Page 1

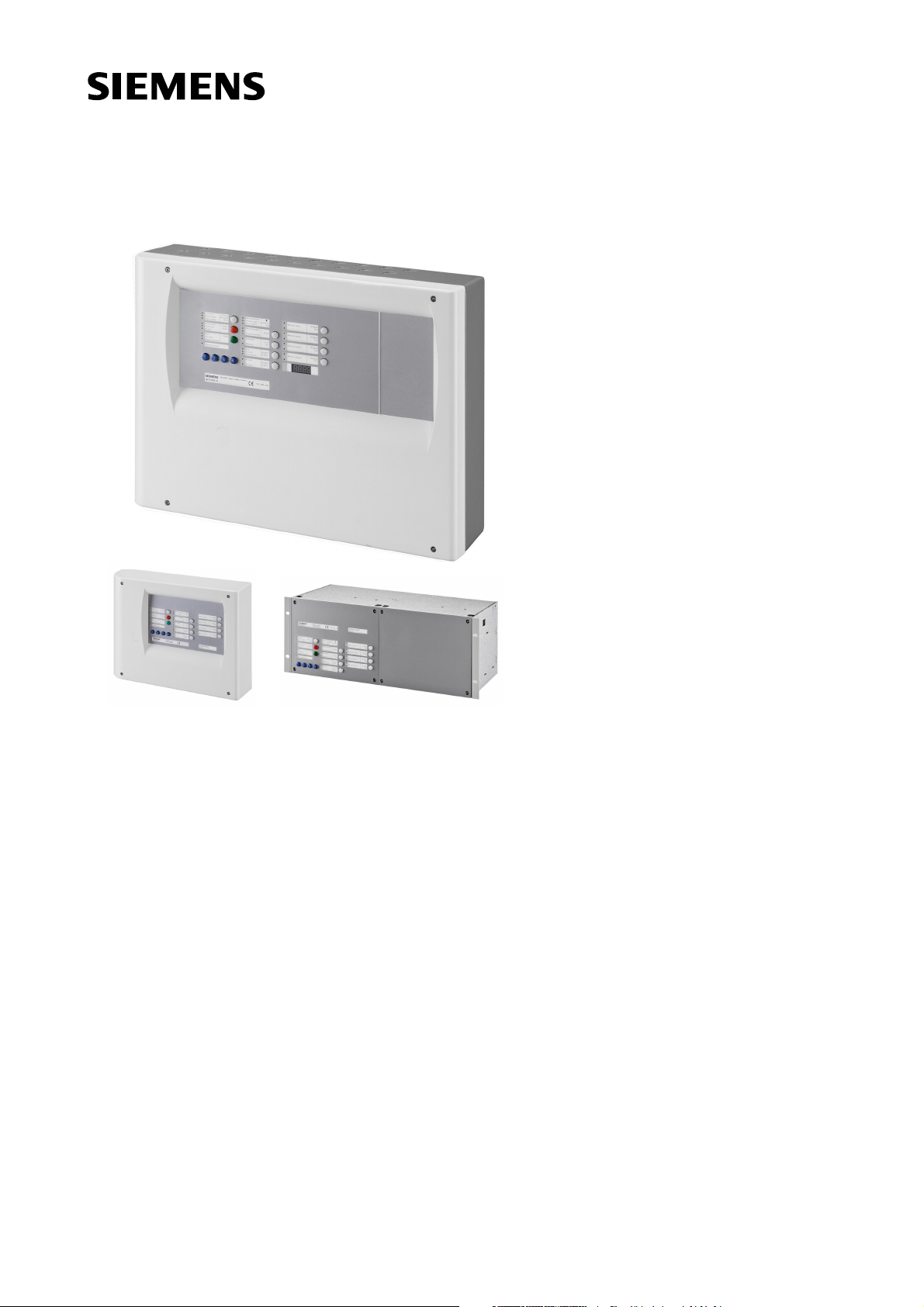

XC10

Extinguishing control unit

XC1001-A / XC1005-A /

XC1003-A

Installation

Commissioning

Maintenance

MP2.1

Building Technologies

Fire Safety & Security Products

Page 2

Liefermöglichkeiten und technische Änderungen vorbehalten.

Data and design subject to change without notice. / Supply subject to availability.

Sous réserve de modifications techniques et de la disponibilité.

© 2010 Copyright by

Siemens Switzerland Ltd

Wir behalten uns alle Rechte an diesem Dokument und an dem in ihm dargestellten Gegenstand vor. Der Empfänger anerkennt diese

Rechte und wird dieses Dokument nicht ohne unsere vorgängige schriftliche Ermächtigung ganz oder teilweise Dritten zugänglich machen

oder außerhalb des Zweckes verwenden, zu dem es ihm übergeben worden ist.

We reserve all rights in this document and in the subject thereof. By acceptance of the document the recipient acknowledges these rights

and undertakes not to publish the document nor the subject thereof in full or in part, nor to make them available to any third party without our

prior express written authorization, nor to use it for any purpose other than for which it was delivered to him.

Nous nous réservons tous les droits sur ce document, ainsi que sur l'objet y figurant. La partie recevant ce document reconnaît ces droits et

elle s'engage à ne pas le rendre accessible à des tiers, même partiellement, sans notre autorisation écrite préalable et à ne pas l'employer

à des fins autres que celles pour lesquelles il lui a été remis.

Page 3

1 About this document ..............................................................................7

2 Safety instructions..................................................................................9

2.1 Danger levels ............................................................................................9

2.2 Safety instructions.....................................................................................9

2.3 Standards and directives complied with..................................................10

3 Standards...............................................................................................11

4 Overview ................................................................................................12

4.1 XC1001-A................................................................................................12

4.2 XC1005-A................................................................................................13

4.3 XC1003-A................................................................................................14

4.4 FCP1004-E .............................................................................................15

4.5 XCM1002 ................................................................................................16

4.6 User interface..........................................................................................18

5 Features .................................................................................................21

6 Installation .............................................................................................22

6.1 XC1001-A / XC1005-A ............................................................................22

6.2 XC1003-A................................................................................................24

6.3 User interface labels ...............................................................................28

7 Connections ..........................................................................................29

7.1 Mains.......................................................................................................29

7.2 Batteries ..................................................................................................29

7.3 Fire detectors/Manual release control buttons........................................30

7.4 Monitored inputs......................................................................................31

7.4.1 Monitored input 1 ....................................................................................31

7.4.2 Monitored input 2 ....................................................................................31

7.4.3 Monitored input 3 ....................................................................................32

7.4.4 Monitored input 4 ....................................................................................32

7.5 Control inputs ..........................................................................................33

7.6 Monitored control outputs .......................................................................34

7.6.1 Monitored control output 1 ......................................................................35

7.6.2 Monitored control output 2 ......................................................................35

7.6.3 Monitored control output 3 ......................................................................35

7.6.4 Monitored control output 4 ......................................................................36

7.6.5 Monitored control output 5 ......................................................................37

7.7 Programmable outputs............................................................................38

7.7.1 Driver outputs..........................................................................................38

7.7.2 Relay outputs ..........................................................................................39

7.8 24V power supply output ........................................................................39

8 Multi-sector installation........................................................................40

8.1 Operationg principle ................................................................................40

8.1.1 Example ..................................................................................................40

8.1.2 XCA1031 common module description...................................................41

8.1.3 XCA1030 Individual module description .................................................42

8.2 Multiple flooding zones modules overview .............................................43

8.3 Multiple flooding zones modules assembly and connection...................44

8.4 Multisector modules technical specification............................................45

9 Accessories ...........................................................................................46

3

Building Technologies A6V10257473_b_en_--.doc

Fire Safety & Security Products 01.2010

Page 4

9.1 FCA1007 – Key switch............................................................................46

9.2 FDCI222 / FDCIO222 – Input/output interfaces......................................46

9.3 Remote transmitter..................................................................................46

10 Operating access levels .......................................................................47

10.1 Operating access level 1.........................................................................47

10.2 Operating access level 2.........................................................................47

10.3 Operating access level 3A ......................................................................47

10.4 Operating access level 3B ......................................................................47

11 Extinguishing process diagrams ........................................................48

12 Programming .........................................................................................49

12.1 Before starting.........................................................................................49

12.2 Presettings ..............................................................................................50

12.3 Steps 01 to 04 – Time duration settings .................................................52

12.4 Step 05 - Sounders .................................................................................53

12.5 Steps 06 to 09 - Remote transmission....................................................53

12.6 Steps 10 to 14 - Monitored outputs 1 to 5 ...............................................54

12.7 Steps 15 to 19 - Relay contact 1 to 5 ......................................................55

12.8 Steps 20 to 27 – Driver outputs 1 to 8 ....................................................56

12.9 Steps 28 to 31 - Monitored inputs 1 to 4 .................................................57

12.10 Steps 32 to 38 - Reset ............................................................................58

12.11 Steps 39 to 43 - Operation ......................................................................58

12.12 Steps 44 to 47 - Faults ............................................................................59

12.13 Steps 48 to 51 – Non monitored control inputs 1 to 4.............................59

12.14 Steps 52 to 55 - Detection zones ............................................................60

12.15 Steps 56 to 57 – Operating access level ................................................60

12.16 Step 58 – Multi-sector .............................................................................61

12.17 Step 59 - Detectors .................................................................................61

13 Commissioning .....................................................................................62

13.1 Powering .................................................................................................62

13.2 Monitored control outputs 4 and 5 calibration.........................................62

13.3 System test..............................................................................................63

13.4 Commissioning validation .......................................................................63

14 Maintenance ..........................................................................................64

14.1 Preventive maintenance..........................................................................64

14.2 Detailed fault display ...............................................................................65

15 Test functions........................................................................................67

15.1 Lamp test.................................................................................................67

15.2 Sounder test............................................................................................67

15.3 Warning panels test ................................................................................67

15.4 RT-alarm test ..........................................................................................68

15.5 RT-fault test.............................................................................................68

15.6 System test..............................................................................................68

15.7 Individual output test ...............................................................................69

15.8 Zone test .................................................................................................70

15.9 Manual release test.................................................................................70

16 Advanced functions..............................................................................71

16.1 Checksum ...............................................................................................71

16.2 Alarm counter..........................................................................................71

17 Special functions ..................................................................................72

4

Building Technologies A6V10257473_b_en_--.doc

Fire Safety & Security Products 01.2010

Page 5

17.1 Anticipated Silence Sounders .................................................................72

17.2 Anticipated Reset ....................................................................................72

18 Maintenance PC ....................................................................................73

19 Components and spare parts ..............................................................74

5

Building Technologies A6V10257473_b_en_--.doc

Fire Safety & Security Products 01.2010

Page 6

Page 7

1 About this document

Purpose of the document

This document describes the installation, the commissioning and the maintenance

of the XC10xx-A equipment. It provides an overview of the structure and functions

of the system as a whole as well as of the individual devices.

While following the instructions, a reliable operation is assured.

Scope

The information contained in this document is valid for the market package MP2.1.

The document also contains information on country-specific components. Countryspecific components are marked with square brackets, e. g. [FR], and may not be

sold/used in your country.

Target audience

This document and the information contained therein are aimed at the target

groups defined below:

Personnel Activity Qualification

Product manager – Performs local product management

– Responsible for exchanging information

between the headquarters and his/her Regional

Company (RC) for his/her product range

Project manager – Performs project management

– Coordinates the use of all persons and

resources involved in the project according to

schedule

– Continuously supplies information necessary for

project realisation

Installer – Assembles and installs the components at the

place of installation

– Performs a subsequent check of the installation

Commissioning personnel – Configure the product at the place of installation

according to customer specific requirements

– Check the product operability and release the

product for use by the operator

– Search for and correct malfunctions

Maintenance personnel – Carry out all maintenance work and check for

correct functioning

– Has suitable specialist training for the

function and for the product range

– Has attended the PM training courses

– Has suitable specialist training for the

– function, scale of the project and product

range

– Has attended the training courses for

Project Managers

– Has received specialized training in the area

of building installation technology or

electrical installations

– Has suitable specialist training for the

function and for the product range

– Have attended the training courses for

commissioning personnel

– Has suitable specialist training for the

function and for the product range

About this document

Reference documents

Designation Heading

A6V10257477_a_fr XC10 range

Operating manual

Identification of the document

Location Definition

Title page – Short name

Last page bottom left-hand side – Document no. (number-modification index-language-country)

Last page bottom right-hand

side

Building Technologies A6V10257473_b_en_--.doc

Fire Safety & Security Products 01.2010

– Name in full

– Document purpose

– Date of issue

– User's guide

– Register

7

Page 8

About this document

Revision history

Document no. Edition date Brief description

A6V10257473_a_en_-- 11/2009 First edition MP2.1

A6V10257473_b_en_-- 01/2010 Corrections after field tests:

- Chap. 3: Standards / 4.19 monitoring the status of

components (spelling mistake)

- Chap.4: fig 4 updated

- Chap. 6.3 label for XC1003-A is Pos. 8 not Pos.4

- Chap. 7.6.2 …. “to equipment outside” (spelling

mistake)

- Chap 7.8: 24V polarity output was wrong. 24V(+) is on

X5-3 and 24V(-) is on X5-4

- Chap. 8.2: note added for the connection of the 24V

power supply

- Chap 8.3: fig 31 modified: resistor 3.3k on RS485 line

removed

- Chap 11: fig 33 and 34 updated

- Chap 14.2: PMI picture is added on the top of the

description table, for an easier checking

- Chap. 16.2: access code for the alarm counter was

wrong

- Spelling mistakes

8

Building Technologies A6V10257473_b_en_--.doc

Fire Safety & Security Products 01.2010

Page 9

2 Safety instructions

2.1 Danger levels

The following pictograms indicate the possible danger levels, their severity and

consequences.

DANGER

WARNING

CAUTION

NOTE

Safety instructions

Imminent danger!

Serious injuries or death.

Potentially dangerous situation

Serious injuries or death.

Potentially dangerous situation

Light injuries or material damage.

Important information requiring special attention.

2.2 Safety instructions

Products are developed and manufactured in accordance with the applicable

international and European security standards.

The local rules of installation, exploitation and destruction of the product apply and

must be respected just like the safety instructions which appear in the

documentation of the product.

Electric installations

CAUTION

CAUTION

Hardware must not be powered during commissioning and maintenance

Affix an external label “DANGER external voltage” on the terminals connected to

an external voltage source

Separately lay the power lines towards the control unit. They must be fitted with

their own, clearly identified fuses

Ground in accordance with the local security standards

Interventions on wiring should be carried out only by qualified personnel.

Respect the safety instructions in explosive zone.

Assembly, installation, commissioning and maintenance

If any tools or accessories such as ladders are required, safe and suitable

devices must be used

When the extinguishing control panel is started up, it must be ensured that no

instable conditions can occur

Controls may only be set to normal function when the product operability has

been completely tested and the system has been handed over to the customer.

Control release for testing should not damage the installation

9

Building Technologies A6V10257473_b_en_--.doc

Fire Safety & Security Products 01.2010

Page 10

Safety instructions

Avoid the inopportune release of RT-alarm

Inform the reception station before an RT-alarm test

Installation and commissioning shall be performed by trained personal

Product operation check

Inform the personnel of the formation of a smoke cloud and presence of noise

Inform the personnel before alarm devices check and anticipate possible panic

reactions

Warn the alarm reception centers and the fault reception stations connected to

the system before carrying out the tests

Design modifications of systems and products

Modifications to the system and to individual products may lead to faults,

malfunctioning and safety risks

Intended system modifications or extensions require written approval from

Siemens and the relevant safety authorities

Components and spare parts

Components and spare parts must comply with the technical specifications

defined by Siemens. Only use products recommended or prescribed by Siemens

Only use fuses with the specified fuse characteristics

Wrong battery types and improper battery changing lead to a risk of explosion.

Only use the same battery type or an equivalent type recommended by Siemens

Batteries must be disposed of in an environmentally friendly manner. Country

specific directives and regulations must be observed. They must be deposited at

the collection places assigned to this purpose.

Note that the cylinders containing the extinguishing agent are under pressure

and that they must consequently be replaced in accordance with the safety

instructions in force

Disregard of the safety regulations

Before they are delivered, products are tested to ensure they function correctly

when used properly. Siemens disclaims all liability for damage or injuries caused

by the incorrect application of the instructions or the disregard of danger warnings

contained in the documentation. This applies in particular to:

Personal injuries or damage to property caused by improper use and incorrect

application

Personal injuries or damage to property caused by disregarding safety

instructions in the documentation or on the product

Personal injury or damage to property caused by poor maintenance or lack of

maintenance

2.3 Standards and directives complied with

A list of the standards and directives complied with is available at your Siemens

contact partner.

10

Building Technologies A6V10257473_b_en_--.doc

Fire Safety & Security Products 01.2010

Page 11

3 Standards

In addition to the requirements of EN12094-1 and EN54-2, the XC10xx-A control

panel complies with the following optional functions:

EN 12094-1

Clause Description

4.17 Delay of extinguishing signal

4.18 Signal representing the flow of extinguishing agent

4.19 Monitoring the status of components

4.20 Emergency hold device

4.21 Control of flooding time

4.23 Manual only mode

4.24 Triggering signals to equipment within the system

4.26 Triggering of equipment outside the system

4.27 Emergency abort device

4.29 Release of the extinguishing media for selected flooding zones (only for XC1003-A)

4.30 Activation of alarm device with different signals

EN 54-2 / A1

Clause Description

7.8 Output to fire alarm devices (Item C – EN54-1)

7.9.1 Control of fire alarm routing equipment (Item E – EN54-1)

7.12.1 Dependencies on more than one alarm signal (Type A)

7.13 Alarm counter (only with XC1005-A)

8.3 Fault signals from point

8.4 Total loss of the power supply

8.9 Output to fault warning routing equipment (Item J – EN54-1)

10 Test condition

Following additional functions are also available:

- transmission of information's outside the panel:

8 programmable digital outputs

programmable relay contacts

- reception of information's from outside:

control inputs (3 are programmable)

- 24V power supply output

Standards

11

Building Technologies A6V10257473_b_en_--.doc

Fire Safety & Security Products 01.2010

Page 12

Overview

4 Overview

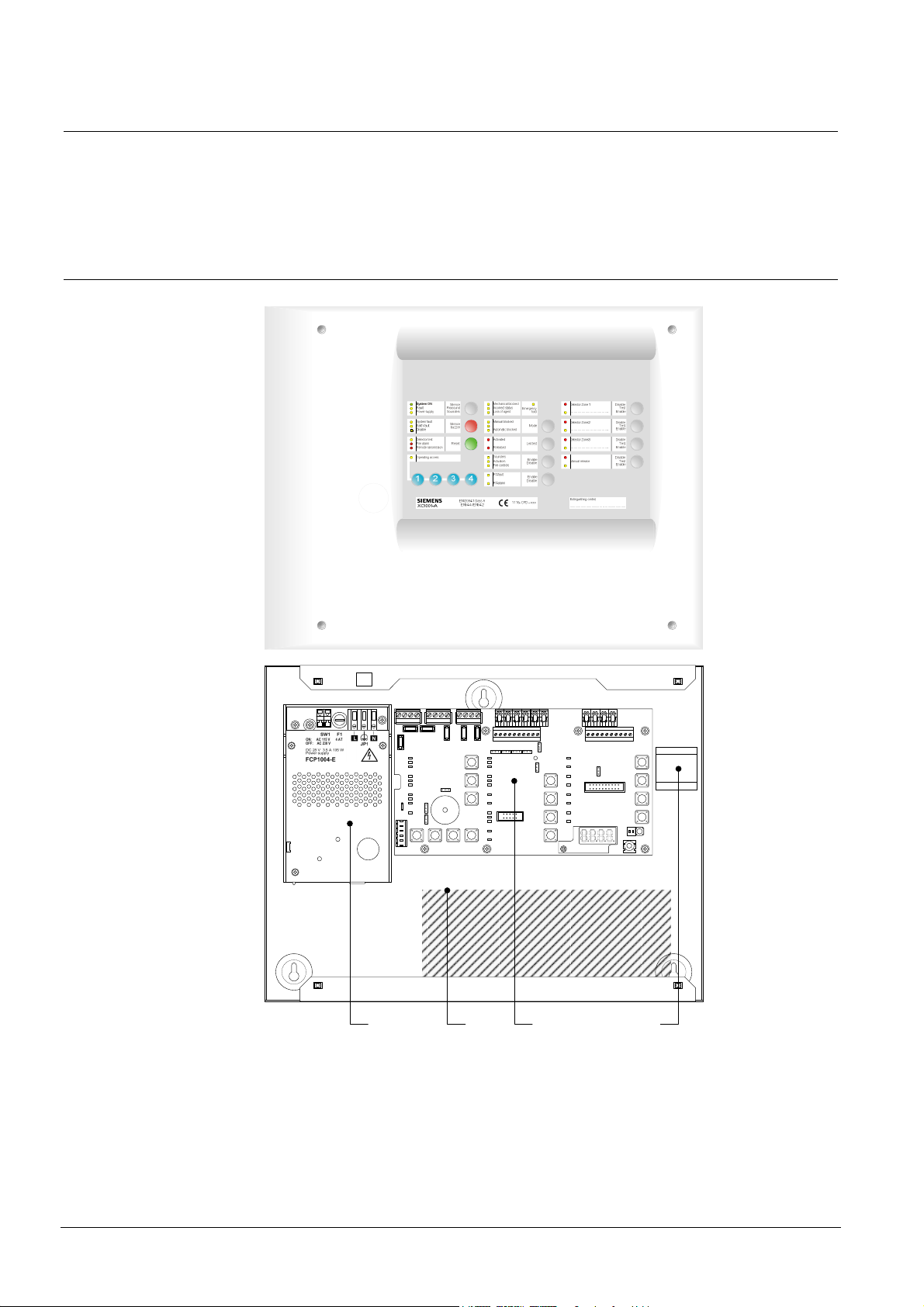

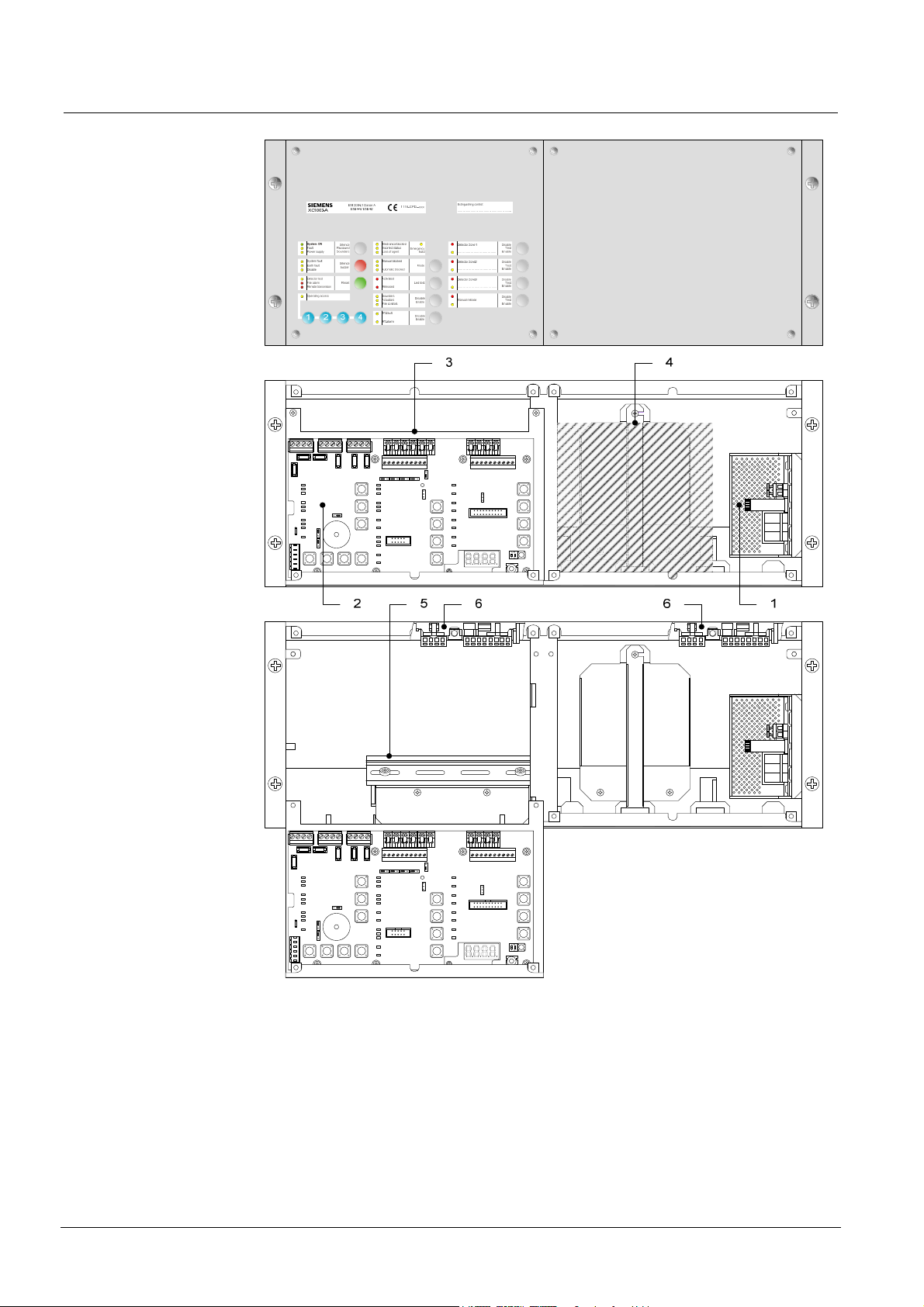

4.1 XC1001-A

The equipment is declined in 3 versions:

- Wall mounting cabinet: XC1001-A / XC1005-A

- 19” rack cabinet: XC1003-A

ON

1 2

3 421

Fig. 1 XC1001-A

1 FCP1004-E power supply unit with charger

2 XCM1002 mainboard

3 4.5 A/h batteries

4 DIN rail for accessory mounting (Z3B171 relay module)

12

Building Technologies A6V10257473_b_en_--.doc

Fire Safety & Security Products 01.2010

Page 13

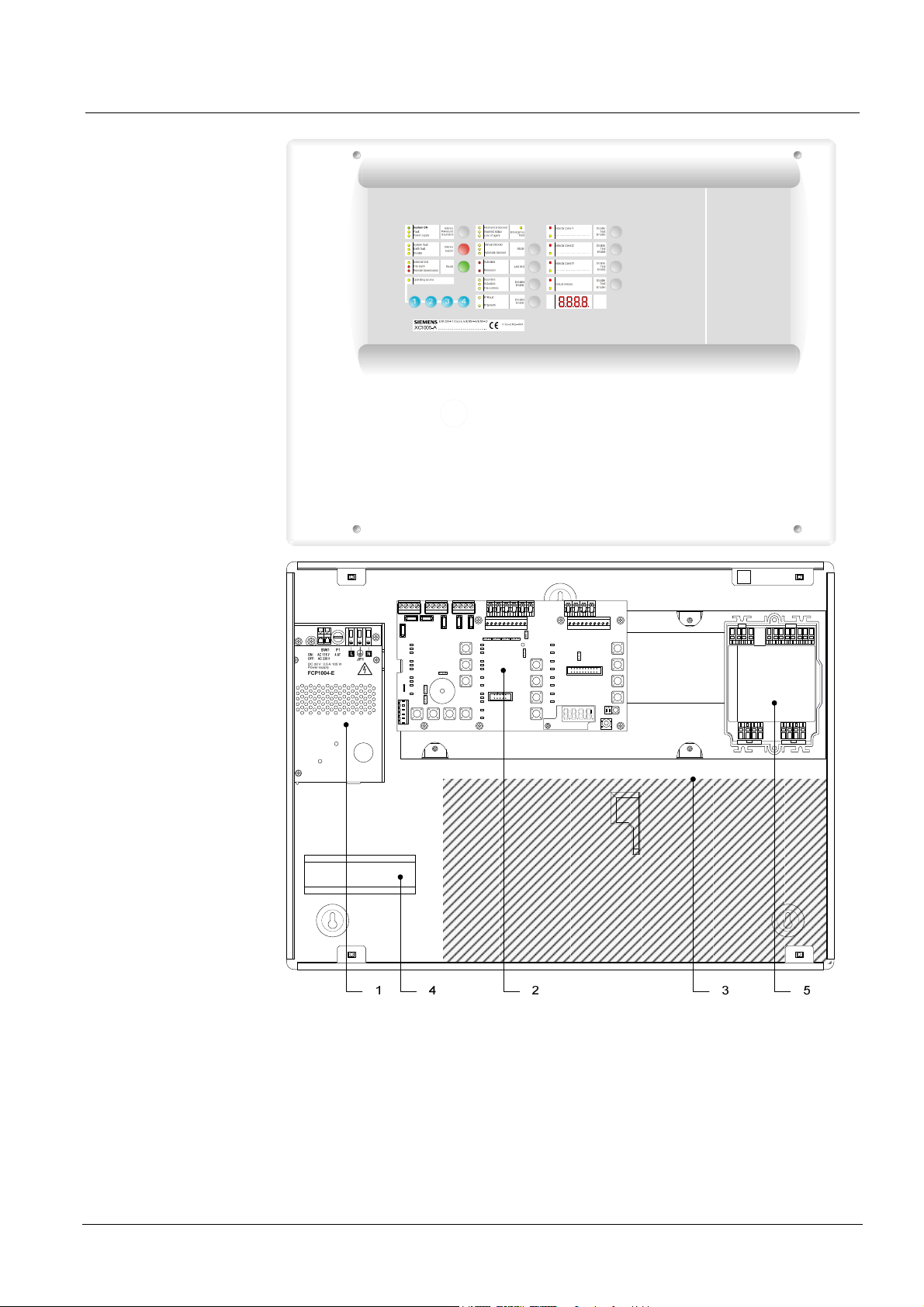

4.2 XC1005-A

Overview

Fig. 2 XC1005-A

1 FCP1004-E power supply unit with charger

2 XCM1002 mainboard

3 17 A/h batteries

4 DIN rail for accessory mounting (Z3B171 relay module)

5 FDCI / FDCIO222 module for the connection to a fire detection system

(option)

13

Building Technologies A6V10257473_b_en_--.doc

Fire Safety & Security Products 01.2010

Page 14

Overview

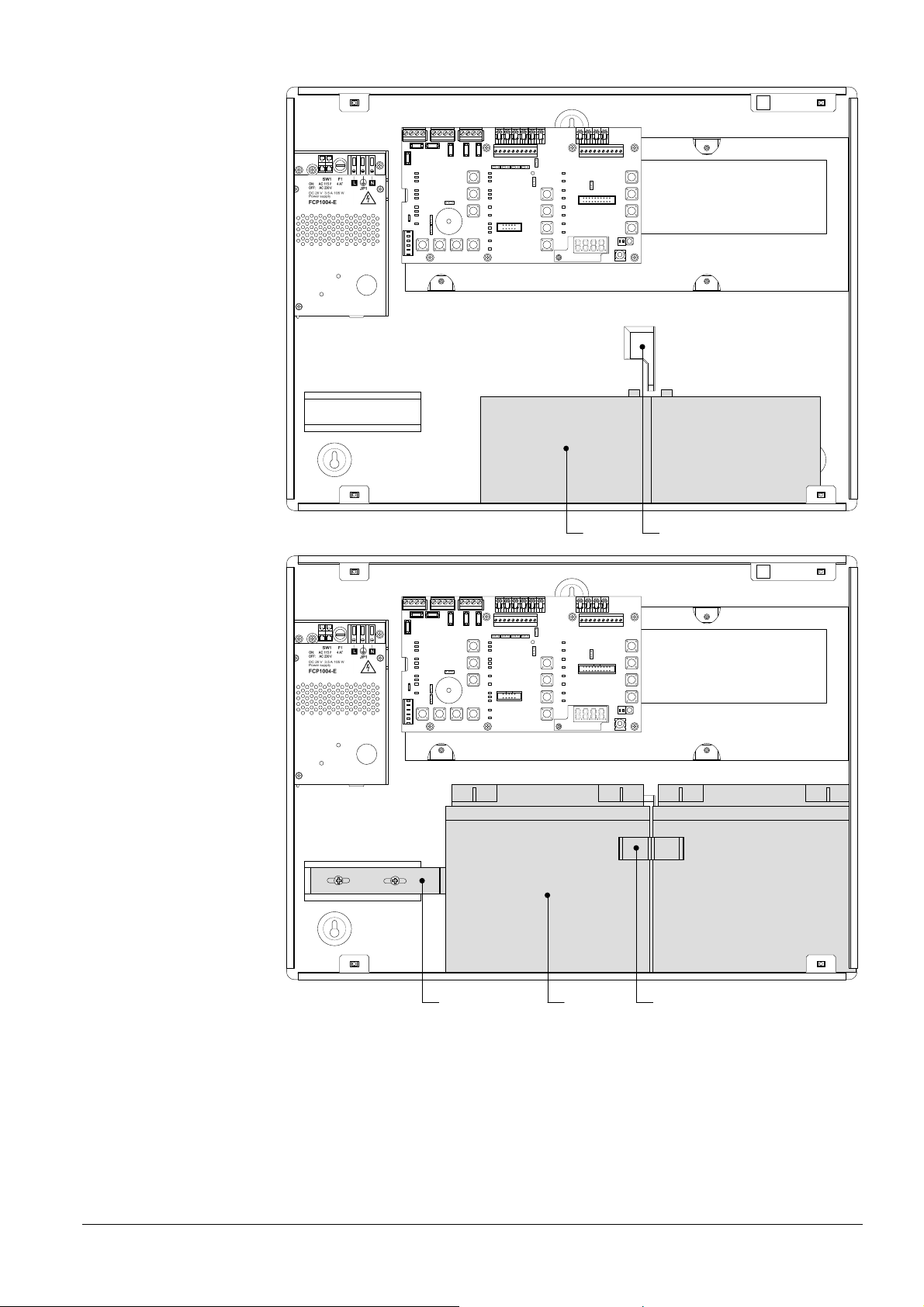

4.3 XC1003-A

Fig. 3 XC1003-A

1 FCP1004-E power supply unit with charger

2 XCM1002 mainboard

3 Removable mainboard holder

4 4.5 A/h or 7.2 A/h batteries

5 DIN rail for accessory mounting (Z3B171 relay module, XCA1030 multi-sector

modules, etc.)

6 FDCI / FDCIO222 module for the connection to a fire detection system

(option)

14

Building Technologies A6V10257473_b_en_--.doc

Fire Safety & Security Products 01.2010

Page 15

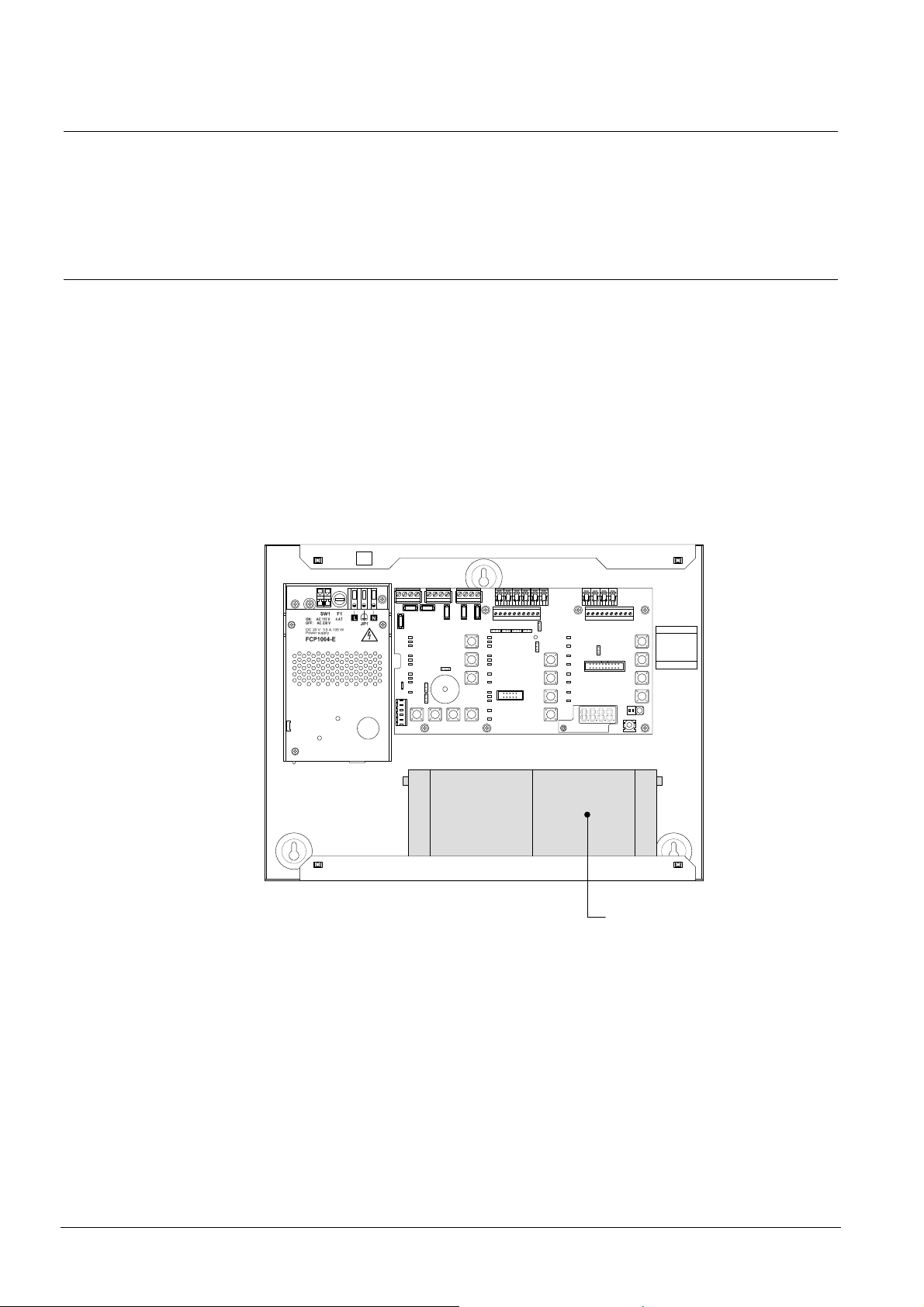

4.4 FCP1004-E

Overview

Fig. 4 FCP1004-E power supply unit

Mark Function Remarks

1 Mains voltage setting Shunt ON = 115VCA, shunt OFF = 230VCA

2 Mains terminal block

3 Mains fuse 4A / 250V

4 System start without mains power Shunt the 2 terminals with a jumper and

5 Temperature sensor for battery charging voltage compensation Do not cover

6 Internal green LED «Mains operation» but visible from the front Not lit if no mains voltage

7 Battery connection

8 XCM1002 main board connection

remove after system start

Security level of terminal blocks 1 and 2: Dangerous voltage

Security level of other terminal blocks: SELV (Safety Extra Low Voltage)

15

Building Technologies A6V10257473_b_en_--.doc

Fire Safety & Security Products 01.2010

Page 16

Overview

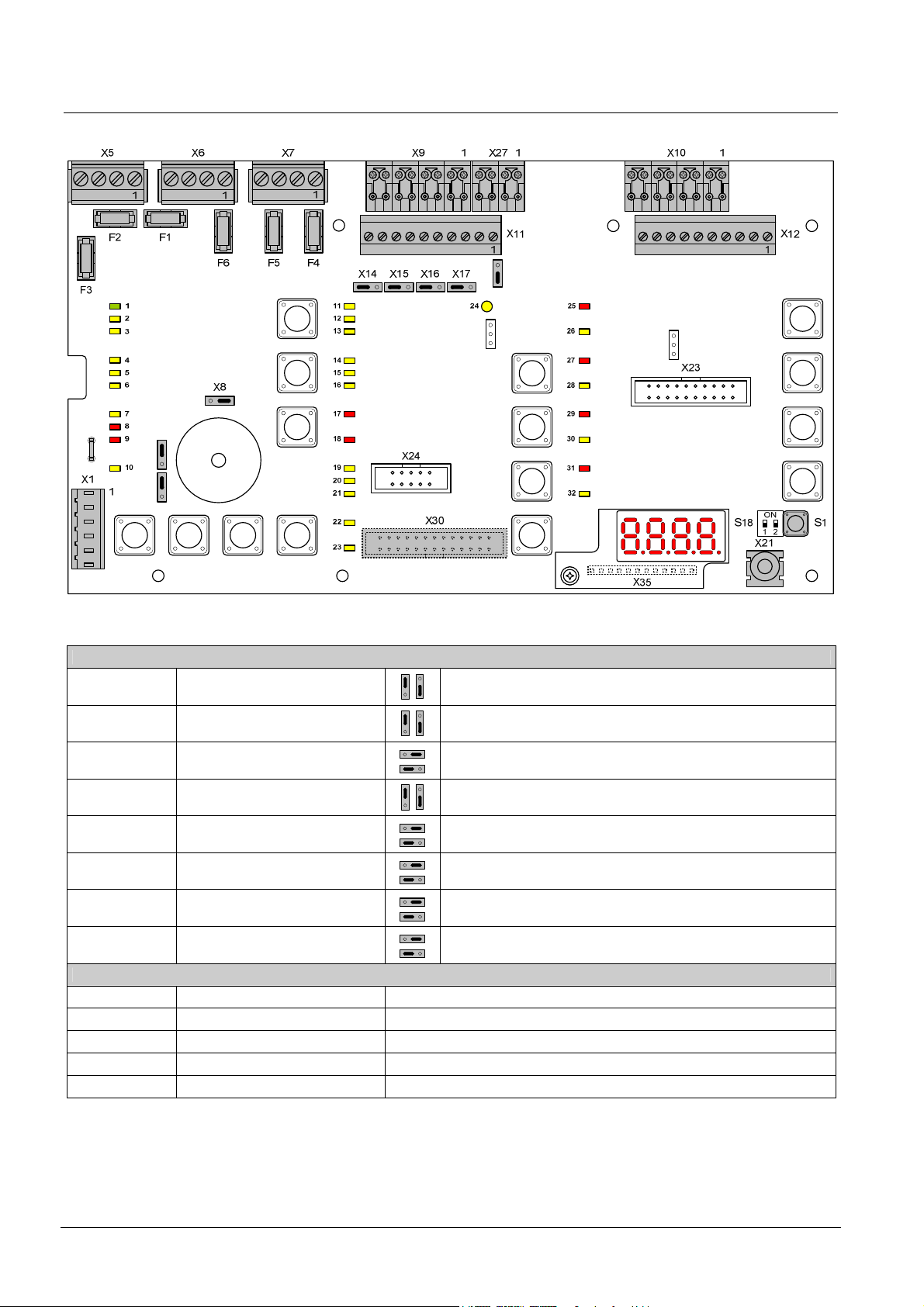

4.5 XCM1002

X13

X18

X28

X3X4

X26

Fig. 5 XCM1002 board

Setting elements

X3 Internal buzzer Enable/Disable

X4 Type of power supply

X8 Operating access Level 2

X13 Relay contact type 1

(NO or NC)

X14 Relay contact type 5

(NO or NC)

X15 Relay contact type 4

(NO or NC)

X16 Relay contact type 3

(NO or NC)

X17 Relay contact type 2

(NO or NC)

Other elements

F1 / F2 Pluggable fuse 2 AF Fuse for protection of control outputs 4 (F1) and 5 (F2)

F3 Pluggable fuse 1 AF Fuse for protection of 24V output

F4 / F5 / F6 Pluggable fuse 1 AT Fuse for protection of control outputs 1 (F4), 2 (F5) and 3 (F6)

S1 Reset —

S18-1 / S18-2 Not used Do not change (factory setting : OFF)

Jumper up (factory setting) : buzzer enabled

Jumper down : buzzer disabled (only for servicing)

Jumper up (factory setting) : FCP1004-E

Jumper down : do not use (for further use of external power supply)

Jumper on the right (factory setting) : Level 2 access using code

Jumper on the left : Level 2 access permanent

Jumper up : NC contact

Jumper down (factory setting) : NO contact

Jumper on the right : NC contact

Jumper on the left (factory setting) : NO contact

Jumper on the right : NC contact

Jumper on the left (factory setting) : NO contact

Jumper on the right : NC contact

Jumper on the left (factory setting) : NO contact

Jumper on the right : NC contact

Jumper on the left (factory setting) : NO contact

16

Building Technologies A6V10257473_b_en_--.doc

Fire Safety & Security Products 01.2010

Page 17

Overview

PCB terminal blocks

(1.5 mm2 max.)

(2.5 mm2 max.)

(2.5 mm2 max.)

(2.5 mm2 max.)

X9 Plug-in block 8 points

X10 Plug-in block 8 points

X11 Plug-in block 10 points

X21 Jack 2.5 mm — Maintenance PC

X28 Faston 5.3 mm (+) To positive of battery (to provide “Total loss of power supply”

X30 (*) Flat cable 26 points — Connection for multi-sector module XCA1030

X35 Terminal 12 points — Connection for 4 digits display

X18, 23, 24,

26

(*) on welding side

Note 1: The XC10 provides the EN54-2 option with requirement 8.4 called “Total loss of power”. This option when selected activates the

(1.5 mm2 max.)

(1.5 mm2 max.)

(1.5 mm2 max.)

(1.5 mm2 max.)

(1.5 mm2 max.)

Not used — —

system fault LED and the buzzer continuously, for at least 1 hour after a low discharge battery disconnection. The option can be

selected by wiring the +BAT terminal to the positive voltage of batteries (use of remaining power after battery disconnection).

1-2 (–) / 5-6 (+) 24V power supply X1 Plug-in block 6 points

3-4 (+) Power supply monitoring

1 (+) / 2 (–) Monitored output 5 X5 Plug-in block 4 points

3 (+) / 4 (–) 24V use output

1 (+) / 2 (–) Monitored output 3 (control polarities, reversed in standby) X6 Plug-in block 4 points

3 (+) / 4 (–) Monitored output 4

1 (+) / 2 (–) Monitored output 1 (control polarities, reversed in standby) X7 Plug-in block 4 points

3 (+) / 4 (–) Monitored output 2 (control polarities, reversed in standby)

1 (+) / 2 (–) Monitored input 1

3 (+) / 4 (–) Monitored input 2

5 (+) / 6 (–) Monitored input 3

7 (+) / 8 (–) Monitored input 4

1 (+) / 2 (–) Fire detectors zone 1

3 (+) / 4 (–) Fire detectors zone 2

5 (+) / 6 (–) Fire detectors zone 3

7 (+) / 8 (–) Extinguishing manual control

1 / 2 Potential-free contact relay 1 (NO or NC)

3 / 4 Potential-free contact relay 2 (NO or NC)

5 / 6 Potential-free contact relay 3 (NO or NC)

7 / 8 Potential-free contact relay 4 (NO or NC)

9 / 10 Potential-free contact relay 5 (NO or NC)

1 … 8 (–) Logical outputs 1 to 8 X12 Plug-in block 10 points

9 / 10 Not used

1 (+) Reset X27 Plug-in block 4 points

2 … 4 (+) Unmonitored inputs 2 to 4

function (see note 1)

17

Building Technologies A6V10257473_b_en_--.doc

Fire Safety & Security Products 01.2010

Page 18

Overview

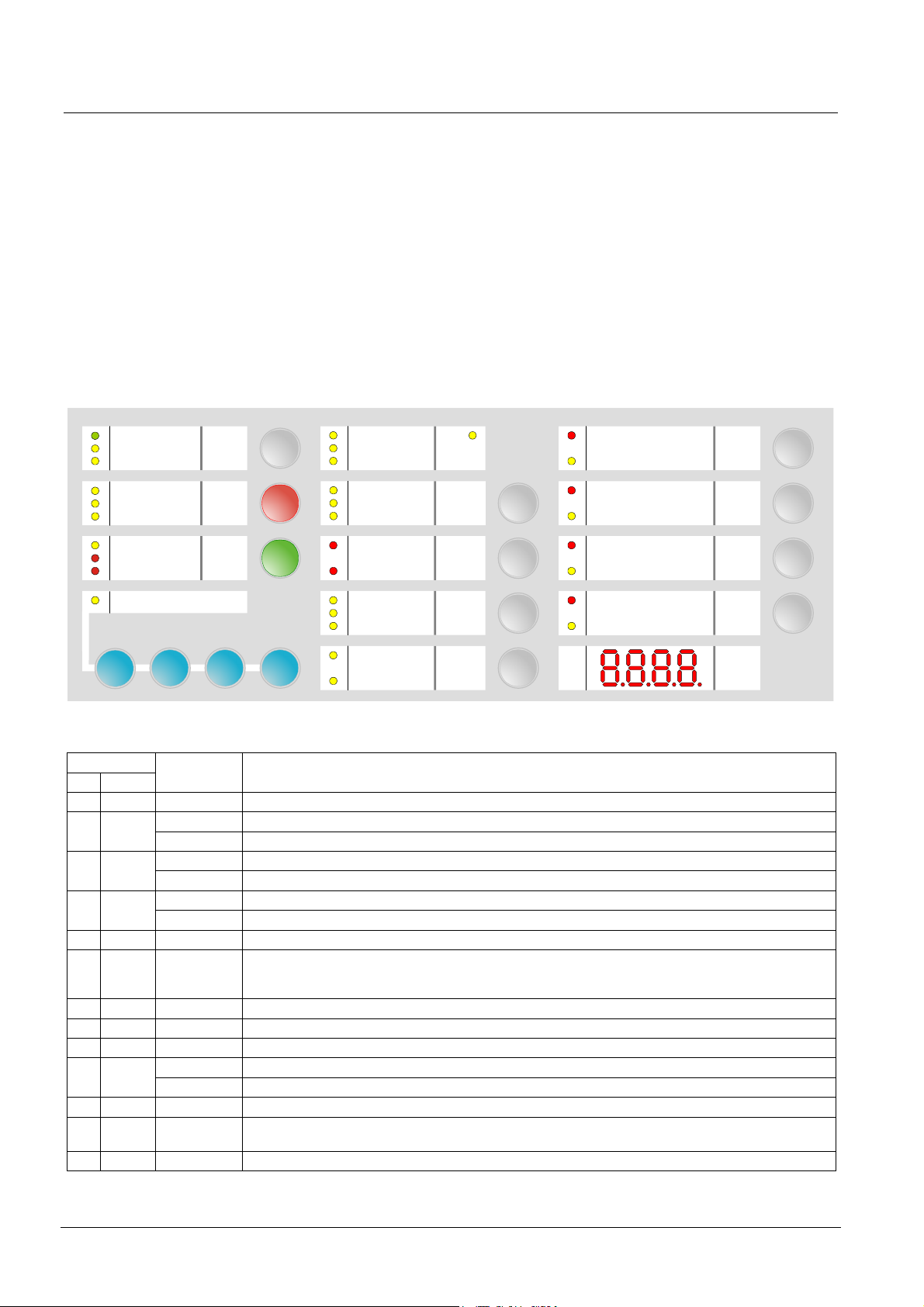

4.6 User interface

All display and control elements, except 4-digit display for XC1001-A and XC1003-A

versions, are accessible to the user:

- Led 1 to 32 indicators for operating condition,

- Keys 1 to 15 allowing :

operating access

operation (reset, off, test, etc)

system test

user functions programming

- 4-digit display showing:

programming steps and options

pre-warning time count down

other information’s (calibration states, alarm counter, etc)

System ON

1

Fault

2

Power supply

3

System fault

4

Earth fault

5

Disable

6

Detector test

7

Fire alarm

8

Remote transmission

9

Operating access

10 19

1

Silence

Re-sound

Sounders

Silence

buzzer

Reset

5 2

6

7

432

11

12

13

14

15

16

17

18

20

21

22

23

Mechanical blocked

Incorrect status

Loss of agent

Manual blocked

Automatic blocked

Activated

Released

Sounders

Actuators

Fire controls

RT-fault

RT-alarm

Emergency

hold

Mode

Led test

Disable

Enable

Disable

Enable

24

10

25

Detector Zone 1

………………………………….

26

27

8

9

Detector Zone 2

……………………………………

28

29

Detector Zone 3

……………………………………

30

31

Manual release

32

11

Fig. 6 XC10xx-A, user interface

Indicators

N° Color

1 Green Fixed The control panel is in operation

5 Yellow Fast At least one component connected to the control panel is grounded

6 Yellow Fixed – At least one component in the system is disabled

7 Yellow Slow At least one detection zone and/or extinguishing manual control is being tested

8 Red Fixed At least one detection zone is in alarm

9 Red Fixed Remote transmission activated (*)

11 Yellow Fixed Mechanical blocking device is in the blocked position

12 Yellow Fast – Mechanical blocking device is in a wrong position

13 Yellow Fast Loss of agent

(*) According to programming

State Description

Fixed The control panel is not able to function any more 2 Yellow

Fast Fault on at least one component in the system (see paragraph 14.2 for the detail)

Slow Mains fault 3 Yellow

Fast Batteries fault

Fixed Microprocessor fault 4 Yellow

Slow Jumper buzzer (X3 - XCM1002 board) not connected (remainder)

– Calibration in progress or error

– Programming in progress

Fixed Level 2 operating access granted 10 Yellow

Slow System test activated

– Selector valve is in a wrong position (used for multi-sector applications)

Disable

Test

Enable

Disable

Test

Enable

Disable

Test

Enable

Disable

Test

Enable

12

13

14

15

18

Building Technologies A6V10257473_b_en_--.doc

Fire Safety & Security Products 01.2010

Page 19

Indicators

N° Color

State Description

14 Yellow Fixed – Manual release is blocked or being tested

15 Yellow Fixed – Standard = not used

– Alternative = automatic and manual release granted (UK)

16 Yellow Fixed – Automatic release is blocked

– At least one detection zone which starts the extinguishing is off or being tested

17 Red

Fixed – All detection zones which start the extinguishing are in alarm condition

– One of the electrical manual triggering device (DM1103-L) is actuated

Fast One of the detection zones which start the extinguishing is in alarm condition

Fixed Extinguishing agent is released 18 Red

Slow / Fast Discharged contact is not activated within 30 seconds after actuators control (*)

19 Yellow

Fixed Sounders are disabled

Slow Sounders test is in progress (real activation)

Fast At least, an output programmed as Sounders is in fault condition (break or short-circuit)

20 Yellow

Fixed Actuators are disabled

Slow Actuators test is in progress (simulated activation)

Fast – At least, one output programmed as actuators is in fault condition (break or short-circuit)

– Calibration in progress or error or no calibration data

21 Yellow

Fixed Fire controls are disabled

Slow Warning panels test is in progress (real activation)

Fast At least, one output programmed as fire controls is in fault condition (break or short-circuit)

Fixed RT-fault is disabled 22 Yellow

Slow RT-fault test is in progress (real activation)

23 Yellow

Fixed RT-alarm is disabled

Slow RT-alarm test is in progress (real activation)

Fast At least, one output programmed as RT-alarm is in fault condition (break or short-circuit)

24 Yellow

Fixed Emergency abort is activated

Slow Emergency hold is activated (DM1101-S)

Fast At least, one input programmed as emergency hold/abort is in fault condition (break or short-circuit)

Fixed Detection zone 1 is in alarm condition 25 Red

Slow Detection zone 1 is in alarm condition (first alarm)

Fixed / Slow Detection zone 1 is disabled (fixed) / being tested (slow) 26 Yellow

Fast Detection zone 1 is in fault condition (break or short-circuit)

Fixed Detection zone 2 is in alarm condition 27 Red

Slow Detection zone 2 is in alarm condition (first alarm)

Fixed / Slow Detection zone 2 is disabled (fixed) / being tested (slow) 28 Yellow

Fast Detection zone 2 is in fault condition (break or short-circuit)

Fixed Detection zone 3 is in alarm condition 29 Red

Slow Detection zone 3 is in alarm condition (first alarm)

Fixed / Slow Detection zone 3 is disabled (fixed) / being tested (slow) 30 Yellow

Fast Detection zone 3 is in fault condition (break or short-circuit)

Fixed Manual release is activated (DM1103-L line) 31 Red

Slow Manual release is activated (DM1103-L line) – First alarm

Fixed / Slow Manual release is disabled (fixed) / being tested (slow) 32 Yellow

Fast Manual release is in fault condition (break or short-circuit)

(*) According to programming

Overview

19

Building Technologies A6V10257473_b_en_--.doc

Fire Safety & Security Products 01.2010

Page 20

Overview

Keys Description

1 … 4 Operating access code input (level 2, programming, system test, etc.)

5 Silence / Restart sounders by successive pressing:

– 1st pressing: silence sounders

– 2nd pressing: restart sounders

– 3rd pressing: silence sounders

– etc

Operating access level required for this operation = level 2 (silence sounders is not possible during pre-warning time)

6 Silence buzzer

Operating access level required for this operation = level 1 or 2 or 2 only (*)

7

8 Mode of operating, by successive pressing:

9 Led and buzzer test (duration = 6 seconds) :

10 Disable / Enable by successive pressing:

11 Disable / Enable by successive pressing:

12 Disable / Enable by successive pressing (not possible in case of fault or alarm):

13 Disable / Enable by successive pressing (not possible in case of fault or alarm):

14 Disable / Enable by successive pressing (not possible in case of fault or alarm):

15 Disable / Enable by successive pressing (not possible in case of fault or alarm):

(*) According to programming

1) Reset of the system. Reset is not possible :

– during pre-warning time, emergency stop and flooding time

– if buzzer and/or sounders are not silenced

– if manual release button and/or discharged contact are not reset (*)

Operating access level required for this operation = level 2

2) Fault reset (*)

Operating access level required for this operation = level 2

– 1st pressing: automatic blocked

– 2nd pressing: automatic and manual blocked

– 3rd pressing: normal mode

Operating access level required for these operations = level 2

All led indicators are activated and the buzzer sounds continuously (during the first three seconds, all the segments of the

display are activated, then the SW version is displayed)

Operating access level required for this operation = level 1

– 1st pressing: actuators are disabled

– 2nd pressing: sounders and actuators are disabled

– 3rd pressing: fire controls are disabled

– 4th pressing: all is disabled

– 5th pressing: all is enabled

Operating access level required for these operations = level 2

– 1st pressing: RT-fault is disabled

– 2nd pressing: RT-fault is enabled / RT-alarm is disabled

– 3rd pressing: RT-fault and RT-alarm are disabled

– 4th pressing: all are enabled

Operating access level required for these operations = level 2

– 1st pressing: zone 1 is disabled

– 2nd pressing: zone 1 is tested

– 3rd pressing: zone 1 is in normal condition

Operating access level required for these operations = level 2

– 1st pressing: zone 2 is disabled

– 2nd pressing: zone 2 is tested

– 3rd pressing: zone 2 is in normal condition

Operating access level required for these operations = level 2

– 1st pressing: zone 3 is disabled

– 2nd pressing: zone 3 is tested

– 3rd pressing: zone 3 is in normal condition

Operating access level required for these operations = level 2

– 1st pressing: manual release is disabled

– 2nd pressing: manual release is tested

– 3rd pressing: manual release is in normal condition

Operating access level required for these operations = level 2

20

Building Technologies A6V10257473_b_en_--.doc

Fire Safety & Security Products 01.2010

Page 21

5 Features

Power supply (FCP1004-E)

XCM1002

Detection lines

Manual release line

Monitored inputs

Control inputs (non

monitored)

Monitored control outputs

Outputs 1 to 3

Driver outputs

Relay outputs (contacts)

Connections

Environmental conditions

Mechanical data

Conformity

Primary source (mains)

Voltage

Current

Power

Secondary source (batteries)

Connectable batteries

Voltage

Charging current max.

Internal resistance max.

Deep discharge (disconnection threshold)

Output

Voltage

Max. available current

Min. current

Power

Switching frequency / Ripple

Input voltage

Current consumption

I/Os security level

Type / number of detectors

Compatible detectors

End of line element (EOL)

Standby condition voltage / current

Alarm condition voltage / current

Line resistance

Type / number of manual actuators

End of line element (EOL)

Voltage / standby line current

Voltage / alarm line current

Line resistance

4

Activation resistance

End of line element (EOL)

Line resistance

4 Activation +24 V, via contact

Outputs 1 to 3

Control voltage / current

End of line element

Outputs 4 and 5

Control voltage / current

End of line element

8 (programmable) 24 V / 40 mA max.

5 (4 programmable) 30 V / 1 A max. / NO or NC

XCM1002

Inputs - outputs type / section

FCP1004-E

mains input type / section

Operating / Storage temperature

Humidity relative at 40 ± 2° C

XC1001-A Cabinet / Protection index

XC1005-A Cabinet / Protection index

XC1003-A Cabinet / Protection index

EN 12094-1, EN 54-2/A1, EN 54-4/A2 —

Color

Dimensions (l x h x p) / Weight

Color

Dimensions (l x h x p) / Weight

Color

Dimensions (l x h x p) / Weight

Features

115 / 230 VCA +10 …-15% – 50 / 60 Hz

1.75 A max.

150 VA max.

2 x 12 V / 4.5 … 17 Ah

23.4 … 27.6 V

1.3 A (with temperature compensation)

1 Ω

20 V +/-3%

27.3 V +/- 0.3 V (25°C)

Imax a : 2 A (batteries loading)

Imax b : 3.5 A (batteries loaded)

0.05 A

105 W max.

132kHz / 70 mVpp max.

22.5 … 27.6 V (25°C)

190 mA max. without primary source

SELV (Safety Extra Low Voltage)

Collective / 32 max. (according to detector type)

Siemens (Algorex, Sinteso, Synova)

Transzorb 18 V (P6KE18CA)

17.1 … 19.3 V (fixed by EOL) / 11 mA max.

5.5 … 16.5 V / 11 … 57.1 mA max.

80 Ω max.

DM1103-L / 32 max.

Transzorb 18 V (P6KE18CA)

17.1 … 19.3 V (fixed by EOL) / 11 mA max.

5.5 … 16.5 V / 11 … 57.1 mA max.

80 Ω max.

680 Ω or 1.2 kΩ

3.3 kΩ resistance

80 Ω max.

24 V / 1 A max.

3.3 kΩ resistance

24 V / 2 A max.

No EOL (line calibration)

Plug-in screw terminal blocks

2.5 mm2 max. (X5, X5, X7)

1.5 mm2 max. (all others)

Plug-in screw terminal block / 2.5 mm2 max.

-5 ... +40° C / -20 ... +60° C

93% max., without condensation

Metal frame with plastic cover / IP30

RAL9003 (cover), RAL9006 (user interface)

370 x 286 x 90 mm / 4.1 kg

Metal case with plastic cover / IP40

RAL9003 (cover), RAL9006 (user interface)

505 / 375 / 125 mm / 6.5 kg

Rack 19’’ 4U / IP30

RAL9006

482.6 (19’’) x 177.8 (4U) x 187 mm / 6.6 kg

21

Building Technologies A6V10257473_b_en_--.doc

Fire Safety & Security Products 01.2010

Page 22

Installation

6 Installation

6.1 XC1001-A / XC1005-A

Generally, the XC10 must be easily accessible and installed:

- outside the protected area

- protected from mechanical shocks and bad weather

The XC10 must be installed on a fixed and stable support, with a height ranging

between 1.60 m and 1.70 m (eliminate the irregularities from the mounting surface

≥ 5 mm).

1. Remove front cover

2. Mark and drill the mounting holes using the drilling template provided (start with

the hole for the top central screw)

3. Fix the chassis using 3 screws Ø 4 x 50 mm (not provided)

4. Cut out the cable entries

5. Cut out the plastic housing according to the cable inputs (XC1001-A)

6. Mount the cable glands is necessary (required for protection rating IP30)

7. Install the batteries and fix the battery holders

ON

1 2

1

1 12 V – 4.5 Ah batteries

Fig. 7 XC1001-A, battery installation

22

Building Technologies A6V10257473_b_en_--.doc

Fire Safety & Security Products 01.2010

Page 23

Installation

ON

1 2

1 4

ON

1 2

23 3 (insert in slot 4)

1 12 V – 12 Ah batteries

2 12 V – 17 Ah batteries

3 FCA1014 battery holder (option)

4 Slot for battery holder

Fig. 8 XC1005-A, battery installation

23

Building Technologies A6V10257473_b_en_--.doc

Fire Safety & Security Products 01.2010

Page 24

Installation

6.2 XC1003-A

Fix the XC1003-A into a 19'' housing cabinet with a protection rating IP ≥ 30.

Cover

ZONE EXTINCTION :

EN12094-1 Classe A

s

1116 -CPD– xxx

EN54-4 / EN54-2

XC1003-A

Sous tension

Arrêt /

Marche

Défaut général

sirènes

Défaut alimentation

Système hors service

Arrêt

signal

Défaut terre

sonore

Hors service

Essai

Réar-

Alarme feu générale

mement

Télé-transmission

Niveau 2

1

s

XC1003-A

Sous tension

Arrêt /

Marche

Défaut général

sirènes

Défaut alimentation

Système hors service

Arrêt

signal

Défaut terre

sonore

Hors service

Essai

Réar-

Alarme feu générale

mement

Télé-transmission

Niveau 2

s

XC1003-A

Sous tension

Arrêt /

Marche

Défaut général

sirènes

Défaut alimentation

Système hors service

Arrêt

signal

Défaut terre

sonore

Hors service

Essai

Réar-

Alarme feu générale

mement

Télé-transmission

Niveau 2

s

XC1003-A

Sous tension

Arrêt /

Marche

Défaut général

sirènes

Défaut alimentation

Système hors service

Arrêt

signal

Défaut terre

sonore

Hors service

Essai

Réar-

Alarme feu générale

mement

Télé-transmission

Niveau 2

s

XC1003-A

Sous tension

Arrêt /

Marche

Défaut général

sirènes

Défaut alimentation

Système hors service

Arrêt

signal

Défaut terre

sonore

Hors service

Essai

Réar-

Alarme feu générale

mement

Télé-transmission

Niveau 2

1

……………………………………………………..

Blocage mécanique

Zone 1

Etat incorrect

Perte agent

Manuel bloqué

Non utilisé

Automatique bloqué

Evacuation

Emission

Sirènes

Déclencheurs

Asservissements

Report de défaut

432

Report d’alarme

EN12094-1 Classe A

EN54-4 / EN54-2

Blocage mécanique

Etat incorrect

Perte agent

Manuel bloqué

Non utilisé

Automatique bloqué

Evacuation

Emission

Sirènes

Déclencheurs

Asservissements

Report de défaut

4321

Report d’alarme

EN12094-1 Classe A

EN54-4 / EN54-2

Blocage mécanique

Etat incorrect

Perte agent

Manuel bloqué

Non utilisé

Automatique bloqué

Evacuation

Emission

Sirènes

Déclencheurs

Asservissements

Report de défaut

4321

Report d’alarme

EN12094-1 Classe A

EN54-4 / EN54-2

Blocage mécanique

Etat incorrect

Perte agent

Manuel bloqué

Non utilisé

Automatique bloqué

Evacuation

Emission

Sirènes

Déclencheurs

Asservissements

Report de défaut

4321

Report d’alarme

EN12094-1 Classe A

EN54-4 / EN54-2

Blocage mécanique

Etat incorrect

Perte agent

Manuel bloqué

Non utilisé

Automatique bloqué

Evacuation

Emission

Sirènes

Déclencheurs

Asservissements

Report de défaut

432

Report d’alarme

Hors

Essai

2

Arrêt

……………………………………..

En

d’urgence

Zone 2

Hors

Mode

Essai

……………………………………..

En

Zone 3

Hors

Test

Essai

signal.

……………………………………..

En

Hors

Hors

Commande manuelle

Essai

En

En

Hors

En

ZONE EXTINCTION :

1116 -CPD– xxx

……………………………………………………..

Zone 1

Hors

Essai

Arrêt

2

……………………………………..

En

d’urgence

Zone 2

Hors

Mode

Essai

……………………………………..

En

Zone 3

Hors

Test

Essai

signal.

……………………………………..

En

Hors

Hors

Commande manuelle

Essai

En

En

Hors

En

ZONE EXTINCTION :

1116 -CPD– xxx

……………………………………………………..

Zone 1

Hors

Essai

2

Arrêt

……………………………………..

En

d’urgence

Zone 2

Hors

Mode

Essai

……………………………………..

En

Zone 3

Hors

Test

Essai

signal.

……………………………………..

En

Hors

Hors

Commande manuelle

Essai

En

En

Hors

En

ZONE EXTINCTION :

1116 -CPD– xxx

……………………………………………………..

Zone 1

Hors

Essai

2

Arrêt

……………………………………..

En

d’urgence

Zone 2

Hors

Mode

Essai

……………………………………..

En

Zone 3

Hors

Test

Essai

signal.

……………………………………..

En

Hors

Hors

Commande manuelle

Essai

En

En

Hors

En

ZONE EXTINCTION :

1116 -CPD– xxx

……………………………………………………..

Zone 1

Hors

Essai

2

Arrêt

……………………………………..

En

d’urgence

Zone 2

Hors

Mode

Essai

……………………………………..

En

Zone 3

Hors

Test

Essai

signal.

……………………………………..

En

Hors

Hors

Commande manuelle

Essai

En

En

Hors

En

Extinguishing zone 1

with power supply

Extinguishing zone 2

with power supply

Extinguishing zone 3

with power supply

Extinguishing zone 4

with power supply

Extinguishing zone 5

with power supply

s

1116 -CPD– x xx

EN54-4 / EN54-2

XC1003-A

Sous tension

Blocage mécanique

Arrêt /

Marche

Défaut général

Etat incorrect

Arrêt

sirènes

Perte agent

d’urgence

Défaut alimentation

Système hors service

Manuel bloqué

Arrêt

signal

Mode

Défaut terre

Non utilisé

sonore

Automatique bloqué

Hors service

Evacuation

Essai

Réar-

Test

Alarme feu générale

mement

signal.

Emission

Télé-transmission

Niveau 2

Sirènes

Hors

Déclencheurs

En

Asservissements

Report de défaut

Hors

432

1

s

XC1003-A

Sous tension

Défaut général

Défaut alimentation

Système hors service

Défaut terre

Hors service

Essai

Alarme feu générale

Télé-transmission

Niveau 2

s

XC1003-A

Sous tension

Défaut général

Défaut alimentation

Système hors service

Défaut terre

Hors service

Essai

Alarme feu générale

Télé-transmission

Niveau 2

s

XC1003-A

Sous tension

Défaut général

Défaut alimentation

Système hors service

Défaut terre

Hors service

Essai

Alarme feu générale

Télé-transmission

Niveau 2

En

Report d’alarme

EN12094-1 Classe A

1116 -CPD– x xx

EN54-4 / EN54-2

Blocage mécanique

Arrêt /

Marche

Etat incorrect

Arrêt

sirènes

Perte agent

d’urgence

Manuel bloqué

Arrêt

signal

Mode

Non utilisé

sonore

Automatique bloqué

Evacuation

Réar-

Test

mement

signal.

Emission

Sirènes

Hors

Déclencheurs

En

Asservissements

Report de défaut

Hors

4321

En

Report d’alarme

EN12094-1 Classe A

1116 -CPD– x xx

EN54-4 / EN54-2

Blocage mécanique

Arrêt /

Marche

Etat incorrect

Arrêt

sirènes

d’urgence

Perte agent

Manuel bloqué

Arrêt

signal

Mode

Non utilisé

sonore

Automatique bloqué

Evacuation

Réar-

Test

mement

signal.

Emission

Sirènes

Hors

Déclencheurs

En

Asservissements

Report de défaut

Hors

4321

En

Report d’alarme

EN12094-1 Classe A

1116 -CPD– x xx

EN54-4 / EN54-2

Blocage mécanique

Arrêt /

Marche

Etat incorrect

Arrêt

sirènes

Perte agent

d’urgence

Manuel bloqué

Arrêt

signal

Mode

Non utilisé

sonore

Automatique bloqué

Evacuation

Réar-

Test

mement

signal.

Emission

Sirènes

Hors

Déclencheurs

En

Asservissements

Report de défaut

Hors

4321

En

Report d’alarme

……………………………………………………..

Zone 1

……………………………………..

Zone 2

……………………………………..

Zone 3

……………………………………..

Commande manuelle

ZONE EXTINCTION :

……………………………………………………..

Zone 1

……………………………………..

Zone 2

……………………………………..

Zone 3

……………………………………..

Commande manuelle

ZONE EXTINCTION :

……………………………………………………..

Zone 1

……………………………………..

Zone 2

……………………………………..

Zone 3

……………………………………..

Commande manuelle

ZONE EXTINCTION :

……………………………………………………..

Zone 1

……………………………………..

Zone 2

……………………………………..

Zone 3

……………………………………..

Commande manuelle

s

XC1003-A

Sous tension

Hors

Arrêt /

Essai

Marche

Défaut général

2

En

sirènes

Défaut alimentation

Système hors service

Hors

Arrêt

Essai

signal

Défaut terre

En

sonore

Hors service

Essai

Hors

Réar-

Essai

Alarme feu générale

mement

En

Télé-transmission

Niveau 2

Hors

Essai

En

1

s

XC1003-A

Sous tension

Hors

Arrêt /

Essai

Marche

Défaut général

2

En

sirènes

Défaut alimentation

Système hors service

Hors

Arrêt

Essai

signal

Défaut terre

En

sonore

Hors service

Essai

Hors

Réar-

Essai

Alarme feu générale

mement

En

Télé-transmission

Niveau 2

Hors

Essai

En

s

XC1003-A

Sous tension

Hors

Arrêt /

Essai

2

Marche

Défaut général

En

sirènes

Défaut alimentation

Système hors service

Hors

Arrêt

Essai

signal

Défaut terre

En

sonore

Hors service

Essai

Hors

Réar-

Essai

Alarme feu générale

mement

En

Télé-transmission

Niveau 2

Hors

Essai

En

s

XC1003-A

Sous tension

Hors

Arrêt /

Essai

Marche

2

Défaut général

En

sirènes

Défaut alimentation

Système hors service

Hors

Arrêt

Essai

signal

Défaut terre

En

sonore

Hors service

Essai

Hors

Réar-

Essai

Alarme feu générale

mement

En

Télé-transmission

Niveau 2

Hors

Essai

En

ZONE EXTINCTION :

EN12094-1 Classe A

ZONE EXTINCTION :

EN12094-1 Classe A

1116 -CPD – xxx

EN54-4 / EN54-2

……………………………………………………..

Blocage mécanique

Zone 1

Etat incorrect

Arrêt

……………………………………..

Perte agent

d’urgence

Manuel bloqué

Zone 2

Mode

Non utilisé

……………………………………..

Automatique bloqué

Evacuation

Zone 3

Test

signal.

……………………………………..

Emission

Sirènes

Hors

Commande manuelle

Déclencheurs

En

Asservissements

Report de défaut

Hors

432

En

Report d’alarme

ZONE EXTINCTION :

EN12094-1 Classe A

1116 -CPD – xxx

EN54-4 / EN54-2

……………………………………………………..

Blocage mécanique

Zone 1

Etat incorrect

Arrêt

……………………………………..

Perte agent

d’urgence

Manuel bloqué

Zone 2

Mode

Non utilisé

……………………………………..

Automatique bloqué

Evacuation

Zone 3

Test

signal.

……………………………………..

Emission

Sirènes

Hors

Commande manuelle

Déclencheurs

En

Asservissements

Report de défaut

Hors

4321

En

Report d’alarme

ZONE EXTINCTION :

EN12094-1 Classe A

1116 -CPD – xxx

EN54-4 / EN54-2

……………………………………………………..

Blocage mécanique

Zone 1

Etat incorrect

Arrêt

……………………………………..

d’urgence

Perte agent

Manuel bloqué

Zone 2

Mode

Non utilisé

……………………………………..

Automatique bloqué

Evacuation

Zone 3

Test

signal.

……………………………………..

Emission

Sirènes

Hors

Commande manuelle

Déclencheurs

En

Asservissements

Report de défaut

Hors

4321

En

Report d’alarme

ZONE EXTINCTION :

EN12094-1 Classe A

1116 -CPD – xxx

EN54-4 / EN54-2

……………………………………………………..

Blocage mécanique

Zone 1

Etat incorrect

Arrêt

……………………………………..

Perte agent

d’urgence

Manuel bloqué

Zone 2

Mode

Non utilisé

……………………………………..

Automatique bloqué

Evacuation

Zone 3

Test

signal.

……………………………………..

Emission

Sirènes

Hors

Commande manuelle

Déclencheurs

En

Asservissements

Report de défaut

Hors

4321

En

Report d’alarme

Cover

Power supply

Extinguishing zones 1 & 2

Hors

Essai

2

Extinguishing zones 1 & 2

En

Hors

Essai

En

Hors

Essai

En

Hors

Essai

En

Hors

Essai

2

Extinguishing zones 3 & 4

En

Hors

Essai

En

Hors

Essai

En

Hors

Essai

En

Hors

Essai

2

Extinguishing zones 5 & 6

En

Hors

Essai

En

Hors

Essai

En

Hors

Essai

En

Hors

Essai

2

Extinguishing zones 7 & 8

En

Hors

Essai

En

Hors

Essai

En

Hors

Essai

En

2U

4U

4U

4U

4U

4U

ZONE EXTINCTION :

EN12094-1 Classe A

s

1116 -CPD– xxx

EN54-4 / EN54-2

XC1003-A

Sous tension

Arrêt /

Marche

Défaut général

sirènes

Défaut alimentation

Système hors service

Arrêt

signal

Défaut terre

sonore

Hors service

Essai

Réar-

Alarme feu générale

mement

Télé-transmission

Niveau 2

s

XC1003-A

Sous tension

Arrêt /

Marche

Défaut général

sirènes

Défaut alimentation

Système hors service

Arrêt

signal

Défaut terre

sonore

Hors service

Essai

Réar-

Alarme feu générale

mement

Télé-transmission

Niveau 2

……………………………………………………..

Blocage mécanique

Zone 1

Etat incorrect

Perte agent

Manuel bloqué

Non utilisé

Automatique bloqué

Evacuation

Emission

Sirènes

Déclencheurs

Asservissements

Report de défaut

4321

Report d’alarme

EN12094-1 Classe A

EN54-4 / EN54-2

Blocage mécanique

Etat incorrect

Perte agent

Manuel bloqué

Non utilisé

Automatique bloqué

Evacuation

Emission

Sirènes

Déclencheurs

Asservissements

Report de défaut

4321

Report d’alarme

Hors

Essai

Arrêt

2

……………………………………..

En

d’urgence

Zone 2

Hors

Mode

Essai

……………………………………..

En

Hors

Zone 3

Test

Essai

signal.

……………………………………..

En

Hors

Hors

Commande manuelle

Essai

En

En

Hors

En

ZONE EXTINCTION :

1116 -CPD– xxx

……………………………………………………..

Zone 1

Hors

Essai

2

Arrêt

……………………………………..

En

d’urgence

Zone 2

Hors

Mode

Essai

……………………………………..

En

Zone 3

Hors

Test

Essai

signal.

……………………………………..

En

Hors

Hors

Commande manuelle

Essai

En

En

Hors

En

Extinguishing zone 6

with power supply

Extinguishing zone 7

with power supply

s

XC1003-A

Sous tension

Arrêt /

Marche

Défaut général

sirènes

Défaut alimentation

Système hors service

Arrêt

signal

Défaut terre

sonore

Hors service

Essai

Réar-

Alarme feu générale

mement

Télé-transmission

Niveau 2

1

ZONE EXTINCTION :

EN12094-1 Classe A

1116 -CPD– x xx

EN54-4 / EN54-2

Blocage mécanique

Etat incorrect

Arrêt

Perte agent

d’urgence

Manuel bloqué

Mode

Non utilisé

Automatique bloqué

Evacuation

Test

signal.

Emission

Sirènes

Hors

Déclencheurs

En

Asservissements

Report de défaut

Hors

432

En

Report d’alarme

……………………………………………………..

Zone 1

……………………………………..

Zone 2

……………………………………..

Zone 3

……………………………………..

Commande manuelle

s

XC1003-A

Sous tension

Hors

Arrêt /

Essai

Marche

Défaut général

2

En

sirènes

Défaut alimentation

Système hors service

Hors

Arrêt

Essai

signal

Défaut terre

En

sonore

Hors service

Essai

Hors

Réar-

Essai

Alarme feu générale

mement

En

Télé-transmission

Niveau 2

Hors

Essai

En

1

ZONE EXTINCTION :

EN12094-1 Classe A

1116 -CPD – xxx

EN54-4 / EN54-2

……………………………………………………..

Blocage mécanique

Zone 1

Etat incorrect

Perte agent

Manuel bloqué

Non utilisé

Automatique bloqué

Evacuation

Emission

Sirènes

Déclencheurs

Asservissements

Report de défaut

432

Report d’alarme

Hors

Essai

2

Arrêt

……………………………………..

d’urgence

Zone 2

Mode

……………………………………..

Zone 3

Test

signal.

……………………………………..

Hors

Commande manuelle

En

Hors

En

Extinguishing zones 9 & 10

En

Hors

Essai

En

Hors

Essai

En

Hors

Essai

En

Power supply

Extinguishing zones 3 & 4

Power supply

Extinguishing zones 5 & 6

Power supply

Extinguishing zones 7 & 8

Power supply

Extinguishing zones 9 & 10

4U

4U

4U

4U

4U

Fig. 9 XC1003-A, mounting examples

The interval between 2 extinguishing racks and there power supply rack should not exceed 12U.

24

Building Technologies A6V10257473_b_en_--.doc

Fire Safety & Security Products 01.2010

Page 25

Installation

XC1003-A, mounting adaptation

The 19” rack is symmetrical. This allows, with some mounting/unmounting

operations, to adapt it to various configurations (2 racks minimum are necessary).

A

Remove parts 1, 2, 3 & 4

from rack A

ON

1 2

5

2 31 4

ON

1 2

6

B

Remove parts 5 & 6

from rack B

B

6

A

ON

1 2

5

A

ON

1 2

ON

1 2

Reassemble parts 5 & 6 from

rack B in rack A

1234

B

Reassemble parts 1, 2, 3 & 4 from

rack A in rack B

Fig. 10 XC1003-A, mounting adaptation

25

Building Technologies A6V10257473_b_en_--.doc

Fire Safety & Security Products 01.2010

Page 26

Installation

XC1003-A, commissioning / connection / maintenance

The removable board holder (1) can be positioned, after screw unmounting (3), as

indicated below to reach the DIN rail (2).

13 3

ON

1 2

2

ON

1 2

Fig. 11 XC1003-A, removable stand in “Commissioning” position

26

Building Technologies A6V10257473_b_en_--.doc

Fire Safety & Security Products 01.2010

Page 27

Installation

4.5 Ah batteries:

1. Remove the holder (1)

2. Install the batteries (3) as shown below

3. Remount the holder (1)

XC1003-A, batteries installation

7.2 Ah batteries:

1. Remove the parts (1) and (2)

2. Install the batteries (4) as shown below

1

ON

1 2

3

2

ON

1 2

4

ON

1 2

Fig. 12 XC1003-A, battery installation

27

Building Technologies A6V10257473_b_en_--.doc

Fire Safety & Security Products 01.2010

Page 28

Installation

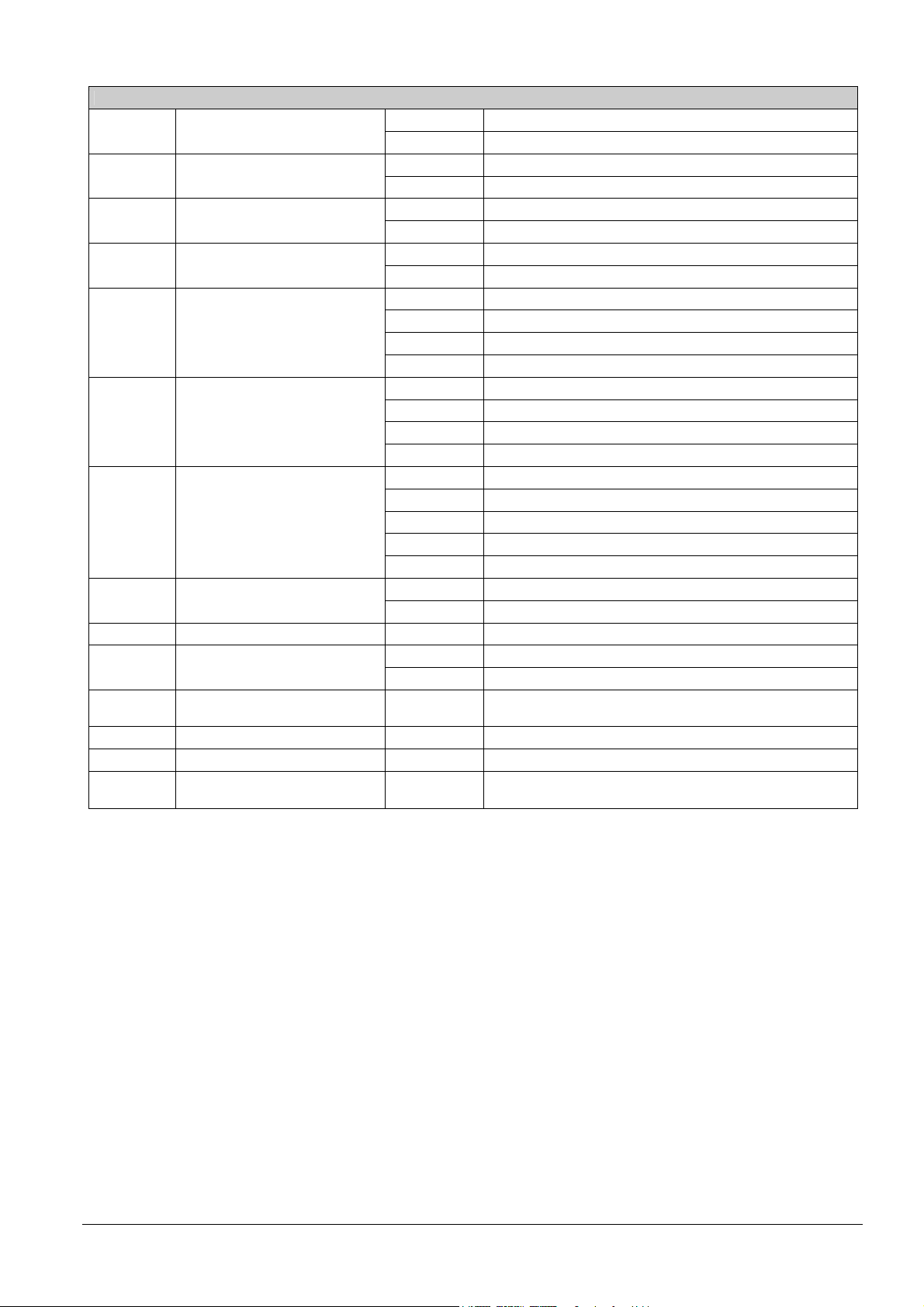

6.3 User interface labels

Insert the labels following the instructions on the board provided with the

equipment.

Pos. 1

System ON

Fault

Power supply

System fault

Earth fault

Disable

Detector test

Fire alarm

Remote transmission

Operating access

Re-sound

Sounders

Silence

Detector Zone 1

…………………………………….

Detector Zone 2

Silence

buzzer

…………………………………….

Detector Zone 3

Reset

…………………………………….

Manual release

Pos. 3

Disable

Detector Zone 1

Test

Enable

…………………………………….

Disable

Detector Zone 2

Test

Enable

…………………………………….

Disable

Detector Zone 3

Test

Enable

…………………………………….

Disable

Test

Manual release

Enable

Pos. 7

XC1001-A

XC1003-A

XC1005-A

Stripe EN

A5Q00034729A-03

Disable

Test

Enable

Disable

Test

Enable

Disable

Test

Enable

Disable

Test

Enable

Pos. 2

Mechanical blocked

Incorrect status

Loss of agent

Manual blocked

Automatic blocked

Activated

Released

Sounders

Actuators

Fire controls

RT-fault

RT-alarm

Pos.5

+0,15

0.0

0

3

Emergency

hold/abort

Mode

Led test

Disable

Enable

Disable

Enable

1

Pos. 2

Mechanical blocked

Incorrect status

Loss of agent

Manual blocked

Automatic blocked

Activated

Released

Sounders

Actuators

Fire controls

RT-fault

RT-alarm

Pos.4

Pos.5

Emergency

hold

Mode

Led test

Disable

Enable

Disable

Enable

Pos. 2

Mechanical blocked

Incorrect status

Loss of agent

Manual blocked

Automatic blocked

Activated

Released

Sounders

Actuators

Fire controls

RT-fault

RT-alarm

Emergency

abort

Mode

Led test

Disable

Enable

Disable

Enable

Pos.8

Pos.6

XC1001-A

XC1003-A

XC1005-A

Fig. 13 XC10xx-A, user interface labels

The label to be inserted in position 2 is different whether the stop/emergency hold function is used or

not.

28

Building Technologies A6V10257473_b_en_--.doc

Fire Safety & Security Products 01.2010

Page 29

7 Connections

The installation must be realised by qualified personnel and in conformity with the

7.1 Mains

applicable national electric standard.

Connection with the mains must be established through an external circuit breaker

(bipolar circuit breaker 1 A).

1. Make sure that the mains voltage is switched off

2. Connect the mains cable to the PSU terminals according to the pin assignment

specified onto the PSU:

– Protection ground ( ), neutral (N) and phase (L)

3. Fix the cable with two fasteners and check, during installation, that these fixings

are well in place

The XC10xx-A equipment is not designed to be connected according to an IT earth network.

If such a network must be used, a separation transformer will have to be installed.

Danger - Electrical voltage

Mortal danger due to electric shock

- Before laying the mains cable, make sure that it is not connected to the power supply.

- Check to make sure that the mains are secured against inadvertently being switched on.

Danger - Short circuit

Potential damage to hardware

- Before installing or dismantling the power supply unit, remove the wire jumper between the two

batteries.

- This ensures that the secondary side is current-free and that no modules can be damaged due to

a short circuit.

Connections

7.2 Batteries

Two 12 V batteries, connected in series, can be connected with the FCP1004-E

power supply. According to the versions, the following batteries can be installed:

- XC1001-A : 4.5 Ah

- XC1005-A : 12 Ah or 17 Ah

- XC1003-A : 4.5 Ah or 7.2 Ah

Fig. 14 Battery connection

In some countries i.e. [FR], it is necessary to indicate the total loss of power supply (option with

requirement EN54-2). In such case, connect the wire provided between + of the batteries and the X28

terminal of XCM1002 mainboard.

29

Building Technologies A6V10257473_b_en_--.doc

Fire Safety & Security Products 01.2010

Page 30

Connections

7.3 Fire detectors/Manual release control buttons

Four monitored inputs are available on the X10 terminal block for the connection of

fire detectors or alarm contact (i.e. contact from FDCIO222) and electrical manual

triggering devices (DM1103-L)

- Detection zones 1 to 3 operation is defined at programming steps 52 to 55 (see

paragraph 12.14)

- Extinguishing manual release control operation does not require programming.

Up to 32 buttons DM1103-L can be connected

Technical data common to the 4 inputs

EOL: transzorb 18V connected at the end of the line

Line resistance max.: 80 Ω

10,6 V

Transzorb 18 VTranszorb 18 V

Fig. 15 XC10xx-A, connection of detectors and manual triggering devices

The number of detectors which can be connected is determined by dividing the

collective system line connection factor (KLK = 32) by the collective element load

factor (KMK = see table below).

Series of detectors Designation KMK Nb

ALGOREX DO1101A / DO1102A / DO1104A 1 32

DT1101A / DT1102A 1 32

DF1191 / DF1192 6 5

SINTESO FDOOT241-9 2 … 1.25 (*) 16 … 25

FDF221-9 / FDF241-9 5 6

FDL241-9 10 3

SYNOVA OP320C / OH320C 1 32

HI320C / HI322C 1 32

(*) Depends on detector index and set of parameters

For Sinteso detectors, select an appropriate set of parameters.

Transzorb 18 V

30

Building Technologies A6V10257473_b_en_--.doc

Fire Safety & Security Products 01.2010

Page 31

7.4 Monitored inputs

Four monitored inputs are available on X9 terminal block for the connection of

various devices. Operation is defined at programming steps 28 to 31 (see

paragraph 12.9).

Technical data common to the 4 inputs

EOL: 3.3 kΩ resistance connected at the end of the line

Line resistance max.: 80 Ω

7.4.1 Monitored input 1

This input is exclusively reserved for the connection of the extinguishing

discharged contact. Operation is defined at programming step 28.

Connections

Fig. 16 XC10xx-A, monitored input 1 connection

1 Discharged contact normally closed (NC)

2 Discharged contact normally open (NO)

7.4.2 Monitored input 2

This input is exclusively reserved for the connection of the loss of agent devices

(manometer or weighing device). Operation is defined at programming step 29.

Fig. 17 XC10xx-A, monitored input 2 connection

1 Loss of agent contact normally closed (NC)

2 Loss of agent contact normally open (NO)

1.2 kΩ

1.2 kΩ

3.3 kΩ

1.2 kΩ

1.2 kΩ

3.3 kΩ

31

Building Technologies A6V10257473_b_en_--.doc

Fire Safety & Security Products 01.2010

Page 32

Connections

7.4.3 Monitored input 3

This input can be used for several purposes. Operation is defined at programming

step 30.

Fig. 18 XC10xx-A, monitored input 3 connection

1 Mechanical blocking device

2 Extinguishing remote activation

3 Automatic blocked / Manual blocked / Automatic and manual blocked

4 Emergency abort

7.4.4 Monitored input 4

This input can be used for several purposes. Operation is defined at programming

step 31.

Fig. 19 XC10xx-A, monitored input 4 connection

1 Emergency abort

2 Emergency hold

3 Automatic blocked / Manual blocked / Automatic and manual blocked

When monitored inputs 3 and 4 are programmed respectively as « Emergency hold » and

« Emergency abort », emergency abort have priority

1.2 kΩ

680 Ω

1.2 kΩ

1.2 kΩ

680 Ω

1.2 kΩ

3.3 kΩ

680 Ω

1.2 kΩ

1.2 kΩ

3.3 kΩ

32

Building Technologies A6V10257473_b_en_--.doc

Fire Safety & Security Products 01.2010

Page 33

7.5 Control inputs

Four control inputs, including three programmable (2 to 4), are available on X27

terminal block to receive controls or information via relay contacts. Operation is

defined at programming steps 48 to 51 (see paragraph 12.13).

Connections

Fig. 20 XC10xx-A, control inputs connection

– These inputs shall not be activated by an external +24 V

– The relays must be installed inside the equipment

– When a control input is programmed as « Reset » or « Level 2 access » or « Manual blocked » or

« Automatic blocked » or « Automatic and manual blocked » or « Silence / Restart Sounders »,

theses controls must only be possible through an operating level 2 access device.

33

Building Technologies A6V10257473_b_en_--.doc

Fire Safety & Security Products 01.2010

Page 34

Connections

7.6 Monitored control outputs

Five monitored control outputs are available on terminal blocks X7, X6 and X5 for

the connection of various devices.

Technical data for control outputs 1 to 3

- activation by reverse polarity (polarities indicated are “activated” polarities,

according to connected device, a diode can be necessary)

- line monitoring: 3.3 kΩ resistance connected at the end of the line

- protection: 1 AT fuse (F4 / F5 / F6)

Technical data for control outputs 4 and 5

- activation polarity is not reversed

- line monitoring: by calibration, within a range between 1 and 900 Ω

- protection: 2 AF fuse (F1 / F2)

Technical data common to the 5 control outputs

The maximum number of devices per output is determined by calculation, in 2

steps (see example below), depending on:

- minimum/maximum XC10 operating voltage = 22.5 V / 27.6 V

- nominal current consumption per device (@24V, see device technical data’s)

- minimum device operating voltage (see device technical data’s)

- protection fuse rating = 1 A or 2 A

- cable resistance (2x1.5 mm2 = 24.2 Ω / km, 2x2.5 mm2 = 14.8 Ω / km)