Page 1

Koellner

UROSKOP ACCESS

Installation Instructions

System

SP

System

0575612205756130

Print No.:

Replaces: SPL5-330.812.01.07.02

SPL5-330.812.01.08.02

© Siemens AG

The reproduction, transmission or use

of this document or its contents is not

permitted without express written

authority. Offenders will be liable for

damages. All rights, including rights

created by patent grant or registration

of a utility model or design, are

reserved.

English

Doc. Gen. Date: 01.06

2004

Page 2

2 Revision / Disclaimer

1Revision / Disclaimer

Document revision level

The document corresponds to the version/revision level effective at the time of system

delivery. Revisions to hardcopy documentation are not automatically distributed.

Please contact your local Siemens office to order current revision levels.

Disclaimer

The installation and service of equipment described herein is to be performed by qualified

personnel who are employed by Siemens or one of its affiliates or who are otherwise

authorized by Siemens or one of its affiliates to provide such services.

Assemblers and other persons who are not employed by or otherwise directly affiliated

with or authorized by Siemens or one of its affiliates are directed to contact one of the

local offices of Siemens or one of its affiliates before attempting installation or service procedures.

UROSKOP ACCESS SPL5-330.812.01.08.02 Siemens AG

01.06 CS PS SP

Page 2 of 90

Medical Solutions

Page 3

Table of Contents 3

1- 0Table of Contents

1 _______ Prerequisites / Notes _____________________________________________ 5

Prerequisites. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Required aids and tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Required documents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Room preparations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Safety information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Product-specific notes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Completing the installation certificate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Tolerance data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Tightening torques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Colors used. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2 _______ Lifting base_____________________________________________________ 9

Installation preparations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Accessories for the lifting base . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Installing the transport rollers on the lifting base . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Positioning and installing the lifting base . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Checking the safety switch (back of the lifting base) . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3 _______ Unit carrier ____________________________________________________ 17

Installation on the lifting base . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Installation of power supply module (M1). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Unit transformer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Wiring of M1/M2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Installation of image intensifier I.I 33/I.I. 40 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Reading the temperature indicators on the I.I. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4 _______ Multileaf collimator _____________________________________________ 26

Installing the collimator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5 _______ TFT monitor support arm ________________________________________ 28

Installing the TFT support arm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

6 _______ Cabling _______________________________________________________ 35

General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Labeling of the cable harnesses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

List of fixed points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

POLYDOROS SX65/80 cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Overview: cable connection and cable layout in the generator cabinet . . . . . . . . . . 39

Generator power connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Connecting the rotating anode cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Siemens AG SPL5-330.812.01.08.02 UROSKOP ACCESS

Medical Solutions

01.06 CS PS SP

Page 3 of 90

Page 4

4 Table of Contents

Connection of the Iontomat measuring chamber. . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Connection of the HV trigger/gray filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

XCU cable connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Inserting the high-voltage transformer into the generator cabinet. . . . . . . . . . . . . . . 43

Connecting the high-voltage cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Connecting the primary cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Monitoring devices and displays for radiation protection. . . . . . . . . . . . . . . . . . . . . . 46

Connecting the ground wires. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Monitors in the control room . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Systems without a urodynamics interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Systems with a urodynamics interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Explanations of the various monitor types. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

FLUOROSPOT Compact imaging system container . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Mouse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Keyboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Laser printer connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Back of the imaging system PC (cabling only as an example) . . . . . . . . . . . . . . . . . 53

Cabling of the imaging system container. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Board D1 (BUC) - connector overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Cable harness installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

W100 system (tube assembly) - POLYDOROS SX . . . . . . . . . . . . . . . . . . . . . . . . . 59

W150 system (I.I.) - POLYDOROS SX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Additional cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

W360 unit (M1) - control console (M11) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

W400 system (M1) - POLYDOROS SX. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

W600 POLYDOROS SX - imaging system container . . . . . . . . . . . . . . . . . . . . . . . . 60

W650 imaging system container - TFT support arm . . . . . . . . . . . . . . . . . . . . . . . . . 61

Data printer connection (label printer, optional). . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Remote control panel cabling (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Installing the endo shelf (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Right-hand version of the endoscopy shelf . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Left-hand version of the endoscopy shelf . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Installing the endo shelf on the unit carrier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Endoscopy interface connection (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Connecting the foot switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

ASPIA imaging system container . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Mouse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Keyboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Laser printer connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Back of the imaging system PC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Cabling of the imaging system container. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

7 _______ Final work steps (covers) ________________________________________ 78

Covers for the imaging system container . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Lifting base covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

8 _______ Changes to Previous Version _____________________________________ 88

UROSKOP ACCESS SPL5-330.812.01.08.02 Siemens AG

01.06 CS PS SP

Page 4 of 90

Medical Solutions

Page 5

Prerequisites / Notes 5

1Prerequisites / Notes

2-

Prerequisites 0

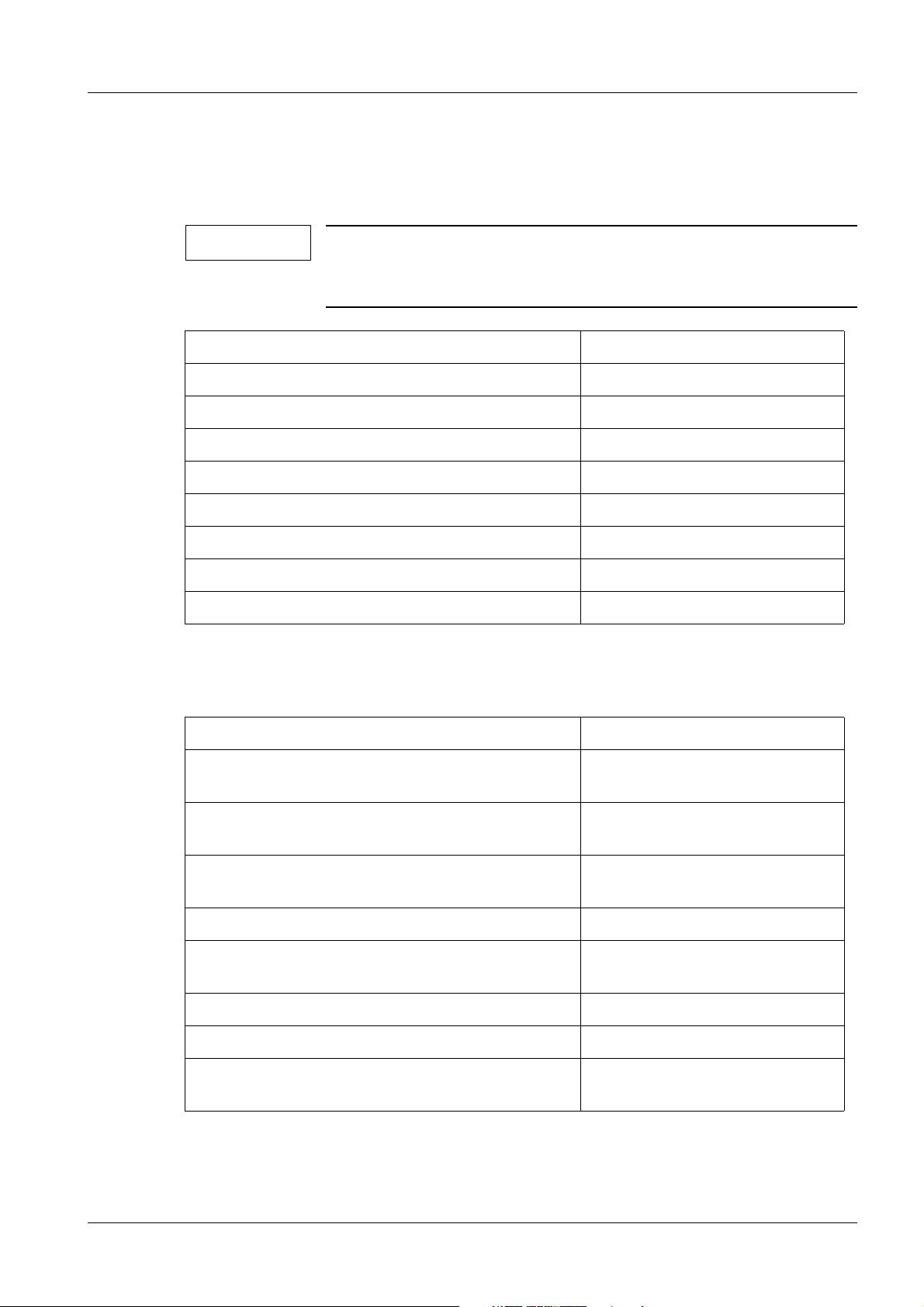

Required aids and tools 0

NOTE

All listed tools and measuring and auxiliary equipment except for

the customary installation tools are listed in the Service Tools Catalogue (as part of the Spare Part Catalogue).

Drilling machine with a tapping drill n.a.

Torque wrench 20-100 Nm 44 30 906 RH090

Torque wrench 40-200 Nm 80 86 142 RE999

Socket head insert, 14 mm 52 66 564

Loctite 221 n.a.

Silicon oil, AK350 17 87 035

Masonry drill (diameter d = 18 mm) n.a.

Transport rollers 11 53 654 G5338

Level (measuring accuracy: 1.0 mm/m) n.a.

Required documents 0

Installation and Start-up; Installation of options SPL5-330.814.02.xx

Installation and Start-up; Urodynamic Inter-

SPL5-330.814.01.xx

face/Scan Converter

Installation Certificate; Service Provider Documen-

SPL5-330.813.01.xx

tation

Installation Instructions for the UROSKOP Access

TFT Support Arm System (Ondal)

1519892/01-2005 (print number

from the manufacturer Ondal)

Project plan n.a.

Wiring Diagram SPL5-330.844.91.01.02 (57 56

130-EFS-01A)

Planning Guide; System; UROSKOP Access (e) SPL5-330.891.01.xx

UROSKOP ACCESS; Help File FLC SPL5-330.880.01.xx

X-Ray Diagnostic System; Installation Instruction;

RX0-000.031.01.xx

High voltage cable RH 098-5DF6 071

Siemens AG SPL5-330.812.01.08.02 UROSKOP ACCESS

Medical Solutions

01.06 CS PS SP

Page 5 of 90

Page 6

6 Prerequisites / Notes

Room preparations 0

• The floor covering must be removed in the area of the base plate and the transformer

trough.

• The lifting base and the transformer trough must be mounted directly on the concrete

floor.

- PVC or tiling must be removed first.

UROSKOP ACCESS SPL5-330.812.01.08.02 Siemens AG

01.06 CS PS SP

Page 6 of 90

Medical Solutions

Page 7

Prerequisites / Notes 7

Notes 0

• This document was originally written in German.

Safety information 0

Mechanical safety information

CAUTION

Risk of injury from mechanical parts!

If not observed, minor to more severe injury, especially to the

hands, can occur. After the covers are opened, parts such as flat

plugs, threaded bolts, cut-off cable ties and component edges are

exposed, and if care is not taken, they can cause crushing,

scrapes and cuts to the skin, particularly to the hands.

¹ Perform the required work with special care and atten-

tion to detail.

¹ If necessary, wear work gloves.

Product-specific notes 0

CAUTION

Risk of the unit carrier tipping!

Pushing on the longitudinal sides of the unit carrier when using

the transport frame and transport rollers to transport the unit carrier can result in tipping.

¹ Push the unit carrier on the front sides and not on the

longitudinal sides.

NOTE

Handle the TFT monitors with care. The monitors at the Uroskop

Access do not have touch screen functionality so that pressing on

the display surface could result in irreversible damage.

• Checking the cabling and power connection

- For safety reasons the power connection may be made only by the SIEMENS service engineer/electrician.

- The complete cabling must also be inspected by the SIEMENS service engineer before the system is switched on.

Completing the installation certificate 0

• Document “Installation Certificate; Service Provider Documentation“

(SPL5-330.813.01.xx) is to be filled out by the responsible service provider at the time

of installation and wiring. The installation result must be confirmed by signature of the

Siemens AG SPL5-330.812.01.08.02 UROSKOP ACCESS

Medical Solutions

01.06 CS PS SP

Page 7 of 90

Page 8

8 Prerequisites / Notes

responsible service provider and the project manager. Both the responsible service

provider and the person responsible for the project should receive a copy. The installation certificate is to be provided to the office specified in the document.

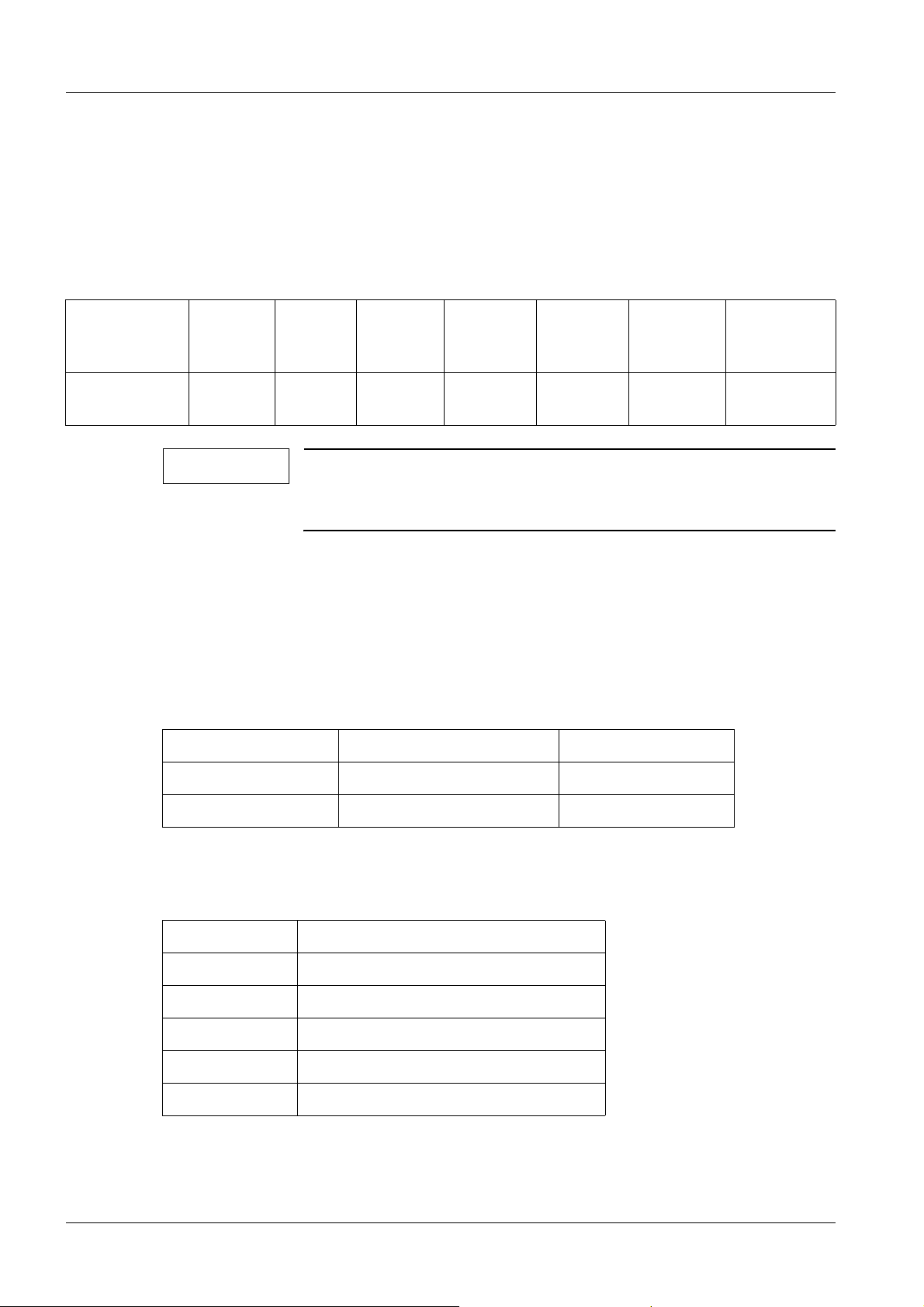

Tolerance data 0

General tolerances for length dimensions according to ISO 2768

Limits of nominal size range

Admissible tolerance

over 3

mm to 6

mm

± 0.5 mm ± 1 mm ± 1.5 mm ± 2.5 mm ± 4 mm ± 6 mm ± 8 mm

NOTE

over 6

mm to

30 mm

These tolerances apply to all dimensions indicated in these instructions, unless other tolerances are specifically indicated after

the value.

over 30

mm to

120 mm

over 120

mm to 400

mm

over 400

mm to

1,000 mm

over 1,000

mm to

2,000 mm

over 2,000

mm to 4,000

mm

Tightening torques 0

• In the case of the tightening torque, a tolerance of ±10% is permissible.

Colors used 0

White Basic unit Part no. 34 42 472

Light Basic Unit Base Part no. 55 06 865

Medical Blue Emphasized areas Part no. 55 06 857

Abbreviations 0

IS Imaging system

II Image intensifier

FLC FLUOROSPOT Compact

TV Television

ISK Allen screw

LAN Local Area Network

UROSKOP ACCESS SPL5-330.812.01.08.02 Siemens AG

01.06 CS PS SP

Page 8 of 90

Medical Solutions

Page 9

Lifting base 9

2Lifting base

3-

Installation preparations 0

Accessories for the lifting base 0

• The lifting base comes with the following installation accessories:

- 6 anchors HSL-3 M12/50

- 6 anchors HSL-3 M12/100

- 6 plate washers

- Caps for the floor plate

-Shims

- Drilling template

Siemens AG SPL5-330.812.01.08.02 UROSKOP ACCESS

Medical Solutions

01.06 CS PS SP

Page 9 of 90

Page 10

10 Lifting base

Installing the transport rollers on the lifting base 0

Fig. 1: Transport frame

• Fasten the 4 transport rollers to the transport frame via 2 Allen screws M12x25 and

washers per transport roller (Fig.1/p.10).

• Unscrew the lifting base from the pallet.

• Move the transport rollers down to just above the floor.

• Bring the lifting base into the examination room.

NOTE

The 4 Allen screws M 12 x 40 mm (3/Fig. 3 / p. 12) are required for

leveling the lifting base.

UROSKOP ACCESS SPL5-330.812.01.08.02 Siemens AG

01.06 CS PS SP

Page 10 of 90

Medical Solutions

Page 11

Lifting base 11

Positioning and installing the lifting base 0

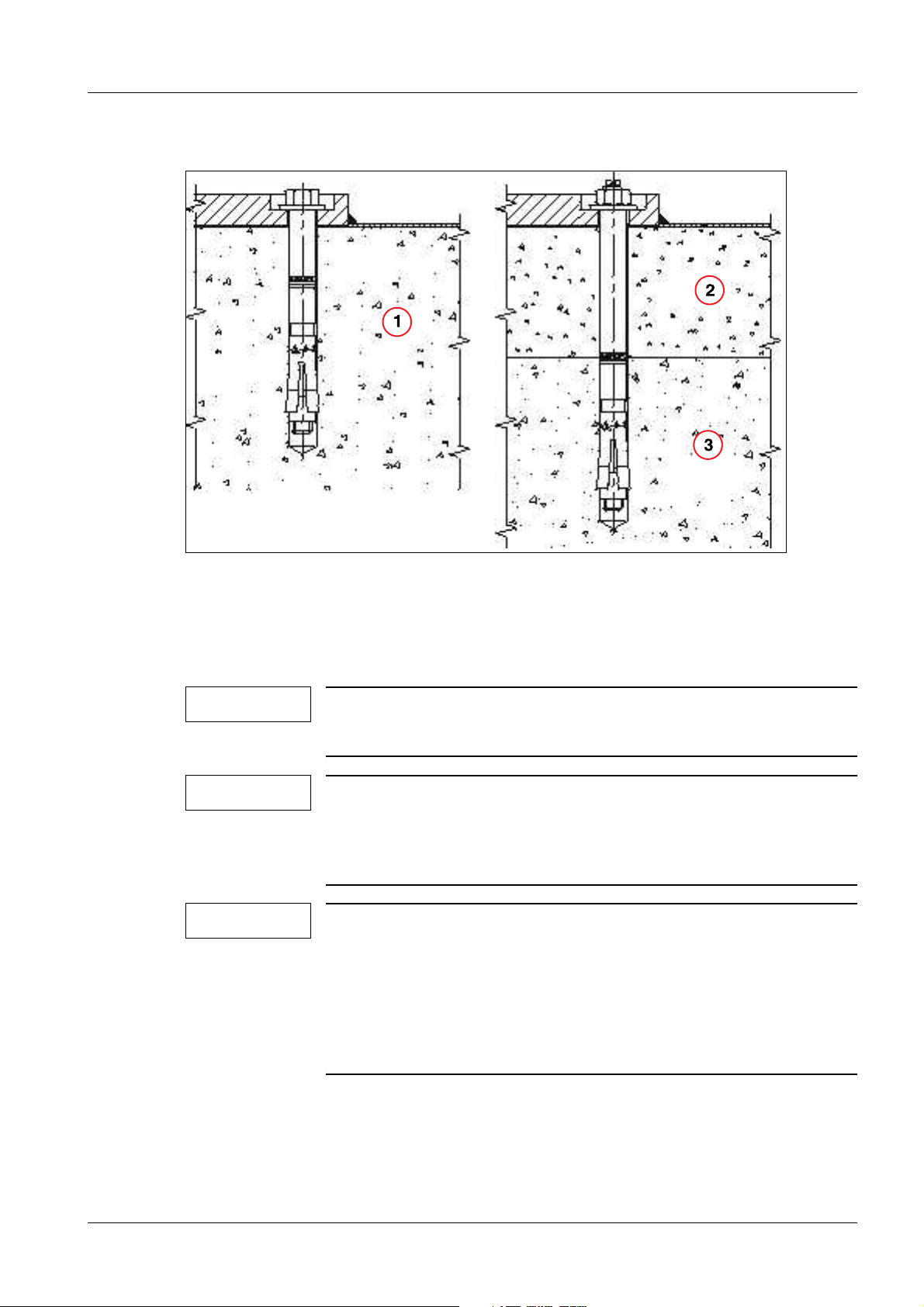

Fig. 2: Lifting base installation

Pos. 1 Concrete

Pos. 2 Screed

Pos. 3 Concrete

NOTE

Installation directly on concrete: (1/Fig.2/p.11)

Use anchors HSL-3 M12/50

NOTE

Installation in the case of a concrete filling when a floor topping

and insulating layer were not used: (2/Fig.2/p.11),

(3/Fig.2/p.11)

Use anchors HSL-3 M12/100

NOTE

The relevant type of safety anchors must be installed according to

the floor condition (also refer to the project plan).

If installing on an installation frame, M12 screws with strength

class 8.8 must be provided by the customer. When installing with

a drilled-through floor, M12 threaded rods with strength class 8.8

must be provided by the customer. Use the supplied washers with

screws or threaded rods. Secure screws or nuts with Loctite 221.

Example of a base plate with a lefthanded design

Siemens AG SPL5-330.812.01.08.02 UROSKOP ACCESS

Medical Solutions

01.06 CS PS SP

Page 11 of 90

Page 12

12 Lifting base

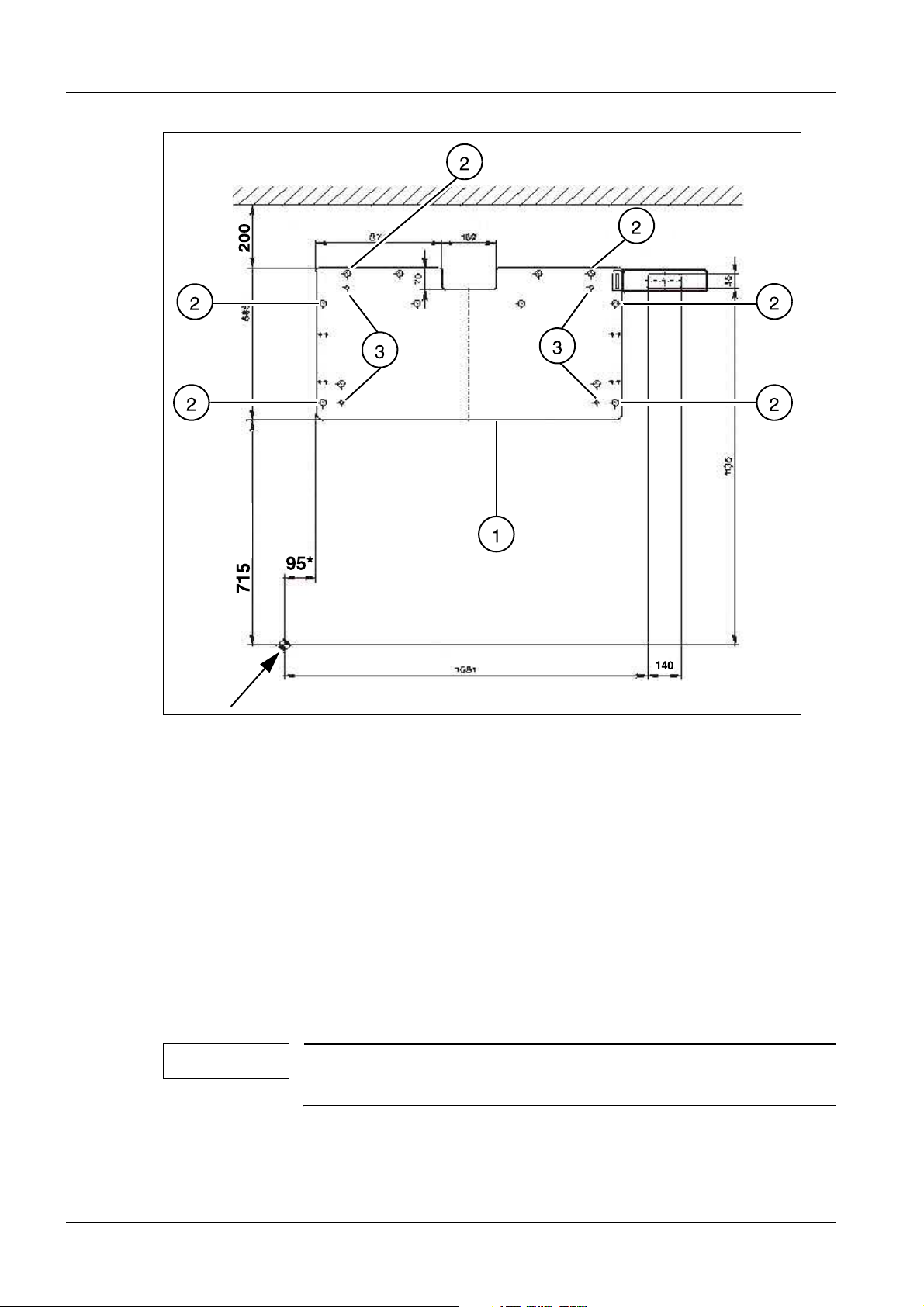

Fig. 3: Left-hand version of the base plate

• Mark the orientation point on the floor according to the project plan (see arrow,

(Fig.3/p.12)).

• Position the drilling template (1/Fig.3/p.12) according to the orientation point and

mark the positions of the 6 holes (2/Fig.3/p.12).

- Use alternative holes if necessary.

• Drill the holes at the marked positions.

• Vacuum the drilling dust out of the holes.

• Position the lifting base above the drilled holes and move it down.

• Insert the anchors in the drilled holes.

• Unscrew the transport rollers and transport holders from the lifting base.

NOTE

The lifting base may only be installed on a concrete floor. Any

flooring, e.g., PVC or tiling, must be removed.

UROSKOP ACCESS SPL5-330.812.01.08.02 Siemens AG

01.06 CS PS SP

Page 12 of 90

Medical Solutions

Page 13

Lifting base 13

NOTE

The transformer trough may only be installed on the concrete

floor. Any flooring, e.g. PVC or tiling, must be removed.

Fig. 4: Base plate

Pos. 1 Safety anchors

Pos. 2 Level

Pos. 3 Shims

Fig. 5: Lifting base transport safety device

Pos. 1 Allen screws

Pos. 2 Allen screws

Pos. 3 Allen screws

• Screw in the leveling screws (M12 x 40) (3/Fig.3/p.12) and align the lifting base with

the aid of a level (2/Fig.4/p.13).

• Place the supplied shims as required underneath the outer edges of the base plate

(3/Fig.4/p.13).

• Place the shims along the opening in the middle of the base plate as needed.

• Loosen the leveling screws (3/Fig.3/p.12).

• Tighten the anchors or screws to check the leveling. Use a level to check the levelling

(2/Fig.4/p.13), if necessary add or remove shims until the base plate is longitudinally

and horizontally in the 0° position.

NOTE

T • Only when leveling is correct in a tightened state can the safety anchors be tightened

with a torque of 80 Nm (1/Fig.4/p.13).

The base plate must not tilt to the front in the direction of the orientation point under any circumstances. The lifting base may,

however, tilt slightly to the rear (max. 0.5°).

• To remove the transport safety device from the lifting base, unscrew the Allen screws

and then remove the transport safety device (1,2,3/Fig. 5 / p. 13).

Siemens AG SPL5-330.812.01.08.02 UROSKOP ACCESS

Medical Solutions

01.06 CS PS SP

Page 13 of 90

Page 14

14 Lifting base

NOTE

The transport safety device can be relieved by lowering the lifting

base with a ratchet (counterclockwise) (1/Fig.6/p.14).

NOTE

Screw (3/Fig.5/p.13) is located on the bottom of the transport

safety device.

• Screw the M12 x 30 screw (3/Fig.5/p.13) back into threaded hole of the gear box.

Fig. 6: Relieving the transport safety device

Pos. 1 Ratchet

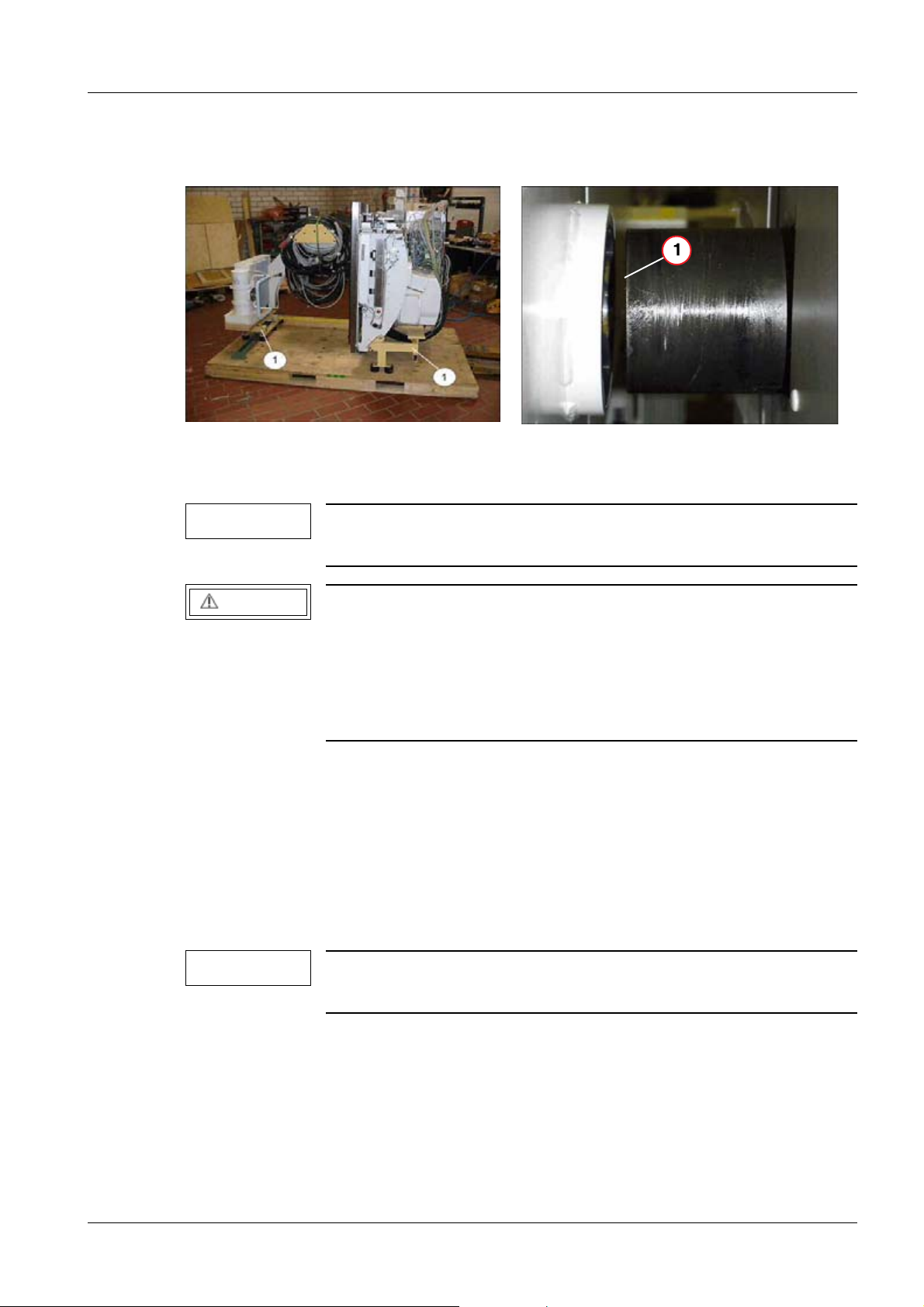

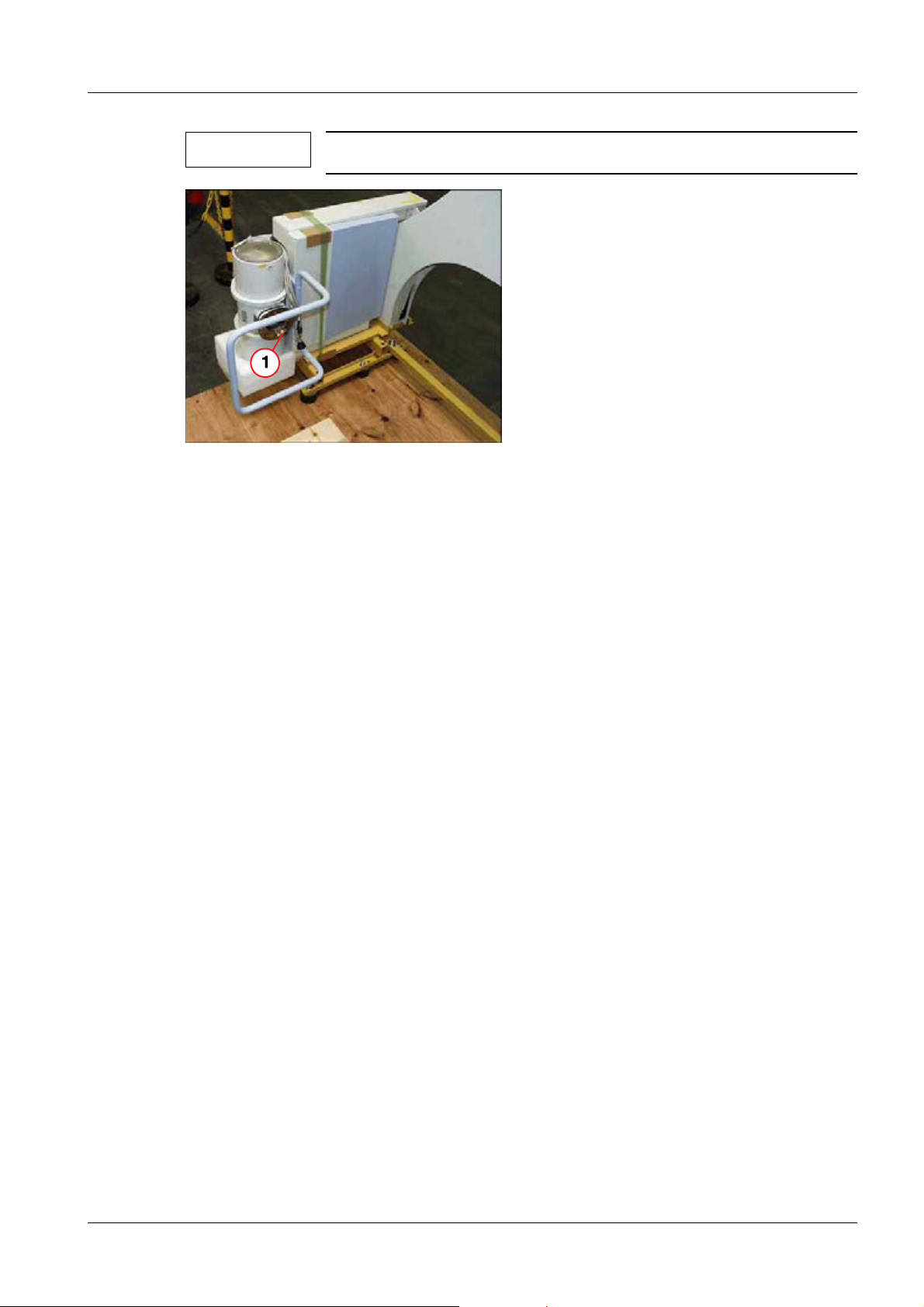

Fig. 7: Removing the system transformer

Pos. 1 System transformer

• Remove the system transformer from the transport frame and place it on the floor

(1/Fig.7/p.14).

Fig. 8: Unit base

Pos. 1 Bolt

Fig. 9: Transformer trough

Pos. 1 Transformer trough including the transformer

holder

• Screw the supplied bolts (1/Fig.8/p.14) into the unit base.

• Then bolt the transformer trough (1/Fig.9/p.14) including the transformer holder to

the unit base.

UROSKOP ACCESS SPL5-330.812.01.08.02 Siemens AG

01.06 CS PS SP

Page 14 of 90

Medical Solutions

Page 15

Lifting base 15

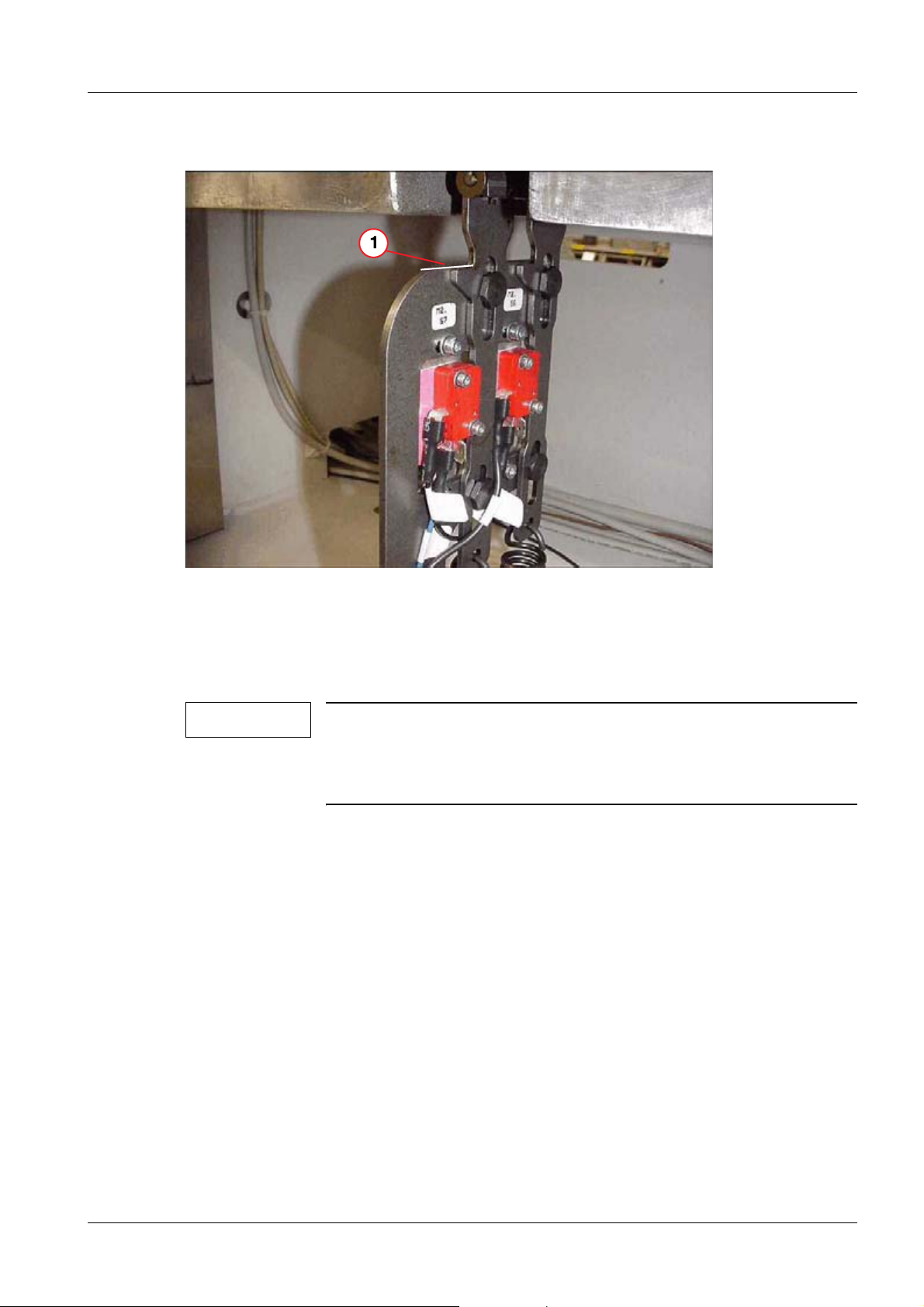

Checking the safety switch (back of the lifting base) 0

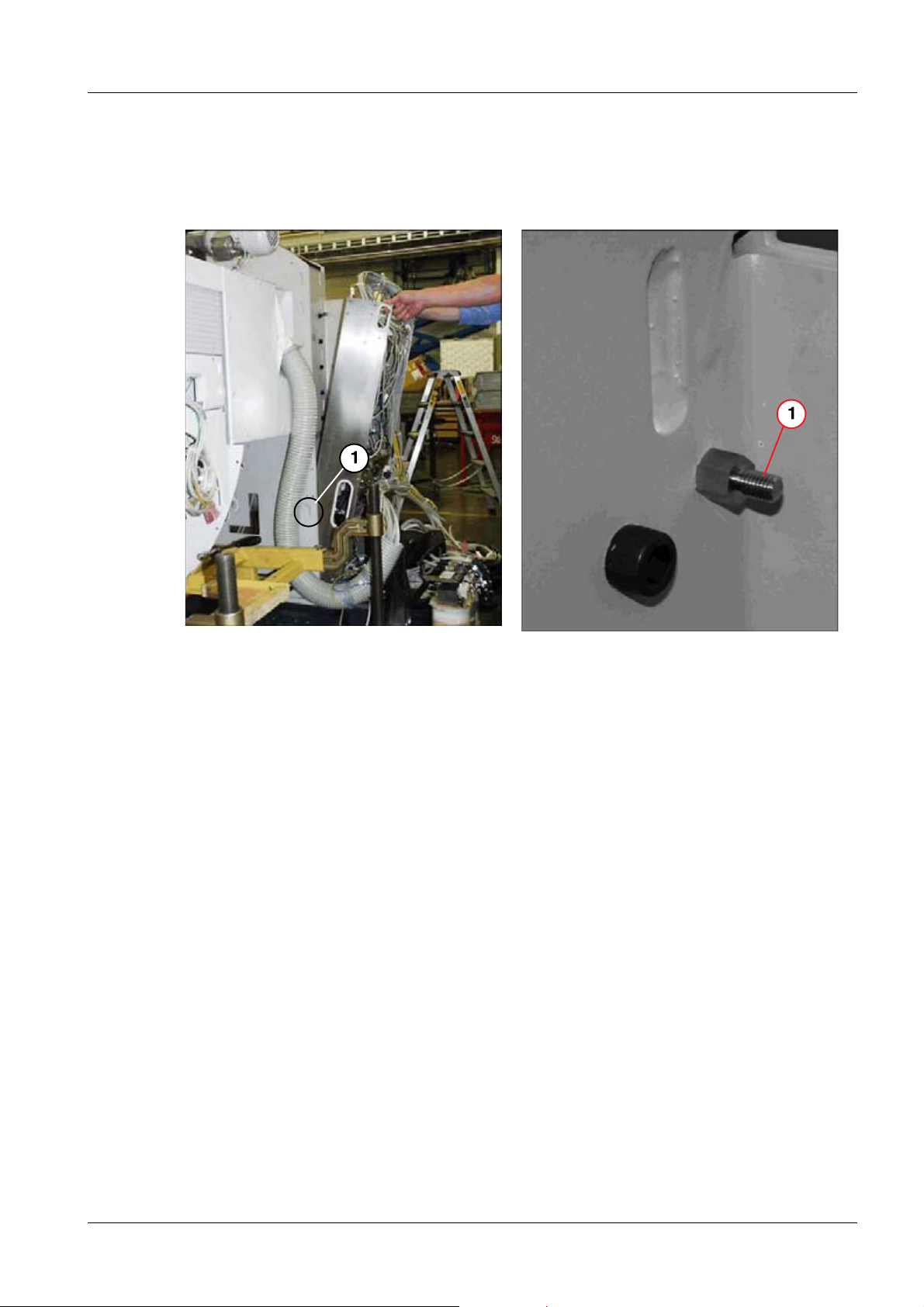

Fig. 10: Safety switch on the back of the lifting base

Pos. 1 Edge

• Align the marked edge of the moving part with the upper edge of the stationary part

(1/Fig. 10 / p. 15).

NOTE

When installing the lifting base, check the setting shown in

(1/Fig. 10 / p. 15) and adjust it if necessary by loosinging the two

Allen screws (1/Fig. 11 / p. 16). Subsequently retighten these

screws.

Siemens AG SPL5-330.812.01.08.02 UROSKOP ACCESS

Medical Solutions

01.06 CS PS SP

Page 15 of 90

Page 16

16 Lifting base

Fig. 11: Lifting base installation

Pos. 1 Allen screws

UROSKOP ACCESS SPL5-330.812.01.08.02 Siemens AG

01.06 CS PS SP

Page 16 of 90

Medical Solutions

Page 17

Unit carrier 17

3Unit carrier

4-

Installation on the lifting base 0

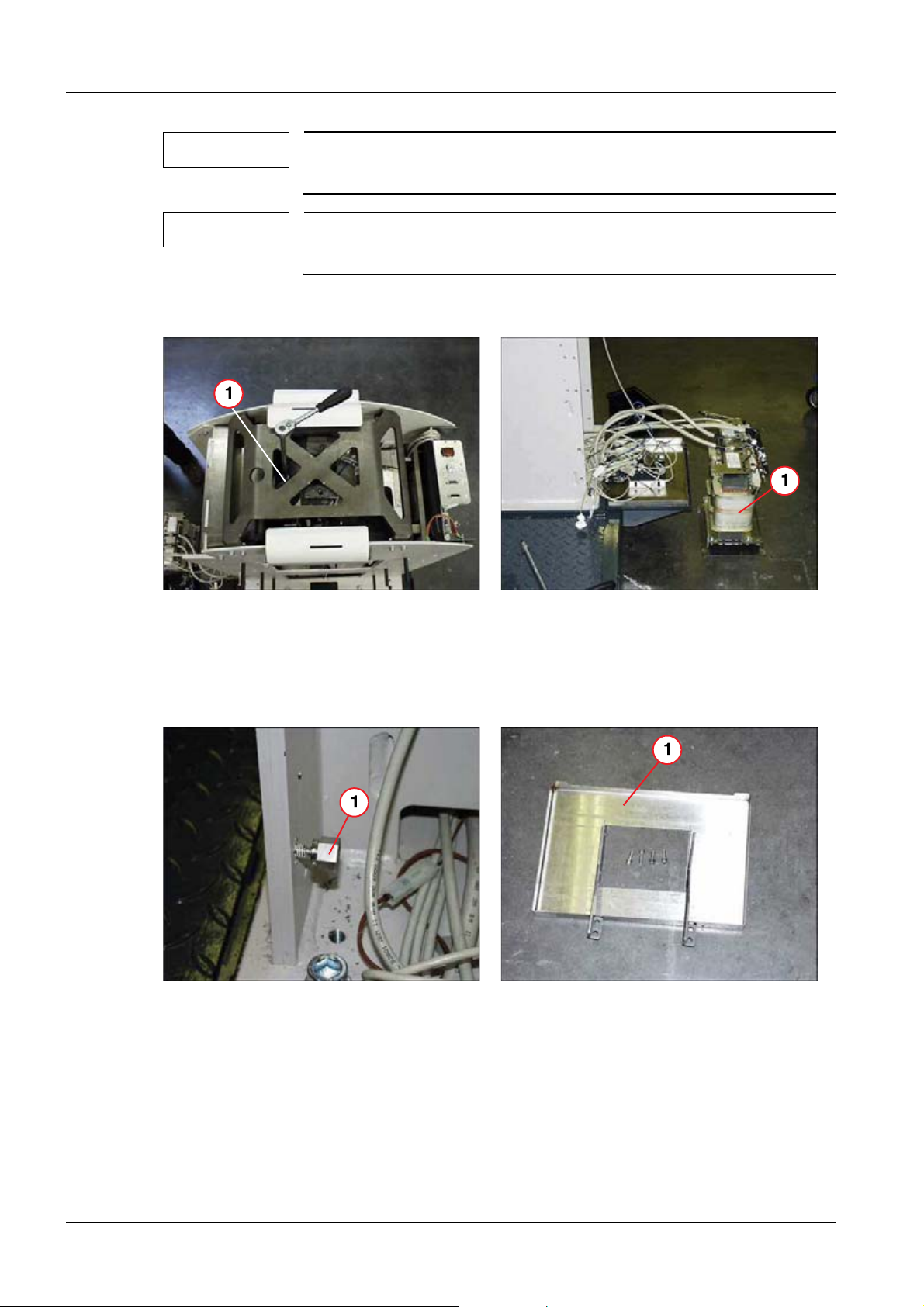

Fig. 12: Screwing on the transport frame

Pos. 1 Transport frame

NOTE

If necessary because of the width of the doors (< 1.15 m), the unit

Fig. 13: Unit carrier/lifting base

Pos. 1 Lifting base flange

carrier can be tilted to the left or right in the transport frame.

CAUTION

Risk of the unit carrier tipping!

Pushing on the longitudinal sides of the unit carrier when using

the transport frame and transport rollers to transport the unit carrier can result in tipping.

¹ Push the unit carrier on the front sides and not on the

longitudinal sides.

• Fasten the 4 transport rollers to the transport frame via 2 Allen screws M12 x 25 and

washers per transport roller (1/Fig. 12 / p. 17).

• Unscrew the transport frame from the pallet.

• Raise the unit carrier approx. 3 cm with the aid of the transport rollers and move it care-

fully off the pallet.

• Move the unit carrier to the lifting base and raise it to the level of the lifting base flange

with the aid of the transport rollers (1/Fig. 13 / p. 17).

NOTE

The collimator is delivered separately and is not on the unit carrier

pallet.

Siemens AG SPL5-330.812.01.08.02 UROSKOP ACCESS

Medical Solutions

01.06 CS PS SP

Page 17 of 90

Page 18

18 Unit carrier

Fig. 14: Relieving the transport safety device

Pos. 1 Ratchet

Fig. 15: Unit carrier installation

Pos. 1 Screws M16 x 40

• Align the unit carrier to the flange of the lifting base by means of the marks made in the

factory (they must for a line) (2/Fig. 15 / p. 18) and carefully push the unit carrier onto

the flange of the lifting base.

NOTE

T • Secure the unit carrier with 12 screws M16 x 40 and Loctite 221 and tighten them

crosswise with a torque of 200 Nm (1/Fig. 15 / p. 18).

The distance between the flange and the lifting base can be

changed as needed via a ratchet (precision adjustment,

(Fig. 14 / p. 18)).

Fig. 16: Removing the transport safety device

Pos. 1 Red screw

• Remove the transport safety device below the chain guide for the transverse table drive

(red screw) (1/Fig. 16 / p. 18).

UROSKOP ACCESS SPL5-330.812.01.08.02 Siemens AG

01.06 CS PS SP

Page 18 of 90

Medical Solutions

Page 19

Unit carrier 19

Installation of power supply module (M1) 0

The layout (connector overview) of M1.D1 (BUC) is shown in this document

(Fig. 64 / p. 58).

Fig. 17: Power supply module

Pos. 1 Guide bolts on the inside of the lifting base

Fig. 18: Top lifting base bolt

Pos. 1 Securing the top bolt

• Remove the transport safety device (have 2 people lift the power supply module) and

insert it in the guide bolts on the lifting base (1/Fig. 17 / p. 19).

• Use 2 nuts to secure the power supply module at the upper bolt of the lifting base.

• Remove the corrugated hose from the transport frame.

• Completely remove the transport frame.

Siemens AG SPL5-330.812.01.08.02 UROSKOP ACCESS

Medical Solutions

01.06 CS PS SP

Page 19 of 90

Page 20

20 Unit carrier

Wiring 0

Unit transformer 0

• Connect cable M2 to the transformer.

• Connect the blue lead (N) and the ground wire to module M1.

Wiring of M1/M2 0

• Connect the following cables to M1.X20:

- 7 (brown),

- 8 (black),

-9 (blue),

- 10 (green-yellow).

• Plug in M1.X20.

• Screw in the strain relief device and tighten it securely.

• Plug in connector M1.X9 (fluoro acquisition) and attach the screws and safety device

again.

• Plug in connectors M1.D1.X111 and M1.D1.X512.

• Plug in connectors M1.X7 and M1.D1.X300.

• Connect the following connectors to M2:

-M2.D21.X2,

- M2.X4 - X7.

• Screw on M2.PE.

• Plug in connector M1.D1.X110 and attach the cable clamp.

UROSKOP ACCESS SPL5-330.812.01.08.02 Siemens AG

01.06 CS PS SP

Page 20 of 90

Medical Solutions

Page 21

Unit carrier 21

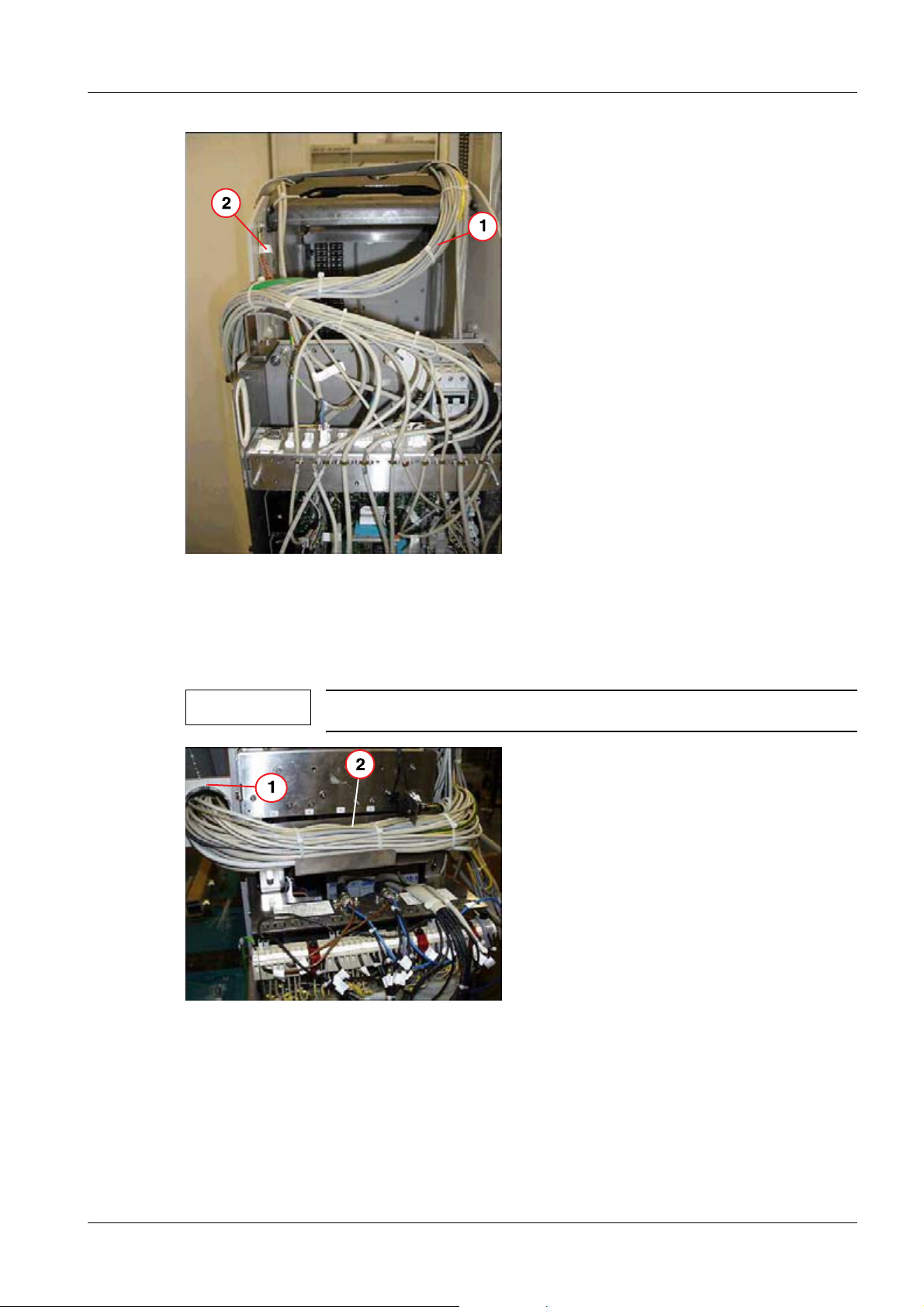

Fig. 19: Wiring

Pos. 1 Cable strand

Pos. 2 Shielding

• Run the cable strand to M2 underneath the cover (1/Fig. 19 / p. 21).

NOTE

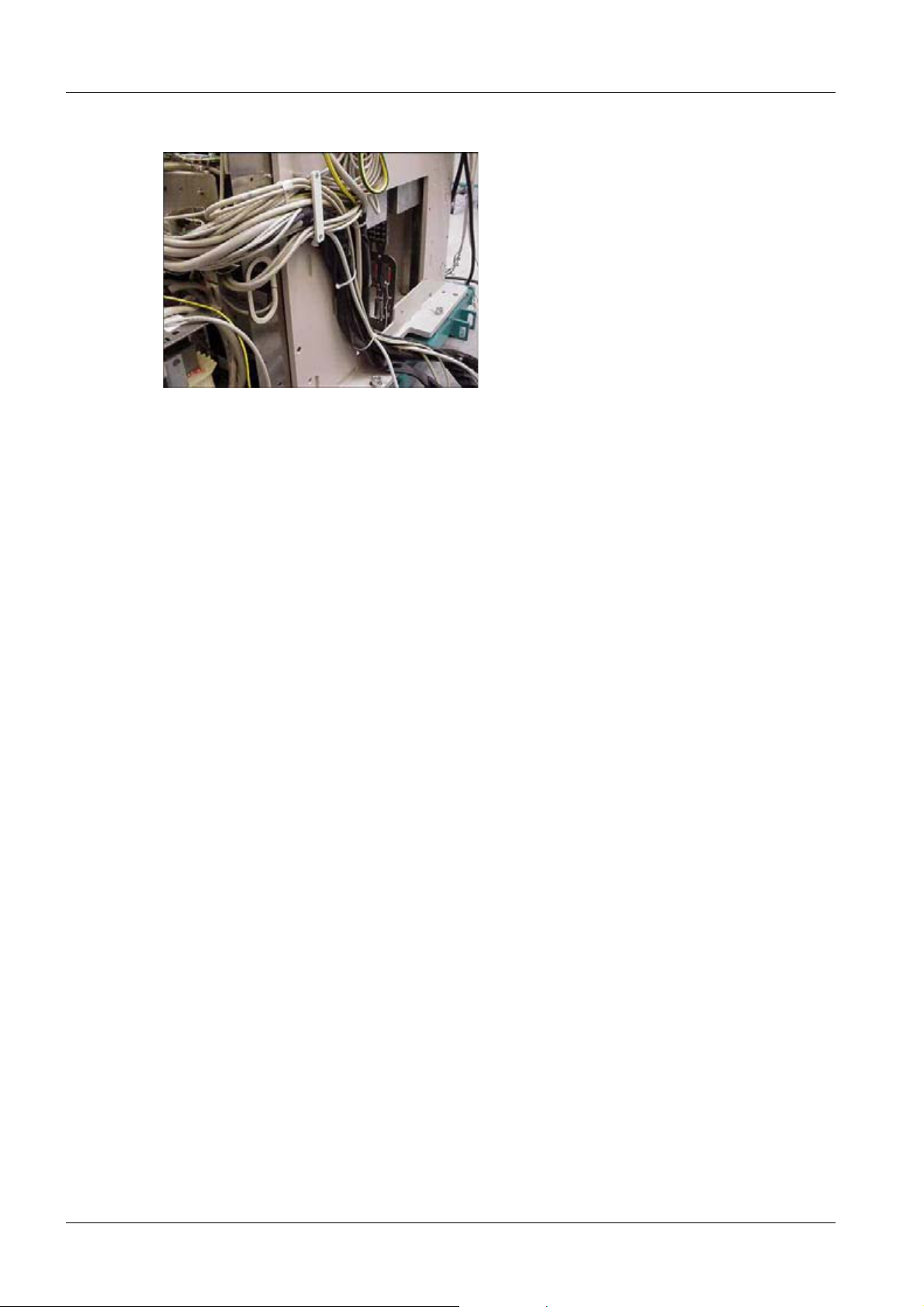

Fig. 20: Holder on the lifting base

Pos. 1 Holder

Pos. 2 Cables

Attach the shielding (2/Fig. 19 / p. 21).

Siemens AG SPL5-330.812.01.08.02 UROSKOP ACCESS

Medical Solutions

01.06 CS PS SP

Page 21 of 90

Page 22

22 Unit carrier

• Use the supplied holder (1/Fig. 20 / p. 21) to connect the corrugated hose to the lifting

base and position the cable according to (2/Fig. 20 / p. 21).

- Take care that the corrugated hose is turned into itself, so that it lies against the lifting

base

Fig. 21: Transformer T1

Pos. 1 Transformer holder

• Attach transformer T1 directly to transformer holder (1/Fig. 21 / p. 22).

NOTE

The transformer holder has a factory-installed rubber buffer.

Do not use any of the additional shims or rubber washers included

with delivery to attach transformer T1 to the transformer holder.

• Route the cable for M1 and M2 according to (Fig. 22 / p. 23), (Fig. 23 / p. 23).

UROSKOP ACCESS SPL5-330.812.01.08.02 Siemens AG

01.06 CS PS SP

Page 22 of 90

Medical Solutions

Page 23

Unit carrier 23

Fig. 22: Cable layout M1

Fig. 23: Cable layout M2

• Cable layout for a lateral cable lead-in according to (1/Fig. 24 / p. 23).

Fig. 24: Lateral cable layout

Pos. 1 Cable lead-in

Siemens AG SPL5-330.812.01.08.02 UROSKOP ACCESS

Medical Solutions

01.06 CS PS SP

Page 23 of 90

Page 24

24 Unit carrier

• Cable layout for the cable outlet at the back of the unit (Fig. 25 / p. 24).

Fig. 25: Cable outlet at the back of the unit

UROSKOP ACCESS SPL5-330.812.01.08.02 Siemens AG

01.06 CS PS SP

Page 24 of 90

Medical Solutions

Page 25

Unit carrier 25

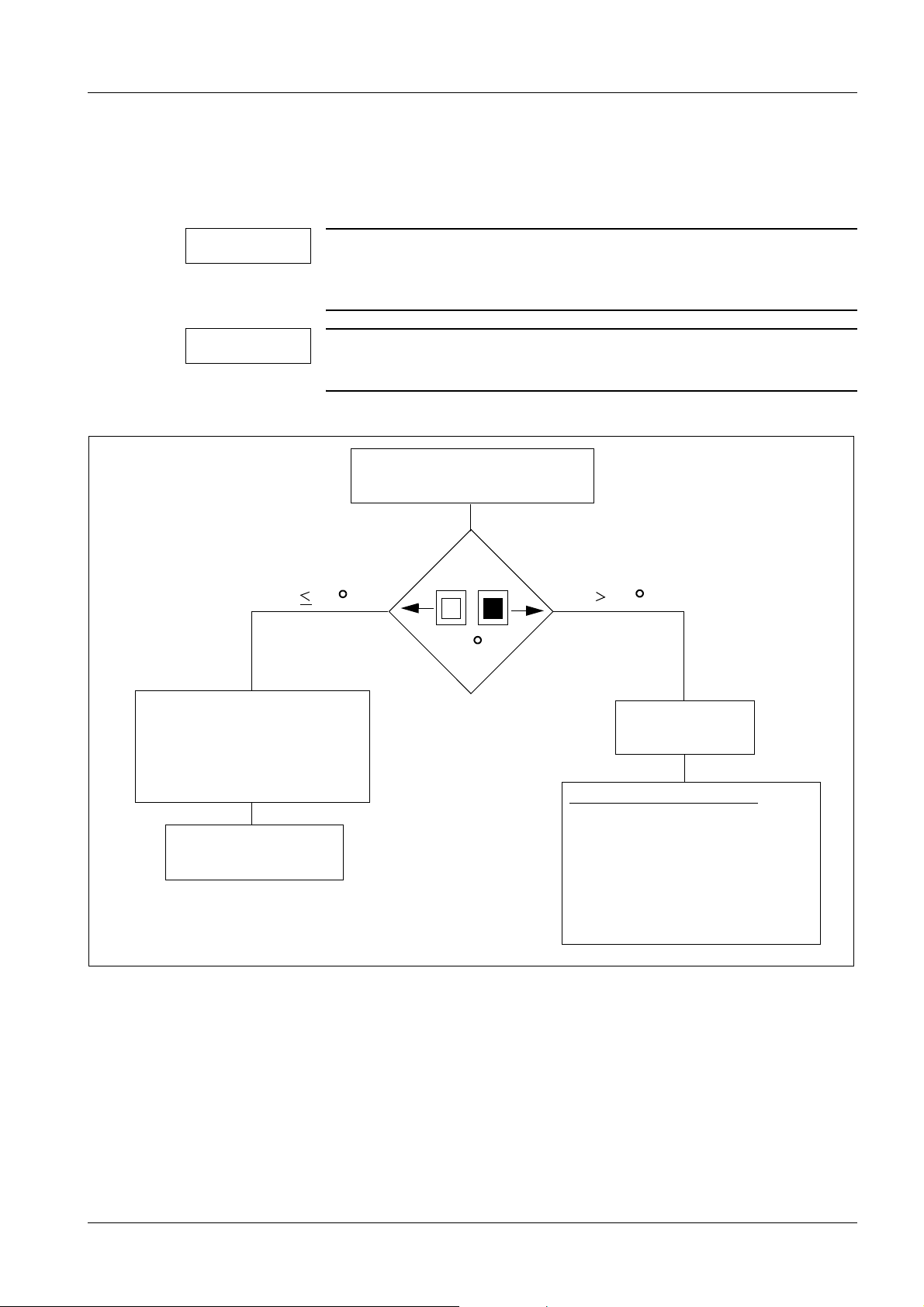

EH111509-110902-02-01

Read off Temperature Indicator

37

Record in

Test Certificate Image Quality

System Binder Reg.: 9

(not in Systems with

FLUOROSPOT Compact)

Remove

Temperature Indicator

Call SIEMENS

Only SIEMENS-engineer

Proceed per:

Installation Instructions

Monitoring Temperatur of

SIRECON Unit and

System Binder Reg.: Installation

37 C

C

37 C

Projectmanager

OPTILUX Tube System

Installation of image intensifier I.I 33/I.I. 40 0

Reading the temperature indicators on the I.I. 0

NOTE

NOTE

The image intensifier is provided with temperature indicators. Exceeding the permissible temperature can negatively influence image quality.

The basic color of the temperature indicators is white. In the case

of an excessive temperature, the inner square turns black.

• Check these temperature indicators as follows:

Fig. 26: Temperature indicator

Siemens AG SPL5-330.812.01.08.02 UROSKOP ACCESS

Medical Solutions

01.06 CS PS SP

Page 25 of 90

Page 26

26 Multileaf collimator

4Multileaf collimator

5-

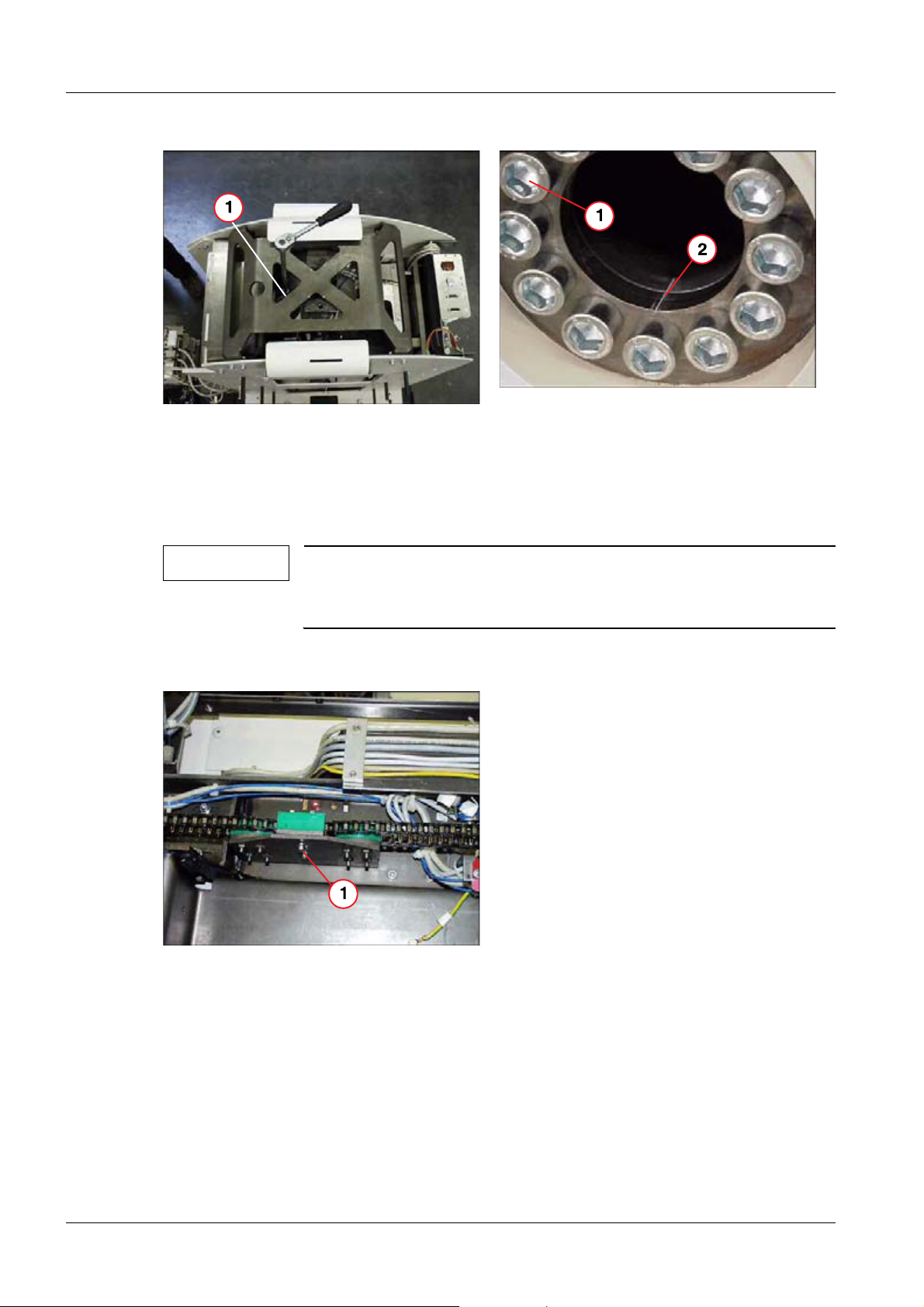

Installing the collimator 0

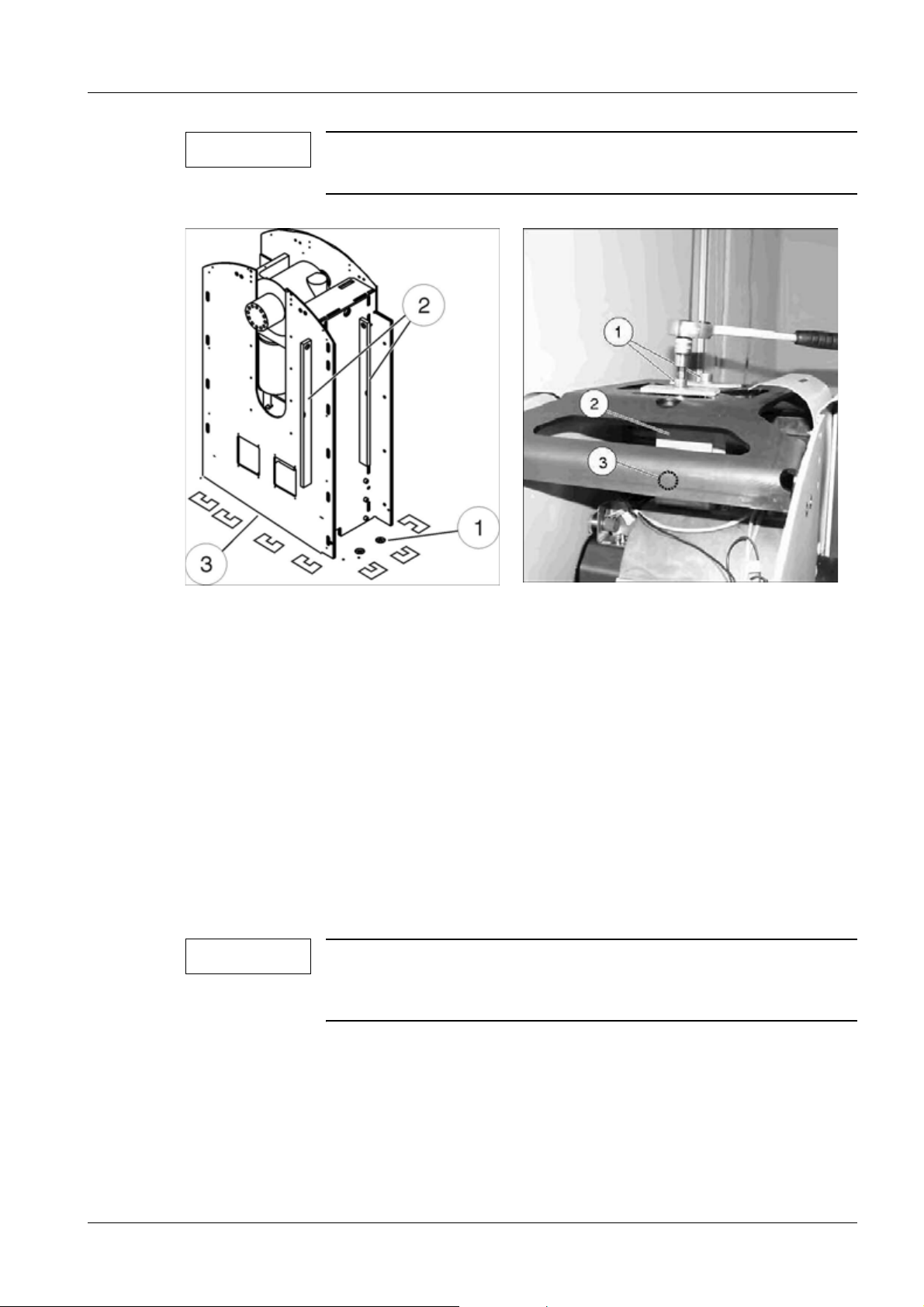

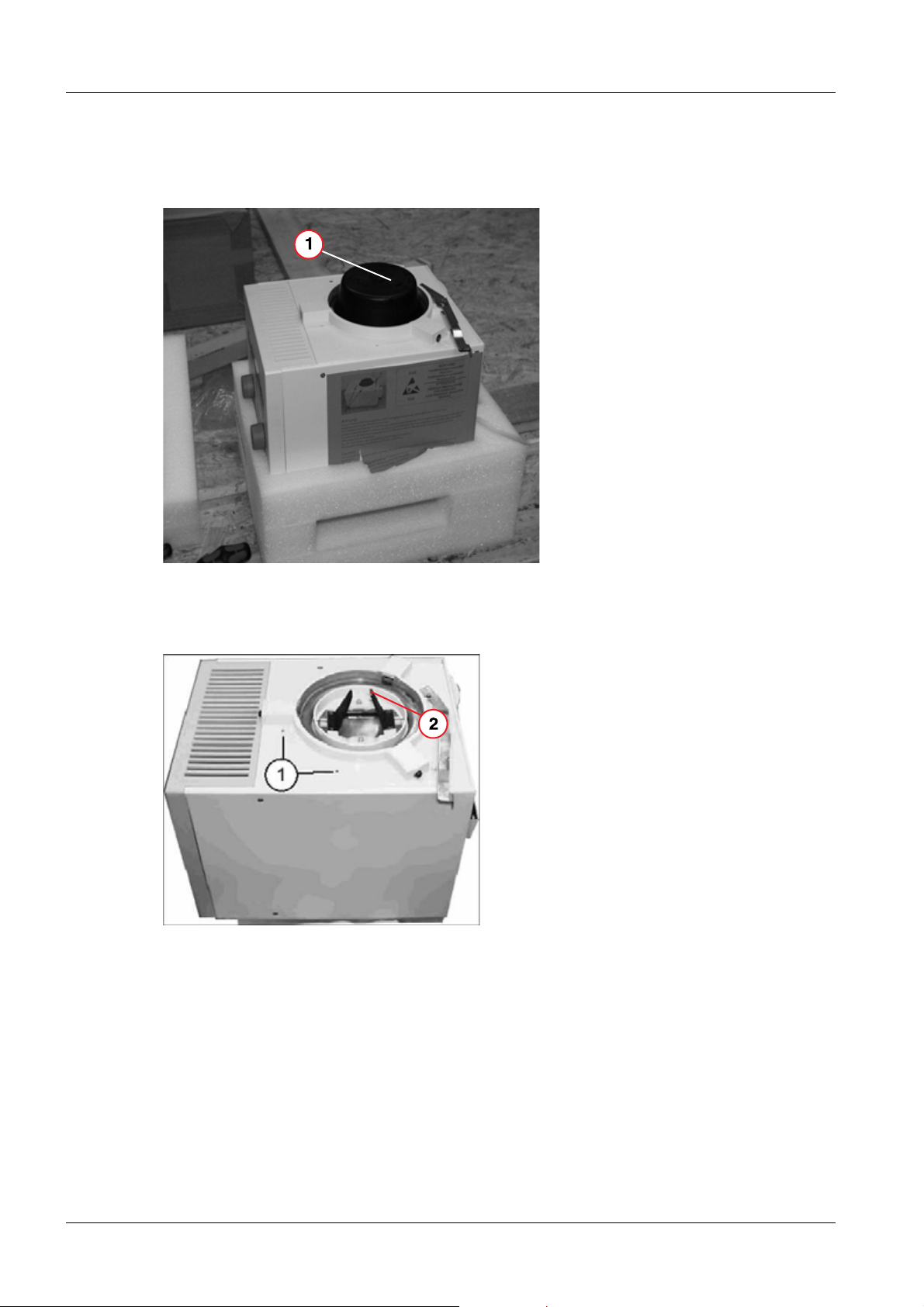

• Remove the protective cover from the collimator (1/Fig. 27 / p. 26) by removing the

Allen screws and threaded pins.

Fig. 27: Collimator installation

Pos. 1 Protective cover

• Remove the red transport safety screws from the collimator (1/Fig. 28 / p. 26).

Fig. 28: Collimator installation

Pos. 1 Transport safety screws

Pos. 2 Blades

• Mount the collimator on the tube assembly flange and align it (1/Fig. 29 / p. 27).

UROSKOP ACCESS SPL5-330.812.01.08.02 Siemens AG

01.06 CS PS SP

Page 26 of 90

Medical Solutions

Page 27

Multileaf collimator 27

NOTE

Fig. 29: Installing the collimator

Pos. 1 Tube assembly flange

Do not damage the collimator blades (2/Fig. 28 / p. 26).

• Connect connector M9.Z66.X1 to the back of the collimator.

- Clamp the cables with the exposed shielding braid under the strain relief device.

• Connect the KermaX cables (optional) together and store them in the tube assembly at-

tachment.

Siemens AG SPL5-330.812.01.08.02 UROSKOP ACCESS

Medical Solutions

01.06 CS PS SP

Page 27 of 90

Page 28

28 TFT monitor support arm

5TFT monitor support a rm

6-

Installing the TFT support arm 0

NOTE

NOTE

CAUTION

This section describes the delivery condition of the UROSKOP Access as of 1/2005 and relates to the TFT support arm with monitor

type DSC 1703 DC-V.

Installation of the TFT support is identical for the left and right

sides but is performed laterally reversed on the opposite side of

the lifting base.

Uncontrolled tilting of the support arm may involve risk of injury.

Proceed with extreme caution.

¹ 2 persons are necessary for installing the TFT support

arm (approx. 75 kg).

¹ The transport safety devices (1/2/Fig. 30 / p. 28) may be

removed only after the support arm has been installed on

the lifting base.

Fig. 30: Transport frame for the support arm

• In the right-side unit layout, screw the flange bolts into the bottom left thread (M8) of the

5 fastening threads on the unit connection of the TFT support arm (Fig. 33 / p. 30) if not

already installed at the factory.

UROSKOP ACCESS SPL5-330.812.01.08.02 Siemens AG

01.06 CS PS SP

Page 28 of 90

Medical Solutions

Page 29

TFT monitor support arm 29

NOTE

The 5 fastening threads are located on the back of the lifting base.

• Screw the securing nut onto the bolt (Fig. 33 / p. 30).

• Remove the holder for the TFT support arm from the transport frame (Fig. 31 / p. 29).

Fig. 31: Support arm attachment

CAUTION

The subsequently described loosening of the cylinder-head

screws results in a risk of injury.

Proceed with extreme caution.

¹ Secure the TFT support arm when loosening these

screws.

• Loosen the remaining 4 of the total of 5 cylinder-head screws M8 x 25 DIN 912

(1/Fig. 32 / p. 30) and remove them with the underlying washers 8,2 x 20 x 2.

NOTE

Ensure that the radiation warning light is not damaged, for example.

• Loosen all cylinder-head screws M8 x 25 DIN 912 from the wedge-shaped transport

holder (2/Fig. 32 / p. 30) and remove it.

Siemens AG SPL5-330.812.01.08.02 UROSKOP ACCESS

Medical Solutions

01.06 CS PS SP

Page 29 of 90

Page 30

30 TFT monitor support arm

NOTE

Follow a laterally reversed procedure for a left-side unit layout.

Fig. 32: Unit connection - transport

Fig. 33: Unit connection for the support arm

• Move the TFT support arm upward over the bolt.

NOTE

UROSKOP ACCESS SPL5-330.812.01.08.02 Siemens AG

The second person secures the support arm to prevent tipping.

Page 30 of 90

01.06 CS PS SP

Medical Solutions

Page 31

TFT monitor support arm 31

• Secure the unit connection of the TFT support arm via the 4 already removed cylin-

der-head screws M8 x 25 DIN 912 incl. washer 8,2 x 20 x 2 to the lifting base

(1/Fig. 34 / p. 31).

• Remove the bolt (Fig. 33 / p. 30).

• Screw in the fifth cylinder-head screw M8 x 25 DIN 912 incl. washer 8,2 x 20 x 2 instead

of the bolt.

NOTE

Use a level to align the unit connection (Fig. 34 / p. 31).

Fig. 34: Support arm connections

T • Tighten all 5 cylinder-head screws M8 x 25 DIN 912 with a tightening torque of 23.5 Nm

+/- 0.5 Nm.

• Secure the 5 cylinder-head screws with Loctite 221.

- Loctite 221 is included in the scope of delivery.

• Screw partial harness W650 with the interface plate onto the unit connection via 2

screws M4 x 10 DIN 912 (1/Fig. 35 / p. 32).

Siemens AG SPL5-330.812.01.08.02 UROSKOP ACCESS

Medical Solutions

01.06 CS PS SP

Page 31 of 90

Page 32

32 TFT monitor support arm

Fig. 35: Support arm connections

• Plug the cables from the TFT support arm into the connectors of the interface plate ac-

cording to their designations.

• Screw the 3 ground wires (M1.PE) onto the central ground point of module M1 via 1 lock

washer S4, 1 serrated washer A4,3 DIN 6798, and 1 screw M4 x 12, DIN 912.

- The fastening means are included in the scope of delivery.

• Plug cable M1.X518 into the corresponding connector of BUC (module M1).

• Run the 2 cables with BNC connector (Y, C) and 9-pin connector X1 to the endoscopy

interface and plug them in according to the labels.

• Fasten the cables to the fastening bolt for the back wall.

NOTE

If there is no endoscopy interface option, fasten the cable ends to

the fastening bolt so that safe operation is ensured.

• Attach connector M12.X5 with cable ties to partial cable harness W650 since it is not

used for the UROSKOP Access.

• Remove the transport safety devices from the TFT support arm (1/2/Fig. 30 / p. 28) and

store these for disassembly of the TFT support arm.

• Install the TFT flat screens according to the document “Installation instructions; TFT

Pendant system; UROSKOP Access“ of the Ondal company.

• Attach the flat screens with 4 hexagon-socket-head cap screws M4 x 16.

UROSKOP ACCESS SPL5-330.812.01.08.02 Siemens AG

01.06 CS PS SP

Page 32 of 90

Medical Solutions

Page 33

TFT monitor support arm 33

CAUTION

Risk of injury, risk of damaging the flat screen!

Insufficient attachment of the TFT monitors to the support arm can

result in injury to patients/operating personnel and damage to the

monitors.

¹ Properly attach the flat screens with 4 hexa-

gon-socket-head cap screws M4 X 16.

Fig. 36: Monitor attachment on the back

• Push the flat screen lightly together in the middle until there is no more gap.

• Position the flat screens at the same height, adjust to be parallel, and secure them via

screws.

• Close the cables of the TFT support arm according to the labels.

NOTE

The cables must not be bent or crushed during installation and

when attaching the cover.

Siemens AG SPL5-330.812.01.08.02 UROSKOP ACCESS

Medical Solutions

01.06 CS PS SP

Page 33 of 90

Page 34

34 TFT monitor support arm

• Fasten the cables via cable ties to the traverse element (Fig. 37 / p. 34).

Fig. 37: Cable attachment - back of the TFT support arm

UROSKOP ACCESS SPL5-330.812.01.08.02 Siemens AG

01.06 CS PS SP

Page 34 of 90

Medical Solutions

Page 35

Cabling 35

6Cabling

7-

General information 0

Labeling of the cable harnesses 0

• The supplied cable harnesses are labeled at the zipper hose ends as follows:

Fig. 38:

Pos. 1 Name of the cable harness

Pos. 2 Level

Pos. 3 Fixed point at which this cable harness is inserted

Pos. 4 Target designation (other cable harness end)

• Run the cable harnesses according to the fixed point designation and feed them into

the relevant cabinet from below, behind, on the left or right.

- The zipper hose must project about 10 cm into the cabinet.

NOTE

NOTE

The cables are labeled and provided with connection elements.

The high-voltage cables are to be run separately. The cables are to

be positioned so that the components can be swiveled out.

Siemens AG SPL5-330.812.01.08.02 UROSKOP ACCESS

Medical Solutions

01.06 CS PS SP

Page 35 of 90

Page 36

36 Cabling

List of fixed points 0

Cable

harness

no.

From

fixed

point

To

fixed

point

Cable

harness

cross-se

ction in

2

mm

Tube,

clear

width in

inches

Minimum

opening in

mm

Maximum

fixed point

distance in

m

Comments

1 P1 PU1 3125 2 1/2 - 3 ∅ 63-75 15 W100 tube assem-

bly/generator

2x high-voltage

cable + control

cable

2 P1 PU1 780 2 1/2 ∅ 63 15 W150 system

(I.I.)/generator

3 P1 PU1 3125 3 ∅ 75 15 W400 system

(M1)/generator

4 IS PU1 2000 2 ∅ 50 18 W600 genera-

tor/imaging system

5 CR1 P1 280 3 ∅ 75 20 W360 system/con-

trol console

6 P (MTA) IS 780 1 1/2 ∅ 38 18 W650 imaging sys-

tem/TFT support

arm

7 P1 IS 125 2 ∅ 50 18 Cable for CCD cam-

era X10

8Network

socket

R2 - - - - Delivery depends on

the manufacturer of

the paper printer

9Network

IS 140 1 14 x 10 4 Network socket

socket

10 VK EN 125 1 ∅ 10 15 Endo shelf

(optional)

Delivery length 20 m

2

(3 x 1.5 mm

)

11 VK PU1 - - - - Network supply line

12 P1 PU1 - - 45 x 15 15 Iontomat cable

Fixed point Subsystem

CR1 Monitor table

EN Endo shelf

UROSKOP ACCESS SPL5-330.812.01.08.02 Siemens AG

01.06 CS PS SP

Page 36 of 90

Medical Solutions

Page 37

Cabling 37

Fixed point Subsystem

IS Imaging system

MTA TFT monitor support

arm

P1 Unit

PU1 Generator

R2 Paper printer

VK Network distributor

box (on-site)

Fig. 39: Fixed point overview

• Feed the power cables into the cabinets from below.

• Secure the plug connections via the screws to the extent possible.

• Relieve the cables of tension, apply the shielding.

NOTE

Excess cable is to be routed in a meandering manner and not

coiled. Additional cable storage space (standard for the generator)

is provided for excess cable.

• Use 2 threaded bolts and washers (2/Fig. 40 / p. 38) to install the hangers

(1/Fig. 40 / p. 38) at the top and bottom of the side generator cover.

- Excess cable can be secured in a meandering manner to the hangers on the generator cover via cable ties (Fig. 41 / p. 38).

- The cable storage space cover is secured by the 4 threaded bolts.

Siemens AG SPL5-330.812.01.08.02 UROSKOP ACCESS

Medical Solutions

01.06 CS PS SP

Page 37 of 90

Page 38

38 Cabling

Fig. 40: Hanger - cable storage space

Fig. 41: Cable routing in the cable storage

space

UROSKOP ACCESS SPL5-330.812.01.08.02 Siemens AG

01.06 CS PS SP

Page 38 of 90

Medical Solutions

Page 39

Cabling 39

POLYDOROS SX65/80 cabling 0

Overview: cable connection and cable layout in the generator cabinet 0

- 1 Connection of the control panel

- 2 Generator power connection

- 3 System power connection

- 4 XCS connection

- 5 I.I. power supply

- 7 Connection of the rotating anode cables

- 8 Connection of high-voltage transformer H1

- 9 Connection of the high-voltage cables

- 10 Connection of the monitoring systems

- 12 hard disk

- 13 Service PC connection

- 14 Connection of the ground wire

(tube assembly, unit base)

- 15 Connection of the IONTOMAT detectors

- 16 Connection of the I.I./TV iris

- 18 Connection of the KermaX (optional)

Fig. 42: Polydoros SX

Siemens AG SPL5-330.812.01.08.02 UROSKOP ACCESS

Medical Solutions

01.06 CS PS SP

Page 39 of 90

Page 40

40 Cabling

Generator power connection 0

NOTE

The PE ground wire must be highly flexible. The armor shielding of

the power supply cable must not be used.

• Connect power supply cables L1, L2, L3, N, PE to terminal block K20 (Fig. 43 / p. 40).

- Be sure to connect them in the correct phase sequence.

Fig. 43: Power connection

CAUTION

Check the jumper at the terminals in M16.K20.

2-pole jumper for systems without an FI protective switch or N lead.

¹ In the case of systems without an FI protective switch or

N lead, the bridge is to be used (see figure below). The

bridge is located in the accessory bag.

UROSKOP ACCESS SPL5-330.812.01.08.02 Siemens AG

01.06 CS PS SP

Page 40 of 90

Medical Solutions

Page 41

Cabling 41

Connecting the rotating anode cables 0

Fig. 44: POLYDOROS SX 65/80

• Draw the rotating anode cables into the frame of the power cabinet on the right side and

run them up to the starter.

• Clamp the shielding braid of the cable to the right side of the starter under the upper

clamping clip (1/Fig. 44 / p. 41).

• Use cable ties (2/Fig. 44 / p. 41) to relieve cable tension.

• Connect the cables as follows:

Stator

cable

0 K3.R4 K31.R4

I K3.R2 K31.R2

II K3.R6 K32.R2

Starter with K3 (old version)

Starter with K31/K32 (new ver-

sion)

Connection of the Iontomat measuring chamber 0

• Connect the SDM measuring cable to D100.X28(F) (1/Fig. 45 / p. 42) and secure the

connector locking mechanism.

• Connect the Iontomat cable to D100.X33(A) (2/Fig. 45 / p. 42).

Siemens AG SPL5-330.812.01.08.02 UROSKOP ACCESS

Medical Solutions

01.06 CS PS SP

Page 41 of 90

Page 42

42 Cabling

Fig. 45: Connection of the Iontomat measuring chamber

Pos. 1 D100.X28(F)

Pos. 2 D100.X33(A)

Connection of the HV trigger/gray filter 0

• Connect the cable with plug names D190.X10 and D190.X11 to the I.I./TV iris connec-

tion (16/Fig. 42 / p. 39).

XCU cable connection 0

Fig. 46: XCU cable connection

• Connect the CAN cable with designation N10.D100.X10 on the left side of the XCU to

D100 (1/Fig. 46 / p. 42).

UROSKOP ACCESS SPL5-330.812.01.08.02 Siemens AG

01.06 CS PS SP

Page 42 of 90

Medical Solutions

Page 43

Cabling 43

Inserting the high-voltage transformer into the generator cabinet 0

Fig. 47:

• Open the bayonet closures of the support (1/Fig. 47 / p. 43).

• Relocate and fold out the support for the high-voltage transformer according to

(Fig. 47 / p. 43).

• Push the pallet with the high-voltage transformer in front of the power cabinet.

• Place the high-voltage transformer on the support.

CAUTION

Do not tilt the high-voltage transformer!

¹ Hold the transformer horizontal!

Siemens AG SPL5-330.812.01.08.02 UROSKOP ACCESS

Medical Solutions

01.06 CS PS SP

Page 43 of 90

Page 44

44 Cabling

Connecting the high-voltage cables 0

Fig. 48: Fig. 49:

• Run the high-voltage cable up to the high-voltage transformer (Fig. 48 / p. 44).

• Install the high-voltage connectors for HV cable type RH 098-5DF6 071 as follows:

- Consult the document “X-Ray Diagnostic System; Installation Instruction; High voltage cable RH 098-5DF6 071” (only necessary if the threaded rings have been loosened).

- Check the oil level in the high-voltage receptacles (approx. 1 cm). If necessary, fill

them with silicone oil AK350 (material number 17 87 035).

- Insert the high-voltage plugs in H1 as designated (Fig. 49 / p. 44).

- Tighten the union nuts and secure them with the threaded pins.

UROSKOP ACCESS SPL5-330.812.01.08.02 Siemens AG

01.06 CS PS SP

Page 44 of 90

Medical Solutions

Page 45

Cabling 45

Connecting the primary cables 0

Fig. 50:

Fig. 51:

• Carefully remove the contact protection on D220 (1/Fig. 50 / p. 45).

• Connect the ground wire clamp to H1 (2/Fig. 50 / p. 45).

• Fasten twisted leads H1.U1 and H1.V1 from the inverter modules to H1 as designated

(3/Fig. 51 / p. 45).

• Run the cable connected to D220.X41 (4/Fig. 51 / p. 45) upward to board D160 and

connect it to X44. Clamp the shielding braid at the cable end with connector X44 under

the prepared clip underneath board D100.

• Connect the X1 cable from D100 to X1 on D220 (5/Fig. 50 / p. 45).

• Clamp the shielding braid under the strain relief device.

NOTE

There must be a ground connection between the cover and

ground.

• Check the nut of the grounding bolt (7/Fig. 51 / p. 45) for firm seating and tighten it if

necessary.

• Reattach the contact protection (1/Fig. 50 / p. 45).

• Push high-voltage transformer H1 into the power cabinet and snap in the bayonet clo-

sures.

• Plug in the connection cable for the fan at X19 (+24 V; red lead - PIN A; blue lead - PIN

B).

Siemens AG SPL5-330.812.01.08.02 UROSKOP ACCESS

Medical Solutions

01.06 CS PS SP

Page 45 of 90

Page 46

46 Cabling

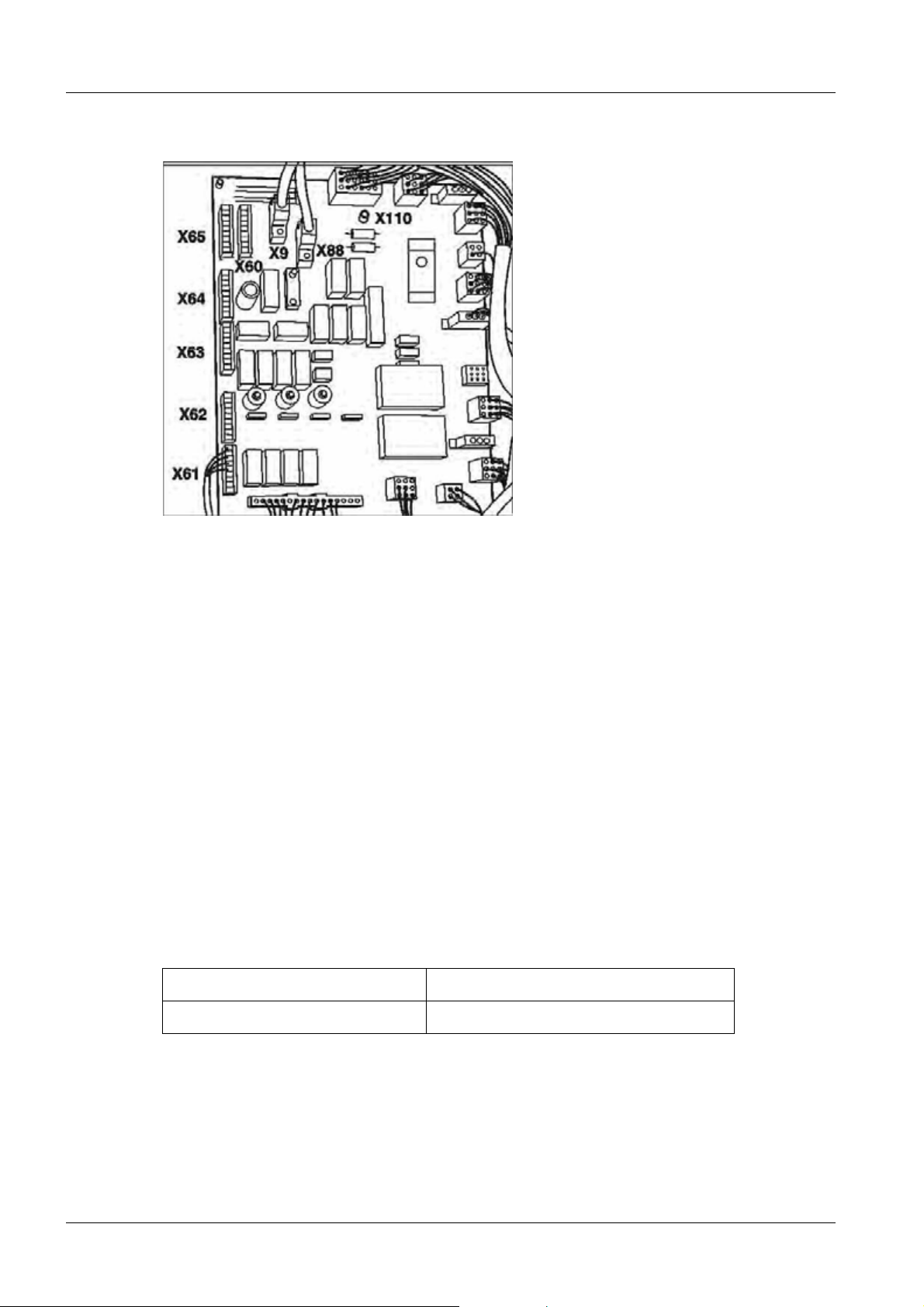

Monitoring devices and displays for radiation protection 0

Fig. 52: Power cabinet connections

• At the customer's request or if required by country-specific regulations (e.g. DHHS), the

following monitoring devices and displays can be connected in the power cabinet to

D160.X61 through X64 (Fig. 52 / p. 46):

Connecting the door contact for radiation blocking

• A door contact can be looped in series to the oil pressure switch between the following

points:

D160.X61.3 and D160.X61.4

Connecting the display lights for the radiation display

(e.g. in front of the door of the examination room)

• If an external radiation display for fluoroscopy and exposure is desired, 2 voltage-free

contacts (230 V, max. 4 A can be switched via these contacts) can be provided on

board D160 with the following connections:

- D160.X60.7-8

- D160.X60.5-6

Display occurs with pre-contact: Bridge X38.1-2 connected to D160

Display only with radiation: Bridge X38.2-3 connected to D160

Room lighting control

A control voltage (24 V~) is provided via D160.X64.5-6 for control purposes. A power

surge relay can be controlled via this.

UROSKOP ACCESS SPL5-330.812.01.08.02 Siemens AG

01.06 CS PS SP

Page 46 of 90

Medical Solutions

Page 47

Cabling 47

Control voltage (24 V~, max. 1 A)

for power surge relay:

Voltage -free normally open contact:

Bridge X8.1-2 connected to D160

Bridge X8.2-3 connected to D160

Connecting the ground wires 0

Fig. 53: Ground wire connection

• Connect the ground wires of the tube assembly in the system cabinet to the ground wire

connection points (1/Fig. 53 / p. 47) in the generator on M16.

NOTE

To avoid disturbances due to ground loops, run the ground wires

in a star pattern to the central ground wire connection point.

Siemens AG SPL5-330.812.01.08.02 UROSKOP ACCESS

Medical Solutions

01.06 CS PS SP

Page 47 of 90

Page 48

48 Cabling

Monitors in the control room 0

The following monitor types are available for selection for the control room as live and reference monitors:

1. Flat panel - Siemens DSB 1803 DC (18.1’’), S/W - 1280 x 1024 pixels

(part number 77 28 657).

2. Flat panel - Eizo Radiforce R11 (18.1’’), color - 1280 x 1024 pixels

(part number 30 99 553).

NOTE

It must be distinguished for each monitor during installation

whether the system is with/without a urodynamics interface.

Systems without a urodynamics interface 0

• The back of monitor 1 is connected via a 3-m BNC/BNC monitor cable, which is provid-

ed in the imaging system container, to the BNC outputs at the video splitters (connections R OUT, B OUT, G BAS OUT) (Fig. 59 / p. 54). The live monitor is connected to the

front video splitter and the reference monitor is connected to the back splitter.

• Monitor 2 must be connected according to the figure via a DVI adapter (part number 77

48 531) (Fig. 54 / p. 49) and a 3-m SVGA/BNC monitor cable (part number 30 79 035)

which is provided with the Eizo monitor to the BNC outputs at the video splitters (connections R OUT, B OUT, G BAS OUT, SV OUT, SH OUT) (Fig. 85 / p. 74). The live

monitor is connected to the front video splitter and the reference monitor is connected

to the back splitter.

Systems with a urodynamics interface 0

Live monitor

• The back of monitor 1 is connected via a 3-m SVGA/BNC cable (part number 30 79

035) to the PC-OUT output (SVGA) of the scan converter.

• The back of monitor 2 is connected via a DVI adapter (part number 77 48 531)

(Fig. 54 / p. 49) and a 3-m SVGA cable (part number 30 89 496) to the PC-OUT output

(SVGA) of the scan converter.

Reference monitor

• Monitors 1/2 are connected as described in chapter (Systems without a urodynamics

interface / p. 48).

NOTE

UROSKOP ACCESS SPL5-330.812.01.08.02 Siemens AG

In the case of problems with image display on the Urodynamic

workstation, the data according to the document “Installation and

Start-up; Urodynamic Interface/Scan Converter“

(SPL5-330.814.01.xx) is to be reviewed.

01.06 CS PS SP

Page 48 of 90

Medical Solutions

Page 49

Cabling 49

Explanations of the various monitor types 0

Eizo Radiforce R11

• The Eizo Radiforce R11 monitor is to be installed as a live and reference monitor in the

control room as described below.

Fig. 54: Eizo Radiforce R11 monitor (back)

Pos. 1 DVI adapter

Pos. 2 SVGA/BNC monitor cable

Pos. 3 Power cable

Pos. 4 Support bracket

Fig. 55: Eizo Radiforce R11 monitor

Siemens AG SPL5-330.812.01.08.02 UROSKOP ACCESS

Medical Solutions

01.06 CS PS SP

Page 49 of 90

Page 50

50 Cabling

Siemens DSB 1803-DC

Fig. 56: Siemens DSB 1803-DC monitor

• The Siemens DSB 1803-DC monitor is to be installed as a live and reference monitor in

the control room as described below.

• Lay the display down and then attach the separately packed monitor base to it via the 4

supplied screws as shown in the figure(Fig. 56 / p. 50).

- Be sure to remove the rear monitor base cover by pulling the recessed grip in a backward direction (see arrow position (Fig. 56 / p. 50)) prior to assembly. This cover is

already removed in the figure (Fig. 56 / p. 50).

• Replace the black rubber lip around the periphery of the display with the supplied silver

rubber lip.

• Connect the power cable and the image signal cable of the monitor to the display.

• Set the power switch to the “ON” position.

• Attach the rear cover to the monitor base.

UROSKOP ACCESS SPL5-330.812.01.08.02 Siemens AG

01.06 CS PS SP

Page 50 of 90

Medical Solutions

Page 51

Cabling 51

FLUOROSPOT Compact imaging system container 0

Fig. 57: Imaging system container

• Install the imaging system container at the location indicated in the project plan.

• Ensure a sufficient distance from the tabletop - at least 10 cm.

NOTE

Siemens AG SPL5-330.812.01.08.02 UROSKOP ACCESS

Medical Solutions

To connect the imaging system container, it is necessary to open

the cover, side wall and rear wall of the container (access to M16,

transformer, power supply connection, and interfaces).

Page 51 of 90

01.06 CS PS SP

Page 52

52 Cabling

• Position cable harness W650 of the TFT support arm with respect to the imaging sys-

tem container.

• Install cable harnesses W600 and W650 as described in the section (Cable harness

installation / p. 59).

NOTE

Strain relief is generally provided for all external cables. Cable ties

to be attached to the provided punched holes in the M16 housing

(imaging system container) are used for securing the cables. The

stripped cable shields are to be clamped under the corresponding

cable clips.

Mouse 0

• Connect the mouse to the right connection with the mouse symbol (1/Fig. 58 / p. 53).

• Provide strain relief via cable ties at the punched holes.

Network 0

• Connect the imaging system PC to the network via an unshielded twisted pair lead

(7/Fig. 58 / p. 53).

NOTE

In the event in which no network connection is initially provided,

this lead should be attached to the back wall of the imaging system

container via cable ties.

Keyboard 0

• Connect the keyboard cable to the left connection with the keyboard symbol

(2/Fig. 58 / p. 53) (next to the mouse connection) and secure the cable via cable ties.

NOTE

Use the supplied extension to extend the keyboard cable.

Laser printer connection 0

NOTE

The laser printer (paper printer) is to be connected to the hospital

network in the case of an existing network connection of the UROSKOP Access. The configuration of the paper printer is described

in document “UROSKOP ACCESS; Help-File FLC“

(SPL5-330.880.01.xx). This help file is installed on the imaging system PC during start-up.

UROSKOP ACCESS SPL5-330.812.01.08.02 Siemens AG

01.06 CS PS SP

Page 52 of 90

Medical Solutions

Page 53

Cabling 53

Back of the imaging system PC (cabling only as an example) 0

Fig. 58: Rear side of the imaging system PC (cabling shown as an example)

Pos. 1 Mouse connection

Pos. 2 Keyboard connection

Pos. 3 Connection D1 imaging system container

Pos. 4 XCS bus cable

Pos. 5 Camera connection

Pos. 6 Graphics card connection (life and reference monitor)

Pos. 7 LAN connection

Siemens AG SPL5-330.812.01.08.02 UROSKOP ACCESS

Medical Solutions

01.06 CS PS SP

Page 53 of 90

Page 54

54 Cabling

Cabling of the imaging system container 0

Fig. 59: Imaging system container cabling

Pos. 1 Monitor connections

Pos. 2 Connection points of the 400 V/440 V/480 V

voltage supply from the generator

Pos. 3 M16.K2

Pos. 4 M16D1.SK111

Fig. 60: Cabling of the imaging system

container

Pos. 1 Video splitter D233 (live image; front)

Pos. 2 Video splitter D233 (reference image; back)

Pos. 3 Live image monitor connections

Pos. 4 Reference image monitor connections

UROSKOP ACCESS SPL5-330.812.01.08.02 Siemens AG

01.06 CS PS SP

Page 54 of 90

Medical Solutions

Page 55

Cabling 55

Fig. 61: Video splitter D233

Pos. 1 Live image video splitter

Pos. 2 Reference image video splitter

NOTE

The signal for the live image is available at the front video splitter

(1/Fig. 61 / p. 55), and the signal for the reference image is avail-

able at the back video splitter (2/Fig. 61 / p. 55).

Siemens AG SPL5-330.812.01.08.02 UROSKOP ACCESS

Medical Solutions

01.06 CS PS SP

Page 55 of 90

Page 56

56 Cabling

Fig. 62: Strain relief overview

Pos. 1 Image signal cables (W650)

Pos. 2 M16.K2 (power cables for the monitors)

Pos. 3 M16.D1.SK111 (W600)

Pos. 4 M16.F1 (W600)

Pos. 5 M16.X1 (W600 + W650)

Pos. 6 M16.X2 (W650)

Pos. 7 M59.X3 (W600) XCS cable

Pos. 8 M16.PE (W600)

Pos. 9 Partial cable harness W600

Pos. 10 Partial cable harness W650 TFT support arm

NOTE

The design of the cable harnesses on the imaging system container is identical, with the exception of the number of BNC cables. Cable harness W650 has 7 coaxial cables with BNC plugs.

UROSKOP ACCESS SPL5-330.812.01.08.02 Siemens AG

01.06 CS PS SP

Page 56 of 90

Medical Solutions

Page 57

Cabling 57

Fig. 63:

Pos. 1 Power and image cables for monitors in the control room, mouse and keyboard cables, optional: Printer cables

Pos. 2 Supply of cables from unit and generator

Siemens AG SPL5-330.812.01.08.02 UROSKOP ACCESS

Medical Solutions

01.06 CS PS SP

Page 57 of 90

Page 58

58 Cabling

Board D1 (BUC) - connector overview 0

Fig. 64: PC board D1 (BUC) - connector overview

UROSKOP ACCESS SPL5-330.812.01.08.02 Siemens AG

01.06 CS PS SP

Page 58 of 90

Medical Solutions

Page 59

Cabling 59

Cable harness installation 0

W100 system (tube assembly) - POLYDOROS SX 0

System (tube

assembly)

H11.+ AP1.H1.+ High-voltage cable (+)

H11.- AP1.H1.- High-voltage cable (-)

H11.PE M16.K20.PE Ground wire

H11.1,2 D160.X61 Oil pressure switch

H11.X2 K31/K32 Rotating anode cable

KermaX Connector Dose measurement

Generator Function

W150 system (I.I.) - POLYDOROS SX 0

Generator System (I.I.) Function

D100.X28(F) D100.X1 SDM sensor

Z108.K1

Conn2/D100.X2

/M61.K1

I.I. voltage supply (zoom)

D190.X10 M8.K5 Gray filter

D190.X10 FK.X2 TV iris

Additional cables 0

NOTE

Imaging system con-

tainer

Imaging system

The subsequently listed cables are routed separately and are not

part of the cable harness.

Generator Unit (II) Function

__

D100.X33(A) M3.JK2 Iontomat cassette

FK.X1

Cable for CCD camera

(X10)

Siemens AG SPL5-330.812.01.08.02 UROSKOP ACCESS

Medical Solutions

01.06 CS PS SP

Page 59 of 90

Page 60

60 Cabling

W360 unit (M1) - control console (M11) 0

Fig. 65: Unit M1.D1 control console (M11)

Pos. 1 Control panel

Pos. 2 Tableside control (optional)

W400 system (M1) - POLYDOROS SX 0

System Generator Function

M1.F1 M16.K4 Voltage supply

M1.PE M16.PE Ground wire

M1.D1.X31 D320.X4US HW radiation release

M1.D1.X301 N10.D100.X10 CAN connection

M1.D1.X32 D160.X61 Radiation display control panel

M1.X109 D160.X9 Control panel on/off

W600 POLYDOROS SX - imaging system container 0

Polydoros SX Cable IS container Name

D320.X4S 1 M59.D100.X3 XCS connection cable

D190.X11 2 M16.D1.SK111 Sync. pulsed FL/DR

UROSKOP ACCESS SPL5-330.812.01.08.02 Siemens AG

01.06 CS PS SP

Page 60 of 90

Medical Solutions

Page 61

Cabling 61

Polydoros SX Cable IS container Name

M16.K30 3 M16.F1

M16.PE 4 M16.PE Ground wire

D160.X64 5 M16.X1 TFT radiation display

Voltage supply for the imaging

system container

W650 imaging system container - TFT support arm 0

IS container Support arm interface M12 Name

M16.K22 M12.X8 Power pack endo-switchover TFT

BS.Live 1 M12.Live 1 RGB Live TFT

BS.Ref 1 M12.Ref 1 RGB Ref TFT

M16.X1 M12.H1 TFT radiation display

M16.BNC1 Mon. switchover URO Urodynamic BAS (B/W)

Data printer connection (label printer, optional) 0

NOTE

• Connect the 9-pole connector on the side to connection X62 of the XCU.

The label printer described here is used for printing patient-related

doses.

Siemens AG SPL5-330.812.01.08.02 UROSKOP ACCESS

Medical Solutions

01.06 CS PS SP

Page 61 of 90

Page 62

62 Cabling

Remote control panel cabling (optional) 0

Fig. 66: Control panel

• Open the back cover of the control panel and connect the cable coming from module

M1 (unit) as labeled (Fig. 67 / p. 62).

Fig. 67: Cable layout in the control panel Fig. 68: Cable layout in the control panel

NOTE

The cable layout in the control panel depends on the cable supply

(1/Fig. 67 / p. 62); (1/Fig. 68 / p. 62).

• Ensure that the cables are free of strain.

• Connector M11.X2 must be situated inside the control panel and may not be routed to-

ward the outside.

• Connect the second tableside control (optional), if available, and place it on the control

panel (2/Fig. 67 / p. 62); (2/Fig. 68 / p. 62).

UROSKOP ACCESS SPL5-330.812.01.08.02 Siemens AG

01.06 CS PS SP

Page 62 of 90

Medical Solutions

Page 63

Cabling 63

• Subsequently reattach the cover.

NOTE

The tableside control on the unit (coding A) and the tableside control on the control panel (coding B, optional) are labeled differently

(see document “Wiring Diagram“ [SPL5-330.844.91.01.02]; tableside control bridge overview).

Siemens AG SPL5-330.812.01.08.02 UROSKOP ACCESS

Medical Solutions

01.06 CS PS SP

Page 63 of 90

Page 64

64 Cabling

Installing the endo shelf (optional) 0

NOTE

The installation of the endo shelf depends on the layout of the

UROSKOP Access (left/right-hand version). The differences between the left/right-hand version are shown in the figures on the

following pages.

Fig. 69: Endo shelf installation

Pos. 1 Ground wire

Fig. 70: Endo shelf installation

Pos. 1 Cable lead-in

• Prior to assembly of the shelf, the ground wire (1/Fig. 69 / p. 64) and the supplied

mm2

20-meter cable (3 x 1.5

(1/Fig. 71 / p. 64). The cable lead-in is shown in (1/Fig. 70 / p. 64).

) must be passed through the flange tube

• After the cables are led in, the flange tube (1/Fig. 71 / p. 64) is fastened to the shelf bot-

tom (Fig. 70 / p. 64) via the supplied screws (M6 x 25) and washers.

Fig. 71: Endo shelf installation

Pos. 1 Flange tube

Fig. 72: Endo shelf installation

• Check the grounding bolts and if necessary tighten these (see arrows) (Fig. 72 / p. 64).

UROSKOP ACCESS SPL5-330.812.01.08.02 Siemens AG

01.06 CS PS SP

Page 64 of 90

Medical Solutions

Page 65

Cabling 65

NOTE

Use increased caution when assembling the shelf. Make sure that

the led-in power cable and the ground wire are not crushed or

damaged.

Right-hand version of the endoscopy shelf 0

NOTE

The figure shows the installation of the right-hand version

(Fig. 73 / p. 65).

Fig. 73: Right-hand version of the endo shelf Fig. 74: Right-hand version of the endo shelf

Pos. 1 Unit connection

• Use the supplied screws M8 x 25 DIN 912 and washers to mount the unit connection

(1/Fig. 74 / p. 65) to the back of the lifting base.

T - Tighten the 5 screws with a torque of 25 Nm.

Left-hand version of the endoscopy shelf 0

NOTE

The figure shows the installation of the left-hand version

(Fig. 75 / p. 66).

Siemens AG SPL5-330.812.01.08.02 UROSKOP ACCESS

Medical Solutions

01.06 CS PS SP

Page 65 of 90

Page 66

66 Cabling

Fig. 75: Left-hand version of the endo shelf Fig. 76: Left-hand version of the endo shelf

Pos. 1 Unit connection

• Use the supplied screws M8 x 25 DIN 912 and washers to mount the unit connection

(1/Fig. 76 / p. 66) to the back of the lifting base.

T - Tighten the 5 screws with a torque of 25 Nm.

Installing the endo shelf on the unit carrier 0

Fig. 77: Endoscopy shelf with endoscopy interface

• Route the connection cable (20 m) through the unit connection of the unit carrier

(1/Fig. 77 / p. 66); (2/Fig. 77 / p. 66).

• Connect the ground wire to the grounding point of the lifting base.

UROSKOP ACCESS SPL5-330.812.01.08.02 Siemens AG

01.06 CS PS SP

Page 66 of 90

Medical Solutions

Page 67

Cabling 67

• Install the shelf in the mount (1/Fig. 77 / p. 66) and secure it with the threaded pin

(2/Fig. 77 / p. 66).

• Install the emergency shutdown plate in the back wall of the unit and secure it tightly via

screws (3/Fig. 77 / p. 66).

NOTE

The connection of the multiple socket outlet (4/Fig. 77 / p. 66) and

the on-site connection of the 20-m connection cable (3 x 1.5 mm

2

may only be performed by an authorized specialist and must follow the country-specific regulations provided by the operator.

This may not be performed at the system contactor (see document

“Planning Guide; System; UROSKOP Access (e) “

[SPL5-330.891.01.xx]).

Outside Germany, the supplied multiple socket outlet may be replaced by a multiple socket outlet meeting the country-specific

regulations. This multiple socket outlet is to be procured locally.

)

Siemens AG SPL5-330.812.01.08.02 UROSKOP ACCESS

Medical Solutions

01.06 CS PS SP

Page 67 of 90

Page 68

68 Cabling

Endoscopy interface connection (optional) 0

Fig. 78: Endoscopy interface connections

Pos. 1 FBAS-In: Composite video from the scan converter (imaging system container) (BNC)

Pos. 2 C-Out: S-Video (C) to the monitor (BNC)

Pos. 3 Y-Out: S-Video (Y) to the monitor (BNC)

Pos. 4 X3: Control signals from M1 (BUC) (15-pole D-sub)

Pos. 5 X2: Power input (230 V AC)

Pos. 6 X1: Serial connection (RS232) to the monitor (9-pole D-sub)

Pos. 7 Ground wire

UROSKOP ACCESS SPL5-330.812.01.08.02 Siemens AG

01.06 CS PS SP

Page 68 of 90

Medical Solutions

Page 69

Cabling 69

Connecting the foot switch 0

• Connect the fluoroscopy foot switch (Fig. 79 / p. 69) to M1.X9 according to the cable la-

beling.

Fig. 79: Fluoroscopy foot switch connection

• Connect the system foot switch (optional) to M1.D1.X303 according to the cable label-

ing (Fig. 80 / p. 69).

Fig. 80: System foot switch

• For the purpose of strain relief/fastening, secure the foot switch cable to the cable har-

ness (2/Fig. 20 / p. 21) via cable ties.

Siemens AG SPL5-330.812.01.08.02 UROSKOP ACCESS

Medical Solutions

01.06 CS PS SP

Page 69 of 90

Page 70

70 Cabling

ASPIA imaging system container 0

NOTE

FLUOROSPOT compact imaging systems as well as ASPIA imaging systems are installed in the installed base.

Fig. 81: ASPIA container

Pos. 1 Keyboard connection

Pos. 2 Mouse connection

Pos. 3 License dongle

Pos. 4 Network connection

Pos. 5 Connection point of the ground wire of the ASPIA PC

UROSKOP ACCESS SPL5-330.812.01.08.02 Siemens AG

01.06 CS PS SP

Page 70 of 90

Medical Solutions

Page 71

Cabling 71

• Install the imaging system container at the location specified in the project plan.

• Ensure a sufficient distance from the tabletop - at least 10 cm.

NOTE

To connect the imaging system container, it is necessary to open

the cover, side wall and rear wall of the container (access to M16,

transformer, network connection, and interfaces).

• Position cable harness W650 of the TFT support arm with respect to the imaging sys-

tem container.

• Install cable harnesses W600 and W650 as described in the section (Cable harness

installation / p. 59).

NOTE

Strain relief is generally provided for all external cables. Cable ties

to be attached to the provided punched holes in the housing (M16,

imaging system container) are used for securing the cables. The

stripped cable shields are to be clamped under the corresponding

cable clips.

Mouse 0

• Connect the mouse to the right connection with the mouse symbol (2/Fig. 81 / p. 70).

• Use cable ties at the punched holes in the imaging system container for strain relief.

Network 0

• Connect the PC to the local network via an unshielded twisted pair lead

(4/Fig. 81 / p. 70).

- The cable is included in the scope of delivery.

NOTE

In the event in which no network connection is initially provided,

this lead should be attached to the back wall of the imaging system

container via cable ties.

Keyboard 0

• Connect the keyboard cable to the left connection with the keyboard symbol and se-

cure the cable via cable ties (1/Fig. 81 / p. 70).

NOTE

Use the supplied extension to extend the keyboard cable.

Siemens AG SPL5-330.812.01.08.02 UROSKOP ACCESS

Medical Solutions

01.06 CS PS SP

Page 71 of 90

Page 72

72 Cabling

Laser printer connection 0

• The following options are possible for connecting the laser printer (paper printer):

- Integration of the printer as a network printer in the local hospital/office network;

- LPT1 connection (parallel interface to the back of the PC);

- Connection directly to the PC network connection (RJ45 connection on the back of

the PC; (4/Fig. 81 / p. 70)).

NOTE

Detailed descriptions regarding the connection of the paper printer are provided in document “Installation and Start-up; Installation

of options“ (SPL5-330.814.02.xx).

Back of the imaging system PC 0

NOTE

The cabling shown here is only an example.

Fig. 82: Cabling at the back of the PC

Pos. 1 Monitor 1 (live)

Pos. 2 Monitor 2 (reference)

Pos. 3 Radiation trigger hardware

Pos. 4 TV camera

Pos. 5 XCS connection (M59.X3)

UROSKOP ACCESS SPL5-330.812.01.08.02 Siemens AG

01.06 CS PS SP

Page 72 of 90

Medical Solutions

Page 73

Cabling 73

Cabling of the imaging system container 0

Fig. 83: Imaging system container cabling

Pos. 1 BNC 1: Urodynamics option

Pos. 2 Connection point of the ground wire of the

ASPIA PC

Pos. 3 Connection point of the ground wire of the

generator voltage supply

Fig. 84: Imaging system container cabling

Pos. 1 Monitor connections

Pos. 2 Connection points of the 400 V/440 V/480 V

voltage supply from the generator

Pos. 3 M16.K2

Pos. 4 M16D1.SK111

Siemens AG SPL5-330.812.01.08.02 UROSKOP ACCESS

Medical Solutions

01.06 CS PS SP

Page 73 of 90

Page 74

74 Cabling

Fig. 85: Imaging system container cabling

Pos. 1 Routing of image signal cables to the con-

tainer

Pos. 2 Supply of the power cables

Fig. 86: Cabling of the imaging system

container

Pos. 1 Video splitter D233 (live image; front)

Pos. 2 Video splitter D233 (reference image; back)

Pos. 3 Live image monitor connections

Pos. 4 Reference image monitor connections

UROSKOP ACCESS SPL5-330.812.01.08.02 Siemens AG

01.06 CS PS SP

Page 74 of 90

Medical Solutions

Page 75

Cabling 75

Fig. 87: Video splitter D233

Pos. 1 Live image video splitter

Pos. 2 Reference image video splitter

NOTE

The live image is available at the front video splitter

(1/Fig. 87 / p. 75), and the reference image is available at the back

video splitter (2/Fig. 87 / p. 75).

Siemens AG SPL5-330.812.01.08.02 UROSKOP ACCESS

Medical Solutions

01.06 CS PS SP

Page 75 of 90

Page 76

76 Cabling

Fig. 88: Strain relief overview

Pos. 1 Image signal cables (W650)

Pos. 2 M16.K2 (power cables for the monitors)

Pos. 3 M16.D1.SK111 (W600)

Pos. 4 M16.F1 (W600)

Pos. 5 M16.X1 (W600 + W650)

Pos. 6 M16.X2 (W650)

Pos. 7 M59.X3 (W600) XCS cable

Pos. 8 M16.PE (W600)

Pos. 9 Partial cable harness W600

Pos. 10 Partial cable harness W650 TFT support arm

NOTE

The design of the cable harnesses on the imaging system container is identical, with the exception of the number of BNC cables.

Cable harness W650 has 7 coaxial cables with BNC plugs.

UROSKOP ACCESS SPL5-330.812.01.08.02 Siemens AG

01.06 CS PS SP

Page 76 of 90

Medical Solutions

Page 77

Cabling 77

Fig. 89:

Pos. 1 Power and image cables for monitors in the control room, mouse and keyboard cables, optional: Printer cables

Pos. 2 Supply of cables from unit and generator

Siemens AG SPL5-330.812.01.08.02 UROSKOP ACCESS

Medical Solutions

01.06 CS PS SP

Page 77 of 90

Page 78

78 Final work steps (covers)

7Final work steps (covers)

8-

Covers for the imaging system container 0

• Attach the cover and side and rear panels of the imaging system container.

Fig. 90: Back of the imaging system container

• Use two Allen screws (M 4 x 16) instead of the cover screws to attach the wall spacer

bracket (Fig. 90 / p. 78).

NOTE

This bracket must never be used as a carrying handle.

• Push the imaging system container against the wall as far as the bracket allows.

Fig. 91: Fig. 92:

NOTE

The fastening screws for the covers are located in a plastic bag attached to the corresponding cover.

UROSKOP ACCESS SPL5-330.812.01.08.02 Siemens AG

01.06 CS PS SP

Page 78 of 90

Medical Solutions

Page 79

Final work steps (covers) 79

• Install the covers in the sequence shown below.

• Attach the cover to the I.I. at the bottom (Fig. 91 / p. 78).

- For installation, move the unit into the +90° position. Fasten the image intensifier cover with 6 cover screws and tighten the screws in the 0° position of the unit.

NOTE

Do not insert the cover screws through the cover since this would

cause the image intensifier collision protection to be permanently

in operation (Fig. 92 / p. 78).

• After installation, check for proper functioning of the collision protection in all unit posi-

tions by lifting the image intensifier cover.

Unit carrier cover plate