Page 1

UROSKOP D3

Start-up Instructions

SP

with POLYDOROS SX

and

FLUOROSPOT H with Supervision

© Siemens AG 1998

The reproduction, transmission or

use of this document or its contents

is not permitted without express

written authority. Offenders will be

liable for damages. All rights,

including rights created by patent

grant or registration of a utility

model _or_ design,_are_ reserved.

Register 4 English

Print No.: RLL5-310.034.04.04.02 Doc. Gen. Date: 12.98

Replaces: RLL5-310.034.04.03.02

Page 2

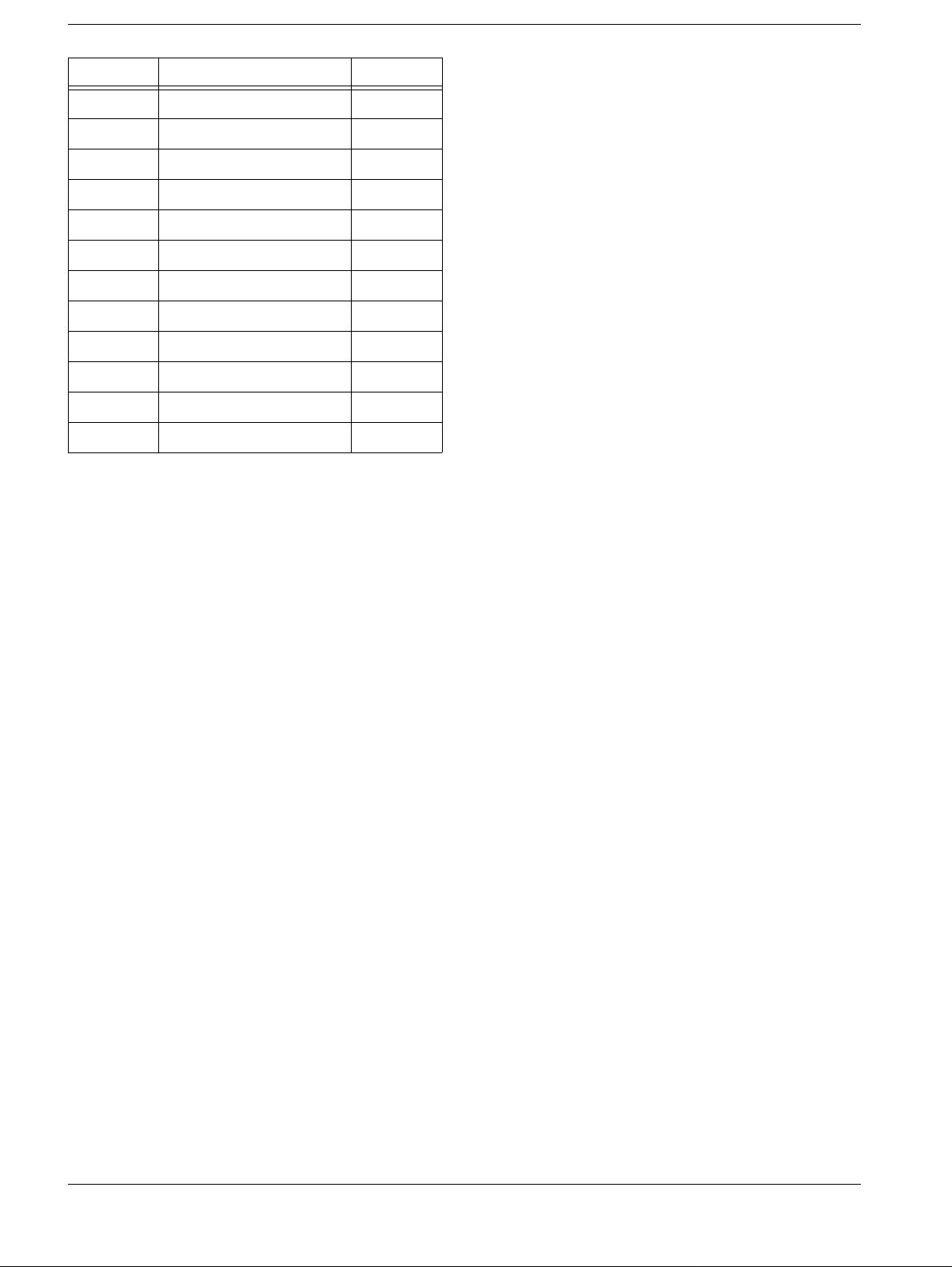

0 - 2Revision

Chapter Page Revision

1all04

2all04

3all04

4all04

5all04

6all04

7all04

8all04

9all04

10 all 04

11 all 04

12 all 04

UROSKOP D3 Register 4 RLL5-310.034.04 Page 2 of 4 Siemens AG

Rev. 04 12.98 TD PS 24 Medical En gineering

Page 3

Contents 0 - 3

Page

1 _______General information ____________________________________________1 - 1

Safety information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 1

General information and information on documentation . . . . . . . . . . . . . . . . 1 - 1

Preliminary information on image quality test . . . . . . . . . . . . . . . . . . . . . . 1 - 2

Purpose: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 2

Sequence of work:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 2

Requirements for start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 2

Required Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 2

Required measuring instruments . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 3

2 _______Start-up preparation ____________________________________________2 - 1

Protective measures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 1

Measuring the line voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 1

Checking the on-site emergency shutdown butto n . . . . . . . . . . . . . . . . . . . 2 - 1

Checking the phase connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 2

Measuring the internal line impedance . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 2

Checking unacceptable ground connections . . . . . . . . . . . . . . . . . . . . . . 2 - 3

Switching on the generator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 3

3 _______Generator functions ____________________________________________3 - 1

Checking the emergency stop switches. . . . . . . . . . . . . . . . . . . . . . . . . 3 - 1

Checking the control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 1

Function check of the anode starter. . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 1

Key to 7-segment display on board D95: . . . . . . . . . . . . . . . . . . . . . . 3 - 1

LED status display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 1

Checking the fluoroscopic and exposure release circuit . . . . . . . . . . . . . . . . 3 - 2

Fluoroscopic circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 2

Exposure release circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 2

Controls and indicator lamps for radiation protection . . . . . . . . . . . . . . . . . . 3 - 3

Door contact for radiation disable function . . . . . . . . . . . . . . . . . . . . . 3 - 3

Indicator lamps for tube assembl y selection. . . . . . . . . . . . . . . . . . . . . 3 - 3

Checking the kV/mA values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 3

Checking the mAs values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 4

Start-up of the automatic exposure control . . . . . . . . . . . . . . . . . . . . . . . 3 - 4

4 _______Unit movements________________________________________________4 - 1

Preparation and limit values for tabletop lift . . . . . . . . . . . . . . . . . . . . . . . 4 - 1

Lifting movement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 2

Oblique projection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 3

Tilting movement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 4

Longitudinal movement of the tabl etop . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 5

Transverse movement of the tabletop. . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 6

Siemens AG Register 4 RLL5-310.034.04 Page 3 of 6 UROSKOP D3

Medical Engineering Rev. 04 12.98 TD PS 24

Page 4

0 - 4 Contents

Page

5 ____ __ Radiation geometry_____________________________________________5 - 1

Test conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 2

Evaluation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 3

Test conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 4

Brief description of the test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 4

Visual check of the fluoroscopic field limitation . . . . . . . . . . . . . . . . . . . 5 - 5

Checking the overframing of the fluoroscopic field size displayed on the monitor . 5 - 5

Checking the centering of radiation fiel d and monitor image center . . . . . . . . 5 - 6

Evaluation of overframing in fluoroscopy . . . . . . . . . . . . . . . . . . . . . . 5 - 6

Evaluation of off-center in fluoroscopy . . . . . . . . . . . . . . . . . . . . . . . 5 - 6

6 ______ Checking the tomographic device_________________________________ 6 - 1

Accuracy of the tomographic height display . . . . . . . . . . . . . . . . . . . . 6 - 2

Resolution and tomographic proc edure . . . . . . . . . . . . . . . . . . . . . . 6 - 2

7 ______ Fluoroscopic dose rate__________________________________________7 - 1

General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 1

Preliminary remarks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 1

Basic information on the dose / dose rate measurement for I.I. workstations . . . 7 - 1

Determining the dose/dose rate directly at the I.I. input . . . . . . . . . . . . . . 7 - 1

Formulas for calculating the dose/dose rate in the measurement plane for

dose/dose rate setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 2

Indirect dose rate test at the customer site. . . . . . . . . . . . . . . . . . . . . . . 7 - 3

Setting when the indirect dose rate is out of tolerance. . . . . . . . . . . . . . . . . 7 - 3

Maximum skin dose rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 4

8 ______ Television system ______________________________________________8 - 1

Function check of ambient light sensor. . . . . . . . . . . . . . . . . . . . . . . . . 8 - 1

B-signal values (without bias li ght/dark current component) . . . . . . . . . . . . . . 8 - 1

Image artifacts (Para. 5 .10 Chapter 5D) . . . . . . . . . . . . . . . . . . . . . . 8 - 2

9 ______ Digital Fluoro Radiography/FLUOROSPOT H________________________9 - 1

General information and remarks . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 1

Dose/pulse test during start-up (indirect dose check) . . . . . . . . . . . . . . . . . 9 - 5

BA (video+blanking) signal values / setting the iris diaphragm in DR operation . . . . 9 - 6

Dynamic test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 7

Edge enhancement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9 - 11

Mean value assessment (GGM= sliding weighted averaging) . . . . . . . . . . .9 - 11

Resolution and minimum contrast . . . . . . . . . . . . . . . . . . . . . . . . . . .9 - 12

Checking the DSA system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9 - 14

Checking the hardcopy camera . . . . . . . . . . . . . . . . . . . . . . . . . . . .9 - 16

Adjusting the hardcopy camera. . . . . . . . . . . . . . . . . . . . . . . . . . .9 - 16

UROSKOP D3 Register 4 RLL5-310.034.04 Page 4 of 6 Siemens AG

Rev. 04 12.98 TD PS 24 Medical En gineering

Page 5

Contents 0 - 5

Page

Preparing and evaluating the SMPTE test image . . . . . . . . . . . . . . . . . 9 - 16

Image artifacts and transmission interference. . . . . . . . . . . . . . . . . . . 9 - 17

Image artifacts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 18

Definition of the rating numbers:. . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 18

Description of the artifacts: . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 18

10 ______Nominal values _______________________________________________10 - 1

I.I. nominal values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 1

ADC measuring field . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 1

MPL system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 1

SDM system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 1

Fluoroscopic dose rate at the I.I. input . . . . . . . . . . . . . . . . . . . . . . . . 10 - 2

VIDEOMED SX, H1X Emulation . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 3

TV monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 3

TV camera . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 3

B signal value (interlaced - Bypass) . . . . . . . . . . . . . . . . . . . . . . . 10 - 3

Vignetting (with bias light) (interlaced - Bypass) . . . . . . . . . . . . . . . . . 10 - 4

AGC measuring field sizes in grid units (GU) . . . . . . . . . . . . . . . . . . . 10 - 4

Pedestal and AGC function

Pedestal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 4

Fixed gain TV unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 4

Dynamic test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 5

Capillary test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 5

Resolution and minimum contrast of the I.I.-TV system (interl . - Bypass). . . . 10 - 6

Image artifacts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 6

Digital Fluoro Radiography / DFR . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 6

FLUOROSPOT H . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 6

Dose/pulse at the I.I. input. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 6

Amplification of DFR system. . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 7

Monitor adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 8

BA signal values / Adjustment of iris diaphr agm in DR mode . . . . . . . . . . . 10 - 8

Dynamic test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 9

Black level cutoff (noise halo) . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 10

Resolution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 10

Minimum contrast . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 10

Checking the DSA equipment . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 11

Image artifacts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 11

11 ______Final steps and electrical safety _________________________________11 - 1

Final work . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 - 1

Measuring the protective conduc tor resistance . . . . . . . . . . . . . . . . . . . . 11 - 1

12 ______Changes to previous version____________________________________12 - 1

Siemens AG Register 4 RLL5-310.034.04 Page 5 of 6 UROSKOP D3

Medical Engineering Rev. 04 12.98 TD PS 24

Page 6

0 - 6 Contents

Page

This page intentionally left blank.

UROSKOP D3 Register 4 RLL5-310.034.04 Page 6 of 6 Siemens AG

Rev. 04 12.98 TD PS 24 Medical En gineering

Page 7

CAUTION

General information 1

Safety information 1

When performing service work and tests, please adhere to the

product-specific safety informati on contained in the document, as

well as the general safety information contained in Register 2 of

the TI binder.

Tests and adjustments performed with radiation ON are identified with the radiation warning symbol . Radiation protection must be worn during these types of adjustments.

General information and information on documentation 1

These instructions contain the checks necessary for system startup.The sequence in

which they are given must be maintained.

The unit movements necessary for these procedures must be carri ed out very carefully

to avoid damaging the equipment in the event of a malfunction.

Since the unit has been adjusted completely at the factory, only the functioning and factory settings (accuracy of tolerance) are checked; the unit must be adapted to on-site

requirements, if necessary.

1 - 1

If any mechanical or electrica l malfunctions oc cur or if tolerances are exceeded (damages

caused by transport etc.), perform ser vi ce work and adjust ments acc ording to adjustm ent

instructions RLL5-310.071.01... or the service instructions for the corresponding components.

Measurement results marked” ” must be entered in the UROSKOP test certificate.

For the acceptance test which is requ ired i n Germany in accordance wit h §16 of the Rönt-

genverordnung (x-ray ordinance) and for the acceptance test required in t he USA, the following checks have already been performed in the factory test area and documented in

the test certificate:

• Visual check of the filt er values.

• Check of the SID display.

• Brightness of the light localizer.

• Coincidence of light fiel d and radiation field.

• Accuracy of the manual format col limation.

• Coincidence of radiatio n field and film center.

• Accuracy of positive beam li mitation (PBL) system for cassett e formats.

• Fluoroscopic field limitat ion.

• Centering of the radiation f ield and monitor image center.

• Function check of the Iontomat measurement fields.

• Unit attenuation facto r.

• Check of the tomographic device.

Siemens AG Register 4 RLL5-310.034.04 Page 1 of 4 UROSKOP D3

Medical Engineering Rev. 04 12.98 TD PS 24

Page 8

1 - 2 General information

NOTICE

Enter the measurement values and the additional values determined during system start-up from the test certificate into the

acceptance certificate (Germany) or in the acceptance test certi fi cate (USA).

Preliminary information on image quality test 1

Purpose: 1

• The image quality test provides objec tive data as a basis for image quality and faci litates

system start-up.

• The test certificate is val id for system acceptance and for futur e service and mainte-

nance work.

Sequence of work: 1

• Follow the sequence of measurements and checks ex actly as describes in order to

ensure correct measurements.

• Enter the results of each measurement i nto the test certificates.

• Compare the measured values with the values indi cated in the list of nominal values .

• If the limit values are exceeded, y ou must determine the cause and correct the er ror or

the erroneous setting before cont inuing the test. Otherwise the measurement s that

follow may be incorrect.

Requirements for start-up 1

• The system must be cabled completely.

• Switch on high voltage only if radi ation is necessary.

Required Documents 1

• Operating instructions UROSKOP D3 RL5-340.208.01...

• Wiring diagram UROSKOP D3 G5403

• Wiring diagram POL YDOROS SX X2075

• Service software

operation UROSKOP D3 RLL5-310.113.02... Logbook, Reg. 10

• Setting Instructions POL YDOROS SX RX63-050.032.02...

• System configuration POL YDOROS SX RX63- 050.034.06...

• IQ T est c ertificate RXD0-000.037.01... Logbook, Reg. 9

• T est certi ficate UROSKOP D3 RLL5-310.035.01... Logbook, Reg.3

• Test certificate POLYDOROS SX X2075 Logbook, Reg. 4

UROSKOP D3 Register 4 RLL5-310.034.04 Page 2 of 4 Siemens AG

Rev. 04 12.98 TD PS 24 Medical En gineering

Page 9

General information 1 - 3

CAUTION

Required measuring instruments 1

• 3-Phase field rotation meter , elect ronic 97 02 713 Y7933

• Internal line impedance meter 84 28 104 RE999

• Service PC

• Oscilloscope > 50 MHz, e.g. Tektronix 2232

with delayed time base

• Multimeter 8060 A (Fluke) 97 02 101 Y4290

• mAs meter 81 60 400 RE999

• Water level 28 69 436 RE999

• Set of Cu filters 44 06 120 RV090

• 17 µm Cu strips (included in the LOG book) 1 1 67 663 G5247

• cm scale

• T omogr aphic cube with resolution test 44 06 054 RV 090

• Protective conductor meter 44 15 899 RV090

• 8x magnifying glass 44 14 850 RH090

• Precision radiation filter 99 00 598 XE999

• Centering cross or lead rul er 96 60 051 RE999 or 28 63 025 RE999

• Mavo monitor , direct ordering 97 02 432 Y0526

• Resolution test patterns, types 41 28 71 820 RE999

• Dynamic test case 37 90 156 X1963

• heart contour diaphragm 37 90 172 X1963

• Capillary test 37 90 180 X1963

• DSA displacement test (with DSA capi llary

test)

• Aperture plate for tomograp hy

97 02 234 Y3155

97 50 019 X1963 (only with DSA)

Successful system start-up can only be ensured by using the

above measurement instruments.

Siemens AG Register 4 RLL5-310.034.04 Page 3 of 4 UROSKOP D3

Medical Engineering Rev. 04 12.98 TD PS 24

Page 10

1 - 4 General information

This page intentionally left blank.

UROSKOP D3 Register 4 RLL5-310.034.04 Page 4 of 4 Siemens AG

Rev. 04 12.98 TD PS 24 Medical En gineering

Page 11

CAUTION

Start-up preparation 2

Protective measures 2

• Observe the protective measures described in Register 1 of the UROSKOP D Logbook.

• Prior to performin g any service work on the generator, swi tch it off with the power OFF

switch on D200.

• In order to deenergize all parts of the system, set the system switc h to the OFF position.

With the generator switched off, line voltage is still present at

transformer T1 and fuse panel D200 (refer to wiring diagram

X2075-1 1 ).

After switching off the generator, approx. 600 V DC voltage are

still present at the inverter; indicated by LEDs V8 and V9 on bo ard

D250 (see X2075-17).

Within approx. 1 1/2 minutes the voltage drops to 0 V; the LEDs go

out at approx. 30 V.

• To prevent unintentional rel ease of high voltage or radiation, set swi tch SS on D200 to

OFF (no actuation of the inverters).

• Remove or insert boards only wit h the generator switched off. Wh en doing so, observe

the ESD guidelines (see TI 219, Info RA.5. RA0- 000.012.19... on microfilm).

2 - 1

• On D211: switch S1 INT OFF (position 2) .

• On D200: switch SS OFF.

Measuring the line voltage 2

• Remove fuses F1, F2 and F3 from the fuse board i n M16 (generator).

• System contactor ON.

• Measure the line voltage.

The voltage must correspond to the val ues indicated in the test certific ate (logbook,

Reg. 3).

Checking the on-site emergency shutdown button 2

• Actuate the emergency shutdown butt on installed by the customer. The entire syst em

must be disconnected from the power line.

• System contactor OFF.

Siemens AG Register 4 RLL5-310.034.04 Page 1 of 4 UROSKOP D3

Medical Engineering Rev. 04 12.98 TD PS 24

Page 12

2 - 2Start-up preparation

Checking the phase connection 2

• Check the correct phase connecti on of the power lines at M16.F1, F2, F3 (X2075-11) ,

using the rotating field instru ment:

• In M16, remove the cover from the fu se holders.

• Connect the3-phase field rotat ion meter to the lower connections of F1, F2, F3 (on the

side of the power supply).

• System contactor ON.

• Perform the measurement.

• System contactor OFF.

• Disconnect the rotating field i nstrument.

Measuring the internal line impedance 2

• Measure the internal line impedan ce at M16. F1. F2. F3 (X2075-11):

- Connect the internal line impedance meter bet ween two phases of F1, F2, F3 (at the

lower connections of the fuse holders ).

- System contactor ON.

- Perform the measurement.

- System contactor OFF.

• Record the measured values in the test certificate (l ogbook Reg. 3)

• Enter the measured values into the ”LINE PARAMETER” module of the system

programming.

Important: In order to obtain the full gener ator power, the internal line impedance

measured may not exceed the following values:

U

line

400 V 0.18 Ohm 0.12 Ohm

440 V 0.20 Ohm 0.16 Ohm

480 V 0.24 Ohm 0.20 Ohm

Internal line impedances of > 250 mOhm reduce power. Refer to RX63-

050.034.05.01.05... Configuration ”LINE PARAMETER”

max. R

SX 50 SX 80

withPOLYDOROS

line

measured

• Reinsert fuses F1, F2 and F3.

• Reattach the cover.

UROSKOP D3 Register 4 RLL5-310.034.04 Page 2 of 4 Siemens AG

Rev. 04 12.98 TD PS 24 Medical En gineering

Page 13

Start-up preparation 2 - 3

CAUTION

Checking unacceptable ground connections 2

(connection between and 0VL ).

• Disconnect the connection l ead between the upper and lower grounding bus (in the

generator power cabinet).

• Using the multimeter, measure the resistance between and 0V

The measured resistance must be approx. > 50 k

Ω.

:

L

• Reconnect the upper and the lower grou nding bus.

Switching on the generator 2

• System contactor ON:

- LED V26 (via fuse F11) must light up on fuse board D200.

In case of an error, check the fuses in M16 and on D200

(X2075-11 and 12).

• Generator ON:

- On fuse board D200, press key and actuate button .

- The LED’s must light up as follows on the service panel of D211:

The +5 V,

If the +5 V voltage is missing, the generator is disabled.

In this case, check the fuses on D200 ( X2075-12). All LED’ s on D200 must l ight

up.

- Following connection of the intermediat e circuit (activation of charging contactor and

power contactor), LEDs V9 and V8 on board D250 must light up (X2075-17).

± 15 V, +24 V supply voltages are immediately present.

A DC voltage > 500 V is applied to the intermediate circuit.

- Following correct initializati on (after approx. 10 sec.), the fol lowing LEDs must light on

the service panel of D211:

( ) ( ) TU1 (after system programming)

GEN-OK,+24 V, +15 V, -15 V, +5 V

If no error has occurred, the 7-segment displays on D210 indi cate ”E000”.

In case of an error, the three-digit error code is displayed.

- When programing the generator, "ALP" appears on the kV di splay of the control deck.

• Check the primary voltage for the s upply voltages (X2075-12) at the coil co nnections of

the GS contactor (X2075-11) in M16:

230 V

250 V

± 10 % at 50 Hz

± 10 % at 60 Hz

• Check the blocking:

On D200: Generator OFF

The generator cannot be switched on again f rom the deck.

Siemens AG Register 4 RLL5-310.034.04 Page 3 of 4 UROSKOP D3

Medical Engineering Rev. 04 12.98 TD PS 24

Page 14

2 - 4Start-up preparation

This page intentionally left blank.

UROSKOP D3 Register 4 RLL5-310.034.04 Page 4 of 4 Siemens AG

Rev. 04 12.98 TD PS 24 Medical En gineering

Page 15

NOTICE

Generator functions 3

Checking the emergency stop switches 3

• System ON.

• Press the three system emergenc y stop switches consecutively:

With the emergency stop switch pr essed in,

- error code ’’U01’ ’ must appear in the

- all system movements must be blocked.

area dose product

Checking the control panel 3

• System ON.

• Select from 40 kV to the max. kV value on t he kV control console by pressing the ± kV

keys.

• Check the mAs display by pressing the ± mAs keys.

display on the control console;

3 - 1

Function check of the anode starter 3

• Generator ON : On D95, display1→2→3

• Set release button S27 to preparati on: the rotating anode boosts.

Display 3

Let go of the release button S27 again: the rotating anode should brake.

Display 6

Key to 7-segment display on board D95: 3

1= Initialization 4= Start-up

2= Init-brakes 5= Continued run

3= Stand-by 6= Brakes

If the ERROR message flashes, please refer to the information contained in the

service so ft ware.

LED status display 3

→4→5

→3

The rotational speed must be checked with the tube assembly

warmed up.

light up depending on the

operating condition

Tube assy. 2 selected

Siemens AG Register 4 RLL5-310.034.04 Page 1 of 4 UROSKOP D3

Medical Engineering Rev. 04 12.98 TD PS 24

*

Tube assy. 1 selected

*

Page 16

3 - 2 Generator functions

NOTICE

Checking the fluoroscopic and exposure release circuit 3

Fluoroscopic circuit 3

• On board D200: SS switch OFF.

• On D211: FL switch ON.

• On D211: the following LED’s must light up (X 2075-23):

- TU1/TU2 TU 1/ TU 2 (acc. to selected workstation/tube assembly)

- small focus

- large focus

- GEN-OK Generator enable state

- DL Fl uoroscopy (FL) "on" (FL request)

- EXT-HW Radiation enable state/safety circuit

- SWR Start/inverter

SWR "start/inverter" is not illuminated as long as Kathotest

(module J05) is programmed.

The "radiation indicator" lights up only with radia tion ON.

• FL switch OFF

• SS switch ON

• FL ON

• Measure the minimum and maximum kV and mA values and enter them int o the

generator certificate.

Exposure release circuit 3

With preparation:

• Set the release button S27 to preparati on .

• On D211, the following LEDs must light up:

- TU1/TU2 TU1/TU2 (acc. to selected workstation/tube assembly)

- / (depending on focus selection)

- GEN-OK Generator enable state

- ZB ZB "ON" (ex posure preparation (ZB) request)

With exposure release:

• Press the release button S27 all the way down.

• On D211, the following LED’s must light up

- VH: Exposure request to unit

- AR: Exposure enable state from unit

- EXT-HW: Radiation enable state/safety circuit

UROSKOP D3 Register 4 RLL5-310.034.04 Page 2 of 4 Siemens AG

Rev. 04 12.98 TD PS 24 Medical En gineering

Page 17

Generator functions 3 - 3

NOTICE

SWR "start/inverter" is not illuminated as long as Kathotest

(module J05) is programmed.

The "radiation indicator" lights up only with radiation on.

• Release radiation release butt on S27.

Controls and indicator lamps for radiation protection 3

At the customer’s request, the following controls and indica tors can be connected in the

power cabinet according to the installation instructions RLL5-310.031.03. .., page 4-6.

Door contact for radiation disable function 3

(e.g. at the door of the examination room)

• Check: When the door is open, radiation release must not be possible.

Indicator lamps for tube assembly selection 3

• Check: For fluoroscopy or exposure preparation, the respect ive indicator lamp

associated with the tube assembly must light up.

Checking the kV/mA values 3

• System OFF.

• Connect oscilloscope to test points MP.kV

• System ON.

• SS switch ON.

• On the control console, sel ect 77 kV, 32 mAs for and focus respectively.

• Release one exposure in each case and check t he kV/mA values of test points

MP.kV

and MP.mA

act

with the oscilloscope.

act

• Enter the measured kV values in to the test generator test certi ficate and compare them

with the values recorded at the fa ctory. They must be within the specifi ed tolerances.

and MP.mA

act

on service board D211.

act

Siemens AG Register 4 RLL5-310.034.04 Page 3 of 4 UROSKOP D3

Medical Engineering Rev. 04 12.98 TD PS 24

Page 18

3 - 4 Generator functions

NOTICE

NOTICE

Checking the mAs values 3

• System OFF.

• On PC board D220 (over H1), remove the jumper from the mAs jacks.

• Connect the mAs meter to the mAs jacks.

• System ON.

• On the control console, select , 77 kV, 80 mAs.

• Release an exposure and check the mAs value on the mAs meter .

• Enter the measured value into the gener ator test certificate.

Start-up of the automatic exposure control 3

Check the functions of the IONTOMAT P and PLANI-IONTOMAT P automatic exposure

control systems according to the generator setting instructions RX63-050.032....

The installation procedures described i n the start -up inst ruct ions

may be disregarded since both subassemblies have alr eady been

installed at the factory.

§16

Since the UROSKOP has no selection for the film-screen keys

H-D-U, identical values must be programmed for H-D-U in the

IONTOMAT.

Checking the reproducibility of the automatic exposure control

• Attach 2.1 mm Cu to the multileaf colli mator.

• Set 77 kV,

100%,

large focus.

• Select Iontomat.

• Release 5 exposures consecutively.

• Enter the measured dose values into the generat or test certificate.

UROSKOP D3 Register 4 RLL5-310.034.04 Page 4 of 4 Siemens AG

Rev. 04 12.98 TD PS 24 Medical En gineering

Page 19

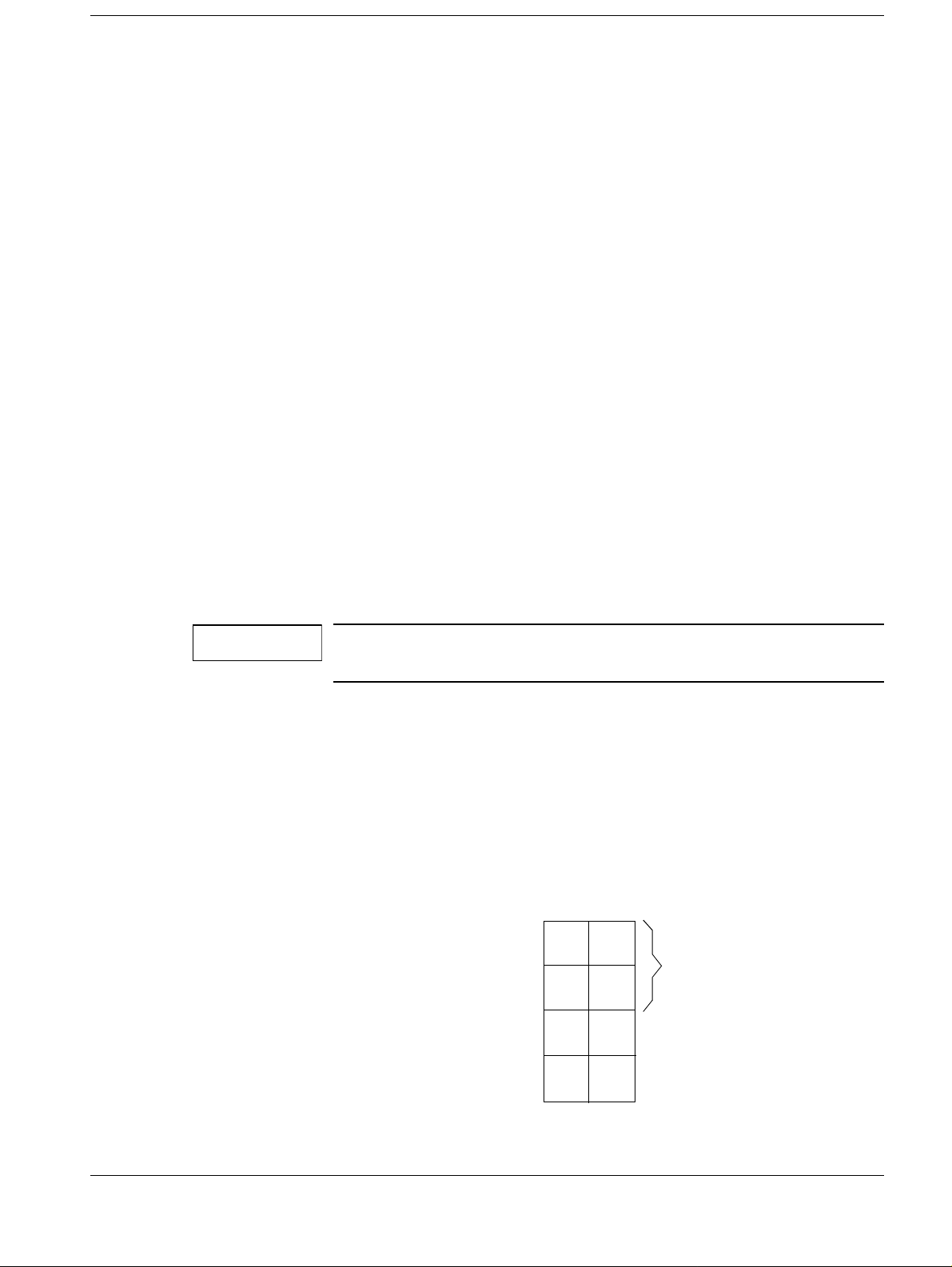

Unit movements 4

Preparation and limit values for tabletop lift 4

• Connect the service PC to connec tor X10 of board D1.

• System (When the emergency stop switch is actuated,” U01” appears in the display).

• If necessary, release th e emergency stop switch.

• Service PC .

• Start the service progra m

(refer to the service soft ware instructions RLL5-310.113.02...) .

Main menu

Info database

4 - 1

Unit parameters

Unit state

Unit errors

Calibration

Options

Download

Unit parameters

Load from unit

Load from file

Show

Modify

Send to unit

Load from unit

Load from file

Tomography

Memoskop 2K/100

Write to file

Output

ceiling height

• For ceiling height enter the act ual room height available

• Press return.

• Press <F4>. Initial questions with Yes.

Siemens AG Register 4 RLL5-310.034.04 Page 1 of 6 UROSKOP D3

Medical Engineering Rev. 04 12.98 TD PS 24

Page 20

4 - 2Unit movements

CAUTION

NOTICE

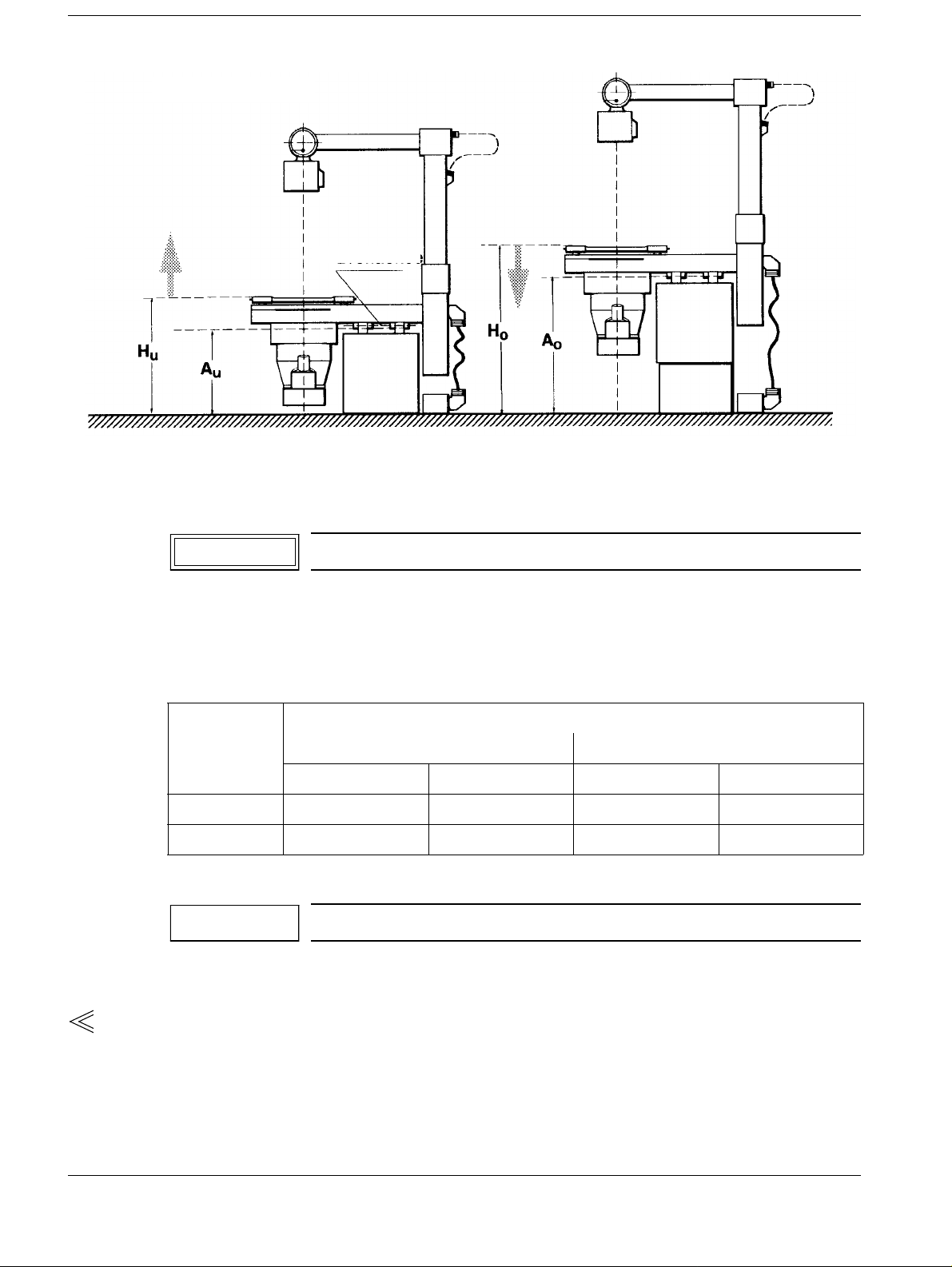

Lifting movement

Rotating axis

Lifting movement 4

Move into the end positions in gradual increments.

• Tilt the unit into the 0° posit ion.

• Successively move the unit into both end pos itions.

• Measure the distance between the floor or top surface of the installation pl ate and the

top surface of the tabletop or rota ting axis for both system positions :

Nominal distance between the floor or top surface of the installation plate

and top surface of the tabletop and rotating axis

H

u

82 cm ± 5 mm 128 cm ± 5 mm 62 cm ± 5 mm 108 cm ± 5 mm

for I.I. 40 86 cm

! minimum distance I.I.

Read the values displayed on the PC and compare them with the factory test values on

the test certificate.

± 5 mm 128 cm ± 5 mm 66 cm ± 5 mm 108 cm ± 5 mm

⇔ floor: 4 cm !

= 128 cm, possible only for room heights 2.60 m and above.

H

o

H

o

A

u

A

o

• Initial the comparison as conf irmation.

Lowest point: 62 cm to center of rot ation with tilted table (+88°).

• Correction: UROSKOP D adjustment instructions

UROSKOP D3 Register 4 RLL5-310.034.04 Page 2 of 6 Siemens AG

Rev. 04 12.98 TD PS 24 Medical En gineering

Page 21

Unit movements 4 - 3

CAUTION

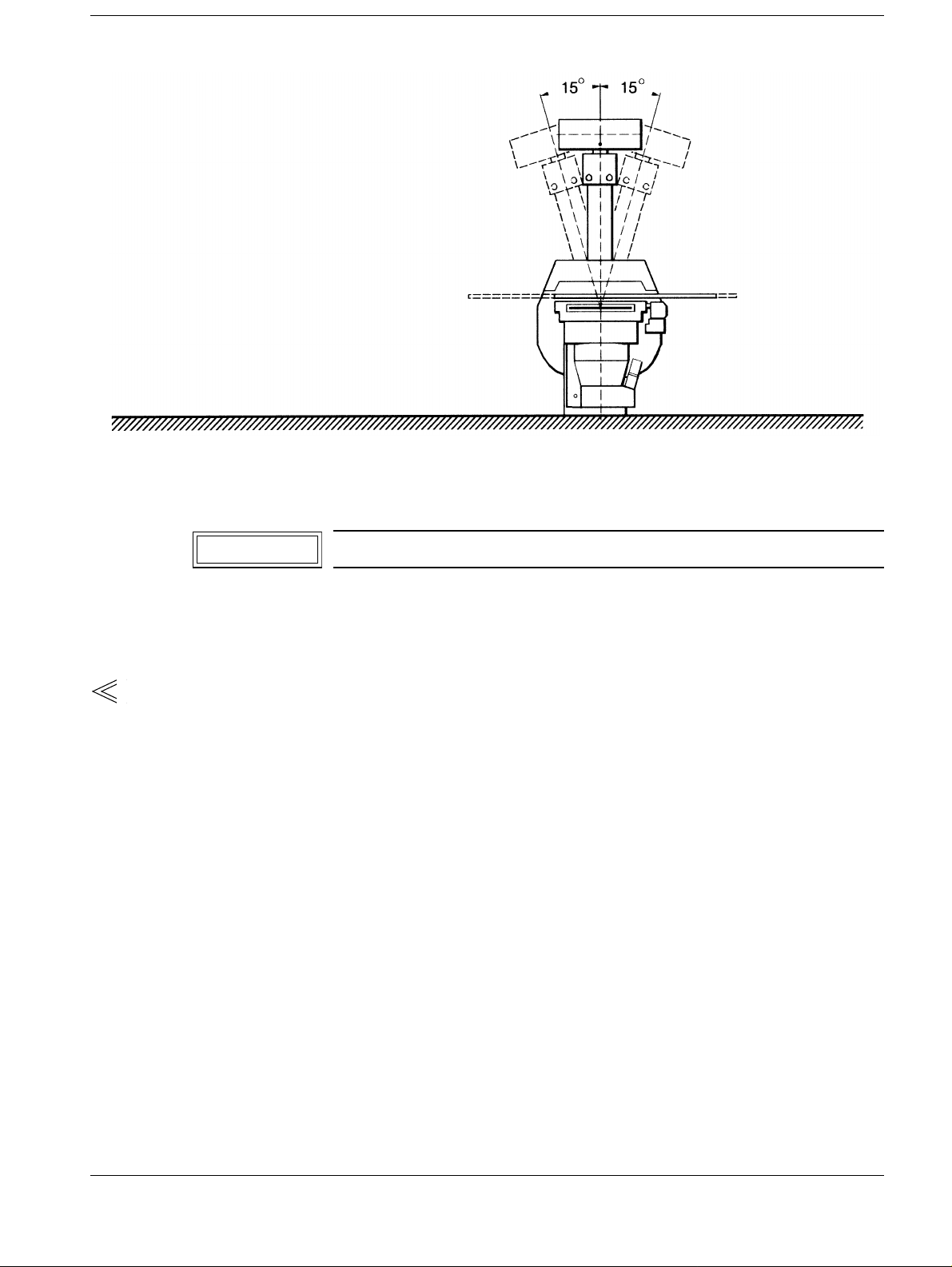

Oblique projection 4

Move into the end positions in gradual increments.

• Swivel the tube assembly support arm i n each case from the 0° position into bot h end

positions, -15° and +15°.

The 15° values must be indicated on the system cont rol console; at the same time, the

safety limit switch must not be pres sed.

• Read the values displayed on the PC under menu it em [

compare them with the factory test v alues in the test certifi cate.

• Initial the comparis on as confirmation.

• Correction: UROSKOP D adjustment instructi ons.

Unit state

], [Current] and

Siemens AG Register 4 RLL5-310.034.04 Page 3 of 6 UROSKOP D3

Medical Engineering Rev. 04 12.98 TD PS 24

Page 22

4 - 4Unit movements

CAUTION

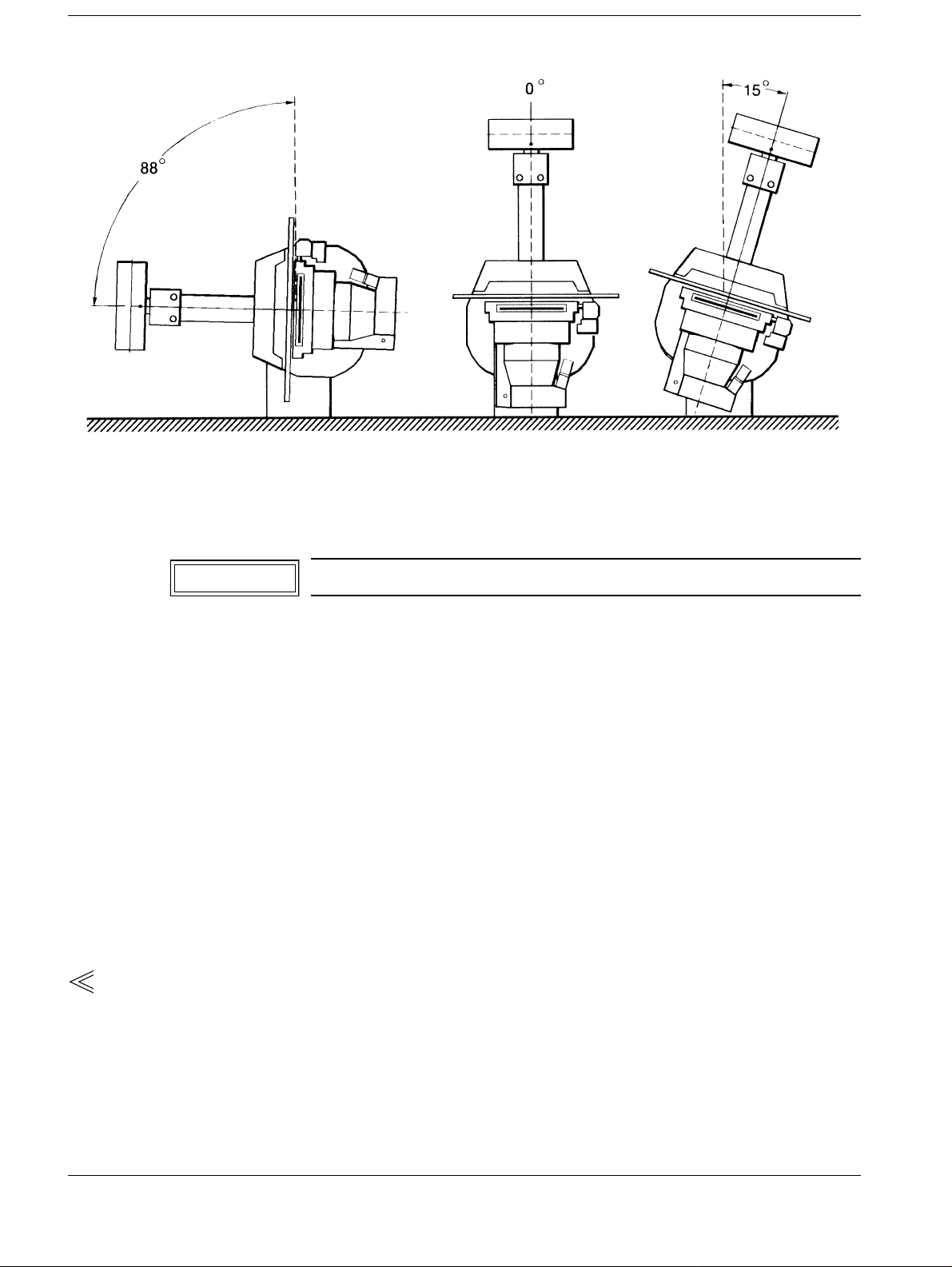

Tilting movement 4

Requirement: The installation plate must be level.

Move into the end positions in gradual increments.

• Tilt the unit in each case from bo th directions into the 0° positi on.

• Check the 0° position in each case with the p recision water level after the automati c stop.

Nominal: 0°

• Swivel from the 0° position in to the +88° end position; the switchi ng cam must not touch

the limit switch.

• Check the +88° end position with th e precision water level.

Nominal: 88°

• Swivel from the +88° end positio n into the -15° end position; the swit ching cam must not

touch the limit switch.

• Check the -15° end position with th e precision water level.

Nominal: - 15°

• Read the values displayed on the PC and compare them with t he factory test values in

the test certificate.

± 0.3°

± 0.5°

± 0.5°

• Initial the comparison as conf irmation.

• Correction: UROSKOP D adjustment instructions .

UROSKOP D3 Register 4 RLL5-310.034.04 Page 4 of 6 Siemens AG

Rev. 04 12.98 TD PS 24 Medical En gineering

Page 23

Unit movements 4 - 5

CAUTION

Wall side

Physician‘s side

Head end

Longitudinal movement of the tabletop 4

Move to the end positions in gradual increments.

• Move the tabletop successivel y into end positions A and K.

• Measure the distance between the l eft tabletop edge and the left front of the front guide

rail for both table pos itions.

Nominal: L

= 573 mm ± 5 mm

a

= 573 mm ± 5 mm

L

k

• Read off the values displayed on the PC and compare them with the factory test value s

of the test certificate.

• Initial the comparis on as confirmation.

• Correction: UROSKOP D adjustment instructi ons.

Siemens AG Register 4 RLL5-310.034.04 Page 5 of 6 UROSKOP D3

Medical Engineering Rev. 04 12.98 TD PS 24

Page 24

4 - 6Unit movements

CAUTION

Wall side

Head end

Physicia n ‘s side

Transverse movement of the tabletop 4

Move to the end positions in gradual increments.

• Tilt the unit into the 0° posit ion.

• Move the transverse carriag e of the tabletop successively into bo th end positions R

and L.

• Measure the distance between the re ar table edge and the front edge of the tub e

assembly support arm for both t able positions:

Nominal: Q

• Initial the comparison as conf irmation.

• Correction: UROSKOP D adjustment instructions .

• End the service program with <F10>.

= 55.5 cm,

l

= 31.5 cm Total tolerance: 5 mm

Q

t

UROSKOP D3 Register 4 RLL5-310.034.04 Page 6 of 6 Siemens AG

Rev. 04 12.98 TD PS 24 Medical En gineering

Page 25

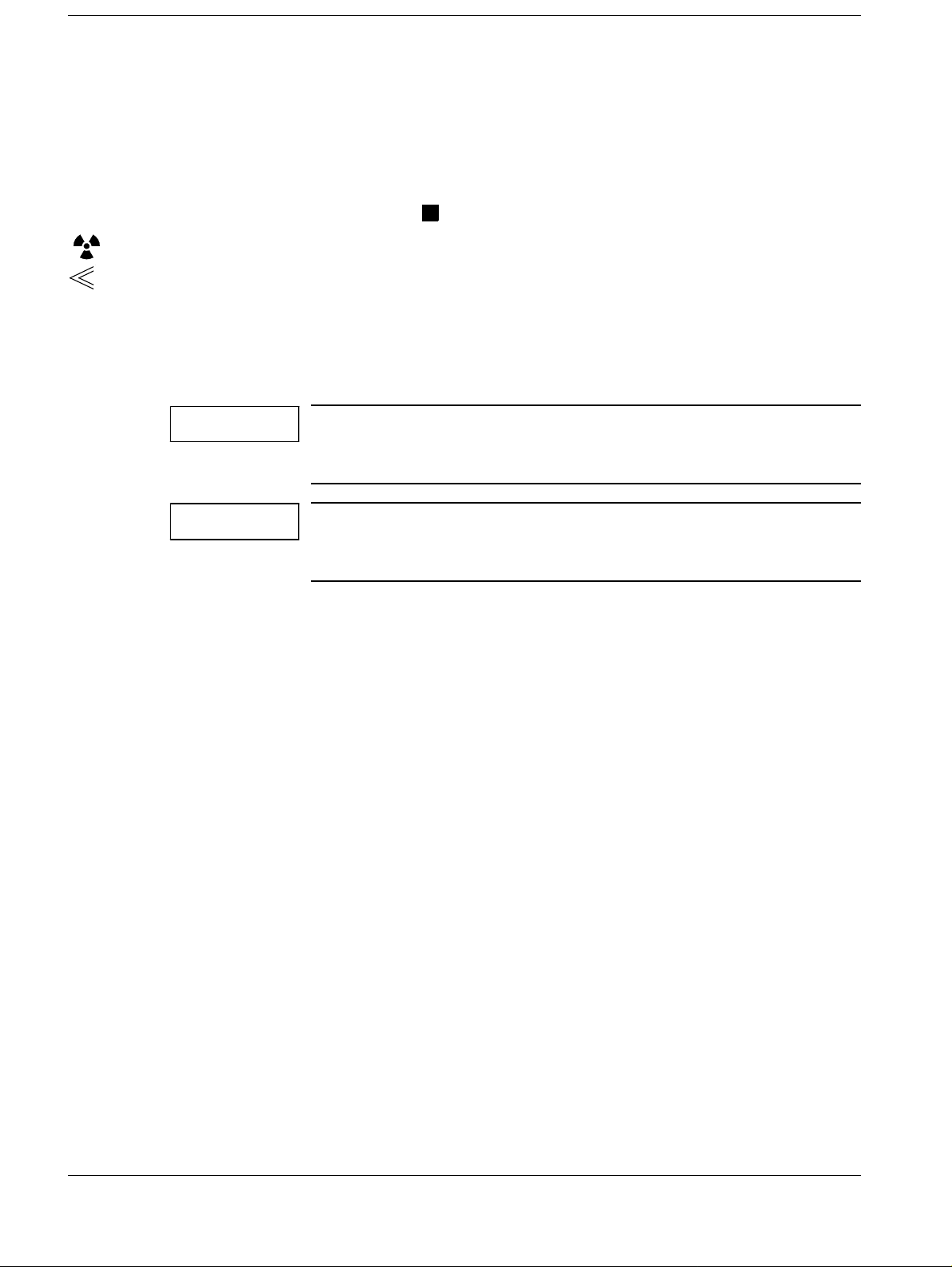

Side

marking

Metal washer

Cassette

center

Head

end

NOTICE

Radiation geometry 5

5 - 1

Fig. 1 Fig. 2

The central beam has been adjusted at the factory and documented on page 4 of the test certificate.

Take a few test exposures to ensure that the setting has not

changed during transport and installation.

The test certificate is contained in the UROSKOP D logbook,

RLL5-310.066.

DHHS

RöV

§16

• Mark the center of a 24 cm x 30 cm (10" x 12") cassette by attaching a metal washer

(Fig. 1).

• Attach a second washer to the casset te as a side marker (Fig. 1).

• Insert the cassette wh ich has been loaded with film in the longi tudinal direction

(side marking at the head end).

Side

marking

Film

drawn diagonals

Z

Metal

washer

Radiation field

exposed film area

Cassette

center

• Collimate the radiation fi eld smaller than the cassette format (approx. 15 cm x 15 cm).

Set the exposure data: approx. 40 kV, 5 mAs and large focus

(with universal film screen) .

• Make one exposure each with the table in th e 0°,+88° and - 15° position in each case.

• Develop the three films.

• Draw the radiation fiel d center onto the developed film (Fig. 2).

• Measure the deviation (z/Fi g. 2) between the radiation field center and the center mar-

king (washer) on the 2 exposures (Z1, Z2) .

• Compare the measured deviations Z1, Z2 with the factory test exposures and enter the

values into the

film center".

The difference from the values determi ned at the factory may be max. 2 mm.

Max. acceptable deviations:

UROSKOP D

test certificate, "Coinc idence of radiation field center and

≤ 1 cm

• If the deviation is greater than > 1 cm, adjust the central beam accordi ng to the adjust-

ment instructions and repeat the test exposures.

Siemens AG Register 4 RLL5-310.034.04 Page 1 of 6 UROSKOP D3

Medical Engineering Rev. 04 12.98 TD PS 24

Page 26

5 - 2Radiation geometry

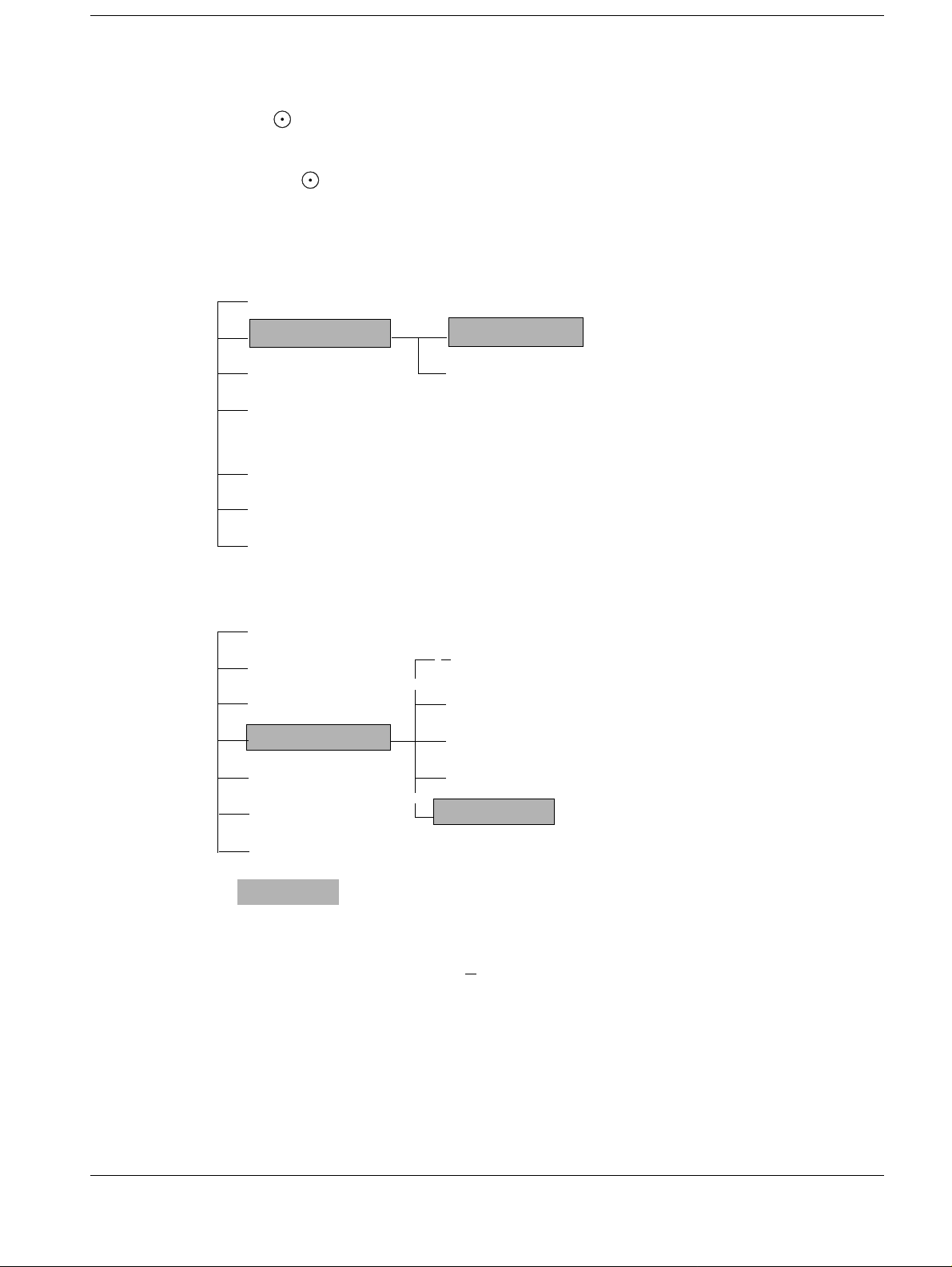

NOTICE

The accuracy of collimation for the PBL system is tested for three formats.

Film subdivisions can also be selected.

The table position is unimportant for this test.

Test conditions 5

• Expose 3 formats onto one film.

• With large focal spot

r

= 115 cm

B

a

= 7 cm

r

DHHS

RöV

§16

B

M

= 108 cm

/ (rB - a) = 1.065

= r

B

rB - a

r

B

a

Radiation field

Test film

Cassette without film

Tabletop

• Use a 35 cm x 35 cm cassette with film and place it on the tabletop diagonal to the table

edges and centered to the central beam.

• Close the collimator all the way.

• At the generator select the lar ge focus and approx. 50 kV, 25 mAs.

• Now insert three cassettes consecuti vely (film subdivisions as well, if necessar y) without

film in the spotfilm device, s tarting with the smallest format. Rel ease one exposure for

each format. Select full vi ew form for all exposures.

• If available, use the three for mats of 18 cm x 24 cm, 24 cm x 30 cm and 35 cm x 35 cm

for the test.

• The three exposures are shot over one anoth er on the same film. The evaluation is pos-

sible due to the different film densi ty of the individual formats.

Ensure that the format is always collimated from the smaller to

the larger collimator aperture.

• Develop and label the film.

UROSKOP D3 Register 4 RLL5-310.034.04 Page 2 of 6 Siemens AG

Rev. 04 12.98 TD PS 24 Medical En gineering

Page 27

Radiation geometry 5 - 3

Evaluation 5

• Measure the length and width (l’ and b’) of the three radiation fields on the f ilm and

record the values.

• Use the factor M for converti ng the radiation fields from measurement pla ne to film plane.

M = r

• Using M, calculate the radiati on field sizes in the film plane (l and b) f rom the measured

field sizes (l’ and b’) and record the values.

/ rB-a = 115 / (115 - 7) = 1.065

B

l=l'×M; b=b'×M

• Calculate and record the devi ations between nominal format (l

radiation field size in the f ilm plane (l and b) referenced to the SID (r

Tolerance:

l l

r

B

N

≤ 0.02; ≤ 0.02 corresponds to 2%

b b

r

B

N

and bN) and actual

N

).

B

Siemens AG Register 4 RLL5-310.034.04 Page 3 of 6 UROSKOP D3

Medical Engineering Rev. 04 12.98 TD PS 24

Page 28

5 - 4Radiation geometry

Check whether the coincidence between the radiation field and fluoro field are displayed

on the monitor for all image int ensi fier formats . I n addit ion, ch eck t he cen tering of the radi ation field to the monitor image center in the extreme table positions.

Test conditions 5

FLUORO field limitation:

• In one table position

• For all I.I. formats

Centering:

• In 3 table positions

• For I.I. full view format

RöV

§16

§16

X1

Y1

X2

Y2

r

r

B

BV

Strahlenfeld

T estfilm

Zentrierkreuz

ZG

Brief description of the test 5

• Center the centering cross to the cent ral beam under fluoroscopy.

• Open the collimator to maximum aperture and verif y that the collimator blades are

visible on the monitor.

If yes, the check for overframing i s not required.

• Count and record the cm scale divisions of the 4 coordinates X

, X2, Y1, Y2.

1

• If the collimator blades are not vis ible, place a film envelope with tes t film in the plane at

the centering and release fluorosco py (approx. 20 sec.).

• Evaluation:

Compare the radiation field on the test f ilm with the field size on the monitor.

Determine overframing in % of the SID.

Determine the off-center and calculate it in % of the SID.

UROSKOP D3 Register 4 RLL5-310.034.04 Page 4 of 6 Siemens AG

Rev. 04 12.98 TD PS 24 Medical En gineering

Page 29

Radiation geometry 5 - 5

Visual check of the fluoroscopic field limitation 5

• Align the central beam perpendi cular to the I.I. and move the tablet op into the horizontal

position or into a frequently use d mid-range position. Record the ti lt angle of this position.

• Do not insert a cassette in t he spotfilm device. Select I. I. full view format.

• Open the collimator to maximum apertur e and verify that the collimator blades ar e still

visible on the monitor.

• Perform this check for all I .I. formats and record whether the coll imator blades are visible

on the monitor.

• Determine and record: source- centering cross distance (r), SID = 115 cm.

• This completes the fluoros copic field limitation check for al l formats in which the collima-

tor blades are visible on the monitor .

• The degree of overframing must be determi ned for those formats in which all co llimator

blades are not visible.

Checking the overframing of the fluoroscopic field size displayed on the

monitor 5

• Maintain the mid-range table posi tion.

• Attach the centering cross to the tabletop so that the X axis is horizon tal.

• Collimate a small radiatio n field and center the centering cr oss to the radiation field

under fluoroscopy.

• Open the collimator to maximum apertur e. Proceeding outward from the center of the

centering cross, read and record the cm divisions of the 4 coordinates X

width and height displayed on the monitor .

, X2, Y1, Y2 in

1

• Perform this for all I.I . formats in which the collimator blades can no longer be seen on

the monitor at maximum collimator apert ure.

• Place a film envelope with t est film in the plane at the centering cros s and release

fluoroscopy at maximum collimator aper ture until sufficient film densit y is obtained.

• Repeat this for all I. I. formats in which the collimator blades are not visible on the

monitor.

• Make one test film each with the fo rmats to be tested and label.

Siemens AG Register 4 RLL5-310.034.04 Page 5 of 6 UROSKOP D3

Medical Engineering Rev. 04 12.98 TD PS 24

Page 30

5 - 6Radiation geometry

Checking the centering of radiation field and monitor image center 5

• Select I.I. full vie w format. Maintain the mid-range tabl e position.

• Unless already done, center the centeri ng cross to the central beam (tabletop) and open

the collimator to maximum aperture.

• Proceeding outward from the center of the c entering cross, read and record the cm

, X2, Y1 and Y2 displayed on the monitor.

1

+ X2 and Y1 + Y2) is determined and calculated in % of the

1

§16

divisions of the 4 coordinates X

• Repeat the same procedure in the two extre me positions of the table: collimate small,

center the centering cross to t he central beam, open the collimator to maximum

aperture, read off and record t he scale divisions in the X and Y axis.

Evaluation of overframing in fluoroscopy 5

• Measure the width and length of the radi ation fields displayed on th e test films and

record the radiation field sizes ( l and w).

The difference (overframing) between the r adiation field size (l and w) and the fiel d size

displayed on the monitor (X

source-centering cross distance:

Tolerance:

b

(

X1 + X2)

r

≤ 0.02; ≤ 0.02 corresponds to 2%

l

(

X1 + X2)

r

Evaluation of off-center in fluoroscopy 5

• The off-center devi ation (z

lated in each case in the X and Y dir ection for all table positio ns (tilt angles) tested:

z

X

X1 X

and zy) of radiation field and monit or image center is calcu-

x

2

z

;

2 2

Y

==

Y1 Y

2

;

• The off-center deviation is cal culated in % of the source-centering cross di stance.

Tolerance:

z

X

≤ 0.02 ≤ 0.02 corresponds to 2%

;

r r

z

Y

;

UROSKOP D3 Register 4 RLL5-310.034.04 Page 6 of 6 Siemens AG

Rev. 04 12.98 TD PS 24 Medical En gineering

Page 31

NOTICE

Checking the tomographic device 6

The tomographic device has been adjust ed a t the fact ory. The setting is documented in the test certificate and via three test exposures included in the shipment. Take a test exposure to ensure

that the setting has not been changed during t ranspor t and ins tallation.

Anode side

20°

2 mm

approx. 115 mm

6 - 1

SH

a

• Move the tabletop into the horizo ntal position and select "tomography" operating mode.

• Place a foam cube with definit ion tests on the tabletop and center it to the light localizer.

One definition test must be located on t he anode side, the other test must face toward s

the tube assembly support arm.

• Ensure that the notches of the t wo definition tests are located at the same height above

the tabletop; measure this dimension ( approx. 11.5 cm) exactly.

• Select the tomographic height so t hat the numerical tomographic height dis play corres-

ponds exactly to the measured "notch hei ght".Record this dimension as select ed tomo-

graphic height ”SH

” in the test certificate under section 12.

a

• Load film into an 18 cm x 24 cm casset te with high-resolution film -screen combination

and insert it into the spotfilm devi ce.

• Collimate the field size onto th e surface of the test phantom.

• Select the small focus ( ) and insert a 0.3 mm Cu filter into the collimator.

• Select the tomographic patte rn indicated in the test certif icate for the 1st exposure and

set the specified kV value and mAs value.

• Release a tomographic exposure and devel op the film.

The basic film density should be approx. D = 1 to 1.4.

• If necessary, repeat the ex posure with a different mAs value.

Siemens AG Register 4 RLL5-310.034.04 Page 1 of 2 UROSKOP D3

Medical Engineering Rev. 04 12.98 TD PS 24

Page 32

6 - 2 Checking the tomographic device

Accuracy of the tomographic height display 6

• The sharply delineated hole of t he definition test is located in the tomogra phic plane.

§16

• If the hole near the notch is delinea ted sharply, the numerically displ ayed tomographic

height SH

• In the case of deviations, dete rmine the height difference ∆ SH

sharply delineated hole and the not ch (the height difference from one hole to the other is

0.2 cm).

When the actual tomographic height is located above the notch, then

When the actual tomographic height i s located below the notch, then

• Determine and record the actual tomographi c height SH =SH

The deviation

coincides with the actual tomogra phic height SH, i.e. ∆ SHa = 0.

a

in mm between the

a

∆ SH

∆ SH

+ ∆ SHa.

a

∆ SH

must be ≤ 0.5 cm.

a

is positive.

a

is negative.

a

Resolution and tomographic procedure 6

Compare the test exposure made during sys tem st art- up at th e cust omer si te wit h t he corresponding test exposure made at the factory:

• Using a magnifying glass (min. 6x magnifi cation), determine and record the maximum

visible resolution of the te st exposures.

The resolution may not deviate from the resol ution of the factory test exposure by mor e

than one line group; the minimum resoluti on must be

≥ 2 Lp/mm.

• The shape and course of the tomographic patt ern and the evenness of the blurring on

the test exposure must be comparable to the fac tory test exposure.

§16

• Assessing the test exposures:

Compared with the resolution of the Bucky ex posure, the resolution of the tomographi c

exposure may not deviate by more than one li ne group.

The blurring shadows of the holes and line s must run in parallel over the ent ire range.

If this is not the case, the n the film path and the focus path are not i n parallel.

Wavy lines may be caused by oscillations in the s ystem.

• The different film densities of the imaged holes may be caused by grid inter ferences

(this cannot be avoided - it is not critical.)

UROSKOP D3 Register 4 RLL5-310.034.04 Page 2 of 2 Siemens AG

Rev. 04 12.98 TD PS 24 Medical En gineering

Page 33

NOTICE

Fluoroscopic dose rate 7

General 7

The following test measurements for the image quality test certificate ensure that the system is functioning correctly and that the factory settings have not changed.

Important: To recor d the measured values, use the IQ test certificate RXD0-

000.037.01... The paragraphs indicated in brackets in the following

text refer to this test certificate.

The test certificate is located in the UROSKOP D logbook, Register 9.

The customer’s address, system overview and the required measurement instruments

(para. 1, 1.1, 1.2 and 1.3) must be recorded.

Preliminary remarks 7

Basic information on the dose / dose rate measurement for I.I. workstations7

For dose measurement at the I.I. input (KB) or dose rate measurement at the I.I. input

), attach the dosimeter chamber as close as possible to the I. I. In the case of spotfilm

(K

B

devices, place it in the cassette shaft.

7 - 1

Press the emergency STOP button on the Uroskop.

If this is not possible, measure the dose (K

ating layers, on the tabletop.

The measured value is converted into the value at the I.I. input using correction factor m

(unit attenuation factor ).

The unit attenuation factor contains al l attenuating layers between patient, image and

receptor including the di stance fact or; it i s specifi ed in the test certificat es and can also be

determined by multiplying the attenuation factors of the individual layers.

A radiation attenuation of 6% by th e dose measurement chamber must al so be taken i nto

account (factor 0.94).

) or the dose ra te (KTg) in front of the attenu-

Tg

Determining the dose/dose rate directly at the I.I. input 7

Place the dose measurement chamber in the beam path (UROSKOP D2, D3) for measurement. After the ADC has stabilized, press the STOP button. Factor 0.94 does not

apply in this case.

Determining the unit attenuation factor from the indi vidual attenuation factors

Attenuation factor of tabletop, back panel spotfilm device etc. m

Attenuation factor of scattered radiation grid m

Attenuation factor of Iontomat chamber m

T

R

I

2

r

Distance factor attenuation factor mA =

Unit attenuation factor m = mT x mR x mI x mA . . . . . . .

Siemens AG Register 4 RLL5-310.034.04 Page 1 of 4 UROSKOP D3

Medical Engineering Rev. 04 12.98 TD PS 24

B

r

T

Page 34

7 - 2Fluoroscopic dose rate

Cu-Filter

Measurement chamber in front of attenuating layers

Tabletop or spotfilm device back panel

Grid

Unit

attenutation

factor

Iontomat chamber

Measurement chamber in I.I. plane (cassette shaft)

I.I. input

K

B/KB

K

Bg/KBg

K

Tg/KTg

r

B

r

T

= dose/dose rate directly at I.I. input

= measured dose/dose rate in I.I.plane

= measured dose/dose rate in front of attenuating layers

= source-image receptor distance

= distance between source and start of the attenuating layers

Formulas for calculating the dose/dose rate in the measurement plane for

dose/dose rate setting 7

During setting, the dose or dose rate required directly at the I.I. input must be converted

into the measuring plane (I.I. plane or in front of attenuating layers). Use the modified formulas to do this.

Dose Dose rate

Ionization chamber in I.I. plane K

Ionization chamber in front of

= K

Bg

B

KTg = KBg x m KTG = KB x m

attenuation layers

Remark: With Polydoros S and SX generators, radiation attenuation via the dose

measurement chamber is already taken into account duri ng setting (for

adjustment: move the dose measurement chamber out of the beam path).

Do not use factor 0.94 for calculating the dose rate to be set.

KBg = K

B

UROSKOP D3 Register 4 RLL5-310.034.04 Page 2 of 4 Siemens AG

Rev. 04 12.98 TD PS 24 Medical En gineering

Page 35

Fluoroscopic dose rate 7 - 3

NOTICE

Indirect dose rate test at the customer site 7

(Para. 4.1.2 Chapter 4)

Before setting different customer-specific fluoroscopic parameters, check via the indirect

dose rate test that the factory settings have not been changed and that the system functions properly.

- Select the operating conditions documented i n the IQ test certificate.

- Place 2.1 mm Cu (precision radiation filter 99 00 598) in the beam path.

- Open the collimator to maximum aperture.

- If the factory values (kV, mA) are obtained, tran sfer the dose rate values from tabl e

4.1.1 to table 4.1.2.

Notes on the acceptance test in Germany according to §16 RöV:

After programming the customer -specif ic fluoros copic parameters , the dose ra te for all FL

control stages and all I.I. formats must be measured and entered in the acceptance cer tif-

§16

icate together with the kV and mA values. Use 25 mm Al + 1.5 mm Cu as prefiltration.

The dose rate values measured with 25 mm Al + 1.5 mm Cu correspond to the values

measured with 2.1 mm Cu; the resulting kV and mA values are different.

Setting when the indirect dose rate is out of tolerance 7

(Para. 4.2.1 Chapter 4)

If the dose rate must be readjusted after repai r work etc., the dose rate measur ed must be

entered in the image quality test certificate under “Resetting the dose rate”.

Perform measurement of the dose rate and determination of the kV and mA values as

well as the documentation as described above.

Switch the dose meter on at least 15 minutes before measurement

and calibrate it.

Test conditions:

For dose rate measurements, program the anti isowatt curve (C00) to Fluoro 2 and then

perform the checks.

- Source-I.I. distance: 118 cm

- Attach 2.1 mm Cu to the collimator.

Sequence of work:

- Connect DVM to POLYDOROS D901 X2.1 and 7.

- Move the table into its center positi on so that table rails lie outside the beam path.

- Select full view I.I. format and open the coll imator to maximum aperture.

- In the”Adjustment” service program, set ”Ski ndoserate” to the maximum value, at

110 kV and 70 kV.

- Press the EMERGENCY STOP button.

- Place the measurement chamber in front of the I.I., measuring range 1.0 µGy/s, and

center it.

- Select ”Adjustment”/”Doserate”.

Siemens AG Register 4 RLL5-310.034.04 Page 3 of 4 UROSKOP D3

Medical Engineering Rev. 04 12.98 TD PS 24

Page 36

7 - 4Fluoroscopic dose rate

- Click on ”Start Measuring”.

- Increase the current until 876 µGy/s are reached and conf irm with ”ok”.

- Remove the measurement chamber.

- During fluoroscopy, the DVM must read 700 mV

distributor) (check with cl osed light distributor).

- Perform the adjustment.

- Exit the service program with ”Syst. di sconnect”.

Maximum skin dose rate 7

(Para. 4.4.2 Chapter 4)

Measure and record only if required by the country-specific regulations (USA, Canada).

- Full I.I. format

-Min. SID

- Cover I.I. to protect it from radiat ion (protects input layer of I.I.) and remove the fuses of

the I.I. power supply (TV-camera).

- Position the dose measurement chamber 30 cm above the tabletop.

- Ensure that the dose measurement chamber is exposed complete ly.

- Measure the resulting dose rate at all ADC cont rol stages.

- In each case, record the kV and mA values produced (di splay of the generator

console).

± 35 mV; adjust with D100/R1 (in light

DHHS

During start-up, perform measurements for all control stages described above that have

not yet been checked at the factory (customer-specifi c ADC control system parameters).

Enter the ADC control system parameters already checked at the factory fr om table 4.4. 1

in 4.4.2.

Notes on the acceptance test in USA and Canada according to DHHS regulations:

Use the maximum skin dose rate val ues obtained at the factory and during st art-up for the

acceptance test certificate.

UROSKOP D3 Register 4 RLL5-310.034.04 Page 4 of 4 Siemens AG

Rev. 04 12.98 TD PS 24 Medical En gineering

Page 37

Television system 8

Function check of ambient light sensor 8

- Switch on the ambient light sensor.

- Cover the ambient light sensor with your hand:

The monitor image must visually change .

- Switch off the ambient light sensor again.

- Perform all other IQ checks with the ambient l ight sensor switched off.

B-signal values (without bias light/dark current component) 8

(Para. 5.3.1 Chapter 5D)

Notice:

Measure the B-signal with expanded t ime base ( greater accur acy of measur ement) in the

line center and noise center of a line in the image center (Fig.1).

Test conditions:

- Insert the grid

- Source-I.I. distance: 118 cm

- Attach prefiltration of 2.1 mm Cu to the co llimator

8 - 1

Sequence of work:

- Switch on fluoroscopy, select or progra m antiisowatt curve C00

- Measure and record the B-signal for all I.I. formats

Table 5.3.2 (without bias li ght/dark current component)

- Switch off fluoroscopy

.

Notes:

During repeat measurements, th

e B-signal values may drop by up to

15 mV compared to the values measured when setting the iris diaphragm

depending on the system. In this case,

repeat the setting and taking the measured deviation into consideration,

remeasure and record the results.

Noise center,

line center

Siemens AG Register 4 RLL5-310.034.04 Page 1 of 2 UROSKOP D3

Medical Engineering Rev. 04 12.98 TD PS 24

Page 38

8 - 2 Television system

Image artifacts (Para. 5.10 Chapter 5D) 8

- Mark all image artifacts which are detected dur ing setting and image quality tests in

the table in the image quality test certificate. The test point s listed in the table indicate

measurements in which each artifact gener ated is stronger and/or can be better

evaluated.

- If any image artifacts are detected which are no t listed in the table, these must be

described under ”Other artifa cts”.

- To assess the respective artifacts, ther e are three rating numbers which indicate the

extent of each artifact:

Definition of the rating numbers:

1 =No artifacts could be determined during start-up.

2 =A few artifacts occurred sporadically during start-up. The cause could not be located

and the”error” could not be corrected. The artif acts do not adversely affect the overall

appearance of the images and do not compromise the diagnostic value of the images

in any way. The artifacts are determined to be tolerable.

3 =During start-up, artifacts of greater severity occurr ed frequently and they negatively

influenced the overall appearance of the images or compromised their diagnostic

value. Therefore, the artifacts were determined to be intolerable and the system could

not be turned over to the customer.

Description of the artifacts

- Hum:

Inhomogeneity caused by electromagnet ic fields in imaging systems. This ar tifact may

significantly influence the diagnostic value of the images depending on the type of

interference. Ideally , this artifact should not occur at all. However, extremely low level s

can be tolerated. Hum artifacts appear as periodic, horizontal bright and dark

structures in the image; they appear randomly and are not specific to one locati on.

- Streaks:

Very high-frequency electromagneti c fields appear in the image as bright or dark,

sometimes very short, tr ansverse streaks in the image. They are t ransient. Streaks

caused by contaminants on the surfaces of lenses, etc. should be included in t his

group. In this case, they are spe cific to one location and are const ant. Streaks are

unacceptable.

- Fraying:

Fraying is caused by strong black-whi te transitions due to ”overmodulated ” video

amplifiers. The object edge is ”d istorted” laterally t o the right. Slight fraying on t he

black-white step can be tolerated.

- Ghosting:

These artifacts are object c ontours displayed twice, with the sec ond contour generally

shifted laterally. They are caused by reflections in long, poo rly adjusted video cables.

Clearly visible ghosting is unacceptable.

- Microphonics:

Microphonics is caused by mechanical oscillations (rotating anode r unning, etc.)

which are transferred to the TV camera, i nfluence the deflection field s of the electron

beam and mostly display very regular interference structures simil ar to those

generated by electromagnetic hum inter ferences in the TV image. Microphonics is not

acceptable.

UROSKOP D3 Register 4 RLL5-310.034.04 Page 2 of 2 Siemens AG

Rev. 04 12.98 TD PS 24 Medical En gineering

Page 39

NOTICE

Digital Fluoro Radiography/FLUOROSPOT H 9

General information and remarks 9

Unless otherwise indicated, the FLUOROSPOT is always enabled

(no bypass) for the following tests.

Use organ programs as indicated; or generate them, if necessary.

List deviations next to the corresponding test point.

Organ programs for test purposes

Fluoro program:

For image quality acceptance test

Name: Fluoro program

edge enhancement (%): 0

filter coefficient: 0

window upper limit: 511

window lower limit: 256

bone display: black

Image: no

motion detection: not enabled

noise filtra ti on (%):

9 - 1

DR single image:

For image quality acceptance test

Enter dose value according to test conditions.

Name: DR single

kV: manual

kV manual: 70

dose: 100

exposure data from fluoro: no

edge enhancement (%): 0

filter coefficient: 0

window upper limit: 511

window lower limit: 256

bone display: black

Image: no

organ curve: manual-kV selected

kV for dose reduction: manual-kV selected

maximum x-ray pulse width (ms): 3000

blackening correction: 0.0

focus: small

Siemens AG Register 4 RLL5-310.034.04 Page 1 of 20 UROSKOP D3

Medical Engineering Rev. 04 12.98 TD PS 24

Page 40

9 - 2 Digital Fluoro Radiography/FLUOROSPOT H

DR series:

For image quality acceptance test

name: DR series

kV: manual

kV manual: 70

dose: 100

exposure data from fluoro: yes

frames per second: 0.5 (1) (8)

maximum x-ray pulse width (ms): 1000 (800) (65)

scene length (sec: 10s

edge enhancement (%): 0

filter coefficient: 0

window upper limit: 511

window lower limit: 256

Bone display: black

Image: no

organ curve: manual kV selected

kV for dose reduction: 109

stop mode of generator: no

blackening correction: 0.0

focus: small

delta kV: fixed focus selected

UROSKOP D3 Register 4 RLL5-310.034.04 Page 2 of 20 Siemens AG

Rev. 04 12.98 TD PS 24 Medical En gineering

Page 41

Digital Fluoro Radiography/FLUOROSPOT H9 - 3

DSA:

For image quality acceptance test

Enter dose value and frame rate according to test conditions.

Name: DSA

kV: manual

kV manual: 70

dose: 100 (200), (500)

exposure data from fluoro: yes

frames per second: 1/0,5/8 (1/6), (1/6/8)

scene length: 10s (10), (5)

native display

edge enhancement (%): 0

filter coefficient: 0

window upper limit: 511

window lower limit: 256

bone display: black

subtracted display

edge enhancement (%): 0

filter coefficient: 0

window center (W1): 80

contrast (W2): 220

Image: no

organ curve: manual kV selected

kV for dose reduction: 109

blackening correction: 0.0

focus: large

delta kV: fixed focus selected

Siemens AG Register 4 RLL5-310.034.04 Page 3 of 20 UROSKOP D3

Medical Engineering Rev. 04 12.98 TD PS 24

Page 42

9 - 4 Digital Fluoro Radiography/FLUOROSPOT H

Image quality test exposures

The following images are stored on har d disk (HD) for syst ems pret ested at th e facto ry as

a reference for the field service techni cian for system start-up.

Compare the test images taken during start-up at the customer site with the test images

taken at the factory. This will allow you to detect and eliminate any deviations (e.g. deviations which have occurred since the factory test).

Name (Pat)

name

DR_Ramp MP 8.2 (SS off) Single / DR expos. => store 1 image

DSA_Ramp MP 8.2 (SS off) DSA series => save 1-2 images (precon-

LIH_Dyn MP 8.5 (Temp=0) LIH => store monitor

DR_Dyn MP 8.5 (

LIH_Resol MP 8.7 (Temp=0) LIH => store monitor for each I.I. format

DR_Resol MP 8.7 (

DSA_Resol MP 8.7 (1/100) DSA series with each I.I. format

DSA_Dyn I MP 8.9 (1/500) DSA series => store 2 images,

DSA_Dyn II MP 8.9 (6/200) DSA series => save 2 images

DR_HOM MP 8.10 (

DSA_HOM I MP 8.10 (1/500) DSA series with solder tin cross

DSA_HOM II MP 8.10 (6/200) DSA series with solder tin cross

Type of examination

Identification

− / 100) Single/DR expos. => store 1 image

− / 100) Single/DR expos. with each I.I. format

− / 100) Single/DR expos. with solder tin cross

(Remarks on storage)

trast), delete remaining images of the series

Save 1-2 images per series (precontr ast) and

delete remaining images

(mask, filling);

delete remaining images of the series

(mask, filling);

delete remaining images of the series

=> save 2 images (mask, filling);

delete remaining images of the series

=> save 2 images (mask, filling);

delete remaining images of the series

UROSKOP D3 Register 4 RLL5-310.034.04 Page 4 of 20 Siemens AG

Rev. 04 12.98 TD PS 24 Medical En gineering

Page 43

Digital Fluoro Radiography/FLUOROSPOT H9 - 5

CAUTION

Dose/pulse test during start-up (indirect dose check) 9

(Para. 8.1.2 Chapter 8A)

No additional filtration must be selected on the multileaf collimator . The dosimeter must be switched on for at least 15 minutes

and calibrated.

The "indirect dose check" is a simple procedure used during system start-up to check

whether the dose values set and recorded at the factory have changed.

For the ”indirect dose check”, place a 2.1 mm Cu filter (precision radiation filter

99 00 5988) in the beam path and measure the mAs value per pulse (Qg/n) with the collimator at maximum aperture. Subsquently, compare the values with the mAs value per

pulse measured at the factory.

For each measurement, set the same o perating parameter s as used at the f actory (IQ test

certificate, page 6-1); (refer also to dose/pulse, page 9-5 to 9-7).

The test conditions and preparations are the same as described under 8.3.1, but without

the dosimeter. The notes and test procedure provided under 8.1.1 apply.

If the results of the i ndire ct dos e test matc h the f act ory val ues f or mAs/p uls e (recor ded on

page 6-1 of the IQ test certif icate) , transfer the dose values from the t ables on page 6-1 to

the tables on page 6-2. If the mAs values deviate by more than

values with identical tube voltage, measure the dose/pulse again as described on page

9-5.

± 15% from the factory

§16

Notes on the acceptance test in Germany according to § 16 RöV:

Enter the measured dose values/pulse in the acceptance test certificate.

The dose values measured

25 mm Al + 1.5 mm Cu. The mAs values/pulse that depend on the prefiltration are not

enteed into the acceptance test certificate.

with 2.1 mm Cu correspond to the values produced with

Siemens AG Register 4 RLL5-310.034.04 Page 5 of 20 UROSKOP D3

Medical Engineering Rev. 04 12.98 TD PS 24

Page 44

9 - 6 Digital Fluoro Radiography/FLUOROSPOT H

BA (video+blanking) signal values / setting the iris diaphragm in

DR operation

(Para. 8.4.2 Chapter 8A)

Test conditions and preparations:

- Source-I.I. distance: 118 cm

- Attach 2.1 mm Cu prefiltration to the collimat or

- I.I. format: 22 cm, 23 cm, 27 cm or 28 cm

- Connect oscilloscope: CH1 to FLUOROSPOT output (video output/Live= Trans.panel

TP5.

Sequence of work:

BA-signal with LIH with Fluoro 1:

- Select fluoro program on the FLUOROSPOT as described on page 9-1: W1 = 511, W2

= 256, etc.

- Switch on dig. FL with Fluoro 1 (C00) and record the st abilized kV value (Ua); FL OFF.

- Measure and record the BA-signal for LIH:

Select a line in the image center (line 256 / 60 Hz, line 312 / 50 Hz); measure th e level

in the line center and noise center.

BA-signal with DR exposures:

- Select DR organ program on the FLUOROSPOT as described on page 9-1: 70 kV, W1

= 511; W2 = 256, etc.

- To ensure that dose control and iris control are interacting properly, make the f ollowing

consecutive exposures and measure and record the BA-signal respectively at the

FLUOROSPOT output:

9

DR single image - dose 50; dose 100, dose 200

DR series with 0.5 f/s - dose 50, dose 100; dose 200

DR series with 8 f/s - dose 50, dose 100, dose 200

- In each case trigger fluoroscopy brief ly before releasing the exp osure.

Remarks: There is only one iris correction value for all indicated DR modes. For

single images and dose 100, set the BA-signal as precisely as possible

to the nominal value to maintain the tolerances for all modes.

- Record the iris correction value for the DR exposur es.

Start-up of systems at the customer site:

When starting-up prestaged systems, check only the BA-signals for dose step 100. The

values must be within the tolerances specified in t he li st of nominal values. If the tolerances are not maintained, the iris correcti on value must be changed and the whole measurement series must be repeated.

UROSKOP D3 Register 4 RLL5-310.034.04 Page 6 of 20 Siemens AG

Rev. 04 12.98 TD PS 24 Medical En gineering

Page 45

Digital Fluoro Radiography/FLUOROSPOT H9 - 7

CAUTION

Dynamic test 9

During measurements with the dynamic test, no additional filter

must be selected on the multileaf collimator. The nominal values

refer to a tube voltage of 70 kV.

Amplitudes/ Setting the iris diaphragm for DSA mode

- The BA-signal amplitudes of the different at tenuation levels of the dynamic test are

measured at the FLUOROSPOT output with a tube voltage of 70 kV. The requi red

video+blanking levels are obtai ned by correctly adjusting the iris di aphragm.

Remarks: The iris diaphragm has already been adjusted for FL mode (test point

5.3) and for DR exposures (test point 8.4) with a homogeneous

(2.1-mm Cu) phantom and may not be changed. Adjust the iris diaphragm with the dynamic test for DSA mode.

Test conditions and preparations:

- Source-I.I. distance:

OT units = 115 cm

- Grid inserted

- I.I. format: 22 cm, 23 cm, 27 cm or 28 cm

- Attach dynamic test close to the I.I. (wit h heart contour diaphragm and new capi llary

displacement test, part no. 97 50 019).

OT units - on the tabletop

Remarks: For UROSKOP D3, position the dynamic test approx. 25 cm above the

tabletop so that the ring-shaped dominant is located in field 1.

The dynamic test must be displayed on the monitor as shown in Fig.1; if necessary,

change the position of the guide ra ils on the test.

- Connect oscilloscope: CH1 to FLUOROSPOT output (video output/Li ve) = Trans.

panel TP5.

Procedure:

Amplitudes with LIH: - Select fluoro program on the FLUOROSPOT as described

on page 8-1: W1 = 51 1, W2 = 256, etc.

- Switch on dig. FL with Fluoro 1 (C00). Center and coll imate

the dynamic test (Fig.1). After collimating, release f luoroscopy for a short time (approx. 5 s) unti l the ADC has adjusted.

Siemens AG Register 4 RLL5-310.034.04 Page 7 of 20 UROSKOP D3

Medical Engineering Rev. 04 12.98 TD PS 24

Page 46

9 - 8 Digital Fluoro Radiography/FLUOROSPOT H

Remarks: The nominal values for the BA amplitudes with LI H can be obtai ned only

if the AGC measurement field is covered completely by the 1st field of

the dynamic test. This is assured by the AGC measuring field size (progressive) marked in 5.6.1.

If the AGC measurement field exceeds the 1st field, shift the dynamic

test until the 2L field is safely outside the AGC measurement field and

only the 5R field projects into the AGC measurement field.

The 5R field does not distort the measurement as much as the 2L field.

This applies to the rectangular ADC measurement field as well.

Do not undercollimate the ADC measurement field so that the dose values for the exposure match.

AGC measuring field

Collimation size

Collimator

Collimation size

Collimator

- For LIH, measure and record the BA-signal amplitudes of fi elds 2L, 1 and 5R of the

dynamic test: Measure a line in the appro x. image center (approx. line 256) and noise

center.

AGC measuring field

Collimation

size

Collimator

UROSKOP D3 Register 4 RLL5-310.034.04 Page 8 of 20 Siemens AG

Rev. 04 12.98 TD PS 24 Medical En gineering

Page 47

Digital Fluoro Radiography/FLUOROSPOT H9 - 9

CAUTION

BA-signal output

FLUOROSPOT

Line in image center

Important: Do not measure on a line which is covered by a capillary. To ensure

this, move the expanded time base back and forth by a few lines;

the amplitude should not change. A capillary reduces the BA-signal.

- Record the resulting kV value (Ua). If t he value deviates from 70 kV, the dynamic