Page 1

A6V10257473_e_en_--

Building Technologies

2015-03-04 Control Products and System

XC10

Extinguishing control unit

XC1001- A / XC1005-A /

XC1003- A

Installation

Commissioning

Maintenance

Page 2

© Siemens Switzerland Ltd, 2015

W e reserve all rights in this document and in t he subject thereof. By acceptance of the document the recipient acknowledges these

rights and undertak es not to publish the doc ument nor the subject thereof in full or in part, nor to make them available to any third

party without our prior express written author ization, nor to use it for any pur pose other than for w hich it was delivered to him.

Page 3

3

Building Technologies A6V10257473_e_en_-Fire Safety 2015-03- 04

1 About this docume nt........................................................................... 7

2 Safety instruc tions .............................................................................. 9

2.1 Dange r levels ........................................................................................ 9

2.2 Safety instruction s ................................................................................. 9

2.3 Standa rds an d direc tives co mp lied w ith ............................................... 10

3 Standar ds .......................................................................................... 11

4 Overv iew ............................................................................................ 12

4.1 XC10 01-A ........................................................................................... 12

4.2 XC10 05-A ........................................................................................... 13

4.3 XC10 03-A ........................................................................................... 14

4.4 FCP100 4-E ......................................................................................... 15

4.5 XCM10 02 ............................................................................................ 16

4.6 User interface ...................................................................................... 18

5 Features ............................................................................................. 21

6 Instal lation ......................................................................................... 22

6.1 XC10 01-A / XC100 5-A ........................................................................ 22

6.2 XC10 03-A ........................................................................................... 24

6.3 User interface labels ............................................................................ 28

7 Connec tions ...................................................................................... 2 9

7.1 Mains .................................................................................................. 29

7.2 Batteries .............................................................................................. 29

7.3 Fire detectors /Manu al releas e control buttons ...................................... 3 1

7.4 Monitored inputs .................................................................................. 33

7.5 Control inputs ...................................................................................... 35

7.6 Monitored cont rol outpu ts .................................................................... 36

7.7 Programmab le outputs ........................................................................ 39

7.8 24V powe r supply outpu t ..................................................................... 42

7.9 Repea te r ter mina l and rep ea te r dis p lay ............................................... 42

8 Multi-s ector insta llation .................................................................... 43

8.1 Function al descript ion .......................................................................... 43

8.2 Detailed description ............................................................................. 45

8.3 Installat ion and wiring .......................................................................... 48

8.4 Modules te chn ica l sp eci fica tion ........................................................... 49

9 Accessories ....................................................................................... 50

9.1 FCA100 7 – Key switch ........................................................................ 50

9.2 FDCI222 / FDCIO22 2 – Input/outp ut inter faces .................................... 5 0

9.3 Remote transmitter .............................................................................. 50

9.4 Repea ters ........................................................................................... 51

10 Operati ng access levels .................................................................... 56

10.1 Operating ac ce s s le vel 1 ..................................................................... 56

10.2 Operating ac ce s s le vel 2 ..................................................................... 56

10.3 Operating acce s s level 3A ................................................................... 56

10.4 Operating acce s s level 3B ................................................................... 56

11 Extingu ishing process diagrams ...................................................... 5 7

Page 4

4

Building Technologies A6V10257473_e_en_--

Fire Safety 2015- 03- 04

12 Programming ..................................................................................... 58

12.1 Before starting ..................................................................................... 58

12.2 Prese ttings .......................................................................................... 59

12.3 Steps 0 1 to 04 - Time duration settings................................................ 62

12.4 Step 05 - Sounde rs ............................................................................. 64

12.5 Steps 06 to 09 - Re mo te transmis s ion ................................................. 6 4

12.6 Steps 10 to 14 - Monitore d outputs 1 to 5 ............................................ 65

12.7 Steps 15 to 19 - Relay contact 1 to 5 ................................................... 6 6

12.8 Steps 20 to 27 - Driver outputs 1 to 8 .................................................. 67

12.9 Steps 28 to 31 - Monitore d inputs 1 to 4 .............................................. 68

12.10 Steps 32 to 38 - Rese t ......................................................................... 70

12.11 Steps 39 to 43 - Operat ion .................................................................. 7 0

12.12 Steps 44 to 47 - Fau l ts ........................................................................ 71

12.13 Steps 48 to 51 - Non monitored control inputs 1 to 4 ............................ 71

12.14 Steps 52 to 55 - Detect ion zon e s ......................................................... 72

12.15 Steps 56 to 57 - Operating acce s s level ............................................... 7 3

12.16 Step 58 - Multi-se cto r .......................................................................... 73

12.17 Step 59 - Dete ctor type ........................................................................ 73

12.18 Steps 60 to 61 - Repe aters .................................................................. 73

12.19 Step 62 - Los s of agent in mu lt i-sector ap p l ica tion ............................... 74

12.20 Steps 63 to 64 - Fire da mpe r ............................................................... 74

12.21 Step 65 to 66 - Pre-discharged warning time in manual release ........... 75

12.22 Step 67 – Op eration if “Discharge” is acti va te d in stand b y ................... 76

13 Commiss ioning ................................................................................. 77

13.1 Powering ............................................................................................. 77

13.2 Monitored con t rol ou tputs 4 and 5 calibra t ion ....................................... 77

13.3 System test ......................................................................................... 78

13.4 Commiss ioning validation .................................................................... 78

14 Maintena nce ...................................................................................... 79

14.1 Prevent ive maintenance ...................................................................... 79

14.2 Detailed faul t display ........................................................................... 82

15 Test functi ons ................................................................................... 84

15.1 Led test ............................................................................................... 84

15.2 Sound er test........................................................................................ 8 4

15.3 Warning pan e ls tes t ............................................................................. 84

15.4 RT-alar m test ...................................................................................... 85

15.5 RT-fault tes t ........................................................................................ 8 5

15.6 System test ......................................................................................... 85

15.7 Individu al outp u t test ........................................................................... 86

15.8 Zone test ............................................................................................. 87

15.9 Manua l releas e test ............................................................................. 87

16 Adva nced functions .......................................................................... 8 8

16.1 Checks um ........................................................................................... 88

16.2 Alarm counter ...................................................................................... 88

17 Special fu ncti ons .............................................................................. 8 9

17.1 Anticipa ted Silence Sounders .............................................................. 8 9

17.2 Anticipa ted Reset ................................................................................ 89

17.3 Extract fan ........................................................................................... 89

Page 5

5

Building Technologies A6V10257473_e_en_-Fire Safety 2015-03- 04

18 Connectio n to Sinte so / Cerber us PRO pa nels ................................ 90

18.1 XC10 zone .......................................................................................... 90

18.2 Detecto rs c o n n e cte d to XC10 pane l .................................................... 91

18.3 Detecto rs co nn e cte d to Sinte s o / Cerb eru s PR O pa n el ........................ 94

19 Maintena nce PC ................................................................................ 97

20 Componen ts an d spa re parts ........................................................... 9 8

Page 6

6

Building Technologies A6V10257473_e_en_--

Fire Safety 2015- 03- 04

Page 7

About this document

7

Building Technologies A6V10257473_e_en_-Fire Safety 2015-03- 04

1 About this document

Purpose of the document

This document describes the installation, the commissioning and the maintenance

of the XC100x-A equipment. It provides an overview of the structure and functions

of the system as a whole as well as of the indiv idual devices.

While following the instructions, a reliable operation is assured.

Scope

The information contained in this document is valid for the market package MP2.3.

The document also contains information on country-specific components. Country specific components are marked with square brackets, e. g. [FR], and may not be

sold/used in your count ry.

Target audience

This document and the information contained therein are aimed at the target

groups defined below:

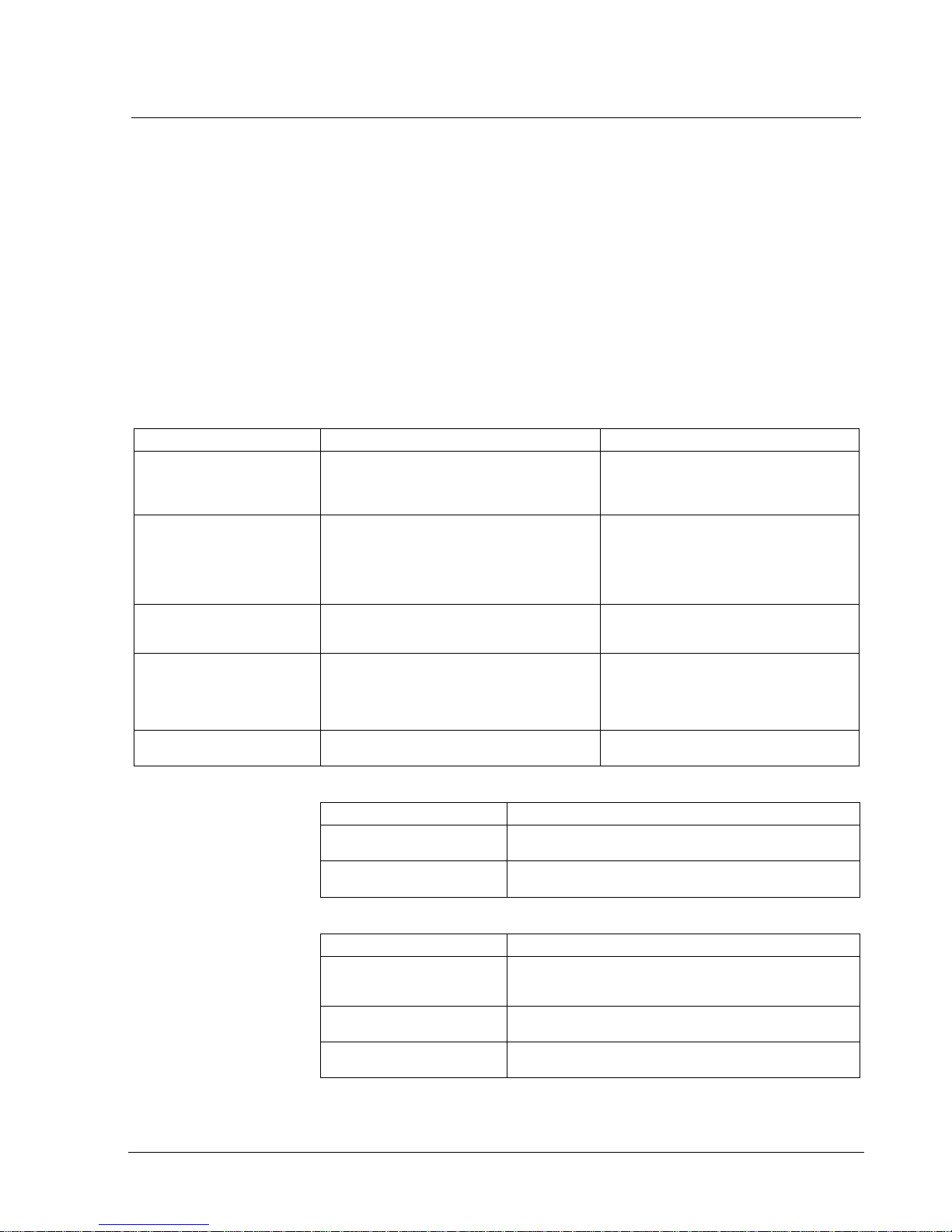

Personnel Activity Qualificatio n

Product m an ag er – Perfor ms local product managem ent

– Respons ible for exchangi ng inform ation

between the headquarters and his/her Regional

Company (RC) for his/her product range

– Has suitabl e speci alis t traini ng for th e

function and for the product range

– Has attend ed the PM train ing courses

Project m an ag er – Performs project manag ement

– Coordi nat es the use of all persons an d

resources involved in the project according t o

schedule

– Contin uous ly suppli es inf ormati on neces s ary for

project realisation

– Has suitabl e speci alis t traini ng for th e

– functi on, sc ale of the project and pr oduct

range

– Has attend ed the training c ours es for

Project M an ag ers

Install er – Assemb les and inst alls th e compon ents at th e

place of installation

– Perf orms a subsequ en t check of the inst allati on

– Has recei ved spec iali z ed traini ng in the area

of buildin g installation techn ology or

electrical installations

Commissioning personnel – Config ur e the produc t at the place of instal lat ion

according to customer specific requirements

– Check th e product oper abil it y and releas e the

product for use by the operator

– Search for and correct malfunc tions

– Has suitabl e speci alis t traini ng for th e

function and for the product range

– Have atten ded the train ing courses for

commissioning personnel

Maintenance pers on n el – Carry out all maint en anc e work and ch eck for

correct functioning

– Has suitabl e speci alis t traini ng for th e

function and for the product range

Reference docu ments

Designation Heading

A6V10257477 XC10 Extinguish ing control unit

Operating manual

001204 Fire alar m si gnal in areas at r isk of expl osi on

Principles, applications, instal lation, m aintenance

Identific ation of the docum ent

Location Definition

Title page – Short name

– Name in f ull

– Docum ent pur pose

Last page bottom left-hand side – Document no. (number-modification index-language-country)

– Date of issue

Last page bottom right-hand

side

– User's guide

– Register

Page 8

About this document

8

Building Technologies A6V10257473_e_en_--

Fire Safety 2015-03- 04

Revision history

Document no. Edition date Brief description

A6V10257473_e_en_-- 03.2015 - MP2.3 SR2

A6V1025 7473_d _en_-- 04.20 12 - MP2.3 SR1

A6V1025 7473_c _en_-- 09. 2010 - chap. 4.5 upd at ed (f ig. 5 and t abl e)

- c h ap 7.2.1 ad d ed: meth od f or c alcu lati on of th e bat t ery

capacity

- ch ap. 7.3: fig. 7.15 upd at ed

- chap. 8 updated

- c h ap. 8.3: f ig. 31 u pd at ed (l oss of ag en t is n orm all y

closed)

- c hap 9.4 add ed: d escri pti on of rep eat er dis pl ay and

repeater terminal

- c h ap 12.1: pr oc edur e st ep 5 upd at ed

- c hap 12.2 : count r y pre-s ettin gs upd ated

- chap 12.9: step 30 option 04 updated

- ch ap 12.18 add ed (step 60)

- c hap 13.1 u pd ated (p ar agr aph n u mber)

- c h ap 13.2 u pd at ed: w arni ng f or t h e calibration add ed

- chap 14.1 updated

- c h ap 14.2 upd at ed (1 0s inst ead of 5s )

- c hap. 15, 16, 17 upd at ed: sev er al word ing

- c hap 18 added

- chap. 19, 20 updated

- C E mar ki ng pap ers add ed at th e en d of th e docu m ent

A6V1025 74 73 _b _ en_ -- 01/20 10 Corrections after field tests:

- Chap. 3: Standar ds / 4.19 m oni t orin g th e st atus of

components (spelling mistake)

- Ch ap.4: fig 4 updated

- Chap. 6.3 label for XC1 0 03-A is Pos. 8 not Pos.4

- Ch ap. 7. 6.2 …. “to equ ipm ent outs id e” (sp elli ng

mistake)

- Ch ap 7.8 : 24V p olarit y out pu t was wr ong . 24V( +) is on

X5-3 and 24V(-) is on X5-4

- C hap. 8. 2: n ote ad d ed for th e conn ec ti on of the 24V

power supply

- Chap 8.3: fig 31 modif i ed: r es istor 3.3k on RS485 li n e

removed

- Ch ap 11: f ig 33 and 34 updat ed

- C h ap 14.2: PMI picture is add ed on t he top of th e

descrip tion table, for an easier checki ng

- Ch ap. 16 .2: acc ess c ode f or the al arm cou nt er w as

wrong

- Spelling mistakes

A6V1025 7473_a_ en_-- 11/2009 First edition MP2. 1

Page 9

Safety instructions

9

Building Technologies A6V10257473_e_en_-Fire Safety 2015-03- 04

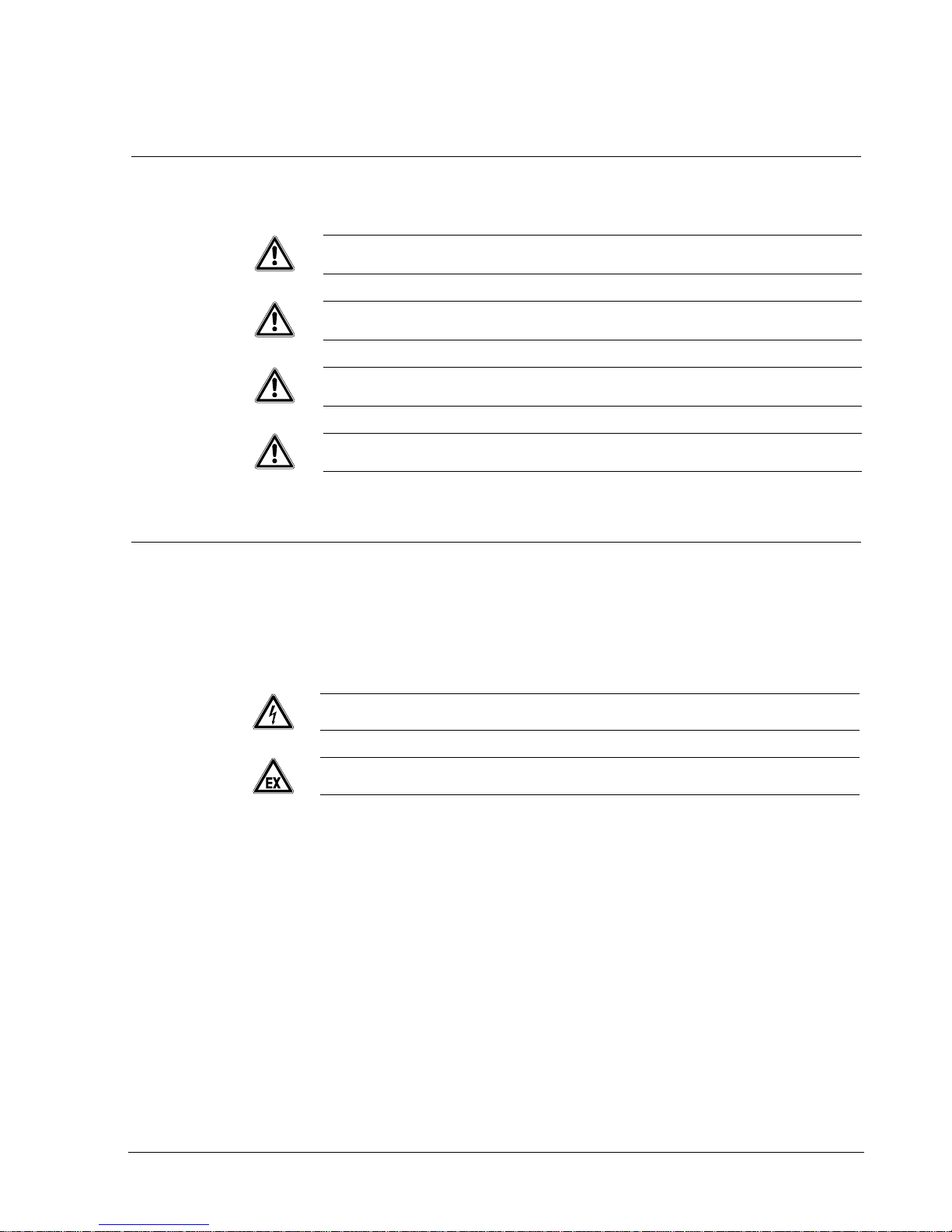

2 Safety instructions

2.1 Danger levels

The following pictograms indicate the possibl e danger levels, their severity and

consequences.

DANGER

Imminent danger!

è Serious in juries or death.

WARNING

Potentially dangerous situation

è Serious in juries or death.

CAUTION

Potentially dangerous situation

è Light in juries or material d am age.

NOTE Importan t information requiring spec ial attention.

2.2 Safety instructions

Products are developed and manufactured in accordance with the applicable

international and European security standards.

The local rules of i nstallation, exploitation and destruction of the product apply and

must be respected just like the safety instructions which appear i n the

documentati on of the product.

Electric installations

CAUTION Interventions on w iring should be carried out only by qualified personnel.

CAUTION Respect the safety instructions in expl osive zon e.

l Hardware must not be powered during commissioning and maintenance

l Affix an external label “DANGER external voltage” on the terminals connected t o

an external voltage source

l Separately lay the power lines towards the control unit. They must be fitted with

their own, clearly identified fuses

l Ground in accordance with the local security standards

Assembly, installation, commissioning and maintenan ce

l If any tools or accessories such as l adders are required, safe and suitable

devices must be used

l When the extinguishing control panel is started up, it must be ensured that no

instable condit ions can occur

l Controls may only be set to normal function when the product operability has

been completely tested and the system has been handed over to the customer.

l Control release for testing should not damage the installation

l Avoid the inopportune release of RT-alarm

l Inform the reception station before an RT-al arm test

l Installation and commissioning shall be performed by trained personal

Page 10

Safety instructions

10

Building Technologies A6V10257473_e_en_--

Fire Safety 2015-03- 04

Product operation check

l Inform the personnel of the formation of a smoke cloud and presence of noise

l Inform the personnel before alarm devices check and ant icipate possible pani c

reactions

l Warn the alarm recepti on centers and the fault reception stations connected to

the system before carrying out the tests

Design modifications of systems and products

l Modifications to the system and to individual products may lead to faults,

malfuncti oning and safety risks

l Intended system modifications or extensions require written approval from

Siemens and the rel ev ant safety authorities

Components and spare parts

l Components and spare parts m ust comply with the technical specifications

defined by Siemens. Only use products recommended or prescribed by Siemens

l Only use fuses with the specified fuse characteristics

l Wrong battery types and improper battery changing lead to a risk of explosion.

Only use the same battery type or an equivalent type recommended by Siemens

l Batteries must be di sposed of in an environmentally friendly manner. Count ry

specific directives and regulations must be observed. They must be deposited at

the collecti on places assigned to this purpose.

l Note that the cylinders containing the extinguishing agent are under pressure

and that they must consequently be replaced in accordance with the safety

instructions in force

Disregard of the safety regulations

Before they are delivered, products are tested to ensure they function correctly

when used properly. Siemens disclaims all liability for damage or injuries caused

by the incorrect application of the instructi ons or the disregard of danger warnings

contained i n the docum entation. This applies in particular to:

l Personal inj uri es or damage to property caused by improper use and incorrect

applicati on

l Personal inj uri es or damage to property caused by disregarding safety

instructi ons i n the docum entation or on the product

l Personal injury or damage to property caused by poor maintenance or lack of

maintenance

2.3 Standards and directives complied with

A list of the standards and directives complied with is available at your Siemens

contact part ner.

Page 11

Standards

11

Building Technologies A6V10257473_e_en_-Fire Safety 2015-03- 04

3 Standards

In addition to the requirements of EN12094-1 and EN54-2, the XC100x-A control

panel complies with the following optional functions:

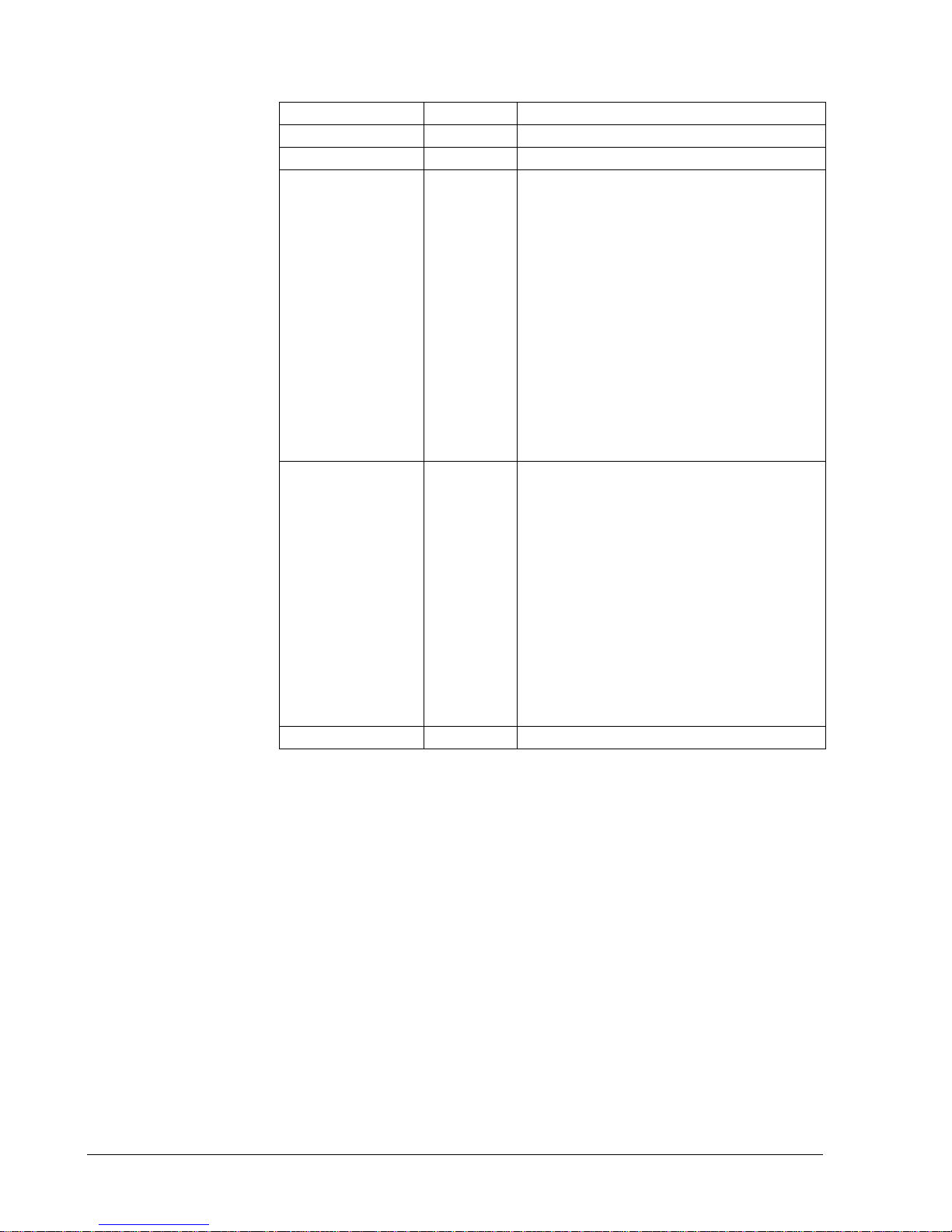

EN 12094-1

Clause Description

4.17 Delay of extinguishing signal

4.18 Signal r epresenti ng t he flow of extinguis hing agent

4.19 Monitoring the status of components

4.20 Emergency hold device

4.21 Control of floodi ng time

4.23 Manual onl y m od e

4.24 Triggering signals to equi pment wit hin the system

4.26 Triggering of equi pment outside the system

4.27 Emergency abort d evice

4.29 Release of the extinguishing media for selected flooding zones (only for XC1003-A)

4.30 Activati on of alarm device with differ ent signals

EN 54-2 / A1

Clause Description

7.8 Output t o fire alarm devices (Item C – EN54-1)

7.9.1 Control of fir e alarm rout ing equipment (Item E – EN54-1)

7.12.1 Depend encies on more th an one alarm sig nal (T ype A)

7.13 Alarm counter (only with XC1005-A)

8.3 Fault signals from point

8.4 Total loss of the p ower supply

8.9 Output to fault warning routing equipment (Item J – EN54-1)

10 Test condition

Following additional functions are also available:

- transmission of i nformation's outside the panel :

8 programmable digital outputs

programmable relay contacts

- reception of information's from outside:

control inputs (3 are programmable)

- 24V power supply output

Page 12

Overview

12

Building Technologies A6V10257473_e_en_--

Fire Safety 2015-03- 04

4 Overview

The equipment is declined in 3 versions:

- Wall mounting cabinet: XC1001-A / XC1005-A

- 19” rack cabinet: XC1003-A

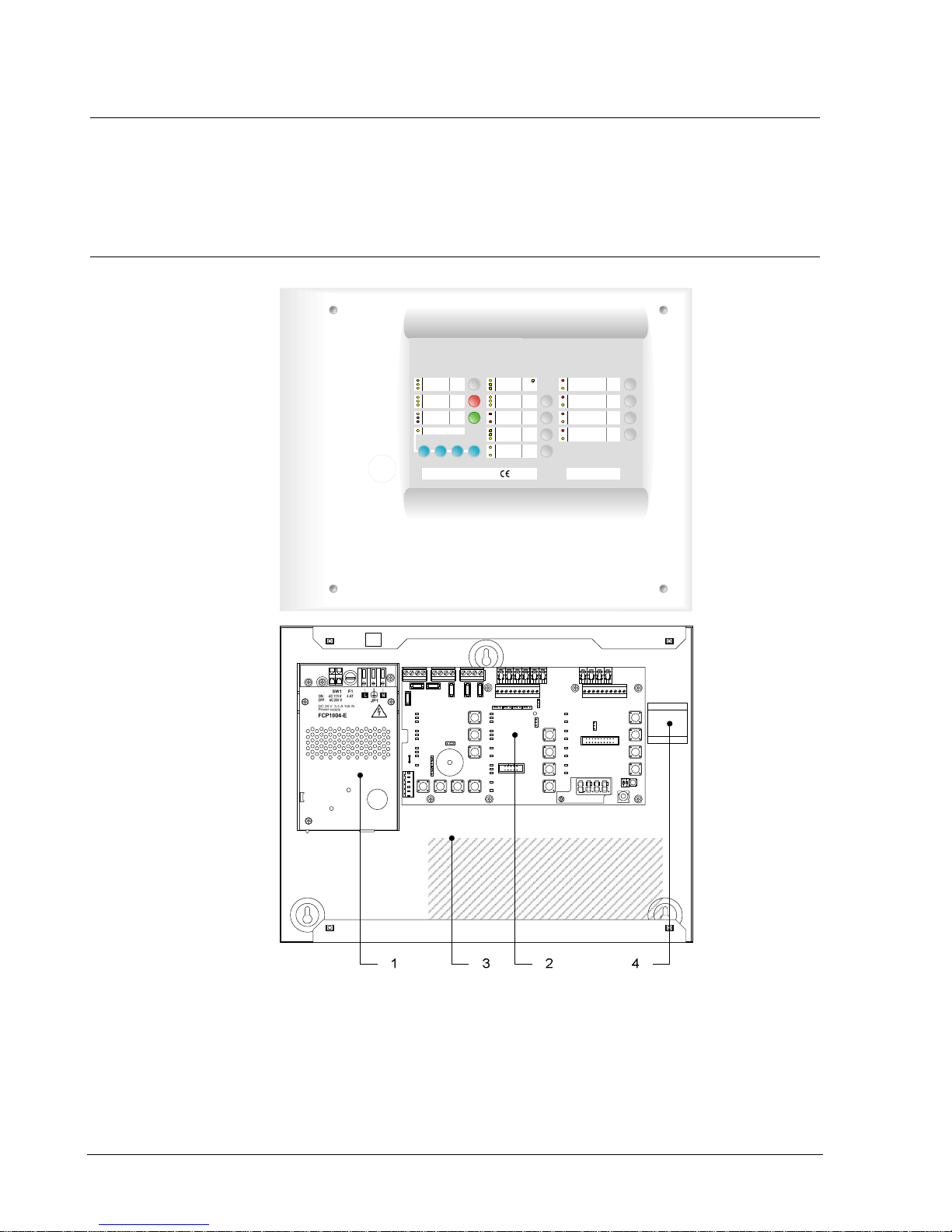

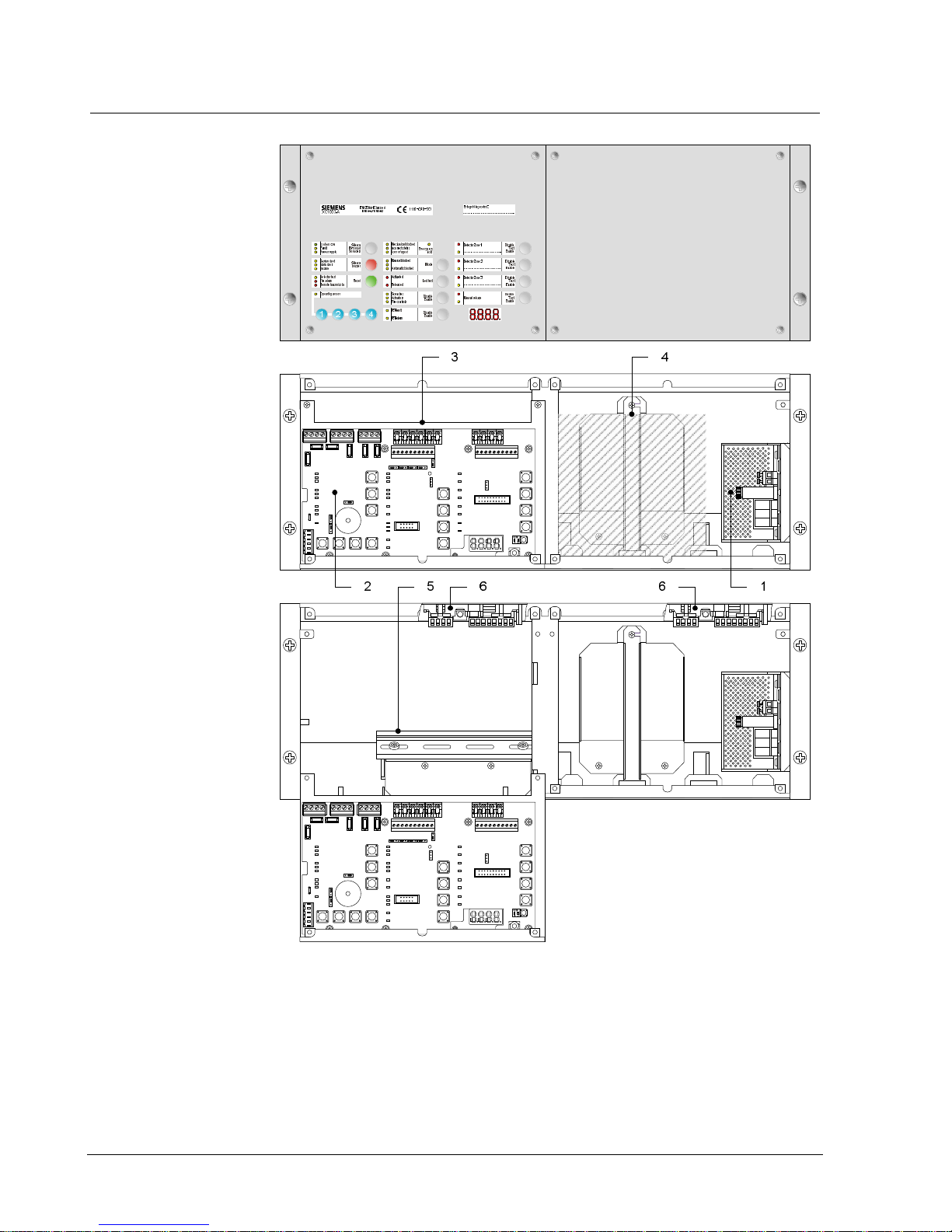

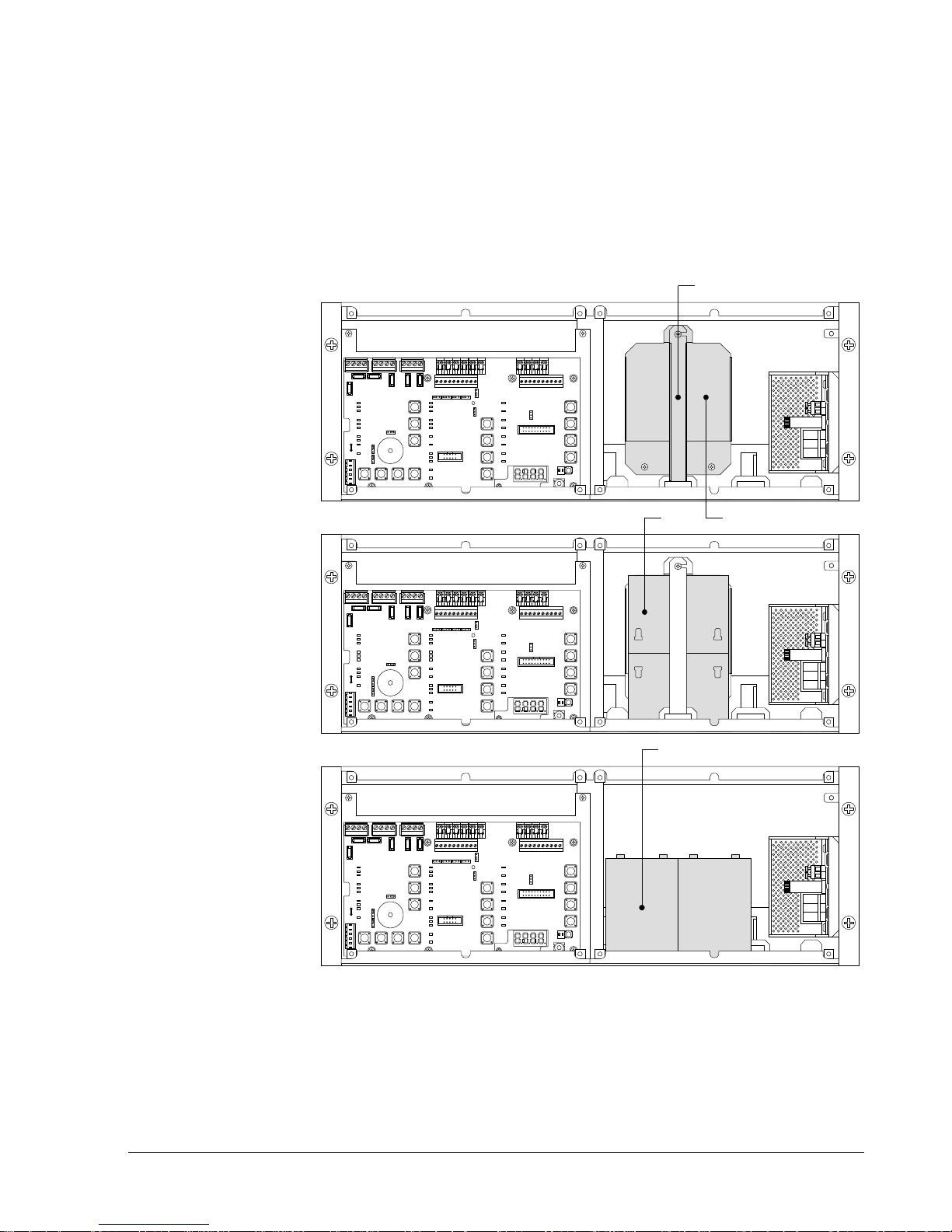

4.1 XC1001-A

System ON

Silence

buzzer

Silence

Re-sound

Sounders

Automatic blocked

Activated

Mode

Operating access

Earth fault

System fault

Disable

Fault

Manual blocked

Manual release

Released

Detector Zone 1

………………………………….

Mechanical blocked

Loss of agent

Incorrect status

Emergency

hold

Sounders

Fire controls

Enable

Disable

Detector test

Fire alarm

Remote ransmission

Disable

Test

Enable

Detector Zone 2

………………………………….

Detector Zone 3

………………………………….

432

1

2

Disable

Test

Enable

Disable

Test

Enable

Disable

Test

Enable

Power supply

Reset

RT-fault

RT-alarm

Actuators

Led test

Enable

Disable

Extinguishing contro l:

……………………………………… ……………..

s

XC1001-A

EN12094-1 Class A

EN54-4 / EN54-2

1116 - CPD– xxx

Fig. 1 XC1001-A

1 FCP1004-E power supply unit with charger

2 XCM1002 mainboard

3 4.5 A/h batteries

4 DIN rail for accessory mounting (Z3B171 relay module)

Page 13

Overview

13

Building Technologies A6V10257473_e_en_-Fire Safety 2015-03- 04

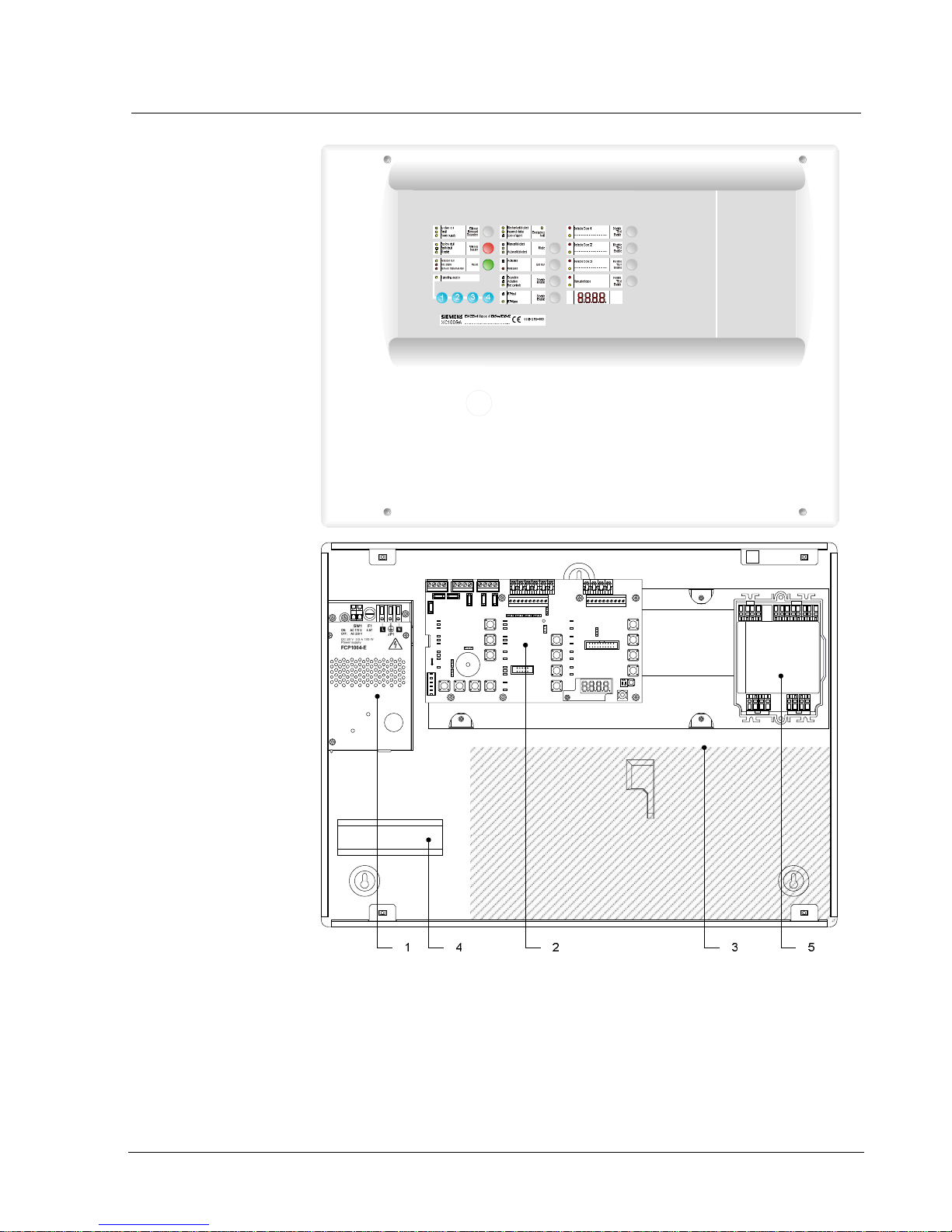

4.2 XC1005-A

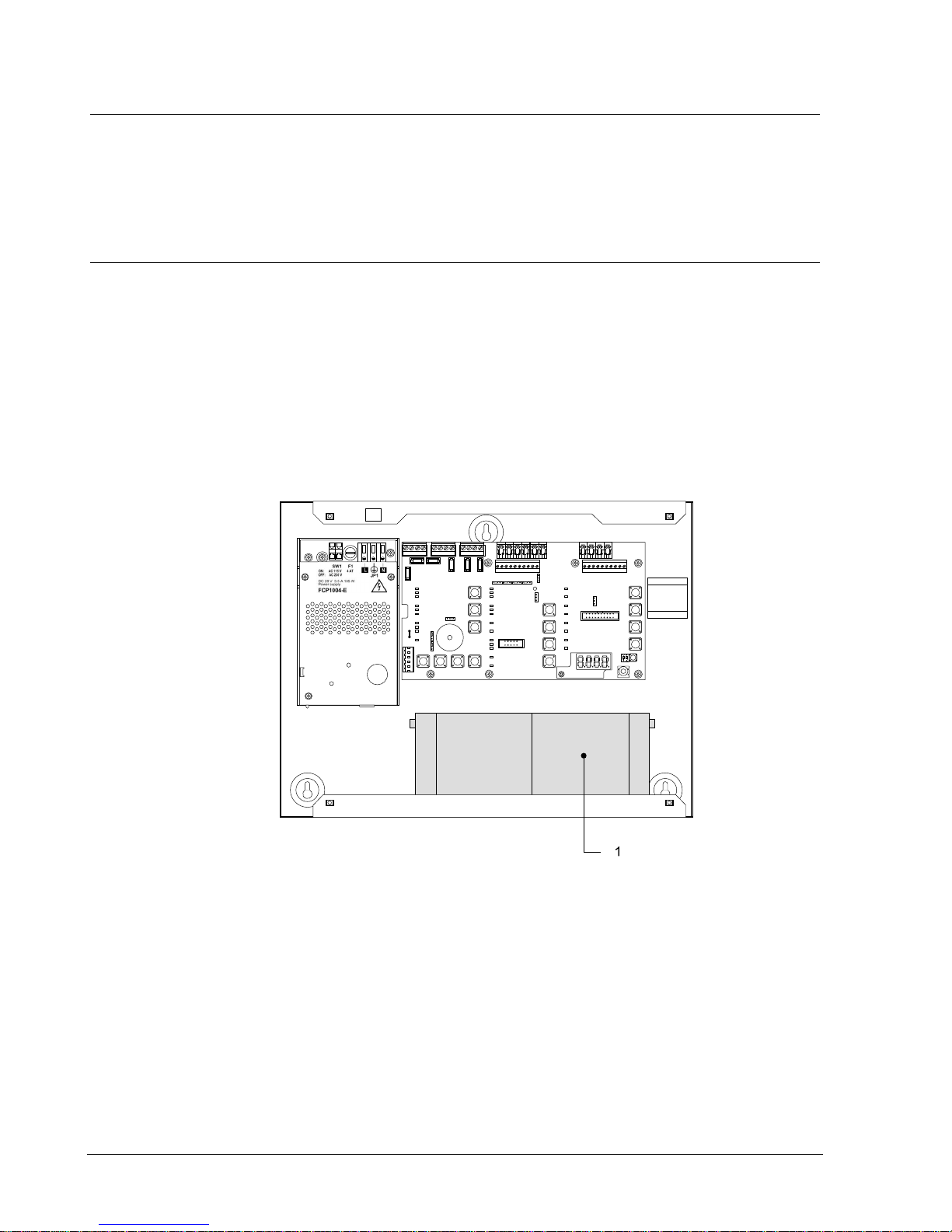

Fig. 2 XC1005-A

1 FCP1004-E power supply unit with charger

2 XCM1002 mainboard

3 17 A/h batteries

4 DIN rail for accessory mounting (Z3B171 relay module)

5 FDCI / FDCI O222 module for the connection to a fire detection system

(option)

Page 14

Overview

14

Building Technologies A6V10257473_e_en_--

Fire Safety 2015-03- 04

4.3 XC1003-A

Fig. 3 XC1003-A

1 FCP1004-E power supply unit with charger

2 XCM1002 mainboard

3 Removable mainboard holder

4 4.5 A/h or 7.2 A/h batteries

5 DIN rail f or accessory mounting (Z3B171 rel ay m odule, XCA1030 multi-sect or

modules, etc.)

6 FDCI / FDCI O222 module for the connection to a fire detection system

(option)

Page 15

Overview

15

Building Technologies A6V10257473_e_en_-Fire Safety 2015-03- 04

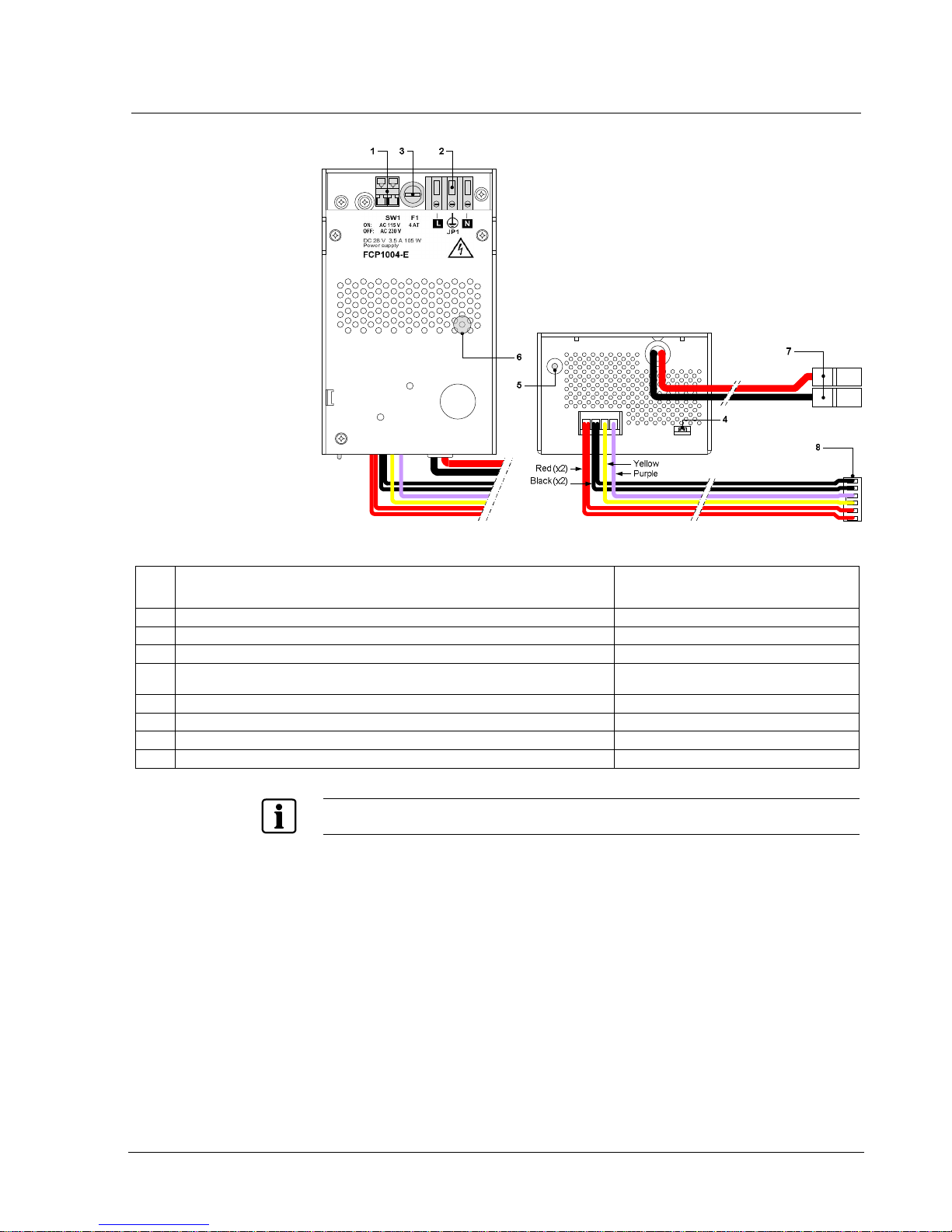

4.4 FCP1004-E

Fig. 4 FCP1004-E power suppl y unit

Mark Function Remarks

1 Mains voltage setting Shunt ON = 115VCA, shunt OFF = 230VCA

2 Mains terminal block

3 Mains fuse 4A / 250V

4 System start without mains power Shunt th e 2 terminals with a jum per and

remove after system start

5 Temperature sensor for battery charging voltage compensation Do not cover

6 Internal green LED «Mai ns operat ion» but visible fr om the f ront Not lit if no m ains volt age

7 Battery connection

8 XCM1002 main board connection

Security level of terminal blocks 1 and 2: Dangerous v oltage

Security level of other terminal blocks: SELV (Safety Extra Low Voltage)

Page 16

Overview

16

Building Technologies A6V10257473_e_en_--

Fire Safety 2015-03- 04

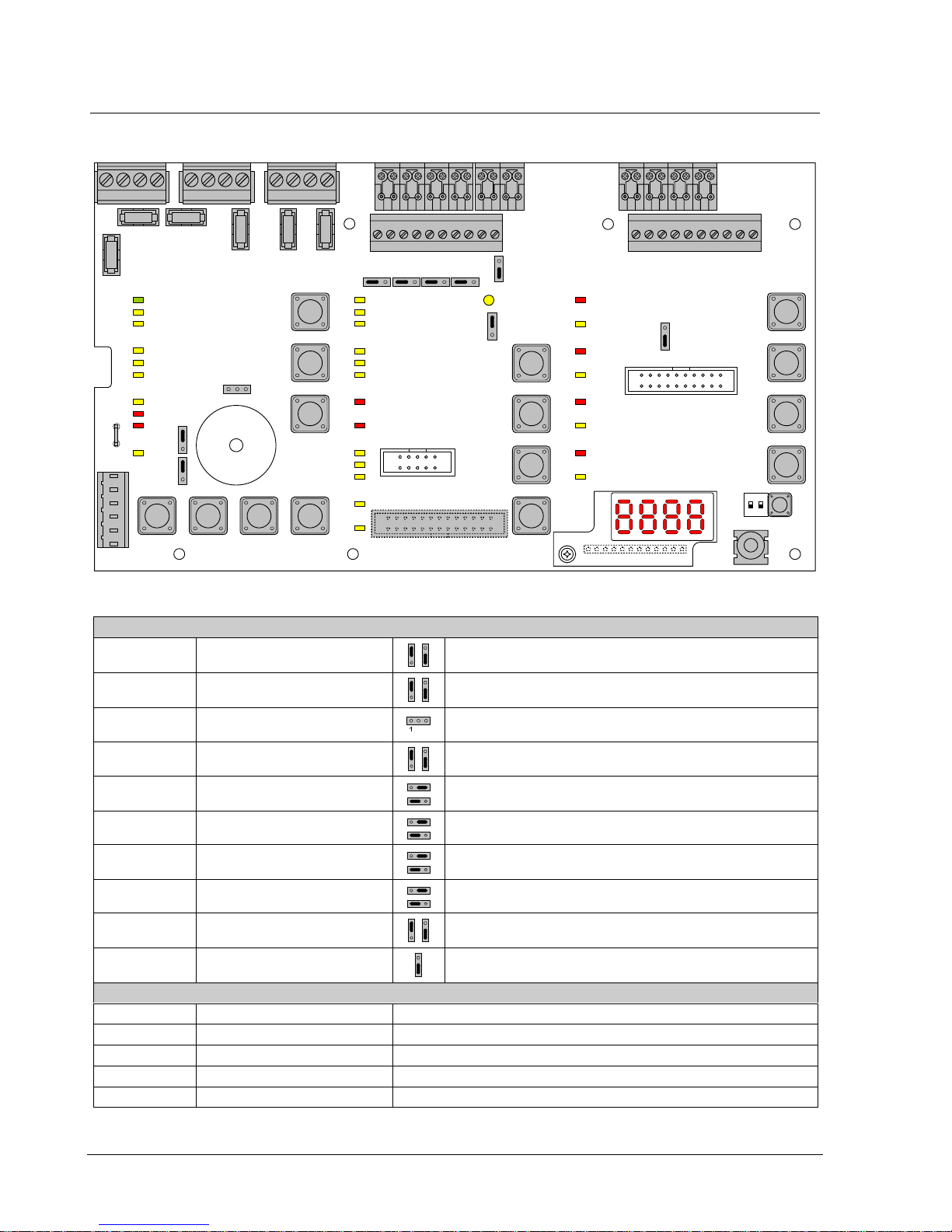

4.5 XCM1002

32

2411

12

13

14

15

16

17

18

19

20

21

22

23

25

26

27

28

29

30

31

10

7

1

2

3

5

6

8

9

4

X23

X24

ON

12

X8

X3X4

X28

X1

F3

F6 F5 F4

F2 F1

X14 X15 X16 X17

X13

X18

X26

S1

X21

1

X11

1

X12

X10X27 1X9

1

X7X6

11

X5 11

1

S18

X35

X20

41 2 3

5

6

7

8

9

10

11

12

13

14

15

1

Fig. 5 XCM1002 board

Setting el ements

X3 Internal buzzer En able/Disable Jumper up (factory setting) : bu zzer enabled

Jumper down : buzzer disabled (only for servicing)

X4 Type of pow er supply Jumper up (factory setting) : FCP100 4-E

Jumper down : do not use (for further use of extern al power supply)

X8 Operati ng access Level 2 Jumper on the left: Level 2 permanent access

1 – 2: external key switch (option)

X13 Relay contact typ e 1

(NO or NC)

Jumper up : NC contact

Jumper d own (factory setting) : NO contact

X14 Relay contact typ e 5

(NO or NC)

Jumper on the right : NC contact

Jumper on the left (factory setting) : NO contact

X15 Relay contact typ e 4

(NO or NC)

Jumper on the right : NC contact

Jumper on the left (factory setting) : NO contact

X16 Relay contact typ e 3

(NO or NC)

Jumper on the right : NC contact

Jumper on the left (factory setting) : NO contact

X17 Relay contact typ e 2

(NO or NC)

Jumper on the right : NC contact

Jumper on the left (factory setting) : NO contact

X18 Repeater (RTNet end of line

element)

Jumper up (factory setting) : EOL connected

Jumper down : do not use

X26 Serial connection (not used) Jumper down (factory setting) : do not change the position

Other elements

F1 / F2 Pluggable fuse 2 AF Fuse for protection of contr ol outputs 4 (F1) and 5 (F2)

F3 Pluggable fuse 1 AT Fuse for protection of 24V output

F4 / F5 / F6 Pluggable fuse 1 AT Fuse for pr otection of control outputs 1 (F4), 2 (F5) and 3 (F6)

S1 Reset —

S18-1 / S18-2 Not u sed Do not change (factory setting : OFF)

Page 17

Overview

17

Building Technologies A6V10257473_e_en_-Fire Safety 2015-03- 04

PCB terminal blocks

X1 Plug-in block 6 points

(1.5 mm2 max.)

1-2 (–) / 5 -6 ( +) 24V p ower s upply

3-4 (+) Power supply m onitoring

X5 Plug-in block 4 points

(2.5 mm2 max.)

1 (+) / 2 (–) Monitored output 5

3 (+) / 4 (–) 24V use output

X6 Plug-in block 4 points

(2.5 mm2 max.)

1 (+) / 2 (–) Monitored outp ut 3 (control polarities, reversed in st andby)

3 (+) / 4 (–) Monitored output 4

X7 Plug-in block 4 points

(2.5 mm2 max.)

1 (+) / 2 (–) Monitored outp ut 1 (control polarities, reversed in st andby)

3 (+) / 4 (–) Monitored outp ut 2 (control polarities, reversed in st andby)

X9 Plug-in block 8 points

(1.5 mm2 max.)

1 (+) / 2 (–) Monitored input 1

3 (+) / 4 (–) Monitored input 2

5 (+) / 6 (–) Monitored input 3

7 (+) / 8 (–) Monitored input 4

X10 Plu g-in block 8 p oints

(1.5 mm2 max.)

1 (+) / 2 (–) Fire d etectors zone 1

3 (+) / 4 (–) Fire d etectors zone 2

5 (+) / 6 (–) Fire d etectors zone 3

7 (+) / 8 (–) Extinguishing manual control

X11 Plu g-i n bl oc k 10 p oints

(1.5 mm2 max.)

1 / 2 Potential-free c ontact relay 1 (NO or NC)

3 / 4 Potential-free c ontact relay 2 (NO or NC)

5 / 6 Potential-free c ontact relay 3 (NO or NC)

7 / 8 Potential-free c ontact relay 4 (NO or NC)

9 / 10 Potential-fr ee c ontact rel ay 5 (NO or NC)

X12 Plu g-i n bl oc k 10 p oints

(1.5 mm2 max.)

1 … 8 (–) Logical outputs 1 t o 8

9 (–) / 10 (+) Repeater display / Repeater t er minal RTNet connection

X21 Jack 2.5 mm — Maintenance PC

X27 Plu g-in block 4 p oints

(1.5 mm2 max.)

1 (+) Reset

2 … 4 (+) Unmonitored inputs 2 to 4

X28 Faston 5.3 mm (+) To positive of battery (to provide “Total loss of power supply”

functi on (see note 1)

X20 (*) Flat cable 26 points — Connection for multi-sector module XC A1030

X35 Ter minal 12 p oints — Connection for 4 digits display

X23, 24 Not u sed — —

(*) on welding side

Note 1: T he XC10 provides th e EN5 4-2 option wit h req uir em en t 8.4 called “Tot al los s of pow er”. This opti on wh en s el ect ed acti v at es th e

system fault LED an d the buzzer continu ously, for at least 1 hour after a l ow discharg e battery disconnection. The option c an be

selected by wiring the +BAT terminal to the posit ive voltage of batteries (use of remainin g power aft er battery disconnection).

Page 18

Overview

18

Building Technologies A6V10257473_e_en_--

Fire Safety 2015-03- 04

4.6 User interface

All display and control elements, except 4-digit display for XC1001-A version, are

accessible to the user:

- Led 1 to 32 indicators for operati ng conditi on,

- Keys 1 to 15 allowing :

è operating access

è operation (reset, off, test, etc)

è system test

è user functions programming

- 4-digit display showing:

è programming steps and opti ons

è pre-discharged warning time count down

è other information’s (calibration states, alarm counter, etc)

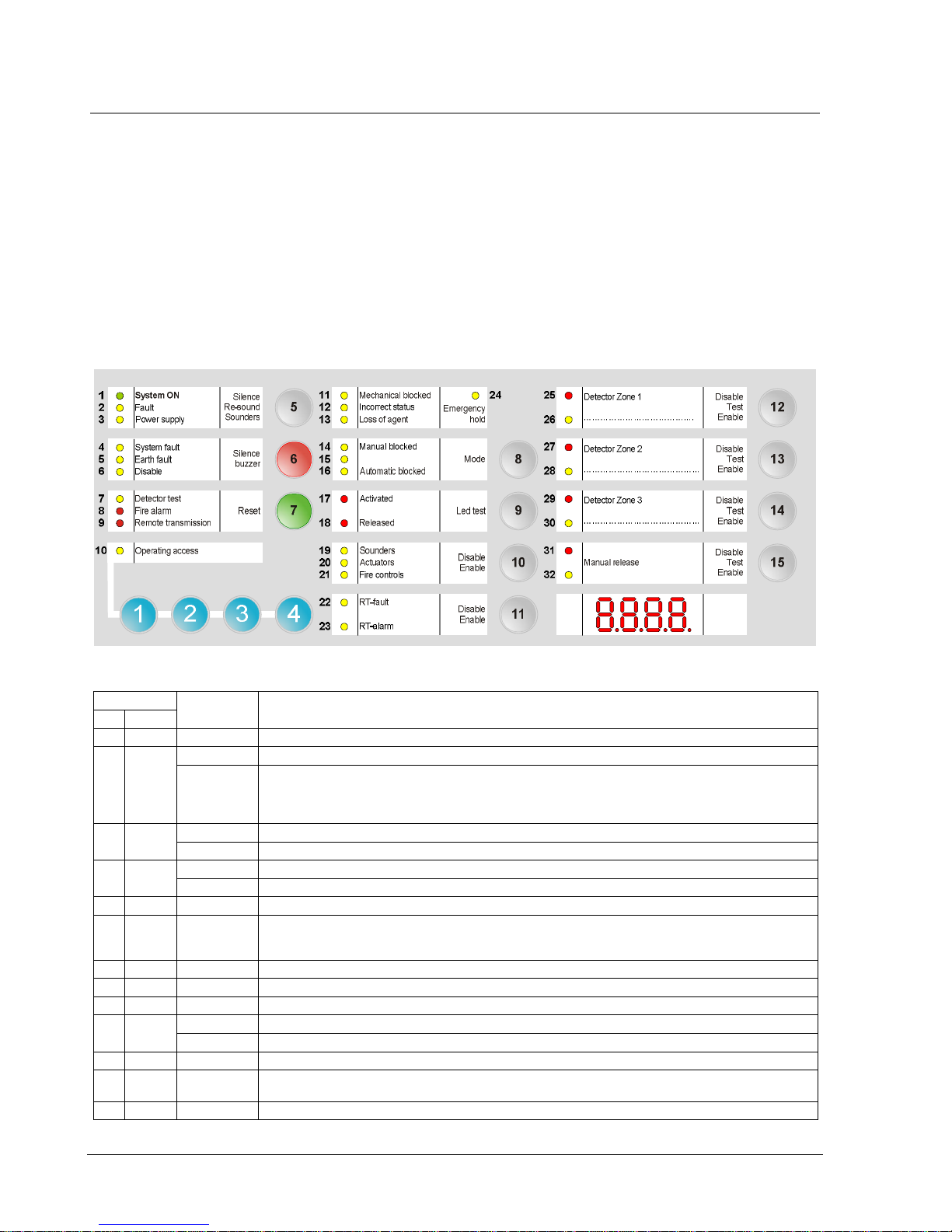

Fig. 6 XC100x-A, user interface

Indicators

State Description

N° Color

1 Green Fixed The control panel is in operation

2 Yellow Fixed The control panel is n ot able to function any more

Fast Fault on at least one component in the system (see paragraph 14.2 for t he detail)

Or,

Non-moni torred Control Input 3 is in active state, ass uming it is programmed as “External device fault”

(Step50 – O ption7)

3 Yellow Slow Mains fault

Fast Batteries fault

4 Yellow Fixed Microprocessor fault

Slow Jumper buzzer (X3 - XCM1002 board) not connected (remainder)

5 Yellow Fast At least on e compon ent connected to the c ontrol panel is grounded

6 Yellow Fixed – At leas t one component in th e system is disabled

– Calibrati on in progress or error

– Programmin g in progress

7 Yellow Slow At least one detection zone and/or extinguish ing manual control is being tested

8 Red Fixed At l eas t one detecti on zone is in alarm

9 Red Fixed Remote transmission activated (according to programming)

10 Yellow Fixed Level 2 oper ating access granted

Slow System test activated

11 Yellow Fixed Mechanical blocki ng device is in the bloc ked positi on

12 Yellow Fast – Mechanical blocki ng device is in a wrong posi tion

– Selector valve is in a wr ong position (used for multi-s ector appl ications)

13 Yellow Fast Loss of ag ent

Page 19

Overview

19

Building Technologies A6V10257473_e_en_-Fire Safety 2015-03- 04

Indicators

State Description

N° Color

14 Yellow Fixed – Manual release is block ed or being tested

15 Yellow Fixed – Standard = not used

– Alternati ve = automatic and manu al releas e grant ed (UK)

16 Yellow Fixed – Automatic release is blocked

– At least one detection zone which starts th e extinguis hing is off or being t ested

17 Red Fixed – All det ection zones which start the extinguishing are in alarm condition

– One of the el ectrical man ual trigg ering devic e (DM1103-L) is actuated

Fast One of the d etection zones which start the extinguishing is in alarm c ondition

18 Red Fixed Extin guishing agent is rel eased

Slow / Fas t Discharged contact is not activat ed within 30 seconds af ter actu ators c ontrol (according to programming)

19 Yellow Fixed Sounders are disabled

Slow Sounders test is in progress (real activation)

Fast At least, an output programmed as Sounders is in fault condition (break or short-circuit)

20 Yellow Fixed Actuators are disabl ed

Slow Actuators test is in progress (simulated activation)

Fast – At least, one output programmed as ac tuators is in fault condition (br eak or short-c ircuit)

– Calibration in progr ess or error or no calibration data

21 Yellow Fixed Fire contr ols are disabled

Slow W arning panels tes t is in progr ess ( real activation)

Fast At least, one output programmed as fire controls is in fault condition (break or short-circuit)

22 Yellow Fixed R T-fault is disabled

Slow RT-f ault test is in progress (real activation)

23 Yellow Fixed R T-alarm is disabl ed

Slow RT-alarm test is in progress (real activ ation)

Fast At least, one output pr ogrammed as RT-alarm is in fault condition (break or short-c ircuit)

24 Yellow Fixed Emergenc y abort is activated

Slow Emergency hold is activat ed (DM1103-S)

Fast At least, one input pr ogrammed as emergency hold/ab ort is in fault condition (break or short-circ uit)

25 Red Fixed Detection zone 1 is in alarm condition

Slow Detection zone 1 is in alarm condition (first alarm)

26 Yellow Fixed / Slow Detection zone 1 is disabled (fixed) / being tested (slow)

Fast Detection zone 1 is in fault cond ition (break or short-circuit)

27 Red Fixed Detection zone 2 is in alarm condition

Slow Detection zone 2 is in alarm condition (first alarm)

28 Yellow Fixed / Slow Detection zone 2 is disabled (fixed) / being tested (slow)

Fast Detection zone 2 is in fault cond ition (break or short-circuit)

29 Red Fixed Detection zone 3 is in alarm condition

Slow Detection zone 3 is in alarm condition (first alarm)

30 Yellow Fixed / Slow Detection zone 3 is disabled (fixed) / being tested (slow)

Fast Detection zone 3 is in fault cond ition (break or short-circuit)

31 Red Fixed Manual releas e is activ ated (DM1103-L lin e)

Slow Manual release is activat ed (DM1103-L line) – F irst alarm

32 Yellow Fixed / Slow Manual release is disabled (fixed) / being tested (slow)

Fast Manual release is in fault condition (break or short-circuit)

Page 20

Features

20

Building Technologies A6V10257473_e_en_--

Fire Safety 2015-03- 04

Keys Description

1 … 4 Operating access code input (level 2, progr amming, system test, etc.)

è W hen op erating access level 2 is selec ted, if the code is ent er ed again, t he system returns t o the level 1, wi thout waiting

for the end of the 4 minutes timeout

5

Silence / Restar

t sounders by successive pressing:

– 1st pressing: silence sounders

– 2nd p ressing: restart sounders etc…

è Operating acc ess level r equired f or this operation = level 2 (silenc e sounders is not possible during pre-dis charged

warning time)

6

Silence buzzer

è Operating access level required for this operation = l evel 1 or 2 or 2 o nly (according to prog ramming)

è If a Repeater Ter minal is connected to the XC10, and if option 61 step 02 is selected, silenc e buzzer on XC10 silences

also buz z er on repeater

7

1)

Reset

of the syst em. Reset is not possible

:

– during pre-discharged warning time, emergency stop and flooding time

– if buzzer and/or sounders are not silenced

– if manual release button and/or discharged contact ar e not reset (accord ing to pr ogramming)

è Operating acc ess level required f or this operati on = level 2

2) Fault reset

è Op er ating acc ess level required f or this operati on = level 2

8

Mode of operating, by successive press ing:

– 1st pressing: automatic blocked

– 2nd pr essing: automatic and manual blocked

– 3rd pressing: normal mode

è Operating access level required for these operations = level 2

9

Led and buzzer test (duration = 6 seconds)

:

All led indicators are activated and the buzzer sounds continuously (during the first three seconds, all the s egments of t he

display are activat ed, then th e SW version is displ ayed)

è Operating acc ess level required f or this operati on = level 1

10

Disable / Enable by successive pres sing:

– 1st pressing: actuators are disabled

– 2nd pr essing: s ounders an d actuat ors ar e disabl ed

– 3rd pressing: fire controls are disabled

– 4th pressing: all is disabled

– 5th pressing: all is enabled

è Operating access level required for these operations = level 2

11

Disable / Enable by successive pres sing:

– 1st pressing: RT-fault is disabled

– 2nd pressin g: RT-fault is en abled / RT -alarm is d isabled

– 3rd pressing: RT-fault and RT -alarm are disabled

– 4th pressing: all are enabled

è Operating access level required for these operations = level 2

12

Disable / Enable by successive pressing (n ot possible in case of fault or

alarm):

– 1st pressing: zone 1 is disabled

– 2nd pr essin g: z one 1 is tested

– 3rd pr essing: zone 1 is in norm al conditi on

è Operating access level required for these operations = level 2

13

Disable / Enable by successive pressing (n ot possible in case of fault o

r alarm):

– 1st pressing: zone 2 is disabled

– 2nd pr essin g: z one 2 is tested

– 3rd pr essing: zone 2 is in norm al conditi on

è Operating access level required for these operations = level 2

14

Disable / Enable b y successive pressing (n ot possible in case of fault

or alarm):

– 1st pressing: zone 3 is disabled

– 2nd pr essin g: z one 3 is tested

– 3rd pr essing: zone 3 is in norm al conditi on

è Operating access level required for these operations = level 2

15

Disable / Enable b y successive pressing (n ot possible in case of fault

or alarm):

– 1st pressing: manual release is disabled

– 2nd pr essin g: m anual rel ease is t ested

– 3rd pr essing: manual release is in normal conditi on

è Operating access level required for these operations = level 2

Page 21

Features

21

Building Technologies A6V10257473_e_en_-Fire Safety 2015-03- 04

5 Features

Power supply (FCP1004-E) Primary source (mains)

Voltage

Current

Power

115 / 230 VCA +10 …-15% – 50 / 60 Hz

1.75 A max.

150 VA max.

Secondary source (batteries)

Connect a bl e batter ies

Voltage

Charging current max.

Internal resistance max.

Deep discharge (disconnection threshold)

2 x 12 V / 4.5 … 17 Ah

23.4 … 27.6 V

1.3 A (with temperature compensation)

1 Ω

20 V +/-3%

Output

Voltage

Max. avai lable current

Min. current

Power

Switching frequency / Ripple

27.3 V +/- 0.3 V (25°C)

Imax a : 2 A (b atteries load ing)

Imax b : 3.5 A (batteries loaded)

0.05 A

105 W max.

132kHz / 7 0 mVpp max.

XCM1002 Input voltag e

Current consumption

I/Os s ecurity level

22.5 … 27.6 V (25°C)

190 mA max. without prim ary source

SELV (Safety Extra Low Voltage)

Detection lines Type / number of detectors

Compatible detectors

End of line element (EOL)

Standby condition voltage / current

Alarm condition voltage / current

Line resistance

Collective / 32 max. (according to detector t ype)

Siemens (Algorex, Sinteso, Synova, Cerberus FD110

series)

Transzorb 18 V (P6KE18CA)

17.1 … 19.3 V (fixed by EOL) / 11 mA max.

5.5 … 16.5 V / 11 … 57.1 mA max.

80 Ω max.

Manual release line Type / number of manual actuators

End of line element (EOL)

Voltage / standby line current

Voltage / al ar m line curr ent

Line resistance

DM1103-L / 32 max.

Transzorb 18 V (P6KE18CA)

17.1 … 19.3 V (fixed by EOL) / 11 mA max.

5.5 … 16.5 V / 11 … 57.1 mA max.

80 Ω max.

Monitored inputs 4

Activation resistance

End of line element (EOL)

Line resistance

680 Ω or 1.2 kΩ

3.3 kΩ r esistance

80 Ω max.

Control inputs (non

monitored)

4 Activation +24 V, via contact

Monitored co ntrol outputs

Outputs 1 to 3

Outputs 1 to 3

Control voltage / current

End of lin e element

24 V / 1 A max.

3.3 kΩ r esistance

Outputs 4 and 5

Control voltage / current

End of lin e element

24 V / 2 A max.

No EOL (line calibration)

Driver outputs 8 (programmable) 24 V / 40 mA max.

Relay outputs (contacts) 5 (4 programmable) 30 V / 1 A max. / NO or NC

Connection s XCM1002

Inputs - outputs type / section Plug-in screw t er minal bloc ks

2.5 mm2 max. (X5, X5, X7)

1.5 mm2 max. (all oth ers )

FCP1004-E

mains input type / section Plug-in screw termi nal block / 2.5 mm2 max.

Environmental conditions Operating / Storage temperature

Humidit y relative at 40± 2° C

-5 ... +40° C / -20 ... +60° C

93% max., without condens ation

Mechanical data XC1001-A Cabinet / Protection index

Color

Dimensions (l x h x p) / Weight

Metal frame with plastic cover / IP30

RAL9003 (cover), RAL9006 (user interface)

370 x 286 x 90 mm / 4.1 kg

XC1005-A Cabinet / Protection index

Color

Dimensions (l x h x p) / Weight

Metal case with plastic cover / IP40

RAL9003 (cover), RAL9006 (user interface)

505 / 375 / 125 m m / 6.5 kg

XC1003-A Cabinet / Protection index

Color

Dimensions (l x h x p) / Weight

Rack 19’’ 4U / IP30

RAL9006

482.6 (19’’) x 177.8 (4U) x 187 mm / 6 .6 kg

Conformity EN 12094-1, EN 54-2/A1, EN 54-4/A2 —

Page 22

Installation

22

Building Technologies A6V10257473_e_en_--

Fire Safety 2015-03- 04

6 Installation

Generally, the XC10 must be easily accessible and i nstalled:

- outside the protected area

- protected from mechanical shocks and bad weather

6.1 XC1001-A / XC1005-A

The XC10 must be installed on a fixed and stable support, with a height ranging

between 1.60 m and 1.70 m (eliminate the irregularities from the mounting surface

≥ 5 mm).

1. Remove the front cover

2. Mark and drill the mounting holes using the drilling template provided (start with

the hole for the top central screw)

3. Fix the chassis using 3 screws Ø 4 x 50 mm (not provided)

4. Cut out the cable entries

5. Cut out the plastic housing according to the cable inputs (XC1001-A)

6. Mount the cable glands if necessary (required for protection rating IP30)

7. Install the batteries and fix the bat tery holders

1 12 V – 4.5 Ah batteries

Fig. 7 XC1001-A, bat tery installation

Page 23

Installation

23

Building Technologies A6V10257473_e_en_-Fire Safety 2015-03- 04

ON

12

1 4

ON

12

23 3(insert in slot 4)

1 12 V – 12 Ah batteries

2 12 V – 17 Ah batteries

3 FCA1014 battery holder (option)

4 Slot for battery holder

Fig. 8 XC1005-A, bat tery installation

Page 24

Installation

24

Building Technologies A6V10257473_e_en_--

Fire Safety 2015-03- 04

6.2 XC1003-A

Fix the XC1003-A into a 19'' housing cabinet with a protecti on rating IP ≥ 30.

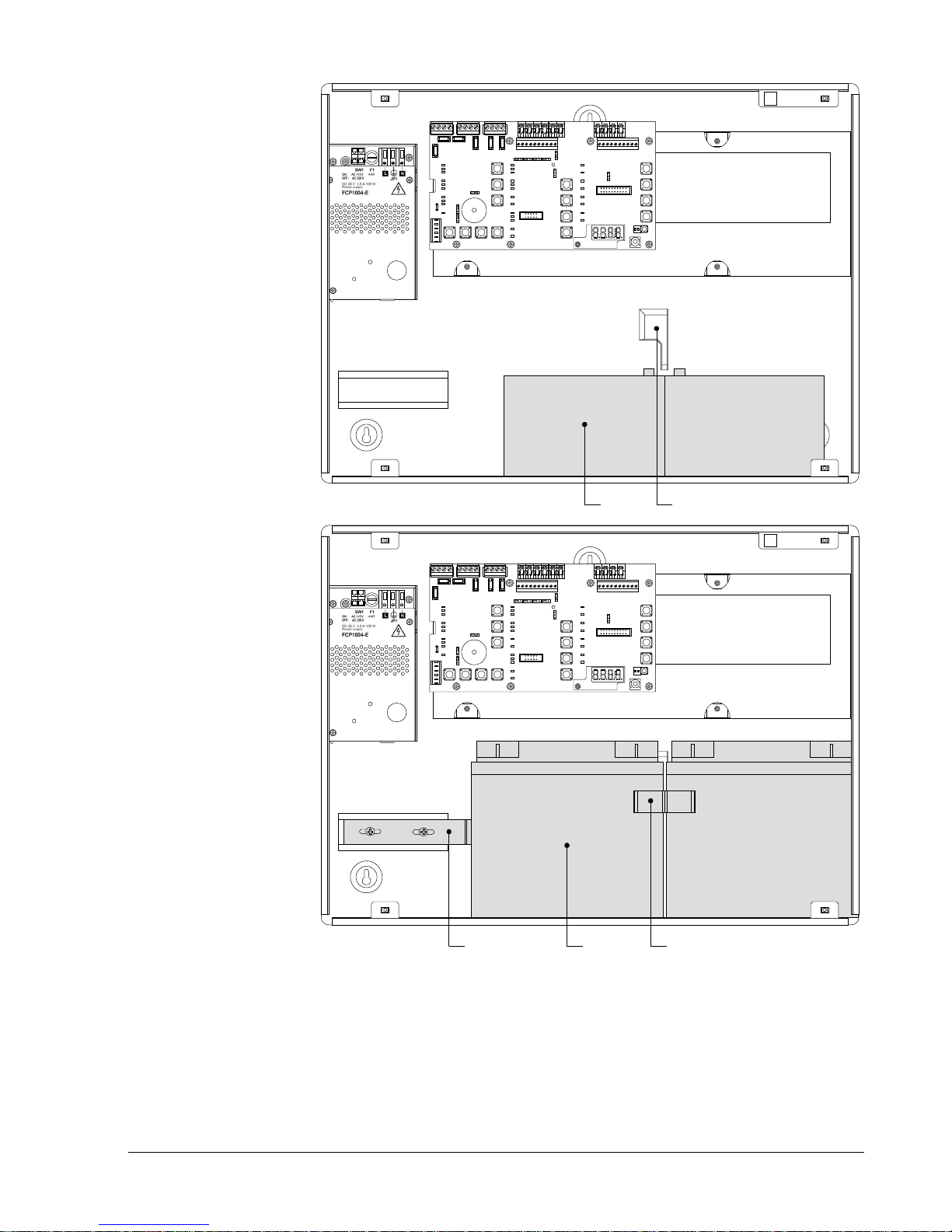

Fig. 9 XC1003-A, mounting examples

The interval between 2 extinguishing racks and there power su pply rack should n ot exceed 12U.

Page 25

Installation

25

Building Technologies A6V10257473_e_en_-Fire Safety 2015-03- 04

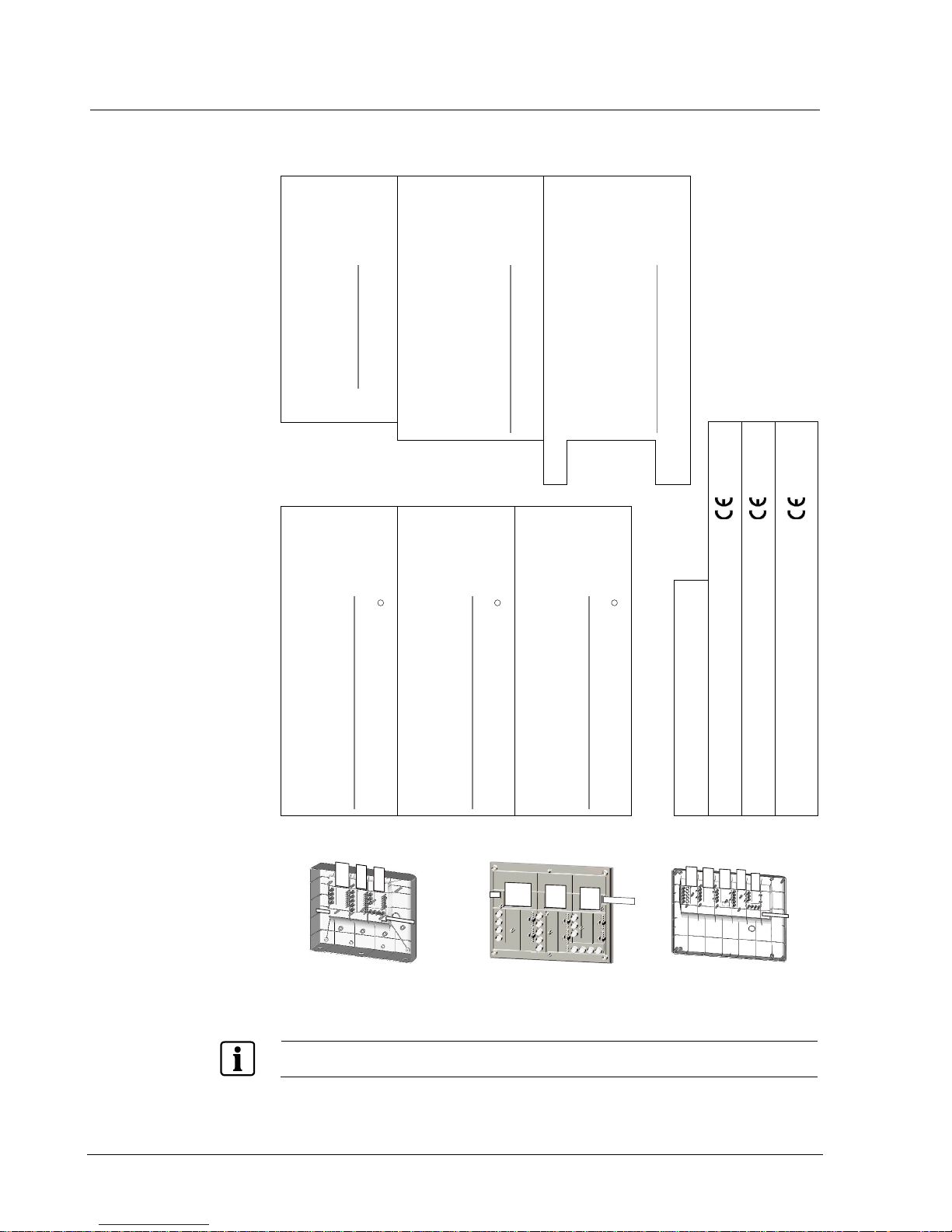

XC1003-A, mounting adaptation

The 19” rack is symmetrical . This allows, with some mounting/ unm ounting

operations, to adapt it to various configurations (2 racks minimum are necessary).

A

B

B

A

B

Remove parts 5 & 6

from rack B

Reassemble parts 1, 2, 3 & 4 from

rack A in rack B

2 31 4

6

6

Remove parts 1, 2, 3 & 4

from rack A

A

Reassemble parts 5 & 6 from

rack B in rack A

1234

ON

12

ON

12

5

ON

12

ON

12

ON

12

5

Fig. 10 XC1003-A, mounting adaptation

Page 26

Installation

26

Building Technologies A6V10257473_e_en_--

Fire Safety 2015-03- 04

XC1003-A, commissioning / connection / maintenance

The removable board hol der (1) can be positioned, after screw unmounting (3), as

indicated bel ow to reach the DIN rail (2).

ON

12

ON

12

13 3

2

Fig. 11 XC1003-A, removable stand in “Commissioning” position

Page 27

Installation

27

Building Technologies A6V10257473_e_en_-Fire Safety 2015-03- 04

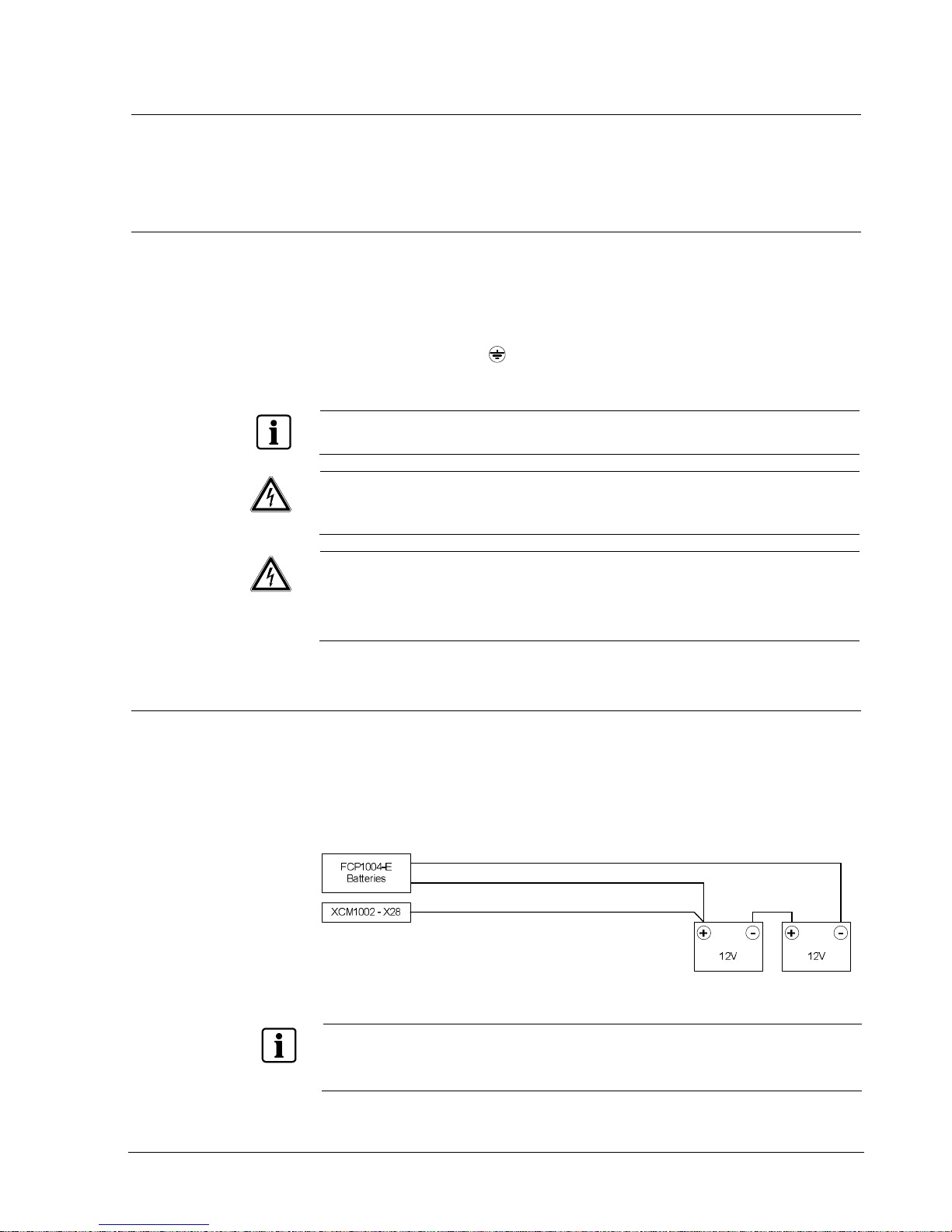

XC1003-A, batteries installation

4.5 Ah batteries:

1. Remove the holder (1)

2. Install the batter ies (3) as shown below

3. Remount the holder (1)

7.2 Ah batteries:

1. Remove the parts (1) and (2)

2. Install the batter ies (4) as shown below

ON

12

ON

12

2

ON

12

1

3

4

Fig. 12 XC1003-A, battery installation

Page 28

Installation

28

Building Technologies A6V10257473_e_en_--

Fire Safety 2015-03- 04

6.3 User interface labels

Insert the l abels f ollowing the instructions on the board provided with the

equipment.

XC1001-A

XC1003-A

XC1005-A

Stripe EN

A5Q00034729A-03

Pos. 2

Mechanical blocked

Incorrect status

Mode

Manual blocked

Loss of agent

Automatic blocked

Led test

Activated

Released

Sounders

Actuators

Fire controls

RT-fault

RT-alarm

Emergency

hold/abort

Pos.2

Mechanical blocked

Incorrect status

Mode

Manual blocked

Loss of agent

Automatic blocked

Led test

Activated

Released

Sounders

Actuators

Fire controls

Disable

Enable

RT-fault

RT-alarm

Emergency

abort

Disable

Enable

Disable

Enable

Disable

Enable

Pos. 2

Mechanical blocked

Incorrect status

Mode

Manual blocked

Loss of agent

Automatic blocked

Led test

Activated

Released

Sounders

Actuators

Fire controls

RT-fault

RT-alarm

Emergency

hold

Disable

Enable

Disable

Enable

Pos. 1

System ON

Fault

Silence

buzzer

System fault

Power supply

Disable

Reset

Detector test

Remote transmission

Operati ng access

Earth fault

Silence

Re-sound

Sounders

Fire alarm

Pos.3

Disable

Test

Enable

Detector Zone 1

…………………………………….

Detector Zone 2

…………………………………….

Detector Zone 3

…………………………………….

Manual release

Disable

Test

Enable

Disable

Test

Enable

Disable

Test

Enable

Pos.7

Disable

Test

Enable

Disable

Test

Enable

Disable

Test

Enable

Disable

Test

Enable

Detector Zone 1

…………………………………….

Detector Zone 2

…………………………………….

Detector Zone 3

…………………………………….

Manual release

Pos. 5

Extinguishing control

…………………………………….

EN12094-1 Classe A

EN54-4 / EN54-2

1116 - CPD – xxx

Pos. 4

s

XC1001-A

EN12094-1 Classe A

EN54-4 / EN54-2

1116 - CPD – xxx

Pos. 8

s

XC1003-A

1116 - CPD – xxx

s

XC1005-A

EN12094-1 Classe A / EN54-4 / EN54-2

…………………………………...

Pos. 6

XC1005-A

Pos.6

Pos.7

Pos.2

Pos.1

XC1001-A

Pos.4

Pos.5

+0,15

0.0

0

1

3

Pos.3

Pos.2

Pos.1

XC1003 -A

Pos.5

Pos.3

Pos.2

Pos.1

Pos.8

Fig. 13 XC100x-A, user interface labels

The label to be inserted in position 2 is different whether the stop/emergency hold function is used or

not.

Page 29

Connections

29

Building Technologies A6V10257473_e_en_-Fire Safety 2015-03- 04

7 Connections

The installation must be realised by qualified personnel and in conformity with the

applicable nati onal electric standard.

7.1 Mains

Connection with the mains must be established through an external circuit breaker

(bipolar circuit breaker 1 A).

3. Make sure that the mains voltage is switched off

4. Connect the mains cabl e to the PSU terminals according to the pi n assignment

specified onto the PSU:

– Protection ground ( ), neutral (N) and phase (L)

5. Fix the cable with two fasteners and check, during installation, that these fixings

are well in place

The XC100x-A equipment is not designed to be c onnected according to an IT earth network .

If such a network must be us ed, a separation transformer will have to be installed.

Danger - Electrical v oltage

Mortal danger due to electric shock

- B ef ore layi n g th e mai ns c abl e, m ak e sur e that it is n ot c on n ect ed t o th e pow er s up pl y.

- Ch eck to mak e sur e that the m ains are secured agai ns t inad ver t ent l y being s witc h ed on.

Danger - Short circuit

Potential damage to hardware

- B ef or e inst al li ng or dismantl in g the power supply unit, rem ov e t h e wir e jum p er between th e two

batteries.

- T his ensu res that th e sec on d ary side is current-fr ee and that no mod ules can be dam ag ed due to

a short circuit.

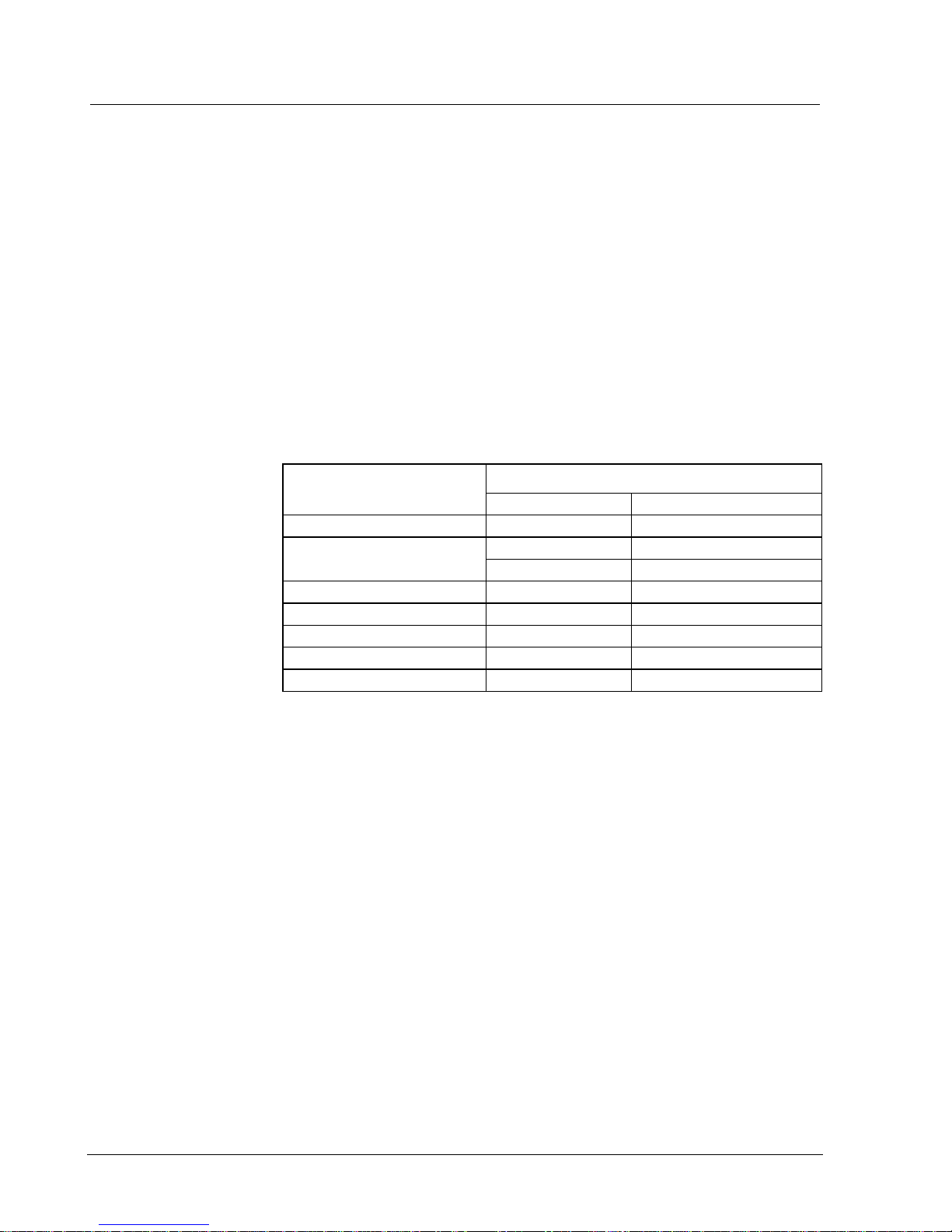

7.2 Batteries

Two 12 V batteries, connected in series, can be connected with t he FCP1004- E

power supply. According to the control units, the following batteries can be

installed:

- XC1001-A : 4.5 Ah

- XC1005-A : 4.5 Ah, 7.2 Ah, 12 Ah or 17 Ah

- XC1003-A : 4.5 Ah or 7.2 Ah

Fig. 14 Battery connection

In some countri es i.e. [ FR], it is r equired to indicate the total loss of power suppl y (opti on with

requirement EN54-2). In such case, connect the wire pr ovided between + of th e batteries and the X28

termin al of XC M1 0 02 m ai nboard.

If this option is not required in your country, do not connect the wire from +b atteries to X28

Page 30

Connections

30

Building Technologies A6V10257473_e_en_--

Fire Safety 2015-03- 04

7.2.1 Battery capacity calculation

Battery capacity must be calculated according to the following formula:

K

Batt

= ((I

R total

* tR) + (I

A total

* tA)) * K

dis

* K

age

K

Batt

: battery capacity (Ah)

I

R total

: operating curr ent , internal and ext ernal in standby condition (A)

I

A total

: operati ng curr ent , internal and external in alarm condition (A)

tR: required backup time in standby condition (hours)

tA: required backup time in alarm condition (hours)

K

dis

: = 1.1 drops i n capacity, applicable only for 12 hours backup time or less

K

age

: = 1.25 safety factor, applicable only for 24 hours backup time or less

To define the operating current, all internal and external devices connected to the

XC10 shall be taken into account:

- all components installed inside the XC100x-A are consi dered as internal

devices, i.e. : XCA1030, XCA1031, relay modules, etc.

- al l components installed outside the XC100x-A are considered as external

devices, i.e.: actuator, sounders, warning panels, repeater terminals (when

supplied by the XC10), etc.

Components

Current consumption (A) / 24 VDC

Standby conditi on

Alarm condition

XCM1002 0.168 0.247

Actuator 0 See component datasheet

Warning panel 0 See component datasheet

Sounder 0 See component datasheet

Fire controls 0 See c om ponent datasheet

XT1001-A1 powered by XC10 0.012 0.020

XCA1031 0.114 0. 141

Single-sector installation example:

– 2 actuators (POUSSAX24) activ ated during 10 seconds (360mA each)

– 6 warning panels (70mA each)

– 10 sounders (20mA each)

– 2 repeaters XT1001-A1 powered by XC10

Battery capacity calculation for 12, 24 and 72 hours backup time, followed by an

alarm conditi on during 15 mn:

è I

R total

= 0.168 + (0.012 x 2) = 0.192 A

è I

A total

= 0.247 + (0.020 x 2) + ((0.360 x 2) x (10 / (15 x 60))) + (0.070 x 6) +

(0.020 x 10) = 0.915 A

è 12 hours : K

Batt

= ((0.192 x 12) + (0.915 x 0.25)) x 1.1 x 1.25 = 3.48 Ah

è 24 hours : K

Batt

= ((0.192 x 24) + (0.915 x 0.25)) x 1.25 = 6.04 Ah

è 72 hours : K

Batt

= ((0.192 x 72) + (0.91 x 0.25)) = 14.05 Ah

Multi-sector installation example:

– 4 solenoid valves (DEMAFM or DEMADE M) activated during 10 seconds

(400mA each)

– 1 actuator POUSSAX24 connected to XCA1031

– 12 warning panels (70mA each)

– 10 sounders (20mA each)

Page 31

Connections

31

Building Technologies A6V10257473_e_en_-Fire Safety 2015-03- 04

– 2 fire controls, solenoid 3 W à door contact for ex.(125mA each)

– 2 repeaters XT1001-A1 powered by XC10

Battery capacity calculation for 12, 24 and 72 hours backup time, followed by an

alarm conditi on during 15 mn:

è I

R total

= 0.168 + 0.114 + (0. 012 x 2) = 0.306 A

è I

A total

= 0.247 + 0.141 + ((0.400 x 4) * ( 10 / (15 x 60))) + 0.360 + (0.070 x 12) +

(0.020 x 10) + (0.125 x 2) + (0.020 x 2) = 2.095 A

è 12 hours : K

Batt

= ((0.306 x 12) + (2.095 x 0.25)) x 1.1 x 1.25 = 5.77 Ah

è 24 hours : K

Batt

= ((0.306 x 24) + (2.095 x 0.25)) x 1.25 = 9.83 Ah

è 72 hours : K

Batt

= ((0.306 x 72) + (2.095 x 0.25)) = 22.55 Ah à not possible with

the XC10 power supply

Install ed batteri es shall have a capacity > K

Batt

calculated

7.3 Fire detectors/Manual release control buttons

7.3.1 Standard wiring

Four monitored inputs are available on the X10 terminal block for the connection of

fire detectors or alarm contact (i.e. contact from FDCIO222) and electrical manual

triggering devices (DM1103-L)

- Detection zones 1 to 3 operation is defined at programming steps 52 to 55 (see

paragraph 12.14)

- Ex tinguishing manual release control operation is defi ned at programming step

65 (see paragraph 12.21). Up to 32 buttons DM1103-L can be connected

Technical data common to the 4 inputs

EOL: transzorb 18V connected at the end of the line

Line resistance max.: 80 Ω

Page 32

Connections

32

Building Technologies A6V10257473_e_en_--

Fire Safety 2015-03- 04

Fig. 15 XC100x-A, connec tion of detect ors and manual triggering devices

The number of detectors which can be connected is determi ned by dividing the

collective system line connection factor (KLK = 32) by the collective element load

factor (KMK = see table bel ow).

Series of detectors Designation KMK Nb

ALGOREX DO1101A / DO1102A / DO1104A 1 32

DT1101A / DT1102A 1 32

DF1191 / DF1192 6 5

SINTESO FDOOT241-9 / FDOOT241-A9 2 … 1.25 (*) 16 … 25

FDF221- 9 / FDF241-9 5 6

FDL241-9 10 3

SYNOVA OP320C / OH320C 1 32

HI320C / HI322C 1 32

CERBERUS FD110 series OH110, OP110, HI110, HI112 1 32

(*) Depen ds on detector index and set of parameters

For Sinteso and C er berus FD110 series detectors, select an appropr iate set of parameters.

Page 33

Connections

33

Building Technologies A6V10257473_e_en_-Fire Safety 2015-03- 04

7.3.2 Wiring for explosion hazard areas

Fig. 16 Wiring for explosion hazard areas

In ex-areas, use only fire detectors that are approved for ex-areas. Between the

explosion-hazard ar ea and the non-ex-area, the detector line must be galvanically

insulated (DC1192) and laid via a safety barrier (SB3). The termination elem ent

EOL22Ex must be provided as line terminator.

Country-specif ic regulations always apply to installation in ex-areas.

The following document provides further informations:

Fire alarm signal in areas at risk of explosion - Principles, applications, instal lation,

maintenance (001204).

7.4 Monitored inputs

Four monitored inputs are available on X9 terminal block for the connection of

various devices. Operation is defined at programming steps 28 to 31 (see

paragraph 12.9).

Technical data common to the 4 inputs

EOL: 3.3 kΩ resistance connected at the end of the line

Line resistance max.: 80 Ω

Page 34

Connections

34

Building Technologies A6V10257473_e_en_--

Fire Safety 2015-03- 04

7.4.1 Monitored input 1

This input is exclusively reserved for the connection of the extinguishing

discharged contact. Operation is defined at programming step 28.

Fig. 17 XC100x-A, monitored input 1 connection

1 Discharged contact normally closed (NC)

2 Discharged contact normally open (NO)

3 No contact connected (3.3kΩ EOL is not required)

7.4.2 Monitored input 2

This input is exclusively reserved for the connection of the loss of agent devices

(manometer or weighing device). Operati on i s defined at programming step 29.

Fig. 18 XC100x-A, monitored input 2 connection

1 Loss of agent contact normally closed (NC)

2 Loss of agent contact normally open (NO)

3 Not used (3.3kΩ EOL is not required)

7.4.3 Monitored input 3

This input can be used for several purposes. Operation is defined at programming

step 30.

Fig. 19 XC100x-A, monitored input 3 connection

1 Mechanical blocking device

2 Extinguishing remote activation

3 Automatic block ed / Manual bl ocked / Automatic and manual blocked

4 Emergency abort

5 Not used (3.3kΩ EOL is not required)

Page 35

Connections

35

Building Technologies A6V10257473_e_en_-Fire Safety 2015-03- 04

7.4.4 Monitored input 4

This input can be used for several purposes. Operation is defined at programming

step 31.

Fig. 20 XC100x-A, monitored input 4 connection

1 Emergency abort

2 Emergency hold

3 Automatic block ed / Manual bl ocked / Automatic and manual blocked

4 Not used (3.3kΩ EOL is not required)

When monitored inputs 3 and 4 are prog rammed r especti vely as « Emergenc y h old » and

« Emergency abort », emergency abort has th e priority

7.5 Control inputs

Four control inputs, including three programmable (2 to 4), are available on X27

terminal block to receive controls or information via relay contacts. Operation is

defined at programming steps 48 to 51 (see paragraph 12.13).

Fig. 21 XC100x-A, control inputs connection

– These inputs shall not be activated by an external +24 V

– Relays must be installed inside the equipment

– When a control input is programmed as « Reset » or « Level 2 access » or « M anual blocked » or

« Automatic blocked » or « A utomatic an d manual blocked » or « Silence / Restart Sounders »,

theses c ontrols must only b e p ossible through an operatin g level 2 access device.

Page 36

Connections

36

Building Technologies A6V10257473_e_en_--

Fire Safety 2015-03- 04

7.6 Monitored control outputs

Five monitored c ontrol outputs are availabl e on terminal blocks X7, X6 and X5 for

the connection of various devices.

Technical data for control outputs 1 to 3

- activ ation by reverse polarity (pol arities indicated are “act ivated” polarities,

according to connected device, a diode can be necessary)

- l ine monitoring: 3.3 k Ω resistance connected at the end of the li ne

- protect ion: 1 AT fuse (F4 / F5 / F6)

Technical data for control outputs 4 and 5

- activation polarity is not reversed

- l ine monitoring: by cali bration, within a range between 1 and 900 Ω

- protecti on: 2 AF fuse (F1 / F2)

Technical data common to the 5 control outputs

The maximum number of devices per output is determined by calculation, in 2

steps (see example below), depending on:

- mi nimum/maximum XC10 operating voltage = 22.5 V / 27.6 V

- nomi nal current consumption per device (@24V, see device technical data’s)

- minim um device operating v oltage (see devi ce technical data’s)

- protect ion fuse rating = 1 A or 2 A

- cable resistance (2x1.5 mm2 = 24.2 Ω / km, 2x2.5 mm2 = 14.8 Ω / km)

Calculation example for a device consuming 0.35 A at 24 V and having a

minimum operating voltage of 17 V:

1. From maximum system voltage (V

SYS MAX

) in order to make sure that device

consumption does not exceed fuse rating.

- Device current consumption at Vsys m ax = (27.6 x 0.35) ÷ 24 = 0.402 A

- Maximum number of devices: 0.402 A x n ≤ 1 A or 2 A

=> n ≤ 1 ÷ 0.402 ≤ 2.48, i.e. 2 devices (outputs 1 to 3)

=> n ≤ 2 ÷ 0.402 ≤ 4.96, i.e. 4 devices (outputs 4 and 5)

2. From minimum system voltage (Vsys min) in order to make sure, that in spite of

the cable resistance voltage drop, device minimum operation voltage is

respected:

- Device consumption at Vsys min = (17 x 0.35) ÷ 24 = 0.248 A

- Max imum voltage drop = 22.5 - 17 = 5.5 V

- Maximum line resistance (outputs 1 to 3) = 5.5 ÷ (0.248 x 2) = 11.08 Ω

- Maximum line resistance (outputs 4 and 5) = 5.5 ÷ (0.248 x 4) = 5.54 Ω

- Maximum line length (1.5 mm2) = (11.08 x 1000) ÷ 24.2 = 456 meters (outputs

1 to 3), = (5.54 x 1000) ÷ 24.2 = 228 meters (outputs 4 and 5)

- Maximum line length (2.5 mm2) = (11.08 x 1000) ÷ 14.8 = 748 meters (outputs

1 to 3), = (5.54 x 1000) ÷ 14.8 = 374 meters (outputs 4 and 5)

Page 37

Connections

37

Building Technologies A6V10257473_e_en_-Fire Safety 2015-03- 04

7.6.1 Monitored control output 1

This output is exclusively reserved for the connection of the Sounders. Operation is

defined at programming steps 05 and 10 (see paragraphs 12.4 and 12.6).

Fig. 22 XC100x-A, monitored control output 1 connection

1 Sounders

2 Control output not used (no EOL required)

7.6.2 Monitored control output 2

This output can be used for several purposes. Operation is defined at programming

step 11 (see paragraph 12.6).

Fig. 23 XC100x-A, monitored control output 2 connection

1 RT-alarm

2 Fire cont rol(s): signal triggering to equi pment outside the system, according to

EN12094-1 option with requirements 4.26

3 Sounder(s)

4 Warning panel(s) « Mechanical blocked » or « Automatic or manual blocked »

or « Automatic and manual blocked »

5 Control output not used (no EOL required)

Page 38

Connections

38

Building Technologies A6V10257473_e_en_--

Fire Safety 2015-03- 04

7.6.3 Monitored control output 3

This output is exclusively reserved for the connection of the warning panels.

Operation is defined at programming step 12 (see paragraph 12. 6).

Fig. 24 XC100x-A, monitored control output 3 connection

1 Warning panel

2 Control output not used (no EOL required)

7.6.4 Monitored control output 4

This output is exclusively reserved for the connection of the actuator release.

These devices can be either electromagnetic or pyrotechnic actuators. O peration is

defined at programming steps 01, 02 and 13 (see paragraphs 12.3 and 12.6).

Step 01

Opt. 00 .. 72

Step 02

Opt. 02 .. 90 or 9 9

Step 13

Opt. 01 ou 02

Step 02

Opt. 01

Step 13

Opt. 01 or 02

Step 01

Opt. 00 .. 72

X6 -3

X6-4

-

+

1 n

1 10

OR

+

-

1 2

F1

2 AF

Fig. 25 XC100x-A, monitored control output 4 connection

1 Electromagnetic actuators

2 Pyrotechnic actuators

Electromagnetic actuators

- O ne or m ore actuators, connected in parallel, can be connected (see example

at paragraph 7.6 to calculate the maximum number of devices per line as well

as maximum line length).

Pyrotechnic actuators

- 1 to 10 actuators maximum, connected i n series, can be connected.

- The table below indicates max. line l engths, in meters, according to cable

section for the Siemens Monopist pyrotechnic actuator :

MONOPIST / code A6E60200462

1 2 3 4 5 6 7 8 9 10

1.5 mm2 1067 972 877 782 687 592 497 402 307 212

2.5 mm2 1745 1590 1434 1279 1123 968 813 657 502 346

Page 39

Connections

39

Building Technologies A6V10257473_e_en_-Fire Safety 2015-03- 04

Option 0 1 at step 02 m ust be imp eratively selected in case of p yrotechnic actuator and not be

selected in case of electromagnetic actuator.

7.6.5 Monitored control output 5

This output can be used for several purposes. Operation is defined at programming

steps 01, 03, 14, 63 and 64 (see paragraphs 12.3, 12.6 and 12.6).

Fig. 26 XC100x-A, monitored control output 5 connection

1 Actuators (electromagnetic or pyrotechnic)

2 Fire cont rol(s): signal triggering to equi pment outside the system according to

EN12094-1 option with requirements 4.26

3 Extract fan

4 Others (example: relay)

5 Output not used (no EOL required)

If this output is used to connect actuators, c haracteristics of the monitored output 4 (line length,

program mi ng options, etc.) apply.

7.7 Programmable outputs

An output, among those descri bed in this chapter, m ust obligatorily be

programmed to transmit the following information’s:

- « Emission » (i n all cases)

- « Mechanical blocking »

(1)

- « Emergency hold/abort »

(1)

- « Automatic blocked » (in all cases)

(1)

When these options with requirements are used.

7.7.1 Driver outputs

Eight programmable drivers outputs (non-monitored), are available on X12 terminal

block. Operati on is defined at programming steps 20 to 27 (see paragraph 12.8).

Technical data

Open collector type 24 Vcc – 40mA max.

Page 40

Connections

40

Building Technologies A6V10257473_e_en_--

Fire Safety 2015-03- 04

Fig. 27 XC100x-A, driver outputs connection

Theses outputs are intended to control external relays like Z3B171, for example:

- Shutting down the v entilation system

- Closing the extinguishing area doors

- Closing the fire dampers

- Status information’s

All relays must be installed inside the control unit.

7.7.2 Relay outputs

Five potential-free contacts, including 4 programmable (1, 2, 4 and 5), are available

on X11 terminal block to forward the event states to a remote transmission device

or to a fire detection system. Operation is defined at programming steps 15 to 19

(see paragraph 12.7). X13 and X17 jumpers make it possible to use either the NO

or NC contact.

Technical data

Contact breaking rating: 30V – 1 A (resistive circuit)

Page 41

Connections

41

Building Technologies A6V10257473_e_en_-Fire Safety 2015-03- 04

Fig. 28 XC100x-A, relay outputs connection

Page 42

Connections

42

Building Technologies A6V10257473_e_en_--

Fire Safety 2015-03- 04

7.8 24V power supply output

A 24V power supply output, protected by fuse 1 AT (F3), is available on terminal

block X5-3 (+) / X5-4 (-) to power various devices (internal or external).

When the fuse F3 is b lown, a general fault indic ati on is displayed (see paragraph 14.2 for details).

7.9 Repeater terminal and repeater display

The repeater terminal/display must be connected to X12-9/10 (RS485 RTnet

connection).

For mor e information’s about r epeater t erminal and r epeater d is play, see paragraph 9.4.

Page 43

Multi-sector ins tallation

43

Building Technologies A6V10257473_e_en_-Fire Safety 2015-03- 04

8 Multi-sector installation

Multi-sector extinguishing systems are capable of protecting several flooding

zones. The basic setup consists of one common cylinder bank. To this cyli nder

bank, a piping net work is connected to every flooding zone by means of selector

valves. By opening t he relevant selector valve, the extinguishing agent is guided to

the desired flooding area.

Up to 16 extinguishing panels (XC1003-A excl usively) can be inter-connected via

there individual modules (XCA1030) to a common module (XCA1031). This

applicati on and its operation are defined at progr amming step 58 (see paragraph

12.16).

8.1 Functional description

Each extinguishing control panel controls everything from one flooding zone.

Panels are networked so that information’s can be exchanged from one panel to

the other.

As soon as an extinguishing control panel is activated (either automatically or

manually), the common pilot cylinder is released. Then, the corresponding sector

valve is opened and the number of cylinders that correspond to the flooding zone is

released.

After having released the extinguishing in one flooding zone, the autom atic release

of other flooding zones can be automatically blocked in order to keep the

concentration in the first flooding zone or to prevent unwanted fire detection in the

others.

All connected devices are monitored like the single-sector application. In addition,

the common cylinder loss of agent information is reported to all linked panels.

Page 44

Multi-sector ins tallation

44

Building Technologies A6V10257473_e_en_--

Fire Safety 2015-03- 04

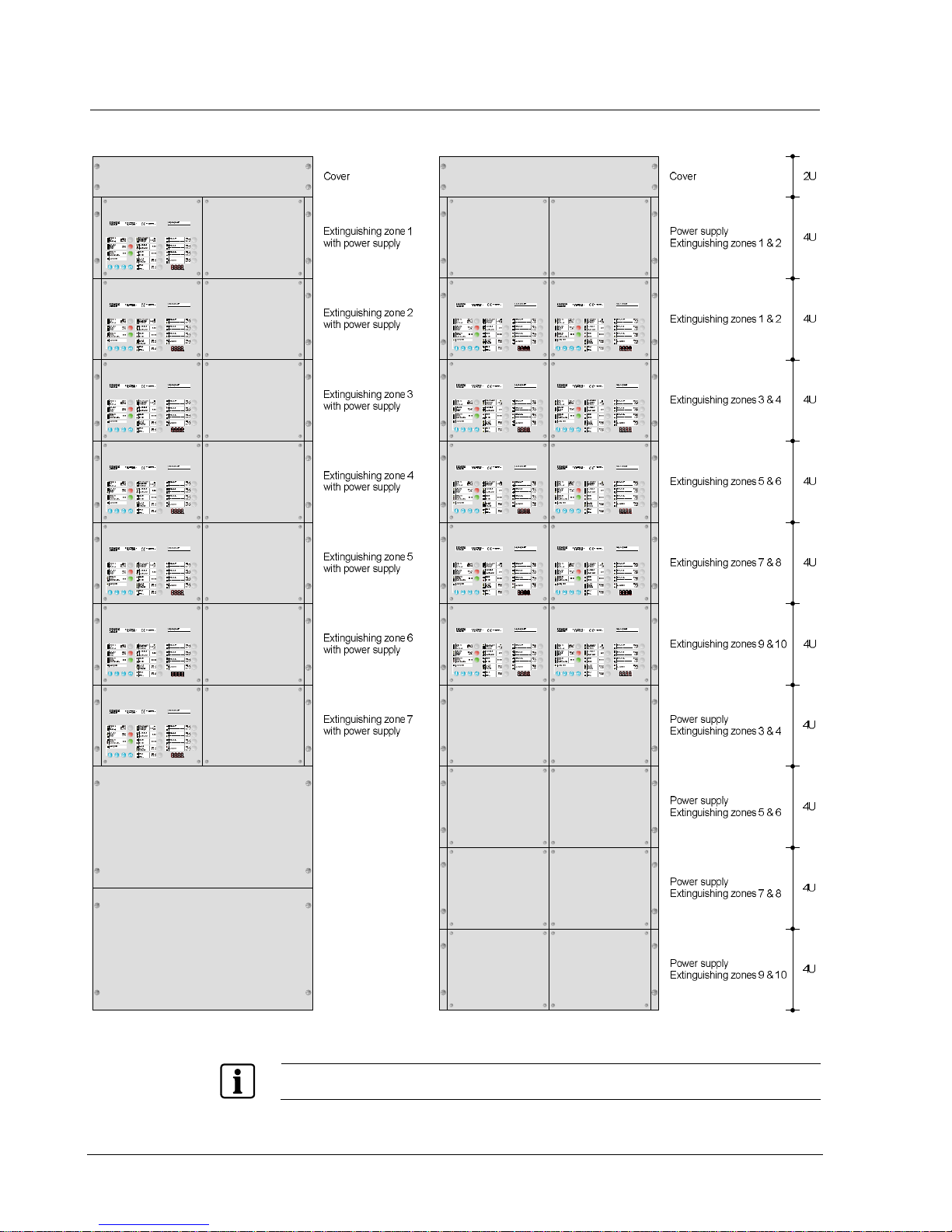

19" cabinet

Mechanical

blocking device

(option)

Solenoid valve

(opens selector

valve)

Selector valve

Sector valve

small room

Non return valve

Loss of agent

contact

Actuator

and cylinder

valve

Manual release

DM1103-L

Emergency hold

DM1103-S

Discharged

contact

Optical Signaling

Equipment

Ventilation system

Alarm sounder

Control

cylinder

Optical Signaling

Equipment

Ventilation system

Alarm sounder

Flooding zone 2

Large room (3 cyli nde rs)

Flooding zone 1

Small room (1 cylinder)

Cylinder battery

Fire detectors

XCA1030

Mul ti-zone

extension module

XCA1030

Mul ti-zone

extension module

XCA1031

Common multi-zone module

XC1003-A

Extinguishing panel rack

XC1003-A

Extinguishing panel rack

Overpressure

flap

Overpressure

flap

Fire detectors

Remote

transmission to

fire brigade

Alarm indicator

Alarm indicator

Repeater display

XT1001-A1

Repeater terminal

XT1002-A1

Repeater display

XT1001-A1

Repeater terminal

XT1002-A1

Caption:

Detector line

Electrical lines

Maniflold (dist ribution pipe)

Control pipe

Control line5

XC10 n°1

Monitored input

XCA1030 / XC10 n°1

Control line4

XC10 n°1

Control line 5

XC10 n°2

Monitored input

XCA1030 / XC10 n°2

Control line4

XC10 n°2

Sector valve

large room

Small room

Large room

Control

pipe

XC10 n°1

small room

XC10 n°2

large room

Fig. 29 XC1003-A, typical multi-sector installation

The example above describes the operation of a typical multi-zone installation on

the basis of the assumption that flooding zone 1 “small room” is activated:

1. XC10 n°1 “sm all room ” is activ ated

At the beginning of the pre-discharged warning time:

2. cont rol cylinder i s released into t he control pipe

3. XC10 n°1 control line 5 is activated

è consequence: the selector valve from the flooding zone 1 “small room” is

opening

At the end of the pre-discharged warning time:

4. XC10 n°1 control line 4 is activated

5. sector valve “small room ” is opening

6. thanks to the non-return valve, only the left cylinder is released into the “small

room” flooding zone

7. XC10 n°2 “large room” is aut omatically blocked (if selected in progr amming)

according to EN12094-1 option with requirements 4.29

At the begening of the floodingtime:

8. discharged contact from the flooding zone 1 “small room” is activated and

“Discharged” led i s indicated on XC10 n°1

Page 45

Multi-sector ins tallation

45

Building Technologies A6V10257473_e_en_-Fire Safety 2015-03- 04

8.2 Detailed description

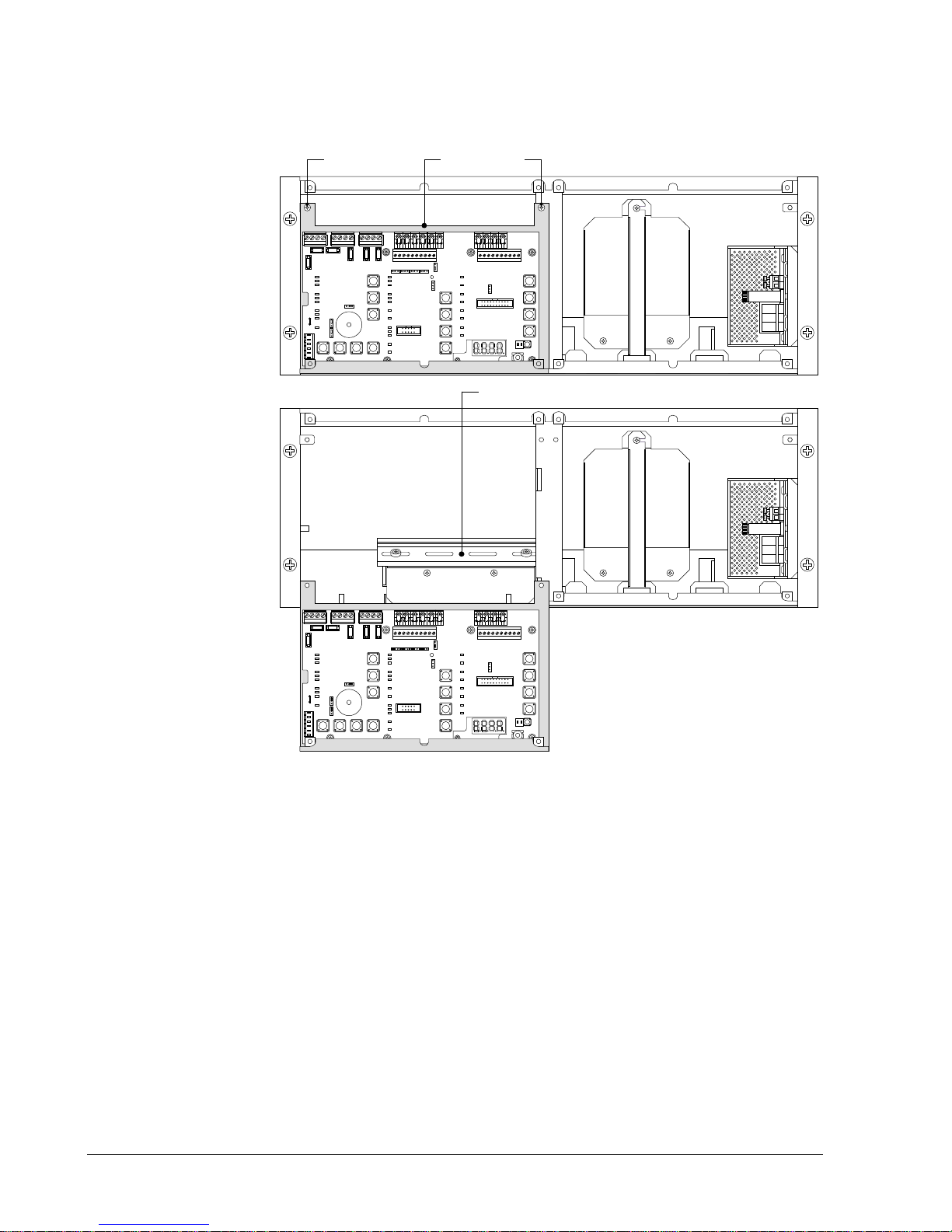

8.2.1 XCA1030 & XCA1031 connection

X6 X8

X4X7

X1

X2

F1F2

1 1

X5 X3

1

3

2

1 1

AXICOM

AXICOM

X6 X8

X4X7

X1

X2

F1F2

1 1

X5 X3

1

3

2

1 1

AXICOM

AXICOM

Multi - sector bus

24V

24V

Control

cylinder

XCA1030

Extension

module

XCA1031

multi-sector common

module

Sector 1

Sector 2

Activation line

X1

1 1

X4

F2

F1

X2

X3

X5

1

123

H1

H2

1

AXICOM

AXICOM

AXICOM

32

2411

12

13

14

15

16

17

18

19

20

21

22

23

25

26

27

28

29

30

31

10

7

1

2

3

5

6

8

9

4

X23

X24

ON

12

X8

X3X4

X28

X1

F3

F6 F5 F4

F2 F1

X14 X15 X16 X 17

X13

X18

X26

S1

X21

1

X11

1