Siemens VALVEGYR LDU11.323A17, VALVEGYR LDU11.523A17, VALVEGYR LDU11.523A27, VALVEGYR LDU11.323A27 User Manual

Page 1

CC1N7696en

20.04.2016

Building Technologies Division

7

696

VALVEGYR®

Valve Proving System for

automatic Shutoff Valves

LDU11...

The LDU11... valve proving system is designed for use with shutoff valves in con-

nection with gas burners and gas appliances. In the event of inadmissible leakage,

the system prevents the burner from starting up.

The LDU11... system conforms to the requirements of EN1643 covering automatic

shutoff valves for use with gas burners and gas appliances to EN161.

The LDU11... and this Data Sheet are intended for use by OEMs which integrate the

valve proving system in their products.

Page 2

2/21

Building Technologies Division CC1N7696en

20.04.2016

Use

The LDU11... is designed for automatic gas valve proving (leakage test) based on the

pressure proving principle. It is for use on gas-fired combustion plant with or without vent

pipe to atmosphere. In the case of plants with no vent pipe where EN standards apply,

the notes given in «Connection examples without vent pipe to atmosphere» must be

observed.

Used in connection with 1 or 2 commercially available pressure switches, valve proving is

automatically initiated with every burner startup, either

- prior to burner startup

- during the prepurge time if it lasts a minimum of 60 seconds

- immediately after a controlled shutdown, or

- on completion of the burner control’s control sequence, e.g. at the end of the

postpurge time

The valve proving test is based on the 2-stage pressure proving principle:

1. The valve on the mains side is tested by evacuating the test space and by monitoring

the atmospheric pressure in it.

2. The valve on the burner side is checked by pressurizing the test space and by monitoring the gas pressure.

If the pressure increases excessively during the first test phase called «Test1», or de-

creases excessively during the second test phase called «Test2», the LDU11.... will in-

hibit burner startup and initiate lockout. In that case, the lockout reset button will light up

to indicate the fault. Remote indication of the fault is also possible. A program indicator,

which stops whenever a fault occurs, indicates which of the valves is leaking. The

LDU11... can be reset either on the unit itself or via an electric remote reset facility.

Warning notes

To avoid injury to persons, damage to property or the environment, the following

warning notes must be observed.

Do not open, interfere with or modify the control unit.

All activities (mounting, installation and service work, etc.) must be carried out by

qualified staff

Before making any wiring changes in the connection area, completely isolate the

plant from mains supply (all-polar disconnection). Ensure that the plant cannot be inadvertently switched on again and that it is indeed dead. If not observed, there is a

risk of electric shock hazard

Ensure protection against electric shock hazard by providing adequate protection for

the valve proving system’s connection terminals

Each time work has been carried out (mounting, installation, service work, etc.),

check to ensure that wiring is in an orderly state

Press the lockout reset button only manually (applying a force of no more than 10 N)

without using any tools or pointed objects

Do not press the lockout reset button on the unit for more than 10 seconds since

longer presses will destroy the lockout relay

Fall or shock can adversely affect the safety functions. Do not put such units into

operation, even if they do not exhibit any damage

Mounting notes

Ensure that the relevant national safety regulations are complied with

Page 3

3/21

Building Technologies Division CC1N7696en

20.04.2016

Installation notes

Live and neutral conductors must not be interchanged

Standards and certificates

Applied directives:

Low-voltage directive 2014/35/EC

Directive for gas-fired appliances 2009/142/EC

Directive for pressure devices 97/23/EC and

2014/68/EC (2016-07-16)

Electromagnetic compatibility EMC (im-

munity) *)

2014/30/EC

*) The compliance with EMC emission requirements must be checked after the valve monitoring system is

installed in the equipment

Compliance with the regulations of the applied directives is verified by the adherence to

the following standards / regulations:

Safety and control devices for gas burners and gas burning ap-

pliances - Valve proving systems for automatic shut-off valves

DIN EN 1643

The relevant valid edition of the standards can be found in the declaration of conformity!

Note on DIN EN 60335-2-102

Household and similar electrical appliances - Safety - Part 2-102:

Particular requirements for gas, oil and solid-fuel burning appliances having electrical

connections.

The electrical connections of the LDU11 and the AGM comply with the requirements of

EN 60335-2-102.

EAC Conformity mark (Eurasian Conformity mark)

ISO 9001:2008

ISO 14001:2004

OHSAS 18001:2007

Certified complete with plug-in base:

Type reference

LDU11.323A17 --- x x x --- x

LDU11.323A27 --- x --- x --- x

LDU11.523A17 x --- x x x --LDU11.523A27 x --- --- x --- ---

Page 4

4/21

Building Technologies Division CC1N7696en

20.04.2016

Life cycle

LDU11... has a designed lifetime* of 250,000 burner startup cycles which, under normal

operating conditions in heating mode, correspond to approx. 10 years of usage (starting

from the production date given on the type field). This lifetime is based on the endurance

tests specified in standard EN298 and the table containing the relevant test documentation as published by the European Association of Component Manufacturers (Afecor)

(www.afecor.org

).

The designed lifetime is based on use of the LDU11... according to the manufacturer’s

Data Sheet. After reaching the designed lifetime in terms of the number of burner startup

cycles, or the respective time of usage, the LDU11... is to be replaced by authorized

personnel.

* The designed lifetime is not the warranty time specified in the Terms of Delivery

Disposal notes

The unit contains electric and electronic components and must not be disposed of together with domestic waste. Local and currently valid legislation must be complied with.

Page 5

5/21

Building Technologies Division CC1N7696en

20.04.2016

Mechanical design

- Plug-in design

- Exchangeable unit fuse (including spare fuse)

- Made of impact-proof and heat-resistant black plastic

- Lockout reset button with viewing window showing:

– The fault signal lamp

– The lockout indication

- Coupled to the program spindle

- With transparent lockout reset button

- Easy-to-remember symbols indicating the type of fault and the time lockout

occurred

- Synchronous motor of the sequence switch with gear train and step action

sequence switch

- Camshaft with 15 nonadjustable cams

- Program indicator at the head of the camshaft

- 1 main and 1 auxiliary relay

- Lockout relay can be electrically reset from a remote location and provides the

«Lockout» and «Reset» functions

- Unit fuse and spare fuse

All electrical components are interconnected via printed circuits.

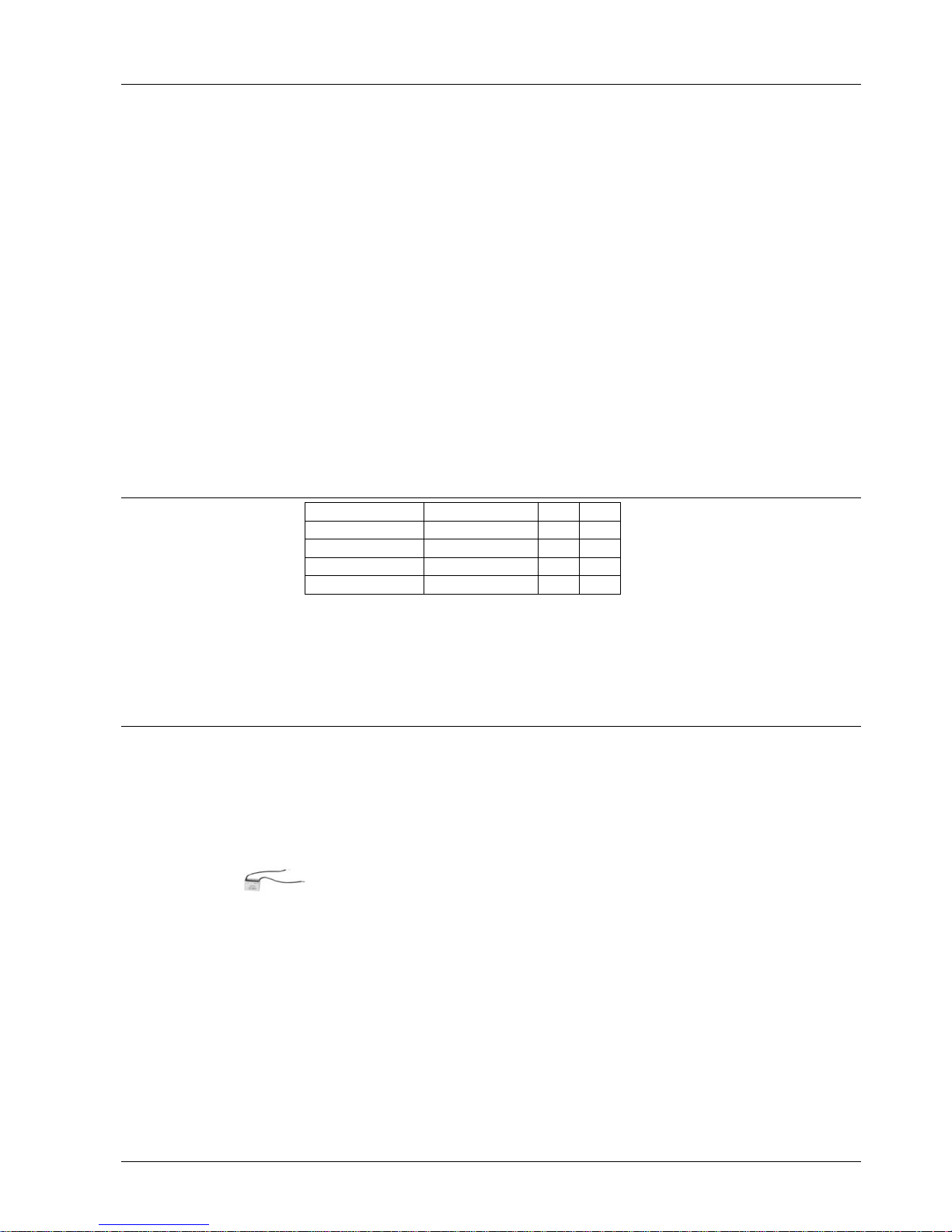

Type summary

Type reference Mains voltage t3 t4

LDU11.323A17 AC 100...110 V 2.5 s 2.5 s

LDU11.323A27 AC 220...240 V 2.5 s 2.5 s

LDU11.523A17 ¹) AC 100...110 V 5 s 5 s

LDU11.523A27 ¹) AC 220...240 V 5 s 5 s

t3 Filling the test space

t4 Evacuating the test space

¹)

Valve opening times do not conform to EN1643

Ordering

Valve proving system LDU11... (without plug-in base) refer to «Type summary»

Plug-in base not included in the delivery, must be ordered as a separate item!

Connection accessories for medium-capacity refer to Data Sheet N7230

- Plug-in base AGM11 with Pg11 threads for cable entry glands

- Plug-in base AGM11.1 with M16 threads for cable entry glands

PTC resistor (AC 230 V) AGK25

- For load on terminal 4 of LMG2...

Valve proving system

LDU11...

Housing

Legend

Page 6

6/21

Building Technologies Division CC1N7696en

20.04.2016

Technical data

Mains voltage

- LDU11.323A27

- LDU11.323A17

A

C 220 V –15 %...AC 240 V +10 %

A

C 100 V –15 %...AC 110 V +10 %

- LDU11.523A27 ¹)

- LDU11.523A17 ¹)

A

C 220 V –15 %...AC 240 V +10 %

A

C 100 V –15 %...AC 110 V +10 %

¹)

Valve opening times do not conform to EN 1643

Mains frequency 50...60 Hz ±6 %

Unit fuse (built-in) T6.3H250V to DIN EN 60127

Primary fuse (external) Max. 10 A (slow)

Weight

A

pprox. 1000 g

Power consumption

- During the test

- During operation

A

pprox. AC 3.5 VA

A

pprox. AC 2.5 VA

Mounting position Optional

Degree of protection IP40 (to be ensured through mounting),

except the connection area (terminal base)

Safety class

I

Perm. input current at terminal 1 Max. 5 A (peak current 20 A / 20 ms)

Perm. current rating of control terminals Max. 4 A (peak current 20 A / 20 ms)

Required current rating of pressure switch

(DW)

Min. 1 A, AC 250 V

Storage

DIN EN 60721-3-1

Climatic conditions Class 1K3

Mechanical conditions Class 1M2

Temperature range -20...+60 °C

Humidity <95 % r.h.

Transport

DIN EN 60721-3-2

Climatic conditions Class 2K2

Mechanical conditions Class 2M2

Temperature range -50...+60 °C

Humidity <95 % r.h.

Operation

DIN EN 60721-3-3

Climatic conditions Class 3K5

Mechanical conditions Class 3M2

Temperature range -20...+60 °C

Humidity <95 % r.h.

Caution!

Condensation, formation of ice and ingress of water are not permitted!

General unit data

LDU11...

Environmental

conditions

Page 7

7/21

Building Technologies Division CC1N7696en

20.04.2016

Function

During the first phase of the valve proving test called «Test1», atmospheric pressure

must exist in the length of pipe between the valves to be tested. In plants with a vent pipe

to atmosphere, atmospheric pressure is available if the valve proving test is made prior to

or during the prepurge time. In plants without vent pipe, atmospheric pressure is made

available as the valve proving system opens the valve on the burner side during evacuating the test space (t4). If the valve proving test LDU11... is performed after burner operation, the valve on the burner side after the controlled shutdown can be kept open until

evacuating the test space (t4) has elapsed, thus lowering the pressure in the test space

and making certain its gas content is burnt off in the combustion chamber during the

postpurge time. Prerequisite for this procedure is a suitable control program of the burner

control as provided by burner controls type LFE..., LFL..., LGK... or LEC...

The test space is closed off after evacuation. During the first test phase «Test1», which

then follows, the LDU11... checks with the pressure switch if the atmospheric pressure in

the test space is maintained. If the valve on the mains side is leaking, causing the pressure to rise above the switching point of the pressure switch, the LDU11... will trigger an

alarm and initiate lockout. The program indicator then stops to indicate «Test1».

If the pressure does not increase because the valve closes correctly, the LDU11... continues its program with the second test phase «Test2». For that purpose, the valve on the

mains side is opened during filling the test space (t3) so that the test space is pressurized

(«filling» the test space). During the second test phase – if the valve on the burner side is

leaking – this pressure must not fall below the switching point of the pressure switch. If it

does, the LDU11... will initiate lockout also, thus preventing the burner from starting up.

On successful completion of the second test phase, the LDU11... closes the internal

control loop between terminals 3 and 6 (circuit path: terminal 3 - contact (ar2) - terminals

4 and 5 - contact III - terminal 6). This control loop is normally included in the burner control’s start control loop.

After the control loop has been closed, the programming mechanism of the LDU11...

returns to its start position to switch itself off. During these so-called idle steps, the positions of the programming mechanism’s control contacts remain unchanged.

Page 8

8/21

Building Technologies Division CC1N7696en

20.04.2016

Program and lockout indicator

In the event of lockout, the programming mechanism stops and thus the position indicator

fitted to the spindle of the mechanism. The symbol that stops above the reading mark

indicates the test phase during which lockout occurred and also gives the number of

programming steps completed from the start of this test phase (1 step = 2.5 seconds).

► Start position = operating position

In plants without vent valve:

Evacuation of test space by opening the valve on the burner side

Test1

«Test1» with atmospheric pressure (valve proving test on the mains side)

Filling the test space by opening the valve on the mains side

Test2

«Test2» with gas pressure (valve proving test on the burner side)

I I I

Idle steps until programming mechanism switches itself off

► Operating position = start position for the next valve proving test

In the event of lockout, all terminals receiving voltage from the valve proving system

LDU11... will be deenergized, except terminal 13, which is used for lockout indication.

After a reset, the programming mechanism automatically returns to its start position to

immediately program a new valve proving test.

Note!

Do not press the reset button for more than 10 seconds.

A power failure prior to evacuating the test space does not cause the control sequence to

change.

If a power failure occurs after the evacuation, the valve proving test will not be continued

when power is restored, but the programming mechanism first returns to its start position

and then performs the complete valve proving test.

Meaning of the symbols:

Control sequence after

a power failure

Page 9

9/21

Building Technologies Division CC1N7696en

20.04.2016

Calculation of the leakage rate escaping from a length of pipe

Q

Leck

=

(P

G

- PW) x V x 3600

P

atm

x t

Test

Q

leck in dm³/h Permissible leakage rate in dm³ per hour or liters per hour

P

G in mbar Overpressure in pipe section between the valves to be tested, at

the beginning of the test phase

P

W in mbar Overpressure set on pressure switch «DW» (normally set to 50

% of the gas mains pressure)

P

atm in mbar Absolute pressure (1.013 mbar normal pressure)

V in dm³ Volume of test space confined by the valves to be tested, includ-

ing the space in the valves themselves

T

test in s Duration of proving time

P

G = 30 mbar

QLeck =

(30 - 15) x 10.36 x 3600

1013 x 27.5

= 20 l/h

P

W = 15 mbar

P

atm

V

= 1013 mbar

= 10.36 dm³

Any valve leakage rate exceeding 20 l/h causes the LDU11...

to initiate lockout

t

Test = 27.5 s

Note!

Select volume of pipe section (V) between the gas valves to be checked and overpressure (PW) set on pressure switch (DW) such that the maximum permissible gas

leakage rate (QLeck) will not exceed the rate specified in the local regulations.

Legend

Example

Page 10

10/21

Building Technologies Division CC1N7696en

20.04.2016

Connection diagram

M

~

L

EK2

18

1

SK

1)

AS

ar2

3

4

5

III

6

a

b

I

8

a

b

V

10 12

19

23

20

a

ba

b

XI

hr1

22 21 24

hr2

HR

b

a

XIII

ab

IX

ar1

br1

IV

15

14

16

17

PGP

DW

Atm.

Gas

VII

b

a

VIII

a

b

ar3

b

a

VI

AR

br2

BR

L1

EK1

)

13

AL

N

2

7911

SM

LDU11

7696a15/0204

S

i

Legend

AL

Alarm signal for «leaking valve»

AR

Working relay with contacts (ar...)

AS

Unit fuse (built-in)

BR

Lockout relay with contacts (br...)

DW

Pressure switch for valve proving test (does not replace the gas pressure switch used to signal lack of gas)

EK1

Lockout reset button

EK2

Remote lockout reset button

GP

Gas pressure switch (for lack of gas)

HR

Auxiliary relay with contacts (hr...)

L1

Lockout warning lamp (built-in)

Si

External primary fuse

SK

Control contact (for initiating the valve proving test)

SM

Synchronous motor of programming mechanism

1)

Do not press lockout reset button (EK) for more than 10 seconds

Page 11

11/21

Building Technologies Division CC1N7696en

20.04.2016

Sequence diagram

ABC

I

III

IV

V

VI

VII

VIII

IX

XI

XIII

AR

Test1 Test2

78

56

9

910

11 15

11 12

t20

t4

t1

t6

t3

t2

t5

7696b01e/0601

a

b

a

b

a

b

a

b

a

b

a

b

a

b

Output terminals

controlled by the

control unit or

electrically

connected

Program indication

Legend

t1 22.1 s First test phase with atmospheric pressure

t2 27 s Second test phase with gas pressure

For LDU11.323...

t3 2.5 s Filling the test space

t4 2.5 s Evacuating the test space

For LDU11.523...

t3 5 s Filling the test space

t4 5 s Evacuating the test space

t5 66.3 s Total duration of valve proving test until burner is released

t6 7.4 s Interval from start to energizing working relay (AR)

t20 22.1 s Running time of programming mechanism until it switches itself off in the operating = start position (idle steps)

A Gas valves controlled to evacuate the test space

B Gas valves controlled to fill the test space

C Vent valve, normally open; closed during valve proving test from the beginning of «Test1»

Page 12

12/21

Building Technologies Division CC1N7696en

20.04.2016

Connection examples with vent pipe to atmosphere using burner controls type LGB2..., LGB3... / LGB4... /

LMG2...

For other connections, refer to the connection diagram of the relevant burner control.

Valve proving test prior to burner startup Valve proving test following immediately the controlled

shutdown

LDU11

17

DW

2

C

54

hr1

GP

23

1116

15

E

B

6

III

ar2

3

SB / R / W

N

1

12

LGB2.../3.../4.../LMG2...

H

L

hr2

XI

20

14 1912 22

5

3

4

A2

A1

M

N

AL

13

2421

10

7696a05/0403

N

L

LDU11

22

5

4

2

C

hr1

7

B

11

E

12

P

III

1

16

14

15

DW

ar2

17 3

LGB2.../3.../4.../LMG2...

H

6

hr2

19 23

20

I

8

12

XI

SB / R / W

A2

A1

5

GP

3

M

N

13

AL

21

24

4

7

696a06/0703

AGK25

3)

³) Only in connection with LMG2...

Plants with vent pipe to atmosphere

GP

E

C

B

DW

LDU

A

A2

A1

C

DW

LDU

B

GP

E

7696s01/0695

Connection examples with vent pipe to atmosphere using burner controls type LFE..., LFL... or LGK..., or the

control unit LEC...

Check during the prepurge time (min. 60 seconds) and

following immediately the controlled shutdown in plants

with vent pipe to atmosphere. Delay on make of relay

d >2 seconds.

2)

Expanding flame burner or interrupted pilot burner

Check following immediately the controlled shutdown

2)

Expanding flame burner or interrupted pilot burner

N

LDU11

hr2

GP

C

14

15

18

1

EK2

2

17

16

6

III

53

ar2

4

B

E

11

201912

hr1

XI

23

8

I

7

10

V

9

14

W

2

d

LFE1

LEC1

LFL1...

LGK16...

18 199

12 13

4

LP

8

5

R

N

4 5°/10°°

18°/17°°

A

AL

22

13

2421

N

7696a10/0401

DW

2)

2)

LDU11

hr2

GP

C

N

BE

6

W

14

15

18 1

17

16

III

53

ar2

4

2

EK2

4

LFE1

LEC1

LFL1...

LGK16...

8

R

N

11

20

19

12

hr1

XI

23

I

7

10

V

9

8

5°/10°°

18°/17°°

A

9

5

AL

7696a11/0401

22132421

N

DW

2)

2)

Page 13

13/21

Building Technologies Division CC1N7696en

20.04.2016

Connection examples with vent pipe to atmosphere using burner controls type LFE..., LFL... or LGK..., or the

control unit LEC...

For other connections, refer to the connection diagram of the relevant burner control.

Check just prior to burner startup Check during the prepurge time (min. 60 seconds)

2)

Expanding flame burner or interrupted pilot burner

2)

Expanding flame burner or interrupted pilot burner

N

LDU11

hr2

GP

E C

B

5

W

14

15

618

1

4

ar2

III

5

EK2

17

16

3

8

4

9

LFE1

LEC1

LFL1...

LGK16...

R

11

19

hr1

XI

2023

12

9

V

10

7

8

I

2

N

5°/10°°

18°/17°°

A

AL

13

N

242122

7696a07/0401

DW

2)

2)

N

LDU11

hr2

GP

CE B

4

14

W

14

15

6

18

1

3

ar2

III

5

EK2

17

16

4

LP

818

19

4951213

LFE1

LEC1

LFL1...

LGK16...

R

11

2019

12

hr1

XI

23

N

9

10

V

7

8

I

2

5°/10°°

18°/17°°

A

AL

22132421

N

7696a08/0401

DW

2)

2)

Valve proving test with 2 pressure switches

DW

G Pressure switch for the valve proving test with gas pressure.

This pressure switch must be set to the minimum gas pressure permitted during the proving test.

If this pressure is not reached during the test, lockout will be initiated.

DW

A Pressure switch for the gas valve proving test with atmospheric pressure.

This pressure switch must be set to the maximum gas pressure permitted during the proving test with atmospheric pressure.

If this pressure is exceeded during the test, lockout will be initiated.

Pressure switch (DW

G) and pressure switch (DWA) must be overload-proof up to the gas pressure value.

16

17

DW

G

DW

A

15

7696a09/0796

Plants with vent pipe (C) to atmosphere

DW

C

B

A

LDU

C

DW

B

LDU

A2

7696s02/0709

) ( RB

C

B

DW

LDU

A

C

B

DW

LDU

A

SKP7...

Page 14

14/21

Building Technologies Division CC1N7696en

20.04.2016

Connection examples without vent pipe to atmosphere (for applications not covered by EN676) using burner

controls type LFE..., LFL... or LGK..., or the control unit LEC...

Check following immediately the controlled shutdown in plants without vent pipe. Valve (A) or valve (A1) remains open

after the controlled shutdown until the start of the first test phase is reached in order to evacuate the test space and to

burn off the gas in the combustion chamber during the afterburn time.

2)

Expanding flame burner or interrupted pilot burner

LDU11

hr2

20

E

GP

N

B

A

R

14

15

18

1

17

16

3

ar2

4

2

EK2

5

III

6

4

LFE1

LEC1

LFL1...

LGK16...

8

9

W

5

11

19

12

hr1

XI

23

I

7

8

V

9

10

M2

N

5°/10°°

18°/17°°177

AL

7696a12/0401

13

24N2122

3

6

DW

2)

2)

Valve proving test with 2 pressure switches

DW

G Pressure switch for the valve proving test with gas pressure. This pressure switch must be set to the mini-

mum gas pressure permitted during the proving test. If this pressure is not reached during the test, lockout

will be initiated.

DW

A Pressure switch for the gas valve proving test with atmospheric pressure. This pressure switch must be set

to the maximum gas pressure permitted during the proving test with atmospheric pressure. If this pressure

is exceeded during the test, lockout will be initiated.

Pressure switch (DW

G) and pressure switch (DWA) must be overload-proof up to the gas pressure value.

16

17

DW

G

DW

A

15

7696a09/0796

Plants without vent pipe to atmosphere

SKP7...

GP

LDU

DW

) ( RB

P

L

A2

A1

LDU

DW

GP

LDU

DW

GP

LDU

DW

GP

Air pressure (PL) for the SKP7... must be sufficiently high to open the SKP7... although the burner’s air damper is

closed. Otherwise, the LDU11... will initiate lockout when performing «Test1».

Page 15

15/21

Building Technologies Division CC1N7696en

20.04.2016

Connection examples without vent pipe to atmosphere using burner controls type LGB2... / LGB3... / LGB4... /

LMG2...

For other connections, refer to the connection diagram of the relevant burner control.

Check prior to burner startup Check following immediately the controlled shutdown

N

LDU11

hr2

22

A1

GP

E

B

N

DW

15

1

3

4

ar2

17

16

SB / R / W

2

5

6

III

LGB2.../3.../4.../LMG2...

12

L

H

9

2311

20

10

hr1

V

XI

12

14

19

53

M

A2

4

AL

13

24

21

N

10

7

696a13/0403

LDU11

hr2

22

E

N

BA1

15

ar2

17

16

III

214

DW

P

GP

L

H

6

5

431

12

LGB2.../3.../4.../LMG2...

N

hr1

11

97

20

23

19

10

8

12

I

V

XI

A2

5

3

M

N

AL

13

N

24

21

4

SB / R / W

7696a14/0703

N

AGK25

3)

³) Only in connection with LMG2...

Plants without vent pipe to atmosphere

GP

E

B

DW

LDU

A

A2

A1

DW

LDU

B

GP

E

7696s04/0695

Page 16

16/21

Building Technologies Division CC1N7696en

20.04.2016

Connection examples without vent pipe to atmosphere using burner controls type LFE..., LFL... or LGK..., or

the control unit LEC...

For other connections, refer to the connection diagram of the relevant burner control.

Check just prior to burner startup Check during the prepurge time (min. 60 seconds)

2)

Expanding flame burner or interrupted pilot burner

2)

Expanding flame burner or interrupted pilot burner

LDU11

hr2

GP

E

N

B

A

W

14

15

618

1

ar2

III

EK2

17

16

3

4

5

DW

8

4

9

LFE1

LEC1

LFL1...

LGK16...

R

11

19

hr1

XI

20

23

12

7

8

I

2 9

10

V

5

5°/10°°

18°/17°°

AL

13

N

2421

22

7696a24/0401

2)

2)

N

LDU11

hr2

GP

E

B

A

14

W

14

15

618

1

3

ar2

III

5

EK2

17

16

4

LP

818

19

49512

13

LFE1

LEC1

LFL1...

LGK16...

R

11

20

19

hr1

XI

23

12

7

8

I

2 9

10

V

4 5°/10°°

18°/17°°

AL

22

13

24

21

N

7696a25/0401

DW

2)

2)

Valve proving test with 2 pressure switches

DW

G Pressure switch for the valve proving test with gas pressure. This pressure switch must be set to the mini-

mum gas pressure permitted during the proving test. If this pressure is not reached during the test, lockout

will be initiated.

DW

A Pressure switch for the gas valve proving test with atmospheric pressure. This pressure switch must be set

to the maximum gas pressure permitted during the proving test with atmospheric pressure. If this pressure

is exceeded during the test, lockout will be initiated.

Pressure switch (DW

G) and pressure switch (DWA) must be overload-proof up to the gas pressure value.

16

17

DW

G

DW

A

15

7696a09/0796

Plants without vent pipe to atmosphere

SKP7...

Air pressure (PL) for the SKP7... must be sufficiently high to open the SKP7... although the burner’s air damper is

closed. Otherwise, the LDU11... will initiate lockout when performing «Test1».

Page 17

17/21

Building Technologies Division CC1N7696en

20.04.2016

Connection examples without vent pipe to atmosphere using burner controls type LFE..., LFL... or LGK..., or

control unit LEC... and actuator SKP7... with expanding flame burners

For other connections, refer to the connection diagram of the relevant burner control

Check just prior to burner startup

Check during the prepurge time (min. 60 seconds)

LDU11

22

GP

E

N

B

A

2

W

6

14

15

18

1

a

r

2

III

EK2

17

16

DW

4

5

3

LP

14

8

18

19

4

9

12

13

LFE1

LEC1

LFL1...

LGK16...

R

5

4

N

hr2

11

2019

hr1

XI

23

12

7

8

I

9

10

V

5°

18°

T

AL

M

13

24

21

N

6/7

3/17

7696a26/0401

LDU11

GP

E

N

B

A

2

LP

W

6

14

15

18

1

ar2

III

EK2

17

16

DW

45

3

14

81819

4

9

12

13

LFE1

LEC1

LFL1...

LGK16...

R

4

5

hr2

11

2019

hr1

XI

23

12

7

8

I

9

10

V

M

5°

18°

AL

13

2421N22

N

6/7

3/17

7696a27/0401

Valve proving test with 2 pressure switches

DW

G Pressure switch for the valve proving test with gas pressure. This pressure switch must be set to the mini-

mum gas pressure permitted during the proving test. If this pressure is not reached during the test, lockout

will be initiated.

DW

A Pressure switch for the gas valve proving test with atmospheric pressure. This pressure switch must be set

to the maximum gas pressure permitted during the proving test with atmospheric pressure. If this pressure

is exceeded during the test, lockout will be initiated.

Pressure switch (DW

G) and pressure switch (DWA) must be overload-proof up to the gas pressure level.

16

17

DW

G

DW

A

15

7696a09/0796

Plants without vent pipe to atmosphere

GP

BE

D

W

A

SKP7...

Page 18

18/21

Building Technologies Division CC1N7696en

20.04.2016

Connection examples without vent pipe to atmosphere using burner controls type LME21.xxxC... /

LME22.xxxC... with expanding flame burners

For other connections, refer to the connection diagram of the relevant burner control.

LME22.xxxC... / LME22.xxxC... with LDU11... valve proving

Before startup of burner

In the case of plants without vent pipe to atmosphere

NT

RESET

A2

Z

AL

T

T

R / W

Gpmin

STB

7101a28e/0210

LP

EK2

K1

K2/1

K3

K4K2/2

N

K5

1)

LDU11...

HR

DW

Gas

A

tmospheric

A1 B

E

Iar2 hr1

hr2

III V XI

MM

1)

LME21.xxxC...

LME22.xxxC...

GP

LDU LDU

GP

1) Fan motor connected to terminal 3 of the LME22.xxxC.... / LME22.xxxC...

Valve proving is started each time the system is switched on, with connection of

terminal 3, after controller ON or after lockout

If the LDU11... initiates lockout, valve proving can take up to 160 seconds. There-

fore, the maximum permissible response time of the air pressure switch is 180 seconds

With the LDU11…, faults during valve proving lead to lockout and, with the

LME22.xxxC.... / LME22.xxxC..., to lockout due to air pressure switch timeout (blink

code 03)

Note!

A faulty air pressure switch (switch does not make) leads to lockout (blink code 03)

on completion of the pressure switch response time of 180 seconds and can be

distinguished from lockout due to faulty valve proving only because the LDU11...

did not go to lockout

The fan motor can be connected either to terminal 3 in connection with a link be-

tween terminals 6 and 24 of the LDU11... (motor active during valve proving) or to

terminal 6 of the LDU11... (motor active on completion of successful valve proving)

Page 19

19/21

Building Technologies Division CC1N7696en

20.04.2016

Connection examples with vent pipe to atmosphere using burner controls type LME21.xxxC... / LME22.xxxC...

with expanding flame burners

For other connections, refer to the connection diagram of the relevant burner control.

LME22.xxxC... / LME22.xxxC... with LDU11... valve proving

Valve supervision before startup of burner

In the case of plants with vent pipe to atmosphere

NT

RESET

A2

Z

AL

T

T

R / W

Gpmin

STB

7101a29e/0210

LP

EK2

K1

K2/1

K3

K4K2/2

N

K5

1)

LDU11...

HR

DW

Gas

A

tmospheric

C

B

E

Iar2hr1

hr2

III V XI

A1

MM

1)

LME21.xxxC...

LME22.xxxC...

GP GP

1) Fan motor connected to terminal 3 of the LME22.xxxC... / LME22.xxxC...

Valve proving is started each time the system is switched on, with connection of ter-

minal 3, after controller ON or after lockout

If the LDU11... initiates lockout, valve proving can take up to 160 seconds. Therefore,

the maximum permissible response time of the air pressure switch is 180 seconds

With the LDU11…, faults during valve proving lead to lockout and, with the

LME22.xxxC... / LME22.xxxC..., to lockout due to air pressure switch timeout (blink

code 03)

Note!

A faulty air pressure switch (switch does not make) leads to lockout (blink code 03)

on completion of the pressure switch response time of 180 seconds and can be

distinguished from lockout due to faulty valve proving only because the LDU11...

did not go to lockout

The fan motor can be connected either to terminal 3 in connection with a link between

terminals 6 and 24 of the LDU11... (motor active during valve proving) or to terminal 6

of the LDU11... (motor active on completion of successful valve proving)

Page 20

20/21

Building Technologies Division CC1N7696en

20.04.2016

Legend

A, A1, A2 Gas valves controlled to evacuate the test space

AGK25 PTC resistor

AL Alarm signal for «leaking valve»

ar... Contacts (operating relay)

B Gas valve controlled to fill the test space

C Vent valve, normally open; closed during valve proving test from the be-

ginning of «Test1»

DW Pressure switch for valve proving test (does not replace the gas pressure

switch used to signal lack of gas)

E Safety shutoff valve, dead closed (optional)

EK Lockout reset button (internal)

EK2 Remote lockout reset button

FSV Flame signal amplifier

GP Gas pressure switch (for lack of gas)

H Main switch

ION Ionization probe

K1...4 Internal relays

hr... Contacts (auxiliary relay)

LP Air pressure switch

M... Fan («M2»: pre- and postpurging)

NT Power supply

PL Reference pressure for SKP7...

R Control thermostat or pressurestat (e.g. boiler control thermostat)

RB Pipe orifice; its diameter must be determined such that in the event of a

leaking ignition gas valve (A), the ignition flame cannot afterburn on com-

pletion of the second safety time so that presence of the main flame can-

not be simulated

SB Safety limit thermostat

STB Safety limit thermostat

T Delay off time relay; the time should be set to approx. «t16» (min. «t7»...

max. «t10») of the burner control

W Limit thermostat or pressure switch or pressure limiter

Z Ignition transformer

t7 Interval between start command and power at terminal 7 (start delay for

«M2»)

t10 Interval from start to the beginning of the air pressure check, excluding

running time of air damper

t16 Interval until OPEN command for the air damper is given

Page 21

21/21

Building Technologies Division CC1N7696en

20.04.2016

Dimensions

Dimensions in mm

1,5

108,5

27,5 27,5

37

7,5

103

103

7696m04/0305

123

LDU11...

2016 Siemens AG Building Technologies Division, Berliner Ring 23, D-76437 Rastatt

Subject to change!

Plug-in base AGM11 / AGM11.1

Loading...

Loading...