material; siehe

auf Seite 3.

Daten

Bei der Montage (mit Conduit) nicht

zu stark anziehen. Handfest ist ausreichend.

Technische

119 mm

(4,68”)

Sensorsendefläche

aus PTFE

XCT-8 Sensor

SanitärClamp

Standrohr

mit 4" Gegenflansch

Ausblendungsabstand

Seite DE-4 XCT-8 Sanitärsensor– BETRIEBSANLEITUNG 7ML19985HX62

Page 15

Montage

Um präzise Messwerte zu erhalten, beachten Sie bei der Sensormontage einen Mindestabstand zum maximalen Materialfüllstand entsprechend der Nahbereichsausblendung.

Angaben zur Einstellung der Ausblendung finden Sie in der zugehörigen Betriebsanleitung

des Messumformers.

Für eine maximale Signalzuverlässigkeit ist der Sensor so anzubringen, dass die Übertragungsachse senkrecht zur Flüssigkeitsoberfläche steht. Ein Beispiel finden Sie unter

des Sensors

Für die Montage des XCT-8 ist

immer eine Isolierdichtung (vom

Kunden geliefert) zu verwenden.

Diese Dichtung stellt eine optimale

Anpassung des Sensors an den

Montageflansch sicher und

gewährleistet genaue Messergebnisse.

Die Sensormontage muss auf

einem 4" Gegenflansch erfolgen.

Der Sensor darf nicht über Einschraubgewinde montiert werden.

auf Seite 8.

XCT-8 Sensor

Isolierdichtung

(kundenseitig)

Sanitär-Clamp

Einbau

Deutsch

Bringen Sie den Sanitär-Clamp an

und stellen Sie ihn nach Bedarf ein,

bis der Sensor hermetisch dicht am

Gegenflansch befestigt ist. Bei der

Montage nicht zu stark anziehen.

Handfest ist ausreichend.

• Sanitär-Clamp – Siemens

Milltronics 7ML1830-1BR

Kann durch ein Clamp mit folgenden Eigenschaften ersetzt werden:

• 4" Sanitär-Clamp mit Einzelscharnier

• Innendurchmesser 4,820”

• Nenndruck 300 psi

• Sanitär-Gegenflansch – kundenseitig

Genaue Angaben zu Ausblendung, Standrohrlänge und Anschluss finden Sie in der

Betriebsanleitung des verwendeten Messumformers.

Sanitär-Gegenflansch 4”

7ML19985HX62 XCT-8 Sanitärsensor– BETRIEBSANLEITUNG Seite DE-5

Page 16

Anschluss

Hinweise:

• Die Installation darf nur durch qualifiziertes Personal und unter Beachtung

der örtlichen, gesetzlichen Bestimmungen durchgeführt werden.

• Die Kabel sollten nicht offen verlegt werden. Zur optimalen Störsicherheit

sind die Kabel getrennt in einem geerdeten Metallrohr zu verlegen.

• Zum Anschluss des Sensors an den Siemens Milltronics Messumformer

verwenden Sie das mitgelieferte, geschirmte 3-adrige Kabel. Das Kabel wird

in einer Länge von 1 m (3 ft) geliefert.

• Alle Gewindeanschlüsse sind so abzudichten, dass das Eindringen von

Feuchtigkeit verhindert wird.

• Vermeiden Sie eine Leitungsführung in der Nähe von Hochspannungs-,

Motorleitungen, Schaltschützen oder Frequenzumrichtern (SCR

Steuerantriebe).

Deutsch

Kabelverlängerung

• Eine Beschreibung der Klemmblöcke des Messumformers finden Sie in der

Betriebsanleitung des Messumformers.

Bezieht sich auf die Messumformer der Baureihe MiniRanger Plus und SITRANS LU/AiRanger. Schließen Sie das mitgelieferte Kabel an einen Anschlusskasten an und verwenden Sie

von da ab ein RG-62 A/U Koaxialkabel bis zum Messumformer. Diese Anordnung gilt für

eine Gesamtlänge von 365 m (1200 ft).

Siemens

Milltronics

Messumformer

Anschlusskasten

Seite DE-6 XCT-8 Sanitärsensor– BETRIEBSANLEITUNG 7ML19985HX62

Page 17

Verlängerung mit verdrillter Leitung

Bezieht sich auf den Messumformer MultiRanger 100/200. Kabelverlängerung unter Verwendung von geschirmtem Kabel mit verdrilltem Aderpaar, 18 AWG.

Anschlusskasten

schwarz

weiß

Schirm

Anschlusskasten

Deutsch

7ML19985HX62 XCT-8 Sanitärsensor– BETRIEBSANLEITUNG Seite DE-7

Page 18

Applikation

A

Einbau des Sensors

Einbaustellen (Siehe Zeichnung unten)

A. Bevorzugte Einbaustelle

Der Sensor sollte nach Möglichkeit an dieser Stelle montiert werden. Die Behältermitte

ergibt die zuverlässigsten Messwerte, da weniger Einbauten vorhanden sind, durch die

Störechos entstehen könnten.

B: Ausweichlösung

Diese Einbaustelle ist geeignet, wenn die Behältermitte nicht frei ist oder die Tankdecke zu

Deutsch

schwach ist, um den Sensor sicher zu montieren.

C: Schlechte Einbaustelle

Vermeiden Sie diese Einbaustelle, da die Echos verspiegelt werden.

Für eine Voll- oder

Nullpunktkalibrierung den Füllstand

auf 100% halten.

.

Das Material darf

nicht in den Ausblendungsbereich

gelangen.

B

C

Schallkegel

Messbereich: Abstand

zwischen Min. und Max.

Füllstand im Prozess.

Nullpunkt für die Ausweichlösung B.

Unterhalb dieses Füllstands kann sich das

Echo vom Sensor verspiegeln.

Reflektorplatte kann notwendig

sein, um Nullpunkt stabil zu halten.

Seite DE-8 XCT-8 Sanitärsensor– BETRIEBSANLEITUNG 7ML19985HX62

Radius

Nullpunkt des

Behälters laut

Herstellerangabe.

Austrag

Page 19

Anmerkungen zu den Einbaustellen

Die Nummern im Folgenden beziehen sich auf die Zeichnung der vorigen Seite.

1. Der Behälterboden sollte nach Möglichkeit nicht erfasst werden.

Falls der Behälterboden erfasst wird, sind die Störechos mittels der Parameter zur

Endbereichserweiterung (bei Messumformern mit entsprechender Funktion)

auszublenden. Der Schallkegel des XCT-8 Sensors beträgt 12°, mit einem Verhältnis

Anstieg:Radius von ca. 10:1. Das bedeutet, dass für 1 m (3,3 ft) Behälterhöhe mit einer

Materialoberfläche von 0,1 m (0,3 ft) für die Reflexion der Ultraschallimpulse gerechnet

werden muss. In den meisten Tanks wird der optimale Messwert durch eine mittige

Montage (ohne Störung durch die Befüllung) erreicht.

2. Die Schallkeule muss senkrecht zum Flüssigkeitsspiegel sein.

Bei einer Montage mit Standrohr und Gegenflansch muss darauf geachtet werden, dass

die Sensorsendefläche parallel zur Flüssigkeitsoberfläche steht.

3. Echoverspiegelung aufgrund eines falschen Sensoreinbaus.

Wie unter Punkt 2 muss auch hier darauf geachtet werden, dass die Sensorsendefläche

parallel zur Flüssigkeitsoberfläche ist.

4. Kalibrierung unter normalen Betriebsbedingungen.

Bei einer Kalibrierung des Null- oder Vollpunkts muss der Behälter unter normalen

Bedingungen (Dampf, Temperatur, ...) betrieben werden.

Hinweise:

• Der Sensor darf nur gemäß den Anweisungen in dieser Betriebsanleitung

verwendet werden.

• Dieser Ultraschallsensor sollte nur zur Messung von Flüssigkeiten eingesetzt

werden.

Temperaturschwankungen im Prozess

Deutsch

Die Sensorsendefläche aus PTFE ist für den Einsatz in Applikationen mit Reinigungszyklen

geeignet. Wird der XCT-8 Sensor in einem System mit Reinigungsprozess bei Hochtemperaturen eingesetzt, so müssen die Temperaturschwankungen im Sensor berücksichtigt werden.

Die Zeitkonstante des Temperaturfühlers beträgt 45 Minuten. Demnach dauert es 45 Minuten, bis 63,2% der Temperaturdifferenz zwischen Sensor und Umgebung kompensiert werden. Angaben zu Temperaturkonstanten finden Sie in Ihrem Handbuch der

Verfahrenstechnik.

7ML19985HX62 XCT-8 Sanitärsensor– BETRIEBSANLEITUNG Seite DE-9

Page 20

Deutsch

Seite DE-10 XCT-8 Sanitärsensor– BETRIEBSANLEITUNG 7ML19985HX62

Page 21

Introducción

Este aparato se ha diseñado para el uso en ámbito industrial. El uso

de este aparato en instalaciones residenciales puede causar

interferencias a las comunicaciones por radio.

El transductor ultrasónico Echomax XCT-8 se

utiliza con los transmisores de nivel Siemens

Milltronics.

El sensor convierte la energía eléctrica de la

pulsación emitida por el transmisor en energía

acústica, y convierte la energía acústica del eco

de retorno en energía eléctrica. El transmisorreceptor Siemens Milltronics interpreta esta señal

mediante los algoritmos patentados Sonic

TM

Intelligence

acústica se reduce (– 3 dB) en un cono de 12° de

la superficie emisora del sensor. Mantener este

cono de emisión libre de obstrucciones para

limitar el registro de falsos ecos.

de Siemens Milltronics. La potencia

sensor

ultrasónico

superficie

emisora (cara)

límite -3dB

El sensor XCT-8 incorpora un sensor de

temperatura que informa al transmisor de la

temperatura ambiente. Se trata de una conexión

transparente ya que los componentes

relacionados con el ultrasonido y con la variable

temperatura utilizan los mismos conductores. Ello

garantiza asimismo la compensación y el ajuste

automático de la velocidad del sonido con el

transmisor Siemens Milltronics cuando se presentan variaciones de temperatura.

El sensor dispone de una superficie emisora de PTFE para aplicaciones con alimentos y

ciclos intensivos de limpieza.

eje de

transmisión,

irradiado

axialmente de la

cara del sensor

Transmisores

El sensor sanitario XCT-8 es funcionalmente compatible con:

• MiniRanger Plus

• MultiRanger 100/200

•HydroRanger 200

• SITRANS LU 01

• SITRANS LU 02

• SITRANS LU 10

•AiRanger SPL

•AiRanger DPL

•AiRanger XPL

Español

7ML19985HX62 Sensor sanitario XCT-8– INSTRUCCIONES DE SERVICIO Página ES-1

Page 22

Indicaciones generales

ADVERTENCIA: Los materiales de construcción son seleccionados en

base a su compatibilidad química (o inertidad) para usos generales.

Antes de instalar los sensores en ambientes específicos recomendamos

consulte las tablas de compatibilidad química.

Nota: Los materiales PVDF y PTFE son inmunes a la mayoría de substancias

químicas, en condiciones nominales de funcionamiento. Antes de instalar el

sensor XCT-8 en ambientes específicos recomendamos consulte las tablas de

compatibilidad química.

Mantenimiento

El sensor XCT-8 no necesita mantenimiento o limpieza.

Reparaciones y límite de responsabilidad

Sólo el personal calificado está autorizado a intervenir en este equipo. Las

modificaciones y reparaciones deberán efectuarse respetando los códigos de práctica

aplicables. Nota importante:

Español

• El usuario es el único responsable de las modificaciones y reparaciones en el

dispositivo efectuadas por él mismo o por su agente.

• Recomendamos utilizar sólo recambios originales Siemens Milltronics Process

Instruments Inc.

• Reparar sólo los componentes defectuosos.

• No reutilizar los componentes defectuosos.

Página ES-2 Sensor sanitario XCT-8– INSTRUCCIONES DE SERVICIO 7ML19985HX62

Page 23

Especificaciones técnicas

Rango de medida

• 0,6 m (2 ft) - 8,0 m (26 ft), según la aplicación.

Rango de temperatura

• – 40 a 125 °C (–40 a 260 °F) a 0,6 m (2 ft)

Ángulo de haz

•12°

Frecuencia

•44 KHz

Condiciones ambientales

• Ubicación: montaje interior/a prueba de intemperie

• Temperatura ambiente: – 40 a 125 °C (–40 a 260 °F)

• Máxima altitud 2000 m

• Grado de contaminación 4

Presión

Español

• 200 kPa (29 psi)

Sensor de temperatura

• Incorporado

Caja

• PVDF con superficie emisora de PTFE

• Brida/férula PTFE

Montaje

• Base: abrazadera sanitaria 4”

• Conducto: rosca 1” NPT o 1” BSP

Cable

• 2 conductores trenzado apantallado con blindaje, 0.55 mm2 (20 AWG), cubierta de PVC

• Máxima separación: 365 m (1200 ft)

Certificaciones

•CE •CSA

7ML19985HX62 Sensor sanitario XCT-8– INSTRUCCIONES DE SERVICIO Página ES-3

NRTL/C

•C-TICK

Page 24

Esquema de dimensiones

1" BSP

o bien

1" NPT

122 mm

(4,8”)

Español

Férula

119 mm

(4,68")

Muchos usuarios solicitan una férula

sanitaria de 4", soldada en un tubo

vertical corto, en la parte superior del

depósito. Es imprescindible

comprobar la ausencia de costuras y

puntos de soldeo en la superficie

interior del tubo vertical. La

instalación deberá cumplir con los

requisitos aplicables.

La instalación no deberá tener una

extensión (férula/parte superior del

depósito) superior a la zona muerta

definida por el transmisor-receptor

Siemens Milltronics. La zona muerta

corresponde al rango de medida

mínimo indicado en las

Especificaciones

, página 3.

superficie emisora de

PTFE

sensor XCT-8

abrazadera

sanitaria

tubo vertical

férula 4”

zona muerta

No apretar excesivamente durante el

montaje. Apretar el material

manualmente.

Página ES-4 Sensor sanitario XCT-8– INSTRUCCIONES DE SERVICIO 7ML19985HX62

Page 25

Montaje

Para máxima fiabilidad instalar el sensor a una distancia por lo menos equivalente a la

zona muerta, por encima del nivel más alto de material. El usuario encontrará más

información sobre el ajuste de la zona muerta en el manual de instrucciones del

transmisor de nivel.

Para maximizar la fiabilidad de las señales, instalar el sensor para que el eje de

transmisión sea perpendicular a la superficie del material. Ver la sección

sensor

, página 7.

Es imprescindible montar el XCT-8

con una junta de estanqueidad

(proporcionada por el cliente). Esta

junta permite optimizar el montaje

y la transmisión de la energía

ultrasónica.

Instalar el sensor ultrasónico en

una ferula de 4”. No instalar el

sensor por medio de las roscas.

sensor XCT-8

Colocación del

junta de

estanqueidad

(proporcionada

por el cliente)

Una vez colocada la abrazadera

sanitaria, efectuar los ajustes

necesarios para garantizar el sello

sensor/férula (depósito). No

apretar excesivamente durante el

montaje.

Apretar el material manualmente.

• Abrazadera sanitaria –

Siemens Milltronics

7ML1830-1BR

Se puede sustituir por una abrazadera que cumpla con las siguientes

especificaciones:

• abrazadera sanitaria 4” de articulación sencilla

• diámetro interior 4,820”

•300 psi

• Férula sanitaria – proporcionada por el cliente

Para más detalles sobre la zona muerta, la longitud del tubo vertical y el cableado ver el

manual de operación del transmisor.

abrazadera

sanitaria

férula sanitaria 4”

Español

7ML19985HX62 Sensor sanitario XCT-8– INSTRUCCIONES DE SERVICIO Página ES-5

Page 26

Interconexiones

Notas:

• Sólo el personal calificado está autorizado a intervenir en este equipo para la

instalación. Observar las indicaciones y los procedimientos de seguridad.

• Instalar protecciones adecuadas para los cables. Instalar los cables

separadamente en tuberías metálicas conectadas a tierra, para tener mayor

inmunidad al ruido ambiental.

• Se recomienda utilizar el cable proporcionado (1 m (3 ft) cable de 3

conductores blindado) para conectar el sensor al transmisor Siemens

Milltronics.

• Sellar todas las conexiones herméticamente para evitar infiltración y

humedad.

• Evitar la instalación del cable cerca de fuentes de alta tensión o alta

intensidad, contactores y sistemas de control, SCR.

• Los bloques de terminales del transmisor-receptor están descritos en el

manual de operación.

Extensión de cable

Para conectar el sensor y los transmisores MiniRanger Plus o AiRanger. Conectar el

cable proporcionado a una caja de conexión. Utilizar un cable coaxial RG–62 A/U para

conectar la caja de conexión y el transmisor. Con este tipo de instalación se admiten

separaciones de hasta 365 m (1200 ft).

Español

caja de conexión

Extensión con cable de par trenzado

Sólo para el transmisor MultiRanger 100/200. Para extensiones de cables, utilizar cable

de par trenzado/apantallado 18 AWG

negro

blanco

transmisor-receptor

Siemens Milltronics

Página ES-6 Sensor sanitario XCT-8– INSTRUCCIONES DE SERVICIO 7ML19985HX62

drenaje/blindaje

caja de conexión

Page 27

Aplicación

A

Ubicación del sensor ultrasónico

Emplazamientos (para más detalles véase la descripción a continuación)

A: Emplazamiento preferido

Emplazamiento recomendado para todas las aplicaciones. La ausencia de obstrucciones

en la parte central del depósito minimiza los falsos ecos y optimiza la fiabilidad de las

medidas.

B: Emplazamiento alternativo

Emplazamiento elegido si el sensor no se puede instalar en la parte central del depósito,

o cuando el techo del depósito no está diseñado para soportar el peso del sensor.

C: Emplazamiento inadecuado

Ubicación inapropiada del sensor. Refleja los ecos lejos de la superficie emisora del

sensor ultrasónico.

la calibración del nivel

proceso lleno o del

desfase precisa

mantener el máximo

.

nivel de líquido en el

depósito. Para ello es

imprescindible no

penetrar la zona

muerta.

B

C

ángulo de

haz

Español

span: distancia entre el

nivel proceso vacío y el

nivel proceso lleno.

nivel proceso vacío para

el emplazamiento B. El

eco se refleja lejos de la

superficie emisora del

sensor por debajo de

este nivel.

puede ser necesario definir

el blanco para medir el nivel

proceso vacío.

7ML19985HX62 Sensor sanitario XCT-8– INSTRUCCIONES DE SERVICIO Página ES-7

run

valor proceso vacío

definido por el

fabricante del depósito.

descarga

Page 28

Notas acerca del emplazamiento

Para más detalles sobre los números de referencia indicados a continuación véase por

favor el diagrama del depósito en la página precedente.

1. Es imprescindible evitar la detección del fondo del depósito.

De no ser posible, utilizar los parámetros de extensión del rango (disponibles en ciertos

transmisores) para no tomar en cuenta los falsos ecos. El sensor XCT- 8 funciona

produciendo un haz de emisión de 12° y una relación flecha/recorrido de 10:1

aproximadamente. Asimismo para obtener la reflexión de los pulsos deberá garantizarse

0,1 m (0,3 ft.) de material por cada metro (3,3 ft.) de altura del depósito. En muchos casos

para garantizar el correcto funcionamiento habrá que comprobar que el sensor esté bien

centrado respecto al depósito (sin interferencias tipo entrada de material).

2. Montar el sensor para que el eje de transmisión sea perpendicular a la

superficie del líquido.

Durante el montaje del tubo vertical y de la férula, asegurarse de que la superficie

emisora del sensor esté paralela a la superficie del líquido.

3. El montaje incorrecto del sensor impide la recepción del eco.

Similar a la Nota 2: durante el montaje del tubo vertical y de la férula comprobar que la

cara del sensor sea paralela a la superficie del líquido.

4. Efectuar la calibración en condiciones de funcionamiento normales.

Realizar la calibración del nivel proceso lleno o vacío en condiciones de funcionamiento

Español

normales: comprobar la concentración de vapor y la temperatura en el depósito.

Notas:

• Es imprescindible seguir las instrucciones proporcionadas en este manual.

• Este sensor está diseñado para su uso en aplicaciones con líquidos.

Variaciones de la temperatura de proceso

La superficie emisora de PTFE está diseñada especialmente para aplicaciones con ciclos

intensivos de limpieza. La instalación del sensor XCT-8 en aplicaciones que combinen

ciclos intensivos de limpieza con altas temperaturas requiere tomar en consideración las

variaciones de temperatura presentes en el sensor.

El sensor de temperatura está diseñado con una constante de tiempo de 45 minutos.

Asimismo se necesitan 45 minutos para compensar 63,2% de la diferencia observada

entre la temperatura del sensor y la temperatura ambiente. Para más detalles sobre las

constantes (temperatura) consulte las reglas de ingeniería.

Página ES-8 Sensor sanitario XCT-8– INSTRUCCIONES DE SERVICIO 7ML19985HX62

Page 29

Introduction

Cet instrument est conçu pour une utilisation en milieu industriel.

Utilisé en zone résidentielle, cet appareil peut provoquer des

perturbations des communications radio.

Le transducteur Echomax XCT-8 est relié aux

contrôleurs de niveau ultrasoniques Siemens

Milltronics.

Le transducteur convertit l'énergie électrique de

l'impulsion transmise et reçue du transmetteur, en

énergie acoustique. L'énergie acoustique de

l'écho est ensuite convertie en énergie électrique.

Le transmetteur Siemens Milltronics met en

oeuvre les algorithmes brevetés Sonic

Intelligence®de Siemens Milltronics pour le

traitement du signal. La puissance de l'impulsion

ultrasonique est réduite de – 3 dB dans un cône

de 12° de la face émettrice du transducteur.

Garder cette zone libre de toute obstruction pour

éviter de détecter des échos parasites.

Le transducteur XCT-8 est équipé d'un capteur

conçu pour mesurer la température ambiante et la

transmettre au transmetteur de niveau. Cette

connexion est transparente : les éléments relatifs

à l'ultrason et à la température utilisent les

mêmes fils de sortie. On obtient ainsi une

compensation automatique de la vitesse du son

avec le transmetteur Siemens Milltronics, indépendamment des variations de

température.

Ce transducteur comporte une face émettrice en PTFE adaptée à l'industrie alimentaire

et aux applications comportant des cycles de nettoyage intensifs.

transducteur

face émettrice

du transducteur

limite -3dB

axe de

transmission

perpendiculaire

à la face

émettrice

Français

Transmetteurs de niveau

Le transducteur sanitaire XCT-8 est compatible avec les transmetteurs suivants :

• MiniRanger Plus

• MultiRanger 100/200

•HydroRanger 200

• SITRANS LU 01

• SITRANS LU 02

7ML19985HX62Transducteur sanitaire XCT-8– INSTRUCTIONS DE SERVICE Page FR-1

• SITRANS LU 10

•AiRanger SPL

•AiRanger DPL

•AiRanger XPL

Page 30

Consignes générales

AVERTISSEMENT : Ce système est conçu avec des matériaux choisis

en fonction de leur compatibilité chimique, pour une exploitation

générale. Se reporter aux tableaux de compatibilité avant toute

utilisation dans un environnement spécifique.

Note : En conditions de fonctionnement nominales, le PVDF et le PTFE résistent

à la plupart des substances chimiques. Veuillez consulter les tableaux de

compatibilité chimique avant toute installation du transducteur XCT-8 dans un

environnement spécifique.

Maintenance

Le transducteur XCT-8 ne requiert pas de maintenance ou de nettoyage particulier.

Réparation de l’unité et limite de responsabilité

Toute modification ou réparation doit être effectuée par un personnel qualifié.

Veuillez respecter les consignes de sécurité. Remarques importantes :

• Toute modification ou réparation du système effectuée par l'utilisateur ou par son

mandataire sera placée sous la responsabilité de l'utilisateur.

• Utiliser seulement des composants fournis par Siemens Milltronics Process

Instruments Inc.

• Réparer uniquement les composants défectueux.

• Les composants défectueux ne doivent pas être réutilisés.

Français

Page FR-2 Transducteur sanitaire XCT-8– INSTRUCTIONS DE SERVICE 7ML19985HX62

Page 31

Caractéristiques techniques

Plage de mesure

• 0,6 m (2 ft) à 8,0 m (26 ft) ; en fonction des conditions dans l'application.

Plage de température

• – 40 à 125 °C (–40 à 260 °F), à 0,6 m (2 ft)

Angle du faisceau

•12°

Fréquence

•44 KHz

Caractéristiques environnementales

• Montage : en intérieur / extérieur

• Température ambiante : – 40 à 125 °C (–40 à 260 °F)

• Altitude : 2000 m maximum

• Degré de pollution 4

Pression

• 200 kPa (29 psi)

Capteur de température

•Interne

Boîtier

• PVDF, face émettrice en PTFE

• Bride PTFE / collier

Montage

• Base : clamp sanitaire 4”

• Conduit : filetage 1” NPT ou 1” BSP

Câble

• 2 conducteurs paire torsadée/blindée, feuille métallique 0,55 mm2 (20 AWG), gaine PVC

• Longueur max. du câble : 365 m (1200 ft)

Français

Homologations

•CE •CSA

7ML19985HX62Transducteur sanitaire XCT-8– INSTRUCTIONS DE SERVICE Page FR-3

US/C

•C-TICK

Page 32

Encombrement

1” BSP

ou

1” NPT

122 mm

(4,8”)

119 mm

(4,68”)

Informations concernant le collier

Le transducteur est généralement

utilisé avec un collier sanitaire 4",

soudé sur un manchon court, situé

sur la partie supérieure du réservoir.

Les parois intérieures et les

extrémités du manchon doivent être

lisses, sans bavures, stries ou

soudures, et doivent répondre aux

dispositions applicables.

Français

La longueur du manchon situé entre

le collier et la partie supérieure du

réservoir ne doit pas être supérieure

à la zone morte définie pour le

transmetteur Siemens Milltronics.

La zone morte correspond à la valeur

minimale de la portée (plage de

mesure) indiquée dans les

Caractéristiques,

page 3.

face émettrice en PTFE

transducteur

XCT-8

clamp

sanitaire

manchon

équipé d'un

collier 4”

zone morte

Eviter un serrage excessif. Le

serrage manuel du matériel est

généralement suffisant.

Page FR-4 Transducteur sanitaire XCT-8– INSTRUCTIONS DE SERVICE 7ML19985HX62

Page 33

Montage

Pour obtenir des mesures fiables, installer le transducteur au dessus du niveau maximum

du matériau, à une distance supérieure à la zone morte. Pour plus de détails sur le

réglage de la zone morte se reporter au manuel d'utilisation du transmetteur associé au

transducteur.

Pour optimiser la fiabilité du signal, installer le transducteur de sorte que l'axe de

transmission soit perpendiculaire à la surface mesurée. Pour plus de détails se reporter à

la section

Il est impératif de toujours utiliser

le transducteur XCT-8 avec un joint

d'isolation (fourni par le client). Ce

joint optimise le montage

transducteur/piquage et la

transmission des signaux

ultrasoniques.

Installer le transducteur sur un

collier 4”. Ne pas fixer le

transducteur avec le filetage

conduit.

Positionnement du transducteur,

page 7.

transducteur XCT-8

joint d'isolation

(fourni par le client)

clamp sanitaire

Installer le clamp sanitaire et

l'ajuster tel que nécessaire pour

garantir le montage étanche

transducteur/réservoir (collier).

Eviter un serrage excessif. Le

serrage manuel du matériel est

généralement suffisant.

• Clamp sanitaire – Siemens Milltronics 7ML1830-1BR

Peut être substitué avec un clamp avec les caractéristiques suivantes :

• clamp sanitaire 4” à charnière simple

• diamètre intérieur 4,820”

•300 psi

• Joint sanitaire – fourni par le client.

Pour plus de détails sur la zone morte, la longueur de la rehausse et le câblage, se

reporter au manuel d'utilisation du transmetteur.

collier sanitaire 4”

Français

7ML19985HX62Transducteur sanitaire XCT-8– INSTRUCTIONS DE SERVICE Page FR-5

Page 34

Interconnexions

Notes :

• L'installation doit être effectuée par un personnel qualifié, en accord avec les

dispositions locales en vigueur.

• Le cheminement du câble doit être effectué avec des protections adaptées.

Installer le câble sous conduit métallique mis à la terre, sans aucun autre

câble, et le protéger des bruits électriques ambiants.

• Connecter le transducteur au transmetteur Siemens Milltronics avec le câble

3 conducteurs blindé fourni. L'unité est livrée avec 1 m de câble (3 ft).

• Assurer un serrage hermétique des connexions pour éviter toute humidité

d'infiltration.

• Eviter l'installation du câble près de sources haute tension ou haute

intensité, contacteurs et systèmes de commande à thyristors.

• Les borniers de connexion du transmetteur sont illustrés dans le manuel

d'utilisation associé.

Extension câble

Utilisable pour les transmetteurs MiniRanger Plus ainsi que la série de transmetteurs

AiRanger et SITRANS LU. Relier le câble fourni à la boîte de jonction puis utiliser un câble

coaxial RG–62 A/U pour la liaison boîte de jonction - transmetteur. Ce type d'installation

est conseillé pour les extensions de câble jusqu'à 365 m (1200 ft).

Extension paire torsadée

Français

Utilisable pour le transmetteur MultiRanger 100/200. Pour les extensions, utiliser un câble

paire blindée/torsadée (18 AWG)

blanc

transmetteur

Siemens

Milltronics

boîte de jonction

noir

Page FR-6 Transducteur sanitaire XCT-8– INSTRUCTIONS DE SERVICE 7ML19985HX62

drain/blindage

boîte de jonction

Page 35

Application

A

Positionnement du transducteur

Emplacement (cf. schéma ci-dessous pour plus de détails)

A: Emplacement recommandé

Installation recommandée, quel que soit le type d'application. L'installation du

transducteur sur la partie centrale du réservoir permet d'optimiser la mesure en limitant

les obstructions et les échos parasites associés.

B: Emplacement acceptable

Ce type d'installation convient lorsque la partie centrale du réservoir n'est pas

accessible, ou lorsque le toit du réservoir ne peut pas supporter le poids du transducteur.

C: Emplacement à éviter

Ce type d'installation n'est pas conseillé. Les echos seront réfléchis loin de la face

émettrice du transducteur.

Maintenir le

niveau plein

(100%) pour

l'étalonnage du

.

100% ou du

décalage. Le

matériau liquide ne

doit pénétrer la

zone morte.

B

C

Angle du

faisceau

Portée : distance entre le

0% (vide) et le 100% (plein

dans le processus de

mesure.

Français

Niveau 0% pour

emplacement B. En

dessous de ce niveau,

l'écho sera réfléchi

loin du transducteur.

Une cible peut être nécessaire

pour obtenir la lecture du niveau

7ML19985HX62Transducteur sanitaire XCT-8– INSTRUCTIONS DE SERVICE Page FR-7

Por tée

Niveau 0% établi par le

fabricant du réservoir.

Sortie produit

Page 36

Consignes relatives au positionnement

Veuillez consulter le schéma sur la page précédente pour repérer les numéros de

référence indiqués ci-dessous.

1. Le faisceau ne doit pas détecter le fond du réservoir.

Dans ce cas, utiliser les paramètres d'extension de la plage de mesure (disponibles sur

certains transmetteurs de niveau) pour ignorer les échos parasites. L'angle d'émission

du transducteur XCT- 8 est de l'ordre de 12°. Il croît dans une proportion de 10:1. Par

conséquent, un niveau minimum de 0,1 m (0,3 ft.) de matériau est requis pour chaque

mètre (3,3 ft.) de hauteur du réservoir. Dans la plupart des cas, pour optimiser la précision

il faut centrer le transducteur le plus possible sur le toit du réservoir, et éviter toute

interférence avec l'entrée de produit.

2. Le faisceau d'émission doit être perpendiculaire à la surface du liquide.

Lorsque le transducteur doit être fixé sur un ensemble rehausse/collier, s'assurer que sa

face émettrice soit perpendiculaire à la surface du liquide mesuré.

3. Installation incorrecte du transducteur : écho réfléchi non reçu.

Similaire à la Note 2 : installer l'ensemble rehausse/collier de sorte que la face émettrice

du transducteur soit parallèle au liquide mesuré.

4. Effectuer l'étalonnage en conditions de fonctionnement normales.

Avant l'étalonnage du niveau vide/plein, vérifier que les conditions à l'intérieur du

réservoir soient normales (température, vapeur, ...).

Notes :

• Le transducteur doit être utilisé suivant les instructions fournies dans ce

manuel.

• Ce transducteur est spécialement conçu pour les applications avec des

liquides.

Variations de la température de process

La face émettrice en PTFE est conçue pour les applications sanitaires avec des cycles de

Français

nettoyage intensifs. En exposant le transducteur XCT-8 à des cycles de nettoyage

associés à des hautes températures, il est nécessaire de compenser les variations de

température.

La constante de temps du capteur de température est 45 minutes. Par conséquent, le

capteur requiert 45 minutes pour compenser 63,2% de l'écart de température entre le

transducteur et la température ambiante. Veuillez consulter les données d'ingénierie

pour plus de détails sur les constantes de température.

Page FR-8 Transducteur sanitaire XCT-8– INSTRUCTIONS DE SERVICE 7ML19985HX62

Page 37

Page 38

www.siemens.com/processautomation

For more information

www.siemens.com/level

www.siemens.com/continuous-weighing

Siemens Milltronics Process Instruments Inc.

Industry Automation (IA)

1954 Technology Drive

P.O. Box 4225

Peterborough, ON

Canada K9J 7B1

email: techpubs.smpi@siemens.com

www.siemens.com/processautomation

Subject to change without prior notice

7ML19985HX62 Rev. 2.0

© Siemens Milltronics Process Instruments Inc. 2010

*7ml19985HX62*

Printed in Canada

Loading...

Loading...