Page 1

Powermite 599 Series

Technical Instructions

Document No. 155-196P25

VF 599-5

February 2, 2023

MT Series Terminal Unit

Two-way Valves

Siemens Industry, Inc.

Description

The Powermite 599 Series ANSI Class 250 MT Series two-way valve bodies work with

any MT Series pneumatic or electronic actuator with a 7/32-inch (5.5 mm) stroke.

Features

• Direct coupled universal bonnet

• Choice of brass or stainless steel trim

• ANSI Leakage Class IV (0.01% of Cv)

Application

A typical application for the Powermite two-way valve is the control of hot or chilled

water or low pressure (<15 psi with stainless steel trim only) steam for convectors, fan

coil units, unit conditioners, radiation, reheat coils, and similar terminal units requiring

an actuator that delivers a minimum of 67 pounds force (300 N).

Product Numbers

See Table 2.

Ordering a Valve

Plus Actuator

Assembly

To order a complete valve plus actuator assembly from the factory, combine the

actuator prefix code with the suffix of the valve assembly product number. See

Technical Bulletin TB251 (155-306P25) for selection procedure and ordering codes.

Valve assemblies can be ordered using the numbers in Table 2.

Specifications

Valve size 1/2 inch to 1 inch (15 mm to 25 mm)

Capacity See Tables 3 through 6 and Figure 1

Body style Globe

Seat style Metal-to-metal

Action Normally open/normally closed

Valve body rating ANSI Class 250; See Table 1.

Stem travel (Stroke) 7/32-inch (5.5 mm)

Page 2

Technical Instructions Powermite 599 MT Series Terminal Unit 2-way Valves

Document Number 155-196P25

February 2, 2023

Page 2 Siemens Industry, Inc.

Specifications

Material

Body

1/2- and 3/4-inch C37700 Forged brass

1-inch UNS CA 844 Bronze

Body trim See Table 2.

Stem Stainless steel ASTM A582 Type 303

Packing Ethylene propylene O-ring

Operating

Spring Range

Normally closed 10 to 15 psi (69 to 102 kPa)

Normally open 3 to 8 psi (21 to 55 kPa)

Controlled medium Water, low pressure steam

(<15psi with stainless steel trim only),

water-glycol solutions to 50%

Medium temperature range 35°F to 250°F (2°C to 120°C)

Maximum inlet pressure See Table 1.

Maximum recommended differential pressure for modulating service

Brass Trim

Stainless Steel Trim

Liquid

25 psi (173 kPa)

50 psi (345 kPa)

Steam

—

15 psi (103 kPa)

Rangeability Cv <1 >50:1

Cv >1 >100:1

Close-off pressures See Table 7, Table 8, and Figure 2

Close-off ratings According to ANSI/FCI 70-2

Leakage rate Class IV (0.01% of Cv)

Flow characteristics Modified equal percentage

Miscellaneous

Canadian Registration Numbers 0H7645.5

0C0838.9

Mounting location NEMA 1 (interior only)

Dimensions See Table 9, Table 10, and Figure 4

Valve Weight See Table 10.

Service Kit

Sealing rings for union valves (package of 25)

1/2-inch (15 mm) 698-088

3/4-inch (20 mm) 599-03394

Union connection kit

1/2-inch (15 mm) 599-02941

3/4-inch (20 mm) 599-02942

Protective black knob

to cover the bonnet

and threads/manual

override.

426888950

Page 3

Powermite 599 MT Series Terminal Unit 2-way Valves Technical Instructions

Document Number 155-196P25

February 2, 2023

Siemens Industry, Inc. Page 3

Table 1. Body Temperature-Pressure Rating.

Valve Body

Temperature

Pressure

°F

°C

psig

(kPa)

Bronze/

Forged Brass

-20 to 150

(-30 to 66)

400

(2758)

200

(93)

385

(2655)

250

(121)

365

(2586)

300

(149)

335

(2300)

350

(177)

300

(2068)

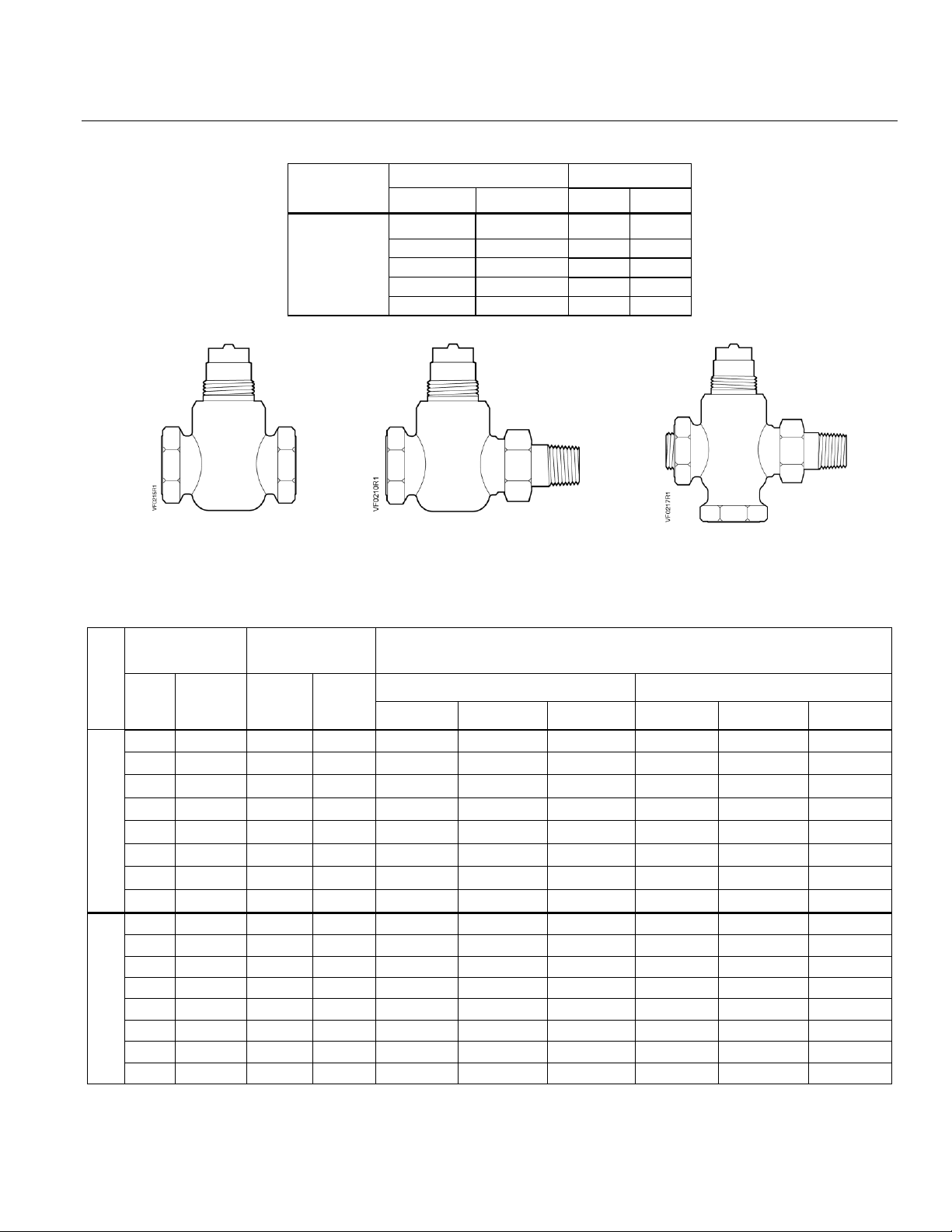

Internal Thread NPT ×

Internal Thread NPT

ITxIT

Internal Thread NPT ×

Union External Thread

ITxUET

Angle Internal Thread ×

Union External Thread

AITxUET

Table 2. Product Part Numbers.

Action

Flow Rate

Nominal Valve

Size

Trim and Connection

Cv

(Kvs)

Inches

(mm)

Stainless Steel

Brass

ITxIT

ITxUET

AF×UM

ITxIT

ITxUET

AITxUET

Normally Closed

0.4

(0.34)

1/2

(15)

599-02015

599-02016

—

599-02000

599-02001

—

0.63

(0.54)

1/2

(15)

599-02017

599-02018

—

599-02002

599-02003

—

1.0

(0.85)

1/2

(15)

599-02019

599-02020

—

599-02004

599-02005

—

1.6

(1.37)

1/2

(15)

599-02021

599-02022

—

599-02006

599-02007

—

2.5

(2.15)

1/2

(15)

599-02023

599-02024

—

599-02008

599-02009

—

4.0

(3.44)

1/2

(15)

599-02025

599-02026

—

599-02010

599-02011

—

6.3

(5.43)

3/4

(20)

599-02027

599-02028

—

599-02012

599-02013

—

10

(8.6) 1 (25)

599-02029

—

—

599-02014

—

—

Normally Open

0.4

(0.34)

1/2

(15)

599-02047

599-02048

—

599-02030

599-02031

—

0.63

(0.54)

1/2

(15)

599-02049

599-02050

—

599-02032

599-02033

—

1.0

(0.85)

1/2

(15)

599-02051

599-02052

—

599-02034

599-02035

—

1.6

(1.37)

1/2

(15)

599-02053

599-02054

—

599-02036

599-02037

—

2.5

(2.15)

1/2

(15)

599-02055

599-02056

599-02057

599-02038

599-02039

599-02040

4.0

(3.44)

1/2

(15)

599-02058

599-02059

599-02060

599-02041

599-02042

599-02043

6.3

(5.43)

3/4

(20)

599-02061

599-02062

—

599-02044

599-02045

—

10

(8.6) 1 (25)

599-02063

—

—

599-02046

—

—

Page 4

Technical Instructions Powermite 599 MT Series Terminal Unit 2-way Valves

Document Number 155-196P25

February 2, 2023

Page 4 Siemens Industry, Inc.

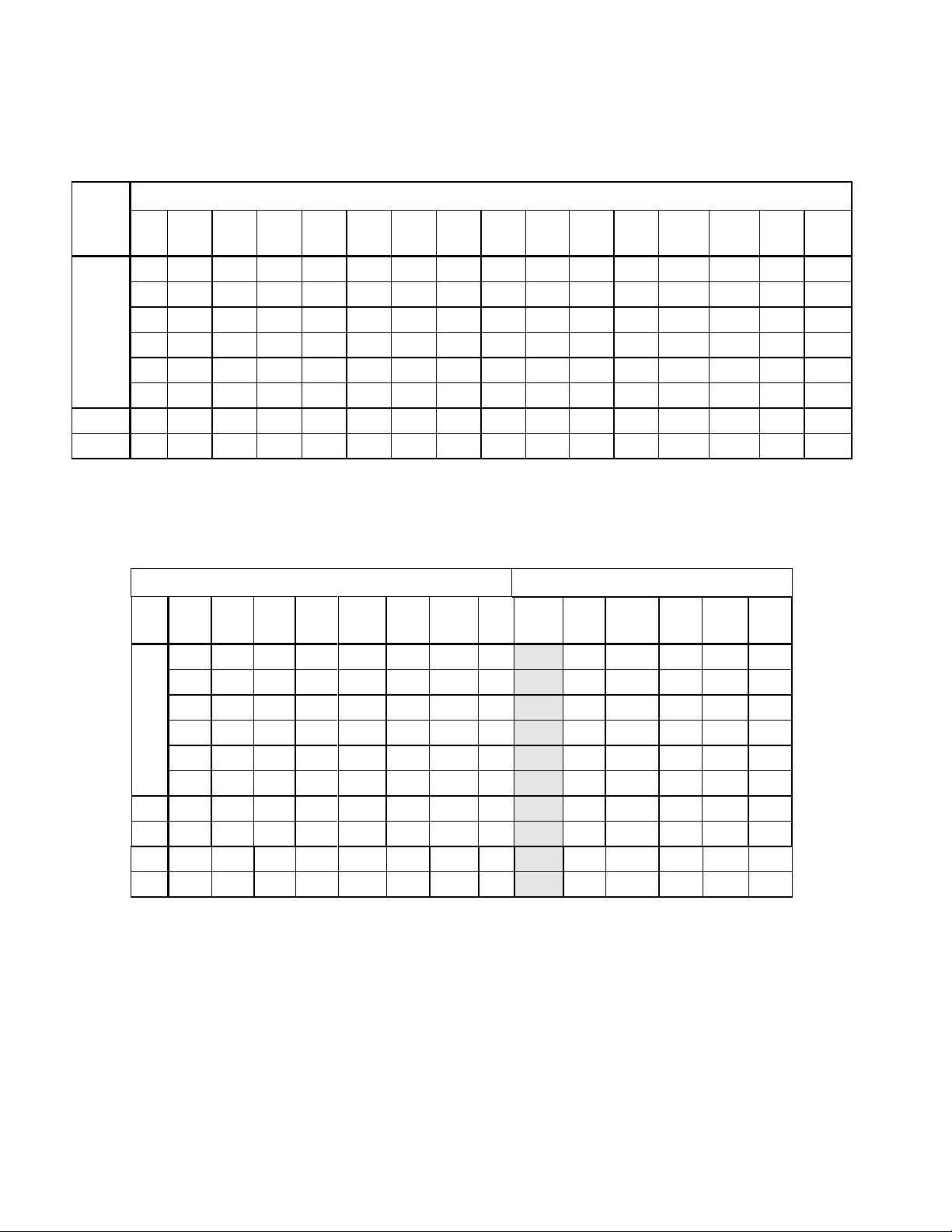

Table 3. Maximum Water Capacity - U.S. Gallons per Minute.

Valve

Size

Inches

Pressure Differential - psi

Cv\1 2 3 4 5 6 8

10

15

20

25

30

40

50

60

75

1/2

0.4

0.6

0.7

0.8

0.9

1.0

1.1

1.3

1.5

1.8

2.0

2.2

2.5

2.8

3.1

3.5

0.63

0.9

1.1

1.3

1.4

1.5

1.8

2.0

2.4

2.8

3.2

3.5

4.0

4.5

4.9

5.5

1.0

1.4

1.7

2.0

2.2

2.5

2.8

3.2

3.9

4.5

5.0

5.5

6.3

7.1

7.8

8.7

1.6

2.3

2.8

3.2

3.6

3.9

4.5

5.1

6.2

7.2

8.0

8.8

10.1

11.3

12.4

13.9

2.5

3.5

4.3

5.0

5.6

6.1

7.1

7.9

9.7

11.2

12.5

13.7

15.8

17.7

19.4

22

4

5.7 7 8.0

8.9

10

11.3

12.6

15.5

17.9

20.0

21.9

25

28

31

35

3/4

6.3

8.9

10.9

12.6

14.1

15.4

17.8

20

24

28

32

35

40

45

49

55 1 10

14.1

17.3

20

22

24

28

32

39

45

50

55

63

71

77

87

Table 4. Maximum Water Capacity - Cubic Meters per Hour (m3/hr).

Valve Size

Pressure Differential - kPa

mm

1

10

20

30

40

50

60

80

Kvs/

100

150

200

300

400

500

15

0.03

0.11

0.15

0.19

0.22

0.24

0.26

0.30

0.34

0.42

0.48

0.59

0.68

0.76

0.05

0.17

0.24

0.30

0.34

0.38

0.42

0.48

0.54

0.66

0.76

0.94

1.08

1.21

0.09

0.27

0.38

0.47

0.54

0.60

0.66

0.76

0.85

1.0

1.2

1.5

1.7

1.9

0.14

0.43

0.61

0.75

0.87

0.97

1.06

1.23

1.37

1.7

1.9

2.4

2.7

3.1

0.21

0.68

0.96

1.17

1.35

1.51

1.66

1.91

2.15

2.6

3.0

3.7

4.3

4.8

0.34

1.1

1.5

1.9

2.2

2.4

2.7

3.1

3.4

4.2

4.9

6.0

6.9

7.7

20

0.54

1.7

2.4

3.0

3.4

3.8

4.2

4.9

5.4

6.7

7.7

9.4

10.9

12.1

25

0.86

2.7

3.8

4.7

5.4

6.1

6.7

7.7

8.6

10.5

12.2

14.9

17.2

19.2

32

1.4

4.4

6.2

7.6

8.7

9.8

10.7

12.3

13.8

16.9

19.5

23.9

27.6

30.9

40

2.2

6.8

9.6

11.8

13.6

15.2

16.7

19.2

22

26

30

37

43

48

Page 5

Powermite 599 MT Series Terminal Unit 2-way Valves Technical Instructions

Document Number 155-196P25

February 2, 2023

Siemens Industry, Inc. Page 5

Table 5. Maximum Steam Capacity - Pounds per Hour.

Valve

Size

Inches

Inlet Pressure - psig

2

5

10

15

Pressure Differential - psi

Cv/1 1 2 1 2 3 4 5 2 4 6 8 10 6 9

12

15

1/2

0.4

4.8

6.7

5.2

7.3

8.8

10.0

11.0

8.2

11.3

13.6

15.3

16.7

15.0

17.9

20.0

21.6

0.63

7.5

10.5

8.2

11.4

13.8

15.7

17.4

12.9

17.8

21.3

24.1

26

23.7

28.2

32

34

1.0

12.0

16.6

13.0

18.2

22

25

28

20

28

34

38

42

38

45

50

54

1.6

19.1

27

21

29

35

40

44

33

45

54

61

67

60

72

80

86

2.5

30

42

33

45

55

62

69

51

71

85

96

104

94

112

125

135

4

48

67

52

73

88

100

110

82

113

136

153

167

150

179

200

216

3/4

6.3

75

105

82

114

138

157

174

129

178

213

241

263

237

282

316

341 1 10

120

166

130

182

219

250

275

204

283

339

382

417

376

447

501

541

Table 6. Steam Capacity - Kilograms per Hour.

Valve

Size

mm

Inlet Pressure - kPa

50

100

Pressure Differential – kPa

Kvs

10

25

10

20

50

15

0.34

1.7

2.7

2.4

3.4

5.4

0.54

2.7

4.3

3.8

5.4

8.5

0.85

4.3

6.8 6 8.5

14

1.37

6.9

10.8

10

14

22

2.15

10.7

17

15

21

34

3.4

17

27

24

34

54

20

5.4

27

43

38

54

85

25

8.6

43

68

60

85

135

Page 6

Technical Instructions Powermite 599 MT Series Terminal Unit 2-way Valves

Document Number 155-196P25

February 2, 2023

Page 6 Siemens Industry, Inc.

Figure 1. Water Capacity Graph.

Selection Example

See Figure 1.

Select a valve given:

Required flow = 20 gpm.

Desired pressure drop = 5 psi.

Choose a 1-inch (25-mm) valve, Cv 10.

Page 7

Powermite 599 MT Series Terminal Unit 2-way Valves Technical Instructions

Document Number 155-196P25

February 2, 2023

Siemens Industry, Inc. Page 7

Table 7. Close-off Pressures for Electronic Actuators.

Action

Valve Size

Inches (mm)

SAS

psi (kPa)

SSC

psi (kPa)

NC

1/2

0.4< Cv <1.6

95 (655)

95 (655)

(15)

(0.34< Kvs <1.37)

1/2

2.5< Cv <4

50 (345)

50 (345)

(15)

(2.15< Kvs <3.44)

3/4 (20)

40 (276)

40 (276)

1 (25)

NO

1/2

0.4< Cv <1.6

160 (1103)

120 (828)

(15)

(0.34< Kvs <1.37)

1/2

2.5< Cv <4

85 (586)

65 (448)

(15)

(2.15< Kvs <3.44)

3/4 (20)

70 (482)

55 (379)

1 (25)

Table 8. Maximum Available Close-off Pressures for Pneumatic Actuators.

Action

Valve Size

Inches (mm)

2-inch Actuator

@ 0 psi (0 kPa)

(with 10 to 15 psi

Valve)

NC

1/2

0.4< Cv <1.6

95 (655)

(15)

(0.34< Kvs <1.37)

1/2

2.5< Cv <4

50 (345)

(15)

(2.15< Kvs <3.44)

3/4 (20

40 (276)

1 (25)

@ 20 psi (103 kPa)

(with 3 to 8 psi

Valve)

NO

1/2

0.4< Cv <1.6

95 (655)

(15)

(0.34< Kvs <1.37)

1/2

2.5< Cv <4

45 (310)

(15)

(2.15< Kvs <3.44)

3/4 (20)

35 (241)

1 (25)

Page 8

Technical Instructions Powermite 599 MT Series Terminal Unit 2-way Valves

Document Number 155-196P25

February 2, 2023

Page 8 Siemens Industry, Inc.

Figure 2. Close-off Pressures.

Operation

Figure 3 shows the normally open valve in the open or full flow position and the

normally closed valve in the closed or zero flow position. The valve spring provides the

necessary force to hold the stem in the raised or normal position.

In the event of power failure, a spring return actuator returns the valve to its normal

position. Non-spring return actuators will hold the last commanded position. See the

Technical Instructions of the various actuators for additional information.

Figure 3.

Sizing

The sizing of a valve is important for correct system operation. An undersized valve will

not have sufficient capacity at maximum load. An oversized valve can initiate cycling,

and the seat and throttling plug can be damaged because of the restricted opening.

Correct sizing of the control valve for actual expected conditions is considered essential

for good control.

See Tables 3 through 6 for valve capacities.

Page 9

Powermite 599 MT Series Terminal Unit 2-way Valves Technical Instructions

Document Number 155-196P25

February 2, 2023

Siemens Industry, Inc. Page 9

Sizing, continued

The following variables must be determined:

• The medium to be controlled: water, etc.

• The maximum inlet temperature and pressure of the medium at the valve.

• The pressure differential that will exist across the valve under maximum load

demand.

• The maximum capacity the valve must deliver.

• The maximum line pressure differential the valve actuator must close against.

See Application Bulletin (AB)-1 Control Valve Selection and Sizing (155-285) for further

recommendations.

Mounting and

Installation

Install the valve so that the flow follows the direction of the arrow indicated on the valve

body.

For best performance, install the valve assembly with the actuator above the valve body.

The valve and actuator can be installed in any position between vertical and horizontal. It is

not recommended to install the valve assembly so that the actuator is below horizontal or

upside-down.

Allow sufficient space for servicing the valve and actuator. See Table 11 for valve body

dimensions. See Figure 4 and Table 10 for dimensions of the service envelope

recommended around the actuator.

NOTE: Instructions for field mounting an actuator, wiring diagrams, and start-up are

covered in the Technical Instructions and Installation Instructions for each

actuator.

Service

Replace the valve if inoperable.

Disposal

Do not dispose of the valve as household waste.

• Special handling of individual components may be mandated by law or make

ecological sense.

• Observe all local and currently applicable laws and regulations.

The actuators are considered electrical and electronic equipment for

disposal in terms of the applicable European Directive and may not be

disposed of as domestic garbage.

• Dispose of the actuators through channels provided for this

purpose.

• Comply with all local and currently applicable laws and regulations.

Page 10

Technical Instructions Powermite 599 MT Series Terminal Unit 2-way Valves

Document Number 155-196P25

February 2, 2023

Page 10 Siemens Industry, Inc.

Dimensions

The letters in Figure 4 refer to the valve centerline to top of actuator, the width of the

actuator, and service envelope dimensions in Table 10. See Table 11 for valve body

dimensions.

Figure 4.

Table 9. Actuator Dimensions and Recommended Service Envelope. Dimensions in Inches (Millimeters).

Actuator

Actuator

Prefix

Code

Valve

Size

Center Line to Top of

Actuator, H1

Service Height, H

Width or

Diameter of

Actuator, W1

Service

Width

W

599-01088

2-Inch

Pneumatic

256

257

258

1/2 (15)

3-1/16 (78)

11 (280)

4 (100)

10 (250)

3/4 (20)

3-1/16 (78)

11 (280)

4 (100)

10 (250)

1 (25)

3-5/16 (84)

11-1/4 (285)

4 (100)

10 (250)

SAS

NSR

363

364

1/2 (15)

7-1/2 (191)

15-1/2 (394)

3-1/2 (89)

7-1/2 (191)

3/4 (20)

7-1/2 (191)

15-1/2 (394)

3-1/2 (89)

7-1/2 (191)

1 (25)

7-3/4 (197)

15-3/4 (400)

3-1/2 (89)

7-1/2 (191)

SAS

SR

365

366

1/2 (15)

7-1/2 (191)

15-1/2 (394)

4 (100)

8 (203)

3/4 (20)

7-1/2 (191)

15-1/2 (394)

4 (100)

8 (203)

1 (25)

7-3/4 (197)

15-3/4 (400)

4 (100)

8 (203)

SSC81U

SSC81.5U

SSC61.5U

259

260

262

1/2 (15)

5-1/2 (140)

13-1/2 (343)

5-1/2 (140)

13-1/2 (343)

3/4 (20)

5-1/2 (140)

13-1/2 (343)

5-1/2 (140)

13-1/2 (343)

1 (25)

5-3/4 (146)

13-3/4 (349)

5-1/2 (140)

13-1/2 (343)

SSC161.05U

261

1/2 (15)

5 (127)

13 (330)

5-1/4 (133)

13-1/4 (337)

3/4 (20)

5 (127)

13 (330)

5-1/4 (133)

13-1/4 (337)

1 (25)

5-1/4 (133)

13-1/4 (337)

5-1/4 (133)

13-1/4 (337)

Page 11

Powermite 599 MT Series Terminal Unit 2-way Valves Technical Instructions

Document Number 155-196P25

February 2, 2023

Information in this publication is based on current specifications. The company reserves the right to make changes in specifications and models as

design improvements are introduced. Product or company names mentioned herein may be the trademarks of their respective owners.

© 2020-2023 Siemens Industry, Inc.

Siemens Industry, Inc.

Smart Infrastructure

1000 Deerfield Parkway

Buffalo Grove, IL 60089

USA

+ 1 847-215-1000

Your feedback is important to us. If you have

comments about this document, please send them

to sbt_technical.editor.us.sbt@siemens.com

Document No. 155-196P25

Printed in the USA

Page 11

Internal Thread NPT ×

Internal Thread NPT

IT×IT

Internal Thread NPT ×

Union External Thread

IT×UET

Angle Internal Thread ×

Union External Thread

AIT×UMET

Table 10. 2-way Valve Dimensions.

Valve

Size

inches

A B C D E

Weight

lb (kg)

IT×IT

&

IT×UET

AIT×UMET

IT×IT

IT×UET

AIT×UMET

1/2

(15)

1-3/8

(35)

2-1/4

(57)

2-15/16

(74)

NO Only

1-5/16

(33)

2-5/8

(67)

1-1/2

(38)

NO only

0.96

(0.44)

1.14

(0.5)

1.4

(0.6)

3/4

(20)

1-5/8

(41)

2-3/8

(59)

—

1-5/16

(33)

3-1/8

(79)

—

1.13

(0.51)

1.45

(0.66)

—

1

(25)

1-15/16

(49)

2-3/4

(69)

—

1-9/16

(39)

—

—

1.7

(0.77)

—

—

Loading...

Loading...