Page 1

Building Technologies

Fire Safety & Security Products

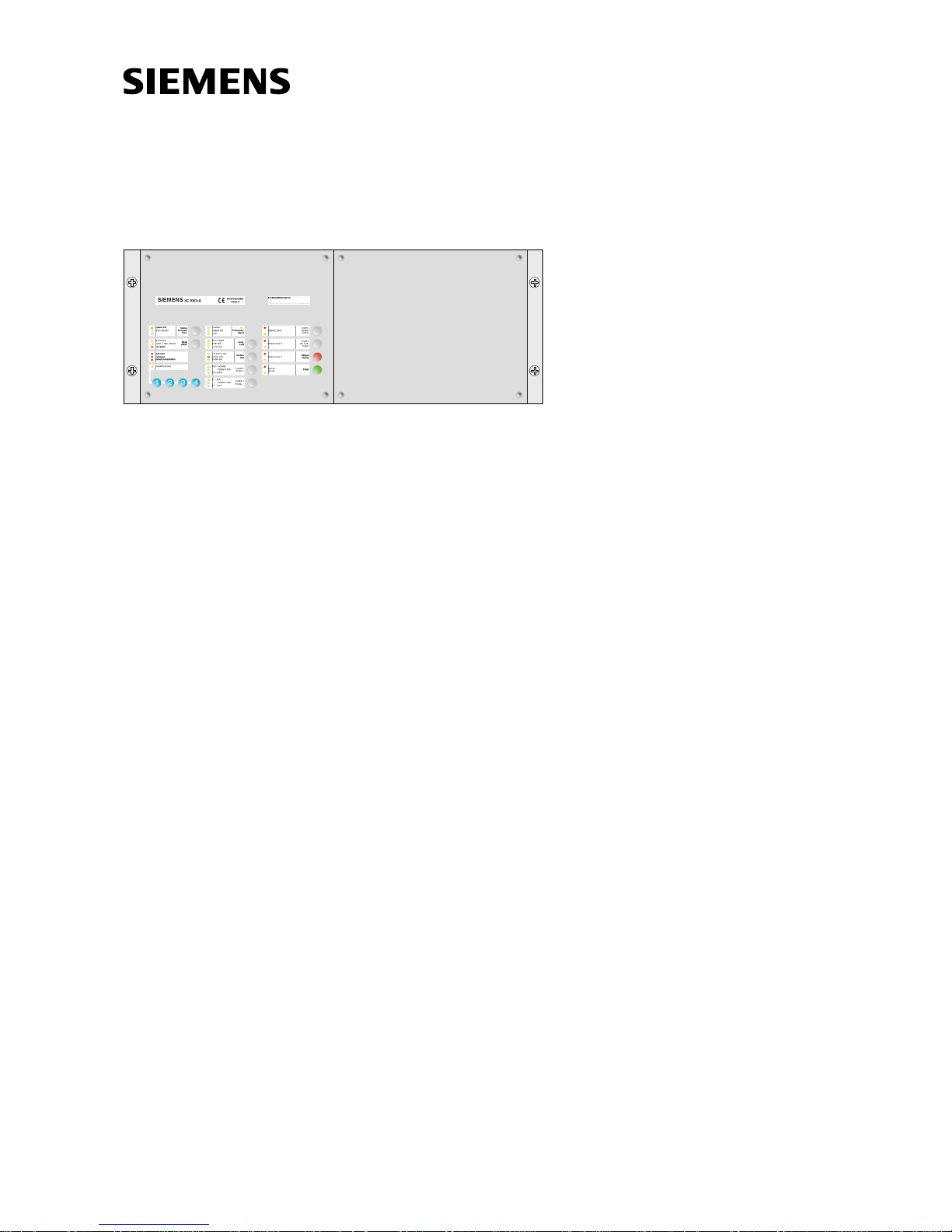

XC1003-A

Extinguishing control unit

Technical manual

Page 2

Liefermöglichkeiten und technische Änderungen vorbehalten.

Data and design subject to change without notice. / Supply subject to availability.

Sous réserve de modifications techniques et de la disponibilité.

© 2008 Copyright by

Siemens Switzerland Ltd

Wir behalten uns alle Rechte an diesem Dokument und an dem in ihm dargestellten Gegenstand vor. Der Empfänger anerkennt diese

Rechte und wird dieses Dokument nicht ohne unsere vorgängige schriftliche Ermächtigung ganz oder teilweise Dritten zugänglich machen

oder außerhalb des Zweckes verwenden, zu dem es ihm übergeben worden ist.

We reserve all rights in this document and in the subject thereof. By acceptance of the document the recipient acknowledges these rights

and undertakes not to publish the document nor the subject thereof in full or in part, nor to make them available to any third party without our

prior express written authorization, nor to use it for any purpose other than for which it was delivered to him.

Nous nous réservons tous les droits sur ce document, ainsi que sur l'objet y figurant. La partie recevant ce document reconnaît ces droits et

elle s'engage à ne pas le rendre accessible à des tiers, même partiellement, sans notre autorisation écrite préalable et à ne pas l'employer

à des fins autres que celles pour lesquelles il lui a été remis.

Page 3

3

Building Technologies

A6V10099837_a_en

Fire Safety & Security Products 12.2007

1

About this document ..............................................................................5

2

Safety regulations...................................................................................8

2.1

Danger levels ............................................................................................8

2.2

Safety-relevant operating instructions.......................................................9

3

System overview...................................................................................11

3.1

Application limitations..............................................................................12

3.2

Specified standards and options.............................................................12

4

Standard applications ..........................................................................13

4.1

Centralized installation............................................................................13

4.2

Modular installation.................................................................................14

5

Structure and function .........................................................................15

5.1

Block diagram .........................................................................................17

5.2

Connections ............................................................................................18

5.2.1

Power supply FCP1004-E.......................................................................19

5.2.2

Connections on XCM1001-1 lower main board without add-on module 20

5.2.3

Connections of the XCM1001-1 lower main board with add-on module 21

5.2.4

Connections of the XCM1001-2 upper main board ................................22

5.3

Adjusting elements..................................................................................23

5.3.1

Adjusting elements of the XCM1001-1 lower main board.......................23

5.3.2

Adjusting elements of the XCM1001-2 upper main board......................24

5.4

Indicator elements...................................................................................25

5.5

Operating elements.................................................................................29

5.6

Accessories.............................................................................................31

5.6.1

Z3B171 Relay module ............................................................................31

5.6.2

XCA1110 Pyrotechnical actuator kit .......................................................31

5.6.3

XCA1016 Add-on module .......................................................................32

5.6.4

FCA 1005-D RT Blocking card................................................................33

5.7

Technical data.........................................................................................34

6

Planning.................................................................................................35

6.1.1

Detector lines ..........................................................................................36

6.1.2

Monitored inputs......................................................................................38

6.1.3

Monitored control lines............................................................................41

6.1.4

Driver outputs..........................................................................................45

6.1.5

Potential-free contacts ............................................................................46

6.2

Detector lines wiring methods.................................................................47

6.2.1

Standard wiring .......................................................................................47

6.2.2

Wiring for explosion hazard areas ..........................................................48

6.2.3

Connection to a fire detector system ......................................................49

6.2.4

First application.......................................................................................50

6.2.5

Second application..................................................................................52

6.3

RT-alarm and fault wiring to a transmitter...............................................54

7

Installation .............................................................................................55

7.1

Installation location..................................................................................55

7.2

Mounting adaptation................................................................................56

7.3

19” cabinet platform mounting examples................................................57

7.4

Housing assembly XC1003-A.................................................................58

7.5

Insert labelling strips ...............................................................................59

7.6

Mounting the accessories XC1003-A......................................................60

7.7

Connecting the control unit .....................................................................61

8

Commissioning .....................................................................................62

Page 4

4

Building Technologies

A6V10099837_a_en

Fire Safety & Security Products 12.2007

8.1

Checking the installation .........................................................................62

8.2

Preparing the control unit........................................................................62

8.3

Switching on the control unit for the first time.........................................63

8.4

System test..............................................................................................63

8.5

Completing commissioning .....................................................................63

9

Service....................................................................................................64

9.1

Testing the extinguishing system............................................................64

9.2

Checking the operating units ..................................................................64

9.3

Checking the extinguishing control unit ..................................................64

10

Detailed procedures..............................................................................65

10.1

Enabling access level 1...........................................................................65

10.2

Checking all optical and acoustic elements of the control unit ...............65

10.3

Enabling access level 2...........................................................................65

10.4

Test the alarm horn.................................................................................65

10.5

Testing the warning panel.......................................................................65

10.6

Calibrating control lines 4 and 5..............................................................66

10.7

Performing system test ...........................................................................67

11

Programming the user functions ........................................................68

11.1

Enabling access level 3...........................................................................68

11.2

Enabling access level 4...........................................................................68

11.3

Exiting program mode.............................................................................68

11.4

Resetting the user functions to default or application setting .................69

11.4.1 Overview of the default and application settings ....................................70

11.4.2 Description of the default settings...........................................................72

11.5

Query checksum .....................................................................................74

11.6

Programming steps.................................................................................75

11.6.1 Step 1, changing the activated time and function of control lines 4/5.....76

11.6.2 Step 2, change the flooding time (active period) of control lines 4/5 ......77

11.6.3 Step 3, change the function of the remote transmission.........................78

11.6.4 Step 4, change the function of the monitored inputs 1 and 2 .................79

11.6.5 Step 5, change the active mode of control lines 1 and 3........................80

11.6.6 Step 6, enable the "Alarm verification" function......................................81

11.6.7 Step 7, define the function of the yellow key (KEY8)..............................81

11.6.8 Step 8, change the function of the monitored input 3 .............................82

11.6.9 Step 9, change the parameters to the "Reset" function..........................84

11.6.10 Step 10, change the indication mode on the operator interface .............85

11.6.11 Step 11, change the function of the detector zones 1 to 3 .....................85

11.6.12 Step 12, change the code for access level 2..........................................86

11.6.13 Step 13, change the parameters of the operator interface .....................87

11.6.14 Step 14, change the fault delay upon "Mains failure" .............................88

11.6.15 Step 15, change the function of the control inputs 2 to 4........................88

11.6.16 Step 16, change the function of the driver outputs 2, 8 and 1 ................89

12

Log sheet of programmed user functions..........................................90

13

Ordering information ............................................................................91

Page 5

About this document

5

Building Technologies

A6V10099837_a_en

Fire Safety & Security Products 12.2007

1 About this document

Objective and purpose

This document describes the planning, installation, commissioning and

maintenance of the XC1003-A extinguishing control unit. Please follow the

instructions carefully, to ensure correct reliable use.

Area of application

The information contained in this document is valid as of hardware/software

version 2.7.

Target group

This documentation and the instructions contains are addressed to the following

groups of people who perform the activities and hold the qualifications shown.

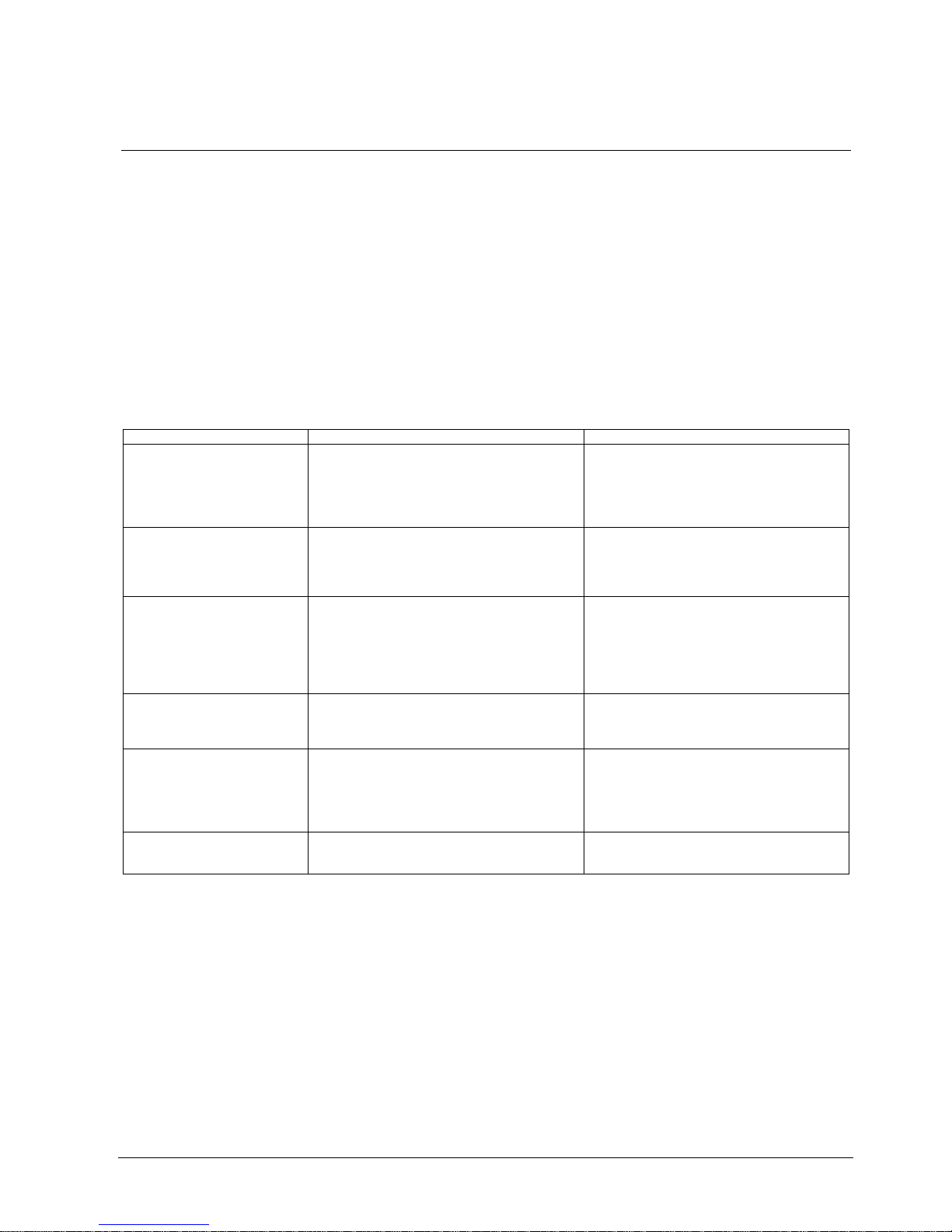

Group Activity Qualification

Product Manager (PM) Responsible for local product management for the

relevant product line and for the information

exchange between the site supplying the

equipment and the RC. Co-ordinates the

information flow between the individual groups for

a project.

Has the technical training and has completed the

training courses appropriate to his function and

to the product line.

Project Manager Responsible for local project management. Co-

ordinates on-time use of all groups and resources

involved in a project. Responsible for ongoing

acquisition of technical information required for

project realization.

Has the technical training appropriate to his

function and the dimensions of the project or the

product line deployed in the project and has

attended the training courses for project

managers at the supplier's works.

Project Engineer Parameterizes the product or equipment or system

in the RC for a specific country or customer.

Monitors the serviceability of the product or

equipment or system and releases it for

commissioning at the place of installation.

Diagnoses and eliminates operating faults and

errors.

Has the technical training appropriate for

parameterizing the products or devices or

systems and has attended the technical training

course for Project Engineers at the plant

supplying the equipment.

Installation Staff Installs and mounts the product or devices or

system components at the place of installation.

After installation, conducts a general performance

check of the installation.

Technical training in the area of building

automation and electrical installations.

Commissioning Personnel Customer-specific configuration of the product or

device or system at the place of installation.

Checks serviceability and officially releases the

product or device or system for operation by the

operator/customer. Diagnoses and eliminates

operating faults and errors.

Has the technical training appropriate to the

function and the products or devices or systems

to be commissioned and has attended the

technical training course for commissioning

personnel.

Maintenance Personnel Performs all maintenance procedures listed in the

product documentation and checks the product for

correct functioning.

Has the technical training appropriate to the

function and the product.

Page 6

About this document

6

Building Technologies

A6V10099837_a_en

Fire Safety & Security Products 12.2007

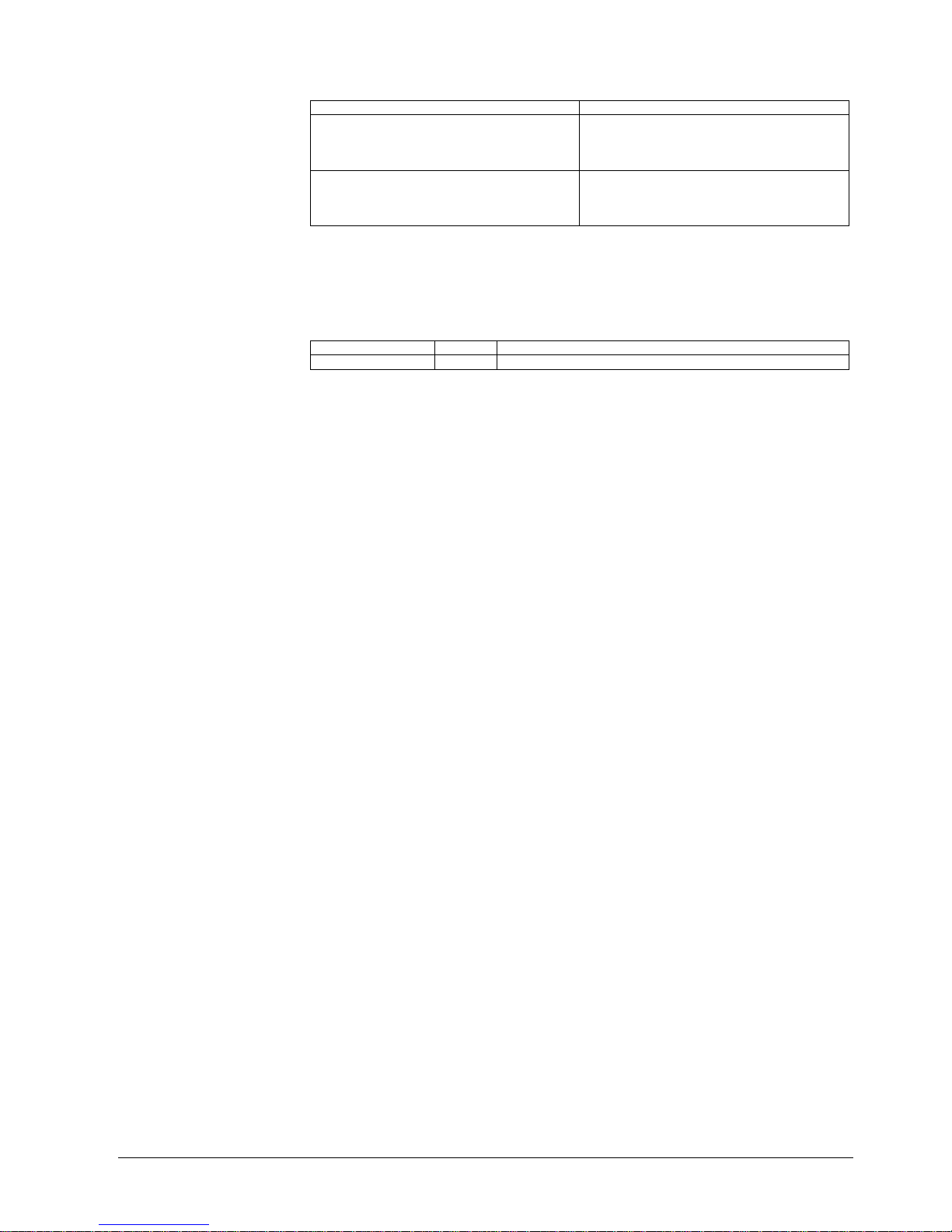

Brief description of chapter contents

Chapter Content Overview

1. About this document General information on documentation and notes

on the target group for which the document was

created.

2. Safety regulations Describes the hazard levels and safety provisions

that are important for planning, installation,

commissioning and maintenance of the

extinguishing control unit.

3. System overview Provides an overview of the function, use and

connection options for peripheral devices.

4. Standard application Illustrates and describes the two possible

topologies (centralized and modular) used in the

standard application.

5. Structure and function Describes the structure of the control unit,

electrical connections and the function of the

indicator elements, the operating elements and

the accessories; it also includes technical data.

6. Planning Describes the principle structural features of an

extinguishing control unit using descriptions of the

connection of peripheral devices.

7. Installation Provides procedural instructions for mounting the

control unit and any accessories.

8. Commissioning Provides procedural instructions for connecting

the peripheral devices and commissioning of the

extinguishing system.

9. Service Describes the recommended maintenance work.

10. Detailed procedures Supplements the instructions on commissioning

and maintenance using detailed, unit-specific

procedures.

11. User function configuration Describes the programming functions for a

customer-specific configuration of the

extinguishing unit.

12. Log sheet of programmed user functions Here you will find the worksheets for completion.

13. Ordering information Information on ordering components, accessories

and replacement parts.

Reference documents

Number/Version Name

A6V10099835_a_en Operating instructions

Standard symbols

Result, Note

' ' Direct quotation

(...) Parentheses contain supplementary text, suggestions, etc.

Technical terms

Term Explanation

Fire alarm The first alarm stage. The fire alarm time is the time between

triggering of the first and the second detector.

Activated condition Second alarm stage. The activated time is the time leading up to

triggering of the extinguishing releasing element.

Pre-discharge-warning time

Time period between the start of the warning indication and the

discharge to warn personnel of impending gas release

Flooding time The period of time during which the extinguishing gas is discharged.

Actuator An electromagnetic or pyrotechnical releasing element for triggering

the valves.

LED An optical indicator element (light-emitting diode).

Page 7

About this document

7

Building Technologies

A6V10099837_a_en

Fire Safety & Security Products 12.2007

Document identification

Location Definition

Title page

–

Product type: XC1003-A extinguishing control

unit

–

Document purpose: Planning, installation,

commissioning, maintenance

Last page bottom left

Last page bottom right

–

Document number

–

Issue date

–

Manual

–

Section

Download

The current documentation can be found on the Intranet.

Index of changes

Version Date Brief description

A6V10099837_a_en 12.2007 First issue

Page 8

Safety regulations

8

Building Technologies

A6V10099837_a_en

Fire Safety & Security Products 12.2007

2 Safety regulations

2.1 Danger levels

The following signal words indicate danger levels; that is, the severity and

probability of a hazard and its consequences.

DANGER

Imminent danger!

Severe physical injury or death.

WARNING

Possible dangerous situation

Severe physical injury or death

CAUTION

Possible dangerous situation

Slight physical injury or property damage

NOTE

Important information that requires special attention

Page 9

Safety regulations

9

Building Technologies

A6V10099837_a_en

Fire Safety & Security Products 12.2007

2.2 Safety-relevant operating instructions

Country-specific standards

The products are developed and produced in accordance with the relevant

international and European safety standards. If additional country-specific, local

safety standards or statutes apply to planning, mounting, installation, operation and

disposal of the product at the place of operation, then any such standards or

statutes shall be observed in addition to those safety prescriptions in the product

documentation.

Electrical installations

WARNING

Work on electrical systems must be carried out in accordance with electrotechnical rules and only by a trained electrical technician or an instructed

person under the management and supervision of an electrical technician.

WARNING

When performing work in explosion-hazard areas, comply with the respective

safety procedures.

When performing commissioning and repair work on units, they must be voltagefree, if possible.

Provide connection terminals with external voltage sources with "DANGER

external voltage" signing.

Lay mains power lines to the control unit separately. These must be fused with

their own, clearly marked fusing.

Provide earthing in accordance with local safety regulations.

When performing work in explosion-hazard areas, comply with the respective

safety procedures.

Mounting, installation, commissioning and maintenance

If you require tools, you must use tools that are safe and intended for the task

such as, for example, a ladder.

If you are activating fire controls for test purposes, there must be no damage

caused to system components.

Release fire controls only when the test has been completed and the system is

finally turned over to the customer.

Avoid unintended triggering of remote transmission.

Notify the receiving station prior to a pending test-remote transmission.

Before actuating manual activation for test purposes, mechanically block the

activation of extinguishing.

Use or require the use of the "General Installation Instructions" as the guideline

for extinguishing systems. This guideline is available from us on request.

Testing and checking product operability

Notify persons in the event of mist and noise.

Notify persons of the testing of the alarm devices and make provisions for

possible panic reactions.

Notify the alarm and fault receiving stations connected to the system of a

pending test-remote transmission.

When testing the extinguishing system, evacuate the extinguishing area and

block it off.

Page 10

Safety regulations

10

Building Technologies

A6V10099837_a_en

Fire Safety & Security Products 12.2007

Changes to system layout and products

Changes to the system and to individual products may result in faults and incorrect

functioning. Request from us and the respective safety authorities written approval

for intended changes and system expansions.

Components and replacement parts

Components and replacement parts procured locally must comply with the

technical requirements defined by the manufacturer. This is ensured in the case

of OEM replacement parts supplied by us.

Use only fuses having the prescribed characteristics.

Incorrect battery types and improper exchange of batteries result in an explosion

hazard. Use only the same battery type or an equivalent type recommended by

us.

Batteries require environmentally appropriate disposal. Bring them to the local

collection centers.

Note that the cylinders containing the extinguishing agent are under pressure

and must be exchanged in accordance with local safety regulations.

Non-compliance with safety regulations

The products are designed for proper use and have been tested for correct

function prior to delivery. We accept no liability for personal injury or property

damage occurring as the result of abuse or by noncompliance with the instructions

or danger notices listed in the documentation. This applies especially to:

Personal injury or property damage that occurs as the result of inappropriate use

and incorrect use.

Personal injuries or property damage that occurs as the result of noncompliance with safety-relevant information in the documentation or on the

product.

Personal injury or property damage that occurs as the result of deficiently

performed or non-performance of maintenance.

Page 11

System overview

11

Building Technologies

A6V10099837_a_en

Fire Safety & Security Products 12.2007

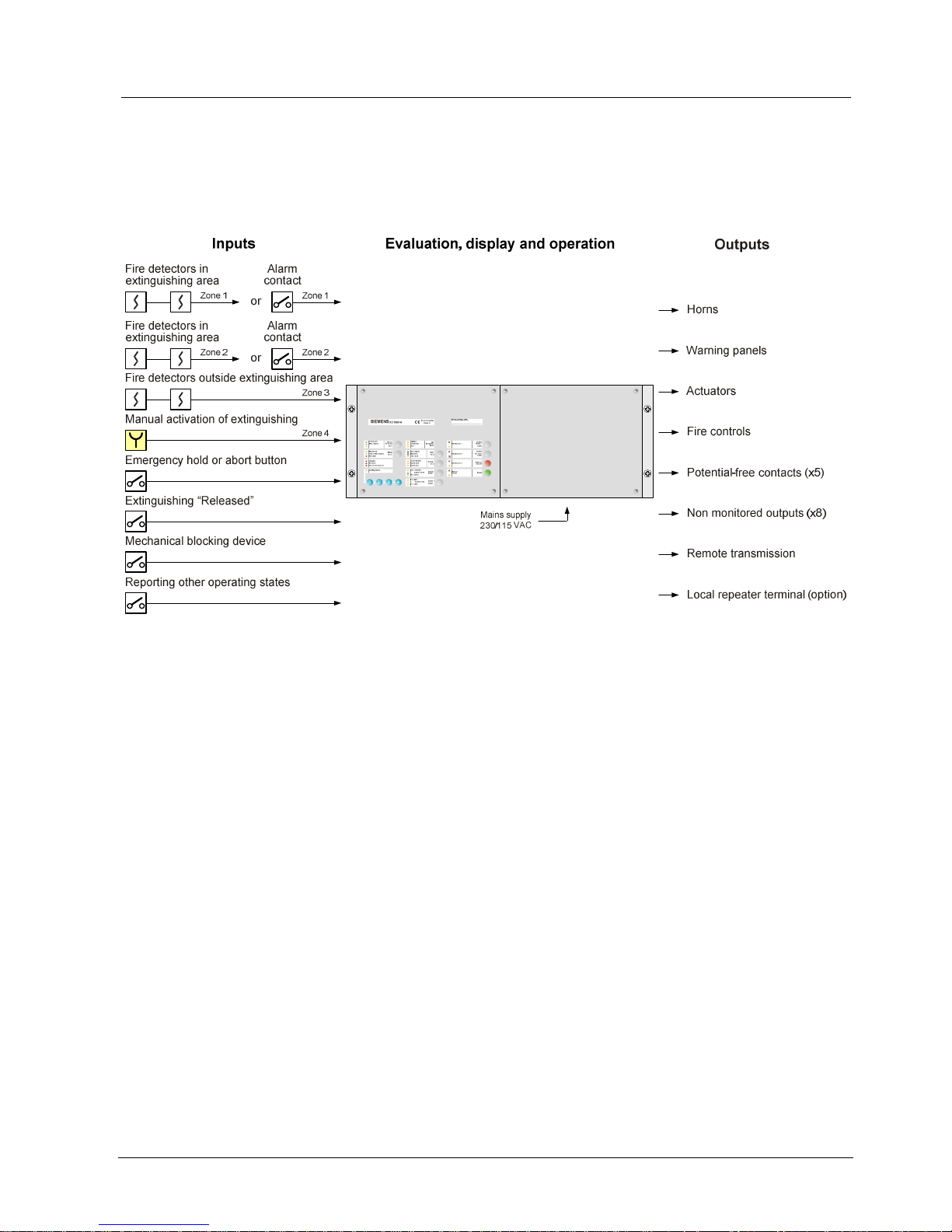

3 System overview

The XC1003-A extinguishing control unit with extinguishing control system and

extinguishing operation and its own fire detection system operates independently

or in conjunction with a fire alarm system. The control unit monitors and controls an

area of a small to medium-size high pressure extinguishing system. It monitors the

area to be flooded, the adjacent areas, the extinguishing process, the control of the

optical and acoustic alarm and the stocks of extinguishing agent.

Fig. 1 XC1003-A Extinguishing control unit system overview

Use

The XC1003-A control unit can be used for:

–

Gas extinguishing installations using common extinguishing agents such as

CO2, FM200, NOVEC and Argon.

–

Deluge installations using water as the extinguishing agent.

–

Foam extinguishing installations using a mixture of water and foaming

substances.

Peripheral equipment

The following peripheral equipment can be connected to the XC1003-A control

unit.

–

Two detector lines with conventional detectors for automatic activation of

extinguishing (zones 1 and 2).

–

One detector line with conventional detectors for monitoring areas adjacent to

the extinguishing zone (zone 3).

–

Manual activation button(s) for manual activation of extinguishing (zone 4).

–

Emergency hold or abort button(s) for manual blocking of extinguishing.

–

Alarm horn(s) for acoustic reporting of a fire alarm and the activated condition.

–

Illuminated warning panel(s) for optical reporting of the impending extinguishing

operation during the activated condition time and the released condition.

–

Remote transmission device to report the "Fire alarm" and "Fault" conditions.

–

Relay for fire control with 230V contact.

–

Potential-free contacts to report the states of the XC1003-A control unit

–

Solenoid or pyrotechnical actuators to trigger the flooding.

–

Repeater indication panel for extinguishing areas with several entrances.

Page 12

System overview

12

Building Technologies

A6V10099837_a_en

Fire Safety & Security Products 12.2007

3.1 Application limitations

–

no monitored remote control panel

–

not usable for multi-sector installations with electrical cylinder allocation and full

redundancy

–

no provision to monitor a spare cylinder bank

–

no facility for secondary flooding control (low pressure installations)

–

no interface for VdS peripherals such as FBF, ÜE, FSD, SST

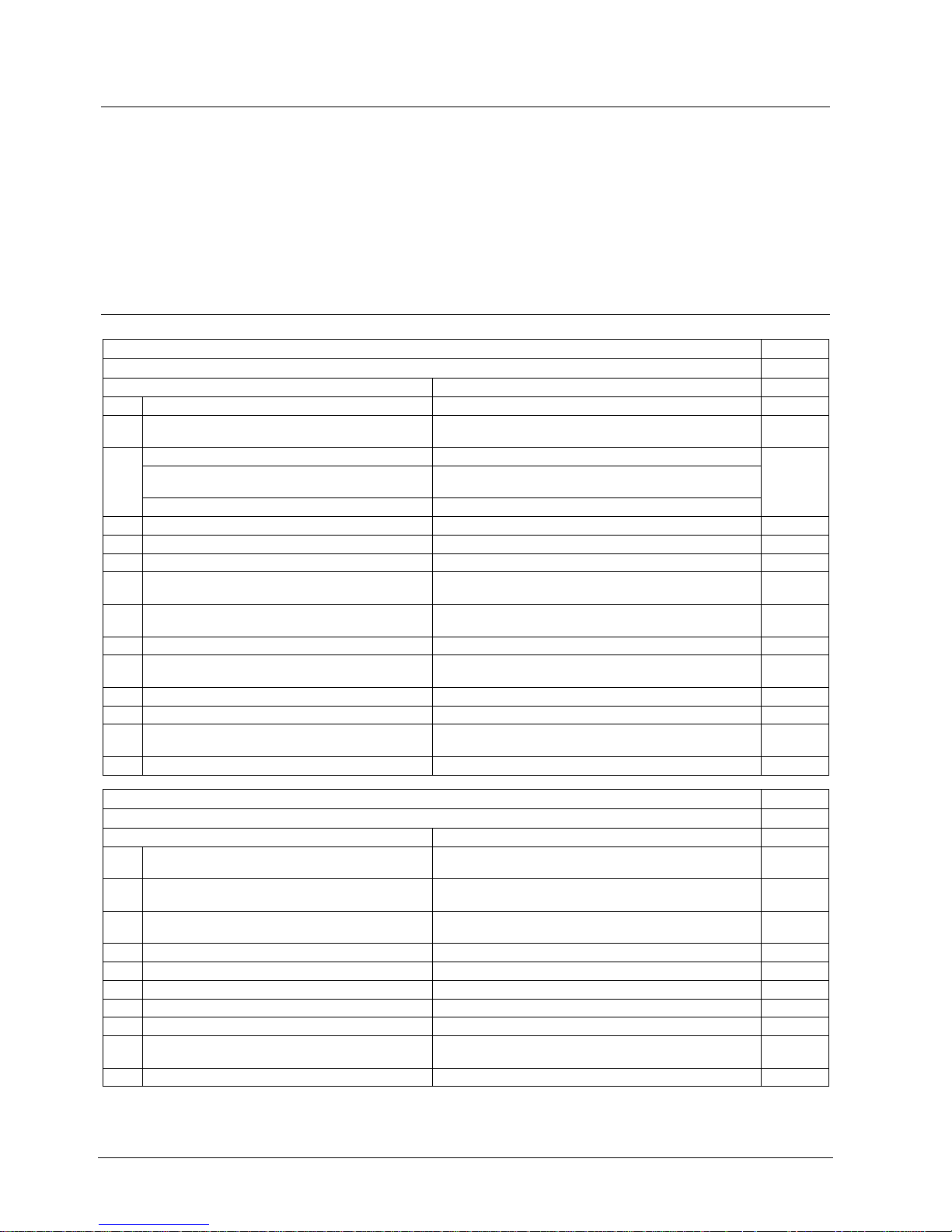

3.2 Specified standards and options

EN12094-1

Fulfilled

Basic functions

x

Options and the associated requirements Related XC10 configuration

4.17

Delay of extinguishing signal

Monitored control line 4, programming step 1 option 1-13 x

4.18

Signal representing the flow of extinguishing

agent

Monitored input 1, programming step 4 option 1

Monitored input 1A (XCA1016) programming step 4 option 1

x

Monitoring of the status of components

Loss of agent

Monitored input 2, programming step 4 option 10

Monitored input 1B (XCA1016) programming step 4 option 1

4.19

Non-electrical blocking device

Monitored input 2, programming step 4 option 6

x

4.20

Emergency hold

Monitored input 3, programming step 8 option 2 x

4.21

Control of flooding time

-

4.22

Initiation of secondary flooding

-

4.23

Manual only mode

Key "Mode select"

Monitored input 3, programming step 8 option 6

x

4.24

Triggering signals to equipment within the

system

Monitored control line 3, programming step 5 option 15-25 x

4.25

Extinguishing signals to spare cylinders

-

4.26

Triggering of equipment outside the system

Driver output 1 and 2

Monitored control line 5, programming step 1 option 17

x

4.27

Emergency abort

Monitored input 3, programming step 8 option 1 x

4.28

Control of extended discharge

-

4.29

Release of the extinguishing media for selected

flooding

-

4.30

Activation of alarm devices with different signals

Monitored control line 1, programming step 5 option 1-10 x

EN54-2

Fulfilled

Basic functions

x

Options and associated requirements Related XC10 configuration

7.8

Output to fire alarm device in accordance with

EN54-1 / C

Monitored control line 1, programming step 5 option 1-10 x

7.9

Output to fire alarm routing equipment in

accordance with EN54-1 / E

Monitored control line 2, programming step 3 option 17 x

7.10

Output to fire protection equipment or in

accordance with EN54-1 / G

Monitored control line 2, programming step 3 option 18 or 19 x

7.11

Delay to outputs

-

7.12

Coincidence detection

Detector zones 1, 2 and 3, programming step 6 option 1-4 x

7.13

Alarm counter

-

8.3

Fault signals from points

x

8.4

Total loss of the power supply

Separate wire from battery to upper main board XCM1001-2 x

8.9

Output to fault warning routing equipment in

accordance with EN54-1 / J

Potential-free contact Nr. 2, programming step 3 option 8-11 x

10

Test condition

x

Page 13

Standard applications

13

Building Technologies

A6V10099837_a_en

Fire Safety & Security Products 12.2007

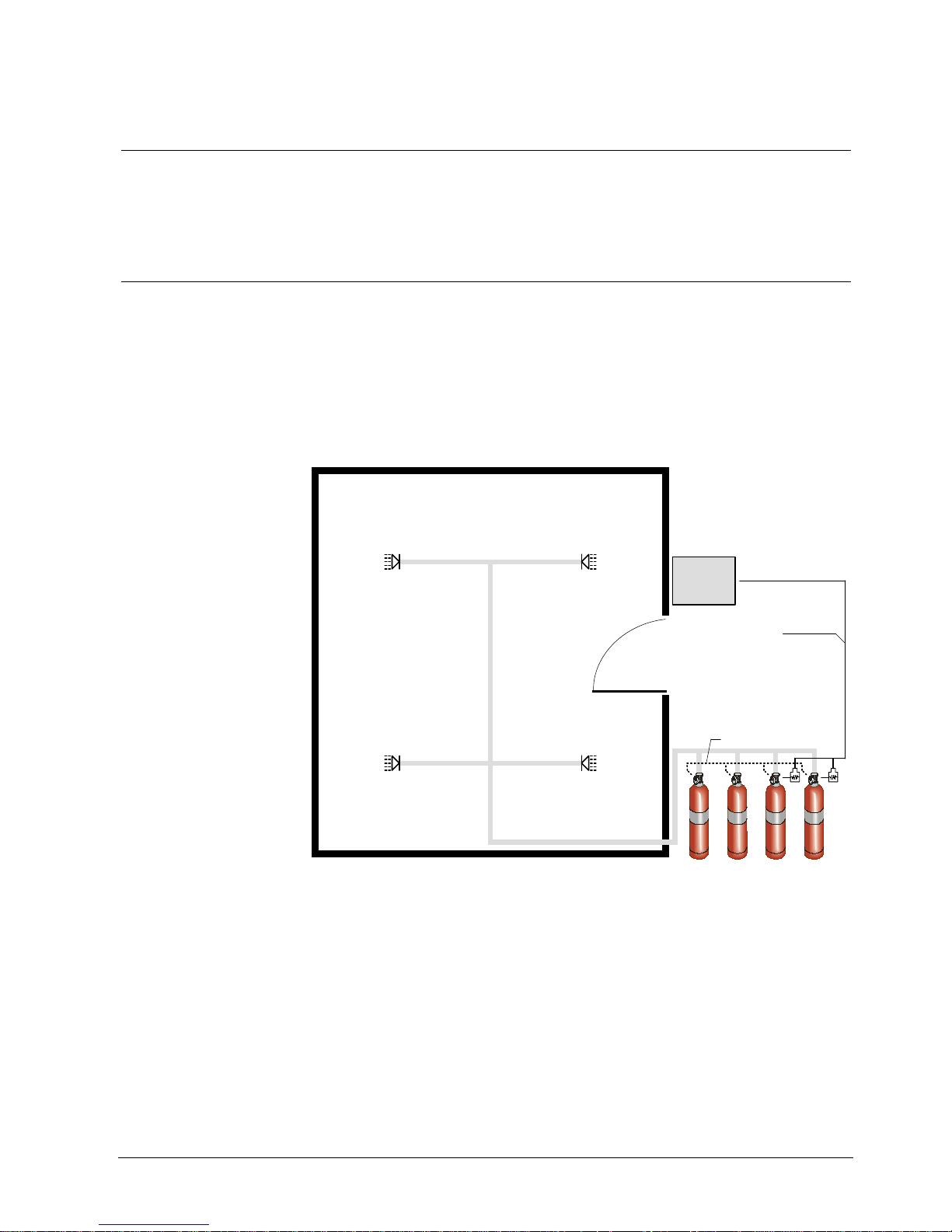

4 Standard applications

The principal field of application of XC1003-A is room protection. Two different

system topologies are used:

–

Centralized

–

Modular

4.1 Centralized installation

Centralized systems consist of a single set of cylinders placed in a storage area.

Pipe and nozzles are used to transfer the gas from the cylinders to the protected

room. A single actuator (electromagnetic or pyrotechnical) triggers a pilot cylinder

which then activates others cylinders by pneumatic activation. Two pilot cylinders

may be used in some countries when activation redundancy is required. In that

case, two electromagnetic solenoids are connected in parallel to the monitored

control output 4 (or 5 if selected), or two pyrotechnical actuators are connected in

series to the monitored control output 4 (or 5 if selected).

Pneumatic activation

Actuator line

(Pyrotechnical or

electromagnetic actuators)

Control

unit

XC103-A

Fig. 2 Centralized installation

Page 14

Standard applications

14

Building Technologies

A6V10099837_a_en

Fire Safety & Security Products 12.2007

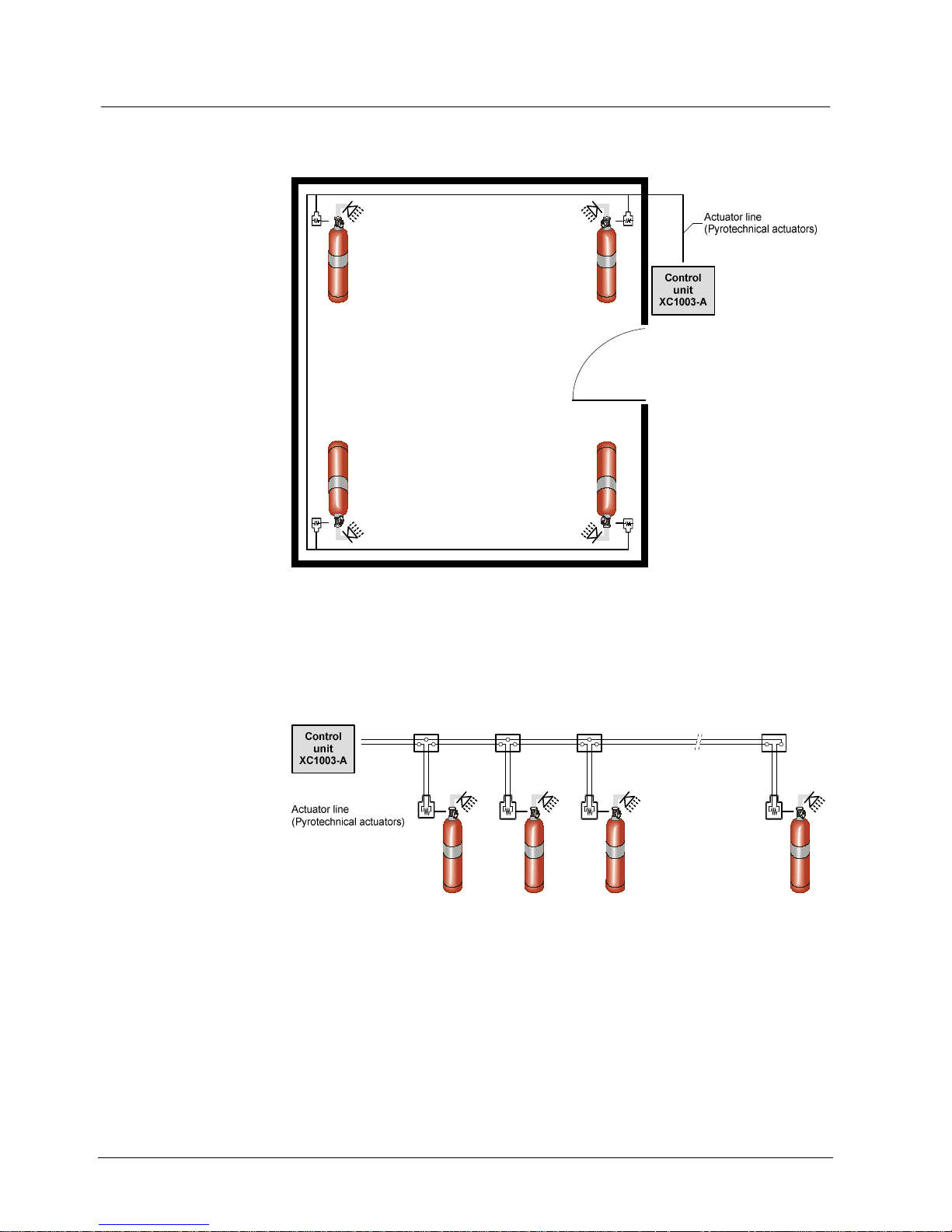

4.2 Modular installation

In contrast to centralized systems, modular systems consist of individual cylinders,

in the protected zone, with directly connected nozzles.

Fig. 3 Modular installation

For such installations, a pyrotechnical actuator is used on each cylinder. All

pyrotechnical actuators are connected in series on the monitored control line 4 (or

5 if option selected). A maximum of 10 pyrotechnical actuators in series can be

activated.

Fig. 4 Pyrotechnical installation

Page 15

Structure and function

15

Building Technologies

A6V10099837_a_en

Fire Safety & Security Products 12.2007

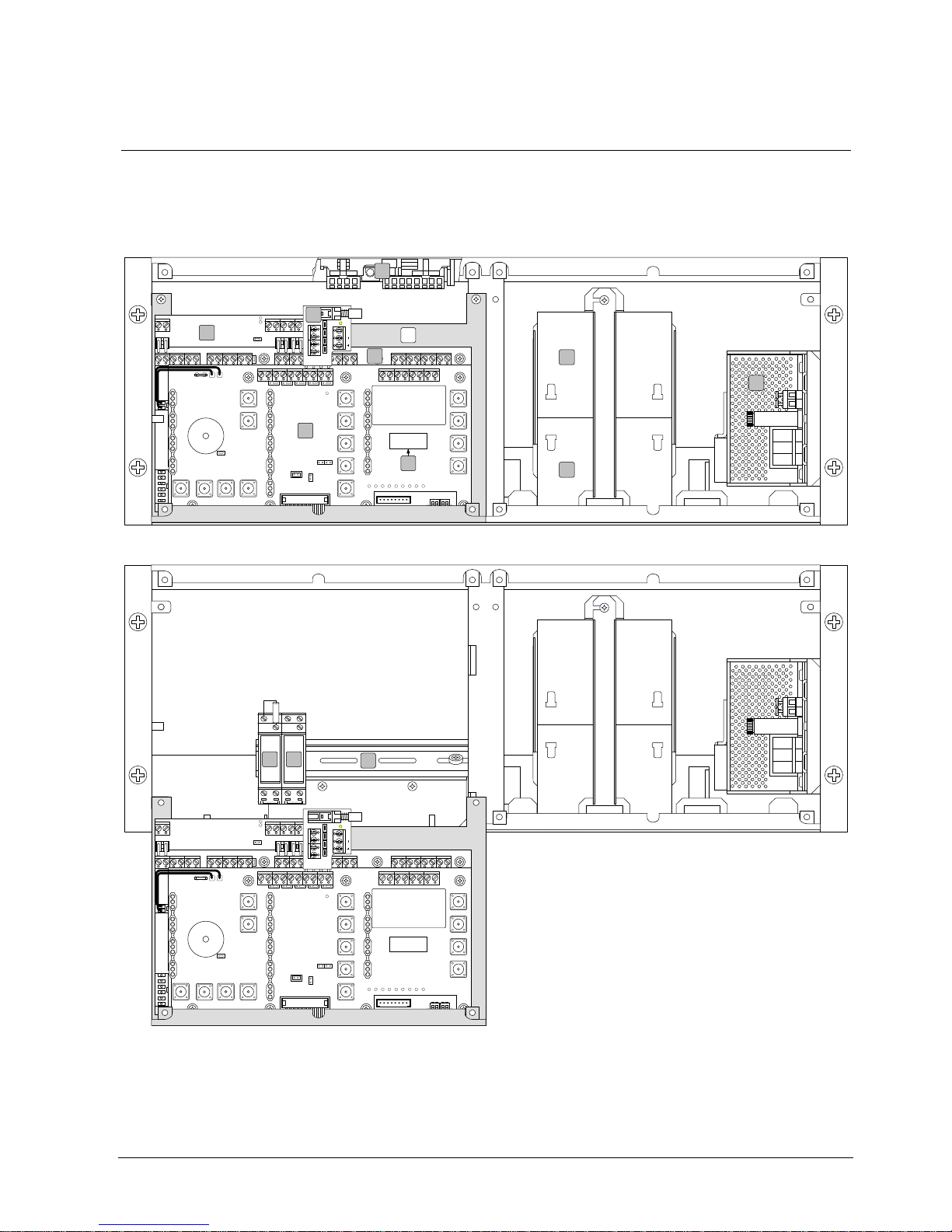

5 Structure and function

This chapter provides an introduction to the structure of the control unit XC1003-A,

describes the connections and provides an overview of the functions of the optical

indicators (LED), the adjusting elements and keys. Here you will also find the

description of the accessories and the technical data.

PU1

DL1

DL2

2A

2A

CN7

CN8

F2

F1

PU1

CN6

CN5

SW2

SW1

4 3 2 1

KEY

PU10

PU9

PU 6

LED34

LED26LED11

LED12

LED13

LED14

LED15

LED16

LED17

LED18

LED19

LED20

LED21

LED22

LED23

LED24

LED25

LED27

LED28

LED29

LED30

LED31

LED32

LED33

KEY 2

LED10

LED7

LED1

LED2

LED3

LED5

LED6

LED8

LED9

LED4

LD1

LD2

LD3

LD4

LD5

LD6

LD7

LD8

LD9

PU 5 PU 4 PU 3 PU 2

KEY 8KEY 9KEY 10KEY 11KEY 12

CN 1

KEY 5

+ BAT + 24V

KEY 4 KEY 6 KEY 7

PU1

LEVEL 3

PU8

B.S TEST FAB

PU7

KEY 1

KEY13

KEY14KEY15

KEY16

Pre-discharge-warning

time

………………. seconds

11

4

4

1

PU1

DL1

DL2

2A

2A

CN7

CN8

F2

F1

PU1

CN6

CN5

SW2

SW1

4 3 2 1

KEY

PU10

PU9

PU 6

LED34

LED26LED11

LED12

LED13

LED14

LED15

LED16

LED17

LED18

LED19

LED20

LED21

LED22

LED23

LED24

LED25

LED27

LED28

LED29

LED30

LED31

LED32

LED33

KEY 2

LED10

LED7

LED1

LED2

LED3

LED5

LED6

LED8

LED9

LED4

LD1

LD2

LD3

LD4

LD5

LD6

LD7

LD8

LD9

PU 5 PU 4 PU 3 PU 2

KEY 8KEY 9KEY 10KEY 11KEY 12

CN 1

KEY 5

+ BAT + 24V

KEY 4 KEY 6 KEY 7

PU1

LEVEL 3

PU8

B.S TEST FAB

PU7

KEY 1

KEY13

KEY14KEY15

KEY16

Pre-discharge-warning

time

………………. seconds

12

3

2

6

10

100Ω 3W

589

PU3 PU1 PU2

DL1

RT FAULT RT ALARM

OUPUT RT

PU4 PU3 PU1 PU2

DL1

RT FAULT RT ALARM

OUPUT RT

PU4

7

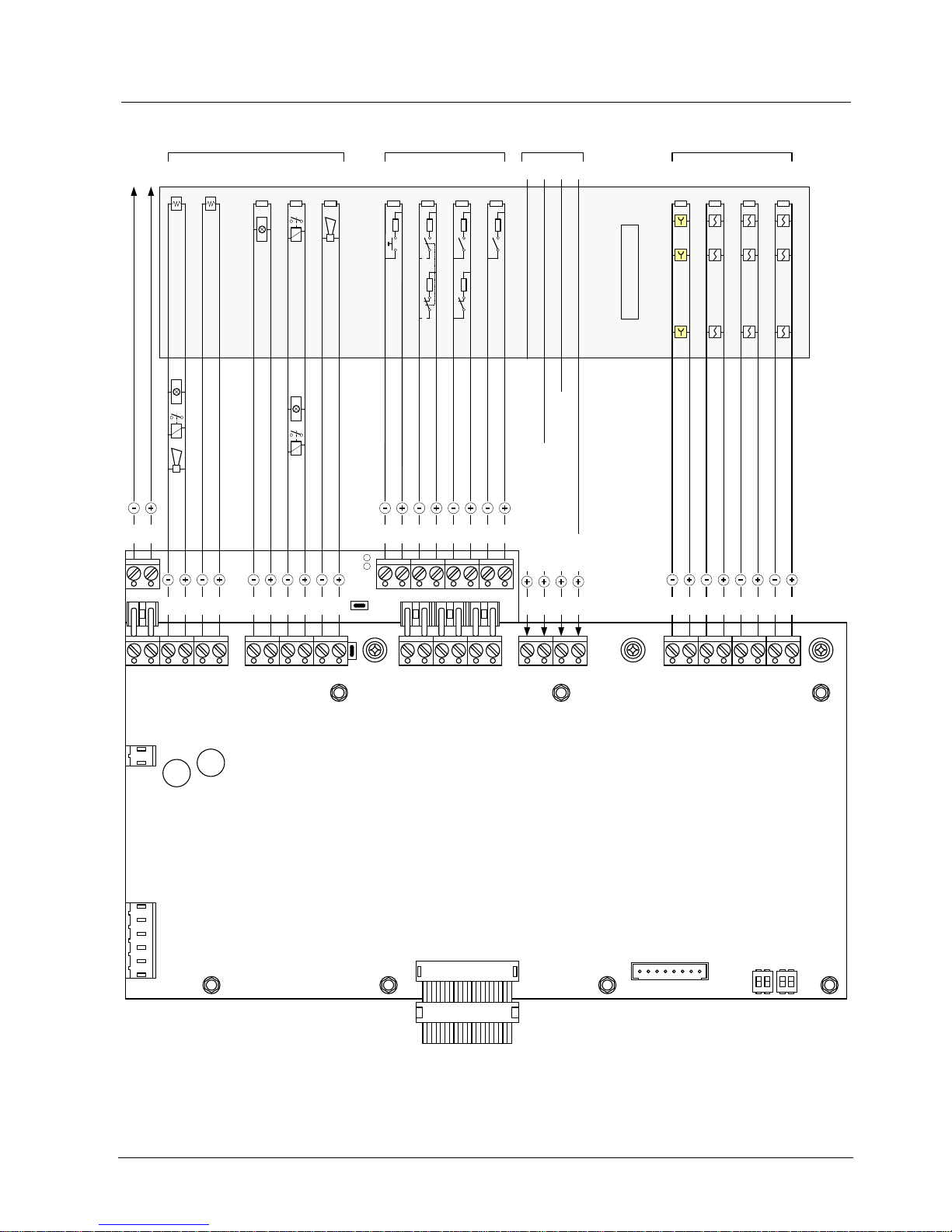

Fig. 5 Rack XC1003-A with electronics components

Page 16

Structure and function

16

Building Technologies

A6V10099837_a_en

Fire Safety & Security Products 12.2007

The basic equipment of the extinguishing control unit XC1003-A consists of

components 1 to 4. Depending on requirements, the control unit can be provided

with accessory parts 5 to 9:

1. FCP1004-E power supply unit with charger

2. XCM1001-1 main board (lower level)

3. XCM1001-2 main board (upper level)

4. Rechargeable batteries 4.5 Ah or 7.2 Ah (see chapter 7.4)

5. XCA1110 pyrotechnical actuator kit (option)

6. XCA1016 add-on module to split the monitored input 1 into the two separate

circuits "1A" and "1B" (option)

7. FCA1005-D RT isolation card for preventing remote transmission of alarms

and faults (option)

8. FDCI222 or FDCIO222 module for the connection to a fire detection system

(option)

9. Z3B171 relay module for fire controls (option)

10. Removable support main boards XCM1001-1 and XCM1001-2

11. DIN rail TS35 to install components such as relays, terminals, etc.

12. Label for indication of pre-discharge-warning time selected

Page 17

Structure and function

17

Building Technologies

A6V10099837_a_en

Fire Safety & Security Products 12.2007

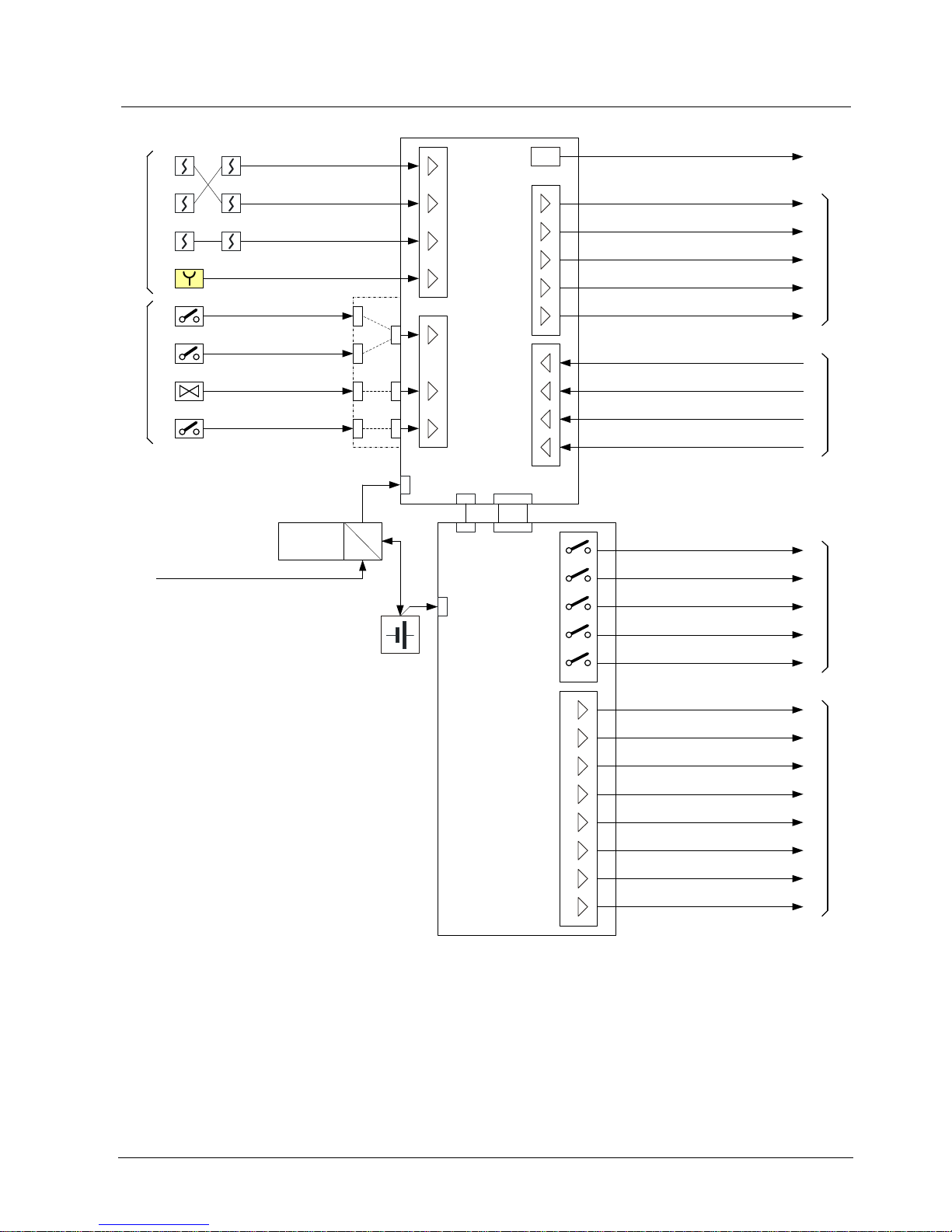

5.1 Block diagram

LIN4

Horn

RT-alarm or other application

Actuator delayed

Actuator immediate or other application

Mains supply

Output 24V / 0.5A max. (for internal use)

CL6

CL12

CL13

CL14

CL15

CN8

CL10

CN6

CN1

XCM1001-1

CL11

CL16

Detector lines

1

2

3

4

5

Monitored inputs

Monitored control linesPotentiel-free contactsDriver outputs

CL7

CL6

CL7

CL8

CL9

CL5 1

2

3

4

5

RT-alarm

RT-fault

Fire alarm or other application

Manual only

Autom. & Man. blocked

Fire alarm / Activated / Released

Released

1

2

3

4

5

CL1

CL2

6

7

8

CL3

CL4

Emergency hold/abort

Activated / Released

Fire alarm

Activated

Manual only mode

Autom. & Man. blocked

Manual release

CL4

LIN1

CL1

LIN2

CL2

LIN3

CL3

Discharged

Loss of agent

Mech. blocking device

Emergency hold or abort

XCA1016

1

2

3

AC

DC

FCP1004E

12V / 4.5Ah or 7.2Ah (x2)

XCM1001-2

CN7

1A

1B

2

3

CL8

CL9

CL10

+ BAT

+ / -

Reset

Silence buzzer or other application

Control inputs

Fault or other application

Silence Re-sound horn or other application

1

2

3

4

Warning panel

Z. 1

Z. 2

Z. 3

230 / 115 VAC

Z. 4

Fig. 6 Block diagram of the XC1003-A control unit

Page 18

Structure and function

18

Building Technologies

A6V10099837_a_en

Fire Safety & Security Products 12.2007

5.2 Connections

The following is a brief, overview of the location of the connections.

On the top of the power unit (see chapter 5.2.1) are the mains connection and

voltage selection.

The XCM1001-1 main board (see chapter 5.2.2 and 5.2.3) principally includes:

–

Detector lines

–

Control inputs

–

Monitored inputs

–

Monitored control lines

The XCM1001-2 main board (see chapter 5.2.4) principally includes:

–

Driver outputs

–

Potential-free contacts

Page 19

Structure and function

19

Building Technologies

A6V10099837_a_en

Fire Safety & Security Products 12.2007

5.2.1 Power supply FCP1004-E

Fig. 7 Components of the power unit FCP1004-E

Ref. Function Remarks

1 Terminal block for setting mains voltage to

115 V

Jumper set for 115 V only (use insulated wire)

2 Terminal block for mains connection

3 4 AT/250 V 20x50mm high break mains fuse

4 Jumper for system start without mains

power

Remove after system start

5 LED green “mains operation” (inside but

visible from the front)

Not lit in the event of power failure

6 Heat sensor for temperature compensation

7 Batteries connection

8 XCM1001-1 connection

9 Connection required in case EN54-2 option

with requirement "Total loss of power" is

mandatory (Mainly for FR).

Connect wire between +battery connection

and +BAT terminal of XCM1001-2

Protection by fuse 630 mA

This product shall be installed, commissioned and maintained by trained service personnel in

accordance with the following:

1. IEE regulations for electrical equipment in buildings

2. Codes of practice

3. Any instructions specifically advised by the manufacturer

This equipment is designed to operate from 230V 50Hz mains supplies. It must be connected to a

protective earthing conductor in the fixed wiring of the installation, and a readily accessible double

pole disconnect device meeting the requirements of EN60950/IEC950 which disconnects live and

neutral simultaneously, shall be incorporated in the fixed wiring.

Failure to ensure that all conductive accessible parts of this equipment are adequately bonded to the

protective earth will render the equipment unsafe.

1. Ensure mains power is switched off

2. Remove mains fuse (3)

3. Connect the mains cable to the FCP1004E power supply terminals (2) Protective earth, live and

neutral)

4. Attach the cable with 2 plastic fastenings

This control panel is environmental class A and is designed for indoor use only at temperatures

between -5°C (+/- 3) and +40°C (+/- 2) and with a m aximum relative humidity of 95%.

The IP rating for the enclosure is IP30. Operation outside of these limits may render the equipment

unsafe.

Page 20

Structure and function

20

Building Technologies

A6V10099837_a_en

Fire Safety & Security Products 12.2007

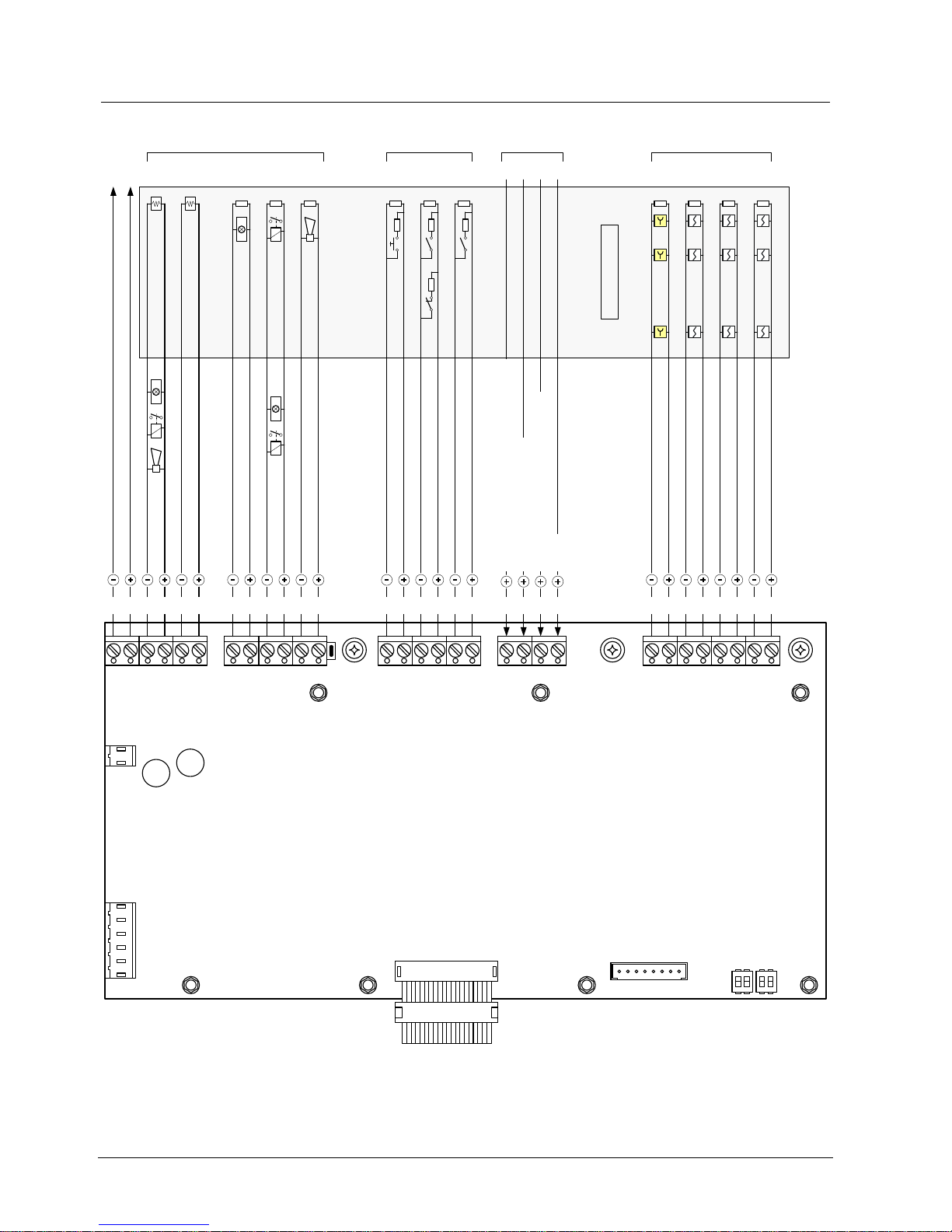

5.2.2 Connections on XCM1001-1 lower main board without add-on module

Standard

2A

2A

Emergency hold or abort

Loss of extinguishing agent

Extinguishing discharged

CN7

CN8

F2

F1

PU1

CN6

CN5

SW2 SW1

4 3 2 1

Alarm horn

Monitored inputs

3 2 1

3K3 3K3 3K3

0K68

0K68

CL16 CL15 CL14 CL13 CL12 CL11 CL10 CL9 CL8 CL7 CL6 CL4 CL3 CL2 CL1

121212

LIN4

Detectors to extinguishing area

Manual release

Detector lines

LIN3

LIN2

LIN1

Detectors to extinguishing area

Detectors outside exting. area

3K3 3K3 3K3 3K3

3 2 1

12121212

4

Reset

Control inputs

3 2 14

1212

Silence Re-sound horn or other application

Fault or other application

Silence buzzer or other application

Supply for internal devices

Actuator delayed

Warning panel

RT-alarm

Monitored control lines

5 34 2 1

..2A ..0.5A ..0.5A..2A ..0.5A

Actuator immediate

24V

..0.5A

12 12 12 12 12 12

Options

Options

EOL

(*)

EOL

(*)

EOL

(*)

(*) Line termination of monitored control lines 1 … 3:

Use FCE1002 (enclosed with delivery from the factory)

Options

Other application

1K2 0K68

NONC

or

Fig. 8 Connections of the XCM1001-1 lower main board without add-on module

Page 21

Structure and function

21

Building Technologies

A6V10099837_a_en

Fire Safety & Security Products 12.2007

5.2.3 Connections of the XCM1001-1 lower main board with add-on module

Standard

2A

2A

PU1

DL1

DL2

CN7

CN8

F2

F1

PU1

CN6

CN5

SW2 SW1

4 3 2 1

Reset

Supply for internal devices

LIN4

Detectors to extinguishing area

Manual release

Actuator delayed

Warning panel

Alarm horn

RT-alarm

Monitored control lines Monitored inputs Control inputs Detector lines

5

3 2 1A

34 2 1

..2A ..0.5A ..0.5A..2A ..0.5A

3 2 14

LIN3

LIN2

LIN1

Detectors to extinguishing area

Detectors outside exting. area

Actuator immediate

24V

..0.5A

EOL

(*)

3K3 3K3 3K3 3K3

3 2 1

12

12 12 12 12 12 1212 12121212

Extinguishing discharged

3K3

0K68

12

Loss of extinguishing agent

3K3

12

Emergency hold or abort

3K3

0K68

12

Mechanical blocking device

3K3

12

1B

Silence Re-sound horn or other application

Fault or other application

Silence buzzer or other application

4

Options

Options

CL16 CL15 CL14 CL13 CL12 CL11 CL10 CL9 CL8 CL7 CL6 CL4 CL3 CL2 CL1

CL3CL2CL4CL5

CL1

or

0K680K68

1K2 0K68

ClosedOpen

(*) Line termination of monitored control lines 1 … 3:

Use FCE1002 (enclosed with delivery from the factory)

EOL

(*)

EOL

(*)

Options

Other application

Fig. 9 Connections of the XCM1001-1 lower main board with add-on module

Page 22

Structure and function

22

Building Technologies

A6V10099837_a_en

Fire Safety & Security Products 12.2007

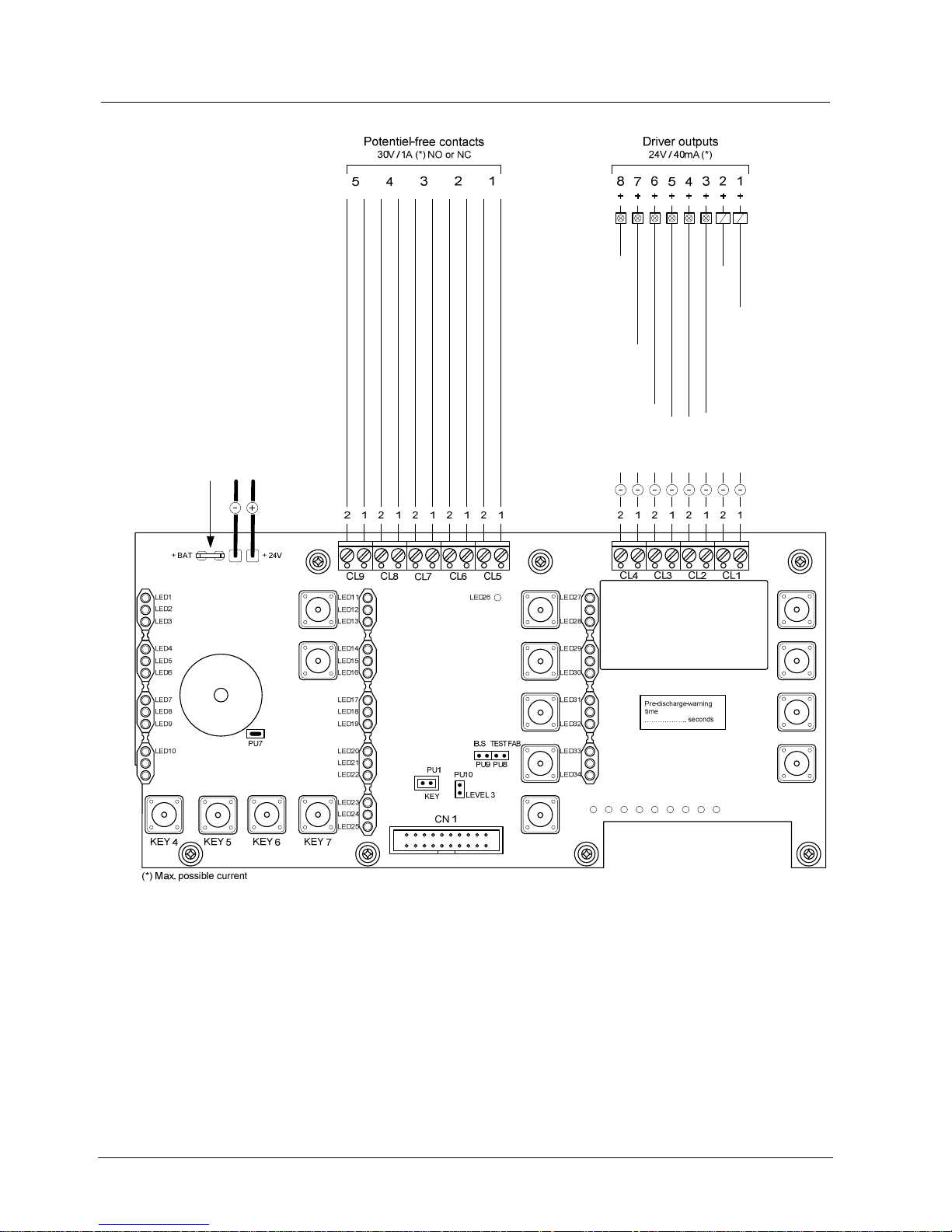

5.2.4 Connections of the XCM1001-2 upper main board

KEY 2

LD1

LD2

LD3

LD4

LD5

LD6

LD7

LD8

LD9

KEY 8KEY 9KEY 10KEY 11KEY 12

To lower main board via connector CN8 (Supply 24V)

To positive of battery to provide function ’’total loss of power’’

Autom. & Man. blocked

RT-alarm

RT-fault

KEY 1

KEY13

KEY14

KEY15

KEY16

Manual only

Fire alarm or other application

Emergency hold / abort or other application

Autom. & Man. blocked

Manual only

Released

Activated

Activated / Released or other application

Fire alarm

Fire alarm / Activated / Released

Fig. 10 Connections of the XCM1001-2 upper main board

XC10 provides EN54-2 option with requirements “Total loss of power”. This option

is mainly mandatory in France. When selected, “System fault” led and buzzer is

activated continuously for at least 1 hour after low discharge battery switch off (in

case the battery voltage fails below 21 V).

This option can be selected by wiring the +BAT terminal to the positive voltage of

batteries (use of remaining power of the battery).

Page 23

Structure and function

23

Building Technologies

A6V10099837_a_en

Fire Safety & Security Products 12.2007

5.3 Adjusting elements

Certain functions can be parameterized using the adjusting elements.

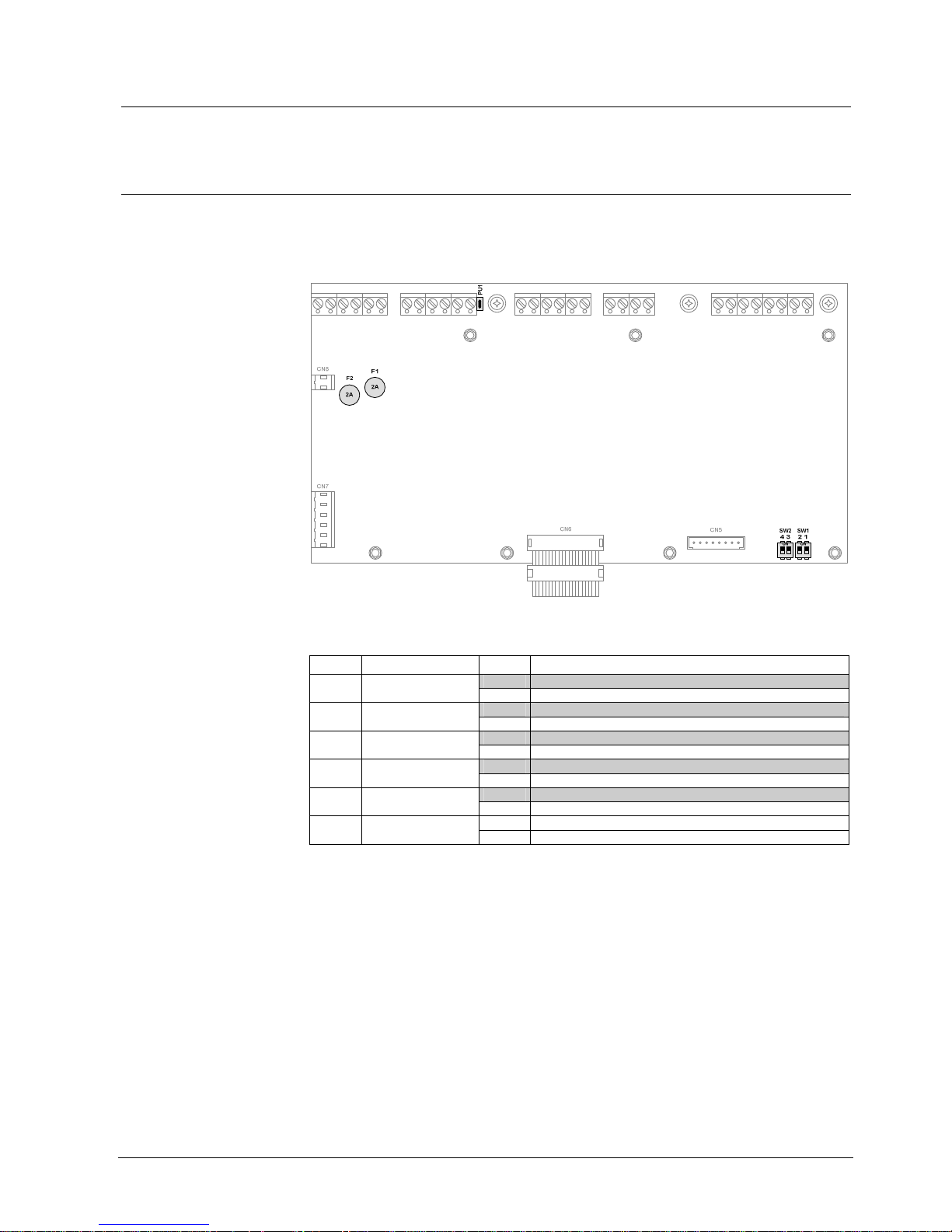

5.3.1 Adjusting elements of the XCM1001-1 lower main board

This board contains parameters for:

–

Disable earth fault monitoring

–

Change type of fire detector

Fig. 11 Adjusting elements of the XCM1001-2 upper main board

Ref. Function State Parameter

ON Activated (factory setting) PU1 Earth short

monitoring unit

OFF De-activated

ON Detector "Siemens" without current limiting (factory setting) SW1-1 Detector line 1

OFF Detector "Synova" with current limiting

ON Detector "Siemens" without current limiting (factory setting) SW1-2 Detector line 2

OFF Detector "Synova" with current limiting

ON Detector "Siemens" without current limiting (factory setting) SW2-3 Detector line 3

OFF Detector "Synova" with current limiting

ON 1) Detector "Siemens" without current limiting (factory setting) SW2-4 Detector line 4

(manual release)

OFF 1) Detector "Synova" with current limiting

Fit Fuse “F1” for control line 4 F1 / F2 Pluggable fuse 2A

Fit Fuse “F2” for control line 5

1

) Manual activation buttons with 820 Ohm resistor or with Z-diode 5.6 V with LED in line function on

both settings correct

Page 24

Structure and function

24

Building Technologies

A6V10099837_a_en

Fire Safety & Security Products 12.2007

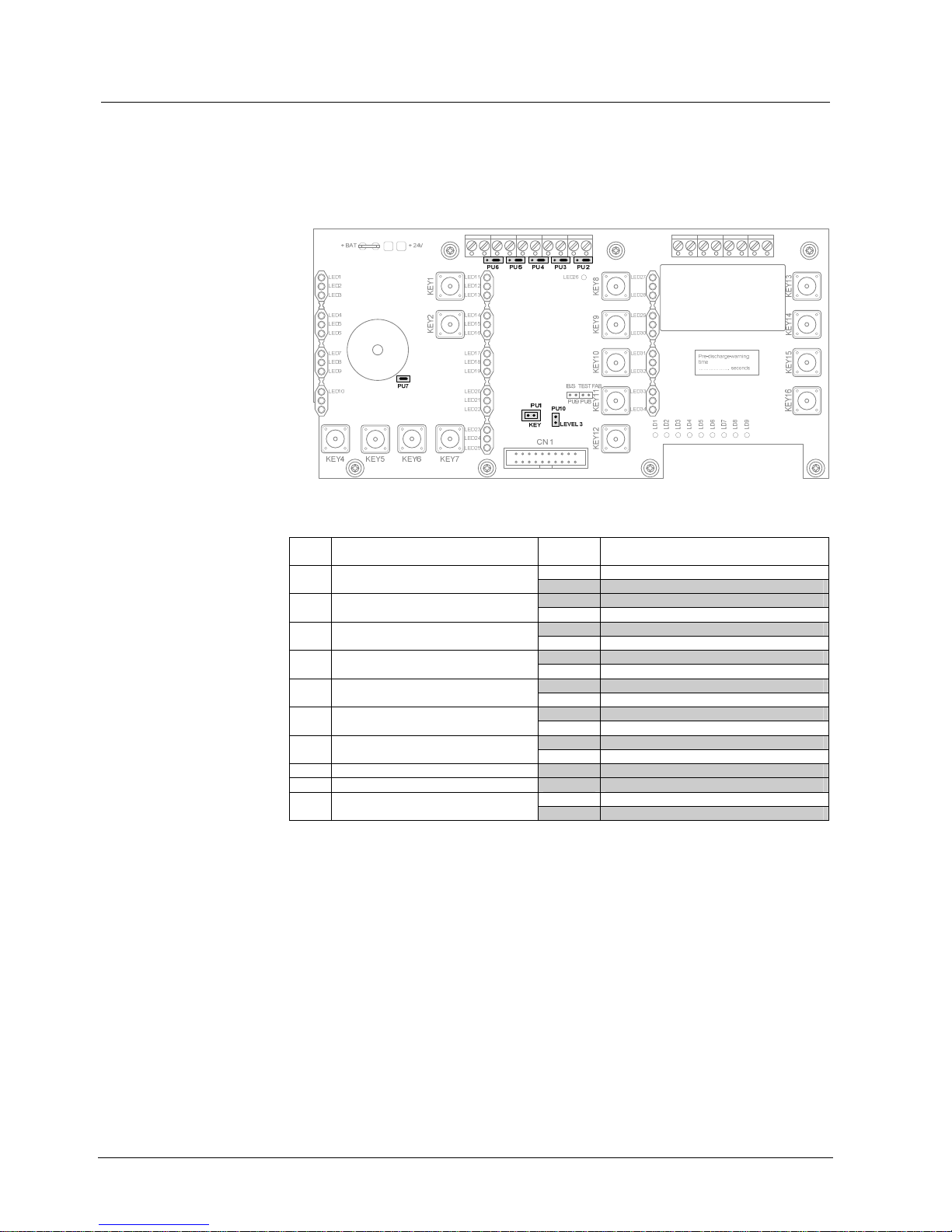

5.3.2 Adjusting elements of the XCM1001-2 upper main board

This board contains parameters for:

–

Permanently activate of operating level 2

–

Change the contact type NO/NC

–

Disable activation of the buzzer

–

Activate the calibration procedure for control lines 4 and 5

Fig. 12 Adjusting elements of the XCM1001-2 upper main board

Ref. Function

Jumper

pos.

Parameter

ON Permanent access PU1 Operating access level 2

OFF Access only using code (factory setting)

ON Right NO contact (factory setting) PU2 Potential-free contact "RT-alarm"

(programmable in step 3/option 1-4)

ON Left NC contact

ON Right NO contact (factory setting) PU3 Potential-free contact "RT-fault"

(programmable in step 3/ option 8-11)

ON Left NC contact (schematic in power off state)

ON Right NO contact (factory setting) PU4 Potential-free contact "Fire alarm"

(programmable in step 3/ option 5-6)

ON Left NC contact

ON Right NO contact (factory setting) PU5 Potential-free contact "Manual only"

ON Left NC contact

ON Right NO contact (factory setting) PU6 Potential-free contact "Autom. & Man.

blocked"

ON Left NC contact

ON Activated (factory setting) PU7 Temporary disabling of buzzer

OFF Not activated (only for servicing)

PU8 Factory test OFF (factory setting)

PU9 Factory test OFF (factory setting)

ON Calibration activated PU10

Calibrating the control lines 4 and 5

(details see chapter 10.6)

OFF Calibration not activated (factory setting)

Page 25

Structure and function

25

Building Technologies

A6V10099837_a_en

Fire Safety & Security Products 12.2007

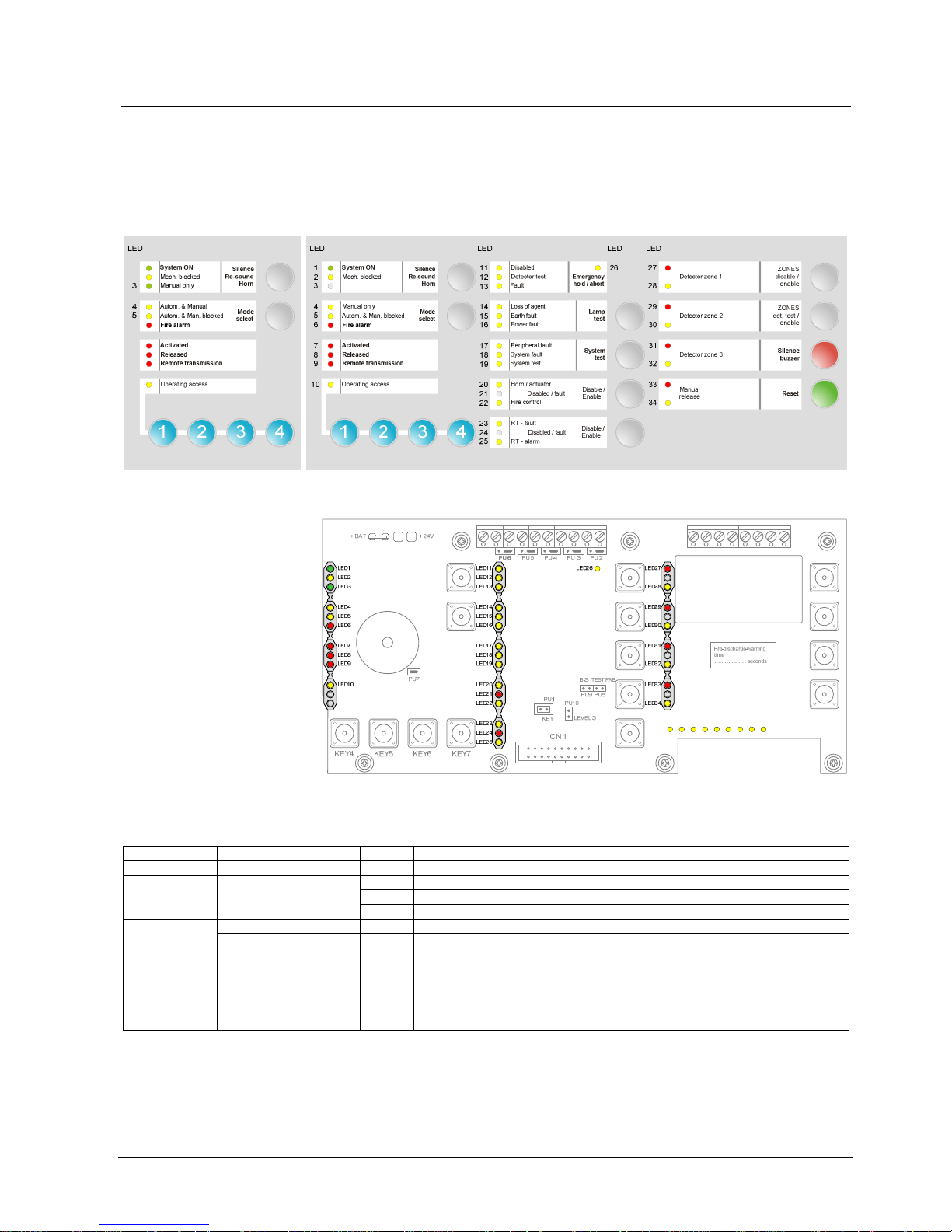

5.4 Indicator elements

The indicator elements (LEDs) are on the XCM1001-2 main board. LEDs 1 to 34

for operating states are visible on the front of the housing. Service LEDs (LD1 to

LD9) provide fault information and are not visible from the outside.

Alternative configuration

Programming step 10/ option 2

Standard configuration

Programming step 10/ option 1

Fig. 13 Indicator elements, housing cover view

KEY2

LD1

LD2

LD3

LD4

LD5

LD6

LD7

LD8

LD9

KEY8KEY9KEY10KEY11KEY12

KEY1

KEY13

KEY14

KEY15

KEY16

Fig. 14 Indicator elements, XCM1001-2 upper main board view

Indicator elements (LED1 to LED34)

Ref. / Colour Identification State Function

LED1 / Green System ON Lit System in operation (microcomputer is running)

- Mechanical blocking device is in the "Open" position

Lit Mechanical blocking device is in the "Closed" position

LED2 / Yellow Mech. blocked

Fast Mechanical blocking device in wrong position

- - Not used LED3 / Green

Manual only Lit

Alternative (step 10 = option 2):

Triggering by fire detector is blocked, initialized by:

– KEY2 "Mode select"

– Disabling of detector zone 1 or 2

– Switching of detector zone 1 or 2 to "Test mode"

– Monitored inputs 2 and 3 (depending on programming, see steps 4 & 8)

– Control inputs 2 and 3 (depending on programming, see step 15)

Page 26

Structure and function

26

Building Technologies

A6V10099837_a_en

Fire Safety & Security Products 12.2007

Indicator elements (LED1 to LED34)

Ref. / Colour Identification State Function

Manual only Lit Triggering by fire detector is blocked, initialized by:

– KEY2 "Mode select"

– Disabling of detector zone 1 or 2

– Switching of detector zone 1 or 2 to Detector "Test mode"

– Monitored inputs 2 and 3 (depending on programming, see steps 4 & 8)

– Control inputs 2 and 3 (depending on programming, see step 15)

LED4 / Yellow

Autom. & Manual Lit

Alternative (step 10 = option 2):

Automatic and manual activation of extinguishing is possible

LED5 / Yellow Autom. & Man. blocked Lit Triggering by fire detector and manual release is blocked, initialized by:

– KEY2 "Mode select"

– Disabling of detector zones 1 & 2 and manual release

– Switching of detector zone 1 & 2 and manual release to "Test mode"

– Monitored inputs 2 and 3 (depending on programming, see step 4 & 8)

– Control input 2 (depending on programming, see step 15)

LED6 / Red Fire alarm Lit On "Alarm" zone 1 or 2 or 3 (if zone 3 is programmed in step 11 option 9, 10, 12

or 13)

Fast Extinguishing is in the pre-activated condition (first fire alarm indication) LED7 / Red Activated

Lit

–

If "Activated" condition is initiated and timer is running

–

If timer runs and state "Emergency hold/abort" is engaged

–

If flooding of extinguishing agent is started

Extinguishing agent is released (reporting by monitored input 1 or 1A)

Variant: Always in steady mode if step 10 = option 4

Fast

Alternative (step 4 = option 3):

State "Released" is indicated as soon as control line 4 is activated (simulation of

"Released" condition)

LED8 / Red Released

Lit If "Released" is not reported within 30 sec after control line 4 has been activated

(can be suppressed if step 4 = option 5)

Contact 1 "RT-alarm" is in state "Active" (function may be inoperative) Lit

In addition (step 3 = option 13):

Contact 2 "RT-fault" is in state "Active"

LED9 / Red Remote transmission

-

Alternative (step 3 = option 14 ):

Facility “Remote transmission” is not used

Lit Operating access level 2 is provided either by code or control inputs 3 and 4

(depending on programming, see step 15)

Timeout if access is provided by code: Void 3 minutes after the last button was

pressed

LED10 / Yellow Operating access

Slow "System test" mode is activated

LED11 / Yellow Disabled Lit A system component is disabled, initialized by the following:

– Detector zones 1 to 3 are disabled or in "Detector Test" mode

– Manual release is disabled or in "Test mode"

– Alarm horn/valve control is disabled

– Fire control is disabled

– RT-alarm is disabled

– RT-fault is disabled

– State "Manual only" is activated

– State "Autom. & Man. blocked" is activated

– Control input 2 is active (depending on programming, see step 15)

– Calibration processing of monitored control line 4 and 5

– Unit is in “System test” mode

LED12 / Yellow Detector test Slow Detector zones 1 to 3 or manual release are in "Test mode"

Fast A system component is in the "Fault" state, initialized by the following:

– Detector line 1 to 3 is on open circuit or short circuit

– Manual release is on open circuit or short circuit

– Monitored inputs 1 to 3 is on open circuit or short circuit

– Control lines 1 to 5 is on open circuit or short circuit or fuse blown (control lines

4 and 5)

– Earth fault

– Battery is disconnected or very low charge

– Mains power off (after expiry of the mains delay time)

– Control inputs 3 and 4 are active (depending on programming, see step 15)

– State discharged not reported within 30sec after release

– Calibration processing of monitored control lines 4 and 5

LED13 / Yellow Fault

Lit Processor failure (the control unit is not operating)

Page 27

Structure and function

27

Building Technologies

A6V10099837_a_en

Fire Safety & Security Products 12.2007

Indicator elements (LED1 to LED34)

Monitored input 1 is in state "Active 2"

Alternative (step 4 = option 2): Monitored input 1 is in state "Inactive 2"

LED14 / Yellow Loss of agent Fast

Alternative (step 4 = option 10): Monitored input 2 is in state "Active 1+2" or

"Inactive 2"

LED15 / Yellow Earth fault Fast A system component has an earth fault

Fast Battery is disconnected or very low charge LED16 / Yellow Power fault

Slow

–

Mains power supply is off (after expiry of the mains delay time) or too low

–

Control input 3 is active (depending on programming, see step15)

LED17 / Yellow Peripheral fault Fast

–

Monitored input 1 line is on open circuit or short circuit

–

Monitored input 2 line is on open circuit or short circuit

–

Monitored control line 3 is on open circuit or short circuit

–

Monitored control line 2 is on open circuit or short circuit if step 3, option 22, 23

or 24 is selected

–

Monitored control line 5 is on open circuit or short circuit or fuse blown if step 1,

option 18, 19 or 21 is selected

–

During calibration processing of monitored control line 5 if step 1, option 18 or

19 is selected

LED18 / Yellow System fault Lit Processor fault (the control unit is not operating)

Lit The unit is in "System test Mode 1" (see chapter 10.7) LED19 / Yellow System test

Slow The unit is in "System test Mode 2" (see chapter 10.7)

Lit

–

Monitored control line 1 is disabled

–

Monitored control line 4 is disabled

–

Monitored control line 2 is disabled if step 3, option 20 or 21 is selected

–

Monitored control line 5 is disabled if step 1, option 14, 15, 16 or 21 is selected

Fast

–

Monitored control line 1 is on open circuit or short circuit

–

Monitored control line 4 is on open circuit or short circuit or fuse blown

–

Monitored control line 2 is on open circuit or short circuit if step 3, option 20 or

21 is selected

–

Monitored control line 5 is on open circuit or short circuit or fuse blown if step 1,

option 14, 15, 16 or 20 is selected

–

During calibration processing of monitored control line 4 and 5

LED20 / Yellow Horn/Actuator

Slow

–

Monitored control line 1 is in state "Horn test" (see chapter 10.4)

–

Monitored control line 1 is in state "Active" in "System test Mode 2" (see

chapter 10.7)

Lit

–

Monitored control line 4 is in state "Active" in "System test Mode 1" (see

chapter 10.7)

–

Calibration processing of monitored control line 4 and 5 is terminated

LED21 / Red -

Slow Monitored control line 4 is in state "Active" in "System test Mode 2" (see chapter

10.7)

Lit – Driver outputs 1, 2, 8 are disabled (depending on programming, see step 16)

– Monitored control line 2 is disabled if step 3, option 18 or 19 is selected

– Monitored control line 5 is disabled if step 1, option 17 is selected

Fast

–

Monitored control line 2 open circuit or short circuit if step 3, option 18 or 19 is

selected

–

Monitored control line 5 open circuit or short circuit or fuse blown if step 1,

option 17 is selected

–

During calibration processing of monitored control line 5 if step 1, option 17 is

selected

LED22 / Yellow Fire control

Slow

–

Monitored control line 3 is in state "Warning panel test"

–

Monitored control line 3 is in state "Active" in "System test Mode 2" (see

chapter 10.7)

Contact 2 is disabled (function may be inoperative) Lit

Alternative (step 13 = option 10):

Automatically activated if access is provided to operating level 2

-

Alternative (step 3 = option 14):

Inoperable, if facility "Remote transmission" not used

LED23 / Yellow RT-fault

Fast Control input 3 or 4 with option "RT-fault" is "Active" (see step 15)

Lit

–

Monitored control line 5 is in state "Active" in "System test Mode 1" (see

chapter 10.7)

–

Calibration processing of monitored control line 4 and 5 is terminated

LED24 / Red -

Slow Monitored control line 5 is in state "Active" in "System Test Mode 2" (see chapter

10.7)

–

Contact 1 is disabled

–

Monitored control line 2 is disabled if step 3, option 17 is selected

Lit

Alternative (step 13 = option 10):

Automatically activated if state operating access 2 is provided

-

Alternative (step 3 = option 14 ):

Inoperable, if facility "Remote transmission" facility not used

LED25 / Yellow RT-alarm

Fast Monitored control line 2 is open circuit or short circuit if step 3, option 17 is

selected

Lit – Monitored input 3 is in state "active 1" (depending on programming, see step 8)

– Control input 2 or 4 is active (depending on programming, see step 15)

LED26 / Yellow Emergency

Hold/Abort

Fast Monitored input 3 is on open circuit or short circuit

Page 28

Structure and function

28

Building Technologies

A6V10099837_a_en

Fire Safety & Security Products 12.2007

Indicator elements (LED1 to LED34)

Lit Zone 1 is in alarm (or test alarm) LED27 / Red Detector zone 1

Slow Zone 1 is in first alarm

Lit Zone 1 is disabled

Slow Zone 1 is in "Test mode"

LED28 / Yellow Detector zone 1

Fast Zone 1 is open circuit or short circuit (fault)

Lit Zone 2 is in alarm (or test alarm) LED29 / Red Detector zone 2

Slow Zone 2 is in first alarm

Lit Zone 2 is disabled

Slow Zone 2 is in "Test mode"

LED30 / Yellow Detector zone 2

Fast Zone 2 is open circuit or short circuit (fault)

Lit Zone 3 is in alarm (or test alarm) LED31 / Red Detector zone 3

Slow Zone 3 is in first alarm

Lit Zone 3 is disabled

Slow Zone 3 is in "Test mode"

LED32 / Yellow Detector zone 3

Fast Zone 3 is open circuit or short circuit (fault)

Lit Manual release is in alarm (or test alarm) LED33 / Red Manual release (Zone 4)

Slow Manual release is in first alarm

Lit Manual release is disabled

Slow Manual release is in "Test mode"

LED34 / Yellow Manual release (Zone 4)

Fast Manual release is open circuit or short circuit (fault)

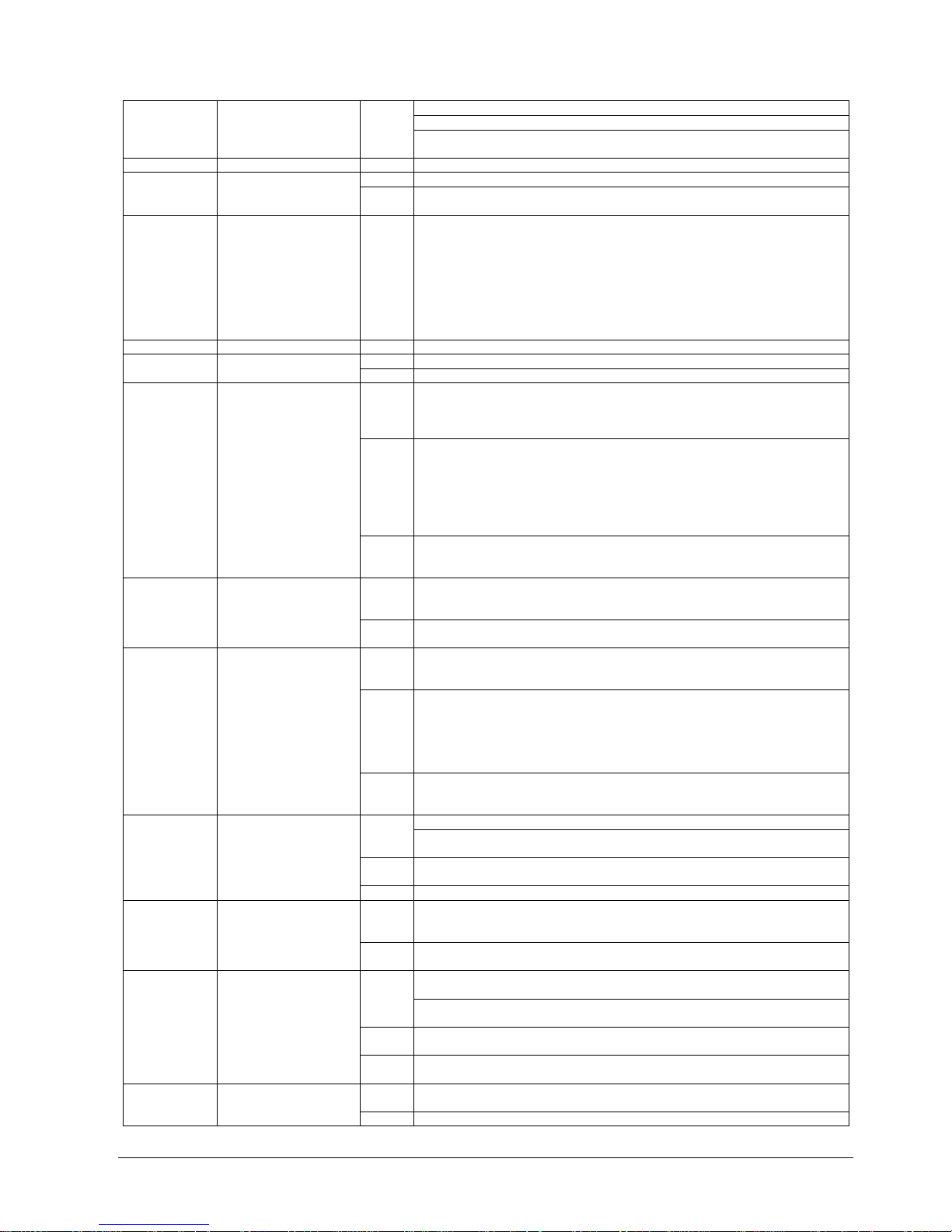

Service LEDs (LD1 to LD9)

Ref. / Colour Identification State Fault Information

Lit Short circuit LD1 / Yellow Monitored control line 1

Fast Open circuit

Lit Short circuit LD2 / Yellow Monitored control line 2

Fast Open circuit

Lit Short circuit LD3 / Yellow Monitored control line 3

Fast Open circuit

Lit Short circuit

Fast Open circuit or fuse blown

LD4 / Yellow Monitored control line 4

Slow Calibration out of tolerance

Lit Short circuit

Fast Open circuit or fuse blown

LD5 / Yellow Monitored control line 5

Slow Calibration out of tolerance

Lit Short circuit LD6 / Yellow Monitored input 1

Fast Open circuit

Lit Short circuit LD7 / Yellow Monitored input 2

Fast Open circuit

Lit Short circuit LD8 / Yellow Monitored input 3

Fast Open circuit

Lit No mains voltage

Fast Battery fault

LD9 / Yellow Mains power supply

Slow Battery very low

Page 29

Structure and function

29

Building Technologies

A6V10099837_a_en

Fire Safety & Security Products 12.2007

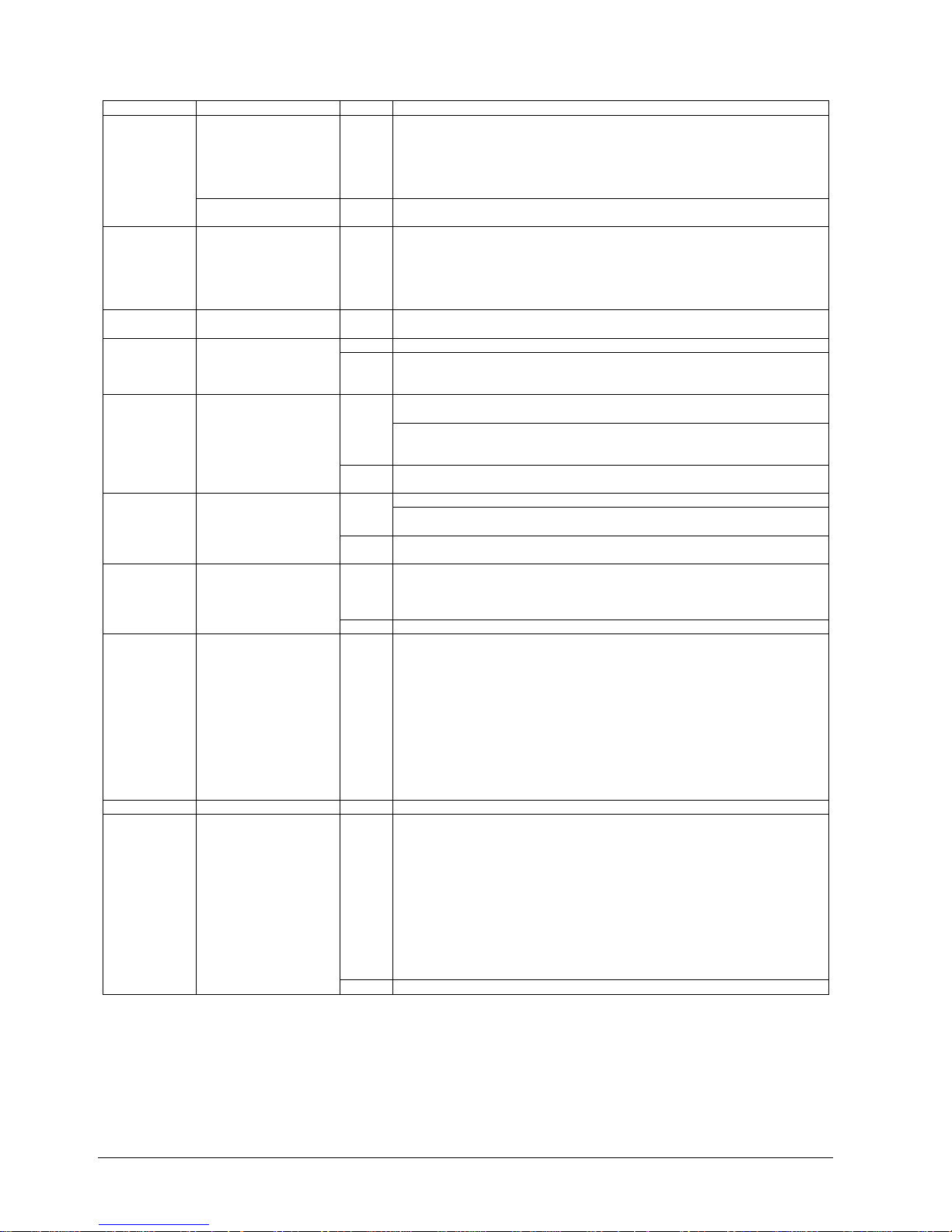

5.5 Operating elements

The operating elements (keys) are on the main board, upper level. The keys can

be pressed on the main board and, when the housing is closed, by using the

membrane keypad. Basically, the function assigned to the key is labeled on the

left, next to the membrane key. Various keys have several functions.

Fig. 15 Operating elements, housing cover view

KEY2

LD1

LD2

LD3

LD4

LD5

LD6

LD7

LD8

LD9

KEY8KEY9KEY10KEY11KEY12

KEY1

KEY13

KEY14

KEY15

KEY16

Fig. 16 Operating elements, XCM1001-2 upper main board view

Keys 4 to 7 are digit keys. These are used for entering the access codes for

release of operation, for the system test and for configuring user functions.

Page 30

Structure and function

30

Building Technologies

A6V10099837_a_en

Fire Safety & Security Products 12.2007

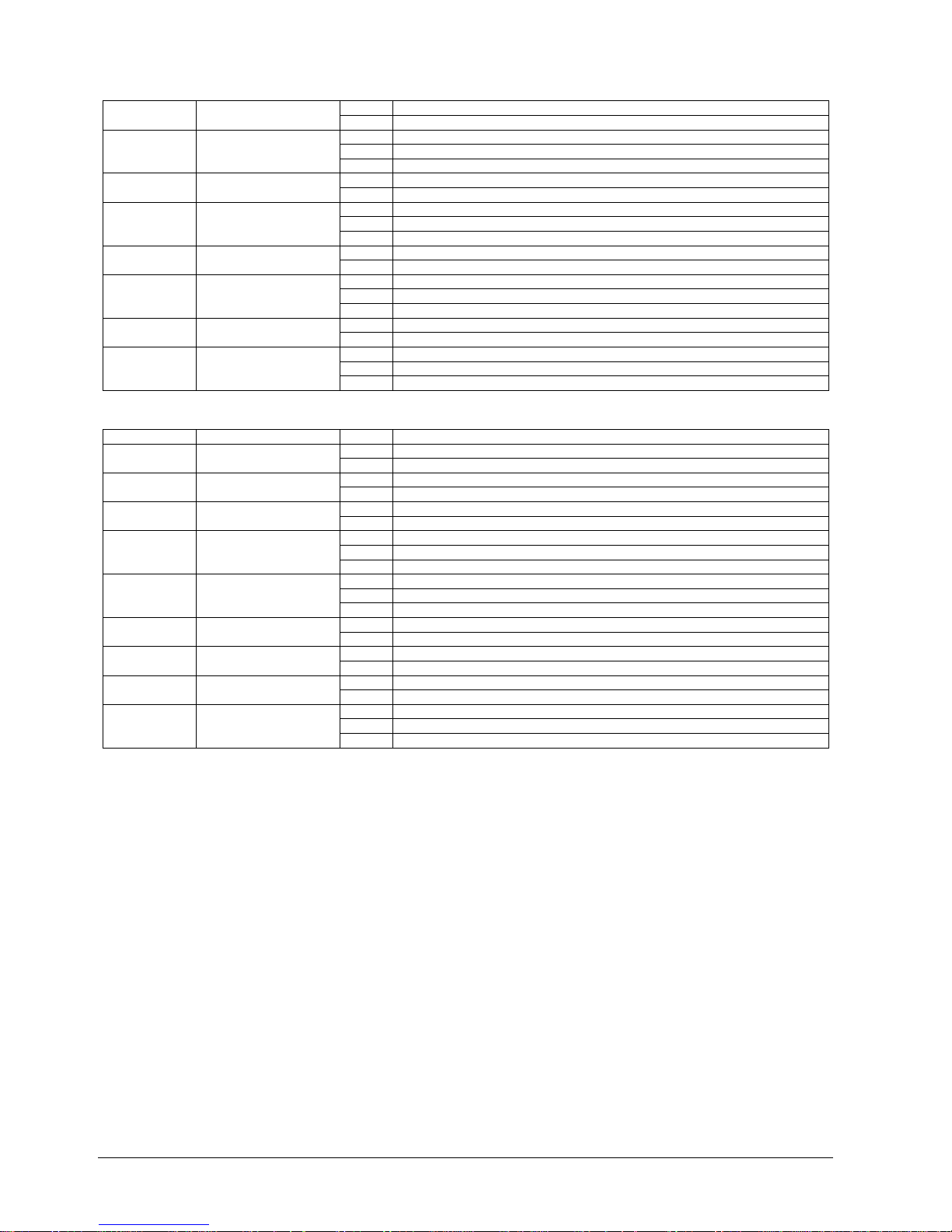

Ref. Identification Access

level

Function

KEY1 Silence

Re-sound

horn

2 Deactivation/activation of monitored control line 1 and, depending on programming also control

line 2 or 5 (blocked in state "Activated" until state "Released" occurs and while timer is running)

Also used from access level 3 to select the programming steps (see chapter 11.6)

KEY2 Mode select 2 Switching mode between:

– Not blocked or "Autom. & Manual" (ready to operate)

– "Autom. blocked" or "Manual only"

– "Autom. & Man. blocked"

Also used from access level 3 to select the programming steps (see chapter 11.6)

KEY4

to

KEY7

Operating access 1 Enabling of access level 2 (enter digits "4233")

Also used from access level 2 for:

– Trigger "Horn test" (see chapter 10.4)

– Trigger "Warning panel test" (see chapter 10.5)

– Switch to "Program user functions" mode (see chapter 11)

– Access to "Performing system test" (see chapter 10.7)

– Access to "Reset user functions to default or application settings" (see chapter 11.4)

KEY8 - - Not used (factory setting)

KEY9 Lamp test 1 Pressing the key activates all LEDs and buzzer for 5 seconds (see chapter 10.2)

Also used from access level 2 for:

– Trigger "Horn test" (see chapter 10.4)

– Trigger "Warning panel test" (see chapter 10.5)

KEY10 System test 2 System setting in mode "System test" 2)

Possible only after previous input of a code (see chapter 10.7)

KEY11 Disable/

Enable

2 Disabling of horn, actuator and fire control:

– First pressing disables horn and actuator (monitored control lines 1 and 4), and possibly 2

and 5 if these lines are programmed as horn or actuator (see step 1 and step 3) 3)

– Second pressing disables fire control (driver outputs 2, 8 and 1 and possibly control line 2 or

5. If these monitored control lines are programmed as fire control, see step 1 and 3 4)

– Third pressing disables both

– Fourth pressing enables both

Disabling is not possible while the system is in the "Activated" condition

Disable/

Enable

2 Disabling of "RT-alarm" and "RT-fault" (inoperable if no remote transmission device is used):

– First pressing disables contact 2 "RT-fault"

– Second pressing disables contact 1 "RT-alarm" and control line 2 if step 3 option 17

– Third pressing disables both

–

Fourth pressing enables both

KEY12

Not used -

Alternative (step 3 = option 14): Inoperable

2

) Monitored control line 5 only when in programming step 1 options 14 and 15 are set (see chapter 11.6.1)

3

) Driver outputs: only when in programming step 16 options 9, 18 and 20 are set (see chapter 11.6.16)

4

) Control line 5 only when in programming step 1 option 17 is set, control line 3 only if programming step 3 option 18 or 19 (see chapter

11.6.1)

ZONES

disable/

enable

2 Disabling of detector zones 1 to 3 and manual release:

– First pressing disables detector zone 1

– Second pressing disables detector zone 2

– Third pressing disables detector zone 1 and 2

– Fourth pressing disables detector zone 3

– Fifth pressing disables manual release

– Sixth pressing disables zones 1 to 3 and manual release

– Seventh pressing enables zones 1 to 3 and manual release

Also used from access level 3 to select the options in programming steps (see chapter 11.6)

KEY13

Not used -

Alternative (step 11 = option 3): Inoperable

ZONES

det. test/

enable

2 Setting of the zones 1 to 3 and manual release to "Test mode":

– First pressing sets zone 1 to "Test mode"

– Second pressing sets zone 2 to "Test mode"

– Third pressing sets zones 1 and 2 to "Test mode"

– Fourth pressing sets zone 3 to "Test mode"

– Fifth pressing sets zone 1 to 3 to "Test mode"

– Sixth pressing sets manual release to "Test mode"

– Seventh pressing sets zones 1 to 3 and manual release to "Test mode"

– Eighth pressing sets zones 1 to 3 and manual release to "Normal mode"

Also used from access level 3 to select the options in programming steps (see chapter 11.6)

KEY14

Not used -

Alternative (step 11 = option 3): Inoperable

Silencing the buzzer upon alarm and fault

Also deactivates contact 2 "RT-fault" if step 3, option 8 is selected

1

Alternative (step 13 = option 4): Silencing the buzzer upon alarm and fault and silencing horn

upon fire alarm

KEY15 Silence buzzer

2

Alternative (step 12 = option 5): Only accessible on access level 2

Also used from access level 3 to select the options in programming steps (see chapter 11.6)

Reset of the system upon alarm

Not available in the state "Activated" and as long as the valve control is active (flooding time)

Alternative (step 9 = option 12): Reset is not available as long as zone 4 is an alarm or

monitored input 1 is in state "active 1" or control line 1 (horn) is activated

KEY16 Reset 2

Alternative (step 13 = option 8): Also to reset fault

Also used from access level 3 to select the options in programming steps (see chapter 11.6)

Page 31

Structure and function

31

Building Technologies

A6V10099837_a_en

Fire Safety & Security Products 12.2007

5.6 Accessories

This chapter describes optional accessories that you can use.

5.6.1 Z3B171 Relay module

Relay module for switching the fire protection devices. The extinguishing control

unit provides space for up to 10 relays. Contact rating 230 V max. 10 A.

Fig. 17 Z3B171 Relay module

5.6.2 XCA1110 Pyrotechnical actuator kit

Actuator kit prevents the risk of an uncontrolled activation when pyrotechnical

actuator(s) are used.

Z3B271

68Ω 3W

Fig. 18 XCA1110 Pyrotechnical actuator kit

Page 32

Structure and function

32

Building Technologies

A6V10099837_a_en

Fire Safety & Security Products 12.2007

5.6.3 XCA1016 Add-on module

The XCA1016 splits the two functions on the monitored input 1 into two

independent monitored input lines "1A" and "1B". This module is only required for

installations in which both conditions "Loss of extinguishing agent" and "Mech.

blocking device open/closed" have to be reported.

Fig. 19 XCA1016 Add-on module

Ref. Element Function

PU1 Jumper Applies to the monitored input 1B (reporting "Loss of extinguishing agent")

OFF = contact type NO used

ON = contact type NC used

DL1 LED yellow Flashing = Open circuit on monitored input 1A

Steady = Short circuit on monitored input 1A

DL2 LED yellow Flashing = Open circuit on monitored input 1B

Steady = Short circuit on monitored input 1B

Page 33

Structure and function

33

Building Technologies

A6V10099837_a_en

Fire Safety & Security Products 12.2007

5.6.4 FCA 1005-D RT Blocking card

The optional RT blocking card can be used to prevent unwanted remote

transmission of alarms and faults by means of a switch. The switch is located on

the card and consequently is accessible only when the control unit is opened.

The control unit has no influence on the RT blocking card.

Function

The switch on the card has the same function as Key12 "Disable/Enable" operation

(to temporarily switch off of the "RT-alarm" and/or "RT-fault" contacts).

When the switch is locked in, the yellow LEDs 23 "RT-fault" and/or 25 "RT-alarm"

on the upper main board XCM1001-2 and the LED on the RT blocking card (DL1)

light up.

The control unit software has no influence on the RT blocking card.

Settings

Jumpers are used on the RT blocking card to select whether the output is to

operate as a normally open (NO) or normally closed (NC) contact. The setting is

dependent on the remote transmission device connected.

DL1

Fig. 20 FCA 1005-D RT Blocking card

Ref. Function Jumper Parameter

Plugged in Contact NC PU1 and PU2 RT-alarm terminal

Not plugged in Contact NO

Plugged in Contact NC PU3 and PU4 RT-fault terminal

Not plugged in Contact NO

RT ALARM Input, RT-alarm

RT FAULT Input, RT-fault

OUTPUT RT Output for "RT blocked" indication

The FCA1005-D is mounted directly onto the connecting terminals (CL5/CL6) of

the upper main board XCM1001-2. It needs a 24 V supply.

The output "OUTPUT RT" has to be wired to the control input 2 (lower main board

XCM1001-1) in order to indicate the blocking state at the control panel.

Recommended setting of user programming:

Control input 2

Enable "RT-alarm" + "RT-fault" disabled step 15 = option 5

Details on programming see chapter 11.6.15.

Page 34

Structure and function

34

Building Technologies

A6V10099837_a_en

Fire Safety & Security Products 12.2007

5.7 Technical data

Supply

Mains supply 115/230 VA.C.; +10 % / -15 %

Power consumption 20 ... 150 VA

Secondary supply (current on low voltage side) max. 3.5 A

System supply voltage 20 ... 28 VD.C.

Ripple max. 400 mV

Indication after total loss of power yes, selectable by additional cable connection

Emergency power supply

Operating time max. 23 h with 4.5 Ah batteries,

max. 38 h with 7.2 Ah batteries

Battery capacity 2 x 12 V / 4.5 Ah or 7.2 Ah (V0 or V1 or V2)

Quiescent current, nominal (battery operation) 132 mA (after fault relay dropped)

Additional power consumption on alarm approx. 50 mA (without power for peripheral devices)

Battery low charge shut-off <19.8 VD.C.

Temperature compensation of charging voltage Yes

Detector lines

Detector lines

– 'LIN 1', 'LIN 2'

– 'LIN 3'

– 'LIN 4'

for detectors within extinguishing area

for detectors outside of extinguishing area

for manual activation button

Line type for conventional detectors

Number of detectors per line max. 32 (max. KLK 32)

Compatible device series Siemens (AlgoRex DS11xx, DC1192, Sinteso

FDOOT241-9, FDL241-9, FDF221-9, FDF241-9)

Standard (SynoLINE 300C)

Operating voltage/quiescent current 18 … 22 V / max. 3.2 mA

Line resistor/line capacity

– Siemens and Synova types

≤ 80 Ω / ≤ 1 µF (if “Break” = “alarm”: the line resistance

should be lower than 50 Ω)

Alarm criteria

– Siemens type / Synova type

17.5 … 39 mA and > 5.1 V / 17…83.6 mA

Alarm activation

– Siemens type / Synova type

Resistor 820 Ω or Z diode 5.6 Volts / Resistor 820 Ω

Line termination element Resistor 3k3

Inputs

Monitored inputs 1 to 3

– Activation resistor

For Active 1 state: Resistor 680 Ω (single device)

Element XCE1002 (multiple devices,

only for monitored input 3)

For Active 2 state: Resistor 1k2

– Line termination Resistor 3k3

– Line resistance max. 50 Ω

Control inputs 1 to 4 (not monitored)

– Activation

24 V positive potential switched via contact

Outputs

Monitored control lines 1, 2 and 3

– Voltage/current in active state

– Line termination

24 V/max. 500 mA (principle of reverse polarity)

Termination element FCE1002

Monitored control lines 4 and 5

– Voltage/current in active state

– Line termination

– Line monitoring

– Admissible external load

24 V/max. 2 A

None

Resistance of external load is monitored

Pyrotechnical actuators >1 Ω / Solenoid 15…850 Ω

Potential-free contacts

– Number / Contact rating

5 / max. 1 A/30 VD.C.

Driver outputs

– Number / Rating

8 / max. 40 mA/24 VD.C.

Connections

Detector lines, Inputs, Outputs

– Design / Wire cross-section

Screw-type terminals / 0,2 ... 1.5 mm2

Mains voltage

– Design / Wire cross-section

Screw-type terminals / 1 ... 2.5 mm2

Environmental conditions

Operating temperature -5 ... +40 °C (Class A)

Storage temperature

Humidity (no condensation) max. 93% rel. at T = 40 ±2 °C

Protection rating IP 30

Mechanical data

Housing type Metal chassis with plastic cover

Colour Cover RAL 9003 white

Dimensions (W x H x D) 370 x 286 x 90 mm

Weight 6.600 kg (without batteries)

Standards and Approvals

Standards EN 12094-1, EN 54-2, EN 54-4

Approvals Notified body N° 1116 : CNPP – France

Page 35

Planning

35

Building Technologies

A6V10099837_a_en

Fire Safety & Security Products 12.2007

6 Planning

This chapter includes an example that shows you how to build an extinguishing

system using the XC1003-A extinguishing control unit. It illustrates all the facilities

offered by the control unit together with references to connection schemes,

configuration and user functions. How you build your system depends essentially

on the relevant circumstances, the local conditions, customer expectations and the

regulations and statutes of the respective country.

Monitored inputs

Monitored control lines

Detector lines

Driver ouputs

Remote transmission to the fire

brigade or to the fire control un it

Extinguishing area Surrounding area

Cylinder bank

Main entrance

Fig. 21 Structure of an extinguishing system (principles)

Page 36

Planning

36

Building Technologies

A6V10099837_a_en

Fire Safety & Security Products 12.2007

6.1.1 Detector lines

Detector lines 1, 2 and 3

The fire detector of detector lines 1 and 2 are used for automatic activation.

The fire detectors of detector line 3 are intended for monitoring of the surrounding